Page 1

EUTECTIC EC-10

OIL-FIRED WATER BOILERS/NO. 2 OIL

ASSEMBLY INSTRUCTIONS

Tools required:

• 1 Phillips screwdriver

• 1 Wide flat screwdriver

• 1 13mm open end wrench

• 1 19mm open end wrench

©Slant/Fin Corp. 2014 • Printed in the U.S.A. 1214 • Part # 470901000 • Publication No. EC-10-50 Rev.B

Page 2

2

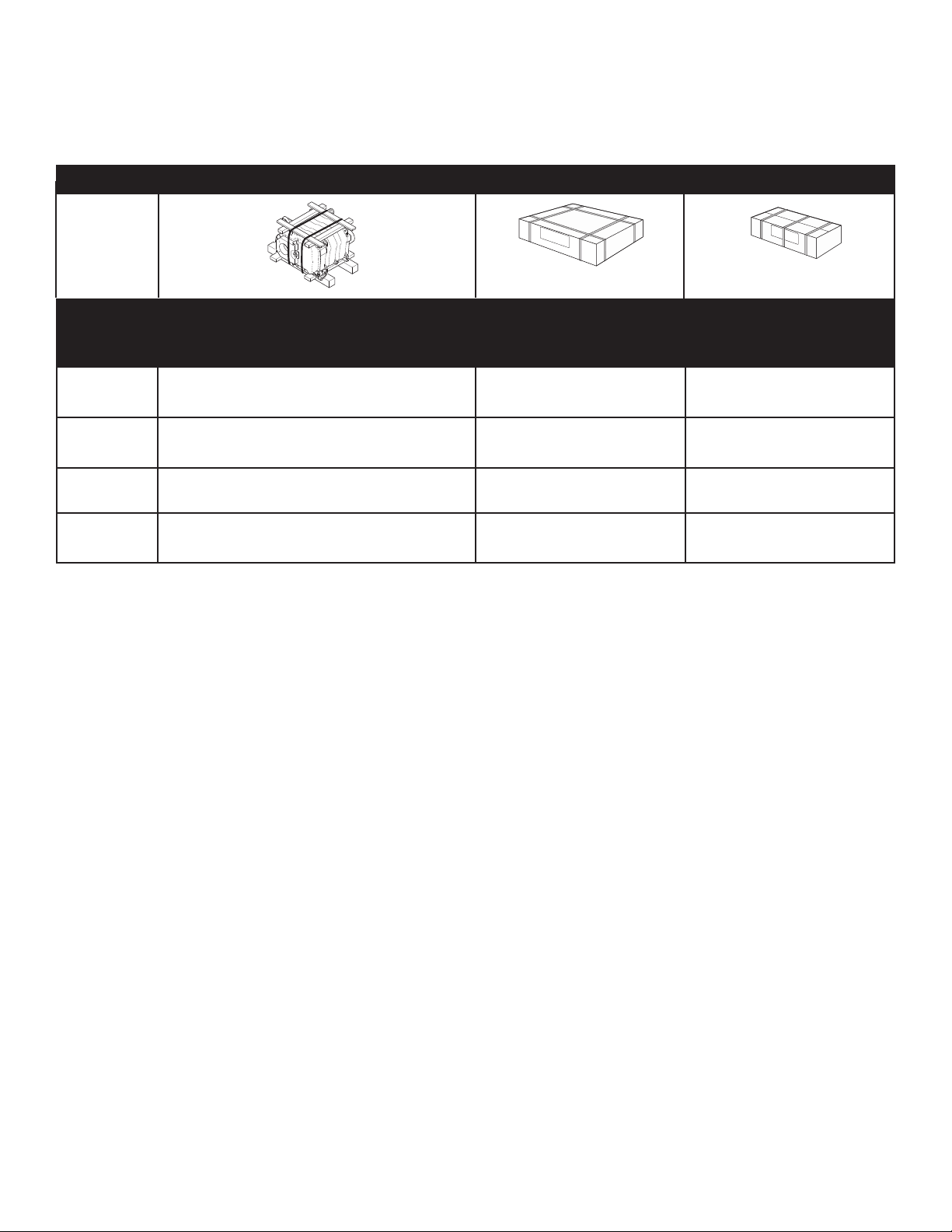

Boiler Boiler Casting Sub-Assembly Jacket and Insulation

Control Panel

Basic or S/F-10

for EC-10 Series

EC-13 470001000 470008200

Basic – 470014000

SF-10 – 470299000

EC-14 470002000 470009200

Basic – 470014000

SF-10 – 470299000

EC-15 470003000 470010200

Basic – 470014000

SF-10 – 470299000

EC-16 470004000 470011200

Basic – 470014000

SF-10 – 470299000

Contains the boiler instructions Contains the control panel instructions

Packaging:

The following table shows the package numbers included with the boiler to be installed.

The packages are presented in the order in which they should be opened for assembly.

EC-10

The assembly of any options delivered with the boiler is described in the instructions accompanying the options.

The list of available options is indicated in the price list in force.

Page 3

3

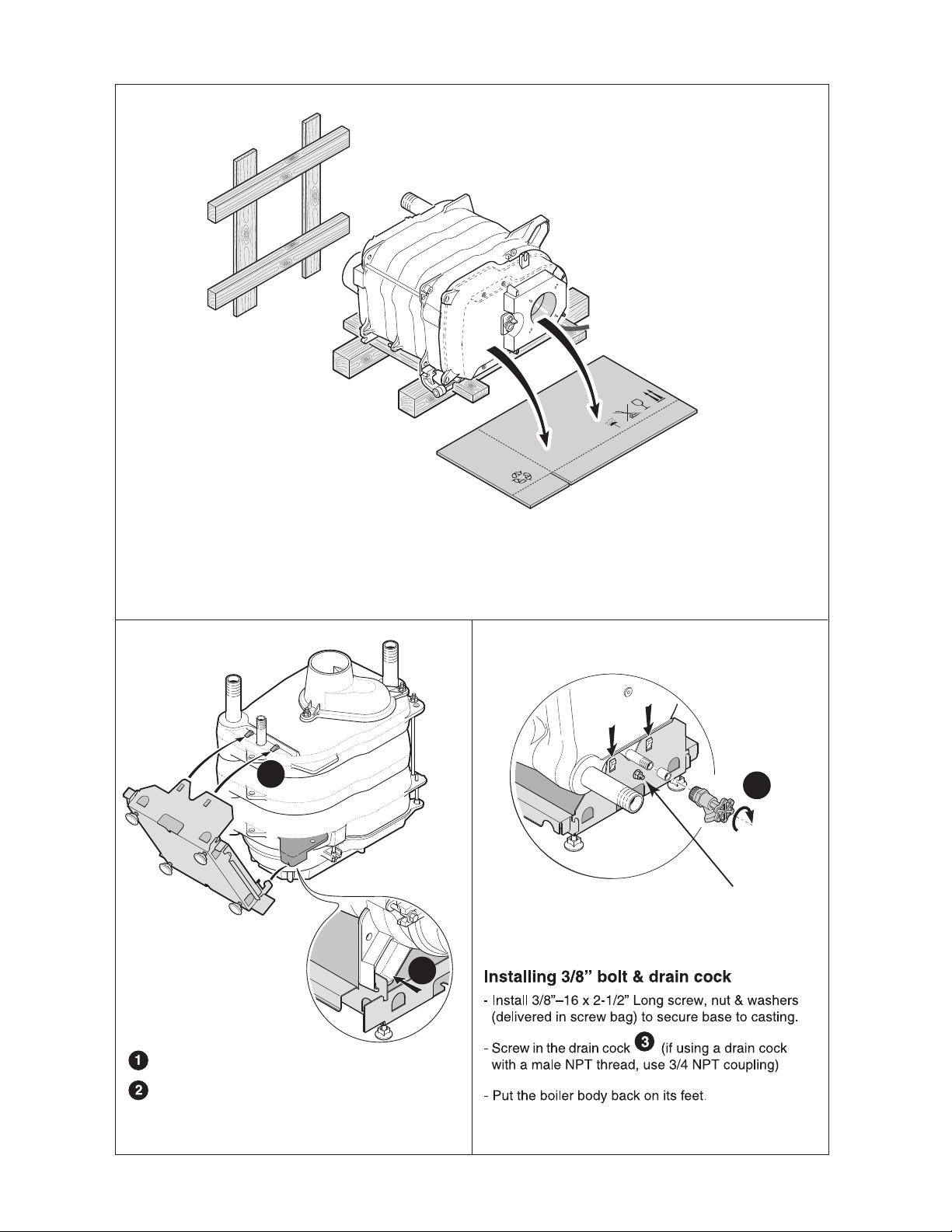

1

Put a protective piece of cardboard on the floor in front

of the boiler casting sub-assembly.

Take the body off the pallet and put it down vertically on

the burner door.

Packagees

2

1

Installing the base

Attach the base onto the front of the boiler.

Clip the base onto the rear section.

32

3

3/8” Bolt, Nut & Washers

Page 4

4

3

4

3

5

4

4.2

4.3

8575N018

8575N019

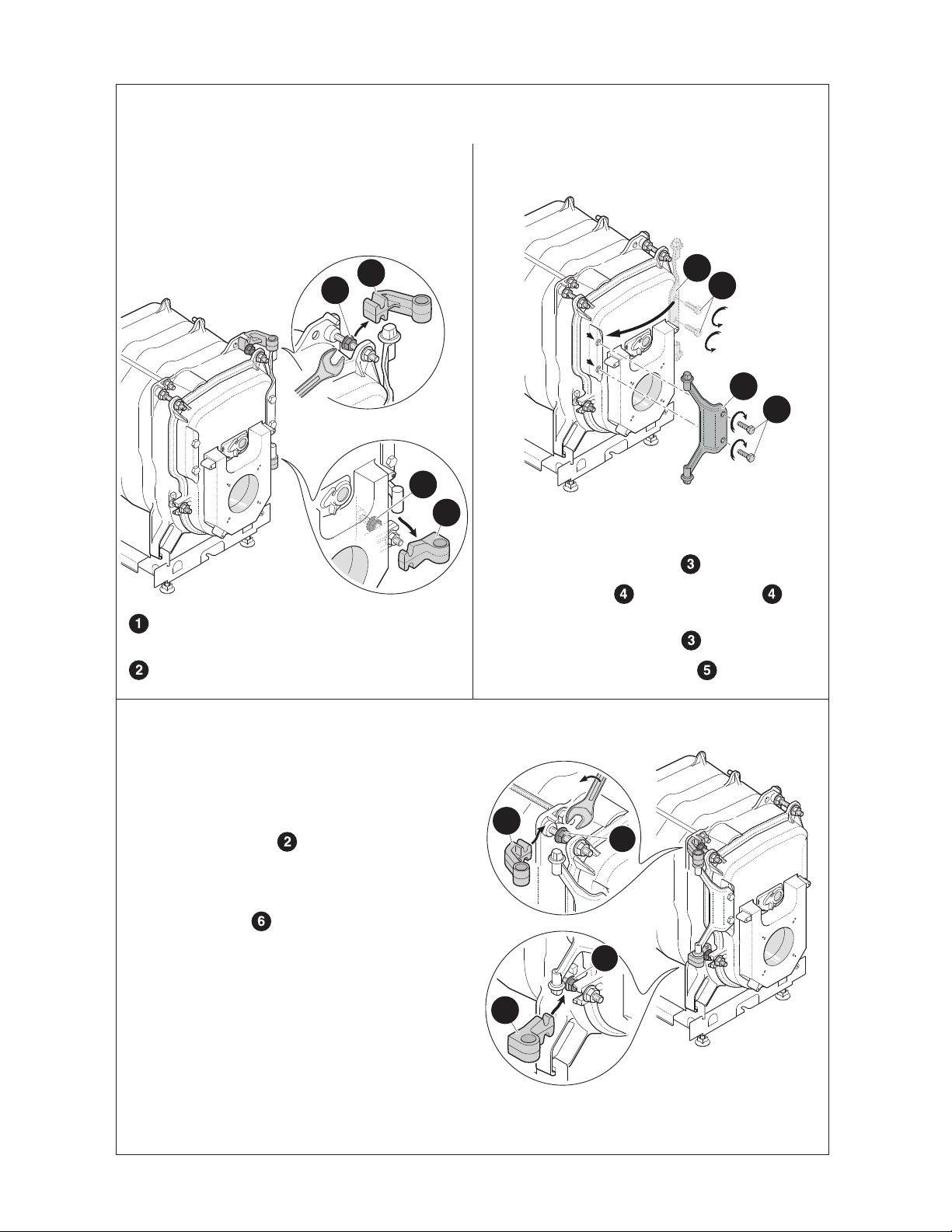

Loosen the 2 top and bottom nuts.

Remove the lower and upper hinges.

8575N020

13

1

2

1

2

- Remove the cast iron hinge pin for the burner door

fixed by the 2 screws . Put the two screws back

on the right-hand side

- Reinstall the cast iron hinge pin for the burner door

on the left side using the 2 screws .

Reverse the direction of opening of the burner door if necessary

(opening at left).

2

6

2

6

- Reinstall the hinge pins on the left side, fixing them

using the nuts located on the burner door hinge pins, on

the left side, as shown on the adjacent figure.

- Tighten the 2 nuts .

4.1

When the burner leaves the factory, the burner

door opens towards the right. Perform operations

4.1, 4.2 and 4.3 below to open the burner door

towards the left (if absolutely necessary).

Page 5

5

5

6

8575N021A

- Pass the strap between the cast iron body and the base.

- Install the insulation around the body, folding the bottom on each side of the boiler inside the base.

1

2

8575N022

Installing the insulating material

3

2

1

Fix the insulation using the strap(s) and the attach-

ment strip .

- Put the back insulation into place and fix it onto the pre-

viously installed insulation using the fasteners .

notch in front

- 1 strap on the 3 and 4 section versions,

- 2 straps on the 5 and 6 section versions

Page 6

6

85

75

N

023

B

1

4

5

6

3

6

2

1

4

7

8

8575N024

9

10

10

7

8

- Put the rear cross bar into place on the lugs of the rear

section facing the outside of the boiler positioning it on:

• the assembly rod ,

• the rear section positioning pin .

- Fix on the rear section with 1 HM8 x 30 screw + 2

flanged nuts .

Installing the control panel support cross bar

- Put the support cross bar into place on the boiler body,

positioning it on :

• the M8 studs at the front,

• the assembly rod and the 3rd section positioning pin

- Fix it at the front with 2 HM8 flanged nuts .

- Fix the 3rd section with :

• 1 HM8 x 30 screw + flanged nuts ,

• 1 flanged nut on the assembly rod.

Assembling the back cross bar (EC-15/16)

Only on 5 and 6 section boilers

EC-13

EC-14

EC-15

EC-16

Page 7

7

9

Putting the burner cable in place

Attach one end of the burner wiring harness (cable)

to control box, and route other end through hole in control

panel support cross bar. (Shown with Honeywell aquastat

control.)

Attach cable clamp (from bag of screw) to cable to

limit travel of cable through hole in control panel support

cross bar. (Cable clamp will need adjustment when installing burner.)

Cable clamp.

Honeywell Aquastat

Cable

Page 8

8

10

Put the front of the side panel into place, engaging

the lower notch of the panel in the cross bar of the base.

Make sure that the lower fold in the panel is cor-

rectly positioned under the fold of the cross bar.

Straighten the side panel and pull it upwards.

Attach the side panel to the lugs of the control panel

support, pulling its upper fold upwards such that the

upper fold of the side panel is centred and blocked between the two notches.

Fix the side panels using 2 self tapping screws +

serrated washers.

5

4

1

1

3

3

1

2

8575N025B

Installing the side panels

Page 9

9

11

Installing the rear panel

Hang up the rear panel on the side panels.

Fix it using four self tapping screws + serrated

washers delivered in the fasteners pack.

Installing the front burner door panels

Fix the two front burner door panels using four RLS

M6 x 10 black screws (delivered in the screw bag).

2

2

1

1

8575N449A

12

8575N031D

2

2

1

Installing the cover

Put the cover into place and push it forwards to

fix it in the two side panel bushings.

Fix it at the back with 2 ø 3.94 x 12.7 screws +

2 ø 4 serrated washers.

8575N032A

13

black screws

Page 10

10

Push the burner into the burner

door until it will not go any further.

Fix the burner using four washers

and hex nuts, supplied.

Note:

After the installation has been

connected and filled with water, start

the burner into service following the

instructions supplied with it.

Connect the connector into the

burner connector after having secured

the burner.

Adjust the cable length so that the burner cable has to be disconnected to

open the burner door.

Fix the cable in position using the

cable clamp and the 2 ø 3.5 x 25

screws.Slide the surplus cable backwards between the insulation and the

side panel. Secure cable clamp after

slack is removed from cable to make

sure cable will disconnect when burner

door is opened.

- Replace the burner cover.

4

Assembling the burner

14

8575N

239B

1

Fix the gasket with the flange on the burner

door using four 3/8”–16 studs, supplied.

(screw shorter length of metric thread into

burner door.)

To be plugged

into molex plug

on burner.

Cable routine must come

from left side for right hand

hinge (factory equipped).

5

If hinged door is changed

to left side, cable routing

must be moved to the right.

Cable clamp.

Page 11

11

16

Final levelling of the boiler

- Level the boiler by adjusting its adjustable feet (preinstalled on the base).

(1) basic height 1”,

adjustment range : 1” – 1-9/16”

N

5758

A5

3

0

1”

(1)

19

19

1”

(1)

15

Assembling the front cap

Lift the window.

Attach the front cap in the openings near the bot-

tom of the side panels.

Slide the two lugs of the front cap into the notches

of the side panels and then fix it in the two spring clips.

Push the front cap into contact with the side panels

and fix it using the two black RLS M 6 x 10 screws

(S/F part no. 470128000) (delivered in the casing screw bag).

4

2

1

3

3

4

Page 12

17

1

Stick the nameplate and other labels on the side of the boiler.

Rating plate.

Place “DANGER” label as shown, near front.

Place nozzle spec/burner set up procedure,

near front as shown.

Place “Installing Boiler Label” near rear as shown.

3

4

Place “ETL” label where shown.

5

2

4

5

SLANT/FIN CORPORATION., Greenvale, N.Y. 11548 • www.slantfin.com

Phone: (516) 484-2600 • Fax: (516) 484-5921

In Canada: Slant/Fin LTD/LTEE, Mississauga, Ontario • www.slantfin.can

©Slant/Fin Corp. 2014 • Printed in the U.S.A. 614 • Part # 470901000 • Publication No. EC-10-50 Rev.B

Loading...

Loading...