Slant/Fin EM-10 Installation

MODEL EM-10

ELECTRIC BOILER CONTROL

OPERATION AND INSTRUCTION MANUAL

The EM-10 Boiler Temperature Control (BTC) is an efficient

boiler operator with a digital LCD display with backlight, a

boiler pump output, an alert output, and four stage outputs.

The control regulates the boiler based upon setpoint, outdoor

reset, and several options for external boiler control.

Features:

• Setpoint Operation

• Outdoor Reset with Reset Override

• Four Stage Outputs

• External Control through BMS Signal

• External Control through Tekmar Boiler Controls

• Boiler Pump Operation

• Parallel Piping

• Primary – Secondary Piping

• Display Backlight

See Service Manual (792840000) for:

• Tekmar 275 and other External Direct Drive

Operation

• Two Setpoint Operation

• Dedicated DHW and Parallel Operation

• External Target/ Setpoint Operation

Publication No. EM-10-40

Printed in U.S.A. 809

Part No. 792820000

How to Use the Data Brochure

Item

Item

Item

This brochure is organized into three main sections.

They are: 1) Sequence of Operation, 2) Installation, and

) Control Settings.

3

Table of Contents

User Interface ..................................................................2

Display and Symbol Description ......................................3

Modes of Operation..........................................................4

Setpoint Operation ..........................................................8

Outdoor Reset Operation ................................................9

Installation ......................................................................10

Control Settings..............................................................11

DIP Switch Settings........................................................11

User Interface

The BTC uses a Liquid Crystal Display (LCD) as a method

of supplying information. You use the LCD in order to setup

and monitor the operation of your system. The BTC uses

three push buttons (Item, p,q) for selecting and adjusting

settings. As you program your control, record your settings

in the settings column of the Adjust menu. The table is

found in the second half of this brochure.

MENU

The Control Settings section of this brochure describes

the various items that are adjusted and displayed by the

ontrol. The control functions of each adjustable item are

c

described in the Sequence of Operation.

Mode 4 and 5 - Outdoor Reset / Setpoint Operation ....12

Default Settings ........................................................13-16

View Menu......................................................................13

Adjust Menu ..................................................................14

View Menu......................................................................15

Error Messages ..............................................................17

Reload Factory Defaults ................................................18

Specifications ................................................................20

ITEM

The abbreviated name of the selected item will be displayed

in the item field of the display.

To view the next available item, press and release the Item

button.

Once you have reached the last available item in a menu,

pressing and releasing the Item button will return the display

to the first item in the selected menu.

All of the items displayed by the control are organized into

two menus:

1) View

2) Adjust

These menus are listed on the upper right hand side of the

display (Menu Field). The default menu for the BTC is the

View menu. While in the View menu, the VIEW segment

is displayed.

To select the Adjust menu, press and hold simultaneously

all three buttons (Item, p,q) for 1 second.

The display then advances to the Adjust menu and the

ADJUST segment is turned on in the display. The display

will automatically revert back to the View menu after 20

seconds of keypad inactivity. Once in a menu, there will be

a group of items that can be viewed within that menu.

ADJUST

To make an adjustment to a setting in the control, begin

by selecting the Adjust menu by pressing and holding

simultaneously all three buttons.

Then select the desired item using the Item button. Finally,

use the p or q button to make the adjustment.

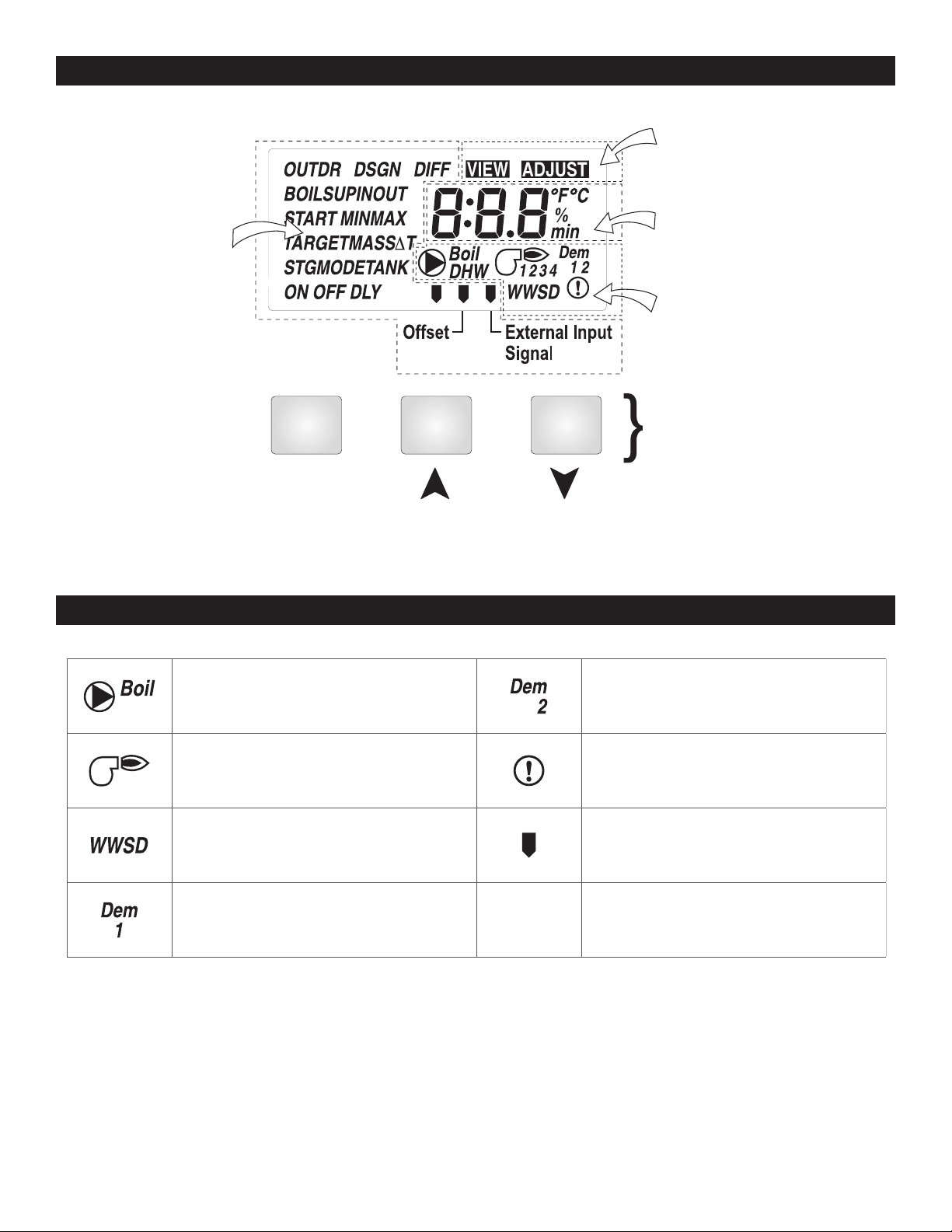

STATUS FIELD

Additional information can be gained by observing the

Status field of the LCD. The status field will indicate which

of the control’s outputs are currently active. Symbols in

the status field are only visible when the View menu is

selected.

2

EM-10-40 Operation and Instruction Manual

Item

Number Field

Displays the current value

of the selected item

Item Field

Displays the current

item selected.

Menu Field

Displays the

c

urrent menu

Buttons

Selects Menus, Items

and adjusts settings

Status Field

Displays the current status of

the control’s inputs, outputs

and operation

Display

BOILER PUMP

Displays when the boiler pump is in

operation.

BURNER

Displays when stage 1, 2, 3, or 4 contact

is on.

WWSD

Displays when the control is in Warm

Weather Shut Down.

DEMAND 1

Displays when a call for heat on demand

1 is present.

DEMAND 2

Displays when a call for heat on demand

2 is present.

ERROR

Displays when an error message is

present.

POINTERS

Displays operation as indicated by the text.

°F,°C

°F or°C

Displays the temperature units.

Symbol Description

EM-10-40 Operation and Instruction Manual

3

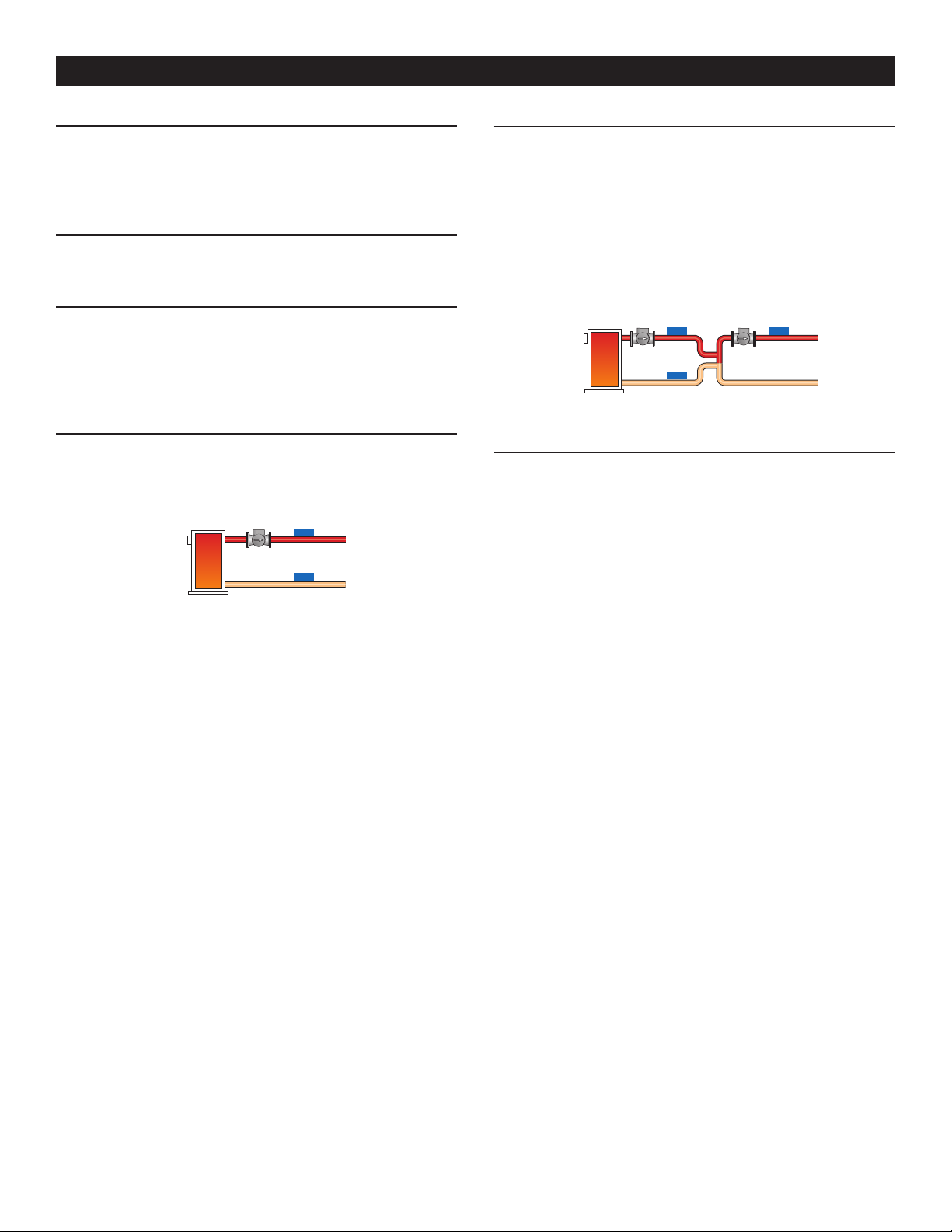

Symbol Description

Boiler Outlet

Sensor

Boiler Inlet

Sensor

Boiler Outlet

Sensor

Boiler Supply

Sensor

Boiler Inlet

Sensor

POWERING UP THE CONTROL

When the control is powered up, the control turns on all

egments in the display for 2 seconds. Next, the software

s

version is displayed for 2 seconds. Last, the control enters

into the normal operating mode.

ISPLAY BACKLIGHT

D

The control’s display has a backlight that is permanently

on while the control is powered.

PIPING

The boiler can be piped in parallel or in primary/secondary to

the system. The type of piping chosen affects the location of

the control’s operating temperature sensor. The

control can either use the boiler outlet sensor or the boiler

supply sensor.

PARALLEL PIPING

In parallel piping applications, the boiler outlet temperature

is typically the same as that delivered to the system.

Therefore the operating temperature sensor is the boiler

outlet sensor.

PRIMARY/SECONDARY PIPING

In primary/secondary applications, the boiler outlet

emperature (primary loop) is typically hotter than the

t

system supply temperature (secondary loop). This occurs

when the system supply pipe has a larger flow rate than

the boiler outlet pipe. Therefore, the control requires an

additional sensor (boiler supply) to measure the temperature

delivered out to the system. The operating temperature

sensor is the boiler supply sensor.

MODES OF OPERATION (MODE)

The control allows for seven modes of operation in order to

define the control operation and piping arrangement used.

The piping arrangement can be categorized into parallel

and primary / secondary. The mode of operation is selected

using the MODE item in the Adjust menu. The temperature

being controlled out to the heating system is measured by the

operating sensor.

The piping arrangement determines which sensor the

control uses as the operating sensor. The operating sensor is

either the boiler outlet sensor or the boiler supply sensor.

4

EM-10-40 Operation and Instruction Manual

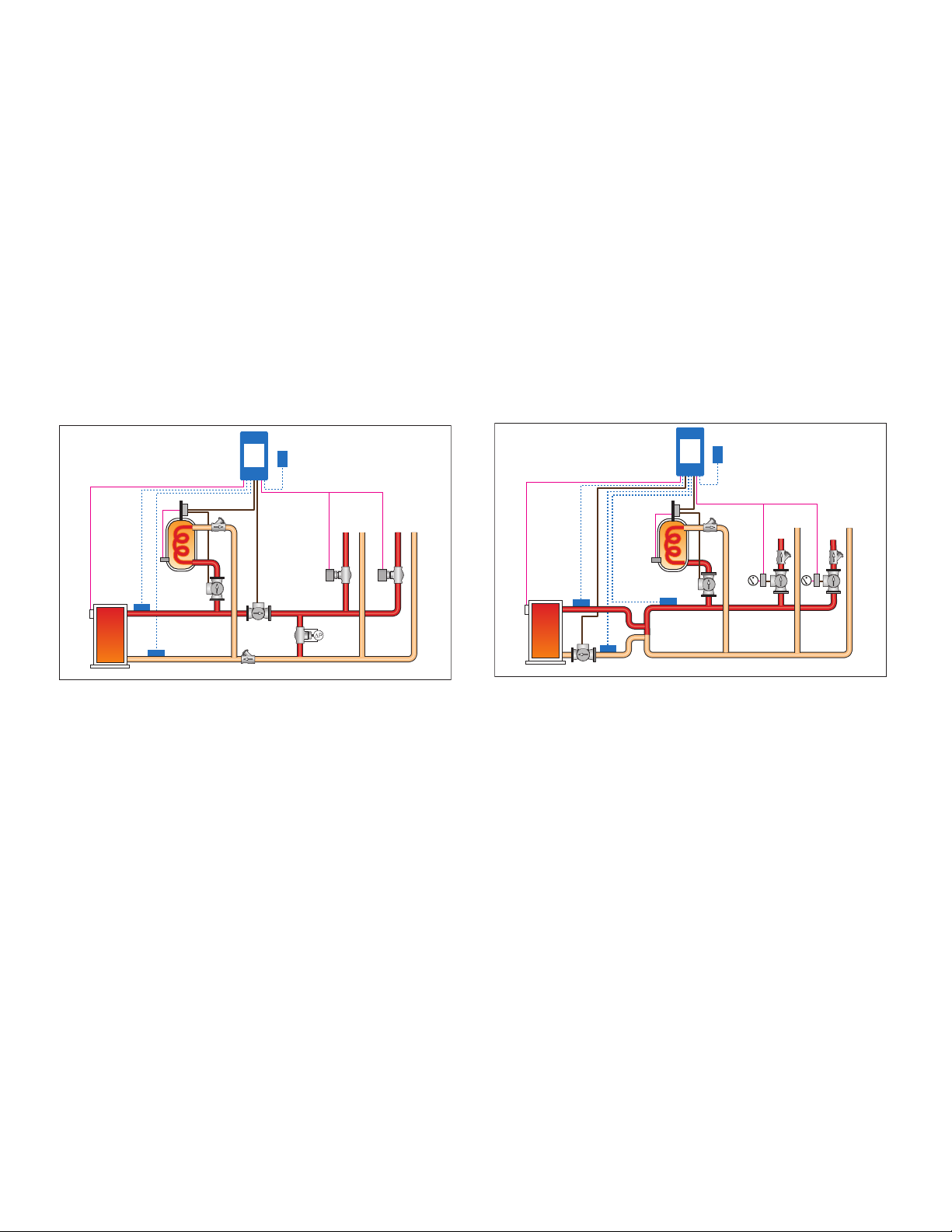

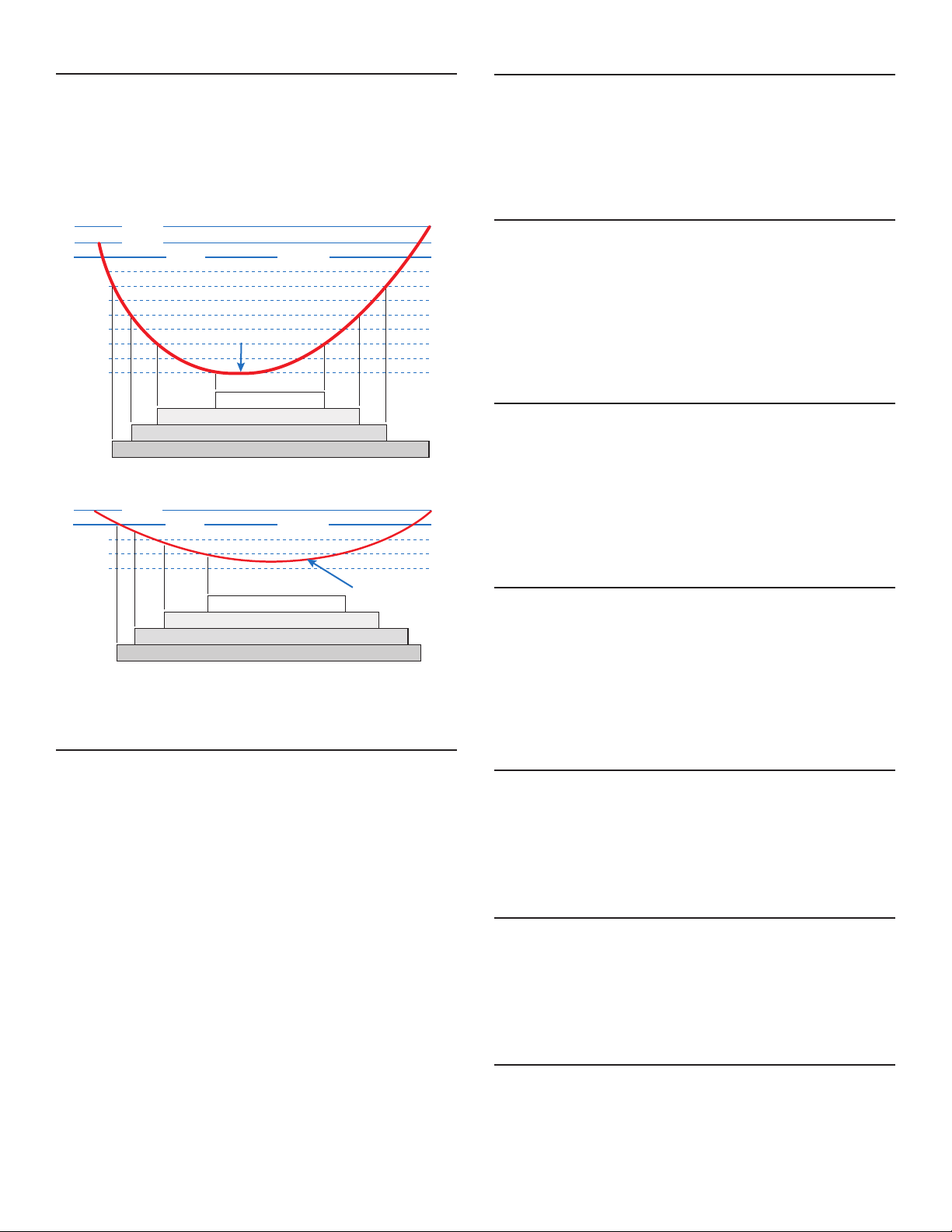

MODE 4

BTC

Mode 5

Boiler

Outlet

Sensor

Boiler Inlet Sensor

Boiler

Supply

Sensor

Outdoor

Sensor

Relay

BTC

Mode 4

Relay

Boiler

Outlet

Sensor

Boiler Inlet Sensor

Outdoor

Sensor

(Outdoor Reset and Setpoint with Parallel Piping)

Mode 4 is designed for outdoor reset and setpoint operation

using parallel piping. The heat demand is available to provide

outdoor reset for space heating systems. The

setpoint can be used to heat an indirect domestic hot

water tank.

Once a heat demand is present, the control stages the

boiler to maintain the calculated outdoor reset target at the

boiler outlet sensor. Refer to “Outdoor Reset Operation”

section for a description of outdoor reset operation.

Once a setpoint demand is present, the control stages the

boiler to maintain the boiler target at the boiler outlet sensor.

If both demands are present at the same time, the control

targets the higher of the two requirements. Refer to “Setpoint

Operation” section for a description of setpoint operation.

MODE 5 (Outdoor Reset and Setpoint with Primary/

Secondary Piping)

Mode 5 is designed for outdoor reset and setpoint operation

using primary / secondary piping. The heat demand is

available to provide outdoor reset for space heating systems.

The setpoint demand can be used to heat an indirect

domestic hot water tank.

Once a heat demand is present, the control stages the

boiler to maintain the calculated outdoor reset target at the

boiler supply sensor. Refer to “Outdoor Reset Operation”

section for a description of outdoor reset operation.

Once a setpoint demand is present, the control stages the

boiler to maintain the boiler target at the boiler supply

sensor. If both demands are present at the same time, the

control targets the higher of the two requirements. Refer to

section “Setpoint Operation” for a description of setpoint

operation.

EM-10-40 Operation and Instruction Manual

5

STAGING MODE (STGMODE)

175 °F

17 0°F

180°F Setpoint

Proportional Staging

185°F

190°F

155 °F

150°F

145 °F

140 °F

160°F

165°F

Stage 4

Stage 3

Stage 2

Stage 1

water

temperature

droop

water

temperature

droop

water

temperature

droop

175 °F

17 0°F

180°F Setpoint

P. I .D . Staging

very little

temperature

droop

185°F

165°F

Stage 4

Stage 3

Stage 2

Stage 1

P. I .D . = Proportional + Integral + Derivative

The control can operate up to four stages in order to

supply the required target temperature. The method of

staging used by the control is either P (proportional) or

PID (Proportional & Integral & Derivative), and is selected

using the STGMODE item in the Adjust menu.

STAGE DELAY (STG DLY)

The stage delay is the minimum time between firing first

to second stage, second to third stage, and third to fourth

stage and is determined by the Stage Delay setting. It can

be manually set, or it can be set to automatic in which the

boiler mass determines the stage delay time.

BOILER MASS (BOIL MASS)

The boiler mass setting allows the installer to adjust the

control to the thermal mass of different types of heat sources

used. The boiler mass setting automatically determines the

stage delay on, stage delay off, minimum on time and

minimum off time of the stages. A higher thermal mass

setting provides slower staging, while a lower thermal mass

provides faster staging.

Proportional (P)

Proportional staging, also known as step staging, is based

on manually adjusted settings that determine when the

next stage is required to turn on. These manual settings are

based on temperature and time. The interstage differential

sets the temperature drop at which the next stage turns on.

However, in order for a stage to fire, the interstage delay

on and minimum off times must first elapse.

Proportional & Integral & Derivative (PID)

PID staging allows the control to determine when the next

stage is required to turn on. After a stage is turned on in

the firing sequence, the control waits a minimum amount of

time (Stage Delay) before turning on the next stage. After

the minimum time delay between stages has expired, the

control examines the control error to determine when the

next stage is to fire. The control error is determined using

PID logic.

Proportional logic compares the actual operating sensor

temperature to the boiler target temperature. The colder the

temperature, the sooner the next stage is turned on.

Integral logic compares the actual operating sensor

temperature to the boiler target temperature over a period

of time.

Derivative logic determines how fast or slow the operating

sensor temperature is changing. If the temperature is

increasing slowly, the next stage is turned on sooner. If

the temperature is increasing quickly, the next stage is

turned on later, if at all.

6

Interstage Differential (STG DIFF)

The interstage differential is the temperature drop at which

the next stage will turn on. Once a stage turns on, the

next stage cannot turn on until the temperature drops

the interstage differential below the temperature at which

the previous stage turned on. The interstage differential

is adjustable through the STG DIFF setting in the Adjust

menu.

Interstage On Delay (ON DLY)

The interstage on delay is the amount of time that must

elapse before turning on the next stage. Once a stage turns

on, the next stage cannot turn on until the interstage delay

on time elapses. The interstage on delay is adjustable

through the ON DLY setting in the Adjust menu.

Interstage Off Delay (OFF DLY)

The interstage off delay is the amount of time that must

elapse before turning off the next stage. Once a stage turns

off, the next stage cannot turn off until the interstage delay

off time elapses. The interstage off delay is adjustable

through the OFF DLY setting in the Adjust menu.

Minimum On Time (MIN ON)

The minimum on time is the minimum amount of time that

a stage must be on before it is allowed to turn off. Once a

stage turns on, it cannot turn off until a minimum on time

elapses. The minimum on time is adjustable through the

MIN ON setting in the Adjust menu.

EM-10-40 Operation and Instruction Manual

Loading...

Loading...