Slant/Fin Gas Hot Water User Manual

®

HOT WATER/GAS Modular Boilers

APPLICATION GUIDE

Guidelines for the design, purchase and installation of Slant/Fin Caravan gas-fired, hot water modular boiler systems.

aterials . . . . . . . . . . . . . . . . . . . . . . . . . .12

CONTENTS

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Ratings and dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . .2,3

Recommended Piping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Optional factory supply and return headers . . . . . . . . . . . . . .5

Boiler room design . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Boiler room air supply requirements . . . . . . . . . . . . . . . . . . . .6

Typical layouts for gas-fired systems . . . . . . . . . . . . . . . . . . .7

Venting a gas-fired system . . . . . . . . . . . . . . . . . . . . . . . . . .8,9

Gas piping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10,11

Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11,12

SC- control bill of

Field wiring at modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

SC-3 system wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

SC-3 ladder wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

SC-9 space heating wiring . . . . . . . . . . . . . . . . . . . . . . . . . .16

SC-9 space heating ladder wiring . . . . . . . . . . . . . . . . . . . . .17

SC-9 space and domestic hot water wiring . . . . . . . . . . . . .18

SC-9 space and domestic hot water ladder wiring . . . . . . . .19

Caravan warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21,22

Request for Caravan rating plate . . . . . . . . . . . . . . . . . . .23,24

m

CODES AND STANDARDS

All Caravan installations must comply to local codes or, in the

absence of local codes, to the National Fuel Gas Code, ANSI,

Z223.1-latest edition.

In addition where required by the authority having jurisdiction, the

installation must conform to American Society of Mechanical

Engineers Safety Codes for controls and safety devices for

automatically fired boilers, No. CSD-1. The installation must also

conform to the additional requirements of Slant/Fin Instruction Book

publication no. GG-100-40 latest edition.

All electrical wiring is to be done in accordance with the National

Electrical Code ANSI/NFPA No. 70-latest edition and all local electri-

cal codes. The unit must be electrically grounded if an external

power source is used.

In Canada, the installation must be in accordance with standards

CGA B149.1 and B149.2, installation codes for gas burning

appliances and equipment and/or local codes. All electrical

connections are to be made in accordance with Standard C.S.A.

C22.1 Canadian Electrical Code Part 1 and/or local codes.

Many state and local codes require intermittent ignition devices for

gas boilers. Please specify if necessary.

LOCAL CODE APPROVALS

INTRODUCTION OF FRESH WATER

Introduction of excessive amounts of fresh water into a system can

cause scaling and leave deposits in the boiler and the surrounding

pipes. This will lead to inefficient boiler operation and breakdown.

Fresh water will enter the system as a result of hidden leaks such

as may occur in underground piping. Relief valves should be piped

to a location that shows visible signs of relief.

Process applications that use fresh water, require the use of heat

exchangers. Any process application that results in introduction of

fresh water into a boiler can cause scaling with deposits forming in

the boiler and surrounding piping. This will damage the boiler.

Introduction of fresh water from leaks will cause similar damage.

In some areas it may be necessary to use a feed water treatment to

control the corrosive makeup of the feed water. Check with the local

authority, to determine if the feed water will need a conditioning

treatment before being supplied to the boiler.

New York City:

GGT and GGHT Caravan Modules - MEA 283-93-E Vol. II

Slant/Fin vent damper NYS approval No. 8859

Pennsylvania:

Caravan boilers are approved in Pennsylvania by PA Cert. 174-BT-S

Publication No. CG-10-HWG

Printed in the U.S.A. 1212

www.slantfin.com

INTRODUCTION

This Caravan application manual is intended to simplify the selection

and application of Slant/Fin modular systems for a variety of space

heating and domestic hot water requirements. It applies to

gas-fired, hot water applications only. Where intermittent pilot, vent

B. Faster, easier installation - modules are completely factory

ass

embled, including individual jackets to save on-site labor.

Optional easy to install return and supply headers with flexible

quick connect fittings are available for hot water systems.

damper or any additional information is required, contact your local

wholesaler, Slant/Fin sales representative, or the Sla

nt/Fin factory.

C. Safety - each module contains an individual high limit control

and a dual combination gas valve. ASME relief valve is provided

Due to design flexibility of a Caravan modular boiler system, BTU

separately for mounting directly on each module.

input capacities are unlimited.

A. Boiler room design, size and flexibility - since Caravan

D. Fast domestic hot water recovery - Carava

heat exchanger of the positive circulating type.

n offers an external

modules have the burner and controls mounted to the front, they

can be installed with minimum clearances as per codes, thus

saving a significant amount of floor space.

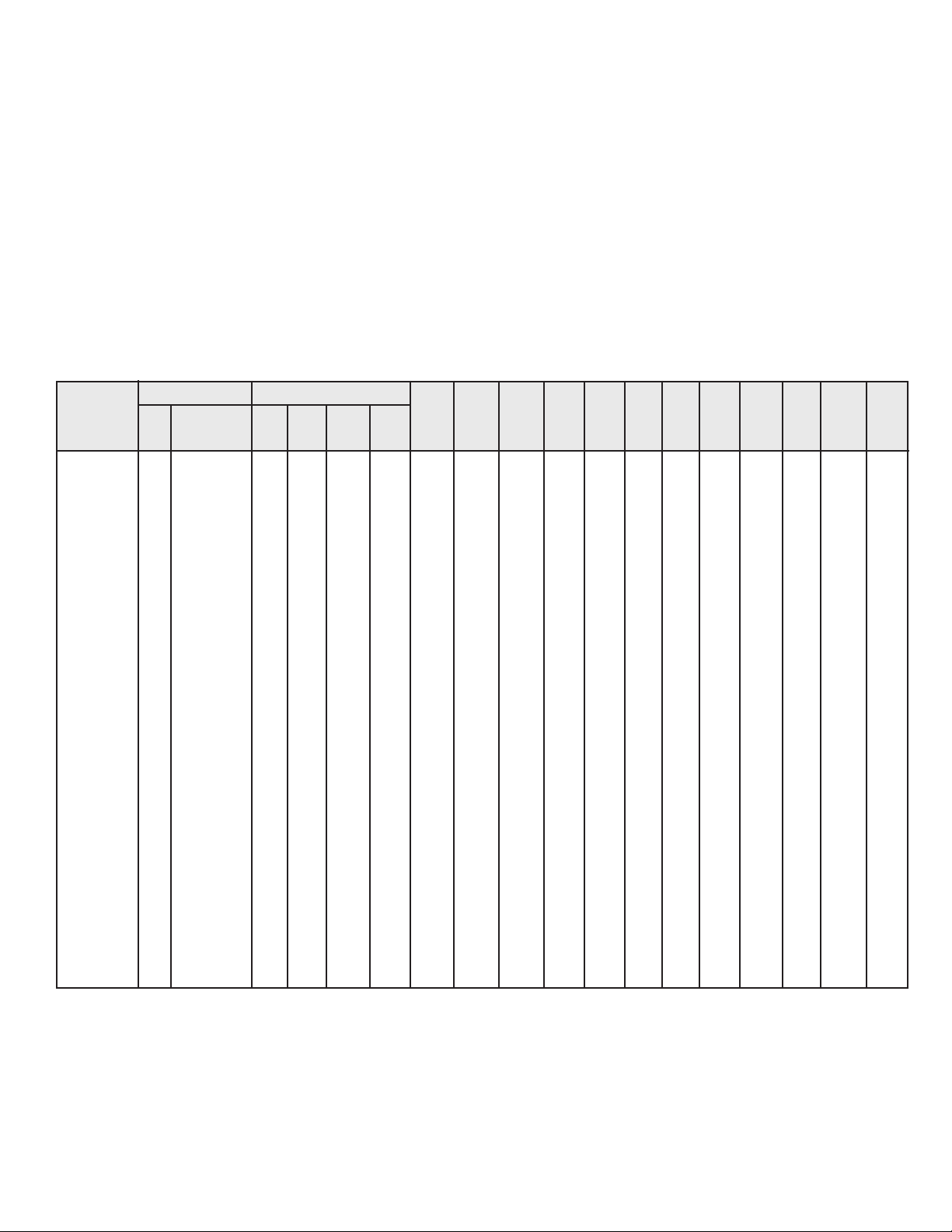

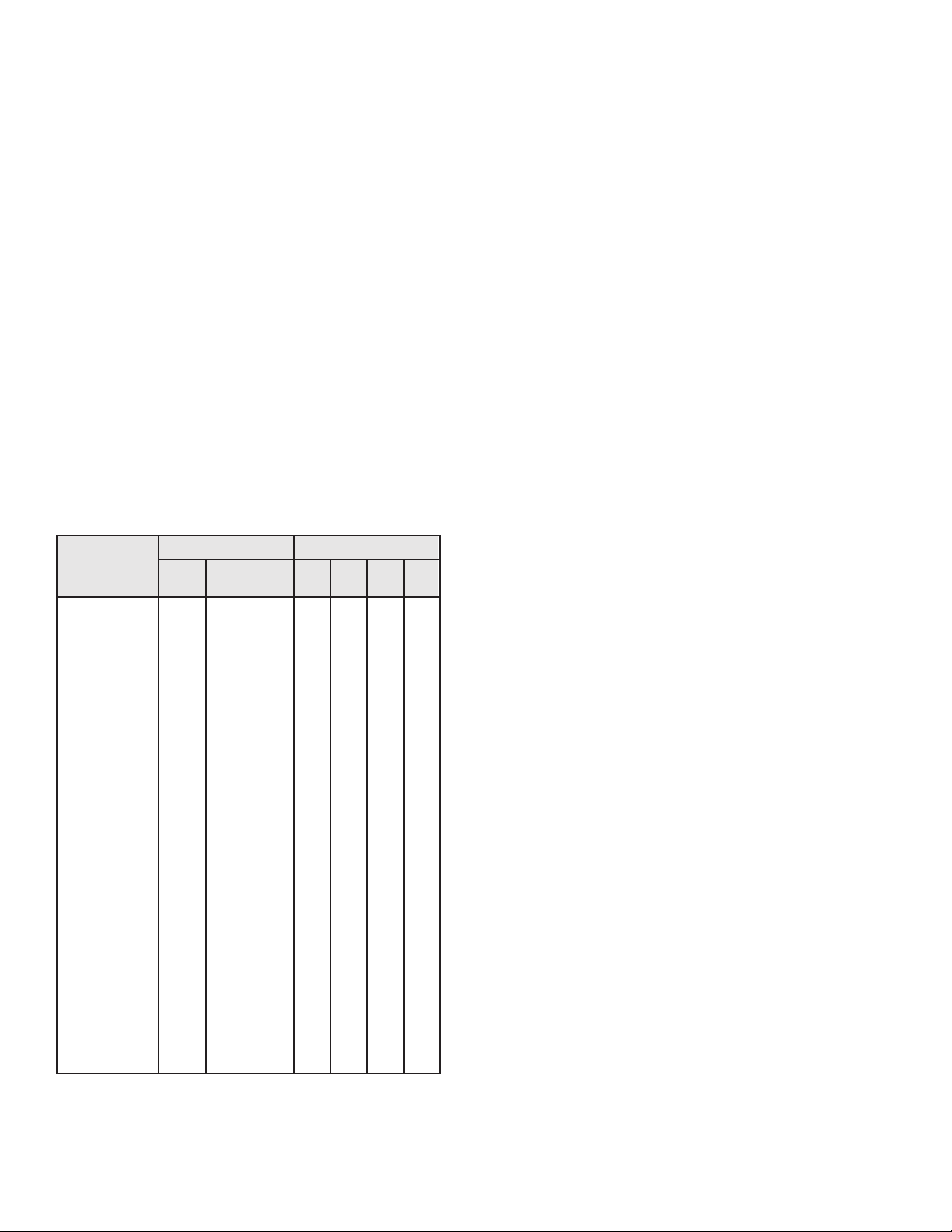

Table 1: Gas Caravan ratings and dimension/hot water model—GGT Series (100 psi maximum working pressure)

Gross

Output

Ratings

Water‡

(Sq.Ft.)

EDR

AHRI

Net

Output†

Boiler

Horse-

power

Thermal

EFF.

%

Water

Content

(gal.)

Ship

Wt.

Jkt.

Width

A§

Draft

Hood

Ht.

B§

Flue

Collar

C§

Draft

Hood

Ht.

D§

Header

to

Header

E§

Space

Btwn.

Mods.

F§

Length

with

Header

L§

Consists of

No.of

Model No.

GGT-600E 2 GG-300ES 600 486 2814 422 14.5 81.10 18.4 1080 2611⁄16 595⁄8 8 121⁄32 2113⁄16 55⁄16 4'11" 2"

GGHT-700E 2 GG-350HES 700 570 3306 496 17.0 81.40 20.6 1230 301⁄16 671⁄8 9 1323⁄32 253⁄16 115⁄16 5'2" 2"

GGHT-750E 2 GG-375HES 750 606 3506 526 18.1 80.90 20.6 1230 301⁄16 595⁄8 10 1323⁄32 253⁄16 115⁄16 5'2" 2"

GGHT-800E 2 GG-399HES 798 644 3734 560 19.2 80.60 20.6 1230 301⁄16 665⁄8 10 1323⁄32 253⁄16 115⁄16 5'2" 2"

GGT-900E 3 GG-300ES 900 729 4221 633 21.8 81.10 27.6 1590 2611⁄16 595⁄8 8 121⁄32 2113⁄16 55⁄16 7'7" 2"

GGHT-1050E 3 GG-350HES 1050 855 4959 744 25.5 81.40 30.9 1830 301⁄16 671⁄8 9 1323⁄32 253⁄16 115⁄16 7'10" 2"

GGHT-1125E 3 GG-375HES 1125 909 5259 789 27.2 80.90 30.9 1830 301⁄16 595⁄8 10 1323⁄32 253⁄16 115⁄16 7'10" 2"

GGHT-1200E 3 GG-399HES 1197 966 5601 840 28.9 80.60 30.9 1830 301⁄16 665⁄8 10 1323⁄32 253⁄16 115⁄16 7'10" 3"

GGT-1200E 4 GG-300ES 1200 972 5628 844 29.0 81.10 36.8 2140 2611⁄16 595⁄8 8 121⁄32 2113⁄16 55⁄16 10'3" 3"

GGHT-1400E 4 GG-350HES 1400 1140 6612 992 34.1 81.40 41.2 2440 301⁄16 671⁄8 9 1323⁄32 253⁄16 115⁄16 10'6" 3"

GGHT-1500E 4 GG-375HES 1500 1212 7012 1052 36.2 80.90 41.2 2440 301⁄16 595⁄8 10 1323⁄32 253⁄16 115⁄16 10'6" 3"

GGT-1500E 5 GG-300ES 1500 1215 7035 1055 36.3 81.10 46.0 2675 2611⁄16 595⁄8 8 121⁄32 2113⁄16 55⁄16 12'11" 3"

GGHT-1600E 4 GG-399HES 1596 1288 7468 1120 38.5 80.60 41.2 2440 301⁄16 665⁄8 10 1323⁄32 253⁄16 115⁄16 10'6" 3"

GGHT-1750E 5 GG-350HES 1750 1425 8265 1240 42.6 81.40 51.5 3050 301⁄16 671⁄8 9 1323⁄32 253⁄16 115⁄16 13'2" 3"

GGHT-1875E 5 GG-375HES 1875 1515 8765 1315 45.3 80.90 51.5 3050 301⁄16 595⁄8 10 1323⁄32 253⁄16 115⁄16 13'2" 3"

GGHT-2000E 5 GG-399HES 1995 1610 9333 1400 48.1 80.60 51.5 3050 301⁄16 665⁄8 10 1323⁄32 253⁄16 115⁄16 13'2" 3"

GGHT-2100E 6 GG-350HES 2100 1710 9918 1488 51.1 81.40 61.8 3660 301⁄16 671⁄8 9 1323⁄32 253⁄16 115⁄16 15'10" 3"

GGHT-2250E 6 GG-375HES 2250 1818 10518 1578 54.3 80.90 61.8 3660 301⁄16 595⁄8 10 1323⁄32 253⁄16 115⁄16 15'10" 3"

GGHT-2400E 6 GG-399HES 2394 1932 11202 1680 57.7 80.60 61.8 3660 301⁄16 665⁄8 10 1323⁄32 253⁄16 115⁄16 15'10" 3"

GGHT-2450E 7 GG-350HES 2450 1995 11571 1736 59.6 81.40 72.1 4270 301⁄16 671⁄8 9 1323⁄32 253⁄16 115⁄16 18'6" 3"

GGHT-2625E 7 GG-375HES 2625 2121 12271 1841 63.4 80.90 72.1 4270 301⁄16 595⁄8 10 1323⁄32 253⁄16 115⁄16 18'6" 3"

GGHT-2800E 7 GG-399HES 2793 2254 13069 1960 67.3 80.60 72.1 4270 301⁄16 665⁄8 10 1323⁄32 253⁄16 115⁄16 18'6" 3"

GGHT-2800AE

GGHT-3000E 8 GG-375HES 3000 2424 14024 2104 72.4 80.90 82.4 4880 301⁄16 595⁄8 10 1323⁄32 253⁄16 115⁄16 21'2" 3"

GGHT-3150E 9 GG-350HES 3150 2565 14877 2232 76.6 81.40 82.4 5490 301⁄16 671⁄8 9 1323⁄32 253⁄16 115⁄16 23'10" 3"

GGHT-3200E 8 GG-399HES 3192 2576 14936 2240 77.0 80.60 82.4 4880 301⁄16 665⁄8 10 1323⁄32 253⁄16 115⁄16 21'2" 3"

GGHT-3375E 9 GG-375HES 3375 2727 15777 2367 81.5 80.90 92.7 5490 301⁄16 595⁄8 10 1323⁄32 253⁄16 115⁄16 23'10" 3"

GGHT-3500E 10 GG-350HES 3500 2850 16530 2480 85.1 81.40 92.7 6100 301⁄16 671⁄8 9 1323⁄32 253⁄16 115⁄16 26'6" 3"

GGHT-3600E 9 GG-399HES 3591 2898 16800 2520 86.6 80.60 92.7 5490 301⁄16 665⁄8 10 1323⁄32 253⁄16 115⁄16 23'10" 3"

GGHT-3750E 10 GG-375HES 3750 3030 17530 2630 90.5 80.90 103.0 6100 301⁄16 595⁄8 10 1323⁄32 253⁄16 115⁄16 26'6" 3"

GGHT-4000E 10 GG-399HES 3990 3220 18670 2800 96.2 80.60 103.0 6100 301⁄16 665⁄8 10 1323⁄32 253⁄16 115⁄16 26'6" 3"

Htg.

Mod.

Module

Model

Number

8 GG-350HES 2800 2280 13224 1984 68.1 81.40 82.4 4880 301⁄16 671⁄8 9 1323⁄32 253⁄16 115⁄16 21'2" 3"

CSA

Input

Min.

Header

Size‡‡

FOR LARGER SIZES, USE MULTIPLES OF THE ABOVE.

* Specify gas by name, "Natural" or "Propane".

† Net ratings are based on piping and pick-up allowance of 1.15. Slant/Fin should

be consulted before selecting a boiler for installation having unusual piping and/or

pick-up requirements. Ratings must be reduced by 4% at 2,000 ft. elevation and

an additional 4% for every additional 1,000 ft. elevation over 2,000 ft.

e

‡ Net ratings in square feet based on

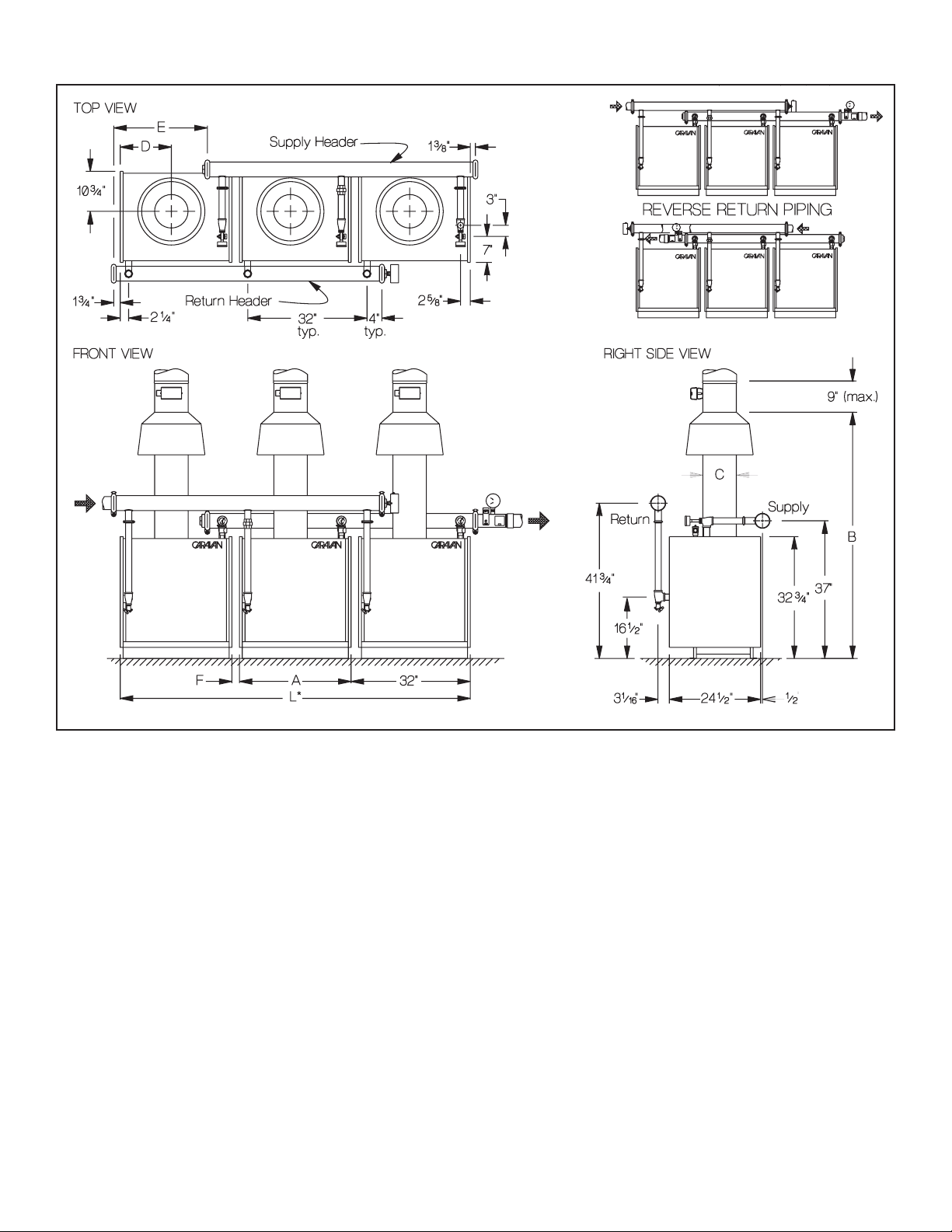

§ Refer to figures 1 and 8. Headers shown are optional.

‡‡All factory supplied headers use 3" system connections.

Modules in excess of 10 should be piped in parallel in two or more batteries.

Note: For higher capacities, specify correct combination of standard Caravan

modules shown.

mission rate of 150 Btuh/sq. ft.

2

Figure 1: Gas Caravan dimensions and typical piping/hot water models

Design Data

Max. ASME Working Pressure: 100 psi

Power Requirements: 120 volts, 60 HZ, .34 amps per module

3

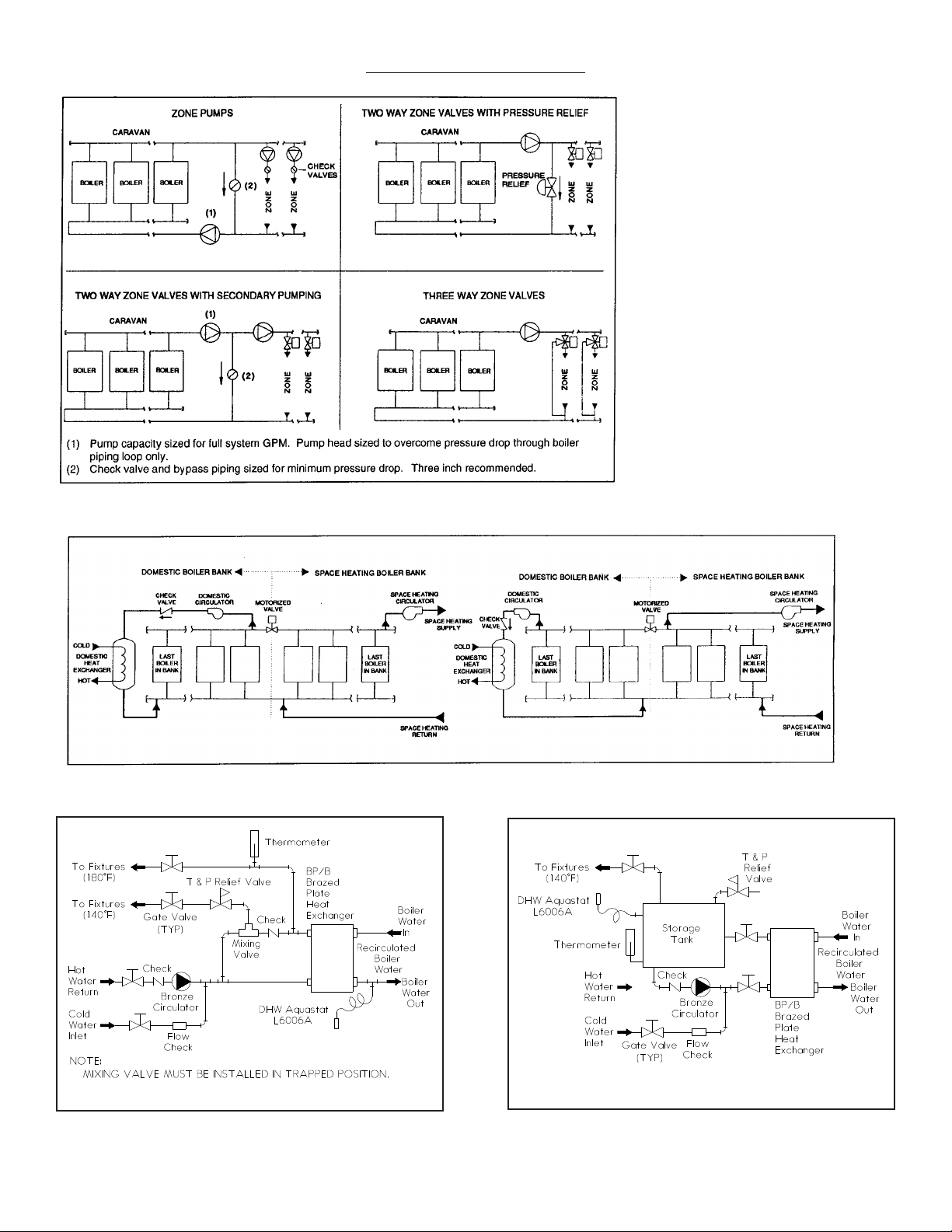

RECOMMENDED PIPING

Figure 2. Recommended boiler piping for variable circulation

Figure 3. Supply and return piping locations

Figure 4. Instantaneous tankless coil—

two temperature with recirculation

Figure 5. Storage tank from tankless coil with recirculation

4

EQUIPMENT INCLUDED

GGT SERIES — Hot Water Models

One per module unless otherwise noted

• Pre-assembled heat exchangers with built-in air separators

and insulated jacket.

• Base.

• Flue collector.

• Gas burners, gas orifices and manifold assembly.

• Combination gas valve including manual shut-off pressure

regulator.

• Hi-limit control.

• System pressure and temperature gauge (unmounted, one

per system).

• Module pressure a

nd temperature gauge (unmounted).

• Module pressure relief valve (ASME) (unmounted). Specify

30, 50 or 100 psi.

• Control header (unmounted, one per system).

• Draft hoods (unmounted).

OPTIONAL EQUIPMENT

• Hot water supply and return header assemblies.

• Control panel with automatic lead lag.

• Spark ignition system.

• Vent dampers.

• External DHW heat exchanger.

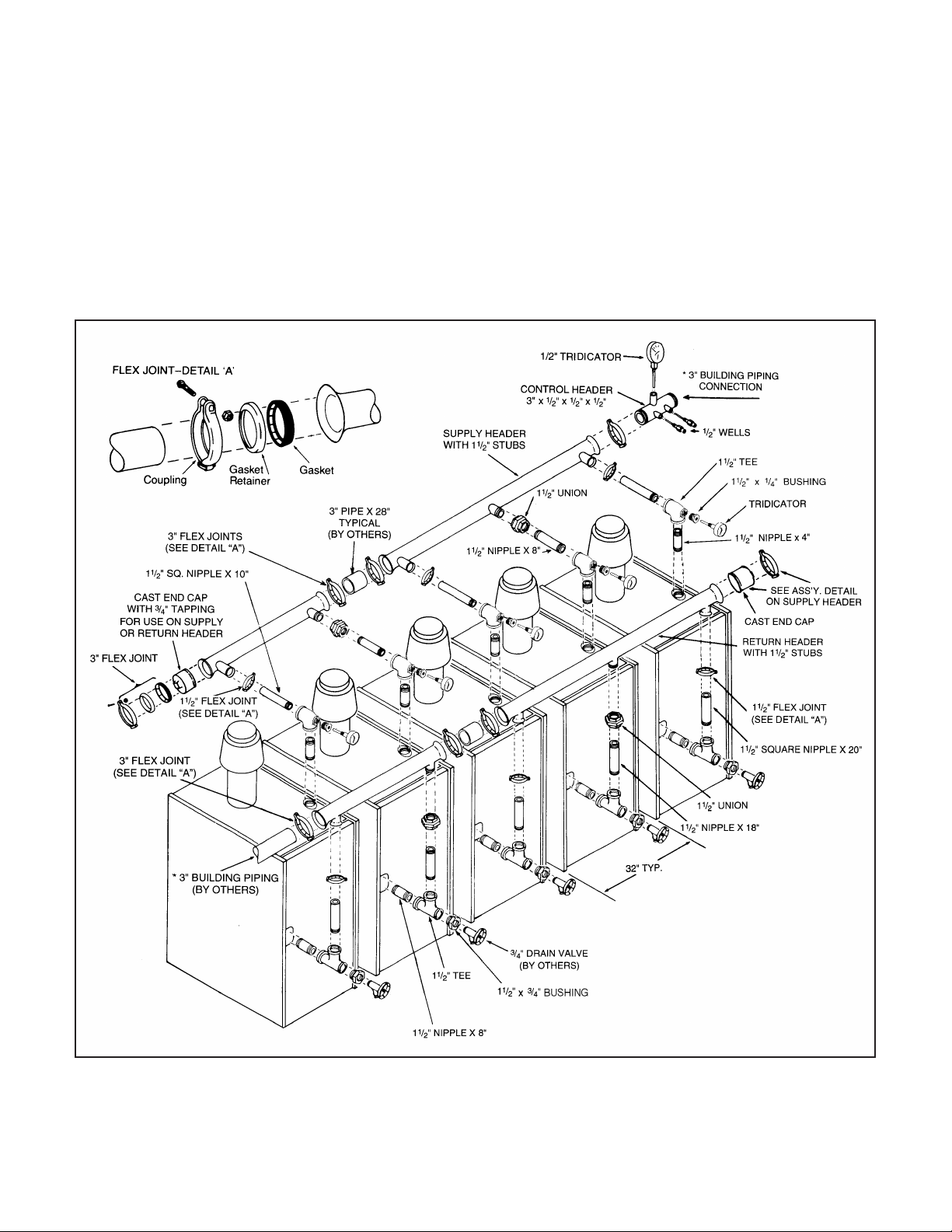

*Building piping must be rigidly secured so it cannot

move where connected to headers.

NOTE:

Shown reverse return (Preferred). For direct return,

header assembly piping connections may be made at

the same end of the boiler bank, not as shown.

Some governing agencies do not allow compression

type couplings. Consult your local code requirements.

Figure 6. Gas Caravan—optional header assembly for all models GGT hot water Caravan systems

5

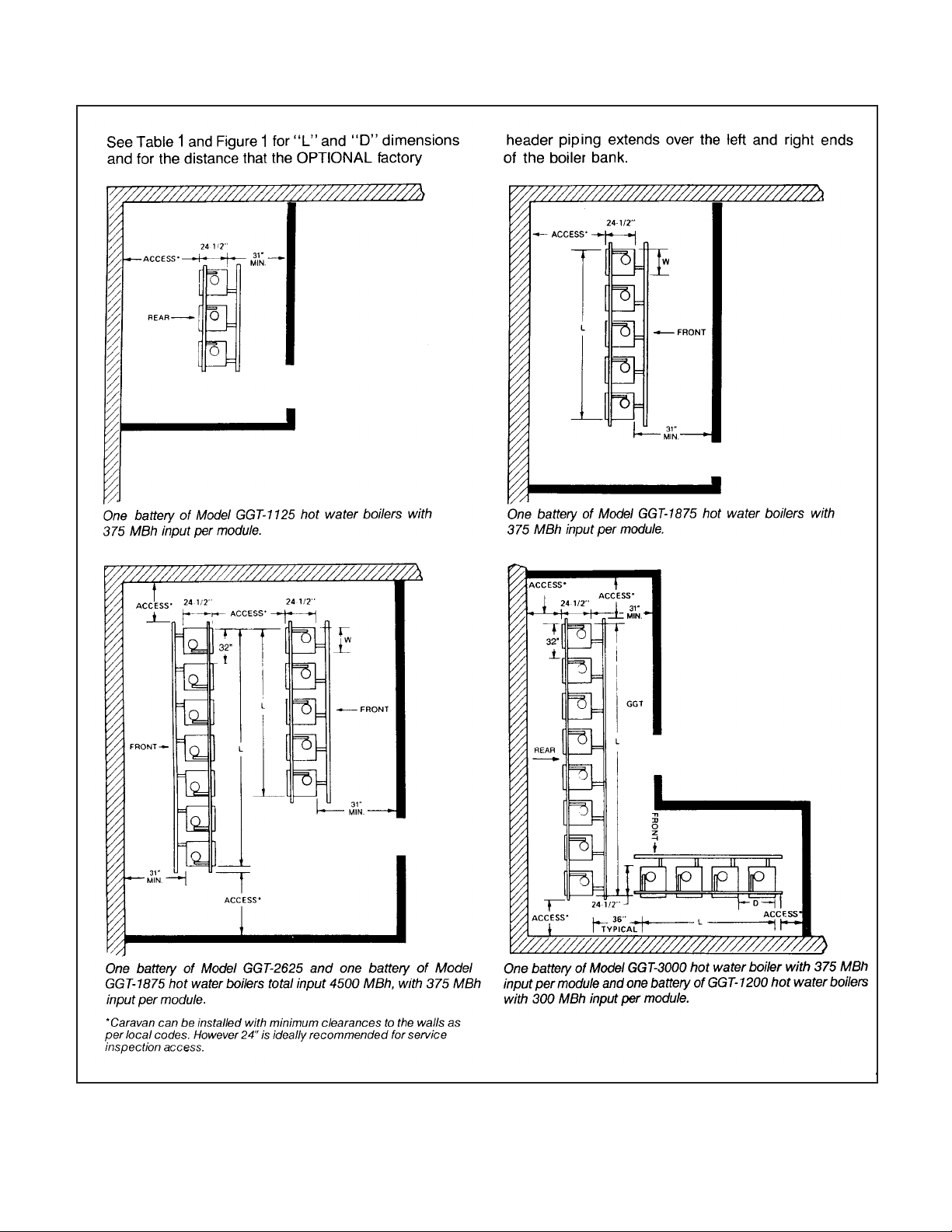

BOILER ROOM DESIGN

Caravan modular boiler systems allow better utilization of floor

space and permit future expansion with minimum cost. Caravan

modules are hand truckable, fit through doorways and often may

be installed around an existing inoperative boiler. They can be

grouped in heating module batteries of single, multiple or angular

rows. Gas-fired boiler systems consisting of 11 or more modules

shou

ld be piped in parallel in two or more batteries. Illustrated on

the following page are typical boiler room layouts and dimensional

data on the size requirements of gas-fired hot water boilers.

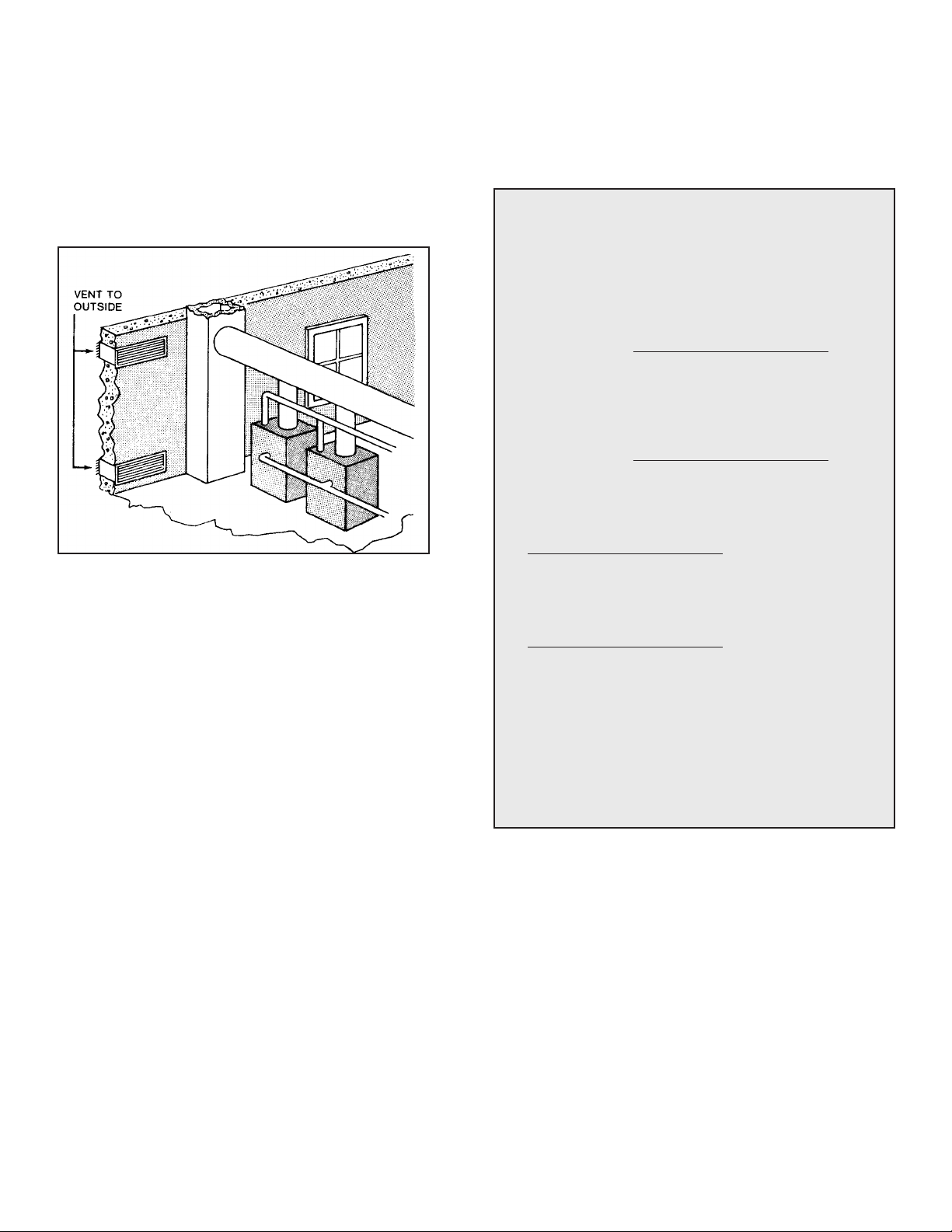

Figure 7: Correct location of combustion-air supply ducts

BOILER ROOM AIR SUPPLY

To ensure safe, efficient operation, the modular boiler system must

be supplied with sufficient air to support complete combustion,

replacing air entering draft dampers or draft hoods and ventilating

the boiler room or areas.

For additional information, not listed below, see ANSI,Z223.1,

section 5.3.3.

I

NSTALLATION IN ENCLOSED BOILER ROOM REQUIRES

TWO UNOBSTRUCTED OPENINGS FOR PASSAGE OF

AIR INTO THE BOILER ROOM:

1. Air drawn horizontally from outdoors DIRECTLY

through an outside wall; one louvered opening near

the floor (below burner air inlet) and one louvered

opening near the ceiling

regulator), each opening with a minimum FREE air

passage area of 1 square inch per 4000 BTUH

system input.

2. Air drawn horizontally through HORIZONTAL DUCTS;

one opening near the floor (below burner inlet) and one

opening near the ceiling (above the highest draft

regulator), each opening with a minimum FREE air

passage area of 1 square inch per 2000 BTUH

system input.

3. Air drawn VERTICALLY from outdoors; one opening

at the floor and one opening at the ceiling, each opening

with a minimum FREE air passage area of

1 square inch per

4. Air drawn from inside the building; one opening near

the floor (below burner inlet) and one opening near the

ceiling (above the highest draft regulator), each opening

with a minimum FREE air passage area of

1 square inch per 1000 BTUH

(

above the highest draft

of total

of total

4000 BTUH of total system input.

of total system input.

IF BOILERS ARE INSTALLED ADJACENT TO OTHER FUEL

BURNING EQUIPMENT, THE AREA OF FREE OPENINGS

MUST BE APPROPRIATELY INCREASED TO ACCOMMODATE

THE ADDITIONAL LOAD.

UNLESS PROPERLY CONTROLLED, AVOID THE USE OF

FORCED VENTILATION, SINCE IT CAN CREATE AN

UNDESIRABLE PRESSURE DIFFERENTIAL BETWEEN

BOILER ROOM AND AIR SOURCE.

6

Figure 8. Typical layouts for gas-fired systems

7

VENTING A GAS-FIRED SYSTEM

A boiler venting system provides an escape path for the products of

combustion. There are three major components for venting a gas-fired

Caravan: a draft hood for each module, a breeching manifold and a

chimney.

Draft Hood

The draft hood is part of each boiler module, although shipped in a

separate carton. It compensates for excessive draft that can be

caused by the venturi effect of winds passing over the top of the chim-

ney. The dimensional relationships between the draft hood, the boiler

and surface on which the boiler is mounted, are critical. These factors

are all interdependent in allowing the draft hood to function without

moving parts. Attempts to alter these dimensions can result in unsafe

operating conditions.

Note: When mounting the modules on a raised platform, be

the platform extends past the edge of the modules at least 3 inches

on all sides.

Breeching

Breeching is a term used to describe a manifold(s) that connects

individual boiler modules to a chimney. Breeching is usually constructed of sheet metal having a smooth interior surface with all joints made

tight against leakage. Pitch breeching up toward chimney. Horizontal

breeching size should be mai

ntained for the total length. Any transitions should be made after 4 modules. Connection should be made at

a 45° angle in the direction of the chimney. See figure 10.

Table 2. Breeching dimensions for gas-fired systems

GGT and GGHT series: hot water boilers.

Consists of Chimney Height*

Model No.

GGT-600E 2 GG-300ES 12" 10" 10" 9"

GGHT-700E 2 GG-350HES 12" 12" 10" 10"

GGHT-750E 2 GG-375HES 12" 12" 12" 10"

GGHT-800E 2 GG-399HES 12" 12" 12" 10"

GGT-900E 3 GG-300ES 14" 12" 12" 12"

GGHT-1050E 3 GG-350HES 14" 14" 14" 12"

GGHT-1125E 3 GG-375HES 14" 14" 14" 12"

GGHT-1200E 3 GG-399HES 16" 14" 14" 12"

GGT-1200E 4 GG-300ES 16" 14" 14" 12"

GGHT-1400E 4 GG-350HES 16" 16" 16" 14"

GGHT-1500E 4 GG-375HES 16" 16" 16" 14"

GGT-1500E 5 GG-300ES 16" 16" 16" 14"

GGHT-1600E 4 GG-399HES 18" 16" 16" 14"

GHT-1750E 5 GG-350HES 18" 18" 16" 14"

G

GGHT-1875E 5 GG-375HES 18" 18" 18" 16"

GGHT-2000E 5 GG-399HES 20" 18" 18" 16"

GGHT-2100E 6 GG-350HES 20" 18" 18" 16”

GGHT-2250E 6 GG-375HES 20" 20" 18" 16"

GGHT-2400E 6 GG-399HES 20" 20" 20" 18"

GGHT-2450E 7 GG-350HES 20" 20" 20" 18"

GGHT-2625E 7 GG-375HES 22" 20" 20" 18"

GGHT-2800E 7 GG-399HES 22" 22" 20" 18"

GGHT-2800AE 8 GG-350HES 22" 22” 20” 18”

GGHT-3000E 8 GG-375HES 24" 22" 22" 20"

GGHT-3150E 9 GG-350HES 24" 22" 22" 20"

GGHT-3200E 8 GG-399HES 24" 22" 22" 20"

GGHT-3375E 9 GG-375HES 24" 24" 22" 20"

GGHT-3500E 10 GG-350HES 24" 24" 22” 20"

GGHT-3600E 9 GG-399HES 26" 24" 24" 20"

GGHT-3750E 10 GG-375HES 26" 24" 24" 22"

GGHT-4000E 10 GG-399HES 26" 26" 24" 22"

No. of

Modules

Module

No.

20

Feet25Feet30Feet50Feet

certain

Run breeching as high as clearance permits to obtain maximum

vertical rise of individual boiler vents. Note that this does not alter

chimney height (the height from hood skirt to chimney top). The

portion of chimney height rising directly above each hood is most

effective in preventing spillage. When the boiler room is in unheated

space, insulate vent pipe and breeching to maintain flue gas temperature and good chimney operation. It is not permitted to lower draft

hood skirt height to achieve pitch, or to compensate for low

ceilings. For some combinations of low chimneys, ceilings and long

breeching, a draft inducer may be needed

. Inducers when required

are locally specified and warrantied. The breeching should extend

into, but not beyond, the chimney liner.

Chimney

Caravan gas-fired modular boilers operate efficiently with masonry or

prefabricated chimneys as well as with “Type B” or double-walled

metal vent pipe. This latter type of chimney construction is generally

the least expensive. Chimney height is usually governed by th

e

building height and the size of the boilers (see Table 1). However, the

chimney should be high enough to minimize the effects of turbulent

winds and pressure common near roof-top obstruction. A vent cap

should be used where permitted for additional protection against

adverse wind conditions and precipitation. The National Board of Fire

Underwriters recommend that the chimney should extend at least 3

f

eet above the roof and be 2 feet higher than any obstruction within 10

feet.

Sizing Horizontal Breeching Connectors and Chimneys for GasFired Systems

Horizontal breeching connectors shall be constant sized. The chimney

and the horizontal breeching connector are sized using Table 2.

When there are multiple banks of boilers, the horizontal breeching

connector for each bank is sized using Table 2. To size

the common

horizontal breeching connector, add up the total input and refer to

Table 2 to size.

The minimum chimney opening will be equal to the size of the largest

horizontal breeching section connected to it.

Horizontal Breeching Connector Length

The MAXIMUM length of the horizontal breeching connector length

between the chimney and the closest boiler shall NOT be longer than

12 inches per inch of horizo

ntal breeching connector diameter, i.e. if

the horizontal breeching connector is 16" D., the MAXIMUM length

from the chimney to the first boiler would be 16" x 12" or 192 inches.

The MINIMUM length shall be 12 inches regardless of the horizontal

breeching connector diameter. See figure 9.

Based on single row of modules with no elbows.

* Height measured from top of draft hood to top of chimney.

NOTE: For conditions other than those shown, consult factory, or

National Fuel Gas Code NFPA 54

8

Loading...

Loading...