SMC Networks D-M9N, D-M9P, D-M9B Installation And Maintenance Manual

D-*S-TFQ39

Page 1 of 3

Installation and Maintenance Manual

[Auto Switch (Solid State)]

Series D-M9N, D-M9P, D-M9B

(Complies with the basic safety principles in accordance with

ISO 13849)

The intended use of this product is to detect a position of a magnet in a

pneumatic cylinder.

Validated D-M9 components according to ISO 13849:

For the part numbers of validated D-M9 products refer to Doc. No. D-*SSMQ0018.

Safety Instructions

This manual contains essential information for the protection of users and

others from possible injury and/or equipment damage.

• Read this manual before using the product, to ensure correct handling,

and read the manuals of related apparatus before use.

• Keep this manual in a safe place for future reference.

• These instructions indicate the level of potential hazard by label of

“Caution”, “Warning” or “Danger”, followed by important safety

information which must be carefully followed.

• To ensure safety of personnel and equipment the safety instructions in

this manual and the product catalogue must be observed, along with

other relevant safety practices.

• Always ensure compliance with relevant safety law s and standards.

Caution

Indicates a hazard with a low level of risk, which if not

avoided, could result in minor or moderate injury.

Warning

Indicates a hazard with a medium level of risk, which

if not avoided, could result in death or serious injury.

Danger

Indicates a hazard with a high level of risk, which if

not avoided, will result in death or serious injury.

This product is class A, group 1 equipment that is only intended for use in

an industrial environment as described by EN55011.

Common Auto Switch Precautions

Design and Selection

Warning

(1) Check the specifications.

If the auto switch is used with an excessive load or used outside of the

specifications, it may cause damage or malfunction.

The product cannot be guaranteed if is used outside of the specification range.

(2) Caution for use in an interlock system.

When an auto switch is used in an interlock system which requires high reliability,

provide a double interlock system, for example a mechanical protection system, for

extra safety, or by also using another switch (sensor) together with the auto switch.

Check the product regularly in order to confirm normal operation.

(3) Do not disassemble, modify (including changing the printed circuit

board) or repair.

An injury or failure can result.

Caution

(1) Pay attention to the length of time the auto switch will operate at an

intermediate stroke position.

When an auto switch is placed at an intermediate stroke position, and a load is

driven during the time when the piston passes, the auto switch will operate, but if

the piston speed is too great, the operating time will be shortened, and the load

may not operate correctly.

The maximum piston speed is:

V [mm/s] =

Auto switch operating range [mm]

×1000

Load operating time [ms]

(2) Take precautions when multiple actuators are used close together.

When using two or more actuators with auto switches in close proximity to each

other, maintain a minimum separation distance of at least 40 mm. (If the separation

distance is specified for the actuator series, then use that value).

The auto switches may malfunction due to magnetic field interference.

Use of a magnetic screen plate (MU-S025) or commercially available magnetic

screening tape can reduce the interference of magnetic fields.

(3) Provide sufficient space for maintenance.

When designing an application, allow sufficient clearance for maintenance and

inspection.

(4) Never mount the actuator with auto switch in a location that will be used

as a footrest.

The product may be damaged if excessive force is applied by stepping or climbing

onto it.

(5) Design the circuit to prevent reverse current during open circuit

conditions or when the product is forced to operate for functional checks.

Reverse current can cause product damage or malfunction.

(6) Precautions for mounting an auto switch

When n number of auto switches is specified for mounting, this indicates the

maximum number of auto switches based on the physical dimensions of the

actuator.

The detection distance varies depending on the auto switch mounting structure

and the auto switch body dimensions. For this reason, the switch may not always

be mounted at the required detection distance or at the required position.

(7) Limitations of the detection position.

There will be mounting positions or surfaces where the auto switch cannot be

mounted due to physical interference (e.g. rear side of the foot bracket), depending

on the mounting conditions of the actuator.

Select an auto switch after confirming that the switch mounting position does not

interfere with the mounting bracket (e.g. trunnion, reinforcement ring).

Mounting and Adjustment

Caution

(1) Do not drop or apply impact.

The auto switch may be damaged or malfunction if it is dropped, bumped or applied

with excessive impact (1000 m/s2 or more).

(2) Observe the required tightening torque for mounting an auto switch.

If an auto switch is tightened beyond the specified tightening torque, the auto

switch, mounting screws, or mounting bracket may be damaged.

Tightening below the specified tightening torque will allow the auto switch to move

out of position.

(3) Do not carry an actuator by the auto switch lead wire.

This may cause a broken lead wire or damage to the auto switch internal elements.

(4) Use only the screws installed in the auto switch body for mounting the

auto switch.

If other screws are used, the auto switch may be damaged.

(5) Mount the auto switch at the centre of its operating range.

Auto switches should be mounted so that the most sensitive position is at the

centre of the operating range.

Mounting the auto switch close to the edge of its operating range (close to the

border of ON/OFF operation) may cause unstable operation.

(The auto switch mounting positions shown in the actuator catalogue indicate the

optimum position at the end of stroke).

Some actuator and cylinder series have their own setting methods. In such cases,

follow the instructions given.

(6) Check and adjust the actual auto switch operation during installation.

The auto switch may not operate in the correct actuator mounting position due to

the installation environment.

Also check and adjust the auto switch operation when used in intermediate stroke

positions, according to the operating environment.

Wiring

Caution

(1) Check the insulation of the wiring.

Check that there is no faulty wiring insulation (short circuits, faulty ground

connections, improper insulation between terminals, etc.), as this may damage the

auto switch due to over current.

(2) Do not route the auto switch wiring in the same place as power cables

or high voltage cables.

Otherwise auto switch malfunction may result due to noise and inrush current.

(3) Avoid repeatedly bending or stretching the lead wire.

Broken lead wires will result if bending stresses or tensile forces are applied to the

lead wires.

Stress and tensile forces applied to the connection between the lead wire and auto

switch increases the possibility of disconnection.

Secure the lead wire to reduce any movement in the area where the lead wire

connects with the auto switch.

The standard of bending radius becomes R20 to 40 mm.

(4) Be sure to confirm the load condition (e.g. connection and current

value) before power is supplied.

Operating Environment

Warning

(1) Do not use the auto switch in the presence of explosive gases.

Auto switches are not designed with an explosion proof construction. Fire or an

explosion may result.

Contact SMC for information regarding ATEX compliant products.

Caution

(1) Do not use in a location where magnetic fields are generated.

Auto switches will malfunction or the magnets inside actuators will become

demagnetized.

(2) Do not use in an environment where the auto switch will be continually

exposed to water.

Although auto switches satisfy the IEC standard IP67 construction, do not use in

applications continually exposed to water splashes or spray. Otherwise, insulation

failure or malfunction may result.

(3) Do not use in an environment where oil or chemical splashes can

occur.

If auto switches are used in an environment with coolants, cleaning solvents, oils or

chemicals for even a short time, they may be adversely affected by insulation

failure, malfunction due to swelling of the potting resin, or hardening of the lead

wires.

(4) Do not use in an environment where there are cyclic temperature

changes.

Temperature cycles other than normal temperature changes can adversely affect

the auto switch internally.

(5) Avoid accumulation of iron debris or close contact with magnetic

substances.

When a large amount of iron waste such as machining chips or spatter has

accumulated, or a magnetic substance (something attracted by a magnet) is

brought into close proximity with the actuator, it may cause the auto switch to

malfunction due to a weakening of the magnetic force inside the actuator.

(6) Contact SMC for information regarding auto switch water resistance,

elasticity of lead wires, applications in welding sites, etc.

(7) Do not use in direct sunlight.

(8) Do not mount the auto switch in locations where it is exposed to radiant

heat.

(9) The auto switch is CE marked, but not immune to lightning strikes. Take

measures against lightning strikes in the system.

Maintenance

Warning

(1) Removal of equipment, and exhausting the compressed air.

When equipment is to be removed, first confirm that measures are in place to

prevent losing control of the equipment or workpieces from falling, etc. Turn off the

power supply, stop the air supply and exhaust all compressed air from the system.

Before restarting the equipment, confirm that measures are taken to prevent

sudden movement.

(2) Never touch the terminals while the power is on.

Otherwise electric shock, malfunction and damage to the product can result.

Caution

(1) Perform the following maintenance regularly to avoid possible danger

due to unexpected auto switch malfunction.

1) Securely tighten the auto switch mounting screws.

If the screws have become loose and the required mounting position has been

lost, re-adjust the auto switch to the correct mounting position and re-tighten the

screws.

2) The mounting screw is not tamper proof therefore it is foreseeable that misuse

could result in system malfunction.

3) Check that there is no damage to the lead wire.

If damage to the lead wire is found, replace the auto switch, or repair the lead

wire, to avoid faulty insulation.

4) Check the detecting position setting.

Confirm that the auto switch most sensitive position is at the centre of the

operating range (red LED range).

Some actuator and cylinder series have their own setting methods. In such

cases, follow the instructions given.

(2) Do not use solvents such as benzene, thinner, alcohol etc. to clean the

auto switch.

This may damage the surface of the body or erase the markings on the body.

For heavy stains, use a cloth soaked with diluted neutral detergent and fully

squeezed, then wipe up the stains again with a dry cloth.

Solid state Auto switch

Design and Selection

Caution

(1) Wiring should be kept as short as possible.

Do not use a cable longer than 100 m.

For long wire lengths, we recommend a ferrite core should be attached to both

ends of the cable, to reduce noise.

(2) Do not use a load which generates a surge voltage.

When a load which generates a surge voltage is to be directly driven, operate such

as a relay or solenoid, use an auto switch with built-in surge protection.

(3) Pay attention to the internal voltage drop of the switch.

In general, the internal voltage drop will be greater with a 2-wire solid state auto

switch than with a reed type auto switch.

When auto switches are connected in series, the voltage drop will be "n" times

larger when "n" auto switches are connected.

Even though an auto switch may operate normally, the load may not operate.

Note that a 12 VDC relay is not applicable.

(4) Pay attention to the leakage current.

<2-wire type>

With a 2 wire solid state auto switch, current (leakage current) flows to the load to

operate the internal circuit even when the switch is in the OFF state.

Current to operate load (OFF condition) > Leakage current

If the criteria given in the above formula are not met, the auto switch will not reset

correctly (stays ON).

Use a 3 wire type auto switch if this specification cannot be satisfied.

In addition, leakage current flow to the load will be "n" times larger when "n" auto

switches are connected in parallel.

(5) The solid state auto switch output will be unstable for 50 ms after power

is supplied.

During the time after supplying power, the input device (e.g. PLC, relay) may

consider the ON position as OFF output or the OFF position as ON output.

Please set up the application to consider the signals will be invalid within 50 ms

after power is supplied.

Perform a similar setting when using the SMC AHC system (Auto Hand Changing

system) MA series.

Wiring

Caution

(1) Do not short-circuit the load.

The auto switch will be damaged if the load is short-circuited.

(2) Avoid incorrect wiring.

1) If connections are reversed on a 2-wire type auto switch, the switch will not be

damaged if protected by a protection circuit, but the switch will always stay in an

ON state.

However, it is still necessary to avoid reversed connections, since the switch

could be damaged by a load short circuit in this condition.

2) If connections are reversed (power supply wire + and -) on a 3-wire type auto

switch, the switch will be protected by a protection circuit. However, if the blue

wire is connected to the power supply (+) and the black wire is connected to the

power supply (-), the auto switch will be damaged.

(3) Please note the correct stripping direction when removing the cable

sheath. The insulator may be split or damaged depending on the

direction used.

Recommended tool:

Description

Part number

Wire stripper

D-M9N-SWY

*: For 2-wire type auto switches, a round wire stripper (2.0) can be used.

ORIGINAL INSTRUCTIONS

D-*S-TFQ39

Page 2 of 3

Operating Environment

Caution

(1) Do not use in a location where surges are generated.

When there are units (solenoid lifter, high frequency induction furnace, motor, etc.)

which generate a large amount of surge in the area around the actuator with solid

state auto switches, this may cause damage to the auto switch internal circuit.

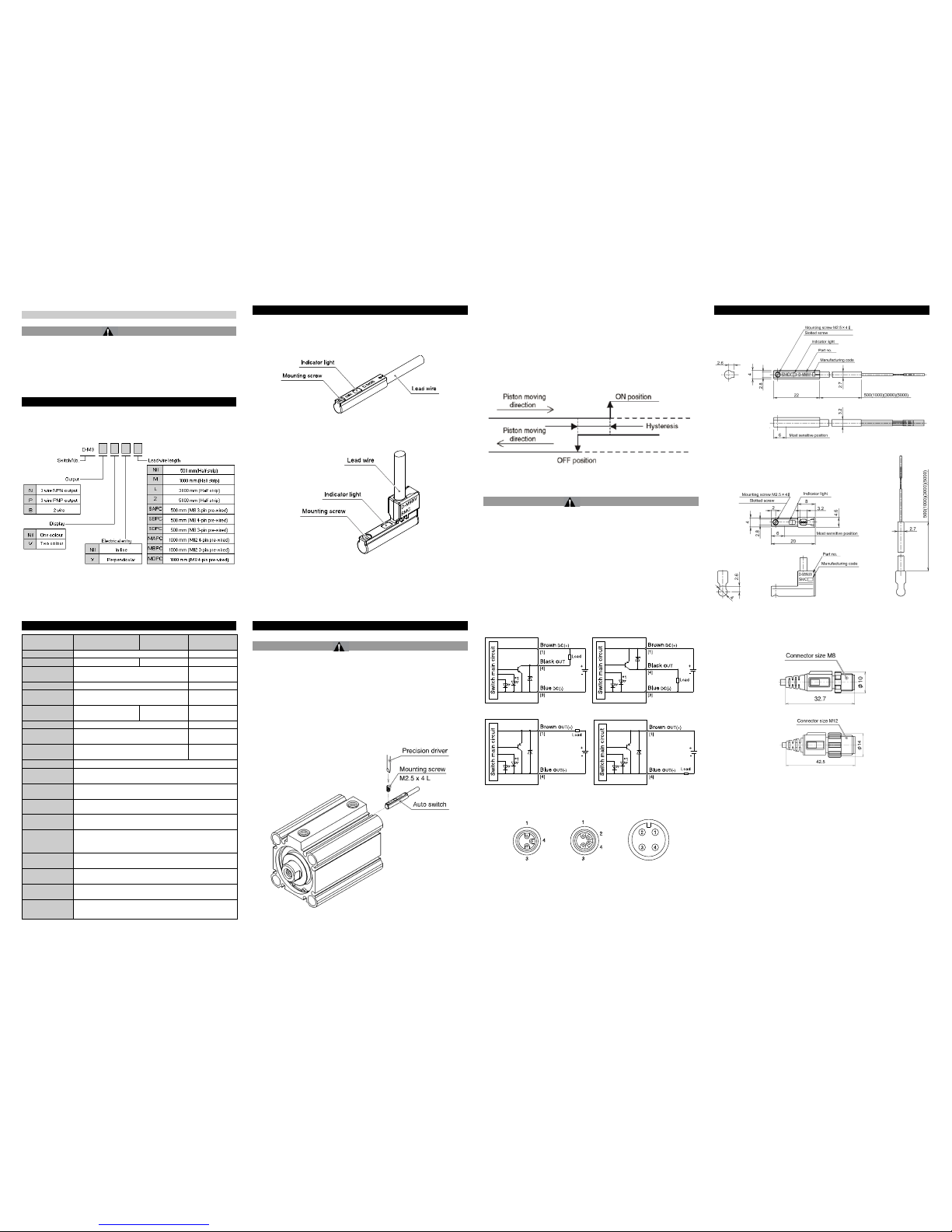

Model Indication and How to Order

Specifications

Switch model

No.

D-M9N

D-M9P

D-M9B

Wiring

3 wire

2 wire

Output

NPN

PNP

-

Application

IC circuit / Relay / PLC

24 VDC

Relay / PLC

Power voltage

5/12/24 VDC (4.5 to 28 VDC)

-

Current

consumption

10 mA or less

-

Load voltage

28 VDC or less

-

24 VDC (10

to 28 VDC)

Load current

40 mA or less

2.5 to 40 mA

Internal

voltage drop

0.8 V or less at 10 mA load current (2

V or less at 40 mA)

4 V or less

Current

leakage

100 A or less at 24 VDC

0.8 mA or

less

Operating time

1 ms or less

Indicator light

Operating position: Red LED lights up

Optimum position: Green LED lights up (D-M9W only)

Electrical entry

system

Grommet

Lead wire

Oil-proof heavy-duty vinyl cord 2.7 x 3.2 oval, 0.15

mm2, 2 wire (D-M9B), 3 wire (D-M9N/D-M9P)

Impact

resistance

1000 m/s2

Vibration

resistance

10 to 150 Hz, at the smaller amplitude,

1.5 mm or 20 m/s2 in X,Y,Z directions for 2 hours each

(De-energized)

Insulation

resistance

50 M or more at 500 VDC mega

Withstand

voltage

1000 VAC for 1 minute

(between terminals and housing)

Ambient

temperature

-10oC to 60oC

Protection

structure

IEC60529 standard IP67, JISC0920

Product Elements

D-M9

D-M9V

Installation

Warning

• Do not install the product unless the safety instructions have been read

and understood.

Mounting

Each actuator has a specified mounting bracket for mounting the auto

switch.

"How to mount / Mounting bracket" depends on the actuator type and the

tube I.D. Please refer to the actuator catalogue.

When an auto switch is mounted for the first time, ensure that the actuator

is a type including a built in magnet, and select a bracket corresponding to

the actuator.

• Setting the detecting position

1) Set the actuator at the end of stroke.

2) Mount the auto switch in the position where the red LED is ON

(detecting position for the actuator end of stroke).

3) Based on the A and B dimensions in the actuator catalogue, set the

switch.

• Hysteresis

Environment

Warning

• Do not use in an environment where corrosive gases, chemicals, salt

water or steam are present.

• Do not install in a location subject to vibration or impact. Check the

product specifications.

D-M9N D-M9P

D-M9B (Sink input mode) D -M9B (Source input mode)

*1: For the D-M9(V) single colour auto switch the green LED is removed.

The number shown in brackets [ ] indicates the connector pin number.

M8 3-pin connector M8 4-pin connector M12 4-pin connector

Outline Dimensions (mm)

D-M9

D-M9V

External dimensions of Pre-wired connector

D-M9

A

,B PC

D-M9 DPC

M2.5 mounting screw

tightening torque should

be 0.05 to 0.15 Nm

Loading...

Loading...