Page 1

™

VICTORY VSPH

This manual must be left

w

ith owner and should be

h

ung on or adjacent to

t

he boiler for reference.

DIRECT-VENT SEALED COMBUSTION BOILERS

HOT WATER MODELS VSPH-60 THROUGH VSPH-180

GAS-FIRED CAST-IRON BOILERS FOR NATURAL AND L.P. PROPANE GASES

INSTALLATION AND OPERATING INSTRUCTIONS

®

TABLE OF CONTENTS

Dimensions, Rating and Orifice Sizes ........................................2

Identification of Parts..................................................................3

Installation Requirements ...........................................................4

Venting Application .....................................................................5

Boiler Room Air Supply and Ventilation......................................5

Flue gas Venting Requirements..................................................5

Vent Material ..............................................................................5

Air Intake Material ......................................................................6

Flue and Air Intake Restrictions .................................................6

Non-Direct Vent Installation ........................................................8

Sidewall Venting, Non-Direct Vent ..............................................8

Vent Termination Location and Clearance ..................................8

Non-Direct Vent Vertical Venting.................................................8

Direct Vent Installation ................................................................8

Sidewall Venting, Direct Vent ......................................................8

Vent/Air Intake Termination Installation.......................................8

Direct Vent, Venting and Air Intake through a Roof ..................13

Venting and Air Intake Regular Inspection ...............................15

Gas Piping ................................................................................15

Electrical Wiring ........................................................................15

Multi Zoning ..............................................................................18

Water Piping .............................................................................18

Wiring Diagram.........................................................................16

Operating Instructions...............................................................19

Gas Input Rate Adjustment ......................................................20

Boiler Control............................................................................22

Sequence of Operation.............................................................21

Status of Indicator Lights (LED’s).............................................22

Safety Check ...........................................................................23

Care and Maintenance .............................................................24

General Troubleshooting Guide ...........................................25-27

WARNING

The venting system of this boiler is under positive pressure. Leakage from this system can be hazardous and if

not avoided can result in death or serious injury. In addition to the recommendations within this manual and the

User’

s Information Manual, the venting system, from the

blower to the outdoor discharge, must be carefully

checked annually by a qualified service agency.

IMPORTANT

READ ALL OF THE FOLLOWING

WARNINGS AND STATEMENTS

BEFORE READING THE

INSTALLATION INSTRUCTIONS

WARNING

LIQUEFIED PETROLEUM (L.P.)

PROPANE GAS-FIRED BOILERS

Installation location ONLY as permitted in paragraph

entitled "LIQUEFIED PETROLEUM (L.P.) PROPANE

GAS-FIRED BOILER LOCATION" on page 4 of this

instruction book.

The above warning does not apply to

fired boilers.

The installation must conform to the requirements of

the authority having jurisdiction or, in the absence of

such requirements, to the National Fuel Gas Code,

ANSI Z223.1-latest edition. The installation must also

conform to the additional requirements in this Slant/Fin

Instruction Book.

In addition where required by the authority having jurisdiction, the installation must conform to American

Society of Mechanical Engineers Safety Code for

Controls and Safety Devices for Automatically Fired

Boilers, No. CSD-1.

WARNING

This boiler, gas piping and accessories must be

installed, connected, serviced and repaired by a

trained, experienced service technician, familiar with all

precautions required for gas-fired equipment and

licensed or otherwise qualified, in compliance with the

authority having jurisdiction.

NATURAL gas-

Heating Contractor

Address

Phone Number

Printed in U.S.A. 207 Part No. 455035 Publication No. VSPH-40 Rev. A

Boiler Model Number

Boiler Serial Number

Installation Date

Page 2

2

VI

CTORY VSPH Models

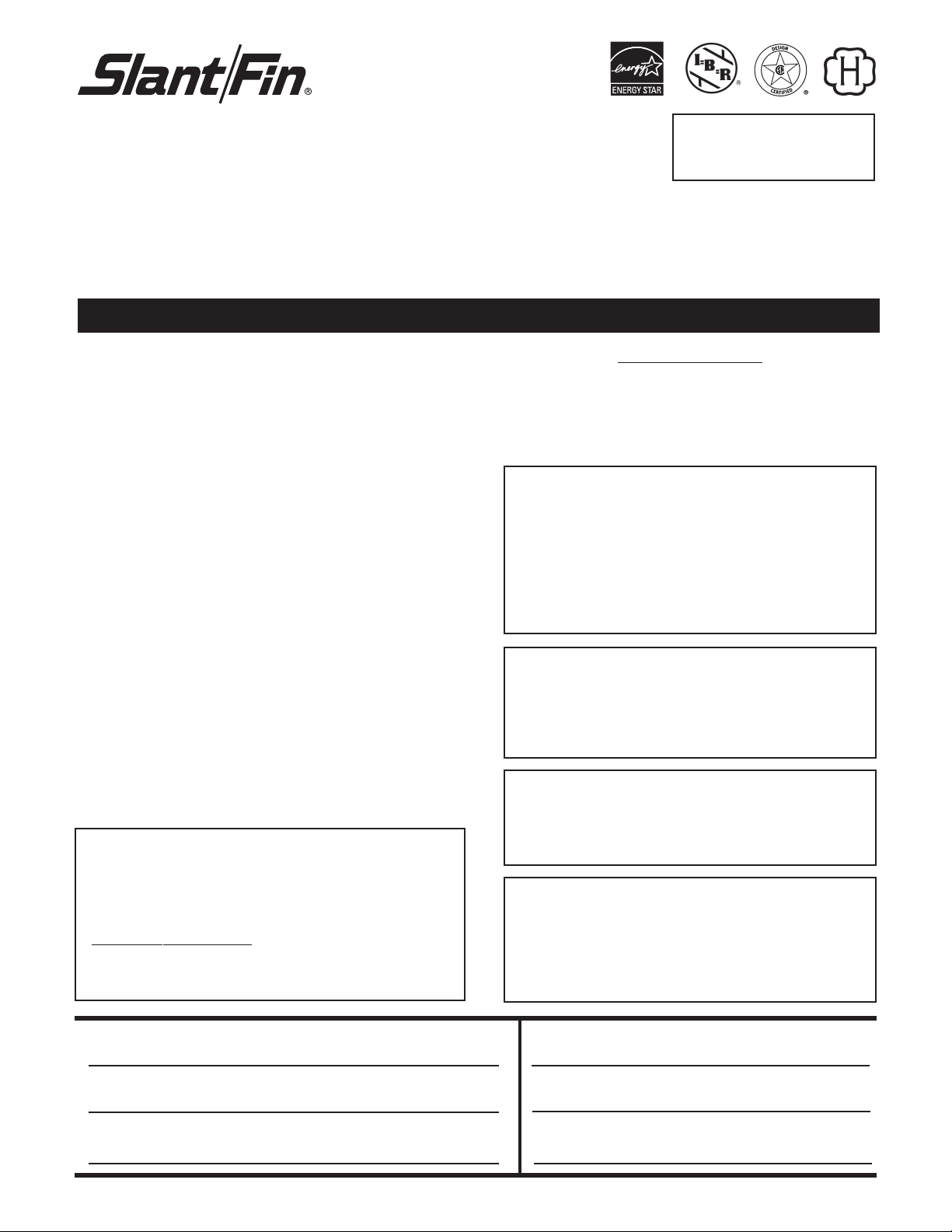

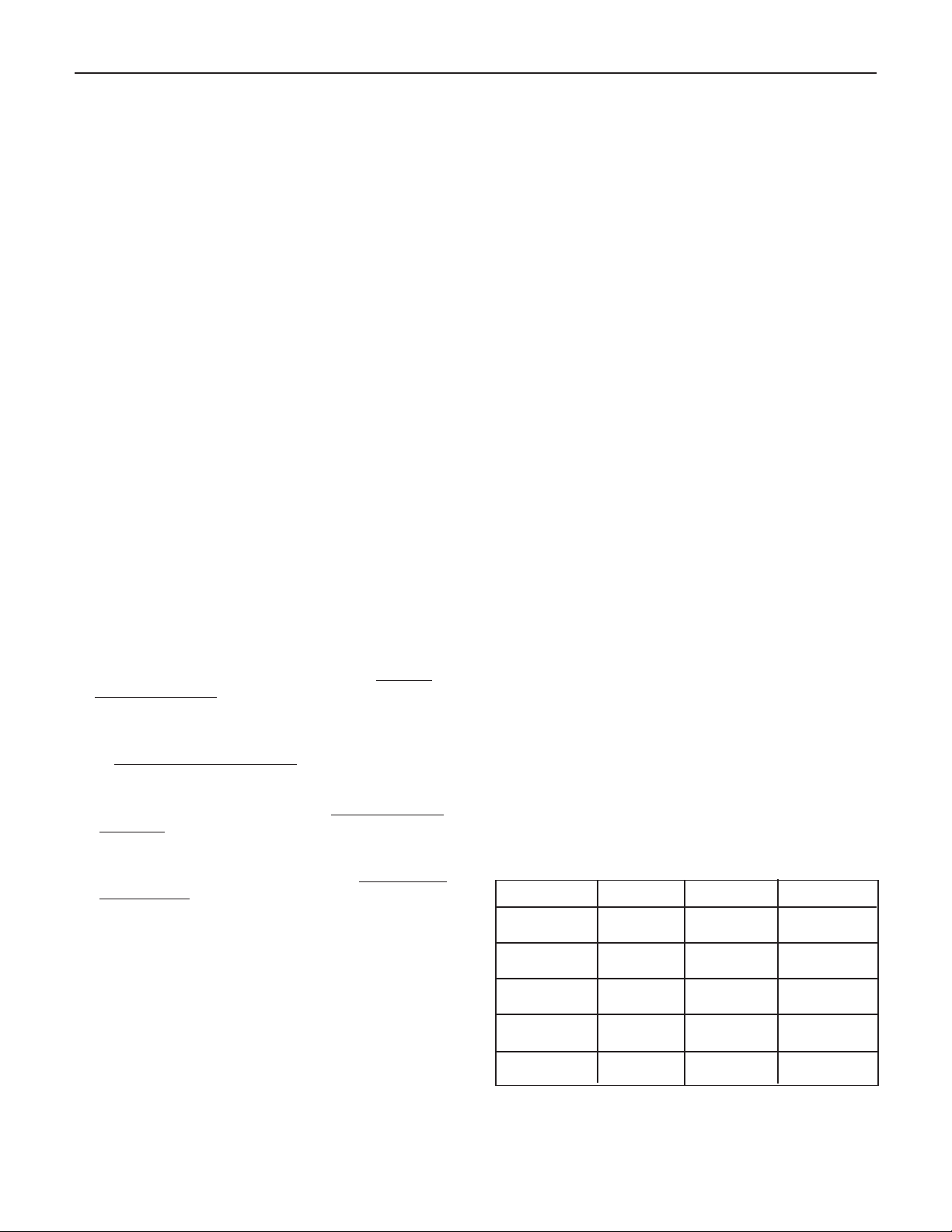

RATINGS AND DIMENSIONS

NOTE: Height dimensions increase by

1

1

⁄2" and depth increases to 281⁄2" when

combustible floor kit is used.

Figure 1. Dimensions data

Boiler

Model

Input

Btuh

VSPH-60 60,000 3 11

VSPH-90 90,000 4 14

VSPH-120 120,000 5 17

VSPH-150 150,000 6 20

VSPH-180 180,000 7 23

No. of

Sections

A

1

⁄8"17

1

⁄8"20

1

⁄8" 233⁄8"

1

⁄8"26

1

⁄8"29

B

3

⁄8"

3

⁄8"

3

⁄8"

3

⁄8"

Gas Orifice Size

Orifice Sizes for High Altitudes

Includes 4% Reduction for Each 1000 Feet

Ele

vation — Feet

Gas

Type

Orifice

Size for

Sea Level

2000 3000 4000 5000 6000 7000 8000 9000 10000

Natural #49 50 50 50 51 51 51 52 52 52

Propane #57 58 59 59 60 60 61 62 63 63

Victory VSPH boiler

Orifice sizes indicated for sea level above are factory installed in boiler unless otherwise specified by the local authority. Orifice

table is based on a higher heating value between 1000 Btuh and 1010 Btuh for Natural Gas (See page 20, if local higher heating value exceeds these numbers). See page 20, for burner input adjustment.

Page 3

VI

CTORY VSPH Models

3

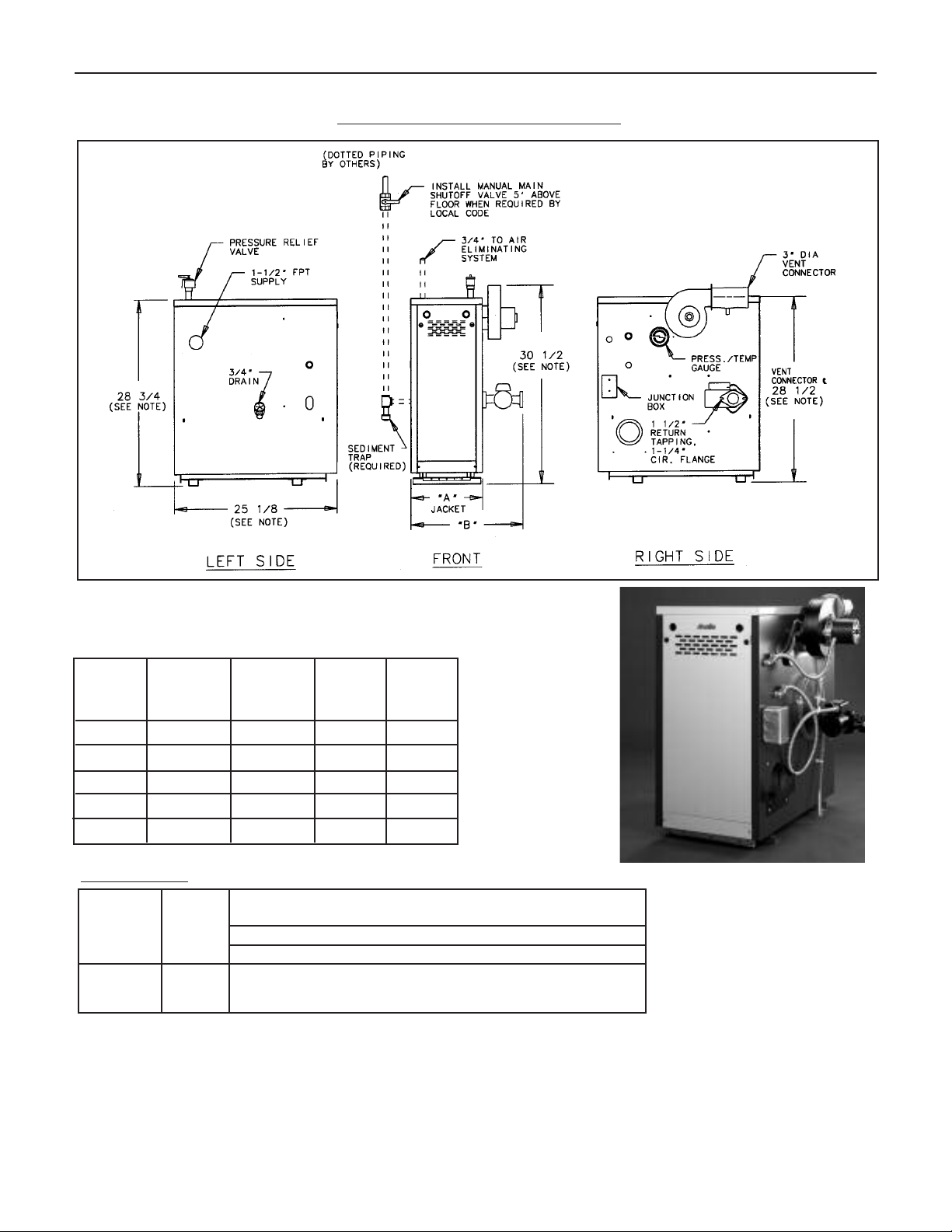

LOCATION AND IDENTIFICATION OF PARTS

Figure 2. Location and identification of parts

Base Assemb

ly

Page 4

4

VI

CTORY VSPH Models

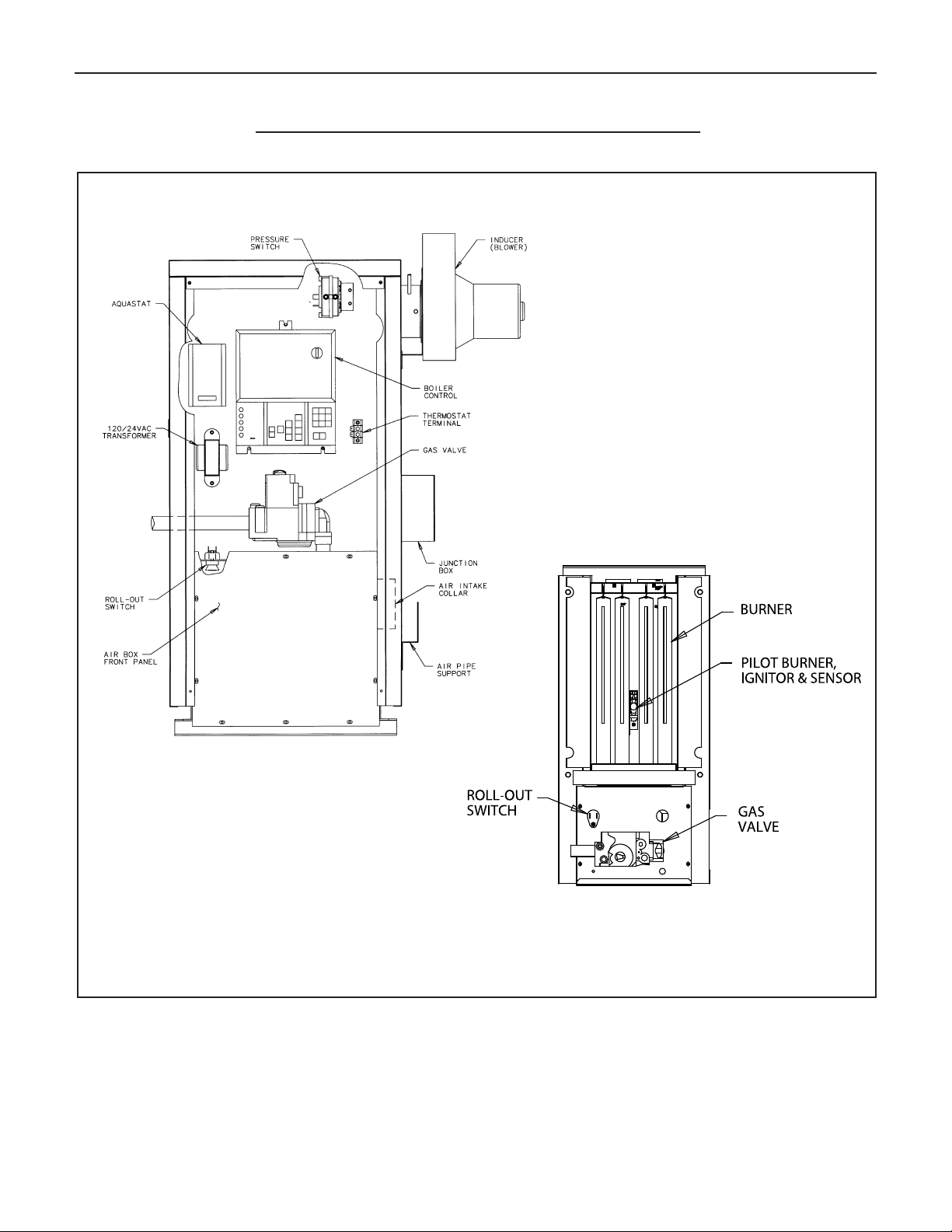

INSTALLATION REQUIREMENTS

The installation must conform to the requirements of the

authority having jurisdiction or, in the absence of such

requirements, to the National Fuel Gas Code, ANSI Z223.1latest edition.

This installation must also conform to the additional requirements in this Slant/Fin Instruction Book.

N

ATURAL GAS-FIRED BOILER LOCATION

Provide a level, solid foundation for the boiler. Location

should be as near as possible to chimney or outside wall so

that the flue pipe from boiler is short and direct. (See Appendix A for vent terminal location restrictions.) The location

should also be such that all boiler components are protected

from water (dripping, spraying, rain, etc.) during appliance

operation and service (circulator replacement, control

replacement, etc.).

WARNING

LIQUEFIED PETROLEUM (L.P.) PROPANE GAS-FIRED

BOILER LOCATION

REQUIRES SPECIAL ATTENTION

Liquefied Petroleum (L.P.) propane gas is

heavier than air.

Therefore, propane boilers, piping, valves should NOT be

installed in locations where propane leaking from defective

equipment and piping will "pool" in a basement or other

space below the leak.

A spark or flame from the boiler or other source may ignite

the accumulated propane gas causing an explosion or fire.

Provide a level, solid foundation for the boiler. Location

should be as near the chimney as possible so that the flue

pipe from boiler to chimney is short and direct.

The UNIFORM MECHANICAL CODE may be in effect in

your geographic area.

The following precautions are cited by the 1994 UNIFORM

MECHANICAL CODE, section 304.6:

"LPG Appliances. Liquefied petroleum gas-burning

appliances shall not be installed in a pit, basement or

similar location where heavier-than-air-gas might collect.

Appliances so fueled shall not be installed in an abovegrade under-floor space or basement unless such location is provided with an approved means for removal of

unburned gas."

Consult Chapter 5 of the 1994 UNIFORM MECHANICAL

CODE for design criteria of the "approved" means for

removal of unburned gas.

MINIMUM CLEARANCES FROM COMBUSTIBLE

CONSTRUCTIONS

A. Minimum clearances to the exterior surfaces of the boiler

shall be as follows:

MINIMUM ALCOVE AND CLOSET CLEARANCE

For Combustible Recommended

Surf

ace Construction for Service

Front 6" 18"

Rear 6" 18"

Left Side 6" 18"

Right Side 12" 24"

Top 12" 12"

Flue Connector:

Enclosed — 6" 6"

Uninclosed — 2" 6"

B. Provide accessibility clearance of 24" on sides requiring

servicing and 18" on sides used for passage.

C. All minimum clearances shown above must be met. This

may result in increased values of some minimum clearances in order to maintain the minimum clearances of

others.

D. Clearance from hot water pipes shall be 1 inch**.

** At points where hot water pipes emerge from a floor, wall or ceiling,

the clearance at the opening through the finished floor boards or wall

or ceiling boards may be not less than 1/2 inch. Each such opening

shall be covered with a plate of uncombustible material.

BOILER FOUNDATION

A. Provide a solid, level foundation, capable of supporting

the weight of the boiler filled with water, and extending at

least 2" past the jacket on all sides. See dimensions of

boilers, page 2.

B. For installation on non-combustible floors only*.

C. If boiler is to be located over buried conduit containing

electric wires or telephone cables, consult local codes or

the National Board of Fire Underwriters for specific

requirements.

* Installation on combustible flooring allowed only with proper Com-

bustible Floor Kit. Kit part number is printed on boiler rating plate.

In no case may the boiler be installed on carpeting.

Figure 3. Victory “VSPH” boiler min. clearances for

combustible construction.

SAFETY

KEEP THE BOILER AREA CLEAR AND FREE FROM

COMBUSTIBLE MATERIALS, GASOLINE AND OTHER

FLAMMABLE VAPORS AND LIQUIDS.

Page 5

VI

CTORY VSPH Models

5

VENTING APPLICATION

V

SPH Series are sealed combustion type boilers, they maybe

installed and vented either as a direct vent boiler which all air

for combustion is obtained directly from outside or as a nondirect vent boiler which air for combustion is taken from inside

the boiler room.

V

SPH boilers must be vented by proper 3" diameter stainless

steel venting system (see “vent material” on this page) through

the roof or sidewall.

BOILER ROOM AIR SUPPLY AND VENTILATION

An ample supply of air is required for combustion and ventilation. When buildings are insulated, caulked and weatherstripped, now or later on, direct openings to outside may be

required and should be provided. If the boiler is not near an

outside wall, air may be ducted to it from outside wall openings.

Provisions for combustion and ventilation air must be made in

accordance with section 5.3, Air for Combustion and Ventilation, of the National Fuel Gas Code, ANSI Z223.1-latest edition, or applicable provisions of the local building codes. The

following recommendation applies to buildings of energy-saving

construction, fully caulked and weatherstripped.

INSTALLATION IN ENCLOSED BOILER ROOM REQUIRES

TWO UNOBSTRUCTED OPENINGS FOR PASSAGE OF AIR

INTO THE BOILER ROOM:

NON-DIRECT VENT INSTALLATION

A.

1. Air drawn horizontally from outdoors DIRECTLY

through an outside wall;

one louvered opening near the

floor and one louvered opening near the ceiling, each opening with a minimum FREE air passage area of

1 square

inch per 4000 Btuh of total appliances’ input.

2. Air drawn horizontally through HORIZONTAL DUCTS;

one opening near the floor and one opening near the ceiling, each opening with a minimum FREE air passage area

1 square inc

of

3.

Air drawn VERTICALLY from outdoors; one opening at

h per 2000 Btuh

of total appliances’ input.

the floor and one opening at the ceiling, each opening with

a minimum FREE air passage area of

1 square inch per

4000 Btuh of total appliances’ input.

4.

Air drawn from inside the building; one opening near

the floor and one opening near the ceiling, each opening

with a minimum FREE air passage area of 1 square inch

per 1000 Btuh of total appliances’ input.

IF BOILERS ARE INSTALLED ADJACENT TO OTHER FUEL

BURNING EQUIPMENT, THE AREA OF FREE OPENINGS

MUST BE APPROPRIATELY INCREASED TO ACCOMMODATE THE ADDITIONAL LOAD.

DIRECT VENT INSTALLATION

B.

Adequate air supply should be provided to prevent overheating

of the boiler controls and boiler room. Openings for passage of

air into the boiler room for direct-vent installation must be at

1

⁄2 of the openings required for the non-direct vent as men-

least

tioned above.

If additional non-direct vent appliances are installed in the same

s

pace and adequate air openings are provided for them, there

are no additional air openings required for the VSPH boiler.

For both direct and non-direct installation, the following must be

considered:

-

Openings must never be reduced or closed. If doors or

windows are used for air supply, they must be locked

open.

-

Protect against closure of openings by snow and debris.

Inspect frequently.

- No mechanical draft exhaust or supply fans are to be

used in or near the boiler area.

- Boiler area must never be under negative pressure. The

flow of combustion and ventilating air to the boiler must

not be obstructed.

FLUE GAS VENTING REQUIREMENTS

The Victory VSPH series boiler is a high efficiency, mechanically induced draft boiler and, therefore, requires different venting

arrangements than natural draft, lower efficiency boilers.

THE FOLLOWING INSTRUCTIONS MUST BE CAREFULLY

READ AND FOLLOWED IN ORDER TO AVOID ANY HAZARDOUS CONDITIONS DUE TO IMPROPER INSTALLATION

OF THE AIR INTAKE AND FLUE GAS VENTING SYSTEM.

The vent piping installation MUST be in accordance with these

instructions and with ANSI Z223.1-latest edition NATIONAL

FUEL GAS CODE, Part 7, Venting of Equipment. Other local

codes may also apply and must be followed. Where there is a

conflict between these requirements, the more stringent case

shall apply.

The use of a vent damper is NOT permitted on this boiler

series.

VENT MATERIAL

The vent system for direct or non-direct vent installation must

be UL listed single wall 3” diameter AL29-4C* stainless steel

material. The following manufacturers’ systems are approved

for use within a specified minimum and maximum equivalent

vent length for each model. Proper adapter must be used as a

connector between Victory VSPH boilers flue collar and venting

system as shown below:

Man

ufacturer

Heat-Fab. Inc. Saf-T Vent Not required RTV 106 or Dow

Heat-Fab. Inc. Saf-T Vent Not required Not Required

ProTech System, FasNSeal FSA-HFA3 Not Required

Inc.

Fle

x-L StaR-34 SRASFA3 GE-IS806

International, Inc.

Z-Fle

x, Inc.

Heat-F

ab Part Numbers for various items of vent system are listed in

Slant/Fin Part List, Publication No.VSPH-10PL

Type/System

EZ Seal

Z-V

ent O2SVSSLA2 GE, RTV 106

Adapter Part

No.

Sealant

Corning 732

*AL29-4C is a registered Trademark of Allegheny Ludlum Corp

Page 6

6

VI

CTORY VSPH Models

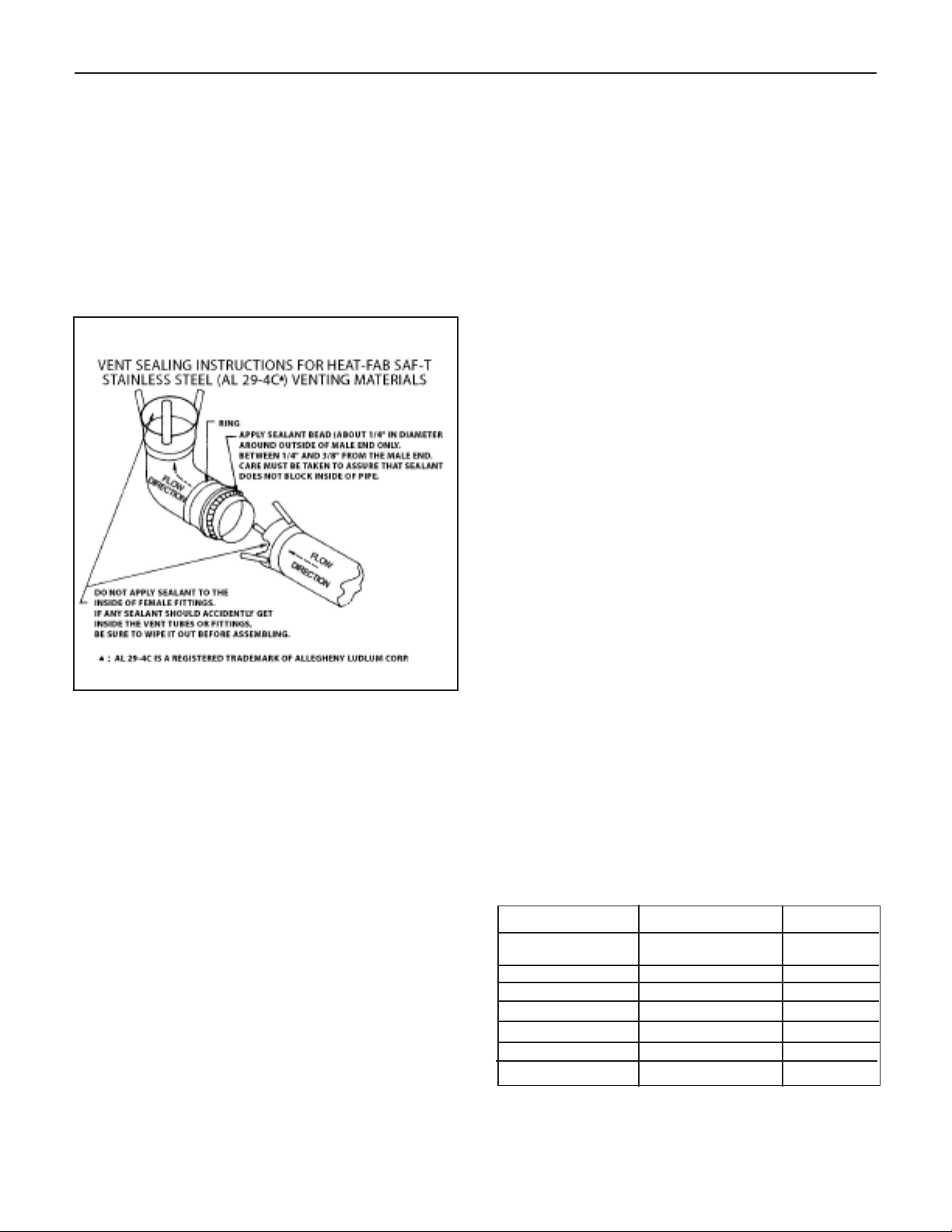

When joining the various components of the above listed

v

ent systems, the manufacturers’ instructions should be

closely followed to insure proper sealing. Use sealant specified by vent system manufacturer for sealing of pipe and fittings. See Figure 4 for proper application of vent pipe sealing

for Saf-T vent system by Heat-Fab, Inc. All vent connections

must be liquid and pressure tight. Flue vent system CANNOT

b

e cut to length. Consult manufacturer’s instructions. For HeatFab system, use slip joint connector to adjust pipe lengths

d

imensions.

DO NOT use plastic or galvanized flue pipe.

EXAMPLE: Boiler model VSPH-180 is to be installed at sea

l

evel.The combustion air is provided by air intake piping

directly to the boiler (direct-vent installation). Flue piping

includes 2 elbows and using Heat-Fab system. Air intake is

PVC and includes 3 elbows.

Maximum straight flue length would be 30-2x3=24 feet.

M

aximum straight air intake pipe would be 40-3x5=25 feet.

If the air for combustion were taken from the boiler room

(

non-direct vent installation), still the maximum straight flue

length would be 24 feet.

6. All Victory VSPH boilers are equipped with a built-in

condensation drain and trap.The trap loop must be

filled with water. DO NOT operate the boiler without

filling the trap with water to prevent flue gas discharge

into space. The drain should extend to a floor drain or

to a container which may require emptying periodically.

7. The horizontal vent pipe must be sloped upward from

the boiler at a pitch of at least

1

⁄4" per 1 foot of run, so

that the condensate from the vent system runs to the

drain trap.

8. The horizontal vent pipes must be supported with pipe

straps at intervals no greater than indicated by vent

pipe manufacturer’s instructions. The vertical portion

vent pipe also must be supported per manufacturer’s

instructions. Support air intake piping in the same

manner as the vent pipes.

Figure: 4 Vent Sealing Instructions

(Consult vent manufacturer’s instructions.)

AIR INTAKE PIPE MATERIAL

3” PVC Schedule 40 or galvanized steel materials are recommended.

All joints must be sealed using appropriate sealants.

FLUE AND AIR INTAKE RESTRICTIONS

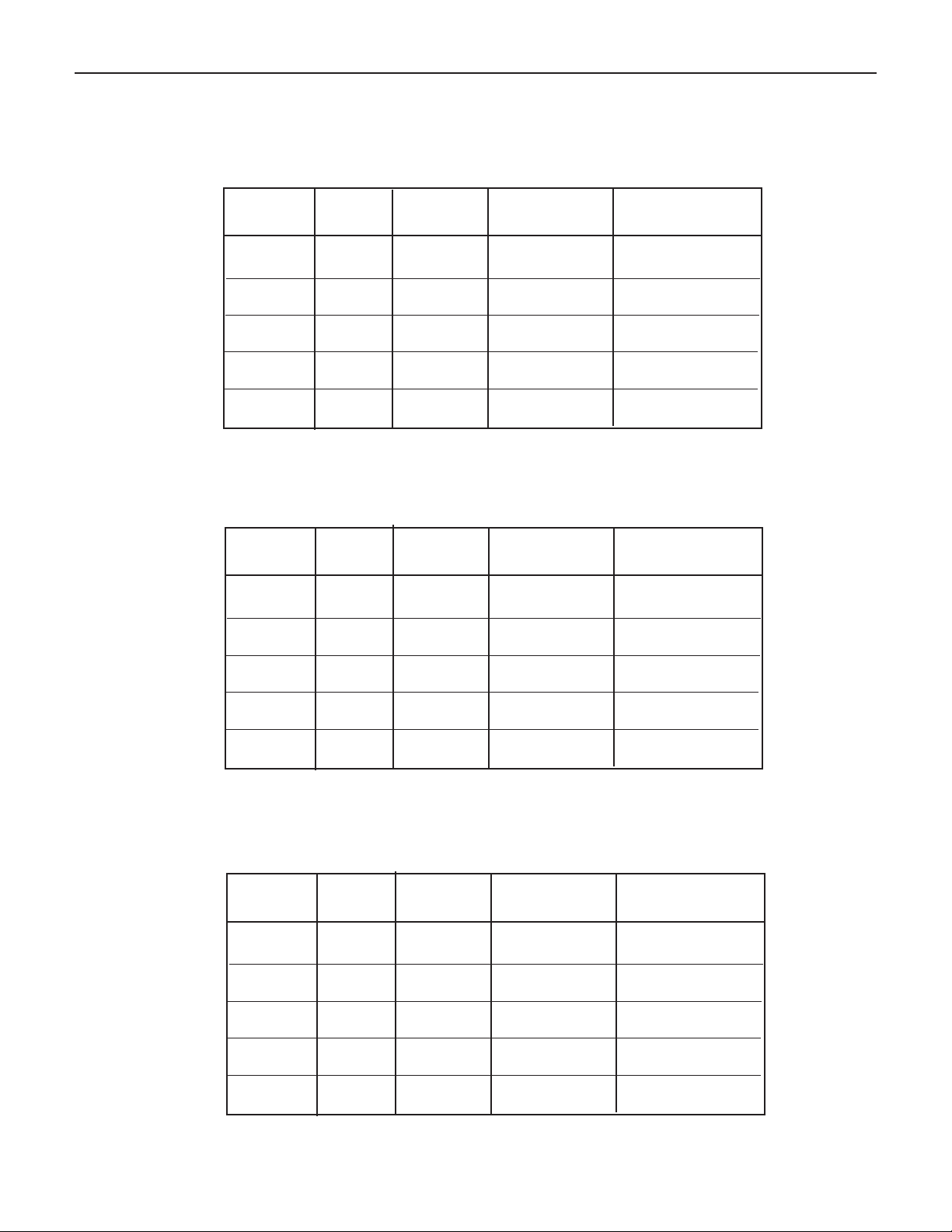

1. Maximum allowed equivalent flue and air intake length for

different flue systems at different altitudes are given in the

tables on page 7.

2. Equivalent of flue or air intake length is sum of the

straight pipe lengths and equivalent length of elbows as

shown in the table on this page.

3. The vent termination is in addition to the allowed equivalent lengths.

4. Minimum flue length is 2 feet.

5. Flue length restriction is for both direct and non-direct

vent installations.

9. Minimum clearances of vent pipes from combustible

constructions must be maintained (see Page 4). Maintain minimum 1" clearance between vent pipes and

PVC air intake pipes.

10. Common venting with other appliances or another

VSPH boiler is not allowed.

11. DO NOT install a vent damper or similar devices in

vent system or on the boiler.

12. Do not insulate venting system.

Equivalent Length of Various 90-Degree Elbows

Manufacturer

Heat-Fab, Inc. Saf-T Standard 3

Heat-Fab, Inc. Saf-T, tight radius elbow 6

ProTech System, Inc. FasNseal 6

Flex-L International, Inc. StaR-34 6

Z-Fle

x, Inc. Z-Vent 6

N/A

N/A

Type/System

elbo

w

PVC, Schedule 40 5

Galv

anized steel 6

Equivalent

Length (Feet)

Page 7

VI

CTORY VSPH Models

7

Maximum allowed flue and air intake equivalent length (Feet)

for

Heat-Fab Saf-T vent system (Including EZ Seal)

Boiler Model

Number

VSPH-60 Flue 40 40 40

VSPH-90 Flue 40 40 35

VSPH-120 Flue 40 35 30

VSPH-150 Flue 35 30 25

VSPH-180 Flue 33 28 23

Piping

Air Intake 40 40 40

Air Intake 40 40 40

Air Intake 40 40 40

Air Intake 40 40 35

Air Intake 40 35 30

0 - 5,000 Ft.

Elevation

5,000 - 7,500 Ft.

Elevation

7,500 - 10,000 Ft.

Elevation

Maximum allowed flue and air intake equivalent length (Feet)

for

Z-Flex Z-Vent and Flex-L StaR-34 vent systems

Boiler Model

Number

VSPH-60 Flue 35 35 35

VSPH-90 Flue 35 35 30

VSPH-120 Flue 35 30 25

VSPH-150 Flue 30 25 20

VSPH-180 Flue 28 23 18

Piping

Air Intake 40 40 40

Air Intake 40 40 40

Air Intake 40 40 40

Air Intake 40 40 35

Air Intake 40 35 30

0 - 5,000 Ft.

Elevation

5,000 - 7,500 Ft.

Elevation

7,500 - 10,000 Ft.

Elevation

Maximum allowed flue and air intake equivalent length (Feet)

for

ProTech FasNSeal vent systems

Boiler Model

Number

VSPH-60 Flue 30 30 30

VSPH-90 Flue 30 30 25

VSPH-120 Flue 30 25 20

VSPH-150 Flue 25 20 15

VSPH-180 Flue 23 18 15

Piping

Air Intake 40 40 40

Air Intake 40 40 40

Air Intake 40 40 40

Air Intake 40 40 35

Air Intake 40 35 30

0 - 5,000 Ft.

Elevation

5,000 - 7,500 Ft.

Elevation

7,500 - 10,000 Ft.

Elevation

Page 8

8

V

ENTING INSTALLATION

Follow the vent material manufacturer’s instructions in conjunction with these instructions for venting system installat

ion.

I. Non-Direct Vent Installation

The air for combustion is taken from the ambient air surrounding the boiler; therefore, ample supply of air is required

for combustion and ventilation (see page 5.)

D

O NOT use this installation method if the surrounding of the

boiler is contaminated. The harmful corrosive contamination

may be from the chlorine-type detergents, cleaners, bleaches, and fabric softeners used in laundry or chlorine-based

swimming pool chemicals.

VI

CTORY VSPH Models

s

age, an appropriate UL listed roof flashing must be used.

An existing chimney (see Figure 8) may be used as a chase

f

or vertical venting. Other appliances CANNOT be vented

into the same chimney or vent pipe with in the chimney.

T

he vertical vent piping must terminate with a screened tee,

combination of 45˚ elbow and a 90˚ screened elbow termination or a rain cap termination.

II. Direct Vent Installation

Air intake piping from outside to the boiler air intake collar

provides the air for combustion.The boiler surrounding may

be contaminated with chlorine-based products such as laundry detergents.

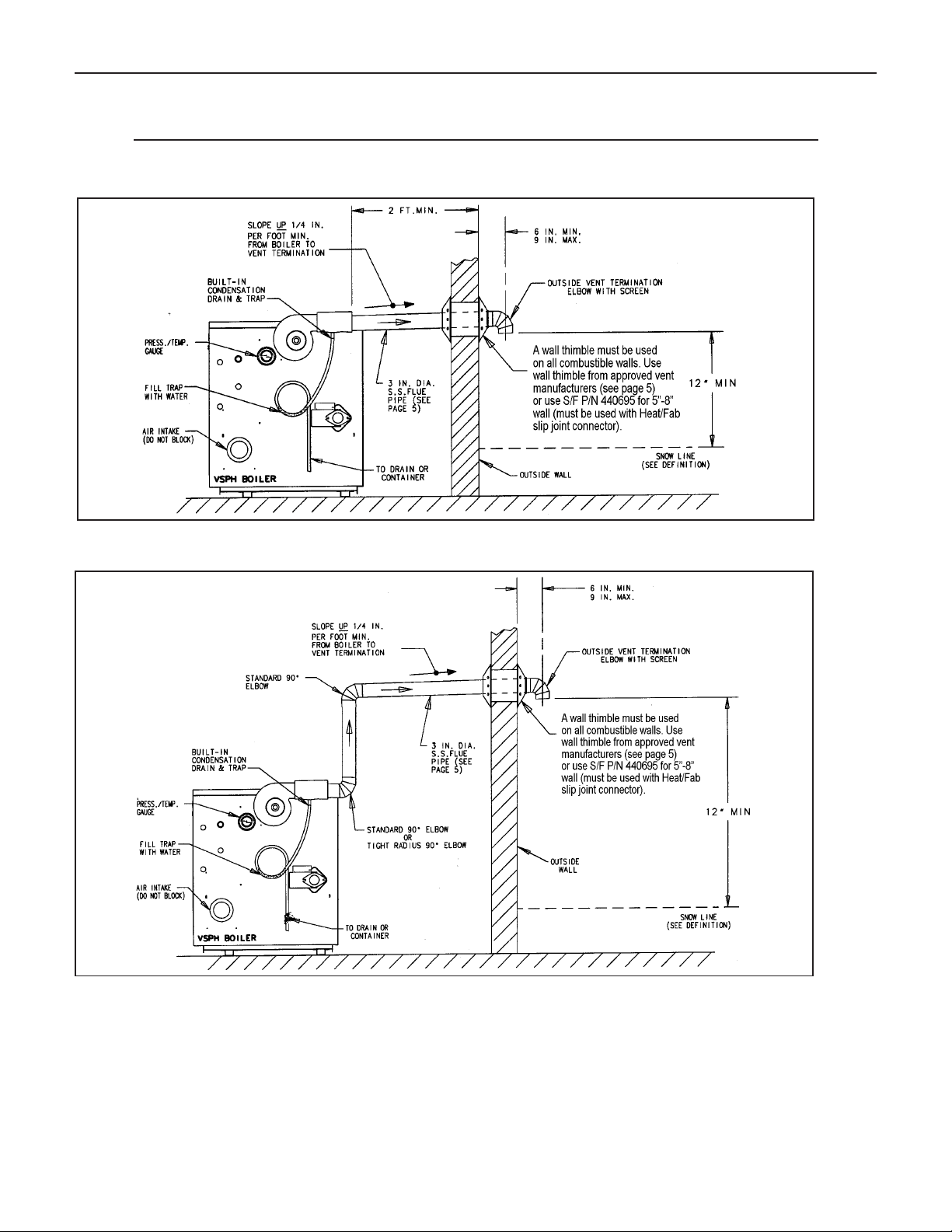

A. SIDEWALL VENTING - NON-DIRECT VENT

Figures 5 and 6 show typical horizontal sidewall venting. For

combustible wall passage of vent piping, a UL listed thimble

must be used, providing the wall thickness from 3" minimum

up to 12" maximum. The vent piping must terminate with a

screened tee or elbow termination facing down.

CAUTION: Flue gasses exiting from the vent terminal will

condense. Building materials in the area of the vent terminal

should be protected from discoloration and degradation.

VENT TERMINATION LOCATION AND CLEARANCES

1. The venting system shall terminate at least 3 feet above

any forced air inlet located within 10 feet.

2. The venting system shall terminate at least 4 feet below,

4 feet horizontally from, or 1 foot above any door, window

or gravity air inlet into any building.The bottom of the vent

terminal or air intake terminal shall be at least 12 inches

above grade or the normal snow level whichever is

greater.

3. Through the wall vents shall not terminate over public

walkways or over areas where condensate or vapor could

create a nuisance or hazard or could be detrimental to

the operation of regulators, relief valves or other equipment. Minimum clearance of 4 feet horizontal distance is

maintained, from electric meters, gas meters, regulators

and relief equipment.

A. SIDEWALL DIRECT VENTING

Figures 9 and 10 show typical sidewall direct venting.

Slant/Fin vent/air intake termination MUST be used for this

method of installation.

CAUTION: Flue gasses existing from the vent terminal will

condense. Building materials in the area of the terminal

should be protected from discoloration and degradation. See

page 8 for vent termination location and required clearances.

VENT/AIR INTAKE TERMINATION INSTALLATION

1. Termination must be installed horizontally.

2. Refer to Figure 11 for installation details.

3. Wall thickness should be 3" to 12" thick

4. Follow instruction for “vent termination location and

clearances” explained on this page

5. Cut a rectangular opening with following dimensions in

the wall.

Height: 5

Width: 123⁄4"

6. From outside of the wall, install outside termination

plate using 4 screws. Make sure the louvers are at

left side.

1

⁄4"

4. Vent termination must not be located in any confined

space (i.e. window wells, alcoves, narrow alleys) or under

any overhang or deck.Vent termination should not allow

flue gas discharge towards neighbor’s windows or where

personal injury or property damages can occur.

B. NON-DIRECT VENT - VERTICAL VENTING

Figure 7 shows typical venting through the roof.The vent

pipe must pass through the ceiling, floor and the roof vertically through a 7" minimum diameter cutout. A fire stop is

required for each ceiling and floor penetration. For roof pas-

7. For combustible wall a 4" galvanized pipe must be

used as a wall thimble.

The length of the 4" galvanized pipe should be

approximately 1" shorter than the wall thickness.

8. From inside the building, fit galvanized pipe over 4"

collar of the outside plate.

9. From inside, fit 3" diameter air intake pipe over 3"

collar located on the air box of the outside plate.

(text continued p.13)

Page 9

VI

CTORY VSPH Models

VICTORY VSPH MODELS NON - DIRECT VENT, SIDEWALL VENTING

9

All joints must be liquid and pressure tight. Use U/L listed single wall 3" dia.

AL29-4C S.S.*. venting materials (See page 5).

Figure 5. Non-direct vent, side wall venting.

Figure 6. Non-direct vent, side wall venting.

Definition of Snow Line: Knowledge of local conditions will reveal the maximum height that repeated snowfalls accumulate to.

The height should be used as the SNO

AL 29-4C IS A REGISTERED TRADEMARK OF ALLEGHENY LUDLUM CORP.

*

W LINE.

Page 10

10

VI

CTORY VSPH Models

VICTORY VSPH MODELS- NON- DIRECT VENT, VENTING THROUGH A ROOF

All joints must be liquid and pressure tight. Use U/L listed single wall 3" dia.

AL29-4C* S.S. venting materials (See page 5).

Figure 7. Victory VSPH models-non-direct vent, venting through the roof

AL 29-4C IS A REGISTERED TRADEMARK OF ALLEGHENY LUDLUM CORP

*

.

Page 11

VI

CTORY VSPH Models

VICTORY VSPH MODELS- NON - DIRECT VENT, UTILIZING AN EXISTING

CHIMNEY AS A CHASE

All joints must be liquid and pressure tight. Use U/L listed single wall 3" dia.

AL29-4C* S.S. venting materials (See page 5).

11

Figure 8. Victory VSPH models-non-direct vent, utilizing an existing chimney as a chase

AL 29-4C IS A REGISTERED TRADEMARK OF ALLEGHENY LUDLUM CORP

*

.

Page 12

12

VI

CTORY VSPH Models

VICTORY VSPH MODELS - DIRECT VENT, SIDEWALL VENTING

All joints must be liquid and pressure tight. Use U/L listed single wall 3" dia.

AL29-4C* S.S. venting materials (See page 5).

Figure 9. Direct vent, sidewall venting illustration; with straight horizontal vent.

Figure 10. Direct vent, sidewall venting illustration; horizontal vent using elbows.

** Definition of Snow Line: Knowledge of local conditions will reveal the maximum height that repeated snowfalls accumulate to.

The height should be used as the SNO

AL 29-4C IS A REGISTERED

*

TRADEMARK OF ALLEGHENY LUDLUM CORP

W

LINE.

.

Page 13

VI

CTORY VSPH Models

13

10. From inside, install inside termination plate using 4

screws. Make sure the 4" collar on the plate, penetrateed into the galvanized pipe.

1

1. Assemble and seal straight screened termination to

the slip joint connector.

1

2. From outside of the building, insert vent pipe (slip joint

connector and termination assembly) through the 3"

holes of the outside and inside termination plate.

13. From outside of the building seal outside termination

plate to building.

14. From inside, proceed with air intake and vent pipe

installation. Follow vent manufacturer’s instructions and

restrictions mentioned on page 6 of this manual. DO

NOT exceed the maximum allowed equivalent lengths

given in tables on page 7.

When joining various components of the vent system and air

intake piping, proper sealant must be used (see page 6).

Install horizontal vent pipe with seams on the top. Connect

and seal air intake piping to air intake collar of the boiler.

Adjust the air pipe support to hold air intake pipe securely

(see Figure 2).

B. DIRECT VENT - VENTING AND AIR INTAKE

THROUGH A ROOF

Figure 12 shows typical vertical venting. The vent pipe must

p

ass through the ceiling, floor and the roof vertically through a

7" minimum diameter cutout. A fire stop is required for each

ceiling and floor penetration. For roof passage an appropriate

U

L listed roof flashing must be used.

The vertical vent piping must terminate with a screened

s

traight termination.

The air intake terminal should be a screened 180˚ elbow facing down. The air intake opening must be at least 1 foot below

the vent opening.

Follow vent manufacturer’s instructions and restrictions mentioned on page 6 of this manual.

DO NOT exceed the maximum allowed equivalent length given

in tables on page 7. When joining various components of the

vent system and air intake piping, proper sealant must be

used (see page 6).

Install horizontal vent pipe with seams on the top. Connect

and seal air intake piping to air intake collar of the boiler.

Adjust the air pipe support to hold air intake pipe securely

(See Figure 2).

Figure 11.

V

ent/Air Intake

T

ermination

Page 14

14

VICTORY VSPH MODELS

DIRECT VENT,VENTING AND AIR INTAKE THROUGH A ROOF

All joints in vent system must be liquid and pressure tight. Use U/L listed

single wall 3” dia. AL29-4C S.S. venting materials (See page 5).

VI

CTORY VSPH Models

Figure 12. Direct vent, venting and air intake through a roof.

Page 15

VI

CTORY VSPH Models

15

VENTING AND AIR INTAKE SYSTEM REGULAR

INSPECTION

A

. Inspect the system regularly for condensation, corrosion

a

nd/or physical damage. A qualified professional should service the boiler annually and include such an inspection at that

time. The homeowner should look over the system monthly for

d

amage, water stains, any signs of rust, other corrosions or

separation of the vent and air intake piping (if direct-vent).

B. Should an inspection turn up signs of condensation, corrosion

or damage, the boiler should be shut down immediately and

t

he condition should be corrected by a qualified professional.

C. All Victory VSPH boilers are equipped with a built-in conden-

sation drain and trap.The trap loop must be filled with water.

DO NOT operate the boiler without filling the trap with water to

prevent flue gas discharge into space. Periodic inspection

should be made of this assembly for deterioration of the tubing and to insure that the trap is not plugged. If it is plugged or

appears to have excessive sediment in it, it should be

removed from the drain assembly, straightened out to clear

the obstruction, reformed, filled with water and reinstalled as

before.

GAS PIPING

A. Local installation codes apply.The pipe joint compound

used on threads must be resistant to the action of liquefied

petroleum gases.

B. The gas supply line to the boiler should run directly from the

meter for natural gas or from the fuel tank for L.P. propane

gas. See page 2 for location of union and manual main

shut-off valve that may be specified locally.

Selecting pipe size for natural gas:

1. Measure or estimate the length of piping from the meter

to the installation site.

2. Consult gas supplier for heating value of gas (Btu/cu. ft.).

3. Divide boiler rated input by heating value to find gas flow

in piping (cu. ft. per hour).

4. Use table below to select proper pipe size.

EXAMPLE: Boiler model VSPH-150 is to be installed. Distance

from gas meter to the boilers is 30ft. Heating value of natural

gas is 1020 Btu/cu. Ft. Select proper pipe size.

Gas flow = 150,000 Btu/hour

1020 Btu/cu. ft.

= 147 cu. ft. per hour

At 30 ft. length of pipe, match required capacity from table on

this page (choose higher capacity, in this case is 152 cu. ft. per

hour). Required pipe size is

3

⁄4".

Improper gas pipe sizing will result in pilot flame outages, insufficient heat and other installation difficulties. For more information and also if other appliances are to be attached to the piping system, see Appendix C of National Fuel Gas Code ANSI

Z223.1-latest edition.

C. The boiler and its gas connection must be leak tested

before placing the boiler in operation. Use liquid soap solution for all gas leak testing. DO NOT use open flame.This

boiler and its individual shutoff valve must be disconnected

f

rom the gas supply piping system during any pressure test-

ing of that system at test pressures in excess of

1

⁄2 PSIG.

This boiler must be isolated from the gas supply piping syst

em by closing its individual manual shutoff valve during any

pressure testing of the gas supply piping system at test

pressures equal to or less than

1

⁄2 PSIG.

D. All gas piping used should be inspected thoroughly for

cleanliness before makeup. A sediment trap must be provide

d, as illustrated on page 2.

E. The minimum and maximum gas supply pressure (at the

inlet of gas valve) are shown on the boiler rating plate for

the type of gas used. Gas supply pressure should never be

less than minimum or more than maximum pressure when

the boiler or any other appliance is turned on or off.

Length

of pipe

in Feet

Gas Flow In piping -- cu. ft. per hr.

Iron Pipe Size (IPS) — inches

1/2

3

/4 11

1

/4

11/2

10 132 278 520 1050 1600

20 92 190 350 730 1100

30 73 152 285 590 890

40 63 130 245 500 760

50 56 115 215 440 670

60 50 105 195 400 610

70 46 96 180 370 560

80 43 90 170 350 530

90 40 84 160 320 490

100 38 79 150 305 460

At pressure drop of 0.3 in.

w

ater, specific gravity = 0.6.

ELECTRICAL WIRING

DANGER:

Before wiring always turn off electric power supply

otherwise, shock or death can result.

1. Power Supply

A separately fused circuit is recommended. Use standard

15 Amp. fuse or breaker and 14 gage conductors in BX

cable or conduit.

Provide disconnect means and overload protection as

required. See boiler wiring diagram (Figure 13a) boiler control (Figure13b) and ladder diagram (Figure 13c).

Boiler must be electrically grounded in accordance with the

requirements of the authority having jurisdiction, or, in the

absence of such requirements, with the National Electrical

Code, ANSI/NFPA 70-latest edition.

Page 16

16

PILOT

BURNERBURNER

MODEL UT-1107MODEL UT-1107

P5P5

P4P4

P1P1

P6P6

P2P2

P3P3

INTEGRATED BOILER CONTROLINTEGRATED BOILER CONTR OL

P6P6

THERMOSTATTHERMOSTAT

K4K4

MVMV

MV/PVMV/PV

PVPV

NEUTRALNEUTRAL

H

OTHOT

MM

120 V/60Hz120 V/60Hz

120VAC120VAC

24VAC24VAC

K5K5

K1K1

MM

CIRCULATO RCIRCULATOR

BLOWER BLOWER

HIGHHIGH

LIMITLIMIT

PRESSUREPRESSURE

SWITCHSWITCH

ROLL-OUT

SWITCH SWITCH

L1L1

11

L2L2

GNDGND

P6P6

44

P5P5

P4P4

11

55

P4P4

11

P5P5

P4P4

22

33

DISCONNECTDISCONNECT

SWITCHSWITCH

P1P1

33

P1P1

11

P2P2

22

P2P2

11

P6P6

33

P6P6

22

P3P3

99

CHASSIS

GNDGND

P3P3

77

P3P3

44

P3P3

66

P3P3

33

P3P3

11

P3P3

55

P3P3

22

NOTE:NOTE:

PXPX

INDICATES CONNECTOR'S TERMINAL ON BOILER CONTROLINDICATES CONNECTOR'S TERMINAL ON BOILER CONTR OL

K3K3

P3P3

88

PRESSURE

SWITCH

R

OLL-OUT

SWITCH

CAUTION:

IF ANY OF THE ORIGINAL WIRE AS SUPPLIED WITH THE

APPLIIANCE MUST BE REPLACED, IT MUST BE REPLACED

WITH TYPE 105

∞C OR ITS EQUIVALENT.

WIRE LEGEND:

FACTORY WIRED

FIELD WIRED, FIELD SUPPLIED

BLOWER

(INDUCER)

LABEL ALL WIRES PRIOR TO DISCONNECTION WHEN SERVICING CONTROLS.

PROPER OPERATION AFTER SERVICING".

1

C

IRCULATO R

MV

GND

VR8204A

1

J

UNCTION

BOX

DISCONNECT

SWITCH

120V/60Hz

AQUASTAT

RED

WHITE

BLACK

L

1-HOT

L2-NEUTRAL

1

2

M

BLACK

1

2

3

6

5

4

P

5

P4

BLACK

G/Y

1

2

3

4

1

2

3

P2

BLACK

WHITE

GREEN

PROVIDE DISCONNECT MEANS & OVERLOAD PROTECTION AS

R

EQUIRED.

120V/24V

TRANSFORMER

1

2

BLACK

WHITE

BROWN

PINK

1

2

3

4

5

6

7

8

9

PV

M

V/PV

L4080B

GAS VALVE

24V

T

HERMOSTAT

RED

BLUE

WHITE

RED

BLACK

YELLOW

YELLOW

P6

P3

P1

GREEN

WHITE

WIRING ERRORS CAN CAUSE IMPROPER AND DANGEROUS OPERATION.

"VERIFY

RED

VI

CTORY VSPH Models

Figure 13b. Boiler control

Figure 13a. Schematic wiring diagram.

Figure 13c. Ladder wiring diagram

Page 17

VI

CTORY VSPH Models

17

MULTIZONING OF VSPH BOILER

ZONE VALVE SYSTEM USING V8043E/F ZONE VALVES

Figure 14.

MULTIZONING OF VSPH BOILER

PUMP ZONING SYSTEM USING R845A RELAY

Figure 15.

MULTIZONING OF VSPH BOILER

PUMP ZONING SYSTEM USING R882A/B RELAYS

Figure 16.

Page 18

18

GATE VALVEGATE VALVE

FACTORYFACTORY

CIRCULATORCIRCULATOR

LOC ATIONLOCATION

3/4" PRESSURE3/4" PRESSURE

RELIEF VALVERELIEF VALVE

AIR VENTAIR VENT

RETURNRETURN

SU PPLYSUPPLY

EXPA N SIONEXPAN SION

TANKTANK

ALTERNATE

CIRCULATORCIRCULATOR

LOLOCATCATIONION

FLO W CON TRO LFLOW CO NTROL

VALVEVALVE

W ATER FE EDW ATER FE ED

PRESSU REPRESSU RE

REDU CINGREDU C ING

(FILL)VALVE(FILL)VALVE

DRAIN COC KDRAIN COCK

VI

CTORY VSPH Models

2. Power Connection

A. Remove electrical junction box cover.

B. Hot connection lead is black. Neutral connection lead is white.

Proper polarity is important for VSPH boilers. Reversed

polarity will cause system lockout and the power LED will

flash continuously.

C. Connect ground wire to ground screw inside the junction box.

D.Replace junction box cover.

THERMOSTAT CONNECTIONS

Install thermostat on an inside wall and away from any heat

sources, sunshine and drafts.Thermostat wires must be connected to terminals block on boiler. See wiring diagram Figure 13a.

Thermostat heat anticipator: For a non-zoned system set thermostat heat anticipator to 0.4 Amps, for zoned system set to match

power requirements of zone valves or relays. Refer to manufacturer’s instructions and specifications. Also see instructions with thermostat.

MULTI ZONING

For multiple zoning, either zone valves or circulators maybe used.

.

22.

C

irculating Systems

Victory VSPH boilers are equipped with a water circulating

pump mounted to the return water connection on the boiler.This

p

ump location is appropriate for most installations. It may be

desired and proper to locate this pump to the alternate location

shown in Figure 17, especially when applied to larger systems

using high-head pumps.

1

When the pump is removed there is a 1

r

eturn pipe may be attached to.

⁄2” FPT tapping that the

At one month intervals after the last call for heat, the circulator

will be energized for 30 seconds. Short operation after long term

i

dle periods prevent damage of the pump from sedimentation.

For zone valve system see Figure 14.

For pump zoning system see Figure 15 and Figure 16.

DO NOT use boiler transformer to power external accessories like

zone valve and relays, overload and/or burned-out transformer

and boiler malfunction can result. Use separate transformer to

power such components. For pump zoning system, remove boiler

circulator wire connector from P5 of electronic boiler control (See

Figure 13b).

WATER PIPING

Always follow good piping practices. Observe minimum 1" clearance to combustibles around all uninsulated hot water pipes or

when openings around pipes are not protected by non-combustible materials.

On a hot water boiler installed above radiation level, the boiler

must be provided with a low water cutoff device at the the time of

installation by the installer (see Figure 17 for piping arrangement).

The low water cutoff must be wired in series with rollout safety

switch and Aquastat (limit control). See wiring diagram Figure

13a.

.

11.

Supply and Return

For tapping sizes see dimensions on page 2. Shut-off valves

are recommended.

Figure 17. Piping arrangement

.

33.

Radiant Floor, Low Water Temperature and large water

volume systems

A boiler by-pass loop, three way valve arrangement, or

primary secondary pumping (with a boiler loop) must be

used to provide a minumum 130˚ return water temperature

to the boiler.This will prevent condensation on the cast-iron

sections that can result in improper operation of the boiler.

.

44.

Air control system

Diaphragm type compression tank is used to control system

pressure. It must be installed at the boiler or between boiler

and supply main pump(s).

An automatic air vent is used to remove air from the system

in Figure 17. If system pressure needs further control, add

an additional tank in parallel with original tank or install a

larger capacity tank. Use appropriate size tank for volume of

water in system. See chart for boiler’s volume.

Boiler Water Content

Model Pounds Gallons

VSPH-60 24.75 3.0

VSPH-90 32.00 3.8

VSPH-120 39.25 4.7

VSPH-150 46.50 5.6

VSPH-180 53.75 6.4

Page 19

VI

CTORY VSPH Models

5. Cold Water Fill

P

ressure reducing (fill) valve and shut-off valve should be

installed.

6

. Relief Valve Discharge Piping

Use same size or larger piping than valve outlet. Must terminate 6" minimum from floor with a plain (no threads)

end. Place a bucket under pressure relief valve discharge.

Make sure discharge is always visible. DO NOT hard-pipe

t

o drain piping.

19

7. Providing Protection from Freezing

A

nti-freeze is sometimes used in hydronic heating systems

to protect against freeze-up in the event of power failure or

control shutdown when the building is unoccupied. It

should be recognized that unless the building is kept

above freezing temperature by some means, the plumbing

system is not protected. Two types of anti-freeze may be

used: ETHYLENE GLYCOL, used in automobiles, has

desirable properties, but is toxic. Its use maybe prohibited

when system water/glycol solution is in contact with a

potable water vessel (as an indirect hot water heater with

built-in heating coils). PROPYLENE GLYCOL is used in

the quick-freeze food industry; it is practically non-toxic. Its

use may be permitted when system solution is in contact

with a potable water vessel. When anti-freeze must be

used, inhibited propylene glycol is recommended. Useful

information on the characteristics, mixing proportions, etc.

of glycol in heating systems is given in Technical Topics

No. 2A, available from the Hydronics Institute, 34 Russo

Place, Berkeley Heights, NJ 07922. Consult glycol manufacturers for sources of propylene glycol.

8. Water Treatment

A good water treatment program will not only extend the

useful life of this boiler but it will also save much of the

time and expense of repairs made necessary by preventable occurrences. A reputable water treatment company should be consulted to evaluate and determine the best

overall treatment program for your boiler equipment.

Figure 18. Cooling system to a water boiler and chiller.

OPERATING INSTRUCTIONS

I. Filling and Venting Water Systems

A. Fill the system with water. Vent or purge of air.

B. Fire the boiler as soon as possible (see following warn-

ing and instructions) and bring water temperature in

the system.

C. Vent air and add water as needed to achieve operating

pressure on boiler gauge. Pressure must be between

approximately 12 psi (cold water) and 25 psi at water

temperature setting of high limit control, for boilers

equipped with 30 psi relief valves. Boilers rated for a

higher pressure and equipped with a matching relief

valve may operate at a higher pressure, but no higher

than 5 psi below the relief valve opening pressure.

D. Check for and repair any leaks before placing system

in service.

BEFORE FIRING BOILER, make these checks:

1. System is full of water. Air is vented or purged.

PIPING A HEATING - COOLING SYSTEM TO A WATER

BOILER AND CHILLER

Figure 18 illustrates a method of piping a heating-cooling system to a water boiler and a chiller. Hand valves (shown) or

automatic valves must be installed to prevent circulation of

chilled water in the boiler or hot water in the chiller.

The air control system and pressure control system must

operate with chiller only, or the boiler only, being valved to the

piping system. Separate control devices on the boiler and

chiller may be used, or a single set of air and pressure controls on the common piping may be preferred.

If the boiler is used to supply hot water to heating coils in air

handling units, flow control valves or other devices must be

installed to prevent g

ing the cooling cycle.

ravity circulation of water in the coils dur-

2. Relief valve is installed in accordance with ASME Boiler and Pressure Vessel Code, Section IV. Valve opening is not closed or reduced in size.

3. Venting is installed according to instructions under

“FLUE GAS VENTING REQUIREMENTS”.

4. All wiring is completed, following applicable wiring diagrams.

5. Using soap solution, check for gas leaks in all gas piping from meter to boiler pilot and manifold. DO NOT

use open flame.

Page 20

20

0FF0FF

ONON

HON EYWELLHON EYWELL

GAS GAS

INLETINLET

GAS CON TRO L KNO BGAS CON TRO L KNO B

SH O W N IN "OFF"SHOW N IN "OFF"

POSITIONPOSITION

OUTLETOUTLET

I

I. Initial Start

Safe lighting and other performance criteria were met when

testing various gas manifold and control assemblies used

on the Victory VSP Series Boilers under the ANSI Z21.13latest edition.

Instructions

Follow the lighting instructions in this manual.These

instructions are also attached to the boiler.

S

AFETY INFORMATION

For Your Safety Read Before Operating

WARNING: If you do not follow these instructions

exactly, a fire or explosion may result causing property

damage, personal injury or loss of life.

A. This appliance is equipped with an ignition device which

automatically lights the pilot. D

hand.

B. BEFORE OPERATING smell all around the appliance area

for gas. Be sure to smell next to the floor because some gas

is heavier than air and will settle on the floor.

O NOT try to light the pilot by

VI

CTORY VSPH Models

1

1. Set thermostat to desired setting.

12. If the appliance will not operate, follow the instructions

“To Turn Off Gas to Appliance” and call your service

technician or gas supplier.

To Turn Off Gas to Appliance

1. Set thermostat to lowest setting.

2. Turn off all electric power to the appliance if service

is to be performed.

3

. Remove jacket front panel.

4

. Turn gas control knob clockwise till knob stops,

then continue to “OFF”. Do not force.

5. Replace jacket front panel.

Gas Valve VR8204 or VR8304

WHAT TO DO IF YOU SMELL GAS:

• DO NOT try to light any appliance.

• DO NOT touch any electric switch: DO NOT use any

phone in your building.

• Immediately call you gas supplier from a neighbor’s

phone. Follow the gas supplier’s instructions.

• If you cannot reach your gas supplier, call the fire department.

C. Use only your hand to turn the gas control knob. Never

use tools. If the knob will not turn by hand, don’t try to

repair it, call a qualified service technician. Force or

attempted repair may result in a fire or explosion.

D. Do Not use this appliance if any part has been under

water. Immediately call a qualified service technician to

inspect the appliance and to replace any part of the

control system and any gas control which has been under

water.

OPERATING INSTRUCTIONS

1.

STOP! Read the safety information above.

2. Set the thermostat to lowest setting.

3. Turn off all electric power to the appliance.

4. This appliance is equipped with an ignition device which

automatically lights the pilot. D

hand.

5. Remove jacket front panel

6. Turn gas control knob clockwise to “OFF”.

NOT force.

DO

7. Wait five (5) minutes (longer for propane) to clear out any

gas, then smell for gas, including near the floor. If you then

smell gas, STOP! Follow “B” in the safety information

above on this page. If you don’t smell gas, go to next

step.

8. Turn as control knob counterclockwise to “ON”.

9. Replace jacket front panel.

10. Turn on all electric power to the appliance.

O NOT try to light the pilot by

Figure 19.

Removing Jacket Front Panel

1. Turn black screws 1⁄4 turn to open position.

2. Remove front panel.

To replace the panel, reverse procedure.

Gas Input Rate Adjustment

1. Consult gas supplier for higher heating value* of gas

(Btu/cu. ft.)

2. Set thermostat high enough so that boiler will remain on

3.

Measure manifold pressure.

Correct manifold pressure for gas used is printed on boiler

rating plate. NOTE: Gas pressure may be adjusted by

turning pressure regulator screw on combination gas valve

(turn clockwise to increase pressure, counterclockwise to

decrease pressure).

* ”Higher Heating” value of gas is commonly known as “heating value”.

Page 21

VI

CTORY VSPH Models

21

VSPH BOILER SEQUENCE OF OPERATION

THERMOSTAT CALLS FOR HEAT

CIRCULATOR ON

4 TIMES RE-TRIALS

FOR IGNITION

CONTROL RE-INSTATE

TRIAL FOR IGNITION

WITH 30 SECONDS

INTER-PURGE

PILOT LIGHTS AND

FLAME SENSED?

NO

YES

NO

NO

SPARK OFF. MAIN VALVE OPENS. BOILER HEATING PERIOD

CONTROL CONTINUOUSLY MONITORS THERMOSTAT, HIGH

LIMIT, PRESSURE SWITCH AND FLAME SENSOR.

BOILER WATER TEMPERATURE IS

B

ELOW HIGH LIMIT SETTING?

YES

PRESSURE SWITCH CONTACTS PROVED

OPEN WITHIN 45 SECONDS?

YES

INDUCER (BLOWER) ON

PRESSURE SWITCH CONTACTS CLOSED

WITHIN 5 MINUTES?

YES

30 SECONDS PRE-PURGE PERIOD

TRIAL FOR IGNITION-15 SECONDS

PILOT VALVE OPENS. IGNITION SPARK STARTS.

PILOT LIGHTS AND FLAME IS SENSED

DURING TRIAL FOR IGNITION?

YES

STARTS

NO

CONTROL LOCKOUT.

POWER AND

PRESSURE

SWITCH LED’S

FLASHING.

1 HOUR WAIT

PERIOD.

NO

CONTROL LOCKOUT

FLAME LED FLASHING.

1/2 HOUR WAIT PERIOD

THERMOSTAT CALLS FOR HEAT ENDS.

CIRCULATOR OFF, PILOT AND MAIN VALVE CLOSE.

15 SECONDS POST PURGE

BOILER WAITS FOR NEXT CALL FOR HEAT.

Page 22

22

VI

CTORY VSPH Models

a. Input for PROPANE is approximately at rating shown on

ating plate when manifold pressure is 9-

b. Input for NATURAL GAS is approximately at rating

when manifold pressure is 3-1/2" water column, but

should be checked on the gas meter:

B

tuh Input = Btu/cu. ft. metered in 3 minutes x 20

EXAMPLE #1:

F

or 1000 Btu/cu. ft. gas, this becomes:

Btuh Input = cu. ft. metered in 3 minutes x 1000 Btu/cu. ft. x 20

EXAMPLE #2:

For 1050 Btu/cu. ft. gas, this becomes:

Btuh Input = cu. ft. metered in 3 minutes x 1050 Btu/cu. ft. x 20

4. The higher heating value of gas varies substantially for

different localities. Consult with Slant/Fin’s Technical Service Department for reorificing procedures if any of the

following apply:

a. Boiler (burner) is over firing.

Gas Code (ANSI Z223. -latest edition) does NOT permit firing at a higher input rate than the input rate indicated on the boiler rating plate in order to avoid hazardous conditions such as explosion or carbon monoxide poisoning.

b. Poor higher heating value of gas is causing the actual

input to be substantially lower than the rating plate

indication.

CAUTION! National Fuel

1

⁄2" water column

Gas Rate Table

Boiler rated input in

cu. ft./hr. of 1000 Btu/cu. ft.

Natural Gas

6

0

9

0

120

1

50

180

The gas metered in 3 minutes to obtain rated input for

each boiler model, using 1000 Btu/cu. ft. gas, is tabulated in gas rate table.

INTEGRATED BOILER CONTROL

The integrated boiler control monitors the status of the room

thermostat, high limit control (Aquastat), pressure switch and

the flame sensor. It controls the operation of circulator, inducer motor, gas valve and spark for pilot ignition. The boiler control also determines the sequence of operation and timing for

pre and post purge periods, trail for ignition and lockout.

The control indicator lights (LED’s) provide information of boiler operation when lights are steady on or diagnostic information when they are flashing in order to help to determine the

cause of boiler failure.

Cubic Feet Gas Consumption

1

000 Btu/cu. ft. gas, in

3

minutes, at rated input

3

.00

4.50

6

.00

7

.50

9.00

A. NORMAL OPERATION - STATUS OF INDICATOR LIGHTS (LED’S)

O = LED off = LED steady on

DESCRIPTION OF OPERATION

Standby-Boiler waits for call for

heat

Thermostat calls for heat

Circulator on

Boiler water temperature below

high limit setting

Inducer on

Pressure switch contacts closed

30 seconds pre-purge period

Trial for ignition

Gas valve open

Pilot flame and main burners on

Boiler heating period

Thermostat call for heat ends

Circulator off

15 seconds post purge period.

Burners off.

POWER

LED

TSTAT/CIRC

LED

O

O

LIMIT

LED

O

O

PRESS

SWITCH

LED

O

O

O

FLAME

LED

O

O

O

O

O

Page 23

VI

CTORY VSPH Models

B. DIAGNOSTIC FLASH CODES

Flashing LED’s provide diagnostic information

WARNING: Only a trained, experienced service technician should perform troubleshooting. Turn off all electric power to

t

he boiler before service

23

L

ED’s FLASHING

POWER LED * 120 V power supply. Polarity is reversed Reverse Hot and NEUTRAL wires in the junction

POWER + TSTAT/CIRC LED’S * 48 VAC on thermostat circuit. Check and correct the thermostat or zone valves

POWER + PRES SWITCH LED’S * Pressure switch contacts are closed prior to Check air pressure switch.

POWER + FLAME LED’S * Flame sensed without call for heat. Remove air box front panel.

FLAME LED * Pilot flame was not established during trial for Check gas valve knob to be in “ON” position.

PRES SWITCH LED Pressure switch opened during boiler run Check pressure switch and its hoses.

* Control Lockout

energizing the blower motor or does not close Check hose connections to pressure switch.

within 5 minutes of the blower being turned on. Check for obstruction/restriction in venting, air

ignition. Check inlet gas pressure.

period. Wind gusts over 40 mph. Check for obstruction in venting, air intake

To reset the lockout condition: Turn down thermostat or turn

INDICATION

SAFETY CHECK

R

EMEDY

box.

wirings.

intake piping and termination.

Turn off power for at least 45 seconds.

Check if pilot flame exists during pre-purge

period (first 30 seconds). If pilot flame exists,

replace gas valve

Check pilot gas line.

Check ignition cable and the connections.

Check pilot flame to be 3/8” to 1/2" long

piping and ter

mination.

power off at disconnect switch for at least 45 seconds, then

restore power or set thermostat at desired setting.

1. Checking for gas leaks:

Using soap solution, check for gas leaks from meter to

gas v

Automatic reset: After one hour (1/2 hour for flame failure),

control will automatically retry.

alve including all pipes and fittings, gas valve connections, manifold and pilot burner gas line and its fittings.

Use liquid soap solution for all gas testing. DO NOT use

open flame.

Flame LED (Red)

Pressure Switch LED (Red)

Hi Limit LED (Red)

Thermostat/Circ. LED (Red)

Power LED (Green)

Figure 20. Integrated boiler control.

2. High limit control (Aquastat) test:

Set room ther

mostat high enough for boiler water temperature to reach high limit setting. When this temperature is

reached, the high limit switch should open. Pilot and main

gas valve should close. Inducer starts 15 seconds postpurge period. POWER and TSTAT/CIRC LED’s will stay

on.

3. Thermostat test:

Set ther

mostat setting to low enough to end call for heat.

Pilot and main gas valve should close circulator off and

inducer will star

t 15 seconds post-purge. POWER LIMIT

and PRESS SWITCH LED’s will stay on during postpurge

. After the post-purge period, POWER and LIMIT

LED’s stay on.

4. Control safety shutdown test:

With main burners firing (all LED’s on) disconnect ignition/sensor cable from boiler control. Gas valve should

shut off burners, FLAME LED starts flashing.

5.

Pressure switch test:

With burners firing, remove plastic hoses from pressure

s

witch or from aluminum tubing (see Figure 21), gas valve

must shut off, PRESS SWITCH LED starts flashing.

Page 24

24

VI

CTORY VSPH Models

Figure 21. Location and identification of pressure

switch and hoses.

CARE AND MAINTENANCE

This section must be brought to the attention of the owner by

the installer so that the owner can make the necessary

arrangements with a qualified service agency for the periodic

care and maintenance of the boiler.The installer must also

inform the owner that the lack of proper care and maintenance

of this boiler and any fuel burning equipment may result in a

hazardous condition. Installer should discuss contents of the

User’s Information Manual (Publication VSPH-UIM) with the

owner.

A trained and qualified service technician should perform the

inspection listed in these instructions before each heating season and at regular intervals.

I. General Maintenance

A. Safety check, see page 23.

B. Vent and air intake system inspection

1. Check for obstruction, condensation, corrosion and

physical damage.

2. Check outside termination. Screen and louvers should

be free of any debris and must be cleaned as required.

3. Perform “Venting and Air intake System Regular

Inspection”, see page 15.

C. Piping

Check the f

1. Water piping and accessories for leaks. Slightest leaks

should be corrected.

2. System to be full of water and pressure to remain stable at correct setting on gauge.

3. Air-control system. Noise and air binding in radiation

should not occur.

4. Low water cutoff for operation (see instructions furnished with unit).

D. Boiler Room Air Supply

Check air vents for continuous positive supply of air as

required. Air needs are greatest in cold weather if boiler

installation is non-direct vent method. Air vents must open

and free of obstruction.

ollowing:

Warning: The flow of combustion and ventilating air to the

I

I. Inspection During Heating Season

A. Check water pressure regularly and add water slowly to

system when needed. If much water is added, venting

may be necessary. Regular loss of water from boiler system may indicate either a system leak, or a faulty air control system, or a faulty automatic fill valve.

B. Check venting system. See “Venting and Air Intake Sys-

tem Regular Inspection” on page 15.

C. Check condensation drain trap to be full of water. Check

for deterioration of the tubing. Check that the trap is not

plugged.

D. With main burner firing all LED’s mst be steady “on”. See

“Normal operation-status of indicator lights” on page 22.

E. To prolong the life of the inducer motor, lubricate with

Anderol 465 or SAE 20 motor oil annually Turn off power

and place 4-6 drops of above mentioned lubricant in each

of two oil holes. Lubricate circulator per manufacturer’s

instruction. DO NOT over oil any motor.

The ceramic combustion chamber in the burner box contains

crystalline silica.

Wear proper dust mask and gloves when servicing combustion chamber or burners.

Crystalline Silica has been identified as a carcinogenic or

possibly carcinogenic to humans.

CLEANING

A. Flue passage cleaning See Figure 22

1. Turn off power to the boiler

2. Remove front jacket panel

3. Remove air box front panel

4. Remove jacket top

5. Remove inducer assembly

6. Remove flue collector

7. Remove combustion air screen

8. Use wire brush to clean flue passages. It is sug-

9. Replace flue collector and re-seal with high tem-

10. Remove and dispose of paper and accumulated

11. Replace all remo

12. Check boiler operation.

B. Cleaning of burners

1. Turn off power to the boiler.

2. Remove jacket front, air box front panel, air intake

3. Disconnect ignitor/sensor cable from the boiler con-

4. Remove pilot gas line from brass fitting located inside

5. Lift burners and remove from orifices.

6. Clean burners. To clean burners, run a clean flue

7. Replace all removed items.

8.

boiler should not be obstructed.

WARNING:

gested that paper be placed on burners to collect

any foreign material in cleaning flue passage.

perature sealer or with furnace cement.

material.

ved items.

screen and combustion air screen located inside the

air box.

trol.

the air box.

brush up the tube until all foreign matter is removed.

Check boiler operation.

Page 25

VI

TOP JACKETTOP JACKET

F

LUE COLLECTORFLUE COLLECTOR

I

NDUCERINDUCER

BRUSHBRUSH

CTORY VSPH Models

25

Figure 22. Flue passage cleaning illustration

General Troubleshooting Guide For Service Personnel

WARNING: Only a trained, experienced service technician should perform troubleshooting.

Turn off all electric power to the boiler before servicing.

A. BURNERS FAIL TO OPERATE- NO HEAT

CA

USE

1. No power, POWER LED off. Main electric switch open.

Blown or defective line fuse.

2. Gas supply valve shut off. Gas valve knob is on “off” position. FLAME LED flashing.

3. Flame sensor contaminated.

4. Pilot flame too low.

5. Roll-out switch open. POWER and TSTAT/CIRC LED’s are

on.

6. Harnesses plug-in connectors are not securely connected

REMED

1. Close switch. Check and replace

2. Open gas supply valve.Turn gas valve knob to “on “ posi-

3. Clean sensor.

4. Adjust pilot flame.

5. Check roll-out switch for continuity replace if blown out

6. Check connectors on boiler control.

Y

tion. Check gas pressure.

(inspect flue passages prior to replacement).

7. Defective transformer.

7. Remove P2 connector from boiler control. Check transformer terminals for 24V. Replace defective transformer.

Page 26

26

VI

CTORY VSPH Models

CAUSE

8. Defective pressure switch. POWER and PRES SWITCH

LED’s flashing

9. Defective high limit control

10. Defective inducer motor

11. Defective gas valve

12. Defective boiler control module

REMEDY

8. Check pressure switch. Replace defective pressure switch.

9. Set high limit setting above boiler water temperature, LIMIT

L

ED should turn on. If not, turn off power to the boiler,

r

emove wires to high limit and check continuity across high

limit contacts. If contacts are open, replace high limit.

10. With thermostat calling for heat and high limit setting above

boiler water temperature, remove blower motor plug from

boiler control (P4 connector). Check for 120 V between terminally 3 and 5 of P4 on control (See Figure 13a and 13b).

If voltmeter indicates 120V, replace inducer assembly.

11. a. Check all above causes.

b. check the gas supply pressure (at the inlet of gas valve)

as shown on the boiler rating plate for the type of gas

used.

c. With thermostat calling for heat and high limit setting

above water temperature, check the voltage across terminal

PV & PV/MV, if 24 VAC presents, replace the gas valve

12. Check all above causes. If all red indicator lights are off

while there is call for heat replace control module.

B. NOT ENOUGH HEAT

CAUSE

1. Thermostat setting is too low

2. Boiler water maintained at too low temperature.

3. Circulator not running.

4. Boiler water level too low.

5. Restriction or obstruction in air intake or venting system.

C. BURNER WILL NOT SHUT OFF

CAUSE

1. Defective Aquastat (high limit control)

REMEDY

1. Set thermostat at higher setting

2. Set Aquastat at higher setting.

3. With thermostat calling for heat, check for power to circulator. If power is O.K but circulator is not running, replace circulator.

4. Carefully snap open relief valve handle to determine if boiler is full of water, if not full of water, check for system leaks

and check water pressure regulator. Repair any system

leaks. Adjust or replace water pressure reducing valve.

5. Inspect flue and air intake piping. Inspect termination.

REMEDY

1. Turn off power to the boiler. Remove red and blue wire from

Aquastat ter

if burners stop firing, replace Aquastat.

minals. Restore power. Check boiler operation,

2. Aquastat sensor is not proper

ly inside Aquastat well.

2. Inser

t the sensor into the well.

Page 27

VI

CTORY VSPH Models

D. BURNER SHORT CYCLES

27

CAUSE

1. Thermostat heat anticipator set too low.

2. Excessive pressure drop due to excess venting or air intake

system.

3

. Blockage or restriction in venting or air intake system.

4. Defective air flow switch (out of adjustment).

E. FUMES AND GAS ODORS

CAUSE

1. Leaks in gas piping or accessories.

2. Gas leaks in service line or meter connections.

REMEDY

1. Reset anticipator.

2. System must be corrected.

3

. Check and Repair

4. Replace. DO NOT adjust.

REMEDY

1. Locate leaks and repair.

2. Close service supply valve - shut down boiler and notify

utility

3. Condensation trap is not full of water.

4. Venting system is physically damaged.

5. Over - firing

IF REPLACEMENT PARTS ARE NEEDED

When parts are needed, refer to boiler model and serial number

shown on the boiler name/rating plate. Refer to publication number VSPH-10PL replacement parts for part numbers. Whenever

possible refer to the original order by number and date.

Control identification and replacement should not be attempted

by unskilled personnel. Only, simple easily - identified controls

and parts may be obtained locally. All other controls and parts

should be identified by and ordered from Slant/Fin. Relief/Safety

valves must be ASME rated for the pressure and gross output of

the boiler.

3. Check and fill with water.

4. Check carefully and repair. Also, see “Venting System

Regular Inspection”.

5. Adjust gas input to that shown on boiler rating plate.

For replacement par

Slant/Fin boiler distributor.

ts, heating contractors should contact their

Page 28

©Slant/Fin Corp. 2007

SLANT/FIN CORPORATION, Greenvale, N.Y. 11548 • Phone: (516) 484-2600

FAX: (516) 484-5921 • Canada: Slant/Fin LTD/LTEE, Mississauga, Ontario

www.slantfin.com

Loading...

Loading...