Slant/Fin CB-45, CB-90, CB-135, CB-180, CONCEPT 21 CB-180 Installation And Operating Instructions Manual

Page 1

CONCEPT 21Models CB-45 through CB-180

• Cast-iron • Hot water boilers • Gas Fired • Sealed Combustion

• Direct Vent, Category I, or Category IV Venting Flexibility

INSTALLATION AND OPERATING INSTRUCTIONS

Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Page

Specifications and Dimensions . . . . . . . . . . . . . . . . . . . . . . . .2

Installation Requirements

Boiler Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Boiler Foundation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Minimum Clearances . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Approved Venting Applications . . . . . . . . . . . . . . . . . . . . 4

Direct Vent Application Requirements . . . . . . . . . . . . . 4–8

Category IV Venting Requirements . . . . . . . . . . . . . 9–11

Category I Venting Requirements . . . . . . . . . . . . . 12–14

Water Piping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Gas Piping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Electrical Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16–17

Operation Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . .18–19

Input Rate Adjustment Specifications . . . . . . . . . . . . . . . . . .20

Testing of System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Sequence of Operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

Wiring Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24-27

Air and Gas Orifices . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28–29

Lighting Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

Maintenance Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

Boiler Package/Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

IMPORTANT

READ ALL OF THE FOLLOWING WARNINGS

AND STATEMENTS BEFORE READING THE

INSTALLATION INSTRUCTIONS

WARNING

LIQUEFIED PETROLEUM (L.P.)

PROPANE FIRED GAS BOILERS

Installation location ONLY as permitted in paragraph entitled

"LIQUEFIED PETROLEUM (L.P.) PROPANE GAS FIRED

BOILER LOCATION" on page 3 of this instruction book.

The above warning does not apply to NATURAL gas fired

boilers.

NOTICE: INSTALLATION AND SERVICE MUST BE PERFORMED BY A

TRAINED AND QUALIFIED TECHNICIAN.

The installation must conform to the requirements of the

National Fuel Gas Code ANSI Z223.1 or the CSA B149.1-00

for natural gas and propane and the requirements of the

authority having jurisdiction as well as the requirements in

this instruction manual. In addition, where required by the

authority having jurisdiction, installation must conform to the

Standard for Controls and Safety Devices for Automatically

Fired Boilers, ANSI/ASME CSD-1 or the CSA B149.1-00 for

natural gas and propane. If there is any conflict in the above

requirements, then the more stringent requirement will apply.

WARNING

This boiler, gas piping and accessories must be installed,

connected, serviced and repaired by a trained, experienced

service technician, familiar with all precautions required for

gas fired equipment and licensed or otherwise qualified, in

compliance with the authority having jurisdiction.

Printed in Canada

Publication No. CB-40 Rev. C

Part No. 66-1001

This manual must be left with owner, hung on or

adjacent to the boiler. Owner should retain manual

for future reference.

Heating Contractor

Address

Phone Number

Boiler Model Number

Boiler Serial Number

Installation Date

®

Page 2

2

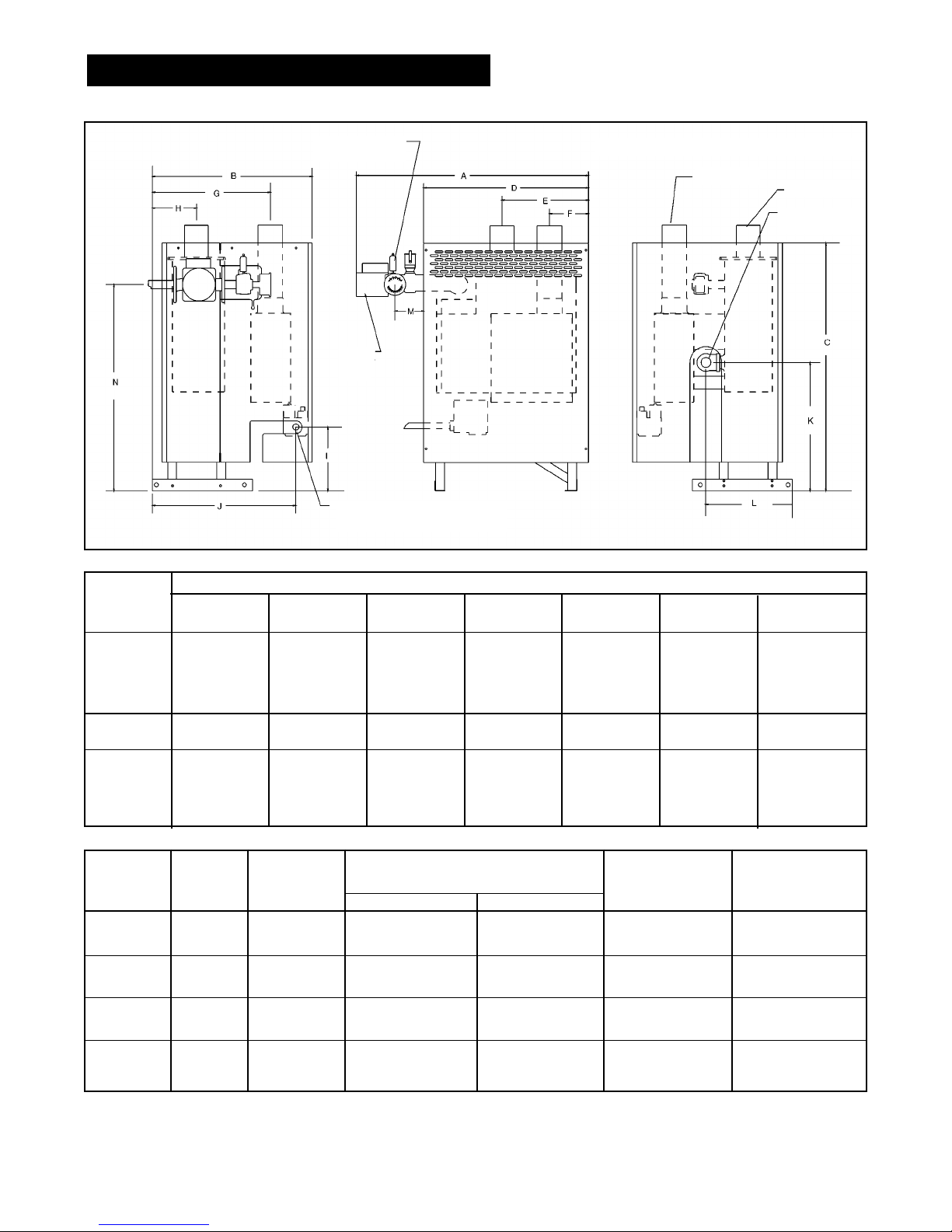

Figure 1. Views — Dimensions — Data

ABCDEFG

mm in mm in mm in mm in mm in mm in mm in

CB-45 743 29.25 508 20 794 31.25 527 20.75 279 11 127 5 356 14

CB-90 743 29.25 584 23 794 31.25 527 20.75 279 11 127 5 432 17

CB-135 743 29.25 660 26 794 31.25 527 20.75 279 11 127 5 508 20

CB-180 743 29.25 737 29 794 31.25 527 20.75 279 11 127 5 584 23

HIJKLMN

mm in mm in mm in mm in mm in mm in mm in

CB-45 127 5 203 8 457 18 413 16.25 273 10.75 95 3.75 660 26

CB-90 165 6.5 203 8 533 21 413 16.25 273 10.75 95 3.75 660 26

CB-135 203 8 203 8 610 24 413 16.25 273 10.75 95 3.75 660 26

CB-180 241 9.5 203 8 686 27 413 16.25 273 10.75 95 3.75 660 26

Boiler

Model

DIMENSIONS INCHES

RATINGS AND DIMENSIONS

Boiler No. of Gas Gas Supply Pressure Shipping Boiler

Model Sections Type Max Min Weight Water Vol.

mm in mm in kg lbs l USG

CB-45 1 Natural 229 9 89 3.5

87 192 1.9 0.5

CB-45 1 Propane 356 14 279 11

CB-90 2 Natural 229 9 89 3.5

112 246 3.8 1.0

CB-90 2 Propane 356 14 279 11

CB-135 3 Natural 229 9 89 3.5

142 312 5.7 1.5

CB-135 3 Propane 356 14 279 11

CB-180 4 Natural 229 9 89 3.5

167 368 7.6 2.0

CB-180 4 Propane 356 14 279 11

WATER SUPPLY

32mm (1 1/4") NPT

GAS SUPPLY

13mm (1/2") NPT

76mm (3") VENT DIA. FOR ALL VENTING, ALL MODELS

AIR INTAKE

EXHAUST

WATER RETURN

32mm (1 1/4")

LEFT SIDE VIEW FRONT VIEW RIGHT SIDE VIEW

CIRC.

PUMP

Page 3

NOTICE: INSTALLATION AND SERVICE MUST BE

PERFORMED BY A QUALIFIED HEATING CONTRACTOR

The installation must conform to the requirements of

the National Fuel Gas Code ANSI Z223.1 and CSA

B149.1-00 for natural gas and propane for Gas Burning

Appliances and Equipment, and the requirements of the

authority having jurisdiction as well as the requirements

in this instruction manual. In addition, where required by

the authority having jurisdiction, installation must

conform to the Standard for Controls and Safety Devices

for Automatically Fired Boilers, ANSI/ASME CSD-1. If

there is any conflict in the above requirements, then the

more stringent requirement will apply.

BOILER LOCATION

Structure through which venting will pass must be free

and clear for opening (i.e. no hidden conduit, telephone

cables or other obstructions).

Boiler location should be such that the gas ignition

system components are protected from water (dripping,

spraying, rain, etc.) during appliance operation and

service (circulator replacement, condensate trap, control

replacement, etc.).

For a closet installation, ventilation openings must be

provided through a door or wall to prevent excessive

heat build-up. Two openings, one near the floor and one

near the ceiling, should be sized to assure sufficient air

circulation in the closet (minimum 64,516mm

2

[100 sq.

inches] each).

WARNING

LIQUEFIED PETROLEUM (L.P.) PROPANE FIRED

GAS BOILER LOCATION

REQUIRES SPECIAL ATTENTION

Liquefied Petroleum (L.P.) propane gas is heavier than

air. Therefore, propane boilers, piping, valves must NOT

be installed in locations where propane leaking from

defective equipment and piping will "pool" in a basement

or other space below the leak.

A spark or flame from the boiler or other source may

ignite the accumulated propane gas causing an

explosion or fire.

Provide a level, solid foundation for the boiler. Location

should be as near the chimney as possible so that the

flue pipe from boiler to the chimney is short and direct.

The UNIFORM MECHANICAL CODE may be in effect

in your geographic area.

The following precautions are cited by the 1994

UNIFORM MECHANICAL CODE, section 304.6 or CSA

B149.1-00 for natural gas and propane.

“LPG Appliances. Liquefied petroleum gas-burning

appliances shall not be installed in a pit, basement

or similar location where heavier-than-air-gas might

collect. Appliances so fueled shall not be installed in

an above-grade under-floor space or basement

unless such location is provided with an approved

means for removal of unburned gas.”

Consult Chapter 5 of the 1994 UNIFORM MECHANICAL

CODE for design criteria of the "approved" means for

removal of unburned gas.

SAFETY—

KEEP THE BOILER AREA CLEAR AND FREE FROM

COMBUSTIBLE MATERIALS, GASOLINE AND OTHER

FLAMMABLE VAPORS AND LIQUIDS.

BOILER FOUNDATION

A. Provide a solid, level foundation, capable of

supporting the weight of the boiler filled with water,

and extending at least 51mm (2") past the jacket on

all sides. See dimensions of boilers, page 2.

B. Boiler can be installed on both combustible and non-

combustible floors, but must NOT be installed on or

above carpeting.

C. If boiler is to be located over buried conduit

containing electric wires or telephone cables, consult

local codes or the National Board of Fire Underwriters

for specific requirements.

MINIMUM CLEARANCES

A. Minimum clearances to the exterior surfaces of the

boiler shall be as follows:

MINIMUM ALCOVE AND CLOSET CLEARANCE.

B. Provide 457mm (18") on sides used for passage.

For Combustible Recommended

Surface

Construction for Service

Front 51mm (2") 457mm (18")

Rear 51mm (2") 203mm (8")

Left Side 51mm (2") 457mm (18")

Right Side 51mm (2") 457mm (18")

Top 254mm (10") 254mm (10")

Flue Connector 76mm (3") 152mm (6")

C. All minimum clearances shown above must be met.

This may result in increased values of some

minimum clearances in order to maintain the

minimum clearances of others.

D. Clearance from hot water pipes shall be

25mm (1") **.

** At points where hot water pipes emerge from a

floor, wall or ceiling, the clearance at the opening

through the finished floor boards or wall or ceiling

boards may not be less than 13mm (1/2"). Each

such opening shall be covered with a plate of

noncombustible material.

3

INSTALLATION REQUIREMENTS

Page 4

APPROVED VENTING APPLICATIONS

This Concept 21 boiler is approved to be vented using

Direct Vent, Category I, or Category IV applications.

These applications are differentiated as follows:

Direct Vent — The air for combustion is piped directly to

the air intake of the boiler from outdoors. The vent piping

may be run horizontally or vertically to the outdoors, to a

common terminal with the combustion air intake or

separate from the combustion air intake means.

Category I— The air for combustion is taken from the

ambient air surrounding the boiler. The vent piping must

be upsized and run into a vertical chimney or vent which

will insure a non-positive vent pressure. There is only one

specified input rate for each model boiler on Category I

installations. See chart 2 on page 20.

Category IV— The air for combustion is taken from the

ambient air surrounding the boiler. The vent piping may be

run horizontally or vertically to the outdoors. The vent

pressure is typically positive in this application.

The following venting installation requirements are divided

into 3 sections, each pertaining to the 3 different

applications described above. Once the appropriate

venting application has been selected, follow only the

requirements specified under that section for venting the

boiler. These requirements must be carefully read and

followed in order to avoid any hazardous conditions due to

improper installation of the flue gas venting system.

DIRECT VENT APPLICATION REQUIREMENTS

VENTING LOCATION

Vent installations shall be in accordance with Part 7,

Venting of Equipment, of the National Fuel Gas Code,

ANSI Z223.1, and CSA B149.1-00 for natural gas and

propane, or applicable provisions of local building codes.

Vent termination must meet the following clearances:

Minimum of 305mm (12”) above grade and normal snow

line to vent terminal bottom; minimum of 305mm (12”)

from any building opening; minimum of 914mm (3 feet)

above any forced air intake located within 3048mm (10

feet); minimum of 1219mm (4 feet) horizontally from, and

in no case above or below, unless 1219mm (4-foot)

horizontal distance is maintained, from electric or gas

meters, regulators and relief equipment.

Vent termination must not be located over any public

walkway, in any confined space (i.e. window wells,

alcoves, narrow alleys) or under any overhang or deck.

Vent termination should not allow flue gas discharge

towards neighbor's windows or where personal injury or

property damage can occur.

DO NOT install the vent into a common venting system.

DO NOT install a vent damper or similar device in vent

tubing or on the boiler.

VENT MATERIAL

A. DO NOT use galvanized or plastic vent system

materials. The vent system for Direct Vent Applications

must be UL listed 76mm (3”) diameter corrosion

resistant stainless steel. The following manufacturer’s

systems are approved for use within a specified

minimum and maximum equivalent vent length for each

model of boiler. Refer to Slant/Fin Parts List, Publication

CB 10PL.

B. When joining the various components of the above

listed vent systems, the manufacturers’ instructions

should be closely followed to insure proper sealing

. Use

GE-RTV106 or Dow-Corning 732 sealant for sealing of

pipe and fittings. See Figure 4 for proper application of

vent pipe sealant.

C. All vent connections must be liquid and pressure tight.

4

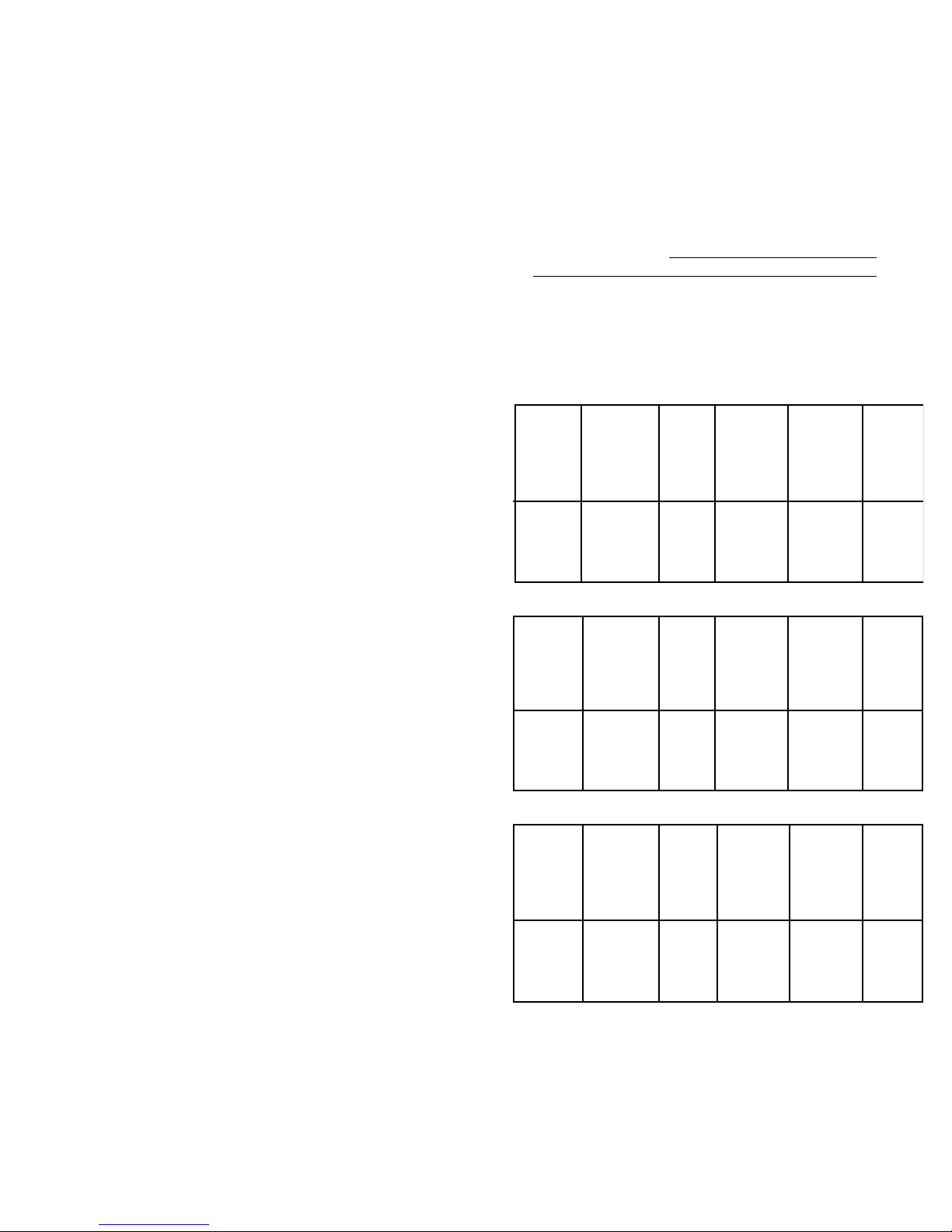

CB-45 30 100 5 914 3 1524 5 1

CB-90 30 100 5 914 3 1524 5 1

CB-135 24 80 5 914 3 1524 5 1

CB-180 12 40 5 914 3 1524 5 1

Boiler

Model

No.

Maximum

Equivalent

Length

including

Elbows

m ft

Max.

No. of

Elbows*

Equivalent

Length of

each

Elbow

mm ft

Minimum

Equivalent

Length*

mm ft

Min.

No. of

Elbows*

* All lengths specified include mandatory minimum use of 610mm (2

feet) of tubing plus one elbow from boiler to vent termination all

models.

Heat Fab Saf-T Vent System

CB-45 30 100 5 1829 6 2438 8 1

CB-90 30 100 5 1829 6 2438 8 1

CB-135 18 60 5 1829 6 2438 8 1

CB-180 9 30 3 1829 6 2438 8 1

Boiler

Model

No.

Maximum

Equivalent

Length

including

Elbows*

m ft

Max.

No. of

Elbows*

Equivalent

Length of

each

Elbow

mm ft

Minimum

Equivalent

Length*

mm ft

Min.

No. of

Elbows*

ProTech Fas-N Seal System

CB-45 30 100 5 1829 6 2438 8 1

CB-90 30 100 5 1829 6 2438 8 1

CB-135 21 70 5 1829 6 2438 8 1

CB-180 11 35 4 1829 6 2438 8 1

Boiler

Model

No.

Maximum

Equivalent

Length

including

Elbows*

m ft

Max.

No. of

Elbows*

Equivalent

Length of

each

Elbow

mm ft

Minimum

Equivalent

Length*

mm ft

Min.

No. of

Elbows*

Flex-L Star-34 System

Page 5

Figure 2. General Vent and Air Intake Piping from Boiler

for Direct Venting

All items shown below are REQUIRED. All vent

joints must be LIQUID and PRESSURE TIGHT.

Figure 3. Floor and ceiling venting passage

All items shown below are REQUIRED.

All vent joints must be LIQUID and PRESSURE TIGHT.

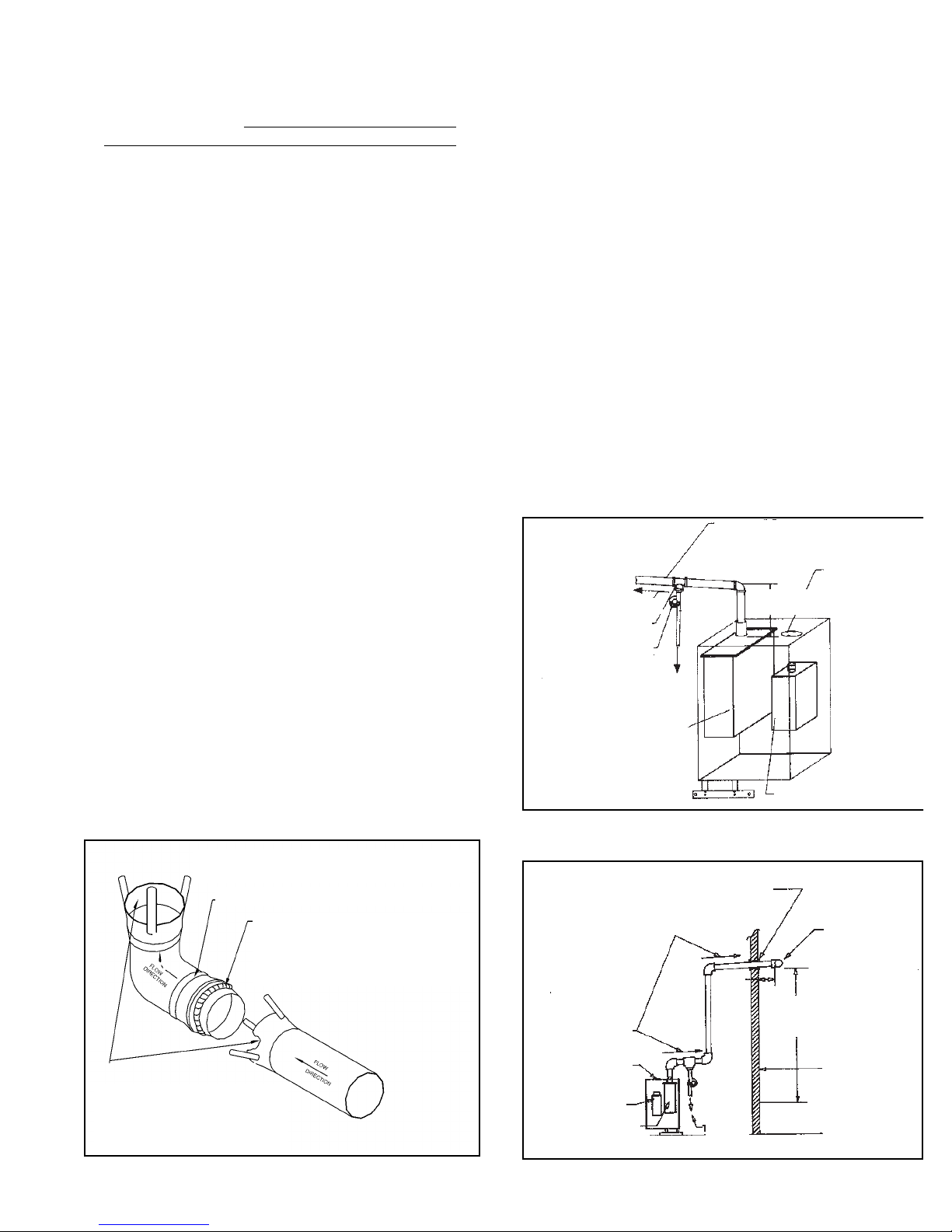

Figure 4. Vent sealing instructions

(Consult vent manufacturer’s instructions.)

5

DIRECT VENT APPLICATION REQUIREMENTS

AIR INTAKE

A. 76mm (3”) diameter PVC piping materials are

recommended. Sewer and drain type material or PVC

schedule 40 piping are best suited for connection to

boiler and vent terminal. Use 76mm (3”) PVC fitting

provided with vent kit to adapt PVC schedule 40 air

intake tubing to air filter box collar. The fitting provided

will fit onto the filter box collar and then a schedule 40

76mm (3”) coupling will fit over that.

B. The venting length requirements specified in this

section also apply to the air intake piping.

C. Seal all joints on air intake piping using appropriate

sealants.

VENTING INSTALLATION

A. Follow the vent material manufacturer’s instructions in

conjunction with these instructions for venting system

installation.

B. Refer to Figures 2, 3 and 4 which illustrate some of

the requirements for venting in a typical installation.

C. A condensate drain and drain trap MUST be installed

on the flue tubing, see Figure 2. The condensate

drain should be installed close to the boiler, as

shown, and must be equipped with a trap formed by

attaching 10mm (3/8”) I.D. clear plastic tubing to the

drain assembly, making a loop approximately 102mm

(4") diameter and securing with cord or a tie wrap

where the loop crosses over itself. This loop should

then be filled with water to form a liquid-filled trap.

DO NOT OPERATE THE BOILER WITHOUT

INSTALLING THIS TRAP AND FILLING WITH WATER

EXHAUST VENT PIPING 76mm (3”) I.D.

AIR INTAKE PIPING 76mm (3”) I.D.

76mm

(3”) PVC

FITTING.

152mm (6”)

MIN. 610mm

(24”) MAX.

CONTINUE WITH PIPING

AS SHOWN IN

FOLLOWING FIGURES

SLOPE UP

20mm/m (1/4”/FT)

CONDENSATE

DRAIN ASSY

FILL TRAP WITH

WATER

HEAT EXCHANGER

ASSY

TO DRAIN

AIR FILTER BOX ASSY

VENT SEALING INSTRUCTIONS FOR HEAT-FAB 29-4C

STAINLESS STEEL VENTING MATERIALS

RING

APPLY ADHESIVE BEAD (6mm [1/4”] DIA. MINIMUM)

AROUND OUTSIDE OF MALE END ONLY, BETWEEN

6mm (1/4”) AND 10 mm (3/8”) FROM THE EDGE OF

THE MALE END. CARE MUST BE TAKEN TO ASSURE

THAT ADHESIVE DOES NOT BLOCK INSIDE OF PIPE

DO NOT APPLY ADHESIVE INSIDE

OF FEMALE FITTINGS IN ORDER TO PREVENT

BLOCKAGE OF INSIDE OF FITTINGS AND TUBING.

IF ANY ADHESIVE SHOULD GET INSIDE, BE SURE

TO WIPE IT OUT BEFORE ASSEMBLING

FIRESTOP

EXHAUST VENT TUBING

76mm (3”) I.D.

CLEARANCE: 152mm

(6”) MIN. FOR 29-4C

STAINLESS STEEL

VENTING

FIRESTOP AND SUPPORT

AIR INTAKE

TUBING 76mm

(3”) I.D.

CLEARANCE:

51mm (2”) MIN.

BETWEEN TUBING

76mm (3”)

MIN. 610mm

(24”) MAX.

TO PREVENT FLUE GAS DISCHARGE INTO SPACE.

Periodic inspection should be made of this assembly for

deterioration of the tubing and to insure that the trap is

filled with water, but not plugged. If it is plugged or

appears to have excessive sediment in it, it should be

removed from the drain assembly, straightened out to clear

the obstruction, reformed, filled with water and reinstalled

as before. The drain must extend to a floor drain.

D. The horizontal pipe must be sloped UPWARD from

the boiler, at a pitch of 20mm/m (*1/4” per 1 foot) of

run, so that the condensate from the vent system runs

to the drain trap. The horizontal portion must also be

supported with 19mm (3/4”) pipe strap at intervals no

greater than 1829mm (6 feet).

E. The vertical portion of the pipe must be supported in

at least one location for each 9m (30 feet) of vertical

run. A firestop is required for each wall, ceiling and

floor penetration.

F. Use tabs on vent collar to secure stainless steel vent

tubing to the boiler.

G. Venting is approved for combustible wall passage

through a 102mm (4”) minimum to 305mm (12”)

maximum thick wall, providing a thimble is used.

Page 6

6

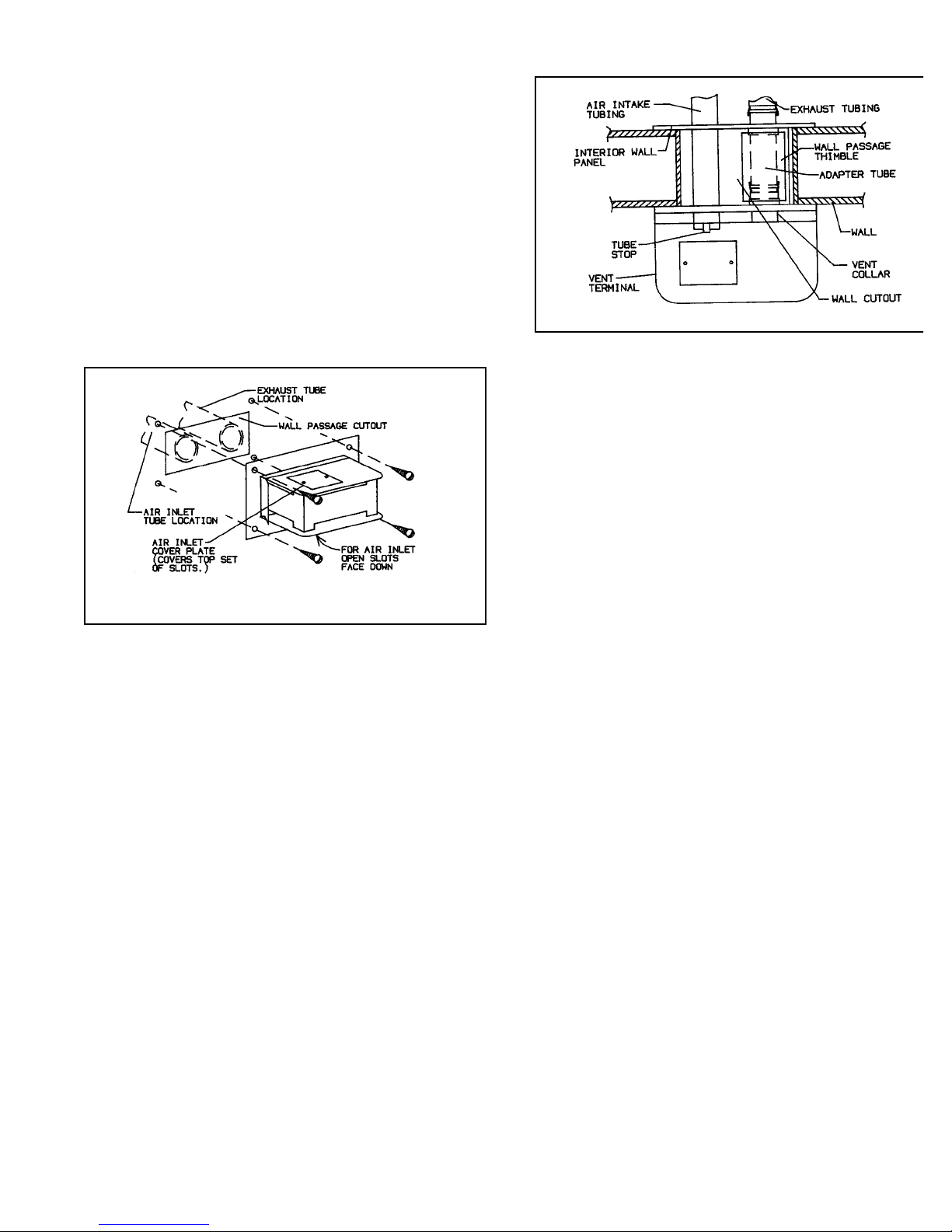

Figure 5a. Vent terminal orientation

Figure 5b. Vent terminal installation

VENT TERMINAL INSTALLATION

Warning: The vent terminal provided is to be used for

horizontal venting only. DO NOT alter this part in any

manner other than shown in these instructions. Only mount

on a vertical surface. DO NOT use when vertically venting

through a roof or chimney.

1. Wall cutout opening:

a) Cut out a rectangular opening 152mm (6”) high and

305mm (12”) wide in the appropriate location of an

exterior wall. Be sure that this location will allow for

the connection of vent materials that come in fixed

lengths, or an adjustable connector will be needed.

b) Boxing in the cutout with wood is allowable, but the

152mm x 305mm (6” x 12”) opening size must be

maintained.

c) Plan on the edge of the cutout to be about 76mm (3”)

from the center of the exhaust tube, when installed.

2. Vent terminal orientation: see Figure 5a.

a) The open slots for the air intake on the vent terminal

must face downward.

b) The air inlet cover plate must face upward to insure

that rain, debris and flue gases do not enter the air

inlet.

3. Vent and air intake tubing orientation: see Figure 5a.

a) Air inlet tubing may be located to the left or to the

right of the flue exhaust tubing.

b) If the air inlet tubing is going to be to the left of the

flue exhaust (viewed from outside of building) then

the vent terminal should be installed as supplied

without alteration.

c) If the air inlet tubing is going to be to the right of t

flue exhaust (viewed from outside building) then t

air inlet cover plate must be removed and reinstall

over the alternate set of slots. This alteration w

insure that the air inlet slots face down when the ve

terminal is installed.

4. Vent terminal installation: see Figure 5b.

a) Center the vent terminal over the wall cutout. T

collar on the back of the vent terminal panel shou

clear the cutout edges by about 12mm (1/2”).

b) Mark and drill out the location of the four screw hol

in the wall for mounting vent terminal.

c) Seal the vent collar adapter tube 76mm (3”) dia. ma

end stainless) into the collar on the back of the ve

terminal box and slide the ring on the tube over t

collar tabs, then bend the tabs back over the rin

This piece will allow easy connection of the fl

exhaust tubing from inside the building.

d) Run a bead of silicone around the perimeter of w

panel and vent collar to prevent water and drafts fro

entering building.

e) Orientate the vent terminal on the wall as describ

in Step 2 and secure it to the wall.

5. Interior wall panel installation:

a) Cut the wall thimble 127mm (5”) diameter galv. pip

about 12mm (1/2”) shorter than the wall thickness

b) Fit thimble onto the collar on the back of the ve

terminal inside the wall.

c) Hold the interior wall panel up to the wall cutout a

fit the collar on this panel into the thimble. Line up t

air inlet holes and secure to wall.

6. Vent and air intake tubing installation to vent terminal:

a) Finish tubing connections back to the boil

following

the requirements in the venting installati

instructions

on pages 4 and 5.

b) Exhaust tubing connects to the vent collar adapt

tube. Observe correct flow direction.

c) Air intake tubing should slip into the air inlet openi

in the back of the vent terminal. Make sure the tubi

extends into the vent terminal box as far as the tu

stop inside the box allows (19mm [3/4”] approx

Seal around the air intake tubing where it pass

through the outside wall plate.

*Shown with air inlet to the left of exhaust

from outside view.

* Shown from top view.

DIRECT VENTING WITH VENT TERMINAL

All Concept 21 boiler models are certified for horizontal

Direct Venting utilizing the vent terminal provided by

Slant/Fin only.

This vent terminal must be mounted on a vertical wall

outside surface. Terminal CANNOT be mounted on a roof

or any horizontal surface.

Vent terminal is designed to deflect flue gases away from

outside building wall; properly installed, it will prevent flue

gas degradation of normal building materials and reduce

the possibility of air intake freeze-up. It is recommended

to utilize this vent terminal on Direct Vent applications

whenever the installation permits.

Page 7

Figure 7a. Vent and air intake run through a pitched roof

Figure 7b. Vent and air intake run through a flat roof

7

EXHAUST WITH SCREEN

AIR INTAKE 180° ELBOW

WITH SCREEN FACE

DOWN

3048mm (10 ft)

or less

610mm (2 ft) min.

ROOF FLASHING

54mm (2“) min.

305mm

(1 ft) min.

54mm (2“) min.

ROOFLINE

SNOWLINE

EXHAUST WITH

SCREEN

3048mm (10 ft)

or less

610mm (2 ft) min.

ROOF

LINE

SNOW

LINE

ROOF FLASHING

54mm (2”) min.

54mm (2”) min.

AIR INTAKE 180° ELBOW

WITH SCREEN FACE DOWN

305mm (1 ft) min.

305mm (1 ft) min.

914mm

(3 ft)

min.

305mm

(1 ft) min.

914mm

(3 ft) min.

Vertical Venting Configurations

All Concept 21 boiler models are certified for vertical

Direct Venting utilizing the following configurations.

1. Vent and air intake piping vertically run up through a

roof in close proximity.

a. For a pitched roof installation, refer to Figure 7a. For

a flat roof installation, refer to Figure 7b. When floor

and ceiling passage is necessary, refer to Figure 3.

Adhere to all clearances and materials specified in

these illustrations.

b. The stainless exhaust vent pipe must pass through

the roof vertically through a 178mm (7”) min.

diameter cutout and appropriate roof flashing. The

pipe must exhaust straight up and terminate with a

screen terminator.

c. The air intake pipe must pass through the roof

vertically. The cutout does not require any clearance,

but must be sealed with a flashing or other means.

The air intake opening must face down by using a

180° elbow with a screen positioned at the opening.

The air intake opening must be at least 305mm (1

foot) below the vent opening.

DIRECT VENTING WITHOUT VENT TERMINAL

Page 8

Figure 8b. Vent piping vertically run up an existing chimney

and air intake horizontally run out a vertical wall.

Figure 8a. Vent run through a roof and air intake run through

a wall

8

REFER TO VENT PIPE

REQUIREMENTS SHOWN IN

PREVIOUS FIGURES FOR

VENT AND AIR INTAKE RUN

THROUGH A PITCHED OR

FLAT ROOF

EXHAUST WITH SCREEN

AIR INTAKE 90° ELBOW WITH

SCREEN FACE DOWN

SNOWLINE

305mm (1 ft) min.

GROUNDLINE

CONDENSATE DRAIN ASSY

TO DRAIN

HEAT EXCHANGER

ASSY

AIR FILTER

BOX ASSY

Slope up

20mm/m

(1/4” per ft)

RUN AIR INTAKE PIPE

THROUGH THE

FOUNDATION OR AN

EXTERIOR WALL

REFER TO

PREVIOUS FIGURE

FOR FLOOR AND

CEILING PASSAGE

ROOF LINE

3048mm

(10 ft) or

less

EXHAUST WITH

SCREEN

305mm (1 ft) min.

CHIMNEY TOP PLATE

AIR INTAKE 90° ELBOW

WITH SCREEN FACE

DOWN

SNOWLINE

305mm (1 ft) min.

GROUNDLINE

CONDENSATE DRAIN ASSY

TO DRAIN

HEAT EXCHANGER

ASSY

AIR FILTER

BOX ASSY

SLOPE UP

20mm/m

(1/4” per ft)

RUN AIR INTAKE PIPE

THROUGH THE

FOUNDATION OR AN

EXTERIOR WALL

SEAL CHIMNEY OPENING

WITH MORTAR OR

COVER PLATE

610mm

(2 ft) min.

Vertical Venting Configurations

2. Vent piping vertically run up through a roof and air

intake horizontally run out a vertical wall.

a. See Figure 8a for general configuration. For a

pitched roof installation, refer to vent pipe

requirements shown in Figure 7a. For a flat roof

installation, refer to the vent pipe requirements

shown in Figure 7b. When floor and ceiling passage

is necessary, refer to Figure 3. Adhere to all

clearances and materials specified in these

illustrations for installing the vent pipe only. For

installing the air intake pipe, refer to the air intake

requirements shown in Figure 8a.

b. The stainless exhaust vent pipe must pass through

the roof vertically through a 178mm (7”) min.

diameter cutout and appropriate roof flashing. The

pipe must exhaust straight up and terminate with a

screen terminator.

c. The air intake pipe must pass through a vertical wall

or foundation horizontally. The cutout does not

require any clearance, but must be sealed with a

flashing or by other means. The air intake opening

must face down by using 90° elbow with a screen

positioned at the opening.

3. Venting piping vertically run up an existing chimney

and air intake horizontally run out a vertical wall.

a. Refer to Figure 8b. Adhere to all clearances and

materials specified in this illustration.

b. The stainless exhaust vent pipe must extend the

total length of the chimney. The pipe must exhaust

straight up and terminate with a screen terminator.

The top of the chimney must be sealed off around

the protruding pipe with an appropriate plate or

flashing. Other appliances CANNOT be vented into

the same chimney or vent pipe within the chimney.

c. The air intake pipe must pass through a vertical wall

or foundation horizontally. The cutout does not

require any clearance, but must be sealed with a

flashing or by other means. The air intake opening

must face down by using a 90° elbow with a screen

positioned at the opening.

DIRECT VENTING WITHOUT VENT TERMINAL

Page 9

BOILER ROOM AIR SUPPLY AND VENTILATION

An ample supply of air is required for combustion and

ventilation. When buildings are insulated, caulked and

weather-stripped, now or later on, direct openings to outside

may be required and should be provided. If the boiler is not

near an outside wall, air may be ducted to it from outside

wall openings.

Provisions for combustion and ventilation air must be made

in accordance with section 5.3, Air for Combustion and

Ventilation, of the National Fuel Gas Code, ANSI Z223.1 and

CSA B149.1-00 for natural gas and propane

, or applicable

provisions of the local building codes. The following

recommendation applies to buildings of energy-saving

construction, fully caulked and weather- stripped:

Provide one GRILLED opening near the floor and one near

the ceiling on an outside wall near the boiler (or duct from

such openings to the boiler), EACH opening to be a

minimum of 645mm

2

(one square inch) per 586w (2000 Btuh)

input to ALL

APPLIANCES in the area. For a total appliance

input of 58 620w

(200,000 Btuh), each opening will be 64 516

mm

2

(100 square inches). A grilled opening 254mm x 254mm

(10"X10") has 64 516mm

2

(100 square inches) of area. If fly

screen must be used over openings, double the area and

inspect and clean the screen frequently.

Openings must never be reduced or closed. If doors or

windows are used for air supply, they must be locked open.

Protect against closure of openings by snow and debris.

Inspect frequently.

No mechanical draft exhaust or supply fans are to be used in

or near the boiler area.

The flow of combustion and ventilating air to the boiler must

not be obstructed.

The air inlet passage hole located on the top of the boiler

jacket should be covered for any installation which does not

require combustion air to be piped into the boiler. (i.e. Direct

Vent Installation)

VENTING LOCATION REQUIREMENTS

Vent installations shall be in accordance with Part 7, Venting

of Equipment, of the National Fuel Gas Code, ANSI Z223.1

and

CSA B149.1-00 for natural gas and propane, or

applicable provisions of local building codes.

This Concept 21 boiler is approved for pressure venting both

horizontally and vertically. The following requirements apply

to both types of venting installation.

Vent termination must meet the following clearances:

Minimum of 305mm (12”) above grade and normal snow line

to vent termination bottom; minimum of 1219mm (4 feet)

below or horizontally, or 305mm (1 foot) above any building

opening; minimum of 914mm (3 feet) above any forced air

intake located within 3048mm (10 feet); minimum of 1219mm

(4 feet) horizontally from, and in no case above or below,

unless 1219mm (4-foot) horizontal distance is maintained,

from electric or gas meters, regulators and relief equipment.

Vent termination must not be located over any public

walkway, in any confined space (i.e. window wells,

alcoves, narrow alleys) or under any overhang or deck.

Vent termination should not allow flue gas discharge

towards neighbor's windows or where personal injury or

property damage can occur.

DO NOT install the vent into a common venting system.

DO NOT install a vent damper or similar device in vent

tubing or on the boiler.

VENT MATERIAL REQUIREMENTS

A. DO NOT use galvanized or plastic vent system

materials. The vent system for Category IV applications

must be UL listed 76mm (3”) diameter corrosion

resistant stainless steel. The following manufacturer’s

systems are approved for use within a specified

minimum and maximum equivalent vent length for each

model of boiler.

Category IV Venting Requirements

CB-45 30 100 5 914 3 1524 5 1

CB-90 30 100 5 914 3 1524 5 1

CB-135 24 80 5 914 3 1524 5 1

CB-180 12 40 5 914 3 1524 5 1

Boiler

Model

No.

Maximum

Equivalent

Length

including

Elbows

m ft

Max.

No. of

Elbows*

Equivalent

Length of

each

Elbow

mm ft

Minimum

Equivalent

Length*

mm ft

Min.

No. of

Elbows*

* All lengths specified include mandatory minimum use of 610mm (2

feet) of tubing plus one elbow from boiler to vent termination all

models.

Heat Fab Saf-T Vent System

CB-45 30 100 5 1829 6 2438 8 1

CB-90 30 100 5 1829 6 2438 8 1

CB-135 18 60 5 1829 6 2438 8 1

CB-180 9 30 3 1829 6 2438 8 1

Boiler

Model

No.

Maximum

Equivalent

Length

including

Elbows*

m ft

Max.

No. of

Elbows*

Equivalent

Length of

each

Elbow

mm ft

Minimum

Equivalent

Length*

mm ft

Min.

No. of

Elbows*

ProTech Fas-N Seal System

CB-45 30 100 5 1829 6 2438 8 1

CB-90 30 100 5 1829 6 2438 8 1

CB-135 21 70 5 1829 6 2438 8 1

CB-180 11 35 4 1829 6 2438 8 1

Boiler

Model

No.

Maximum

Equivalent

Length

including

Elbows*

m ft

Max.

No. of

Elbows*

Equivalent

Length of

each

Elbow

mm ft

Minimum

Equivalent

Length*

mm ft

Min.

No. of

Elbows*

Flex-L Star-34 System

Page 10

B. When joining the various components of the above

listed vent systems, the manufacturers’ instructions

should be closely followed to insure proper sealing. Use

GE-RTV106 or Dow-Corning 732 sealant for sealing of

pipe and fittings. See Figure 4 for proper application of

vent pipe sealant.

C. All vent connections must be liquid and pressure tight.

VENTING INSTALLATION

A. Follow the vent material manufacturer’s instructions in

conjunction with these instructions for venting system

installation.

B. Refer to Figures 4 and 9 which illustrate some of the

requirements for venting in a typical installation.

C.

A condensate drain and drain trap MUST be installed on

the flue tubing, see Figure 9. The condensate drain should

be installed close to the boiler, as shown, and must be

equipped with a trap formed by attaching 9mm (3/8") I.D.

clear plastic tubing to the drain assembly, making a loop

approximately 102mm (4") diameter and securing with cord

or a tie wrap where the loop crosses over itself. This loop

should then be filled with water to form a liquid-filled trap.

DO NOT OPERATE THE BOILER WITHOUT INSTALLING

THIS TRAP AND FILLING WITH WATER TO PREVENT

FLUE GAS DISCHARGE INTO SPACE. Periodic inspection

should be made of this assembly for deterioration of the

tubing and to insure that the trap is filled with water, but not

plugged. If it is plugged or appears to have excessive

sediment in it, it should be removed from the drain

assembly, straightened out to clear the obstruction,

reformed, filled with water and reinstalled as before. The

drain must extend to a floor drain.

D. The horizontal pipe must be sloped UPWARD from the

boiler, at a pitch of 20mm/m (1/4” per 1 foot) of run, so

that the condensate from the vent system runs to the

drain trap. The horizontal portion must also be

supported with 19mm (3/4”) pipe strap at intervals no

greater than 1828mm (6 feet).

Category IV Venting Requirements

E.

The vertical portion of the pipe must be supported in at leas

one location for each 9m (30 feet) of vertical run. A firestop

is required for each wall, ceiling and floor penetration.

F. Use tabs on vent collar to secure stainless steel vent

tubing to the boiler.

G. Venting is approved for combustible wall passage

through a 102mm (4”) minimum to 305mm (12”)

maximum thick wall, providing a thimble is used.

HORIZONTAL CATEGORY IV VENTING

All Concept 21 boiler models are certified for horizontal

Category IV venting provided the following conditions are met

1. For combustible wall passage of vent piping, a UL and

CUL listed thimble must be used, providing the wall

thickness is 102mm (4”) minimum to 305mm (12”)

maximum.

2. The venting piping must terminate with a screened tee,

elbow, or straight termination at the minimum distance

from the outside wall shown in Figure 10.

10

Figure 9. General Vent Piping from Boiler for Category IV Ventin

All items shown below are REQUIRED.

All vent joints must be LIQUID and PRESSURE TIGHT.

Figure 4. Vent sealing instructions

(Consult vent manufacturer’s instructions.)

Figure 10. Horizontal Category IV Venting through outside wall

CONTINUE WITH VENT

PIPING AS SHOWN IN

FOLLOWING FIGURES

EXHAUST VENT

PIPING 76MM (3”) I.D.

AIR INLET COVER

203mm (8”) MIN.

610mm (24”) MAX.

AIR FILTER BOX ASSY.

HEAT

EXCHANGER

ASSY.

TO DRAIN

FILL TRAP WITH WATER

CONDENSATE DRAIN ASSY.

SLOPE UP 20mm/m (1/4” PER FT.)

76mm (3”) MIN.

610mm (24”) MAX.

VENT SEALING INSTRUCTIONS FOR HEAT-FAB 29-4C

STAINLESS STEEL VENTING MATERIALS

RING

APPLY ADHESIVE BEAD (6mm [1/4”] DIA.

MINIMUM) AROUND OUTSIDE OF MALE END ONLY,

BETWEEN 6mm (1/4”) AND 9mm (3/8”) FROM THE

EDGE OF THE MALE END.

CARE MUST BE TAKEN TO ASSURE THAT

ADHESIVE DOES NOT BLOCK INSIDE OF PIPE

DO NOT APPLY ADHESIVE INSIDE

OF FEMALE FITTINGS IN ORDER TO

PREVENT BLOCKAGE OF INSIDE OF

FITTINGS AND TUBING. IF ANY ADHESIVE

SHOULD GET INSIDE, BE SURE TO WIPE IT

OUT BEFORE ASSEMBLING

WALL

THIMBLE

VENT

TERMINATION

WITH SCREEN

305mm

(1 FT.)

MIN.

OUTSIDE WALL

SNOW LINE

GROUNDLINE

HEAT EXCHANGER

ASSY.

AIR FILTER BOX

ASSY.

AIR INLET COVER

VENT PIPE

SLOPE UP 20mm/m

(1/4” PER FT.)

102mm

(4”)

MIN.

TO

DRAIN

Page 11

1

Figure 11. Vertical Category IV Venting through a roof Figure 12. Vertical Category IV Venting up an existing

chimney

VERTICAL CATEGORY IV VENTING

All Concept 21 boiler models are certified for vertical

Category IV venting through a roof provided the

following conditions are met:

1. For roof passage of vent piping, a CUL listed roof

flashing must be used.

2. The vent piping must terminate with a screened tee,

elbow, straight, or cap termination at the minimum

distance from the roof shown in Figure 11.

All Concept 21 boiler models are certified for vertical

Category IV venting up an existing chimney provided the

following conditions are met:

1. To utilize an existing chimney as a chase, the vent

pipe must extend the total length of the chimney. The

top of the chimney must be sealed off around the

protruding pipe with an appropriate plate or flashing.

2. The vent piping must terminate with a screened tee,

elbow, straight or cap termination at the minimum

distance from the roof shown in Figure 12.

3. Other appliances CANNOT be vented into the same

chimney or vent pipe within the chimney.

VENT TERMINATION WITH

SCREEN

305mm (1 FT.) MIN.

SNOWLINE

ROOFLINE

FIRESTOP AND

SUPPORT

152mm (6”) MIN.

CLEARANCE

CONDENSATE DRAIN

ASSY.

TO DRAIN

HEAT EXCHANGER

ASSY.

AIR FILTER BOX

ASSY.

AIR INLET COVER

SLOPE UP 20mm/m (1/4” PER FT.)

FIRE STOP AND

SUPPORT

ROOF FLASHING

610mm (2 FT.) MIN.

3048mm

(10 FT.)

OR LESS

VENT TERMINATION WITH

SCREEN

305mm (1 FT.) MIN.

CHIMNEY TOP PLATE

SEAL CHIMNEY OPENING

WITH MORTAR OR COVER

PLATE

CONDENSATE DRAIN

ASSY.

TO DRAIN

HEAT EXCHANGER

ASSY.

AIR FILTER BOX

ASSY.

AIR INLET COVER

SLOPE UP 20mm/m (1/4” PER FT.)

610mm (2 FT.) min.

ROOF LINE

3048mm

(10 FT.)

OR LESS

Page 12

VENTING REQUIREMENTS

If the boiler vent is to be installed into a natural draft

masonry chimney or Type “B” venting, it must be in

accordance with Part 7, Part 11 and Appendix G,

of the

National Fuel Gas Code, ANSI Z223.1 and

CSA B149.1-00 for

natural gas and propane

.

For a masonry vitreous tile-lined chimney which is not

exposed to the outdoors, use Table 1 in this Slant/Fin

manual for venting requirements. DO NOT install this

system into an unlined masonry chimney.

If a masonry chimney is exposed to the outdoors on one or

more sides below the roof line (exposed chimney), it must

be re-lined with a UL listed metallic liner system. See Table

2 in this Slant/Fin manual for venting requirements of

metallic re-lined chimneys.

If a Type “B” vent system is used, it must NOT be exposed

to the outdoors below the roof line. See Table 2 in this

Slant/Fin manual for venting requirements. Vent

connectors serving appliances vented by natural draft shall

NOT be connected into any portion of mechanical draft

systems operating under positive pressure. Single or

multiple appliance venting is shown in Figures 13 and 14.

The 76mm to 127mm (3” to 5”) vent adapter MUST be used

on the vent collar of ALL models of the Concept boiler for

these installations. In some cases, the vent connector

diameter must be upsized further to 152mm or 178mm (6”

or 7”). Refer to Table 1 and 2 for installations requiring this

increased size.

Standard vent connector materials such as galvanized or

stainless steel are allowed for these installations. NO types

of plastic material can be used as a part of the venting

system in any installation.

All Concept boilers require a condensate drain and drain

trap. Vent connectors must be liquid tight.

The condensate drain should be installed as close to the

boiler as possible and must be equipped with a trap formed by

attaching 9mm (3/8") I.D. clear plastic tubing to the drain

assembly, making a loop approximately 102mm (4") diameter

and securing with cord or a tie wrap where the loop crosses

over itself. This loop should then be filled with water to form a

liquid filled trap. DO NOT OPERATE THE BOILER WITHOUT

INSTALLING THIS TRAP AND FILLING WITH WATER. Periodic

inspection should be made of this assembly for deterioration

of the tubing and to insure that the trap is filled with water, but

not plugged. If it is plugged or appears to have excessive

sediment in it, it should be removed from the drain assembly,

straightened out to clear the obstruction, reformed, filled with

water and reinstalled as before. The drain should extend to a

floor drain or to a plastic container which may require

emptying periodically.

Category I Venting Requirements

BOILER ROOM AIR SUPPLY AND VENTILATION

An ample supply of air is required to obtain combustion

and ventilation. When buildings are insulated, caulked and

weather-stripped, now or later on, direct openings to

outside may be required and should be provided. If the

boiler is not near an outside wall, air may be ducted to the

installation area from outside wall openings.

Provisions for combustion and ventilation air must be made

in accordance with section 5.3, Air for Combustion and

Ventilation,

of the National Fuel Gas Code, ANSI Z223.1 and

CSA B149.1-00 for natural gas and propane, or applicable

provisions of the local building codes. The following

recommendation applies to buildings of energy-saving

construction, fully caulked and weather stripped:

Provide one GRILLED opening near the floor and one near th

ceiling on an outside wall near the boiler (or duct from suc

openings to the boiler), EACH opening to be a minimum o

645 mm

2

(one square inch) per 586w (2000 Btuh) input to AL

APPLIANCES in the area. For a total appliance input of 58,620w

(200,000 Btuh), each opening will be 64 516mm2 (100 squar

inches). A grilled opening 254mm x 254mm (10"X10") ha

64 516mm

2

(100 square inches) of area. If fly screen must b

used over openings, double the area and inspect and clea

the screen frequently.

Openings must never be reduced or closed. If doors o

windows are used for air supply, they must be locked open

Protect against closure of openings by snow and debris

Inspect frequently.

No mechanical draft exhaust or supply fans are to be used

in or near the boiler area.

The flow of combustion and ventilating air to the boile

must not be obstructed.

The air inlet passage hole located on the top of the boile

jacket should be left covered with the plate provided, to

prevent debris from falling into the air intake.

On all Category I installations, the air pressure switch provided

on the boiler must be replaced with the switch provided in ven

kit 665194. This switch is set to prevent the boiler from

operating below the approved Category I input rate.

12

Page 13

1

Natural Draft Chimney and Type “B” Venting Diagrams

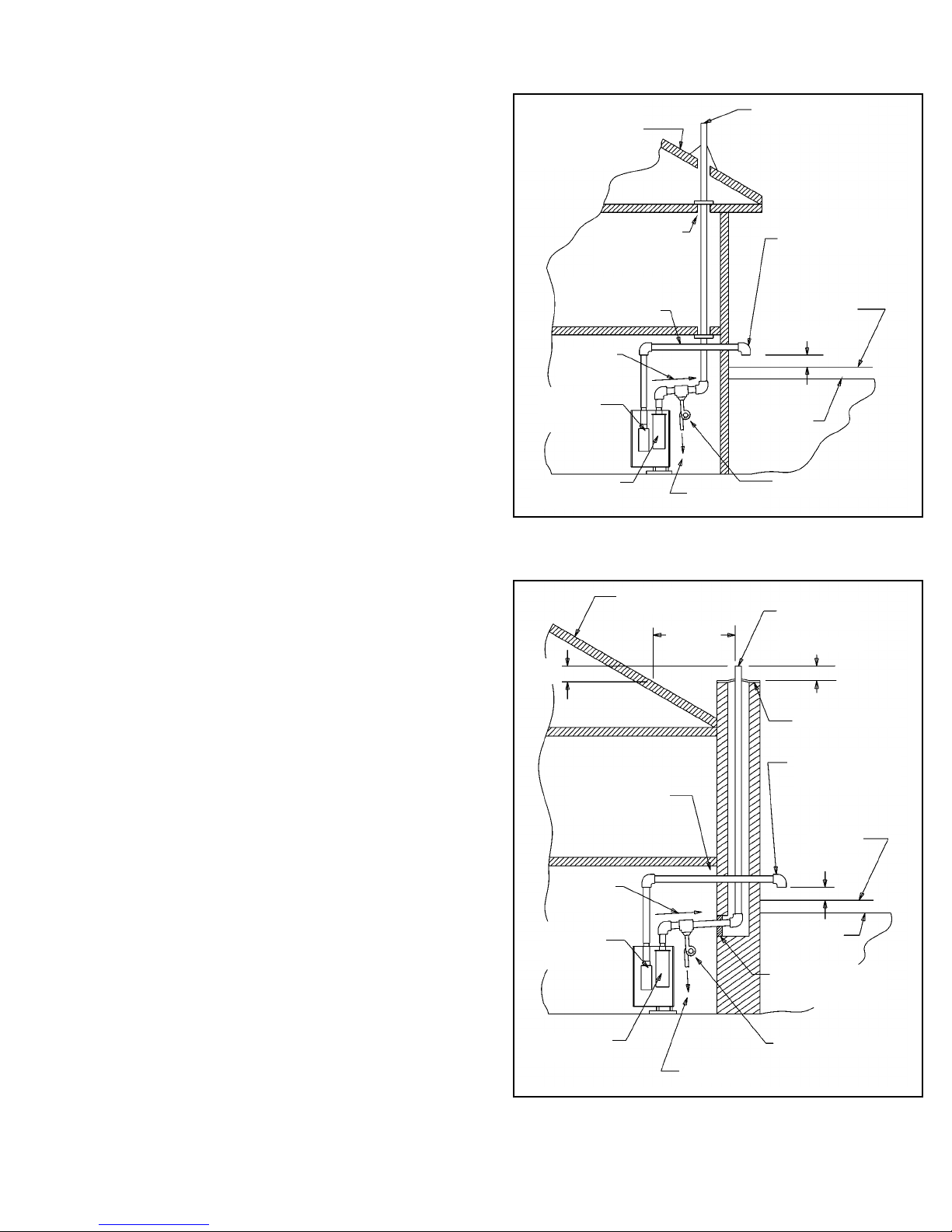

Figure 13. Chimney Venting for models specified in Table 1 only.

Minimum vent connectors diameter is 127mm (5 inches). It may have to be upsized to 152mm or 178mm (6 or 7

inches) [see Table 1].

Single or multiple appliance venting into chimney using single wall or type “B” metal connectors. Must be installed in

accordance with part 7 or 11 of the National Fuel Gas Code, ANSI Z223.1 and CSA B149.1-00 for natural gas and

propane. DO NOT use galvanized risers and connectors in cool boiler rooms.

ALL ITEMS SHOWN BELOW ARE REQUIRED.

All vent connector joints must be liquid tight.

Figure 14. Venting with “B” vent or metal-lined chimney for models specified in Table 2 only.

Minimum vent connectors diameter is 127mm (5 inches). It may have to be upsized to 152mm or 178mm (6 or

7 inches) [see Table 2].

Single or multiple appliance venting into Type “B” double wall metal vent with single or Type “B” metal connectors. Must

be installed in accordance with part 11 of the National Fuel Gas Code, ANSI Z223.1 and CSA B149.1-00 for natural gas

and propane. DO NOT use galvanized risers and connectors in cool boiler rooms.

ALL ITEMS SHOWN BELOW ARE REQUIRED EXCEPT WHERE OTHERWISE INDICATED.

All vent connector joints must be liquid tight.

TYPE “B” VENT

OTHER GAS

APPLIANCE

ADDITIONAL CONDENSATE DRAIN: A

DRAIN AT THE BOTTOM OF THE “B”

VENT MAY BE NECESSARY IF

OTHER APPLIANCES OR THE VENT

IS CONDENSING

TO DRAIN OR

CONTAINER

FILL TRAP WITH

WATER

BOILER

CONDENSATE

DRAIN

ASSEMBLY

TO DRAIN OR

CONTAINER

FILL TRAP WITH

WATER

CONCEPT

BOILER

INSTALL 127mm

(5”) VENT

ADAPTER

610mm (24”) MIN.

203mm (8”) MAX.

152mm (6”) MIN.

406mm (16”) MAX.

CONNECTORS:

PITCH UP TO CHIMNEY

20mm/m (1/4” PER FT.) MIN.

INSTALL WITH SEAM ON TOP

305mm (12”)

MIN.

CONNECTORS: PITCH UP TO

CHIMNEY 20mm/m (1/4” PER FT.)

MIN. INSTALL WITH SEAM ON TOP

152mm (6”) MIN.

457mm (18”) MAX.

610mm (24”) MIN.

203mm (8”) MAX.

INSTALL 127mm

(5”) VENT ADAPTER

CONCEPT

BOILER

TO DRAIN OR CONTAINER

FILL TRAP

WITH WATER

BOILER

CONDENSATE

DRAIN

ASSEMBLY

305mm (12”) MIN.

CHIMNEY (NOT EXPOSED TO THE

OUTDOORS BELOW THE ROOF

LINE)

OTHER

GAS

APPLIANCE

Page 14

14

Natural Draft Chimney and Type “B” Venting Tables

Table 1. Masonry Vitreous Tile-Lined Chimney (not metal lined)

Chimneys not exposed to the outdoors below the roof line. (127mm [5"] dia. vent adapter must be used)

Concept Additional CSA B149.1-00

Boiler Gas Appliance for natural gas

Model(s) † in Venting System Connector Requirements* and propane

CB-90 No Type “B” 1.

Connector diameter must be upsized to 178mm (7").

Table 5

CB-135 2.

Chimney height limits: Min. 4.6m (15 ft.), Max. 9.1m (30 ft.)

CB-180 3. Lateral length restriction applies (see Table 11-3)

4.

Internal area of chimney: Min. 32 200mm2 (50 sq. in.),

Max. 173 500mm2 (269 sq. in.)

CB-180 No Single-wall 1.

Connector diameter must be upsized to 178mm (7").

Table 6

2.

Chimney height limits: Min. 4.6m (15 ft.), Max. 9.1m (30 ft.)

3. Max. lateral length may not exceed 610mm (2 ft.)

4.

Internal area of chimney: Min. 32 200mm2 (50 sq. in.),

Max. 173 500mm2 (269 sq. in.)

CB-90 Yes Type “B” 1. See Table 7 for chimney height and connector Table 7

CB-135 length restrictions.

CB-180 2.

Connector may have to be upsized to 152mm (6") diameter

to meet requirement of Table 7.

CB-135 Yes Single-wall 1. See Table 8 for chimney height and connector Table 8

CB-180 length restrictions.

2.

Connector may have to be upsized to 152mm (6") diameter

to meet requirement of Table 8.

Table 2. Type “B” Venting and Metal-Lined Masonry Chimney

UL LISTED MATERIALS ONLY. (127 mm [5"] dia. vent adapter must be used)

Concept Additional CSA B149.1-00

Boiler Gas Appliance for natural gas

Model(s) † in Venting System Connector Requirements* and propane

All Models No Type “B” See Table 1 for minimum and maximum of vent Table 1

height and lateral length restriction.

CB-90 No Single-wall See Table 2 for minimum and maximum of vent Table 2

CB-135 height and lateral length restriction.

CB-180

CB-90 Yes Type “B” 1. See Table 3 for vent height and connector Table 3

CB-135 length restrictions.

CB-180 2.

Connector and vent diameter may have to be increased

to 152mm or 178mm (6" or 7") to meet requirement

of Table 3.

CB-90 Yes Single-wall 1. See Table 4 for vent height and connector Table 4

CB-135 length restrictions.

CB-180 2.

Connector and vent diameter may have to be

increased

to 152mm (6") to meet requirement of Table 4.

† Only Concept boiler models shown for each application permitted to be installed in that manner specified.

Page 15

FILL AND PURGE HEATING SYSTEM

• Make sure flow direction arrows on components are

facing in direction of flow.

• Place bucket under pressure relief valve discharge.

Baseboard & radiant floor systems

• Close all shutoff valves, drain valves and air vents.

• Open supply shutoff valve and return drain valve on

first zone (or return drain valve on non-zoned system).

If zoned with zone valves, manually open zone valve.

• Attach a hose from return drain valve to a drain. Open

fill line shutoff valve. Manually operate fill valve

regulator. When water runs out of hose in a steady

stream (with no air bubbles), close return drain valve.

• Repeat procedure for additional zones (one at a time).

• On completion, open all return shutoff valves.

Standing iron radiation & systems

with manual vents at high points

• Close all shutoff valves, drain valves and air vents.

• Open supply and return shutoff valves. If zoned with

zone valves, manually open all zone valves.

• Open fill line shutoff valve. Manually operate fill valve

regulator. Open pressure relief valve manual operator

to fill boiler. When water runs out of discharge pipe in

a steady stream (with no air bubbles), close operator.

• Starting with nearest manual air vent, open vent until

water flows out; close vent. Repeat procedure,

working your way toward farthest air vent.

When finished

• Place fill valve regulator and all zone valve operators in

automatic position.

• Check that temperature/pressure gage reads minimum

of 82.7 kPa (12 psi) (fill pressure) cold. If piping

system rises more than 4877mm (16 ft.) vertically

above boiler, higher fill pressures are required.

• Check for and repair any water leaks.

15

WATER PIPING

Always follow good piping practices. Observe minimum

25mm (1") clearance to combustibles around all

uninsulated hot water pipes or when openings around

pipes are not protected by non-combustible materials.

On a hot water boiler installed above radiation level, the

boiler must be provided with a low water cut off device at

the time of installation by the installer.

Boiler must not be used in connection with a refrigeration

system. If the boiler supplies hot water to heating coils in

air handling units, flow control valves or other devices

must be installed to prevent gravity circulation of boiler

water in the coils during the cooling cycle.

Expansion T

ank: Install into water outlet manifold as

shown in Figure 11. Use appropriate size tank for volume

of water in system. Boiler volume on page 2 chart.

Relief V

alve Discharge Piping: Use same size or larger

piping (iron or copper) than valve outlet. Must terminate

152mm (6") from floor (or local codes) with a plain (no

threads) end. Do not hard-pipe to drain piping. Make

sure discharge is always visible.

Cold W

ater Fill: Pressure reducing (fill) valve and shutoff

valve should be installed.

Supply & Return

: For tapping sizes, see dimensions on

page 2. Recommend shutoff valve in supply (and shutoff

and drain valves in return on non-zoned system).

Radiant Floor & Standing Iron Radiant Systems

: A boiler

by-pass loop (or equivalent) will be required to avoid flue

gas condensation on cast iron sections for low

temperature application. I.E. radiant floor systems.

Zone Piping

: See page 17 for zoning with zone valves

and domestic hot water installation.

Figure 15. Water piping

Note: Orientation of piping drawn for clarity. Observe relative location of components.

Page 16

ELECTRICAL WIRING

Boiler must be electrically grounded in accordance with the

requirements of the authority having jurisdiction or, in the

absence of such requirements, with the Canadian Electric

Code - CSA-C22.1, Part 1.

P

ower supply: A separately fused circuit is recommended.

Use a standard 15-amp fuse or breaker and 14-gauge

conductors in BX cable or conduit.

Thermostat connections

: Wire connections to T1 and T2

terminal block must be from an isolated circuit. DO NOT

BRING VOLTAGE FROM AN EXTERNAL SOURCE HERE.

Wires should be only run from thermostats, zone valve end

switches, or circulator end switches. 3 wire zone valves which

do not have isolated end switches cannot be used unless a

relay is added with the dry contacts wired to T1 and T2.

Thermostat heat anticipator

: For zoned system, set to match

amp draw of zone valve or circulator relay. For a non-zoned

system, set to .3 amps.

Circulator relay on board: Do not exceed 5 amp/120V max. rating.

Circulator pump: Wire to BX harness from boiler junction box.

GAS PIPING

A. Local installation codes apply. The pipe joint

compound used on threads must be resistant to the

action of liquefied petroleum gases.

B.

The gas supply line to the boiler should be run directly

from the meter for natural gas or from the fuel tank for

L.P. propane gas. See figure 16 for location of union and

manual main shut off valve that may be specified locally.

Selecting pipe size for natural gas:

1. Measure or estimate the length of piping from the

meter to the installation site.

2. Consult gas supplier for heating value of gas-W/m

3

(BTU/cu. ft.).

3. Divide boiler rated input by heating value to find

gas flow in piping (m

3

/hr) (cu. ft. per hour).

4. Use table below to select proper pipe size.

Example: Boiler model CB-180 is to be installed.

Distance from gas meter to the boiler is 6.1m (20 ft).

Heating value of natural gas is 10350 W/m

3

(1000

BTU/cu. ft.) Select proper pipe size.

At 6.1m (20 ft.) length of pipe, match required

capacity from table below (choose higher capacity, in

this case is 5.4 m

3

[190 cu. ft.] per hour). Required

pipe size is 19mm (3/4").

Improper gas pipe sizing will result in insufficient heat

and other installation difficulties. For more information

and also if other appliances are to be attached to the

piping system, see Appendix C of National Fuel Gas

Code ANSI Z223.1-latest edition, and CSA B149.00

C.

The boiler and its gas connection must be leak tested

before placing the boiler in operation. Use liquid soap

solution for all gas leak testing. Do not use open flame.

This boiler and its individual shutoff valve must be

disconnected from the gas supply piping system

during any pressure testing of that system at test

pressures in excess of 3.5 kPa (1/2 PSIG).

This boiler must be isolated from the gas supply

16

Figure 16. Gas piping components location

13mm (1/2”) 19mm (3/4”) 25mm (1”) 32mm (1-1/4”) 38mm (1-1/2”)

mft

m3/hr cu.ft./ hr. m3/hr cu.ft./ hr. m3/hr cu.ft./ hr. m3/hr cu.ft./ hr. m3/hr cu.ft./ hr.

3.0 10 3.7 132 7.9 278 14.7 520 29.7 1050 45.3 1600

6.1 20 2.6 92 5.4 190 9.9 350 20.7 730 31.1 1100

9.1 30 2.1 73 4.3 152 8.1 285 16.7 590 25.2 890

12.2 40 1.8 63 3.7 130 6.9 245 14.2 500 21.5 760

15.2 50 1.6 56 3.3 115 6.1 215 12.5 440 19.0 670

18.3 60 1.4 50 3.0 105 5.5 195 11.3 400 17.3 610

21.3 70 1.3 46 2.7 96 5.1 180 10.5 370 15.9 560

24.3 80 1.2 43 2.5 90 4.8 170 9.9 350 15.0 530

27.4 90 1.1 40 2.4 84 4.5 160 9.1 320 13.9 490

30.5 100 1.1 38 2.2 79 4.2 150 8.6 305 13.0 460

Length

of Pipe

Gas Flow In Piping

Pressure Drop = 8mm (.3”) in water Specific Gravity = 0.60

Iron Pipe Size (Ips)—inches

At pressure drop of 0.3 in. water, specific gravity = 0.60.

piping system by closing its individual manual shutoff

valve during any pressure testing of the gas supply

piping system at test pressures equal to or less than

3.5 kPa (1/2 PSIG).

D. All gas piping used should be inspected thoroughly

for cleanliness before makeup. A sediment trap must

be provided, as illustrated in figure 16.

E. The minimum and maximum gas supply pressure (at

the inlet of gas valve) are shown on the boiler rating

plate for the type of gas used. Gas supply pressure

should never be less than minimum or more than

maximum pressure when the boiler or any other

appliance is turned on or off.

Gas flow = = 5.1 m3/hr

52 760 W/hr

10 350 W/m

3

INSTALL MANUAL MAIN SHUTOFF

VALVE 1524mm (5 FT) ABOVE FLOOR

WHEN REQUIRED BY LOCAL CODE

UNION

GAS

VALVE

FULL SIZE

SEDIMENT

TRAP

(Gas flow = = 180 cu. ft. per hour)

180,000 BTU/hour

1000 BTU/cu. ft.

DANGER: BEFORE WIRING, ALWAYS TURN OFF ELECTRIC POWER SUPPLY.

OTHERWISE, SHOCK OR DEATH CAN RESULT.

WARNING: DO NOT USE BOILER TRANSFORMER TO POWER EXTERNAL

ACCESSORIES (I.E. ZONE VALVES, RELAYS). OVERLOADED/BURNED-OUT

TRANSFORMER CAN RESULT.

Page 17

Figure 17. Power and thermostat wiring

Power Connections

• Remove electrical junction box cover.

• HOT CONNECTION LEAD IS BLACK.

• NEUTRAL CONNECTION LEAD IS WHITE.

• Connect ground inside box.

DO NOT REVERSE POWER CONNECTIONS: if

reversed, ignition control will not detect a flame and

will go into safety shutdown.

OPTIONS AVAILABLE

Alarm system:

A remote-type alarm device may

be connected the boiler that will be activated if

the boiler shuts down due to a malfunction, or if

power is turned off. Fault contactor terminals on

electronic boiler control board are a dry contact (5

amp 120 V max) that makes on a system fault or

power outage.

Domestic hot water installation: Connect zone valve

end switch to T1 and T2 terminal block on control

board mounting panel. Water heater thermostat

operates zone valve. DO NOT bring power from an

external source to these terminals.

Note: 3 wire zone valves which do not have isolated

end switches cannot be used unless a relay is

added with the dry contacts wired to T1 and T2.

Figure 18. Zone valves (with indirect fired water heater) piping & wiring

17

Page 18

CONTROL BOARD INDICATOR LIGHTS. See Figure 19.

Flame indicator (amber): Steady on means burner is lit

and producing sufficient flame current signal.

P

ower indicator (green): Steady on means there is

electrical power to the control board.

Diagnostic fault indicator (red): Steady on or intermittent

flashing indicates a system operation problem. See page

24 for codes and following pages for causes and solutions.

CALIBRATION EQUIPMENT:

Pressure measurement fittings:

There are 3 service

fittings with caps provided on this boiler for convenient

calibration of the air/gas ratio and input in the field. See

Figure 20 for the location of each.

Pressure measurement gauge

: Magnehelic or Incline

differential pressure gauge with 0-25mm/w.c. (0 - 1.0”

w.c.) range and 0.5mm (0.02”) increments

recommended.

Available from Slant/Fin is a calibration gauge kit (part

number 665185) that has a gauge mounted on a stand

with a “toggling” feature which allows the user to switch

between the blower and gas valve calibration without

moving the tubing connections.

T

ubing and connectors for gauge: Need 2 lengths of

5mm (3/16”) I.D. plastic tubing with female adapters

which mate to the service fittings.

STEP A: CALIBRATE BLOWER AIR FLOW

Note: This step will set the air flow required at the proper

air/gas ratio for the specified input rate. Refer to the

Input Rate Adjustment Specifications Charts on page 20

for the appropriate air flow differential pressure required

to achieve the desired input rate of the boiler.

1. With power off, set differential pressure gauge on a

level surface and adjust to zero.

2. Locate blower outlet pressure fitting and burner

enclosure pressure fitting. See Figure 20.

3. Remove cap on blower outlet pressure fitting and

connect to high side of gauge tubing.

4. Remove cap on burner enclosure pressure fitting and

connect to low side of gauge tubing.

5. Turn power on. Raise thermostat to start boiler.

6. Boiler should start after 20 seconds. Amber flame

indicator light will come on.

7. While the boiler is running, perform the air flow

calibration to set the differential pressure to the

required reading for the desired input.

8. Locate knurled adjustment knob on side of air filter

box. See Figure 20.

9. Loosen air adjustment locking screw on knob by

turning counterclockwise. DO NOT remove.

10. Turn knurled adjustment knob to set pressure.

Observe gauge while adjusting. Turn clockwise to

decrease reading if over the desired differential

pressure. Turn counterclockwise to increase reading

if under the desired differential pressure.

11. When reading is set correctly, retighten the air

adjustment locking screw finger tight. Hold knurled

adjustment knob steady while doing this to maintain

setting. Double check gauge reading.

12. Disconnect both sides of gauge tubing from fittings

and replace service fitting caps hand tight.

18

Basic Operation Principle

The gas valve on the Concept 21 boiler is “coupled” to the

combustion blower; so that the gas flow is proportional to

the air flow, even under the most adverse conditions. This

insures a high level of safety and reliability when the

following Operation Procedures are carefully followed. Note

that the proper input is obtained by adjusting the air damper

on the blower for a certain air flow, which will feed back to

the gas valve and produce a proportionate gas flow. See

Step A. DO NOT adjust the gas valve adjustment screw to

set input rate, only use this adjustment to set the differential

pressure between the blower outlet and gas valve outlet to

zero as shown in Step B.

Figure 19. Control board indicator lights Figure 20 . Location of calibration pressure fittings and

adjustment devices

OPERATION PROCEDURES

BURNER ENCLOSURE

PRESSURE FITTING

BLOWER OUTLET

PRESSURE FITTING

KNURLED

ADJUSTMENT

KNOB

GAS VALVE OUTLET

PRESSURE FITTING

AIR

ADJUSTMENT

LOCKING

SCREW

GAS VALVE

ADJUSTMENT

SCREW

Page 19

1

STEP B: CALIBRATE GAS VALVE

Note: This step will set the air/gas ratio for optimum

combustion. The purpose of this step is NOT to set input

rate. Follow Step A and/or Step C to adjust input.

1. With power off, set differential pressure gage on a level

surface and adjust to zero.

2. Locate blower outlet pressure fitting and gas valve

outlet pressure fitting. See figure 20.

3. Remove cap on blower outlet pressure fitting and

connect to high side of gage tubing.

4. Remove cap on gas valve outlet pressure fitting and

connect to low side of gage tubing.

5. Turn power on. Raise thermostat to start boiler.

6. Boiler should start after 20 seconds.Let run for about 1

minute.

7. Gauge reading should register a differential pressure

reading of 0. If so, proceed to line 11.

8. If gage reading is not at 0, re-adjustment is necessary.

Locate gas valve adjustment screw cap on top of gas

valve.See figure 20.

9. Remove gas valve adjustment screw cap by turning

counterclockwise with a screwdriver.

10. Position screwdriver into adjustment screw slot

carefully. Observe gage while adjusting and turn screw

slowly. Turn adjustment screw clockwise to decrease

reading if over 0 set point. Turn adjustment screw

counterclockwise to increase reading if under 0

setpoint.

Note:

Remember that the gas pressure is on the low

side of the gage. Consequently, decreasing the

differential reading actually is INCREASING the gas

pressure reading, since the blower outlet pressure is

on the high side of the gage and not changing.

11. When reading is set correctly to 0, retighten the gas

valve adjustment screw cap tightly with screwdriver.

Double check gage reading.

12. Turn power off, disconnect both sides of gage from

fittings and replace service fitting caps hand tight.

STEP C: CHECK BOILER INPUT RATE

1. Turn power on. Raise thermostat to start boiler. Let

boiler run steady about 10 minutes.

2. At meter, observe number of M

3

(cu. ft.) of gas the

boiler uses in 3 minutes. Be sure that only this

appliance is running on the gas meter at this time.

3. Consult gas supplier for heating value of gas

- usually 10,350 W/m

3

(1000 BTU/cu.ft.) for natural gas,

25,875 W/m

3

(2500 BTU/cu.ft.) for propane.

4. Verify input using following formula:

m

3

in 3 minutes X heating value X 20 = W/hr input

(

Cu.ft. in 3 minutes X heating value X 20 = BTU/hr input)

Example:

0.1274m

3

X 10,350 W/m3X 20 = 26,400 W/hr input

(4.5 cu.ft. X1000 BTU/cu.ft. X 20 = 90,000 BTU/hr input)

5. If gas flow is not at the specified input rate, it is

necessary to adjust the air shutter to attain the correct

input rate.

6. Locate the knurled adjustment knob on side of air filter

box. See figure 20.

7. Loosen air adjustment locking screw on knob. Do not

remove.

8. Turn knurled adjustment knob clockwise to reduce air

flow, and consequently, reduce gas flow and input rate

Turn adjustment rod counterclockwise to increase air

flow, and consequently, increase gas flow and input

rate.

Note:

Make adjustments in small increments and re-

check input as in line 4.

9. When input is set properly, retighten the air adjustment

locking screw finger tight. Hold knurled adjustment

knob steady while doing this to maintain setting.

10. Restore operation to any appliance shut off for meter

clocking.

Notes on Input Rate:

1. Refer to the Input Rate Adjustment Specifications

Charts on page 20 for the appropriate input rate setting

on each model boiler for each venting application.

2. The procedure in Step A is adequate for setting the

input rate. If a gas meter is available, it can be used to

verify the setting or as an alternate method for setting

the input.

3. For altitudes above 610m (2,000 ft.), ratings shall be

reduced at the rate of 4% for each 305m (1,000 ft.)

above sea level.

4. Re-orificing for altitude change IS NOT necessary on

this Concept 21 boiler.

5. By maintaining the air flow differential pressure set in

Step A, this Concept 21 boiler will derate itself

accordingly, due to air and gas density reduction as

altitude increases.

Page 20

The input rate for the Concept boiler, on Direct Vent or

Category IV installations, may be set up to a maximum of

15% above to 25% below the nominal specified rating plate

input of each model. See Chart 1. This allowance is useful in

better sizing the boiler’s input rate to each installation site's

heat load.

The input rate for the Concept boiler, on Category I

installations, must only be set to one specified input rate for

each model. See Chart 2. This rate, which is typically higher

than the nominal specified rating plate input for each model

(except the CB-180), will ensure that a high enough flue

temperature is obtained to safeguard against condensation

forming in the flue piping and chimney stack. On all Category

I installations, the air pressure switch provided on the boiler

must be replaced with the switch provided in vent kit 665194.

This switch is set to prevent the boiler from operating below

the approved Category I input rate.

Input Rate Adjustment Specifications

To set the input rate of the Concept boiler perform the

following adjustment procedure:

A. Refer to the Operation Procedures on pages 18 and 19

which specify the methods of calibrating the boiler’

components for proper input rate and air/gas ratio.

B. Note that Step A and Step C are followed to set rate only

depending on whether a differential pressure gauge or a

gas meter is available. Either method is adequate to se

input, or both can be performed as a verification of inpu

rate. Use these procedures, in conjunction with the

appropriate chart below, to adjust the input rate a

specified for that venting application.

C. Note that Step B is followed to set the air/gas ratio only

not to set input rate. Follow Step B precisely as specified

in the instruction manual.

20

CB-45 CB-90 CB-135 CB-180

w BTUH w BTUH w BTUH w BTUH

mm w.c. in.w.c.

9 890 33,750 19 780 67,500 29 670 101,250 39 560 135,000 10.67 .42 Reduced by 25%

10 550 36,000 21 100 72,000 31 650 108,000 42 200 144,000 12.19 .48 Reduced by 20%

11 210 38,250 22 420 76,500 33 630 114,750 44 840 153,000 13.72 .54 Reduced by 15%

11 870 40,500 23 740 81,000 35 610 121,500 47 480 162,000 15.49 .61 Reduced by 10%

12 530 42,750 25 060 85,500 37 590 128,250 50 120 171,000 17.27 .68 Reduced by 5%

13 190 45,000 26 380 90,000 39 570 135,000 52 760 180,000 19.05 .75 Nominal 0%

13 850 47,250 27 700 94,500 41 550 141,750 55 400 189,000 21.08 .83 Increased by 5%

14 510 49,500 29 020 99,000 43 530 148,500 58 040 198,000 23.11 .91 Increased by 10%

15 170 51,750 30 340 103,500 45 510 155,250 60 680 207,000 25.15 .99 Increased by 15%

Boiler Model and Allowable Input *

Air Flow

Differential

Pressure †

Percent of change

to nominal boiler

input rate

* Follow instruction manual operation procedures, Step C, to set with meter. Ability to attain input rates over the nominal rating plate specifications

may be constrained by installation variables such as vent length, altitude, and calorific value of the gas, particularly on the larger models of boilers.

† Follow instruction manual operation procedures, Step A, to set with gauge.

w BTUH mm w.c. in. w.c.

CB-45 16 120 55,000 25.40 1.00 22%

CB-90 30 480 104,000 21.59 .85 15%

CB-135 42 500 145,000 19.05 .75 7%

CB-180 52 760 180,000 16.51 .65 0%

Boiler

Model

Category I Input Rate * Air Flow

Differential Pressure †

Percent of increase

over nominal boiler

input rate

Chart 2:

This chart must be used for Input Rate Adjustment for Category I Installations

* Follow instruction manual operation procedures, Step C, to set with meter.

† Follow instruction manual operation procedures, Step A, to set with gauge.

Provisions for combustion and ventilation air must be made in accordance with Section 5.3, air for combustion and ventilation, CSA 149.1-00 for

natural gas and propane..

Chart 1:

Input Rate Adjustment Specifications for Direct Vent and Category IV Installations

Page 21

2

NORMAL SYSTEM STARTUP

Follow lighting instructions on page 30. Safe lighting and

other performance criteria were met with the gas manifold

and control assembly provided on the boiler when the