Page 1

User Manual

Fully Automatic Front Loading Washing Machine

Model:

F701202ND

F751202ND

Page 2

Content

Specification

Safety Notice

Parts Name

Installation

Door Lock and Unlock

Use of Detergent Box

Function Introduction of Main Control Board

Introduction of Programs

Introduction of Washing Programs

Maintenance

Varieties of Functions

Notice before Washing

Not Fault Situation

Fault Solving Guidance

1

Specifications

2

3

4

9

9

10

12

21

22

24

26

28

29

30

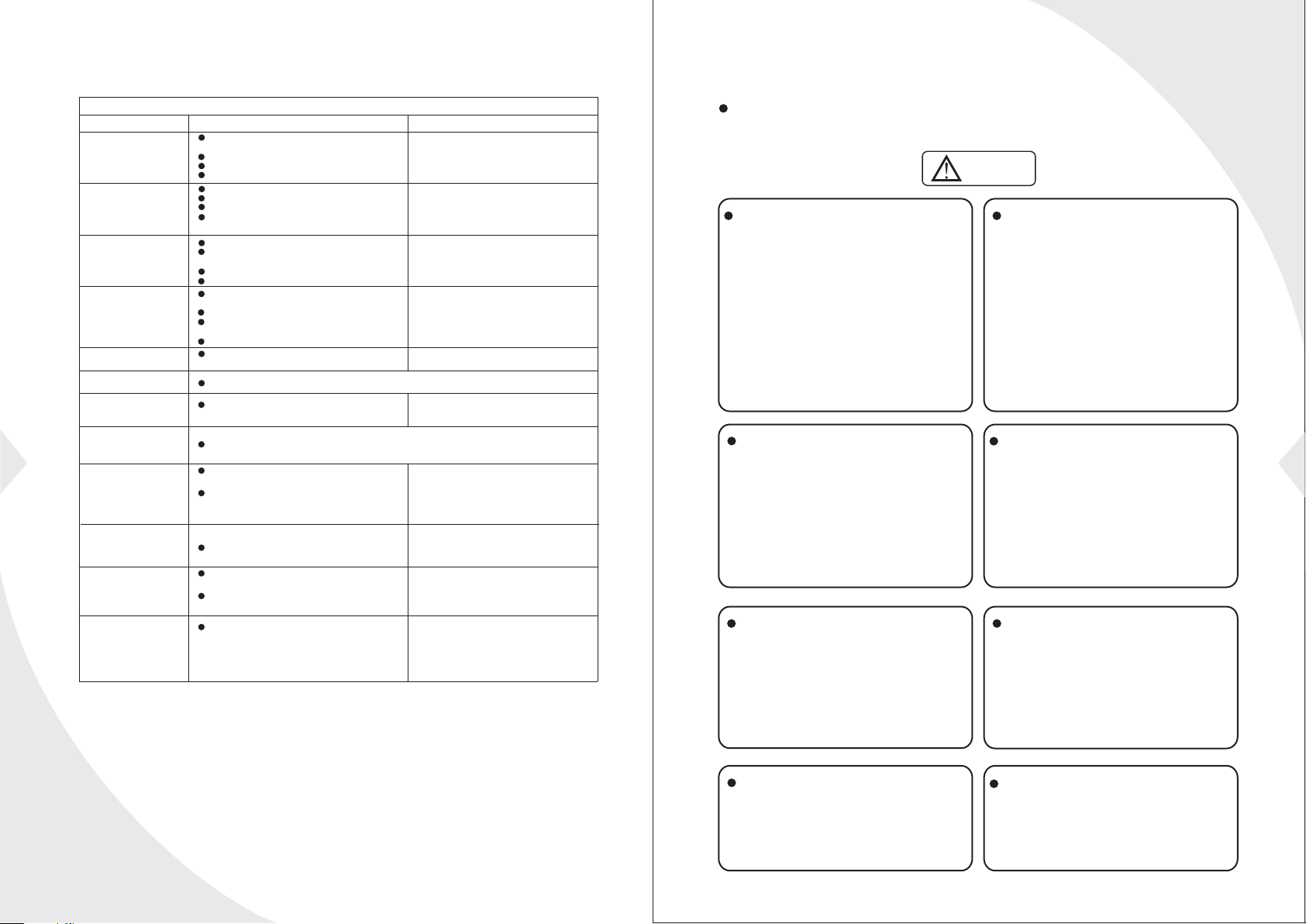

Model

Rated washing capacity

Rated spinning capacity

Rated water consumption

Rated voltage

Rated washing power

Rated spinning power

Rated heating power

Maximum power

Washing noise

Spinning noise

Energy efficiency rate

clean

Power consumption

Water pressure

External dimension

Executive standard

F701202ND

7kg

7kg

49

( )L/work cycle

220V-50HZ

200W

380W

2000W

2200W

60dB(A)

72dB(A)

Class 1

1.03

0.77

( )KWH/Cycle

0.03-1Mpa

595*600*850

GB4706.1、 、GB4706.24、GB/T4288、GB4706.26、

GB19606、GB17625.1、GB12021.4、GB/T2828.1;GB/T4288、

GB/T17499-2008

GB4343.1

F751202ND

7.5kg

7.5kg

52

( )L/work cycle

220V-50HZ

200W

400W

2000W

2200W

60dB(A)

72dB(A)

Class 1

1.03

0.825

( )KWH/Cycle

0.03-1Mpa

595*600*850

30

Accord with the noise limit stipulated by GB19606.

The procedures of energy efficiency test are default programs

Half loading/Full Loading The process of energy test is as below:

F701202ND/F751202ND Standard Wash( without soak function)+ Intensive+ rinse 2 times+ water

temperature 40℃+ Spin Speed 400

Page 3

29

Model:

F651003S\F751203N

Phenomenon

Washer can't start

Spinning screen

shows “UE”

Water inflow

screen shows “IE”

Water outflow

screen shows “OE”

Door trouble

screen shows “DE”

Not heating,

screen shows

Keep water inletting

without stop, screen

shows “FE”

The wash drum does

not running, screen

shows “LE” or “CE”

Too much bubble

The fault of motor

sensor, the screen

shows “HE”

The fault of water

level sensor, the

screen shows “PE”

Power off, the screen

shows “PF”

“ ”EE

Troubleshooting guide

check points

Check if press the power button or

start/pause button?

Is the plug pulling out?

Is there a power failure?

Check if cut the leakage protector?

Check if disassemble the carriage bolt?

Is the machine placed steadily?

Are the clothes too small or light?

Are the locknuts on under the feet

tightened up?

Check if turn the tap off?

Is the water supply cut off or the water

pressure too low?

Are the water inlet pipes frozen?

Are the filters blocked?

Are the outlet pipe placed too highly?

Are the outlet pipes frozen?

Are the outlet pipes blocked?

Are the floor drain blocked?

Make sure if start the washer without

closing the door well.

Please pull out the plug and call for the after sale service

Due to the abnormal of water inlet valve

and water level sensor

Please pull out the plug and call for the after sale service

If adding the amount of detergent is more

than the suggested?

If use the low bubble detergent which is

especially for front loading washing

machine?

If the position sensor motor fall off or not?

If the water level sensor has fallen off

or not?

If the water level sensor pipe blocked or

there is a big pressure?

Power off then power on, push the

“power” button, the screen display

“PF” to indicate that the power has

powered off before. The machine can

be in normal operation.

Press the power button or start/

pause button.

Connect the plug.

Please wait.

Open the leakage protector.

Disassemble the carriage bolt.

Place the machine on a steady ground.

Add more clothes.

Tighten up the locknuts.

Open the stopcock.

Please wait.

Use hot water to unfreeze the pipes.

Take out the filters and clean them.

Please put away the outlet pipes

and make sure the height within 1M.

Use hot water to unfreeze the pipes.

Take out the foreign matter and

dredge the pipes.

Clean the floor drain.

Make sure the door truly closed

Shut the water tap, pull out the plug

and call for the after sale service

Add proper amount of detergent.

Use the correct type of detergent.

To firmly connect the sensor and

motor stator

Tighten the sensor. Open the water

pipe excluded congestion or pressure

To push the button of” Start/Pause”

can continue the operations before

power off. And the other operations

can be processed.

solutions

Safety Notifications (Please Must Follow)

In order to prevent the harm or damage to the user or the person and

property of others, please make sure to follow the safety issues.

Warnings

The risk of electric shock.

1.Please use 220v, above 10A with

ground wire dedicated socket.

2.When inserting and pulling out the

power cord please use the plug, please.

Don't use the damaged power cord.

When the power cord pin is dirty please

wipe clean with dry cloth in time.

3.Do not use the wet hand to insert or

pull out the plug.

4.Please pull out the plug when finishing,

repairing or cleaning.

The danger of high temperature

1.When washing in high temperature,

the door glass will be heating. Please do

not touch the door glass, especially

Children.

2.When opening the door after high

temperature washing, please wait for the

temperature cooled down to a safe level

and the door will unlocked automatically.

The danger of injury

1.Do not put any heavy things on the

top of the washing machine.

2.If you want to move the machine,

please remember ask for help.

3.Please do not ask unprofessional

people to repair the machine.

The danger of fire and current leakage

1.Do not allow the washing machine

close to the fire, or lighted cigarettes,

candles and volatile materials.

2.Please do not sprinkle the water on

the control panel of washing machine.

3.Please do not put the washing

machine in the place of wet and outside

place.

4.Please fix the drain pump and make

sure the sewer unobstructed.

The danger of getting hurt

1.Please handle the carton box after

removing, don't let the children touch or

eat.

2.Do not allow the children to operate or

climb up to the washing machine.

3.Please close the door after use to

avoid the children enter into the drum.

The danger of damage the cloths

1.Please do not wash the cloths which

is waterproof, like Raincoat, feather

products, sleeping bags

2.Please wash the cloths which can be

washed, if you have any doubt, please

following the instructions.

2

The danger of explosion

1.Please do not washing the cloths which

stained with kerosene, gasoline, thinner,

inflammable goods.

2.Please do not washing when gas leakage.

If want to open the door when the

machine running or other circumstances,

please check the water level in the drum

first in order to avoid the water overflow

tand cause unnecessary loss.

Page 4

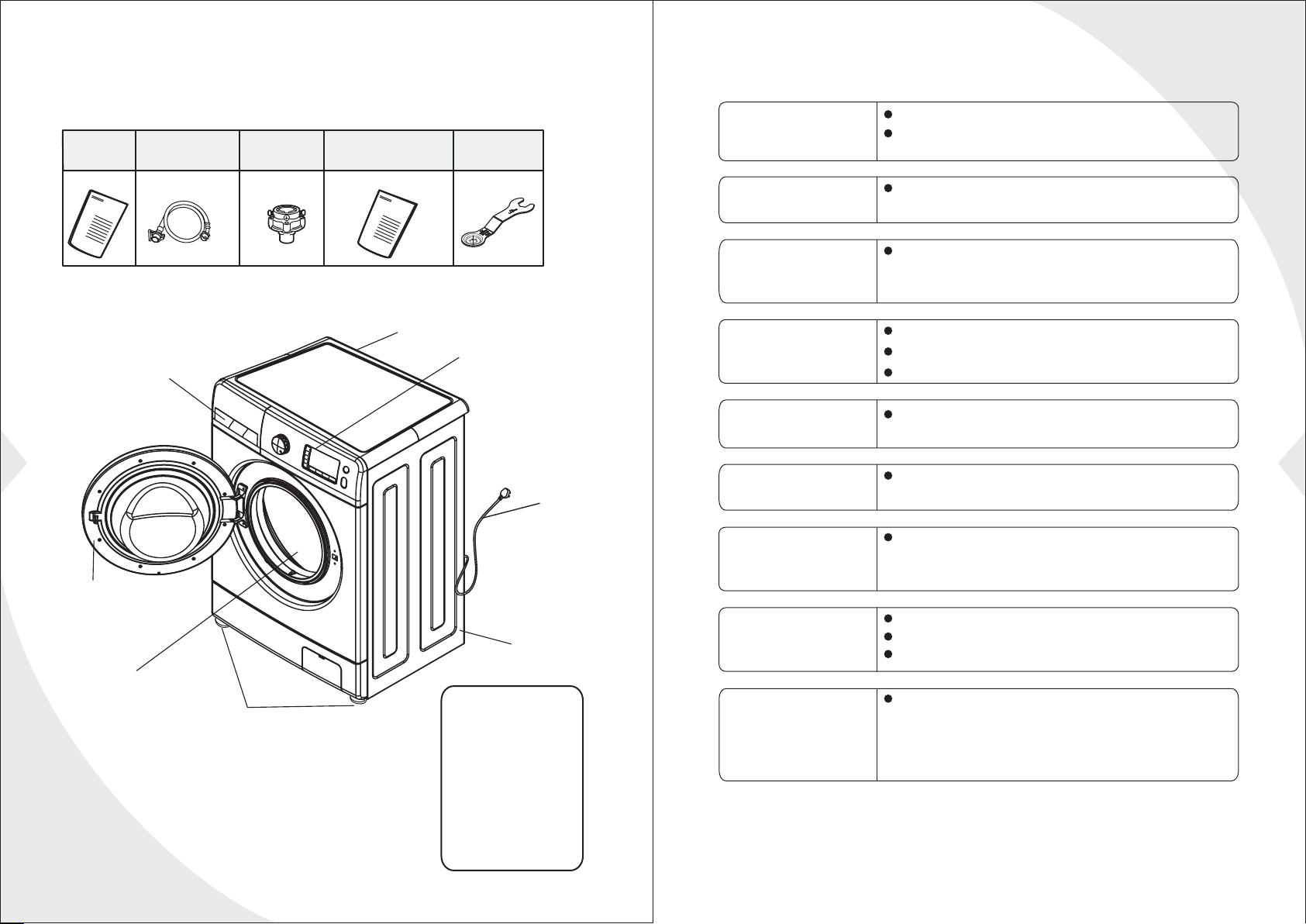

Part name

Non-fault conditions

Attachment specification

Instruction

water supply hose universal joint

installation instruction

wrench

The door can't

open.

There is an odor.

There is too little

water when wash

Part name

Inlet valve

Control Panel

Detergent box

and rinse.

No water

inflowing.

Water inflows

halfway

3

Water outflows

Power line

when washing.

Remaining time

changes

Door assembly

he program is running.

There are clothes between the door and

door seals.

There may be a smell of rubber because

some components are made up of rubber.

Roller washing machine just needs a little

water when operating.

Is the tap turned on?

Is the inlet pipe frozen?

Are the filters blocked?

If the water level declines, the washer will

supply water automatically.

Check if add the detergent with too much

bubbles.

If clothes are off center when spin,

spinning time will extend to correct the

deviation.

28

Wash and spin tub

Adjustable feet

The above picture is just for refference,the detailed

information should be based on the real product!

Cabinet

Notice:

1.the first use may drain

some water out. It's

residual water after

performance test,

belong to the normal

phenomenon.

2.After each use, please

pull the plug and turn off

the faucet to prevent

accidental flood or fire.

There is abnormal

noise when spin.

The washer can't

work after the

failure of electricity.

Check if the power line touches with cabinet.

Have the transport bolts been dismantled?

Are there some hairpins or coins in the roller?

The washer will stop working after the

failure of electricity. When the power is

restored, it still can't continue to work.

Please press the power button and

reset the program.

Page 5

3.Notes

Installation instruction

27

When put big and small clothes together, put the big first and they

have to be less than half of total clothes. Please don't wash single

cloth because it may cause the trouble of imbalance.

Please add one or two similar clothes.

Small clothes like silk stockings and handkerchiefs should be put

into mesh bags to wash. Before washing the bra with steel rings,

please take the rings off. If it is inconvenient to do this, please put

them into mesh bags to prevent the bra slipping into the gap between

internal and external tubs.

Check all pockets and make sure nothing in them. Nails, hairpin,

match, pen, coin and key will damage your washer and clothes.

Zip up all clothes, fix the button and hook and tie the loose belt,

make sure that other clothes cannot be damaged by them.

Firstly use the water with a little detergent to wash the parts with too

many stains, such as collar and cuffs, which can make the clothes

cleaner.

Check the door seals and make sure nothing on them.

Make sure there is nothing in the tub before washing.

Please use the low bubble detergent specially for front loading

washing to wash the cloths.

Make sure the temperature of the places where the washer is installed

or placed above 0℃ or put it outside.

Place the washer correctly according to management standards and

regulations.

Keep the base of washer ventilated when it is placed on the ground

with carpet.

There are too much pests in villages. Please keep the surroundings

clean because any damages caused by cockroaches or other pests

don't belong to warranty.

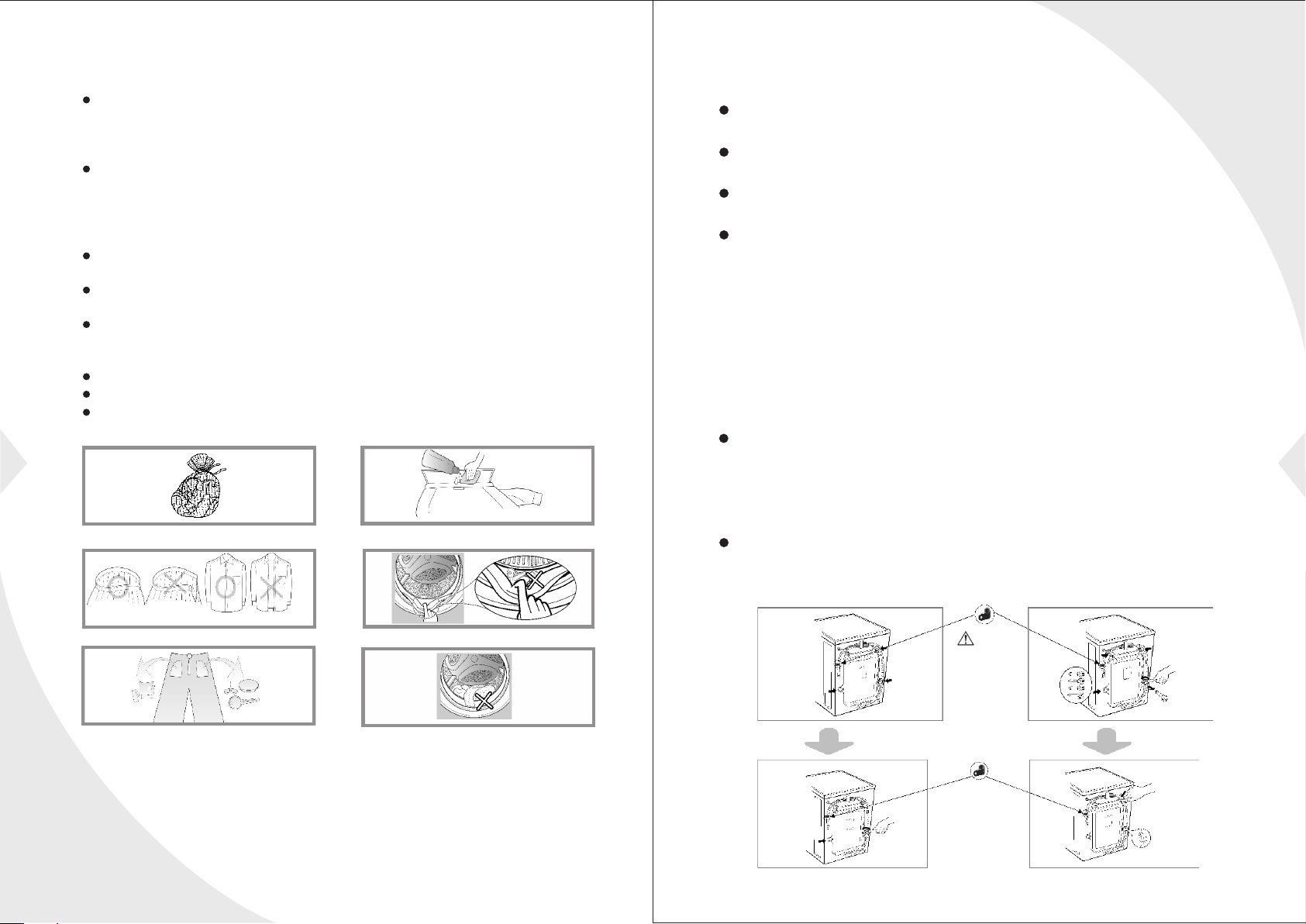

Transport bolt

Washers are installed with transport bolt to prevent internal damage

in transit.

Dismantle the transport bolt

1.In order to prevent internal damage in transit, 4 bolts are installed.

Before using the washer, dismantle the bolt.(see chart I )

If the bolts are not dismantled, violent vibration, noise and trouble

will be caused.

2.Use the attached wrench to loosen the 4 bolts. (see chart 2)

3.Twist the bolt rubber slightly and then pull out the bolts, keep the

bolts and wrench as standby.(see chart 3)

The bolts should be remounted no matter when to transport the washer.

4.Use attached stopples to seal the screw holes. (see chart 4)

4

see chart 1

see chart 2

Notice:

please don't

dismantle the

drainpipe fixed

device.

see chart 3

the plug

of trans

portation

bolt

see chart 4

Page 6

Requires for positions

Horizontal adjustment:

The slant angle should be less than 1 degree.

Drain pipe

Power outlet

The distance between any side of washer and

power outlet should be within 1.5 meters.

Wash tub

A

bo

u

t 2

c

m

Don't use too many electrical appliances

in one outlet.

Environment cleaning

It's necessary to clean the wall, door and ground.

Install the washer on a hard and steady ground with floor drain rather

than soft blanket or wooden floor.

Don't put dirty clothes or some other goods on a washer's head cover,

otherwise it may impact the normal operation.

Notice

Power connection

Push"Start/Pause"button to start the washing machine, it is normal to hear

"Clicking" sound, which is door locking sound not an error. If it occurs"dE"

warnings, please use hand to push and shut the door. Push two times of

"Start/Pause"button to continue running of the machine.

9. Quick entering into the functions: Power on, push "Power" button, directly

push the following functional button(no need to turn the knob).

Push "Start/Pause" to enter standard washing mode directly.

Quick entering into the functions: Power on, push "Power" button, directly

push the following functional button(no need to turn the knob).

"Spin speed" button,the washing machine enter" Spin only"mode(You can

choose spin speed),push "Start/Pause"button to start the washing machine.

10. Eliminate the sound: Push "Prewash"button for 3 seconds to start/close

the sound.

11. Power off memory: After power off for a while,the machine can continue

the programs as before when power on.

12. Power off memory: After power off for a while,the machine can continue

the programs as before when power on.

1.Don't use the wiring board or something like that.

2.If the power lines are damaged, please contact professionals to repair.

3.After the use of washer, pull the plug and turn the tap off.

5

4.Connect the washer with grounded outlet to correspond to the wiring

principles.

26

NOTICE

5.Place the washer in which is easy to connect the outlet.

Contact the maintenance center and ask professionals to repair the

washer. Laypeople may cause damages and troubles on the washer.

Don't put the washer in the place where the temperature is below zero.

The pipes will be frozen and break. Moreover, the temperature below

zero will damage the programming controller.

If move the washer in an environment whose temperature is below

zero, please keep the washer at room temperature for a few hours

before starting it.

Grounding introduction

A washer must have the grounding devices. If a trouble happens, the

1.Washing guide identification

Please check cloths washing guide identification,which shows

cloths texture and washing method.

2.Classification washing

Please wash cloth of the same texture, different texture,

different water temperature, speed and washing procedure,

please split deep colored cloths from white cloths.Split dyed

cloths from cotton,otherwise the white cloths would be

discolored.If possible, please do not washing high contaminated

cloths with clean ones together.

device can reduce the risk of electrical shock. The device is equipped

with a cable (including a wire and a grounded plug). The grounded plug

must be inserted in an appropriate outlet. If you want to know if the

The degree of pollution

(serious,moderate,slight)

classify clothes and wash

according to the degree.

washer is grounded correctly, please contact with professional

maintenance staff. If the plug can't match with the outlet, please don't

change the plug by yourself.

Once your washer smokes or emits an odor, please cur the power and

contact with professional maintenance staff.

color (white,light color,deep color)

velveteen

(easy to fall off, easy to be adhered)

classify them and wash.

classify the white and the

deep color.

Page 7

25

6. Drum clean: The program of drum clean is use the high water level, high

water temperature, high speed to clean the drum and kill the bacteria. The

detailed operations ways, please take reference of Page 18.

7. Child Lock function: You can lock and unlock the child lock function by

pushing 3 seconds when the machine is running.

Once the child lock function set, all the other buttons will be locked except

the power button.

After setting child lock function, the lamp will light up, meanwhile the screen

will display “CL” intermittently.

When the washing process ending or push “power off” button or default

warning, the child lock function cannot be unlocked. It means that the child

lock function must be unlocked by hand. When the power on and start the

machine, if the child lock function is going on(the lamp of child lock light up

and the screen display CL),you need to push “prewash” button for 3 second

to unlock the child lock function and then continue to operate the washing

machine.

Already set the child lock function and then want to change the programs.

Firstly remove the child lock function and push the "Start/Pause" button to

stop running, then select the required function, then push the "Start/Pause"

button to restart running.

8. Add garment function: During the process running, if you want to add

garment, please push "Start/Pause"button to stop running;

After around 5 seconds, it has a sound of unlocking, meanwhile the door

lock mark in the screen disappear then you can open the door.

Add the additional garment into the drum(Don't let the door clamp clothes,

this will cause failure of leakage and error).

Forced to open the door part, damage may occur, such as safety problem.

When there are many bubble in the inner barrel and plenty of water, open

the door, water and foam will flow out .

When the inner drum is running, it is in danger status since the temperature

of water is above 45℃ and there is plenty of water inside. At this time, the

door can not be forced to open. If want to open the door, please follow the

below instructions:

(1) Wait till the inner drum stop running.

(2) Wait till the water temperature cool down to below 45℃. If want to

open the door when the water temperature is above 45℃,please shut off

the power and open the door after 5 minutes.

(3) When there is plenty of water inside of inner drum, please restart the power

and select "spin speed" button to drain out the water then open the door.

Abnormal power off for 2 minutes, you can open the door. During the process

of running, the required condition for opening door(water level below door

gasket, water temperature below 45℃,spin speed is 0),push "Start/Pause"

button, wait till door lock mark disappear, then open the door. When closing

the door, press the middle place of the door handle.

Washers should be connected with water inlet. Please use

attached new plumbing rather than the old.

In order to ensure the quality, water injection tests are carried out

before the washer leaves factory, so there may be water inside the

internal tub, door seals and door panel, which are normal.

Water inlet connection

1.The pressure of supply water should be between

30kpa and 1000kpa.

2.Don't abrade the screw thread when connect the

inlet pipes with valves.

3.Please install dropping equipment if the pressure

of supply water surpasses 1000kpa.

Two seals are supplied in the connectors of both ends

of the pipe to prevent water leaking.

Turn on the tap and check if the connectors leak.

Check the pipes regularly. Please change them if necessary.

Make sure the pipes don't be damaged or twine with each other.

Use the standard faucet

standard faucet

longer faucet

square faucet

water pipe connector

rubber gasket

The connection of inlet pipes and taps

Hold the connecting seat in one hand and

press the retaining ring and pull it down by

the other hand. Separate the seat and pipe.

connector

Retaining

ring

Retaining

ring

Adjust the four screws evenly to make the

two screws near the wall fully contact with

the tap.

The screw close to the wall can insert some part.

As shown in picture ,two screws to make

it in the opposite rotating wall after

contact with the faucet with a screwdriver.

Inlet

Faucet

Loosen the four fixed screws in the top

connector and rotate the bottom connector

to make enough space between the top and

bottom connector so that the screws can be

installed.

Plastic cup

If the diameter if the faucet is too big, the plastic cup can be

removed.

Make the top connecting seat block the tap

and make the seal fully contact with the tap

(please don't take out the seal).

Please use the standard faucet. The mouth of faucet

must be flat. If not flat,please smooth it.

Unscrew the connector till it is tightened

(if not tightened,leakage will happen).

After unscrewing, the gap between up and

down connector is below 3mm.

up connector

Down connector

6

Page 8

Take Off the Inlet Pipe: Press down the

retaining ring of the inlet pipe.

Retaining

ring

Please make sure the connector and the inlet pipe joint tightly.

please tighten the connector of inlet pipe and inlet valve, turn on the water faucet

slowly to check whether leak.

If leak happens, please turn off the stopcock and install again.

It will loosen after long period of usage, please stall again as per 1--9.

Remark:

If you use special stopcock. Please install as following processes.

Replace the original

connector to the

standard connector

provided.

replace

standard

connector

7

Such washing machine is designed for home appliances, please

In one hand holds the

connector, the other

hand holds the buckle

down,to seperate the

inlet pipe and connector.

Retaining

ring

do not install it on ship,traveling truck or plane.

Please turn off the stopcock if long time out of use.

(e.g vacation)

Please remove plug and cancel door lock function to avoid child

locking himself/herself inside.

Packing materials(e.g film, foam) could harm child's safety and

cause asphyxia! Attention: MAKE ALL PACKING MATERIEALS

OUT OF CHILD REACH.

Install drain-pipe

Please fix the drain-pipe by a lifting rope.

For the sake of lightening damage of leak towards ground, please

place the drain-pipe correctly.

In order to avoid siphon,the height of drain-pipe should between

(0.85m-1.25m),moreover, the terminal of is should not be placed in

water.

If the drain-pipe is too long, please do not force to insert it into

washing machine, which would cause abnormal noise.

(Please check sketch map next page)

Install the inlet pipes, please insert it up

into the connector,then undo the retaining

ring.

Make sure

the retaining

ring on the

connector

standard

connector

Inlet

standard

connector

Inlet

Retaining

ring

To pull the buckle

down,connect the

inlet pipe directly

inserted into the

standard connetor.

Retaining

ring

Function Introduction of Operating Panel

1. Prewash: If the cloths are too dirty, you can choose this program

before washing.

2. Soak: After selecting this function, there is a period of time for cloth

soaking, which can enhance the performance of washing. If the

program has the “weight” function, push one more time for “soak”

button can select the function of “weight”. If the programs do not have

“weight” function, or the “weight” function finished and the screen

display the remaining time, push the button of “soak”, you can

choose “soaking 16mins.”- “soaking 24mins”-cancelling soaking” for

optional. (The above operation should be done before running.)

3. Rinse: After selecting this function, the machine will heat the water

during last time of rinse in order to enhance the performance of rinse.

4. Memory: Used to memory the commonly used programs make it

convenient for users to select the used program by push one time

button. Push the “memory” button for 3 seconds and hear a chime,

at this time this program has been already memorized successfully. If

you want to use the memorized program, you can push the program

button when it is not running. (Do not push the buttons too long time,

just light up the lamp; the above operation should be done when it is

not running).

5. Prewash Function: When use “Prewash” function for washing, the

delay time is 3 hours to 19 hours.

When pushing the button for the first time, the screen display “3:00”, then

the maximum prewash time can be 19 hours.

Push one more time for button, it will increase 1 hour.

If want to cancel the prewash function, push “power: button or push one

cycle of “prewash” button.

The prewash time means from prewash to wash ending time.

You should operate the prewash function after selecting the grogram

and before push the button of “start/pause”.

6. Drum clean: The program of drum clean is use the high water level,

high water temperature, high speed to clean the drum and kill the bacteria.

The detailed operations ways, please take reference of Page 18.

24

Page 9

23

Maintenance

When washing machine is frozen

1.Cover stopcock and the universal coupling with hot towel.

2.ake off the inlet pipe, and put it into 50 degree water.

3.Pour into the drum about 2-3L of 50 degree water.

4.Connect inlet pipe, turn on the stopcock and start the washing

machine, please check whether inlet and outlet is normal.

a.

Faucet

Connecting part

Inlet pipe

ake off the inlet pipe,

b.

and put it into 50

degree water.

50 degree

water

The Clearance of dewatering-pump filter( Suggest: once/monthly)

1.Press fastener on the pump after dewtering and power off, open the

lid of water-pump filter.(Attention: if hot water inside, please go

ahead after it be cold.)

2.Take off the filter anti-anticlockwise.

3.Wash the filter.

4.Direct at pump and insert the filter, tighten it clockwise and tighten

the lid.

Attention: a. Please tighten the filter well to avoid leak.

b. Please do not clean during operation.

c.Pour into the drum

about 2-3L of 50

degree water.

50 degree

water

Wash tub

pipe holder

m

5cm

5c

2

8

.

. 1

x

in

M

Ma

the instruction of installation of pipe

wire harness

Horizontal Adjustment

To avoid noise and vibrate by adjusting washing machine level.

place it at the room corner preferably.

If ground not level, please adjust alignment

pins.(Do not put wood pieces or something

like), please make sure four alignment pins

touch ground tightly, and machine level

completely.

Adjust alignment pins

After adjusting alignment pins.

The diagonal check

Applying force downward on the diagonal of the

washing machine, washing machine should not

shake. (both diagonal need to check, if the

washing machine shake, must readjust

adjustable foot.)

ajustable

foot

up down

locknut

m

m

5c

c

2

. 1

.85

x

in

M

Ma

8

The Drum Clearance (Suggest once/monthly)

After using for a period, some dirt maybe exist. You can clean the

inside and outside of drum by operating the drum procedure.

Attention: please do not put cloths and detergent when clearing the

drum.

Page 10

Methods of Door Lock and Remove

Maintenance

DOOR LOCK

After operating,the door will be locked automatically and

Please maintenance washing machine to extend service life.

Before maintenance, please unplug.

light/picture on the panel is lighting.“DOO LOCK”

Remove Door Lock

When

“DOO LOCK”light/picture is lighting,press“START/PAUSE”,

WASHING/DEWATERING drum stop operting.Please wait for about

10s, door lock will be removed automatically.

Unplug directly and wait for about 65s~85S,door lock will be

removed automatically.

Foam overflowing if open the door during operating, please

catch foam with towel.

If temperature is too high, the door can not be opened during

operating.

If water level is too high, the door can not be open during operating.

The Usage Method of the Detergent Box

9

Synthetic Detergent

Powder

Please dissolve detergent

(e.g soap pieces)before

putting into detergent box.

Liquid detergent. Bleach

Please use detergent with

less foam.

Please use two times water

to dilute the concentrated

type detergent before putting

into detergent box.

Please add softener before last time

washing, it will be added into the drum

during the last time of rinse.

Please use concentrated fabric

softeners, use the corresponding

percentage of water to dilute then pour

into the washing machine.

Do not surpass the mark of "MAX".

Softener

Body of washing machine

After washing, please clean it with soft

cloth. If much contamination ,please

use appropriate detergent or soap.

Do not watering directly.

Do not use putty-powder,diluent,

gasoline,alcohol to clean machine

body.

Door Gasket Ring

After washing, please remove

contamination, wastepaper and so

on, if foreign matter exists, please

remove.

The Clearance of Universal coupling ( Suggest:Once/ half year)

If waste accumulated, it will influence

water inlet speed.

1.Take off the soft pipe from the

universal coupling side.

2.Take off the screwing device according to the arrow showed.

3.Wash the inside of the screwing device.

4.Install the cleaned crewing device with the inlet soft pipe.

The clearance of inlet water valve ( Suggest:Once/ half year)

The Clearance of

Detergent Box

Please clean the detergent

box regularly. Pall it out

and wash with clean water,

then insert back.

Push down

pull out

22

Tightening device

1.Take off the soft pipe from washing machine side.

Softener

2.Take off the filter net from water valve.

3.Clean the filter net with tooth-brash.

Please put softener before washing,

which will pour into drum

automatically when last potch

happening.

When using concentrated type

softener, please dilute it with

appropriate water.

Do not exceed MAX mark.

Use special detergent.

Do not use too much detergent which will cause

too much foam and affect washing quality or will

cause malfunction.

Select detergent according to cloths variety, color,

water temperature and contamination level.

Please use moderate detergent to get washing

effect and protect environment.

4.Install the soft inlet pipe.

valve of water

inlet

Page 11

21

Model :F701202ND/F751202NDNo.

Program

Stardard

/Cotton

Eco

Synthetic

Duvet

Delicate

Sports

Wear

Wool/

Hand wash

Mix

Down

Jacket

Baby Care

Tub Clean

Quick 15'

Spin only

Rinse+

Spin

Temperature

(℃)

40℃(cold,

30℃,60℃,

96℃)

30℃(cold,

40℃,60℃)

40℃(cold,

30℃,60℃)

40℃(cold,

30℃)

30℃(cold,

40℃)

cold(30 ,

℃

40℃)

40℃(cold,

30℃)

cold(30

℃

40℃)

30℃(cold,

40℃)

60℃(cold,

40℃)

60℃

cold(30 ,

℃

40℃)

Rinse

(times)

3

(1,2,

4,5)

2

(1,3,

4)

3

(1,2,

4,5)

2

(1,3,

4)

2

(3,4)

2

(1,3)

2

(3,4)

3

(1,2,

4,5)

3

(2,4)

3

(2,4,

5)

2

1

(2,3)

1

(2,3)

Spin Speed

(Run/Min.)

1000(0,

400,800,

1200)

1000(0,

400,800)

1000(0,

400,800)

800(0,

400)

800(0,

400)

800(0,

400)

800(0,

400)

800(0,

400)

800(0,

400)

800(0,

400,

1000)

800

800(0,

400)

1000(0,

400,800,

1200)

1000(0,

400,800,

1200)

Time(m)

96

59

88

80

63

46

51

83

77

138

75

15

12

18

Max.Load

(Kg)

Rated

≤4. 0

Rated

≤5. 0

≤2. 0

≤4. 0

≤2. 0

Rated

≤2. 5

≤4. 0

≤4. 0

≤2. 0

Rated

Rated

Cloth Materials

Normal Co tt on

Fab ri c

Normal Co tt on

Fab ri c

Syn th et ic F ab ri c

Sheet/ Cu rt ai n

Gau ze /S il k

Fab ri c

Apply to Ma ch in e

-w as ha bl e

Sportsw ea r

Apply to Ma ch in e

-washable Woo l

Fab ri c

Normal Co tt on

Fab ri c an d

Syn th et ic F ab ri c

Apply to Ma ch in e

-wash ab le D ow n

Jacke t

Infan t cl ot hi ng n ee d

to re mo ve b ac te ri as

and mits

Clothes to be c ha ng ed

Fri eq ue nt ly, n ot t oo

dirty a nd t hi n cl ot he s

Norma l Co tt on F ab ri c

and Synth et ic F ab ri c

Norma l Co tt on F ab ri c

and Synth et ic F ab ri c

Instruction:

1 .The needed time can be changed due to water pressure,drain condition,clothing textile,weight,water

temperatue changing.

2 .During the process of washing,the time of washing and spining will be different with the real running time.

3 .During the process of washing, the real display time will beat according to sensing the weight chaning

of clothing.

4 .Due to different weight of clothing and detergent, if the spin speed is too low,the rinse performance will not be

good,please increase times of rinse.

5 .The data in the chart can be different from different models.

6 .When editing the default program as energy efficiency program, washing time will increase automatically.

7 .Delicate and down jacket program can be only used in model F751202ND.

Soak

(Additional)

YES

NO

YES

YES

NO

NO

NO

NO

YES

NO

NO

NO

NO

NO

Wash options

Cotto n( Sa vi ng

tim e, I nt en st iv e)

Savin g ti me

(Cott on )

Cotto n( Sa vi ng

tim e, I nt en si ve )

Cotto n( Sa vi ng

tim e, I nt en si ve )

Cotto n( Sa vi ng

tim e, I nt en si ve )

Cotto n( Sa vi ng

tim e, I nt en si ve )

Cotto n

(In te ns iv e)

Savin g ti me

(Cott on ,I nt en si ve )

Savin g ti me

(Cott on ,I nt en si ve )

Savin g ti me

(Cott on ,I nt en si ve )

Savin g ti me

(Cott on ,I nt en si ve )

Savin g ti me

(Cott on ,I nt en si ve )

Function Introduction of Operating Panel(One)

6

7

8

5

4

3

2

1

1 START/PAUSE

Press START button to start operation.

Press PAUSE button to stop, and press it again to continue.

2 POWER

Press it to turn off/on power.

Procedure over, power off automatically.

3 SELECT

Press it to select additional function.

4 “Washing” button

When push the power button to start the machine and select the program,

you can choose the washing mode (saving time, standard, intensive) by

this button.

5 “Rinse” Button

When push the power button to start the machine and select the program,

you can choose the times of rinse by this button, which can make better

washing performance.

6 “Temperature” button

When push the power button to start the machine and select the program,

you can choose proper water temperature according to the material of cloths.

7 “Spin” button

When push the power button to start the machine and select the program,

you can choose different spin speed (1200, 1000, 800, 400, avoid dehydration ).

8 ”Additional Function” Button

According to your request, you can add the additional function to the basic

programs. The additional function will be different according to different basic

programs. (Please take reference the additional functions introduction in

details).

10

Page 12

11

Child Lock Lamp

9

To avoid the children wrongly operations

If you want to start child lock function, you should push prewash buttonfor 3

seconds during the running process of washing machine. To unlock child lock

function, you can push prewash button for 3 seconds during the running

process or under non- running process. (Please check the detailed introduction

of child lock function in the “additional function introduction”).

1 0 Display Screen

To display the remaining time or prewash time

Remaining time gradually reduce in accordance with the washing.

During the process of washing, if there is a abnormal phenomenon, the screen

will display the error code accordingly.

If the remaining time is different with the real time, the program will adjust

according to the real situation. It is not an error.

If the program has self-weight function, the screen will display” - - -“. If washing

machine is in the process of weighting, the screen will flash” –“. If the weighting

function ends, the screen will display the remaining time of washing.

11 The reminding window of washing status

There are four indicator lamp on the top, represent weighting, washing, rinse

and spin.

When setting the programs before washing, if some indicator lamp lights, it

means that this washing program has the following washing process; When the

machine is running, if one indicator lamp lights, it means the current washing

process is under this status; If some indicator lamp always flash, it means that

the following washing process include the corresponding programs.

The introduction for single spinning program

The machine will not wash and rinse, only spin.

1. preparation for washing

Open the door, put clothes in and closes the door.

2. Press the power button, connect the power.

3. Rotate the program button and choose the “single spinning”

The default rotate speed is 88r/m, pressing “rotate speed” button

can adjust the speed.

4.Press the start/pause button

Begin to drain away water and spin.

5.When the program ends, it will have a hum sound.

If you want to change the current settings during the process of spin,

please push the “Start/Pause” button to stop the washing machine

and then push “spin speed” button to change.

During the process of spinning, the actual spinning speed may be

inconsistent with the program speed, which is because the washer

adjust the speed according to the balance between clothes.

There may be rhythmic drone during spinning, which is the normal

voice of drain bump rather than the machine fault.

Rinse and Spin function Introduction

The machine will not wash, only rinse and spin.

1.Prepare washing

Open the door and put the cloths then close the door

2. Push “Power” button and connect to the power

3. Turn the program button to choose”Rinse+ Spin” program

The washing program will be selected automatically. Take reference on

page 21.

Choose the proper spin speed and rinse times.

4.Push “Start/Pause “button to start washing.

5.When the program ends, it will have a hum sound.

20

。

If you want to change the current setting, please push “Start/Pause”

button first and stop washing, then push “Rinse” and “Spin Speed”

button to reset.

The Spin speed can be selected the highest, but the temperature

cannot be set.

Page 13

19

If you want to change the current setting during the process of

washing, please firstly push"Start/Pause" button to stop the operation,

then to reset different programs.

This mode can not adjust the temperature, spin speed and rinse

times, but can adjust the washing time.

During the process of setting tub clean program, it will alternatingly

display washing remainning time and "CL n".During the process of

operating, it will onl display remainning time.

When the program ends,open the door and dry the inner part of

washing machine in order to prevent the doformation of gasket.

If there are children at home, please don't open the door for too

much time.

Quick Wash 15’ Program Introduction

To wash clothes that are changed frequently, not too dirty and thin clothes

1.Prepare for washing.

Open the door, put the clothes then close the door.

Taking the detergent box and add detergent then close it.

Connect the water inlet pipe well and make sure the faucet is running.

2.Push “Power” button and connect to the power.

3.Turn the program button to choose “quick wash” program

The washing program will be selected automatically. Take reference

on page 21.

Choose the needed water temperature, spin speed, rinse times and

washing intensity.

4.Push “Start/Pause “button to start washing.

5.When the program ends, it will have a hum sound.

If you want to change the current setting during the process of

washing, please push “Start/Pause” button first and stop washing,

then push button to reset.

In order to prevent clothing damage, speed cannot set the highest

speed, the temperature cannot be set to “cold”,” 30℃”,”40℃”

prevent the door from distorting.

In order to ensure the washing effect, washing is suitable for the

washing capacity under 2 k g.

The introduction of function and program

Usage of routine clothes

1.Preparations

Open the door put clothes in and closes the door.

Pull out the detergent box, add detergent and close the box.

Connect the inlet pipes and make sure the tap turned on.

2.Press the power button

3.The programs can be selected according to requirements.

Standard-Eco-Synthetic-Duvet-Delicate-Sports Wear-Wool/Hand wash-Mix-

-Down Jacket-Baby Care-Tub Clean-Quick 15’-Spin Only-Rinse+Spin

4.Press start/pause button and begin to wash

5.Washing Ending

The screen displays “End” with a hum.

Open the door and take out the cloth.

Pull out the plug and close the faucet.

The usage of self-compiled program

You can use it when need to set washing intensity, rinse times, water

temperature, spin speed.

1.Prepare to wash

Open the door, put clothes in and close the door.

Pull out the detergent box, add detergent and close the box.

Connect the inlet pipes and make sure the tap turned on.

2.Press the power button

3. The programs can be selected according to requirements.

4. Push “wash”/”rinse”/”temperature” button to set washing intensity,

rinse times, water temperature, spin speed.

5. Press the start/pause button to start washing.

6.When the program ends, it will have a hum sound.

The screen displays “End” with a hum.

Open the door and take out the cloth.

Pull out the plug and close the faucet.

12

Page 14

Cotton Program Introduction

This program is suitable for the clothes which are moderate or mild dirty,

like cotton, beddings, underwear, towels and shirt, etc…

1.Preparation for washing

Open the door, put the clothes then close the door

Taking the detergent box and add detergent then close it.

Connect the water inlet pipe well and make sure the faucet is running.

2.Push “Power” button and connect to the power

3.Turn the program button to choose “cotton” program

The washing program will be selected automatically. Take reference on page 21.

page 21.

Choose the needed water temperature, spin speed, rinse times and

washing intensity.

4.Push “Start/Pause “button to start washing

5. When the program ends, it will have a hum sound.

Baby Care Function

This program is to wash infant clothing, allergy people clothing and clothing

need high temperature bacteria suppression mite.

1.Prepare for washing

Open the door, put the clothes then close the door.

Taking the detergent box and add detergent then close it.

Connect the water inlet pipe well and make sure the faucet is running.

2.Push “Power” button and connect to the power

3.Turn the program button to choose “quick wash” program

The washing program will be selected automatically. Take reference

on page 21.

Choose the needed water temperature; spin speed, rinse times and

washing intensity.

4.Push “Start/Pause “button to start washing

5.When the program ends, it will have a hum sound.

13

If you want to change the current setting during the process of washing, please

push “Start/Pause” button first and stop washing, then push button to reset.

When the washing machine washing towel, the yarn will be squeezed, washing

will get rough surface, using the fiber softening agent, to prevent this kind of

phenomenon happens to the greatest extent.

The introduction for energy-saving program

To wash the clothes that is not too dirty, it will save time and water.

1.Preparation for washing

Open the door, put clothes in and closes the door.

Pull out the detergent box, add detergent and close the box.

Connect the inlet pipes and make sure the tap turned on.

2. Press the power button, connect the power.

3. Rotate the program button and choose the “energy-saving”

The washing program will be selected automatically. Take reference on

page 21.

Choose the needed water temperature, spin speed, rinse times and

washing intensity.

4. Press the start/pause button and begin to wash.

5. When the program ends, it will have a hum sound.

When the washer is working, if you want to change its setting, please press

the start/pause button to stop running temporarily and then choose the

program you need.

If you want to change the current setting during the process of

washing, please push “Start/Pause” button first and stop washing,

then push button to reset.

Reach the best temperature aseptic divide mite effect, can choose

"9 6 ℃".

When taking the clothes out, pay attention to the internal heating

steam.Before opening the door to take out clothes, please

Tub Clean Function

Tub Clean program is to use high water level, high temperature and high

spin speed to clean and sterilize the inner tube.

1.Preparation for washing

Please make sure nothing in the tub before cleaning.

Open the distribution box, add the liquid bleach in the main box.

Don't add detergent or laundry detergent to prevent causing too much

foam.

Close the distribution box.

Please make sure the inlet pipes connected well and the tap turned on.

2.Press the power button, connect the power.

3.Turn the program button to choose “tub clean” program.

The washing program will be selected automatically. Take reference

on page 21.

4.When the program ends, it will have a hum sound.

18

Page 15

17

Mix Washing Function

This function can be used to wash mix clothes like cotton,synthetic and

so on (please do not mix wash the clothes that easily rub off.

1.Prepare for washing

Open the door, put the clothes then close the door

Taking the detergent box and add detergent then close it.

Connect the water inlet pipe well and make sure the faucet is running.

2.Push “Power” button and connect to the power

3.Turn the program button to choose “duvet” program

The washing program will be selected automatically. Take reference

on page 21.

Choose the needed water temperature, spin speed, rinse times and

washing intensity.

4.Push “Start/Pause “button to start washing

5.When the program ends, it will have a hum sound.

If you want to change the current setting during the process of washing,

please push “Start/Pause” button first and stop washing, then push button

to reset.

In order to prevent clothing damage, speed cannot set the highest speed,

the temperature cannot be set to "60 ℃ and "96 ℃

Please separate white or bright color clothes from dark clothes.

Down Jacket Function

Washing down fill clothing.

1.Prepare for washing

Open the door, put the clothes then close the door

Taking the detergent box and add detergent then close it.

Connect the water inlet pipe well and make sure the faucet is running.

2. Push “Power” button and connect to the power

3. Turn the program button to choose “duvet” program

The washing program will be selected automatically. Take reference

on page 21.

Choose the needed water temperature, spin speed, rinse times and

washing intensity.

4. Push “Start/Pause “button to start washing

5. When the program ends, it will have a hum sound.

If you want to change the current setting during the process of washing,

please push “Start/Pause” button first and stop washing, then push button

to reset.

In order to prevent clothing damage, speed cannot set the highest speed, the

temperature can only be set to “cold”, "30 ℃ and "40 ℃

Synthetic Program Introduction

To wash the synthetic clothes

1.Preparation for washing

Open the door, put the clothes then close the door.

Taking the detergent box and add detergent then close it.

Connect the water inlet pipe well and make sure the faucet is running.

2.Push “Power” button and connect to the power

3.Turn the program button to choose “synthetic” program

The washing program will be selected automatically. Take reference

on page 21.

Choose the needed water temperature, spin speed, rinse times and

washing intensity.

4.Push “Start/Pause “button to start washing

5.When the program ends, it will have a hum sound.

If you want to change the current setting during the process of

washing, please push “Start/Pause” button first and stop washing,

then push button to reset.

In order to prevent clothing damage, speed cannot set the highest

speed, the temperature cannot be set to "96 ℃

Duvet Program Introduction

The cloths have the machine-washable mark, like bedding, bed

sheets, curtains, etc

1.Prepare for washing

Open the door, put the clothes then close the door

Taking the detergent box and add detergent then close it.

Connect the water inlet pipe well and make sure the faucet is running.

2.Push “Power” button and connect to the power

3.Turn the program button to choose “duvet” program

The washing program will be selected automatically. Take reference on

page 21.

Choose the needed water temperature, spin speed, rinse times and

washing intensity.

4.Push “Start/Pause “button to start washing

5.When the program ends, it will have a hum sound.

If you want to change the current setting during the process of washing,

please push “Start/Pause” button first and stop washing, then push button

to reset.

In order to prevent clothing damage, speed cannot set the highest speed,

the temperature cannot be set to "60 ℃ and "96 ℃

The electric blanket and carpet cannot be washed.(It will damage the

machine and clothes).

14

Page 16

15

Put the clothes in the washing drum properly and uniform when

spining, in order to avoid large vibration and drying time may be

extended.

Heavy clothes can not be entanglement, need to put inside the

washing machine after shaking loose.

Uneven clothes can lead to not spining(display UE), take out again

in the after washing to shake loose.

Delicate Function

Washing gauze, silk underclothes.

1.Prepare for washing

Open the door, put the clothes then close the door.

Taking the detergent box and add detergent then close it.

Connect the water inlet pipe well and make sure the faucet is running.

2.Push “Power” button and connect to the power.

3.Turn the program button to choose “duvet” program.

The washing program will be selected automatically. Take reference on

page 21.

Choose the needed water temperature, spin speed, rinse times and

washing intensity.

4.Push “Start/Pause “button to start washing.

5.When the program ends, it will have a hum sound.

If you want to change the current setting during the process of

washing, please push “Start/Pause” button first and stop washing,

then push button to reset.

In order to prevent clothing damage, speed cannot set the highest

speed, the temperature cannot be set to "60 ℃ and "96 ℃.

Sports Wear Function

Wash the machine- washable sports clothes

1. Prepare for washing

Open the door, put the clothes then close the door

Taking the detergent box and add detergent then close it.

Connect the water inlet pipe well and make sure the faucet is running.

2. Push “Power” button and connect to the power

3. Turn the program button to choose “duvet” program

The washing program will be selected automatically. Take reference on

page 21.

Choose the needed water temperature, spin speed, rinse times and

washing intensity.

4.Push “Start/Pause “button to start washing

5.When the program ends, it will have a hum sound.

If you want to change the current setting during the process of

washing, please push “Start/Pause” button first and stop washing,

then push button to reset.

In order to prevent clothing damage, speed cannot set the highest

speed, the temperature cannot be set to "60 ℃ and "96 ℃

Wool/Hand Wash Function

Wash wool fiber texture, such as machine washable wool fabrics, etc.

1.Prepare for washing

Open the door, put the clothes then close the door

Taking the detergent box and add detergent then close it.

Connect the water inlet pipe well and make sure the faucet is running.

2.Push “Power” button and connect to the power

3.Turn the program button to choose “duvet” program

The washing program will be selected automatically. Take reference

on page 21.

Choose the needed water temperature, spin speed, rinse times and

washing intensity.

4.Push “Start/Pause “button to start washing

temperature, dewatering speed and appoint time.

5. When the program ends, it will have a hum sound.

If you want to change the current setting during the process of

washing, please push “Start/Pause” button first and stop washing,

then push button to reset.

In order to prevent clothing damage, speed cannot set the highest

speed, the temperature cannot be set to "60 ℃ and "96 ℃

After washing completed, take the clothes in time, drying, after

shaking loose plastic deformation in order to avoid placing time

is too long.

Please separate white or bright color clothes from the dark clothes

for washing.

Using special wool detergent can reduce clothing damage, improve

the washing effect.

16

Loading...

Loading...