Page 1

™

XXLL--22000000

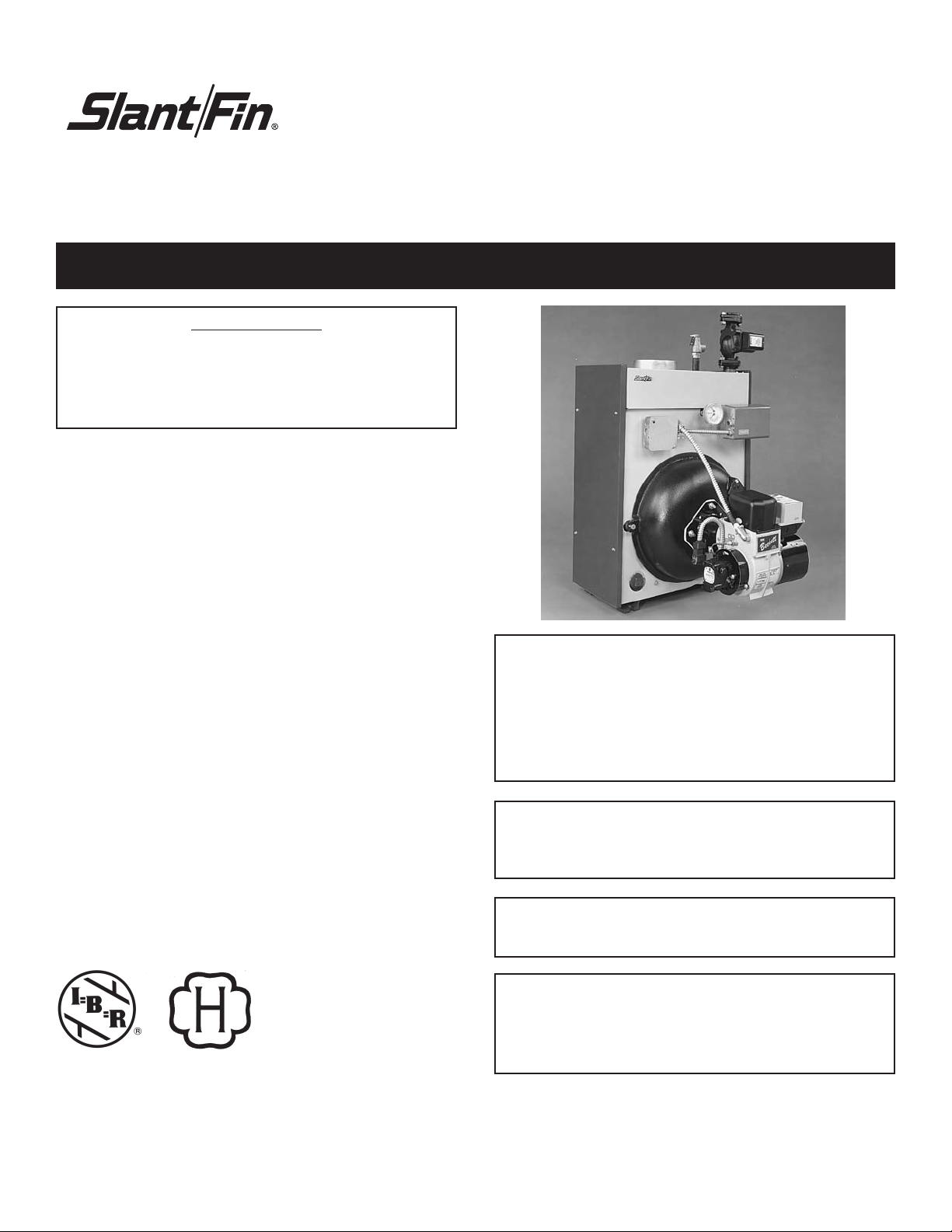

OIL-FIRED WATER BOILERS/NO. 2 OIL

INSTALLATION AND OPERATING INSTRUCTIONS

SAFETY WARNING:

KEEP BOILER AREA CLEAR AND FREE FROM COMBUSTIBLE MATERIALS, GASOLINE AND OTHER FLAMMABLE VAPORS AND LIQUIDS. FAILURE TO ADHERE TO

ABOVE SAFETY WARNING, MAY RESULT IN PERSONAL

INJURY OR DEATH AND PROPERTY DAMAGE.

CONTENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .PAGE

Ratings and Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Installation Requirements:

Boiler Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Clearances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Chimney Requirements . . . . . . . . . . . . . . . . . . . . . . . . . .3

Air Supply and Venting . . . . . . . . . . . . . . . . . . . . . . . . . .3,4

Controls and Accessories . . . . . . . . . . . . . . . . . . . . . . . . .5

Piping for Water Units . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Installing Burner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Oil Supply Piping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Wiring the Boiler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Vent Piping and Draft Regulator . . . . . . . . . . . . . . . . . . . .5

Operating Instructions:

Precautions Before Starting . . . . . . . . . . . . . . . . . . . . . . .7

Start-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Cleaning and Filling New Water Boiler . . . . . . . . . . . . . . .8

Care and Maintenance:

Extended Shutdown . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Freezing Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Oil Burner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

General Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Wiring Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Burner Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11,12

IIMMPPOORRTTAANNTT:

form to the requirements of the authority having jurisdiction

or, in the absence of such requirements, to the Installation of

Oil Burning Equipment, ANSI/NFPA 31, latest edition, and to

the National Electrical Code ANSI/NFPA 70, latest edition.

The installation must also conform to the additional requirements in this Slant/Fin Instruction Manual. Where there is any

difference, the more stringent requirement shall govern.

In addition, where required by the authority having jurisdiction,

the installation must conform to American Society of Mechanical

Engineers Safety Code for Controls and Safety Devices for

Automatically Fired Boilers, No. CSD-1, latest edition.

:

The installation of this equipment must con-

THIS MANUAL MUST BE LEFT WITH OWNER AND

SHOULD BE HUNG ON OR ADJACENT TO THE BOILER

FOR REFERENCE.

IMPORTANT: This boiler must be installed, serviced and

repaired by a trained, experienced, service technician,

licensed for the installation and servicing of oil burning hot

water heating system equipment or otherwise qualified by the

author

ities having jurisdiction over the installation.

Printed in U.S.A.305 Publication No. XL-40

Part No. 48-0090 Revision C

Page 2

2

3

/4" RELIEF

VALVE TAPPING

1

1/2 SUPPLY

T

APPING

1

/2" AIR VENT

O

R EXPANSION TANK

T

APPING

T

OP VIEW

1/4 NPT PRESSURE

& TEMPERATURE TAPPING

F

RONT VIEW

3/4 REAR DRAIN

1 1/2 ALTERNATE

REAR RETURN

1 1/2 RETURN

TAPPING

1/2 NPT

CONTROL TAPPING

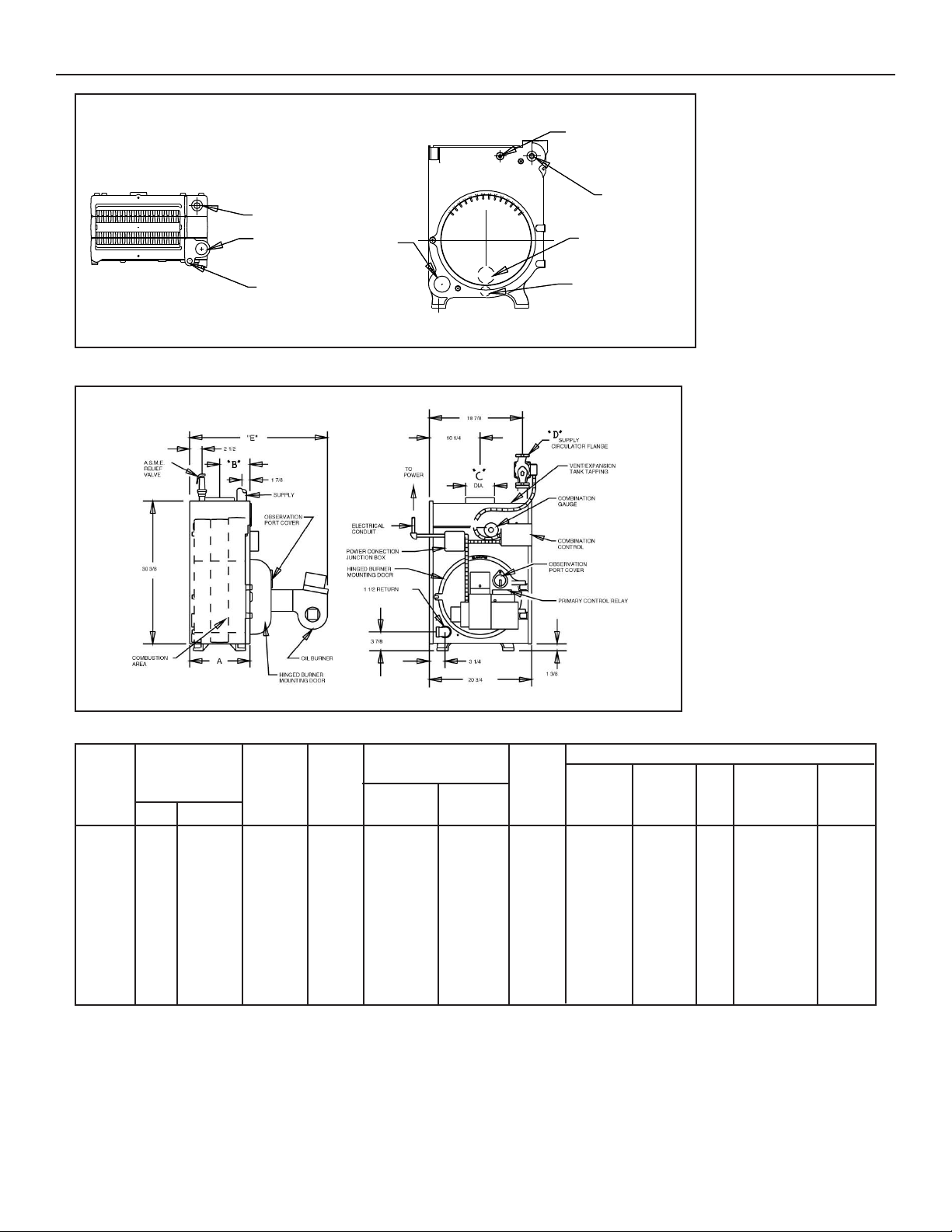

Figure 2.

XL-2000

Figure 1.

TABLE 1: Ratings and Dimensions

BOILER

MODEL

NO.

I=B=R

BURNER

CAPACITY

OIL INPUT † §

GPH BTUH

D

.O.E.

HEATING

CAPACITY

MBH *

W

ATER

I=B=R

WATER

NET

RATING

MBH *

NOM.

X HEIGHT‡

(in x in x ft)

I=B=R

CHIMNEY SIZE

I.D

RECT

. ROUND

X HEIGHT

(in x ft)

XL-20 0.65 91,000 78 68 8 x8x15 6 x 15 83.56 8

XL-30H 0.85 119,000 104 90 8 x8x15 6 x 15 86.00 12

XL-30 1.00 140,000 121 105 8 x8x15 6 x 15 85.04 12

1.15 161,000 138 120 8 x8x15 6 x 15 84.12 12

XL-40H 1.25 175,000 152 132 8 x8x15 7 x 15 86.00 15

XL-40 1.35 189,000 162 141 8 x8x15 7 x 15 85.05 15

1.55 217,000 186 162 8 x8x15 7 x 15 84.38 15

XL-50 1.80 252,000 217 189 8 x8x15 8 x 15 85.00 19

2.00 280,000 239 206 8 x8x15 8 x 15 84.19 19

Standard working pressure 30 psi.

All boilers hydrostatically tested — A.S.M.E.

* For forced hot water heating systems where the boiler and all piping are

located within the area to be heated, the boiler may be selected on the basis

of D.O.E. capacity output. The net I=B=R output ratings shown are based on

an allowance for piping and pickup of 1.15 (water) or 1.33 (steam). D.O.E.

capacity output is divided b

Technical Service department should be consulted before selecting a boiler

for unusual piping and pickup requirements such as intermittent system operation, extensive piping, etc.

† Ratings apply to the use of light oil at 140,000 Btu per gallon and apply only

when burner models listed on pages 11 and 12 of this manual are used, and

y the allowance to obtain net rating. The Slant/Fin

are properly adjusted to produce 13% CO2.

‡

Nominal clay tile liner dimensions.

§ Water boiler models XL-30 and larger have two firing rates. The boiler is factory shipped at the lower firing rate. To obtain the higher firing rate, refer to

the XL-2000 boiler installation instructions for the appropriate field adjustments

¶

Oblong flue collar. Fits 6” dia. vent connectors.

#

All dimensions subject to nor

NOTE: All boilers under 300,000 Btuh (87.9 kw) input are tested and rated for

capacity under the U.S. Depar tment of Energy (D.O.E.) Test Procedures for

Boilers.

DIMENSIONS (inches) #

BOILER

LENGTH

AFUE %

. “H” models have only one firing rate.

“A”

11

FRONT TO

FLUE

“B”

/

16

3

/

16

3

/

16

3

/

16

11

/

16

11

/

16

11

/

16

3

/

16

3

/

16

9

4

/

5

6

/

5

6

/

5

6

/

1

8

/

1

8

/

1

8

/

13

9

13

9

mal manufacturing tolerance.

FLUE

DIA.

“C”

6¶ 1

16

61

16

6 1

16

61

16

71

16

7 1

16

71

16

/

81

16

/

81

16

CIRCULA

SUPPLY

FLANGE

NPT

1

1

1

1

1

1

1

1

1

/

/

/

/

/

/

/

/

/

TOR

4

4

4

4

4

4

4

2

2

“D”

APPROX.

OVERALL

LENGTH

“E”

3

25

/

8

7

28

/

8

7

28

/

8

7

28

/

8

3

32

/

8

3

32

/

8

3

32

/

8

7

35

/

8

7

35

/

8

Page 3

XL-2000

3

T

HE INSTALLATION INSTRUCTIONS IN THIS MANUAL

ARE ABBREVIATED. SEE THE FRONT COVER OF THIS

MANUAL FOR REFERENCES TO CODES AND STANDARDS.

BOILER LOCATION

Provide a level, solid foundation for the boiler. Location should

be near the chimney so that the Flue Pipe Connector or

B

reeching to the chimney is short and direct.

A. The foundation must be capable of supporting the weight

of the boiler when filled with water:

Boiler Approximate Total Weight of Boiler

Size Assembly*, filled with water

XL-20 317

XL-30 405

XL-40 493

XL-50 581

* Includes burner, circulator and controls

B. The XL-2000 Boiler has full wet base sections which sur-

round fire-box for maximum heat absorption of burning

fuel, and low floor temperature.

C. If boiler is to be located over buried conduit containing

electric wires or telephone cables, consult local codes or

the National Board of Fire Underwriters for specific requirements.

MINIMUM CLEARANCE

Provide accessibility clearance of 24" from surfaces requiring

servicing (top and front) and 18" on any side requiring passage. The boiler shall be installed with the following MINIMUM

clearances from combustible materials:

A. CHIMNEY CONNECTOR-18"

B. BACK AND SIDES- 6" EXCEPT as limited by 18" clear-

ance from chimney connector

NOTE: Except in closets and alcoves, clearances above in (A)

and (B) may be reduced by providing forms of protection as

specified in NFPA 31, latest edition.

C

HIMNEY REQUIREMENTS (see NFPA 31, latest edition)

A. The chimney must be constructed in accordance with all

l

ocal applicable codes and the National Board of Fire

Underwriters. See boiler models and rating table shown on

page 2 for chimney sizes.

B

. Check chimney condition.

Existing chimneys and stacks may have deteriorated; without repairs their use would be hazardous. Before connecti

ng to an old chimney or stack:

1. Clean it.

2. Inspect it thoroughly.

3. Remove obstructions.

4. Replace worn sections of metal stacks.

5

. Seal bad masonry joints.

6. Repair damaged lining.

C. Where more than one appliance vents into a common

chimney, the area of the common breeching should at least

equal the area of the largest appliance flue plus 50% of the

additional flue areas.

D. Breeching area must not be reduced at connection into

chimney. Breeching must be inserted into, but not beyond,

inside of chimney liner.

E. Chimney height shall extend at least 3 feet above where it

passes through the roof of the building, and at least 2 feet

above any ridge within 10 feet of the chimney.

F. The use of a vent cap, where permitted by code, gives

additional protection against adverse wind conditions and

precipitation.

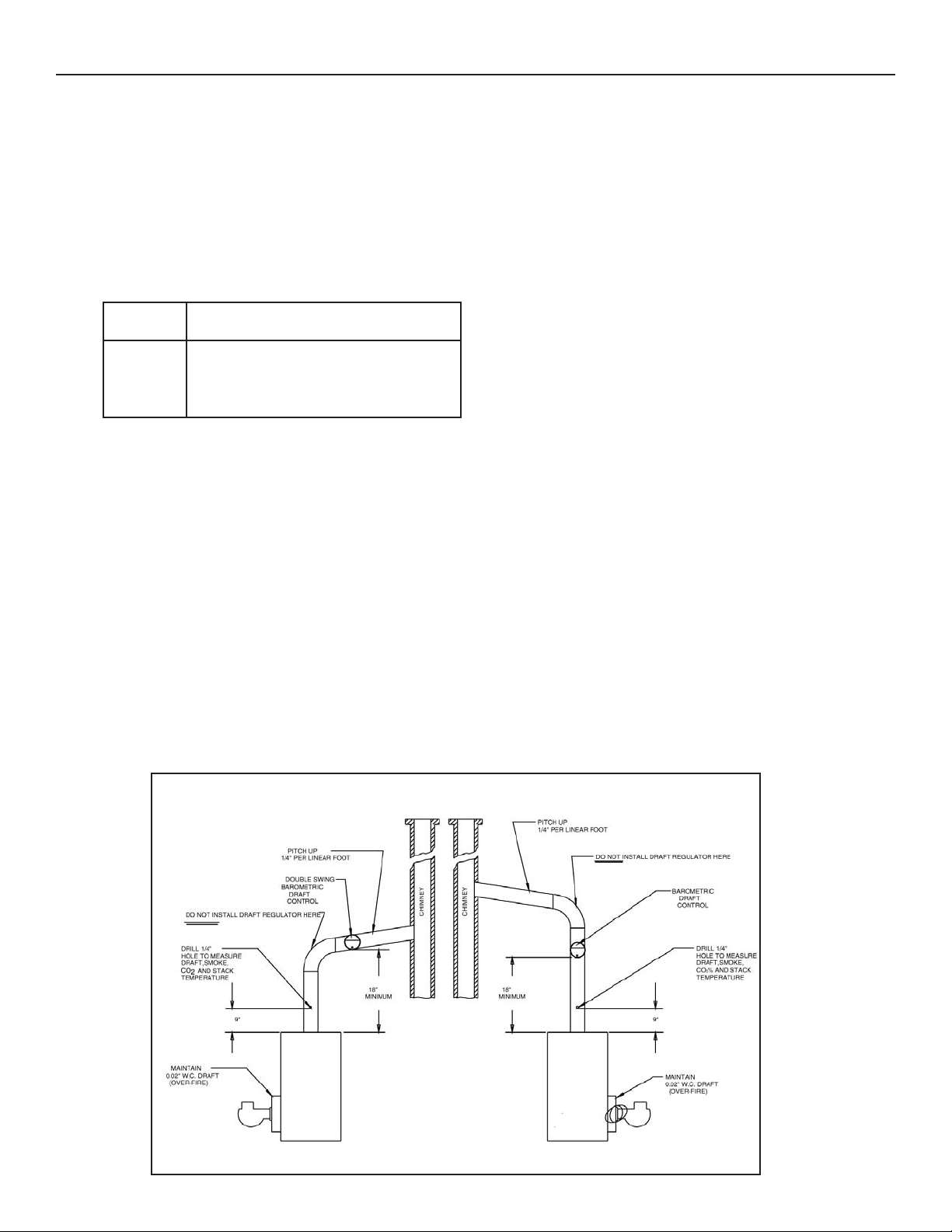

G. Flue Connection: Connect flue pipe between top of boiler

and chimney. Horizontal sections of flue pipe must be

pitched upward to the chimney at least 1/4" per foot. Flue

must be inserted into, but not extend beyond, the inside

wall of the chimney flue. Install draft regulator in flue pipe,

as shown in figure 3.

AIR SUPPLY AND VENTILATION (see NFPA 31, latest edition)

Sufficient air for combustion and ventilation in the boiler room

must be provided. Failure to do this will result in poor combus-

Figure 3.

Barometric Draft

Regulator

Location

Page 4

4

XL-2000

tion, heavy sooting and health hazards. Any oil-fired boiler

must have a steady draft* and an ample supply of combustion

air at all times during firing. If air supply or chimney draft* is

unreliable, CO

D

O NOT vent this boiler to the same chimney flue used by a

and overfire draft* will change unpredictably.

2

fireplace or coal or wood burning furnace or boiler. The draft*

produced by solid fueled devices varies tremendously

between high fire and low fire:

In modern, weather stripped, energy-saving buildings or older

buildings which have been modified similarly, natural infiltrat

ion may not supply enough air for combustion, particularly if

other fuel burning appliances, exhaust fans or draft inducers

are competing for the same air supply. Fireplaces, other solid

fuel burning appliances and exhaust fans consume great

quantities of air; if air supply is not ample, such an appliance

* Draft is negative or suction pressure

will create a downdraft in the oil-fired boiler flue. This can create a hazardous condition. Flue gases can be sucked out of

t

he chimney through the vent regulator into the living space.

DO NOT operate this boiler and a solid fuel burning appliance

at the same time, unless the solid fuel burner is provided with

i

ts own outside air supply.

See Table 2, “Provisions for Combustion and Ventilation Air

Supply” for determining need and method of providing air for

combustion and ventilation.

If fly screen must be used over air supply openings, areas calculated should be doubled; the screen should be inspected

and cleaned frequently to maintain free air flow.

Protect air openings against closure by snow, debris, etc.

Openings such as doors or windows, if used, must be locked

open.

TABLE 2: Provisions for Combustion and Ventilation Air Supply. See NFPA 31, latest edition for more detailed information.

Boiler Location Air Supply

2.1 Unconfined space Is there sufficient air for combus-

Action Required

NONE

tion by natural infiltration (see

NOTE (1), “Test...” below)?

2.2 Unconfined space If there in NOT sufficient air for

combustion by natural infiltration

due to tight construction or other

conditions, then it REQUIRES AIR

Provide air from outdoors directly through a permanent outside wall opening or openings with a free open area of not

less than 1 sq. in. per 4000 Btu/hr of TOTAL input of ALL fuel

burning appliances in the building. See Note (1) and (3).

FROM OUTDOORS. SEE

“ACTION REQUIRED” column at

right. See Notes (1) and (2) below.

2.3 Confined space If there is sufficient air for combustion from within building but it

comes from outside of the

confined space, see “ACTION

REQUIRED” column at right.

See Note (1) below.

The confined space shall be provided with two permanent air

openings, one near the top of the enclosure and one near the

bottom. EACH opening shall have a free air opening of not

less than 1 sq. in. per 1000 Btu/hr. of TOTAL input of ALL fuel

burning appliances within the enclosure. The two openings

shall freely communicate with the interior areas of the building

which in turn would have to have adequate infiltration of air

from outdoors. See Notes (1, 3) and Figure 3a.

2.4 Confined space If there is NOT sufficient air for

combustion due to tight construction or other conditions it

REQUIRES AIR FROM OUTDOORS. SEE “ACTION

REQUIRED” column at right.

See NOTE (2) below.

(a) Air from the outdoors shall be provided to the confined

space by two permanent openings, one in or near the top

of the enclosure space and one in or near the bottom. The

openings shall communicate directly, or by means of

ducts, with outdoors or to such spaces (crawl or attic) that

freely communicate with outdoors (See figures 3b, 3c

and 3d).

(b) Where directly communicating with outdoors or by means

of vertical ducts, each opening shall have a free area of

not less than 1 sq. in. per 4,000 Btu/hr. (35 sq. in. per gal.

per hr.) of total input rating of all appliances in the enclosure. If horizontal ducts are used, each opening shall have

a free area of not less than 1 sq. in. per 2,000 Btu/hr. (70

sq. in. per gal. per hr.) of total input of all appliances in the

confined space. See Figures 3b, 3c and 3d.

(1) Test for sufficient air for combustion by infiltration by running this boiler for 30 minutes under all of the following conditions and at the same time: a) all doors, win-

dows and other like openings must be closed, b) all fuel burning appliances should be FIRING, c) all exhaust fans and clothes dryers turned ON. At the above

conditions the CO2, smok

.04” W.C. negative pressure.)

(2) Aside from tight construction, some of the conditions that steal air for combustion from a boiler are other fuel burning appliances, exhaust fans and clothes dryers.

(3) Generally, louvers made of wood have a free open area of 20% and those made of metal have a 60% to 70% free open area. Screens also reduce the open area

of the louvers.

e and draft readings must be normal. (CO

betw

een 11% and 13%, smoke between ZERO and a TRACE, draft between .02” W.C. and

2

Page 5

XL-2000

5

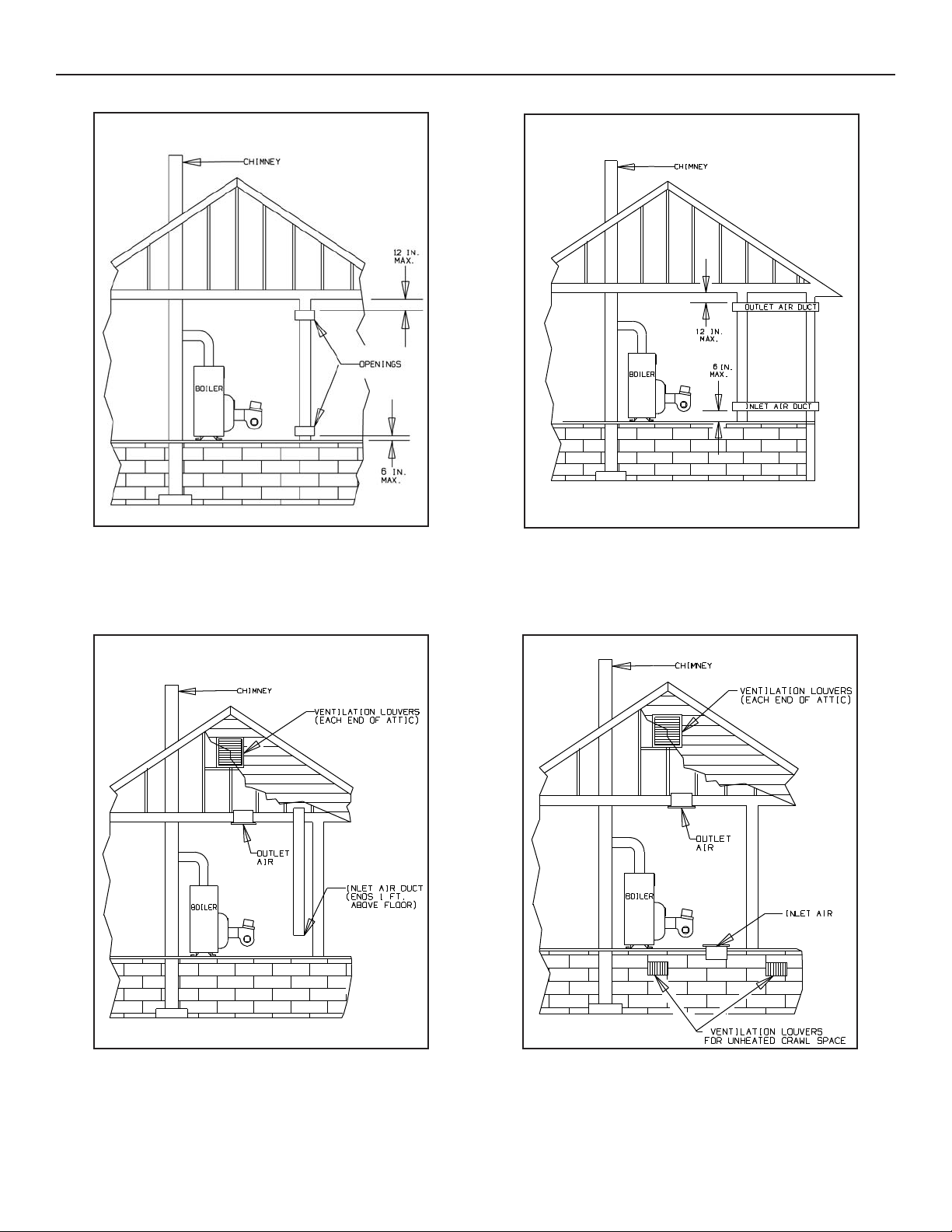

Figure 3a.

Appliances located in confined spaces. Air from

inside the building. See Table 2 (2.3).

Figure 3b.

Appliances located in confined spaces. Air from outdoors. See Table 2 (2.4).

Figure 3c.

Appliances located in confined spaces. Air from outdoors through ventilated attic. See Table 2 (2.4).

Figure 3d.

Appliances located in confined spaces. All air from

outdoors through ventilated crawl space and outlet

air to ventilated attic. See Table 2 (2.4).

Page 6

6

XL-2000

The opening size recommendation just given is for guidance

only. It is the installer’s responsibility to provide air for combust

ion and ventilation to all appliances, under all operating con-

ditions, for each installation. See NFPA 31, latest edition for

more specific details.

I

NSTALLING CONTROLS AND ACCESSORIES

ON BOILER UNITS

:Jacket must be installed on boiler units prior to installa-

Notes

tion of trim.

WATER BOILER TRIM, see page 2, figures 1 and 2 for tapping locations.

WATER PIPING FOR HOT WATER HEATING BOILERS

NOTE: On knocked-down boiler only, jacket may be installed

after supply piping connection, but must be installed prior to

adding trim and piping returns and drain valve.

I. CIRCULATING SYSTEM

A. FORCED CIRCULATION hot water heating system: Use

the top tapping as supply tapping, and use the front or

rear bottom tappings for the return.

B. A FLOW CONTROL VALVE will prevent gravity circula-

tion and is required when an external tankless heater,

an indirect water heater or multiple circulators are

installed.

II. AIR CONTROL SYSTEMS

A. DIAPHRAGM-TYPE COMPRESSION TANKS are used

to control system pressure in an AIR ELIMINATING

SYSTEM: an automatic air vent is used to REMOVE air

from the system water. (See figures 5 and 6)

If system pressure needs further control, add an additional tank or install a larger capacity tank.

The automatic air vent should be installed in the top of

the boiler, as in figures 5 and 6 and at radiation high

points (see “C”).

B

. CONVENTIONAL COMPRESSION TANKS (non-

diaphragm type) are used to control system pressure in

an AIR COLLECTING SYSTEM. Within the system,

a

fter initial start-up and venting, air is collected in the

tank and acts in contact with the water to control pressure (see dashed area in figure 5 and paragraph “E”).

A

ir is not vented from this system except at radiation

high points (see “C”).

If system pressure needs further control, add another

tank in parallel with the original tank or install a large

capacity tank. Locate the tank at the inlet end of the

p

ump near the boiler. (See figure 5)

C. HOT WATER RADIATION VENTING - Manual air vents

should be installed at the top of all "drops" (where piping goes downward). Air must be vented or purged from

all zone lines to permit proper system heating.

D. PUMP LOCATION - Locating low-head pump(s) on

return to boiler is only acceptable in residences of one

or two stories. (See figure 6) The pump location shown

in figure 5 is required in large, multi-story building installations, especially when high-head pumps are used and

is also recommended for all applications.

E. A conventional compression tank may be connected

directly to the 1/2" tapping on the boiler (see “Alternate

Compression Tank”, figure 5).

IMPORTANT: Hot water heating systems containing high

water volume, such as would occur with cast iron radiation,

require special care with air elimination.

The circulator pump should be located on the boiler supply

pipe and the expansion tank and air scoop should be located

near the pump suction. (as shown in figures 5 and 6) For

alternate circulator pump location on return for low-head

pumps and one or two story buildings ONLY (see figure 6).

Figure 5. Air Eliminating System or Alternating Collecting

System

Figure 6. Alternate Air Eliminating System

Page 7

XL-2000

7

DOMESTIC HOT WATER

For Indirect-fired storage water heater application, see

S

lant/Fin publication WH-10, Sizing Guide WH-SG and

Installation manual WH-40. The installation manual includes

several control systems and relay centers for space and

domestic water heating in addition to plumbing.

INSTALLING THE BURNER

See Burner Data, pages 11 and 12, and Burner Manual supplied with burner. If burner is not mounted as received, mount

t

o boiler, placing flange over mounting studs. Use gasket

between flange and boiler. Distance between flange and nose

of burner must be as shown on pages 11 and 12. Check to

see that nozzle and settings are as given in burner data

tables, pages 11 and 12.

OIL SUPPLY PIPING

Install the oil tank or tanks and piping from tank to burner.

Follow local codes and practices, INSTALLATION OF OIL

BURNING EQUIPMENT, NFPA 31, latest edition, and the

instruction sheet attached to the oil burner pump. A one-pipe

system should be used for gravity-fed fuel systems and for lift

systems, where the total lift is less than 8 feet. Where the total

lift is greater than 8 feet, a two-pipe system must be used. In

some instances, local codes may require a two-pipe system

for below grade fuel oil tanks. Be sure to set up the fuel oil

pump for the piping system used; follow the instructions

attached to the pump. Be sure to include a good quality, low

pressure drop fuel oil filter in the supply line from the tank.

This is necessary, especially at low fuel oil flow rates (small

nozzle sizes), to prevent nozzle plugging. Fuel oil shutoff

valves should be installed at the burner on the supply (and

return if two-pipe) to facilitate servicing. See Slant/Fin publication on one-pipe and two-pipe fuel oil systems.

WIRING THE BOILER

(see National Electric Code ANSI/NFPA 70-latest edition)

A. The wiring diagrams for the burner and boiler may be found

on page 10.

B. 24 volt control wiring should be approved Safety Circuit

wire, protected as needed.

C. Power supply wiring to the burner must be 14 gauge, as

required, and should have a properly fused disconnect switch.

120 volt wiring to pumps and safety controls must also be 14

gauge. Wire must be enclosed in approved conduit.

D. The wires supplying power to the burner MUST go through

the quick disconnect plugs provided with the boiler.

E. All wiring must be installed in compliance with the National

Electric Code, or any local or insurance codes having jurisdiction.

VENT PIPING AND DRAFT REGULATOR

(see NFPA 31, latest edition)

A. Vent connectors must be the same diameter as the boiler

flue collar. (See page 2)

B. Vent pipes and breeching must be pitched upward a mini-

mum of 1/4" per foot.

C. Connect vent pipe to the chimney using as few elbows as

possible and as short as possible within NFPA 31 or

authority.

D. Horizontal vent connector into the chimney should not be

inserted beyond the inside wall of the chimney.

E. Install barometric draft regulator on horizontal breeching,

near chimney, with hinge horizontal and face vertical conditions permitting as in Figure 3a. See Figure 3b as a second

choice. See manufacturer's instructions packed in carton

w

ith barometric draft regulator.

F. If two or more appliances are used on the same chimney,

see CHIMNEY, page 3.

G

. Make up all joints with minimum air leaks, secure with

sheet metal screws.

P

RECAUTIONS BEFORE STARTING OIL BURNER

Make a positive check of A through F before starting burner:

A. Boiler and system are full of water. All air is vented from

system. See below.

B

. All wiring is completed. See page 10.

C. Oil supply is connected to the burner; nozzle is installed

correctly; oil valve is open at tank.

D. Main cast iron door on which burner is mounted is bolted

shut and fiberglass rope seal is making good contact.

E. Smokepipe is connected to chimney.

F. All combustible materials are cleared away.

G. Combustion air supply is provided. See page 3.

H. Burner settings are adjusted as per pages 7, 8, 11 and 12

and as shown on boiler jacket.

W

ARNING: NEVER OPERATE any natural draft* boiler

(XL-2000 boiler is a natural draft boiler) with zero draft or

overfire pressure: early failure of the burner, nozzle and

chamber is inevitable if you do. Use a draft gauge, and

make sure that overfire draft* is .02" to .04", during all

operating conditions.

* Draft is negative or suction pressure.

START-UP (COMBUSTION TEST INSTRUMENTS MUST

BE USED)

A. Make sure the boiler is installed and wired properly and is full

of water.

B. The observation port cover is mounted on the hinged burner

mounting door (see figure 2 on page 2). NEVER touch the

port cover or any surrounding surfaces with hands. They may

be HOT. Use tools. Loosen the screw that fastens the observation port cover, swing the cover open and tighten the

screw. See the burner instructions for bleeding air, etc. Step

away from the boiler and start the oil burner.

C. IMMEDIATELY, set burner air bands to obtain a bright fire

without smoke or oil stain. Set the DRAFT REGULATOR to

obtain .02" overfire draft*. Take draft reading through slot in

observation door after first closing the observation door.

D. Tighten the observation door screw. Allow the burner to fire

for at least one hour total firing time, to bake out the volatile

binders in the combustion chamber before taking final combustion readings.

E. By alternate adjustment of the barometric draft regulator, the

burner air regulation and head regulation devices (whichever

apply), set for a zero to a trace of smoke and 12% CO

.

2

Then open the air bands or shutter (whichever apply) an

additional 1/8". This should result in zero smoke with NO raw

oil on the smoke paper and a smooth light-off. DO NOT

ATTEMPT TO SET FIRE BY EYE. Flame retention burners

may appear efficient and smoke free from an inefficient 7%

up to an overly high 14% CO

. However, a very low CO2can

2

also result in poor ignition and raw (unburned) oil entering the

fire box. At very high CO

, any slight decrease in air flow for

2

any reason will cause incomplete combustion, with high

Page 8

8

XL-2000

smoke and dry soot formation in the fire box.

F. If smoke reading is satisfactory, but CO

can not be

2

increased to a satisfactory level (12%) or overfire draft of

0

.02" W.C. can not be obtained, check for proper sealing

between sections, between the hinged burner mounting

door and front section, around burner blast tube and

a

round flue collector and collar. If seal is not satisfactory,

reseal with furnace putty or silicone with a temperature rating of at least 400° F. (All safety precautions indicated on

material package must be followed.)

G. Once burner and draft have been set up, then smoke, CO

and stack temperature should be checked and recorded. If

s

moke is greater than trace, review the burner instructions

and replace the nozzle if necessary. Normal smoke to be

expected is zero to a trace.

H. Make sure that the observation port cover is closed and

the screw is tightened.

CLEANING AND FILLING A NEW WATER BOILER

I. There are a number of commercial preparations available

from your distributor for cleaning and for corrosion protection

conditioning the internal (waterside) surfaces of boilers.

Follow the preparation manufacturer’s instructions.

DANGER: Use CAUTION when handling chemicals and

draining hot water from a boiler. Scalding water and/or

chemicals can cause permanent injury to the skin, eyes

and respiratory system.

II. Filling and venting the water boiler after cleaning

A. Refill the system with fresh water.

B. Bring water temperature to at least 180° F promptly.

C. Circulate water through entire system.

D. Vent the system, including the radiation.

E. The boiler is now ready to be put into service or on

standby.

F. If brand name air-control devices are used, venting

instructions furnished with the devices should

be followed.

W

ATER CONTENT OF BOILER (GALLONS)

XL-20 XL-30

5.5 7.0

VOLUME OF WATER IN STANDARD PIPE OR TUBE

Nominal

Pipe

Siz

e

Inches

3/8 — — — 0.430 0.0075

1/2 40 0.622 0.0157 0.545 0.0121

5/8 — — — 0.666 0.0181

3/4 40 0.824 0.0277 0.785 0.0251

1 40 1.049 0.0449 1.025 0.0429

1 1/4 40 1.380 0.0779 1.265 0.0653

1 1/2 40 1.610 0.106 1.505 0.0924

2 40 2.067 0.174 1.985 0.161

2 1/2 40 2.469 0.249 2.465 0.248

3 40 3.068 0.384 2.945 0.354

Standard Steel Pipe Type L Copper Tube

Inside

.

Diameter

Inches

Schedule

No

XL-40

8.5 10.0

Gallons

per

Lin. Ft.

XL-50

Inside

Dia.

Inches

Gallons

per

Lin.

ft..

III. Safety check for control system

High limit control test: Set thermostat high enough for boiler

water temperature to reach high limit control setting. When

this temperature is reached, the high limit switch should

o

pen, and the burner should shut off automatically. If the

high limit does not operate to shut off the burner, the high

limit or the wiring is faulty. Repair or replace immediately.

C

ARE AND MAINTENANCE

I. EXTENDED SHUTDOWN, CLEANING OR REMOVAL OF

2

BOILER FROM SERVICE.

DANGER: Use CAUTION when handling chemicals and

dra

ining hot water from a boiler

c

hemicals can cause per

. S

calding water and/or

manent injury to the skin, eyes

and respiratory system.

A.Shut down burner by disconnecting all electrical power to

the burner by turning OFF the BURNER EMERGENCY

SWITCH of this boiler. After shutting down burner, while

the boiler is still hot (180°F to 200°F), drain water from

the bottom of the boiler until it runs clear.

B.Provide corrosion protection conditioning to the boiler

water in the heating system. There are a number of commercial heating system preparations available from your

distributor. Follow the preparation manufacturer’s instructions.

o clean the fireside boiler surfaces, first shut down

C.T

burner by disconnecting all electrical power to the burner

by turning OFF the OIL BURNER EMERGENCY

SWITCH of this boiler in order to perform the following

work in (1) through (10) below.

1. Remove the flue pipe from the boiler flue collar and

clean thoroughly.

2. Inspect the entire vent connector back to the chimney and clean if necessary.

3. Inspect the chimney for soot, debris and other unsafe

conditions of the chimney and take the necessary

action.

4. Remove the flue collector by first removing the top

jacket panel. The flue collector is held in place by two

hex 1/4-20 screws. Remove the screws and carefully

remove the flue collector. Try not to disturb the flat

fiberglass rope under the flue collector.

5. When necessary to clean the combustion chamber

you must first CLOSE the suction valve (and return

valve if two pipe). Then disconnect the oil lines from

the burner. The flexible electric conduit connected

from the junction box on the boiler to the burner via a

plastic connector must be disconnected from the

burner by grasping the plastic half of the connector

closest to the flexible conduit and gently pulling it in

the direction of the conduit until it is disconnected.

Remove the single 3/8-16 hex head screw on the

LEFT side of the swinging door. You will need a 9/16”

drive socket. Open the door to completely expose the

combustion chamber for thorough cleaning and for

inspection of target wall, blanket (provided in certain

models;

see rating plate), main cast iron burner door

insulation and burner door fiberglass sealing rope. If

combustion chamber parts above are badly deteriorated then replace with or

iginal factory parts avail-

able at your distributor.

Page 9

XL-2000

9

6. Use the flue brush to clean the pinned flueways

b

etween the sections.† A wire brush may be used

to remove any carbon accumulation that may have

d

eveloped in the combustion chamber. Vacuum the

loose soot and debris from the boiler.

7. Inspect the burner combustion head. Clean if necessary and make sure all the adjustments are correct. (See burner data pages for the burner

installed.) Replace oil nozzle with new one and

r

eadjust electrodes. To insure proper burner operation ONLY THE NOZZLES SPECIFIED IN THIS

M

ANUAL OR ON THE BURNER LABEL SHOULD

BE USED FOR REPLACEMENT.

8. Protect all of the fireside surf

aces by swabbing with

neutral mineral oil.

9. Close main cast iron b

urner door (door on which

burner is mounted). Make sure that the entire seal

(fiberglass rope) is making good contact with the

boiler casting when replacing 3/8-16 x 1” long hex

head bolt and tightening.

10. Check the flue collector seal. This is the flat rope

seal on top of the heat exchanger. The rope must

be in place adjacent to the long bosses on front and

rear sections and adjacent to the short bosses on

the intermediate sections. The rope should be

directly under the flue collector flanges when the

flue collector is replaced. Use the two 1/4-20 x 3/4”

washer hex head screws to fasten the flue collector.

In order to assure a proper seal be sure that the

flue collector is compressing the flat rope and not

hanging up on the section bosses. Tighten the two

screws.

D.If boiler room is damp, provide ventilation.

II. PROVIDING PROTECTION FOR FREEZING

Anti-freeze is sometimes used in hydronic heating systems to protect against freeze-up in the event of power

failure, or safety control shutdown when the building is

unoccupied. It should be recognized that unless the

building is kept above freezing temperature by some

means, the plumbing system is not protected.

PROPYLENE GLYCOL is used in the quick-freeze food

industry; it is practically non-toxic. Its use may be permitted when indirect water heaters are used. When antifreeze must be used, inhibited propylene glycol is recom-

mended. Useful information on the characteristics, mixing

p

roportions, etc. of glycol in heating systems is given in

Technical Topics No. 2A, available from the Hydronics

D

ivision of GAMA, 35 Russo Place, Berkeley Heights, NJ

07922. Consult glycol manufacturers for sources of propylene glycol.

D

O NOT USE ETHYLENE GLYCOL BECAUSE IT IS TOXIC.

I

II. OIL BURNER

Inspect and clean annually and following any period of

i

mproper operation. Recheck and adjust settings as specified for burner model and nozzle size.

Set burner air and draft regulator, using test instruments

to obtain recommended CO

and draft without smoke.

2

See the Burner Data page in this manual that corresponds to the burner installed.

IV. GENERAL MAINTENANCE

These operations are recommended to be performed at

regular intervals:

A.BOILER HEATING SURFACES: clean off all coatings

found. Reseal covers.

B.BOILER CONTROLS: check contacts, settings, correct

functioning.

C.PIPING: check piping and accessories for leaks.

D.CHIMNEY or STUB VENT and BREECHING: check for

obstructions and leaks.

E.COMBUSTION AIR TO BURNER: check for continued

POSITIVE supply of air as required. Air needs are

greatest in coldest weather. Refer to AIR SUPPLY,

page 3.

F. WATER SYSTEM: check

1. System to be full of water and pressure to remain

stable (between 12 psi and 25 psi).

2. Air-control system: noise and air binding in radiation

should not occur.

3. Water lines: slightest leaks should be corrected.

G.BOILER ROOM AIR SUPPLY: air vents should be open

and free of obstruction. See page 3.

† A flue brush (2-1/4" dia.) is supplied with boiler.

Replacements are available from dealer or

hardware stores.

Page 10

10

XL-2000

Page 11

XL-2000

BURNER DATA—CARLIN BURNERS FOR PACKAGED BOILERS ONLY

11

NOZZLES

ANGLE

AND

TYPE

MFR.

OIL PUMP

PRESSURE

SETTING

(PSIG)

“A”

APPROXIMATE

HEAD SETTING

NO.

APPROXIMATE

AIR BAND

OPENING %

(1)

SHUTTER

NON-

ADJUSTABLE

BOILER

MODEL

CARLIN BURNER

MODEL (2) (3)

FIRING

RATE

NO. 2 OIL

(GPH)

SIZE

(GPH)

XL-20 99-FRD 0.65 0.65 70° A DELAVAN 100 0 50 Closed

71399-00F-XL-20 0.65 70° W DELAVAN 100 0 50 Closed

XL-30 99-FRD 1.00 1.00 70° A DELAVAN 100 2 80 Closed

71399-00F-XL-30 1.15 1.00 70° A DELAVAN 130 3 90 Closed

XL-40 99-FRD 1.35 1.35 60° W DELAVAN 100 4 50 Closed

71399-00F-XL-40 1.55 1.35 60° W DELAVAN 130 4 65 Closed

XL-50 99-FRD 1.80 1.75 60° B DELAVAN 105 4 20 Open

71399-00F-XL-50 2.00 1.75 60° B DELAVAN 130 5 40 Open

NO

TES:

(1) Single slotted air band for XL-20 and XL-30, double slotted air band for XL-40 and XL-50.

(2) See “PRECAUTIONS BEFORE STARTING OIL BURNERS” and “START-UP” on page 7 and burner figures on this page.

(3) All burner models shown are single stage.

Page 12

12

EMBOSSED AIR BAND ADJUSTMENT

OPENS WHEN ROTATED CLOCKWISE

EXAMPLE: SHOWN AT

N° 2 POSITION

SEE TABLE FOR CORRECT SETTINGS

SHUTTER ADJUSTMENT SHUTTER

OPENS WHEN ROTATED CLOCKWISE

E

XAMPLE: SHOWN AT N°6 POSITION

AIR BAND

ADJUSTMENT

SCREW

OIL

PUMP

BURNER DATA—BECKETT BURNERS FOR PACKAGED BOILERS ONLY

XL-2000

NOZZLES

ANGLE

AND

TYPE

MFR.

OIL PUMP

PRESSURE

SETTING

PSIG)

(

APPROXIMATE

AIR SHUTTER

SETTING NO.

1)

(

APPROXIMATE

AIR BAND

SETTING NO.

STATIC DISK

DIAMETER

INCHES

BOILER

MODEL

BECKETT

BURNER

MODEL

(2) (3)

BECKETT

BURNER

HEAD

FIRING

RATE

NO. 2 OIL

(GPH)

SIZE

(GPH)

XL-20 (4) AFG F0 0.65 0.65 80° A DELAVAN 100 7 Blank/Closed 3

SF2201

XL-30H

AFG F3 0.85 0.85 70° W DELAVAN 100 6

Blank/Closed

2

SF2204

XL-30 AFG F3 1.00 1.00 80° W DELAVAN 100 8 0 2

S

F2202 1.15 1.00 80° W DELAVAN 130 10 2 2

XL-40H

AF F6 1.25 1.25 80° W DELAVAN 100 10 2 None

SF2205

XL-40 AF F6 1.35 1.35 80° W DELAVAN 100 10 2

/

2

None

1

SF2203 1.55 1.35 80° W DELAVAN 130 10 5 None

XL-50 AF F12 1.80 1.75 70° B DELAVAN 105 10 3 None

SF2207

NOTES:

(1) Blank (closed) air band for XL-20, 2 slot band for XL-30, 4 slot band for XL-40 and 8 slot air band for XL-50.

(2) See “PRECAUTIONS BEFORE STARTING OIL BURNERS” and “START-UP” on page 7 and burner figures on this page.

(3) All burner models shown are single stage.

(4) XL-20 is supplied with a low fire baffle (Beckett No. 31760) installed.

3

/

8

3

/

4

3

/

4

3

/

4

TOP VIEW OF GUN ASSEMBLY

Page 13

XL-2000

BURNER DATA - RIELLO BURNERS FOR PACKAGED BOILERS ONLY

(RIELLO R-40 SERIES W/SHORT TUBE)

13

BOILER

MODEL

RIELLO

BURNER

MODEL

XL-20 R-40 F-3 48-0242-100

X

L-30 R-40 F-5 48-0243-100

XL-40 R-40 F-5 48-0244-100

XL-50 R-40 F-10 48-0245-100

† Air shutter and head settings shown are approximate ONLY. See START-UP page 7

NOTE: For proper insertion into combustion chamber see figure 8

SLANT/FIN

B

URNER

P/N SINGLE

S

TAG E

OIL PUMP

S

TAGES

1 0.65 0.5

1 1 0.85 70˚ES

1

1 1.35 1.2 80˚B

1 1.5 1.2 80˚B

1 1.8 1.5 60˚B DELAVAN 145 1 3.8

FIRING

RATE

S

GPH

IZE

(

GPH)

1.15 0.85 70˚ES

Figure 7A. Riello 40 Series

Model F-3 & F-5

Electrode Setting

NOZZLES

P

ANGLE

&

TYPE

70˚SS

NOZZLE

M

FR.

H

AGO 170 1 3-1/2

80˚ES

HAGO 140 1 2.6

HAGO 185 1 3.2

DELAVAN 130 3 4

DELAVAN 160 4 4.75

Figure 7B. Riello 40 Series

Model F-10

Electrode Setting

OIL PUMP

RESSURE

SETTING

(PSIG)

APPROX.

HEAD

SETTING

NO. †

APPROX.

AIR

S

HUTTER

SETTING

NO. †

Figure 8

For proper inser

tion into combustion chamber

Page 14

14

XL-2000

BURNER DATA - RIELLO (continued)

REGULATION OF THE TURBULATOR AND AIR SHUTTER

F

OR PROPER COMBUSTION

Turbulator Setting

1. Loosen nut, 1, then turn the screw, 2, until the index marker,

3, is aligned with the correct index number.

2. Retighten the retaining nut, 1.

TURBULATOR SETTINGS - RIELLO 40 SERIES

The numbers on the casting are there to denote the high and low

end of the scale - in all cases the first mark is “Zero”.

T

he air/oil ratio depends on accurate setting of the turbulator disc.

Be careful when making this adjustment as an incorrect setting

will result in an unsatisfactory installation. See figure 9A and 9B.

Figure 9A

1. Regulation of the combustion air flow is made by adjustment

of the manual AIR ADJUSTMENT PLATE (4) after loosening

the FIXING SCREWS (3&5). The initial setting of the air

adjustment plate should be made according to page 13.

2. The proper number on the manual AIR ADJUSTMENT PLATE

(

4) should line up with the SETTING INDICATOR (2) on the

fan housing cover. Once set, the air adjustment plate should

be secured in place by tightening SCREWS 3 and 5. For F-10

model, manually open and release the hydraulic air shutter to

ensure it has free movement.

3. The final position of the air adjustment plate will vary on each

installation. Use instruments to establish the proper settings for

maximum CO

NOTE: Variations in flue gas, smoke, CO

and a smoke reading of zero.

2

and temperature

2

readings may be experienced when the burner cover is

put in place. Therefore, the burner cover MUST be in

place when making the final combustion instrument

readings, to ensure proper test results.

Figure 10A

Model F-3, F-5

Air Adjustment

Figure 9B

SETTING THE AIR ADJUSTMENT PLATE

Note: For F-3 and F-5 models, the air shutter is

operated on a 120V 60 Hz.

motor, the

burner will not operate until the air

shutter is in its fully open position; and

for F-10 model is operated by Hydraulic

Jack. (see figures 10 A & B).

Figure 10B

Model F-10

Air Adjustment

Page 15

©Slant/Fin Corp. 1996.

SLANT/FIN CORPORATION, Greenvale, N.Y. 11548 • Phone: (516) 484-2600

F

AX: (516) 484-5921 •

Canada:

Slant/Fin

L

TD/LTEE,

Mississauga, Ontar

www.slantfin.com

io

Loading...

Loading...