Page 1

Models KC-45 and KC-90

USER’S INFORMATION

MANUAL

For Your Safety, Before Operating

The Boiler, Read This Manual

WELCOME TO OUR VALUED CUSTOMER

You are now the owner of a Slant/Fin Prodigy 21

gas-fired boiler, another quality heating product

designed and manufactured by an industry leader ,

to provide your family with many years of reliable

comfort and trouble-free performance.

The care and maintenance of your new boiler is

important to prevent a hazardous condition which

might result from lack of proper servicing.

Therefore, you should perform regular “owner”

inspections as described in this manual (and

report any concerns to a qualified service

technician) as well as have y our boiler serviced by

a qualified service technician at least once a year,

preferably before the beginning of each heating

season.

LIGHTING INSTR

UCTIONS

Locate, read and then follow the procedures on

the lighting instructions label attached to the

boiler. For reference, we have reproduced those

instructions in this manual.

WARNING: If the information in this

manual is not followed exactly, a fire

or explosion may result causing

property damage, personal injury or

loss of life.

- DO NOT store or use gasoline or other

flammable vapors and liquids in the

vicinity of this or any other appliance.

- WHAT TO DO IF YOU SMELL GAS

• DO NOT tr y to light any appliance.

• DO NOT touch any electrical switch;

DO NOT use any phone in your

building.

• Immediately call your gas supplier

from a neighbor’s phone. Follow the

gas supplier’s instructions.

• If you cannot reach your gas

supplier, call the fire department.

- Installation and service must be

performed by a qualified installer,

service agency or the gas supplier.

This manual must be left with owner, hung on

or adjacent to the boiler. Owner should retain

manual for future reference

PUBLICATION P-UIM Rev.C

Residential • Gas-fired • Hot Water Boilers

Printed in USA 396

Part No. 65-0647

®

®

Page 2

2

At least once each month during the heating

season, perform the following inspections:

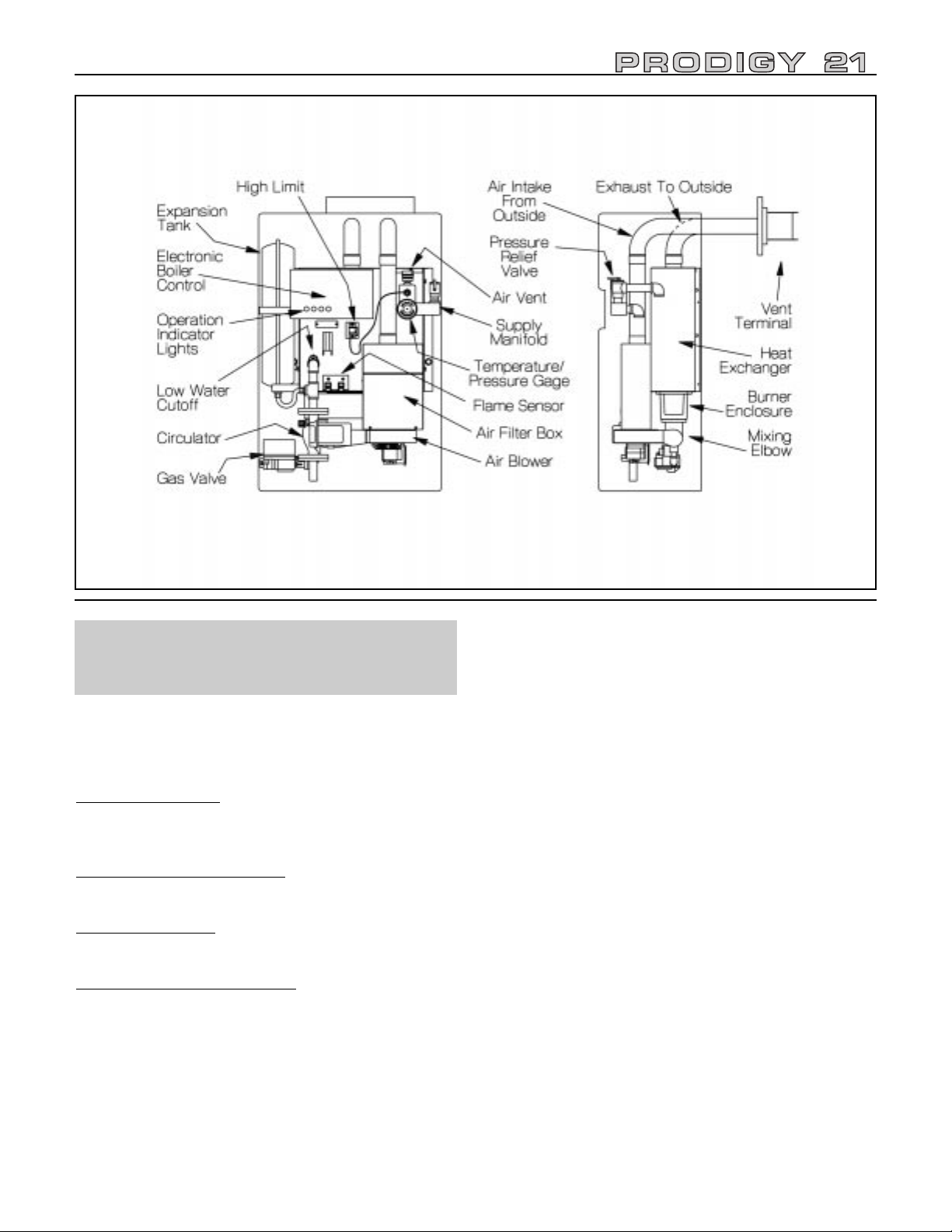

Check Vent Tubing: Look for leakage at joints and

sagging of vent tubing runs. If evident, call a qualified

service technician.

Check Vent Terminal (Outside): Look for and remove any

obstructions (i.e. leaves, shrubs, snow).

Check Water Piping: Look for leaks around boiler and at

all joints. If evident, call a qualified service technician.

Check System Water Pressure: The temperature/pressure gage indicates the pressure in the boiler for each

water temperature. For most installations, it should

indicate about 12 psi to 15 psi for 70° to 100° water

temperatures and from 15 psi to 25 psi for temperatures

up to 240°. Ask your installer or service technician to

explain and show you what normal pressures to look for.

If pressure decreases from normal, the system is losing

water; if pressure increases from normal, the boiler relief

valve will open to relieve pressure (water will be evident

on floor below relief valve discharge piping). In either

case, call a qualified service technician.

At least once a year, check the air filter: Replace it

(recommended) or clean it. For access to the filter,

remove boiler front cover by pushing down on top center

portion of cover until support clip releases cover at top,

then lift off of support clips at bottom of cover.

Open air filter box cover by rotating the 1/4 turn fastener

on top of cover, then swing open at hinge.

Slant/Fin replacement air filter, part number 65-0524,

must be used. The filter can be cleaned with soap and

water. Shake off excess moisture before replacing.

In the case of severe outside dust/dirt conditions which

cause above-average accumulation on the filter, it may

be necessary to change it (or clean it) more often. This

procedure may be done by user or service technician,

providing a record is kept of each replacement or

cleaning date to assure an established diligent routine.

TAKING CARE

OF Y OUR BOILER

®

Page 3

ANNUAL TECHNICIAN INSPECTIONS

Before each heating season, call your qualified

service technician to perform the following

inspections (and repair any problems encountered).

Check Vent System: For corrosion, obstructions, leaks

or sagging. Will require disassembling and resealing of

vent tubing.

Check Water System: For water piping leaks, properly

filled boiler and proper system air elimination.

Check Gas Piping:

For gas valve and piping leaks.

Check Boiler Controls:

For correct settings and

functioning. To include safety controls and calibration.

Check Air Filter: Replace (recommended) or clean.

System Heat Exchanger and Burner: For sooting,

corrosion or improper operation.

Blower and Circulator: Sealed components which do

not require lubrication.

The PRODIGY 21 control light panel has a complete set

of LED indicator lights which provide important

information at a glance about boiler operation:

Power Indicator (RED): Steady ON means there is

electrical power to the boiler. Light will come on when

power is provided to boiler.

Diagnostic Indicator (RED):

Steady ON or intermittent

flashing indicates a system operation problem.

Full Input Indicator (AMBER): Steady ON means the

boiler is running in high-fire mode. Light will come on

when boiler starts up; will go off when the boiler enters

the low-fire mode or shuts off.

Reduced Input Indicator (GREEN): Steady ON means

boiler is running in low-fire mode. Light will come on

when the boiler automatically switches to the fuelsaving low-fire mode; will go off when boiler returns to

high-fire mode or shuts off.

WHA T THE INDICA T OR

LIGHTS TELL Y OU

Before calling a qualified service technician, check

the following first:

• Room thermostat is calling for heat?

• Fuse or circuit breaker is OK?

• Boiler service switch is ON?

• Gas supply is available to gas meter?

• Manual main gas shutoff is open?

• Boiler gas control arm is in ON position?

Then, observe indicator lights: You can help provide

useful information to the service technician so the

technician can arrive with appropriate replacement parts.

Carefully note the red diagnostic indicator light. When a

system failure occurs, and there’s power to the boiler,

the indicator light will show a series of quick flashes.

There will be a short interval between the series when

the indicator stops flashing.

Count the number of flashes that occur after the short

no-flashing interval. Using the chart above, determine

correct failure code for number of flashes you counted.

Call a qualified service technician and report your boiler

model plus the number of flashes you counted and the

code for the flashes.

Note: The boiler will attempt restart each hour and after

a power interruption. If boiler restarts, diagnostic light

will turn OFF. If boiler does not restart, diagnostic light

will return to either steady-on or the series of flashes.

IN CASE YOUR

BOILER SHUTS DOWN

BOILER FAILURE CODES

Continuous Flashing-- Electronic Control Failure

1 Flash ------------------- High Limit Open 1 Hour

2 Flashes ---------------- No Ignition

3 Flashes ---------------- Pressure Switch Open

4 Flashes ---------------- Hot Surface Ignitor Failure

5 Flashes ---------------- Blower RPM Too Low

6 Flashes ---------------- Low Water Cutoff Open

7 Flashes ---------------- Improper Flame Signal

Steady ON -------------- Loss Of Flame Signal

3

®

Page 4

FOR YOUR SAFETY READ BEFORE OPERATING

FOR YOUR SAFETY READ BEFORE OPERATING

A. This appliance does not have a pilot. It is equipped with an

ignition device that automatically lights the burner.

DO NOT try to light the burner by hand.

B. BEFORE OPERATING smell all around the appliance area

for gas. Be sure to smell next to the floor because some

gas is heavier than air and will settle on the floor.

WHAT TO DO IF YOU SMELL GAS

• DO NOT try to light any appliance.

• DO NOT touch any electric switch; DO NOT use any

phone in your building.

• Immediately call your gas supplier from a neighbor's

phone. Follow the gas supplier's instructions.

• If you cannot reach your gas supplier, call the fire

department.

C. Use only your hand to turn the gas control selector arm.

NEVER use tools. If the selector arm will not move by

hand, DON'T try to repair it, call a qualified service

technician. Force or attempted repair may result in a fire or

explosion.

D. DO NOT use this appliance if any part has been under-

water. Immediately call a qualified service technician to

inspect the appliance and to replace any part of the control

system and any gas control which has been underwater.

• STOP! Read the safety information above on this label.

• Set the room thermostat to lowest setting.

• Turn off all electric power to the appliance.

• This appliance is equipped with an ignition device which

automatically lights the burner. DO NOT try to light the

burner by hand.

• Remove boiler front cover.

• Depress and move gas control selector arm left to

“OFF” position. Note: Arm cannot be turned to “OFF”

unless arm is pushed in slightly. DO NOT force.

• Wait five (5) minutes to clear out any gas. Then smell for

gas, including near the floor. If you smell gas, STOP!

Follow "B" in the safety information above on this label. If

you don't smell gas, go to the next step.

• Depress and move gas control selector arm right to

“ON” position.

• Replace boiler front cover.

• Turn on all electric power to the appliance.

• Set room thermostat to desired setting.

• If the appliance will not operate, follow the instructions “To

Turn Off Gas To Appliance” and call your service

technician or gas supplier.

T

O TURN OFF GAS TO APPLIANCE

• Set room thermostat to lowest setting.

• Turn off all electric power to the appliance if service is to be

performed.

• Remove boiler front cover.

• Depress and move gas control selector arm left to

“OFF” position.

• Replace boiler front cover.

Your boiler must be installed, serviced and repaired

by a qualified service technician only. Owner must

not attempt to install, service or repair this boiler.

Should overheating occur or the gas supply fail to

shut off, DO NOT turn off or disconnect the

electrical supply to the pump. Instead, shut off the

gas supply at a location external to the appliance.

DO NOT use this boiler if any part has been underwater. Immediately call a qualified service

technician to inspect the boiler and to replace any

part of the control system and any gas control

which has been underwater.

DO NOT attempt to add water to boiler or system.

An automatic water feed should have been installed

(based on local codes) to maintain proper water

level; ask your installer if this device was installed.

Keep boiler area clear and free from combustible

materials, gasoline and other flammable vapors and

liquids.

DO NOT store anything against the boiler or let

anything accumulate in area surrounding the boiler.

DO NOT allow anything to accumulate around or

block air flow at outside vent terminal (i.e. leaves,

shrubs, snow).

For closet installations, DO NOT allow anything to

block air flow at closet ventilation air openings.

DO NOT use water from heating system for

cleaning.

DO NOT place clothing on the boiler or venting

system to dry.

WARNING:If you do not follow these instructions

exactly, a fire or explosion may result causing

property damage, personal injury or loss of life.

SLANT/FIN CORPORATION, Greenvale, N.Y. 11548 • Phone: (516) 484-2600

FAX: (516) 484-5921 •

Canada: Slant/Fin

LTD/LTEE

, Mississauga, Ontario

www.slantfin.com

®

LIGHTING INSTRUCTIONS

OPERATING INSTRUCTIONS

4

Gas Valve 7200 DERN

IMPORTANT SAFETY

INFORMATION FOR YOU

Selector

Arm

OFF

ON

®

Loading...

Loading...