Page 1

EUTECTIC

EC-10DV Series

DIRECT VENT OIL-FIRED WATER BOILER/NO. 2 OIL

INSTALLATION AND OPERATING INSTRUCTIONS

SAFETY WARNING:

KEEP BOILER AREA CLEAR AND FREE FROM

COMBUSTIBLE MATERIALS, GASOLINE AND

OTHER FLAMMABLE VAPORS AND LIQUIDS.

FAILURE TO ADHERE TO ABOVE SAFETY

WARNING, MAY RESULT IN PERSONAL INJURY

OR DEATH AND PROPERTY DAMAGE.

CONTENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .PAG E

Ratings and Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Installation Requirements:

Boiler Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Clearances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Vent Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Vent Piping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Installing Water trim . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Installing Burner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Oil Supply Piping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Wiring the Boiler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Operating Instructions:

Precautions Before Starting . . . . . . . . . . . . . . . . . . . . . .5

Start-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Cleaning and Filling New Water Boiler . . . . . . . . . . . . . .5

Wiring Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-7

Burner Data:

Riello . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-9

Care and Maintenance:

Extended Shutdo

Freezing Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Oil Burner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

al Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . .

Gener

THIS BOILER OPERA

THE FLUE AND OVER FIRE, ALL SEALS MUST BE IN

PLACE WHEN OPERATING THE BOILER. ALL VENTING

MUST BE INSTALLED AND SEALED ACCORDING TO THE

VENT MANUFA

wn . . . . . . . . . . . . . . . . . . . . . . . . . . .

TES WITH POSITIVE PRESSURE IN

CTURER’S INSTRUCTIONS

.

10

10

IMPORTANT: The installation of this equipment must conform

to the requirements of the authority having jurisdiction or, in

the absence of such requirements, to the Installation of Oil

ning Equipment, ANSI/NFPA 31, latest edition, and to the

Bur

National Electrical Code ANSI/NFPA 70, latest edition. The

installation must also conform to the additional requirements in

this Slant/Fin Instruction Manual. Where there is any difference, the more stringent requirement shall govern.

In addition, where required by the authority having jurisdiction,

the installation must conform to American Society of

Mechanical Engineers Safety Code for Controls and Safety

vices for A

De

edition.

THIS MANUAL MUST BE LEFT WITH OWNER AND

SHOULD BE HUNG ON OR ADJ

utomatically Fired Boilers, No. CSD-1, latest

BOILER FOR REFERENCE.

CENT

A

THE

O

T

UTION

CA

The information in this manual must be followed exactly

to avoid personal injury, property damage or loss of life.

IMPORTANT: This boiler must be installed by a trained,

ienced, ser

xper

e

vicing of oil b

and ser

the author

vice technician, licensed f

ning equipment or otherwise qualified by

ur

ities having jurisdiction over the installation.

Part No. 470908000 Publication No. EC-10DV-40

or the installation

Printed in U.S.A. 407

Page 2

2

1

-1/4 threaded

s

upply

Flue outlet øD

1

-1/4 threaded

r

eturn pipe

D

rain outlet

R

elief valve 3/4’’

Supply Pipe Mounted

T

ridicator

P

anel Mounted

Tridicator Pressure

Sensor Well

Panel Mounted

Tridicator Temperature

S

ensor Well

A

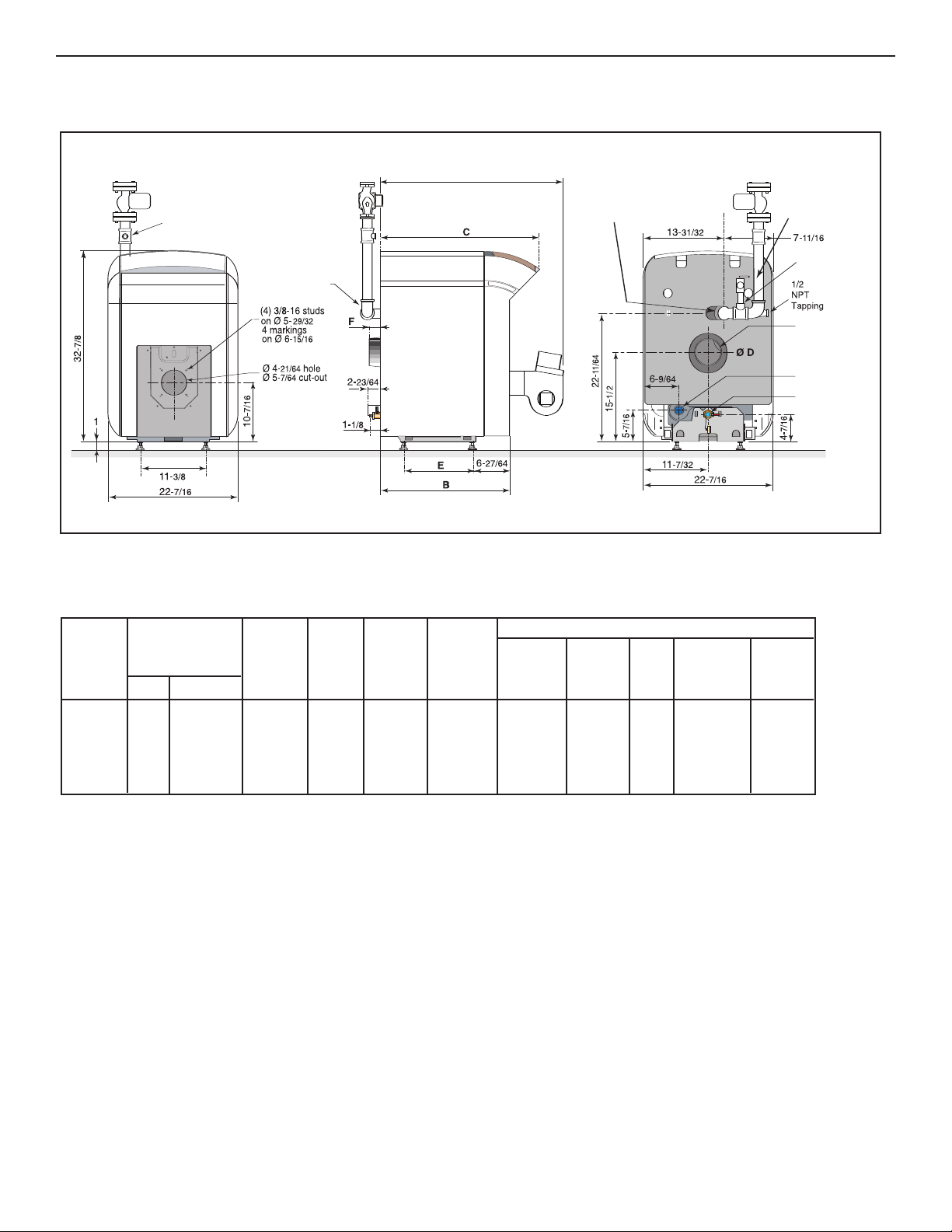

Figure 1: Dimensions (inches)

EUTECTIC EC-10 DV

TABLE 1: Ratings and Dimensions

BOILER

MODEL

NO.

I=B=R

BURNER

CAPACITY

OIL INPUT †

GPH BTUH

D.O.E.

HEATING

CAPACITY

MBH *

WATER

I=B=R

WATER

NET

RATING

MBH *

AFUE %

APPROX.

OVERALL

LENGTH

“A”

BOILER

LENGTH

“B”

DIMENSIONS (inches) #

BOILER

LENGTH

“C”

FLUE

DIA.

“D”

DISTANCE

BETWEEN

LEGS

“E”

OUTLET

LENGTH

EC-13DV 0.65 91,000 79 69 87 36 22-1/4 27 5 11-13/16 2

EC-14DV 0.80 112,000 98 85 87 41 27-1/4 32 5 16-13/16 2

EC-15DV 1.00 140,000 123 107 87 46 32-1/4 37 5 21-13/16 2

EC-16DV 1.15 161,000 141 123 87 51 37-1/4 42 6 26-13/16 4

Maximum operating pressure 60 psi.

All boilers h

ydrostatically tested — A.S

.M.E.

* For forced hot water heating systems where the boiler and all piping are

located within the area to be heated, the boiler may be selected on the basis

capacity output. The net I=B=R output ratings shown are based on

.E.

of D.O

an allowance for piping and pickup of 1.15 (water). D.O.E. capacity output is

divided by the allowance to obtain net rating. The Slant/Fin Technical Service

department should be consulted before selecting a boiler for unusual piping

and pickup requirements such as intermittent system operation, extensive

piping, etc.

† Ratings apply to the use of light oil at 140,000 Btu per gallon and apply only

ner models listed on pages 8 of this manual are used, and are

ur

when b

properly adjusted to produce 13% CO2.

ufacturing tolerance.

All dimensions subject to nor

#

mal man

NOTE: All boilers under 300,000 Btuh (87.9 kw) input are tested and rated for

capacity under the U.S. Depar tment of Energy (D.O.E.) Test Procedures for

Boilers.

FLUE

“F”

Page 3

UTECTIC EC-10 DV

E

3

I

NSTALLATION REQUIREMENTS

BOILER LOCATION

Provide a level, solid foundation for the boiler.

A. The foundation must be capable of supporting the weight of

the boiler when filled with water:

Boiler Approximate Total Weight of Boiler

Size Assembly*, filled with water

EC-13-DV 353

EC-14-DV 426

EC-15-DV 501

EC-16-DV 575

* Includes burner, circulator and controls

B. These boilers have full wet base sections which surround firebox for maximum heat absorption of burning fuel, and low floor

temperature.

. If boiler is to be located over buried conduit containing electric wires

C

or telephone cables, consult local codes or the National Board of Fire

Underwriters for specific requirements.

MINIMUM CLEARANCE

Provide accessibility clearance of 24" from surfaces requiring servicing (top

and front) and 18" on any side requiring passage. The boiler shall be

installed with the following MINIMUM clearances from combustible materials:

BACK AND SIDES- 6"

NOTE: Except in closets and alcoves, clearances above in (A) and

(B) may be reduced by providing forms of protection as specified in

NFPA 31, latest edition.

VENTING REQUIREMENTS

• The terminal shall not be closer than 3 feet above or 10 feet horizontally from any forced air inlet into the building.

• The terminal shall not be closer than 4 feet below, 4 feet horizontally

or 1 foot above any door, window or gravity air inlet into the building.

• The terminal shall not be less than 3 ft from an inside corner of an “L”

shaped building.

• The terminal shall not be less than 7 ft above grade when located

adjacent to public walkways.

• The terminal shall not be less than 2 ft from an adjacent building.

• The terminal shall be located at a height not liable to blockage from

leaves, snow or other debris, at least 1 ft above grade or anticipated

snow line.

• The terminal shall be positioned so that flue gases are not directed

where they can jeopardize people, overheat combustible structures

or enter buildings.

• Vent terminal should be away from shrubbery or other obstructions

that would prevent free air flow to and from vent terminal. Do not ter-

ent under dec

minate v

locations under windows should be avoided.

mination should not be mounted directly abo

ent ter

V

•

horizontally from an oil tank vent.

, stairways or car ports. When ever possible,

ks

e or within 3 ft

v

BOILER INTERNAL BAFFLES

TANT: EC-10 series boilers Direct Vent version is different from

IMPOR

standard series. Direct Vent version boilers usually have fewer internal cast

iron baffles.

E

E

C-14 & 15

EC-16

C-13

e

S

rsion

tandard V

(

3) Baffle Plates

(

2) Baffle Plates

c

enter & right side

when viewing from

front

(0)

e

nt Version

D

irect V

(

2) Baffle Plates center

& right side when

viewing from front

(

0)

(0)

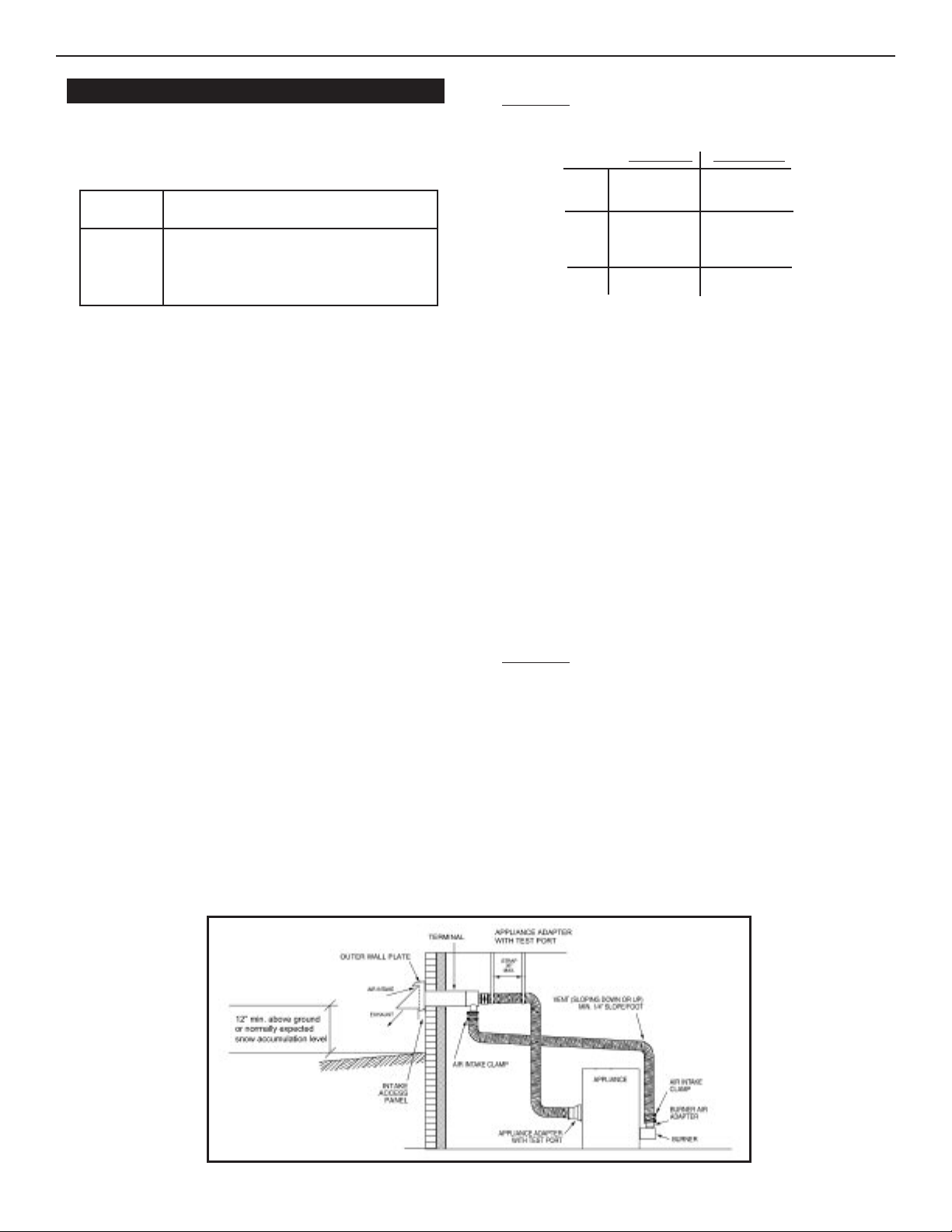

VENT PIPING

A. The vent piping minimum bend radius is 12”.

B. Place metal strapping every 36” to support vent pipe and prevent it

from sagging.

C. Maximum wall thickness is 14”. Contact Slant/Fin Corp. for

recommendations in case of thicker wall.

D. Gases will form white plume in winter. Plume could obstruct window view.

E. Prevailing winds could cause freezing of condensate and water/ice

buildup on building, plants or roof.

. Locate or guard vent to prevent accidental contact by people or pets, and

F

condensate from damaging exterior finish.

G.Do not terminate vent in window well, stairwell, alcove, courtyard, or other

recessed areas.

All venting kits must be double wall construction for the flue gas piping.

Field

Controls is the only approved manufacturer for venting kits. When installing

the vent kits the manufacturers instructions must be followed.

I

NSTALLING WATER TRIM

Notes: Jacket must be installed on boiler units prior to installation of trim.

PIPING

IMPORTANT: Boilers are to be used with closed system. Any application

that uses water from system, causes the introduction of a frequent supply of

fresh water into the boiler. This will cause damage to the boiler. Use of heat

exchangers will prevent this damage.

PIPING FOR WATER UNITS

NOTE: On knock down boiler only, jacket may be installed after return piping connection, but must be installed prior to adding trim & supply piping.

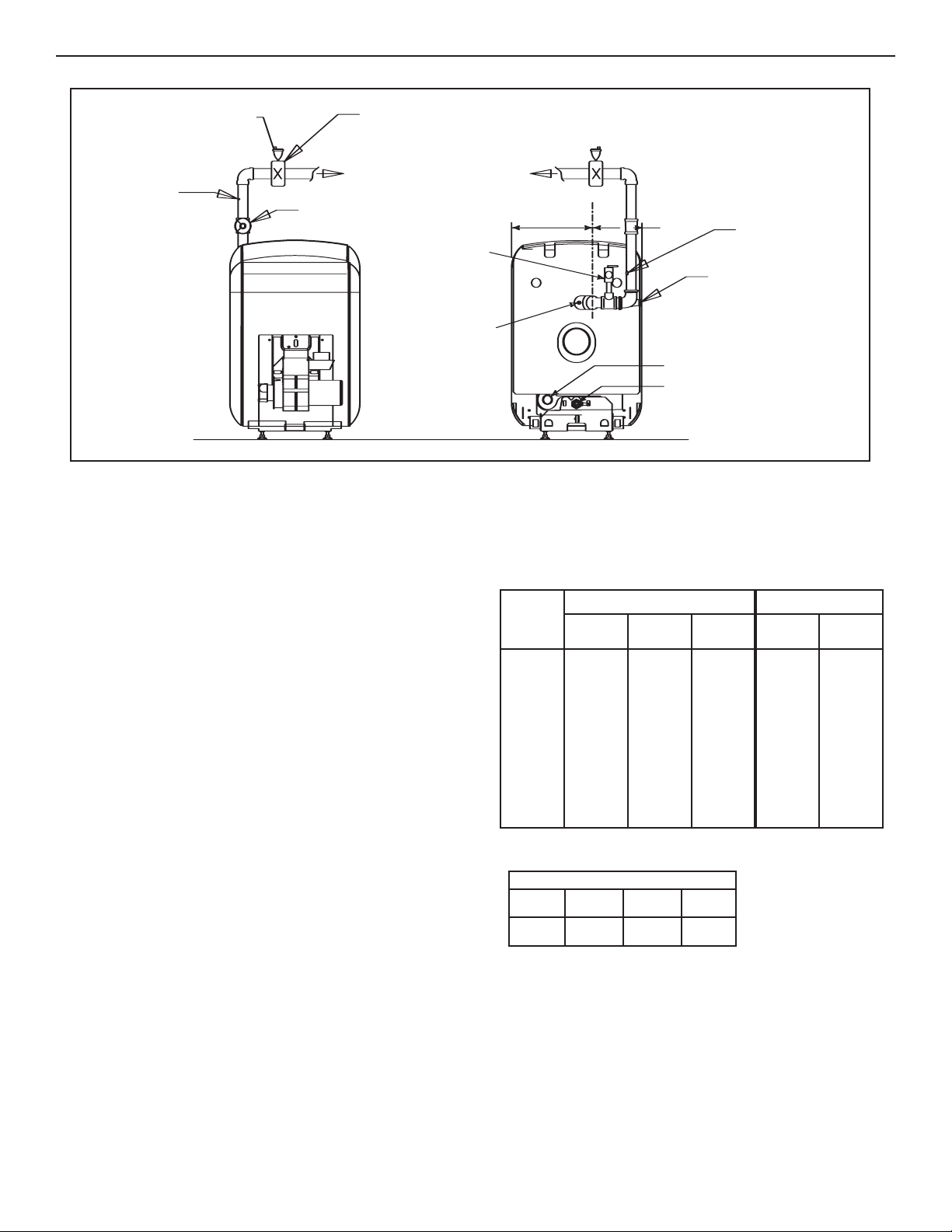

I. CIRCULATING SYSTEM

A. FORCED CIRCULATION hot water heating system: Use the top

tapping as supply tapping, and use the rear bottom tappings for

the return.

B. A FLOW CONTROL VALVE will prevent gravity circulation.

II. AIR CONTROL SYSTEMS

A. DIAPHRAGM-TYPE COMPRESSION TANKS are used to control

system pressure in an AIR ELIMINATING SYSTEM: an automatic

air vent is used to REMOVE air from the system water. See figure 3.

Figure 2. Typical Installation

Page 4

4

1

3-31/32

7

-11/16

Relief valve 3/4

1/2” NPT Tapping

for Feed Valve and

E

xpansion Tank

1-1/4 NPT

r

eturn tapping

Drain outlet

Panel Mounted

T

ridicator Temperature

Sensor Well

A

ir Eliminator

a

s per Manufacturer

Specifications

To Circ. (s)

and Zones

1

-1/4”

NPT

Supply

Automatic

Air Vent

S

uppy Pipe Mounted

Tridicator

Panel Mounted

Tridicator Pressure

Sensor Well

Figure 3. Air Eliminating System or Alternating Collecting System

EUTECTIC EC-10 DV

If system pressure needs further control, add an additional tank or install a

larger capacity tank. The automatic air vent should be installed in the top of

the boiler, as in figure 3.

B. CONVENTIONAL COMPRESSION TANKS (non-diaphragm type) are

used to control system pressure in an AIR COLLECTING SYSTEM. Within

the system, after initial start-up and venting, air is collected in the tank and

acts in contact with the water to control pressure. Air is not vented from this

system. If system pressure needs further control, add another tank in

parallel with the original tank or install a large capacity tank. Locate the

tank at the inlet end of the pump near the boiler. (See figure 3)

C. HOT WATER RADIATION VENTING - Manual air vents should be installed

at the top of all "drops" (where piping goes downward). Air must be vented

or purged from all zone lines to permit proper system heating.

D. PUMP LOCATION - Locating low-head pump(s) on return to boiler is

acceptable for smaller boiler sizes in residences of one or two stories.

The pump location sho

wn in figure 3 is required in large

, m

y

ulti-stor

building installations, especially when high-head pumps are used.

IMPORTANT: Hot water heating systems containing high water volume, such

ould occur with cast iron r

as w

adiation, require special care with air elimination. The circulator pump should be located on the boiler supply pipe and the

expansion tank and air scoop should be located near the pump suction.

INSTALLING THE BURNER

ner Data, pages 8-9, and Bur

See Bur

ner Man

ual supplied with b

ur

ner. If

burner is not mounted as received, mount to boiler, placing flange over

mounting studs

flange and nose of burner must be as shown on pages 8-9. Check to see

. Use gasket between flange and boiler. Distance between

that nozzle and settings are as given in burner data tables, pages 8-9.

VOLUME OF WATER IN STANDARD PIPE OR TUBE

Standard Steel Pipe Copper Pipe

⁄

4

⁄

2

⁄

2

Pipe

Schedule

40 0.622 0.0157 0.545 0.0121

40 0.824 0.0277 0.785 0.0251

40 1.380

40 1.610 0.106 1.505 0.0924

40

40 2.469 0.249 2.465 0.248

Nominal

pipe Dia.

3

⁄

8

1

⁄

2

5

⁄

8

3

⁄

4

1 40 1.049 0.0449 1.025 0.0429

1

1

1

1

2

1

2

Pipe ID

Inch

Gal. per

Lin.Ft.

Pipe ID

Inch

Gal. per

Lin. Ft.

– – – 0.430 0.0075

– – – 0.666 0.0181

1.265 0.0653

1.985 0.161

2.067

0.0779

0.174

3 40 3.068 0.384 2.945 0.354

WATER CONTENT OF BOILER (GALLONS)

EC-13 EC-14

5 6.5 8 8.5

EC-15 EC-16

Page 5

UTECTIC EC-10 DV

E

5

OIL SUPPLY PIPING

Install the oil tank or tanks and piping from tank to burner. Follow local

codes and practices, NFPA No. 31, INSTALLATION OF OIL BURNING

EQUIPMENT and the instruction sheet attached to the oil burner pump. A

one-pipe system should be used for gravity fed fuel systems and for lift systems, where the total lift is less than 8 ft. Where the total lift is greater than 8

ft., a two-pipe system must be used. In some instances, local codes may

require a two-pipe system for below grade fuel oil tanks. Be sure to set-up

the fuel oil pump for the piping system used; follow the instructions attached

to the pump. Be sure to include a good quality, low pressure drop fuel oil filter in the supply line from the tank. This is necessary, especially at low fuel

oil flow rates (small nozzle sizes), to prevent nozzle plugging.

WIRING THE BOILER

• The wiring diagrams for the burner and boiler may be found on pages 6-7.

• 24 volt control wiring should be approved Safety Circuit wire, protected

as needed.

• Power supply wiring to the burner must be 14 gauge or heavier, as

required, and should have a properly fused disconnect switch. 120 volt

wiring to pumps and safety controls must also be 14 gauge or heavier.

ust be enclosed in approved conduit.

Wire m

• All wiring must be installed in compliance with the National Electric

Code, or any local or insurance codes having jurisdiction.

OPERATING INSTRUCTIONS

PRECAUTIONS BEFORE STARTING OIL BURNER

Make a positive check of A through I before starting burner:

A. Boiler and system are full of water. All air is vented from system.

See below.

B. All wiring is completed. See pages 6-7.

C. Oil supply is connected to the burner; nozzle is installed correctly; oil

valve is open at tank.

D. All combustible materials are cleared away.

E. All vent piping is properly installed and sealed.

F. Burner settings are adjusted as per pages 8 & 9 and as shown on

boiler jacket label.

G. Main cast iron door on which burner is mounted is bolted shut and

fiberglass rope seal is making good contact.

H. Make sure boiler has correct quantity of baffles (see bottom of pag 3).

I. Make sure vent pipe, vent terminal and air supply pipe are properly

installed and clear of obstruction.

Note: Neither overfire nor flue draft should

exceed 0.35" WC during burner operation

CLEANING AND FILLING A NEW WATER BOILER

I. BEFORE FILLING WATER BOILER

A. Check burner to be certain it is ready for firing. DO NOT FIRE

into an empty boiler.

B. Be prepared to heat raw water to at least 180°F. as soon as it is

introduced into the boiler. This procedure will remove dissolved,

corrosive gases.

C. Provide drain line, with valve, from boiler. Use a bottom tapping.

Line and drain must be suitable for handling caustic solution.

II. CLEANING WATER BOILER SYSTEM

A. Use a commercial cleaning solution, such as

9100 Cleaner as directed in product instructions.

B. Use a commercial treatment solution, such as

Treatment as directed in product instructions.

III. FILLING AND VENTING THE WATER BOILER

A. Refill the system with fresh water.

B. Bring water temperature to at least 180° F. promptly.

C. Circulate water through entire system.

D. Vent the system, including the radiation.

E. The boiler is now ready to be put into service or on standby.

. If brand-name air-control devices are used, venting instructions

F

furnished with the devices should be followed.

IV. SAFETY CHECK FOR CONTROL SYSTEM

High limit control test: Set thermostat high enough for boiler water

ature to reach high limit control setting. When this temperature is

temper

reached, the high limit switch should open, and the burner should shut off

automatically. If the high limit does not operate to shut off the burner, the

high limit or the wiring is faulty. Repair or replace immediately.

Rhomar Hydro-Solv

Rhomar Pro-Tek 922

START-UP (COMBUSTION TEST INSTRUMENTS MUST

BE USED) THIS BOILER IS A POSITIVE PRESSURE BOILER.

A. Make sure the boiler is installed and wired properly and is full

of water.

B. The observation port cover is mounted on the hinged burner

mounting door. NEVER touch the port cover or any surrounding

surfaces with hands. They may be HOT. Use tools. Loosen the

screw and swing cover to be able to insert probe through slot,

when necessary. See the burner instructions for bleeding air, etc.

C. Take a smoke reading soon after starting burner. If smoke is not

zero or trace, open air to clear smoke and let burner fire.

D. DO NOT ATTEMPT TO SET FIRE BY EYE. A smoke gun and a

combustion analyzer must be used. Adjust the air to get approximately 12% C

O

2

ero or trace smoke. Then check and

with a z

record draft and flue temperature.

ation port cover is closed tight, the

Make sure that the obser

E.

urner is secure. Turn burner on and off at least 3 times to

b

v

check ignition.

THE FLUE IS UNDER POSITIVE PRESSURE DURING

OPERATION. ALL VENTING MUST BE SEALED AND

CHECKED ON A REGULAR INTER

VAL.

Page 6

6

Honeywell L 7248C–1030 Aquastat Control Single Zone Wiring

EUTECTIC EC-10 DV

Page 7

UTECTIC EC-10 DV

E

7

Honeywell L 7248C–1030 Aquastat Control Multiple Zoned (Circulator or Zone Valve)

Page 8

8

EUTECTIC EC-10 DV

RIELLO BURNER DATA

Riello

Burner

odel

Boiler Model

EC-13DV BF-3 Long 0.65 0.55 80*A Delavan 133 0 4.5 2 7"

EC-14DV BF-3 Long 0.8 0.7 80*B Delavan 130 3 5.5 none 7"

EC-15DV BF-5 Short 1 0.75 60*A Delavan 178 1 4.4 none 4-1/4"

EC-16DV BF-5 Short 1.15 0.85 60*W Delavan 182 2 4.2 none 4-1/4"

M

Blast

ube

T

Firing

Rate

PH

G

Size

GPH)

(

Nozzles

Angle &

Type

M

fg.

Oil Pump

PSIG)

(

Approx.

Head

etting

S

Approx.

Air

etting

S

Boile

Flue

affle

B

Models BF-3 & BF-5 Electrode Setting

Figure 4.

Burner

Insertion

epth

D

Turbulator location

3

2

1

Picture 1.

TURBULATOR SETTING

Loosen n

1.

2. Retighten the retaining nut, 1.

The numbers on the casting are there to denote the high and lo

scale indicators only. From left to right, the first line is 4 and the last line is 0.

ut, 1, then turn the screw, 2, until the index marker, 3, is aligned with the correct index number.

w end of the scale – F

or Model BF-5, zero and four are

The air/oil ratio depends on accurate setting of the turbulator disc and air damper.

Be careful when making this adjustment as an incorrect setting will result in an unsatisfactory operation.

See figure 5 & 6.

Page 9

UTECTIC EC-10 DV

E

9

Figure 5. Model F-5

Figure 6. Model F-3

SETTING THE AIR DAMPER ADJUSTMENT (see figure 7 & picture 2)

1. The initial air damper setting is made by turning screw (2) until the top edge of the air damper (3) is aligned with the

number according to the burner setup chart.

2. Further adjustments can be made with the burner cover in place by removing plastic plug on the top right hand side

of the cover. Turn the screw counter clockwise (+ indicator) to increase combustion air, turn the screw clockwise ( indicator) to decrease combustion air.

3. The final position of the air damper will vary on each installation. Use instruments to establish the proper settings

for maximum CO2 and a smoke reading of trace to zero.

NOTE: Variations in flue gas, smoke, CO2 and temperature readings may be experienced when the burner cover

is put in place. Therefore, the burner cover MUST be in place when making the final combustion instrument

readings, to ensure proper test results.

2

1

Figure 7. Air Damper Setting

Picture 2. Air Damper Location

3

Page 10

0

1

EUTECTIC EC-10 DV

CARE AND MAINTENANCE

I. EXTENDED SHUTDOWN, CLEANING OR REMOVAL OF

OILER FROM SERVICE.

B

DANGER: Use CAUTION when handling chemicals and

ining hot water from a boiler

dra

chemicals can cause permanent injury to the skin, eyes

nd respiratorysystem.

a

A.Shut down burner by disconnecting all electrical power to

the burner by turning OFF the BURNER EMERGENCY

SWITCH of this boiler. After shutting down burner, while

he boiler is still hot (180°F to 200°F), drain water from

t

the bottom of the boiler until it runs clear.

B.Provide corrosion protection conditioning to the boiler water

in the heating system. There are a number of commercial

heating system preparations available from your distributor.

Follow the preparation manufacturer’s instructions.

o clean the fireside boiler surfaces, first shut down

C.T

burner by disconnecting all electrical power to the burner

by turning OFF the OIL BURNER EMERGENCY

SWITCH of this boiler in order to perform the following

work in (1) through (10) below.

1. Remove the flue pipe from the boiler flue collar and

clean thoroughly.

2. Inspect the entire vent connector back to the chimney and clean if necessary.

3. Inspect the chimney for soot, debris and other unsafe

conditions of the chimney and take the necessary

action.

4. The burner mounting door must be fully open to

clean the flue passages and the combustion

chamber

be disconnected from the burner during the cleaning

process. The flexible electric conduit connected from

the junction box on the boiler to the burner via a

plastic connector must be disconnected from the

burner by grasping the plastic half of the connector

closest to the flexible conduit and gently pulling it in

the direction of the conduit until it is disconnected.

Remove all four 13 mm hex head screws on the

sides of the s

open end or box wrench. Open the door to

completely e

thorough cleaning and f

iron burner door insulation and burner door fiberglass

sealing rope.

5. Use the flue br

iron baffle plates for cleaning [(2) baffle plates in EC13, (0) baffle plates in EC-14, 15, and EC-16.]† A wire

brush may be used to remove any carbon accumulation that may ha

ber

Replace baffle plates.

6. Inspect the burner combustion head. Clean if necessary and make sure all the adjustments are correct.

(See b

Replace oil nozzle with new one and readjust electrodes. To insure proper burner operation ONLY THE

NOZZLES SPECIFIED IN THIS MANUAL OR ON

THE BURNER LABEL SHOULD BE USED FOR

REPLACEMENT.

† A flue brush (triangular shape) is supplied with boiler.

. If the oil line is not flexible enough it should

winging door.You will need a 13 mm

xpose the comb

ush to clean the fluew

e de

v

acuum the loose soot and debris from the boiler.

V

.

ner data pages f

ur

calding water and/or

. S

ustion chamber for

or inspection of main cast

. Remove cast

ys

a

eloped in the combustion cham-

v

or the burner installed.)

. Protect all of the fireside surfacesby swabbing with

7

neutral mineral oil.

8. Close main cast iron b

burner is mounted). Make sure that the entire seal

fiberglass rope) is making good contact with the

(

boiler casting when replacing four 13 mm hex head

crews and tightening.

s

D.If boiler room is damp, provide ventilation.

II. PROVIDING PROTECTION FOR FREEZING

Anti-freeze is sometimes used in hydronic heating systems to protect against freeze-up in the event of power

failure, or safety control shutdown when the building is

unoccupied. It should be recognized that unless the building is kept above freezing temperature by some means,

the plumbing system is not protected.

PROPYLENE GLYCOL is used in the quick-freeze food

industry; it is practically non-toxic. Its use may be permitted

when indirect water heaters are used. When anti-freeze

must be used, inhibited propylene glycol is recommended.

Useful information on the characteristics, mixing proportions, etc. of glycol in heating systems is given in Technical

Topics No. 2A, available from the Hydronics Division of

GAMA, 35 Russo Place, Berkeley Heights, NJ 07922.

Consult glycol manufacturers for sources of propylene

glycol.

DO NOT USE ETHYLENE GLYCOL BECAUSE IT IS TOXIC.

III. OIL BURNER

Inspect and clean annually and following any period of

improper operation. Recheck and adjust settings as specified for burner model and nozzle size.

Set burner air using test instruments to obtain recommended CO

page in this manual that corresponds to the burner

installed.

IV. GENERAL MAINTENANCE

These operations are recommended to be performed at

regular intervals:

A.BOILER HEATING SURFACES: clean off all coatings

B.BOILER CONTROLS: check settings, correct functioning.

C.PIPING: check piping and accessories for leaks.

D.STUB VENT and BREECHING: check for obstructions

E.COMBUSTION AIR TO BURNER: check for continued

F

G.BOILER ROOM AIR SUPPLY: air vents should be open

and draft without smoke. See the Burner Data

2

found. Reseal covers.

and leaks.

POSITIVE supply of air as required. Air needs are greatest in coldest w

page 3.

ATER SYSTEM: check

W

.

1. System to be full of water and pressure to remain

stable (between 12 psi and 25 psi).

Air-control system:

2.

should not occur

3. Water lines: slightest leaks should be corrected.

and free of obstr

eather.

uction.

urner door (door on which

er to AIR SUPPL

Ref

noise and air binding in r

.

,

Y

adiation

Page 11

SLANT/FIN CORPORATION, Greenvale, N.Y. 11548 • Phone: (516) 484-2600

(516) 484-5921 •

AX:

F

Canada:

Slant/Fin

L

TD/L

TEE,

Mississauga, Ontar

www

.slantfin.com

io

Loading...

Loading...