SLE 4000, 5000 Service Manual

Software/Manual application Information:

Note: This manual is to be used only with model A ventilators using the following software version:

Version 3, 3.1, 3.2, 3.3, 4 & 4.1

Contact Information:

SLE Limited |

|

|

Twin Bridges Business Park |

|

|

232 Selsdon Road |

|

|

South Croydon |

|

|

Surrey |

CR2 6PL |

|

Telephone: |

+44 (0)20 8681 1414 |

|

Fax: |

+44 (0)20 8649 8570 |

|

E-mail: |

service@sle.co.uk |

(E-mail’s should be addressed to the Service Manager) |

Web site: |

www.sle.co.uk |

|

|

|

|

All rights reserved. No part of this publication may be reproduced, stored in any retrieval system, or transmitted in any form or by any means, electronic, mechanical, photocopy, recording or otherwise, without prior permission of SLE. © Copyright SLE 12/04/2007.

Manual : SM0015 Issue 10

SLE Part Nº: N6645

Page 2 |

(Model A) |

Contents |

|

1. Warnings and Cautions ............................................................................................. |

10 |

1.1. Warnings ........................................................................................................ |

10 |

1.2. Cautions ......................................................................................................... |

11 |

2. Principles of Operation .............................................................................................. |

14 |

2.1. Electronic System........................................................................................... |

14 |

2.2. Pneumatic System ......................................................................................... |

15 |

3. Description of Symbols ............................................................................................. |

18 |

4. Equipment list ........................................................................................................... |

22 |

5. ENGMODE ............................................................................................................... |

24 |

5.1. Accessing the Calibration Programs .............................................................. |

24 |

5.2. Ventilator Calibration Program ....................................................................... |

26 |

5.3. O2 & Flow System Calibration........................................................................ |

28 |

5.4. Reset Elapsed Time ....................................................................................... |

29 |

5.5. Exit ................................................................................................................. |

29 |

5.6. Touch Screen Calibration Program ................................................................ |

29 |

6. Component Replacement Procedure ........................................................................ |

32 |

7. Preparing the SLE5000 ............................................................................................. |

33 |

8. Component Replacement (Electronic unit) ............................................................... |

35 |

8.1. N6634 CAN Card ........................................................................................... |

35 |

8.2. BIOS battery................................................................................................... |

35 |

8.3. Disk-on-Chip................................................................................................... |

36 |

8.4. N6631/01 PC Board ....................................................................................... |

37 |

8.5. N6631/06 Serial controller (Touch screen)..................................................... |

38 |

8.6. A0763/02 Control and Monitor Board............................................................. |

39 |

8.7. M0900 Power Supply Unit.............................................................................. |

41 |

8.8. M0901 Batteries ............................................................................................. |

42 |

8.9. A0761 Transducer PCB Assembly................................................................. |

43 |

8.10. Inverter PCB................................................................................................. |

44 |

8.11. N6631/02 LCD & N6631/05 Touch Screen .................................................. |

47 |

9. Component Replacement (Pneumatic unit) .............................................................. |

56 |

9.1. N2185/05 & 06 Duckbill and conical filters. .................................................... |

56 |

9.2. L0287 Blender Assembly ............................................................................... |

57 |

9.3. N2195/06 Fresh Gas Supply solenoid (SV7).................................................. |

58 |

9.4. N6612 Purge Regulator (PR7) Pre PAM (Proximal Airway Modification)....... |

59 |

9.5. N6612 Purge Regulator (PR7) Post PAM (Proximal Airway Modification)..... |

59 |

9.6. N6614 Speed controller (FR1)........................................................................ |

60 |

9.7. N6613 Purge Regulator (PR5) Pre Proximal Airway Modification.................. |

61 |

9.8. N6613 or /03 Purge Regulator (PR5) Post Proximal Airway Modification...... |

63 |

9.9. N6615/01 Input Air Regulator (PR1)............................................................... |

65 |

9.10. N6615/02 Input Oxygen Regulator (PR2)..................................................... |

67 |

9.11. N6624 High Speed Jet Valves (SV9/10/11/12) ............................................ |

68 |

(Model A) |

Page 3 |

9.12. N6623, N6623/33 or N6623/S38 Pressure regulators (PR6)........................ |

69 |

9.13. N6623, N6623/33 or N6623/S38 Pressure regulators (PR3 &PR4) ............. |

71 |

10. A0763/02 Monitor and control board ....................................................................... |

74 |

10.1. U23 and U33 socket configurations for A0760 Rev D base PCB. ................ |

74 |

10.2. A0763/02 board progammable devices ........................................................ |

75 |

10.3. A0763/02 Board Hardware Identifier............................................................. |

76 |

11. Electrical Safety Testing of the SLE5000 ................................................................ |

79 |

12. PSU Testing. ...........................................................................................................83 |

|

13. Maintenance and Overhaul ..................................................................................... |

86 |

13.1. Preventative Maintenance ............................................................................ |

86 |

13.2. 6, 18, 30 & 42 month preventative maintenance procedure ......................... |

88 |

13.3. 12 and 36 month preventative maintenance procedure................................ |

94 |

13.4. 24 month and 48 month overhaul procedures .............................................. |

98 |

13.5. 24 month / 10,000 hour overhaul procedure................................................. |

100 |

13.6. 48 month / 20,000 hour overhaul procedure................................................. |

108 |

13.7. 48 month overhaul procedure using N9010/48 overhaul kit. ........................ |

110 |

14. Calibration Procedure for V3, V3.1 & 3.2 software .................................................. |

128 |

14.1. Preliminary Inspection before calibration ...................................................... |

128 |

14.2. Pneumatic set up .......................................................................................... |

129 |

14.3. Calibration of Controller and Monitor subsystems ........................................ |

130 |

14.4. Controller “Block and Leak” pressure sensor calibration .............................. |

132 |

14.5. Controller Blender Pressure Sensor zeroing and Input pressure reg. trim ... |

133 |

14.6. Mean Jet Pressure Regulator Calibration ..................................................... |

134 |

14.7. Forward Jet Pressure Regulator Calibration................................................. |

135 |

14.8. Wave shaping for leading and trailing edge of insp. phase .......................... |

137 |

14.9. Reverse Jet Pressure Regulator Calibration................................................. |

138 |

14.10. O2 System Calibration ................................................................................ |

139 |

14.11. Flow System Calibration ............................................................................. |

139 |

14.12. Pressure Triggering Verification.................................................................. |

139 |

14.13. Gas Fail Detection Verification.................................................................... |

139 |

14.14. Blender and Oxygen Monitoring Verification............................................... |

140 |

14.15. Soak Test.................................................................................................... |

141 |

14.16. Battery Charge Verification ......................................................................... |

142 |

14.17. Battery Life Verification ............................................................................... |

142 |

14.18. Total Power Fail Alarm Test........................................................................ |

142 |

14.19. Pressure Calibration Verification................................................................. |

143 |

15. Calibration Procedure for V3.3 software ................................................................. |

146 |

15.1. Preliminary Inspection before calibration ...................................................... |

146 |

15.2. Pneumatic set up .......................................................................................... |

147 |

15.3. Calibration of Controller and Monitor subsystems ........................................ |

148 |

15.4. Controller “Block and Leak” pressure sensor calibration .............................. |

150 |

15.5. Controller Blender Pressure Sensor zeroing and Input pressure reg. trim ... |

151 |

15.6. Mean Jet Pressure Regulator Calibration ..................................................... |

152 |

15.7. Forward Jet Pressure Regulator Calibration................................................. |

153 |

Page 4 |

(Model A) |

15.8. Reverse Jet Pressure Regulator Calibration ................................................ |

155 |

15.9. Time Constant for pressure measurement waveform .................................. |

156 |

15.10. Wave shaping for leading and trailing edge of insp. phase........................ |

156 |

15.11. O2 System Calibration................................................................................ |

157 |

15.12. Flow System Calibration............................................................................. |

157 |

15.13. Pressure Triggering Verification ................................................................. |

157 |

15.14. Gas Fail Detection Verification ................................................................... |

158 |

15.15. Blender and Oxygen Monitoring Verification .............................................. |

159 |

15.16. Soak Test ................................................................................................... |

160 |

15.17. Battery Charge Verification......................................................................... |

161 |

15.18. Battery Life Verification .............................................................................. |

161 |

15.19. Total Power Fail Alarm Test ....................................................................... |

161 |

15.20. Pressure Calibration Verification ................................................................ |

162 |

16. Calibration Procedure for V4 & 4.1 software ........................................................... |

164 |

16.1. Preliminary Inspection before calibration...................................................... |

164 |

16.2. Pneumatic set up.......................................................................................... |

165 |

16.3. Calibration of Controller and Monitor subsystems........................................ |

166 |

16.4. Controller “Block and Leak” pressure sensor calibration.............................. |

168 |

16.5. Controller Blender Pressure Sensor zeroing and Input pressure reg. trim... |

169 |

16.6. Mean Jet Pressure Regulator Calibration..................................................... |

170 |

16.7. Forward Jet Pressure Regulator Calibration ................................................ |

171 |

16.8. Reverse Jet Pressure Regulator Calibration ................................................ |

173 |

16.9. Time Constant for pressure measurement waveform .................................. |

174 |

16.10. Wave shaping for leading and trailing edge of insp. phase........................ |

174 |

16.11. O2 System Calibration................................................................................ |

175 |

16.12. Flow System Calibration............................................................................. |

175 |

16.13. Pressure Triggering Verification ................................................................. |

175 |

16.14. Gas Fail Detection Verification ................................................................... |

176 |

16.15. Blender and Oxygen Monitoring Verification .............................................. |

177 |

16.16. Soak Test ................................................................................................... |

178 |

16.17. Battery Charge Verification......................................................................... |

179 |

16.18. Battery Life Verification .............................................................................. |

179 |

16.19. Total Power Fail Alarm Test ....................................................................... |

179 |

16.20. Pressure Calibration Verification ................................................................ |

180 |

17. Functional Testing ................................................................................................... |

182 |

17.1. Ventilator setup ............................................................................................ |

182 |

18. Trouble Shooting Chart ........................................................................................... |

216 |

19. Software Version History ........................................................................................ |

226 |

19.1. SLE4000 Software ....................................................................................... |

226 |

19.2. SLE5000 Software ....................................................................................... |

227 |

20. Oxygen Calibration Routines .................................................................................. |

230 |

20.1. One point or 100% Oxygen system calibration ............................................ |

230 |

20.2. Two point or 21% & 100% Oxygen system calibration................................. |

230 |

(Model A) |

Page 5 |

21. Alarms ..................................................................................................................... |

232 |

21.1. Alarm Protocols............................................................................................. |

232 |

21.2. Alarm Sounds ............................................................................................... |

232 |

21.3. Alarm Descriptions and actions to be taken.................................................. |

233 |

21.4. Software and System Fail Protocols ............................................................. |

252 |

22. Cleaning, disinfection and sterilization .................................................................... |

253 |

22.1. Preparation of a new ventilator ..................................................................... |

253 |

22.2. Cleaning and disinfection of an in-service ventilator..................................... |

253 |

22.3. Cleaning method........................................................................................... |

254 |

22.4. Disinfection method ...................................................................................... |

255 |

22.5. Sterilization method ...................................................................................... |

256 |

23. Technical Specification ............................................................................................ |

257 |

23.1. Operating Modes Conventional Ventilation................................................... |

257 |

23.2. HFO Ventilation............................................................................................. |

258 |

23.3. Measurement ................................................................................................ |

263 |

23.4. Alarms........................................................................................................... |

265 |

23.5. Patient circuits............................................................................................... |

266 |

23.6. Outputs ......................................................................................................... |

267 |

23.7. Gas supplies ................................................................................................. |

268 |

23.8. Power, Dimensions, Standards etc............................................................... |

269 |

23.9. Environmental Storage Conditions ............................................................... |

269 |

24. Pneumatic Unit Schematic ...................................................................................... |

270 |

25. Ventilator labelling ................................................................................................... |

271 |

25.1. SLE4000 ....................................................................................................... |

271 |

25.2. SLE5000 ....................................................................................................... |

272 |

26. Illustrated Parts List ................................................................................................. |

274 |

Ventilator assembly ............................................................................................... |

276 |

Base plate and side door assembly ...................................................................... |

284 |

Front facia assembly ............................................................................................. |

286 |

Electronic module ................................................................................................. |

288 |

Pneumatic module (Pre proximal airway modification) .......................................... |

321 |

Pneumatic module ................................................................................................ |

327 |

HFO module (Pre proximal airway modification) ................................................... |

334 |

HFO module .......................................................................................................... |

344 |

Oxygen regulator module ...................................................................................... |

357 |

Partition assembly ................................................................................................. |

360 |

Pneumatic module, sub assembly ........................................................................ |

364 |

27. Equipotential stud modification ................................................................................ |

374 |

27.1. Equipotential stud connection ....................................................................... |

375 |

28. Electrical Block Diagram ......................................................................................... |

378 |

Page 6 |

(Model A) |

29. Pneumatic Unit Schematic ...................................................................................... |

379 |

29.1. Schematic Pre PAM (Proximal Airway Modification).................................... |

379 |

29.2. Schematic Post PAM.................................................................................... |

380 |

30. Pneumatic Unit Tubing connections ....................................................................... |

381 |

30.1. Tubing Connections Pre PAM ...................................................................... |

381 |

30.2. Tubing Connections Post PAM..................................................................... |

382 |

31. Main Loom Circuit Diagram .................................................................................... |

383 |

32. A0761 circuit diagram ............................................................................................. |

386 |

32.1. Transducer PCB Assembly .......................................................................... |

386 |

33. A0763/02 circuit diagrams ...................................................................................... |

388 |

33.1. Micro Controller ............................................................................................ |

388 |

33.2. Conventional Valve Drive ............................................................................. |

389 |

33.3. Power Distribution And Hardware Identifier.................................................. |

390 |

33.4. Analogue Valve Drive / Non Volatile Memory / Interboard Comms.............. |

391 |

33.5. High Speed Valve Drive ............................................................................... |

392 |

33.6. Analogue Data aquisition/Monitor port ......................................................... |

393 |

33.7. Control & Monitor, PCB PSU Circuit............................................................. |

394 |

33.8. Control & Monitor, Micro Non-isolated.......................................................... |

395 |

33.9. Control & Monitor, Micro Isolated ................................................................. |

396 |

33.10. Control & Monitor, Analog Isolated............................................................. |

397 |

33.11. Control & Monitor, Alarm Controller............................................................ |

398 |

Appendix 1. Calibration Checklist ................................................................................. |

401 |

Appendix 2. Check list .................................................................................................. |

409 |

Appendix 3. RS232 ....................................................................................................... |

414 |

33.12. Warnings for RS232 ................................................................................... |

414 |

33.13. Location of RS232 Port .............................................................................. |

414 |

33.14. Overview .................................................................................................... |

415 |

33.15. Data and Pinout description. ...................................................................... |

415 |

33.16. Cable .......................................................................................................... |

415 |

33.17. Parameter Descriptions and format............................................................ |

416 |

33.18. List of parameters....................................................................................... |

416 |

33.19. Table of current alarm condition codes. ..................................................... |

419 |

33.20. RS232 Connection Settings and Testing Data Output ............................... |

421 |

33.21. Glossary ..................................................................................................... |

421 |

Appendix 4. VueLink Technical Data ............................................................................ |

424 |

33.22. Glossary ..................................................................................................... |

424 |

33.23. Connecting the SLE5000 to the VueLink patient monitor........................... |

424 |

33.24. Parameter Descriptions.............................................................................. |

425 |

33.25. Data transferred to the VueLink system from the SLE5000 ....................... |

426 |

33.26. Alarm and inoperative indications............................................................... |

428 |

(Model A) |

Page 7 |

34. |

VueLink Task Window Layout ................................................................................. |

431 |

|

34.1. Notes on General System Behaviour............................................................ |

432 |

35. |

Activation of VueLink ............................................................................................... |

433 |

|

35.1. Disabling VueLink. ........................................................................................ |

434 |

Page 8 |

(Model A) |

Warnings and Cautions

(Model A) |

Page 9 |

1. Warnings and Cautions

1.1 Warnings

1.The electronic and pneumatic units of the SLE5000 infant ventilator are sealed at the factory with two Warranty Void If Label Broken seals. If the ventilator is subject to a warranty agreement do not attempt to carry out any procedure that would involve breaking these seals. If you make a warranty claim and these seals are broken SLE may deem the warranty claim null and void. If the ventilator develops a fault within the warranty period please refer to your warranty documentation.

2.Oxygen - Fire Hazard. Oxygen vigorously supports combustion and its use requires special precaution to avoid fire hazards. Keep all sources of ignition away when oxygen is in use. Do not use oil or grease on oxygen fittings or where oxygen is used.

3.Check the condition of the gas supply hoses to the ventilator. Do not use any hose that shows signs of cracking, abrasion, kinking, splits, excessive wear or ageing. Make sure that the Air or O2 hose has not come into contact with oil or grease.

4.The SLE5000 ventilator contains temperature dependant devices which perform normally in controlled environments in hospitals. However if the ventilator has been stored at a temperature different to that in which it will be used, allow the unit to acclimatize before powering up.

5.Failure to comply with the recommended service programs could lead to injury of the patient, operator or damage to the ventilator. It is the owners responsibility to ensure that the equipment is regularly maintained.

6.The SLE5000 contains static sensitive electrical devices. Anti static precuations must be observed at all time when working on the ventilator.

Page 10 |

(Model A) |

1.2 Cautions

1.When working on the pnuematic unit, protect the front facia panel by resting it on a soft pad.

2.Do not use a sharp instrument, such as a pen to activate the controls as the excessive pressure applied by the point will damage the touch screen membrane.

3.The Ventilator must be connected to a suitably rated and grounded electrical power source.

4.If the SLE5000 is adversely affected by equipment emitting electromagnetic interference then that equipment should be switched off or removed from the vicinity of the SLE5000. Conversely, if the SLE5000 is the source of interference to other neighbouring equipment, it should be switched off or taken to another location.

5.The functioning of this machine may be adversely affected by the operation of equipment such as high frequency surgical (diathermy) equipment, defibrillators, mobile phones or short-wave therapy equipment in the vicinity.

7.The equipment is not suitable for use with, or in the presence of flammable anaesthetic mixtures.

6.The SLE5000 flow monitoring system is calibrated to work in an air / oxygen mixture, the use of other gas mixtures may affect the flow monitoring accuracy of the ventilator.

7.Disposal of the Oxygen Sensor should be in accordance with local regulations for hazardous substances. Do not incinerate. SLE offer a cell disposal service.

8.The SLE5000 contains four batteries, three 2 cell sealed lead acid batteries and one

PCB mounted lithium battery. At the end of their useful life these batteries should be disposed of in accordance with local authority guidelines.

9.Apart from the above, the SLE5000 and accessories do not contain any hazardous components therefore no special precautions are required for their disposal.

10.Care should be taken when attaching other equipment as this may affect mechanical stability.

11.Any computer connected to the ventilator must be specified for medical use (ie. it must comply with the requirements of BS-EN-60601:1990).

(Model A) |

Page 11 |

12.There is no special protection provided against ingress of water or liquids.

13.Do not use solvent based cleaning solutions to clean the touch screen or covers.

Page 12 |

(Model A) |

Principles of Operation

(Model A) |

Page 13 |

2. Principles of Operation

The SLE5000 infant ventilator consists of an electronic system in the upper section of the ventilator and a pneumatic system in the lower.

2.1 Electronic System

The electronic system comprises three autonomous subsystems, one responsible for monitoring the patient, one responsible for controlling the valves of the pneumatic system and one for the user interface (touchscreen and displayed data). They are connected together by three serial communication links in a delta configuration.

The ventilator has an internal battery that can power the ventilator in the event of a mains power fail. If the mains power fails with the battery fully charged, then operation will continue for 30 to 60 minutes depending on ventilation mode.

See “Electrical Block Diagram” on page 378.

Page 14 |

(Model A) |

2.2 Pneumatic System

The pneumatic system comprises of the tubing and electro-mechanical valves necessary to provide the gas in conventional and oscillatory ventilation modes. The two gas controlling functions are blending and pressure generation

2.2.1 Blending

The method used for blending air and oxygen in known proportions is to pressure regulate the two supplies (air and oxygen) so they produce equal flow rates and then allow each supply into a mixing chamber for a time period equivalent to the proportions required. For example, delivering oxygen at a set flow rate into a mixing chamber for 1 second and air at the same flow rate for 2 seconds will result in a mixture of 1 part oxygen to 2 parts air

(resulting in a mix of 47.3%).

2.2.2 Pressure Generation

There are three nozzles within the exhalation block in the pneumatic subsystem. One for generating negative pressure in the patient circuit and the other two for generating positive pressure. The pressures generated from the three nozzles are controlled by three electronically controlled pressure regulators. The negative and one of the positive nozzle pressures can also be switched on and off rapidly with in-line (high speed) solenoid valves.

The other positive nozzle (the mean jet) is used to generate steady pressures in ventilation

(CPAP or PEEP pressures in conventional modes and mean pressures in HFO modes).

These three nozzles (or jets) are used in various combinations to generate all ventilation modes.

2.2.3 Conventional ventilation

In non HFO modes the negative (or reverse) jet is used in a steady mode to provide a small amount of flow to offset the inadvertent patient circuit pressure generated from the fresh gas flow of 8 lpm. The mean jet is also used in a steady mode to generate the base pressure level (CPAP or PEEP) and the forward jet is used to generate the PIP pressure during the inspiratory phase. The rise time of the inspiratory phase is controlled by dynamically controlling the forward jet pressure regulator rather than switching a steady pressure with the high speed valves.

This provides a smooth rise in pressure and allows user adjustable rise times rather than abrupt changes and pressure “ringing” which can result from high speed switching. The fall of the inspiratory wave is also controlled by the forward jet pressure regulator to bring the pressure down quickly and smoothly, using the high speed valves to do this would again result in inadvertent ‘ringing’ which causes difficulties for the monitor subsystem in trying to detect a patient breath attempt by monitoring the pressure alone. Once the pressure has been brought close to the base pressure, after about 100 ms, the forward jet solenoid is switched off to prevent any further artefact causing false triggering.

(Model A) |

Page 15 |

Note that all jet pressures actually sum in the exhalation block, for example, to ventilate a patient with a PEEP pressure of 5 mbar and a PIP pressure of 30 mbar, the mean jet will be set to generate a continuous circuit pressure of 5 mbar and the forward jet will be set to generate a circuit pressure varying between zero (exp phase) and 25 mbar (insp. phase).

Since the jet pressures will sum, this will result in the desired patient pressure.

2.2.4 HFO ventilation

In pure HFO mode the mean jet pressure regulator is used purely to set the mean pressure. The forward and reverse jet pressure regulators are used to generate steady positive and negative delta P components that will be superimposed on the mean pressure. These components are switched quickly using the high-speed solenoid valves to generate the HFO pressures.

For example to ventilate a patient with a mean pressure of 10 mbar and a delta P pressure of 60 mbar, the mean jet will be set to generate a continuous pressure of 10 mbar, the forward jet will be set to generate a continuous pressure of 30 mbar and the reverse jet will be generating a continuous pressure of –30 mbar. The HFO rate is determined by the rate of switching between the forward and reverse pressures on the high-speed valves. Again, because the jet pressures sum, the resulting patient pressures will be switching between –

20 mbar and +40 mbar.

Mean HFO pressures up to 35mbar are required but the mean jet can only generate pressures up to about 20 mbars. To obtain higher mean pressures than 20mbars in HFO it is necessary to apply a higher pressure on the forward pressure regulator and a lower pressure on the reverse pressure regulator. Using this method, the desired mean must be less than half the desired delta p pressure plus 20 mbars.

See “Pneumatic Unit Schematic” on page 379.

Page 16 |

(Model A) |

Description of Symbols

(Model A) |

Page 17 |

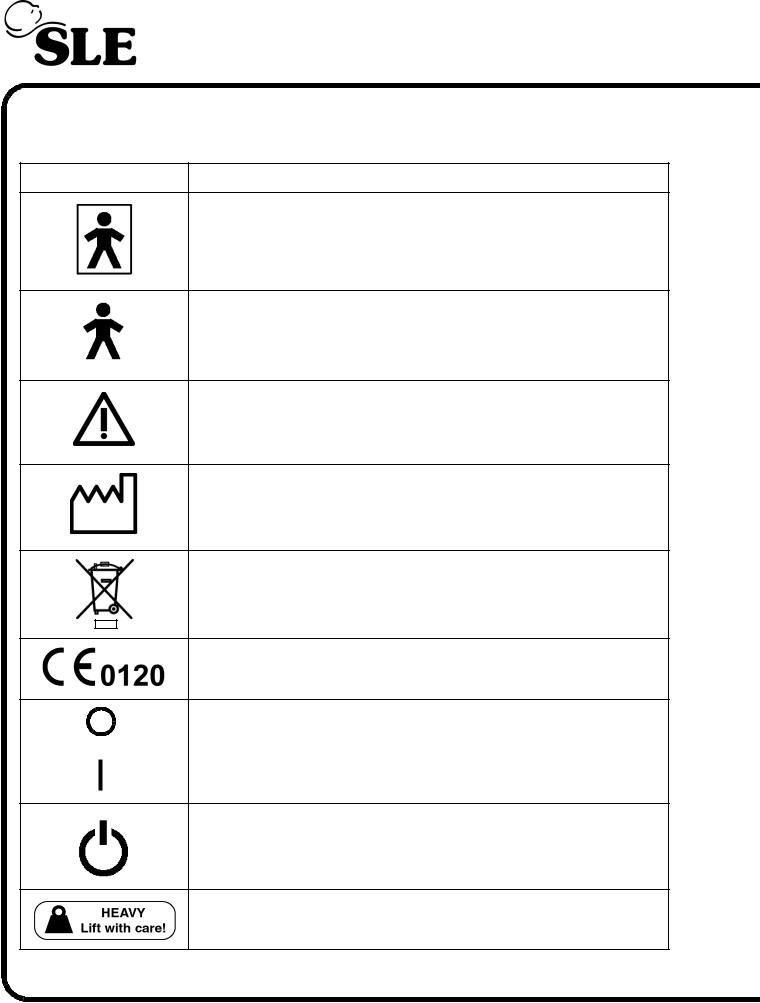

3. Description of Symbols

Symbol |

Description |

Type BF connection (Situated on front panel)

Type B device (Situated on rear panel)

Read manual (Situated on rear panel)

Date of Manufacture (Appears on serial number label)

Do not dispose of as general waste (WEEE directive).

(Appears on serial number label).

EEC conformity marking showing compliance with the Medical

Devices Directive (Appears on serial number label)

Power Off

(Embossed on power switch)

Power ON

Indicates the mains power switch

Heavy, Lift with care (Situated on rear panel)

Page 18 |

(Model A) |

Symbol |

Description |

Mains/Battery power indicator (Situated on front panel)

Indicates a warning in the manual

Observe anti static precuations

Indicates a note in the manual

Indicates a caution in the manual

Check list item.

(Model A) |

Page 19 |

This page is intentionally blank.

Page 20 |

(Model A) |

Equipment List

(Model A) |

Page 21 |

4. Equipment list

To service the SLE5000 infant ventilator the service personnel will require the following equipment. Items marked with an SLE part number can be obatined by contacting the service department.

• Electronic engineers tool kit. |

|

|

• |

a/b Calibration analyser (calibrated in mbar) ....... |

SLE Part Nº: N2830 |

• |

a Patient circuit .................................................... |

SLE Part Nº: N5188 |

• |

a Humidification chamber (MR220 ...................... |

SLE Part Nº: N3220 |

• |

b Test lung ........................................................... |

SLE Part Nº: N6647 |

•c Foam support pad

•a Digital Multimeter (1mv resolution)

•a 24V power supply

•a ‘Y’ piece tube connector fitted with 0-2 bar reliving regulator on one limb.

•a Assorted tubing to connect analysers to ventilator.

•cStatic protection wrist band

•cAnti-static protective bags (300mm x 300mm)

• |

a Flow sensor cable............................................. |

SLE Part Nº: N6635 |

• |

a Flow sensor ...................................................... |

SLE Part Nº: N5201 |

• |

a Exhalation block ............................................... |

SLE Part Nº: N6622 |

•a Oxygen supply

•a Air supply

aNote all items marked with an ‘a’ are required for servicing and overhaul. Without these items the user will be unable to service or overhaul the SLE5000 ventilator.

bNote items marked with a ‘b’ are required to carry out the functional testing routine.

Page 22 |

(Model A) |

Engineering Mode Software

(Model A) |

Page 23 |

5. ENGMODE

The SLE5000 ventilator is calibrated via two calibration programs, one for the ventilator and one for the Touch screen. The calibration programs are accessed via the Controller Services panel in the user interface.

5.1 Accessing the Calibration Programs

Step 1 Press the Options and Service Data

Button.

¦

Step 2 Press the next button.

Step 3 Press the version button.

Page 24 |

(Model A) |

Step 4 Press the Controller button.

Step 5 Enter the code supplied by SLE into the ventilator via the controller services panel to activate the required calibration program.

Begin psv is the A button.

End psv is the B button.

Apnea sup is the C button.

Enter your code here____________________

(Model A) |

Page 25 |

5.2 Ventilator Calibration Program

The calibration program has four main functions.

1.Sensor Calibration

2.Jet Calibration

3.O2 & Flow System Calibration

4.Elapsed Time Reset.

5.Exit

5.2.1 Sensor Calibration

The sensor calibration panel allows the following sensors to be calibrated.

Controller

The setting of the Block and leak sensor Offset and Gain.

The setting of the Blender sensor Offset and Gain.

Monitor

The setting of the Blender sensor Gain.

Page 26 |

(Model A) |

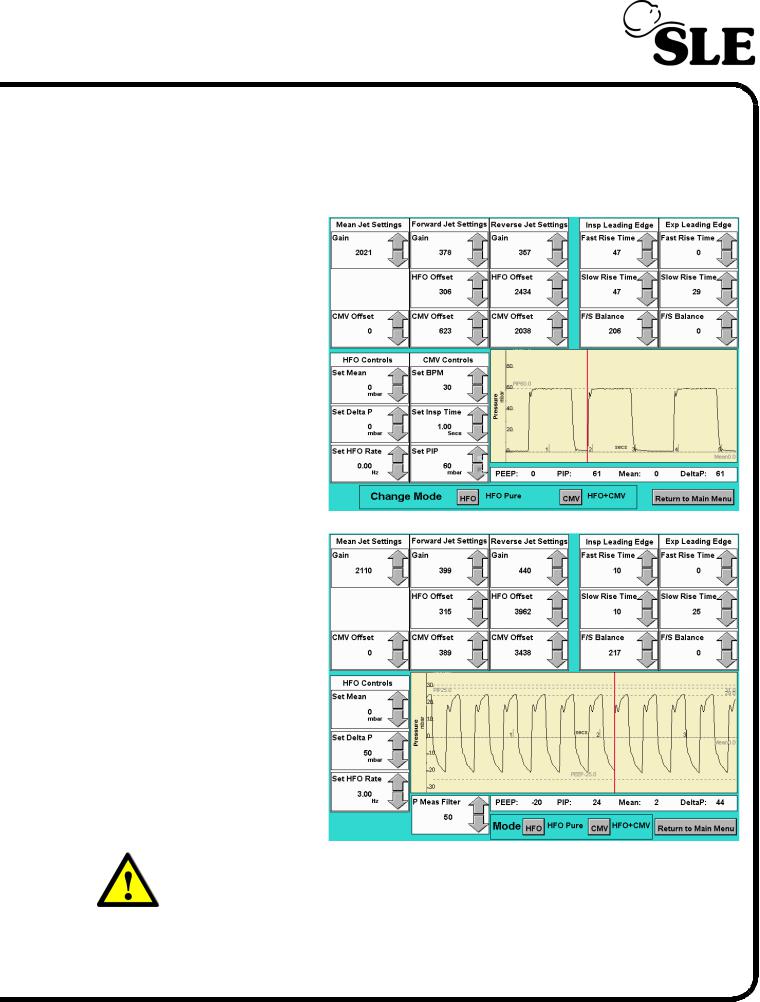

5.2.2 Jet Calibration

The jet calibration panel allows the forward jet, reverse jet and mean jet to be adjusted. Also contained within this panel are the controls to adjust the inspiratory and expiratory leading edges of the CMV wave form. Associated controls to set the ventilator in CMV or HFO mode are also displayed.

Layout for Version 3 to 3.2 software

Layout for Version 3.3 software

Warning: Version 3.3 software has a new parameter the “P Meas Filter”. This is a low pass filter which removes high frequency components from the displayed waveform.

This is required as the new N6623/33 pressure regulators produce a greater initial high frequency component. N6623/33 pressure regulator can only be used in conjunction with version 3.3 software.

(Model A) |

Page 27 |

Warning: N6623/33 regulators cannot be used with version 3 to 3.2 software as the high frequency component can not be removed making the ventilator unusable.

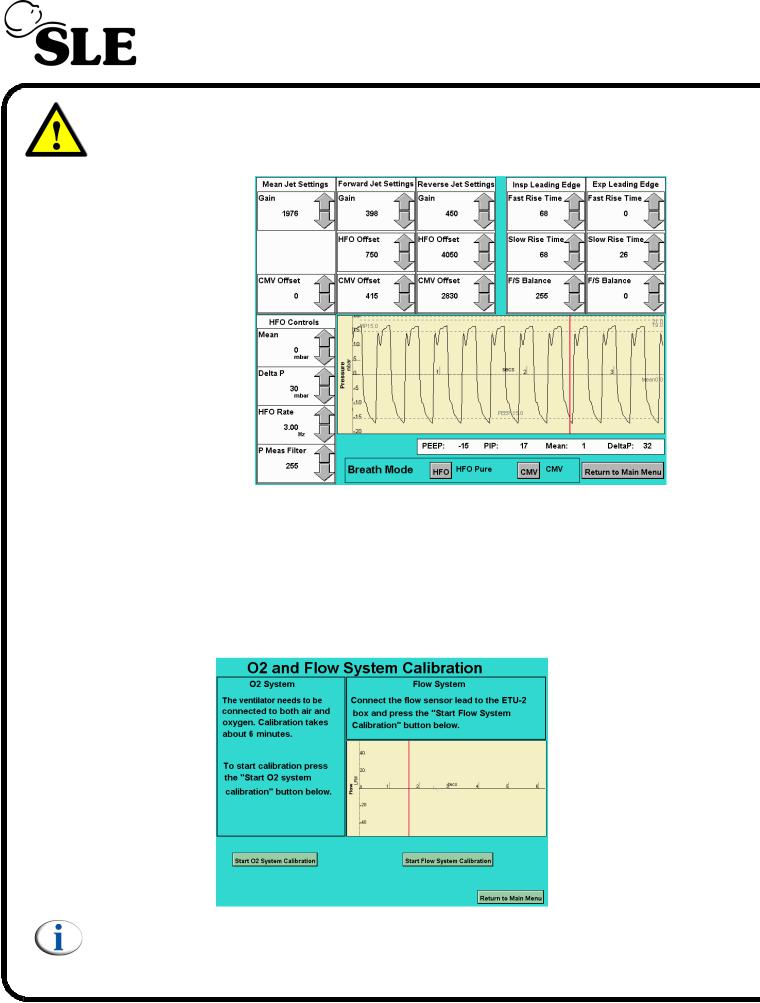

Layout for Version 4 software

5.3 O2 & Flow System Calibration

The O2 & Flow System Calibration panel allows the calibration of the oxygen

monitoring system (2 point calibration, 100% and 21%) and the calibration of the flow system.

The flow system is a factory set system and requires an ETU-2 for calibration.

Note: For version 3.3 & 4 software O2 calibration time is 7 minutes.

Page 28 |

(Model A) |

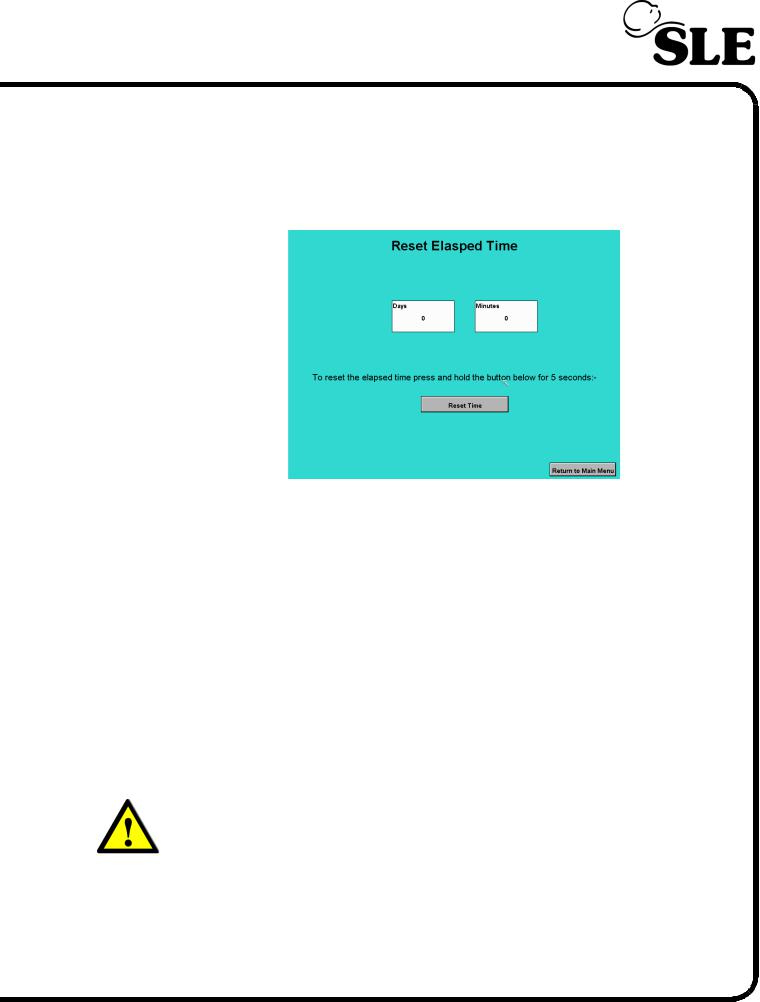

5.4 Reset Elapsed Time

The reset elapsed time panel allows the ventilators time counter to be reset to zero days and minutes.

This function is only used at the 20,000 hour overhaul.

5.5 Exit

The exit button will return the user to a DOS prompt. To return to the ventilator to its normal operating mode, restart the ventilator.

5.6 Touch Screen Calibration Program

The touch screen calibration program is accessed by the same method as for the calibration program. See ’5.1 Accessing the Calibration Programs’ on page 24.

Enter you code here____________________

Four the touch screen please follow the on screen instructions.

To return to the ventilator to its normal operating mode, restart the ventilator.

Warning: Failure to carry out the touch screen calibration correctly can cause the ventilator to become unusable. A failed touch screen calibration can only be corrected by connection of a specialist device. Please contact SLE or your distributor in this situation.

(Model A) |

Page 29 |

This page is intentionally blank.

Page 30 |

(Model A) |

Loading...

Loading...