Page 1

Gas Conversion Field Assembly Kit

Natural Gas to Liquefied Petroleum (Propane) or

Liquefied Petroleum (Propane) Gas to Natural

Only for use with Slant/Fin boilers equipped with Honeywell VR8200, VR8204, VR8300 and

VR8304 gas valves, either standing (continuous burning) pilots or intermittent ignition

systems.

WARNING

This conversion kit shall be installed by a

qualified service agency in accordance with

the manufacturer’s instructions and all

applicable codes and requirements of the

authority having jurisdiction. If the information in these instructions is not followed

exactly, a fire, an explosion or production of

carbon monoxide may result causing property damage, personal injury or loss of life.

The qualified service agency is responsible

for the proper installation of this kit. The

installation is not proper and complete until

the operation of the converted appliance is

checked as specified in the manufacturer’s

instructions supplied with the kit.

WARNING-IMPORTANT

1. This conversion kit is supplied with the

same parts normally provided on

SLANT/FIN factory built boilers which are

Design Certified by CSA International.

However, because we have no way of

applying our own quality control procedures

to field alterations made by others on this

boiler, these alterations are not the responsibility of SLANT/FIN. These alterations are

the responsibility of the installer of this conversion kit. The instructions below must be

carefully followed in order to duplicate

factory installation.

WARNING

LIQUEFIED PETROLEUM (L.P.) PROPANE GASFIRED BOILER LOCATION

REQUIRES SPECIAL ATTENTION

Liquefied Petroleum (LP) propane gas is heavier

than air. Therefore, propane boilers, piping, valves

must NOT be installed in locations where propane

leaking from defective equipment and piping will

"pool" in a basement or other space below the leak.

A spark or flame from the boiler or other source

may ignite the accumulated propane gas causing

an explosion or fire. Provide a level, solid foundation for the boiler. Location should be as near the

chimney as possible so that the flue pipe from boiler to chimney is short and direct.

THE UNIFORM MECHANICAL CODE may be in

effect in your geographic area.

The following precautions are cited by the 1994

UNIFORM MECHANICAL CODE, section 304.6:

"LPG Appliances. Liquefied petroleum gasburning appliances shall not be installed in a pit,

basement or similar location where heavierthan-air gas might collect. Appliances so fueled

shall not be installed in an above-grade underfloor space or basement unless such location is

provided with an approved means for removal of

unburned gas."

Consult Chapter 5 of the 1994 UNIFORM

MECHANICAL CODE for design criteria of the

"approved" means for removal of unburned gas.

2. The installation must conform to the requirements of the authority having jurisdiction or,

in the absence of such requirements, to the

National Fuel Gas Code ANSI Z223. 1-latest edition.

The boiler warranty is void unless this field assembly conversion kit has been properly installed,

labels completed and applied to boiler and registration card completed and received

by Slant/Fin within 10 days after kit has been installed in boiler.

PUBLICATION No. GCK-40

Part No. 46-0527

Printed in U.S.A. 708

Page 2

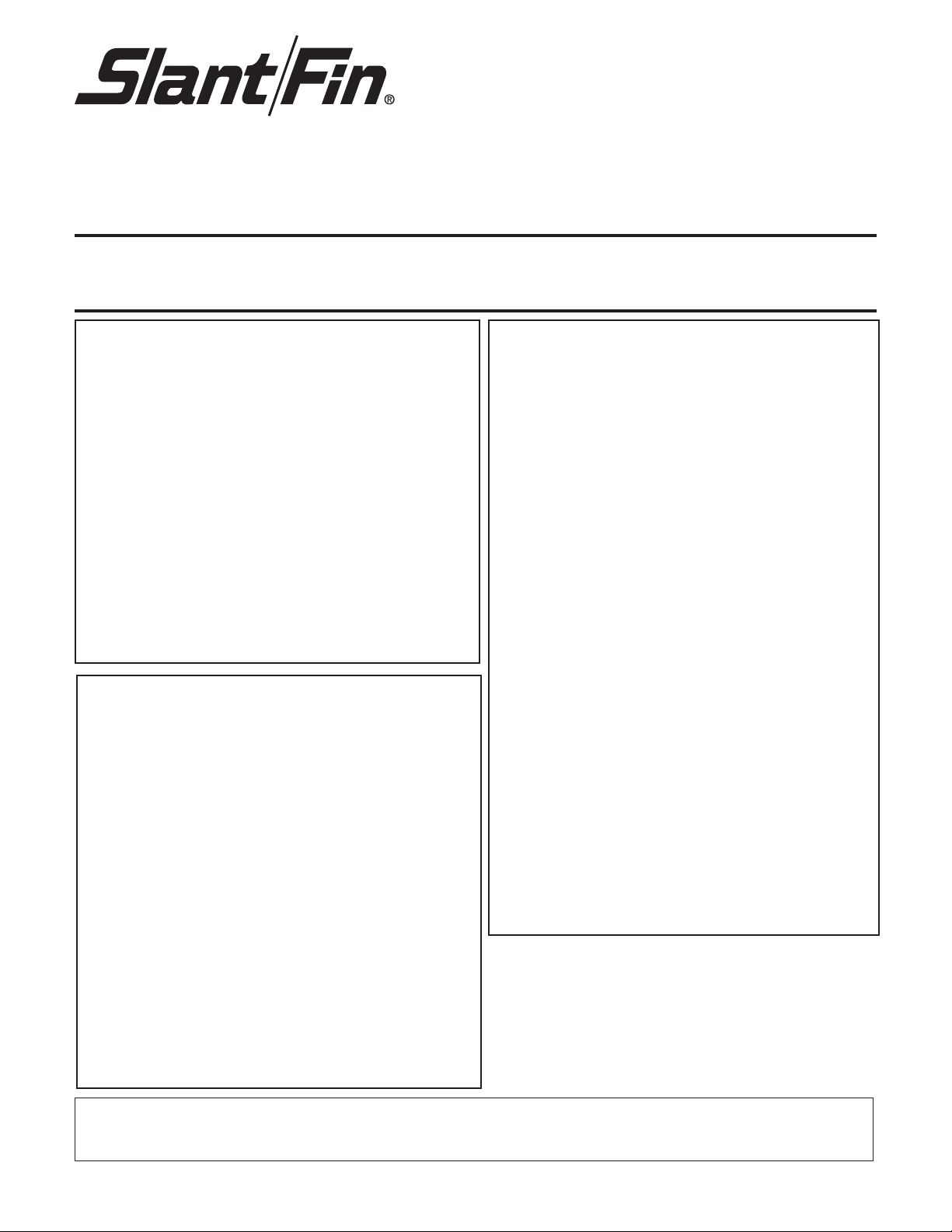

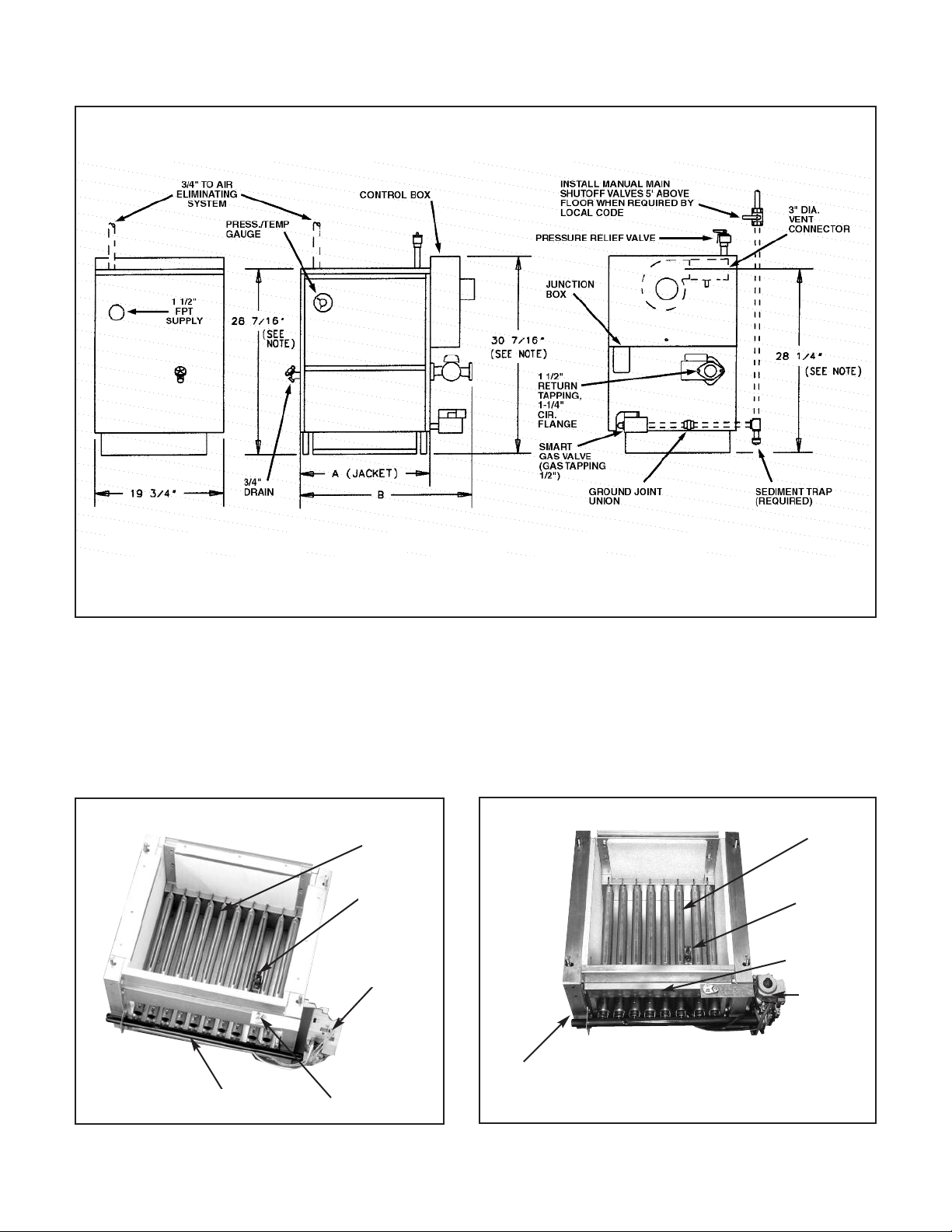

ENTRY SERIES BOILER

S

Location and identification of parts.

Base Assembly

Front and Right End View

(Sentry “S” Series shown)

Burners

Pilot

Burner

Access

Door

Gas Valve

2

Page 3

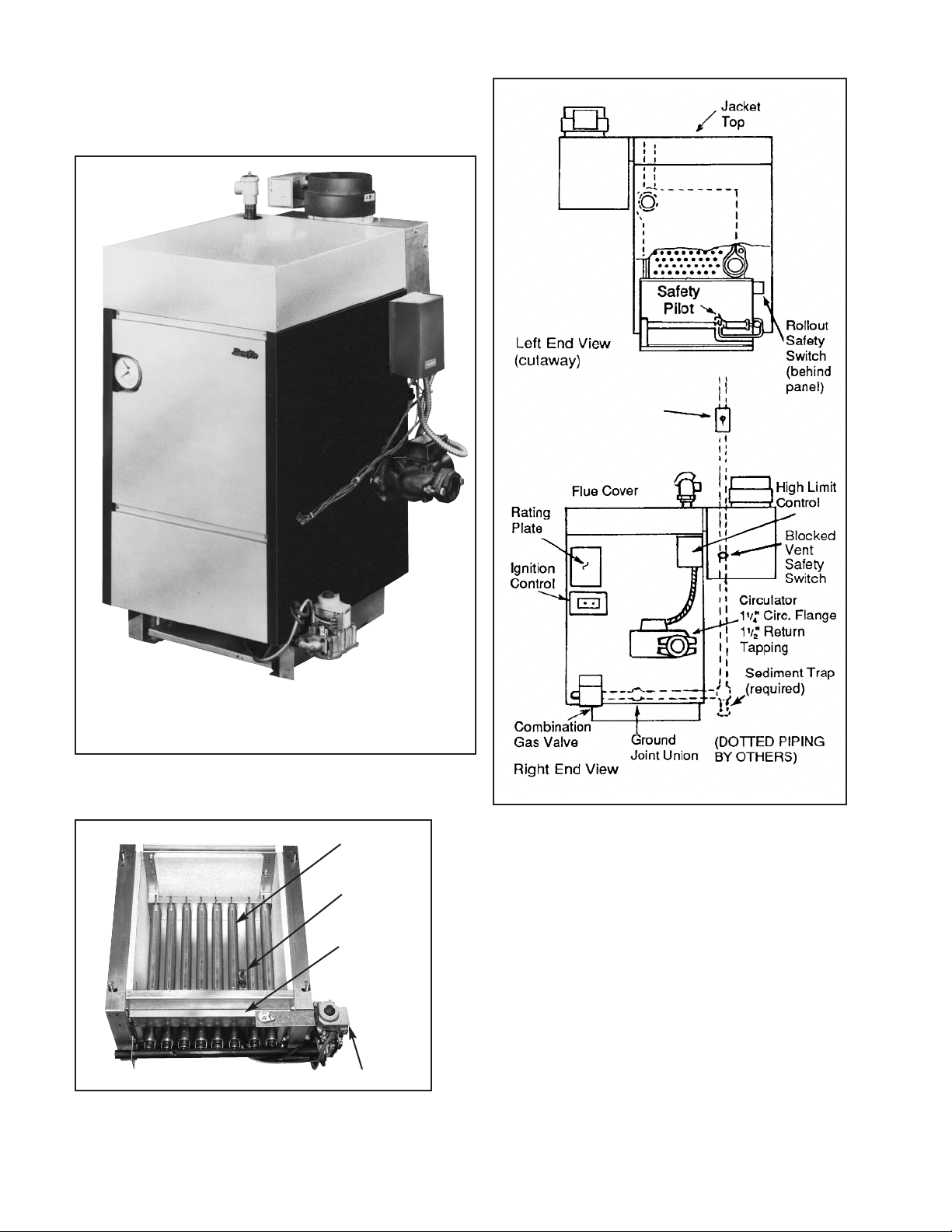

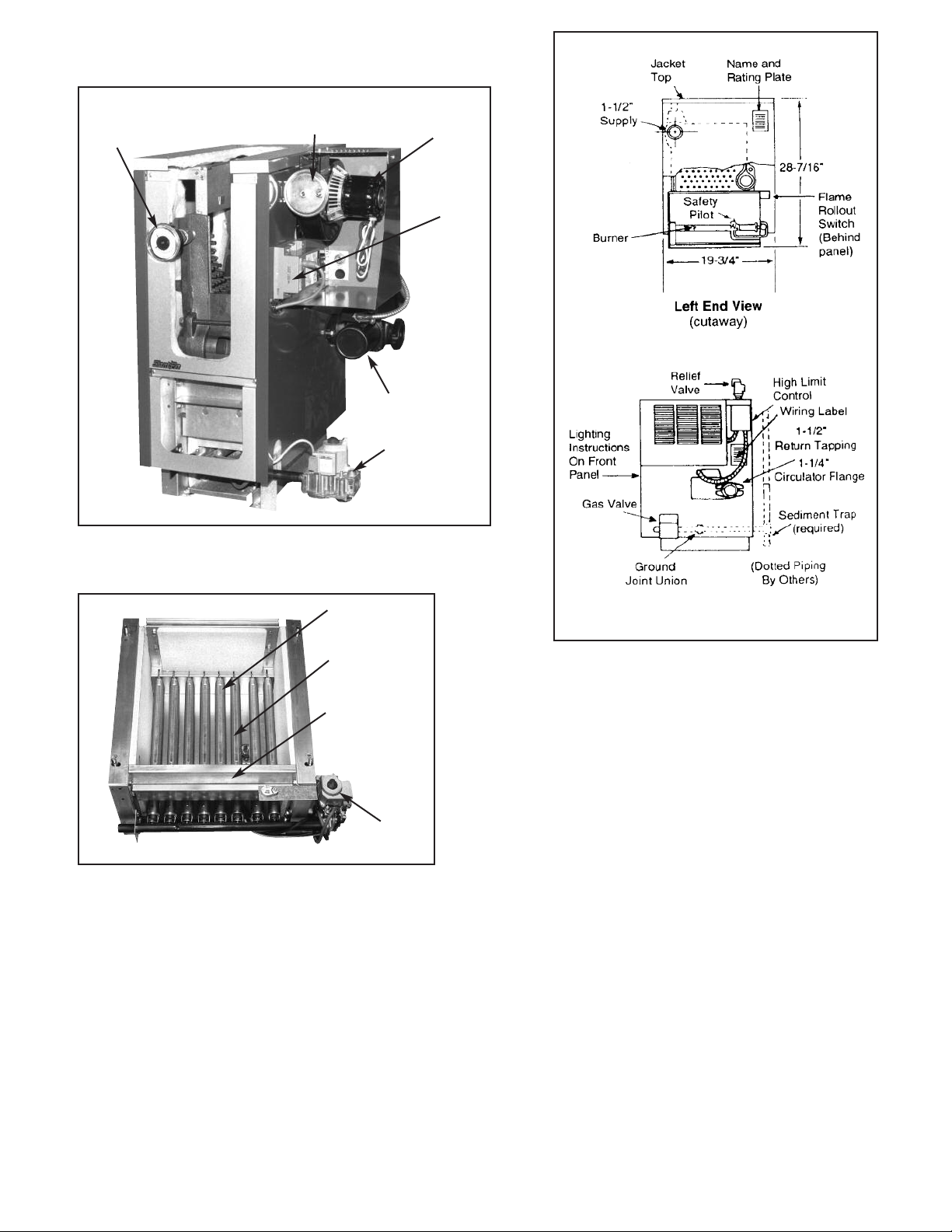

VICTORY VSP AND VSPH SERIES BOILERS

ocation and identification of parts.

L

Base Assembly

3

Page 4

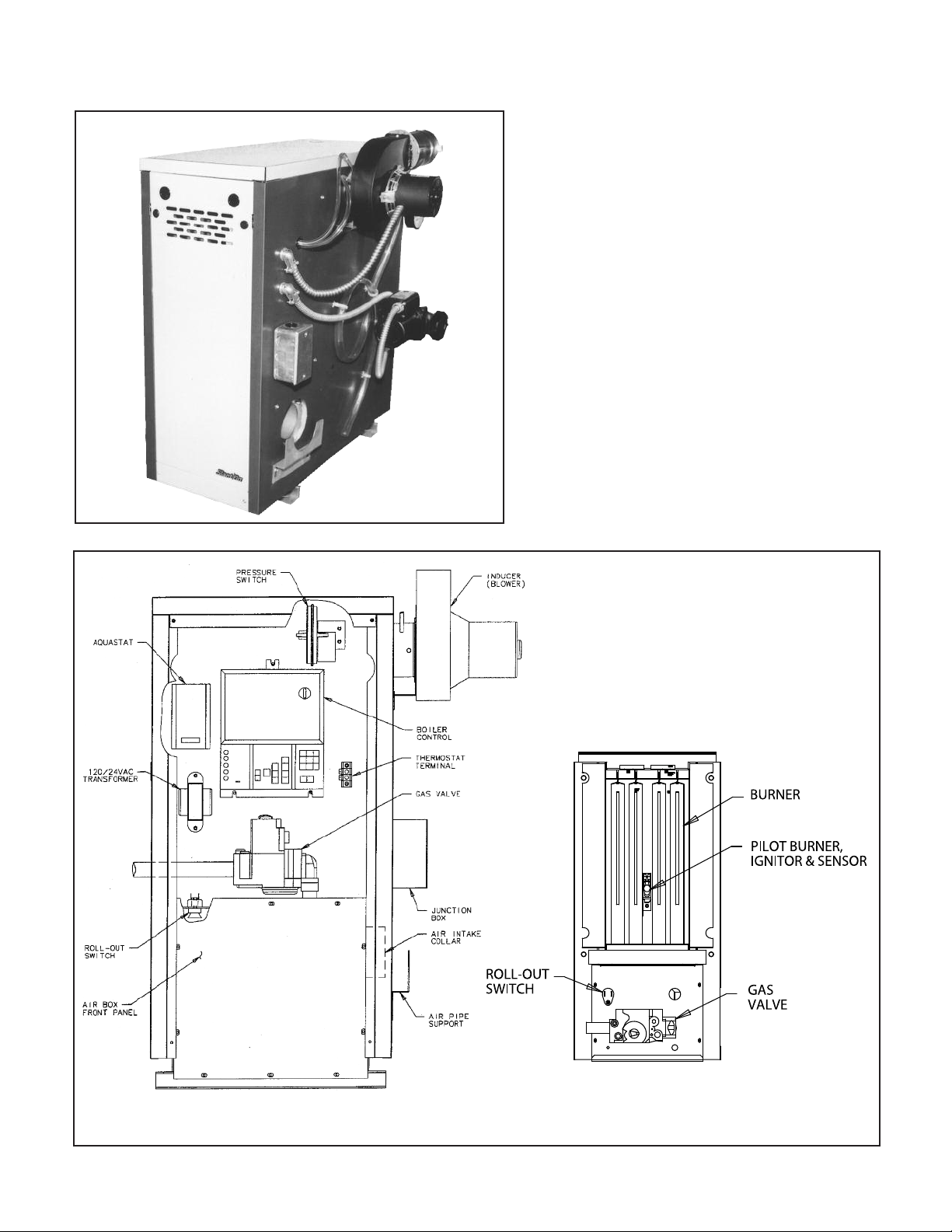

SENTINEL SERIES BOILER

ocation and identification of parts.

L

Burners

Pilot

LEFT END VIEW

Burner

Access

Door

RIGHT END VIEW

Gas Valve

4

Page 5

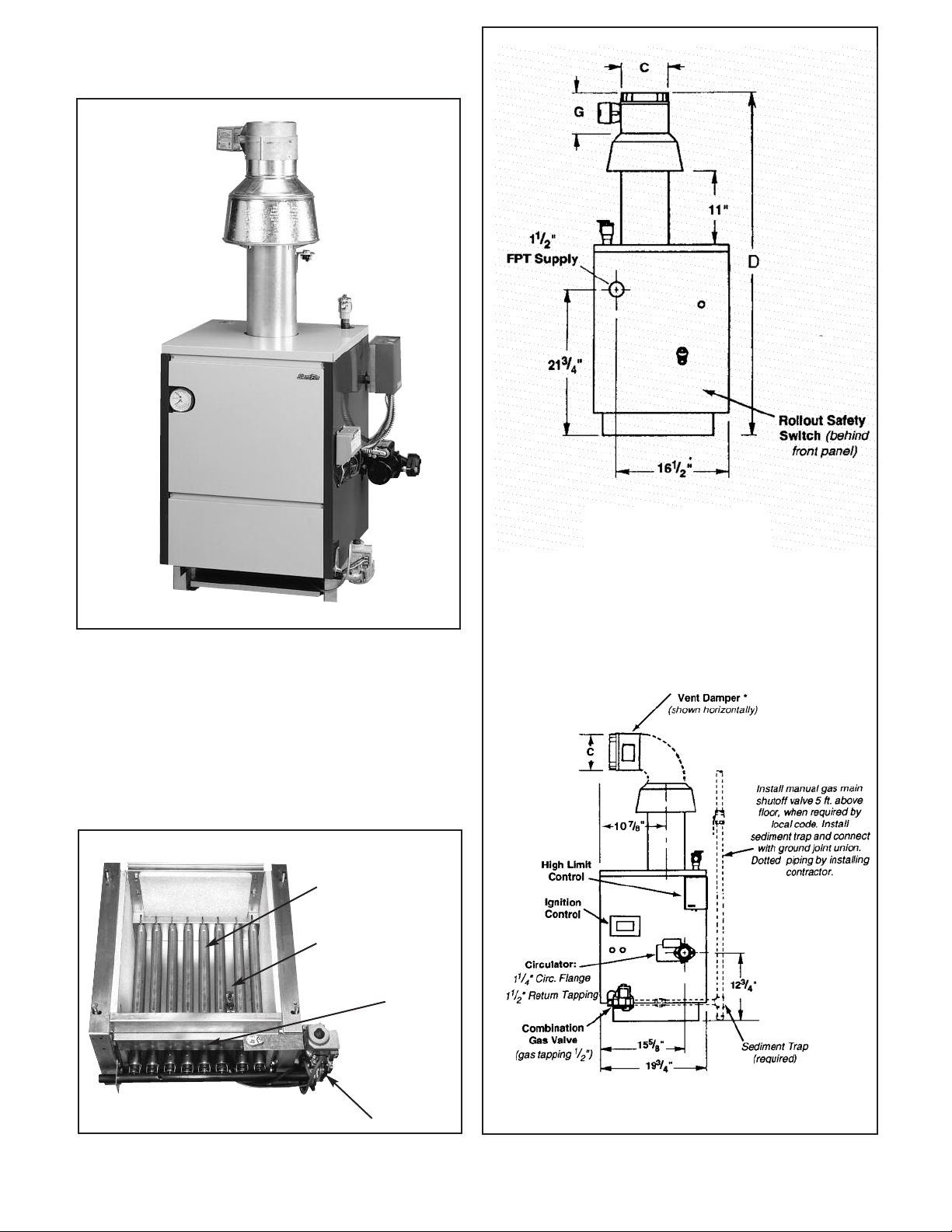

VICTORY II SERIES BOILER

ocation and identification of parts.

L

LEFT END VIEW FRONT VIEW RIGHT END VIEW

VICTORY II - VH, VHL BASE ASSSEMBLY

Location and identification of parts.

Burner

Pilot burner,

ignitor and

sensor

Smart Valve

VICTORY II - VHS, VHLS BASE ASSEMBLY

Location and identification of parts.

Burners

Pilot

Burner

access door

Gas valve

Gas manifold

Roll-out safety

Gas Manifold

switch

5

Page 6

VICTORY V SERIES BOILER

ocation and identification of parts.

L

Pressure/

Temperature

Gauge

Air Flow

Proving Switch

Draft Inducer

Assembly

Ignition

Control

Circulator

Gas Valve

Base Assembly

Burners

Pilot

Burner

Access

Door

Gas Valve

Right End View

6

Page 7

ALAXY BOILER

G

Remove front panel (Figure 1) by pressing hand

against panel and pushing up. Remove burner access

door (Figure 2) by removing 2 wing nuts, slide panel

orward and out.

f

Figure 1. Front Panel

Jacket Top

Name and

Rating Plate

ighting

L

Instructions

(inside front

panel)

as Valve

G

Burner

Access Door

Burners

Relief Valve

emperature

T

and Pressure

Gauge

Gas Manifold

EFORE STARTING

B

heck contents for kit:

C

All components are either marked with a red stripe, a

label with a model number or a stamped number on

them.

1. Honeywell Conversion Kit:

a) Spring: propane = red; natural = stainless steel

b) Regulator adjusting screw

c) Cap screw: propane = black; natural = silver

) Instructions

d

e) Label

2. Main Burner Orifices:

See Table 1 for the correct size orifice as it applies to

this conversion.

3. Pilot Burner Assembly:

a) Pilot burner:

Standing pilot—Honeywell Q314A

Intermittent ignition—Honeywell Q345A

b) Pilot orifice:

Propane—Honeywell BBR-10

Natural—Honeywell BCR-18

4. Ignition Control (for IID only):

Honeywell S8600M (for Sentry, Sentinel or Victory V

series boilers) or S8670E (for Galaxy boilers).

Required for conversion to propane only.

5. Three Labels: Boiler Conversion Label, Affidavit Label

and Gas Valve Label.

6. Registration Card

Caution: The gas supply shall be shut off prior to disconnecting the electrical power, before proceeding with the

conversion.

Figure 2.

Pop Safety Valve

Jacket Top

INSTALLATION

1. Turn Off Gas to Appliance

a) Set thermostat to lowest level.

b) Turn off all electric power to the appliance.

c) Turn the gas control knob clockwise to the off

position.

d) Close all gas cocks.

e) CAUTION: LET BOILER COOL.

f) Remove front jacket panel.

g) Remove burner access door.

2. Gas Valve Conversion

a) Remove pressure regulator cap screw.

b) Remove pressure regulator adjusting screw.

c) Remove regulator spring.

d) Insert appropriate replacement spring (tapered

end down).

Pressure Gauge

Figure 3.

Figure 4. Conversion Kit Installation in Regulator

7

Page 8

) Install new pressure regulator adjustment screw

SHUTTER

BURNER

RETAINER CLIP

M ANIFOLD

MANIFOLD

BURNER

PILOT

e

until it is flush with the top of the casting.

f) After e) above, turn adjustment screw clockwise

as follows:

Propane Gas — 5-

atural Gas — 6 full turns

N

3

⁄4 full turns

g) Install the NEW cap screw.

) Place the gas valve conversion label from the

h

Honeywell kit over the gas valve model number.

3. Pilot Burner Conversion

a) Disconnect pilot line from gas valve.

b) Disconnect flame sensor.

Standing pilot— disconnect thermocouple from

gas valve.

Intermittent ignition — disconnect ignition wire

from S8600 ignition control.

c) BE SURE BURNERS ARE COOL BEFORE

CONTINUING. NOTE LOCATION OF BURNER

WITH PILOT. REMOVE THE BURNER RETAINER

CLIP OF THE PILOT-BURNER. REMOVE THE

BURNER. DISCONNECT THE PILOT TUBE AND

EITHER THE THERMOCOUPLE FOR STANDING

PILOT OR IGNITION WIRE FROM IGNITION

CONTROL. (See figure 6).

d) Remove pilot burner and replace with new pilot

burner.

e) Replace pilot tubing on pilot burner. (It is best to

cut off old ferrule and use new one to ensure a

proper seal.)

f) Replace thermocouple or ignition wire on pilot

assembly.

g) Remove existing main burner orifice from the

manifold and replace with an orifice from the kit.

(See figure 7).

h) Replace the pilot-burner into the boiler. Replace

the burner retainer clip.

4. Orifice Replacement - Remove all other burner

retainer clips and remove the rest of the burners.

a) Remove existing main burner orifices from the

manifold.

b) Install the orifices from the kit. (There may be

more orifices than required.)

c) Reinstall the main burners making sure that the

pilot burner is in the same position as above.

5. Ignition Control Replacement (for IID only)

IMPORTANT

FOR CONVERSION OF BOILERS EQUIPPED

WITH AN INTERMITTENT IGNITION SYSTEM

TO PROPANE, THE IGNITION CONTROL MUST

BE CHANGED. FAILURE TO INSTALL THE CORRECT IGNITION CONTROL COULD CAUSE A

AZARDOUS CONDITION RESULTING IN AN

H

EXPLOSION OR CARBON MONOXIDE POISONING AND WOULD VOID ANY WARRANTY.

a) Remove the S8600F Control from the right side of

the boiler. Note the location of the wires so that

hey may be installed on the proper terminals of

t

the replacement control.

b) Install the NEW S8600M or S8670E control

supplied in the kit. Reconnect the wires, including

the ignition wire. Check applicable wiring diagram

on pages 9 to 15 or the diagram on the boiler to

make certain that the wiring is correct.

6. Registration Card and Labels:

a) Fill out the Boiler Conversion Label, Affidavit Label

and Gas Valve Label. Affix the Boiler Conversion

Label adjacent to the rating plate on the boiler

jacket. Affix the Affidavit Label to the front jacket

panel adjacent to the Slant/Fin logo. Affix the Gas

Valve label on the inside jacket panel above the

gas valve.

b) Fill out the Registration Card. REMEMBER THAT

THIS CARD MUST BE RECEIVED WITHIN 10

DAYS OR THE WARRANTY COULD BE VOIDED.

FINAL CHECKS:

1. Are the burners installed correctly (ports are up)?

2. Is the pilot in the correct position?

3. All of the wiring is correct?

4. All the labels have been filled out and affixed to

the boiler?

5. Has the Registration Card been filled out?

GAS LEAK TESTS

Warning: DO NOT OMIT these tests. Open all gas cocks

upstream of the boiler gas valve. Paint all pipe joints from

the main gas cock to the gas valve with a rich soap and

water solution. Bubbles indicate gas leakage. To stop the

leak, tighten the joints and fittings. DO NOT USE AN

OPEN FLAME FOR TESTING.

Figure 5. Gas Valve — top view

8

Figure 6. Burner/Manifold

Figure 7. Pilot/Burner

Page 9

Wiring Diagram - Victory “V” Series Boilers

CAUTION: Label all wires prior to disconnection when servicing controls.

Wiring errors can cause improper and dangerous operation. “Verify proper

operation after servicing.”

9

Page 10

Wiring Diagrams- Victory II - VH, VHL Series

10

Page 11

Wiring Diagrams- Victory II - VHS, VHLS Series (Spark Ignition)

11

Page 12

Wiring Diagrams- Victory, VSP, VSPH

12

Page 13

WIRING DIAGRAM - GALAXY/SENTRY—CONTINUOUS (STANDING) PILOT

CAUTION: Label all wires prior to disconnection when servicing controls.

Wiring errors can cause improper and dangerous operation. “Verify proper operation after servicing.”

13

Page 14

WIRING DIAGRAM - GALAXY/SENTRY—INTERMITTENT PILOT IGNITION (IID)

CAUTION: Label all wires prior to disconnection when servicing controls.

Wiring errors can cause improper and dangerous operation. “Verify proper operation after servicing.”

14

Page 15

WIRING DIAGRAMS FOR SENTINEL HOT WATER BOILERS

CAUTION: Label all wires prior to disconnection when servicing controls.

Wiring errors can cause improper and dangerous operation. “Verify proper operation after servicing.”

Damper circuit is designed to be controlled by low voltage controls. DO NOT use line voltage operating

Models with Intermittent Pilot Ignition (IID) Models with Continuous Burning Pilot

controls to interrupt supply voltage to the L8148E aquastat.

15

Page 16

SENTRY AND SENTINEL SERIES

Boiler

Model

All Sentinel models and

entry S-34

S

entry S-60 thru

S

S-150 & SX-150 thru

X-210

S

Gas

Type

atural 47 48 48 49 49 49 50 50 51 51

N

Propane 56 56 56 57 57 57 58 59 59 60

Natural 50 51 51 51 51 52 52 52 53 53

ropane 57 58 59 59 60 60 61 62 63 63

P

VICTORY SERIES

Boiler

Model

-33

V

-60 thru V-180

V

SP, VSPH, VH & VHS

V

Gas

Type

Natural 48 49 50 50 50 51 51 52 52 52

ropane 56 56 56 57 57 57 58 59 59 6

P

atural 50 51 51 51 52 52 52 52 53 53

N

Propane 57 58 59 59 60 60 61 62 63 63

atural 49 50 50 50 51 51 51 52 52 52

N

ropane 57 58 59 59 60 60 61 62 63 63

P

Orifice

Size

for

ea

S

Level*

Orifice

Size

for

Sea

Level*

TABLE 1

ORIFICE SIZE TABLE

Orifice Sizes for High Altitudes

Includes 4% Reduction for Each 1000 Feet

levation - Feet

E

2000 3000 4000 5000 6000 7000 8000 9000 10000

Orifice Sizes for High Altitudes

Includes 4% Reduction for Each 1000 Feet

Elevation - Feet

2000 3000 4000 5000 6000 7000 8000 9000 10000

GALAXY SERIES

Orifice

Size

for

Boiler

Model

GG/GX Except Natural 42 43 43 43 43 44 44 45 46 47

GG-399H & GG-350H Propane 54 54 55 55 55 55 55 56 56 56

GG-399H Natural 40 41 42 42 42 43 43 44 44 45

GXH-105 Natural 44 45 45 45 46 47 47 48 48 49

through 275 Propane 54 54 55 55 55 55 55 56 56 56

GXH-300 Natural 43 44 44 44 45 45 46 47 47 48

GXH-300H Natural ** 42 43 43 43 43 44 45 45 46 47

GXHA Natural 45 46 47 47 47 48 48 49 49 50

Gas

Type

Propane 53 54 54 54 54 54 54 55 55 55

Propane 54 54 55 55 55 55 55 56 56 56

Gas Only

Gas Only 55 55 55 55 56 56 56 56 56 57

Sea

Level*

2000 3000 4000 5000 6000 7000 8000 9000 10000

Includes 4% Reduction for Each 1000 Feet

Orifice Sizes for High Altitudes

Elevation - Feet

SENTINEL SERIES

Orifice Sizes for High Altitudes

Includes 4% Reduction for Each 1000 Feet

Elevation - Feet

Boiler

Model

Sentinel

Orifice

Size

for

Gas

Type

Natural 47 48 48 49 49 49 50 50 51 51

Propane 56 56 56 57 57 57 58 59 59 60

Sea

Level*

2000 3000 4000 5000 6000 7000 8000 9000 10000

16

VICTORY II - VHL, VHLS Series (Under 2000 Ft. Only)

Orifice

Boiler

Model

VHL, VHLS

Size

Gas

Type

Natural 49

Propane 57

Sea

Level*

for

* Orifice indicated for sea level above are factory installed in boiler unless

otherwise specified by the local authority.

See page 19 for burner input adjustment.

** For L.P. Propane consult factory.

Page 17

TABLE 2

INPUT RATING OF BOILERS

Note: All models of the boilers will have the same input rating after converted.

17

Page 18

LIGHTING INSTRUCTIONS

Continuous Burning Pilot (24V).

OR BOILERS EQUIPPED WITH GAS VALVES

F

VR8200

and VR8300.

SAFETY INFORMATION

FOR YOUR SAFETY READ BEFORE LIGHTING

WARNING: If you do not follow these instructions

exactly, a fire or explosion may result causing

property damage, personal injury or loss of life.

A. This appliance has a pilot which must be lighted by

hand. When lighting the pilot, follow these instructions exactly.

B. BEFORE LIGHTING smell all around the appliance

area for gas. Be sure to smell next to the floor

because some gas is heavier than air and will settle

on the floor.

WHAT TO DO IF YOU SMELL GAS

• DO NOT try to light any appliance.

• DO NOT touch any electric switch; DO NOT use

any phone in your building.

• Immediately call your gas supplier from a

neighbor's phone. Follow the gas supplier's

instructions.

• If you cannot reach your gas supplier, call

the fire department.

C. Use only your hand to push in or turn the gas control

knob. NEVER use tools. If the knob will not push

in or turn by hand, DON'T try to repair it, call a

qualified service technician. Force or attempted

repair may result in a fire or explosion.

D. DO NOT use this appliance if any part has been

underwater. Immediately call a qualified service

technician to inspect the appliance and to replace

any part of the control system and any gas control

which has been underwater.

Lighting Instructions

1. STOP! Read the safety information above on this

page.

2. Set the thermostat to lowest setting.

3. Turn off all electric power to the appliance.

4. Remove control access panel. (Galaxy models only.)

5. Push in gas control knob slightly and turn clockwise

to "OFF".

6. Wait five (5) minutes (longer for propane) to clear

out any gas. If you then smell gas, STOP! Follow

"B" in the safety information. If you don't

smell gas, go to next step.

. Remove the pilot access panel located

7

below and behind the gas control unit.

8. Find pilot—follow the aluminum tubing from the

gas valve. The pilot is between two burner tubes

behind the burner access panel.

9. Turn knob on gas control counterclockwise to

"PILOT".

10. Push in red button all the way and hold in.

Immediately light the pilot with a match. Continue

to hold the red button in for about one (1) minute

after the pilot is lit. Release knob and it will pop

back up. Pilot should remain lit. If it goes out,

repeat steps 5 through 10.

• If knob does not pop up when released, stop

and immediately call your service technician

or gas supplier.

• If the pilot will not stay lit after several tries,

turn the gas control knob to "OFF" and call

your service technician or gas supplier.

11. Replace pilot access panel.

12. Turn gas control knob counterclockwise to

“ON".

13. Replace control access panel. (Galaxy models

only.)

14. Turn on all electric power to the appliance.

15. Set thermostat to desired settings.

To Turn Off Gas To Appliance

1. Set the thermostat to lowest setting.

2. Turn off all electric power to the appliance if service is to be performed.

3. Remove control access panel. (Galaxy models

only.)

4. Turn gas control knob clockwise to "OFF".

DO NOT force.

5. Replace control access panel. (Galaxy models

only.)

VALVE VR8200

OR VR8300

RED BUTTON

18

GAS CONTROL

KNOB SHOWN IN

“OFF” POSITION.

Page 19

HONEYWELL IID SYSTEM .

FOR BOILERS EQUIPPED WITH GAS VALVE VR8204 OR

VR8304

.

SAFETY INFORMATION

FOR YOUR SAFETY READ BEFORE LIGHTING

ARNING: If you do not follow these instructions exactly,

W

a fire or explosion may result causing property damage,

personal injury or loss of life.

A. This appliance is equipped with an ignition device

hich automatically lights the pilot. DO NOT try to

w

light the pilot by hand.

B. BEFORE OPERATING smell all around the appli-

ance area for gas. Be sure to smell next to the

floor because some gas is heavier than air and will

settle on the floor.

WHAT TO DO IF YOU SMELL GAS

• DO NOT try to light any appliance.

• DO NOT touch any electric switch; DO NOT use

any phone in your building.

• Immediately call your gas supplier from a neighbor's phone. Follow the gas supplier's instructions.

• If you cannot reach your gas supplier, call the

fire department.

C. Use only your hand to push in or turn the gas control

knob. NEVER use tools. If the knob will not push in

or turn by hand, DON'T try to repair it, call a qualified

service technician. Force or attempted repair may

result in a fire or explosion.

D. DO NOT use this appliance if any part has been

underwater. Immediately call a qualified service

technician to inspect the appliance and to replace any

part of the control system and any gas control which

has been underwater.

Lighting Instructions

1. STOP! Read the safety information above.

2. Set the thermostat to lowest setting.

3. Turn off all electric power to the appliance.

4. This appliance is equipped with an ignition device

which automatically lights the pilot. DO NOT try to

light the pilot by hand.

To Turn Off Gas To Appliance

1. Set the thermostat to lowest setting.

2. Turn off all electric power to the appliance if service

s to be performed.

i

3. Remove control access panel. (Galaxy models only.)

4. Turn gas control knob clockwise till knob stops,

then continue to "OFF". DO NOT force.

5. Replace control access panel. (Galaxy models only.)

VALVE VR8204

OR VR8304

BURNER ADJUSTMENT

A. Adjust gas input rate:

1. Consult gas supplier for higher heating value of gas

(Btu/cu.ft.)

2. Set thermostat high enough so that boiler will remain

on while checking rate.

3. Measure manifold pressure at 1/8" tapping. See

label provided with the conversion kit for the correct

manifold pressure for the gas that is being supplied.

NOTE: Gas pressure may be adjusted by turning

pressure regulator screw on combination gas valve

(turn clockwise to increase pressure, counterclock

wise to decrease pressure).

See page 17 for the input rate of your boiler.

a. Input for PROPANE is approximately at rating shown on

rating plate when manifold pressure is 91/2" water

column.

b. Input for NATURAL GAS is approximately at rating

when manifold pressure is 31/2" water column, but

should be checked on the gas meter:

GAS VALVE VR8204

OR VR8304

GAS CONTROL KNOB

SHOWN IN “OFF”

POSITION

5. Remove control access panel. (Galaxy models only.)

6. Turn gas control knob clockwise till knob stops,

continue to "OFF". DO NOT force.

7. Wait five (5) minutes (longer for propane) to clear out

any gas. If you then smell gas, STOP! Follow "B" in

the safety information. If you don't smell gas, go to

next step.

8. Turn gas control knob counterclockwise to "ON".

9. Replace control access panel. (Galaxy models only.)

10. Turn on all electric power to the appliance.

11. Set thermostat to desired setting.

12. If the appliance will not operate, follow the instructions

"To Turn Off Gas To Appliance" and call your service

technician or gas supplier.

Btuh Input = Btu/cu. ft. x cu. ft. metered

in 3 minutes x 20

Example 1

For 1000 Btu/cu.ft. gas, this becomes:

Btuh Input = cu. ft. metered in 3 minutes

Example 2

For 1050 Btu/cu.ft. gas, this becomes:

Btuh Input = cu. ft. metered in 3 minutes

4. The higher* heating value of gas varies substantially

for different localities. Consult with Slant/Fin’s

Technical Service Dept. for re-orificing procedures

if any of the following apply:

a. Boiler (burner) is overfiring. CAUTION! National

Fuel Gas Code ANSI Z223.1-latest edition does

NOT permit firing at a higher input rate than the

input rate indicated on the boiler rating plate in

order to avoid hazardous conditions such as

explosion or carbon monoxide poisoning.

b. Poor higher* heating value of gas is causing the actual

input to be substantially lower than

:

x 1,000 Btu/cu.ft. x 20

:

x 1050 Btu/cu.ft. x 20

the rating plate

indication.

* “Higher heating” value of gas is commonly known as “heating value”.

19

Page 20

GAS RATE TABLE

Cubic Feet

Boiler rated input Gas Consumption

cu. ft./hr. of 1000 Btu/cu. ft. 1000 Btu/cu.ft. gas, in 3

Natural Gas minutes, at rated input

33 1.65

34 1.70

60 3.00

70 3.50

75 3.75

90 4.50

100 5.00

105 5.25

120 6.00

125 6.25

140 7.00

150 7.50

175 8.75

180 9.00

200 10.00

210 10.50

225 11.25

245 12.25

250 12.50

275 13.75

300 15.00

325 16.25

350 17.50

375 18.75

399 19.95

The gas metered in 3 minutes to obtain rated input for each boiler

model using 1000 Btu/cu.ft. gas is tabulated in the gas rate table.

B. Main Burner

1. Fire the boiler continuously for at least 15 minutes,

to reach burner operating temperature.

2. Observe the flames, all burners. The base of all

flame jets should be blue. The tips should be blue

shading to orange.

NOTE: Dust, disturbed by any movement, will

cause bright orange flames. Wait for dust to settle.

3. For one burner, close the air shutter until some of

its flame jet tips turn yellow-white, indicating insufficient primary air. Then open shutter until whitish

tips disappear completely. Set all burner shutters

to the same opening. Observe to make sure that

no yellow-white tips appear over any portion of

the flame. Small yellow tips at the pilot location are

permitted.

NOTE: This adjustment method gives MINIMUM

primary air setting for safe combustion. DO NOT

attempt to make this adjustment unless burners

are at operating temperature. Adjustment should

e made with burner access panel in final operat-

b

ing position. Use of a mirror may be helpful to

observe flames. Note that burner ports are on top

of main burner tube.

C.Main Burner Ignition Checkout and Pilot Adjustment

1. The pilot flame must not smother or snuff out

when tested as follows:

a. Main burner ignition from cold start-repeat.

b. Continued operation of main burner.

c. Main burner ignition with appliance at maxi

mum operating temperature after prolonged

operation.

NOTE: Observe operation of the pilot burner with

appliance doors in the final operating position.

Use of a mirror may be helpful.

Flame Tips

Blue Flame Base

Main Burner

Manifold

Front-back sliding primary air

shutter locking screw on top.

2. Safety Shutdown Checkout

a. For proper operation the pilot should engulf the

thermocouple or flame sensor as shown below.

b. To adjust pilot, turn pilot flow adjustment screw

on valve clockwise or counterclockwise to give

a steady flame enveloping 3/8" to 1/2" inch of

the tip of the thermocouple or flame sensor.

Note that turning the pilot adjustment screw

clockwise will decrease the pilot flame.

Gas Pressure (inches of wc)

Gas Manifold Minimum Inlet Maximum Inlet

Natural Gas 3.5” 5” 11”

LP Propane 9.5” 11” 14”

SLANT/FIN CORPORATION, Greenvale, N.Y. 11548 • Phone: (516) 484-2600

FAX: (516) 484-5921 • Canada: Slant/Fin LTD/LTEE, Mississauga, Ontario

www.slantfin.com

Loading...

Loading...