Slant/Fin Jaguar User Manual

HOT WATER/GAS

MULTIPLE AND

CASCADING BOILERS

®

APPLICATION GUIDE

Guidelines for the design, purchase and installation of Slant/Fin Jaguar J-390C Caravan gas-fired, hot water multiple boiler systems.

CONTENTS

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Ratings and Dimensions . . . . . . . . . . . . . . . . . . . . . . . . .2

Boiler room design & layout . . . . . . . . . . . . . . . . . . . . . .4

Fresh air and contamination prevention . . . . . . . . . . . . .6

Piping and Wiring Flow

Boiler room air supply & ventilation . . . . . . . . . . . . . . . . .6

Venting requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Water piping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Condensate removal . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Gas line sizing and layout . . . . . . . . . . . . . . . . . . . . . . .16

Jaguar Multiple Boiler System Control . . . . . . . . . . . . .18

Cascading – Jaguar link method and wiring . . . . . . . . .19

Reset curves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

External signal & energy management (Tekmar 275) . . . . . . .28

Hybrid Boiler System . . . . . . . . . . . . . . . . . . . . . . . . . . .34

CODES AND STANDARDS

All Caravan installations must comply to local codes or, in the

absence of local codes, to the National Fuel Gas Code, ANSI,

Z223.1-latest edition.

In addition where required by the authority having jurisdiction, the

installation must conform to American Society of Mechanical

Engineers Safety Codes for controls and safety devices for

automatically fired boilers, No. CSD-1. The installation must also

conform to the additional requirements of Slant/Fin Instruction Book

publication no. J-40 latest edition.

All electrical wiring is to be done in accordance with the National

Electrical Code ANSI/NFPA No. 70-latest edition and all local electrical codes. The unit must be electrically grounded if an external

power source is used.

In Canada, the installation must be in accordance with standards

CGA B149.1 and B149.2, installation codes for gas burning

appliances and equipment and/or local codes. All electrical

connections are to be made in accordance with Standard C.S.A.

C22.1 Canadian Electrical Code Part 1 and/or local codes.

INTRODUCTION OF FRESH WATER

Introduction of excessive amounts of fresh water into a system can

cause scaling and leave deposits in the boiler and the surrounding

pipes. This will lead to inefficient boiler operation and breakdown.

Fresh water will enter the system as a result of hidden leaks such

as may occur in underground piping. Relief valves should be piped

to a location that shows visible signs of relief.

Process applications that use fresh water, require the use of heat

exchangers. Any process application that results in introduction of

fresh water into a boiler can cause scaling with deposits forming in

the boiler and surrounding piping. This will damage the boiler.

Introduction of fresh water from leaks will cause similar damage.

In some areas it may be necessary to use a feed water treatment to

control the corrosive makeup of the feed water. Check with the local

authority, to determine if the feed water will need a conditioning

treatment before being supplied to the boiler.

Printed in the U.S.A. 711 Publication No. CJ-10-HWG

www.slantfin.com

Jaguar Caravan Multiple and Cascading Boilers2

1. INTRODUCTION

If additional information is desired please contact your local

Slant/Fin Sales Representative or Slant/Fin Technical Services.

Slant/Fin may be found on the web at www.slantfin.com

This application manual is intended to provide the piping and control

method for applying multiple Jaguar J-390C boilers to a space heating and domestic hot water heating system. Use this manual, in

conjunction with the Jaguar J-390C Installation and Operating

Instructions, publication J-40.

The following sections of the Installation and Operating Instructions

(J-390C) must be adhered to:

1. Boiler location and foundation

2. Clearances to combustibles

3. Contamination prevention

4. Air supply and ventilation

5. Venting application and materials*

6. Water treatment

7. Condensate disposal

8. Operating instructions

9. Care and Maintenance

2. RATINGS AND DIMENSIONS

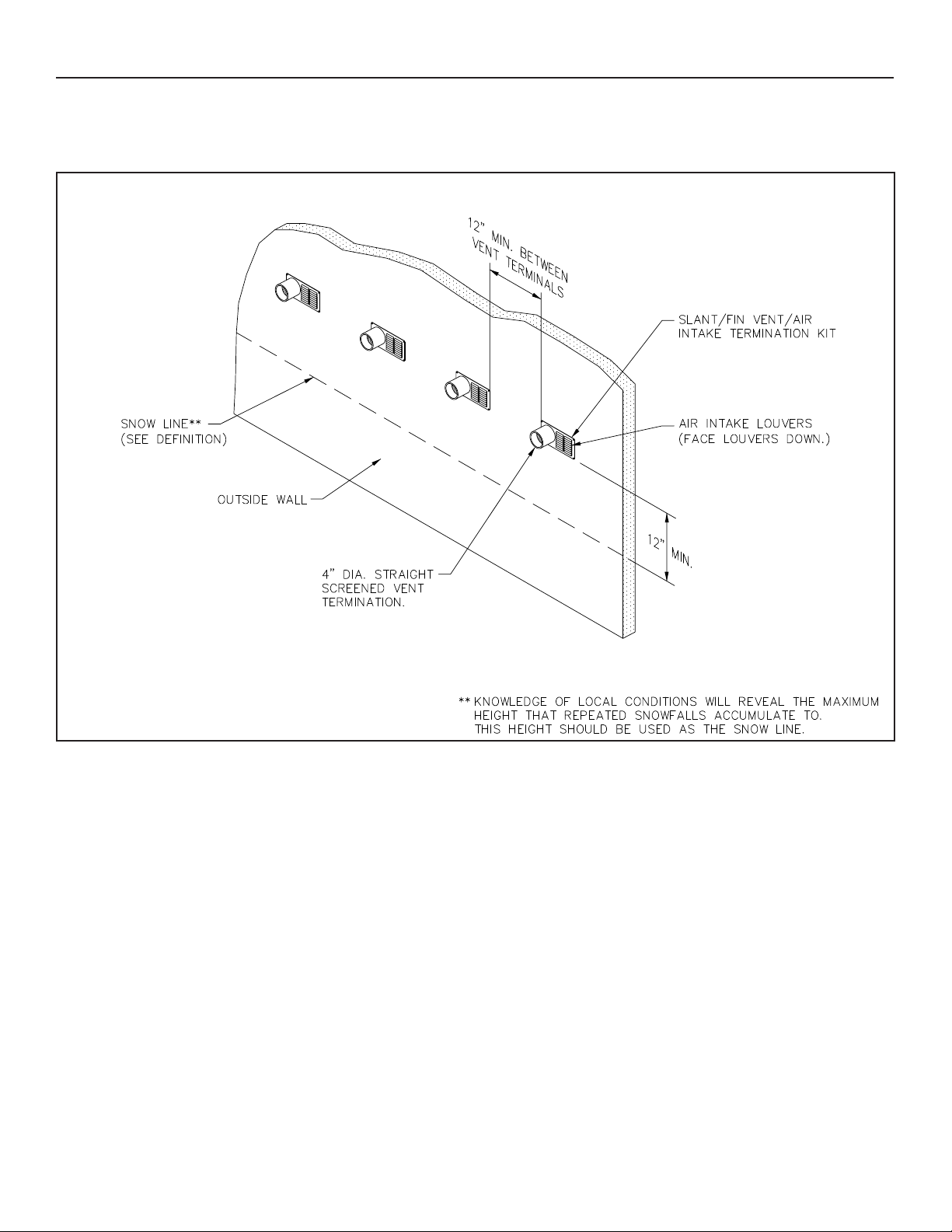

*Common venting of these appliances is not permitted. Direct vent

terminals cannot be clustered together or stacked vertically. Direct

vent terminals can be mounted side by side horizontally, provided

there is a 12" minimum distance between them.

There are two methods available to control J-390C Caravan boilers:

1. Jaguar link method to operate up to 8 boilers. An optional system

sensor is required for operation of this method. Supply water

system sensor (Part no. 833433000) max be ordered to

Slant/Fin boiler distributor.

2. External signal (0-10 Vdc input). Control such as Tekmar control

265 or 275 (operates up to 4 boilers). Energy Management

System may be used with this method. One optional interface

control is required for operation of each boiler in the system.

Part number for interface control kit is 830130000.

Jaguar boilers may also be used in a heating system with a

Caravan cast iron modular boiler system. Since high efficiency condensing boilers only condense when the return water temperature is

low, around 130 F or lower, it makes sense to use a lower cost

Caravan cast iron boiler at higher water temperature. We call a combination Caravan Cast Iron Modular Boiler used in a system with a

Jaguar Multiple Boiler a “Hybrid Boiler System”. We address Hybrid

Boiler Systems within this manual.

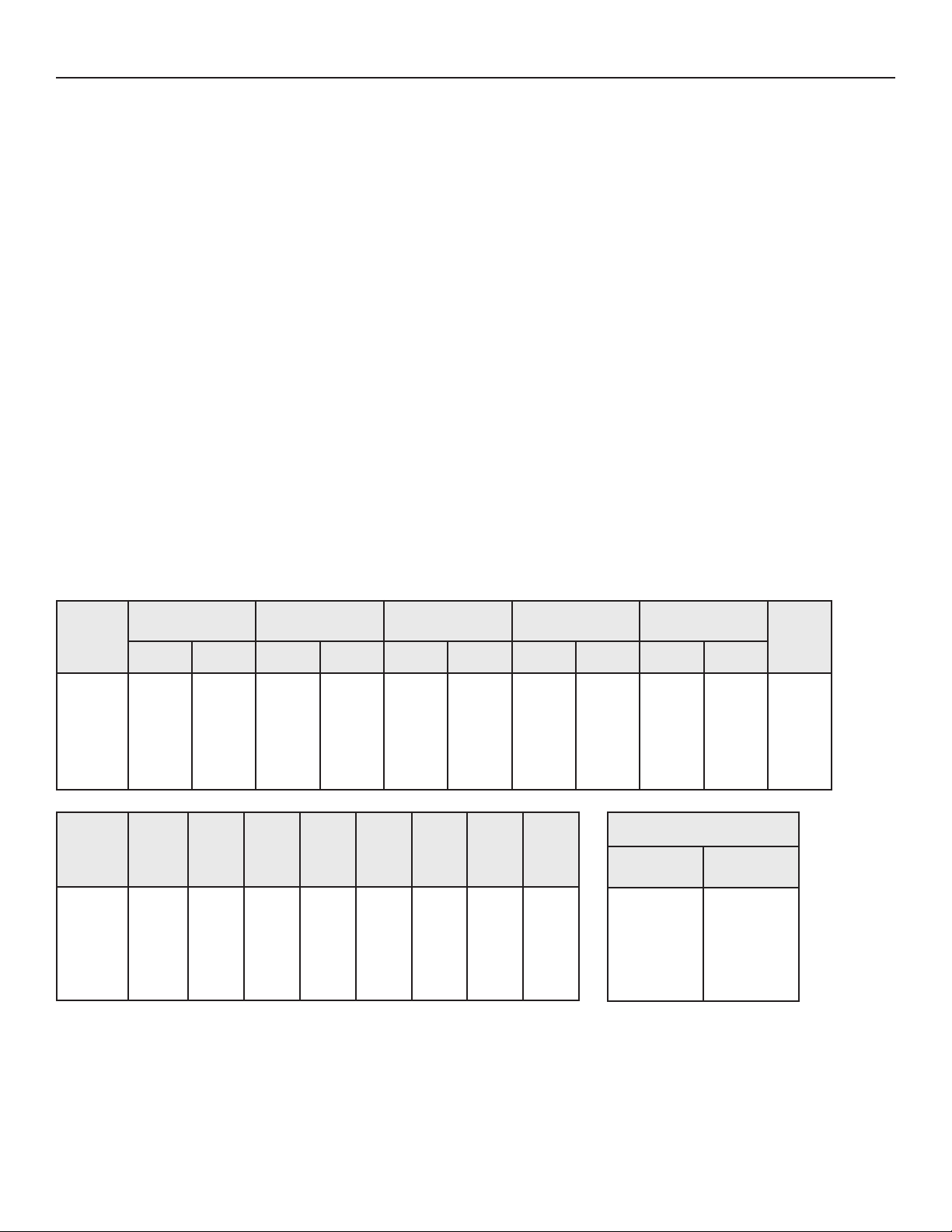

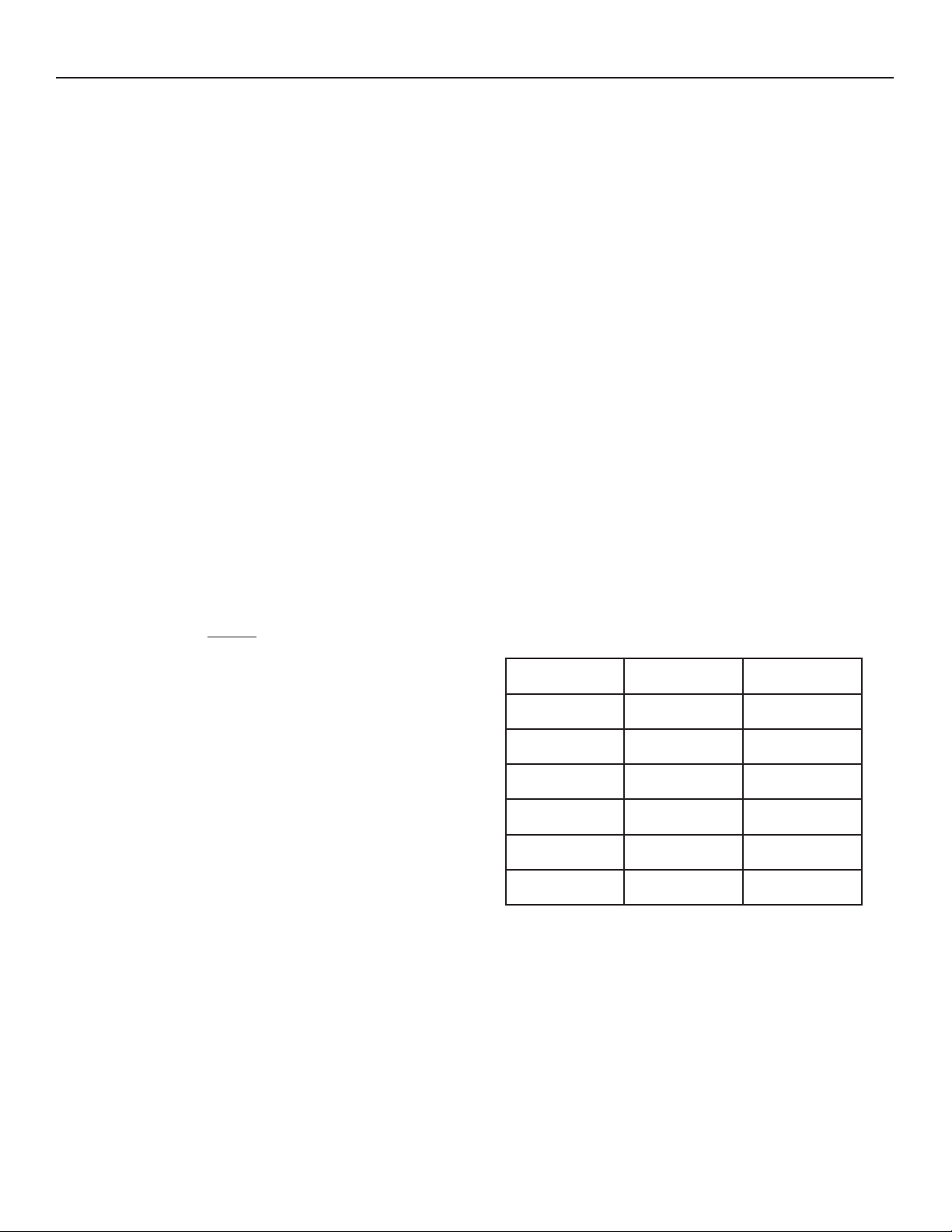

Table 1: Gas multiple boiler ratings and dimension/hot water model 50 psi maximum working pressure

Model

No.

J-390C 2B

J-390C 3B

J-390C 4B

J-390C 5B

J-390C 6B

J-390C 7B

J-390C 8B

Model

No.

J-390C 2B

J-390C 3B

J-390C 4B

J-390C 5B

J-390C 6B

J-390C 7B

J-390C 8B

Consists of

No. of Htg.

Boiler

2

3

4

5

6

7

8

Water

Content

(gal.)

4

6

8

10

12

14

16

Boiler

Model No.

J-390C

J-390C

J-390C

J-390C

J-390C

J-390C

J-390C

Ship

Wt.

Lbs.

600

900

1200

1500

2340

2730

3120

CSA Input

(MBH)

Max Min Max Min Max Min Max Min

780

1170

1560

1950

2340

2730

3120

Vent

Conn

4"

4"

4"

4"

4"

4"

4"

Air

Intake.

4"

4"

4"

4"

4"

4"

4"

110

110

110

110

110

110

110

Water

Correction

at Boiler

1-1/4

1-1/4

1-1/4

1-1/4

1-1/4

1-1/4

1-1/4

CSA output

704

1056

1408

1760

2112

2464

2816

Space

Btwn.

Boilers

3-1/4

3-1/4

3-1/4

3-1/4

3-1/4

3-1/4

3-1/4

(MBH)

106

106

106

106

106

106

106

**

Length

with

Header

50-1/2"

77-3/4"

104-1/4"

131-1/8"

158"

184-7/8"

211-3/4"

I=B=R Net

612

918

1224

1530

1836

2142

2448

**

Min.

Header

Size

2"

2"

3"

3"

3"

3"

3"

(MBH)

92

92

92

92

92

92

92

Combustion

Efficiency

91.6

91.6

91.6

91.6

91.6

91.6

91.6

System Turndown

Model

No.

J-390C 2B

J-390C 3B

J-390C 4B

J-390C 5B

J-390C 6B

J-390C 7B

J-390C 8B

96.7

96.7

96.7

96.7

96.7

96.7

96.7

Turndown

Ratio

7 to 1

10.6 to 1

14.2 to 1

17.7 to 1

21.3 to 1

24.8 to 1

28.4 to 1

Boiler

HorsePower

21

31.5

42

52.6

63.1

73.6

84.1

** “Length with headers allows for 3 1/4" between boiler.

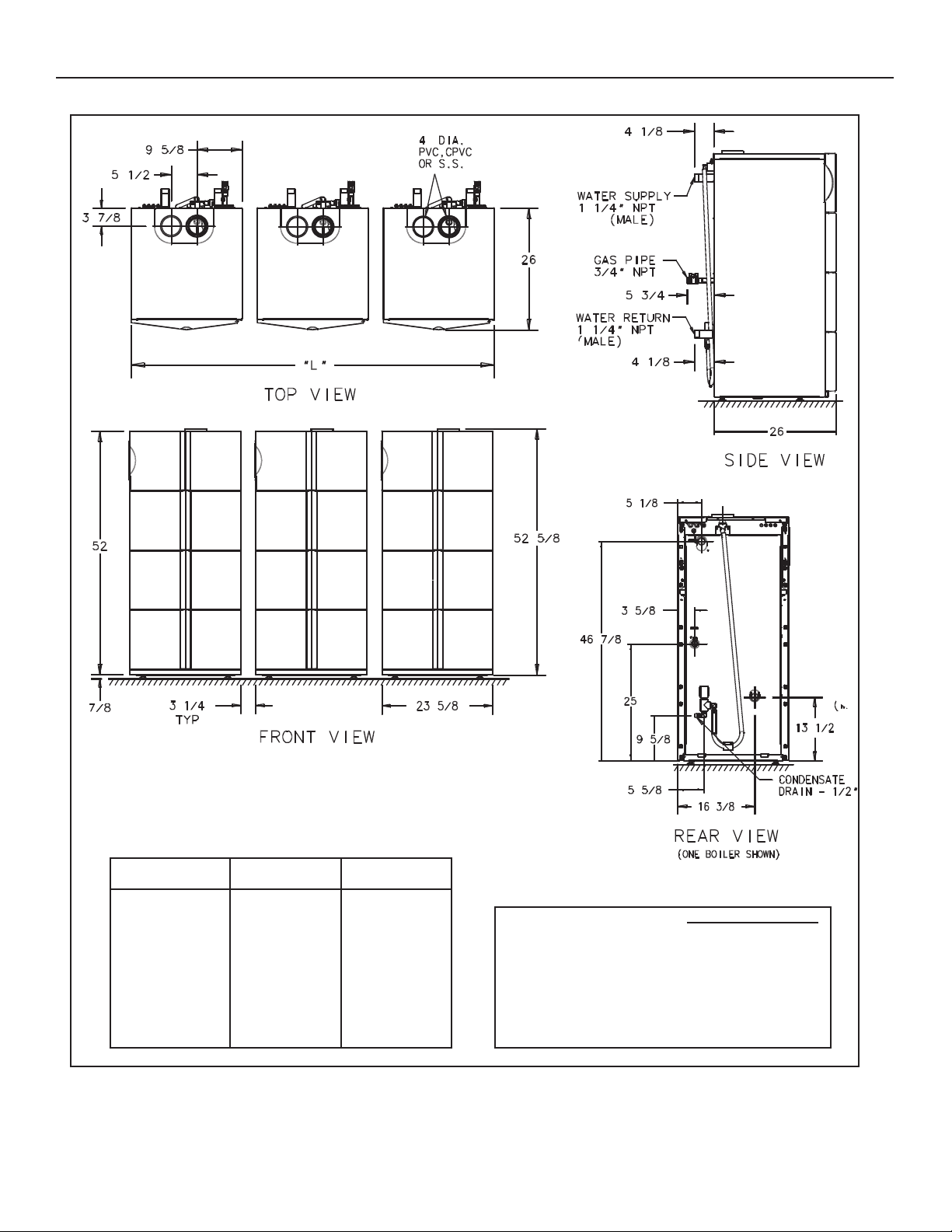

Jaguar Caravan Multiple and Cascading Boilers 3

‘’

‘’

‘’‘’ ‘’

‘’

‘’

‘’

‘’

‘’

‘’

‘’

‘’

‘’

‘’

‘’

‘’

‘’

‘’

‘’

‘’

‘’

** “L” Dimensions and spacing between boilers are for Slant/Fin headers.

†

Based on 150 BTUH per square foot E.D.R. at 170˚F water temperature.

No. of Boilers Model No. “L” inches

Figure 1. Dimensions

1

2

3

4

5

6

7

8

J-390C 1B

J-390C 2B

J-390C 3B

J-390C 4B

J-390C 5B

J-390C 6B

J-390C 7B

J-390C 8B

104-1/4

131-1/8

184-7/8

211-3/4

23-5/8

50-1/2

77-3/8

158

BOILER DESIGN DATA

– Max. ASME Working Pressure: 50 PSI

– Power Requirements

120 Volts, 60 Hz, 1 Phase

– 1.6 Amps per module, not including

primary circulator

Jaguar Caravan Multiple and Cascading Boilers4

3. BOILER ROOM DESIGN AND LAYOUT

Jaguar Caravan Multiple Boilers allow better utilization of floor space

and permit future boiler system expansion with minimum cost.

Jaguar boilers are hand truckable, fit through doorways and can

often be installed around existing boilers. Boilers can be installed in

line, back to back, at angles or in multiple rows. Layout is flexible.

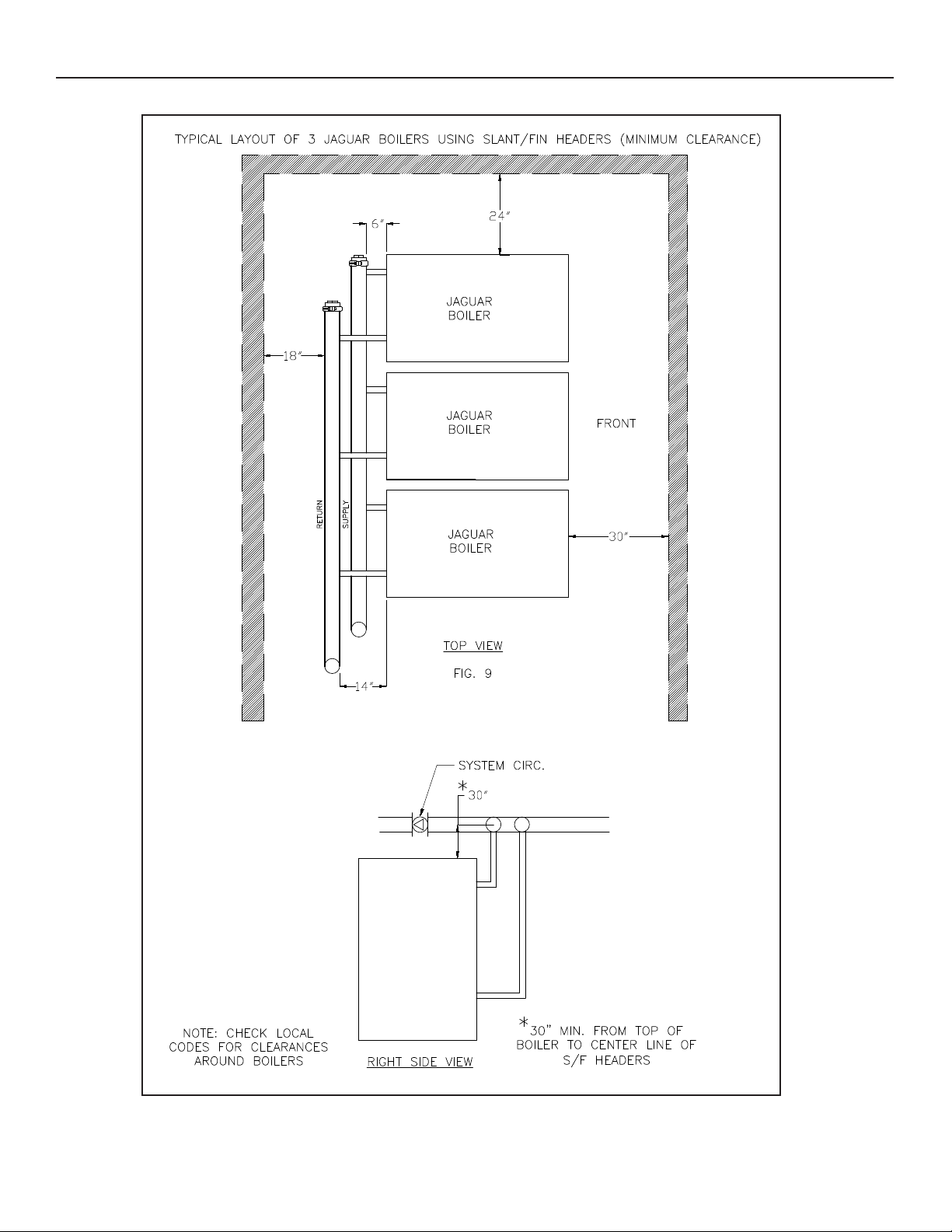

Figure 2 gives a typical layout using Slant/Fin Headers.

Boiler rooms and enclosures should comply with local code requirements. Provide a level and solid foundation for the boilers.

Equipment pads should be capable of supporting the boilers filled

with water and extend past the boiler jackets by at least 2 inches.

Jaguar boilers are approved for installation on combustible and noncombustible floors, however Jaguar boilers must not be installed on

or above carpeting. All boiler components should be protected from

water during installation, set up, operation and service.

Minimum clearances to combustible materials should comply with

local code requirements. Slant/Fin minimum clearances are listed

below.

MINIMUM CLEARANCES FROM COMBUSTIBLE

CONSTRUCTIONS

A. Minimum clearances to the exterior surfaces of the boiler shall

be as follows:

MINIMUM ALCOVE AND CLOSET CLEARANCE

For Combustible Recommended

Surface

Construction for Service

Front 0" 24"

Rear 0" 8"

Left Side 0" 0"

Right Side 0" 0"

Top 4" 6"

Flue Connector:

Enclosed — 2" 6"

Uninclosed — 1" 6"

B. Provide accessibility clearance of 8" on sides requiring servic-

ing and 18" on sides used for passage.

C. All minimum clearances shown above must be met. This may

result in increased values of some minimum clearances in

order to maintain the minimum clearances of others.

D. Clearance from hot water pipes shall be 1 inch**.

** At points where hot water pipes emerge from a floor, wall or ceiling, the clear-

ance at the opening through the finished floor boards or wall or ceiling boards

may be not less than 1/2 inch. Each such opening shall be covered with a

plate of uncombustible material.

SAFETY

KEEP THE BOILER AREA CLEAR AND FREE FROM

COMBUSTIBLE MATERIALS, GASOLINE AND OTHER

FLAMMABLE VAPORS AND LIQUIDS.

Jaguar Caravan Multiple and Cascading Boilers 5

Figure 2. Typical layout of 3 Jaguar Boilers using Slant/Fin Headers (Minimum Clearance)

Jaguar Caravan Multiple and Cascading Boilers6

4. FRESH AIR AND CONTAMINATION PREVENTION

The combustion air supply must not be susceptible to contamination sources, whether the combustion air comes from the interior

or exterior of the building. Contaminated air can cause corrosion

or other damage to the heat exchanger and components of the

boiler, causing failure of these parts or unsafe operation.

Below is a list of products and areas which may cause

contaminated combustion air:

PRODUCTS TO AVOID

• Spray cans containing chloro/fluorocarbons

• Permanent wave solutions

• Chlorinated waxes/cleaners

• Chlorine-based swimming pool chemicals

• Calcium chloride used for thawing

• Sodium chloride used for water softening

• Refrigerant leaks

• Paint or varnish removers

• Hydrochloric acid/muriatic acid

• Cements and glues

• Antistatic fabric softeners used in clothes dryers

• Chlorine-type bleaches, detergents, and cleaning

solvents found in household laundry rooms

• Adhesives used to fasten building products and other

similar products

AREAS LIKELY TO HAVE CONTAMINANTS

• Dry cleaning/laundry areas and establishments

• Swimming pools

• Metal fabrication plants

• Beauty shops

• Refrigeration repair shops

• Photo processing plants

• Auto body shops

• Plastic manufacturing plants

• Furniture refinishing areas and establishments

• New building construction

• Remodeling areas

• Garages with workshops

5. BOILER ROOM AIR SUPPLY AND VENTILATION

An ample supply of air is required for combustion and ventilation.

When buildings are insulated, caulked and weather-stripped, now

or later on, direct openings to outside may be required and should

be provided. If the boiler is not near an outside wall, air may be

ducted to it from outside wall openings.

Provisions for combustion and ventilation air must be made in

accordance with section 5.3, Air for Combustion and Ventilation, of

the National Fuel Gas Code, ANSI Z223.1-latest edition, or applicable provisions of the local building codes. The following recommendation applies to buildings of energy-saving construction, fully

caulked and weatherstripped.

INSTALLATION IN ENCLOSED BOILER ROOM REQUIRES

TWO UNOBSTRUCTED OPENINGS FOR PASSAGE OF AIR

INTO THE BOILER ROOM.

A. NON-DIRECT VENT INSTALLATION

1. Air drawn horizontally from outdoors DIRECTLY through

an outside wall; one louvered opening near the floor and one

louvered opening near the ceiling, each opening with a minimum FREE air passage area of 1 square inch per 4000

Btuh of total appliances’ input.

2. Air drawn horizontally through HORIZONTAL DUCTS; one

opening near the floor and one opening near the ceiling, each

opening with a minimum FREE air passage area of 1 square

inch per 2000 Btuh of total appliances’ input.

3. Air drawn VERTICALLY from outdoors; one opening at the

floor and one opening at the ceiling, each opening with a minimum FREE air passage area of 1 square inch per 4000

Btuh of total appliances’ input.

4. Air drawn from inside the building; one opening near the

floor and one opening near the ceiling, each opening with a

minimum FREE air passage area of 1 square inch per 1000

Btuh of total appliances’ input.

IF BOILERS ARE INSTALLED ADJACENT TO OTHER FUEL

BURNING EQUIPMENT, THE AREA OF FREE OPENINGS

MUST BE APPROPRIATELY INCREASED TO ACCOMMODATE

THE ADDITIONAL LOAD.

B. DIRECT VENT INSTALLATION

Adequate air supply should be provided to prevent overheating of

the boiler controls and boiler room. Openings for passage of air

into the boiler room for direct-vent installation must be at least

1

⁄2 of

the openings required for the non-direct vent as

mentioned above.

If additional non-direct vent appliances are installed in the same

space and adequate air openings are provided for them, there are

no additional air openings required for the Jaguar

J-390C boiler.

For both direct and non-direct installation, the following must be

considered:

-

Openings must never be reduced or closed. If doors or windows

are used for air supply, they must be locked open.

- Protect against closure of openings by snow and debris.

Inspect frequently.

- No mechanical draft exhaust or supply fans are to be used in

or near the boiler area.

- Boiler area must never be under negative pressure. The flow of

combustion and ventilating air to the boiler must not be

obstructed.

Jaguar Caravan Multiple and Cascading Boilers 7

6. VENTING REQUIREMENTS

The Jaguar J-390C is a sealed combustion type boiler, it may be

installed and vented either as a direct vent boiler which all air for

combustion is obtained directly from outside or as a non-direct

vent boiler which air for combustion is taken from inside the boiler

room.

The Jaguar J-390C boiler must be vented by 4" diameter

PVC/CPVC schedule 40 pipe, or the proper 4” diameter stainless

steel venting system (see “vent material” on this page) through the

roof or sidewall.

FLUE GAS VENTING REQUIREMENTS

The Jaguar J-390C series boiler is a high efficiency, mechanically

forced draft boiler and, therefore, require different venting arrangements than natural draft, lower efficiency boilers.

THE FOLLOWING INSTRUCTIONS MUST BE CAREFULLY

READ AND FOLLOWED IN ORDER TO AVOID ANY HAZARDOUS CONDITIONS DUE TO IMPROPER INSTALLATION

OF THE AIR INTAKE AND FLUE GAS VENTING SYSTEM.

The vent piping installation MUST be in accordance with these

instructions and with ANSI Z223.1-latest edition NATIONAL FUEL

GAS CODE, Part 7, Venting of Equipment. Other local codes may

also apply and must be followed. Where there is a conflict

between these requirements, the more stringent case shall apply.

The use of a vent damper is NOT permitted on this boiler series.

ADDITIONAL REQUIREMENTS FOR THE COMMONWEALTH

OF MASSACHUSETTS

When the Jaguar is installed and used in the Commonwealth of

Massachusetts, the following additional

Massachusetts code 248 CMR MUST be met:

(1). Exisiting chimneys shall be permitted to have their use continued when a

gas conversion burner is installed, and shall be equipped with a manual reset

device that will automatically shut off gas to the burner in the event of a sustained back-draft.

(2)(a). For all side wall horizontally vented gas fueld equipment installed in

every dwelling, building or structure used in whole or part for residential purposes, including those owned or operated by the Commonwealth and where

the side wall exhaust vent termination is less than seven (7) feet above finsihed grade in the area of the venting, including but not limited to decks and

porches, the following requirements shall be satisfied:

1. INSTALLATION OF CARBON MONOXIDE DETECTORS. At the time of

installation of the side wall horizontal vented fueled equipment, the installing

plumber or gasfitter shall observe that a hard wired carbon monoxide detector

with an alarm and battery back-up is installed on the floor level where the gas

equipment is to be installed. In addition, the installing plumber or gasfitter

shall observe that a battery operated or hard wired carbon monoxide detector

with an alarm is installed on each additional level of the dwelling, building or

structure served by the side wall horizontal vented gas fueled equipment. It

shall be the responsibility of the property owner to secure the services of qualified licensed professionals for the installation of hard wired carbon monoxide

detectors.

a. In the event that the side wall horizontally vented gas fueld equipment is

installed in a crawl space or an attic, the hard wired carbon monoxide detector

with alarm and battery back up may be installed on the next adjacent floor

level.

b. In th event that the requirements of this subdivision can not be met at the

time of completion of installation, the owner shall have a period of thirty (30)

days to comply with the above requirements; provided, however, that during

said thirty (30) day period, a battery operated carbon monoxide detector with

an alarm shall be installed.

requirements pursuant to

2. APPROVED CARBON MONOXIDE DETECTORS. Each carbon monoxide detector as required in accordance with the above provisions shall comply

with NFPA 720 and be ANSI/UL 2034 listed and IAS certified.

3. SIGNAGE. A metal or plastic identification plate shall be permanently

mounted to the exterior of the building at a minimum height of eight (8) feet

above grade directly in line with the exhaust vent terminal for the horizontally

vented gas fueled heating appliance or equipment. The sign shall read, in

print size no less that one-half (1/2) inch in size, “GAS VENT DIRECTLY

BELOW, KEEP CLEAR OF ALL OBSTRUCTIONS”.

4. INSPECTION. The state or local gas inspector of the side wall horizontally

vented gas fueled equipment shall not approve the installation unless, upon

inspection, the inspector observes carbon monoxide detectors and signage

installed in accordance with the provisions of 248 CMR 5.08(2)(a)1 through 4.

(b) EXEMPTIONS. The following equipment is exempt from 248 CMR

5.08(2)(a)1 through 4:

1. The equipment listed in Chapter 10 entitled “Equipment Not Required

TO Be Vented” in the most current edition of NFPA 54 as adopted by the

Board; and

2. Product Approved side wall horizontally vented gas fueled equipment

installed in a room or structure separate from the dwelling, building or

structure used in whole or part for residential purposes.

VENT AND AIR INTAKE MATERIALS

The vent and air intake system for direct or non-direct vent installation must be 4” diameter PVC/CPVC schedule. 40 pipe, or UL

listed single wall 4” diameter AL29-4C* stainless steel material.

The following manufacturers’ systems are approved for use within

a specified minimum and maximum equivalent vent length in this

manual.

Manufacturer Type/System Sealant

Heat-Fab. Inc.

ProTech System,

Inc.

Flex-L International

Inc.

Metal-Fab, Inc. Corr Guard Not Required

N/A

N/A

Saf-T Vent

EZ Seal

FasNSeal Not Required

StaR-34 GE-IS806

PVC pipe,

Schedule 40

CPVC pipe,

Schedule 40

Not Required

PVC primer

and cement

CPVC primer

and cement

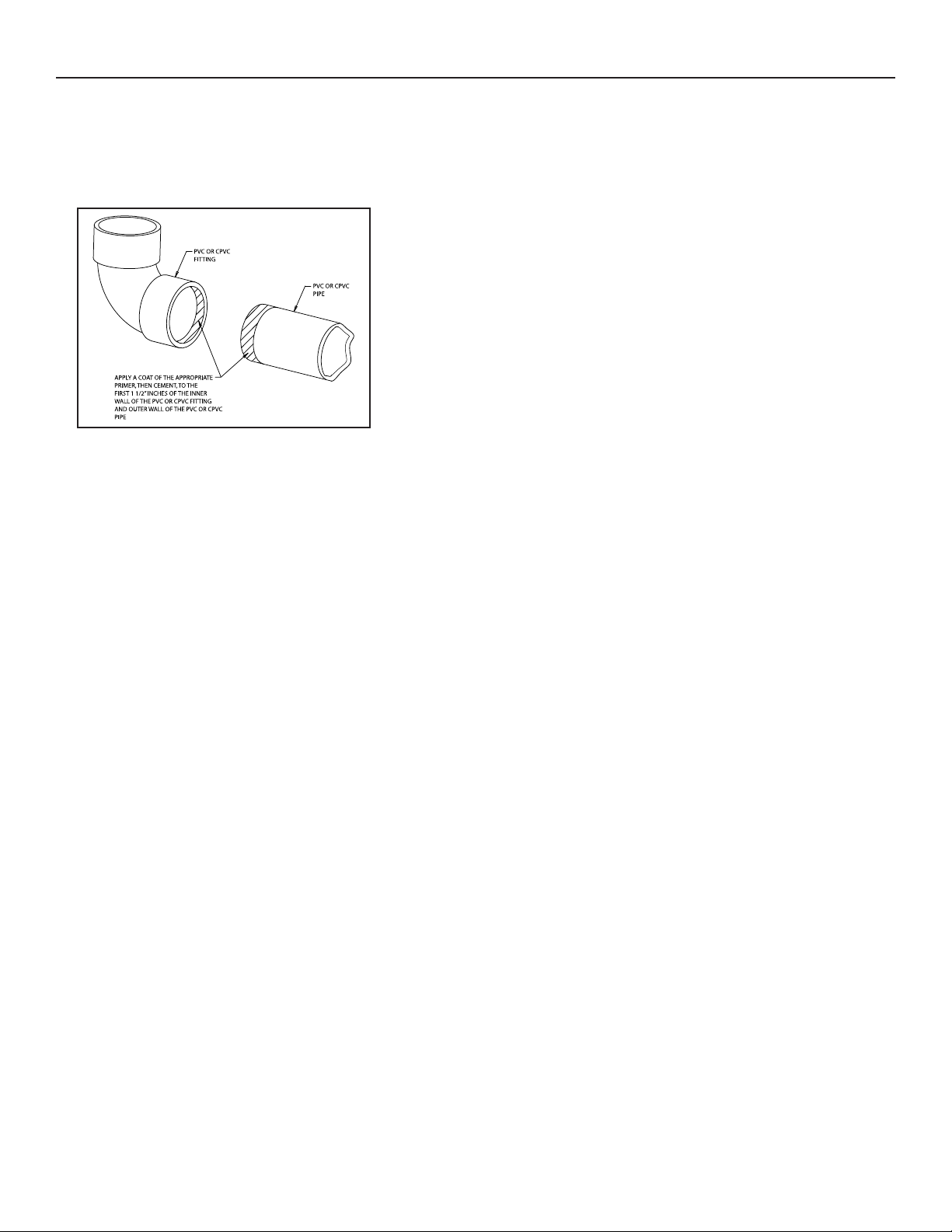

When joining the various components of the listed stainless steel vent

systems, the manufacturers’ instructions should be closely followed to

insure proper sealing. Use sealant specified by vent system manufacturer for sealing of pipe and fittings, if required. When joining the

PVC/CPVC pipe and fittings, follow the instructions provided in this

manual. All connections must be liquid and pressure tight. DO NOT

use galvanized flue pipe or any plastic-type materials other than

PVC/CPVC Schedule 40.

* Maximum exhaust vent length = 100 feet

* Maximum air intake length = 100 feet

* Each elbow is eqivalent to 10 feet of straight pipe

Jaguar Caravan Multiple and Cascading Boilers8

VENT AND AIR INTAKE RESTRICTIONS

1. Maximum allowed equivalent vent and air intake length for all of

the approved vent and air intake materials is 100 equivalent feet.

2. Equivalent of vent or air intake length is sum of the straight pipe

lengths and equivalent length of elbows. Each 90˚ elbow is equivalent

to 10 ft. of 4" pipe.

Figure 3.

3. The vent termination is in addition to the allowed equivalent lengths.

4. Minimum vent length is 2 feet of straight pipe, plus one 90˚ elbow.

5. Vent length restriction is for both direct and non-direct vent installations.

EXAMPLE: The combustion air is provided by air intake piping directly

to the boiler (direct-vent installation). The vent piping will be PVC and

installation location will require the use of 4 elbows for the vent to run

the termination. The air intake piping will also be PVC, and also will

require the use of 4 elbows.

In this case, the maximum straight pipe vent length that can be utilized

with the 4 elbows would be: 100’ - (4’ x 10’) = 60’. Since the air intake

pipe also is PVC and requires the use of 4 elbows, the maximum

straight pipe air intake length that can be utilized is also 60 feet.

If the air for combustion were taken from the boiler room (non-direct vent

installation), still the maximum straight vent length would be 60 feet.

6. The Jaguar J-390C boiler is equipped with a built-in condensation

drain and trap system. The traps must be filled with water. DO NOT

operate the boiler without filling the trap with water to prevent flue gas

discharge into space. The drain must dispose of possibly large

quantities of condensate, which may require a neutralizing system.

Refer to the “Condensate Drainage” section of this manual. No

additional condensation drain and trap is required on the vent piping

system itself.

7. The horizontal vent pipe must be sloped upward from the boiler at a

pitch of at least 1/4” per 1 foot of run, so that the condensate from the

vent system runs to the boiler vent adapter pipe, then out the built-in

condensation drain and trap.

8. The horizontal vent and air intake pipes must be supported with pipe

straps, at intervals no greater than 5 feet, when PVC/CPVC pipe is

utilized. This support spacing applies also to stainless steel vent pipe,

unless the manufacturer’s instructions permit otherwise. The vertical

vent and air intake pipes also must be supported, wherever the

building construction provides allowance for it, such as ceiling or

roof passage openings where a firestop and support or

braces can be affixed.

9. Minimum clearances of vent pipes from combustible constructions

must be maintained (Pub J-40). No clearance is required between the

vent and air intake pipes of this boiler.

10. Common venting with other appliances or another Jaguar boiler is

not allowed.

11. DO NOT install a vent damper or similar devices in vent system or on

the boiler.

12. DO NOT insulate venting system.

VENTING INSTALLATION

Only PVC/CPVC and approved stainless steel materials listed on page 7

may be used for the venting system installation. If stainless steel vent systems are used, follow the manufacturer’s instructions, in conjunction with

these instructions.

I. Non-Direct Vent Installation

The air for combustion is taken from the ambient air surrounding the boiler; therefore, ample supply of air is required for combustion and ventilation (see page 6.)

DO NOT use this installation method if the surrounding of the boiler is

contaminated. See page 6 for the list of harmful contaminants and their

sources, to avoid.

CAUTION: Flue gasses exiting from the vent terminal will condense.

Building materials in the area of the vent terminal should be protected

from discoloration and degradation.

VENT TERMINATION LOCATION AND CLEARANCES

1. The venting system shall terminate at least 3 feet above any forced

air inlet located within 10 feet.

2. The venting system shall terminate at least 12 inches below, or 12

inches horizontally from any door, window or gravity air inlet into

any building. The bottom of the vent terminal or air intake terminal

shall be at least 12 inches above grade or the normal snow level

whichever is greater.

3. Through the wall vents shall not terminate over public walkways or

over areas where condensate or vapor could create a nuisance or

hazard or could be detrimental to the operation of regulators, relief

valves or other equipment. Minimum clearance of 4 feet horizontal

distance is maintained, from electric meters, gas meters, regulators

and relief equipment.

4. Vent termination must not be located in any confined space (i.e.

window wells, alcoves, narrow alleys) or under any over hang or deck.

Vent termination should not allow flue gas discharge towards neighbor’s windows or where personal injury or property damages can occur.

A. NON-DIRECT VENT - VERTICAL VENTING

Figure shows typical venting through the roof. The vent pipe must pass

through the ceiling, floor and the roof vertically through a 8" minimum diameter cutout. A fire stop is required for each ceiling and floor penetration. For

roof passage, an appropriate UL listed roof flashing must be used.

An existing chimney may be used as a chase for vertical venting. Other

appliances CANNOT be vented into the same chimney or vent pipe with in

the chimney.

The vertical vent piping must terminate with a screened tee, combination of

45˚ elbow and a 90˚ screened elbow termination or a rain cap termination.

II. Direct Vent Installation

Air intake piping from outside to the boiler air intake adapter provides the

air for combustion. The boiler surrounding may be contaminated (See

page 6). Piping the air intake to the outside can prevent contaminants

from the boiler surrounding from entering the combustion air supply.

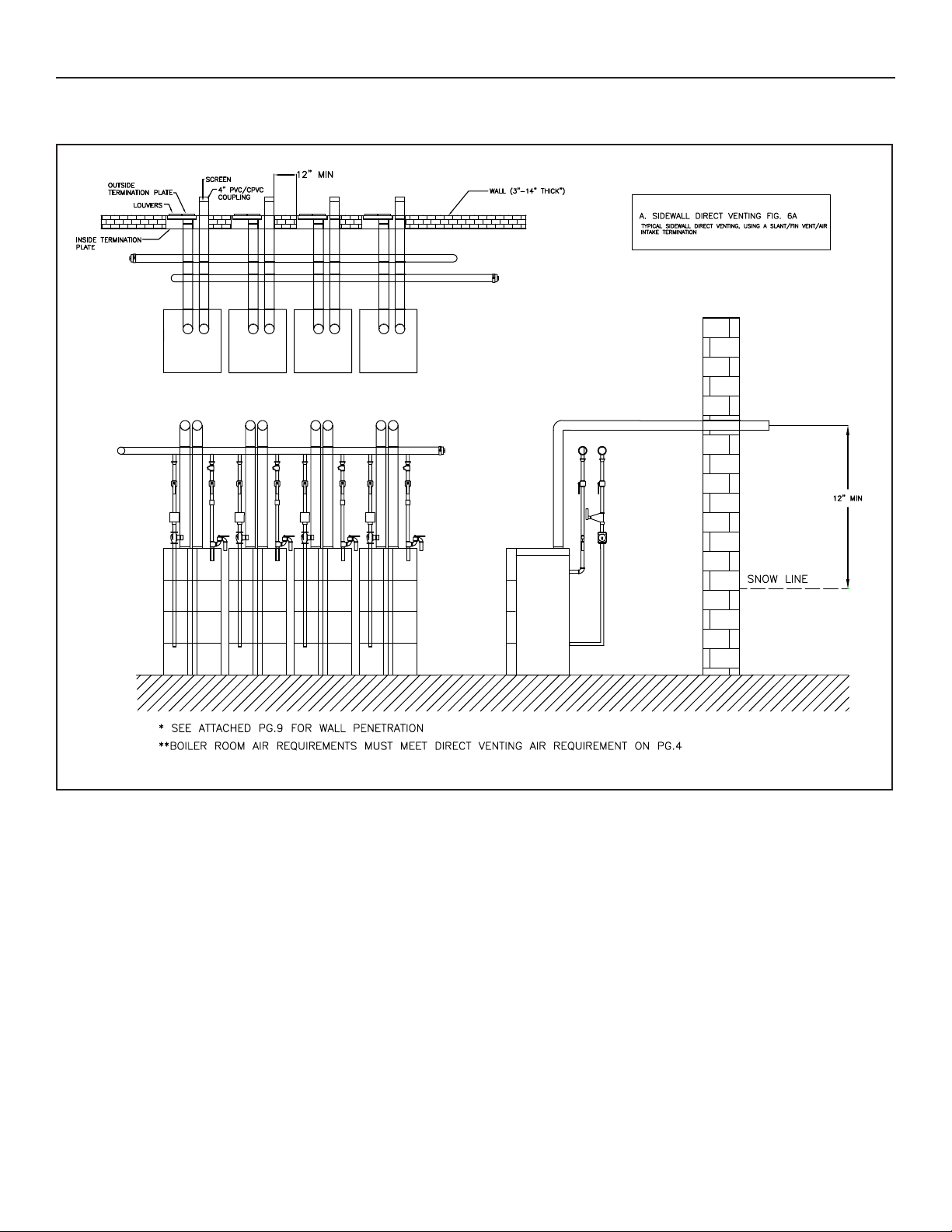

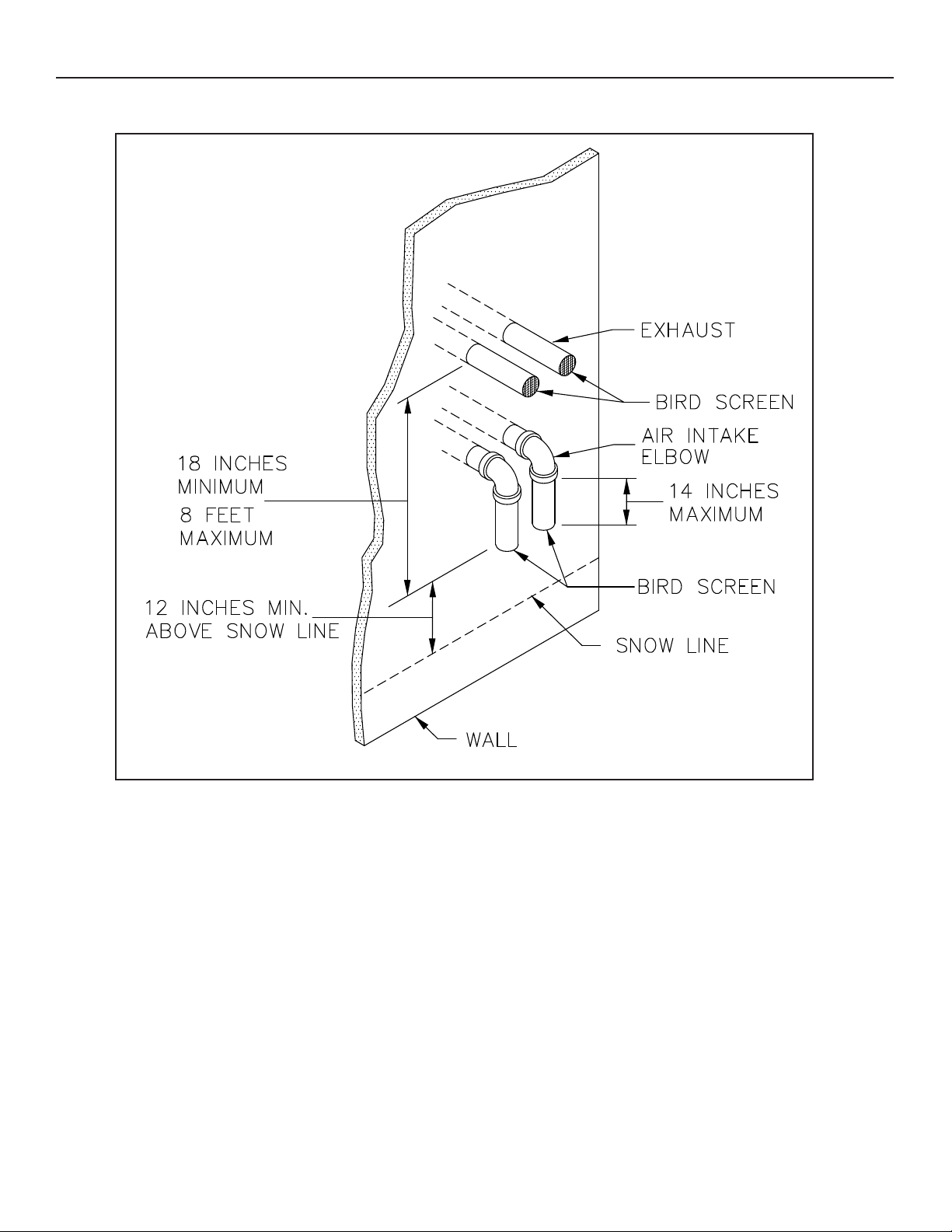

B. SIDEWALL DIRECT VENTING

Vent termination location and clearances for non-direct vent stated

in paragraph I, also applies to sidewall direct venting.

• See figure 4, 5 & 6 for direct vent side wall venting using the

Slant/Fin vent/air intake termination.

• See figure 6 for direct vent side wall venting with close spacing.

• See figure 7 & 8 for direct vent through the roof.

CAUTION: Flue gasses existing from the vent terminal will condense.

Building materials in the area of the terminal should be protected from

discoloration and degradation.

Jaguar Caravan Multiple and Cascading Boilers 9

Wall opening for Slant/Fin

vent air intake termination

Height - 5 3/4"

Width - 12 3/4”

Wall thickness - 3” to 14”

Figure 4.

Jaguar Caravan Multiple and Cascading Boilers10

Figure 5.

Jaguar Caravan Multiple and Cascading Boilers 11

**

**

Figure 6. Alternative multiple side wall air intake & exhaust venting.

Note:

• Air intake opening must be 12 inches minimum above snow line or grade if it does not snow in

area boilers are located.

• No minimum horizontal distance between outlets or inlets.

• Exhaust termination to extend beyond air intake, prevent condensation from falling onto air intake

** Knowledge of local conditions will reveal the maximum height that repeated snowfalls

accumulate to. This height should be used as the snow line.

Loading...

Loading...