Slant/Fin Gas Steam User Manual

®

STEAM / GAS

APPLICATION GUIDE

WET-BASE CAST-IRON MODULAR BOILERS

Guidelines for the design, purchase and installation of Slant/Fin gas-fired steam modular boiler systems.

CONTENTS

Introduction .............................................................................1

Ratings and dimensions .........................................................2

Boiler room air supply.............................................................3

Venting gas fired system .....................................................4,5

Gas main sizing ...................................................................6,7

Typical steam system layout ...................................................8

Steam piping design ...............................................................9

Installation and piping ......................................................10,11

Boiler feed pump sizing ...................................................12,13

Wiring at module .............................................................14-16

CODES AND STANDARDS

All Caravan installations must comply to local codes or, in the

absence of local codes, to the National Fuel Gas Code, ANSI,

Z223.1 latest edition.

In addition where required by the authority having jurisdiction,

the installation must conform to American Society of

Mechanical Engineers Safety Codes for controls and safety

devices for automatically fired boilers, No. CSD-1. The instal

ation must also conform to the additional requirements of

l

Slant/Fin Instruction book publication No. GG-100-40 latest

edition.

All electrical wiring is to be done in accordance with the

National Electrical Code ANSI/NFPA No. 7 latest edition and

all local electrical codes. The unit must be electrically grounded if an external power source is used.

In Canada, the installation must be in accordance wi

dards CGA B149.1 and B149.2, installation codes for gas

burning appliances and equipment and/or local codes. All

electrical connections are to be made in accordance with

Standard C.S.A. C22.1 Canadian Electrical Code Part 1

and/or local codes.

Many state and local codes require intermittent ignition

devices for gas boilers. Please specify if necessary.

th s

tan-

INTRODUCTION OF FRESH WATER

Introduction of excessive amounts of fresh water into a system can cause scaling and leave deposits in the boiler and

the surrounding water pipes. This will lead to inefficient boiler

operation and breakdown. Fresh water will enter the system

as a result of leaks such as may occur in underground piping.

-

Process applications that use fresh water require the use of

heat exch

duction of fresh water into a boiler can cause scaling, with

deposits forming in the boiler and surrounding piping. This will

damage the boiler. Introduction of fresh water from leaks will

cause similar damage.

In some areas it may be necessary to use a feed water treatment to control the corrosive makeup of the fill water. Check

with the local

a conditioning treatment before being supplied to the boiler.

angers. A

ny process application that results in intro-

uthority to determine if the feed water will need

a

INTRODUCTION

There are many varieties of steam heating systems. Because

of the wide range of field conditions, the design of these systems is beyond the scope of this manual. However, when

designing a steam Caravan boiler plant, certain guidelines

should be followed that are common to all modular steam

heating application.

This entire manual should be read prior to installing the

Slant/Fin Caravan steam system.

Safety – each module contains a dual combination gas valve,

ASME 15 lb Relief valve and pressure gauge.

Publication No. CG-10-SG

Printed in the U.S.A. 1112

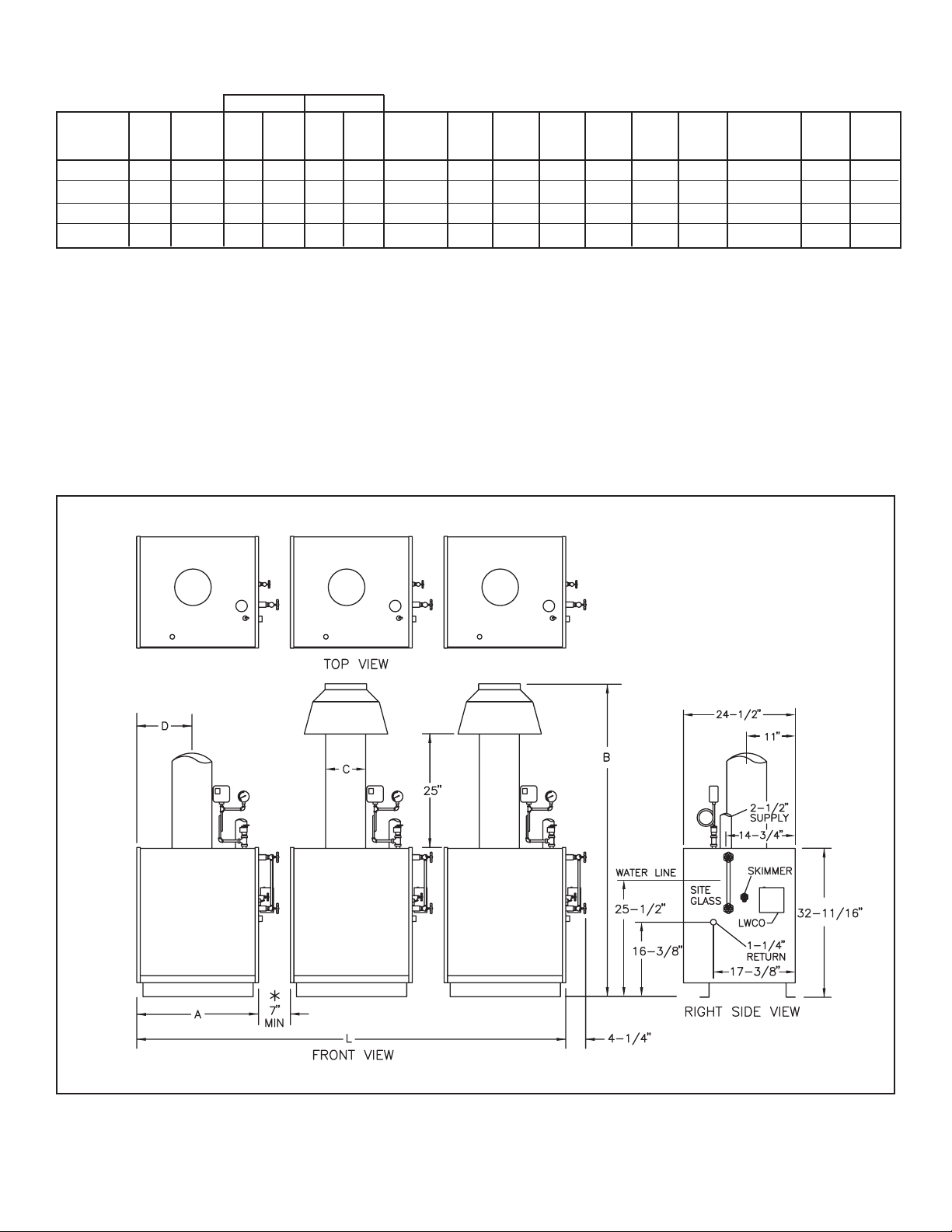

Table 1: Ratings and dimensions

Net

Output

M.B.H

AHRI

Net

Sq. Ft.

Steam

Horsepower

Boiler

Water

Content

(Gals)

Shipping

Weight

Lbs.

“A”

Dim

“B”

Dim

“C”

Dim

Minimum

Space

Between

Modules

Recommended

Header

Size

“D”

Dim

“L”

Dim

Model No.

Number

of

Modules

Module

Model

Number

Input

M.B.H

CSA

Gross

Output

.B.H

M

GXHT-600 Z 2 GXH-300 600 478 358 1492 14.78 16.8 1075 26 1⁄16” 59 1⁄8” 9” 7” 3” 11 17⁄32” 4’ 11 1⁄8”

GXHT-900 Z 3 GXH-300 900 717 537 2238 21.42 25.2 1595 26 1⁄16” 59 1⁄8” 9” 7” 4” 11 17⁄32” 7’ 8 3⁄16”

GXHT-1200 Z 4 GXH-300 1200 956 716 2983 28.56 33.6 2115 26 1⁄16” 59 1⁄8” 9” 7” 5” 11 17⁄32” 10’ 5 1⁄4”

GXHT-1500 Z 5 GXH-300 1500 1195 895 3729 35.70 42 2635 26 1⁄16” 59 1⁄8” 9” 7” 6” 11 17⁄32” 13’ 2 5⁄16”

For larger sizes, use multiple of the above

Specify gas by name, “natural” or “propane”.

Net ratings are based on piping and pick-up

allowance of 1.33. Slant/Fin should be consulted before selecting a boiler for installation

having unusual piping and/or pick-up requirements.

Ratings must be reduced by 4% at 2000 ft.

elevation and an additional 4% for every

additional 1000 ft. elevation over 2000 ft.

Modules in excess of 5, should be piped

in banks of 5, parallel with each other.

Figure 1: For McDonnel & Miller PS 801-24 L.W.C.O Min. clearance 9"

2

BOILER PLANT SIZING

Older buildings may have a heat loss significantly less than that

of the original building. To size a replacement steam boiler plant,

consider the following: Replacement steam boiler plants must be

sized to match the connected radiation load. Under-sizing will

prevent steam from reaching distant radiation quickly.

BOILER ROOM DESIGN

Caravan modular boiler systems allow better utilization o

space and permit future expansion with minimum cost. The modules are hand truckable, fit through doorways and often may be

installed around an existing inoperative boiler. They can be

grouped in single or multiple banks. Systems consisting of five or

more modules should be piped in two or more banks.

f floor

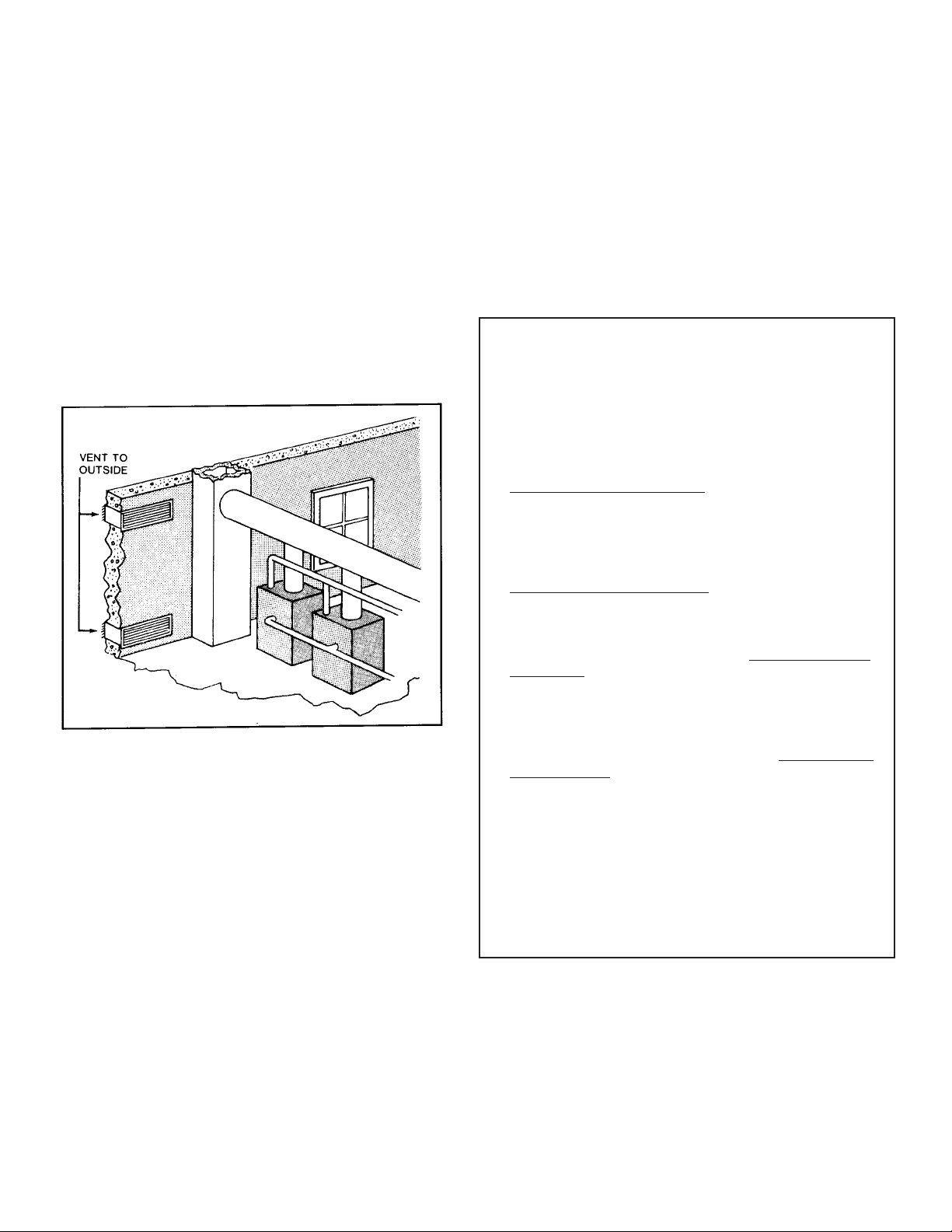

BOILER ROOM AIR SUPPLY

To ensure safe, efficient operation, the modular boiler syst

st be supplied with sufficient air to support complete combus-

mu

tion, replacing air entering draft dampers or draft hoods and ventilating the boiler room or areas.

For additional information, not listed below, see ANSI. Z223.1,

section 5.3.3.

INSTALLATION IN ENCLOSED BOILER ROOM REQUIRES

TWO UNOBSTRUCTED OPENINGS FOR PASSAGE OF AIR

INTO THE BOILER ROOM:

1. Air drawn horizontally from outdoors DIRECTLY

through an outside wall; one louvered opening near the

floor (below burner air inlet) and one louvered opening

near the ceiling (above the highest draft regulator), each

opening with a minimum FREE air passage area of

1 square inch per 4000 BTUH

of total system input.

em

Figure 2: Correct location of combustion-air supply ducts.

2. Air drawn horizontally through HORIZONTAL DUCTS;

one opening near the floor (below burner inlet) and one

opening near the ceiling (above the highest draft regulator),

each opening with a minimum FREE air passage area of

1 square inch per 2000 BTUH.

3. Air drawn VERTICALLY from outdoors; one opening at

the floor and one opening at the ceiling, each opening with

a minimum FREE air passage area of 1 square inch per

4000 BTUH of total system input.

4. Air drawn from inside the building; one opening near

the floor (below burner inlet) and one opening near the

ceiling (above the highest draft regulator), each opening

with a minimum FREE air passage area of 1 square inch

per 1000 BTUH of total system input.

IF BOILERS ARE INSTALLED ADJACENT TO OTHER FUEL

BURNING EQUIPMENT, THE AREA OF FREE OPENINGS

MUST BE APPROPRIATELY INCREASSED TO ACCOMMODATE THE ADDITIONAL LOAD.

UNLESS PROPERLY CONTROLLED, AVOID THE USE OF

FORCED VENTILATION, SINCE IT CAN CREATE AN

UNDESIRABLE PRESSURE DIFFERENTIAL BETWEEN

BOILER ROOM AND AIR SOURCE.

3

VENTING A GAS-FIRED SYSTEM

A boiler venting system provides an escape path for the products

of combustion. There are three major components for venting a

gas-fired Caravan: a draft hood for each module, a breeching

manifold and a chimney.

Draft Hood

The draft hood is part of each boiler module, although shipped in

a separate carton. It compensates for excessive draft. The dimensional relationships betwe

en the draft hood, the boiler and surface on which the boiler is mounted, are critical. These factors

are all interdependent in allowing the draft hood to function without moving parts. Attempts to alter these dimensions will result in

unsafe operating conditions.

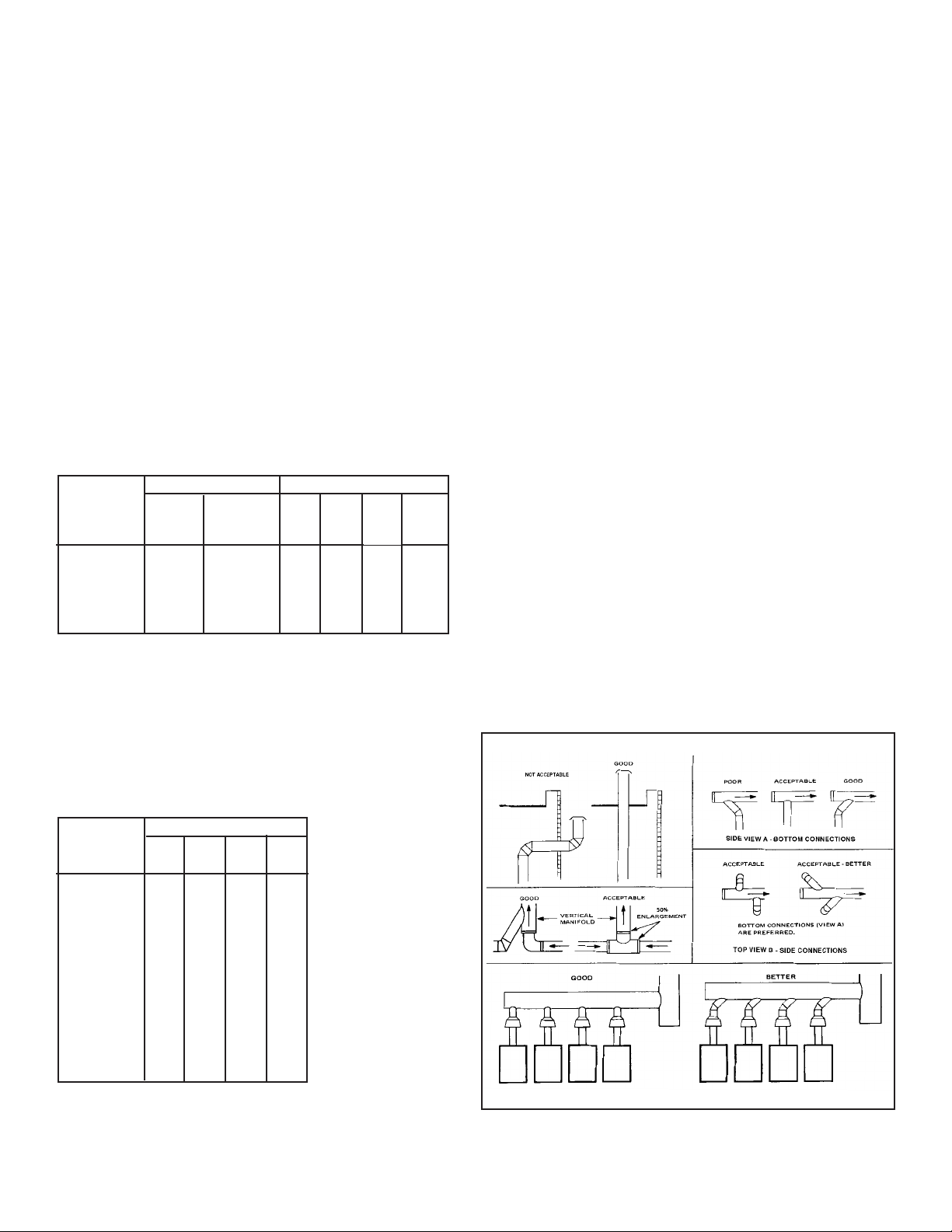

Breeching

Breeching is a term used to describe a manifold(s) that connects

individual boiler modules to a chimney. Breeching is usually

tructed of sheet metal having a smooth interior surface with all

s

con-

joints made tight against leakage. Pitch breeching up toward

chimney. Horizontal breeching size should be maintained for the

total length. Connections from the modules into the breeching are

best made at 45˚ angles in the direction of the chimney.

See figure 3.

Table 2: Breeching dimensions: gas fired systems

Model No.

Consist of

No. of

Modules

Module

No.

Chimney Height*

25

20

Feet30Feet50Feet

Feet

GXHT600Z 2 GXH300 12” 10” 10” 9”

GXHT900Z 3 GXH300 14” 12” 12” 12”

GXHT1200Z 4 GXH300 16” 14” 14” 12”

GXHT1500Z 5 GXH300 16” 16” 16” 14”

The bottom portion of the breeching should be installed at least 3

feet above the top of modules’ draft hoods. If this height cannot be

obtained, install the breeching as high as possible. See Page 5,

Table 3 for heights less than 3 feet. The portion of chimney height

rising directly above each draft hood is most effective in preventing

flue gas spillage. When the boiler room is in an unheated space,

insulate vent pipe and breeching to maintain flue gas temperature

and good chimney operation. Do not lower draft hoods’ skirt

height. For some combinations of low chimneys, low ceilings and

long breeching, a draft inducer may be needed. Inducers, when

required, are locally specified and warrantied. The breeching should

extend into but not beyond the chimney liner.

Chimney

Caravan gas-fired modular boilers

operate efficiently with masonry

or prefabricated chimneys as well as with “Type B” or double-walled

metal vent pipe. The latter type of chimney construction is generally

the least expensive. Chimney height is usually governed by the

building height and the size of the boilers (See Table 1). However,

the chimney should be high enough to minimize the effects of turbulent winds and pressure common ne

ar rooftop obstructions. A vent

cap should be used where permitted for additional protection

against adverse wind conditions and precipitation. The National

Board of Fire Underwriters recommends that the chimney should

extend at least 3 feet above the roof and be 2 feet higher than any

obstruction within 10 feet.

Sizing horizontal breeching connectors and chimneys for

gas-fired systems

Horizontal breechi

ng connectors shall be constant sized. The chimney and the horizontal breeching connector are sized using Table 2.

When there are multiple banks of boilers, the horizontal breeching

connector for each bank is sized using Table 2. To size the common

horizontal breeching connector, add up the total input and refer to

Table 2A.

The minimum chimney opening will be equal to the size of the

largest horizon

tal breeching section connected to it.

Based on single row of modules with no elbows.

• Height measured from the top of draft hood to top of chimney

Note: For conditions other than those shown, consult factory, or National

fuel gas code NFPA 54.

Table 2A: Chimney and breeching sizing for multiple banks **

Chimney Height*

25

20

Feet30Feet50Feet

BTU Input

Feet

1,800,000 18” 18” 18” 16”

2,100,000 20” 18” 18” 16”

2,400,000 20” 20” 20” 18”

2,700,000 22” 22” 20” 18’

3,000,000 24” 22” 22” 20”

3,300,000 24” 24” 22” 20”

3,600,000 26” 24” 24” 20”

3,900,000 26” 26” 24” 22”

4,200,000 26” 26” 24” 22”

4,500,000 28” 26” 26” 24”

•• Based upon system total BTU input

Figure 3: Suggested venting system constructions.

4

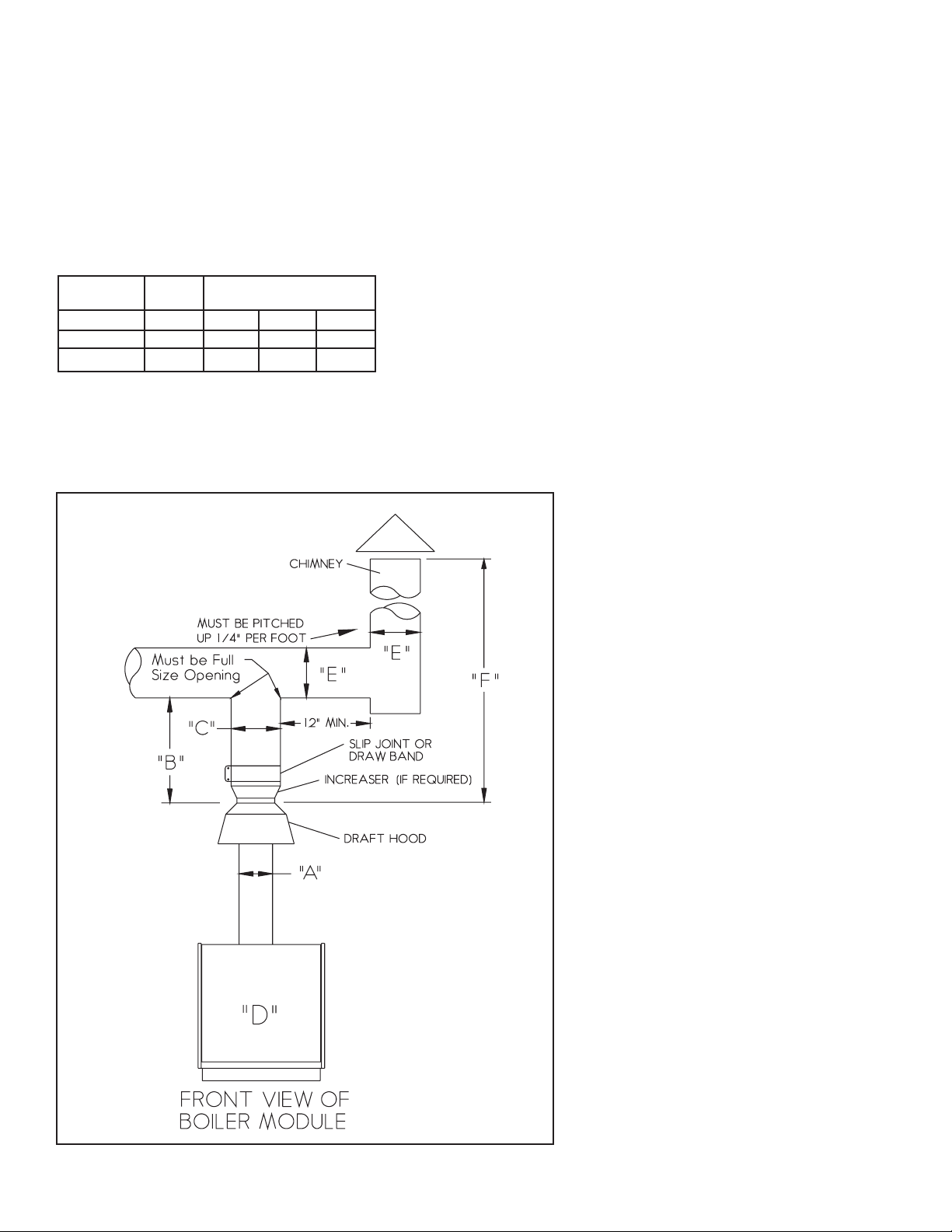

CONNECTOR RISE:

Connector rise is the length of the pipe connecting the top of the

draft hood to the system breeching above. The diameter of this

pipe varies depending upon BTU input, chimney height and the

length of the connector. Fig.4 (Dim. “B”) shows the location of this

pipe in a typical application. Table 3 depicts the proper diameter

(Dim. ”C”) of the connector rise depending upon its total leng

(top of the draft hoods to the breeching above).

Table 3

Vent connector diameters (20Ft. Chimney “F” Dim.)

Model

Flue

Outlet

Connector Rise “B”

Size”A” 3’ High 2’ High 1’ High

“C” “C” “C”

GXH300 9” 9” 10” 10”

Based on single row of modules with no elbows.

Note: For conditions other than those shown, consult factory, or National

fuel gas code NFPA 54.

th

HORIZONTAL BREECHING

CONNECTOR LENGTH:

The maximum length of the horizontal breeching connector length

between the chimney and the closest boiler shall not be longer

than one foot per inch of horizontal breeching connector diameter,

i.e. if the horizontal breeching connector is 16” D., the maximum length from the chimney to the first boiler would be 16

X 1 FT. or 16 feet. The minimum length shall be on

less of the horizontal breeching connector diameter. See figure 4.

ot regard-

e fo

Figure 4: Connector Rise “B”

5

Loading...

Loading...