10 - INSTALLATION - Vent and combustion air

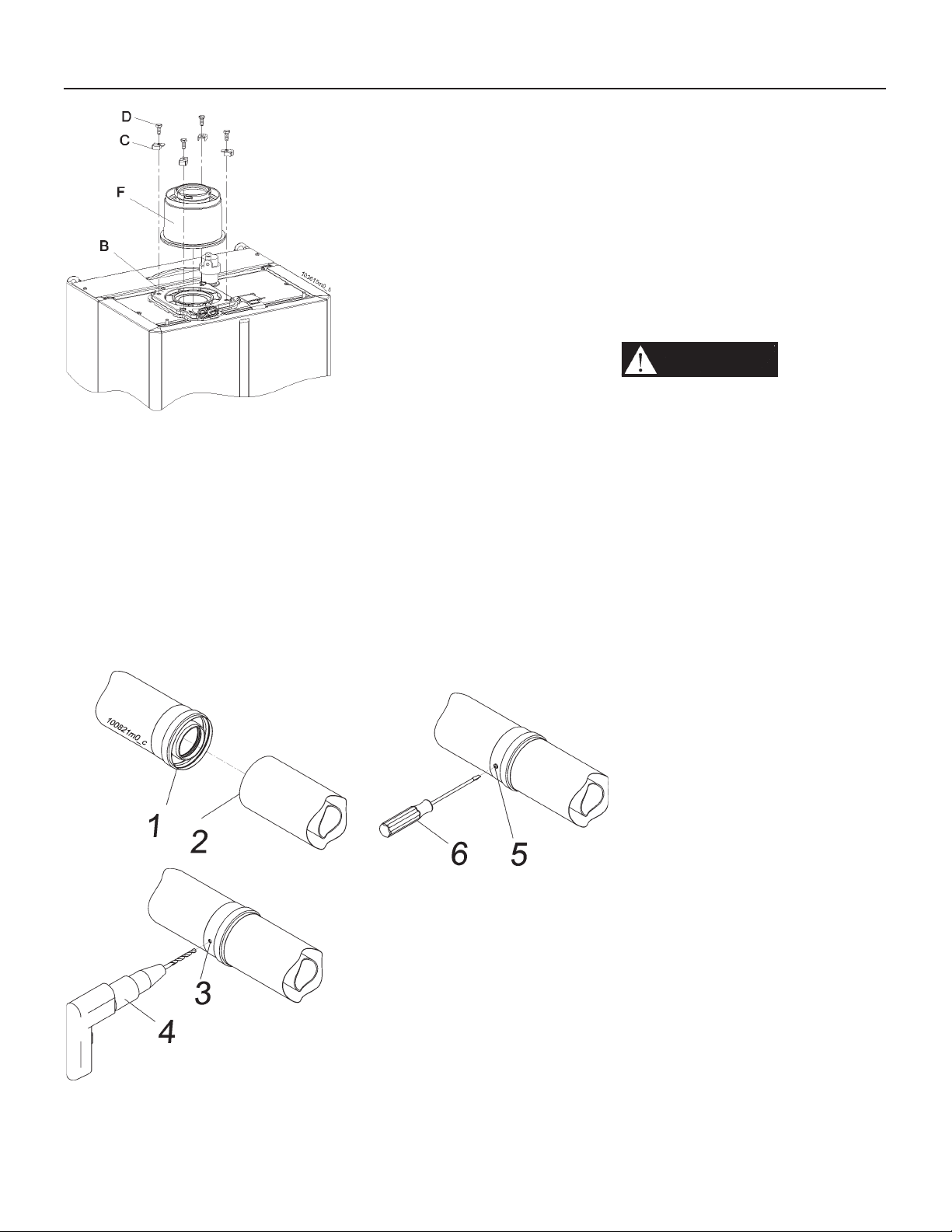

2. insert the clamp “D” into convertor

“A” in the “C” side.

3. insert the adapter “E” into connection

“C” of the convertor “A”;

4. use the precedent clamp “D” to

mechanically secure the adapter “E”

to the adapter “A”. To do this tighten

the half clamp on the adapter “A”

and half clamp on the adapter “E”.

Tight the clamps with a tork of 1.5 - 2

lbf ft (2-3 Nm).

5. insert the clamp “F” into convertor

“E”.

6. insert the air inlet PVC/CPVC pipe,

for 2” into the adapter “E”;

7. use the precedent clamp “F” to

mechanically secure the pipe to

the adapter “E”. To do this tighten

the half clamp on the pipe and half

clamp to the adapter “E”. Tight the

clamps with a tork of 1.5 - 2 lbf ft

(2-3 Nm).

Vent connection (see Figure

10-8 Item “B”). This connection

is used to provide a passageway for

conveying combustion gas to the

outside. Vent piping must be supported

per the National Building Code, Section

305, Table 305.4 or as local codes

dictate.

To connect a PVC/CPVC pipe to the

vent connection proceed as follow

while referring to Figure 10-8:

1. install boiler adapter “A” above

boiler. Rotate boiler adapter “A” so

as air intake and vent connections

are in the desired left or right side.

Check stamped arrow to understand

which is the vent and air intake

connection.

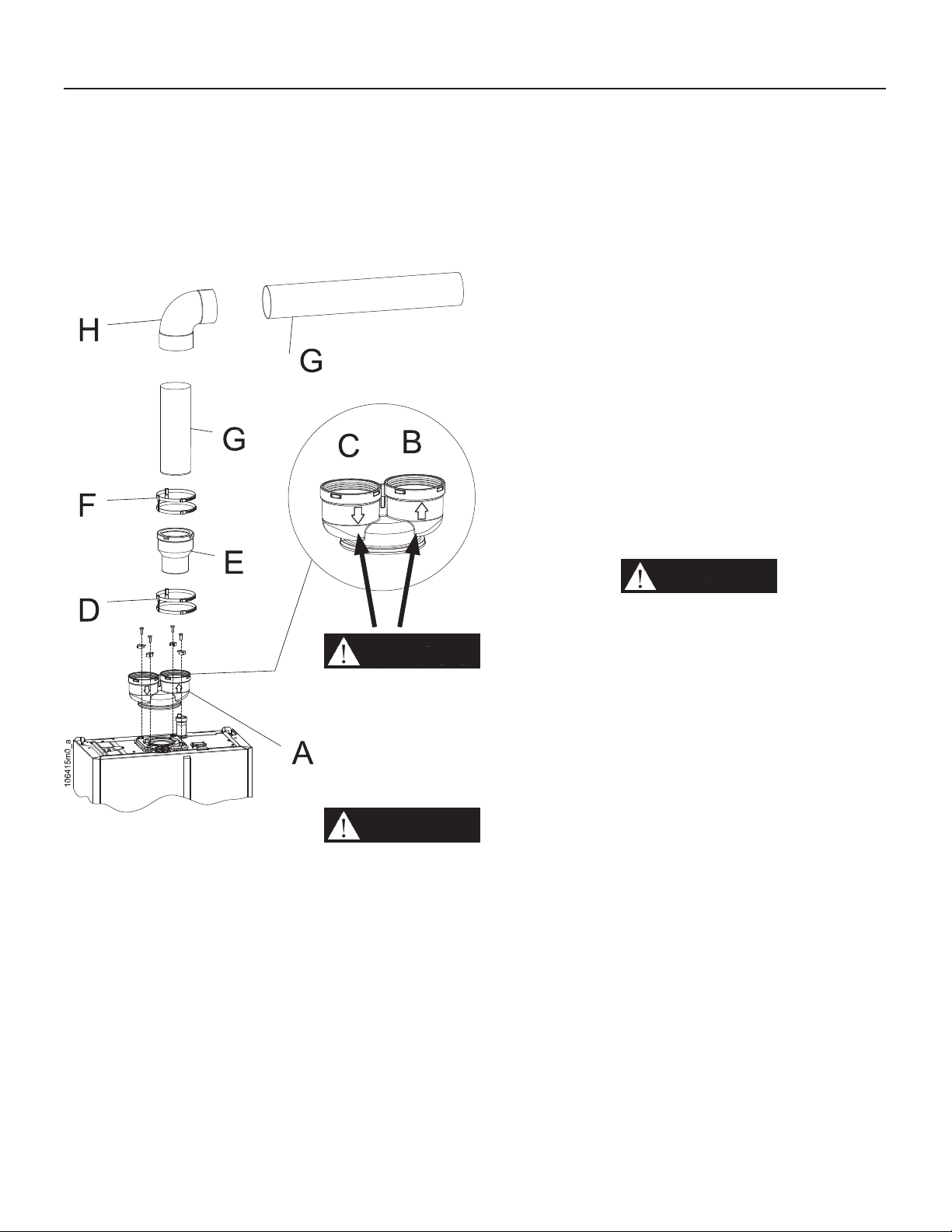

A = Two pipes boiler adapter

B = Flue exhaust connection

C = Air intake connection

D = Fixing clamp

E = PVC/CPVC adapter

F = Fixing clamp

G = PVC/CPVC pipe

H = 90° elbow

WARNING!!!

arrow on boiler adapter for the

correct side of fl ue exhaust and

air intake. Failure to follow this

warning could result in excessive

levels of carbon monoxide or a

fi re, which can result in severe

personal injury or death!

WARNING!!!

PVC/CPVC exhaust pipe nor

install into an enclosure or

any other obstruction thereby

preventing the cooling of the

exhaust pipe. Failure to follow

this warning could result in

excessive levels of carbon

monoxide or a fi re, which can

result in severe personal injury or

death!

Check stamped

Do not insulate

WARNING!!!

stamped arrow on boiler adapter

for the correct side of vent.

Failure to follow this warning

could result in excessive levels

of carbon monoxide or a fi re,

which can result in severe

personal injury or death!

2. Insert one side of clamp “D” onto the

air intake of boiler adapter “A” (side

C).

3. Insert adapter “E” into side “C” of

boiler adapter “A”;

4. Use clamp “D” to mechanically

secure adapter “E” to boiler adapter

“A”. To do this, tighten one side of

clamp “D” onto boiler adapter “A”

and the other half of clamp “D” onto

adapter “E”. Tight the clamps with a

tork of 1.5 - 2 lbf ft (2-3 Nm).

5. Insert clamp “F” into adapter “E”.

6. Insert the PVC/CPVC pipe “G”, into

adapter “E” for at least 2”;

7. Use clamp “F” to mechanically

secure pipe “G” to adapter “E”. To

do this, tighten one side of clamp “F”

onto pipe “G” and the other side of

clamp “F” to the adapter “E”. Tight

the clamps with a tork of 1.5 - 2 lbf ft

(2-3 Nm).

Check

Figure 10-8 PVC/CPVC Venting connection

37

10 - INSTALLATION - Vent and combustion air

10.8 - Stainless

steel vent piping

materials

WARNING!!!

materials, vent systems, and

terminations listed in Tables

10-1 and 10-2. DO NOT mix

vent systems of different types

or manufacturers, unless

listed in this manual. Failure to

comply could result in severe

personal injury, death, or

substantial property damage.

Use only the

WARNING!!!

appliance requires a special

venting system. The fi eld

provided vent fi ttings must

be connected to the boiler

following Section 10.8.1.

Failure to follow this warning

could result in fi re, personal

injury, or death.

WARNING!!!

installation of Stainless steel

systems may result in injury or

death.

WARNING!!!

water-based lubricants on joints.

Never use hydrocarbons-based

lubricants because they would

destroy gaskets.

follow this warning could result

in excessive levels of carbon

monoxide, which can result

in severe personal injury or

death!

This

Improper

Use only

Failure to

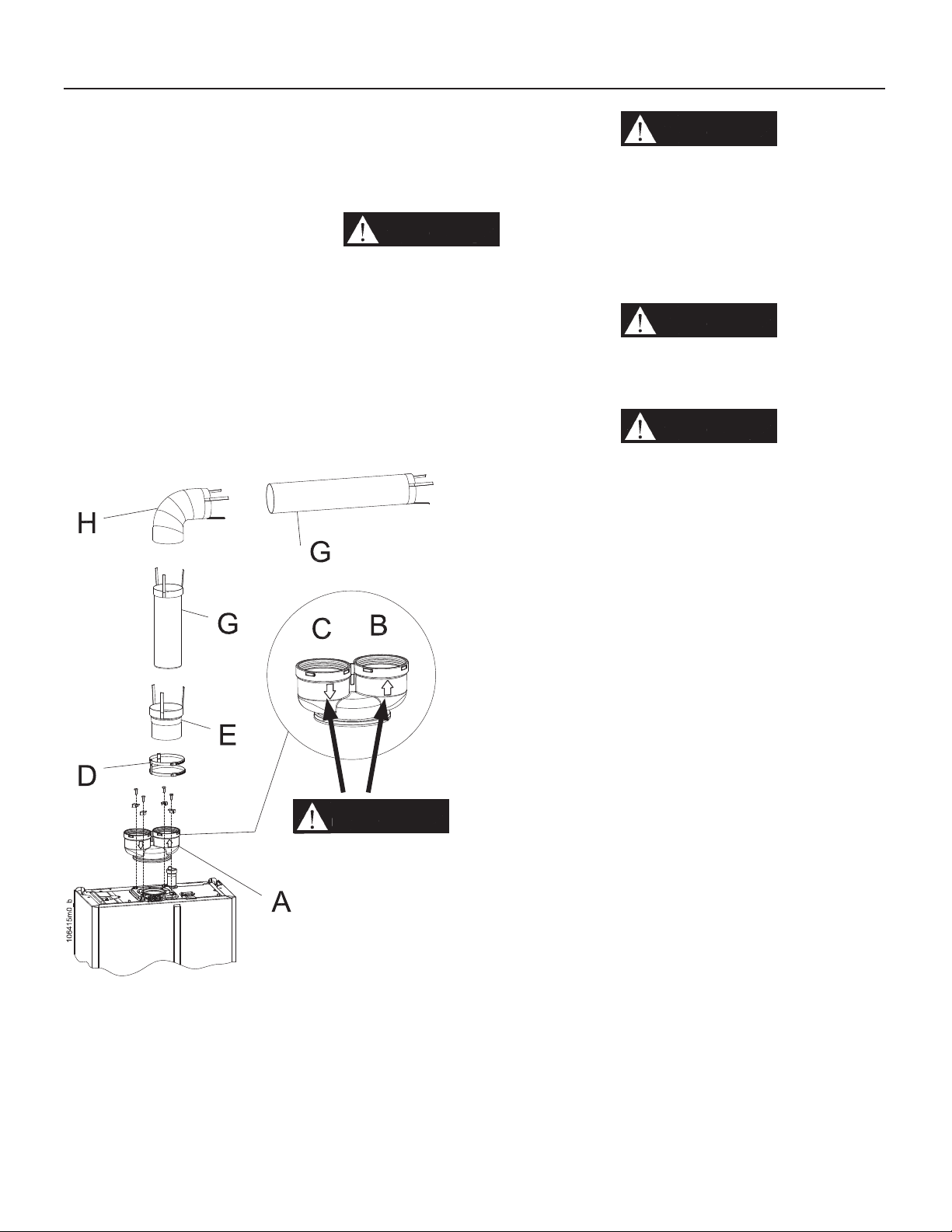

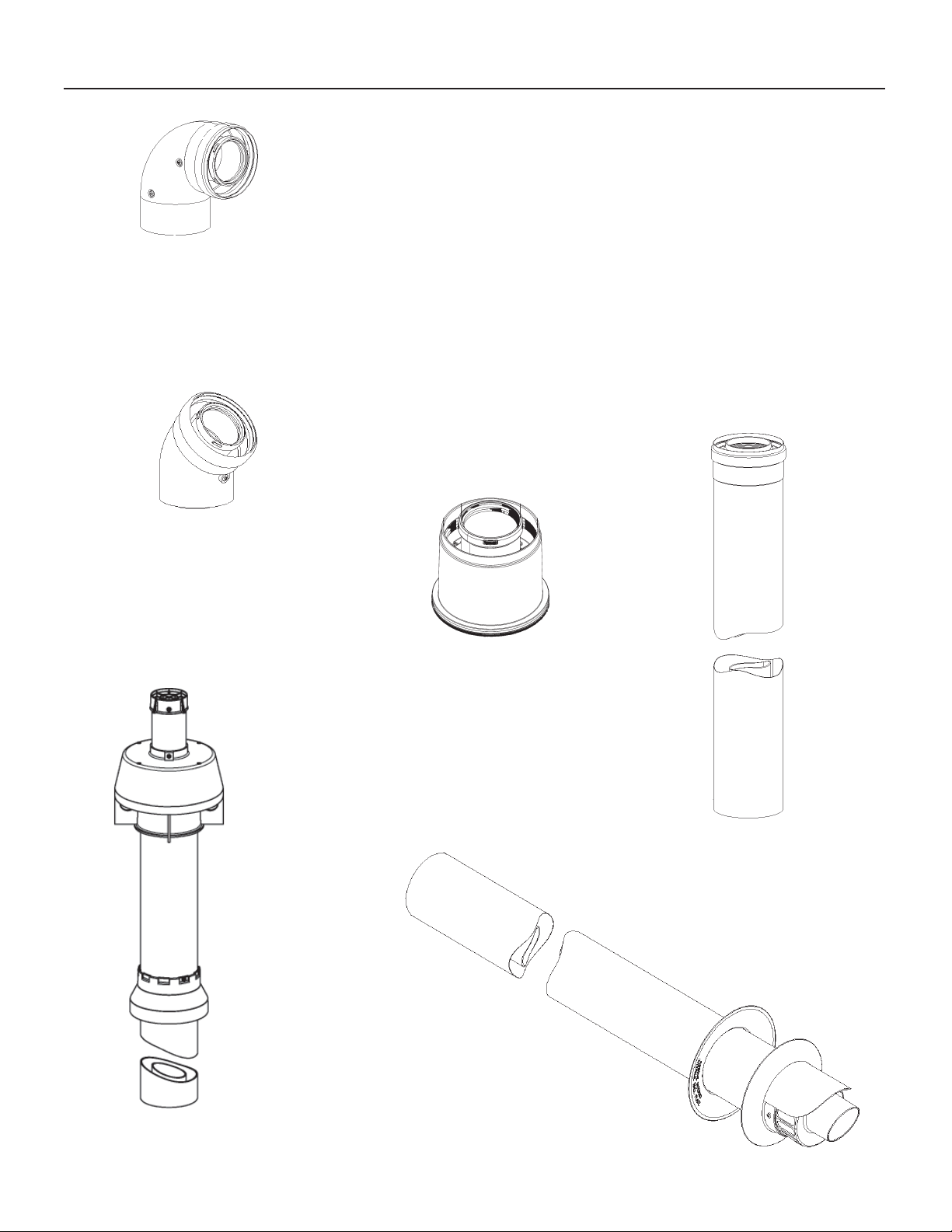

A = Flue exhaust connection

B = Combustion air intake connection

C = Fixing clamp

D = Stainless steel elbow

E = Stainless steel adaptor

F = Stainless steel extension

G = Air intake pipe

WARNING!!!

arrow on boiler adapter for the

correct side of fl ue exhaust and

air intake. Failure to follow this

warning could result in excessive

levels of carbon monoxide or a

fi re, which can result in severe

personal injury or death!

Check stamped

NOTICE Installation must comply with

local requirements and with the National

Fuel Gas Code, ANSI Z223.1 for U.S.

installations or CSA B149.1 for Canadian

installations.

For installation in Canada, vent pipe

system must be certifi ed to ULC-S636

(see Table 10-1).

NOTICE All vent pipes connections

must be secured following manufacturer

instruction, properly supported, and the

exhaust must be pitched a minimum of

a 1/4 inch per foot back to the boiler (to

allow drainage of condensate).

NOTICE Installation of a stainless

steel vent system should adhere to

the stainless steel vent manufacturer’s

installation instructions supplied with

the vent system.

NOTICE The installer must use a

specifi c vent starter adapter at the

fl ue collar connection, supplied by the

vent manufacturer to adapt to its vent

system. See Table 10-2 for approved

vent adapters.

Figure 10-9 Stainless Steel Venting connection

38

10 - INSTALLATION - Vent and combustion air

10.8.1 - Stainless steel air

intake/vent connections

Combustion Air Intake

connection (see Figure 10-9

Item “C”). This connection is used

to provide combustion air directly to

the boiler from outdoors. Combustion

air piping must be supported per

guidelines listed in the National

Mechanical Code, Section 305, Table

305.4 or as local codes dictate.

To connect a PVC/CPVC pipe to the

air intake connection follow section

10.7.2.

Vent connection (Figure

10-9 item “A”) is used to provide

a passageway for conveying

combustion gases to the outside. Vent

piping must be supported per the

National Building Code, Section 305,

Table 305.4 or as local codes dictate.

To connect a stainless steel pipe to

the vent connection proceed as follow:

while referring to Figure 10-9:

1. install boiler adapter “A” above

boiler. Rotate boiler adapter “A” so

as air intake and vent connections

are in the desired left or right side.

Check stamped arrow to understand

which is the vent and air intake

connection.

WARNING!!!

stamped arrow on boiler adapter

for the correct side of vent.

Failure to follow this warning

could result in excessive levels

of carbon monoxide or a fi re,

which can result in severe

personal injury or death!

Check

2. Insert clamp “D” onto side “B” of

boiler adapter “A” .

3. Insert adapter “E” into side “B” of

boiler adapter “A”;

4. Use clamp “D” to mechanically

secure adapter “E” to boiler adapter

“A”. To do this tighten one side of

clamp “D” onto boiler adapter “A”

and the other half of clamp “D” onto

adapter “E”.

tork of 1.5 - 2 lbf ft (2-3 Nm).

5. Insert vent pipe “G”, into adapter

“E”, following instruction of stainless

steel pipe manufacturer.

Tight the clamps with a

39

10 - INSTALLATION - Vent and combustion air

10.9 - Polypropylene

vent piping materials

WARNING!!!

the materials listed in Tables

10-1 and 10-2 for vent pipe,

and fi ttings.

systems of different types or

manufacturers, unless listed in

this manual.

could result in severe personal

injury, death, or substantial

property damage.

WARNING!!!

requires a special venting

system. The fi eld provided vent

fi ttings must be connected to the

boiler following Section 10.9.1.

Failure to follow this warning

could result in fi re, personal

injury, or death.

WARNING!!!

installation of Polypropylene

systems may result in injury or

death.

Use only

DO NOT mix vent

Failure to comply

This appliance

Improper

WARNING!!!

water-based lubricants on joints.

Never use hydrocarbons-based

lubricants because they would

destroy gaskets.

follow this warning could result

in excessive levels of carbon

monoxide, which can result

in severe personal injury or

death!

NOTICE Installation must comply with

local requirements and with the National

Fuel Gas Code, ANSI Z223.1 for U.S.

installations or CSA B149.1 for Canadian

installations.

For installation in Canada, vent pipe

system must be certifi ed to ULC-S636

(see Table 10-1).

NOTICE All vent pipes connections

must be secured following manufacturer

instruction, properly supported, and the

exhaust must be pitched a minimum of

a 1/4 inch per foot back to the boiler (to

allow drainage of condensate).

NOTICE Installation of a

Polypropylene vent system should

adhere to the polypropylene vent

manufacturer’s installation instructions

supplied with the vent system.

Use only

Failure to

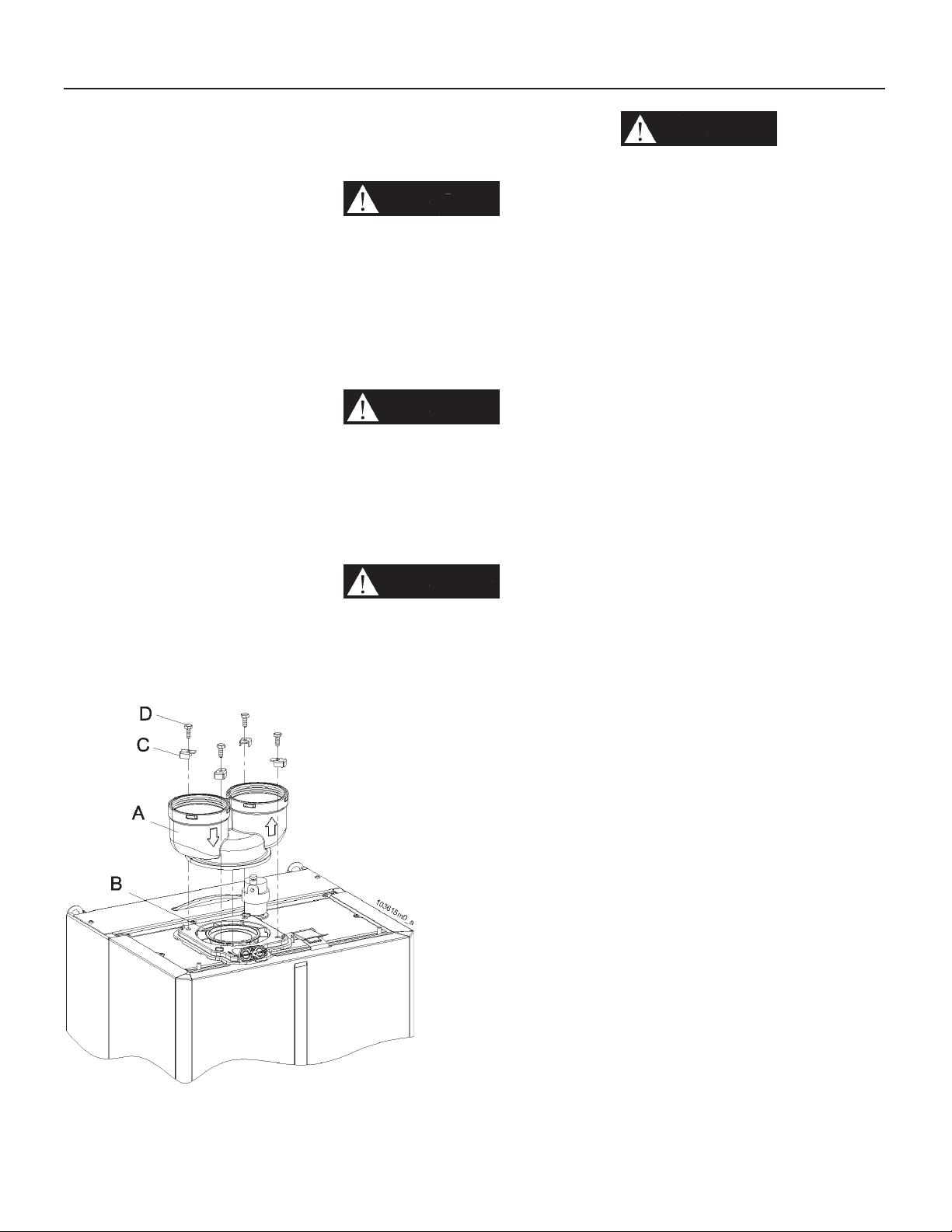

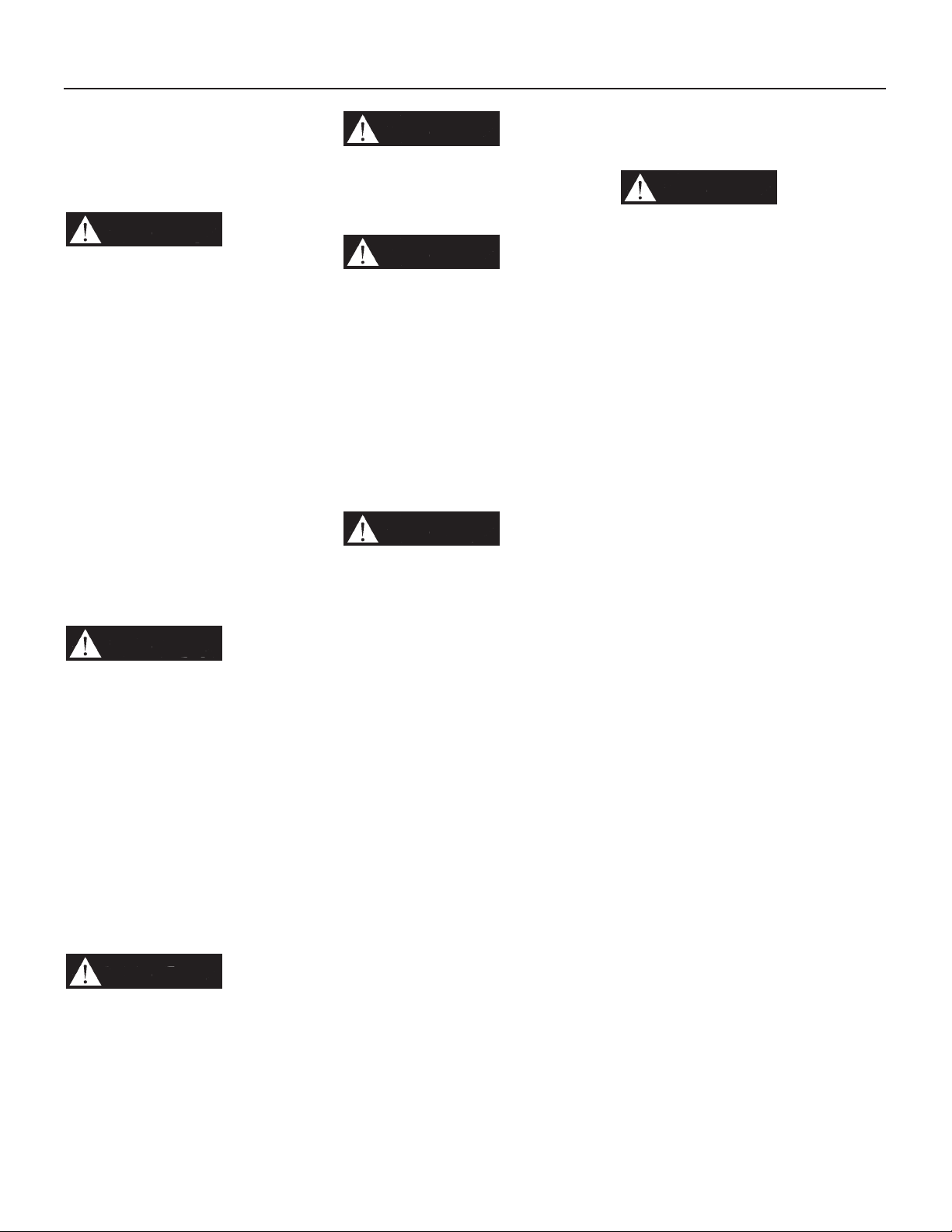

Figure 10-10 Polypropylene boiler adaptor

40

10 - INSTALLATION - Vent and combustion air

10.9.1 - Polypropylene

two pipes air intake/vent

connections

Combustion air piping and vent piping

must be supported per guidelines

listed in the National Mechanical

Code, Section 305, Table 305.4 or as

local codes dictate.

The boiler is not supplied with the

fi ttings needed for separate vent and

combustion air systems. A special kit

must be ordered to connect the boiler

to separate vent and combustion air

systems. Figure 10-10 shows fi tting

“A” that can freely turn 360 degrees

for optimum installation versatility (see

section 10.9.2 for P/N of “A” fi tting).

Tork screws “D” at 2 lbf ft (3 Nm).

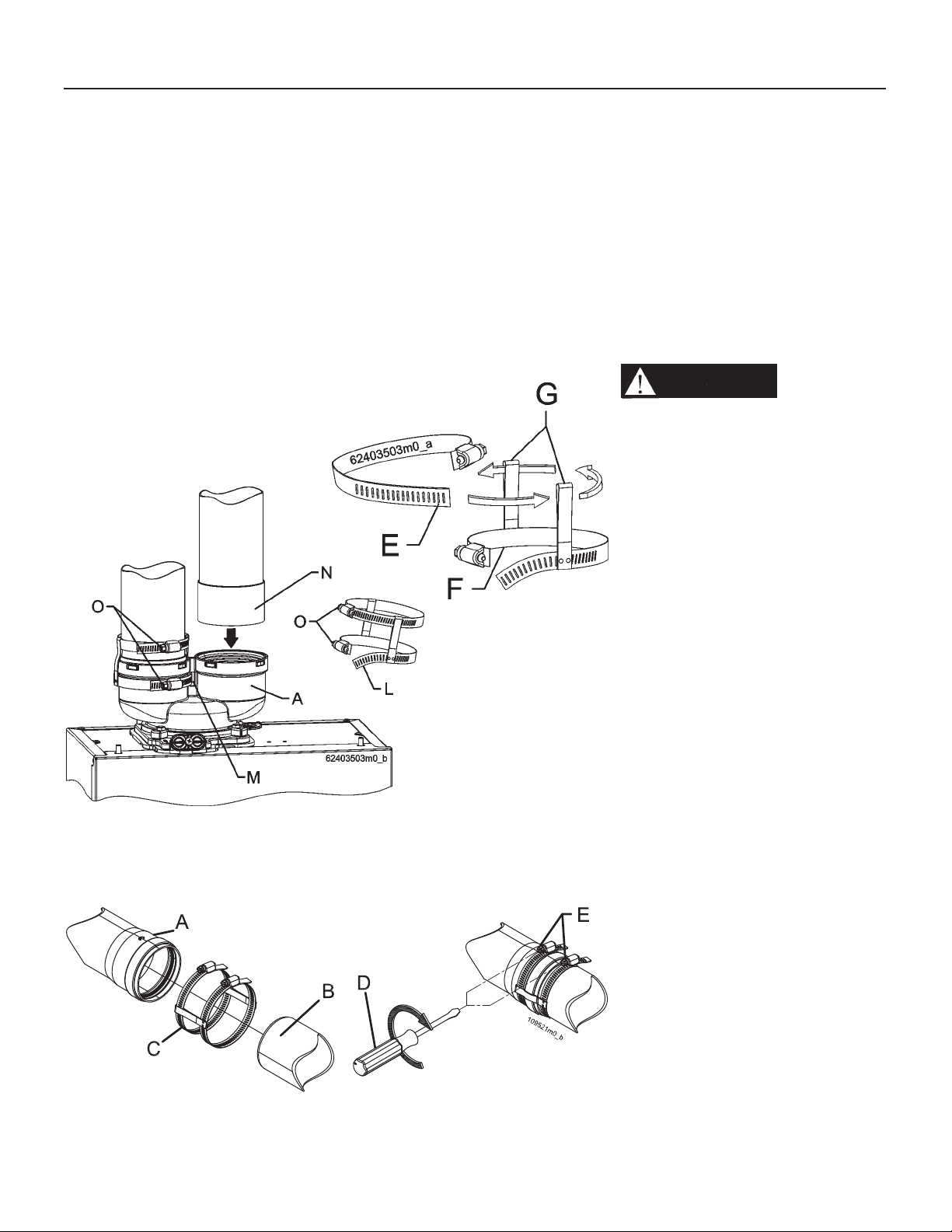

Pipes or elbows connected directly

to the boiler, must be mechanically

secure. Follow these instructions to

connect pipes to the boiler (make

reference to Figure 10-11):

1. Prepare the two collars “G” with

Band Clamps “E” and “F”;

2. Insert the end of Band Clamp “L”

into hole “M” of boiler adapter “A”

3. Insert vent pipe “N” into boiler

adapter “A”

4. Tight the two Band Clamps “O” to

mechanically secure vent pipe “N”

to boiler adapter “A”. Tight band

clamps with a tork of 1.5 - 2 lbf ft

(2-3 Nm).

The vent system must be both gas

tight and watertight. All seams and

joints must be joined and sealed in

accordance with the vent system

manufacturer’s instructions.

WARNING!!!

follow the installation steps

below for the assembling the

two pipes venting system

(elbows and extensions), as

illustrated in Figure 10-12. it is

necessary to properly insert

the male side onto the female

side and mechanically secure

them by using the proper

clamps. Improper venting can

result in excessive levels of

carbon monoxide or a fi re,

which can result in severe

personal injury or death!

Carefully

Figure 10-11 Polypropylene Venting connection

Mechanically secure each joint

with the supplied band clamps as

shown in Figure 10-12. Follow this

procedure:

1. Insert the Male side (“B”) of a vent

pipe into the Female side “A” of

another;

2. Use Band Clamp “C” to keep the

two pipes together;

3. Use screws “E” to tighten the Band

Clamp onto both pipes. Tight band

clamps with a tork of 1.5 - 2 lbf ft

(2-3 Nm).

Figure 10-12 Connecting extensions and elbows

41

10 - INSTALLATION - Vent and combustion air

10.9.2 - Polypropylene two pipes

system components

Some of the most commonly used components

for installing the two pipes polypropylene vent

and combustion air systems are listed below:

P/N 81 9001 000 - Two pipes adaptor 80/80 PP

P/N 81 9171 000 - 3ft PP M/F extension

P/N 81 9772 000 - 60 ft PP fl exible extension

P/N 81 9173 000 - Spacer for PP fl exible extension

P/N 81 9003 000 - 90° PP M/F in line elbow

P/N 81 9174 000 - 45° PP M/F in line elbow

P/N 81 9175 000 - Secure clamp for PP extensions

P/N 81 9177 000 - Split vertical terminal

P/N 81 9181 000 - Air intake grid

P/N 81 9182 000 - Flue exhaust grid

Figure 10-13 Dimensions of two pipes system

81 9001 000

81 9182 000

81 9181 000

81 9177 000

81 9772 000

81 9173 000

81 9003 000

81 9171 000

81 9175 000

42

81 9174 000

10 - INSTALLATION - Vent and combustion air

10.9.3 - Polypropylene

concentric system

The boiler is not supplied with the

fi ttings needed for connecting a

coaxial vent/combustion air system.

A special kit must be ordered to

connect the boiler with the Coaxial

polypropylene vent. Figure 10-14

shows how to install the Coaxial fi tting

above the boiler. Tight the screws “D”

of Figure 10-14 with a tork of 2 lbf ft

(3 Nm)

B = Connection fl ange

C = Fasten clip

D = Fasten clip screw

F = Coaxial vertical adaptor

Figure 10-14 Installation of the coaxial fi tting

WARNING!!!

follow installation steps below,

for the coaxial pipe assembly

(elbows and extensions), as

illustrated in Figure 10-15. It is

necessary to properly insert

the internal and external pipe

and mechanically secure them

by using a stainless steel

self tapping screw. Improper

venting can result in excessive

levels of carbon monoxide or a

fi re, which can result in severe

personal injury or death!

In particular:

1. slip-fi t the extension “1” and “2”

(see Figure 10-15) together;

2. drill a suitable hole “3” with a drill

“4” (see Figure 10-15) in a position

where the two pipes “1” and “2” are

overlapped;

3. insert a suitable stainless steel self

tapping screw “5” and tight it with a

screwdriver “6”

Carefully

Figure 10-15 Securing extensions and elbows together

43

It is recommended that wall sleeve

be used when installing the coaxial

system through an exterior wall.

This will allow the system to be

easily slipped out for access during

routine maintenance.

Horizontal coaxial systems must

always be pitched by at least 1/4 in/

ft, (21 mm/m) towards the boiler.

10 - INSTALLATION - Vent and combustion air

10.9.4 - Polypropylene concentric

system components

The following coaxial polypropylene vent and

combustion air system components are available, on

request, for installing the Coaxial system

P/N 81 9183 000 - In line 90° PP coaxial M/F elbow

P/N 81 9176 000 - In line 45° PP coaxial M/F elbow

81 9183 000

P/N 81 9170 000 - 3ft (1m) PP coaxial extension

P/N 81 9005 000 - PP coaxial roof end piece

P/N 81 9184 000 - PP Coaxial wall end piece

P/N 81 9185 000 - PP straight coaxial adaptor

81 9176 000

81 9185 000

81 9170 000

81 9005 000

81 9184 000

44

10 - INSTALLATION - Vent and combustion air

10.10 - Single pipe

vent (not sealed

combustion)

WARNING!!!

utilizing the single pipe method,

provisions for combustion

and ventilation air must be

in accordance with Air for

Combustion and Ventilation, of

the latest edition of the National

Fuel Gas Code, ANSI Z223.1,

in Canada, the latest edition of

CGA Standard B149 Installation

Code for Gas Burning Appliances

and Equipment, or applicable

provisions of the local building

codes.

Commercial applications utilizing this

boiler may be installed with a single

pipe carrying the fl ue products to the

outside while using combustion air from

the equipment room. In this case the

following conditions and considerations

must be followed.

WARNING!!!

equipment room MUST be

provided with properly sized

openings to assure adequate

combustion air from outside.

Failure to comply could result in

severe personal injury, death, or

substantial property damage.

• There will be a noticeable increase

in the noise level during normal

operation from the inlet air opening.

• Vent system and terminations must

comply with the venting instructions

set forth in sections 10.1, 10.2,

10.3, 10.4, 10.5, 10.7, 10.8 and

10.9.

WARNING!!!

materials, vent systems, and

terminations listed in Tables

10-1 and 10-2. DO NOT mix vent

systems of different types or

manufacturers, unless listed in

this manual. Failure to comply

could result in severe personal

injury, death, or substantial

property damage.

When

The

Use only the

WARNING!!!

due to fl ammable materials or

liquids. Do not store fl ammable

materials and liquids in the

immediate vicinity of the boiler.

WARNING!!!

must be clear and free from

combustible materials, gasoline

and other fl ammable vapors and

liquids, and corrosive liquids

and vapors. Never use chlorine

and hydrocarbon containing

chemicals (such as spray

chemicals, solution and cleaning

agents, paints, glues etc.) in the

vicinity of the boiler. Do not store

and use these chemicals in the

boiler room. Avoid excessive dust

formation and build-up.

WARNING!!!

fans, clothes dryers, and kitchen

ventilation systems interfere

with the operation of appliances,

makeup air shall be provided.

NOTICE Installation must comply with

local requirements and with the National

Fuel Gas Code, ANSI Z223.1 for U.S.

installations or CSA B149.1 for Canadian

installations.

For installation in Canada, vent pipe

system must be certifi ed to ULC-S636 (see

Table 10-1).

NOTICE All vent pipes connections

must be secured following manufacturer

instruction, properly supported, and the

exhaust must be pitched a minimum of a

1/4 inch per foot back to the boiler (to allow

drainage of condensate).

Fire danger

Boiler

Where exhaust

10.10.1 - Combustion Air

and Ventilation openings

Outdoor combustion air shall be provided

through opening(s) to the outdoors. The

minimum dimension of air openings shall

not be less than 3 in. (80 mm) diameter.

Two Permanent Openings Method.

Two permanent openings, one

commencing within 12 in. (300 mm)

of the top and one commencing within

12 in. (300 mm) of the bottom, of the

room shall be provided. The openings

shall communicate directly, or by ducts,

with the outdoors or spaces that freely

communicate with the outdoors, as

follows:

1. Where directly communicating with the

2. Where communicating with the

One Permanent Opening Method. One

permanent opening, commencing within

12 in. (300 mm) of the top of the room,

shall be provided. The appliances shall

have clearances of at least 1 in. (25 mm)

from the sides and back and 6 in. (150

mm) from the front of the appliance.

The opening shall directIy communicate

with the outdoors or shall communicate

through a vertical or horizontal duct

to the outdoors or spaces that freely

communicate with the outdoors and shall

have a minimum free area of 1 in2 each

3000 Btu/hr (700 mm2 /kW) of the total

input rating of all appliances located in

the room

45

WARNING!!!

combustion air and ventilation

openings are suffi ciently sized

and no reduction or closure of

openings takes place. Please

note these restrictions and its

dangers to the operator of the

boiler and to the homeowner.

Failure to comply could result in

severe personal injury, death, or

substantial property damage.

outdoors or where communicating to

the outdoors through vertical ducts,

each opening shall have a minimum

free area of 1 in2 each 4000 Btu/hr

(550 mm2/kW) of total input rating of

all appliances located in the room.

outdoors through horizontal ducts,

each opening shall have a minimum

free area of 1 in2 each 2000 Btu/hr

(1100 mm2/kW) of total input rating of

all appliances located in the room.

Make sure that

10 - INSTALLATION - Vent and combustion air

10.10.2 - Determine

location

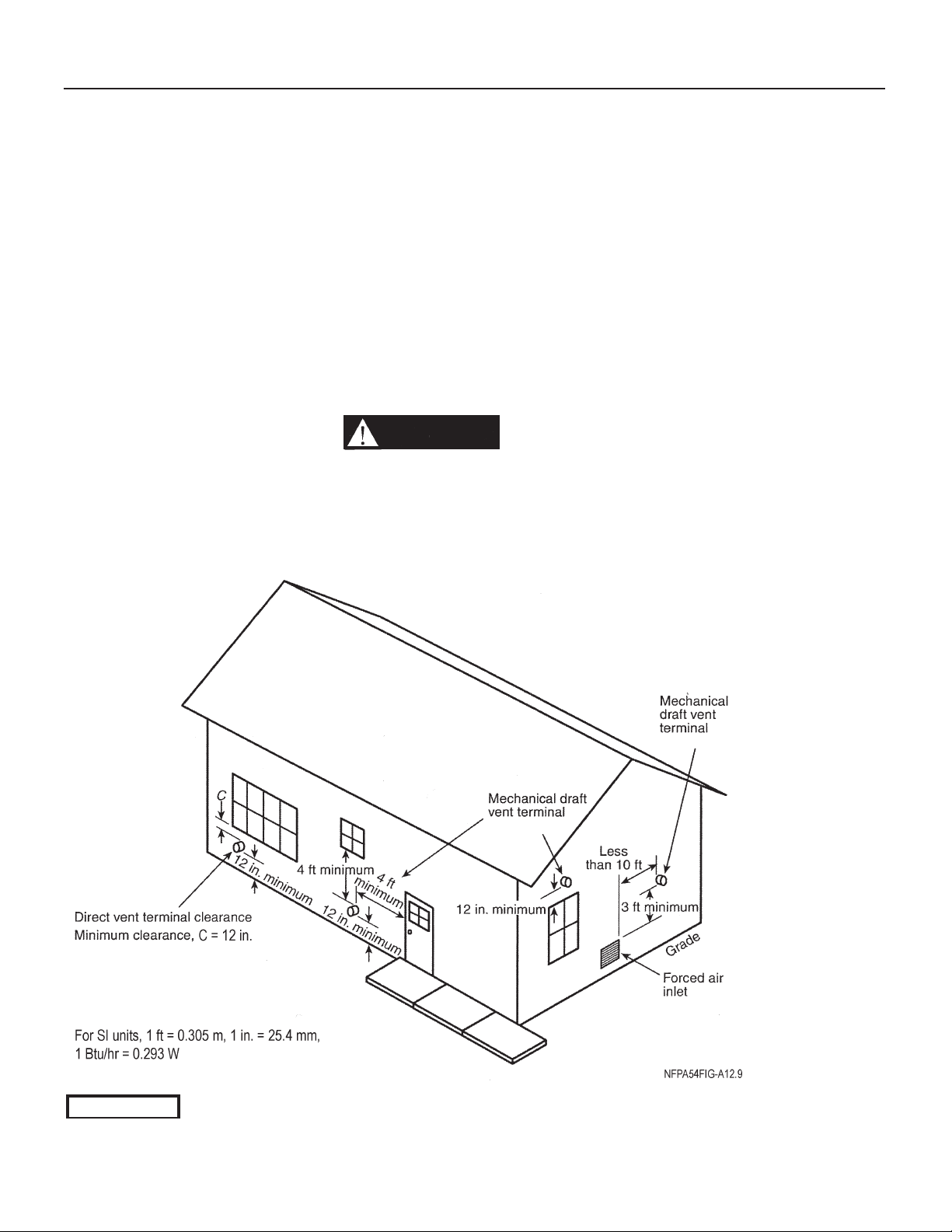

Locate the vent termination using the

following guidelines:

1. The total length of piping for vent must

not exceed the limits given in the

Section 10.4.

2. You must consider the surroundings

when terminating the vent:

a. Position the vent termination where

vapors will not damage nearby

shrubs, plants or air conditioning

equipment or be objectionable.

b. The fl ue products will form a

noticeable plume as they condense

in cold air. Avoid areas where

the plume could obstruct window

views.

c. Prevailing winds could cause

freezing of condensate and water/

ice buildup where fl ue products

impinge on building surfaces or

plants.

d. Avoid possibility of accidental

contact of fl ue products with people

or animals.

e. Do not locate the terminations

where wind eddies could affect

performance or cause recirculation,

such as inside building corners,

near adjacent buildings or surfaces,

window wells, stairwells, alcoves,

courtyards, or other recessed

areas.

f. Do not terminate above any door or

window. Condensate can freeze,

causing ice formations.

g. Locate or guard vent to prevent

condensate damage to exterior

fi nishes.

4. The vent piping must terminate in an

elbow pointed outward as shown in

Figure 10-12 or 10.13.

WARNING!!!

exceed the maximum lengths

of the outside vent piping

shown in Figures 10-12 or 10-13.

Excessive length exposed to the

outside could cause freezing

of condensate in the vent pipe,

resulting in potential boiler

shutdown.

Do not

5. Maintain clearances as shown in

Figure 10-11 (get references to

“Mechanical draft vent terminal”

only). Also maintain the following:

a. Vent must terminate:

• At least 6 feet from adjacent walls.

• No closer than 12 inches below

roof overhang.

• At least 7 feet above any public

walkway.

• At least 3 feet above any forced

air intake within 10 feet.

• No closer than 4 feet below or

horizontally from any door or

window or any other gravity air

inlet.

b. Do not terminate closer than 4

feet horizontally from any electric

meter, gas meter, regulator, relief

valve, or other equipment. Never

terminate above or below any of

these within 4 feet horizontally.Item

unique to CANADA: vent system

shall terminate at least 6 ft from

electrical and gas meters.

6. Locate termination so it is not likely to

be damaged by foreign objects, such as

stones or balls, or subject to buildup of

leaves or sediment.

CAUTION!!!

Increase the grade clearances of the snow line quote

Figure 10-16 Vent position of a Direct vent boiler and of a Mechanical draft boiler (not sealed)

46

10 - INSTALLATION - Vent and combustion air

10.11 - Sidewall

termination - Two

pipes

10.11.1 - Vent/air

termination

WARNING!!!

extending through an exterior

wall shall not terminate

adjacent to a wall or below

building extensions such as

eaves, parapets, balconies, or

decks. Failure to comply could

result in severe personal injury,

death, or substantial property

damage.

WARNING!!!

connect any other appliance

to the vent pipe or multiple

boilers to a common vent

pipe. Failure to comply could

result in severe personal injury,

death, or substantial property

damage.

NOTICE Installation must comply

with local requirements and with the

National Fuel Gas Code, ANSI Z223.1

for U.S. installations or CSA B149.1

for Canadian installations.

A gas vent

Do not

10.11.2 - Determine

location

Locate the vent/air terminations using

the following guidelines:

1. The total length of piping for vent or

air must not exceed the limits given

in the Section 10.4.

2. You must consider the surroundings

when terminating the vent and air:

a. Position the vent termination

where vapors will not damage

nearby shrubs, plants or air

conditioning equipment or be

objectionable.

b. The fl ue products will form

a noticeable plume as they

condense in cold air. Avoid areas

where the plume could obstruct

window views.

c. Prevailing winds could cause

freezing of condensate and

water/ice buildup where fl ue

products impinge on building

surfaces or plants.

d. Avoid possibility of accidental

contact of fl ue products with

people or animals.

e. Do not locate the terminations

where wind eddies could

affect performance or cause

recirculation, such as inside

building corners, near adjacent

buildings or surfaces, window

wells, stairwells, alcoves,

courtyards, or other recessed

areas.

f. Do not terminate above any door

or window. Condensate can

freeze, causing ice formations.

g. Locate or guard vent to prevent

condensate damage to exterior

fi nishes.

47

Loading...

Loading...