Page 1

Printed in U.S.A. 1114 Publication No. VSPH-UIM

Part No. 455036 Rev. A

Residential • Gas fired • Hot Water Boilers

User’s Information Manual

VICTORY VSPH SERIES GAS BOILERS

Sealed Combustion - Direct Vent Models

FOR YOUR SAFETY:

• Before operating this boiler, READ this manual.

• DO NOT attempt to install, service or repair this boiler yourself. There are no user serviceable

parts. Contact a qualified service agency if your boiler needs repair or maintenance. Ask your gas supplier for a

list of qualified service agencies.

• A qualified service agency should inspect the venting system of this boiler on an annual basis.

__ DO NOT store or use gasoline or other

flammable vapors and liquids in the

vicinity of this or any other appliance.

__ WHAT TO DO IF YOU SMELL GAS

• DO NOT try to light any appliance.

• DO NOT touch any electrical switch

• DO NOT use any phone in your

building.

• Immediately call your gas supplier

from a neighbor’s phone. Follow the

gas supplier’s instructions.

• If you cannot reach your gas supplier,

call the fire department.

__ Installation and service must be performed by

a qualified installer, service agency or the gas

supplier.

WARNING: If the information in this manual is not

followed exactly, a fire or explosion may result

causing property damage, personal injury or loss

of life.

Your gas boiler must be installed and serviced by a qualified service agency or gas

supplier. The lack of proper service can result in a dangerous condition.

This manual must be left with owner, hung on or

adjacent to the boiler. Owner should retain manual

for future reference.

Page 2

VICTORY VSPH Models

2

WELCOME TO OUR VALUED CUSTOMER

You are now the owner of a Slant/Fin Victory VSPH gas-fired

boiler, another quality heating product designed and manufactured by an industry leader, to provide your family with

many years of reliable comfort and trouble-free performance.

The care and maintenance of your new boiler is important to

prevent a hazardous condition which might result form lack

of proper servicing. Therefore, you should perform regular

“owner” inspections as described in this manual (and report

any concerns to a qualified service technician) as well as

have your boiler serviced by a qualified service technician at

least once a year, preferably before the beginning of each

heating season.

LIGHTING INSTRUCTIONS

Locate, read and then follow the procedures on the lighting

instructions label attached to the boiler. For reference, we

have reproduced those instructions in this manual.

DO NOT use this boiler if any part has been

underwater. Immediately call a qualified service

technician to inspect the boiler and to replace

any part of the control system and any gas

control which has been underwater.

WARNING

Should overheating occur or the gas supply

fail to shut off, DO NOT turn off or disconnect

the electric supply to the circulator pump.

Instead, shut off the gas supply at a location

EXTERNAL to the appliance.

WARNING

SLANT/FIN DOES NOT PERMIT THE USE OF

VENT DAMPERS ON VICTORY SERIES

BOILERS. OTHER DAMPERS OR DEVICES

WITH SIMILAR PURPOSE ARE NOT

PERMITTED.

Keep the boiler area clean and free of all materials that can burn.

NEVER close or reduce openings that supply air for the boiler fire and for ventilation.

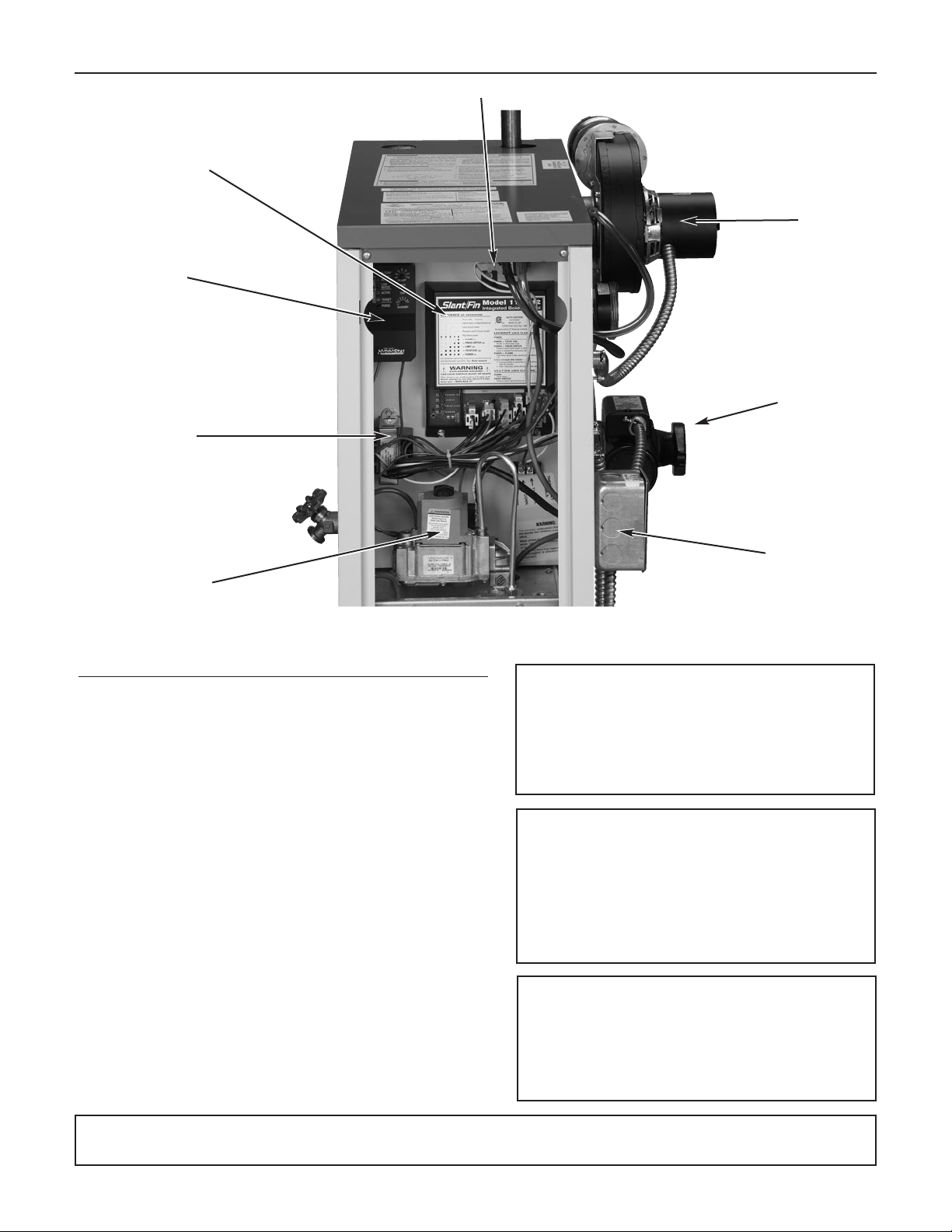

Figure 1. Location and Identification of parts.

Air flow proving switch

Blower assembly

Circulator

Gas valve

120/24V transformer

Water

Temperature

Control

Integrated boiler control

Junction Box

Page 3

VICTORY VSPH Models

3

INSPECTION

Your boiler and heating system will last an indefinitely

long time at full efficiency, if it is inspected regularly

and is kept in good repair and adjustment. You, the

user, should make regular inspections, and report any

problems to your service agency. At regular intervals,

you should have that agency inspect the system,

clean the boiler and make repair adjustments as necessary. what you and the service agency should do is

listed below. Contact your gas supplier for a list of

qualified service and repair agencies.

USER INSPECTION

The user should make the following inspections at

least once each month during the heating season

and once just before cold weather starts.

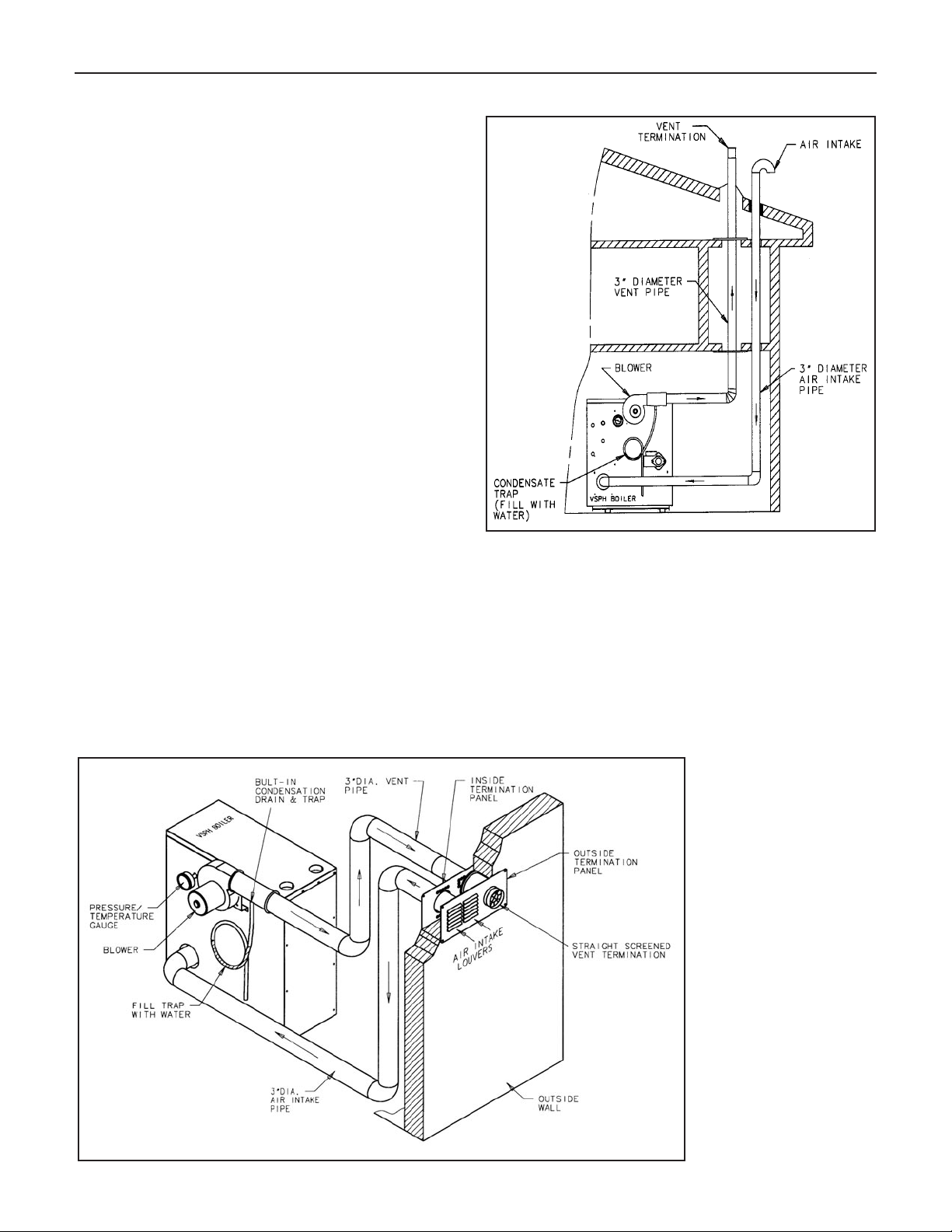

VSPH boilers maybe installed and vented either

as direct-vent boiler, which all air for combustion is

obtained directly from outside through the air intake

piping or as non-direct-vent boiler, which all air for

combustion is taken from inside the boiler room.

Typical direct-vent installations are shown on FIgures

2 and 3. Non-direct-vent installation is shown on Figures 4, 5 and 6.

1. VENTING AND AIR INTAKE SYSTEM REGULAR

INSPECTION

Inspect the system regularly for condensation, corrosion

and/or physical damage. A qualified professional should

service the boiler annually and include such an inspection at that time. The homeowner should look over the

system monthly for damage, water stains, any signs of

rust, other corrosions or separation of the vent and air

intake piping (if direct-vent).

Figure 2.

Figure 3.

Should an inspection turn up signs of condensation, corrosion or damage, the boiler should be shut down immediately and the condition should be corrected by a qualified

professional.

If the boiler is vented horizontally through the wall, the outside termination, louvers and screen should be checked

for any debris blocking the opening and cleaned as

required.

Page 4

VICTORY VSPH Models

4

Figure 4.

Figure 5.

Page 5

VICTORY VSPH Models

5

Figure 6.

2. CONDENSATION DRAIN

All Victory VSPH boilers are equipped with a built-in

condensation drain and trap. The trap loop must be filled

with water. DO NOT operate the boiler without filling the

trap with water to prevent flue gas discharge into space.

Periodic inspection should be made of this assembly for

deterioration of the tubing and to insure that the trap is

not plugged. If it is plugged or appears to have excessive sediment in it, it should be removed from the drain

assembly, straightened out to clear the obstruction,

reformed, filled with water and reinstalled as before.

3. PIPING INSPECTION

Look at all water piping. There should be no leaks or

signs of leaks at any pipe joints or around the boiler.

4. SYSTEM WATER PRESSURE INSPECTION

The temperature and pressure gauge indicates the

pressure in the boiler at each water temperature. For

most installations, it should indicate about 12 to 15 psi

pressure when temperature is about 70 to 100F and

from 15 psi to 25 psi when temperature is up to 240F.

FOR YOUR SYSTEM, there is one correct pressure for

each temperature. ASK YOUR INSTALLER OR SERVICEPERSON TO EXPLAIN AND SHOW YOU. Learn

what normal pressure to look for. If pressure rises from

normal, the relief valve will open to relieve the pressure.

Call your service organization if pressures are higher or

lower than normal, and if the relief valve spills water.

Repair or adjustment is needed.

5. UNUSUAL NOISE

Stand near the boiler and look and listen. As the burners start and shut off, there should be no unusual noise.

6. BOILER ROOM AIR SUPPLY

Ample boiler room fresh air is required for combustion

(non-direct vent installation) and ventilation (direct-vent

installation).

Check air vents for continuous positive supply of air as

required. Air needs are greatest in cold weather if boiler

installation is non-direct vent method. Air vents must be

open and free of obstruction.

Warning: The flow of combustion and ventilating air to the

boiler should not be obstructed.

Warning: If you find any problem during your inspection, call

for service immediately.

Page 6

VICTORY VSPH Models

6

ANNUAL SERVICE AND GENERAL MAINTENANCE

A trained and qualified service technician should perform inspection and general maintenance listed in

Installation and Operating Instructions (Publication No.

VSPH-40) before each heating season and at regular

intervals.

SAFETY AND OPERATING INSTRUCTIONS

Follow the lighting instructions in this manual. These

instructions are also attached to the boiler.

SAFETY INFORMATION

For Your Safety Read Before Operating

A. This appliance is equipped with an ignition device

which automatically lights the pilot. DO NOT try to light

the pilot by hand.

B. BEFORE OPERATING smell all around the appliance

area for gas. Be sure to smell next to the floor because

some gas is heavier than air and will settle on the floor.

WHAT TO DO IF YOU SMELL GAS:

• DO NOT try to light any appliance.

• DO NOT touch any electric switch: DO NOT use any

phone in your building.

• Immediately call you gas supplier from a neighbor’s

phone. Follow the gas supplier’s instructions.

• If you cannot reach your gas supplier, call the fire

department.

C. Use only your hand to turn the gas control knob. Never

use tools. If the knob will not turn by hand, don’t try to

repair it, call a qualified service technician. Force or

attempted repair may result in a fire or explosion.

D. DO NOT use this appliance if any part has been under

water. Immediately call a qualified service technician to

inspect the appliance and to replace any part of the

control system and any gas control which has been

under water.

OPERATING INSTRUCTIONS

1. STOP! Read the safety information above.

2. Set the thermostat to lowest setting.

3. Turn off all electric power to the appliance.

4. This appliance is equipped with an ignition device

which automatically lights the pilot. DO NOT try to light

the pilot by hand.

5. Remove jacket front panel

6. Turn gas control knob clockwise to “OFF”.

DO NOT force.

7. Wait five (5) minutes (longer for propane) to clear out

any gas, then smell for gas, including near the floor. If

you then smell gas, STOP! Follow “B” in the safety infor

mation above on this page. If you don’t smell gas, go to

next step.

8. Turn as control knob counterclockwise to “ON”.

9. Replace jacket front panel.

10. Turn on all electric power to the appliance.

11. Set thermostat to desired setting.

12. If the appliance will not operate, follow the instructions

“To Turn Off Gas to Appliance” and call your service

technician or gas supplier.

To Turn Off Gas to Appliance

1. Set thermostat to lowest setting.

2. Turn off all electric power to the appliance if service

is to be performed.

3. Remove jacket front panel.

4. Turn gas control knob clockwise till knob

stops, then continue to “OFF”. Do not force.

5. Replace jacket front panel.

Removing Jacket Front Panel

1. Turn black screws

1

⁄4 turn to open position.

2. Remove front panel.

To replace the panel, reverse procedure.

INTEGRATED BOILER CONTROL

The integrated boiler control monitors the status of the

room thermostat, high limit control (Aquastat), pressure

switch (air flow proving switch) and the flame sensor. It

controls the operation of the circulator, inducer motor

(blower), gas valve and spark for pilot ignition. The boiler

control also determines the sequence of operation and

timing for pre and post purge periods, trial for ignition adn

lockout. The control indicator lights (LED’s) provide information of boiler operation when lights are steady on or

diagnostic information when they are flashing in order to

help to determine the cause of boiler failure.

WARNING: If you do not follow these instructions exactly, a

fire or explosion may result causing property damage, personal injury or loss of life.

0FF0FF

ONON

HONEYWELLHONEYWELL

GAS GAS

INLETINLET

GAS CONTROL KNOBGAS CONTROL KNOB

SHOWN IN "OFF"SHOWN IN "OFF"

POSITIONPOSITION

OUTLETOUTLET

Gas Valve VR8204 or VR8304

Figure 7.

Page 7

VICTORY VSPH Models

7

Flame LED (Red)

Pressure Switch LED (Red)

Hi Limit LED (Red)

Thermostat/Circ. LED (Red)

Power LED (Green)

Figure 8.

INTEGRATED BOILER CONTROL

Page 8

VICTORY VSPH Models

8

O = LED off = LED steady on

A. NORMAL OPERATION - STATUS OF INDICATOR LIGHTS (LED’S)

Standby-Boiler waits for call for

heat

Thermostat calls for heat

Circulator on

Boiler water temperature below

high limit setting

Inducer on

Pressure switch contacts closed

30 seconds pre-purge period

Trial for ignition

Gas valve open

Pilot flame and main burners on

Boiler heating period

Thermostat call for heat ends

Circulator off

15 seconds post purge period.

Burners off.

DESCRIPTION OF OPERATION

POWER

LED

TSTAT/CIRC

LED

LIMIT

LED

PRESS

SWITCH

LED

FLAME

LED

O

O

O

O

O

O

O

O

O

O

O

O

B. DIAGNOSTIC FLASH CODES

Flashing LED’s provide diagnostic information

WARNING: Only a trained, experienced service technician should perform troubleshooting. Turn off all electric power to

the boiler before service

POWER LED * 120 V power supply. Polarity is reversed Reverse Hot and NEUTRAL wires in the junction

box.

POWER + TSTAT/CIRC LED’S * 48 VAC on thermostat circuit. Check and correct the thermostat or zone valves

wirings.

POWER + PRES SWITCH LED’S * Pressure switch contacts are closed prior to Check air pressure switch.

energizing the blower motor or does not close Check hose connections to pressure switch.

within 5 minutes of the blower being turned on. Check for obstruction/restriction in venting, air

intake piping and termination.

POWER + FLAME LED’S * Flame sensed without call for heat. Remove air box front panel.

Turn off power for at least 45 seconds.

Check if pilot flame exists during pre-purge

period (first 30 seconds). If pilot flame exists,

replace gas valve

FLAME LED * Pilot flame was not established during trial for Check gas valve knob to be in “ON” position.

ignition. Check inlet gas pressure.

Check pilot gas line.

Check ignition cable and the connections.

Check pilot flame to be “to 1/2" long”

PRES SWITCH LED Pressure switch opened during boiler run Check pressure switch and its hoses.

period. Wind gusts over 40 mph. Check for obstruction in venting, air intake

piping and termination.

LED’s FLASHING

INDICATION

REMEDY

* Control Lockout

SLANT/FIN CORPORATION, Greenvale, N.Y. 11548 • Phone: (516) 484-2600

FAX: (516) 484-5921 • Canada: Slant/Fin LTD / LTE E , Mississauga, Ontario

www.slantfin.com

©Slant/Fin Corp. 2013

Loading...

Loading...