Page 1

COMMERCIAL FIN-TUBE ENCLOSURES

MODELS J, JR, R, RR, EM, AND F

INSTALLATION INSTRUCTIONS

GENERAL INFORMATION

Use the following table for recommended numbers of bracket-hanger assemblies for each piece of enclosure.

Element

J-SERIES R-SERIES TBG-SERIES

2 3 4 2 3 4 2 3 4

C-340

C-440

C-540

S-532

S-540

S-832

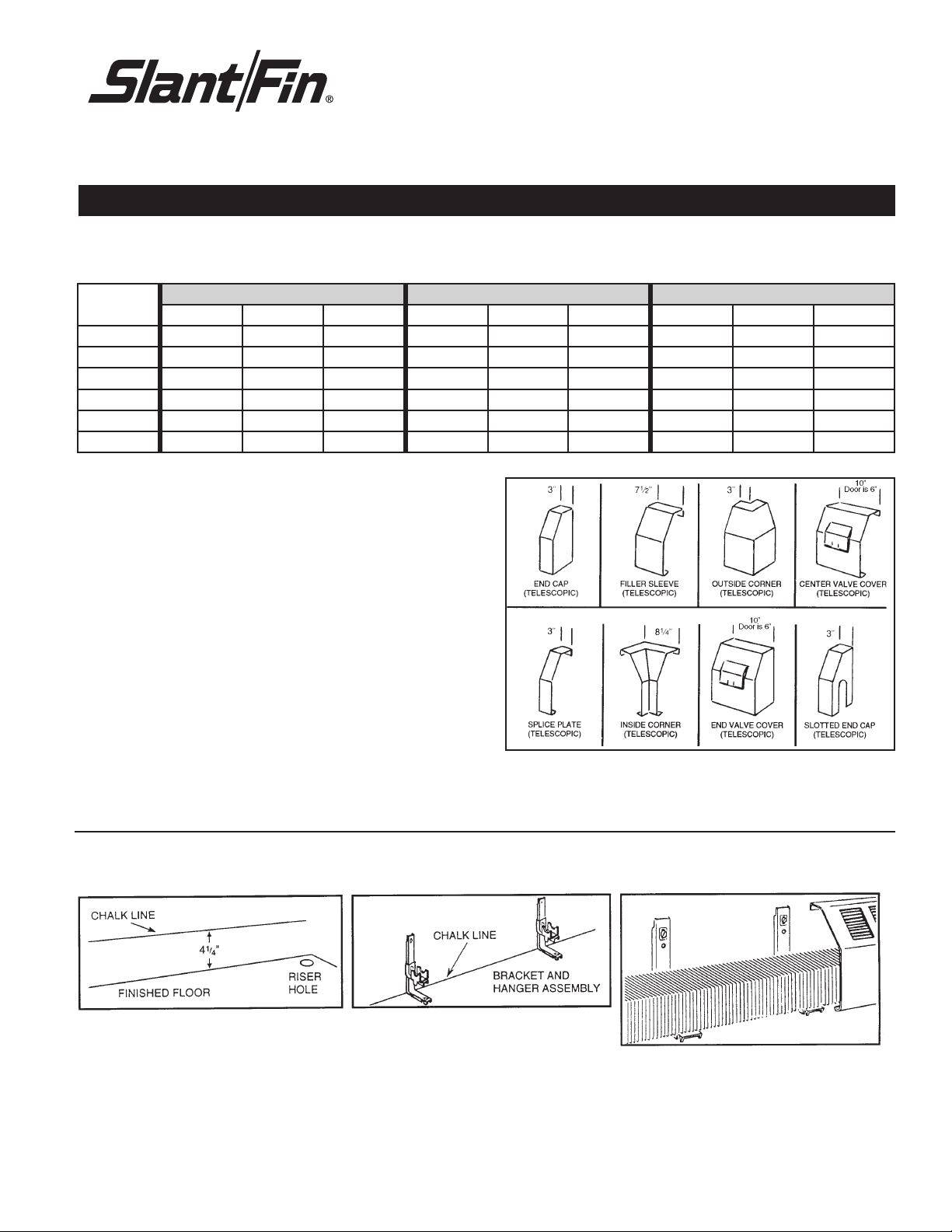

Telescopic accessories

These accessories telescope up to 2” of total length dimension. Wall to

wall dimension, figured at job site, is not effected.

Joining Commercial Enclosures

1. J Series- use internal splice plate to join enclosures together. Internal

Splice plate instructions are in the back of this manual. Generally, use

of external splice plate is not required.

2. R, RR, JR and TBG Series- Use double slip joint to join enclosures.

Joining strip for insertion in double slip joint included and packed

with cover panels. Generally, use of external splice plate is not required.

3. EM and F Series- Use external splice plate to join enclosures.

Damper

When specified, the damper is factory installed except the damper knob

and rod assembly. See instructions in this manual for field installation.

Accessories

JA-14 & JL illustrated: similar accessories available for other enclosures.

2-5 ft. 6-8 ft.

2-5 ft. 6-8 ft.

2-5 ft. 6-8 ft.

–

–

–

2-5 ft. 6-8 ft.

2-5 ft. 6-8 ft.

2-5 ft. 6-8 ft.

2-5 ft. 6-7 ft. 8 ft. 2-4 ft. 5-7 ft. 8 ft. 2-5 ft. 6-7 ft. 8 ft.

2-5 ft. 6-7 ft. 8 ft. 2-4 ft. 5-7 ft. 8 ft. 2-5 ft. 6-7 ft. 8 ft.

2-4 ft. 5-6 ft. 7-8 ft. 2-4 ft. 5-6 ft. 7-8 ft. 2-5 ft. 6 ft. 7-8 ft.

–

–

–

NOTE: When using valve covers, an additional bracket should be

installed at the right or left end of the valve cover for additional

support.

2-5 ft. 6-7 ft. 8 ft.

2-5 ft. 6-7 ft. 8 ft.

2-5 ft. 6-7 ft. 8 ft.

SERIES J & R ENCLOSURES WITHOUT BACK PANEL

STEP 1: STEP 2: STEP 3:

Mark chalk line.

Publication No. CP-40

Part # 00-5175

a) Attach hanger to bracket with Sems

screws furnished (1/4" x 20 x 1/4").

b) Mount assembly to w

c) Align hanger for necessary pitch.

all at chalk line.

a) Install elements, connect and

test system

b) Install cover by inserting the top lip

between wall and bracket. Pull down

and back until bottom lip snaps into

slot on bracket.

c) Follow through with accessories.

Page 2

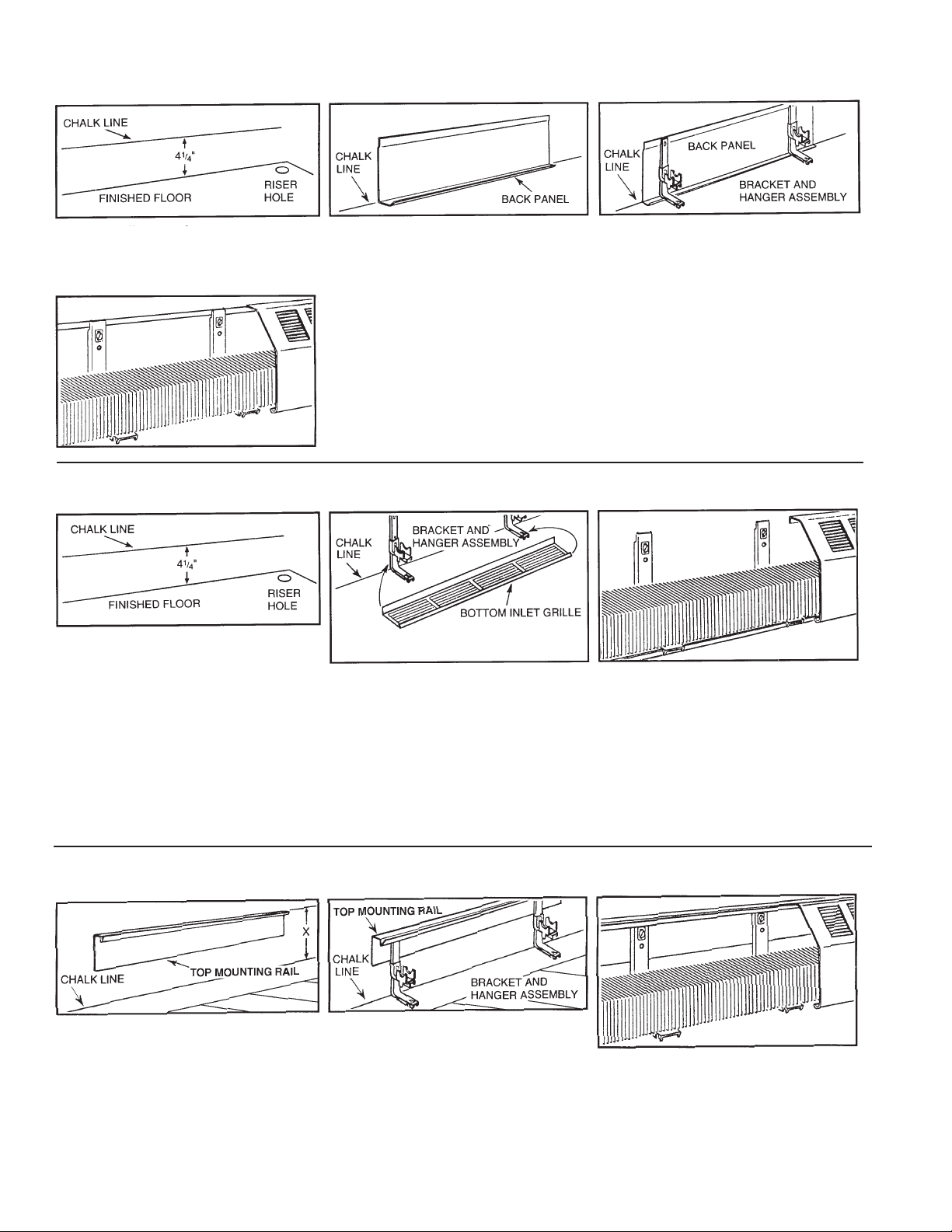

SERIES J & R ENCLOSURES WITH BACK PANEL

STEP 1: STEP 2: STEP 3:

Mark chalk line, as above.

Install back panel at chalk line

.

a) Attach hanger to bracket with Sems

screws furnished (1/4" x 20 x 1/4").

b) Mount assembly to back panel.

STEP 4:

c) Align hanger for necessary pitch.

a) Install elements, connect and test

system.

b) Insert top lip between wall and back

panel. Pull down and back until

bottom lip snaps into slot on bracket.

c) Follow through with accessories.

SERIES J & R ENCLOSURES

WITH BOTTOM INLET GRILLE

STEP 1: STEP 2: STEP 3:

Mark chalk line.

a) Attach hanger to brac

ket with Sems

screws furnished (1/4" x 20 x 1/4").

b) Mount to wall at chalk line. Leave

bottom screws loose for friction fit of

back edge of bottom inlet grille.

c) Install bottom inlet grille to bracket.

Complete mounting of bracket

a) Install elements, connect and test

system.

b) Snap on cover, insert top lip between

wall and bracket. Pull down and back

until bottom lip snaps into slot on

bracket.

c) Follow through with accessories.

to wall.

d) Align hanger for necessary pitch.

SERIES JR & RR ENCLOSURES WITH 4" TOP MOUNTING RAIL (BPT)

STEP 1: STEP 2: STEP 3:

Attach hanger to bracket with Sems

a) Mark chalk line.

b) Install top mounting rail above chalk

line using the following dimensions:

for enclosures with 1-tier of element

10", 1-tier of element 14", 2-tier 21"

and 3-tier 28".

a)

screws furnished (1/4" x 20 x 1/4").

Mount assemb

b)

ly to back panel.

c) Align hanger for necessary pitch.

a) Install elements, connect and

test system

b) Insert cover in the “V” channel in top

mounting rail. Pull down and back until

bottom lip snaps into slot on bracket.

c) Follow through with accessories.

2

Page 3

DAMPERS

DAMPER KNOB & LEAD SCREW

ASSEMBLY

INSTRUCTIONS

1. Screw LEAD SCREW into LEAD SCREW NUT about 10 turns clock

wise in direction shown.

2. Line up LEAD SCREW with BUSHING hole by sliding DAMPER left or right.

3. Swing DAMPER toward COVER and guide LEAD SCREW through

BUSHING hole until beginning of SCREW thread is against BUSHING and

SCREW EXTENSION protrudes through front of COVER. Hold in place and

proceed to step 4.

4. Place KNOB on to SCREW EXTENSION and line up allen head SET

SCREW in KNOB with FLAT of SCREW EXTENSION and tighten set

screw with an allen wrench.

SERIES EM, F AND BARE ELEMENT

STEP 1: STEP 2: STEP 3:

Mark chalk line.

a) Mount required hanger at chalk line.

b) Align hanger for necessary pitch.

ACCESSORIES

FIT BOTH EM & F COVERS:

TYPICAL ARRANGEMENTS OF ENCLOSURES FOR SERIES J OR R

TYPE EM

TYPE F

a) Install elements, connect and test system

b) Slip on cover, insert top flange of cover

between wall and fins, cover rests on fins.

SERIES EM OR F

3

Page 4

INTERNAL SPLICE PLATE INSTALLATION INSTRUCTIONS

Cover sections may be tightly joined with internal splice plates for a neat, trim fit. They may be used instead of external splice plates.

Step 1:

After installing support brackets on the

wall at the desired height, place the cover

over the brackets and snap in place.

Step 4:

Place the next cover in place on support

brackets.

Step 2:

Insert the internal splice plate just shy of

the halfway slots. Slots must remain

visible and not slide under cover.

Step 5:

Slide the next cover over the internal

splice plate up to the screws, nails or

slotted screw drivers.

Step 3:

Insert screws, nails or slotted screw drivers into

the 2 halfway slots of the internal splice plate to

hold it in the correct location and prevent the

halfway slots from sliding under cover.

Step 6:

Remove the 2 screws, nails or screw

drivers.

Note: Product shown is unpainted and

does not represent finished installation.

Step 7:

Continue sliding cover sections together

until a snug fit is obtained.

©Slant/Fin Corp. 2009 Printed in the U.S.A. 909 Publication No. CP-40

SLANT/FIN CORPORATION, Greenvale, N.Y. 11548 • Phone: (516) 484-2600

FAX: (516) 484-5921 • Canada: Slant/Fin LTD/LTEE, Mississauga, Ontario

www.slantfin.com

Loading...

Loading...