Page 1

This manual must be left

®

C US

with owner and should be

hung on or adjacent to the

boiler for reference.

HIGH EFFICIENCY FIRETUBE

CONDENSING GAS BOILER

MODELS CHS-85 through CHS-399

– APPENDIX A –

CONTROLLER AND DISPLAY INSTRUCTIONS

IMPORTANT

READ ALL OF THE FOLLOWING WARNINGS AND STATEMENT

SYMBOLS AND DEFINITIONS BEFORE READING THE

INSTALLATION INSTRUCTIONS

DANGER

!

Danger Sign: Indicates a hazardous situation which,

if not avoided, will result in serious injury or death.

WARNING

!

Warning Sign: Indicates a hazardous situation which,

if not avoided, could result in serious injury or death.

CAUTION

!

Caution Sign plus Safety Alert Symbol: Indicates a hazardous situa-

tion which, if not avoided, could result in minor or moderate injury.

CAUTION

Caution Sign without Safety Alert Symbol: Indicates a hazardous

situation which, if not avoided, could result in property damage.

NOTICE

Notice Sign: Indicates a hazardous situation which, if

not avoided, could result in property damage.

WARNING

!

This Boiler must be installed by a licensed and trained Heating Technician or the Warranty is Void. Failure to properly install thisunit may re-

sult in property damage, serious injury to occupants, or possibly death.

©Slant/Fin Corp. 2013 • 813 • PUBLICATION CHS-CD-40

Page 2

Table of Contents

1.0 INTRODUCTION ........................................................................................................................... 1

1.1 Clearing a Lockout .................................................................................................................... 1

1.2 Keypad ....................................................................................................................................... 1

1.3 Home Screen ............................................................................................................................. 2

2.0 I-INFORMATION SCREEN (MAIN MENU) ................................................................................ 4

2.1 Quick Start ................................................................................................................................. 5

2.2 Login ......................................................................................................................................... 6

2.3 Test ............................................................................................................................................ 6

2.3.1 Forced Rate ................................................................................................................... 7

2.3.2 Manual Burner and Pump Operation ............................................................................ 8

2.4 Advanced Setup ......................................................................................................................... 9

2.4.1 CH Config .................................................................................................................. 10

2.4.1.1 CH Config – CH Config ............................................................................. 10

2.4.1.2 CH Config - Outdoor Reset Config ............................................................ 12

2.4.1.3 CH Config - Warm Weather Shutdown ...................................................... 13

2.4.2 DHW Config .............................................................................................................. 14

2.4.3 Lead Lag Config ......................................................................................................... 15

2.4.3.1 Lead Lag Master Config ............................................................................. 16

2.4.3.2 Use of 4-20mA Input .................................................................................. 17

2.4.3.3 Lead Lag Slave Config ............................................................................... 18

2.4.3.4 Lead Lag Outdoor Reset ............................................................................. 19

2.4.4 System Config ............................................................................................................ 20

2.4.4.1 System ID & Access ................................................................................... 20

2.4.4.2 Pump Config ............................................................................................... 22

2.4.4.3 Statistics Config .......................................................................................... 23

2.4.4.4 High & Stack Limits ................................................................................... 24

2.4.4.5 System Config ............................................................................................. 25

2.4.5 Modulation Config ..................................................................................................... 26

2.4.6 Delta T & T-rise Limits .............................................................................................. 27

2.4.7 Frost Protection Config .............................................................................................. 28

2.4.8 Burner Control Ignition and Timings & Rates ........................................................... 29

2.5 Diagnostics .............................................................................................................................. 30

2.5.1 History ........................................................................................................................ 31

2.6 Display Setup .......................................................................................................................... 32

Page 3

1

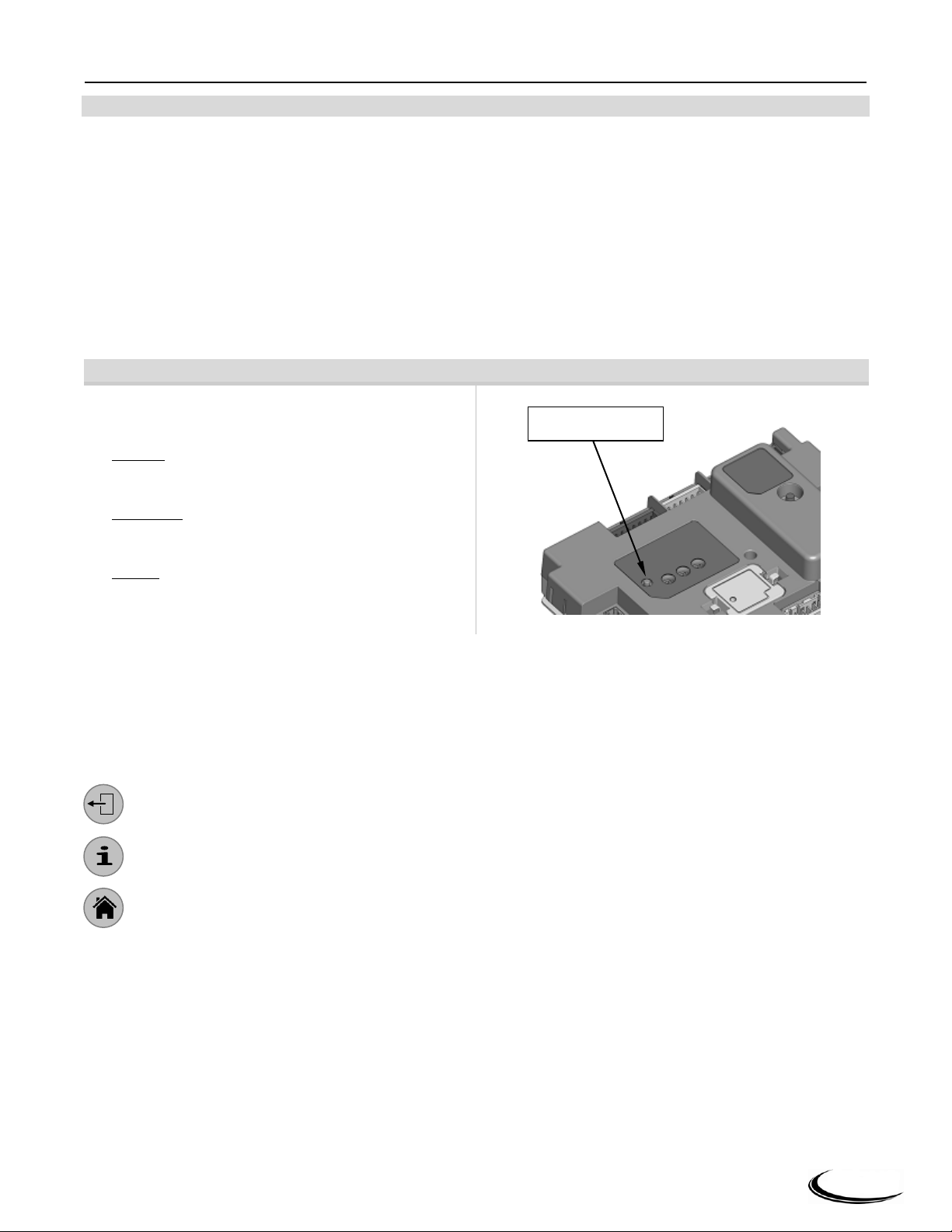

Clearing a Lockout – Any of the following methods

can be used to clear a Lockout:

1. Display - Clear the lockout from the display Home

Screen; press “OK” button on the keypad (see

Figure 1-2).

2. Controller - Clear the lockout by pressing the

RESET button situated on the boiler controller near

the indicator lights (see Figure 1-1).

3. Switch - Cycle power to the boiler using the power

on/off switch situated on the display console.

Reset Button

CHS Series Controller and Display │Slant Fin Corp.

1.0 INTRODUCTION

The Controller and Display, together, form the control system of the Slant/Fin CHS boiler. All control

configuration parameters are stored in non-volatile memory in the CHS controller. Access to controller status

and configuration is achieved with the display. Interaction with the display is performed by physically touching

the buttons on the display keypad. Communication between the CHS controller and display is via EIA-485

interface using the Modbus RTU protocol.

When the appliance is powered there is a brief interval while the display retrieves data from the boiler control.

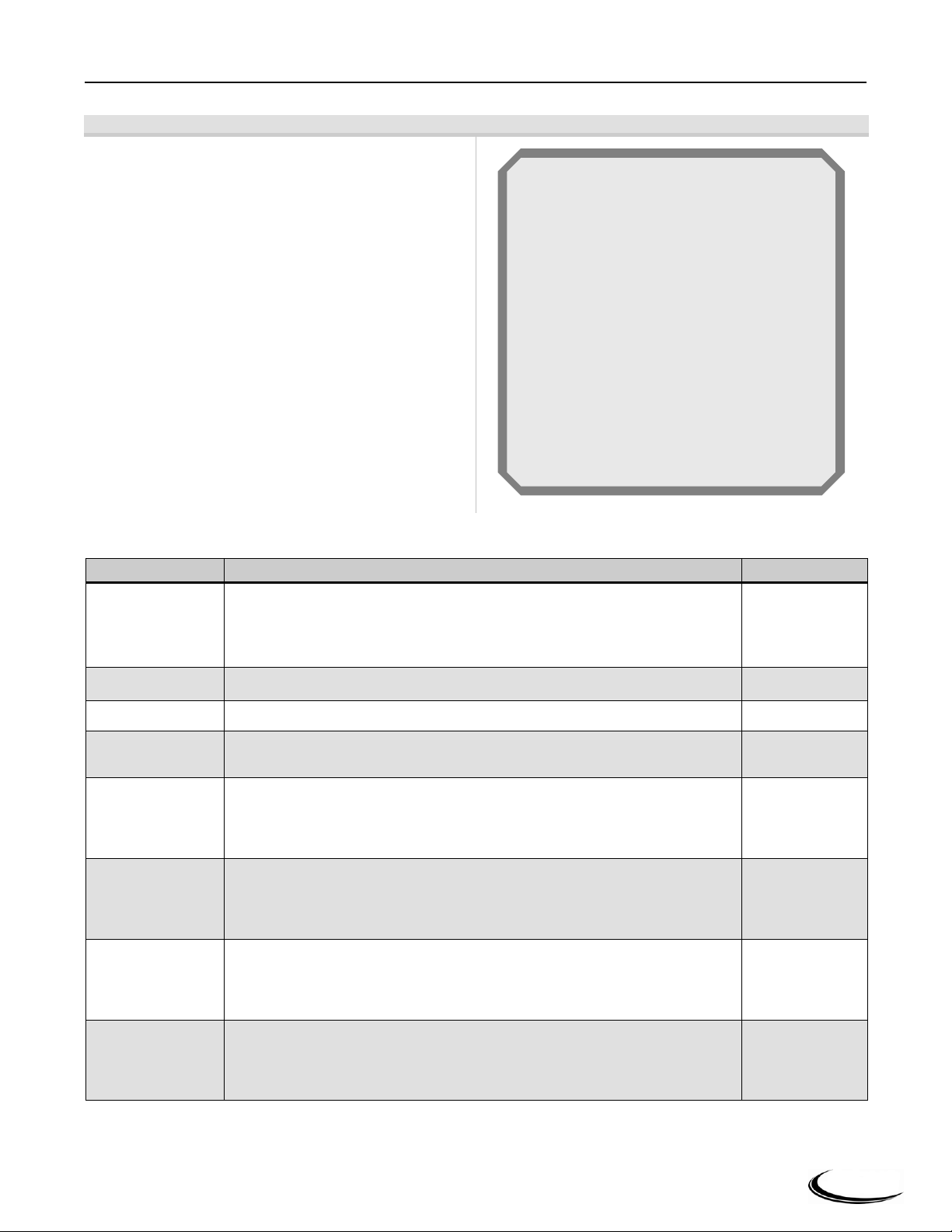

The display then shows the Home Screen (Summary screen) similar to the one depicted in Figure 1-2. The Home

Screen provides a summary of the overall operational status of the boiler. A series of menus, entered by pressing

the “i-Information” button, provide access to all boiler configuration parameters, information and diagnostics.

1.1 Clearing a Lockout

Figure 1-1 Clearing a Lockout

1.2 Keypad

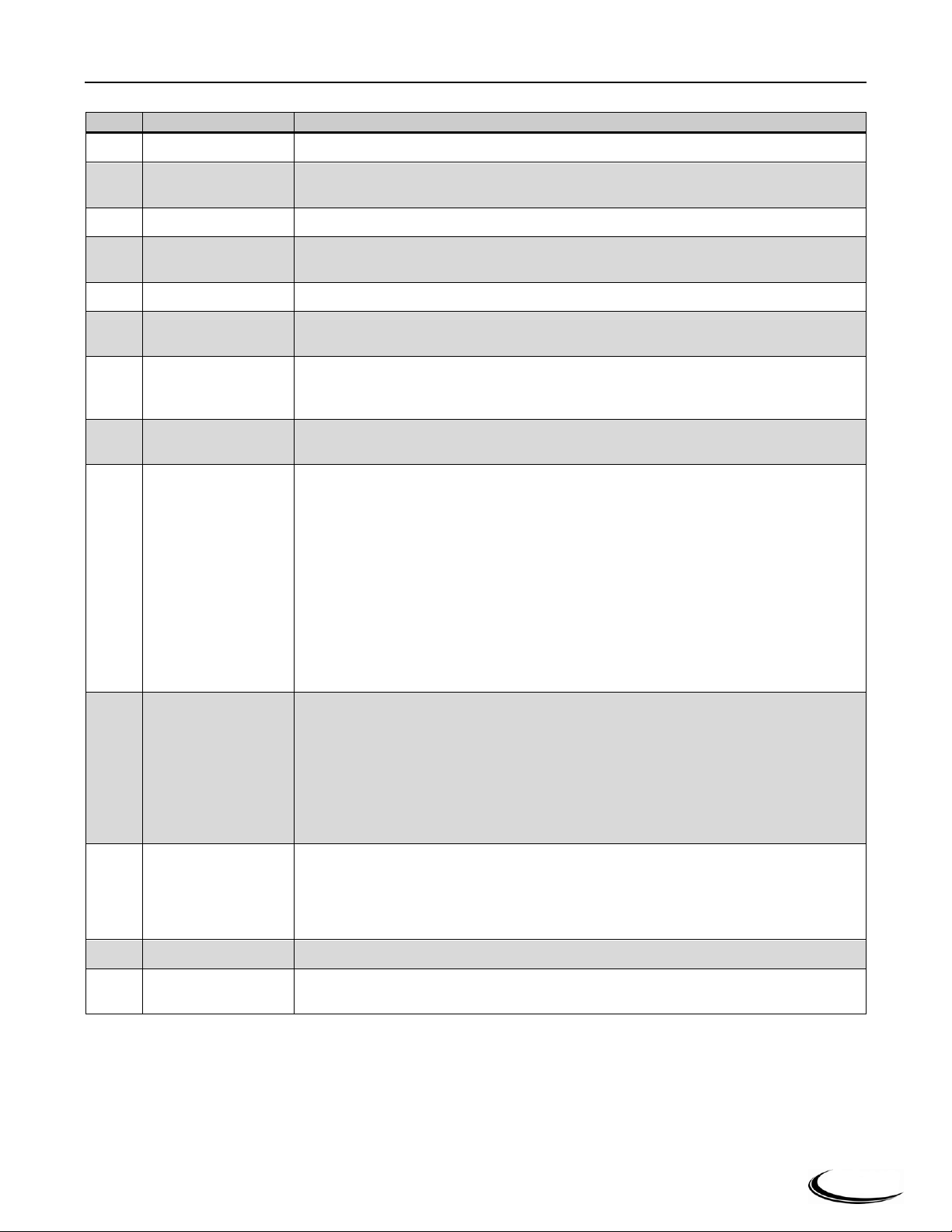

See Figure 1-2 and Table 1-1 for a complete description of the functions of each keypad button.

Directional Arrow Buttons – are used to quickly navigate through the menu structures and within each

individual screen.

OK Button – Confirms/enters an item selection.

Back Button – returns the user to the previous screen.

i-Information Button – accesses the Main Menu where all control settings, diagnostics, etc are accessed

Home Button – immediately returns the display to the Home Screen.

via a series of sub-menus.

Page 4

2

Analog Sensors I/O

Digital I/O

Outlet temp

Inlet temp

Delta T

DHW temp

Stack temp

Outdoor temp

Fan speed

Flame signal

Firing rate

4-20mA input

System sensor

70 oF

70 oF

1 oF

OPEN

71 oF

OPEN

LOW

0.00 A

0 RPM

OPEN

Outlet

Boiler pump (B)

CH pump (C)

DHW pump (A)

Blower/HSI

Eternal ignition

Pilot valve

Main valve

Alarm

Interlock (ILK)

Pre-ignit interlock (PTI)

Load control input (LCI)

STAT (Demand)

Time Of Day

Safety relay

off

off

off

off

off

off

off

off

on

off

off

off

off

off

7

1 2 3

6

4

5 9 8

10

11

12

13

Slant Fin Corp. │Controller and Display CHS Series

1.3 Home Screen

The Home Screen is displayed following initial power-up and can be displayed at anytime by simply pressing the

“Home” button. The Home Screen provides a summary of the current boiler status, most recent Alert or Lockout,

and readings from chosen boiler sensors. Figure 1-2 below, identifies each Home Screen and keypad item; Table

1-1 describes them.

Figure 1-2 Home Screen & Key Pad Identification

From the Home Screen the display offers easy access to diagnostic screens through the use of the horizontal

directional buttons (◄ ►) on the display keypad. Pressing either of the horizontal buttons advances you through

the Analog Sensor I/O (inputs/outputs), Digital I/O, and then back to the Home Screen.

Figure 1-3 Diagnostic Screens

Page 5

3

Item

Name

Description

1

Back button

Returns the display to the previous screen in the menu structure.

2

i-Information button

Displays the Main Menu screen, where all control settings, diagnostics, etc are accessed

via a series of sub-menus.

3

Home button

Returns the display to the Home Screen (screen illustrated in Figure 1-2).

4

Directional buttons

(horizontal)

Left and right buttons (◄ ►) allow navigation within some display screens. Also

provide access, via the Home Screen, to controller input and output diagnostic screens.

5

OK button

Used to select highlighted display items, necessary for confirming settings.

6

Direction buttons

(vertical)

Up and down buttons (▲ ▼) allow navigation within display screens.

7

Boiler summary

Provides the status of five (5) boiler readings (i.e. sensor inputs or boiler operating

conditions). From a list of 15 readings, the user can select which 5 will be displayed

/summarized on the Home Screen, see Section 2.6 Display Setup

8

Boiler name

Provides the name of the boiler, i.e. 110MBH; user can choose to change the name, see

Section 2.4.4.1 System ID & Access.

9

State

Indicates the current state of burner operation:

Initiate

Standby delay

Standby

Safe startup

Prepurge - Measured purge time

Prepurge - Drive to lightoff rate

Pre ignition test

Direct Burner ignition

Run

Postpurge

Lockout

10

Demand

Indicates the current heat demand source:

OFF (no heat demand)

CH (Central Heat demand – CH1)

LL [ Lead Lag heat demand – CH2 (LL)

DHW (Domestic Hot Water demand)

CH frost protection

DHW frost protection

LL frost protection

11

Access Status

Indicates the present level of access:

User (indicates that no password has been entered – adjustment of certain settings

will be blocked.

Installer (indicates that the installer password, “sola” has been entered, allowing

adjustment of all field adjustable parameters).

12

Lockout/alert/hold

Indicates the most recent Alert, or a current Hold or Lockout.

13

Clear

When selected, clears the most recent Alert from the Home Screen; also resets and clears

a current Lockout.

CHS Series Controller and Display │Slant Fin Corp.

Table 1-1 Home Screen & Key Pad Description (Reference Figure 1-2)

Page 6

4

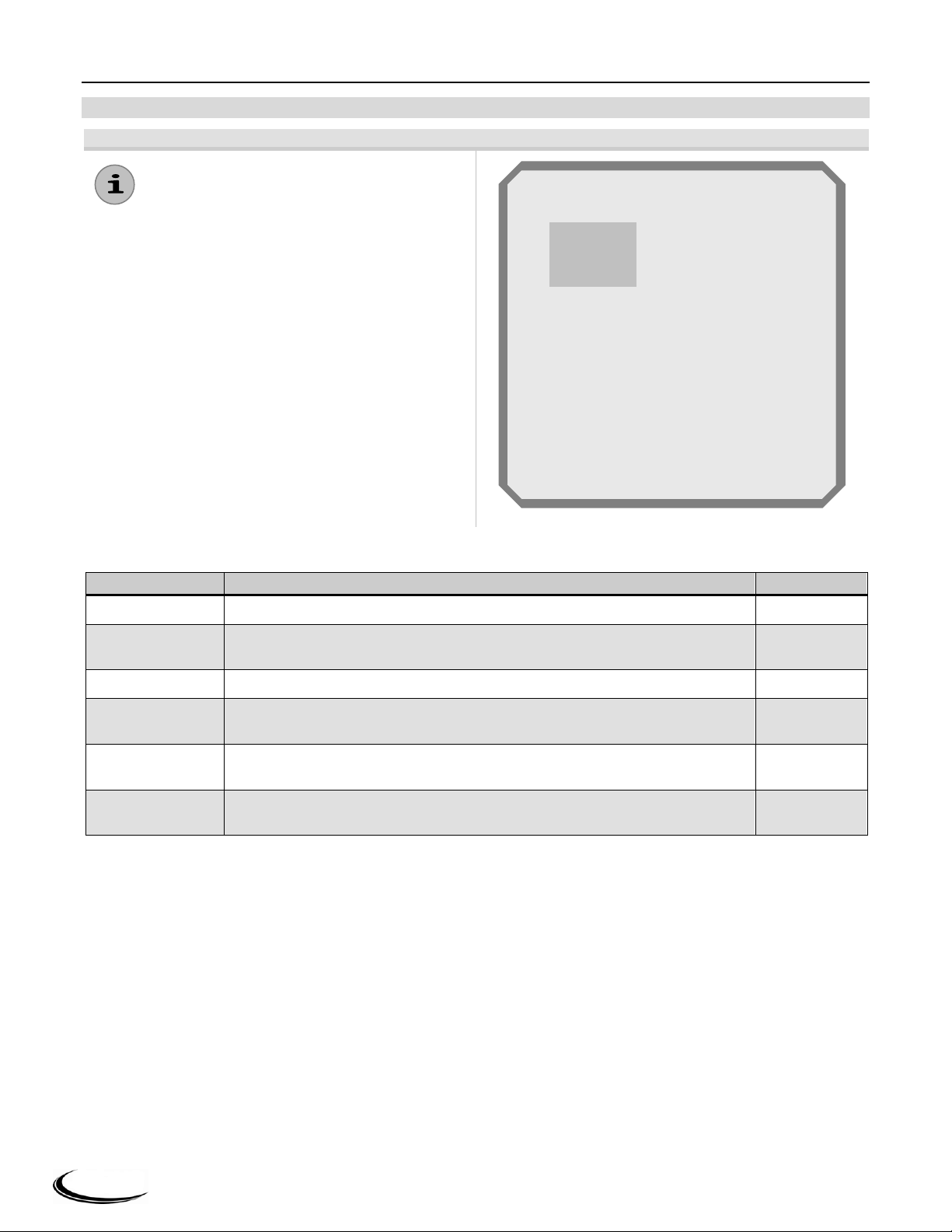

i-Information – Main Menu screen, accessed

by pressing the “i” button, lists the major submenus. Use the arrow buttons to navigate the

menu options; when the desired option is

highlighted it will appear at the top of the

screen (i.e. Quick Start in the example right);

select by pressing the “OK” button.

Menu Item

Description

Reference

Quick Start

Provides a summary of the most common settings for installer adjustment.

Section 2.1

Login

Provides access to a keypad for entry of the installer password – many

parameters are installer level password protected.

Section 2.2

Test

Allows the installer to test specific firing rates and pump operation manually.

Section 2.3

Advanced Setup

Provides access to all parameter settings (including those in Quick Start), for

more advanced settings.

Section 2.4

Diagnostics

Lists the status of all controller inputs and outputs (i.e. sensors and switches);

also provides access to a history of Alerts and Lockouts.

Section 2.5

Display Setup

Allows the installer to set what information (i.e. sensor status) is displayed on the

Home Screen.

Section 2.6

Quick

Start

Test

Diagnostics

Login

Advanced

Setup

Display

Setup

Quick Start

Slant Fin Corp. │Controller and Display CHS Series

2.0 i-Information Screen (Main Menu)

Figure 2-1 i-Information Screen

Table 2-1 i-Information Screen Menu Options

Page 7

5

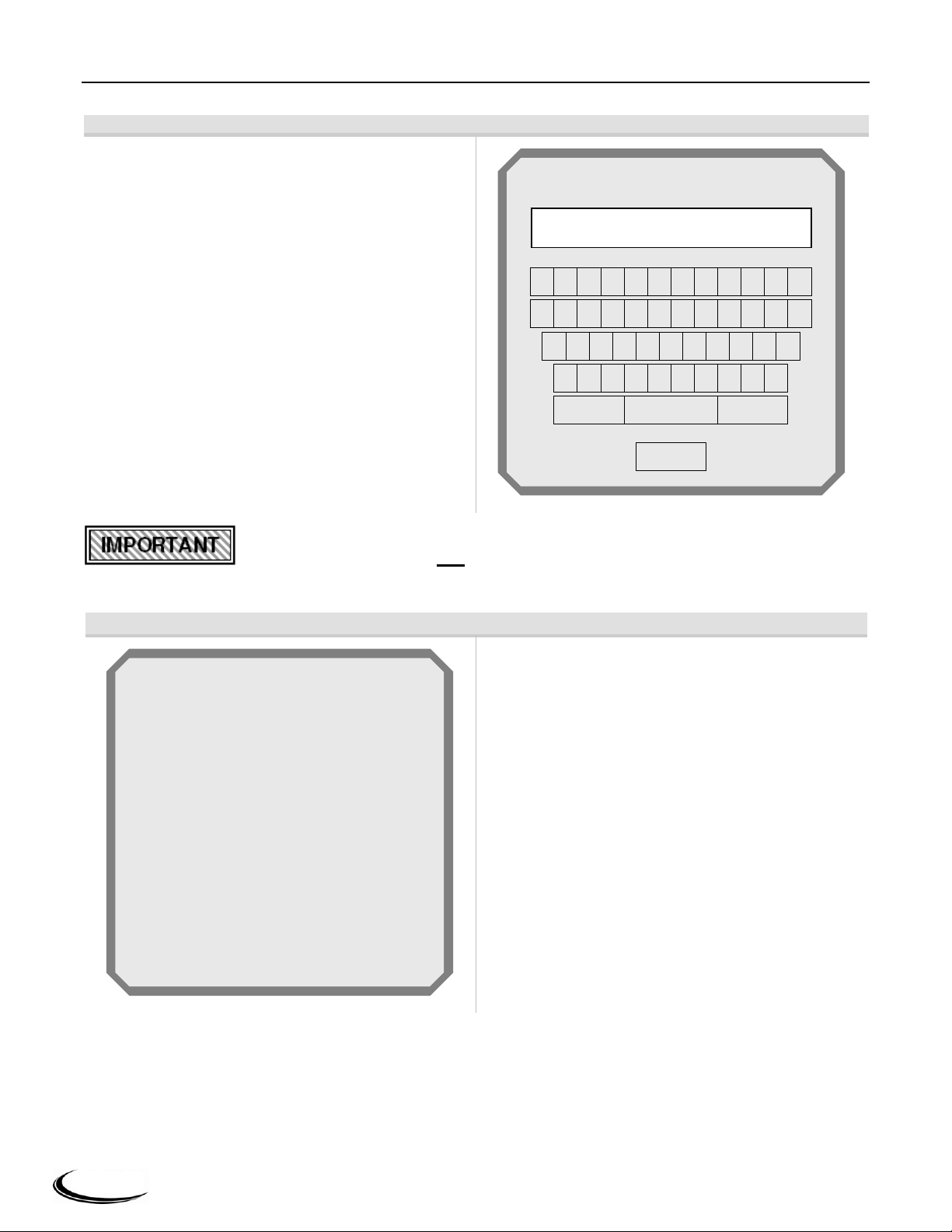

Quick Start – screen, accessed by selecting

“Quick Start” from the “i-Information” screen,

provides a summary of the most common settings

that will need to be adjusted (or considered) when

initially setting up the boiler. Use the up and down

(▲▼) buttons to navigate the menu options; when

the desired option is highlighted select by pressing

the “OK” button.

Each of the parameters under Quick Start are also

listed under separate setting groups under

“Advanced Setup”; where more advanced settings

can be accessed..

Parameter

Description

Factory Setting

CH setpoint

Setpoint value for CH modulation. If “Outdoor reset” is set to “Disable”, this is

the target temperature at the “Modulation sensor”. If “Outdoor reset” is set to

“Enable”, this is the maximum target temperature at the “Modulation sensor”

(Setpoint for CHI heat input).

180ºF

DHW setpoint

Boiler setpoint for DHW modulation. Range 60°F to 190°F

180ºF

Outdoor reset

Enables or disables CH outdoor reset function for CH1 heat inputs.

Enable

Low water temp

Minimum boiler setpoint; occurs when the outdoor temperature is equal to or

greater than the “Max outdoor temp”. Range 60°F to 140°F

95ºF

Max outdoor temp

Outdoor temperature that corresponds to the “Low water temp” setting.

Example: If the “Low water temp” setting is 95°F, and the “Max outdoor

temp” setting is 70°F, the boiler setpoint will be 95°F when the outdoor

temperature is 70°F or higher. Range 50°F to 95°F

70ºF

Min outdoor temp

Design Temperature - Outdoor temperature that corresponds to the “CH

setpoint” setting. Example: If the “CH setpoint” is 180°F, and the “Min

outdoor temp” setting is 0°F, the boiler setpoint will be 180°F when the

outdoor temperature is 0°F or lower. Range -40°F to 40°F

0ºF

Adjustable high

limit

Outlet water temperature high limit. Controller will not permit burner

operation above this setting. Recommend leaving configured as 200ºF. Range

100°F to 200°F

200ºF

Adjustable stack

limit

Stack exhaust gas high limit. Controller will lockout if exhaust gas

temperature exceeds this setting. Range 145°F to 220°F

220ºF

CH setpoint

DHW setpoint

Outdoor reset

Low water temp

Max outdoor temp

Min outdoor temp

Adjustable high limit

Adjustable stack limit

180 oF

180 oF

Enable

95

o

F

70

o

F

0

o

F

200

o

F

220

o

F

Quick Start

CHS Series Controller and Display │Slant Fin Corp.

2.1 Quick Start

Figure 2-2 Quick Start Screen

Table 2-2 Quick Start Configuration Parameters

Page 8

6

Login - Parameters that are password protected

require an installer to enter the password before they

can be changed. A message indicating this may

appear when a password protected parameter is

selected. To enter the password, touch the “iInformation” button and select Login to access the

keyboard screen.

Use the horizontal and vertical directional buttons

(▼▲◄►) on the keypad to navigate the keyboard

screen. Once the desired letter or number is

selected/highlighted, press the round “OK” button on

the keypad to confirm selection.

Once the password is filled in, select/highlight “OK”

on the keyboard, and press the round OK button on

the keypad to confirm selection.

Figure 2-4 Test Screen Menu

Test – menu screen, accessed by selecting “Test”

from the “i-Information” screen, lists the three test

screen options. Use the up and down (▲▼) buttons

to navigate the menu options; when the desired option

is highlighted select by pressing the “OK” button.

1 2 3 4 5 6 7 8 9 0 -

=

q w e r t y u i o

p

[

]

a s d f g h j k l

;

'

z x c v b n m , .

/

Shift

BS

OK

Password

sola

Forced Rate

Manual Burner Operation

Manual Pump Operation

Test

Slant Fin Corp. │Controller and Display CHS Series

2.2 Login

Figure 2-3 Login Screen

Password - Many of the configuration parameters are password protected. The required

case-sensitive password is "sola" and must be entered in lower-case letters.

2.3 Test

Page 9

7

Figure 2-5 Forced Rate Test Screen

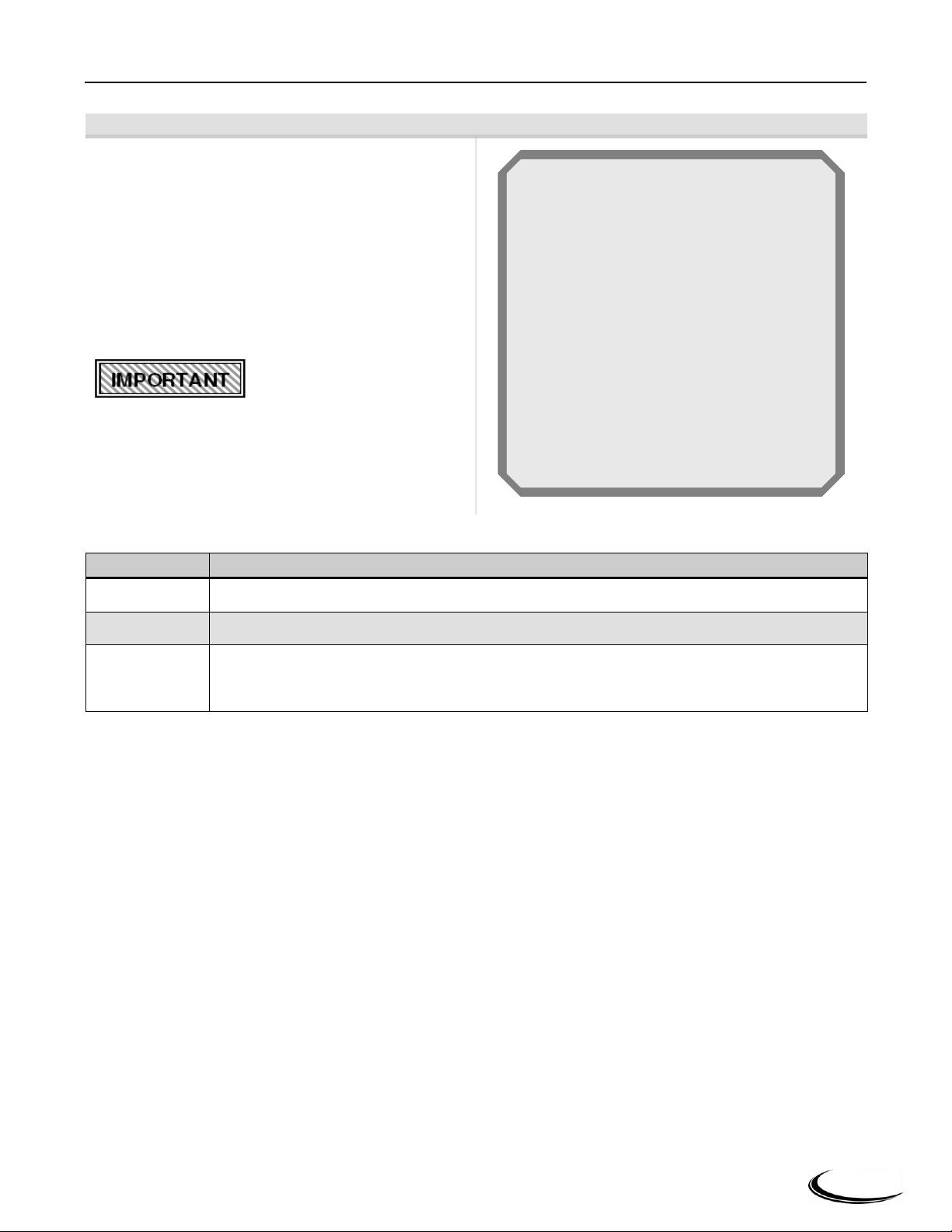

Forced Rate – test screen, permits the installer to

force the burner to operate at “high fire” or “low fire”

for the purpose of combustion setup and diagnoses.

Set the “Manual firing rate” to high or low fire by

using the up and down (▲▼) buttons to highlight

either “Set high fire” or “Set low fire”; then select it

by pressing the “OK” button.

When the test is complete, select “Stop test” to return

firing rate control to automatic.

The burner MUST be firing

to initiate “Start test”.

Parameter

Description

Set high fire *

When selected, sets “Manual firing rate” setting equal to the maximum modulation rate of the boiler.

Set low fire *

When selected, sets “Manual firing rate” setting equal to the minimum modulation rate of the boiler.

Start test *

When selected, initiates the forced rate test, burner will operate at the “Manual firing rate” setting

indicated on the screen. To stop test select “Stop test”; which will be displayed in place of “Start test”

once the test is initiated.

* = Password protected

State

Firing rate

Fan speed

Outlet temp

Manual firing rate

Test State: Idle

Test Timer: 0 sec

Set high fire

Set low fire

Start test

Standby

0 RPM

Low

71 oF

1625 RPM

Forced Rate

Burner must be in run state

CHS Series Controller and Display │Slant Fin Corp.

2.3.1 Forced Rate

Table 2-3 Forced Rate Parameters

Page 10

8

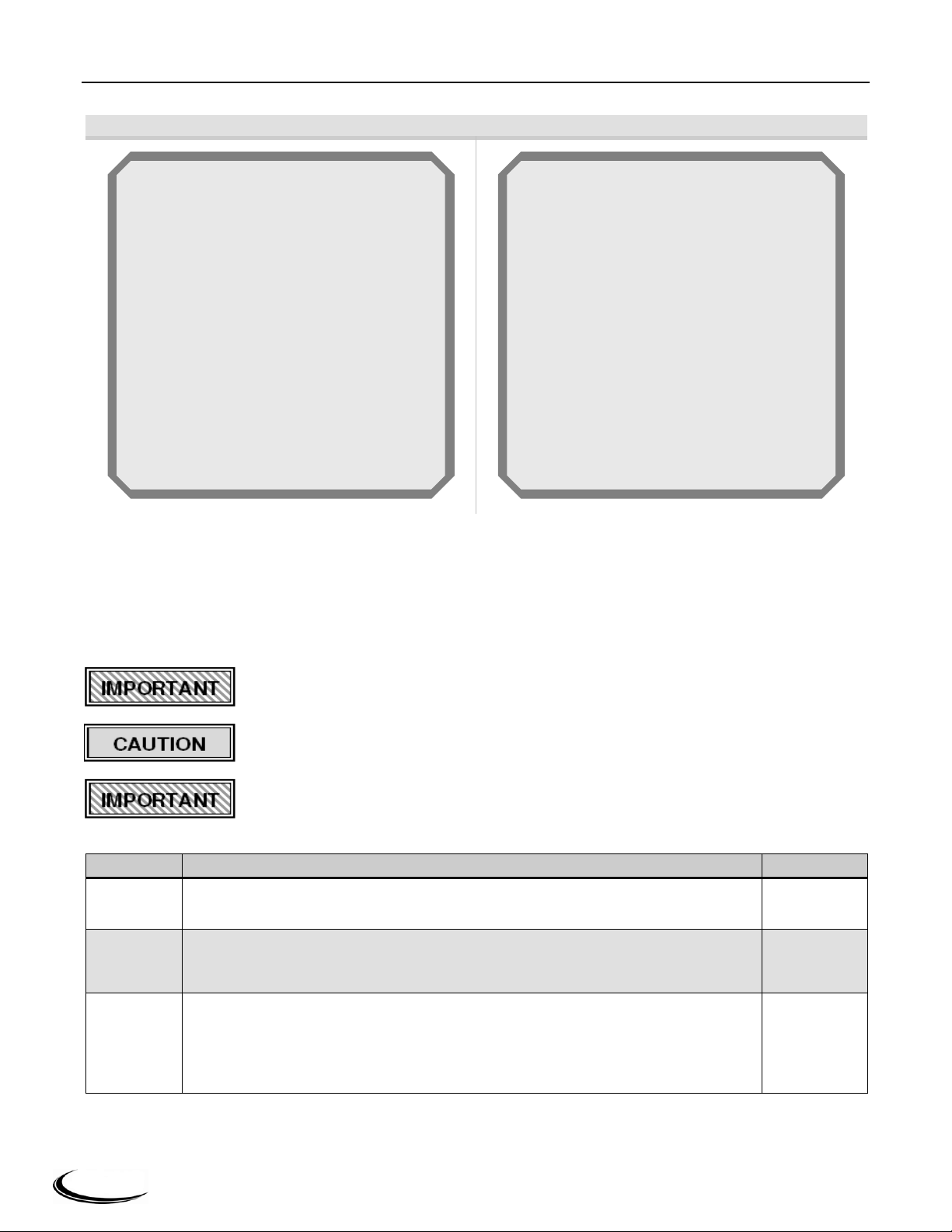

Figure 2-6 Manual Burner and Pump Operation Test Screens

Parameter

Description

Default

Burner

Switch *

Allows the installer to manually switch the burner off and on.

On

Manual

firing rate *

Establishes the burner firing rate (blower RPM) when “Firing rate control” is set to

“Manual in Run” or “Manual in Run & Standby”. Feature may be useful as a diagnostic

tool; i.e. to test burner operating characteristic at a specific firing rate.

N/A

Firing rate

control *

Establishes the firing rate control of the boiler:

Auto (firing rate – blower RPM is controlled by the boiler control)

Manual in Run (blower RPM is set to the “Manual firing rate” setting; only when

burner is running).

Manual in Run & Standby (blower RPM is set to the “Manual firing rate” setting).

Auto

* = Password protected

Burner switch

Manual firing rate

Firing rate control

Off

1625 RPM

Auto

Manual Burner Operation

CH Pump Control

DHW Pump Control

Boiler Pump Control

Auto

Auto

Auto

Manual Pump Operation

Slant Fin Corp. │Controller and Display CHS Series

2.3.2 Manual Burner and Pump Operation

Manual Burner Operation – test screen, allows the installer to manually control the firing rate of the burner.

Using the up and down (▲▼) buttons to highlight the menu options, and the “OK” button to select them, set

“Firing rate control” to “Manual”, then adjust “Manual firing rate” to the desired value.

Manual Pump Operation – test screen, allows the installer to manually turn the individual pumps on. Using the

up and down (▲▼) buttons to highlight the menu options, and the “OK” button to select them, set the desired

“Pump Control” to “On”.

Table 2-4 Manual Burner Operation Parameters

The burner MUST be firing to initiate Manual Burner Operation.

Setting “Burner switch” to “Off” will inhibit burner operation, regardless of the operating

conditions.

When the test is complete, return the settings to “Auto” to allow the control to

automatically turn the circulators off and on and modulate the burner firing rate as needed.

Page 11

9

Figure 2-7 Advanced Setup (Menu) Screen

Advanced Setup – menu screen, accessed by

selecting “Advanced Setup” from the “i-Information”

screen, lists all of the configuration parameter groups.

Use the up and down (▲▼) buttons to navigate the

menu options; when the desired option is highlighted

select by pressing the “OK” button.

Login – adjustment of many of the advanced settings

will prompt the user to login.

Name

Description

Reference:

CH Config

Edit Central Heat settings; CH1 heat input.

Section 2.4.1

DHW Config

Edit Domestic Hot Water settings.

Section 2.4.2

Lead Lag Config

Edit Lead-Lag Master and Slave settings; CH2 (LL) heat input.

Section 2.4.3

System Config

Edit temperature units, anti-short-cycle time, alarm silence time.

Section 2.4.4

Modulation Config

Edit burner modulation settings.

Section 2.4.5

Delta T Limits

Edit delay time for delta-t limit.

Section 2.4.6

T-rise Limits

Edit delay time for T-rise limit.

Section 2.4.6

Frost Protection Config

Enable/disable CH, DHW and LL frost protection

Section 2.4.7

Burner Timings & Rates

Read only, for information only.

Section 2.4.8

Burner Control Ignition

Read only, for information only.

Section 2.4.9

CH Config

DHW Config

Lead Lag Config

System Config

Modulation Config

Delta T Limits

T-rise Limits

Frost Protection Config

Burner Control Timings & Rates

Burner Control Ignition

Advanced Setup

CHS Series Controller and Display │Slant Fin Corp.

2.4 Advanced Setup

Table 2-5 Advanced Setup Menu Options

Page 12

10

Figure 2-8 Central Heat Configuration Main Menu Screen

CH Config – main menu screen, accessed by

selecting “CH Config” from the “Advanced Setup”

screen, lists the sub-menus specific to the Central Heat

Configuration. Use the up and down (▲▼) buttons to

navigate the menu options; when the desired option is

highlighted select by pressing the “OK” button.

The settings under “CH Config” are specific to boiler

operation given a local central heat demand, i.e. CH1

heat input.

Figure 2-9 Central Heat Configuration Sub-menu Screen

CH Config – sub-menu screen, allows the installer to

set parameters specific to the boiler response and

operation for local (i.e. non Lead Lag) Central Heat

demands. Use the up and down (▲▼) buttons to

navigate the menu options; when the desired option is

highlighted select by pressing the “OK” button.

Demand switch - Central heat demand can be

initiated by a contact closure to CH1, “LCI”, or by

boiler temperature, “Sensor only”.

Setpoint source – The boiler setpoint can be “Local”,

i.e. the “CH setpoint” set from the display, or “420mA” set from an external source.

Modulation sensor – With the “Setpoint source” set

to “Local”, the control can be set to use either the

“Outlet”, “Inlet” or “S10” (pipe) sensor for regulation

of burner modulation.

Mod rate source – The burner modulation can either

be controlled by the boiler control, “Local”, or by an

external source, “4-20mA”.

Demand switch

Setpoint source

CH setpoint

Off hystersis

On hysteresis

Modulation sensor

Mod rate source

CH Config

LCI

Local

180 oF

10 oF

20 oF

Outlet

Local

CH Config

Outdoor Reset Config

Warm weather shutdown

CH Config

Slant Fin Corp. │Controller and Display CHS Series

2.4.1 CH Config

2.4.1.1 CH Config – CH Config

Page 13

11

Parameter

Description

Factory Settings

Demand

switch *

Source of CH demand:

Sensor only (modulation sensor – no contact closure required)

LCI (contact closure of “CH1” to “R”, i.e. via a thermostat)

LCI

Setpoint

source *

Select the Central Heat setpoint source:

Local (control references “CH setpoint” setting)

4-20mA with sensor on/off [remote source]

Local

CH setpoint

Setpoint value for CH modulation. If “Outdoor reset” is set to “Disable”, this is the

target temperature at the “Modulation sensor”. If “Outdoor reset” is set to “Enable”,

this is the maximum target temperature at the “Modulation sensor” (see Section

2.4.1.2 Outdoor Reset Config). Range 60°F to 190°F

180°F

Off hysteresis

Value added to CH setpoint to determine water temperature at which the burner will

shut off e.g. if CH setpoint is 180°F, and CH off hysteresis is 10°F, the burner will be

shut off at 190°F. Range 2°F to 20°F

10°F

On hysteresis

Value subtracted from “CH setpoint” to determine water temperature at which the

burner will fire e.g. if “CH setpoint” is 180°F, and “CH on hysteresis” is 20°F, the

burner will fire at 160°F. Range 2 °F to 40°F

20°F

Modulation

sensor *

Select which sensor Central Heat will modulate to:

Outlet

Inlet

S10 [System (pipe) temperature sensor]

Outlet sensor

Mod rate

source *

Select which source controls the modulation rate:

Local [PID control]

4-20mA with sensor on/off [remote source]

Local

* = Password protected

CHS Series Controller and Display │Slant Fin Corp.

Use of 4-20mA Input

Setpoint source – If “Local” is selected as the “Setpoint source”, the “CH setpoint” value entered on the screen,

depicted in Figure 2-10, is used for control. If 4-20mA is selected as the “Setpoint source”, the boiler determines

its setpoint from the 4-20mA signal. The setpoint is calculated from a factory-set scale between 60°F

corresponding to 4mA, and 190°F corresponding to 20mA. If the 4-20mA input signal is invalid, out of range, or

absent, the “CH setpoint” is used until the signal is valid again. Regardless of the “Setpoint source”, “Local” or

“4-20mA”, the controller’s internal PID algorithm modulates the burner.

Mod rate source – The Slant/Fin CHS controller supports two methods of burner modulation for CH, selected

by the “Mod rate source” parameter, depicted on Figure 2-10; the factory set method is by internal PID

algorithm. The installer has the option to use a 4-20mA signal from an external control to directly modulate the

burner. Rates vary (see Section 2.4.5 Modulation Config) from minimum at 4mA to CH maximum at 20mA.

The 4-20mA signal does not create burner demand; a call for heat must be present; i.e. CHI input made when

“Demand Switch” = LCI..

Table 2-6 Central Heat Configuration Parameters

Page 14

12

Figure 2-10 Outdoor Reset Configuration Screen

(CH Config) Outdoor Reset Config – sub-menu

screen, allows the installer to set parameters specific

to the effect the outdoor temperature has on the

operation of the boiler during local (i.e. non Lead

Lag) Central Heat demands. Use the up and down

(▲▼) buttons to navigate the menu options; when

the desired option is highlighted select by pressing the

“OK” button.

Outdoor Reset is in effect only if the following two

conditions are met: “Outdoor reset” is set to "Enable",

and an outdoor temperature sensor is connected to the

boiler. The “Outdoor Reset Config” parameters,

together with the “CH Config” parameters, define the

relationship of boiler temperature setpoint to outdoor

temperature. Refer to Figure 2-12 for an example of

the relationship between outdoor temperature and

boiler temperature, with a given set of settings.

Parameter

Description

Factory Settings

Outdoor reset

enable

Enables or disables Outdoor reset

Enabled

Max outdoor

temp

Outdoor temperature that corresponds to the “Low water temp” setting. Example:

If the “Low water temp” setting is 95°F, and the “Max outdoor temp” setting is

70°F, the boiler setpoint will be 95°F when the outdoor temperature is 70°F or

higher. Range 50°F to 95°F

70ºF

Min outdoor

temp

Design Temperature - Outdoor temperature that corresponds to the “CH

setpoint” setting. Example: If the “CH setpoint” is 180°F, and the “Min outdoor

temp” setting is 0°F, the boiler setpoint will be 180°F when the outdoor

temperature is 0°F or lower. Range -40°F to 40°F

0ºF

Low water temp

Minimum boiler setpoint; occurs when the outdoor temperature is equal to or

greater than the “Max outdoor temp”. Range 60°F to 140°F

95ºF

Outdoor boost

max off point

Read only – functional in future revisions.

130ºF

Figure 2-11 Outdoor Reset Graph

Outdoor reset

Max outdoor temp

Min outdoor temp

Low water temp

Outdoor boost max off point

Enable

70 oF

0 oF

95 oF

130 oF

Outdoor Reset Config

Point defined by:

Min outdoor temp= 0ºF

Point defined by:

Max outdoor temp= 70ºF

Slant Fin Corp. │Controller and Display CHS Series

2.4.1.2 CH Config - Outdoor Reset Config

Table 2-7 Outdoor Reset Configuration Parameters

Page 15

13

Figure 2-12 WWSD Configuration Screen

(CH Config) Warm Weather Shutdown

(WWSD) – sub-menu screen, allows the installer to

enable the WWSD function for local (i.e. non Lead

Lag) Central Heat demands, and define at what

outdoor temperature it is initiated. Use the up and

down (▲▼) buttons to navigate the menu options;

when the desired option is highlighted select by

pressing the “OK” button.

When “Warm weather shutdown” is set to one of the

“Shutdown” options, and the outdoor temperature is

above the “Warm weather shdn setpoint”, CH

operation is inhibited.

CH operation is restored when the outdoor

temperature drops below the WWSD setpoint by a

fixed value of 4ºF.

Parameter

Description

Factory Settings

Warm weather

shutdown

Enable or Disable Warm Weather Shutdown and select shutdown options

Shutdown after demand ends

Shutdown immediately

Disable

Disable

Warm weather

shdn setpoint

Temperature at which local Central Heat operation is inhibited. Not applicable

when “Warm weather shutdown” is set to “Disable”. Range 50°F to120°F

60°F

Warm weather shutdown

Warm weather shdn setpoint

Disable

60 oF

Warm Weather Shutdown

CHS Series Controller and Display │Slant Fin Corp.

2.4.1.3 CH Config - Warm Weather Shutdown

Table 2-8 Warm Weather Shutdown Configuration Parameters

Page 16

14

Figure 2-13 Domestic Hot Water Configuration Screen

DHW Config – menu screen, accessed by selecting

“DHW Config” from the “Advanced Setup” screen, lists

the configuration parameters specific to boiler operation

for a DHW demand. Use the up and down (▲▼)

buttons to navigate the menu options; when the desired

option is highlighted select by pressing the “OK” button.

Demand switch - DHW demand can be initiated by a

contact closure, “DHW switch”, or by a tank

temperature sensor, “DHW Sensor with On/Off Temp”.

Mod sensor – The control can be set to use the “Outlet”

or “Inlet” sensor for regulation of burner modulation.

When “Demand switch” is set to

“DHW Sensor with On/Off

Temp”, demand is determined by

the Demand ON and OFF temp settings.

Parameter

Description

Factory Settings

Demand

switch *†

Select which sensor is the DHW demand source:

DHW switch

DHW Sensor with On/Off Temp

(If “DHW Sensor with On/Off Temp is selected, a tank sensor must be used to

generate a demand.)

DHW switch

Mod

sensor *

Select the DHW modulation sensor:

Outlet

Inlet

Outlet

DHW

setpoint

Setpoint for DHW modulation. If “Mod sensor” is set to “DHW” or “Inlet”, reduce

setting accordingly. Range 60°F to 190°F

180°F

Off

hysteresis *

Value added to “DHW setpoint” to determine water temperature at which the burner

will shut off e.g. if “DHW setpoint” is 180°F, and “Off hysteresis” is 10°F, the

burner will be shut off at 190°F. Range 5°F to 70°F

10°F

On

hysteresis *

Value subtracted from “DHW setpoint” to determine water temperature at which the

burner will fire e.g. if “DHW setpoint” is 180°F, and “On hysteresis” is 10°F, burner

ignition occurs at 170°F. Range 2°F to 40°F

10°F

Priority

time *

Time period during which a DHW demand has priority. If override time has elapsed,

the boiler and CH pump (Pump C) will service a CH demand regardless of DHW

demand. Value=0 inhibits DHW priority. Range 0 to 18 hours.

2 hour

Demand

ON temp *

DHW demand is switched ON when DHW tank temperature is < this setting.

Applied when “Demand switch” is set to “DHW Sensor with on/off temperatures”.

Range 60°F to 165°F.

135 oF

Demand

OFF temp *

DHW demand is switched OFF when DHW tank temperature is ≥ this setting.

Applied when “Demand switch” is set to “DHW Sensor with on/off temperatures”.

Range 65°F to 170°F.

140 oF

* = Password protected

† = If “Demand switch” is set to “DHW Sensor with On/Off Temp”, demand is determined by the Demand ON and OFF temp settings.

DHW tank sensor MUST be used in conjunction with a DHW temperature safety shutoff

switch. Failure to provide such a switch may result in property damage, serious injury to

occupants, or possibly death.

Demand switch

Mod sensor

DHW setpoint

Off hystersis

On hysteresis

Demand ON temp

Demand OFF temp

DHW switch

Outlet

180 oF

10 oF

10 oF

135 oF

140 oF

DHW Config

Slant Fin Corp. │Controller and Display CHS Series

2.4.2 DHW Config

Table 2-9 DHW-Domestic Hot Water Configuration Parameters

Page 17

15

CHS Series Controller and Display │Slant Fin Corp.

2.4.3 Lead Lag Config

The CHS boiler can be used as a stand-alone unit or as part of a cascaded arrangement with as many as 8 CHS

boilers. The Lead Lag Configuration parameters determine the boiler’s (or group of boilers) behavior during a

Lead Lag heat demand [i.e. CH2 (LL) heat input]. Only a demand on CH2 (LL) will initiate Lead-Lag, or

“staging”, of cascaded boilers. For stand-alone boilers, the CH2 (LL) demand simply behaves as a second heat

input (CH1 being the first). Note: a demand for central heat from CH1, takes priority over a demand for central

heat from CH2 (LL).

To enable, or allow the use of Lead-Lag function and the CH2 (LL) input, the “Lead Lag Master Config”

parameter “Master enable”, must be set to “Enable”; see Section 2.4.3.1 Lead Lag Master Config. In Lead Lag

cascade boiler arrangements, only one boiler has “Master enable” set to “Enable”, the others are set to “Disable”

(factory default).

Check List for Lead Lag Installation:

1. All Boilers in Cascade

a. Wire boilers together – Daisy-chain Data Communication wiring between boilers. See Installation and

Operating Instructions (Not applicable for stand-alone boiler applications).

b. Lead Lag Slave Configuration Settings (Optional) – Adjust the “Lead Lag Slave Config” setting “Slave

mode”, as desired. See Section 2.4.3.2.

c. MB2 Modbus address – set a unique “MB2 Modbus address” for each boiler. See Section 2.4.4.1 System

ID & Access.

2. Master Boiler in Cascade

a. Set “Master enable” to “Enable” – Select one boiler in the cascade to be Master; set its “Master enable”

setting to “Enable”. Other boilers are left as “Disable” (factory default). For stand-alone boilers the lone

boiler must have “Master enable” configured as “Enable”. See Section 2.4.3.1 Lead Lag Master Config.

b. Lead Lag Master Configuration Settings – Adjusted the “Lead Lag Master Config” and “Outdoor Reset”

settings to the desired values on the boiler with “Master enable” configured as “Enable”. No need to

adjust these settings on other boilers.

c. Heat Demand Input [CH2 (LL)] – Wire the head demand input to CH2 (LL) of the boiler with “Master

enable” configured as “Enable”.

d. System Sensor (Optional) – Wire the system (pipe) sensor to the boiler with “Master enable” configured

as “Enable”.

3. Any Boiler in Cascade

a. Outdoor Sensor (Optional) – Wire the outdoor sensor to any boiler within the cascade. Note: only one

outdoor sensor is required for a multiple boiler application.

b. System Pump Control (Optional) – With “CH pump use for LL master” set to “On”. The respective boiler

will operate the CH pump (Pump C) anytime there is a Lead Lag heat demand. See Section 2.4.4.2 Pump

Config.

Page 18

16

Figure 2-14 Lead Lag Configuration Main Menu Screen

Lead Lag Config – main menu screen, accessed by

selecting “Lead Lag Config” from the “Advanced

Setup” screen, lists the sub-menus specific to the Lead

Lag Configuration. Use the up and down (▲▼)

buttons to navigate the menu options; when the

desired option is highlighted select by pressing the

“OK” button.

Figure 2-15 LL Master Configuration Screen

Lead Lag Master Config – sub-menu screen,

allows the installer to set parameters specific to the

boiler response and operation for Lead Lag CH2 (LL)

demands. Use the up and down (▲▼) buttons to

navigate the menu options; when the desired option is

highlighted select by pressing the “OK” button.

Master enable – must be set to “enable” in order for

the boiler to respond to a CH2 (LL) demand (only one

boiler in the cascade can have “Master enable” set to

“Enable”.

Setpoint source – The boiler LL setpoint can be

“Local”, i.e. the “Setpoint” set from the display, or “420mA” set from an external source.

System Sensor – When using the optional system

(pipe) sensor; the controller automatically uses it as

the modulation sensor – reduce the “Setpoint”

accordingly.

Master enable

Setpoint source

Setpoint

Off hysteresis

On hysteresis

P gain

I gain

Base load common rate

Disable

Local

150 oF

15 oF

15 oF

30

15

70%

Lead Lag Master Config

Lead Lag Master Config

Lead Lag Slave Config

Lead Lag Outdoor Reset

Lead Lag Config

Slant Fin Corp. │Controller and Display CHS Series

2.4.3.1 Lead Lag Master Config

Page 19

17

Parameter

Description

Factory Settings

Master

enable *

Enable or Disable Lead Lag Master. One (and only one) unit must be set to

“Enable” for Lead Lag operation to function.

Disable

Setpoint

source *

Select the Lead Lag setpoint source:

Local (control references “Setpoint” setting)

4-20mA (control references 4-20mA signal from an external control). “Outdoor

reset enable” must be set to “Disable” when using a 4-20mA signal; see Section

2.4.3.3 Lead Lag Outdoor Reset.

Local

Setpoint

Setpoint value for Lead Lag modulation. Range 60°F to 190°F.

150°F

Off

Hysteresis *

Value added to the “Setpoint” to determine water temperature at which the burner

will shut off. Example: If “Setpoint” is 150°F, and “Off hysteresis” is 15°F, the

burner will be shut off at 165°F. Range 5 °F to 70°F.

15°F

On

Hysteresis *

Value subtracted from “Setpoint” to determine water temperature at which the

burner will fire. Example: If “Setpoint” is 150°F, and “On hysteresis” is 10°F,

burner ignition occurs at 140°F. Range 2°F to 40°F.

10°F

P Gain *

Gain applied to the proportional term of the LL PID control algorithm. Range 5 to

50 (no units). Decrease to slow rate of control response.

30

I Gain *

Gain applied to the integral term of the LL PID control algorithm. Range 5 to 50 (no

units). Decrease to slow rate of control response.

15

Base load

common *

Maximum modulation rate of all firing units when other units are still available and

idle. Range 25 - 100%.

70%

* Password protected

CHS Series Controller and Display │Slant Fin Corp.

Table 2-10 Lead Lag Master Configuration Parameters

Use of 4-20mA Input

Setpoint source – If “Local” is selected as the “Setpoint source”, the “Setpoint” value entered on the screen,

depicted in Figure 2-16, is used for control. If 4-20mA is selected as the “Setpoint source”, the boiler

determines its setpoint from the 4-20mA signal. The setpoint is calculated from a factory-set scale between 60°F

corresponding to 4mA, and 190°F corresponding to 20mA. If the 4-20mA input signal is invalid, out of range, or

absent, the “Setpoint” is used until the signal is valid again. Regardless of the “Setpoint source”, “Local” or “4-

20mA”, the controller’s internal PID algorithm modulates the burner. The 4-20mA signal does not create

burner demand; a call for heat must be present at the CH2 (LL) input.

Page 20

18

Figure 2-16 LL Slave Configuration Screen

Lead Lag Slave Config – sub-menu screen, allows

the installer to set the “Slave mode” which establishes

the order in which the boiler is chosen during the

staging sequence of a Lead Lag demand.

Use First – This mode has priority over all others. A

unit with its “Slave mode” set to "Use First", will

always fire first before any other slave in the cascade

and it will be the last one dropped.

Equal run time – This mode stages the units based

on run time equalization where the unit with the least

burner hours fires first and the most burner hours

fires last. Only "Use First" has higher priority.

Use Last – This mode has the lowest priority. A unit

with its “Slave mode” set to "Use Last", will always

fire last after every other slave in the cascade is

running. It will be the last slave to fire and the first

one dropped.

Parameter

Description

Factory Settings

Slave mode *

Select slave mode from drop down list:

Use First

Equal run time

Use Last

Equal run time

* Password protected

Slave mode

Equal run time

Lead Lag Slave Config

Slant Fin Corp. │Controller and Display CHS Series

2.4.3.2 Lead Lag Slave Config

Table 2-11 Lead Lag Slave Configuration Parameters

Page 21

19

Figure 2-17 LL Outdoor Reset Screen

(LL Config) Outdoor Reset Config – sub-menu

screen, allows the installer to set parameters specific

to the effect the outdoor temperature has on the

operation of the boiler during a CH2 (LL) demand.

Use the up and down (▲▼) buttons to navigate the

menu options; when the desired option is highlighted

select by pressing the “OK” button.

Outdoor Reset is in effect only if the following two

conditions are met: “Outdoor reset enable” is set to

"Enable", and an outdoor temperature sensor is

connected to the boiler. The “Lead Lag Outdoor

Reset” parameters, together with the “Lead Lag

Master Config” parameters, define the relationship of

boiler temperature setpoint to outdoor temperature.

Refer to Figure 2-12 for an example of the

relationship between outdoor temperature and boiler

temperature, with a given set of settings.

Parameter

Description

Factory Settings

Outdoor reset

enable *

Enables or disables Outdoor reset

Enabled

Max outdoor

temp *

Outdoor temperature that corresponds to the “Low water temp” setting. Example:

If the “Low water temp” setting is 85°F, and the “Max outdoor temp” setting is

70°F, the boiler setpoint will be 85°F when the outdoor temperature is 70°F or

higher. Range 50°F to 95°F

70ºF

Min outdoor

temp *

Design Temperature - Outdoor temperature that corresponds to the “Setpoint”

setting. Example: If the “Setpoint” is 150°F, and the “Min outdoor temp” setting

is 0°F, the boiler setpoint will be 150°F when the outdoor temperature is 0°F or

lower. Range -40°F to 40°F

0ºF

Low water

temp *

Minimum boiler setpoint; occurs when the outdoor temperature is equal to or

greater than the “Max outdoor temp”. Range 60°F to 140°F

85ºF

Outdoor boost

max off point *

Read only – functional in a future revision.

130ºF

* = Password protected

Outdoor reset enable

Max outdoor temp

Min outdoor temp

Low water temp

Outdoor boost max off point

Enable

70 oF

0 oF

85 oF

130 oF

Lead Lag Outdoor Reset

CHS Series Controller and Display │Slant Fin Corp.

2.4.3.3 Lead Lag Outdoor Reset

Table 2-12 Lead Lag Outdoor Reset Config Parameters

Page 22

20

Figure 2-18 System Configuration Main Menu Screen

System Config – main menu screen, accessed by

selecting “System Config” from the “Advanced

Setup” screen, lists the sub-menus specific to the

System Configuration. Use the up and down (▲▼)

buttons to navigate the menu options; when the

desired option is highlighted select by pressing the

“OK” button.

Figure 2-19 System Identification & Access Screen

System ID & Access – sub-menu screen contains

information about the CHS controller; it also provides

the installer with the ability to change the “Boiler

name” as it appears on the display, and the “Modbus

address”, which is necessary for configurating Lead

Lag multiple boiler installations. Use the up and

down (▲▼) buttons to navigate the menu options;

when the desired option is highlighted select by

pressing the “OK” button.

MB2 Modbus address – each boiler in a Lead Lag

multiple boiler installation, must have a unique MB2

Modbus address.

Boiler name

OEM ID

MB1 Modbus address

MB2 Modbus address

Modbus address

Modbus port used

Product ID

Product family

OS number

Model name

Software version

Date code

Application revision

Safety revision

110MBH

F/T110v06-18-12

1

1

1

MB1

IResidential

Hydronic boiler

R7910B1015

R7910B1015s1m

4104.2901

1117

19

13

System ID & Access

System ID & Access

Pump Config

Statistics Config

High Limits

System Config

System Config

Slant Fin Corp. │Controller and Display CHS Series

2.4.4 System Config

2.4.4.1 System ID & Access

Page 23

21

Parameter

Description

Factory Settings

Boiler name *

Name describing the specific boiler. Limited to 20 characters.

e.g.: 110MBH

OEM ID

Name identifying factory configuration settings; field is read only.

N/A

MB1 Modbus

address *

Modbus communication address used by the display to identify the attached

controller. No need to change this setting. Range: 1 – 8.

1

MB2 Modbus

address *

Unique controller I.D. needed when multiple boilers are connected together in a

Lead Lag cascade configuration. Each boiler in a Lead Lag cascade

configuration must have a unique setting. Range: 1 – 8.

1

Modbus address

Displays the “MB1 Modbus address” setting – do not adjust this setting.

1

Modbus port used

Identifies the Modbus port used by the display to controller; field is read only.

MB1

Product ID

Controller type identification; field is read only.

Residential

Product family

Hydronic boiler

OS number

Controller model identification; field is read only.

R7910B1015

Model name

Software version

Controller software version identification; field is read only.

N/A

Date code

Controller date code; field is read only.

N/A

Application

revision

Controller application revision; field is read only.

N/A

Safety

revision

Controller safety revision; field is read only.

N/A

CHS Series Controller and Display │Slant Fin Corp.

Table 2-13 System Identification & Access Parameters

* = Password protected

Page 24

22

Figure 2-20 Pump Configuration

Pump Config – sub-menu screen allows adjustment

of the individual pump overrun times; also allows the

individual pumps to be manually turned on for testing

purposes. Use the up and down (▲▼) buttons to

navigate the menu options; when the desired option is

highlighted select by pressing the “OK” button.

CH pump use for LL Master – for Lead Lag

multiple boiler configurations; set this parameter to

“On” on the boiler that is controlling the System

pump with the Pump C output.

pump control – This may be

used to manually override

automatic control of the pumps for testing purposes.

If used in this manner, ensure that it is set back to

“Auto”; otherwise, the selected pump(s) will remain

powered on indefinitely.

Parameter

Description

Factory Settings

CH pump

control *

Switches CH pump (Pump C) control from Automatic to ON.

Auto

CH overrun

time *

Amount of time the CH pump (Pump C) will continue to run after a CH [CH1

or CH2 (LL)] demand ends. Range 0 to 1080 minutes.

0 sec

CH pump use for

LL master *

Check box used to allocate Pump C output as the system pump operator for

Lead Lag applications.

off

Boiler pump

control *

Switches Boiler pump (Pump B) control from Automatic to ON.

Auto

Boiler pump

overrun time *

Amount of time the Boiler pump (Pump B) will continue to run after burner

shutdown. Range 0 to 1080 minutes.

30 sec

DHW pump

control *

Switches DHW pump (Pump A) control from Automatic to ON.

Auto

DHW pump

overrun time *

Amount of time the DHW pump (Pump A) will continue to run after a DHW

demand ends. Range 0 to 1080 minutes.

10 sec

* = Password protected

CH pump control

CH pump overrun time

CH pump use for LL Master

Boiler pump control

Boiler pump overrun time

DHW pump control

DHW pump overrun time

Auto

0 sec

off

Auto

30 sec

Auto

10 sec

Pump Config

Slant Fin Corp. │Controller and Display CHS Series

2.4.4.2 Pump Config

Table 2-14 Pump Configuration Parameters

Page 25

23

Figure 2-21 Statistics Configuration Screen

Statistics Config – sub-menu screen displays the

number of burner and pump cycles, as well as burner

run time. Use the up and down (▲▼) buttons to

navigate the menu options; when the desired option is

highlighted select by pressing the “OK” button.

Pump cycle counts can be reset by the installer, for

example when a circulator is replaced.

Burner cycles and Burner run

time counters cannot be reset.

Parameter

Description

Factory Settings

Burner cycle

count

Number of burner cycles on controller. Not resettable by the installer. Range 0 to

999,999.

0

Burner run time

Total number of hours of burner operation. Range 0 to 999,999 hours.

0 hour

Boiler pump

cycle count *

Number of Boiler pump (Pump B) cycles since last reset. Range 0 to 999,999.

0

CH pump cycle

count *

Number of CH pump (Pump C) cycles since last reset. Range 0 to 999,999.

0

DHW pump

cycle count *

Number of DHW pump (Pump A) cycles since last reset. Range 0 to 999,999.

0

Burner cycle count

Burner run time

Boiler pump cycle count

CH pump cycle count

DHW pump cycle count

29

7 hour

75

56

74

Statistics Config

CHS Series Controller and Display │Slant Fin Corp.

2.4.4.3 Statistics Config

Table 2-15 Statistics Configuration Parameters

* = Password protected

Page 26

24

Figure 2-22 High Limit Screen

Parameter

Description

Factory

Outlet high limit

response

Indicates controller response to an outlet temperature exceeding the “Outlet high

limit setpoint”. Parameter is read only.

Recycle & Hold

Outlet high limit response

Recycle & hold

High Limit

Slant Fin Corp. │Controller and Display CHS Series

2.4.4.4 High Limit

High Limit – sub-menu screen displays the outlet limit response. This value is “read only” and cannot be

adjusted.

Table 2-16 High & Stack Limit Parameters

Page 27

25

Figure 2-23 System Configuration Screen

System Config – sub-menu screen allows the

operator to set the temperature units (ºF/ºC) and the

burner “Anti short-cycle time”. Use the up and down

(▲▼) buttons to navigate the menu options; when

the desired option is highlighted select by pressing the

“OK” button.

Anti short-cycle time - This

feature does not apply to

Domestic Hot Water demand or recycle events.

The Anti short-cycle feature is designed to prevent

excessive burner on/off cycling due to short or rapid

thermostat cycles, low heating load, etc.

Parameter

Description

Factory Settings

Temperature

units

Select which temperature units to display:

Fahrenheit

Celsius

Fahrenheit

Anti shortcycle time *

Whenever the burner is turned off due to no demand the anti-short-cycle timer is

started and the burner remains in a Standby Delay condition waiting for this time to

expire.

Range 0 to 60 minutes (1 hour).

5 min

Burner off

inhibit time *

If demand changes from a high-temperature setpoint to a lower setpoint (e.g. from

DHW to CH), water temperature may exceed the burner off point for the new

demand. This value determines how long the control will ignore the burner off

hysteresis or threshold before shutting down the burner, in order to reduce burner

cycling. Range 0 to 30 minutes.

10 sec

General

Config

Allows for advanced parameter configuration modifications – only use when

instructed by Slant/Fin technical support.

N/A

* Password protected

Temperature units

Anti short-cycle time

Burner off inhibit time

General Config

Fahrenheit

5 min

10 sec

System Config

CHS Series Controller and Display │Slant Fin Corp.

2.4.4.5 System Config

Table 2-17 System Configuration Parameters

Page 28

26

Figure 2-24 Modulation Configuration Screen

Modulation Config – menu screen, accessed by

selecting “Modulation Config” from the “Advanced

Setup” screen, allows for adjustment of the min. and

max. modulation rates of the boiler. Use the up and

down (▲▼) buttons to navigate the menu options;

when the desired option is highlighted select by

pressing the “OK” button.

Modulation rates are listed by model number:

CH and DWH

Max Modulation Rate

Min Modulation

Rate

CHS-85 = 6300

CHS-110 = 7000

CHS-155 = 3700

CHS-175 = 4100

CHS-200 = 4650

CHS-250 = 5900

CHS-300 = 5000 (4800 on LP)

CHS-399 = 6900 (6600 on LP)

85 = 1525

110 = 1625

155 = 900

175 = 900

200 = 900

250 = 900

300 = 1500

399 = 1500

Parameter

Description

Factory Settings

CH max

modulation rate *

Maximum permissible blower speed during CH demand [CH1 or CH2 (LL)].

Range is model dependent.

Model dependent

DHW max

modulation rate *

Maximum permissible blower speed during DHW demand. Range is model

dependent.

Model dependent

Min modulation

rate *

Minimum permissible blower speed. Range is model dependent.

Model dependent

* = Password protected

CH max modulation rate

DHW max modulation rate

Min modulation rate

7000 RPM

7000 RPM

1625 RPM

Modulation Config

Slant Fin Corp. │Controller and Display CHS Series

2.4.5 Modulation Config

Table 2-18 Modulation Configuration Parameters

Page 29

27

Figure 2-25 Delta T & T-rise Limits Screens

Parameter

Description

Factory Settings

Delta T

delay *

Delay time between burner cycles when Delta T limit is exceeded. Range 1 to 60

minutes.

5 min

Outlet T-rise

delay *

Delay time between burner cycles when T-rise limit is exceeded. Range 1 to 60

minutes.

5 min

*=Password Protected

Outlet T-rise delay

5 min

T-rise Limits

Delta T delay

5 min

Delta T Limits

CHS Series Controller and Display │Slant Fin Corp.

2.4.6 Delta T & T-rise Limits

Delta T Limits – accessed by selecting “Delta T Limits” from the “Advanced Setup” screen; Delta T is the

difference in water temperature between Inlet and Outlet of the boiler. If the temperature difference (Delta T) is

greater than 60oF the burner is shut off for the time specified before firing again. An initial cycle and two recycles

are allowed before Lockout occurs.

T-rise Limits – accessed by selecting “T-rise Limits” from the “Advanced Setup” screen; T-rise is the rate of

increase of the boiler Outlet temperature. If the boiler outlet temperature increases by a rate greater than

4oF/second the burner will recycle with a delay equal to the “Outlet T-rise delay” setting. An initial cycle and two

recycles are allowed before Lockout occurs.

Table 2-19 Delta T & T-rise Limits Parameters

Page 30

28

Figure 2-26 Frost Protection Screen

Frost Protection Config – accessed by selecting

“Frost Protection Config” from the “Advanced

Setup” screen. Provides optional freeze protection

for the boiler system. Use the up and down (▲▼)

buttons to navigate the menu options; when the

desired option is highlighted select by pressing the

“OK” button.

When set to “Enable”, causes the respective

circulators to operate when the inlet temperature

drops below 45°F; and the burner to fire (at the min.

modulation rate) when the outlet temperature drops

below 38°F.

Parameter

Description

Factory Settings

CH frost

protection *

Enable or Disable frost protection for central heat (i.e. Pumps B and C).

Enabled

DHW frost

protection *

Enable or Disable frost protection for DHW (i.e. Pumps A and B).

Disabled

Lead Lag frost

protection *

Enable or Disable frost protection for lead lag (i.e. Pumps B and C). Each slave

detects frost protection and notifies the Master.

Disabled

* Password protected

CH frost protection

DHW frost protection

Lead Lag frost protection

Enable

Disable

Disable

Frost Protection Config

Slant Fin Corp. │Controller and Display CHS Series

2.4.7 Frost Protection Config

Table 2-20 Frost Protection Configuration Parameters

Page 31

29

Figure 2-27 Burner Control Ignition and Timings & Rates Screens

Parameter

Description

Factory Settings

Postpurge rate *

Rate the blower will operate following the shutdown of the burner. Parameter

is read only.

4500 RPM

Postpurge time *

Time the blower will operate following the shutdown of the burner.

Parameter is read only.

25 sec

Adjustable

lightoff rate *

Rate the blower will operate during burner ignition. Range 2500 rpm to 5000

rpm.

4000 RPM

Postpurge rate

Postpurge time

4500 RPM

20 sec

Burner Timings & Rates

Adjustable lightoff rate

4000 RPM

Burner Control Ignition

CHS Series Controller and Display │Slant Fin Corp.

2.4.8 Burner Control Ignition and Timings & Rates

Burner Timings & Rates – accessed by selecting “Burner Timings & Rates” from the “Advanced Setup” screen.

Displays the Postpurge rate and time settings; values are “read only” and cannot be adjusted.

Burner Control Ignition – accessed by selecting “Burner Control Ignition” from the “Advanced Setup” screen.

Displays the “Adjustable lightoff rate” setting.

Table 2-21 Burner Control Ignition and Timings & Rate Parameters

* Password protected

Page 32

30

Figure 2-28 Diagnostic Input/Output Screens

Diagnostics – menu screen, accessed by selecting

“Diagnostics” from the “i-Information” screen, allows

the user to view the operational status of the boiler.

Use the up and down (▲▼) buttons to navigate the

menu options; when the desired option is highlighted

select by pressing the “OK” button.

Analog Sensors – indicates the status of all

temperature sensors, flame sensor, blower speed (both

demanded and actual), and optional 4-20mA input

signal; see Figure 2-31.

Digital IO – indicates the status of each on/off input

and output, i.e. pump outputs and thermostat inputs;

see Figure 2-31.

Analog Sensors

Digital IO

Analog Sensors

Digital IO

History

Diagnostics

Outlet temp

Inlet temp

Delta T

DHW temp

Stack temp

Outdoor temp

Fan speed

Flame signal

Firing rate

4-20mA input

System sensor

70 oF

70 oF

1 oF

OPEN

71 oF

OPEN

LOW

0.00 A

0 RPM

OPEN

Outlet

Boiler pump (B)

CH pump (C)

DHW pump (A)

Blower/HSI

Eternal ignition

Pilot valve

Main valve

Alarm

Interlock (ILK)

Pre-ignit interlock (PTI)

Load control input (LCI)

STAT (Demand)

Time Of Day

Safety relay

off

off

off

off

off

off

off

off

on

off

off

off

off

off

Slant Fin Corp. │Controller and Display CHS Series

2.5 Diagnostics

Figure 2-29 Diagnostic Screens

Page 33

31

Figure 2-30 History Screen

History – sub-menu screen provides access to a log

of past Lockouts and Alerts. Use the up and down

(▲▼) buttons to navigate the menu options; when

the desired option is highlighted select by pressing

the “OK” button.

Figure 2-31 Example Lockout History Record Screen

Lockout/Alert Record – by selecting a Lockout or

Alert event from the list of Lockouts/Alerts, the

display provides specific information about the

operating condition of the boiler during the

Lockout/Alert (see example left). This information

can be helpful for troubleshooting.

Lockout History

Alert Log

History

Lockout 67

ILK OFF

Cycle: 8 Hours: 3

Time: 0 sec

State: Run

First out: None

Outlet: 77ºF

Inlet: 76ºF

DHW: 110ºF

Lockout History Record 1

CHS Series Controller and Display │Slant Fin Corp.

2.5.1 History

The CHS controller identifies and records two kinds of events and categorizes them as either Lockouts or Alerts.

The bulleted lists below indicate the significance of each type of fault:

Lockouts:

Cause the burner to shutdown and require manual intervention to reset the controller from Lockout

Always cause the Alarm contacts to close

Are logged in the Lockout History

Alerts:

Events reported by the controller

For informational purposes only

Page 34

32

Figure 2-32 Display Setup User Customizable Screen

Display Setup – menu screen, accessed by selecting

“Display Setup” from the “i-Information” screen,

allows the user to select which value (operating

parameter or sensor reading) is displayed on each of

the first 5 lines of the Home Screen. Use the up and

down (▲▼) buttons to navigate the menu options;

when the desired option is highlighted select by

pressing the “OK” button.

The comprehensive list of sensor I/O is identified in

Table 2-22 below.

Value

Description

System setpoint

Indicates the actual local CH setpoint (i.e. for a CH1 demand); adjusts for outdoor reset.

Operating temp

Indicates the temperature at the sensor used for burner modulation during a local CH or DHW

demand, i.e. boiler inlet, boiler outlet or system/pipe sensor.

Outlet temp

Indicates the temperature reading from the boiler outlet sensor.

Inlet temp

Indicates the temperature reading from the boiler inlet sensor.

Outdoor temp

Indicates the temperature reading from the outdoor sensor.

Delta T

Indicates the temperature difference between the boiler inlet and outlet sensors.

LL Operating temp

Indicates the temperature at the sensor used for burner modulation during a Lead Lag demand, i.e.

boiler outlet or system/pipe sensor.

LL System setpoint

Indicates the actual Lead Lag setpoint [i.e. for a CH2 (LL) demand]; adjusts for outdoor reset.

Fan speed

Indicates the speed that the combustion blower is running at – tachometer reading.

Flame signal

Indicates the flame current sensed from the flame probe.

Firing rate

Indicates the speed that the combustion blower is being commanded to operate at.

DHW temp

Indicates the dhw tank temperature (if used) or OPEN/CLOSED for Aquastat switch status.

Stack temp

Indicates the temperature reading from the boiler stack sensor.

4-20mA input

Indicates the input signal from an external 4-20mA source (used for direct burner modulation or

establishing temperature setpoint).

Lead Lag temp

Indicates the temperature reading from an optional system/pipe sensor.

LCD contrast 270

Home screen l ine 1: System setpo 180oF

Home screen l ine 2: Operating tem 71oF

Home screen l ine 3: Outlet temp 71oF

Home screen l ine 4: Inlet temp 71oF

Home screen l ine 5: Outdoor temp OPEN

OS number DSP49G2094

Software version 0.14

Display Setup

Slant Fin Corp. │Controller and Display CHS Series

2.6 Display Setup

Table 2-22 List of Optional Values for Display on Home/Summary Screen

Page 35

33

CHS Series Controller and Display │Slant Fin Corp.

NOTES

Page 36

©Slant/Fin Corp. 2013

SLANT/FIN CORPORATION, Greenvale, N.Y. 11548 • Phone: (516) 484-2600

FAX: (516) 484-5921 • Canada: Slant/Fin LTD/LTEE, Mississauga, Ontario

www.slantfin.com

Loading...

Loading...