Slant/Fin CB-45,CB-90,CB-135,CB-180,CONCEPT 21 CB-180 Installation And Operating Instructions Manual

CONCEPT 21Models CB-45 through CB-180

• Cast-iron • Hot water boilers • Gas Fired • Sealed Combustion

• Direct Vent, Category I, or Category IV Venting Flexibility

INSTALLATION AND OPERATING INSTRUCTIONS

Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Page

Specifications and Dimensions . . . . . . . . . . . . . . . . . . . . . . . .2

Installation Requirements

Boiler Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Boiler Foundation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Minimum Clearances . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Approved Venting Applications . . . . . . . . . . . . . . . . . . . . 4

Direct Vent Application Requirements . . . . . . . . . . . . . 4–8

Category IV Venting Requirements . . . . . . . . . . . . . 9–11

Category I Venting Requirements . . . . . . . . . . . . . 12–14

Water Piping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Gas Piping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Electrical Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16–17

Operation Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . .18–19

Input Rate Adjustment Specifications . . . . . . . . . . . . . . . . . .20

Testing of System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Sequence of Operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

Wiring Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24-27

Air and Gas Orifices . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28–29

Lighting Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

Maintenance Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

Boiler Package/Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

IMPORTANT

READ ALL OF THE FOLLOWING WARNINGS

AND STATEMENTS BEFORE READING THE

INSTALLATION INSTRUCTIONS

WARNING

LIQUEFIED PETROLEUM (L.P.)

PROPANE FIRED GAS BOILERS

Installation location ONLY as permitted in paragraph entitled

"LIQUEFIED PETROLEUM (L.P.) PROPANE GAS FIRED

BOILER LOCATION" on page 3 of this instruction book.

The above warning does not apply to NATURAL gas fired

boilers.

NOTICE: INSTALLATION AND SERVICE MUST BE PERFORMED BY A

TRAINED AND QUALIFIED TECHNICIAN.

The installation must conform to the requirements of the

National Fuel Gas Code ANSI Z223.1 or the CSA B149.1-00

for natural gas and propane and the requirements of the

authority having jurisdiction as well as the requirements in

this instruction manual. In addition, where required by the

authority having jurisdiction, installation must conform to the

Standard for Controls and Safety Devices for Automatically

Fired Boilers, ANSI/ASME CSD-1 or the CSA B149.1-00 for

natural gas and propane. If there is any conflict in the above

requirements, then the more stringent requirement will apply.

WARNING

This boiler, gas piping and accessories must be installed,

connected, serviced and repaired by a trained, experienced

service technician, familiar with all precautions required for

gas fired equipment and licensed or otherwise qualified, in

compliance with the authority having jurisdiction.

Printed in Canada

Publication No. CB-40 Rev. C

Part No. 66-1001

This manual must be left with owner, hung on or

adjacent to the boiler. Owner should retain manual

for future reference.

Heating Contractor

Address

Phone Number

Boiler Model Number

Boiler Serial Number

Installation Date

®

2

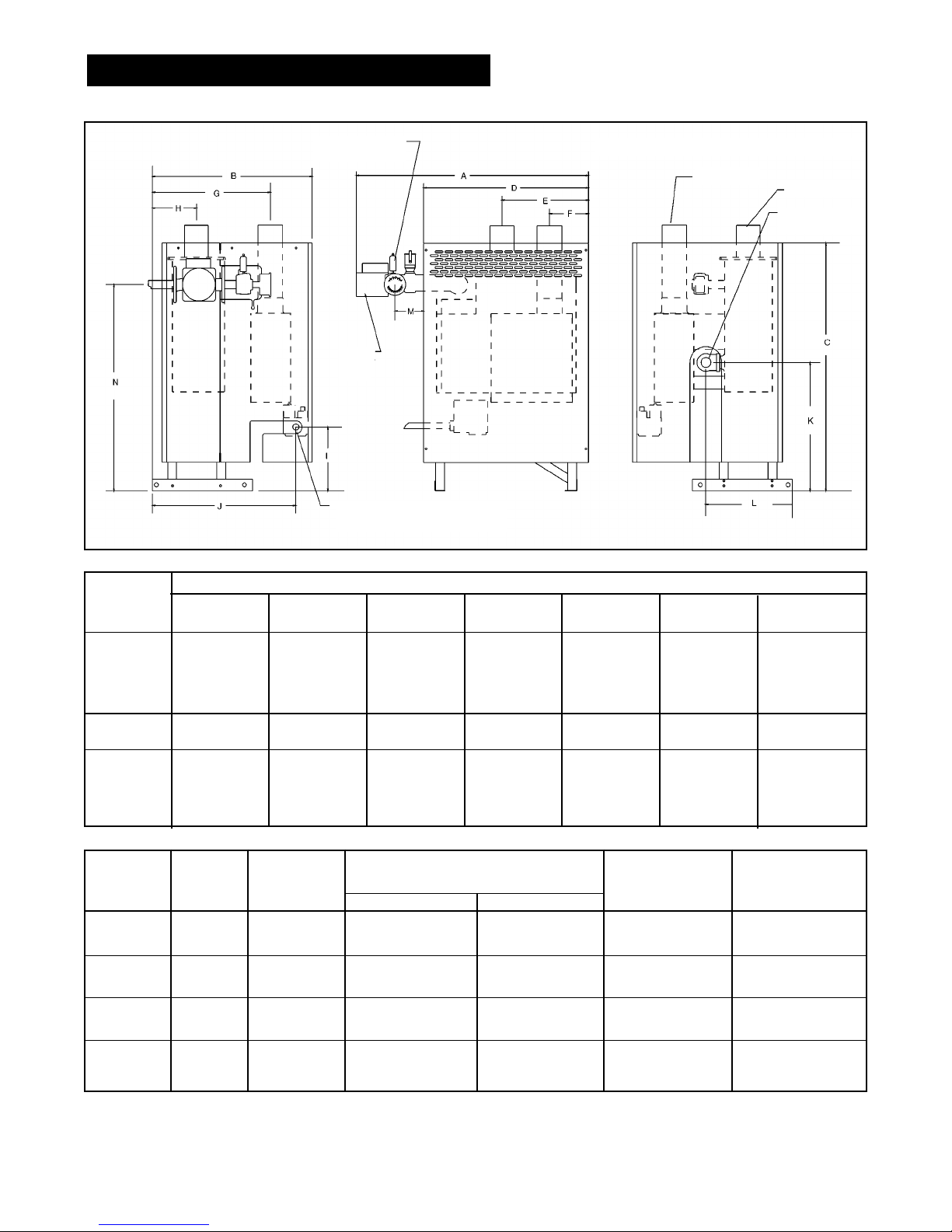

Figure 1. Views — Dimensions — Data

ABCDEFG

mm in mm in mm in mm in mm in mm in mm in

CB-45 743 29.25 508 20 794 31.25 527 20.75 279 11 127 5 356 14

CB-90 743 29.25 584 23 794 31.25 527 20.75 279 11 127 5 432 17

CB-135 743 29.25 660 26 794 31.25 527 20.75 279 11 127 5 508 20

CB-180 743 29.25 737 29 794 31.25 527 20.75 279 11 127 5 584 23

HIJKLMN

mm in mm in mm in mm in mm in mm in mm in

CB-45 127 5 203 8 457 18 413 16.25 273 10.75 95 3.75 660 26

CB-90 165 6.5 203 8 533 21 413 16.25 273 10.75 95 3.75 660 26

CB-135 203 8 203 8 610 24 413 16.25 273 10.75 95 3.75 660 26

CB-180 241 9.5 203 8 686 27 413 16.25 273 10.75 95 3.75 660 26

Boiler

Model

DIMENSIONS INCHES

RATINGS AND DIMENSIONS

Boiler No. of Gas Gas Supply Pressure Shipping Boiler

Model Sections Type Max Min Weight Water Vol.

mm in mm in kg lbs l USG

CB-45 1 Natural 229 9 89 3.5

87 192 1.9 0.5

CB-45 1 Propane 356 14 279 11

CB-90 2 Natural 229 9 89 3.5

112 246 3.8 1.0

CB-90 2 Propane 356 14 279 11

CB-135 3 Natural 229 9 89 3.5

142 312 5.7 1.5

CB-135 3 Propane 356 14 279 11

CB-180 4 Natural 229 9 89 3.5

167 368 7.6 2.0

CB-180 4 Propane 356 14 279 11

WATER SUPPLY

32mm (1 1/4") NPT

GAS SUPPLY

13mm (1/2") NPT

76mm (3") VENT DIA. FOR ALL VENTING, ALL MODELS

AIR INTAKE

EXHAUST

WATER RETURN

32mm (1 1/4")

LEFT SIDE VIEW FRONT VIEW RIGHT SIDE VIEW

CIRC.

PUMP

NOTICE: INSTALLATION AND SERVICE MUST BE

PERFORMED BY A QUALIFIED HEATING CONTRACTOR

The installation must conform to the requirements of

the National Fuel Gas Code ANSI Z223.1 and CSA

B149.1-00 for natural gas and propane for Gas Burning

Appliances and Equipment, and the requirements of the

authority having jurisdiction as well as the requirements

in this instruction manual. In addition, where required by

the authority having jurisdiction, installation must

conform to the Standard for Controls and Safety Devices

for Automatically Fired Boilers, ANSI/ASME CSD-1. If

there is any conflict in the above requirements, then the

more stringent requirement will apply.

BOILER LOCATION

Structure through which venting will pass must be free

and clear for opening (i.e. no hidden conduit, telephone

cables or other obstructions).

Boiler location should be such that the gas ignition

system components are protected from water (dripping,

spraying, rain, etc.) during appliance operation and

service (circulator replacement, condensate trap, control

replacement, etc.).

For a closet installation, ventilation openings must be

provided through a door or wall to prevent excessive

heat build-up. Two openings, one near the floor and one

near the ceiling, should be sized to assure sufficient air

circulation in the closet (minimum 64,516mm

2

[100 sq.

inches] each).

WARNING

LIQUEFIED PETROLEUM (L.P.) PROPANE FIRED

GAS BOILER LOCATION

REQUIRES SPECIAL ATTENTION

Liquefied Petroleum (L.P.) propane gas is heavier than

air. Therefore, propane boilers, piping, valves must NOT

be installed in locations where propane leaking from

defective equipment and piping will "pool" in a basement

or other space below the leak.

A spark or flame from the boiler or other source may

ignite the accumulated propane gas causing an

explosion or fire.

Provide a level, solid foundation for the boiler. Location

should be as near the chimney as possible so that the

flue pipe from boiler to the chimney is short and direct.

The UNIFORM MECHANICAL CODE may be in effect

in your geographic area.

The following precautions are cited by the 1994

UNIFORM MECHANICAL CODE, section 304.6 or CSA

B149.1-00 for natural gas and propane.

“LPG Appliances. Liquefied petroleum gas-burning

appliances shall not be installed in a pit, basement

or similar location where heavier-than-air-gas might

collect. Appliances so fueled shall not be installed in

an above-grade under-floor space or basement

unless such location is provided with an approved

means for removal of unburned gas.”

Consult Chapter 5 of the 1994 UNIFORM MECHANICAL

CODE for design criteria of the "approved" means for

removal of unburned gas.

SAFETY—

KEEP THE BOILER AREA CLEAR AND FREE FROM

COMBUSTIBLE MATERIALS, GASOLINE AND OTHER

FLAMMABLE VAPORS AND LIQUIDS.

BOILER FOUNDATION

A. Provide a solid, level foundation, capable of

supporting the weight of the boiler filled with water,

and extending at least 51mm (2") past the jacket on

all sides. See dimensions of boilers, page 2.

B. Boiler can be installed on both combustible and non-

combustible floors, but must NOT be installed on or

above carpeting.

C. If boiler is to be located over buried conduit

containing electric wires or telephone cables, consult

local codes or the National Board of Fire Underwriters

for specific requirements.

MINIMUM CLEARANCES

A. Minimum clearances to the exterior surfaces of the

boiler shall be as follows:

MINIMUM ALCOVE AND CLOSET CLEARANCE.

B. Provide 457mm (18") on sides used for passage.

For Combustible Recommended

Surface

Construction for Service

Front 51mm (2") 457mm (18")

Rear 51mm (2") 203mm (8")

Left Side 51mm (2") 457mm (18")

Right Side 51mm (2") 457mm (18")

Top 254mm (10") 254mm (10")

Flue Connector 76mm (3") 152mm (6")

C. All minimum clearances shown above must be met.

This may result in increased values of some

minimum clearances in order to maintain the

minimum clearances of others.

D. Clearance from hot water pipes shall be

25mm (1") **.

** At points where hot water pipes emerge from a

floor, wall or ceiling, the clearance at the opening

through the finished floor boards or wall or ceiling

boards may not be less than 13mm (1/2"). Each

such opening shall be covered with a plate of

noncombustible material.

3

INSTALLATION REQUIREMENTS

APPROVED VENTING APPLICATIONS

This Concept 21 boiler is approved to be vented using

Direct Vent, Category I, or Category IV applications.

These applications are differentiated as follows:

Direct Vent — The air for combustion is piped directly to

the air intake of the boiler from outdoors. The vent piping

may be run horizontally or vertically to the outdoors, to a

common terminal with the combustion air intake or

separate from the combustion air intake means.

Category I— The air for combustion is taken from the

ambient air surrounding the boiler. The vent piping must

be upsized and run into a vertical chimney or vent which

will insure a non-positive vent pressure. There is only one

specified input rate for each model boiler on Category I

installations. See chart 2 on page 20.

Category IV— The air for combustion is taken from the

ambient air surrounding the boiler. The vent piping may be

run horizontally or vertically to the outdoors. The vent

pressure is typically positive in this application.

The following venting installation requirements are divided

into 3 sections, each pertaining to the 3 different

applications described above. Once the appropriate

venting application has been selected, follow only the

requirements specified under that section for venting the

boiler. These requirements must be carefully read and

followed in order to avoid any hazardous conditions due to

improper installation of the flue gas venting system.

DIRECT VENT APPLICATION REQUIREMENTS

VENTING LOCATION

Vent installations shall be in accordance with Part 7,

Venting of Equipment, of the National Fuel Gas Code,

ANSI Z223.1, and CSA B149.1-00 for natural gas and

propane, or applicable provisions of local building codes.

Vent termination must meet the following clearances:

Minimum of 305mm (12”) above grade and normal snow

line to vent terminal bottom; minimum of 305mm (12”)

from any building opening; minimum of 914mm (3 feet)

above any forced air intake located within 3048mm (10

feet); minimum of 1219mm (4 feet) horizontally from, and

in no case above or below, unless 1219mm (4-foot)

horizontal distance is maintained, from electric or gas

meters, regulators and relief equipment.

Vent termination must not be located over any public

walkway, in any confined space (i.e. window wells,

alcoves, narrow alleys) or under any overhang or deck.

Vent termination should not allow flue gas discharge

towards neighbor's windows or where personal injury or

property damage can occur.

DO NOT install the vent into a common venting system.

DO NOT install a vent damper or similar device in vent

tubing or on the boiler.

VENT MATERIAL

A. DO NOT use galvanized or plastic vent system

materials. The vent system for Direct Vent Applications

must be UL listed 76mm (3”) diameter corrosion

resistant stainless steel. The following manufacturer’s

systems are approved for use within a specified

minimum and maximum equivalent vent length for each

model of boiler. Refer to Slant/Fin Parts List, Publication

CB 10PL.

B. When joining the various components of the above

listed vent systems, the manufacturers’ instructions

should be closely followed to insure proper sealing

. Use

GE-RTV106 or Dow-Corning 732 sealant for sealing of

pipe and fittings. See Figure 4 for proper application of

vent pipe sealant.

C. All vent connections must be liquid and pressure tight.

4

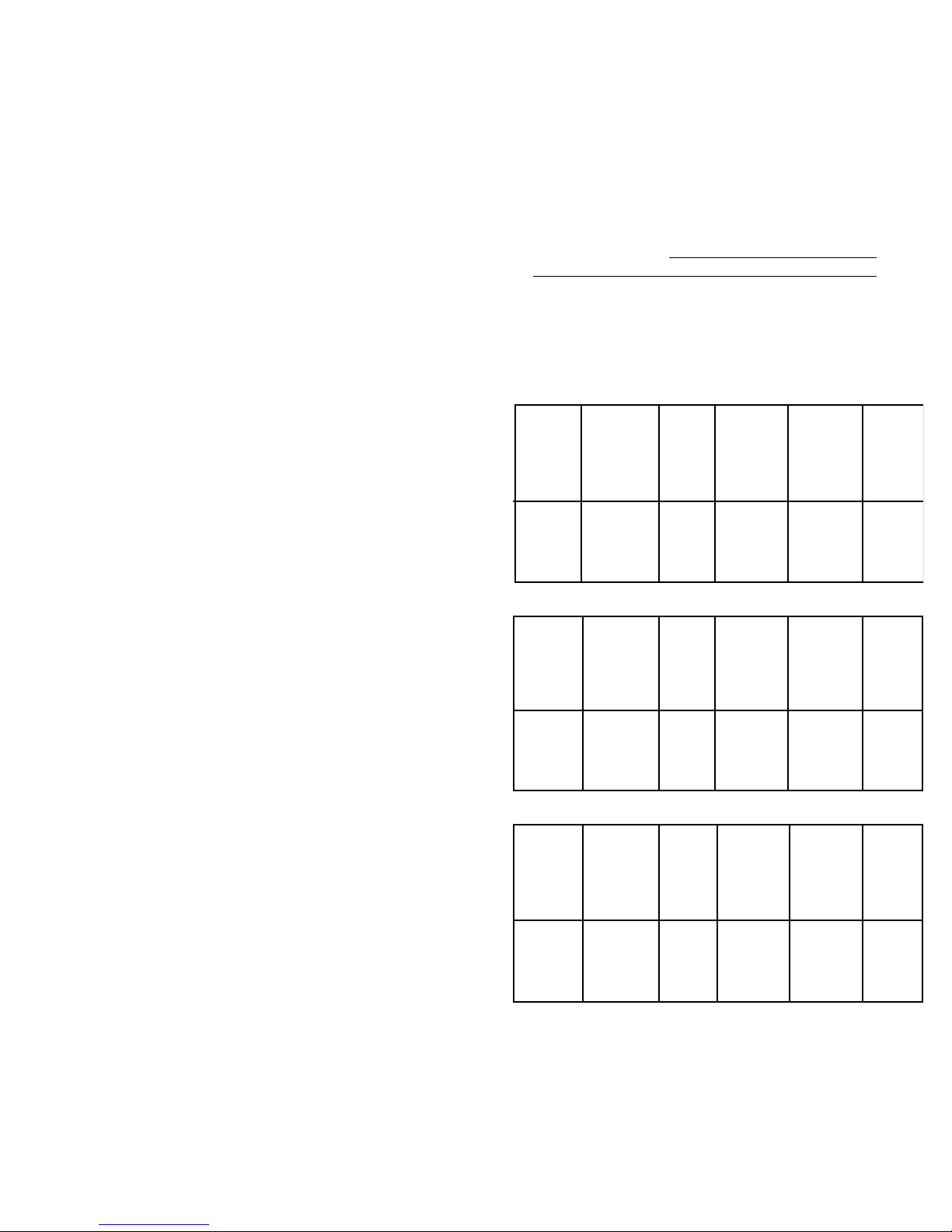

CB-45 30 100 5 914 3 1524 5 1

CB-90 30 100 5 914 3 1524 5 1

CB-135 24 80 5 914 3 1524 5 1

CB-180 12 40 5 914 3 1524 5 1

Boiler

Model

No.

Maximum

Equivalent

Length

including

Elbows

m ft

Max.

No. of

Elbows*

Equivalent

Length of

each

Elbow

mm ft

Minimum

Equivalent

Length*

mm ft

Min.

No. of

Elbows*

* All lengths specified include mandatory minimum use of 610mm (2

feet) of tubing plus one elbow from boiler to vent termination all

models.

Heat Fab Saf-T Vent System

CB-45 30 100 5 1829 6 2438 8 1

CB-90 30 100 5 1829 6 2438 8 1

CB-135 18 60 5 1829 6 2438 8 1

CB-180 9 30 3 1829 6 2438 8 1

Boiler

Model

No.

Maximum

Equivalent

Length

including

Elbows*

m ft

Max.

No. of

Elbows*

Equivalent

Length of

each

Elbow

mm ft

Minimum

Equivalent

Length*

mm ft

Min.

No. of

Elbows*

ProTech Fas-N Seal System

CB-45 30 100 5 1829 6 2438 8 1

CB-90 30 100 5 1829 6 2438 8 1

CB-135 21 70 5 1829 6 2438 8 1

CB-180 11 35 4 1829 6 2438 8 1

Boiler

Model

No.

Maximum

Equivalent

Length

including

Elbows*

m ft

Max.

No. of

Elbows*

Equivalent

Length of

each

Elbow

mm ft

Minimum

Equivalent

Length*

mm ft

Min.

No. of

Elbows*

Flex-L Star-34 System

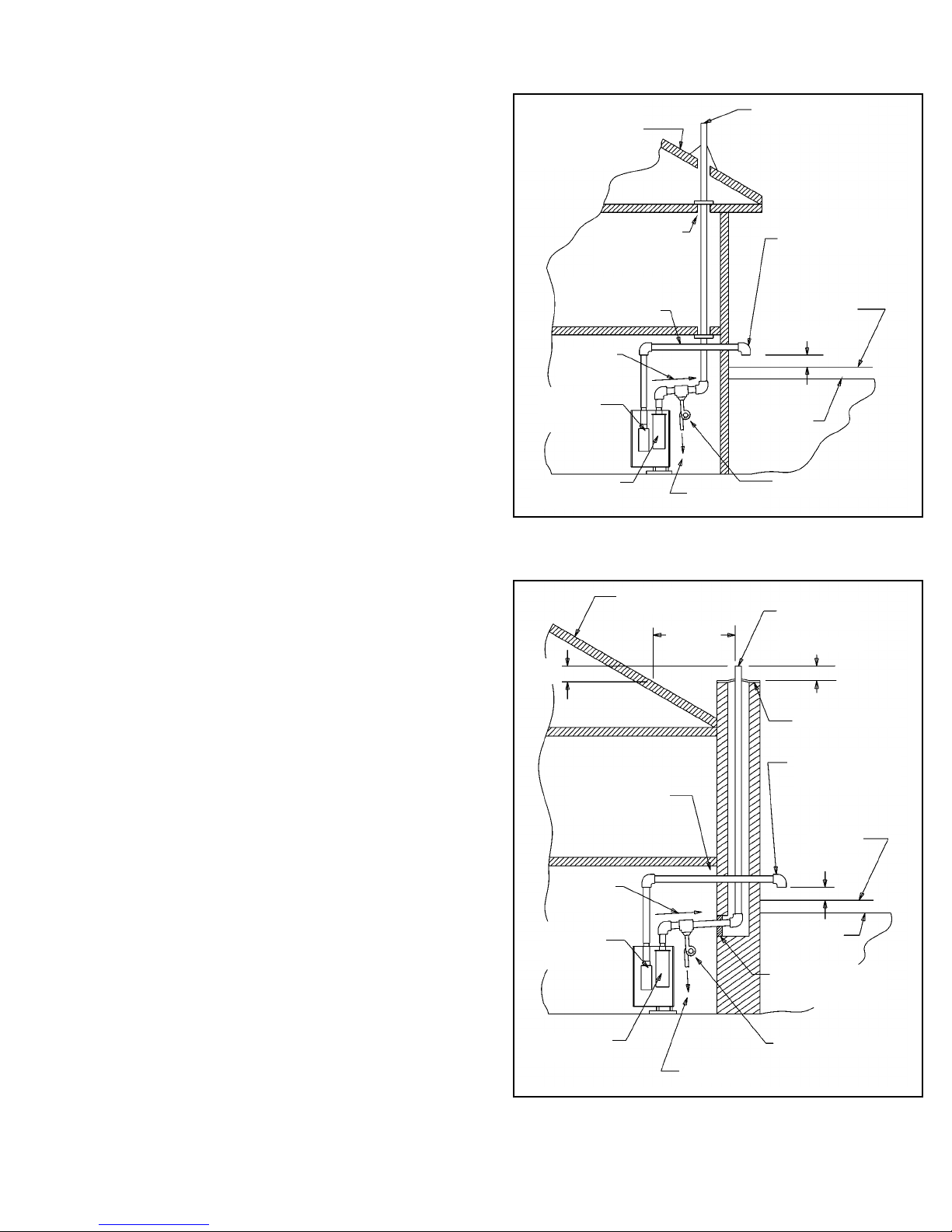

Figure 2. General Vent and Air Intake Piping from Boiler

for Direct Venting

All items shown below are REQUIRED. All vent

joints must be LIQUID and PRESSURE TIGHT.

Figure 3. Floor and ceiling venting passage

All items shown below are REQUIRED.

All vent joints must be LIQUID and PRESSURE TIGHT.

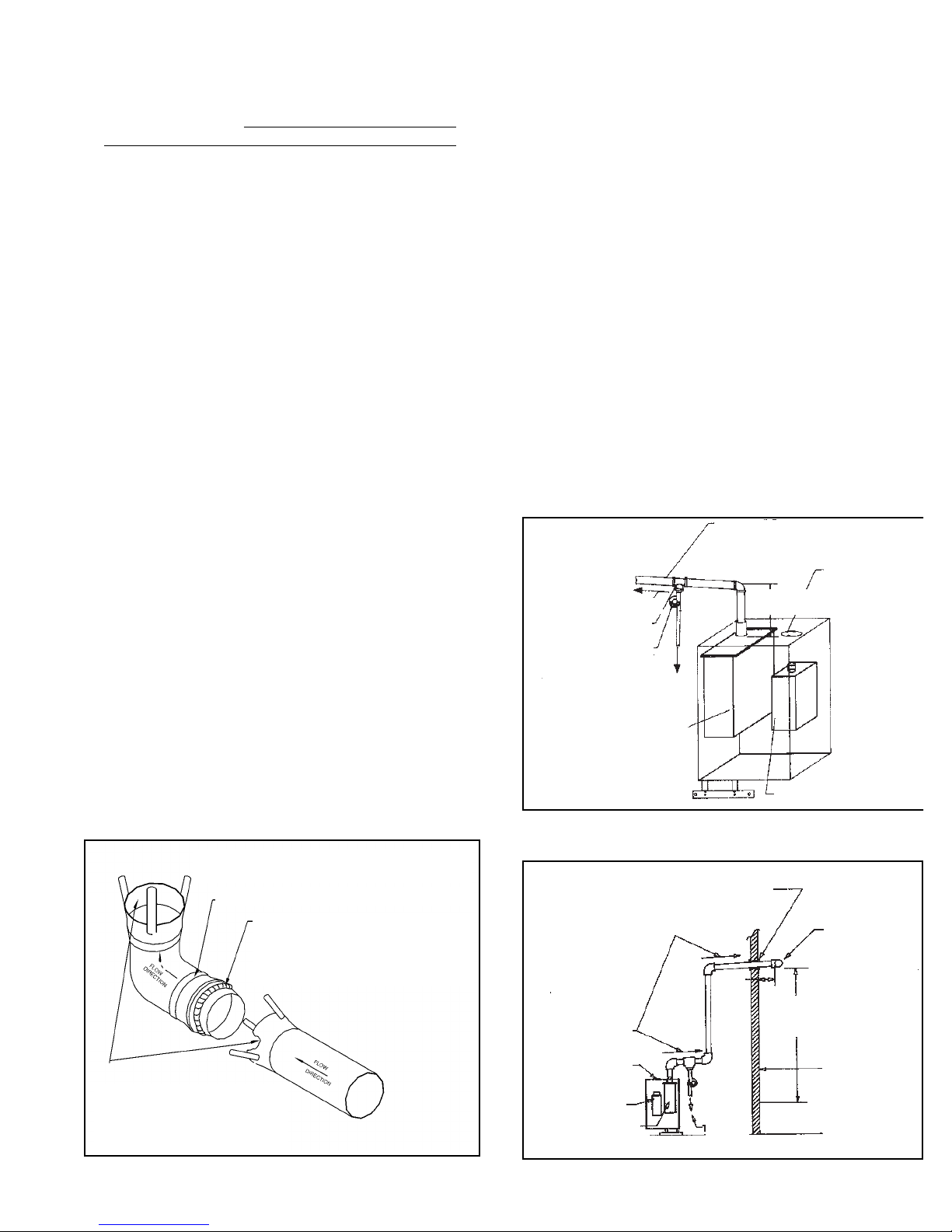

Figure 4. Vent sealing instructions

(Consult vent manufacturer’s instructions.)

5

DIRECT VENT APPLICATION REQUIREMENTS

AIR INTAKE

A. 76mm (3”) diameter PVC piping materials are

recommended. Sewer and drain type material or PVC

schedule 40 piping are best suited for connection to

boiler and vent terminal. Use 76mm (3”) PVC fitting

provided with vent kit to adapt PVC schedule 40 air

intake tubing to air filter box collar. The fitting provided

will fit onto the filter box collar and then a schedule 40

76mm (3”) coupling will fit over that.

B. The venting length requirements specified in this

section also apply to the air intake piping.

C. Seal all joints on air intake piping using appropriate

sealants.

VENTING INSTALLATION

A. Follow the vent material manufacturer’s instructions in

conjunction with these instructions for venting system

installation.

B. Refer to Figures 2, 3 and 4 which illustrate some of

the requirements for venting in a typical installation.

C. A condensate drain and drain trap MUST be installed

on the flue tubing, see Figure 2. The condensate

drain should be installed close to the boiler, as

shown, and must be equipped with a trap formed by

attaching 10mm (3/8”) I.D. clear plastic tubing to the

drain assembly, making a loop approximately 102mm

(4") diameter and securing with cord or a tie wrap

where the loop crosses over itself. This loop should

then be filled with water to form a liquid-filled trap.

DO NOT OPERATE THE BOILER WITHOUT

INSTALLING THIS TRAP AND FILLING WITH WATER

EXHAUST VENT PIPING 76mm (3”) I.D.

AIR INTAKE PIPING 76mm (3”) I.D.

76mm

(3”) PVC

FITTING.

152mm (6”)

MIN. 610mm

(24”) MAX.

CONTINUE WITH PIPING

AS SHOWN IN

FOLLOWING FIGURES

SLOPE UP

20mm/m (1/4”/FT)

CONDENSATE

DRAIN ASSY

FILL TRAP WITH

WATER

HEAT EXCHANGER

ASSY

TO DRAIN

AIR FILTER BOX ASSY

VENT SEALING INSTRUCTIONS FOR HEAT-FAB 29-4C

STAINLESS STEEL VENTING MATERIALS

RING

APPLY ADHESIVE BEAD (6mm [1/4”] DIA. MINIMUM)

AROUND OUTSIDE OF MALE END ONLY, BETWEEN

6mm (1/4”) AND 10 mm (3/8”) FROM THE EDGE OF

THE MALE END. CARE MUST BE TAKEN TO ASSURE

THAT ADHESIVE DOES NOT BLOCK INSIDE OF PIPE

DO NOT APPLY ADHESIVE INSIDE

OF FEMALE FITTINGS IN ORDER TO PREVENT

BLOCKAGE OF INSIDE OF FITTINGS AND TUBING.

IF ANY ADHESIVE SHOULD GET INSIDE, BE SURE

TO WIPE IT OUT BEFORE ASSEMBLING

FIRESTOP

EXHAUST VENT TUBING

76mm (3”) I.D.

CLEARANCE: 152mm

(6”) MIN. FOR 29-4C

STAINLESS STEEL

VENTING

FIRESTOP AND SUPPORT

AIR INTAKE

TUBING 76mm

(3”) I.D.

CLEARANCE:

51mm (2”) MIN.

BETWEEN TUBING

76mm (3”)

MIN. 610mm

(24”) MAX.

TO PREVENT FLUE GAS DISCHARGE INTO SPACE.

Periodic inspection should be made of this assembly for

deterioration of the tubing and to insure that the trap is

filled with water, but not plugged. If it is plugged or

appears to have excessive sediment in it, it should be

removed from the drain assembly, straightened out to clear

the obstruction, reformed, filled with water and reinstalled

as before. The drain must extend to a floor drain.

D. The horizontal pipe must be sloped UPWARD from

the boiler, at a pitch of 20mm/m (*1/4” per 1 foot) of

run, so that the condensate from the vent system runs

to the drain trap. The horizontal portion must also be

supported with 19mm (3/4”) pipe strap at intervals no

greater than 1829mm (6 feet).

E. The vertical portion of the pipe must be supported in

at least one location for each 9m (30 feet) of vertical

run. A firestop is required for each wall, ceiling and

floor penetration.

F. Use tabs on vent collar to secure stainless steel vent

tubing to the boiler.

G. Venting is approved for combustible wall passage

through a 102mm (4”) minimum to 305mm (12”)

maximum thick wall, providing a thimble is used.

6

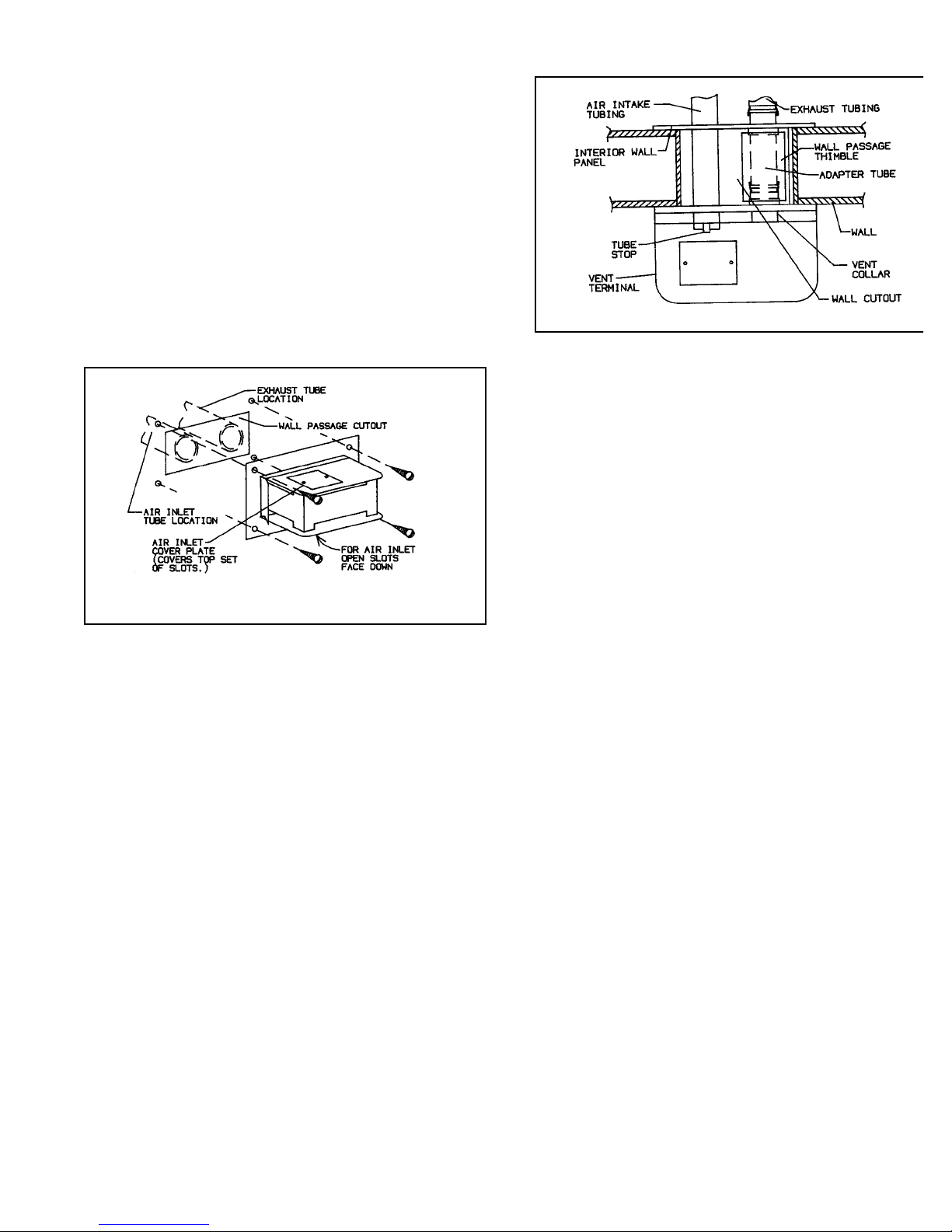

Figure 5a. Vent terminal orientation

Figure 5b. Vent terminal installation

VENT TERMINAL INSTALLATION

Warning: The vent terminal provided is to be used for

horizontal venting only. DO NOT alter this part in any

manner other than shown in these instructions. Only mount

on a vertical surface. DO NOT use when vertically venting

through a roof or chimney.

1. Wall cutout opening:

a) Cut out a rectangular opening 152mm (6”) high and

305mm (12”) wide in the appropriate location of an

exterior wall. Be sure that this location will allow for

the connection of vent materials that come in fixed

lengths, or an adjustable connector will be needed.

b) Boxing in the cutout with wood is allowable, but the

152mm x 305mm (6” x 12”) opening size must be

maintained.

c) Plan on the edge of the cutout to be about 76mm (3”)

from the center of the exhaust tube, when installed.

2. Vent terminal orientation: see Figure 5a.

a) The open slots for the air intake on the vent terminal

must face downward.

b) The air inlet cover plate must face upward to insure

that rain, debris and flue gases do not enter the air

inlet.

3. Vent and air intake tubing orientation: see Figure 5a.

a) Air inlet tubing may be located to the left or to the

right of the flue exhaust tubing.

b) If the air inlet tubing is going to be to the left of the

flue exhaust (viewed from outside of building) then

the vent terminal should be installed as supplied

without alteration.

c) If the air inlet tubing is going to be to the right of t

flue exhaust (viewed from outside building) then t

air inlet cover plate must be removed and reinstall

over the alternate set of slots. This alteration w

insure that the air inlet slots face down when the ve

terminal is installed.

4. Vent terminal installation: see Figure 5b.

a) Center the vent terminal over the wall cutout. T

collar on the back of the vent terminal panel shou

clear the cutout edges by about 12mm (1/2”).

b) Mark and drill out the location of the four screw hol

in the wall for mounting vent terminal.

c) Seal the vent collar adapter tube 76mm (3”) dia. ma

end stainless) into the collar on the back of the ve

terminal box and slide the ring on the tube over t

collar tabs, then bend the tabs back over the rin

This piece will allow easy connection of the fl

exhaust tubing from inside the building.

d) Run a bead of silicone around the perimeter of w

panel and vent collar to prevent water and drafts fro

entering building.

e) Orientate the vent terminal on the wall as describ

in Step 2 and secure it to the wall.

5. Interior wall panel installation:

a) Cut the wall thimble 127mm (5”) diameter galv. pip

about 12mm (1/2”) shorter than the wall thickness

b) Fit thimble onto the collar on the back of the ve

terminal inside the wall.

c) Hold the interior wall panel up to the wall cutout a

fit the collar on this panel into the thimble. Line up t

air inlet holes and secure to wall.

6. Vent and air intake tubing installation to vent terminal:

a) Finish tubing connections back to the boil

following

the requirements in the venting installati

instructions

on pages 4 and 5.

b) Exhaust tubing connects to the vent collar adapt

tube. Observe correct flow direction.

c) Air intake tubing should slip into the air inlet openi

in the back of the vent terminal. Make sure the tubi

extends into the vent terminal box as far as the tu

stop inside the box allows (19mm [3/4”] approx

Seal around the air intake tubing where it pass

through the outside wall plate.

*Shown with air inlet to the left of exhaust

from outside view.

* Shown from top view.

DIRECT VENTING WITH VENT TERMINAL

All Concept 21 boiler models are certified for horizontal

Direct Venting utilizing the vent terminal provided by

Slant/Fin only.

This vent terminal must be mounted on a vertical wall

outside surface. Terminal CANNOT be mounted on a roof

or any horizontal surface.

Vent terminal is designed to deflect flue gases away from

outside building wall; properly installed, it will prevent flue

gas degradation of normal building materials and reduce

the possibility of air intake freeze-up. It is recommended

to utilize this vent terminal on Direct Vent applications

whenever the installation permits.

Figure 7a. Vent and air intake run through a pitched roof

Figure 7b. Vent and air intake run through a flat roof

7

EXHAUST WITH SCREEN

AIR INTAKE 180° ELBOW

WITH SCREEN FACE

DOWN

3048mm (10 ft)

or less

610mm (2 ft) min.

ROOF FLASHING

54mm (2“) min.

305mm

(1 ft) min.

54mm (2“) min.

ROOFLINE

SNOWLINE

EXHAUST WITH

SCREEN

3048mm (10 ft)

or less

610mm (2 ft) min.

ROOF

LINE

SNOW

LINE

ROOF FLASHING

54mm (2”) min.

54mm (2”) min.

AIR INTAKE 180° ELBOW

WITH SCREEN FACE DOWN

305mm (1 ft) min.

305mm (1 ft) min.

914mm

(3 ft)

min.

305mm

(1 ft) min.

914mm

(3 ft) min.

Vertical Venting Configurations

All Concept 21 boiler models are certified for vertical

Direct Venting utilizing the following configurations.

1. Vent and air intake piping vertically run up through a

roof in close proximity.

a. For a pitched roof installation, refer to Figure 7a. For

a flat roof installation, refer to Figure 7b. When floor

and ceiling passage is necessary, refer to Figure 3.

Adhere to all clearances and materials specified in

these illustrations.

b. The stainless exhaust vent pipe must pass through

the roof vertically through a 178mm (7”) min.

diameter cutout and appropriate roof flashing. The

pipe must exhaust straight up and terminate with a

screen terminator.

c. The air intake pipe must pass through the roof

vertically. The cutout does not require any clearance,

but must be sealed with a flashing or other means.

The air intake opening must face down by using a

180° elbow with a screen positioned at the opening.

The air intake opening must be at least 305mm (1

foot) below the vent opening.

DIRECT VENTING WITHOUT VENT TERMINAL

Figure 8b. Vent piping vertically run up an existing chimney

and air intake horizontally run out a vertical wall.

Figure 8a. Vent run through a roof and air intake run through

a wall

8

REFER TO VENT PIPE

REQUIREMENTS SHOWN IN

PREVIOUS FIGURES FOR

VENT AND AIR INTAKE RUN

THROUGH A PITCHED OR

FLAT ROOF

EXHAUST WITH SCREEN

AIR INTAKE 90° ELBOW WITH

SCREEN FACE DOWN

SNOWLINE

305mm (1 ft) min.

GROUNDLINE

CONDENSATE DRAIN ASSY

TO DRAIN

HEAT EXCHANGER

ASSY

AIR FILTER

BOX ASSY

Slope up

20mm/m

(1/4” per ft)

RUN AIR INTAKE PIPE

THROUGH THE

FOUNDATION OR AN

EXTERIOR WALL

REFER TO

PREVIOUS FIGURE

FOR FLOOR AND

CEILING PASSAGE

ROOF LINE

3048mm

(10 ft) or

less

EXHAUST WITH

SCREEN

305mm (1 ft) min.

CHIMNEY TOP PLATE

AIR INTAKE 90° ELBOW

WITH SCREEN FACE

DOWN

SNOWLINE

305mm (1 ft) min.

GROUNDLINE

CONDENSATE DRAIN ASSY

TO DRAIN

HEAT EXCHANGER

ASSY

AIR FILTER

BOX ASSY

SLOPE UP

20mm/m

(1/4” per ft)

RUN AIR INTAKE PIPE

THROUGH THE

FOUNDATION OR AN

EXTERIOR WALL

SEAL CHIMNEY OPENING

WITH MORTAR OR

COVER PLATE

610mm

(2 ft) min.

Vertical Venting Configurations

2. Vent piping vertically run up through a roof and air

intake horizontally run out a vertical wall.

a. See Figure 8a for general configuration. For a

pitched roof installation, refer to vent pipe

requirements shown in Figure 7a. For a flat roof

installation, refer to the vent pipe requirements

shown in Figure 7b. When floor and ceiling passage

is necessary, refer to Figure 3. Adhere to all

clearances and materials specified in these

illustrations for installing the vent pipe only. For

installing the air intake pipe, refer to the air intake

requirements shown in Figure 8a.

b. The stainless exhaust vent pipe must pass through

the roof vertically through a 178mm (7”) min.

diameter cutout and appropriate roof flashing. The

pipe must exhaust straight up and terminate with a

screen terminator.

c. The air intake pipe must pass through a vertical wall

or foundation horizontally. The cutout does not

require any clearance, but must be sealed with a

flashing or by other means. The air intake opening

must face down by using 90° elbow with a screen

positioned at the opening.

3. Venting piping vertically run up an existing chimney

and air intake horizontally run out a vertical wall.

a. Refer to Figure 8b. Adhere to all clearances and

materials specified in this illustration.

b. The stainless exhaust vent pipe must extend the

total length of the chimney. The pipe must exhaust

straight up and terminate with a screen terminator.

The top of the chimney must be sealed off around

the protruding pipe with an appropriate plate or

flashing. Other appliances CANNOT be vented into

the same chimney or vent pipe within the chimney.

c. The air intake pipe must pass through a vertical wall

or foundation horizontally. The cutout does not

require any clearance, but must be sealed with a

flashing or by other means. The air intake opening

must face down by using a 90° elbow with a screen

positioned at the opening.

DIRECT VENTING WITHOUT VENT TERMINAL

BOILER ROOM AIR SUPPLY AND VENTILATION

An ample supply of air is required for combustion and

ventilation. When buildings are insulated, caulked and

weather-stripped, now or later on, direct openings to outside

may be required and should be provided. If the boiler is not

near an outside wall, air may be ducted to it from outside

wall openings.

Provisions for combustion and ventilation air must be made

in accordance with section 5.3, Air for Combustion and

Ventilation, of the National Fuel Gas Code, ANSI Z223.1 and

CSA B149.1-00 for natural gas and propane

, or applicable

provisions of the local building codes. The following

recommendation applies to buildings of energy-saving

construction, fully caulked and weather- stripped:

Provide one GRILLED opening near the floor and one near

the ceiling on an outside wall near the boiler (or duct from

such openings to the boiler), EACH opening to be a

minimum of 645mm

2

(one square inch) per 586w (2000 Btuh)

input to ALL

APPLIANCES in the area. For a total appliance

input of 58 620w

(200,000 Btuh), each opening will be 64 516

mm

2

(100 square inches). A grilled opening 254mm x 254mm

(10"X10") has 64 516mm

2

(100 square inches) of area. If fly

screen must be used over openings, double the area and

inspect and clean the screen frequently.

Openings must never be reduced or closed. If doors or

windows are used for air supply, they must be locked open.

Protect against closure of openings by snow and debris.

Inspect frequently.

No mechanical draft exhaust or supply fans are to be used in

or near the boiler area.

The flow of combustion and ventilating air to the boiler must

not be obstructed.

The air inlet passage hole located on the top of the boiler

jacket should be covered for any installation which does not

require combustion air to be piped into the boiler. (i.e. Direct

Vent Installation)

VENTING LOCATION REQUIREMENTS

Vent installations shall be in accordance with Part 7, Venting

of Equipment, of the National Fuel Gas Code, ANSI Z223.1

and

CSA B149.1-00 for natural gas and propane, or

applicable provisions of local building codes.

This Concept 21 boiler is approved for pressure venting both

horizontally and vertically. The following requirements apply

to both types of venting installation.

Vent termination must meet the following clearances:

Minimum of 305mm (12”) above grade and normal snow line

to vent termination bottom; minimum of 1219mm (4 feet)

below or horizontally, or 305mm (1 foot) above any building

opening; minimum of 914mm (3 feet) above any forced air

intake located within 3048mm (10 feet); minimum of 1219mm

(4 feet) horizontally from, and in no case above or below,

unless 1219mm (4-foot) horizontal distance is maintained,

from electric or gas meters, regulators and relief equipment.

Vent termination must not be located over any public

walkway, in any confined space (i.e. window wells,

alcoves, narrow alleys) or under any overhang or deck.

Vent termination should not allow flue gas discharge

towards neighbor's windows or where personal injury or

property damage can occur.

DO NOT install the vent into a common venting system.

DO NOT install a vent damper or similar device in vent

tubing or on the boiler.

VENT MATERIAL REQUIREMENTS

A. DO NOT use galvanized or plastic vent system

materials. The vent system for Category IV applications

must be UL listed 76mm (3”) diameter corrosion

resistant stainless steel. The following manufacturer’s

systems are approved for use within a specified

minimum and maximum equivalent vent length for each

model of boiler.

Category IV Venting Requirements

CB-45 30 100 5 914 3 1524 5 1

CB-90 30 100 5 914 3 1524 5 1

CB-135 24 80 5 914 3 1524 5 1

CB-180 12 40 5 914 3 1524 5 1

Boiler

Model

No.

Maximum

Equivalent

Length

including

Elbows

m ft

Max.

No. of

Elbows*

Equivalent

Length of

each

Elbow

mm ft

Minimum

Equivalent

Length*

mm ft

Min.

No. of

Elbows*

* All lengths specified include mandatory minimum use of 610mm (2

feet) of tubing plus one elbow from boiler to vent termination all

models.

Heat Fab Saf-T Vent System

CB-45 30 100 5 1829 6 2438 8 1

CB-90 30 100 5 1829 6 2438 8 1

CB-135 18 60 5 1829 6 2438 8 1

CB-180 9 30 3 1829 6 2438 8 1

Boiler

Model

No.

Maximum

Equivalent

Length

including

Elbows*

m ft

Max.

No. of

Elbows*

Equivalent

Length of

each

Elbow

mm ft

Minimum

Equivalent

Length*

mm ft

Min.

No. of

Elbows*

ProTech Fas-N Seal System

CB-45 30 100 5 1829 6 2438 8 1

CB-90 30 100 5 1829 6 2438 8 1

CB-135 21 70 5 1829 6 2438 8 1

CB-180 11 35 4 1829 6 2438 8 1

Boiler

Model

No.

Maximum

Equivalent

Length

including

Elbows*

m ft

Max.

No. of

Elbows*

Equivalent

Length of

each

Elbow

mm ft

Minimum

Equivalent

Length*

mm ft

Min.

No. of

Elbows*

Flex-L Star-34 System

B. When joining the various components of the above

listed vent systems, the manufacturers’ instructions

should be closely followed to insure proper sealing. Use

GE-RTV106 or Dow-Corning 732 sealant for sealing of

pipe and fittings. See Figure 4 for proper application of

vent pipe sealant.

C. All vent connections must be liquid and pressure tight.

VENTING INSTALLATION

A. Follow the vent material manufacturer’s instructions in

conjunction with these instructions for venting system

installation.

B. Refer to Figures 4 and 9 which illustrate some of the

requirements for venting in a typical installation.

C.

A condensate drain and drain trap MUST be installed on

the flue tubing, see Figure 9. The condensate drain should

be installed close to the boiler, as shown, and must be

equipped with a trap formed by attaching 9mm (3/8") I.D.

clear plastic tubing to the drain assembly, making a loop

approximately 102mm (4") diameter and securing with cord

or a tie wrap where the loop crosses over itself. This loop

should then be filled with water to form a liquid-filled trap.

DO NOT OPERATE THE BOILER WITHOUT INSTALLING

THIS TRAP AND FILLING WITH WATER TO PREVENT

FLUE GAS DISCHARGE INTO SPACE. Periodic inspection

should be made of this assembly for deterioration of the

tubing and to insure that the trap is filled with water, but not

plugged. If it is plugged or appears to have excessive

sediment in it, it should be removed from the drain

assembly, straightened out to clear the obstruction,

reformed, filled with water and reinstalled as before. The

drain must extend to a floor drain.

D. The horizontal pipe must be sloped UPWARD from the

boiler, at a pitch of 20mm/m (1/4” per 1 foot) of run, so

that the condensate from the vent system runs to the

drain trap. The horizontal portion must also be

supported with 19mm (3/4”) pipe strap at intervals no

greater than 1828mm (6 feet).

Category IV Venting Requirements

E.

The vertical portion of the pipe must be supported in at leas

one location for each 9m (30 feet) of vertical run. A firestop

is required for each wall, ceiling and floor penetration.

F. Use tabs on vent collar to secure stainless steel vent

tubing to the boiler.

G. Venting is approved for combustible wall passage

through a 102mm (4”) minimum to 305mm (12”)

maximum thick wall, providing a thimble is used.

HORIZONTAL CATEGORY IV VENTING

All Concept 21 boiler models are certified for horizontal

Category IV venting provided the following conditions are met

1. For combustible wall passage of vent piping, a UL and

CUL listed thimble must be used, providing the wall

thickness is 102mm (4”) minimum to 305mm (12”)

maximum.

2. The venting piping must terminate with a screened tee,

elbow, or straight termination at the minimum distance

from the outside wall shown in Figure 10.

10

Figure 9. General Vent Piping from Boiler for Category IV Ventin

All items shown below are REQUIRED.

All vent joints must be LIQUID and PRESSURE TIGHT.

Figure 4. Vent sealing instructions

(Consult vent manufacturer’s instructions.)

Figure 10. Horizontal Category IV Venting through outside wall

CONTINUE WITH VENT

PIPING AS SHOWN IN

FOLLOWING FIGURES

EXHAUST VENT

PIPING 76MM (3”) I.D.

AIR INLET COVER

203mm (8”) MIN.

610mm (24”) MAX.

AIR FILTER BOX ASSY.

HEAT

EXCHANGER

ASSY.

TO DRAIN

FILL TRAP WITH WATER

CONDENSATE DRAIN ASSY.

SLOPE UP 20mm/m (1/4” PER FT.)

76mm (3”) MIN.

610mm (24”) MAX.

VENT SEALING INSTRUCTIONS FOR HEAT-FAB 29-4C

STAINLESS STEEL VENTING MATERIALS

RING

APPLY ADHESIVE BEAD (6mm [1/4”] DIA.

MINIMUM) AROUND OUTSIDE OF MALE END ONLY,

BETWEEN 6mm (1/4”) AND 9mm (3/8”) FROM THE

EDGE OF THE MALE END.

CARE MUST BE TAKEN TO ASSURE THAT

ADHESIVE DOES NOT BLOCK INSIDE OF PIPE

DO NOT APPLY ADHESIVE INSIDE

OF FEMALE FITTINGS IN ORDER TO

PREVENT BLOCKAGE OF INSIDE OF

FITTINGS AND TUBING. IF ANY ADHESIVE

SHOULD GET INSIDE, BE SURE TO WIPE IT

OUT BEFORE ASSEMBLING

WALL

THIMBLE

VENT

TERMINATION

WITH SCREEN

305mm

(1 FT.)

MIN.

OUTSIDE WALL

SNOW LINE

GROUNDLINE

HEAT EXCHANGER

ASSY.

AIR FILTER BOX

ASSY.

AIR INLET COVER

VENT PIPE

SLOPE UP 20mm/m

(1/4” PER FT.)

102mm

(4”)

MIN.

TO

DRAIN

Loading...

Loading...