Page 1

INSTALLATION INSTRUCTIONS

D O M E S T I C H O T W A T E R G E N E R A T O R

DHWG designed for use with Slant/Fin Bobcat and Lynx series

and other similar boilers with DHW priority control capabilities.

Contents Page

Components Included . . . . . . . . . . . . . . . . . . . . . . . . . 2

Dimensions & Specifications . . . . . . . . . . . . . . . . . . . . 3

Wall Mounting Instructions. . . . . . . . . . . . . . . . . . . . . . 3

Water Piping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Electrical Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

System Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Warning - Hot Water Can SCald!

A tempering valve is recommended to be installed on

the hot water outlet to all fixtures where direct user contact can be made with the water supplied by the DHW

system, to prevent any possible scalding conditions. See

Figure 3 for the appropriate installation method of this

device (not supplied with the DHWG system).

Heating Contractor

Address

Phone Number

Printed in U.S.A. 111 PUBLICATION DHWG-40

Part No. 67 5025

Model Number

Serial Number

Installation Date

Page 2

DHWG Domestic Hot Water Generator

Installation Instructions

Use these instructions in conjunction with the boiler Installation and Operating

Instructions (publication BA-40 for Bobcat and LX1-40 for Lynx boilers) for utilizing this

domestic hot water generator with the boiler.

Components included:

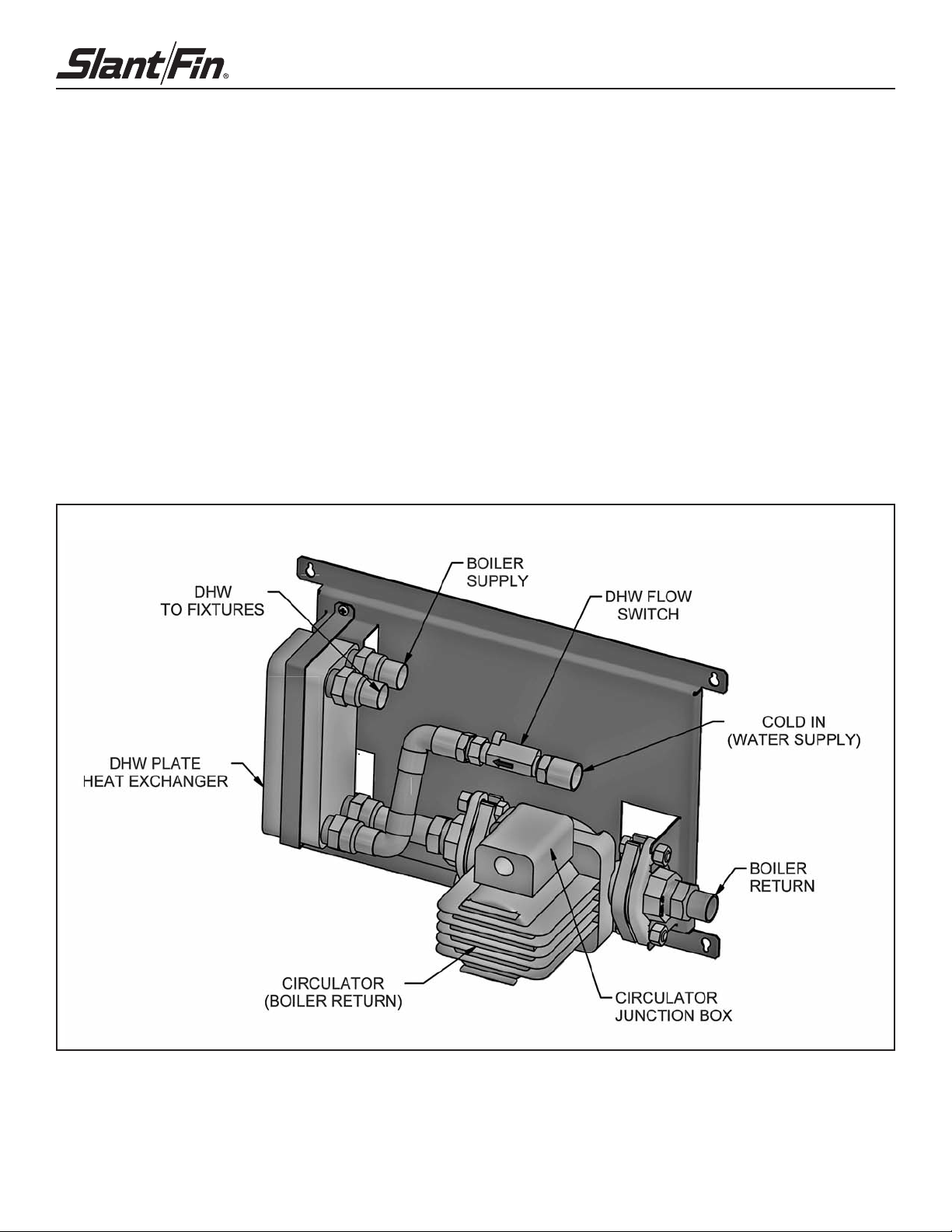

1. See Figure 1 for the identification and location of each component and piping

connection provided in the DHWG system.

2. The DHWG pump is sized for the required flow rate through the plate exchanger

to provide adequate hot water production.

3. A flow switch is provided to detect any flow of domestic water, and will energize

the DHWG pump and give a call for the burner to operate as required for the demand.

4. DHWG pump provided has integral flow check, to prevent water flow in

the DHW boiler loop when it is running for space heating demand.

Figure 1. Components and piping of DHWG.

2

Page 3

DHWG Domestic Hot Water Generator

Dimensions:

Width = 17" Height = 12" Depth = 83⁄8"

Specifications:

Weight (empty) = 21 lbs

Water content = 0.2 gallons

Piping connections = 3/4" nom. I.D. copper

Min. DHW flow = 0.3 gpm

Max. working pressure = 125 psi

Mounting to a Wall:

1. DHWG must be installed with water pipes at right or left

side of the unit (see figure 2).

Figure 2.

2. Be sure that the wall is vertically plumb, and capable

of carrying the weight of the DHWG system and all

associated piping, when full of water. See the

specifications above.

3. The system may be mounted onto a combustible wall,

but the water piping must be kept a minimum of 1” away

from any combustible materials.

4. For stud type walls, be sure that there are studs available

in the desired location, and the appropriate fasteners are

utilized for the wood or metal stud type and weight

capacity.

5. For masonry walls, utilize anchors of the appropriate

design for the material and weight capacity.

6. Do not attempt to support the system with anchors driven

into sheetrock only.

Table 1. DHWG pressure drop vs. flow

Temp.

rt –˚F

100

80

70

60

55

Table 2. DHWG temperature rise vs. water flow*

LX-85A

Boiler

1.4

1.8

2.1

2.5

2.8

DHWG Flow Rate–GPM

LX-90

Boiler

1.6

2.0

2.3

2.7

3.0

B-120A or LX-120

Boiler

2.0

2.5

3.0

3.5

4.0

LX-150

Boiler

2.3

3.3

4.0

4.5

5.0

B-200A

Boiler

2.5

3.75

4.75

5.75

6.5

3

Page 4

DHWG Domestic Hot Water Generator

DOMESTIC HOT WATER GENERATOR

DHWG

Water Piping:

1. Make all piping connections to and from the DHWG system

as shown in Figure 3.

2. Isolation valves and unions are recommended on all

piping connections to the DHWG system, to facilitate any

possible service needs. Use full port valves to insure

proper water flow through the system.

3. The piping to and from the boiler should be kept as short

as possible, with a minimum number of restrictions, such

as elbows. The diameter of the piping must not be

reduced from the DHWG system’s provided connection size.

4. The piping for the domestic water in and out should be

adequately sized for the desired flow rates at each

fixture. The distance to each fixture should be considered,

for the response rate of adequate hot water to each.

5. Refer to the boiler manual “Water Piping” section, for

proper installation of the space heating system and all

other piping.

CAUTION: A tempering valve is recommended to be installed

on the hot water outlet to all fixtures where direct user contact

can be made with the water supplied by the DHWG system to

prevent any possible scalding conditions. See Figure 3 for the

appropriate installation method of this device (not supplied with

the DHWG system).

Figure 3. Water piping from boiler to DHWG system (Bobcat B-120A shown)

4

Page 5

DHWG Domestic Hot Water Generator

Electrical Wiring:

1. Make all wiring connections to the DHWG system as

shown in Figure 4.

2. Wire the DHWG system circulator’s junction box leads

to

the boiler’s “DHW CIRC” line voltage terminals. Use 14

gage conductors in BX or conduit, secured to the

connectors provided (See figure 5).

3. Wire the DHWG system water flow switch to the

boiler’s “DHW T-STAT” low voltage terminals. (terminal

#3 and #4 of boiler low voltage terminals, See figure 5).

4. Refer to the boiler manual’s “Electrical Wiring”

section, for proper installation of all additional wiring

necessary for the space heating system and operation

of the boiler.

System Settings:

Refer to the boiler manual’s “Boiler Control and Display

Features”, in the “Operating Instructions” section, for

setting the boiler parameters properly to operate with the

DHWG system.

1. The domestic hot water post pump time (see Table 5 of

the boiler manual) should be set for the minimum value

of 1 second, when the alternating letter indication of

“P-d” is selected.

2. The domestic hot water mode must be set for # 2

(see Table 5), when the alternating letter indication of

“d-t” is selected.

3. The priority mode must be set for 0, DHW priority with

no time limit (see Table 5), when the alternating letter

indication of “b-t” is selected.

4. Set all other parameters as appropriate for the space

heating system and operation of the boiler.

Figure 4. Wiring DHWG system to the Bobcat or Lynx boilers.

5

Page 6

DHWG Domestic Hot Water Generator

TO TERMINAL #3 AND 4

ON BOILER'S LOW VOLTAGE

TERMINALS

TO DHW CIRCULATOR

TERMINALS ON BOILER

LINE VOLTAGE TERMINALS

Figure 5. Electrical wiring connections

6

Page 7

DHWG Domestic Hot Water Generator

NOTES

7

Page 8

©Slant/Fin Corp. 2011. Printed in the U.S.A. 111. Publication No. DHWG-40

SLANT/FIN CORPORATION, Greenvale, N.Y. 11548 • Phone: (516) 484-2600

FAX: (516) 484-5921 • Canada: Slant/Fin LTD/LTEE, Mississauga, Ontario

www.slantfin.com

Loading...

Loading...