Page 1

CA

US

Accessories for PV Inverters

SMA CONNECTION UNIT 600-US / 1000-US

Installation Manual

CU600-1000US-IA-en-10 | IMEN-CU-US | Version 1.0

Page 2

Page 3

SMA America, LLC Legal Provisions

Legal Provisions

Copyright © 2013 SMA America,LLC. All rights reserved.

No part of this document may be reproduced, stored in a retrieval system, or transmitted, in any form

or by any means, electronic, mechanical, photographic, magnetic or otherwise, without the prior

written permission of SMA America,LLC.

Neither SMA America,LLC nor SMA Solar Technology Canada Inc. makes representations, express

or implied, with respect to this documentation or any of the equipment and/or software it may

describe, including (with no limitation) any implied warranties of utility, merchantability, or fitness for

any particular purpose. All such warranties are expressly disclaimed. Neither SMA America,LLC nor

its distributors or dealers nor SMA Solar Technology Canada Inc. nor its distributors or dealers shall

be liable for any indirect, incidental, or consequential damages under any circumstances.

(The exclusion of implied warranties may not apply in all cases under some statutes, and thus the

above exclusion may not apply.)

Specifications are subject to change without notice. Every attempt has been made to make this

document complete, accurate and up-to-date. Readers are cautioned, however, that

SMAAmerica,LLC and SMA Solar Technology Canada Inc. reserve the right to make changes

without notice and shall not be responsible for any damages, including indirect, incidental or

consequential damages, caused by reliance on the material presented, including, but not limited to,

omissions, typographical errors, arithmetical errors or listing errors in the content material.

All trademarks are recognized even if these are not marked separately. Missing designations do not

mean that a product or brand is not a registered trademark.

The Bluetooth

any use of such marks by SMA America,LLC and SMA Solar Technology Canada Inc. is under

license.

®

word mark and logos are registered trademarks owned by Bluetooth SIG, Inc. and

SMA America, LLC

3801 N. Havana Street

Denver, CO 80239 U.S.A.

SMA Solar Technology Canada Inc.

2425 Matheson Blvd. E

7th Floor

Mississauga, ON L4W 5K4

Canada

Installation Manual CU600-1000US-IA-en-10 3

Page 4

IMPORTANT SAFETY INSTRUCTIONS SMA America, LLC

IMPORTANT SAFETY INSTRUCTIONS

SAVE THESE INSTRUCTIONS

This manual contains important instructions for the following products:

• CU 600-US-10 (SMA Connection Unit 600-US)

• CU 1000-US-10 (SMA Connection Unit 1000-US)

This manual must be followed during installation and maintenance.

The product is designed and tested according to international safety requirements, but as with all

electrical and electronic equipment, certain precautions must be observed when installing and/or

operating the product. To reduce the risk of personal injury and to ensure the safe installation and

operation of the product, you must carefully read and follow all instructions, cautions and warnings

in this manual.

Warnings in this document

A warning describes a hazard to equipment or personnel. It calls attention to a procedure or practice,

which, if not correctly performed or adhered to, could result in damage to or destruction of part or all

of the SMA equipment and/or other equipment connected to the SMA equipment or personal injury.

Symbol Description

DANGER indicates a hazardous situation which, if not avoided, will result in

death or serious injury.

WARNING indicates a hazardous situation which, if not avoided, could result

in death or serious injury.

CAUTION indicates a hazardous situation which, if not avoided, could result

in minor or moderate injury.

NOTICE is used to address practices not related to personal injury.

4 CU600-1000US-IA-en-10 Installation Manual

Page 5

SMA America, LLC IMPORTANT SAFETY INSTRUCTIONS

Warnings on this product

The following symbols are used as product markings with the following meanings.

Symbol Description

Warning regarding dangerous voltage

The product works with high voltages. All work on the product must only

be performed as described in the documentation of the product.

Beware of hot surface

The product can become hot during operation. Do not touch the product

during operation.

Risk of Fire

Improper installation of the product may cause a fire.

Observe the operating instructions

Read the documentation of the product before working on it. Follow all

safety precautions and instructions as described in the documentation.

Installation Manual CU600-1000US-IA-en-10 5

Page 6

General Warnings SMA America, LLC

General Warnings

Al l el ect ric al ins tal lat ions m ust be m ade in acc ord anc e wi th the local and NationalElectrical Code®

ANSI/NFPA 70 or the Canadian Electrical Code® CSAC22.1. This document does not and is not

intended to replace any local, state, provincial, federal or national laws, regulation or codes

applicable to the installation and use of the product, including without limitation applicable

electrical safety codes. All installations must conform with the laws, regulations, codes and

standards applicable in the jurisdiction of installation. SMA assumes no responsibility for the

compliance or noncompliance with such laws or codes in connection with the installation of the

product.

The product contains no user-serviceable parts.

For all repair and maintenance, always return the unit to an authorized SMA Service Center.

Before installing or using the product, read all of the instructions, cautions, and warnings in this

manual.

Wiring of the product must be made by qualified personnel only.

6 CU600-1000US-IA-en-10 Installation Manual

Page 7

SMA America, LLC Table of Contents

Table of Contents

1 Information on this Document. . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2 Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.1 Intended Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.2 Skills of Qualified Persons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.3 Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3 Scope of Delivery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

4 Product Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

4.1 Connection Unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

4.2 Type Label . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

4.3 DC Switch-Disconnector. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

4.4 String Fuses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

4.5 Reverse Polarity Detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

5 Mounting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

5.1 Requirements for Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

5.2 Mounting the Connection Unit on a Wall . . . . . . . . . . . . . . . . . . . . . 23

5.3 Mounting the Connection Unit to a Post . . . . . . . . . . . . . . . . . . . . . . 25

6 Electrical Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

6.1 Safety during Electrical Connection. . . . . . . . . . . . . . . . . . . . . . . . . . 26

6.2 Overview of the Connection Area. . . . . . . . . . . . . . . . . . . . . . . . . . . 27

6.2.1 Enclosure Openings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

6.2.2 Interior View of the Connection Unit 600-US. . . . . . . . . . . . . . . . . . 28

6.2.3 Interior View Connection Unit 1000-US . . . . . . . . . . . . . . . . . . . . . 29

6.3 Connecting Conduits to the Connection Unit. . . . . . . . . . . . . . . . . . . 30

6.4 Connecting the Grounding Conductor . . . . . . . . . . . . . . . . . . . . . . . 31

6.5 Connecting the PV Array to the Connection Unit 600-US . . . . . . . . . 33

6.6 Connecting the PV Array to the Connection Unit 1000-US. . . . . . . . 35

6.7 Operating the Reverse Polarity Detection . . . . . . . . . . . . . . . . . . . . . 36

6.8 Connecting the DC Output Cable for the Inverter to the

Connection Unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Installation Manual CU600-1000US-IA-en-10 7

Page 8

Table of Contents SMA America, LLC

7 Commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

7.1 Inserting the String Fuses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

7.2 Commissioning the Connection Unit . . . . . . . . . . . . . . . . . . . . . . . . . 42

8 Disconnecting the Connection Unit from Voltage Sources . . . 43

9 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

9.1 LED Signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

9.2 Replacing the String Fuses. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

10 Decommissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

10.1 Disassembling the Connection Unit . . . . . . . . . . . . . . . . . . . . . . . . . . 47

10.2 Packing the Connection Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

10.3 Disposing of the Connection Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

11 Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

12 Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

13 Contact . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

8 CU600-1000US-IA-en-10 Installation Manual

Page 9

SMA America, LLC 1 Information on this Document

1 Information on this Document

Validity

This document is valid for the following device types:

• CU 600-US-10 (SMA Connection Unit 600-US)

• CU 1000-US-10 (SMA Connection Unit 1000-US)

Target Group

This document is intended for qualified persons. Only qualified personnel with the appropriate skills

are allowed to perform the tasks described in this document (see Section 2.2 "Skills of Qualified

Persons", page 11).

Additional Information

Links to additional information can be found at www.SMA-Solar.com:

Document title Document type

Sunny Tripower 12000TL-US / 15000TL-US / 20000TL-US /

24000TL-US

Sunny Boy 6000TLUS / 7000TLUS / 8000TLUS / 9000TLUS /

10000TLUS / 11000TLUS

Installation manual

Installation manual

Symbols

Symbol Explanation

Information that is important for a specific topic or goal, but is not

safety-relevant

☐ Indicates an essential requirement for achieving a specific goal

☑ Desired result

✖ A problem that could occur

Nomenclature

Complete designation Designation in this document

SMA America Production, LLC SMA

SMA Solar Technology Canada Inc. SMA

SMA Connection Unit 600-US / 1000-US Connection Unit, product

Installation Manual CU600-1000US-IA-en-10 9

Page 10

2 Safety SMA America, LLC

2 Safety

2.1 Intended Use

The Connection Unit is a String-Combiner to which up to eight strings can be connected.

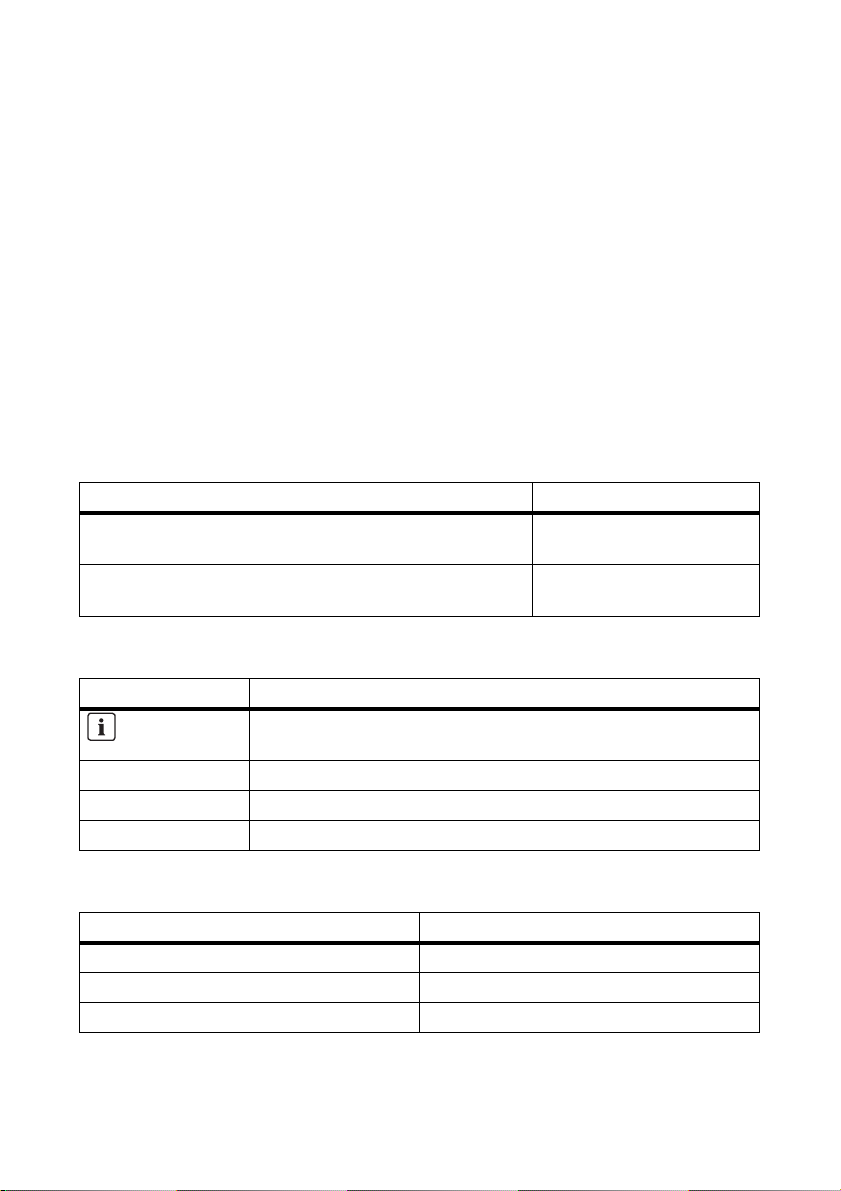

Figure 1: Example design of a PV system with Connection Unit

Item Designation

APV modules

B Connection Unit

C Sunny Tripower

D Circuit breaker

E Utility grid

The Connection Unit is suitable for indoor and outdoor use.

The Connection Unit must only be used in ungrounded PV systems. Do not use grounded PV modules

with the Connection Unit. Only ground the mounting frame of the PV modules.

All DC inputs of an ungrounded PV system must be equipped with an overcurrent protection

according to the National Electrical Code

requirements contained in Section690.35 of the National Electrical Code®, ANSI/NFPA 70. The

Connection Unit must only be used with the following transformerless SMA inverters:

• SB 6000TLUS-12 / 7000TLUS-12 / 8000TLUS-12 / 9000TLUS-12 / 10000TLUS-12 /

11000TLUS-12

• STP 12000TL-US-10 / 15000TL-US-10 / 20000TL-US-10 / 24000TL-US-10

For safety reasons, it is forbidden to modify the product or install components that are not explicitly

recommended for this product or distributed by SMA.

Use this product only in accordance with the enclosed documentation and with the local standards

and directives. Any other use can result in personal injury or property damage.

• Do not mount the product in areas where flammable gases may occur.

• Do not mount the product in areas where highly flammable materials are stored.

• Do not install the product in potentially explosive atmospheres.

10 CU600-1000US-IA-en-10 Installation Manual

®

NEC 690. The Connection Unit shall be installed per the

Page 11

SMA America, LLC 2 Safety

The enclosed documentation is an integral part of this product.

• Read and observe the documentation.

• Keep the documentation in a convenient place for future reference.

2.2 Skills of Qualified Persons

The tasks described in this document must be performed by qualified persons only. Qualified persons

must have the following skills:

• Knowledge of how electrical devices and plants work and are operated

• Training in how to deal with the dangers and risks associated with installing and using electrical

devices and plants

• Training in the installation and commissioning of electrical devices and plants

• Knowledge of all applicable standards and directives

• Knowledge of and adherence to this document and all safety precautions

Installation Manual CU600-1000US-IA-en-10 11

Page 12

2 Safety SMA America, LLC

2.3 Safety Precautions

This section contains safety precautions that must be observed at all times when working on or with

the product.

To pre ven t pe rsona l in jur y or pr ope rty damag e an d to ensur e lo ng-term operation of the product, read

this section carefully and follow all safety precautions at all times.

Danger to life due to high voltages in the Connection Unit

High voltages that can cause fatal electric shocks when touched are present in the live components

of the Connection Unit.

• All work on the Connection Unit must be carried out by qualified persons only.

• Before working on the Connection Unit carry out the following steps:

– Switch off all devices that are connected to the Connection Unit (e.g. inverter) and protect

against reconnection.

–Cover the PV modules.

– Turn the DC switch-disconnector of the Connection Unit counterclockwise by 90° and set

to OFF.

• While operating the Connection Unit, do not remove the sealing plugs.

• All work on the Connection Unit should only be carried out as described in this document.

Danger to life due to operating a damaged Connection Unit

Using a damaged Connection Unit can lead to serious or lethal injuries through electric shock.

• Only operate the Connection Unit when it is functioning properly and safely.

• Regularly check the Connection Unit for visible damage.

• Ensure that all safety equipment is freely accessible at all times.

Damage to the Connection Unit due to electrostatic discharges

By touching electronic components you can damage or destroy the Connection Unit through

electrostatic discharge.

• Ground yourself before touching any components.

12 CU600-1000US-IA-en-10 Installation Manual

Page 13

SMA America, LLC 3 Scope of Delivery

3 Scope of Delivery

Check the scope of delivery for completeness and any externally visible damage. Contact your

distributor if the scope of delivery is incomplete or damaged.

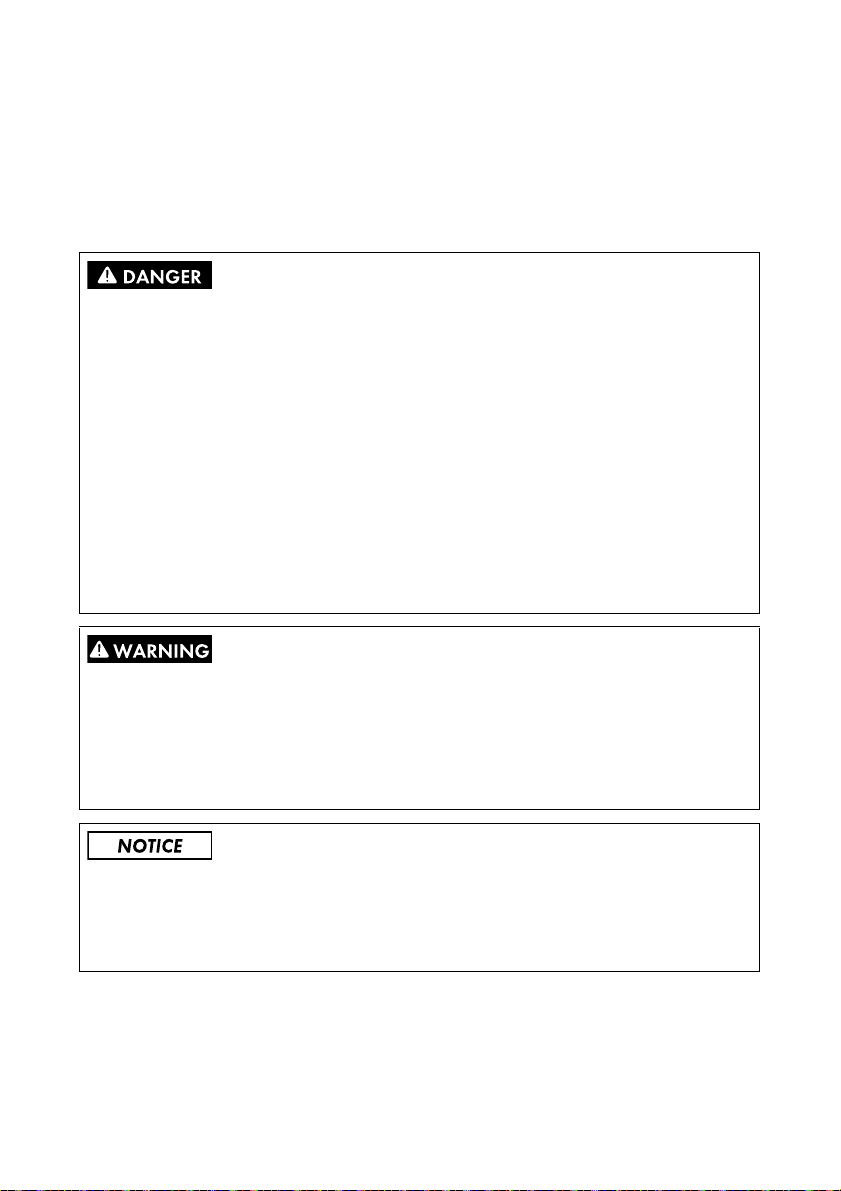

Figure 2: Components included in the scope of delivery

Item Quantity Designation

A1Connection Unit

B 1 Installation manual, Production Test Report

Installation Manual CU600-1000US-IA-en-10 13

Page 14

4 Product Description SMA America, LLC

4 Product Description

4.1 Connection Unit

The Connection Unit is a String-Combiner to which up to eight strings can be connected.

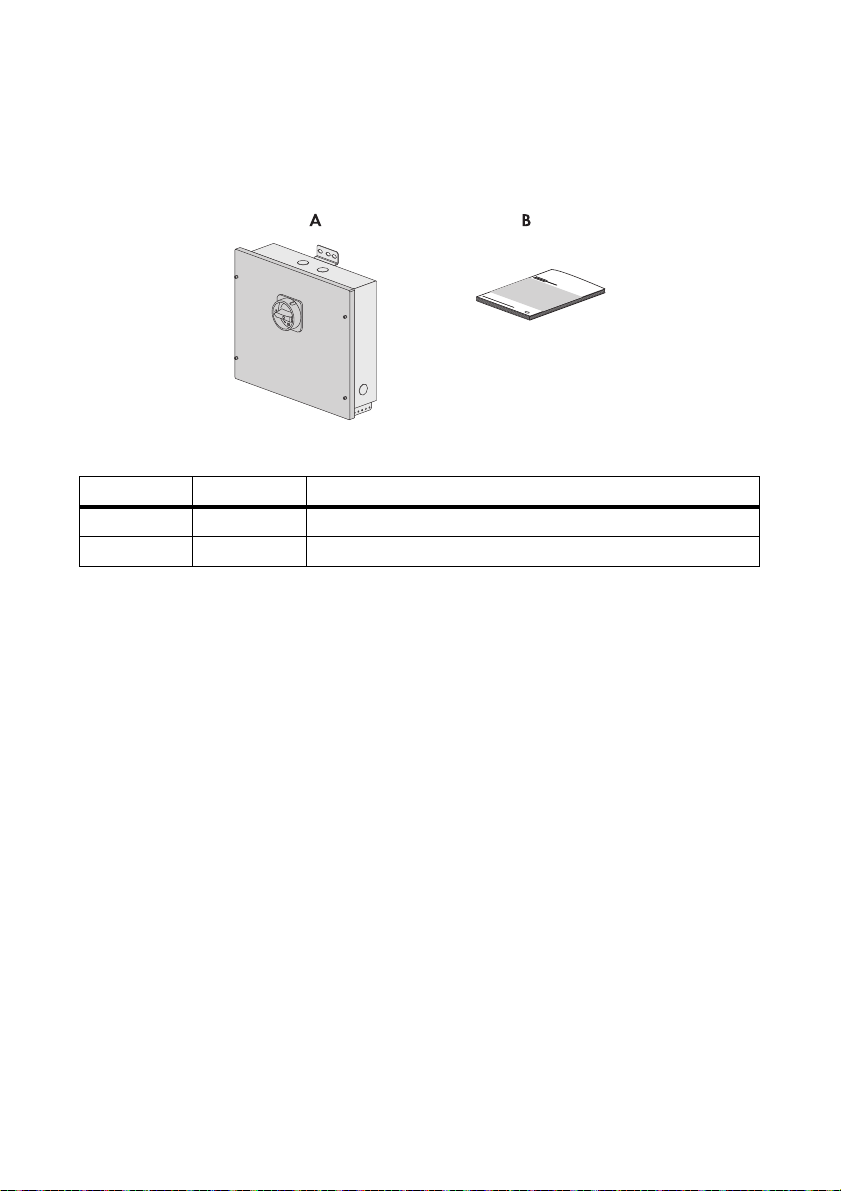

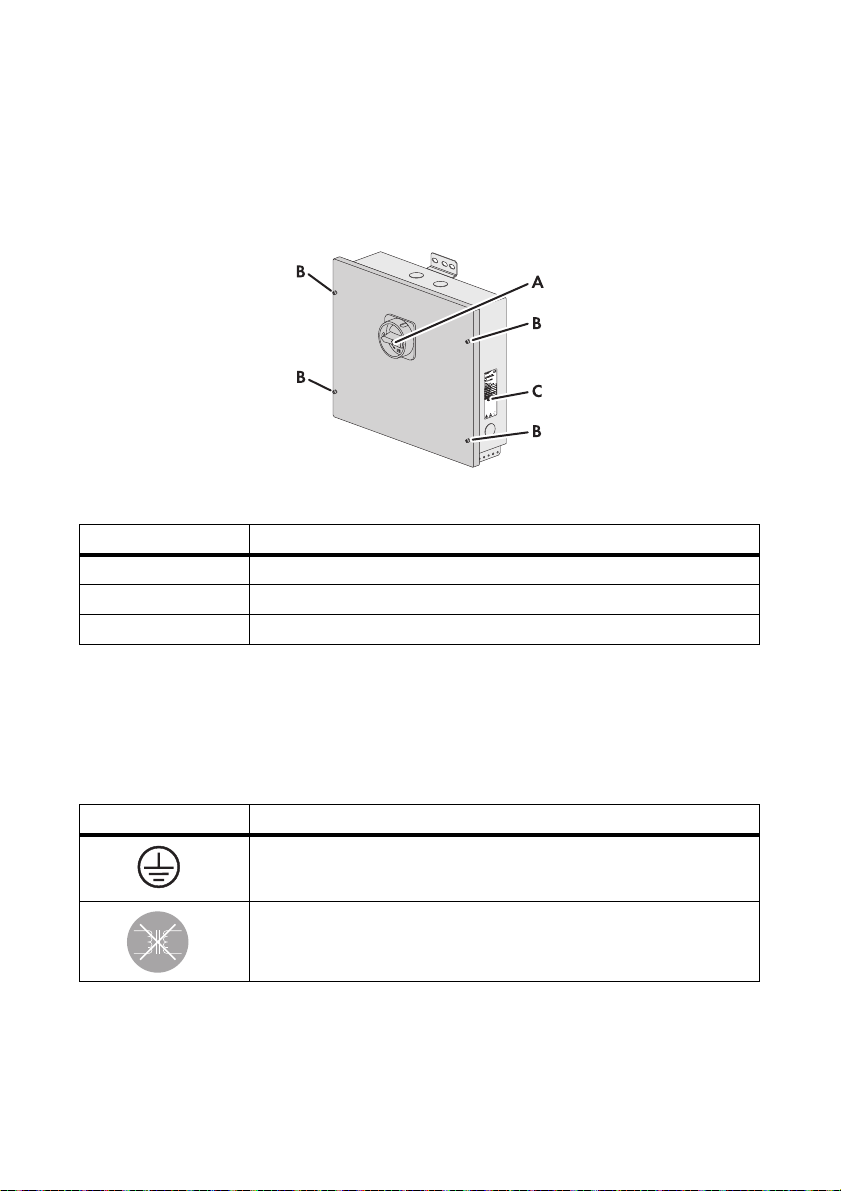

Figure 3: Design of the Connection Unit

Item Designation

A DC switch-disconnector

B Captive screws of the lid

CType label

In the Connection Unit the PV array strings are combined and routed into the inverter via cables. The

integrated fuse holders are designed to be used with string fuses for overcurrent protection. The

Connection Unit is equipped with a DC switch-disconnector and therefore serves as a DC

disconnection unit.

Symbols on the Connection Unit

Symbol Explanation

Equipment grounding

No galvanic isolation

14 CU600-1000US-IA-en-10 Installation Manual

Page 15

SMA America, LLC 4 Product Description

4.2 Type Label

The type label clearly identifies the Connection Unit. The type label is located on the right-hand side

of the enclosure. You will find the following information on the type label:

• Device type (Item No.)

•Serial number (Serial No.)

• Date of manufacture,

• Device-specific characteristics

You will require the information on the type label to use the Connection Unit safely and when seeking

customer support from the SMA Service Line. The type label must be permanently attached to the

Connection Unit.

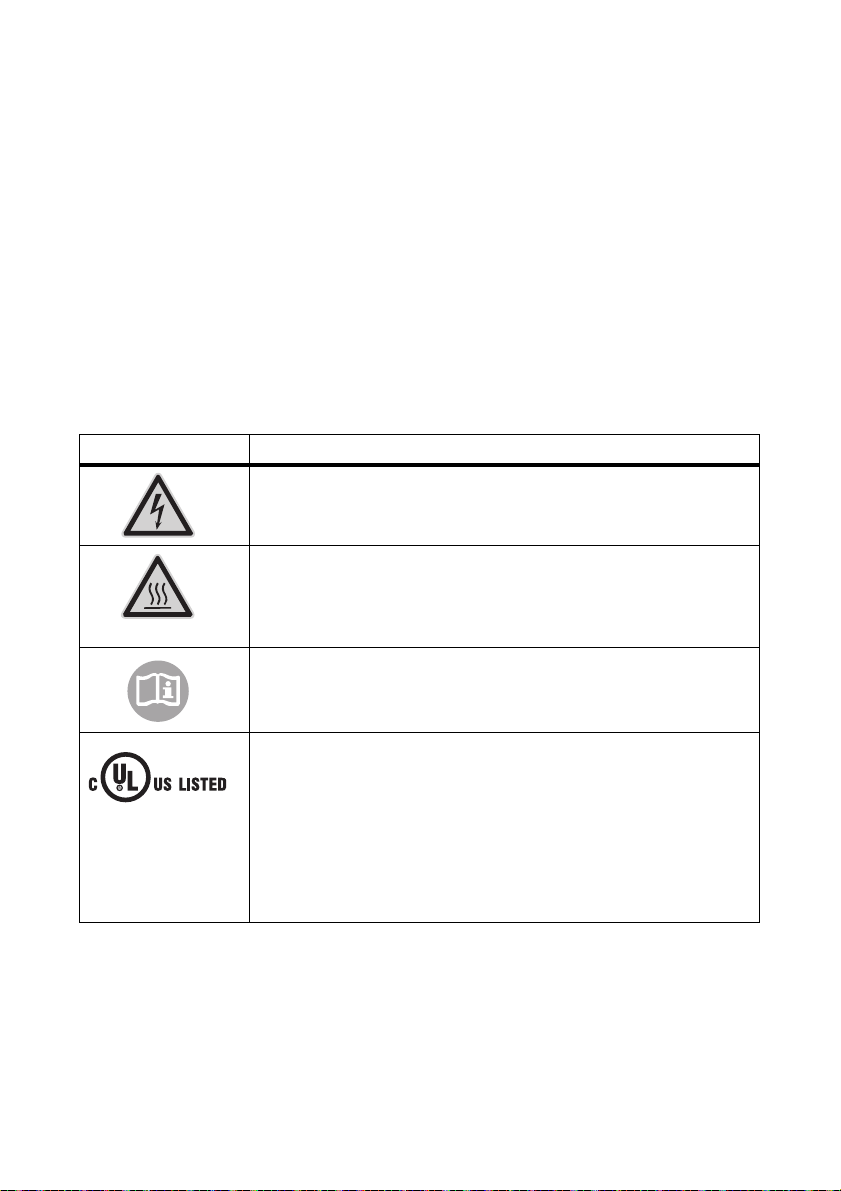

Symbols on the Type Label

Symbol Explanation

Danger to life due to high voltages

The product operates at high voltages. All work on the product must be

carried out by qualified persons only.

Risk of burns from hot surfaces

The product can get hot during operation. Avoid contact during operation.

Allow the product to cool down sufficiently before carrying out any work.

Wear personal protective equipment such as safety gloves.

Observe the documentation

Observe all documentation that is supplied with the product.

UL certification mark

UL1741 is the standard applied by Underwriters Laboratories to the

product to certify that it meets the requirements of the

National Electrical Code

®

, the Canadian Electrical Code® CSA C22.1

and IEEE-929-2000. IEEE 929-2000 provides recommendations

regarding the proper equipment and functionality necessary to ensure

compatible operation when power generation is connected to the utility

grid.

Installation Manual CU600-1000US-IA-en-10 15

Page 16

4 Product Description SMA America, LLC

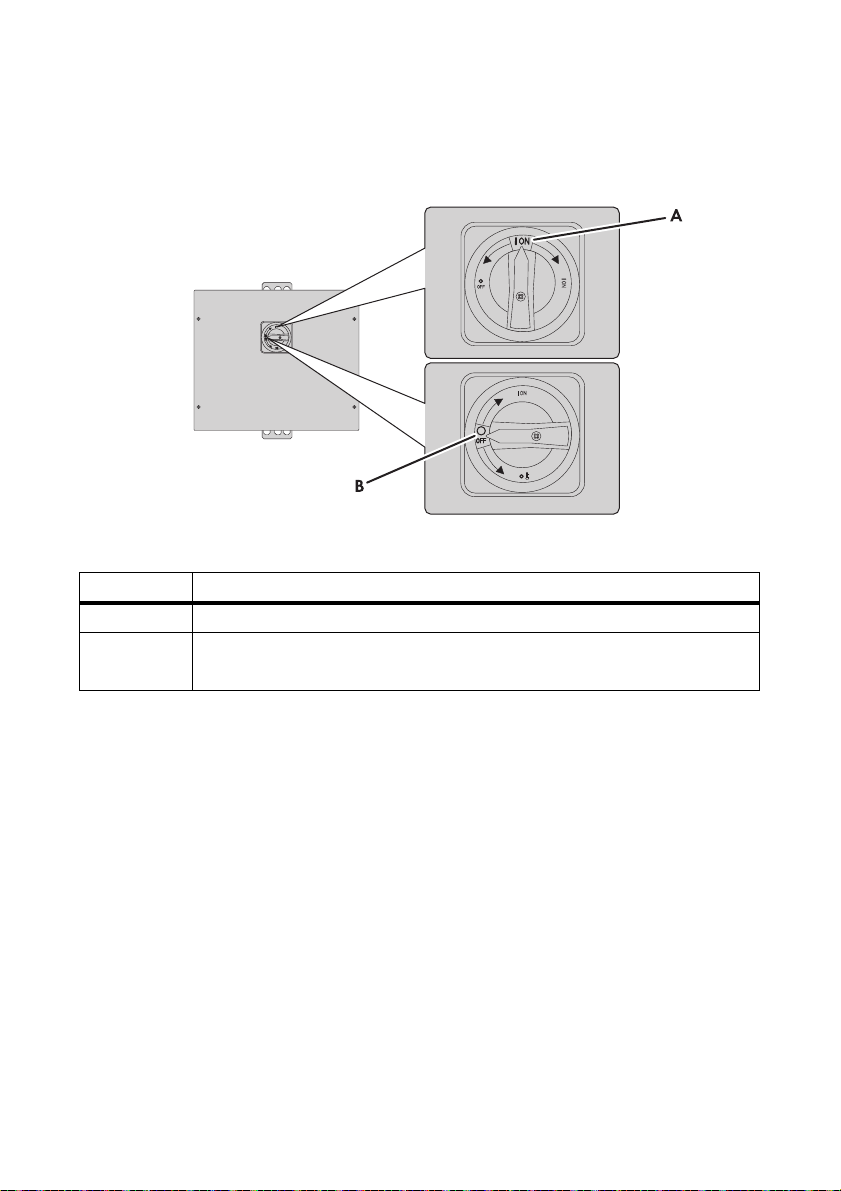

4.3 DC Switch-Disconnector

The Connection Unit is equipped with a DC switch-disconnector. The DC switch-disconnector enables

disconnection of the inverter from the PV array. The disconnection takes place at all poles.

Figure 4: DC switch-disconnector of the Connection Unit

Item Designation

A Switch position ON

B Switch position OFF

Opening for padlock to protect against restarting

When the DC switch-disconnector is switched OFF, it can be protected against restarting with a

padlock via one of the three openings.

4.4 String Fuses

St rin g fu ses are use d to pro tec t wi rin g an d equi pme nt f rom exc essive currents that can cause damage,

heating, or in extreme cases, even fire.

If the string fuses are designed too small, they may open too early and cause interference. If the string

fuses are designed too large, they do not provide the required protection as they open too late.

In PV s yst ems , th e mini mum and max imum s ize of t he s tri ng fus e is det erm ine d by th e el ect ric al n omi nal

sizes of the PV module as well as by UL and National Electrical Code

manufacturer of the PV modules in order to obtain the corresponding nominal sizes of the string fuses.

The maximum nominal size for string fuses in the Connection Unit is 20 A.

16 CU600-1000US-IA-en-10 Installation Manual

®

requirements. Contact the

Page 17

SMA America, LLC 4 Product Description

The minimum size of the string fuses and cables is calculated by means of the short-circuit current

rating (

of the PV module. The National Electrical Code® stipulates that all string fuses and cables

ISC)

are designed to be at least 1.56 times as large as the Isc of the PV module being used. The correct

size of the string fuse is determined by calculating the minimum size and then rounding it up to the

nearest standard size for string fuses.

Example: calculating the minimum size of the string fuses

For example, if the Isc of the PV module equals 6.9 A, then the size of the string fuses is determined

as follows: 1.56 x 6.9 = 10.76

The nearest standard size for string fuses would be a 12 A fuse.

4.5 Reverse Polarity Detection

The SMA Connection Unit 1000-US is equipped with reverse polarity detection.

Figure 5: Reverse polarity detection in the SMA Connection Unit 1000-US

Item Designation

A LED for visualizing a polarity-reversed string at INPUT A

B LED for visualizing a correct connection for INPUT A and INPUT B

C LED for visualizing a polarity-reversed string at INPUT B

D Button for activating the reverse polarity detection

The reverse polarity detection will test if the polarity of the connected conductors is correct once a

string has been newly connected. Testing occurs by operating the integrated button. As long as there

is sufficient DC voltage, the test result is visualized by the LEDs flashing.

Installation Manual CU600-1000US-IA-en-10 17

Page 18

5 Mounting SMA America, LLC

5 Mounting

5.1 Requirements for Mounting

Requirements for the mounting location:

Danger to life due to fire or explosion

Despite careful construction, electrical devices can cause fires.

• Do not mount the Connection Unit in areas where flammable gases may occur.

• Do not mount the Connection Unit near highly flammable materials.

• Do not mount the Connection Unit in potentially explosive atmospheres.

Risk of burns due to hot enclosure parts

Some parts of the enclosure can get hot during operation.

• Mount the Connection Unit in such a way that it cannot be touched inadvertently.

☐ A solid building ground is required for installation, e.g. a concrete wall, brick work, a post.

☐ Studs must be present behind the mounting points on plasterboard sheets or panels.

☐ The mounting location must be suitable for the weight and dimensions of the Connection Unit

(see Section 11 "Technical Data", page 48).

☐ When mounting directly below the inverter, the minimum clearances to the inverter must be

observed (see the inverter installation manual).

☐ The mounting location should be freely and safely accessible at all times without the necessity

for any auxiliary equipment, such as scaffolding or lifting platforms. Non-fulfillment of these

criteria may restrict servicing.

☐ The mounting location should not be exposed to direct solar irradiation. Direct solar irradiation

can cause the Connection Unit to overheat.

☐ The ambient temperature must be within a permissible range (see Section 11 "Technical Data",

page 48). This will ensure optimal operation of the Connection Unit.

18 CU600-1000US-IA-en-10 Installation Manual

Page 19

SMA America, LLC 5 Mounting

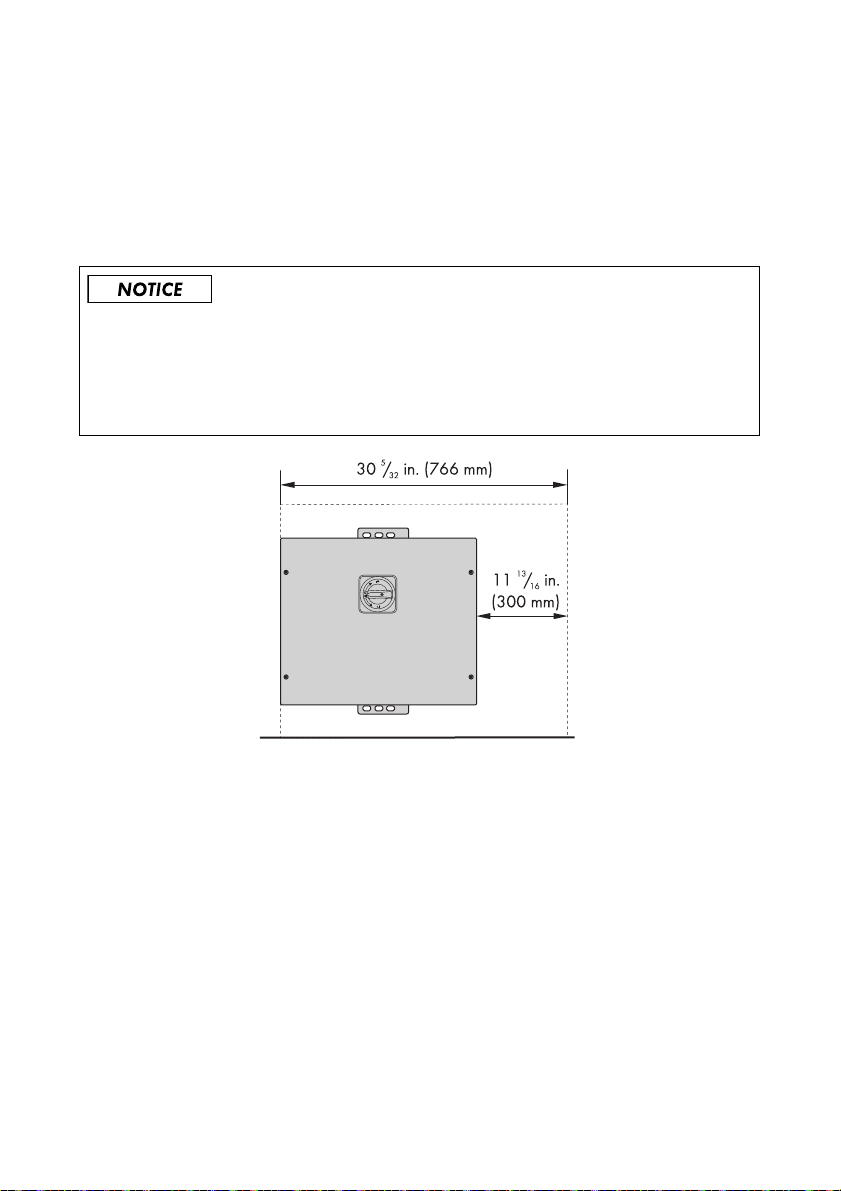

Dimensions for mounting:

Figure 6: Dimensions of the mounting points

Installation Manual CU600-1000US-IA-en-10 19

Page 20

5 Mounting SMA America, LLC

Information on mounting the Connection Unit below a Sunny Tripower

• You can mount the Connection Unit directly below the Sunny Tripower. The output

openings of the Connection Unit must be exactly below the openings for the DC

connection of the Sunny Tripower.

• Align the oblong holes of the mounting straps of the Connection Unit, the oblong holes

of the wall mounting brackets of the Sunny Tripower, and the drill holes for the screw in

the rear panel of the Sunny Tripower to each other.

• In order to have the conduits at the Sunny Tripower and at the Connection Unit correctly

positioned, the left oblong hole of the wall mounting bracket of the Sunny Tripower and

the left oblong hole of the Connection Unit must be flush one below the other.

Example:

20 CU600-1000US-IA-en-10 Installation Manual

Page 21

SMA America, LLC 5 Mounting

Recommended clearances:

☐ Observe recommended clearances to the walls or other objects. Thus, you can read the

following data from the type label at all times.

☐ The clearances to the front must be chosen in such a way that the DC switch-disconnector is

accessible at all times. Thus, you can operate the DC switch-disconnector anytime and read out

the switch position.

Damage to the Connection Unit by mounting it in regions with a high probability of snow

Position the Connection Unit in such way that it will not be covered entirely with snow when

mounting it in regions with a high probability of snow drifts. Snow drifts can damage the seals of the

conduits and moisture can get into the Connection Unit.

• To protect the Connection Unit from freezing, provide sufficient clearance to the ground.

Figure 7: Recommended clearances

Installation Manual CU600-1000US-IA-en-10 21

Page 22

5 Mounting SMA America, LLC

Permitted mounting positions:

☐ The Connection Unit must be mounted in a permitted position. That prevents moisture from

entering the Connection Unit.

Figure 8: Permitted and prohibited mounting positions

22 CU600-1000US-IA-en-10 Installation Manual

Page 23

SMA America, LLC 5 Mounting

5.2 Mounting the Connection Unit on a Wall

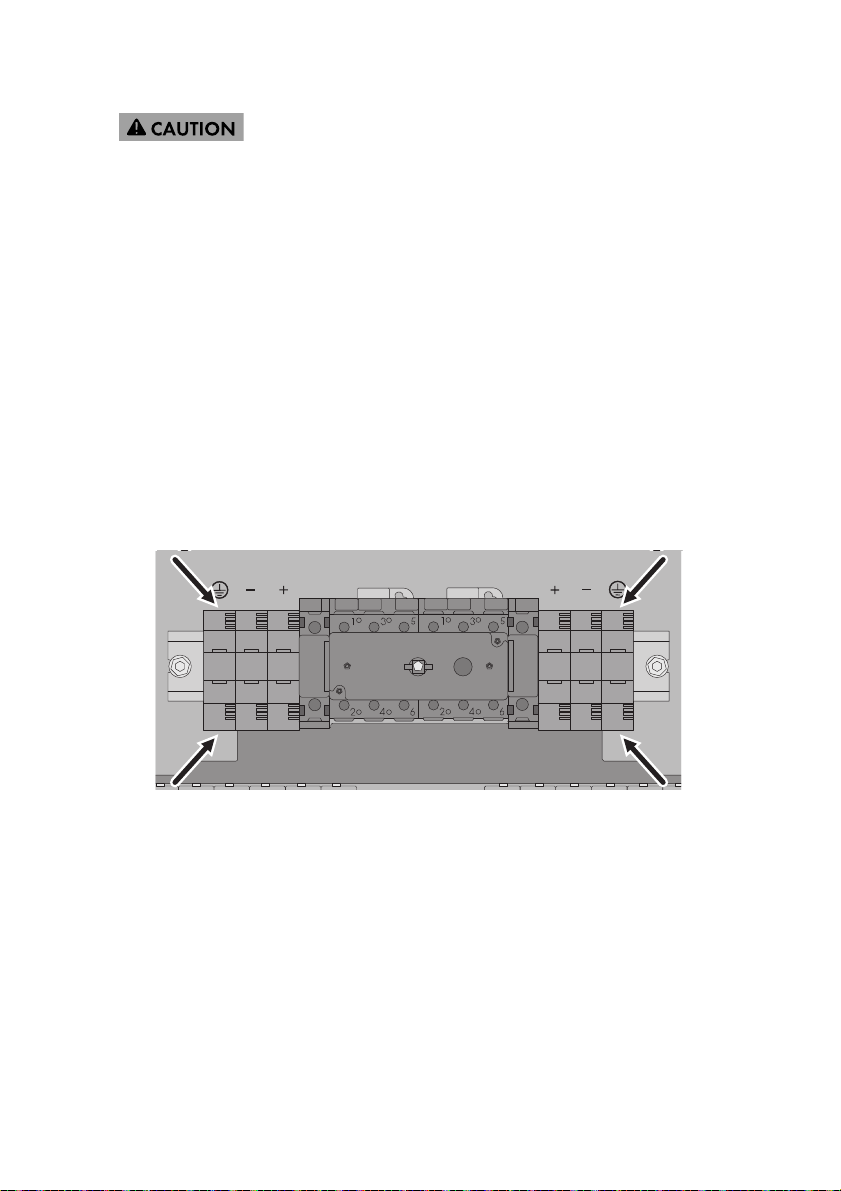

Damage to the Connection Unit due to moisture and dust intrusion

Dust or moisture intrusion can damage the Connection Unit.

• Only mount the Connection Unit with its lid closed and with inserted filler plugs.

Additionally required mounting material (not included in the scope of delivery):

☐ At least two screws that are suitable for the foundation

☐ At least two washers that are suitable for the screws

☐ At least two screw anchors that are suitable for the foundation and for the screws

Risk of burns due to hot enclosure parts

Some parts of the enclosure can get hot during operation.

• Mount the Connection Unit in such a way that it cannot be touched inadvertently.

Risk of injury when lifting the Connection Unit, or if it is dropped

There is a risk of injury if the Connection Unit is lifted incorrectly or dropped during transport or

mounting

• Keep in mind that the Connection Unit weighs 22 lbs. (10 kg) when mounting it.

• Use suitable mounting material for the mounting location of the Connection Unit.

– Do not use hollow-wall anchors or toggle bolts for mounting on drywall.

Procedure:

1. Position the Connection Unit on the wall.

2.

Danger of electric shock if electric cables and other supply lines are damaged by

drilling

• Before drilling, ensure that there are no electric cables and supply lines in the wall that

could be damaged.

3. Mark the drill hole positions by means of the oblong holes in the brackets of the Connection

Unit. Use at least one of the oblong holes at the top and at the bottom.

4. Remove the Connection Unit from the wall.

5. Drill holes at the markings.

6. Insert suitable screw anchors into the drill holes.

Installation Manual CU600-1000US-IA-en-10 23

Page 24

5 Mounting SMA America, LLC

7. Insert screws with washers through the oblong

holes of the Connection Unit into the drill holes.

8. Tighten the screws. Ensure that no screws are loose.

9. Ensure that the Connection Unit is firmly positioned.

24 CU600-1000US-IA-en-10 Installation Manual

Page 25

SMA America, LLC 5 Mounting

5.3 Mounting the Connection Unit to a Post

Damage to the Connection Unit due to moisture and dust intrusion

Dust or moisture intrusion can damage the Connection Unit.

• Only mount the Connection Unit with its lid closed and with inserted filler plugs.

Additionally required mounting material (not included in the scope of delivery):

☐ 2 screws suitable for the building ground

☐ 2 washers to match the screws

☐ 2 screw anchors suitable for the building ground and the screws.

Procedure:

1. Position the Connection Unit on the post.

2. Mark the drill hole positions by means of the oblong holes in the brackets of the Connection

Unit. Use at least one of the oblong holes at the top and at the bottom.

3. Remove the Connection Unit from the post.

4. Drill holes at the markings.

5. Insert suitable screw anchors into the drill holes.

6. Insert screws with washers through the oblong

holes of the Connection Unit into the drill holes.

7. Tighten the screws. Ensure that no screws are loose.

8. Ensure that the Connection Unit is firmly positioned.

Installation Manual CU600-1000US-IA-en-10 25

Page 26

6 Electrical Connection SMA America, LLC

6 Electrical Connection

6.1 Safety during Electrical Connection

Danger to life due to high voltages in the Connection Unit

High voltages that can cause fatal electric shocks when touched are present in the live components

of the Connection Unit.

• All work on the Connection Unit must be carried out by qualified persons only.

• Prior to performing any work on the Connection Unit, disconnect it from any voltage source

as described in this document (see Section 8).

• All work on the Connection Unit should only be carried out as described in this document.

Damage to the seal of the enclosure lid during frost

When opening the Connection Unit during frost, the seal of the enclosure lid can be damaged.

There may be an ingress of moisture damaging the Connection Unit.

• Do not open the Connection Unit when the ambient temperature is below 23°F ( − 5°C).

There might be ice on the seal of the lid when there is frost or the temperatures are below

freezing. Remove it prior to opening the Connection Unit (e.g. by melting the ice with warm

air). Adhere to the corresponding safety precautions.

Damage to the Connection Unit due to moisture ingress during electrical installation

• Do not open the Connection Unit in the event of rain or a high level of humidity (> 95%).

• F or a tta chi ng t he c ond uit s to the enc los ure , on ly u se U L-l ist ed rainproof or wet location conduit

fittings in accordance with UL514B.

• Close all unused openings tightly.

Electrostatic discharge

By touching electronic components you can damage or destroy the Connection Unit through

electrostatic discharge.

• Ground yourself before touching any components.

Ground faults, unreliable and highly resistive connections due to Wire Nuts

Potential damage to or failure of the Connection Unit.

•Do not use Wire Nuts

®

.

®

26 CU600-1000US-IA-en-10 Installation Manual

Page 27

SMA America, LLC 6 Electrical Connection

Electrical installations

All electrical installations must be made in accordance with the local electrical standards and

the National Electrical Code

®

ANSI/NFPA70 or the Canadian Electrical Code®.CSA C22.1.

• Use only +194°F (+90°C) copper wire for all DC wiring connections to the screw

terminals between the PV modules and the Connection Unit and between the Connection

Unit and the inverter.

• The DC input and output circuits are isolated from the enclosure and that sys tem grounding,

if required by Section 250 of the

National Electrical Code®, ANSI/NFPA 70, is the

responsibility of the installer.

• Make sure that no damaged cables are being used.

6.2 Overview of the Connection Area

6.2.1 Enclosure Openings

Figure 9: Enclosure openings of the Connection Unit

Item Designation

A Output opening in the enclosure for connecting the conduits

(diameter: 1

B Input opening in the enclosure with filler plugs for connecting the conduits

(diameter: 1

Installation Manual CU600-1000US-IA-en-10 27

23

⁄64 in. (34.5 mm) to 13⁄8 in. (34.7 mm))

3

⁄32 in. (27.8 mm) to 17⁄

in. (28.0 mm))

64

Page 28

6 Electrical Connection SMA America, LLC

6.2.2 Interior View of the Connection Unit 600-US

Figure 10: Components and connection areas in the interior of the Connection Unit 600-US

Item Designation

A Shaft of the DC switch-disconnector

B Terminals for connecting the DC output cables (INPUT B)

C Equipment grounding terminal

D Fuse holders for string fuses and terminals for connecting the negative DC cables

of the PV array ( − ) (INPUT B)

E Fuse holders for string fuses and terminals for connecting the positive DC cables of

the PV array (+) (INPUT B)

F Fuse holders for string fuses and terminals for connecting the negative DC cables

of the PV array ( − ) (INPUT A)

G Fuse holders for string fuses and terminals for connecting the positive DC cables of

the PV array (+) (INPUT A)

H Equipment grounding terminal

I Terminals for connecting the DC output cables (INPUT A)

28 CU600-1000US-IA-en-10 Installation Manual

Page 29

SMA America, LLC 6 Electrical Connection

6.2.3 Interior View Connection Unit 1000-US

Figure 11: Components and connection areas in the interior of the Connection Unit 1000-US

Item Designation

A Shaft of the DC switch-disconnector

B Terminals for connecting the DC output cables (INPUT B)

C Equipment grounding terminal

D Fuse holders for string fuses (INPUT B)

E Terminals for connecting the positive DC cables of the PV array (+) (INPUT B)

F Terminals for connecting the negative DC cables of the PV array ( − ) (INPUT B)

G Reverse polarity detection

H Terminals for connecting the negative DC cables of the PV array ( − ) (INPUT A)

I Terminals for connecting the positive DC cables of the PV array (+) (INPUT A)

K Fuse extractor for string fuses (INPUT A)

L Equipment grounding terminal

M Terminals for connecting the DC output cables (INPUT A)

Installation Manual CU600-1000US-IA-en-10 29

Page 30

6 Electrical Connection SMA America, LLC

6.3 Connecting Conduits to the Connection Unit

Additionally required material (not included in the scope of delivery):

☐ Conduits made out of metal that match the openings of the Connection Unit

☐ UL-listed rainproof or wet location conduit fittings complying with UL514B that match the

openings of the Connection Unit

☐ UL-listed type 3R filler plugs for closing unused output openings in the enclosure at the top of

the Connection Unit

Procedure:

1.

Danger to life due to electric shock

• Make sure that all devices (e.g. inverter) connected to the Connection Unit are switched

off and protected against reconnection (see manual of the respective device).

2.

Damage to the Connection Unit due to moisture ingress

Electronic components in the Connection Unit can be destroyed or damaged as a result of

moisture ingress.

• Do not enlarge enclosure openings.

3. Switch the DC switch-disconnector OFF. Turn the

DC switch-disconnector counterclockwise by 90°.

4. Disassemble the lid of the Connection Unit. Loosen

all captive screws with an Allen key (AF 4) and

remove the lid by lifting it from below.

5. Remove the adhesive tape from both output openings on top of the Connection Unit.

30 CU600-1000US-IA-en-10 Installation Manual

Page 31

SMA America, LLC 6 Electrical Connection

6.

Risk of injury when pressing out the filler plugs

• T o co nne ct t he c ond uit s to the inp ut o pen ings of th e Co nne cti on U nit , gently p res s ou t on e

filler plug for each conduit from the inside with a blunt object (e.g screwdriver handle).

Make sure not to damage components of the Connection Unit or of the filler plugs.

7. Insert one conduit fitting each into the corresponding enclosure opening and tighten from within

using the counter nut.

8. Attach the conduit to the enclosure opening.

9. Close an unused output opening on top of the Connection Unit with UL-listed type 3R filler plugs.

10. Close unused input openings of the Connection Unit with the factory-mounted filler plugs.

6.4 Connecting the Grounding Conductor

The Connection Unit is equipped with two terminals for connecting the grounding conductors. Each

terminal has two connection points.

Overview

Figure 12: Terminals for connecting the grounding conductors

Cable requirements:

☐ The cable must be designed in accordance with the local installation requirements and for

temperatures of over +194°F (+90°C).

☐ Cable type: copper wire

☐ Use only solid wire or rough wire strands.

☐ Conductor cross-section: AWG 8 to AWG 2 (10 mm² to 35 mm²)

Installation Manual CU600-1000US-IA-en-10 31

Page 32

6 Electrical Connection SMA America, LLC

Requirements:

☐ All conduits must be correctly connected to the Connection Unit (see Section 6.3).

☐ The DC switch-disconnector must be turned OFF and the lid of the Connection Unit must be

dismantled.

Procedure:

1.

Danger to life due to electric shock

• Make sure all devices connected to the Connection Unit (e.g inverter) are switched off

and protected against reconnection (see manual of the respective device).

•Ensure that no DC voltage is present.

2. Lead the grounding conductors trough the conduit into the interior of the Connection Unit.

3. Strip the insulation of the grounding conductor

23

⁄32 in. (18 mm).

4. Connect the grounding conductor to one of the

termination points of the terminal with the symbol

and tighten with a screwdriver (blade width: 6

mm) (torque: at least 44.3 in-lb. (5 Nm)).

5. Ensure that the grounding conductor is firmly positioned.

32 CU600-1000US-IA-en-10 Installation Manual

Page 33

SMA America, LLC 6 Electrical Connection

6.5 Connecting the PV Array to the Connection Unit 600-US

Cable requirements:

☐ The DC cables of the PV array must be designed in accordance with the installation

requirements applicable on site and for temperatures of +194°F (+90°C).

☐ The DC input and output circuits are isolated from the enclosure and that system grounding, if

required by Section 250 of the National Electrical Code

of the installer.

☐ The maximum cable length, which is dependent on the conductor cross-section, must be

adhered to.

☐ Cable type: copper wire

☐ Conductor cross-section: AWG 12 to AWG 8 (4 mm² to 8 mm²)

Requirements:

☐ The conduits must be correctly connected to the Connection Unit (see Section 6.3).

☐ The DC switch-disconnector must be switched OFF and the lid must be dismantled.

Procedure:

Connect the DC cables of the PV array to each INPUT A and INPUT B as follows:

1.

Danger to life due to electric shock

• Make sure that all devices (e.g. inverter) connected to the Connection Unit are switched

off and protected against reconnection (see manual of the respective device).

•Cover the PV modules.

®

, ANSI/NFPA 70, is the responsibility

2.

Danger to life due to electric shock

The strings in the Connection Unit are combined to one main string. If there is reverse polarity

of a PV string, there can be short-circuit current flowing when string fuses are inserted, string

safety levers are closed, and the DC switch-disconnector is open.

• Open all safety levers all the way.

3. Lead the DC cables of the PV array through the connected conduits into the interior of the

Connection Unit.

4. Strip the insulation of all cables

Installation Manual CU600-1000US-IA-en-10 33

23

⁄64 in. (9 mm).

Page 34

6 Electrical Connection SMA America, LLC

5. Check the positive DC cables for correct polarity

and insert them all the way into the square opening

with the plus sign (+) on the bottom of the fuse

holder.

6. Tighten the fuse holder screws with a Philips

screwdriver (Philips size: 2) (torque: 30 in-lb.

(3.4 Nm)).

7. Check the negative DC cables for correct polarity

and insert them all the way into the square opening

with the minus sign ( − ) on the bottom of the fuse

holder.

8. Tighten the fuse holder screws with a Philips

screwdriver (Philips size: 2) (torque: 30 in-lb.

(3.4 Nm)).

9. Ensure that all conductors are securely in place and cannot be detached by pulling.

34 CU600-1000US-IA-en-10 Installation Manual

Page 35

SMA America, LLC 6 Electrical Connection

6.6 Connecting the PV Array to the Connection Unit 1000-US

Cable requirements:

☐ The DC cables of the PV array must be designed in accordance with the installation

requirements applicable on site and for temperatures of +194°F (+90°C).

☐ The DC input and output circuits are isolated from the enclosure and that system grounding, if

required by Section 250 of the National Electrical Code

of the installer.

☐ The maximum cable length, which is dependent on the conductor cross-section, must be

adhered to.

☐ Cable type: copper wire

☐ Conductor cross-section: AWG 12 to AWG 6 (4 mm² to 16 mm²)

Requirements:

☐ The conduits must be correctly connected to the Connection Unit (see Section 6.3).

☐ The DC switch-disconnector must be switched OFF and the lid must be dismantled.

Procedure:

Connect the DC cables of the PV array to INPUT A and B as follows:

1.

Danger to life due to electric shock

• Make sure that all devices (e.g. inverter) connected to the Connection Unit are switched

off and protected against reconnection (see manual of the respective device).

•Cover the PV modules.

®

, ANSI/NFPA 70, is the responsibility

2.

Danger to life due to electric shock

The strings in the Connection Unit are combined to one main string. If there is reverse polarity

of a PV string, there can be short-circuit current flowing when string fuses are inserted, string

safety levers are closed, and the DC switch-disconnector is open.

• Open all safety levers all the way.

3. Lead the DC cables of the PV array through the connected conduits into the interior of the

Connection Unit.

Installation Manual CU600-1000US-IA-en-10 35

Page 36

6 Electrical Connection SMA America, LLC

4. Strip the insulation of all cables by 13⁄32 in. (10 mm).

5. Check the positive DC cables for correct polarity

and connect them to the terminals with the plus sign

(+). Tip: the reverse polarity detection can be

carried out after connecting each string (see

Section 6.7 "Operating the Reverse Polarity

Detection", page 36).

6. Tighten the screw terminals with a screwdriver

(blade width: 4) (torque: 15 in-lb. (1.7 Nm)).

7. Check the negative DC cables for correct polarity

and connect them to the terminals with the minus

sign ( − ). Tip: the reverse polarity detection can be

carried out after connecting each string (see

Section 6.7 "Operating the Reverse Polarity

Detection", page 36).

8. Tighten the screw terminals with a screwdriver

(blade width: 4) (torque: 15 in-lb. (1.7 Nm)).

9. Ensure that all cables are connected with the right

polarity using the reverse polarity detection (see Section 6.7 "Operating the Reverse Polarity

Detection", page 36).

6.7 Operating the Reverse Polarity Detection

The reverse polarity detection of the Connection Unit 1000-US allows you to test if all cables have

been connected with the correct polarity.

Requirements:

☐ The DC cables of the PV array must be connected to the terminals.

☐ The DC switch-disconnector must be turned OFF and the lid dismantled.

☐ For the reverse polarity detection to function, the DC voltage must be at least 100 V.

Danger to life due to electric shock

The strings in the Connection Unit are combined to one main string. If there is reverse polarity of a

PV string, there can be short-circuit current flowing when string fuses are inserted, string safety levers

are closed, and the DC switch-disconnector is open.

• All safety levers must be opened all the way before you can use the reverse polarity detection.

36 CU600-1000US-IA-en-10 Installation Manual

Page 37

SMA America, LLC 6 Electrical Connection

Procedure:

1. Establish the DC voltage supply.

2. Press the button for reverse polarity detection once.

☑ The middle LED glows green for a few seconds.

All DC cables are correctly connected. How long the LED glows depends on the level of the

applied DC voltage.

✖ The left LED glows red for a few seconds? How long the LED glows depends on the level of

the applied DC voltage.

At least two of the connected cables at INPUT B are connected with reversed polarity.

• Check polarity and connect the cable to the correct terminal.

✖ The red LED glows red for a few seconds? How long the LED glows depends on the level of

the applied DC voltage.

At least two of the connected cables at INPUT B are connected with reversed polarity.

• Check polarity and connect the cable to the correct terminal.

✖ All LEDs are off?

The polarity test could not be carried out.

• Make sure that the DC voltage ist at least 100 V and wait for about 1 minute. Then press

the button again.

• If there is sufficient DC voltage and the problem still persists, check the polarity at each

terminal with a suitable multimeter. In case of reverse polarity, connect the respective

cable to the correct terminal.

Installation Manual CU600-1000US-IA-en-10 37

Page 38

6 Electrical Connection SMA America, LLC

6.8 Connecting the DC Output Cable for the Inverter to the Connection Unit

Additionally required mounting material (not included in the scope of delivery):

☐ Two cables for connecting the Connection Unit to the inverter.

☐ If the DC switch-disconnector should be protected against restarting, a padlock can be used.

Cable requirements:

☐ The DC output cables must be designed in accordance with the installation requirements

applicable on site and for temperatures of +194°F (+90°C).

☐ Cable type: copper wire

☐ Use only solid wire or rough wire strands.

☐ Conductor cross-section: AWG 8 to AWG 2 (10 mm² to 35 mm²)

Padlock requirements:

☐ The material must be non-corrosive and weather-proof.

☐ The shackle of the padlock must be hardened.

☐The lock cylinder must be secured.

Requirements:

☐ The conduits must be correctly connected to the Connection Unit (see Section 6.3).

☐ The DC switch-disconnector must be switched OFF and the lid must be dismantled.

Procedure:

Connect the DC output cables for connecting the Connection Unit to the inverter for INPUT A and

INPUT B as follows:

1.

Danger to life due to electric shock

• Make sure all devices connected to the Connection Unit (e.g inverter) are switched off

and protected against reconnection (see manual of the respective device).

•Cover the PV modules.

2. Strip the insulation of the cable ends of the two cables for connecting the Connection Unit to the

inverter by

3. Connect a cable to the screw terminal with the

minus sign for connecting the Connection Unit to the

inverter.

4. Tighten the screw terminals with a screwdriver

(blade width: 6 mm) (torque 51 in-lb. (5.8 Nm)).

38 CU600-1000US-IA-en-10 Installation Manual

5

⁄16 in. (18 mm).

Page 39

SMA America, LLC 6 Electrical Connection

5. Connect a cable to the screw terminal with the plus

sign for connecting the Connection Unit to the

inverter

6. Tighten the screw terminals with a screwdriver

(blade width: 6 mm) (torque 51 in-lb. (5.8 Nm)).

7. Mount the lid of the Connection Unit:

• Position the lid in such a way that the protruding

shaft in the Connection Unit snaps into the

provided opening of the DC

switch-disconnector.

• Tighten all lid screws with an Allen key (AF 4)

(torque: 35 in-lb. (4 Nm)).

8. In order to protect the DC switch-disconnector

against restarting, lead the shackle of the padlock through the opening in the switch and lock it.

9. Lead the connected DC output cables through the conduit of the Connection Unit and connect

to the inverter (see inverter installation manual).

Installation Manual CU600-1000US-IA-en-10 39

Page 40

7 Commissioning SMA America, LLC

7 Commissioning

7.1 Inserting the String Fuses

Insert the string fuses before commissioning the Connection Unit.

Requirements:

☐ Only UL-listed string fuses according to UL 2579 are permitted.

☐ 600 V string fuses must be inserted for the Connection Unit 600-US.

☐ 1,000 V string fuses must be inserted for the Connection Unit 1000-US.

☐ The fuse size must be 10 mm x 38 mm (midget format).

☐ Only maximum 20 A string fuses are permitted.

Procedure:

1.

Danger to life due to electric shock

• Make sure that all devices (e.g. inverter) connected to the Connection Unit are switched

off and protected against reconnection (see manual of the respective device).

•Ensure that no DC voltage is present.

2. Turn the DC switch-disconnector OFF. Turn the DC

switch-disconnector counterclockwise by 90°.

3. Remove the lid of the Connection Unit. Loosen all

captive screws with an Allen key (AF 4) and

remove the lid by lifting it from below.

40 CU600-1000US-IA-en-10 Installation Manual

Page 41

SMA America, LLC 7 Commissioning

4. Open all safety levers needed all the way.

5. Insert 1 string fuse into each fuse holder.

6. Close all safety levers all the way.

☑ The safety levers audibly click into place.

7. Mount the lid of the Connection Unit:

• Position the lid in such a way that the protruding

shaft in the Connection Unit snaps into the

provided opening of the DC

switch-disconnector.

• Tighten all screws of the lid with an Allen Key

(AF 4) (torque: 35 in-lb. (4 Nm)).

8. In order to protect the DC switch-disconnector against restarti ng, le ad t he s hackl e of the pad lock

through the opening in the switch and lock it.

9. Commission the Connection Unit (see Section 7.2).

Installation Manual CU600-1000US-IA-en-10 41

Page 42

7 Commissioning SMA America, LLC

7.2 Commissioning the Connection Unit

The Connection Unit is part of the PV system. All parts of the PV system must be mounted and set up

prior to commissioning the Connection Unit.

Commissioning occurs via the three-pole circuit breaker (see inverter installation manual).

Requirements:

☐ The Connection Unit must be correctly mounted.

☐ All DC cables must be correctly connected.

☐ String fuses must be inserted in the Connection Unit.

☐ Unused output openings on top of the Connection Unit must be closed with UL-listed type 3R

filler plugs.

☐ Unused input openings of the Connection Unit must be closed tightly. The factory-mounted filler

plugs can be used for that purpose.

☐ Connection Unit must be connected to the inverter.

☐ The Connection Unit and the inverter must be connected by a grounding conductor.

☐ The lid of the Connection Unit must be installed.

☐ The three-pole circuit breaker must be correctly rated.

Procedure:

1. Commission the inverter (see inverter installation manual).

2. If the DC switch-disconnector has been protected against restarting, open and detach the

padlock.

3. Turn the DC switch-disconnector of the Connection

Unit counterclockwise by 90° and set to ON.

42 CU600-1000US-IA-en-10 Installation Manual

Page 43

SMA America, LLC 8 Disconnecting the Connection Unit from Voltage Sources

8 Disconnecting the Connection Unit from Voltage

Sources

1.

Danger to life due to electric shock

• Make sure that all devices (e.g. inverter) connected to the Connection Unit are switched

off and protected against reconnection (see manual of the respective device).

•Cover the PV modules.

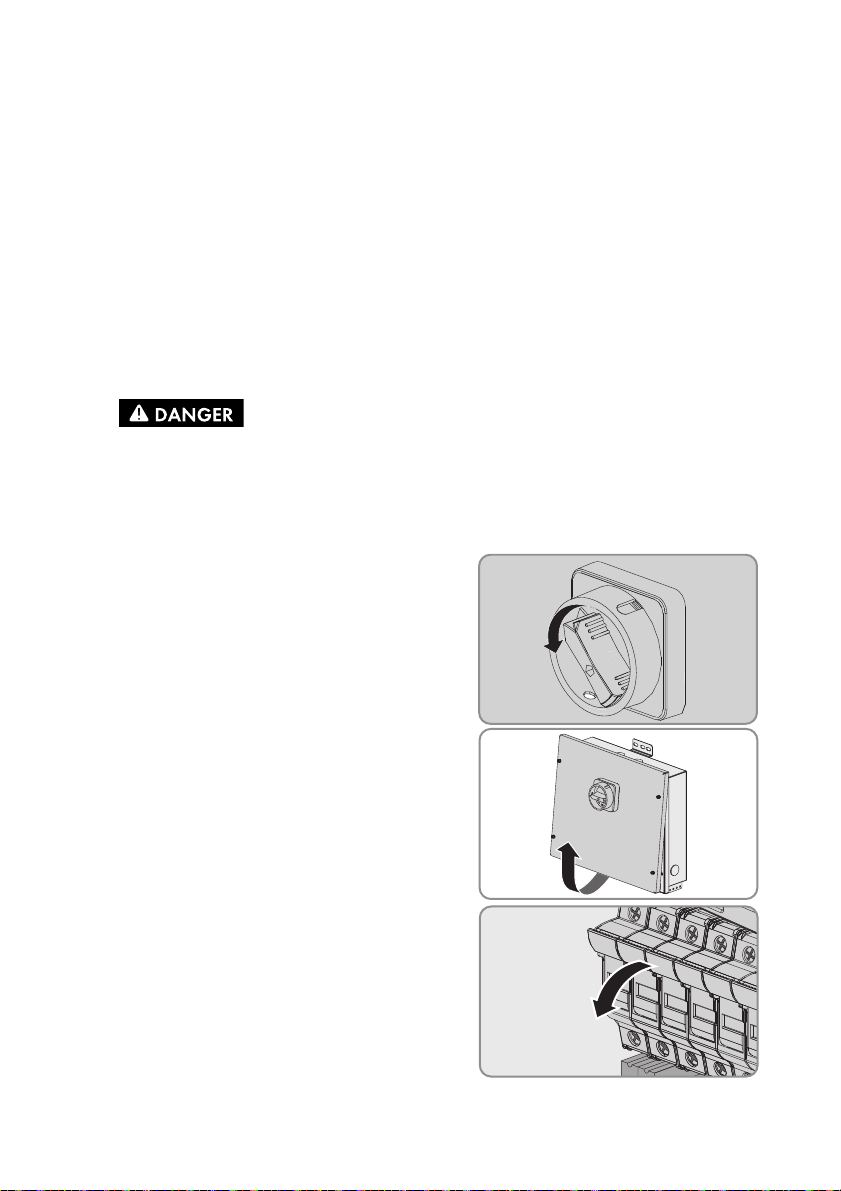

2. Turn the DC switch-disconnector of the Connection

Unit counterclockwise by 90° and set to OFF.

3. Disassemble the lid of the Connection Unit. Loosen

all captive screws with an Allen key (AF 4) and

remove the lid by lifting it from below.

4. Open all safety levers all the way.

5.

Danger to life due to electric shock

The DC cables are still live if there is sufficient irradiation. Detaching the live DC cables from

the terminals can cause life-threatening electric shocks.

• Ensure that the terminals are voltage-free using a suitable multimeter.

6. Detach all DC cables from the terminals using a screwdriver.

Installation Manual CU600-1000US-IA-en-10 43

Page 44

9 Troubleshooting SMA America, LLC

9 Troubleshooting

9.1 LED Signals

The LEDs are part of the reverse polarity detection of the Connection Unit 1000-US and signalize if a

string has been connected correctly or with the wrong polarity.

Figure 13: LED signals of the reverse polarity detection for the SMA Connection Unit 1000-US

Item LED Status Explanation

ALED INPUT A glowing red String at INPUT A is connected with the wrong polarity.

B LED middle glowing green String at INPUT A and/or INPUT B is connected

correctly

CLED INPUT B glowing red String at INPUT B is connected with the wrong polarity

44 CU600-1000US-IA-en-10 Installation Manual

Page 45

SMA America, LLC 9 Troubleshooting

9.2 Replacing the String Fuses

Each string fuse is assigned to one string. If one or several string fuses are blown or defective, you

have to replace the respective string fuses.

Requirements:

☐ Only UL-listed string fuses according to UL 2579 are permitted.

☐ 600 V string fuses must be inserted for the Connection Unit 600-US.

☐ 1,000 V string fuses must be inserted for the Connection Unit 1000-US.

☐ The fuse size must be 10 mm x 38 mm (midget format).

☐ Only maximum 20 A string fuses are permitted.

Procedure:

1.

Danger to life due to electric shock

• Make sure that all devices (e.g. inverter) connected to the Connection Unit are switched

off and protected against reconnection (see manual of the respective device).

•Ensure that no DC voltage is present.

2. Turn the DC switch-disconnector OFF. Turn the DC

switch-disconnector counterclockwise by 90°.

3. Remove the lid of the Connection Unit. Loosen all

captive screws with an Allen key (AF 4) and

remove the lid by lifting it from below.

4. Open all safety levers needed all the way.

Installation Manual CU600-1000US-IA-en-10 45

Page 46

9 Troubleshooting SMA America, LLC

5. Remove blown or defective string fuses from the

fuse holders.

6. Insert one new string fuse into each fuse holder.

7. Close all safety levers all the way.

☑ The safety levers audibly click into place.

8. Mounting the lid of the Connection Unit:

• Position the lid in such a way that the protruding

shaft in the Connection Unit snaps into the

provided opening of the DC

switch-disconnector.

• Tighten all screws of the lid with an Allen Key

(AF 4) (torque: 35 in-lb. (4 Nm)).

9. Commission the Connection Unit (see Section 7.2).

46 CU600-1000US-IA-en-10 Installation Manual

Page 47

SMA America, LLC 10 Decommissioning

10 Decommissioning

10.1 Disassembling the Connection Unit

1. Disconnect the PV system from voltage sources (see inverter installation manual).

2. Remove all cables from the Connection Unit:

• Disconnect the Connection Unit from voltage sources (see Section 8).

• Release all cables from the terminals using a screwdriver and pull the cables out of the

Connection Unit.

• Unscrew the counter nut of the conduit fittings from the inside.

• Remove the conduit fittings and conduits with cables.

3. Mount the lid of the Connection Unit:

• Position the lid in such a way that the protruding shaft in the Connection Unit snaps into the

provided opening of the DC switch-disconnector.

• Attach all screws of the lid (torque: 35.4 in-lb. (4 Nm)).

4. Detach the screws from the mounting straps.

5. Remove the Connection Unit from the building ground.

6. To seal the Connection Unit, insert the original filler plugs or type 3R filler plugs into the

enclosure openings.

10.2 Packing the Connection Unit

• Pack the Connection Unit. Use the original packaging or packaging that is suitable for the

weight and dimensions of the Connection Unit.

10.3 Disposing of the Connection Unit

• Dispose of the Connection Unit in accordance with the applicable local disposal regulations for

electronic waste.

Installation Manual CU600-1000US-IA-en-10 47

Page 48

11 Technical Data SMA America, LLC

11 Technical Data

DC Input

CU 600-US-10 CU 1000-US-10

Maximum number of incoming strings 8 8

Strings for INPUT A 4 4

Strings for INPUT B 4 4

Maximum input voltage 600 V 1,000 V

DC Output

CU 600-US-10 CU 1000-US-10

Maximum number of outgoing strings 2 2

Protective Devices

CU 600-US-10 CU 1000-US-10

DC reverse polarity detection Not available available

Overcurrent protection String fuses String fuses

Torques

CU 600-US-10 CU 1000-US-10

Fuse holder / terminals for connecting the DC

input cables

Terminals for connecting the DC output cables 51 in-lb. (5.8 Nm) 51 in-lb. (5.8 Nm)

Grounding terminals 51 in-lb. (5.8 Nm) 51 in-lb. (5.8 Nm)

Lid screws 35.4 in-lb. (4.0 Nm) 35.4 in-lb. (4.0 Nm)

48 CU600-1000US-IA-en-10 Installation Manual

30 in-lb. (3.4 Nm) 15 in-lb. (1.7 Nm)

Page 49

SMA America, LLC 11 Technical Data

General Data

Width x height x depth 18 23⁄64 in. x 15 11⁄16 in. x 5 11⁄32 in.

(466 mm x 398 mm x 136 mm)

Weight 22 lb. (10 kg)

11

Length x width x height of packaging 22

Transport weight 24 lb. (11 kg)

Operating temperature range − 40°F to +140°F

Storage temperature range − 40°F to +140°F

Maximum permissible value for relative humidity,

non-condensing

Maximum operating altitude above MSL 6,561 ft. (2,000 m)

Enclosure Type Rating Type 3R

Approvals and national standards,

as per 05/2013

⁄64 in. x 21 3⁄8 in. 5 11⁄32 in.

(563 mm x 543 mm x 240 mm)

( − 40°C to +60°C)

( − 40°C to +60°C)

100%

UL1741

CAN/CSA C22.2 No. 107.1-01

Installation Manual CU600-1000US-IA-en-10 49

Page 50

12 Accessories SMA America, LLC

12 Accessories

You will find the corresponding accessories and spare parts for your product in the following

overview. If required, these can be ordered from SMA or your specialty retailer.

Designation Brief Description SMA order number

String fuses Retrofit kit with ten fuses, listed

according to UL2579

-

50 CU600-1000US-IA-en-10 Installation Manual

Page 51

SMA America, LLC 13 Contact

13 Contact

If you have technical problems concerning our products, contact the SMA Service Line. We require

the following information in order to provide you with the necessary assistance:

• Device type of the Connection Unit

• Serial number of the Connection Unit

• Type and number of the PV modules connected

• Mounting location and mounting height of the Connection Unit

• LED signal and error message of the inverter if applicable

Country Company name SMA Service Line

United States/

Estados

Unidos

Canada/

Canadá

* toll free for USA, Canada and Puerto Rico / Llamada gratuita en EE. UU., Canadá y Puerto Rico

** international / Internacional

*** toll free for Canada / gratuit pour le Canada

Installation Manual CU600-1000US-IA-en-10 51

SMA America, LLC

Rocklin, CA

SMA Canada, Inc.

Toronto

+1 877-MY-SMATech (+1 877-697-6283)*

+1 916 625-0870**

+1 877-MY-SMATech (+1 877-697-6283)***

Page 52

SMA Solar Technology

www.SMA-Solar.com

SMA America, LLC

www.SMA-America.com

Loading...

Loading...