Page 1

®

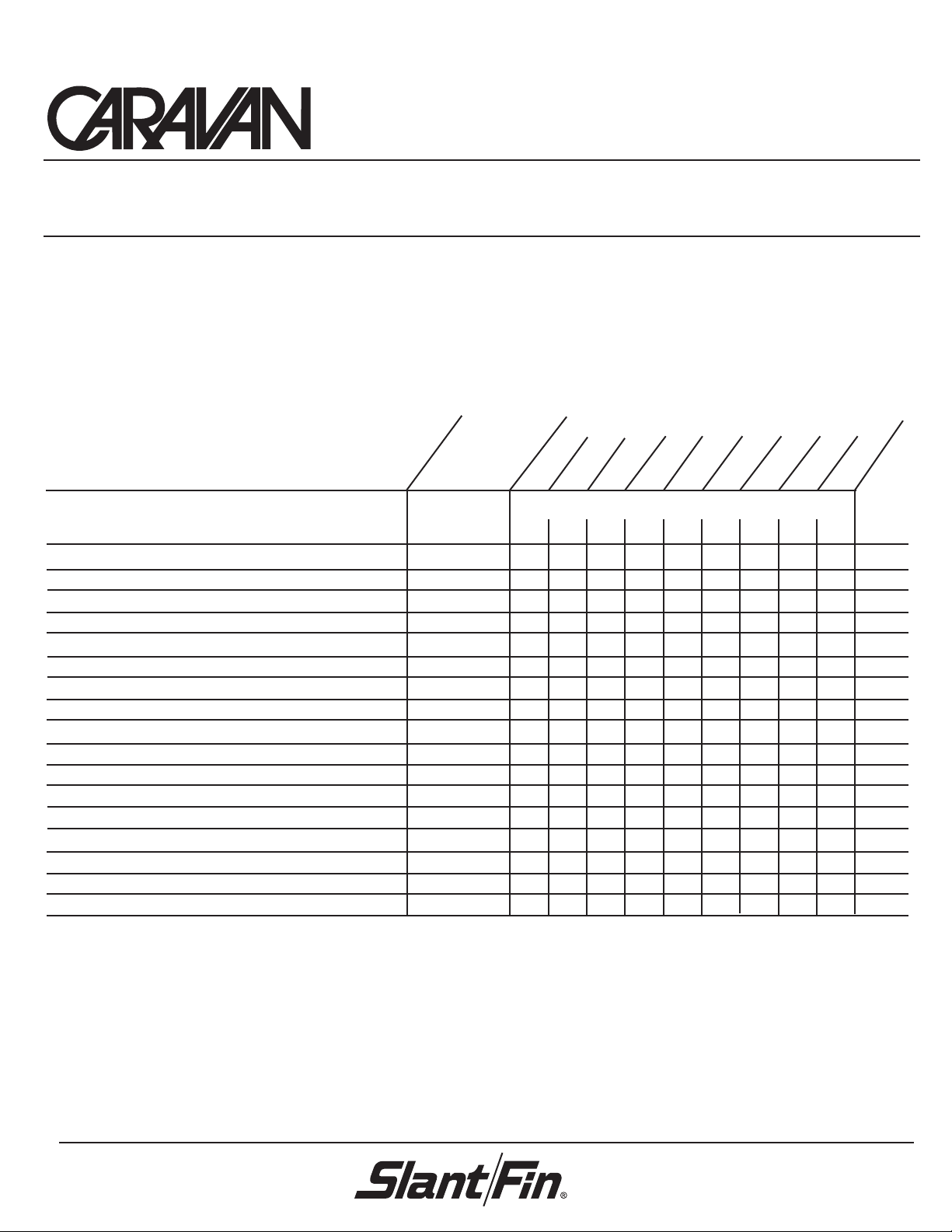

HOT WATER SUPPLY AND RETURN HEADERS

PARTS LIST AND ASSEMBLY INSTRUCTIONS

L-Series: Oil-fired Modular Boilers

Header Parts List

43-2572

43-2573

Item Part No. 234 56 78910

1-1/2" Stub Header - 2 stub - 27" C-C (pkgd. separately) 43-0920 2–4 2– 42–4

1-1/2" Stub Header - 3 stub - 27" C-C (pkgd. separately) 43-0921 –2–24 2464

Flex Joint - 1-1/2" pipe 43-2023 244 68 810 12 12

Flex Joint - 3" pipe 41-1755 448 8812 12 12 16

Cast End Cap - 3/4" NPT 41-1780 111 11 1111

Cast End Cap - No tap 41-1753 111 11 1111

Nipple - 1-1/2" x 4" 43-0904 346 7810 11 12 14

Nipple - 1-1/2" x 15" 43-0923 234 56 78910

Nipple - 1-1/2" x 30" 43-0924 112 24 4566

Nipple - 1-1/2" x close 43-0927 234 56 78910

Square Nipple - 1-1/2" x 8" T.O.E. 43-0925 122 34 4566

Square Nipple - 1-1/2" x 34" T.O.E. 43-0926 122 46 5666

Union - 1-1/2" 902428071 224 44 6668

Tee - 1-1/2" 43-0917 234 56 78910

Bushing - 1-1/2" x 3/4" 902179321 23456 78910

Elbow - 1-1/2" 902454071 46810 12 14 16 18 20

Installation Instructions 43-0901 111 11 1111

Header Package Order Code

Number of Modules

Part No. 43-0901

Publication CH-40L

Printed in U.S.A. 906

Page 2

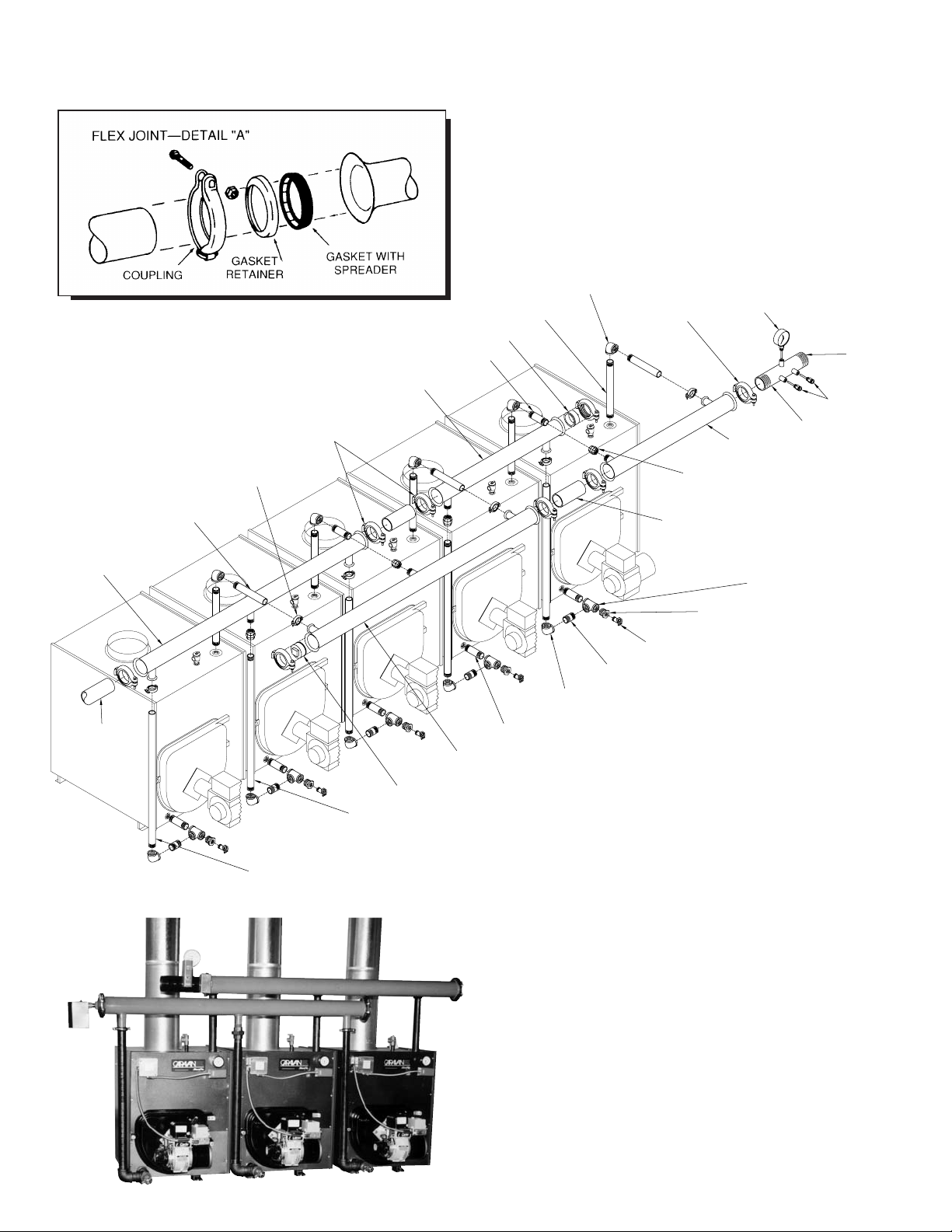

FACTORY SUPPLY AND RETURN HEADER ASSEMBLY — OIL

1

1

/2'' X 8'' SQUARE NIPPLE

3'' RETURN HEADER

1

WITH 1

/2'' STUBS

(3 MODULE)

1

/2'' FLEX JOINT

1

(SEE DETAIL "A")

3'' FLEX JOINTS

(SEE DETAIL "A")

3'' RETURN HEADER

1

WITH 1

/2'' STUBS

(2 MODULE)

CAST END CAP

1

1

/2'' X 4'' NIPPLE

*Building piping must be rigidly secured so it cannot

move where connected to headers.

1

1

1

/2'' X 15'' NIPPLE

1

/2'' ELBOW

3'' FLEX JOINT

(SEE DETAIL "A")

3'' PIPE X 20''

(BY OTHERS)

1

1

/2'' UNION

1

/2'' PRESSURE

TEMPERATURE

GAUGE

3'' SUPPLY HEADER

1

WITH 1

/2'' STUBS

(2 MODULE)

1

/2'' X 11/2'' X 11/2'' TEE

1

*3'' BUILDIING PIPE

1

/2'' WELLS

CONTROL HEADER

1

/2'' x 1/2'' x 1/2''

3'' x

CONNECTION

* 3'' BUILDING

PIPING

(BY OTHERS)

1

1

/2'' X 34'' SQUARE NIPPLE

1

/2'' X 30'' NIPPLE

1

CAST END CAP

3

WITH

/4'' TAPPING.

SUPPLY OR RETURN.

FOR USE WITH LWCO.

1

1

/2'' X 4'' NIPPLE

3'' SUPPLY HEADER

1

WITH 1

/2'' STUBS

(3 MODULE)

NOTE:

Shown reverse return (Preferred). For direct

return, header assembly piping connections

may be made at the same end of the boiler

bank, not as shown. Some governing agencies do not allow compression type couplings.

Consult your local code requirements.

1

/2'' ELBOW

1

3

1

/2'' X CLOSE NIPPLE

1

/4'' DRAIN VALVE

1

/2'' X 3/4'' BUSHING

1

Page 3

Caravan Flex Joint Assembly Instructions

1. Slip the metal retainer on the system piping with the larger

diameter side facing the end of the pipe to be joined. The

3" flex joint has a single piece serrated metal retaining

ring. This retaining ring should be seated in the recess in

the inner diameter of the gasket with its mounting tabs

overlapping slightly where the ring splits. The 1-1/2" flex

joint has a 2 piece serrated retaining ring that must be

installed in the inner recess of the gasket with its ends

butting.

Work the gasket with the serrated metal retaining ring onto the pipe. When installing the gasket be sure the retaining rings seat

properly around the pipe. On the 1-1/2" flex joint install the bottom half of the gasket first leaving the other half of the retaining ring

free at the top. Then stretch the top of the gasket with the ring over the top of the pipe. When installing the gaskets if a lubricant

is needed, use a soap and water solution only. DO NOT use any oil based lubricants.

2. The gasket must be fully seated in the metal retainer (press together with pliers if necessary). BE SURE THE GASKET IS

SEATED ON AN UNTHREADED SECTION OF PIPE AT LEAST 1" FROM THE END. Slip the flared end of the Slant/Fin

header tube over the pipe and seat against the gasket. Follow illustration a or b for cast end cap or piping.

a) b)

3. Open hinged metal clamp and slip over joint. Be sure that the flared end of the steel tubing, the retainer ring and the gasket

are enclosed within the clamp.

4. Install the bolt and lock nut and tighten the lock nut to

the following torque values: 1-1/2" flex joint is 140-160

inch-pounds, 3" flex joint is 220-240 inch-pounds.

NOTE: On 3” schedule 40 pipe, spacing between clamps is

approximately 3/8” when properly torqued.

On 1-1/2" schedule 40 pipe, spacing between clamps

is approximately 1/4" when properly torqued.

Page 4

SLANT/FIN CORPORATION, Greenvale, N.Y. 11548 • Phone: (516) 484-2600

FAX: (516) 484-5921 • Canada: Slant/Fin LTD/LTEE, Mississauga, Ontario

www.slantfin.com

Loading...

Loading...