Page 1

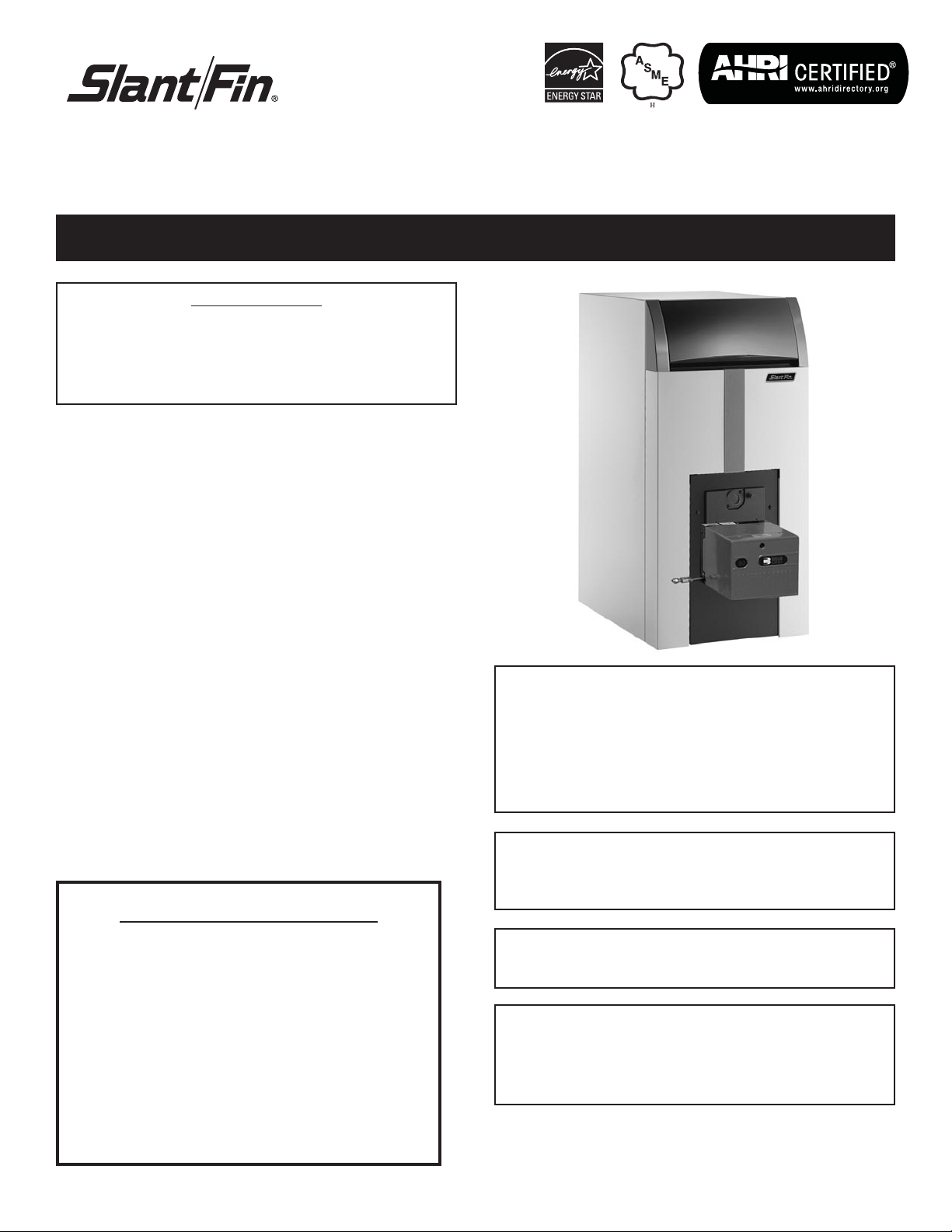

EUTECTIC EC-20

OIL-FIRED WATER BOILERS/NO. 2 OIL

INSTALLATION AND OPERATING INSTRUCTIONS

SAFETY WARNING:

KEEP BOILER AREA CLEAR AND FREE FROM COMBUSTIBLE MATERIALS, GASOLINE AND OTHER FLAMMABLE VAPORS AND LIQUIDS. FAILURE TO ADHERE TO

ABOVE SAFETY WARNING, MAY RESULT IN PERSONAL

INJURY OR DEATH AND PROPERTY DAMAGE.

CONTENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .PAGE

Ratings and Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Installation Requirements:

Boiler Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Clearances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Chimney Requirements . . . . . . . . . . . . . . . . . . . . . . . . . .3

Air Supply and Venting . . . . . . . . . . . . . . . . . . . . . . . . .3-5

Controls and Accessories . . . . . . . . . . . . . . . . . . . . . . . . .6

Piping for Water Units . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Installing Burner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Oil Supply Piping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Wiring the Boiler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Vent Piping and Draft Regulator . . . . . . . . . . . . . . . . . . . .7

Operating Instructions:

Precautions Before Starting . . . . . . . . . . . . . . . . . . . . . . .7

Start-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Wiring Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-12

Cleaning and Filling New Water Boiler . . . . . . . . . . . . . . . .13

Care and Maintenance:

Extended Shutdown . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Freezing Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Oil Burner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

General Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Burner Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15-16

IMPORTANT: The installation of this equipment must conform to the requirements of the authority having jurisdiction

or, in the absence of such requirements, to the Installation of

Oil Burning Equipment, ANSI/NFPA 31, latest edition, and to

the National Electrical Code ANSI/NFPA 70, latest edition.

The installation must also conform to the additional requirements in this Slant/Fin Instruction Manual. Where there is any

difference, the more stringent requirement shall govern.

In addition, where required by the authority having jurisdiction,

the installation must conform to American Society of Mechanical

Engineers Safety Code for Controls and Safety Devices for

Automatically Fired Boilers, No. CSD-1, latest edition.

THIS MANUAL MUST BE LEFT WITH OWNER AND

SHOULD BE HUNG ON OR ADJACENT TO THE BOILER

FOR REFERENCE.

IMPORTANT: This boiler must be installed, serviced and

repaired by a trained, experienced, service technician,

licensed for the installation and servicing of oil burning hot

water heating system equipment or otherwise qualified by the

authorities having jurisdiction over the installation.

Printed in U.S.A. 1113 Publication No. EC-20-40 Rev.A

Part No. 470910000

SERVICE COMPANY

Name ______________________________

Address_____________________________

___________________________________

Telephone ___________________________

Model # _____________________________

Serial # _____________________________

Page 2

EUTECTIC EC-20

2

Maximum operating pressure 60 psi.

All boilers hydrostatically tested — A.S.M.E.

* For forced hot water heating systems where the boiler and all piping are

located within the area to be heated, the boiler may be selected on the basis

of D.O.E. capacity output. The net AHRI output ratings shown are based on

an allowance for piping and pickup of 1.15 (water). D.O.E. capacity output is

divided by the allowance to obtain net rating. The Slant/Fin Technical Service

department should be consulted before selecting a boiler for unusual piping

and pickup requirements such as intermittent system operation, extensive

piping, etc.

† Ratings apply to the use of light oil at 140,000 Btu per gallon and apply only

when burner models listed on page 12 of this manual are used, and are

properly adjusted to produce 13% CO2.

# All dimensions subject to normal manufacturing tolerance.

NOTE: All boilers under 300,000 Btuh (87.9 kw) input are tested and rated for

capacity under the U.S. Department of Energy (D.O.E.) Test Procedures for

Boilers.

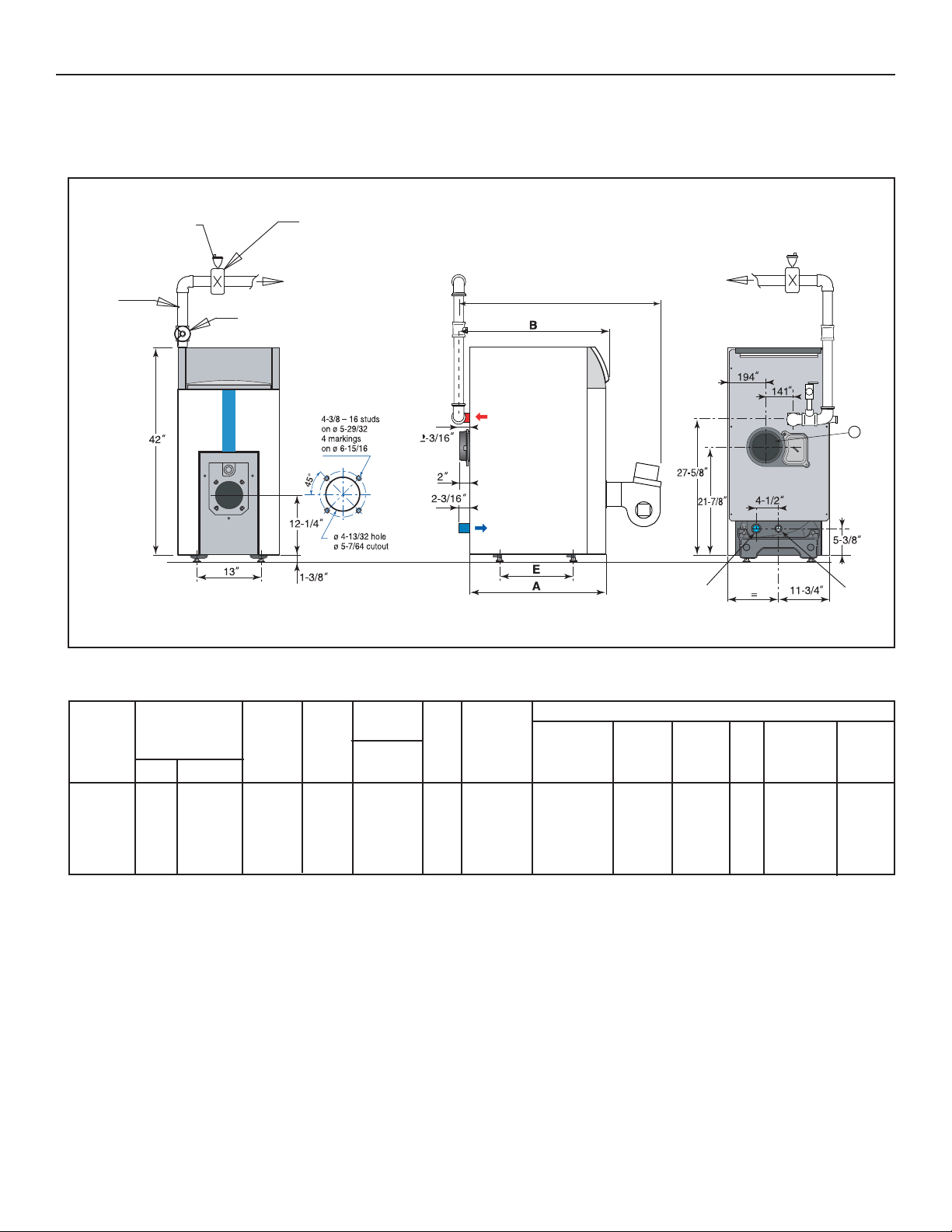

TABLE 1: Ratings and Dimensions

EC-25 1.55 217,000 190 165 6 x 15 86.5 N/A 32-9/16 35-3/8 46-3/8 6 20 2

EC-26 1.90 266,000 232 202 7 x 15 86.5 N/A 37-9/16 40-3/8 51-3/8 7 25 2

EC-27 2.25 315,000 269 234 7 x 15 N/A 85.3 42-9/16 45-3/8 56-3/8 7 30 2

EC-28 2.50 350,000 298 259 7 x 15 N/A 85.3 47-9/16 50-3/8 61-3/8 7 35 2

BOILER

MODEL

NO.

GPH BTUH

AHRI

BURNER

CAPACITY

OIL INPUT † §

D.O.E.

HEATING

CAPACITY

MBH *

WATER

APPROX.

OVERALL

LENGTH

“A”

THERMAL

EFF. (%)

AHRI

WATER

NET

RATING

MBH *

AHRI

CHIMNEY SIZE

DIMENSIONS (inches) #

I.D. ROUND

X HEIGHT

(in x ft)

AFUE

%

BOILER

LENGTH

“B”

BOILER

LENGTH

“C”

FLUE

DIA.

“D”

DISTANCE

BETWEEN

LEGS

“E”

FLUE

OUTLET

LENGTH

“F”

Figure 1: Dimensions

1-1/2”

NPT

Supply

Automatic

Air Vent

Air Eliminator

as per Manufacturer

Specifications

To Circ. (s)

and Zones

Suppy Pipe Mounted

Tridicator

A

D

1-1/2”

NPT

Return

3/4”

NPT

Drain

Page 3

EUTECTIC EC-20

3

THE INSTALLATION INSTRUCTIONS IN THIS MANUAL ARE

ABBREVIATED. SEE THE FRONT COVER OF THIS MANUAL

FOR REFERENCES TO CODES AND STANDARDS. SEE

ASSEMBLY INSTRUCTIONS (Part No. 47091100)

BOILER LOCATION

Provide a level, solid foundation for the boiler. Location should

be near the chimney so that the Flue Pipe Connector or

Breeching to the chimney is short and direct.

A. The foundation must be capable of supporting the weight

of the boiler when filled with water:

* Includes burner, circulator and controls

B. The EC-20 Boiler has full wet base sections which sur-

round fire-box for maximum heat absorption of burning

fuel, and low floor temperature.

C. If boiler is to be located over buried conduit containing

electric wires or telephone cables, consult local codes or

the National Board of Fire Underwriters for specific requirements.

MINIMUM CLEARANCE

Provide accessibility clearance of 24" from surfaces requiring

servicing (top and front) and 18" on any side requiring passage. The boiler shall be installed with the following MINIMUM

clearances from combustible materials:

A. CHIMNEY CONNECTOR-18"

B. BACK AND SIDES- 6" EXCEPT as limited by 18" clear-

ance from chimney connector

NOTE: Except in closets and alcoves, clearances above in (A)

and (B) may be reduced by providing forms of protection as

specified in NFPA 31, latest edition.

CHIMNEY REQUIREMENTS (see NFPA 211, latest edition)

A. The chimney must be constructed in accordance with all

local applicable codes and the National Board of Fire

Underwriters. See boiler models and rating table shown on

page 2 for chimney sizes.

B. Check chimney condition.

Existing chimneys and stacks may have deteriorated; without repairs their use would be hazardous. Before connecting to an old chimney or stack:

1. Clean it.

2. Inspect it thoroughly.

3. Remove obstructions.

4. Replace worn sections of metal stacks.

5. Seal bad masonry joints.

6. Repair damaged lining.

C. Breeching area must not be reduced at connection into

chimney. Breeching must be inserted into, but not beyond,

inside of chimney liner.

D. Chimney height shall extend at least 3 feet above where it

passes through the roof of the building, and at least 2 feet

above any ridge within 10 feet of the chimney.

E. The use of a vent cap, where permitted by code, gives

additional protection against adverse wind conditions and

precipitation.

F. Flue Connection: Connect flue pipe between back of boiler

and chimney. Horizontal sections of flue pipe must be

pitched upward to the chimney at least 1/4" per foot. Flue

must be inserted into, but not extend beyond, the inside

wall of the chimney flue. Draft regulator is not required but

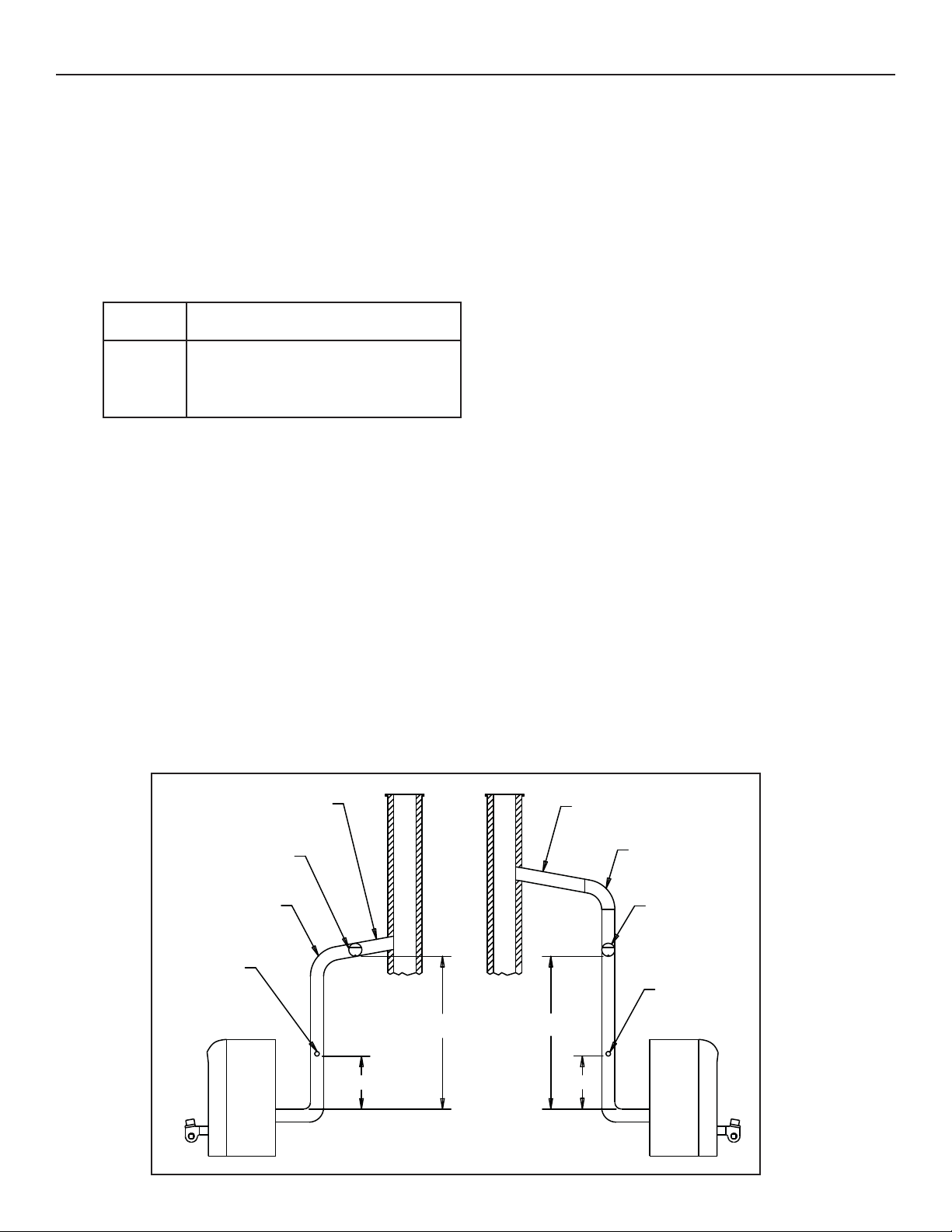

may be installed if conditions warrant it. Install draft regulator in flue pipe, as shown in figure 2.

AIR SUPPLY AND VENTILATION (see NFPA 31, latest edition)

Sufficient air for combustion and ventilation in the boiler room

must be provided. Failure to do this will result in poor combustion, heavy sooting and health hazards. Any oil-fired boiler

must have a steady draft* and an ample supply of combustion

air at all times during firing. If air supply or chimney draft* is

CHIMNEY

BOILERBOILER

PITCH UP

1/4" PER LINEAR FOOT

DO NOT INSTALL DRAFT REGULATOR HERE

BAROMETRIC DRAFT CONTROL

INSTALLED ON VERTICAL RISE

18"

MINIMUM

9"

PITCH UP

1/4" PER

LINEAR FOOT

BAROMETRIC DRAFT CONTROL

INSTALLED ON HORIZONTAL

CONNECTOR

DRILL 1/4" HOLE TO MEASURE

DRAFT,SMOKE,CO % AND STACK

TEMPERATURE

DO NOT INSTALL DRAFT REGULATOR HERE

9"

18"

MINIMUM

2

DRILL 1/4" HOLE TO MEASURE

DRAFT,SMOKE,CO % AND STACK

TEMPERATURE

2

CHIMNEY

Boiler Approximate Total Weight of Boiler

Size Assembly*, filled with water

EC-25 701

EC-26 815

EC-27 906

EC-28 1,008

Figure 2.

Barometric Draft

Regulator

Location

Page 4

EUTECTIC EC-20

4

unreliable, CO2and overfire draft* will change unpredictably.

DO NOT vent this boiler to the same chimney flue used by a

fireplace or coal or wood burning furnace or boiler. The draft*

produced by solid fueled devices varies tremendously

between high fire and low fire:

In modern, weather stripped, energy-saving buildings or older

buildings which have been modified similarly, natural infiltration may not supply enough air for combustion, particularly if

other fuel burning appliances, exhaust fans or draft inducers

are competing for the same air supply. Fireplaces, other solid

fuel burning appliances and exhaust fans consume great

quantities of air; if air supply is not ample, such an appliance

will create a downdraft in the oil-fired boiler flue. This can create a hazardous condition. Flue gases can be sucked out of

the chimney through the vent regulator into the living space.

DO NOT operate this boiler and a solid fuel burning appliance

at the same time, unless the solid fuel burner is provided with

its own outside air supply.

See Table 2, “Provisions for Combustion and Ventilation Air

Supply” for determining need and method of providing air for

combustion and ventilation.

If fly screen must be used over air supply openings, areas calculated should be doubled; the screen should be inspected

and cleaned frequently to maintain free air flow.

Protect air openings against closure by snow, debris, etc.

Openings such as doors or windows, if used, must be locked

open.

TABLE 2: Provisions for Combustion and Ventilation Air Supply. See NFPA 31, latest edition for more detailed information.

Boiler Location Air Supply

2.1 Unconfined space Is there sufficient air for combustion by natural infiltration (see

NOTE (1), “Test...” below)?

2.2 Unconfined space If there is NOT sufficient air for

combustion by natural infiltration

due to tight construction or other

conditions, then it REQUIRES AIR

FROM OUTDOORS. SEE

“ACTION REQUIRED” column at

right. See Notes (1) and (2) below.

2.3 Confined space If there is sufficient air for combustion from within building but it

comes from outside of the

confined space, see “ACTION

REQUIRED” column at right.

See Note (1) below.

2.4 Confined space If there is NOT sufficient air for

combustion due to tight construction or other conditions it

REQUIRES AIR FROM OUTDOORS. SEE “ACTION

REQUIRED” column at right.

See NOTE (2) below.

Action Required

NONE

Provide air from outdoors directly through a permanent outside wall opening or openings with a free open area of not

less than 1 sq. in. per 4000 Btu/hr of TOTAL input of ALL fuel

burning appliances in the building. See Note (1) and (3).

The confined space shall be provided with two permanent air

openings, one near the top of the enclosure and one near the

bottom. EACH opening shall have a free air opening of not

less than 1 sq. in. per 1000 Btu/hr. of TOTAL input of ALL fuel

burning appliances within the enclosure. The two openings

shall freely communicate with the interior areas of the building

which in turn would have to have adequate infiltration of air

from outdoors. See Notes (1, 3) and Figure 3a.

(a) Air from the outdoors shall be provided to the confined

space by two permanent openings, one in or near the top

of the enclosure space and one in or near the bottom. The

openings shall communicate directly, or by means of

ducts, with outdoors or to such spaces (crawl or attic) that

freely communicate with outdoors (See figures 3b, 3c

and 3d).

(b) Where directly communicating with outdoors or by means

of vertical ducts, each opening shall have a free area of

not less than 1 sq. in. per 4,000 Btu/hr. (35 sq. in. per gal.

per hr.) of total input rating of all appliances in the enclosure. If horizontal ducts are used, each opening shall have

a free area of not less than 1 sq. in. per 2,000 Btu/hr. (70

sq. in. per gal. per hr.) of total input of all appliances in the

confined space. See Figures 3b, 3c and 3d.

(1) Test for sufficient air for combustion by infiltration by running this boiler for 30 minutes under all of the following conditions and at the same time: a) all doors, win-

dows and other like openings must be closed, b) all fuel burning appliances should be FIRING, c) all exhaust fans and clothes dryers turned ON. At the above

conditions the CO2, smoke and draft readings must be normal. (CO2between 11% and 13%, smoke between ZERO and a TRACE, draft between .02” W.C. and

.04” W.C. negative pressure.)

(2) Aside from tight construction, some of the conditions that steal air for combustion from a boiler are other fuel burning appliances, exhaust fans and clothes dryers.

(3) Generally, louvers made of wood have a free open area of 20% and those made of metal have a 60% to 70% free open area. Screens also reduce the open area

of the louvers. Fly screen can reduce air opening by 50%.

* Draft is negative or suction pressure

Page 5

EUTECTIC EC-20

5

6 IN.

MAX.

12 IN

MAX

CHIMNEY

6 IN.

MAX.

12 IN

MAX

CHIMNEY

CHIMNEY

CHIMNEY

Figure 3a.

Appliances located in confined spaces. Air from

inside the building. See Table 2 (2.3).

Figure 3b.

Appliances located in confined spaces. Air from outdoors. See Table 2 (2.4).

Figure 3c.

Appliances located in confined spaces. Air from outdoors through ventilated attic. See Table 2 (2.4).

Figure 3d.

Appliances located in confined spaces. All air from

outdoors through ventilated crawl space and outlet

air to ventilated attic. See Table 2 (2.4).

Page 6

EUTECTIC EC-20

6

The opening size recommendation just given is for guidance

only. It is the installer’s responsibility to provide air for combustion and ventilation to all appliances, under all operating conditions, for each installation. See NFPA 31, latest edition for

more specific details.

INSTALLING CONTROLS AND ACCESSORIES

ON BOILER UNITS

Notes:Jacket must be installed on boiler units prior to

installation of trim.

WATER BOILER TRIM, see page 2, figures 1 for tapping

locations.

WATER PIPING FOR HOT WATER HEATING BOILERS

NOTE: On knocked-down boiler only, jacket may be installed

after return piping connection, but must be installed prior to

adding trim, supply piping and drain valve.

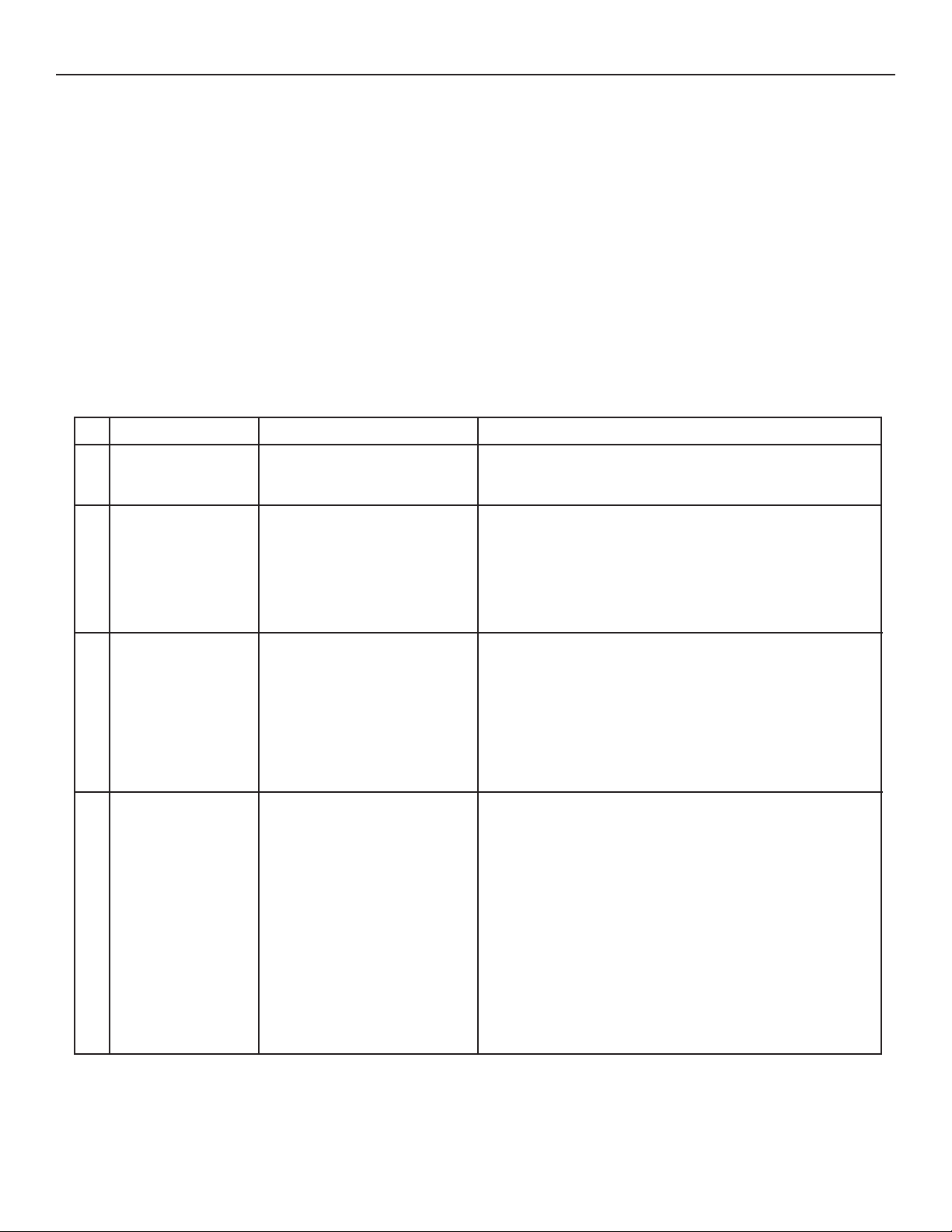

I. CIRCULATING SYSTEM

A. FORCED CIRCULATION hot water heating system: Use

the top tapping as supply tapping, and use the rear bottom tapping for the return.

B. A FLOW CONTROL VALVE will prevent gravity circula-

tion and is required when an external tankless heater,

an indirect water heater or multiple circulators are

installed.

II. AIR CONTROL SYSTEMS

A. DIAPHRAGM-TYPE COMPRESSION TANKS are used

to control system pressure in an AIR ELIMINATING

SYSTEM: an automatic air vent is used to REMOVE air

from the system water. (See figure 4)

If system pressure needs further control, add an additional tank or install a larger capacity tank.

The automatic air vent should be installed in the top of

the boiler, as in figure 4 and at radiation high points.

B. CONVENTIONAL COMPRESSION TANKS (non-

diaphragm type) are used to control system pressure in

an AIR COLLECTING SYSTEM. Within the system,

after initial start-up and venting, air is collected in the

tank and acts in contact with the water to control pressure. Air is not vented from this system except at radiation high points.

If system pressure needs further control, add another

tank in parallel with the original tank or install a large

capacity tank. Locate the tank at the inlet end of the

pump near the boiler.

C. HOT WATER RADIATION VENTING - Manual air vents

should be installed at the top of all "drops" (where piping goes downward). Air must be vented or purged from

all zone lines to permit proper system heating.

D. PUMP LOCATION - Locating low-head pump(s) on

return to boiler is only acceptable in residences of one

or two stories. The pump location shown in figure 4 is

required in large, multi-story building installations, especially when high-head pumps are used and is also rec-

ommended for all applications.

IMPORTANT: Hot water heating systems containing high water

volume, such as would occur with cast iron radiation, require

special care with air elimination.

The circulator pump should be located on the boiler supply pipe

and the expansion tank and air scoop should be located near

the pump suction. For alternate circulator pump location on

return for low-head pumps and one or two story buildings ONLY.

Figure 4. Air Eliminating System or Air Collecting System

Air Eliminator

as per Manufacturer

Specifications

To Circ. (s)

and Zones

Tridicator

1-1/2”

NPT

Supply

Automatic

Air Vent

Suppy Pipe Mounted

1-1/2”

NPT

Return

3/4”

NPT

Drain

Page 7

EUTECTIC EC-20

7

DOMESTIC HOT WATER

For Indirect-fired storage water heater application, see

Slant/Fin publication WH-10, Sizing Guide WH-SG and

Installation manual WH-40. The installation manual includes

several control systems and relay centers for space and

domestic water heating in addition to plumbing.

INSTALLING THE BURNER

See Burner Data, page 12, and Burner Manual supplied with

burner. If burner is not mounted as received, mount to boiler,

placing flange over mounting studs. Use gasket between

flange and boiler. Distance between flange and nose of burner

must be as shown on page 12. Check to see that nozzle and

settings are as given in burner data tables, page 12.

OIL SUPPLY PIPING

Install the oil tank or tanks and piping from tank to burner.

Follow local codes and practices, INSTALLATION OF OIL

BURNING EQUIPMENT, NFPA 31, latest edition, and the

instruction sheet attached to the oil burner pump. A one-pipe

system should be used for gravity-fed fuel systems and for lift

systems, where the total lift is less than 8 feet. Where the total

lift is greater than 8 feet, a two-pipe system must be used. In

some instances, local codes may require a two-pipe system

for below grade fuel oil tanks. Be sure to set up the fuel oil

pump for the piping system used; follow the instructions

attached to the pump. Be sure to include a good quality, low

pressure drop fuel oil filter in the supply line from the tank.

This is necessary, especially at low fuel oil flow rates (small

nozzle sizes), to prevent nozzle plugging. Fuel oil shutoff

valves should be installed at the burner on the supply (and

return if two-pipe) to facilitate servicing. See Slant/Fin publication on one-pipe and two-pipe fuel oil systems.

WIRING THE BOILER

(see National Electric Code ANSI/NFPA 70-latest edition)

A. The wiring diagrams for the burner and boiler may be found

on pages 10 and 11.

B. 24 volt control wiring should be approved Safety Circuit

wire, protected as needed.

C. Power supply wiring to the burner must be 14 gauge, as

required, and should have a properly fused disconnect switch.

120 volt wiring to pumps and safety controls must also be 14

gauge. Wire must be enclosed in approved conduit.

D. The wires supplying power to the burner MUST go through

the quick disconnect plugs provided with the boiler.

E. All wiring must be installed in compliance with the National

Electric Code, or any local or insurance codes having jurisdiction.

VENT PIPING AND DRAFT REGULATOR

(see NFPA 31, latest edition)

A. Vent connectors must be the same diameter as the boiler

flue collar. (See page 2)

B. Vent pipes and breeching must be pitched upward a mini-

mum of 1/4" per foot.

C. Connect vent pipe to the chimney using as few elbows as

possible and as short as possible within NFPA 31 or

authority.

D. Horizontal vent connector into the chimney should not be

inserted beyond the inside wall of the chimney.

E. Install barometric draft regulator on horizontal breeching,

near chimney, with hinge horizontal and face vertical conditions permitting as in Figure 3a. See Figure 3b as a second

choice. See manufacturer's instructions packed in carton

with barometric draft regulator.

F. If two or more appliances are used on the same chimney,

see CHIMNEY, page 3.

G. Make up all joints with minimum air leaks, secure with

sheet metal screws.

PRECAUTIONS BEFORE STARTING OIL BURNER

Make a positive check of A through F before starting burner:

A. Boiler and system are full of water. All air is vented from

system. See below.

B. All wiring is completed. See pages 10 and 11.

C. Oil supply is connected to the burner; nozzle is installed

correctly; oil valve is open at tank.

D. Main cast iron door on which burner is mounted is bolted

shut and fiberglass rope seal is making good contact.

E. Smokepipe is connected to chimney.

F. All combustible materials are cleared away.

G. Combustion air supply is provided. See page 3.

H. Burner settings are adjusted as per page 12 as shown on

boiler jacket.

START-UP (COMBUSTION TEST INSTRUMENTS MUST

BE USED) THIS BOILER IS A POSITIVE PRESSURE BOILER.

A. Make sure the boiler is installed and wired properly and is full

of water.

B. The observation port cover is mounted on the hinged burner

mounting door (see figure 2 on page 2). NEVER touch the

port cover or any surrounding surfaces with hands. It may be

HOT. See the burner instructions for bleeding air, etc. Step

away from the boiler and start the oil burner.

C. IMMEDIATELY, set burner air bands to obtain a bright fire

without smoke or oil stain. Set the DRAFT REGULATOR to

obtain .02" – .04" draft at the breeching.

D. Allow the burner to fire for at least one hour total firing time,

to bake out the volatile binders in the combustion chamber

before taking final combustion readings.

E. By alternate adjustment of the barometric draft regulator, the

burner air regulation and head regulation devices (whichever

apply), set for a zero to a trace of smoke and 12% CO

2

.

Then open the air bands or shutter (whichever apply) an

additional 1/8". This should result in zero smoke with NO raw

oil on the smoke paper and a smooth light-off. DO NOT

ATTEMPT TO SET FIRE BY EYE. Flame retention burners

may appear efficient and smoke free from an inefficient 7%

up to an overly high 14% CO2. However, a very low CO2can

also result in poor ignition and raw (unburned) oil entering the

fire box. At very high CO

2

, any slight decrease in air flow for

any reason will cause incomplete combustion, with high

smoke and dry soot formation in the fire box.

F. Once burner and draft have been set up, then smoke, CO

2

and stack temperature should be checked and recorded. If

smoke is greater than trace, review the burner instructions

and replace the nozzle if necessary. Normal smoke to be

expected is zero to a trace.

G. Probe slot can be accessed by removing 1/4" plug (Next to

observation port on door) with an adjustable wrench.

Replace plug and tighten to prevent leaks when finished.

Page 8

EUTECTIC EC-20

8

Page 9

EUTECTIC EC-20

9

Page 10

EUTECTIC EC-20

10

Honeywell L7248L,

Beckett 7600A and

Hydrostat 3250 Controls

See “Adjusting Settings”

& “error Codes” for

L7248L on page 12

Page 11

EUTECTIC EC-20

11

Aquastat Control Multiple Zoned (Circulator or Zone Valve)

FOR SLANT/FIN THERMATIC CONTROL WIRING,

SEE “THERMATIC CONTROL PANEL” MANUAL,

PART NO. 470902000.

Page 12

EUTECTIC EC-20

12

ADJUSTING SETTINGS

To discourage unauthorized changing of Aquastat settings, a procedure

to enter the ADJUSTMENT mode is required. To enter the ADJUSTMENT mode, press the UP, DOWN, and I buttons simultaneously for

three seconds. Press the I button until the feature requiring adjustment

is displayed:

. HL_ . High Limit.

. LL_ . Low Limit. (L7224 only)

. Ldf . Low Limit Differential. (L7224 only)

. °F . °C.

.ELL_ External Low Limit (L7248L only)

Then press the UP and/or DOWN buttons to move the set point to the

desired value, to change between ˚F and C˚, or to enable (On) or disable (Off) the External Low Limit. After 60 seconds without any button

inputs, the control will automatically return to the RUN mode.

DISPLAY

In the RUN mode, the Aquastat will flash .bt. (boiler temp) followed by

the temperature (i.e., 220), followed by °F or °C.

To read boiler settings, press the I key to read the parameter of interest.

For example, press I High Limit

(HL) is displayed, followed by a three-digit number, i.e., 220, followed by

°F or °C. Pressing the I button again (on L7224 models) will display the

Low Limit (LL) followed by a three-digit number and the corresponding

degree designator.

After approximately 60 seconds without any key presses, the display will

enter a dim display mode. To return to the bright display mode, simply

press any key.

DESCRIPTION

Boiler Temperature –

High Limit –

Low Limit –

Low Limit Differential –

Local Thermostat Status –

Enviracom Thermostat Status –

Error Code –

Degrees Fahrenheit –

Degrees Celsius –

FOR L7248L

Aquastat

;tluaf MOCE2rrE

Err3 Excessive electrical noise or frequency out of range. Hardware fault; replace controller. 18, 58

a

Err6

b

Err 8

a

Err9

a

Err 10

a

Err 11

a

Warnings are generated to enunciate the system is not operating optimally, but the Aquastat is still operating and

maintaining boiler temperature. In the instance where an Outdoor Reset Module is used, the warnings may indicate a

reset curve setting error one or more fe atures is not running optimally, and the Aquastat is reverting to default settings

or has stopped running the Outdoor Reset algorithms. The warnings are cleared when the issue(s) is resolved.

b

To clear Err 8 condition, depress and hold all three user keys simultaneously for 60 seconds. Err 8 condition clears

and display returns to normal. Err 8 condition is designed to catch welded relays on the Aquastat and will normally

only occur near end of life for the control. If Err 8 condition has occurred early in the controls life, be sure to check for

voltage feedback to B1 when B1 should be o and check current draw on b terminal to be sure oil burner is not drawing excessive current. Err 8 condition will keep repeating if B1 fault is not cleared.

:gninraW7rrE

Repeated B1 fault (voltage present at B1 wh en output is turned o); check B1 wiring/voltage. 25

Warning: Outdoor Reset System failure; communication to Outdoor Reset Module lost,

Outdoor Reset Module failure, multiple outdoor tempera ture sensors detected on the bus, or

outdoor temperature sensor failure. Check EnviraCOM wiring (1, 2, 3), check sensor wiring.

Warning: Boost Failure; Boost Mode active at least once per cycle for the last 60

consecutive cycles. Check Outdoor Reset curve settings.

DHW Module/Sensor failure; communication to DHW Module lost, DHW Module failure, or

temperature sensor failure. Check EnviraCOM wiring (1, 2, 3), check sensor wiring.

noitcA/esuaCedoC rorrE

EnviraCOM

Alarm

81.rosnes retaw kcehc ;tluaf rosnes tatsauqA1rrE

81.gniriw ™MOCarivnE kcehc

46.egatlov/gniriw 1B kcehc ;tluaf 1B4rrE

95.caV 011 ,2L-1L kcehc ;eniL woL5rrE

29.esuf ecalper ,seriw MOCE kcehc ;esuF :gninraW

A/N.seulav tluafed ot teser ;fdL ,fdH ,LL ,LH ,MORPEE

50, 53, 149

150

146, 147,

148

Page 13

EUTECTIC EC-20

13

CLEANING AND FILLING A NEW WATER BOILER

I. There are a number of commercial preparations available

from your distributor for cleaning and for corrosion protection

conditioning the internal (waterside) surfaces of boilers.

Follow the preparation manufacturer’s instructions.

DANGER:

Use CAUTION when handling chemicals and

draining hot water from a boiler. Scalding water and/or

chemicals can cause permanent injury to the skin, eyes

and respiratory system.

II. Filling and venting the water boiler after cleaning

A. Refill the system with fresh water.

B. Bring water temperature to at least 180° F promptly.

C. Circulate water through entire system.

D. Vent the system, including the radiation.

E. The boiler is now ready to be put into service or on

standby.

F. If brand name air-control devices are used, venting

instructions furnished with the devices should

be followed.

III. Safety check for control system

High limit control test: Set thermostat high enough for boiler

water temperature to reach high limit control setting. When

this temperature is reached, the high limit switch should

open, and the burner should shut off automatically. If the

high limit does not operate to shut off the burner, the high

limit or the wiring is faulty. Repair or replace immediately.

CARE AND MAINTENANCE

I. EXTENDED SHUTDOWN, CLEANING OR REMOVAL OF

BOILER FROM SERVICE.

DANGER:

Use CAUTION when handling chemicals and

draining hot water from a boiler. Scalding water and/or

chemicals can cause permanent injury to the skin, eyes

and respiratory system.

A.Shut down burner by disconnecting all electrical power to

the burner by turning OFF the BURNER EMERGENCY

SWITCH of this boiler. After shutting down burner, while

the boiler is still hot (180°F to 200°F), drain water from

the bottom of the boiler until it runs clear.

EC-25 EC-26 EC-27 EC-28

11.5 13 15 17

WATER CONTENT OF BOILER (GALLONS)

3/8 — — — 0.430 0.0075

1/2 40 0.622 0.0157 0.545 0.0121

5/8 — — — 0.666 0.0181

3/4 40 0.824 0.0277 0.785 0.0251

1 40 1.049 0.0449 1.025 0.0429

1 1/4 40 1.380 0.0779 1.265 0.0653

1 1/2 40 1.610 0.106 1.505 0.0924

2 40 2.067 0.174 1.985 0.161

2 1/2 40 2.469 0.249 2.465 0.248

3 40 3.068 0.384 2.945 0.354

Nominal

Pipe

Size

Inches

Schedule

No.

Inside

Diameter

Inches

Gallons

per

Lin. Ft.

Inside

Dia.

Inches

Gallons

per

Lin. ft..

Standard Steel Pipe Type L Copper Tube

VOLUME OF WATER IN STANDARD PIPE OR TUBE

B.Provide corrosion protection conditioning to the boiler water

in the heating system. There are a number of commercial

heating system preparations available from your distributor.

Follow the preparation manufacturer’s instructions.

C.To clean the fireside boiler surfaces, first shut down

burner by disconnecting all electrical power to the burner

by turning OFF the OIL BURNER EMERGENCY

SWITCH of this boiler in order to perform the following

work in (1) through (10) below.

1. Remove the flue pipe from the boiler flue collar and

clean thoroughly.

2. Inspect the entire vent connector back to the chimney and clean if necessary.

3. Inspect the chimney for soot, debris and other unsafe

conditions of the chimney and take the necessary

action.

4. The burner mounting door must be fully open to

clean the flue passages and the combustion

chamber. If the oil line is not flexible enough it should

be disconnected from the burner during the cleaning

process. The flexible electric conduit connected from

the junction box on the boiler to the burner via a

plastic connector must be disconnected from the

burner by grasping the plastic half of the connector

closest to the flexible conduit and gently pulling it in

the direction of the conduit until it is disconnected.

Remove both 16 mm (5/8") special nuts on the sides

of the swinging door. You will need a 16 mm (5/8") open

end or box wrench. Open the door to completely

expose the combustion chamber for thorough

cleaning and for inspection of main cast iron burner

door insulation and burner door fiberglass sealing

rope. If combustion chamber parts above are badly

deteriorated then replace with original factory parts

available at your distributor.

5. Use the flue brush to clean the flueways. Remove cast

iron baffle plates for cleaning See figure 5 for removal

and replacement of baffle plates. A wire brush (supplied with boiler) may be used to remove any carbon

accumulation that may have developed in the combustion chamber. Vacuum the loose soot and debris from

the boiler. Replace baffle plates.

6. Inspect the burner combustion head. Clean if necessary and make sure all the adjustments are correct.

(See burner data pages for the burner installed.)

Replace oil nozzle with new one and readjust electrodes. To insure proper burner operation ONLY THE

NOZZLES SPECIFIED IN THIS MANUAL OR ON

THE BURNER LABEL SHOULD BE USED FOR

REPLACEMENT.

Page 14

EUTECTIC EC-20

14

7. Protect all of the fireside surfaces by swabbing with

neutral mineral oil.

8. Close main cast iron burner door (door on which

burner is mounted). Make sure that the entire seal

is making good contact with the boiler casting when

replacing both 16 mm (5/8") special nuts and

tightening.

D.If boiler room is damp, provide ventilation.

II. PROVIDING PROTECTION FOR FREEZING

Anti-freeze is sometimes used in hydronic heating systems to protect against freeze-up in the event of power

failure, or safety control shutdown when the building is

unoccupied. It should be recognized that unless the

building is kept above freezing temperature by some

means, the plumbing system is not protected.

PROPYLENE GLYCOL is used in the quick-freeze food

industry; it is practically non-toxic. Its use may be permitted when indirect water heaters are used. When antifreeze must be used, inhibited propylene glycol is recommended. Useful information on the characteristics, mixing

proportions, etc. of glycol in heating systems is given in

Technical Topics No. 2A, available from the Slant/Fin

website, go to http://slantfin.com. Go to library, select

current literature, select boiler model. See related topics

and select antifreeze and hydronic systems. Consult

glycol manufacturers for sources of propylene glycol.

DO NOT USE ETHYLENE GLYCOL BECAUSE IT IS TOXIC.

III. OIL BURNER

Inspect and clean annually and following any period of

improper operation. Recheck and adjust settings as specified for burner model and nozzle size.

Set burner air and draft regulator, using test instruments

to obtain recommended CO

2

and draft without smoke.

See the Burner Data page in this manual that corresponds to the burner installed.

IV. GENERAL MAINTENANCE

These operations are recommended to be performed at

regular intervals:

A.BOILER HEATING SURFACES: clean off all coatings

found. Reseal covers.

B.BOILER CONTROLS: check contacts, settings, correct

functioning.

C.PIPING: check piping and accessories for leaks.

D.CHIMNEY or STUB VENT and BREECHING: check for

obstructions and leaks.

E.COMBUSTION AIR TO BURNER: check for continued

POSITIVE supply of air as required. Air needs are

greatest in coldest weather. Refer to AIR SUPPLY,

page 3.

F. WATER SYSTEM: check

1. System to be full of water and pressure to remain

stable (between 12 psi and 25 psi).

2. Air-control system: noise and air binding in radiation

should not occur.

3. Water lines: slightest leaks should be corrected.

G.BOILER ROOM AIR SUPPLY: air vents should be open

and free of obstruction. See page 3.

Put the baffles in place. Align the convection accelerators with the first fins.

BCDE

EC-25

XX

EC-26

XXXX

EC-27

XXXX

EC-28

XXXX

Figure 5. Baffle plates.

Page 15

EUTECTIC EC-20

15

BURNER DATA - FOR RIELLO BURNERS SHIPPED WITH BOILERS ONLY

† Air shutter and head settings shown are approximate ONLY. See START-UP page 7. Seal joint between flange and air tube with a suitable high

temperature sealant, if joint was not sealed at factory.

It is suggested that due to the positive pressure observed in the chamber that the air tube hole and any other passages of the flue gas leakages

be sealed to avoid combustion gas fumes from leaking into the boiler room.

5/ 32” or 4 mm

13/ 64” or 5 mm

13/ 64”

5 mm

D6003

Figure 6. Riello 40 Series. Model F-10 Electrode Setting

TURBULATOR SETTING

A) Loosen NUT (1), then turn SCREW (2) until the INDEX

MARKER (3) is aligned with the correct index number as per the

Burner Set-up chart, on page 12.

B) Retighten the RETAINING NUT (1).

NOTE: Zero and five are scale indicators only. From left to right,

the first line is 5 and the last line 0.

SETTING THE AIR ADJUSTMENT PLATE

A) Regulation of the combustion air flow is made by

adjustment of the manual AIR ADJUSTMENT PLATE

(1) after loosening the FIXING SCREWS (2 & 3).

The initial setting of the air adjustment plate should be

made according to Column 5 in the Burner Set-up Chart.

B) The proper number on the manual AIR ADJUSTMENT

PLATE (1) should line up with the SETTING INDICATOR

(4) on the fan housing cover. Once set, the air adjustment

plate should be secured in place by tightening SCREWS

2 and 3.

C) The final position of the air adjustment plate will vary on

each installation. Use instruments to establish the proper

settings for maximum CO2 and a smoke reading of zero.

NOTE: Variations in flue gas, smoke, CO2 and temperature

readings may be experienced when the burner cover is put

in place. Therefore, the burner cover must be in place when

making the final combustion instrument readings, to ensure

proper test results.

3

2

1

D5997

Figure 7. Riello 40 Series. Model F-10 Turbulator Setting

D5231

2

1

34

Figure 8. Riello 40 Series. Model F-10

Setting the Air Adjustment Plate

Boiler

Model

Burner

Model

Blast

Tube

Firing

Rate

GPH

Nozzles

Oil Pump

(PSIG)

Approx.

Head

Setting †

Approx.

Air

Setting †

Burner

Insertion

Depth

Size

GPH

Angle &

Ty pe

MFR.

EC-25 F-10 Long 1.55 1.25 60˚ B Hago 158 1.5 2.8 7"

EC-26 F-10 Long 1.9 1.5 45˚ B Hago 160 2.0 4.0 7"

EC-27 F-10 Long 2.25 1.75 45˚ B Hago 165 4.0 4.5 9.5"

EC-28 F-10 Long 2.5 2.0 45˚ B Delavan 155 5.0 4.5 9.5"

Page 16

SLANT/FIN CORPORATION, Greenvale, N.Y. 11548 • Phone: (516) 484-2600

FAX: (516) 484-5921 • Canada: Slant/Fin LTD / LTE E , Mississauga, Ontario

www.slantfin.com

©Slant/Fin Corp. 2011.

EC-25 P2-KA Short 1.55 1.25 60˚ B Delavan 155 8 4.5

EC-26 P2-KA Short 1.9 1.5 60˚ B Hago 160 9 8

EC-27 P2-KA Short 2.25 1.75 60˚ B Hago 165 15 11

EC-28 P2-K Short 2.5 2 60˚ B Delavan 155 8 10

Boiler

Model

Burner

Model

Blast

Tube

Firing

Rate

GPH

Size

(GPH)

Angle &

Type Mfg.

Oil Pump

(PSIG)

Approx.

Head

Setting

Approx.

Air

Setting

Nozzles

FIRING HEAD ADJUSTMENT

By turning the head adjustment screw clockwise, the

burner head will move inside the blast tube AWAY from

the end cone. This achieves lower firing rates. Similarly,

by turning the head adjustment screw counter-clock-

wise, the burner head will move inside the blast tube

toward the end cone, increasing the firing rate.

AIR SHUTTER ADJUSTMENT

Air adjustment is set at the factory. By turning the air

adjustment screw clockwise, the air shutter opening

increases. To achieve proper combustion, the air shutter

may need to be adjusted.

Head adjustment

Air band

adjustment

Scale

Scale

Picture 10

Figure 9

Figure 11

Figure 12

HEAT WISE BURNER DATA – BURNERS MODEL P2-KA and P2-K

Loading...

Loading...