Page 1

13 - USE

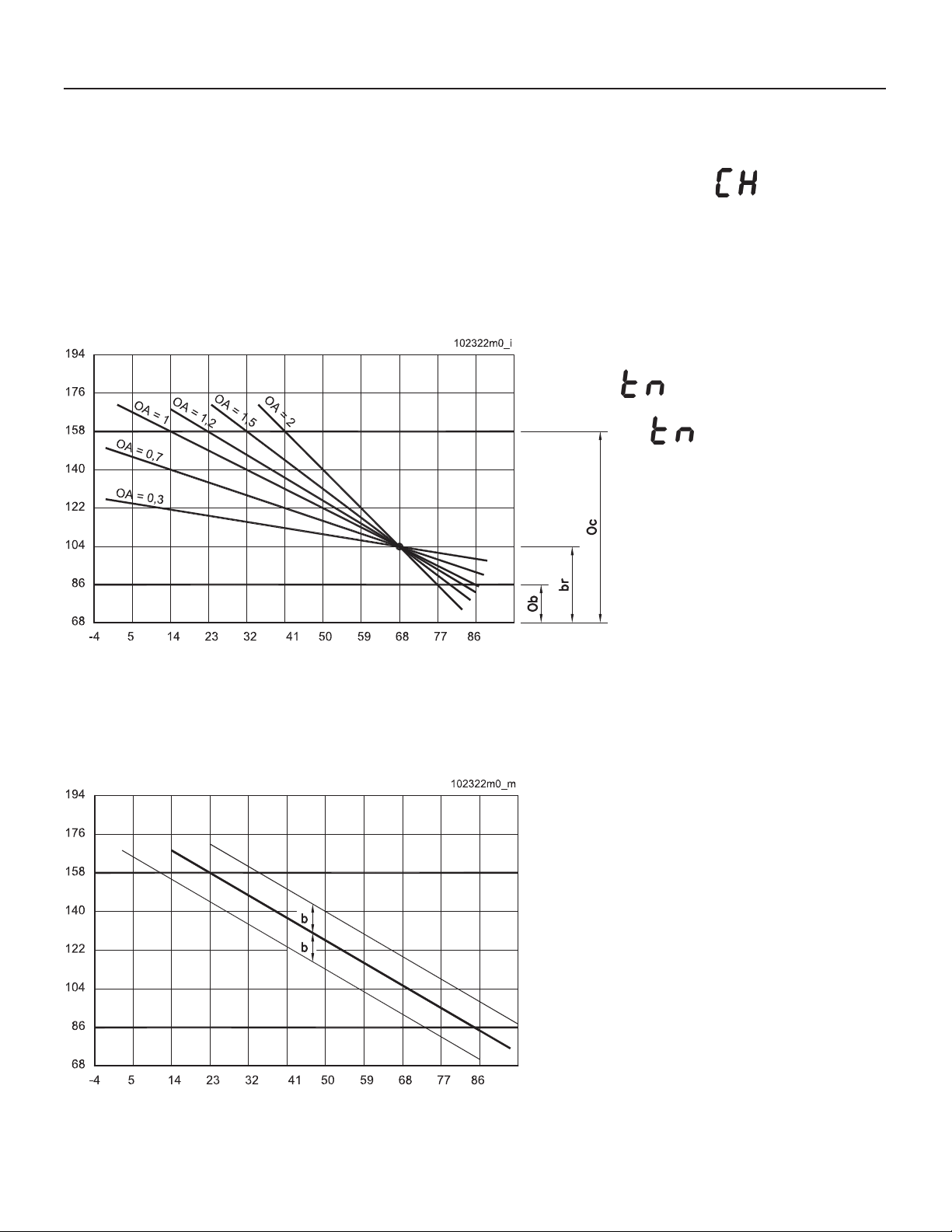

13.10.6 – Outdoor reset

with room compensation

While in the “Installers’ Menu” (section

13.17) set the parameter to 02.

The system will function exactly as

described in the previous “Outdoor

reset adjustment” sections except

that now the boiler pump will stay on

permanently . The opening of the room

thermostat contacts will translate into

a parallel downward movement of

the curve in Figures 13-2 and 13-3.

The value by which the curve moves

downwards can be adjusted by the

parameter present in the

“Installers’ Menu”, see section 13.17.

The parameter can range

from 1 °F (1 °C) to 36 °F, (20°C). The

suggested values for this parameter

are:

- 18 °F (10°C) for high temperature

radiator systems;

- 6 °F (3°C) for low temperature radiant

panel systems

Calculated temperature (°F)

Outside temperature (°F)

Figure 13-2 - Graph of the outdoor reset adjustment

(infl uence of parameters “br”, “OA”, “Ob” and “Oc”)

Calculated temperature (°F)

Outside temperature (°F)

Figure 13-3 - Graphs of the outdoor reset adjustment

(infl uence of parameter “b”)

V alues of this parameter that are

too high may translate into room

temperature instability . Values that are

too low may make the action of the

room thermostat ineffective.

Climatic adjustment with room

compensation can be used in all the

systems described in Section 13.10.1.

The advantage being that the constant

running of the pump will stabilize and

standardize the room temperatures.

This is especially true when some loops

in the heating system have considerably

greater volume than others.

OA = Slope of the line

Ob = Minimum heating

temperature

Oc = Maximum heating

temperature

br = “Fix point” of the angle

fulcrum of the line

b = parallel shift of the line

(adjusted by the heating

knob, item “7” of fi gure 13-1)

73

Page 2

13 - USE

13.11 - Boiler

switch settings

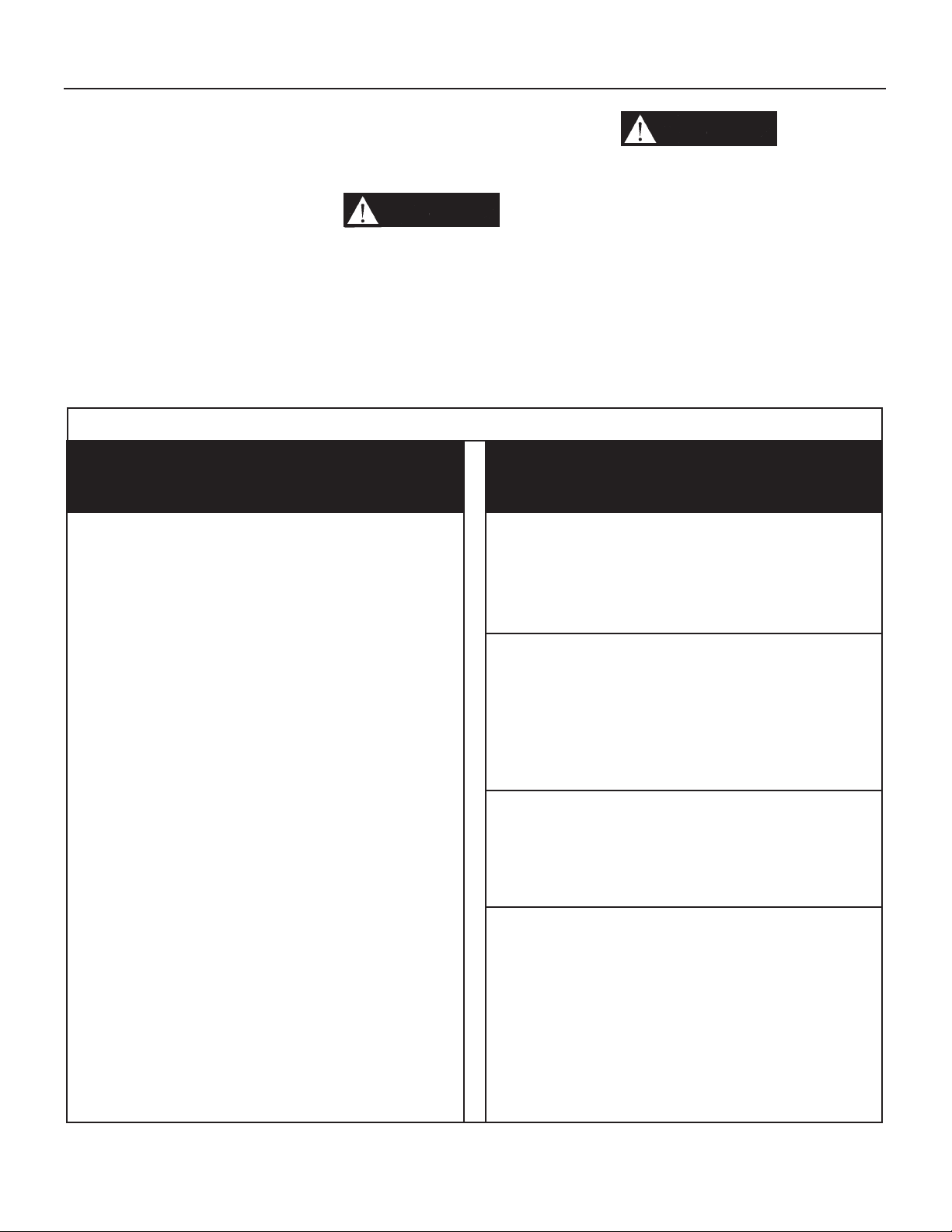

The control board shown in Figure

3-1, item “14”, contains a series of

switches that allow the boiler to be

confi gured to match the application.

The table below lists each switch and

its corresponding funtions.

SWITCH Position Description

1 OFF Boiler without production of D.H.W

ON Boiler with production of D.H.W. via storage tank

2 OFF Boiler with production of instantaneous D.H.W.

ON Position not available for this serie of boilers

3 OFF Heating pressure switch, disabled

ON Heating pressure switch, enabled

4 OFF EBM PAPST brand fan

ON Position not available for this serie of boilers

5 OFF Combination boiler for heating and D.H.W.

ON Boiler for heating only

6 OFF High temperature heating service, 86°F (30°C) to 176°F (80°C)

ON Low temperature heating service, 68°F (20°C) to 113°F (45°C)

7 OFF Boiler confi guration change, disabled

ON Boiler confi guration change, enabled

8 OFF Maximum heating supply water temperature of 176°F (80°C)

ON Position not available for this kind of boilers

CAUTION!!!

of these switches could cause the

boiler to malfunction resulting in

improper system performance.

Only a qualifi ed technician, with an

in-depth knowledge of the boilers’

control system, should change

them.

Improper setting

13.12 - Delays,

alarms and

protective actions

To protect the life of the appliance,

improve comfort, and maximize energy

savings, the following timings have

been incorporated into the control

logic:

a - Pump delay: each time the room

thermostat is satisfi ed, the circulator

pump continues to run for 1 minute;

b - DHW delay: each time the domestic

hot water demand is satisfi ed, a 2

minutes delay must pass before the

heating service is allowed to restart;

c - Protection against legionnaires

bacteria: if the boiler is connected

to a DHW storage tank the boiler

will increase the tank temperature

to 140 °F (60 °C) every seven days,

prevent the formation of legionnaires

bacteria. This function is displayed

by

d - DHW alarm: if the call for domestic

hot water lasts for longer than two

hours, an

This function is only for boilers set

up to provide instantaneous DHW.

.

01 alarm is generated.

e - Time delay in restarting the burner:

in its normal functioning state, except

when providing domestic water,

every time the burner stops, there is

a delay time of 3 minutes before the

boiler restarts again.

13.13 - Circulator

pump and three way

valve protection

During the summer months, the

circulator is run once a day for around

15 seconds to prevent it from seizing.

At the same time, the three way valve

(if present) is activated for the same

reason.

13.14 - Boiler’s

Freeze protection

CAUTION!!!

protection function to work, the

boiler must remain connected

to the electrical and gas

supplies with knobs “7” and

“11” in Figure 13-1, in the OFF

position.

For the freeze

CAUTION!!!

protection function is

conceived to protect the boiler

only, not the heating system.

CAUTION!!!

boiler’s freeze protection

function depends from the

electrical supply and from the

gas supply, it is mandatory

install a safety device that

alarm the user in a case

the boiler room will reach a

temperature near 35°F (2°C)

Once the boiler has reached a

temperature of 45 °F (7 °C), the

heating pump will automatically

comes on. If the temperature falls

below 35 °F (2 °C), the burner

will light to prevent the boiler from

freezing.

If the boiler will not be used for long

time it should be drained per Sections

14.10 and 14.11.

This freeze

Because the

74

Page 3

13 - USE

13.15 - Display

in energy saving

mode

If desired, the display, item “1” and

“2” in Figure 13-1, can be switched

permanently off, with the exception

of when it displays errors or settings.

To switch the display off, access the

“Installers’ Menu”, in section 13.17

and set the

other than zero. Keep in mind that

each value will correspond to a delay

in minutes until the display goes into

Energy Saving mode.

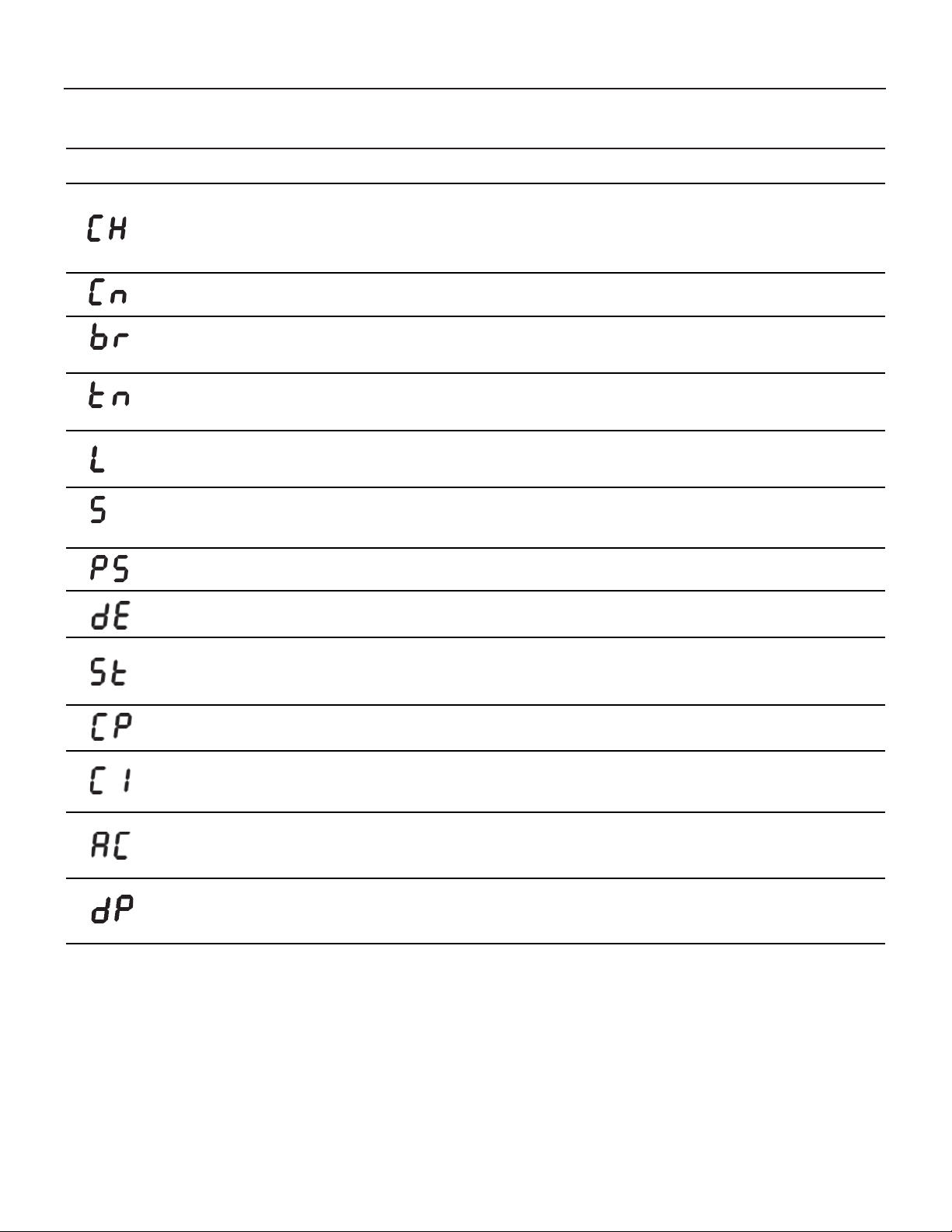

PARAMETER DESCRIPTION INFORMATION ON DISPLAY ITEM “2” of Figure 13-1

parameter at a value

Adjustment of the curve angel as shown in

Figure 13-2 when outdoor reset is active per

section 13.9.

13.16 - “Users’

menu”

When entering the “Users’ menu”, the

display, item “1” in Figure 13-1, will

start blinking indicating that a change

of mode has taken place. To access

the “Users’ menu” (see also Section

17 to better understand the several

menus):

1. press the button for 2

seconds until the display starts

blinking;

2. press and release the button

several times until the desired

parameter is displayed;

3. use the or keys, to

change the value of the selected

parameter;

Setting range: 0,1 to 5,0

4. press to save the parameter

change before going to the next

parameter.

When the last parameter has been

reached and the button

pressed, the display will stop blinking

indicating exit from the menu.

NOTE: If no key is pressed for

more than 60 seconds, the control

automatically exits the “Users’ menu”.

Any parameter change not saved

using the button, will be lost.

The table below lists each “Users’

menu” parameter, what it affects and

its adjustment range.

Adjustment of the “Minimum heating

temperature” as shown in Figure 13-2 when

outdoor reset is active per section 13.9.

Adjustment of the “Maximum heating

temperature” as shown in Figure 13-2 when

outdoor reset is active per section 13.9.

Adjustment of the parallel shift of the curve as

shown in Figure 13-3 when outdoor reset is

active per section 13.9.

Display of the calculated heating temperature

when outdoor reset is active per section 13.9,

or display of the temperature set by knob “7”

shown in Figure 13-1.

Display of the domestic hot water temperature

when set by knob “11” shown in Figure 13-1.

Display of last error code registered, Section

13.18.2

Setting range: see section 13.10.3

Setting range: see section 13.10.3

The adjustment is made by turning knob “7” shown

in Figure 13-1. The selected curve can be shifted

up or down by 36 °F (20 °C).

Temperature display only, with a range between 68

°F (20 °C) and 189 °F (87 °C).

Temperature display only with a range between 104

°F (40 °C) and 158 °F (70 °C), see section 13.7.

Error code display per section 13.18.2

Display of last lockout occurred, Section

13.18.1

Lockout code per section 13.18.1

75

Page 4

13 - USE

13.17 - “Installer’s

menu”

CAUTION!!!

parameters could cause the

boiler and therefore the system

to malfunction. For this reason,

only a qualifi ed technician who

has in-depth knowledge of the

boiler should change them.

The boiler’s micro-processor makes

this menu of parameters available

to the qualifi ed technician for the

analysis of the functioning and

adjustment of the appliance to the

system. When entering the “Installers’

Menu”, the display item “1” in Figure

13-1, will start to blink indicating that

a change of mode has taken place. To

access the “Installers’ Menu” just (see

also Section 17 to better understand

the several menus):

Changing these

1. press and hold the button

down for 12 seconds until the

parameter is displayed;

2. press and release the button

to scroll through the list of the

parameters;

3. once the parameter has been

displayed, it can be changed using

the or keys;

4. press and release the button

to confi rm the amended data before

moving to the next parameter.

When the last parameter has been

reached and the button

pressed, the display will stop blinking

indicating the exit from the menu.

NOTE: If no key is pressed for

more than 60 seconds, the control

automatically exits the “Installers’

menu”. Any parameter change not

saved using the button, will be

lost.

The next table lists each “Installers’

menu” parameter, what it affects and

its adjustment range.

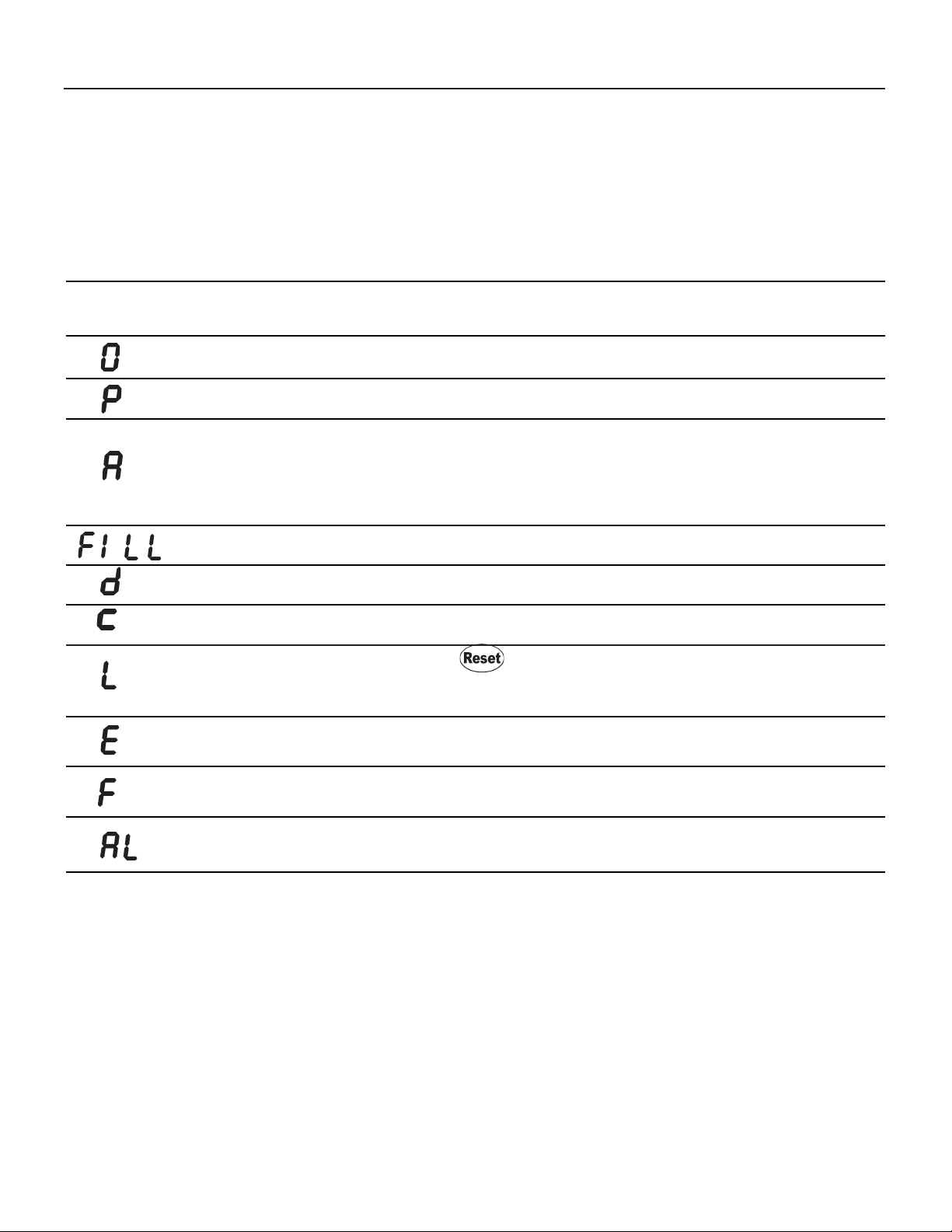

PARAMETER DESCRIPTION INFORMATION ON DISPLAY ITEM “2” OF FIGURE 13-1

Boiler temperature, measured by U1

sensor

DHW temperature, measured by U2

sensor

Domestic cold water (or ind. water heater)

temperature , measured by U3 sensor

Outdoor temperature, measured by U4

sensor

Ionization current value

High limit temperature, measured by U6

sensor

Flue gas temperature, measured by U7

sensor

Heating return temperature, measured

by U8 sensor

Type of basic setting of control board

Status of room thermostat contact

Value in °F (cannot be changed)

Value in °F (cannot be changed)

Value in °F (cannot be changed)

Value in °F (cannot be changed) (displayed only if outdoor reset is

active, as per section 13.9)

Value from 0 to 99 (cannot be changed)

(30 corresponds to a current of 1uA)

(99 corresponds to a current of 5.5 uA)

Value in °F (cannot be changed)

Value in °F (cannot be changed)

Value in °F (cannot be changed)

Can be changed in accordance with Section 11.6

00 = contact open (heating service off)

01 = contact closed (heating service on)

Measurement of fan speed rotation

BTU input for heating service

Value in g/1’/100 (rpm/100) (cannot be changed)

Adjustable according to the instructions of section 12.10

Continue

76

Page 5

13 - USE

Continued

PARAMETER DESCRIPTION INFORMATION ON DISPLAY ITEM “2” OF FIGURE 13-1

Can be changed (see Section 13.9):

Heating service functioning mode

00 = thermostatic adjustment;

01 = outdoor reset;

02 = outdoor reset with room compensation;

Reaction to external temperature

Angle fulcrum of climatic adjustment

Reduction of temperature generated by

the opening of the room thermostat

Boiler knobs’ status

Display “1” and “2” as per fi gure 13-1

energy saver

Parameter disabled for this kind of boiler

Domestic sensitivity setting

Minimum domestic setpoint during sleep

mode

Proportional band of the heating PID

modulation

Keep always at value of 1

Can be changed from 16°F (-9°C) to 149°F (65°C) (active only with

outdoor reset).

See section 13.10.3 for its adjustment.

Can be changed: from 1°F (1°C) to 36°F (20°C) (active only with

outdoor reset featuring room compensation)

See section 13.10.6 for its adjustment.

Can be changed:

01 = knobs presents;

00 = knobs absent.

Can be changed: 00 = display always on; any other value,

corresponds to a delay in the switching off of the display, expressed

in minutes (see also Section 13.15)

No infl uence in this kind of boiler

No infl uence in this kind of boiler

Must be maintained at 20 value

Integral of the heating PID modulation

Burner Anticycling: minimum delay from

a burner light-off to the sequent light-on.

Value expressed in sec x 10

Indirect water heater priority selection:

Value expressed in minutes.

Must be maintained at 40 value

Can be changed between 1 and 54. Default value is 18 (180 sec).

Can be modifi ed only in conjunction with factory technicians.

Can be changed between 00 (function disabled) and 99 minutes.

Default value is 00 (See also section 9.1.1).

77

Page 6

13 - USE

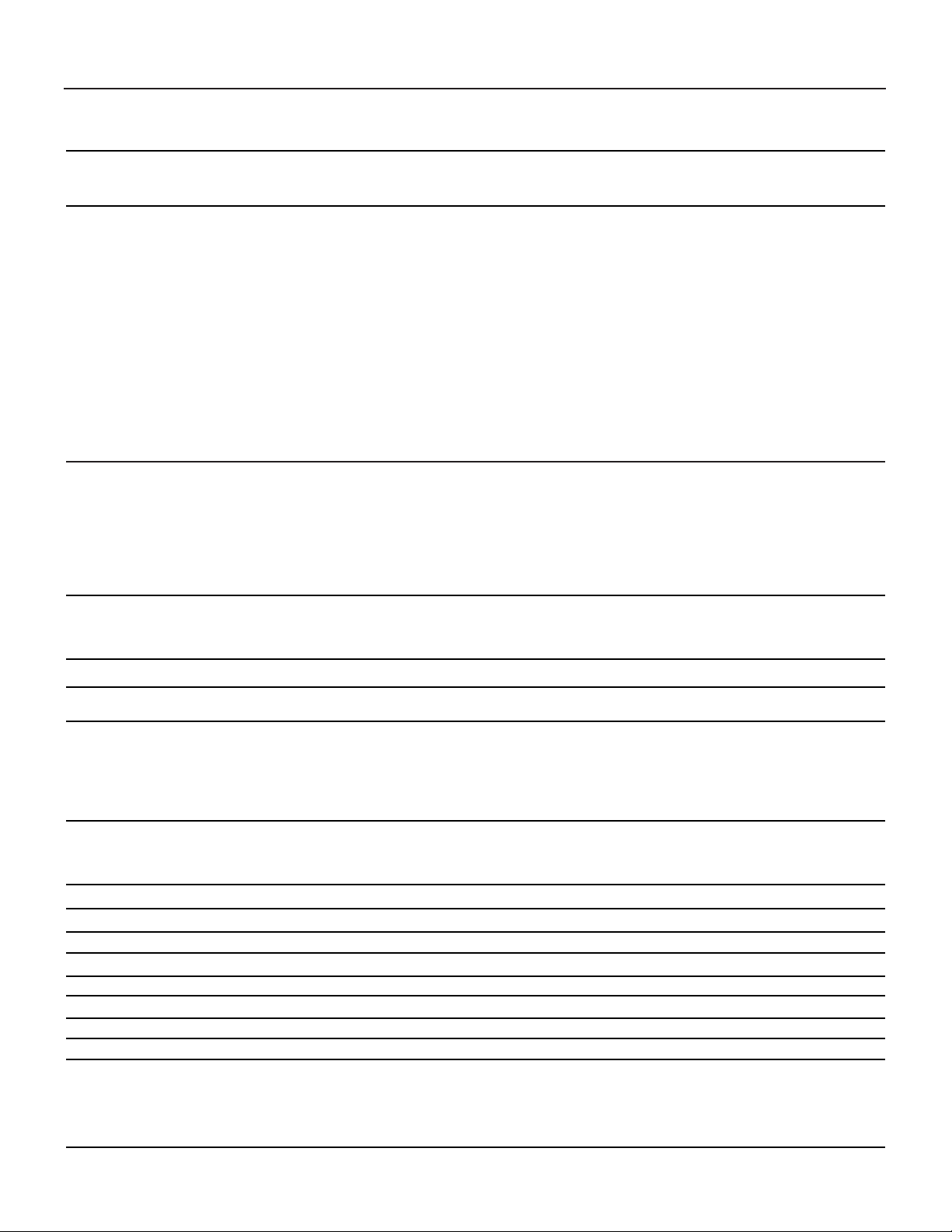

13.18 Diagnostics

During the normal operation of the

boiler, the display, of Figure 13-1,

continually shows the operating

status of the boiler as shown below

(see also section 17):

PARAMETER

PARAMETER REFERENCE DISPLAY READ OUT (ITEM “2”, FIGURE 13-1)

Boiler in stand-by mode or pause (no request for heating or

domestic hot water)

Anti-freeze function active

Boiler not in lock-out mode but in Attention mode.

System pressure too low, system must be fi lled. See section 13.1.

Domestic hot water service active

Heating service active

Boiler in lock-out mode. To reset it, press the

the lock-out occurs frequently, contact a professionally qualifi ed

technician

Blocking error. Contact a professionally qualifi ed technician. Blocking

errors automatically reset if the condition causing the block disappears

.

button. If

Boiler temperature (°F)

Boiler temperature (°F)

01 = Boiler temperature (°F) Domestic hot

water service active for more than 120

minutes. Turn domestic hot water to OFF

position to reinstate heating.

02 = Data connection interrupted between

cascade boilers

No display

Domestic hot water temperature (°F)

Heating temperature (°F)

Lock-out code (see section 13.18.1 for

decodifi cation).

Error code (see section 13.18.2 for

decodifi cation).

Auto-purging procedure that last 3 minutes in progress (see

section 13.4).

Boiler in Anti-legionella functioning (see section 13.12)

78

Boiler temperature (°F)

Storage tank temperature (°F)

Page 7

13 - USE

13.18.1 - Diagnostics: “L” lock-outs

“L”

Code

L01

L02

L03

L04

L05

L06

Lock-out

description

No fl ame detected after

three ignition attempts.

Flame extinguishes three

times.

Boiler temperature is over

203° F (95°C).

Gas valve command relay

Safety relay

Flue gas sensor over

210°F (99°C)

Checks to make

Check:

a-correct gas supply pressure (see

section 12.7);

b-ignition spark (see section 14.4);

c-correct combustion air pressure (see

section 12.8);

d-120Vac at the gas valve;

e-resistance of the two gas valve coils

should be 0.18 kohm and 1.1 kohm;

f- If the burner lights, but goes out at the

end of the ignition attempt, check: that

the ionization current is set at a value

greater than 60 (follow procedure in

section 14.12.4)

Check:

a-that the ionization current is set

at a value greater than 60 (follow

procedure in section 14.12.4);

b-check that gas valve open fast

enough;

a-Check that the circulator pump is

working;

b-Check if the water fl ow is not less than

5 GPM

Check for correct polarity of the wires to

the pump. Try to switch the wires.

Check:

a - that the electrical resistance of the

fl ue gas sensor complies with the graph

in Section 14.13;

b - that the effi ciency of the boiler is

over 86%

Solutions

a-If the gas supply pressure is incorrect, it must be adjusted to

the correct pressure;

b-If spark is not present, check for correct ignition ectrode

position and gap as per section 14.4; If position is correct,

check for 120Vac at the supply of the spark generator.

c-if the combustion air pressure is incorrect, inspect the vent

system and eliminate any obstructions;

d-if the voltage to the gas valve is not 120Vac the power control

board must be replaced;

e-if the resitance of the gas valve coils is not 0.18 kohm and/or

1.10 kohm, the gas valve must be replaced.

f-If the ionization current is not greater than 60, confi rm that

the the CO2 content is adjusted properly (see section

12.9). Check the fl ame detection electrode (section 14.4)

and if necessary replace it, check the integrity of the fl ame

detection electrode electrical wires.

a-If the ionization current is not greater than 60, confi rm that

the the CO2 content is adjusted properly (see section

12.9). Check the fl ame detection electrode (section 14.4)

and if necessary replace it, check the integrity of the fl ame

detection electrode electrical wires.

b-Following procedure as per Section 14.12.4, check few times

if passing from low fi re to high fi re the fl ame estinguish. If

estinguish, change the gas valve.

a-If the circulator pump is bad, replace it, if is good, replace the

power control board.

b-If the water fl ow is less than 5 GPM check for any zone

valves that must be opened.

Replace the power control board

If the pump won’t run replace it. If the pump is good try to

replace the power control board.

a-If the fl ue gas sensor resistance does not correspond with the

correct values, replace it;

b-if the boiler effi ciency is less than 86% and the CO2 content

is correct, the primary heat exchanger has to be replaced

and proper water treatment methods employed to prevent

mineral build up on the water side

L07

L08

L09

L10

L12

L13

L14

L15

L16

L17

Electrical circuit of fl ue

gas sensor is interrupted

Spark generator relay

RAM memory

E2prom memory damaged

E2prom memory damaged

Program error

Program error

Program error

Program error

The temperature

difference between the

U1 and U6 sensors is too

great

Check that the electrical resistance of

the fl ue gas sensor corresponds with the

graph in section 14.13;

Check that:

a - the electrical resistance of the two

sensors corresponds with the graph in

section 14.13;

b -check that the heating water fl ow is

not too low.

79

If the sensor resistance does not correspond with the correct

values, replace it;

Replace the power control board

Replace the power control board

Replace the power control board

Replace the power control board

Replace the power control board

Replace the power control board

Replace the power control board

Replace the power control board

a-If one or both sensors does not have the correct resistance

value, it must be replaced;

b-If temperature difference between U1 and U8 is higher than

55°F at maximum input, the heating water fl ow rate is too

low. The heating water fl ow rate must be corrected.

Page 8

13 - USE

13.18.1 - Diagnostics: “L” lock-outs (continued)

“L”

Code

L18

L19

L20

L21

L25

L32

L33

L45

L46

Lock-out

description

Program error

Flame sensed for 10

seconds, after the closure

of the gas valve

Flame sensed before

opening of the gas valve.

Boiler in blocking state for

more than 20 hours

U1 or U6 sensor increase

its temperature too fast

Program error

Fan rotation error

Heating circuit fi lling time

longer than 10 minutes.

Filling of heating circuit

repeated 16 times in 24

hours

Controls

Check:

a - that the heating water fl ow is not too

low;

b - that the circulator pump is working

Check that the voltage to the fan is

163(±10)Vdc.

Check:

a - that the heating pressure switch

setting pressure, FILL appears when

the pressure drops below 8.7 psi

(0,6 bar), and disappears when the

pressure rises above 22 psi (1.5

bar);

b - check that there are no water leaks

in the heating system.

Solutions

Replace the power control board

Call technical service

Call technical service

Press RESET button and check the blocking error “E” on

Section 13.18.2

a - If temperature difference between U1 and U8 is higher than

55°F (31°C), at maximum input, the heating water fl ow rate

is too low. The heating water fl ow rate must be corrected.

b - If the pump works, replace the power control board.

Replace the power control board

If the fan is powered with 163Vdc, replace the fan. If the voltage

to the fan is not 163 Vdc, replace the board.

a -If the heating pressure switch is not correctly set, it must be

replaced;

b - if the system has a leak, it must be fi xed.

L47

Flue pressure switch

open time longer than 60

minutes

Check:

a - that no obstructions are in the fl ue

discharge/air intake line

b - check the fl ue pressure switch

setting point, setting is 4.5 in.W.C

c - check that the electrical resistance of

the fl ue gas sensor corresponds with

the graph in section 14.13;

d - check that the electrical connection

cables between the fl ue pressure

switch, the fl ue sensor and the

power control board.

a -If ther’is an obstruction, it must be removed;

b - If the fl ue pressure switch is not correctly set, it must be

replaced;

c - If the fl ue sensor resistance does not correspond, it must be

replaced;

d - if the electrical circuit is damaged, it must be repaired;

if the previous four cases do not apply, replace the power

control board

80

Page 9

13 - USE

13.18.2 - Diagnostics: “E” blocking errors

“E”

Code

E01

E02

E04

E07

Blocking

description

U1 boiler temperature

sensor circuit interrupted.

U2 domestic hot water

temperature sensor circuit

interrupted.

U8 return temperature

sensor circuit interrupted

U3 cold water or indirect

water heater sensor circuit

interrupted

Checks to make

Check that the electrical resistance of

the sensor corresponds with the graph in

section 14.13;

check that the electrical connection cables

between the sensor and the power control

board have continuity and carry current

Check that the electrical resistance of

the sensor corresponds with the graph in

section 14.13;

check that the electrical connection cables

between the sensor and the power control

board have continuity and carry current

Check that the electrical resistance of

the sensor corresponds with the graph in

section 14.13;

check that the electrical connection cables

between the sensor and the power control

board have continuity and carry current

Check that the electrical resistance of

the sensor corresponds with the graph in

section 14.13;

check that the electrical connection cables

between the sensor and the power control

board have continuity and carry current

Solutions

If the sensor resistance does not correspond, it must be

replaced;

if the electrical circuit is damaged, it must be repaired;

if the previous two cases do not apply, replace the power

control board

If the sensor resistance does not correspond, it must be

replaced;

if the electrical circuit is damaged, it must be repaired;

if the previous two cases do not apply, replace the power

control board

If the sensor resistance does not correspond, it must be

replaced;

if the electrical circuit is damaged, it must be repaired;

if the previous two cases do not apply, replace the power

control board

If the sensor resistance does not correspond, it must be

replaced;

if the electrical circuit is damaged, it must be repaired;

if the previous two cases do not apply, replace the power

control board

E08

E11

E12

E13

U6 boiler temperature

sensor circuit interrupted.

U1 boiler temperature

sensor circuit shortcircuited.

U2 domestic hot water

temperature sensor circuit

short-circuited

Erroneous temperature

reading.

Check that the electrical resistance of

the sensor corresponds with the graph in

section 14.13;

check that the electrical connection cables

between the sensor and the power control

board have continuity and carry current

Check that the electrical resistance of

the sensor corresponds with the graph in

section 14.13;

check that the electrical connection cables

between the sensor and the power control

board have continuity and carry current

Check that the electrical resistance of

the sensor corresponds with the graph in

section 14.13;

check that the electrical connection cables

between the sensor and the power control

board have continuity and carry current

If the sensor resistance does not correspond, it must be

replaced;

if the electrical circuit is damaged, it must be repaired;

if the previous two cases do not apply, replace the power

control board

If the sensor resistance does not correspond, it must be

replaced;

if the electrical circuit is damaged, it must be repaired;

if the previous two cases do not apply, replace the power

control board

If the sensor resistance does not correspond, it must be

replaced;

if the electrical circuit is damaged, it must be repaired;

if the previous two cases do not apply, replace the power

control board

Replace the power control board

81

Page 10

13 - USE

13.18.2 - Diagnostics: “E” blocking errors (continued)

“E”

Code

E14

E15

E16

E17

E18

E19

E20

E21

E22

E23

E30

Blocking

description

U8 return temperature

sensor short-circuited

U4 outside sensor shortcircuited

Erroneous temperature

reading.

U3 cold water temperature

or indirect water heater

temperature sensor circuit

shorted

U6 boiler temperature

sensor circuit shorted

E2prom memory damaged

Flame presence with gas

valve closed

Phase and neutral inverted

Electrical supply frequency

other than 60Hz

Ground connection is

absent

Erroneous temperature

reading.

Checks to make

Check that the electrical resistance of

the sensor corresponds with the graph in

section 14.13;

check that the electrical connection cables

between the sensor and the power control

board have continuity and carry current

Check that the electrical resistance of

the sensor corresponds with the graph in

section 14.14;

check that the electrical connection cables

between the sensor and the power control

board have continuity and carry current

Check that the electrical resistance of

the sensor corresponds with the graph in

section 14.13;

check that the electrical connection cables

between the sensor and the power control

board have continuity and carry current

Check that the electrical resistance of

the sensor corresponds with the graph in

section 14.13;

check that the electrical connection cables

between the sensor and the power control

board have continuity and carry current

Invert phase and neutral

Check the electrical frequency of the

system.

Check if CS parameter is at 03 (see

section 17)

Check if the boiler is properly grounded

Solutions

If the sensor resistance does not correspond, it must be

replaced;

if the electrical circuit is damaged, it must be repaired;

if the previous two cases do not apply, replace the power

control board

If the sensor resistance does not correspond, it must be

replaced;

if the electrical circuit is damaged, it must be repaired;

if the previous two cases do not apply, replace the power

control board

Replace the power control board

If the sensor resistance does not correspond, it must be

replaced;

if the electrical circuit is damaged, it must be repaired;

if the previous two cases do not apply, replace the power

control board

If the sensor resistance does not correspond, it must be

replaced;

if the electrical circuit is damaged, it must be repaired;

if the previous two cases do not apply, replace the power

control board

Replace the command and control board

Replace the gas valve

If phase and neutral are correctly wired, replace the power and

control board

If the electrical supply frequency is other than 60Hz, contact

the electric company;

if the mains frequency is 60Hz, replace the command and

control board.

Make sure that the CS parameter is at 03.

if the boiler is properly grounded, replace the power control

board

Replace the power control board

E31

E32

E33

E42

E50

E51

E52

E53

Erroneous temperature

reading.

Erroneous temperature

reading.

Erroneous temperature

reading.

Program error

Error in the boiler tY

parameter selection

Reset button pressed too

often in a short period time

Heating fl ow switch

closed

Heating fl ow switch

open

Move ON switches 7 an set again the

correct tY value (see section 17)

Check if the heating pump is running.

Check if the fl ow switch contact is stuck

Check if the heating pump is running.

Check if the fl ow switch contact is

broken

82

Replace the power control board

Replace the power control board

Replace the power control board

Replace the power control board

If tY value is correct, change the power control board

The pump should not run and the contanct should open

The contact must be open

The pump should run and the contact should closed

The contact must be closed

Page 11

14 - MAINTENANCE

14.1 - Care and

maintenance

This section must be brought to the attention

of the user by the installer so that the user

can make the necessary arrangements with

a qualifi ed service agency for the periodic

care and maintenance of the boiler. User

must check its boiler follow Table 14-1

column “User maintenance”.

The installer must also inform the user that

the lack of proper care and maintenance of

this boiler and any fuel burning equipment

may result in a hazardous condition.

Installer should discuss contents of the

Section 13 (User’s section) with the user.

Service and maintenance schedules

Service Technician User maintenance

Annual Startup:

A trained and qualifi ed service technician

should perform the inspection listed in these

instructions before each heating season and

at regular intervals.

WARNING!!!

inspection and adjustment must

be done by a trained technician

in accordance with all applicable

local and national codes. Improper

servicing or adjustment could

damage the boiler! Failure to

comply with this warning can

result in a fi re or explosion

causing property damage,

personal injury or loss of life!

Servicing,

Daily:

WARNING!!!

combustible materials, gasoline or

any product containing fl ammable

vapors and liquids in the vicinity

of the boiler. Failure to comply

with this warning can result in

extensive property damage, severe

personal injury or death!

Never store

- Address reported problems (Follow section 14.1.1);

- Check all piping for leaks (Follow section 14.1.2)

- Verify fl ue and air lines in good condition and

sealed tight (Follow section 14.1.3);

- Check system water pressure/system piping/

expansion tank (Follow section 14.1.4);

- Check control settings (Follow section 14.1.5);

- Check ignition and fl ame sense electrodes (Follow

section 14.1.6);

- Check wiring and connections (Follow section

14.1.7);

- Perform performance verifi cation (Follow section

14.1.8);

- Flame inspection (Follow section 14.1.9);

- Check fl ame signal (Follow section 14.1.10);

- Clean the heat exchanger if fl ue temperature

is more than 72°F (40°C) above return water

temperature (Follow section 14.3).

- Clean condensate trap (Follow section 14.5).

- Check combustion air pressure (Follow section

12.8).

- Check relief valve (Follow section 14.1.11);

- Check for any air inside the domestic heat

exchanger (Follow section 12.1.4);

- Check any domestic water softener if need any

maintenance (follow softener’s manufacturer

instructions)

- Check boiler area (Follow section 14.1.12);

- Check pressure gauge (Follow section 14.1.13);

Monthly:

- Check vent piping (Follow section 14.1.14);

- Check air piping (Follow section 14.1.15);

- Check condensate drain system (Follow section

14.1.16);

Every six month:

- Check boiler piping (gas and water) for leaks

(Follow section 14.1.17);

End of season months:

- Shut boiler down (unless boiler used for domestic

hot water) (Follow section 14.1.18);

Table 14-1 - Service and Maintenance Schedules

83

Page 12

14 - MAINTENANCE

WARNING!!!

obstruct the fl ow of combustion

and ventilation air. Failure to

provide adequate combustion

air for this boiler can result

in excessive levels of carbon

monoxide which can result in

severe personal injury or death!

WARNING!!!

maintenance is performed on

the vent-air intake system it

must be properly reassembled

and sealed. Failure to properly

maintain the vent-air system

can result in excessive levels

of carbon monoxide which can

result in severe personal injury

or death!

WARNING!!!

performing any maintenance

operations, shut the boiler

off, close the manual gas

shut-off valve (Figure 11-1)

and shut off electrical power

to the boiler. Follow the

Operating Instructions outlined

in the section “SAFETY

INSTRUCTIONS” (Beginning of

the manual).

Never

If

Before

14.1.1 - Address reported

problems

Inspect any problems reported by the

owner and correct before proceeding.

14.1.2 - Check all piping

for leaks

CAUTION!!!

or boiler leaks. Continual fresh

makeup water will reduce boiler

life. Minerals can build up in

sections, reducing heat transfer,

overheating heat exchanger,

and causing heat exchanger

failure. Leaking water may also

cause severe property damage.

1. Inspect all water and gas piping and

verify to be leak free.

2. Look for signs of leaking lines and

correct any problems found.

Eliminate all system

3. Check for gas leaks: using soap

solution, check for gas leaks from

meter to boiler including all pipes and

fi ttings and boier connections. Use

liquid soap solution for all gas testing.

WARNING!!!

check for gas leaks with an

open fl ame. Use the bubble

test. Failure to use the bubble

test or check for gas leaks

with an open fl ame can cause

explosion, severe personal

injury, death, or substantial

property damage.

Do not

14.1.3 - Verify fl ue and air

lines in good condition

and sealed tight;

1. Check for obstruction, condensation,

corrosion and physical damage,

water stains, any signs of rust, other

corrosions or separation of the vent

and air intake piping.

2. Check outside terminations. Screens

and louvers should be free of any

debris and must be cleaned as

required.

14.1.4 - Check system

water pressure/system

piping/expansion tank;

1. Check water piping and accessories

for leaks. Slightest leaks should be

corrected.

2. Check the system to be full of water

and pressure to remain stable at

correct setting on gauge.

14.1.5 - Check control

settings

1. Thermostat Test (control knobs items

“7” and “11”, Figure 13-1): Set knobs

setting to low enough to end call for

heat. Gas valve should close and

burner should stop fi ring. Fan go into

a post purge, then shuts off.

2. Control Safety Shutdown test: with

the burner fi ring, close the manual

gas shut off valve (Figure 11-1) .

Gas valve should close and burner

should stop fi ring. The boiler will try

for ignition three times after this,

then should lock out with an “L 01”

error shown on the display. Open the

manual gas shut-off valve, and press

the “Reset” button to return to normal

operation.

84

14.1.6 - Check ignition and

fl ame sense electrodes

1. Remove the fan-burner assembly

unit (see section 14.3)

2. Remove any deposits accumulated

on the ignition/fl ame sense electrode

using sand paper.

3. Check electrodes positioning meet

Section 14.4

14.1.7 - Check wiring and

connections

Inspect all boiler wiring, making

sure wires are in good condition and

securely attached.

14.1.8 - Perform

performance verifi cation.

1. Start boiler and perform a

combustion test as per section 12.9.

2. Verify cold fi ll pressure is correct and

that operating pressure does not go

too high (could be a problem on the

expansion tank).

14.1.9 - Flame inspection

1. Inspect fl ame through observation

window.

2. If the fl ame is unsatisfactory at either

high fi re or low fi re, clean the burner

following section 14.3.

14.1.10 - Check fl ame

signal

1. Follow section 14.12.4 to check the

fl ame signal.

2. At high fi re and low fi re the fl ame

signal shown on the display should

be within values given in Section 15,

header “ionisation current”. A lower

fl ame signal may indicate a fouled or

damaged fl ame sense electrode. If

cleaning the fl ame sense electrode

does not improve, ground wiring

is in good condition, and ground

continuity is satisfactory, replace the

fl ame sense electrode.

14.1.11 - Check relief valve

Inspect the relief valve and lift the lever

to verify fl ow. Before operating any

relief valve, ensure that it is piped with

its discharge in a safe area to avoid

severe scald potential. Read Section

7.2.2 before proceeding further. Relief

vavle should be re-inspected at least

once every three years, by a licensed

Page 13

14 - MAINTENANCE

plumbing contractor or authorized

inspection agency, to ensure that

the product has not been affected

by corrosive water conditions and to

ensure that the valve and discharge line

have not been altered or tampered with

illegally.

Certain naturally occurring conditions

may corrode the valve or its

components over time, rendering the

valve inoperative. Such conditions are

not detectable unless the valve and its

components are physically removed

and inspected. This inspection must

only be conducted by a plumbing

contractor or authorized inspection

agency – not by the user.

WARNING!!!

re-inspect the boiler relief valve

as directed could result in unsafe

pressure buildup, which can result

in severe personal injury, death, or

substantial property damage.

Failure to

14.1.12 - Check boiler area

WARNING!!!

potential of severe personal

injury, death, or substantial

property damage, eliminate

all materials discussed below

from the boiler vicinity and the

vicinity of the boiler combustion

air inlet.

If contaminants are found:

Remove products immediately

from the area. If they have

been there for an extended

period, call a qualifi ed service

technician to inspect the boiler

for possible damage from acid

corrosion.

If products cannot be removed,

immediately call a qualifi ed

service technician to re-pipe

vent and air piping and locate

vent termination/air intake away

from contaminated areas.

1. Combustible/fl ammable materials --

Do not store combustible materials,

gasoline or any other fl ammable

vapors or liquids near the boiler.

Remove immediately if found.

To prevent

2. Air contaminants -- Products

containing chlorine or fl uorine,

if allowed to contaminate the

boiler intake air, will cause acidic

condensate in the boiler. This will

cause signifi cant damage to the

boiler if allowed to continue. Read

the list of potential materials listed in

Section 10.2. If any of these products

are in the room from which the boiler

takes its combustion air, they must

be removed immediately or the boiler

combustion air (and vent termination)

must be relocated to another area.

14.1.13 - Check pressure

gauge

1. Make sure the pressure reading

on the boiler pressure gauge does

not exceed 25 psi. Higher pressure

may indicate a problem with the

expansion tank.

2. Contact a qualifi ed service technician

if problem persists.

14.1.14 - Check vent

piping

1. Visually inspect the fl ue gas vent

piping for any signs of blockage,

leakage, or deterioration of the

piping. Notify your qualifi ed service

technician at once if you fi nd any

problems.

WARNING!!!

to inspect the vent system

as noted above and have it

repaired by a qualifi ed service

technician can result in vent

system failure, causing severe

personal injury or death.

Failure

14.1.15 - Check air piping

1. Visually inspect the air inlet

termination to be sure it is

unobstructed. Inspect the entire

length of air piping to ensure piping

is intact and all joints are properly

sealed.

2. Call your qualifi ed service technician

if you notice any problems.

14.1.16 - Check

condensate drain system

1. Inspect the condensate drain line,

condensate fi ttings and condensate

trap for signs of weeping or leakage.

2. If you detect signs of leakage,

immediately contact your qualifi ed

service technician to inspect the

boiler and system.

14.1.17 - Check boiler

piping (gas and water)

1. If gas odor or leak is detected,

immediately shut down the boiler

following the procedures on page 3.

Call a qualifi ed service technician.

2. Visually inspect for leaks around

water piping. Also inspect the

circulators, relief valve, and fi ttings.

Immediately call a qualifi ed service

technician to repair any leaks.

WARNING!!!

fi xed at once by a qualifi ed

service technician. Failure to

comply could result in severe

personal injury, death, or

substantial property damage.

Have leaks

14.1.18 - Shut boiler down

(unless boiler is used for

Domestic Water)

1. Follow “To Turn Off Gas to Appliance”

on page 3 of this manual.

2. Do not drain the system unless

exposure to freezing temperatures

will occur.

3. Do not drain the system if it is fi lled

with an antifreeze solution.

4. DO NOT shut down boilers used for

domestic water heating, they must

operate year-round.

85

Page 14

14 - MAINTENANCE

14.2 - Removing the

casing

In order to remove the casing, follow

the steps below while refering to

Figure 14-1:

1. remove screws “A”;

2. raise latch “C”;

3. remove the front cover;

4. press the two plastic springs, item

“L”, down;

5. lower the electrical box;

6. lift latch “G”;

7. pull the bottom of cover “H” out by

around 4 in (10 cm);

8. lift cover “H” up by around 1in (2

cm) and remove it.

Figure 14-1 Removing the casing

86

Page 15

14 - MAINTENANCE

14.3 - Cleaning the

burner and primary

heat exchanger,

fl ue gas side

Burner and primary heat exchanger

must be checked every year and

cleaned if required. To correctly clean

the burner and the fl ue gas side of

the heat exchanger follow the steps

below:

WARNING!!!

proceeding to the next step,

verify that the electrical supply

to the boiler, and any other

electrical supply near the

boiler, is off. Failure to comply

with this warning can cause

extensive property damage,

severe personal injury or

death!

1. follow the steps in Section 14.2

to gain access to the sealing

chamber;

2. unscrew nut “D” (Figure 14-2) from

the gas valve (taking care not to

lose gasket “E” in Figure 14-4);

3. disconnect the two wires from the

ignition electrodes and the wire

from the fl ame detection electrode,

Figure 3-1, details “47” and “50”;

4. disconnect the wire from safety

sensor “F” in Figure 14-2;

5. unscrew the four nuts “C” in Figure

14-2;

Before

6. prepare a suitable cover for the

gas valve outlet under nut “D” so

that no dirt, water, or other foreign

objects can fall into the gas valve

during cleaning;

7. remove the entire fan - burner

assembly, detail “A” in Figure 14-2;

8. use a cylindrical brush with plastic

bristles to clean the inside of the

combustion chamber, detail “H” in

Figure 14-2;

9. use a vacuum cleaner to remove

any unburned residue from the

combustion chamber “H” in fi gure

14-2;

10. using the same vacuum cleaner,

clean the surfaces of the burner

and around the electrodes;

WARNING!!!

performing the next step,

carefully wash only the inside

of the combustion chamber

“H” of Figure 14-2, and do not

get water on the outside of the

combustion chamber opening.

Failure to comply with this

warning can cause extensive

property damage, severe

personal injury or death!

while

11. using only water, wash the inside

of the combustion chamber, detail

“H” in Figure 14-2. The water, will

drain into the condensate drain.

Clean the condensate trap (see

Section 14.6) before reassembling

components;

12. reassemble the components by

proceeding in reverse order;

13. open the manual gas shutoff

valve;

14. restore electrical power to the

boiler;

15. check that there are no gas leaks.

WARNING!!!

an open fl ame to test for gas

leaks. Always use an approved

leak detection method. Failure

to comply with this warning

can cause extensive property

damage, severe personal injury

or death!

Never use

Figure 14-2 Remove the fan-burner assembly unit

87

Page 16

14 - MAINTENANCE

14.4 - Correct

positioning of

the ignition and

fl ame detection

electrodes

For the boiler to work properly the

electrodes must be positioned as

shown in Figure 14-3:

the distance between the ignition

electrodes “A” and “B”, must be

between 0.08 in (2 mm), and 0.10

in (2.5 mm);

the distance of the ignition

electrodes to the burner surface

must be between 0.20 in (5.0 mm),

and 0.22 in (5.5 mm);

the distance of the fl ame detection

electrode to the burner surface

must be between 0.23 in (6.0 mm),

and 0.27 in (7.0 mm).

A = Left ignition electrode

B = Right ignition electrode

C = Flame detection electrode

Figure 14-3 Positioning electrodes on burner

(Use a hand caliper to verify the distances of the

electrodes)

NOTE: To insure correct

functioning of boiler the distances

listed above shall be verifi ed with a

hand caliper.

14.5 - Domestic

hot water heat

exchanger (only for

160-C model)

The production of DHW takes place

in the secondary heat exchanger,

detail “42” in Figure 3-1. If this heat

exchanger loses effi ciency over

time, it may be necessary to clean or

replace it.

88

Page 17

14 - MAINTENANCE

14.6 - Condensate

trap cleaning

The condensate trap must be checked

every year and cleaned if required.

Follow the steps below to properly

clean the condensate trap and its

associated components while referring

to Figure 14-4:

1. turn the power switch to on, item

“12” in Figure 13-1;

2. press the and keys

together for more than 10 seconds,

until a blinking is displayed;

3. the combustion blower will run at

maximum speed for 10 minutes.

During this time the burner will not

light. This will minimize the amount

of liquid present in the trap, item

“A”;

4. press the button

WARNING!!!

proceeding to the next step,

verify that the electrical supply

to the boiler, and any other

electrical supply near the

boiler, is off. Failure to comply

with this warning can cause

extensive property damage,

severe personal injury or death!

5. follow the steps in Section 14.2

to gain access the internal

components;

6. carefully cover the electrical panel

“B” with a waterproof material to

prevent water from entering the

electrical system;

7. grip spring clamp “G” with a pair of

pliers and slide it downwards;

8. pull the condensation trap hose “H”

off the trap;

9. remove the fan-burner assembly

unit, follow steps of section 14.3;

10. cover the gas valve outlet

to ensure that no objects or

condensate water enters the gas

valve;

11. disconnect the condensate hose

“O” from the condensate trap “A”.

12. unscrew nut “I” from the bottom of

the trap, “A”, and pull it upwards,

taking care not to spill the

condensation;

13. open the condensate trap taking

care not to lose o ring “L” and clean

the inside “M”;

14. re-assemble everything in reverse

order, taking care that oring “L” is

placed in the proper location;

15. refi ll the condensate trap per

Section 12.1.2.

16. open the manual gas shutoff valve;

17. restore electrical power to the

boiler;

18. check that there are no gas leaks.

Before

Figure 14-4 Removing the condensing trap

89

WARNING!!!

an open fl ame to test for gas

leaks. Always use an approved

leak detection method. Failure

to comply with this warning

can cause extensive property

damage, severe personal injury

or death!

Never use

Page 18

14 - MAINTENANCE

Figure 14-5 Replacing the pump motor (only for 160-C

model)

14.7 - Circulator

pump motor

replacement (only

for 160-C model)

To replace the circulator pump follow

the steps below while, refering to

Figure 14-5:

1. follow the steps in Section 14.10 to

isolate and drain the water from the

boiler;

2. follow the steps in Section 14.2

to gain access the internal

components;

3. remove screws “B”;

4. remove the circulator pump motor

“A”;

5. label the electrical wires of the

circulator pump motor, phase and

neutral must be respected;

6. disconnect the electrical wires from

the circulator pump motor

7. install the new circulator pump

motor and reassemble the boiler

8. open the heating system isolation

valves and heating system fi ll valve

9. follow the steps in Section 12.1.3

to bleed the air from the heating

system.

NOTE: If display shows L05 reverse

polarity (phase and neutral) to the

pump

90

14.8 - Expansion

tank pressure (only

for 160-C model)

To check the expansion tank pressure

follow the steps below:

1. follow the steps in Section 14.10 to

isolate and drain the water from the

boiler

2. follow the steps in Section 14.2,

to gain access the internal

components;

3. check the pressure of the

expansion tank, item “4” of Figure

3-1 (The air inlet probe is on the

top of the expansion tank). It must

be 14 psi (1 bar). If the pressure is

lower recharge the expansion tank

while letting the water run out of the

heating system drain valve.

Page 19

14 - MAINTENANCE

Figure 14-6 Supply fi ttings removal (only for

160-C model)

14.9 - 3-way valve

removal (only for

160-C model)

The 3-way valve, details “M” and “Q”

in Figures 14-6 and 14-7, directs hot

water produced by the primary heat

exchanger to the heating circuit or to

the secondary heat exchanger for the

production of D.H.W. To replace or

clean it, follow the steps below while

referring to Figures 14-6 and 14-7:

1. follow the steps in Section 14.10

and 14-11 to isolate and drain the

water from the boiler;

2. follow the steps in Section 14.2,

to gain access the internal

components;

3. disconnect fi ttings “A”;

4. remove screws “C”;

5. rotate “D” fl ange in the direction of

the black arrow (See particular fi g.

1);

6. remove the bracket “E”;

5. remove fi tting “F”;

6. remove fi tting “L”;

7. remove fi tting “M” and check its

state.

8. remove spring “N”;

9. remove servomotor “O”;

10. remove the fi tting “P”

11. remove the spring “Q” and check

for any dirt.

Figure 14-7 3-way valve servomotor removal

91

Page 20

14 - MAINTENANCE

14.10 - Draining the

heating side of the

boiler

To drain the heating side of the boiler

follow the steps below:

1. cool boiler turning knob “7” in

Figure 13-1 to 114°F (45°C). Wait

until the display, item “1” in Figure

13-1, shows a temperature less

than 114°F (45°C);

2. turn off the boiler;

3. shut off electrical power to the

boiler;

4. close the manual gas shutoff valve,

Figure 11-1;

5. close the boiler isolation valves,

in the heating system. If isolation

valves haven’t been installed, the

entire heating system will have to

be drained.

6. close the heating system fi ll valve;

7. follow the steps in Section 14.2,

to gain access the internal

components;

8. connect a hose to the boiler drain

valve intem “4” in Figure 7-6 and

7-7, and place the other end in a

sink or some other suitable drain;

9. open the boiler drain valve and

drain the boiler;

10. if boiler isolation valves have

not been installed in the heating

system open any bleed valves at

the highest point of the system;

11. after draining out all the water,

close the bleed valves and the

boiler drain valve;

NOTICE: The boiler cannot be

drained completely of water without

purging the unit with an air pressure

of 15 psi.

WARNING!!!

recover and/or re-use water

drained from the heating

circuit for any purpose as it

could be contaminated. Failure

to comply with this warning

can cause extensive property

damage, severe personal injury

or death!

Do not

14.11 - Draining the

domestic hot water

side of the boiler

To drain the domestic hot water side

of the boiler follow the steps below:

1. turn off the boiler;

2. close the valve in the water main

supplying the DHW system;

3. open all the hot and cold faucets in

the building;

4. if there isn’t a faucet or drain valve

below the boiler level, disconnect

DHW connections “10” and “12” in

Figure 3-1.

14.12 – Overrides

To carry out specifi c checks covered

in the manual, it is possible to override

the control logic of the boiler. See the

following sections:

14.12.1 - Auto-purging

To reset the auto-purging procedure

press the and keys

together for 10 seconds. When the

blinking appears on the display,

press .

14.12.2 - Fan

To run just the fan at full speed press

the and keys together

for 10 seconds, until the blinking

appears on the display. The fan

will run at full speed for 10 minutes. To

shut the fan off before the 10 minutes

is up press the

14.12.3 – Minimum and

maximum output

The boiler can be run at its minimum

or maximum output in both the

heating and domestic hot water

modes by following the steps below:

1. generate a demand for the mode to

be overridden:

- for heating turn up the room

thermostat and turn knob “7” in

Figure 13-1 to its maximum;

key.

- for domestic hot water turn

knob “11” in Figure 13-1 to its

maximum and fully open a hot

water faucet;

2. press the and keys

together for more than 10 seconds,

until a blinking appears on

the display;

3. press the key until the

display shows:

- for minimum heating

output;

- for maximum heating

output adjusted by P parameter,

see section 12.10;

- for maximum heating

output;

- for minimum DHW output;

- for maximum DHW output;

4. press the key in order to

restore the boiler to normal running

conditions.

14.12.4 – Checking the

fl ame current

While running at the minimum and

maximum output described in Section

14.12.3, the display will show the

letter of the mode checked. In the

second part of the display the value

of the ionization current will be

shown. 30 corresponds to a current

of 1 uA, 99 to a current of 5.5 uA.

The fl ame current must always be at

the correspondent value as shown

in Section 15, header “ionisation

current”. If the value is not within the

above values, check:

a - positioning of the fl ame sensor

electrod as per section 14.4;

b - CO2 content as per section 12.9;

c - combustion air pressure as per

section 12.8.

92

Page 21

14 - MAINTENANCE

14.13 - Water and

fl ue temperature

sensor

The boiler has a number of sensors

that measure temperature. The

electrical resistance between the

sensor wires must correspond with

the values shown in Figure 14-8.

The temperature sensors are: U1; U2,

U3, U5, U6, U7 and U8. The location

of each sensor can be found in Figure

3-1 and Section 14.15 and 14.16.

Figure 14-8 Water temperature sensors’ curve

14.14 - Outdoor

temperature sensor

(optional)

An outdoor temperature sensor

can be connected to the boiler

(see section 8.1.4). The electrical

resistance existing between the

sensor wires must correspond with

the values shown in Figure 14-9.

Figure 14-9 Outdoor temperature sensor curve

93

Page 22

WARNING!!!

14 - MAINTENANCE

14.15 - Functional

wiring diagram

WARNING!!!

Label all wires prior

to disconnection when servicing

controls. Wiring errors can cause

improper and dangerous operation!

Verify proper operation after

servicing Failure to comply with

this warning can cause extensive

property damage, severe personal

injury or death!

ATTENTION!!!

Au moment

de l’entretien des commandes,

étiquetez tous les fi ls avant de les

débrancher. Des erreurs de câblage

peuvent entraîner un fonctionnement

inadéquat et dangereux. S’assurer

que l’appareil fonctionne

adéquatement une fois l’entretien est

terminé.

LEGEND:

ALA - Alarm output

CM - Power control board

CR - Remote command (only for outdoor models)

EA - Ignition electrode

ER - Flame detection electrode

EPO - External pump (REQUIRED FOR MODEL 160-B)

EV3V - External three way valve (optional)

F1 - Fuse 2Amps

FPS - Flue pressure switch

GS - Spark generator

IG - Main electrical switch

J1 - Six poles connector

J2 - Four poles connector

J3 - Twelve poles connector

J4 - Four poles connector

J5 - Sixteen poles connector

J10 - Ten poles connector

J18 - Height poles connector

U1 - Supply temperature sensor

U2 - Domestic hot water temperature sensor

U3 - Domestic cold water temperature sensor

U3 TANK - Storage tank temperature sensor (optional)

U4 - Outside temperature sensor (optional)

U6 - Heating Safety high limit temperature sensor

U7 - Flue gases temperature sensor with integrated safety

high limit switch

U8 - Return temperature sensor

PO1 - Heating pump

PR - Heating pressure switch

SDC - Electrical connection board

RT1 - Room thermostat connection

RT2 - Room thermostat connection on remote control

“CR” (optional)

VE - Fan

VG1 - Gas valve

V3V - Three way valve

94

Page 23

14 - MAINTENANCE

95

Page 24

WARNING!!!

14 - MAINTENANCE

14.16 - Multiwire

wiring diagram

WARNING!!!

wires prior to disconnection

when servicing controls. Wiring

errors can cause improper and

dangerous operation! Verify proper

operation after servicing Failure

to comply with this warning can

cause extensive property damage,

severe personal injury or death!

ATTENTION!!!

de l’entretien des commandes,

étiquetez tous les fi ls avant de

les débrancher. Des erreurs

de câblage peuvent entraîner

un fonctionnement inadéquat

et dangereux. S’assurer

que l’appareil fonctionne

adéquatement une fois

l’entretien est terminé.

Label all

Au moment

LEGEND:

ALA - Alarm output

CM - Power control board

CR - Remote command (only for outdoor models)

EA - Ignition electrode

ER - Flame detection electrode

EPO - External pump (REQUIRED FOR 160-B model)

EV3V - External three way valve (optional)

F1 - Fuse 2Amps

FPS - Flue pressure switch

GS - Spark generator

IG - Main electrical switch

J1 - Six poles connector

J2 - Four poles connector

J3 - Twelve poles connector

J4 - Four poles connector

J5 - Sixteen poles connector

J10 - Ten poles connector

J18 - Height poles connector

U1 - Supply temperature sensor

U2 - Domestic hot water temperature sensor

U3 - Domestic cold water temperature sensor

U3 TANK - Storage tank temperature sensor (optional)

U4 - Outside temperature sensor (optional)

U6 - Heating Safety high limit temperature sensor

U7 - Flue gases temperature sensor with integrated safety high limit switch

U8 - Return temperature sensor

PO1 - Heating pump

PR - Heating pressure switch

SDC - Electrical connection board

RT1 - Room thermostat connection

RT2 - Room thermostat connection on remote control “CR” (optional)

VE - Fan

VG1 - Gas valve

V3V - Three way valve

96

Page 25

14 - MAINTENANCE

97

Page 26

15 - TECHNICAL DATA

MODEL VSL-160-B; VSL-160-C;

Country of destination USA and Canada

Type of boiler Direct Vent and room combustion air

Category of discharge chimney IV

CSA certifi cate N° 2045300 (114696)

Maximum Heat input Btu/hr 160,000

Minimum heat input Btu/hr 30,000

Effi ciency at maximum heat input (160°F/140°F) % 93

Maximum Heat output (160°F/140°F) Btu/hr 148,800

Effi ciency at minimum heat input (122°F/86°F) % 97

Minimum heat output (122°F/86°F) Btu/hr 29,100

Certifi ed AFUE rate % 91.5

Gas fl ow rate Natural gas ft3/hr 156

LP Gas gal/hr 1.75

Gas supply pressure Natural gas In.W.C. 7

LP Gas In.W.C. 11

Minimum gas supply pressure Natural gas In.W.C. 3

LP Gas In.W.C. 3

Maximum gas supply pressure Natural gas In.W.C. 13

LP Gas In.W.C. 13

Combustion air pressure with min. length Natural gas In.W.C. 2.5 to 3.1

LP Gas In.W.C. 2.1 to 2.7

Combustion air pressure with max. length Natural gas In.W.C. 2.1 to 2.7

LP Gas In.W.C. 1.8 to 2.4

Instantaneous d.h.w production [rise 75°F (42°C)] gal/min 4.32

Maximum heating temperature °F 189

Minimum heating temperature °F 68

Maximum heating pressure PSI 30

Minimum heating pressure PSI 8

Maximum pressure of domestic hot water circuit PSI 150

Minimum pressure of domestic hot water circuit PSI 1

Capacity of expansion tank (160-C model only) gal 2.64

Supply voltage 120Vac - 60Hz

Absorbed electric power W 170

Flue gas pipes diameter (split) “ (mm) 3.15” (80)

Max. length fl ue gas pipes (split) ft 300

Flue gas pipes diameter (coaxial) “ (mm) 2.36/3.94 (60/100)

Max. length fl ue gas pipes (coaxial) ft 70

Equivalent length of one elbow ft 45° elbow = 3ft, 90° elbow = 5ft

CO (Carbon monoxide) with natural gas ppm <150

CO (Carbon monoxide) with LP gas ppm <250

NOx (0% O2 with natural gas) ppm <30

CO2 (Carbon dioxide) for Natural gas at high fi re % 9.1 to 9.3

CO2 (Carbon dioxide) for Natural gas at low fi re % 8.4 to 9

CO2 (Carbon dioxide) for LP gas at high fi re % 9.3 to 9.7

CO2 (Carbon dioxide) for LP gas at low fi re % 9.2 to 9.8

O2 (Oxygen) for Natural gas at high fi re % 4.4 to 4.6

O2 (Oxygen) for Natural gas at low fi re % 5.1 to 5.7

O2 (Oxygen) for LP gas at high fi re % 5.7 to 5.9

O2 (Oxygen) for LP gas at low fi re % 6.1 to 6.7

Ionisation current 71 to 90

Maximum fl ue gas temperature °F 210

Flue gas mass-fl ow lb/hr 160

Head pressure available for fl ue vent/air intake line In.W.C. 3.6

Maximum condensation fl ow rate gal/hr 1.32

Average acidity of condensation PH 4

Boiler weight (empty of water) (160-C model) lb 125

Boiler weight (empty of water) (160-B model) lb 93

98

Page 27

16 - SPARE PARTS

99

Page 28

16 - SPARE PARTS

100

Page 29

16 - SPARE PARTS

101

Page 30

16 - SPARE PARTS

Bottom side of the 160-B model

Spare parts list

1 - 81 9010 000 - CABLE UL IGNITOR CONN 90° L155

2 - 81 9011 000 - NUT ZINC COATED 6MA

3 - 81 9012 000 - SILICONE PIPE D 4X8

4 - 81 9013 000 - TEE FOR DRY WATER CONDENSATION

5 - 81 9014 000 - SPARK GENERATOR NO CABLE UL

6 - 81 9015 000 - SENSOR NTC 10 KOHM A KLIP DIAM.22

7 - 81 9016 000 - COPPER PIPE D22 M/F 3/4”G-1”G

8 - 81 9017 000 - 3/4” RING NUT

9 - 81 9018 000 - O-RING NBR 2,62 X 20,63

10 - 81 9019 000 - PRIMARY HEAT EXCHANGER C.R.R ASME

11 - 81 9020 000 - GASKET EPDM X OSSIDO D84 H7

12 - 81 9021 000 - SENSOR NTC 10 KOHM 1/8”

13 - 81 9022 000 - GASKET COPPER 1/8” SP.1,5

14 - 81 9023 000 - SILICONE TAP

15 - 81 9024 000 - SCREW 6X35 ZINC TC-CR

16 - 81 9025 000 - WASHER 6X18X1,5 PIA-ZIN-LAR UNI6593

17 - 81 9026 000 - BRACKET SIPHON L84 H130 P32

18 - 81 9027 000 - O-RING 134 EPDM 3,53 X 25,8

19 - 81 9028 000 - SCREW SELFTAPPING 3.9 X 9.5 CROSS HEAD

20 - 81 9029 000 - SIPHON

21 - 81 9030 000 - SCREW SELFTAPPING 2.9 X 6.5 CROSS HEAD

22 - 81 9031 000 - SPRING 28,7

23 - 81 9032 000 - PRESSURE SWITCH ON 4,5 INWC

24 - 81 9033 000 - BRACKET PRESSURE SWITCH

25 - 81 9034 000 - POLIETYLENE PIPE L=1000

26 - 81 9035 000 - SEALING CHAMBER DOOR

27 - 81 9036 000 - 1P GASKET

28 - 81 9006 000 - PUMP GRUNDFOS UP 15/58U BRUTE USA

29 - 81 9038 000 - COPPER PIPE D22 RETURN SEALING CHAMBER

30 - 81 9039 000 - SENSOR NTC 10K BAIO

31 - 81 9040 000 - OUTDOOR SENSOR

32 - 81 9041 000 - SCREW 4,8X19 ZINC AF TC-CR UNI6954

33 - 81 9042 000 - PLUG FOR FLUE AIR FITTING

34 - 81 9043 000 - O-RING 2050 EPDM 1,78 X 12,42

35 - 81 9044 000 - DISCHARGE RACCORD PP

36 - 81 9045 000 - GASKET ROUND SPONGE D.3,5 MM IP44 S3

37 - 81 9046 000 - AUTOMATIC AIR VENT

102

Page 31

16 - SPARE PARTS

38 - 81 9047 000 - 3/8G MALE to 1/8NPT FEMALE BUSHING

39 - 81 9048 000 - GASKET EPDM D38 F20 SP6

40 - 81 9049 000 - 45xx WALL MOUNTING BRACKET

41 - 81 9050 000 - SCREW SELFTAPPING 5X50 WOOD

42 - 81 9051 000 - EXP TANK LT. 8 561X203X80 RETT.

43 - 81 9052 000 - GLASS WINDOW WITH GASKET

44 - 81 9053 000 - 3/8” G GASKET

45 - 81 9054 000 - FAIRLEAD 6 POLES SILICONE

46 - 81 9055 000 - EXP TANK PIPE

47 - 81 9056 000 - PLASTIC CAP TPP 8.5

48 - 81 9057 000 - TANK SENSOR

49a - 81 9058 000 - EXTERNAL JACKET 500X840X245 WITHOUT DOOR

50 - not used

51 - not used

52a - 81 9191 000 - VSL 160 LP TO NATURAL CONVERSION KIT

53a - 81 9190 000 - VSL 160 NATURAL TO LP CONVERSION KIT

54a - 81 9063 000 - VSL 160 USER’S INSTRUCTIONS

55a - 81 9506 000 - VSL 160 INSTALLER’S INSTRUCTIONS FROM S/N 12130000

56 - 81 9065 000 - BURNER HEAD

57 - 81 9066 000 - EXTRUSION L.25MM

58 - 81 9067 000 - THERM. INSULATION VERMICULITE D117 F74 SP21,5

59 - 81 9068 000 - GASKET. SIL. D157 F145 H6,7

60 - 81 9069 000 - BASE MANIFOLD AIR ALUMINUM

61 - 81 9070 000 - GASKET SIL.MANIFOLD FAN D83 SP3,5

62 - 81 9071 000 - SCREW SELFTAPPING 4X12 TC S-TT UNI-8112

63 - 81 9072 000 - MANIFOLD AIR CUTTED

64 - 81 9073 000 - MIXER AIR/GAS “COSMOMIX”

65 - 81 9074 000 - O-RING 3350 NBR 2,62 X 88,57

66 - 81 9075 000 - O-RING 3200 NBR 2,62 X 50,47

67 - 81 9076 000 - DIAPHRAGM COSMOMIX 9 HOLES D.10

68 - 81 9077 000 - O-RING 165 NBR 3,53 X 61,91

69 - 81 9078 000 - FAN 45 KW USA

70 - 81 9079 000 - BACK FLUE-GASES PREVENTER

71 - 81 9080 000 - O-RING 3825 SIL 2,62 X 209,22

72 - 81 9081 000 - COVER MANIFOLD AIR ALUMINUM

73 - 81 9082 000 - SCREW SELFTAPPING 4X10 TC S-TT UNI-8112

74 - 81 9083 000 - SELFTAPPING BOLT 6.3X38

75 - 81 9084 000 - GASKET FRIZITE D15,5 F11,5 SP1,5

76 - 81 9085 000 - GLASS PIREX D15,5 SP3,3

77 - 81 9086 000 - FLANGE L21,2 H34

78 - 81 9087 000 - SCREW SELFTAPPING 4X8 TC S-TT NI-8112

79 - 81 9088 000 - LEFT IGNITION ELECTRODE

80 - 81 9089 000 - RIGHT IGNITION ELECTRODE

81 - 81 9090 000 - DETECTION ELECTRODE

82 - 81 9091 000 - SCREW 5X12 EXAGONAL HEAD

83 - 81 9092 000 - SPRING MIXER

84 - 81 9093 000 - O-RING 3056 NBR (118) 2,62X13,95

85 - 81 9094 000 - GAS PIPE (SIT) USA

86 - 81 9095 000 - GASKET 3/4P 24X15X2 KLINSIL

87 - 81 9096 000 - SCREW 4X10 ZINC TC-CR

88 - 81 9097 000 - FLANGE GAS 32X32 3/4P

89 - 81 9098 000 - O-RING 130 2,62 X 22,22

90 - 81 9099 000 - GAS VALVE SIGMA848 120V

91 - 81 9100 000 - BOLT 5X12 CROSS HEAD

92 - 81 9101 000 - PIPE D18 F/F 3/4P-3/4P SIT USA

93 - 81 9102 000 - CONTROL KNOB S3

94 - 81 9103 000 - O-RING NBR 1,6 X 11,1

95 - 81 9104 000 - FRONT INTERFACE

96 - 81 9105 000 - TREE POTMETER-KNOB

97 - 81 9106 000 - KEYS RUBBER 3 POSITIONS

98 - 81 9107 000 - PRESSURE GAUGE DIAM.38 - 1/4” PSI

99 - 81 9108 000 - MAIN SWITCH

100 - 81 9109 000 - BASE ELECTRICAL BOX

101 - 81 9110 000 - FAIRLEAD SX

102 - 81 9111 000 - FAIRLEAD DX

103 - 81 9112 000 - POWER CONTROL BOARD PHC 120V

104 - 81 9113 000 - SCREW 4X8 ZINC TC-CR DIN4042

105 - 81 9114 000 - JUNCTION BOARD 45

106 - 81 9115 000 - INTERFACE OPENTERM

107 - 81 9116 000 - COVER ELECTRICAL BOX

108 - 81 9117 000 - FAIRLEAD 7 EXIT

109 - 81 9118 000 - COVER JUNCTION BOX

110 - 81 9119 000 - COPPER PIPE D.22 SUPPLY SEALING CHAMBER

111 - 81 9120 000 - 3 WAY VALVE MOTOR 120V

112 - 81 9121 000 - PLUG PISTON BODY OT.

113 - 81 9122 000 - SPRING FORCK 3V

114 - 81 9123 000 - UPPER PISTON

115 - 81 9124 000 - HYDRONIC SUPPLY GROUP.

116 - 81 9125 000 - HEATING PRESSURE SWITCH

117 - 81 9126 000 - GASKET COPPER 1/4P

118 - 81 9127 000 - SCREW 5X18 ZINC TC-ES-INC UNI5931

119 - 81 9128 000 - ASME SAFETY RELIEF VALVE

120 - 81 9129 000 - BRASS NIPPLE 1” - 3/4”

121 - 81 9130 000 - COVER PISTON HEATING

122 - 81 9131 000 - PISTON HEATING SIDE

123 - 81 9132 000 - PLUG BRASS 1/4P M WITH O-RING

124 - 81 9133 000 - NIPPLE OT 1”-22X1,5 MM

125 - 81 9134 000 - O-RING 2075 EPDM 1,78 X 18,77

126 - 81 9135 000 - HYDRONIC RETURN GROUP

127 - 81 9136 000 - BY-PASS VALVE

128 - 81 9137 000 - 3/8” MALE CAP

129 - 81 9138 000 - DOMESTIC HEAT EXCHANGER “ACQUAJET”

130 - 81 9139 000 - SENSOR NTC 10 KOHM KLIP WITH SCREW

131 - 81 9140 000 - NUT ZINC COATED 4MA

132 - 81 9141 000 - O-RING 3037 EPDM 2,62 X 9,19

133 - 81 9142 000 - PURGING PIPE

134 - 81 9143 000 - PURGING VALVE M10X1

135 - 81 9144 000 - FORCK BY-PASS PIPE

136 - 81 9145 000 - BY-PASS PIPE

137 - 81 9146 000 - O-RING 4075 EPDM 3,53 X 18,64

138 - 81 9147 000 - FRONT THERM. INSULATION “ACQUAJET”

139 - 81 9148 000 - REAR THERM. INSULATION “ACQUAJET”

140 - 81 9149 000 - BRACKET EXAGONAL HOLES SHORT

141 - 81 9150 000 - BRACKET EXAGONAL HOLES LONG

142 - 81 9151 000 - NIPPLE OTT 3/4NPT-3/4P USA

143 - 81 9152 000 - BRACKET EXAGONAL HOLE SMALL

144 - 81 9153 000 - 1/2” G GASKET

145 - 81 9154 000 - FAIRLEAD PA 107 SCREW HILO 3,5X14,5

146 - 81 9155 000 - CONNECTION BRASS 3/4P TO 1P

147 - 81 9156 000 - CONNECTION BRASS 1/2P TO 1P