Keep this manual with the vehicle at all times.

8990504

OWNERS/OPERATORS

MANUAL

Model MMV

(S/N MV201 & After)

(Tier 2)

OM0652

TM 10794B-12/1

Printed in U.S

.A. 10/11

PCN 500 107943 00

WARNING: Improper operation of this vehicle can

CALIFORNIA

Proposition 65 Warning

Diesel Engine exhaust and some of its constituents

are known to the State of California to cause

cancer, birth defects and other reproductive harm.

CALIFORNIA

Proposition 65 Warning

Battery posts, terminals and related accessories

contain lead and lead compounds, chemicals

known to the State of California to cause cancer

and birth defects or other reproductive harm.

Wash hands after handling

.

cause injury or death. Only trained and authorized operators

should operate this vehicle.

Before starting the engine, do the following:

1. Read this owner/operators manual.

2. Read all the safety decals on the vehicl e.

3. Clear the area of other persons.

Learn and practice safe use of vehicle controls in a safe,

clear area before you operate this vehicle on a worksite.

It is your responsibility to observe applicable laws and

regulations and to follow manufacturer's instructions on

vehicle operation and maintenance.

Revision Log

Revision Log

December 17, 2004 - B - Replaced all branding with JLG.

October 12, 2011 - C - Revised pages 22, 27, 66, 67, 70, 157, 170, 171, 182 thru

185, 193, 201, 218, 219, 221, 222 & 246.

REVISION LOG

8990504

a

Revision Log

b

8990504

Table of Contents

Revision Log

Introduction

The Manual....................................2

Replacement Parts........................2

Reports..........................................2

Disclaimer......................................3

Safety Practices

Hazard Classification System........3

Accident Prevention Tags..............5

New or Additional Operators .........5

Instructional Symbols ....................6

Hazard Symbols............................7

Avoidance Symbols.......................8

Avoidance Symbols (cont’d)..........9

Personal Considerations .............10

Operational Considerations.........14

Equipment Considerations ..........20

Operation

Operator Controls........................23

Front Dash Panel.........................54

Instruments and Indicators..........61

Pre-Operation Inspection.............66

Normal Starting............................67

Cold Starting................................68

Slave Starting..............................70

Refueling .....................................71

Operating.....................................73

Carriages.....................................84

Using the Capacity Chart.............92

Load Capacity To Travel

Speed Tables ...........................94

Fork Rating................................104

How To Pick, Carry & Place

A Load.................... ... .............105

Elevating Personnel...................107

Shut-Off.....................................113

Emergency Operations

Towing a Disabled Vehicle........114

Emergency Boom Lowering ......123

General Maintenance

Introduction................................137

Maintenance Schedule and

Checklist.................................138

1. Lubrication Points ................141

2. Air Cleaner...........................143

3.Closed Cab Air Filters...........147

4.Engine Cooling System ........148

5.Engine Oil and Filter .............152

6.Engine Fuel System..............157

7.Engine Fan Belt....................162

8.Air Conditioner

Compressor Belt ...............163

9.Hydraulic Oil and Filter .........164

10.Transmission Oil

and Filter...........................169

11.Axle Oil ...............................172

12.Brake Disk Inspection.........175

13.Wheel End Oil.....................179

14.Transfer Case Oil................182

15.Wheels and Tires................186

16.Emergency Tire

Inflation System.................188

17.Batteries..............................192

18.Fuse & Relay

Replacement.....................194

19.Boom Chains and

Wear Pads ........................203

Storage and Transport ..............218

Short Term Storage...................218

Long Term Storage...................220

Counterweight Removal

and Reassembly.....................223

Transport...................................226

Test Procedures

Stabil-TRAK™ System Test ......236

Parking Brake/Transmission

De-Clutch

Test Procedures.....................241

Four Wheel Steer Indexing

Procedure...............................244

Specifications

Fluid & Lubrication Capacities...245

Tires .......................................... 247

Weights .....................................248

Vehicle Dimensions...................249

Electrical System.......................250

Engine.......................................252

Index.............................................255

Accident Prevention Tags

Replacement Manuals...................1

This document has been prepared by JLG Industries Inc. for the USMC, 2004.

Approved for public release; distribution is unlimited.

1

Introduction

OM1370

1

Introduction

The Manual

This Owners/Operators Manual provides the information you need to

operate and maintain this vehicle.

IMPORTANT! Before

and carefully so you will understand the instructions and the operation of

the controls and equipment. You must comply with all Danger, Warning,

and Caution notices; they are for your benefit.

All references to the right side, left side, front, or rear are given from the

operator's seat looking forward.

you operate this vehicle, read this manual completely

Replacement Parts

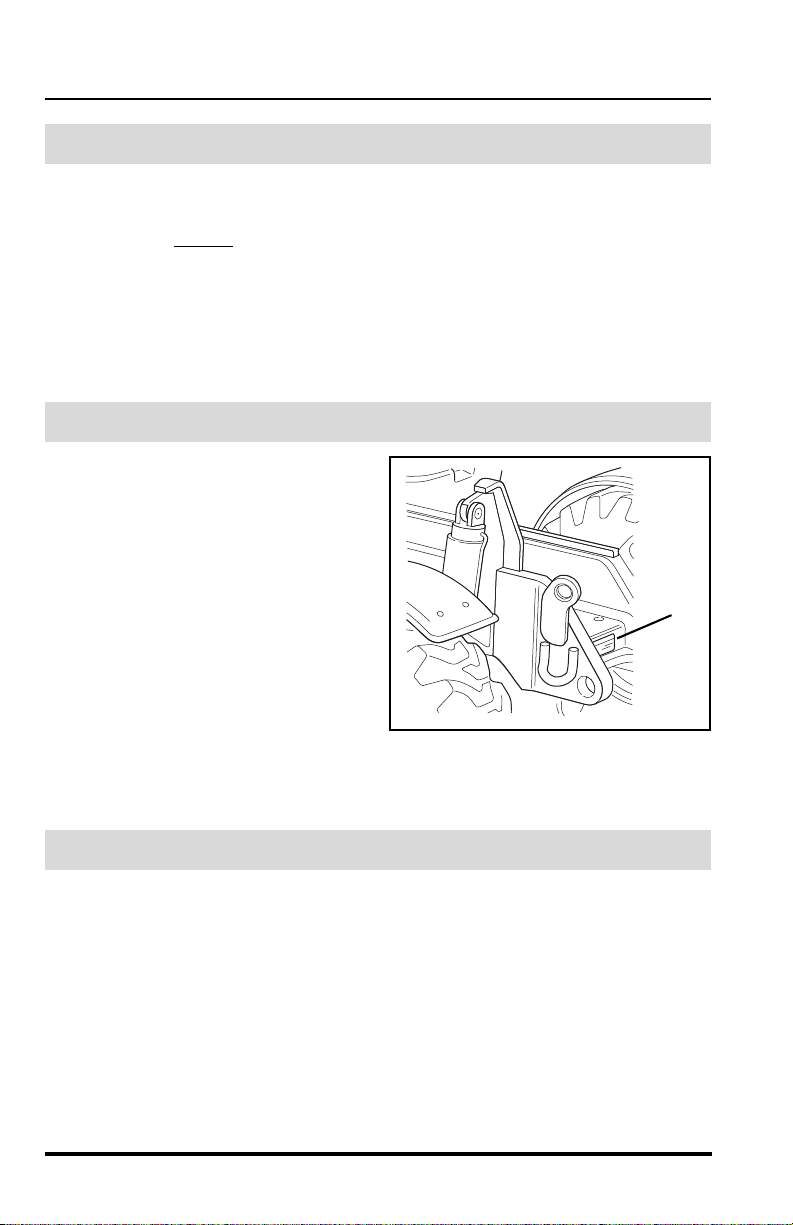

For easy reference when ordering

replacement parts or making service

inquiries on this vehicle, record its

model and serial number on the back

cover of this manual. The serial

number is stamped into the serial

number plate (1) which is located on

the vehicle’s frame.

IMPORTANT! The re pla ce m en t of

any part on this vehicle by anything

other than a JLG authorized

replacement part may adversely

affect the performance, durability or

safety of this vehicle and may void the warranty. JLG assumes no liability

for unauthorized replacement parts which adve rsely affect the perfo rmance,

durability or safety of this vehicle.

Reports

IMPORTANT! A Warranty Registration form must be filled out by the JLG

Authorized Service Center (ASC), signed by the purchaser, and returned to

JLG once the product is sold and/or put into service. This report activates

the warranty period, assuring that your claims during the warranty period

will be processed promptly. To guarantee full warranty service, make sure

your Authorized Service Center (ASC) has returned th e business reply card

of this form to JLG.

2

Model MMV Rev. 10/11

Safety Practices

OP0330

Disclaimer

JLG reserves the right to make changes on and to add improvements upon

its products at any time without public notice or obligation. JLG also

reserves the right to discontinue manufacturing any product at its d iscretion

at any time.

NOTICE: Under OSHA rules, it is the responsibility of the employer to

provide operator training. Successful completion and certification of Safety

Training for Rough Terrain Forklifts is required. Operator Training Kits are

available by calling Ken Cook Company at (414) 466-6060. An order form

for these kits is available through our website,

http://www.jlg.com.

The information in this manual does not replace any safety rules and laws

used in your area. Before operating this vehicle, learn the rules and laws for

your area. Make sure the vehicle has the correct equipment according to

these rules and laws.

Your safety and the safety of others in the worksite depend significantly

upon your knowlege and understanding of all correct operatin g practices

and procedures for this vehicle.

WARNING: DO NOT modify or alter (weld, drill, etc.)

any part of this vehicle without consulting JLG. Modifications can

weaken the structure creating a hazard that can cause death or

serious personal injury.

Safety Practices

Hazard Classification System

This safety alert symbol is used with the following signal words to attract

your attention to messages found within the manual and on hazard decals

located on the vehicle. They are reproduced herein and pertain to proper

operation and procedure messages contained throughout the manual. The

message that follows the symbol contains important information about

Safety. To avoid possible death or serious personal injury, carefully read

and follow the messages! Be sure to fully understand the potential causes

of death or injury.

Model MMV Rev. 10/11

3

Safety Practices

Signal Word

A signal word is a distinctive word located on hazard decals and used

throughout this manual that alerts the viewer to the e xistence of and relative

degree of the hazard.

DANGER:

The signal word “DANGER” indicates an imminently hazardous situation

which, if not avoided, will result in death or serious personal injury.

WARNING:

The signal word “WARNING” indica tes a potentially hazardous situation

which, if not avoided, could result in death or serious personal injury.

CAUTION:

The signal word “CAUTION” indicates a potentially hazardous situation

which, if not avoided, may result in minor or moderate injury.

CAUTION:

The signal word “CAUTION”, used without the safety alert symbol, indicates

a potentially hazardous situation which, if not avoided, may result in

property damage.

For safe maintenance of the vehicle, read, understand and follow all

DANGER, WARNING and CAUTION information.

4

Model MMV Rev. 10/11

Safety Practices

DANGER

DANGER

OM1750

1

2

3

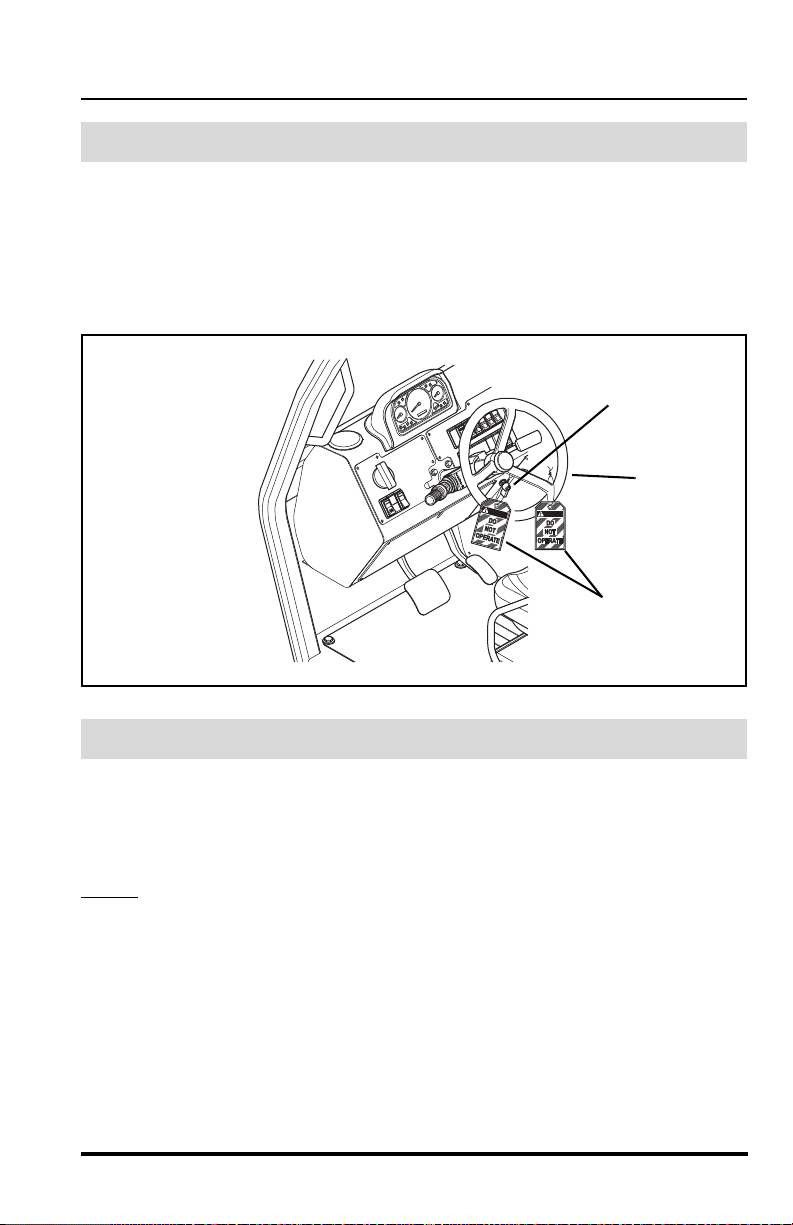

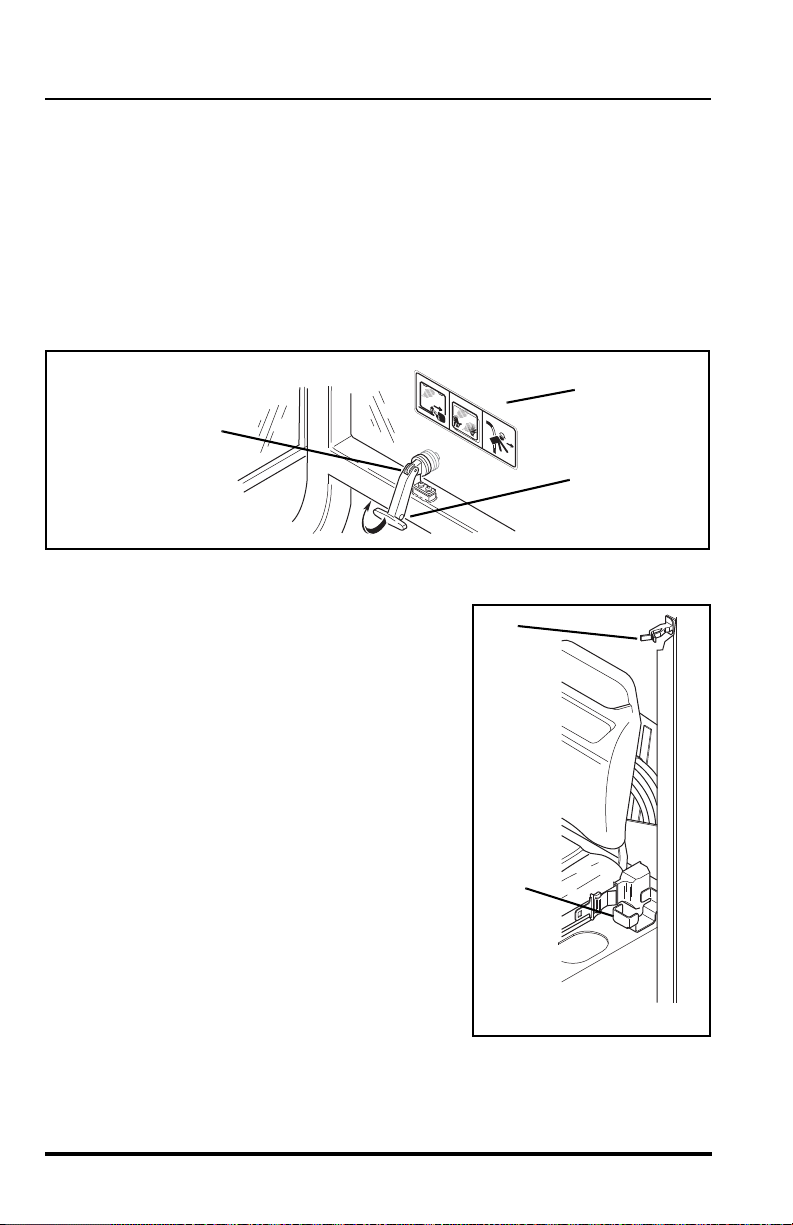

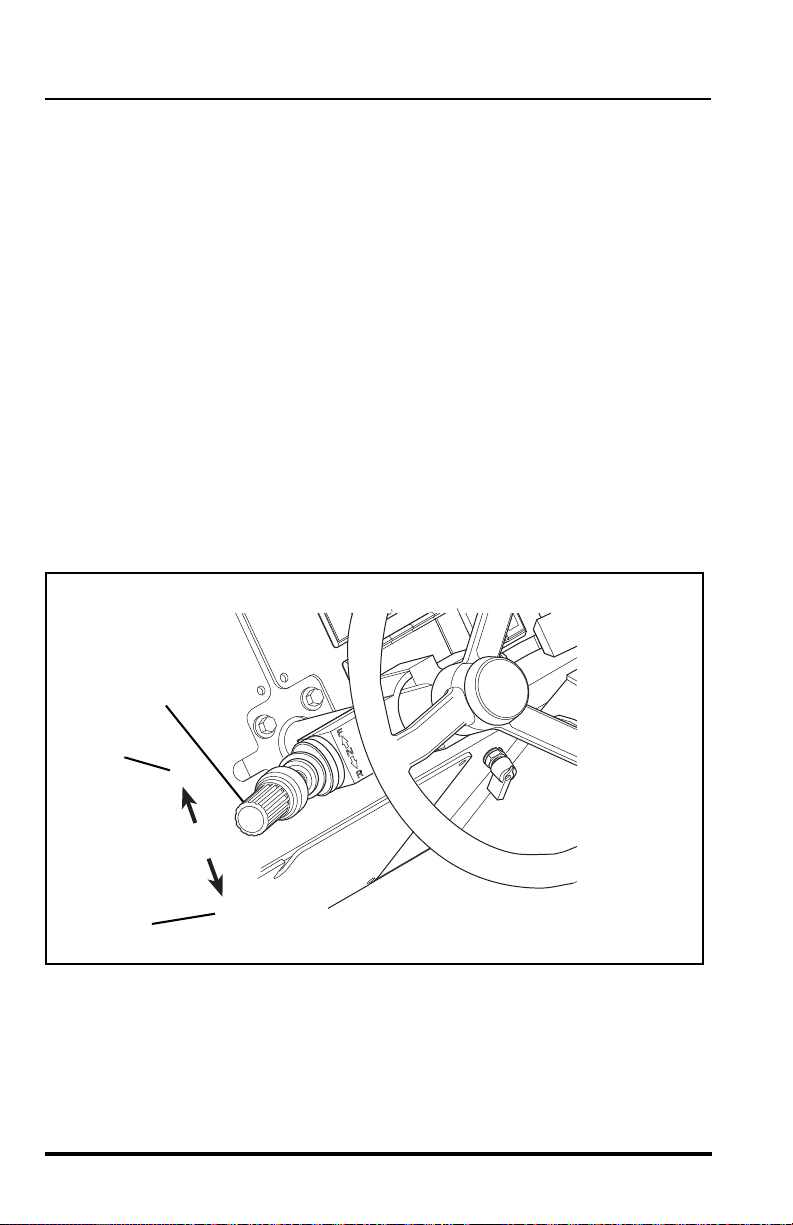

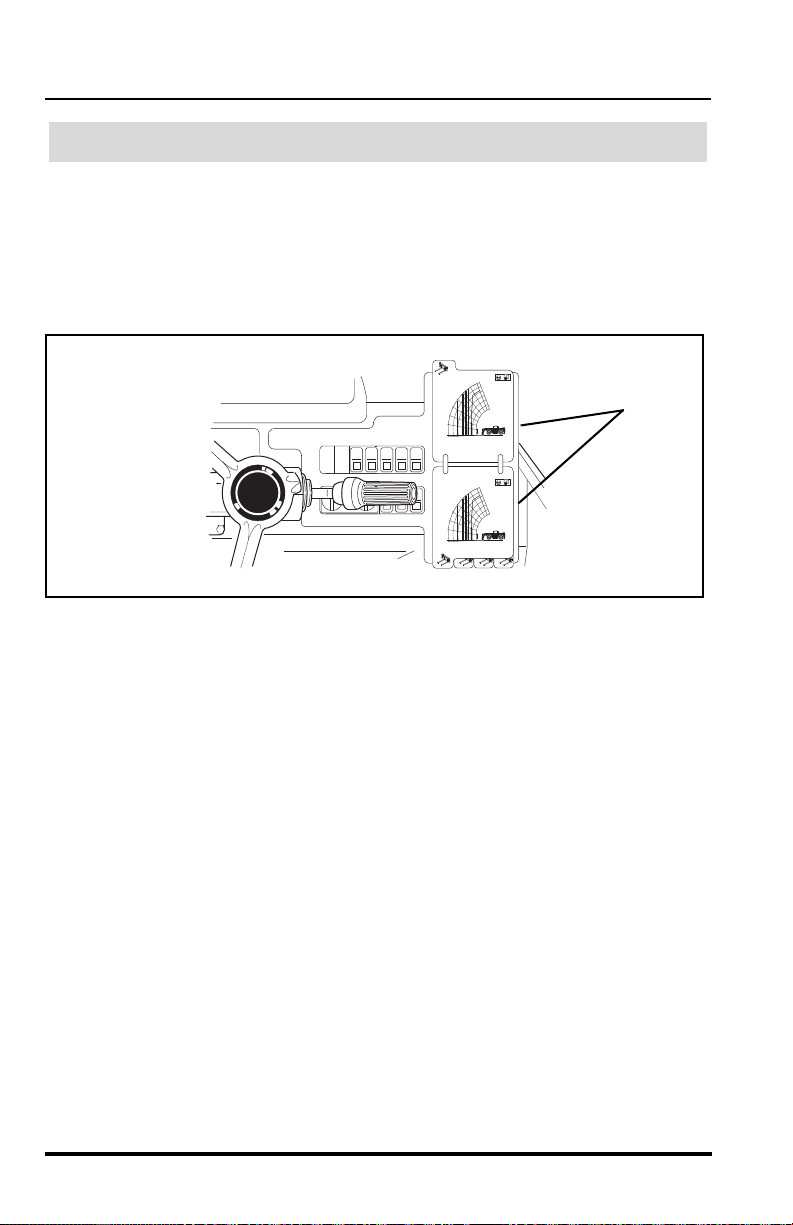

Accident Prevention Tags

Before beginning any maintenance or service, place an Accident

Prevention Tag (1) on both the ignition switch (2) and t he steering wheel (3),

stating that the vehicle should not be operated. Actual Accident Prevention

Tags, which can be punched out and used, are included as the last page of

this manual. Retain these Accident Prevention Tags for reuse at a later

date.

New or Additional Operators

At the time of original purchase, the purchaser of this vehicle was instruct ed

by the seller on its proper use. If this vehicle is to be used by an employee

or is loaned or rented to someone other than the purchaser, make certain

that the new operator is trained, in accordance with the OSHA re gu la tio ns

referenced on page 3, and reads and understands this Operators Manual

before

operating the vehicle.

In addition, make sure that the new operat or has completed a walk-around

inspection of the vehicle, is familiar with all decals on the vehicle, and has

demonstrated the correct use of all controls.

Model MMV Rev. 10/11

5

Safety Practices

OP0330

OH2100

OH2090

Safety Alert Symbol

Read Operator’s Manual

Fasten Seat Belt

Instructional Symbols

The following symbol definitions will help you understand all hazard

related decals used on this vehicle.

6

Model MMV Rev. 10/11

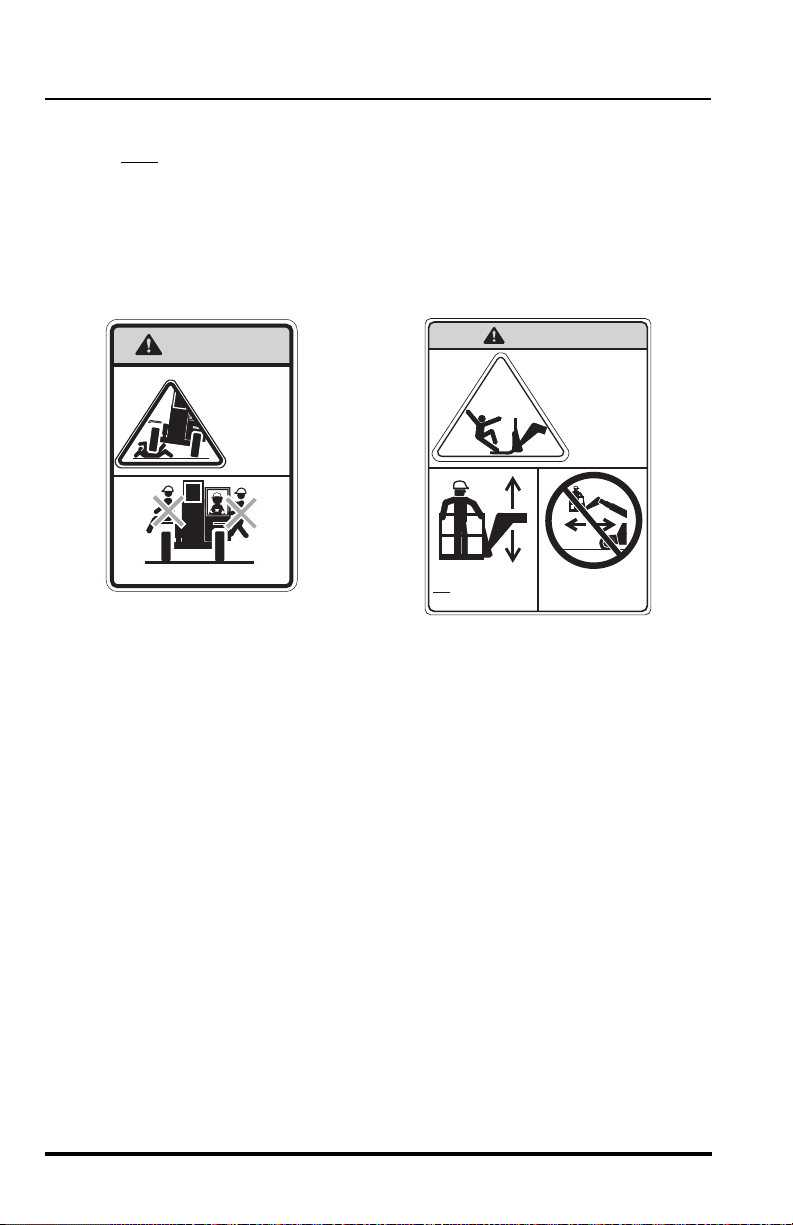

Hazard Symbols

-

OH2110

Lead Acid Batteries

Generate Explosive Gases

OH2120

OH2300

OH2161

OH2130

OH2140

OH2150

Rotating Fan Blades

Can Cut

Rotating Belts Can Cut

Or Entangle

Vehicle Tipover Can

Crush

Vehicle Roll Away Can Cause

Death Or Serious Injury

Electrocution Can

Cause Death Or

Serious Injury

FALLING OFF ATTACHMENT

Can Result In Death Or Serious

Injury

OH3160

OU1450

ENGINE EXPLOSION

Can Result In Death

Or Serious Injury

AVOID CRUSHING, Falling Off

Vehicle Can Cause Death Or

Serious Injury

Safety Practices

Model MMV Rev. 10/11

7

Safety Practices

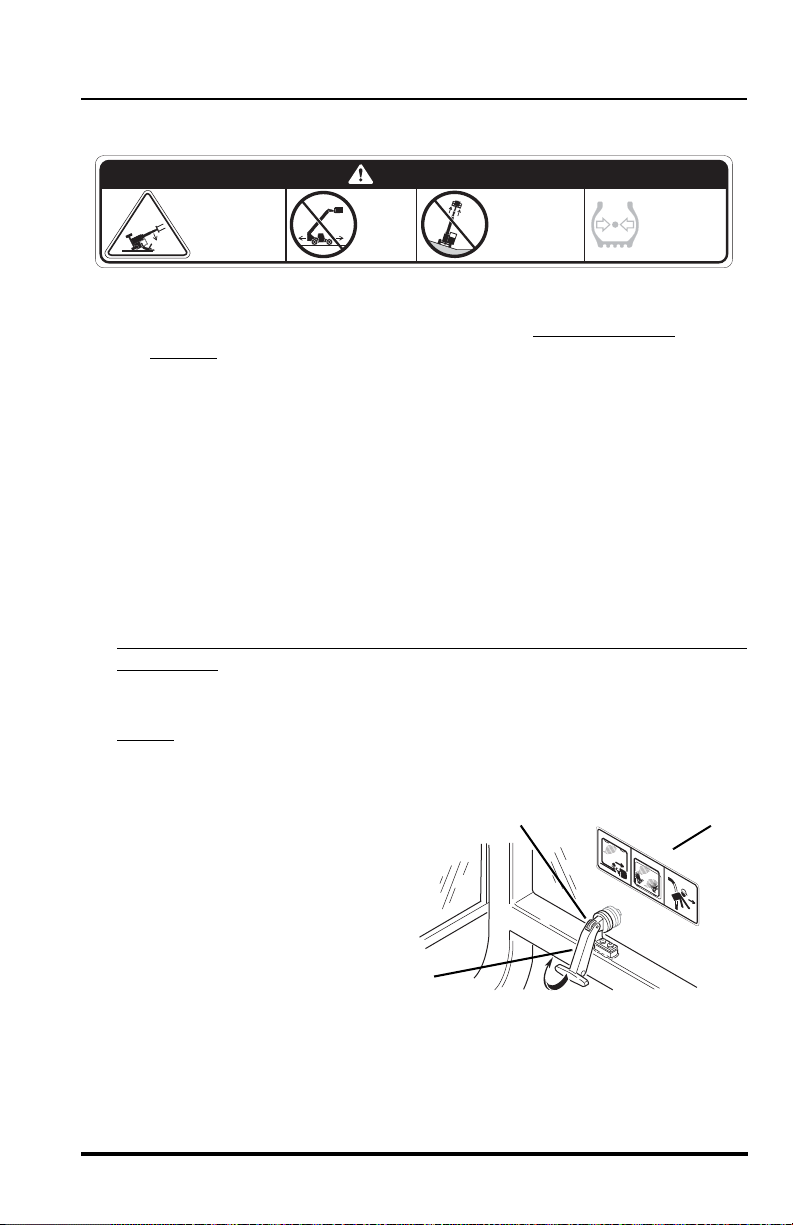

OH2320

Keep Lit Cigarettes

Away

OH2310

OH2280

OH2330

OH2270

OH2290

Keep Away From

Rotating Fan Blades

Do Not Raise Boom

While On A Slope

Keep Flames and

Ignition Sources Away

Do Not Travel With

Boom Raised

Maintain Proper Air

Pressure In Tire

OU1460

DO NOT Use Ether Or

Other High Energy

Starting Aids.

Engine Equipped With

Grid Heating System.

Avoidance Symbols

8

Model MMV Rev. 10/11

Safety Practices

OH2260

Engage Parking Brake

OH2240

OH2220

OH2250

OH2230

OH2170

Do Not Travel With

Personnel In Work

Platform

DO NOT JUMP

Keep Clear Of Power

Lines

Carry No Riders

Use Only Compliant

Work Platforms To

Raise Or Lower

Personnel

• Brace Yourself and Stay

With Vehicle

• Keep Seat Belt Fastened

• Hold On Firmly

• Lean Away From The

Point Of Impact

Avoidance Symbols (cont’d)

Model MMV Rev. 10/11

9

Safety Practices

ALWAYS

engage parking brake

before dismounting

WARNING

VEHICLE

ROL LAWAY

can cause

death or

serious

injury

OU0340

Personal Considerations

1. Seat Belt

Always fasten the seat belt before starting the engine.

2. Clothing and Safety Gear

DO NOT wear loose clothing or jewelry that can get caught on controls

or moving parts. Wear protective clothing and personal safety gear

issued or called for by job conditions.

3. Dismounting

DO NOT get off the vehicle until you:

• level the vehicle,

• ground the carriage,

• place the travel select lever in (N)

NEUTRAL,

• place the neutral lock lever in (N)

NEUTRAL LOCK,

• engage the parking brake switch,

• turn the engine off, if appropriate,

• unbuckle the seat belt,

• exit the vehicle using the hand holds.

4. Chemical Hazards

A. Exhaust Fumes

Fumes from the engine exhaust can cause death or serious

personal injury. DO NOT operate vehicle in an enclosed area

without a ventilation system capable of routing the hazard ous

fumes outdoors.

B. Explosive Fuel

Engine fuel is flammable and can cause a fire and/or an explosion.

Avoid danger by keeping sparks, open flames and smoking

materials away from the vehicle and from fuel during refueling or

when servicing the fuel system. Know where fire extinguishers are

kept on the worksite and how to use them.

10

Model MMV Rev. 10/11

Safety Practices

4110460

ENGINE EXPLOSION can

result in death or serious

personal injury.

DO NOT use Ether or other

high energy starting aids.

Engine equipped with

grid heating system.

OU1470

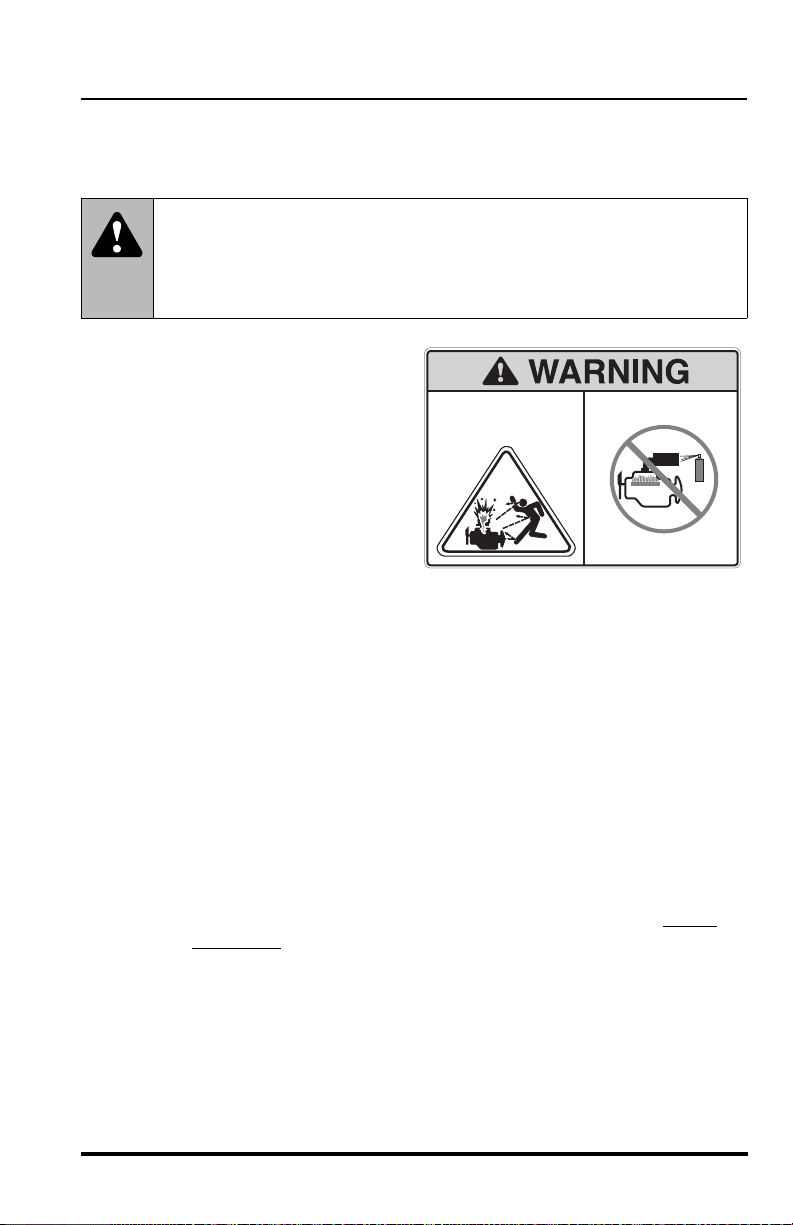

C. Ether or High Energy Starting Aids

The engine utilizes a grid heating system inside the induction

manifold for cold starting conditions.

WARNING: This diesel engine uses a grid heating sys-

tem inside the induction manifold. DO NOT use ether or any high

energy fuels to assist starting. An explosion may cause death or

serious personal injury or engine damage.

DO NOT use ether or any

other high energy starting

aids during cold starting. An

engine explosion can result

in death or serious personal

injury.

D. Hydraulic Fluid

DO NOT attempt to repair or tighten any hydraulic hoses or fittings

while the engine is running or when the hydraulic system is under

pressure. Fluid in the hydraulic system is under enough pressure

that it can penetrate the skin causing death or serious personal

injuries.

Model MMV Rev. 10/11

HOT HYDRAULIC FLUID WILL CAUSE SEVERE BURNS. Wait

for fluid to cool down before disconnecting lines.

DO NOT use your hand to check for leaks. Use a piece of

cardboard or paper to search for leaks. Wear gloves to protect

hands from spraying fluid.

Hydraulic fluid can cause permanent eye injury. Wear appropriate

eye protection and stop engine. Relieve pressure before

disconnecting lines. Pressure can typically be relieved by slowly

and cautiously

loosening one end of a hose at the swivel

connection.

If anyone is injured by or if any hydraulic fluid is injected into the

skin, obtain medical attention immediately or gangrene may result.

11

Safety Practices

-

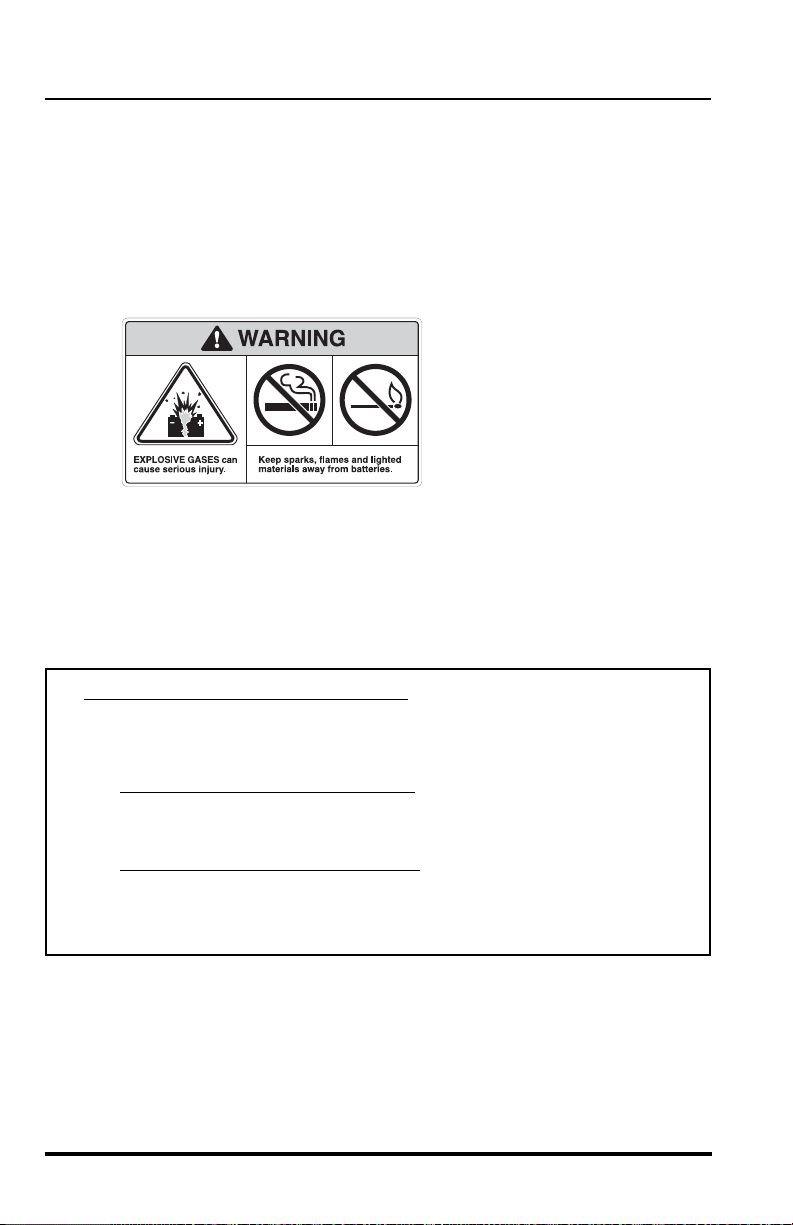

OS0621

Battery Electrolyte First Aid:

• External Contact — Flush with water.

• Eyes — Flush with water for at least 15 minutes and

get medical attention immediately

.

• Internal Contact — Drink large quantities of water. Follow

with Milk of Magnesia, beaten egg or vegetable oil.

Get medical attention immediately

.

IMPORTANT! In case of internal contact, DO NOT give fluids that

would induce vomiting!

E. Batteries

The following WARNING is intended to supplement and does not

replace the warnings and information provided on the batteries by

the battery manufacturer.

When slave starting the vehicle, carefully follow instruction s f ound

under “Slave Starting” on page 70.

Keep sparks, flames and lit smoking materials away from the

batteries at all times. Lead acid batteries generate explosive

gases. Severe chemical burns can result from improper handling of

battery electrolyte. Wear safety glasses and proper protective gear

when handling batteries to prevent electrolyte from coming in

contact with eyes, skin or clothing.

12

Model MMV Rev. 10/11

Safety Practices

MOVING PARTS can cut.

Keep clear of fan and belts

while engine is running.

MOVING PARTS can entangle.

OT0810

5. Moving Parts Hazard

DO NOT place limbs near moving parts. Severing of any body part can

result.

Turn of f engine and wait until fan and belts stop moving before

servicing.

6. Lowering Boom or Falling Load Hazard

DO NOT get under a raised boom unless it is blocked up sa fely. Always

empty the attachment of any load and block the boom up before doing

any servicing that would require the boom to be raised.

NEVER allow anyone to walk or stand under the boom. A lowering

boom or falling load can result in death or serious personal injury.

Model MMV Rev. 10/11

13

Safety Practices

Operational Considerations

1. Preparation and Prevention

Know the location and function of all vehicle controls.

Make sure all persons are away from the vehicle and that the travel

select lever is in the (N) NEUTRAL position and the Neutral Lock Lever

is in the (N) NEUTRAL LOCK position with the parking brake switch

engaged before starting the engine.

Holes, obstructions, debris and other worksite hazard s can cause death

or serious personal injury. Always walk around and look for these and

other hazards before operating the vehicle in a new worksite.

Prevent accidents when you move the vehicle around the worksite.

Know the rules for movement of people and vehicles on the worksite.

Have a person act as a lookout for you. Follow the instructions of

signals and signs.

DO NOT operate the vehicle unless all hazard and instructional decals

are in place and readable. (Replace all missing, illegible, or damaged

decals.)

2. Clearances

Look out for and avoid other personnel, machiner y and vehicles in the

area. Use a spotter if you do not have a clear view of conditions that

affect clearances. Travel with the boom fully retracted and lowered as

far as possible while still maintaining enough ground clearance for

conditions.

Always check boom clearances carefully before driving underneath

door openings, bridges, etc.

Always check for power lines when raising the boom. Beware of

overhead wires. Contact with electrical power lines can result in

electrocution. See “Electrocution Hazards” on page 15.

3. Visual Obstruction

Dust, smoke, fog, etc. can decrease vision and cause an accident.

Always stop or slow the vehicle until the obstruction clears and the

worksite is visible again. Have a lookout person assist you.

Where the load will obstruct the operator’s vision, it is recommended

that the vehicle be operated in REVERSE, looking backwards in the

direction of travel. Travel at a slower speed and get someone to direct

you.

14

Model MMV Rev. 10/11

Safety Practices

OS0063

4. Underground Hazards

Know the location of all underground hazards before operating this

vehicle in a new area or worksite. Electrical cables, ga s an d wa te r

pipes, sewer, or other underground objects can cause death or serious

personal injury . Contact your local underground utility service or diggers

hotline to mark all underground hazards.

5. Electrocution Hazards

NEVER operate this vehicle in an area where overhead powe r lines,

overhead or underground cables, or other power sour ces may exist

without first requesting that the appropriate power or utility company deenergize the lines, or take other suitable precauti ons.

Model MMV Rev. 10/11

15

Safety Practices

WARNING

Allow no riders

AVOI D

CRUSHING,

falling off

vehicle can

cause death

or serious

injury

FALLING OFF ATTACHMENT,

can result in death or

serious injury.

DO NOT TRAVEL

with personnel in

a work platform.

4110389

Lift or lower personnel

only in a compliant

work platform.

WARNING

OU0620

OH3180

6. Elevating Personnel

Use only a compliant work platform meeting the ASME B5 6.6 standards

for lifting and lowering per sonnel. NEVER transpo rt personnel in a work

platform for even the shortest distance.

Death or serious personal injury can occur if these rules are not

obeyed. Riders can fall and be crushed or run over. Avoid accidents.

For other specific precautions, See “Elevating Personne l” on page 107..

16

Model MMV Rev. 10/11

Safety Practices

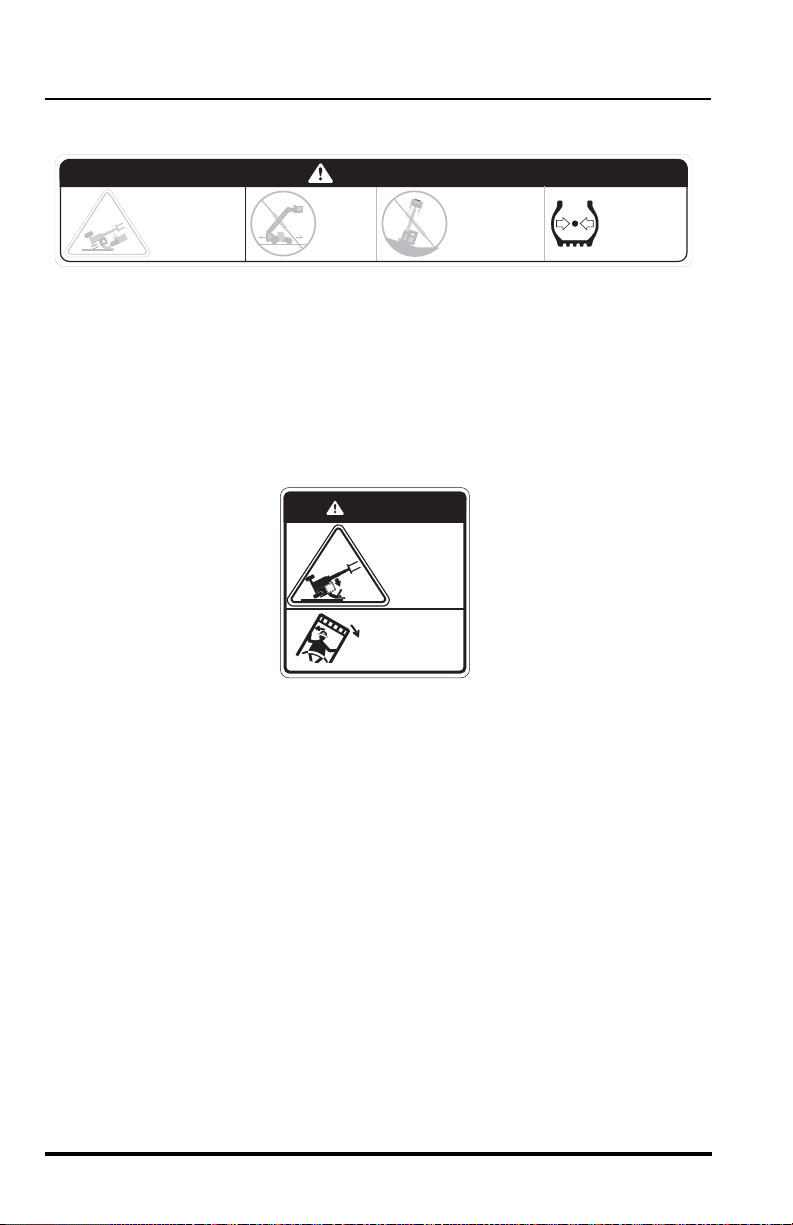

DANGER

DO NOT raise

boom while

on a slope

unless load

is level.

VEHICLE

TIPOVER

can result

in death or

serious injury.

DO NOT

travel

with the

boom

raised.

MAINTAIN

proper tire

pressure at

all times.

OS0086

2.

3.

1.

2

1

3

OU09201

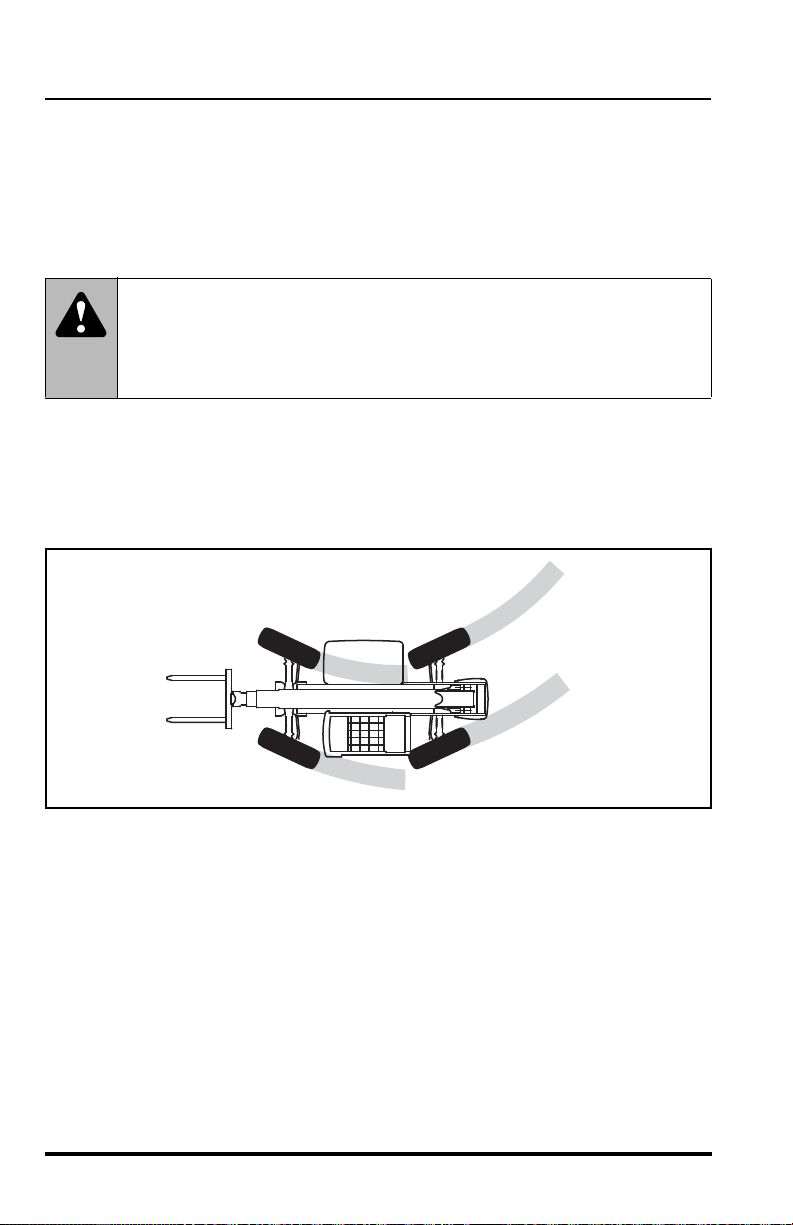

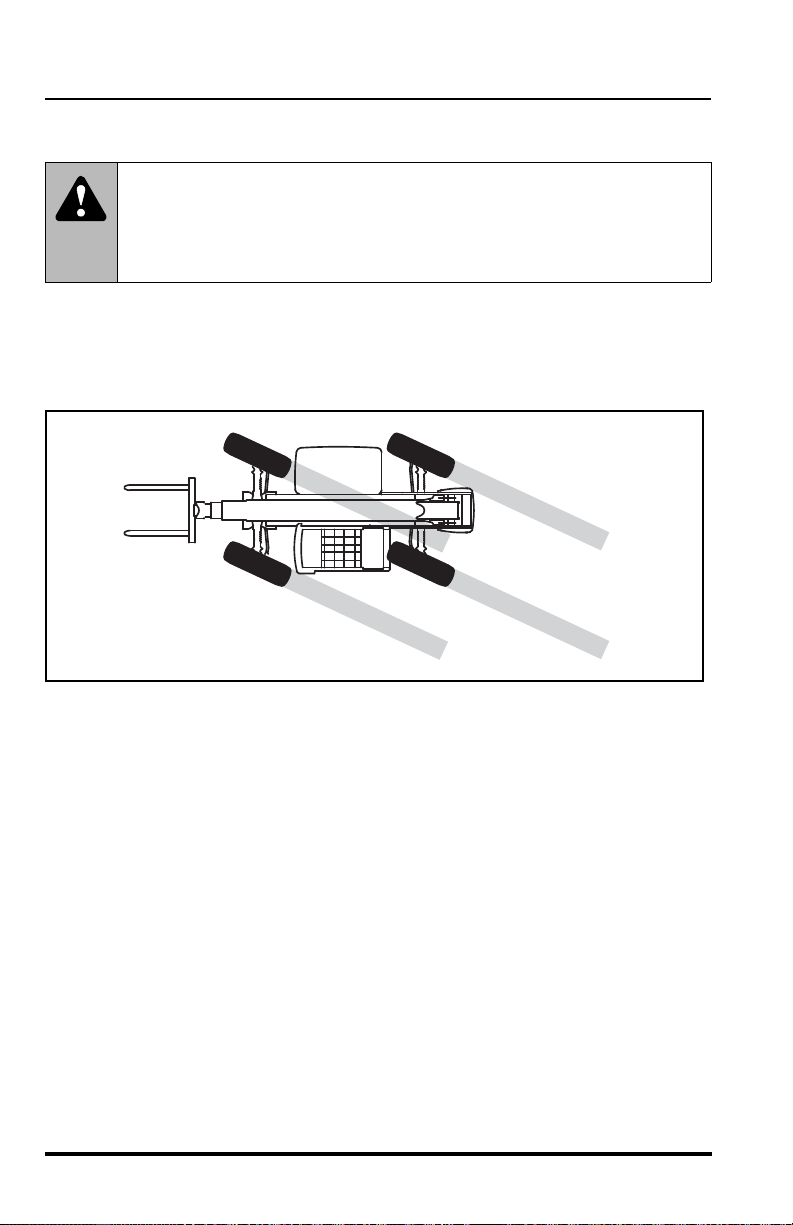

7. Tip Over Hazard

Traveling with the boom raised is dangerous and can cause tipover.

Keep the boom as low as possible. Travel with ex treme caution

the slowest

possible speed.

Keep the vehicle under control at all times. When negotiating turns,

slow down and turn the steering wheel in a smooth sweeping motion.

Avoid jerky turns, starts or stops. Reduce vehicle speed on rough

ground and slopes.

DO NOT exceed the rated lift capacity of the vehicle as structural

damage and unstable conditions will result.

To ensure that the vehicle is positioned in the most stable condition

before operating an attachment, use the frame sway control (frame tilt)

to level the vehicle. The vehicle is level when the frame level indicator

gauge reaches (0°) zero degrees.

If the vehicle cannot be leveled using the frame sway control, repositio n

the vehicle.

Frame swaying left or right with the boom raised above horizontal is

dangerous. Always use the frame sway control to level the vehicle

before

raising the boom above horizontal, with or without a load. If t he

vehicle cannot be leveled using frame sway control, reposition the

vehicle.

8. Emergency Exit Rear

Window

and at

The rear window (1) in the

enclosed cab can be used

as an emergency exit by

removing the latch pin (2)

located on the window latch

(3). The window is then free

to swing open.

Model MMV Rev. 10/11

17

Safety Practices

DANGER

DO NOT raise

boom while

on a slope

unless load

is level.

VEHICLE

TIPOVER

can result

in death or

serious injury.

DO NOT

travel

with the

boom

raised.

MAINTAIN

proper tire

pressure at

all times.

OS0085

DO NOT JUMP.

Brace yourself.

Stay in cab.

Keep seat belt on.

if vehicle tips.

Jumping can

result in death

or serious

injury.

DANGER

AVOID CRUSHING

OH3190

9. Tire Pressure

MAINTAIN proper tire pressures at all times. An underpressurized

tire(s) adversely affects vehicle stability. If proper tire pressures are not

maintained, this vehicle can tip over.

To ensure proper vehicle stability, check all four tire pressures before

operating the vehicle.

10.Do Not Jump

If a vehicle ever becomes unstable and starts to tip over:

• BRACE YOURSELF and STAY WITH THE VEHICLE,

• KEEP YOUR SEAT BELT FASTENED,

• HOLD ON FIRMLY and

• LEAN AWAY FROM THE POINT OF IMPACT.

Indecision and trying to escape from a tipping vehicle can result in

death or serious personal injury.

18

Model MMV Rev. 10/11

Safety Practices

11. Slopes

DO NOT park the vehicle on an incline and leave it unattended.

• Driving across a slope is dangerous, as unexpected changes in

the slope can cause tipover. Ascend or descend slopes slowly

and with caution

• Ascend or descend slopes with the heavy end of the vehicle

pointing up

NOTE: The rear of the vehicle is normally considered the he avy end unless

the carriage is fully loaded. In this case the front of the vehicle is now the

heavy end.

• Unloaded vehicles should be operated on all slopes with the

carriage pointing down

• On all slopes, the load must be tilted back and raised only as far

as necessary to clear the ground.

• When operating on a downhill slope, reduce travel speed and

downshift to a low gear to permit compression braking by the

engine and aid the application of the service brakes.

.

the slope.

the slope.

12.Falling Load Hazard

DO NOT exceed the total rated load capacity of the specific type fork

being used. Each fork is stamped with a maximum load capacity. If the

capacity is exceeded, forks may break. See “Fork Rating” on page 104.

DO NOT downshift at a high ground speed. Sudden slowing can cause

the load to drop off the forks.

13.Ventilation

Sparks from the electrical system and the engine exhau st can cause an

explosion. DO NOT operate this vehicle in an area with flammable dust

or vapors unless good ventilation has removed the hazard.

Carbon monoxide fumes from the engine exhaust can cause

suffocation in an enclosed area. Good ventilation is very important

when operating this vehicle.

Model MMV Rev. 10/11

19

Safety Practices

4110468

CAUTION

ENGINE OVERHEATING

can occur.

Consult Operator Manual

for coolant filling

procedure.

OM2290

Equipment Considerations

WARNING: DO NOT modify or alter (weld, drill, etc.)

any part of this vehicle without first consulting JLG. Modifications

can weaken the structure creating a hazard that can cause death

or serious personal injury.

DO NOT by-pass or disconnect any electrical or hydraulic circuits.

Consult the JLG Service Department or your local JLG Authorized

Service Center (ASC) if any circuit is malfunctioning.

DO check for frayed or cut seat belt webbing, damaged buckles or

loose mounting brackets. Replace immediately if required.

ALWAYS wear a seat belt when operating the vehicle.

DO check tire pressure on all four tires. Add air if required.

DO check the condition of all four rims. Check for bent flanges and/or

bead mounting areas.

DO check the parking brake/transmission de-clutch operation. Refer to

the test procedures on page 241. Repair immediately if required.

DO keep all non-skid surfaces clean and free of debris. Replace if worn,

damaged or missing.

DO check the condition of decals and/or decal plates. Replace decals

or decal plates if missing, damaged or illegible. The following page s

show the proper location of the decals and/or decal plates.

Engine cooling system MUST be properly filled and all trapped air bled

from the cooling system. Refer to “Drain and Flush Radiator” on

page 149 for filling and bleeding procedures.

20

Model MMV Rev. 10/11

Safety Practices

WARNING

Allow no riders

AVOID

CRUSHING,

falling off

vehicle can

cause death

or serious

injury

DO NOT JUMP.

Brace yourself.

Stay in cab.

Keep seat belt on.

if vehicle tips.

Jumping can

result in death

or serious

injury.

DANGER

AVOID CRUSHING

SAFETY

INSTRUCTIONS

4110361

1. Read operator's

manual before

operating.

2. Fasten

seat

belt.

3. Allow

no

riders.

4. Use a compliant

work platform to lift

or lower personnel.

0000000

RPM X 100

5

10

15

30

20

25

F

1/2

E

104

176

80

248

120

°C

°F

D

r/min

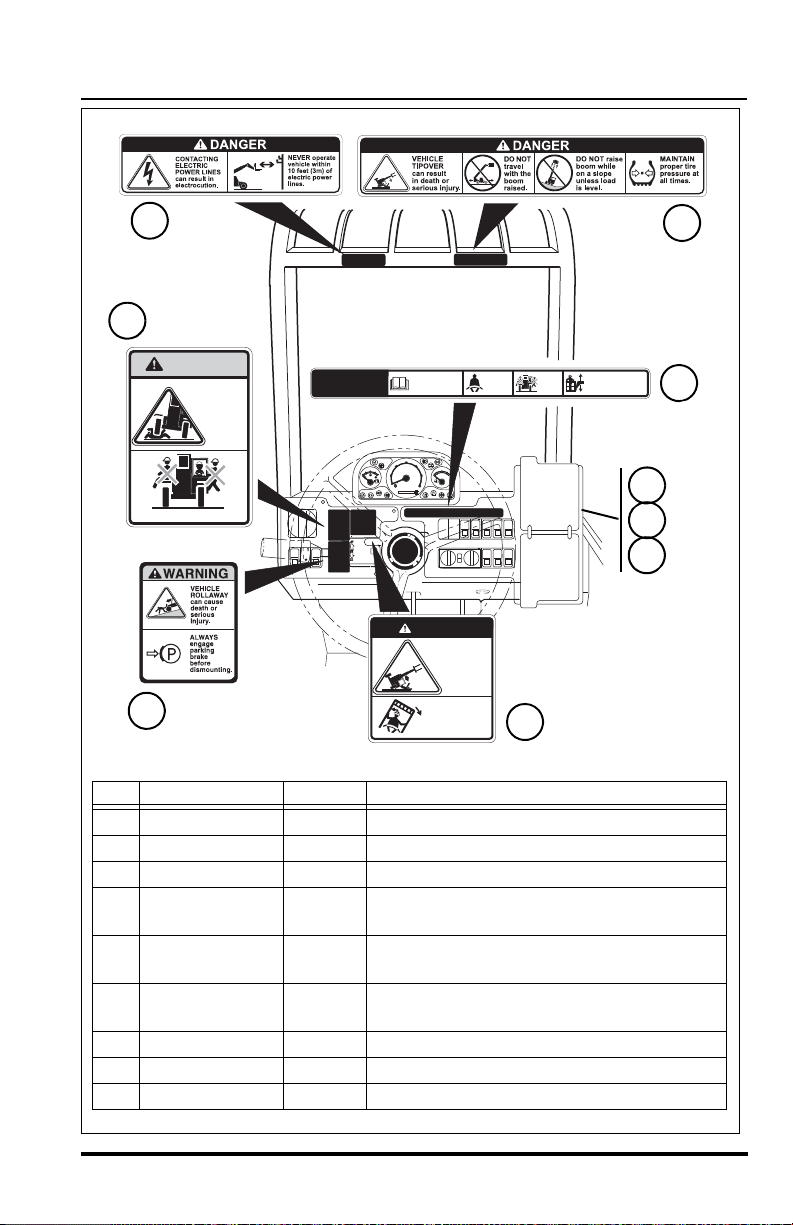

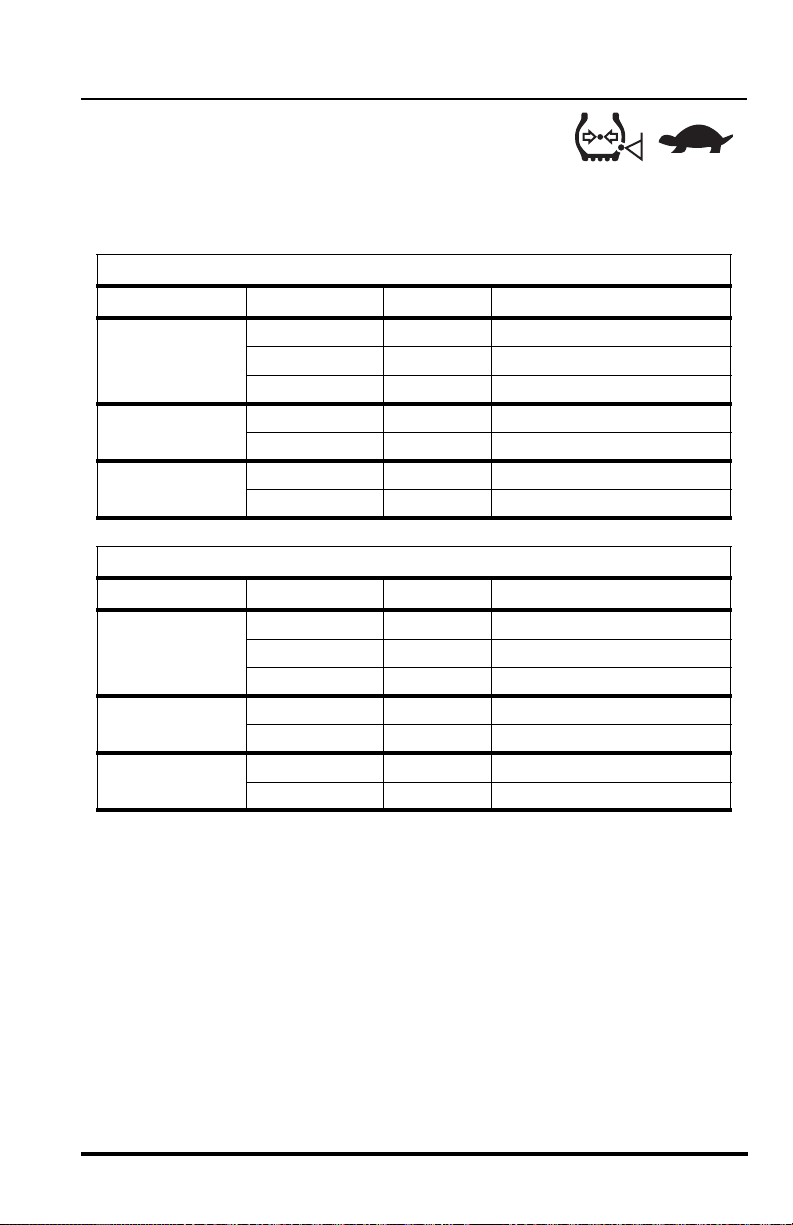

Item Part Number Quantity Decal Description

1

4110358 1 No Riders Warning

2 4110358 1 Vehicle Rollaway Warning

3 4108991 1 Electrocution Danger

4 6623762 1

Load Chart Booklet - 87 psi (600 kPa)

Full Tire Pressure

5 6623944 1

Load Chart Booklet - 60 psi (414 kPa)

Reduced Tire Pressure

6 6623997 1

Load Chart Booklet - 45 psi (310 kPa)

Reduced Tire Pressure

7 4110137 1 Tipover Danger

8 4110358 1 Do Not Jump Danger

9 41 10361 1 Safety Instructions

OM1760

3

9

1

8

7

2

4

5

6

Model MMV Rev. 10/11

21

Safety Practices

A

MOVING PARTS can cut.

Keep clear of fan and belts

while engine is running.

MOVING PARTS can entangle.

B

ENGINE EXPLOSION

can result in death or

serious personal injury.

DO NOT use Ether or

other high energy

starting aids.

Engine equipped with

grid heating system.

3Y949-4110463

3Y949-4110304

WARNING

DO NOT TRAVEL

with personnel in

a work platform.

FALLING OFF ATTACHMENT,

can result in death or

serious injury.

Lift or lower personnel

only in a compliant

work platform.

4110468

CAUTION

ENGINE OVERHEATING

can occur.

Consult Operator Manual

for coolant filling

procedure.

1YHH8-1706549

CAGE CODE

PIN

S/N

NSN

CONTRACT NO.

NOMENCLATURE

TRUCK, LIFT FORK, VARIABLE REACH ROUGH TERRAIN

MODEL: SKYTRAK MMV GVW: 26,900 LBS

CAPACITY: 11000 LB SHIPPING WEIGHT: 30,500 LBS

NSN:

DES. ACT/MFR: 1YHH8 HEIGHT 93.6 IN.

WARRANTY: MO. WIDTH 100.2 IN.

DATE OF MFR.: CUBE 1796.5 CU. FT.

DATE SHIPPED: REG. NO.

DATE INSPECTED & STAMP:

CONTRACT

SERIAL

NO.

1YHH8-1001092290

1001121649_A

SLAVE 24

VOLTS DC

SHIPPING DATA FOR

SKYTRAK MMV

TRUCK, LIFT FORK, VARIABLE REACH

ROUGH TERRAIN, 11,000 POUND CAPACITY

1YHH8-4110306

1YHH8-1706549

CAGE CODE

PIN

S/N

NSN

CONTRACT NO.

NOMENCLATURE

Model

1YHH8-6623990

Serial Number

Year of Manufacture

Max Weight Without Attachments Max Capacity

Sky Trak

OM20502

1YHH8-1706549

CAGE CODE

PIN

S/N

NSN

CONTRACT NO.

NOMENCLATURE

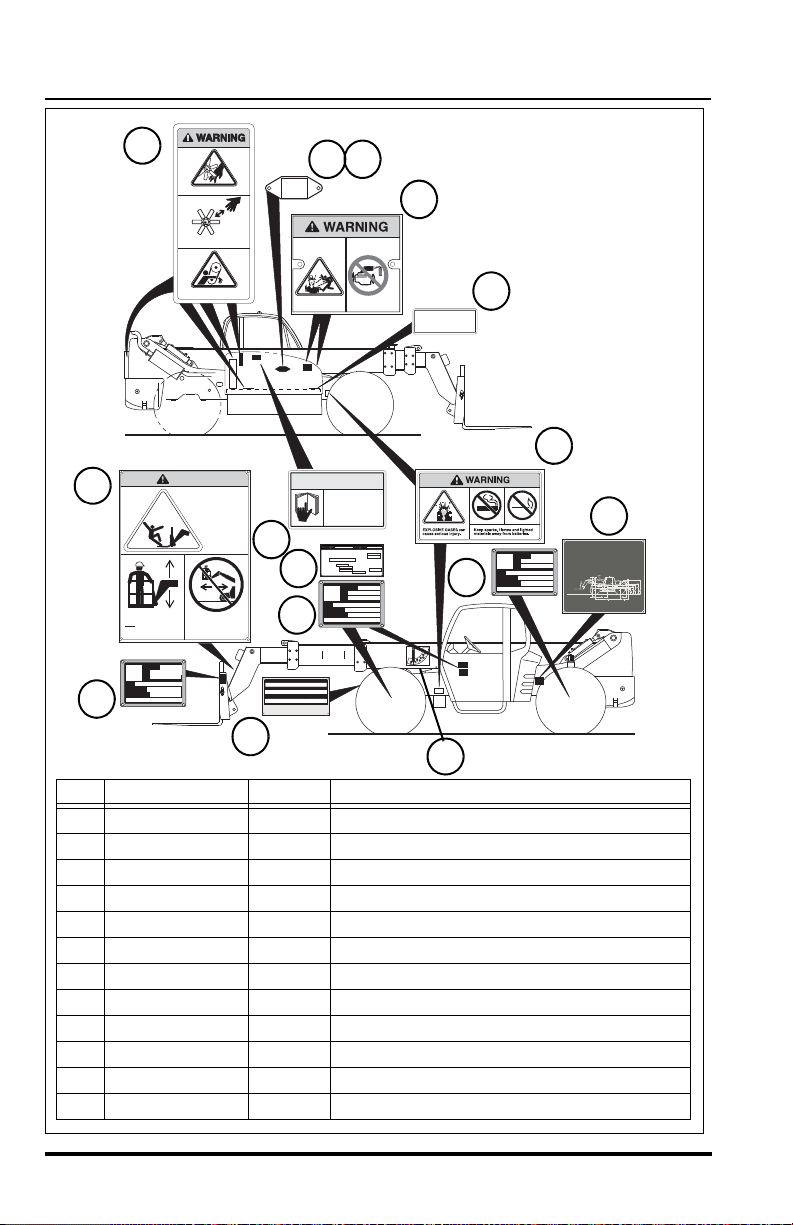

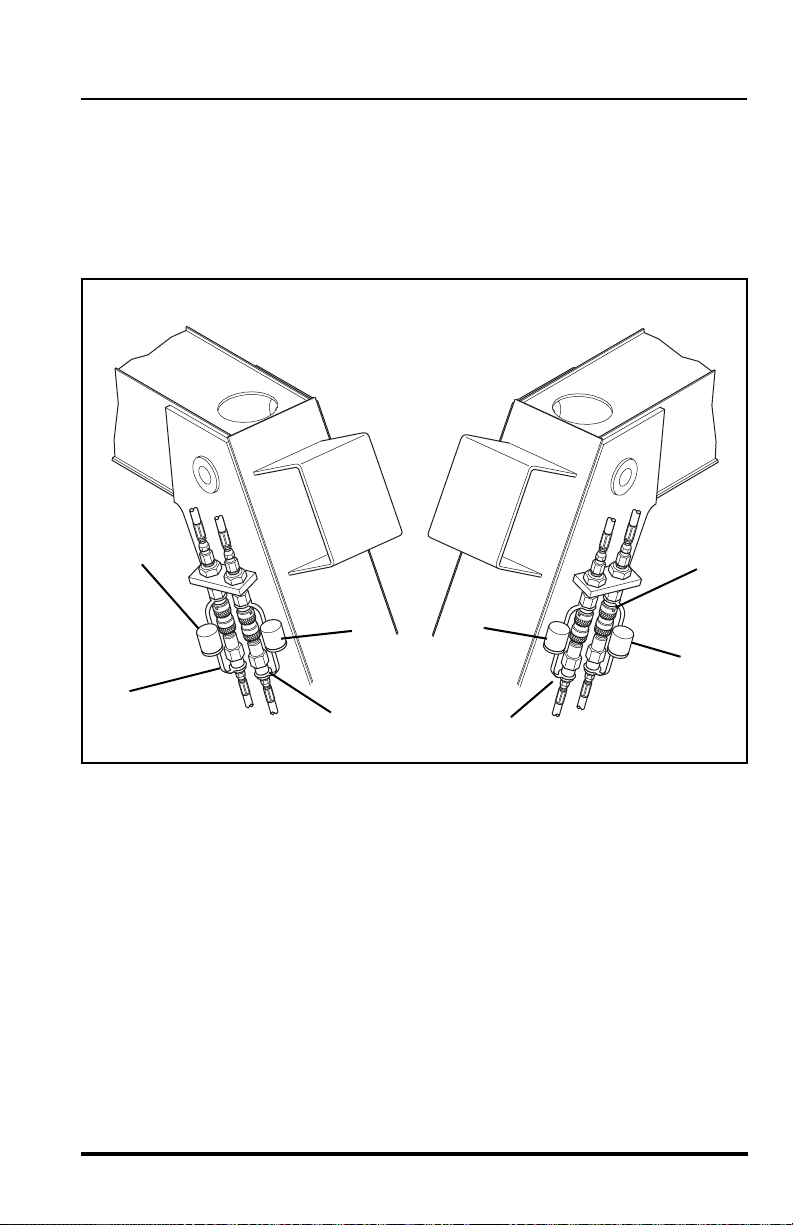

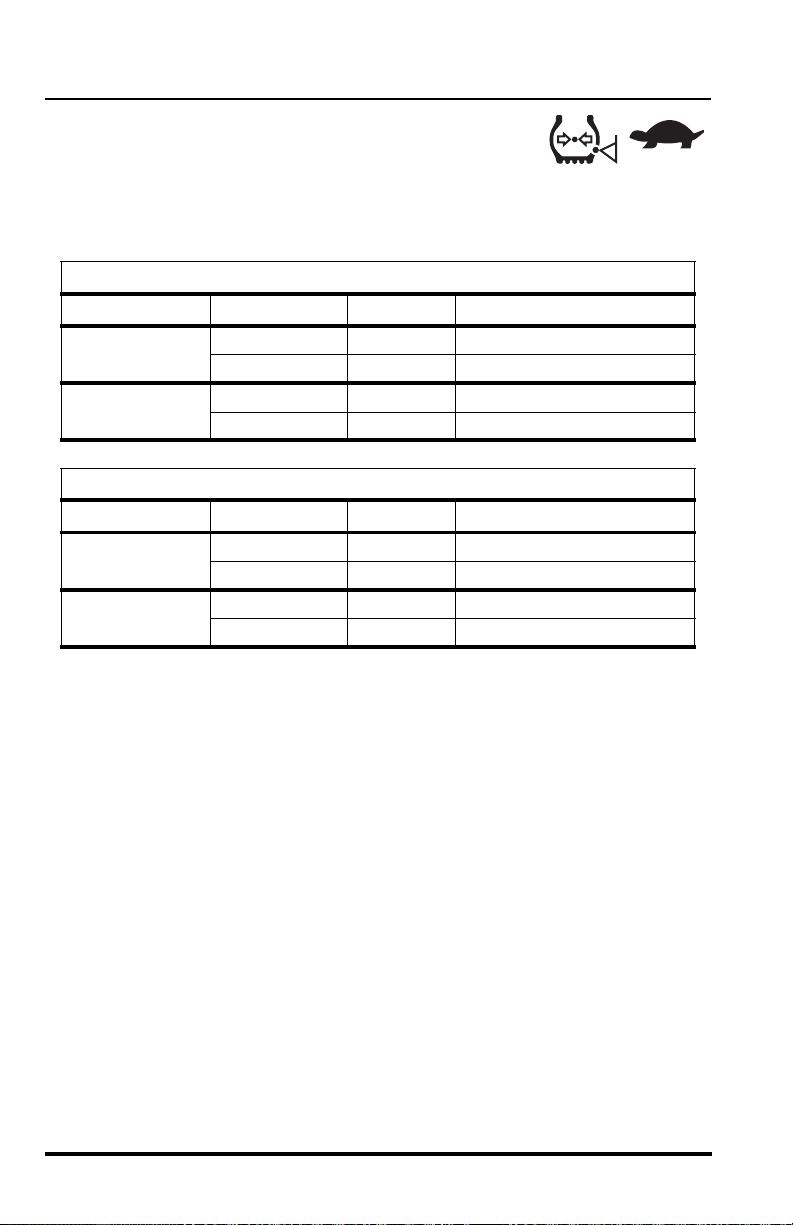

Item Part Number Quantity Decal Description

1

4110184 4 Moving Parts Warning

2 4110303 2 Explosive Gases Warning

3 4110304 1 Carrying Personnel Warning

4 4110305 1 Boom Angle Indicator

5 4110463 2 Ether Start Warning

6 4110468 1 Coolant Filling Caution

7 1001092290 1 Machine Identification Plate

8 1706549 6 Universal ID Plate

9 6623390 1 MMV Serial Number Plate

10 4110306 1 Shipping Data Plate

11 1001121649 1 Slave Decal, 24V DC

12 3576086 1 Engine Identification Plate

2

1

3

5

4

6

7

8

9

8

10

11

1288

22

Model MMV Rev. 10/11

Operation

8

7

9

10

OM1770

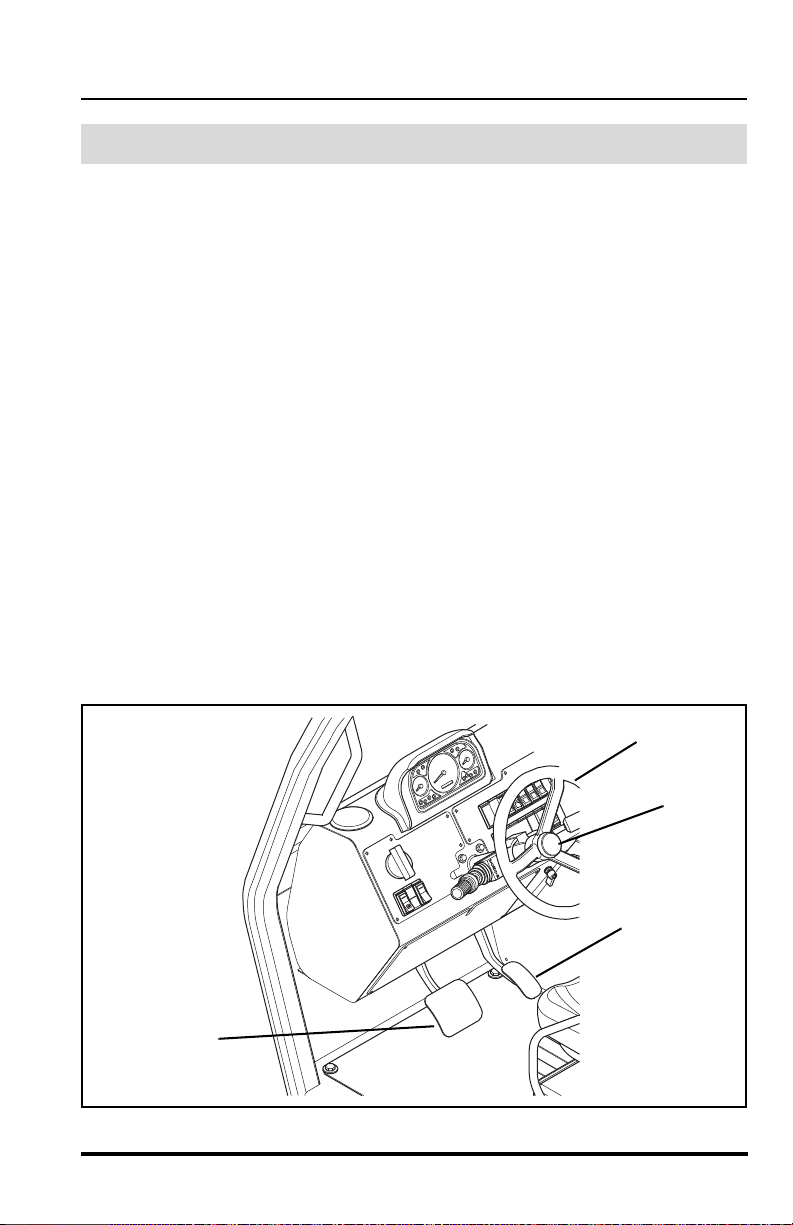

Operation

Operator Controls

Accelerator Pedal

Pressing down the accelerator pedal (7) increases engine and hydraulic

speed of the vehicle. The pedal is spring-loaded to return to idle speed.

NOTE: The accelerator pedal is also used to activate the Cummins ECM

diagnostic system. With the ignition in the RUN position, depress and

release the pedal 3 times to activate the system.

Service Brake Pedal

Pressing down the brake pedal (8) decreases the speed of the vehicle by

applying the service brakes located in the axles. In the event of engine

power loss, the service brake pedal can also be used for braking.

Steering Wheel

Turning the steering wheel (9) to the left or right steers the vehicle in the

corresponding direction. Any one of the steering modes are selectable.

Refer to “Steering Mode Selector” on page 25.

Horn Button

Pressing the horn button (10) sounds the horn. When the blackout light

system is activated the horn will not operate.

Model MMV Rev. 10/11

23

Operation

OM1780

2

3

4

1

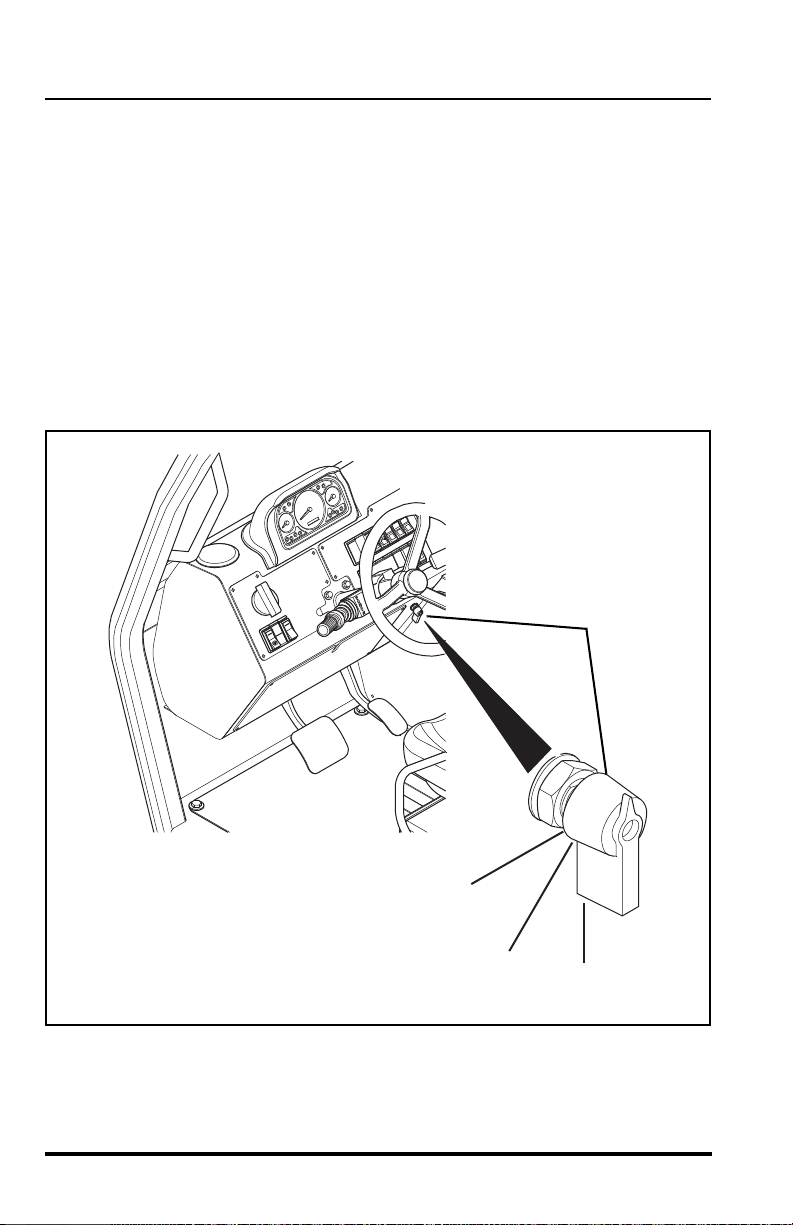

Ignition Switch

The ignition switch (1) is located on the right side of the lower front dash.

The switch may be turned clockwise from the OFF (2) position to the RUN

(3) and START (4) positions. To rotate the switch to the START position,

push the switch IN and rotate to the START position. The START position is

spring-loaded to return to the RUN position and must be manually held in

place for starting.

OFF position (2) — The entire electrical system is shut down.

RUN position (3) — All controls and indicators are operable.

ST ART position (4) — Engages st arter motor to crank the engine when the

parking brake switch is engaged and the transmission is in NEUTRAL.

24

Model MMV Rev. 10/11

Operation

5

OM1790

786

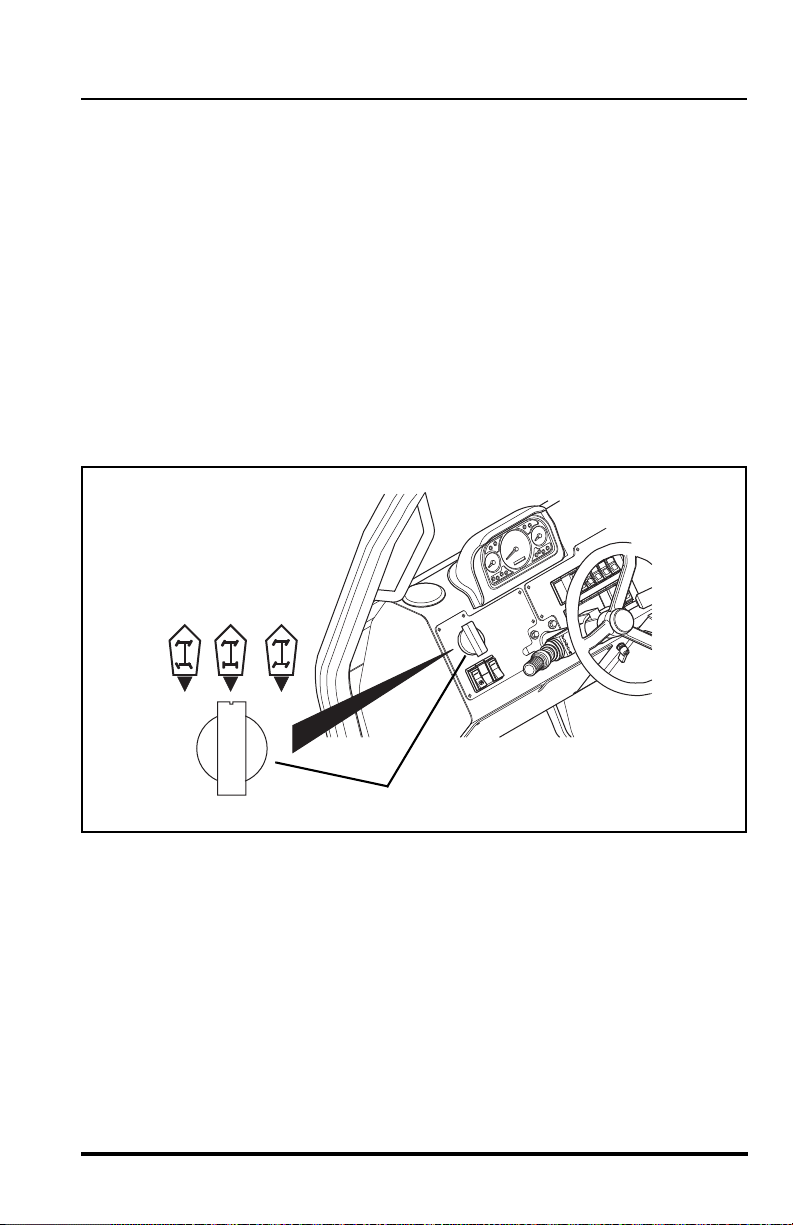

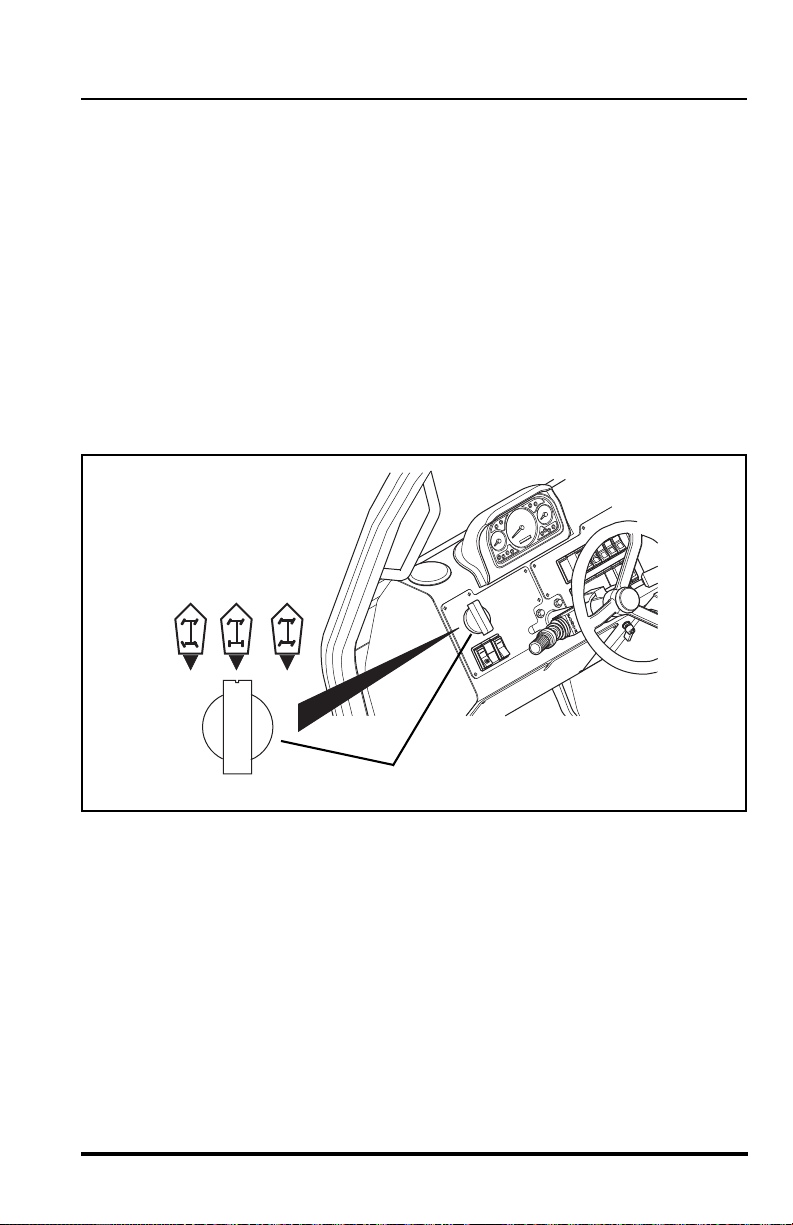

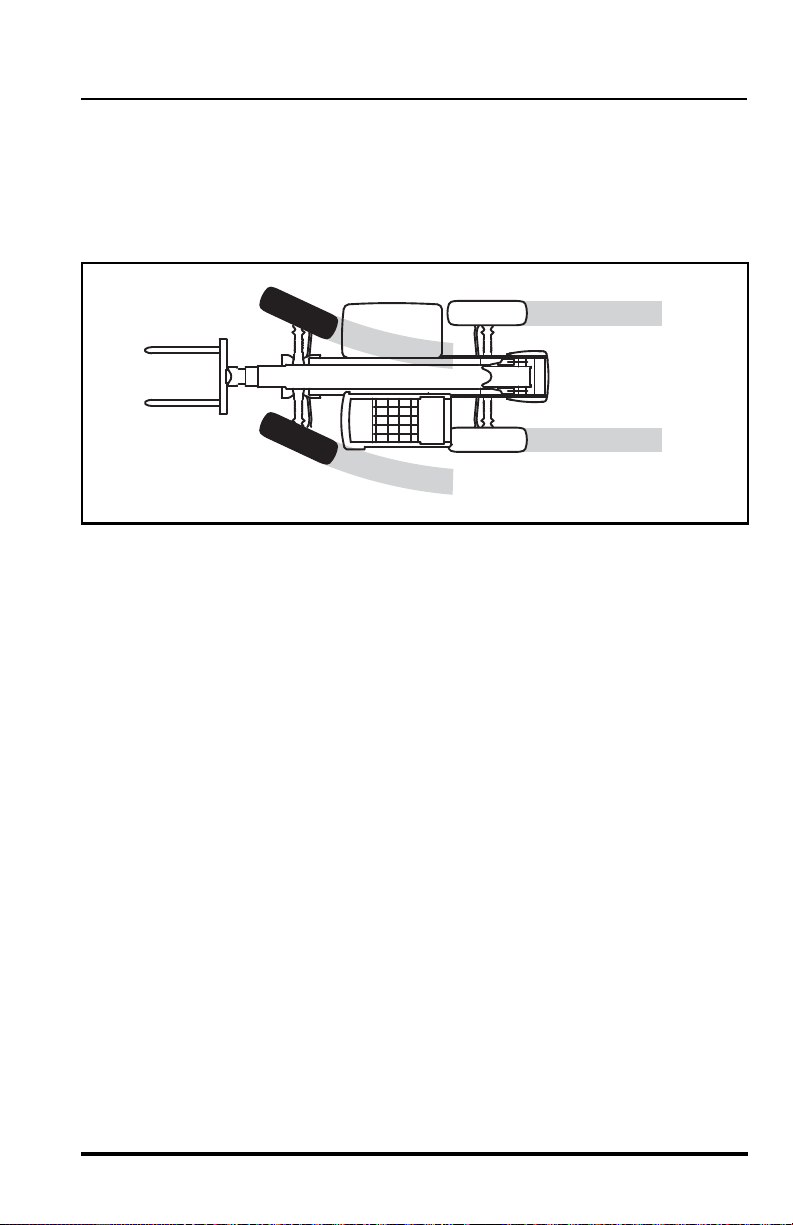

Steering Mode Selector

Three Mode Steer Select

This vehicle has one steering mode selector (5) located on th e left side of

the front dash. The selector has three positions.

• Front Wheel Steer (6).

• Crab Steer (7).

• Four Wheel Steer (8).

Turn the steer mode selector until the notch at the top of the knob points to

the desired steering mode selection. You will feel the knob of the selector

slip into a detent position for each mode.

Refer to “Steering Modes” on page 79 for detailed information.

Model MMV Rev. 10/11

25

Operation

P

P

OS0121

OS1323

5

F

1/2

E

D

OU0381

1

2

3

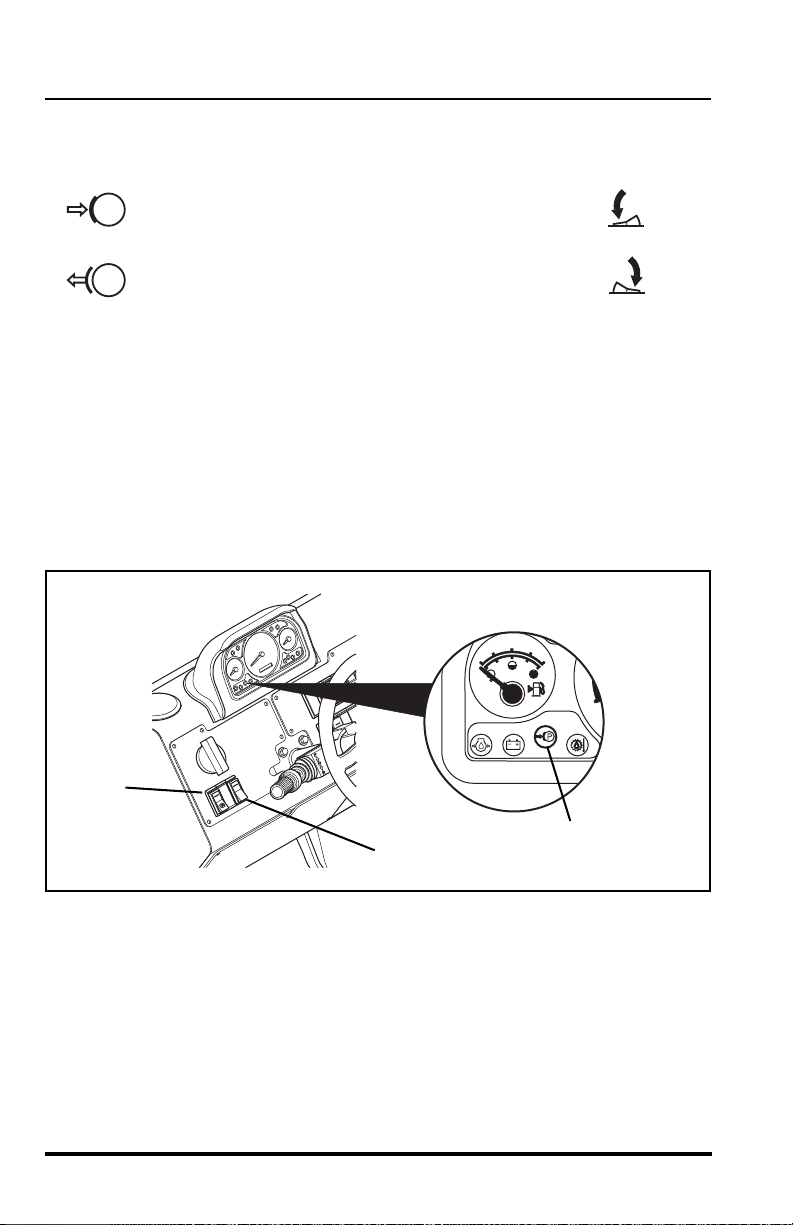

Parking Brake Switch

The Parking Brake Switch (1) has two positions:

ENGAGED............toggle switch downward

DISENGAGED...........toggle switch upward

The Parking Brake Switch must be ENGAGED to permit engine starting. A

red LED, on the parking brake switch, will indicate the brake is ENGAGED.

The parking brake engaged light (2) will illuminate on the front dash panel

any time the parking brake is engaged.

The parking brake may be used to stop in an EMERGENCY situation.

However, use caution because the stop will be abrupt and the operator and

the load may be jolted forward unexpectedly.

With boom angles greater than 40°, this switch activates the locked mode of

the Stabil-TRAK system.

26

Model MMV Rev. 10/11

Operation

OH2591

OH2611

OM3630

OFF

ON

1

Transmission Disconnect Switch

The transmission Disconnect switch (3) is located on the left side of the

front dash and has two positions.

• Push the TOP of the rocker switch in to

DEACTIVATE the transmission disconnect

function.

• Push the BOTTOM of the rocker switch in to

ACTIVATE the transmission disconnect

function.

With the transmission disconnect activated, when the

service brake pedal is applied, the transmission will be disconnected

allowing the engine speed to be increased without the need to place the

transmission shifter in the (N) NEUTRAL.

This feature eliminates the need to shift the trans mis sio n to the (N)

NEUTRAL before operating the hydraulic system at high engine speed.

When the transmission disconnect is active, the drivetrain is disconnected

and the hydraulic system has full engine power.

IMPORTANT! W ith the disconnect feature active and the service brake

pedal being released, the transmission will be reconnected in the same

gear and direction of travel as when it was originally disconnected. The

service brakes must remain fully applied for this feature to be functional.

Battery Disconnect Switch (S/N MV1210 & After)

The battery disconnect switch (1) is located in the engine compartment.

This switch, when turned to the "OFF" position, disconnects the circuit

between the batteries and the electrical syste m . The ba ttery disconnect

switch should be turned to the "OFF" position during periods of ext ended

storage.

Model MMV Rev. 10/11

27

Operation

0000000

RPM X 100

5

10

15

30

20

25

F

1/2

E

104

176

80

248

120

°C

°F

D

r/min

N D

1

2

OM1800

OT0570

OT0580

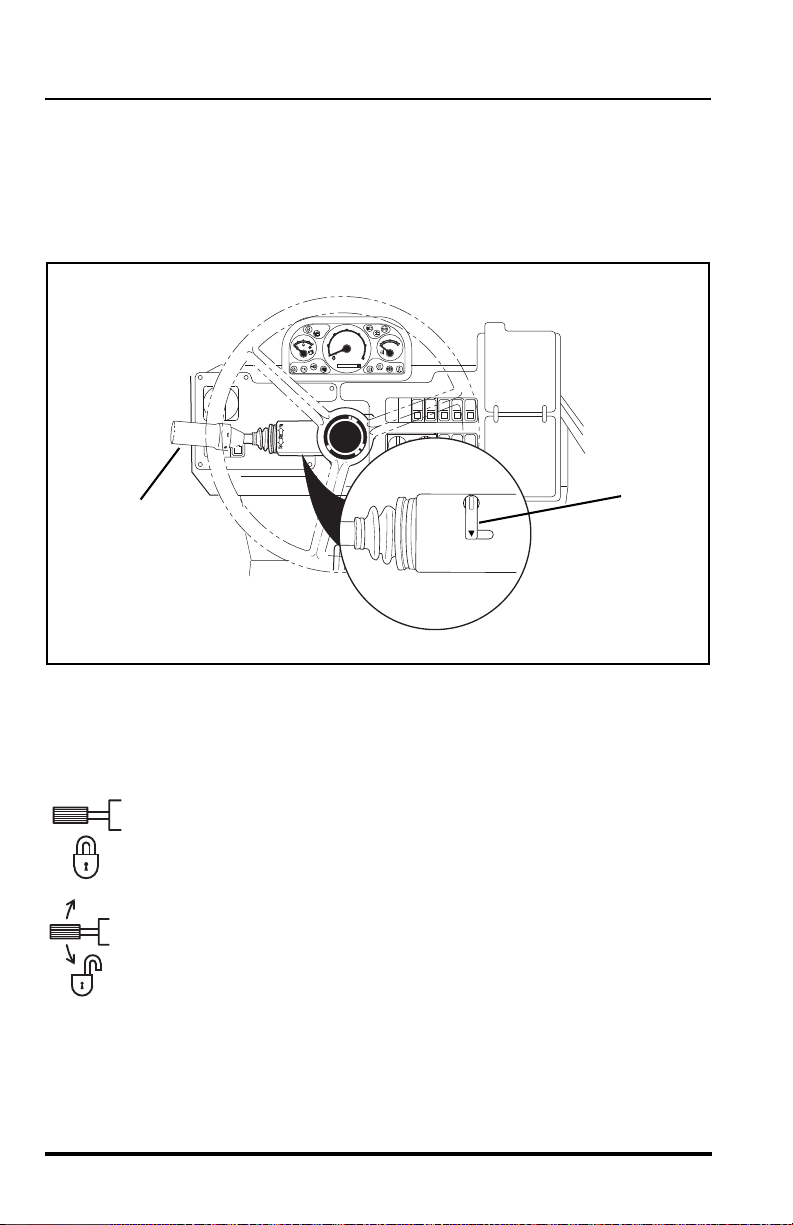

Neutral Lock Lever

The Travel Select Lever (1) is equipped with a neutral lock. The Neutral

Lock Lever (2) locks the Travel Select Lever in NEUTRAL or unlocks the

Travel Select Lever so that it can be moved into the FORW ARD or

REVERSE drive position.

To lock the Travel Select Le ver (1) in the NEUTRAL position, pla ce the lever

in the NEUTRAL position and move the Neutral Lock Lever (2) to the (N)

NEUTRAL LOCK position.

To unlock, move the Neutral Lock Lever to the (D) DRIVE position.

N = NEUTRAL LOCK ..................all the way LEFT

D = DRIVE......... ... .......................all the way RIGHT

Model MMV Rev. 10/11

28

Operation

OS0340

F

N

R

3

OM1810

4

5

6

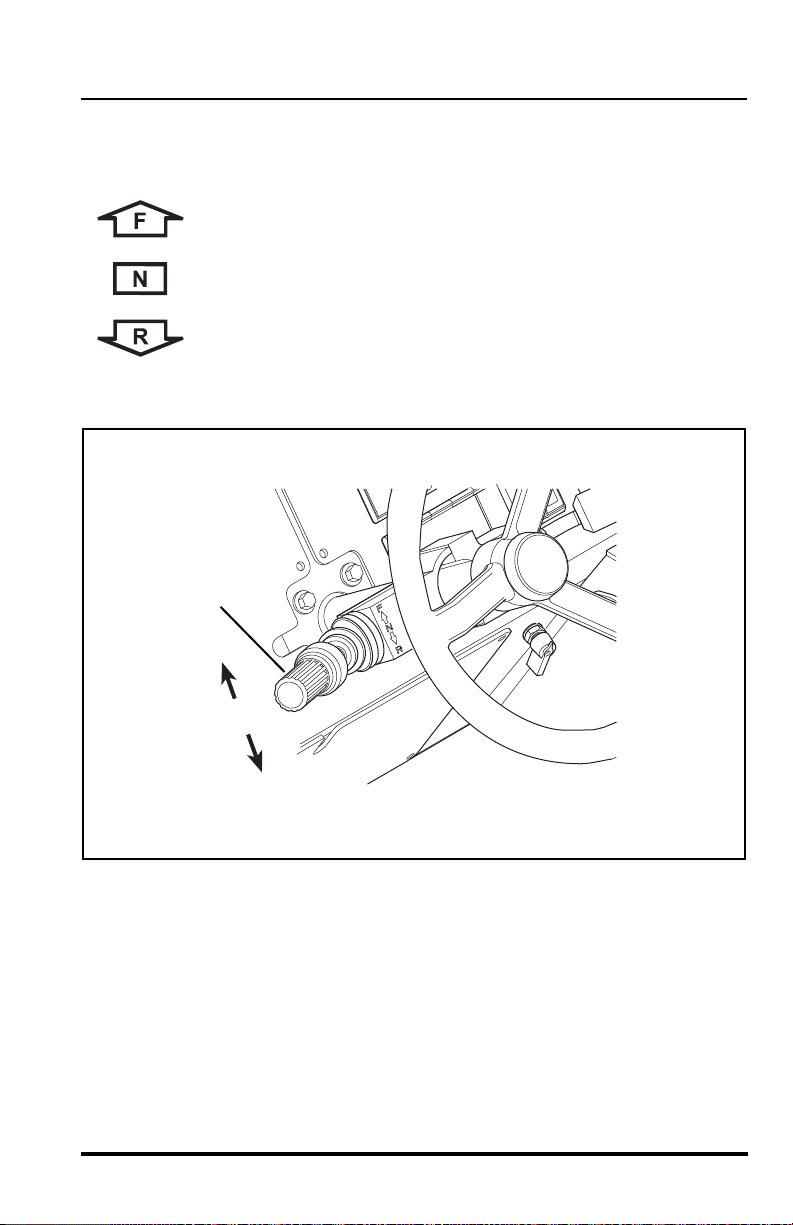

Travel Select Lever

The Travel Select Lever (3) has three positions to select direction of travel:

F = FORWARD (4)......... all the way UP

N = NEUTRAL (5) .......... CENTER position

R = REVERSE (6)...........all the way DOWN

To change travel selections, move the lever UP or DOWN to the desired

selection.

When the Travel Select Lever is shifted to REVERSE, the back-up alarm

will automatically sound. When the blackout light system is activated the

back-up alarm will not operate.

NOTE: The Travel Select Lever must be in the (N) NEUTR A L po sit ion to

permit engine starting.

Model MMV Rev. 10/11

29

Operation

1st

4th

3rd

2nd

1

OM1820

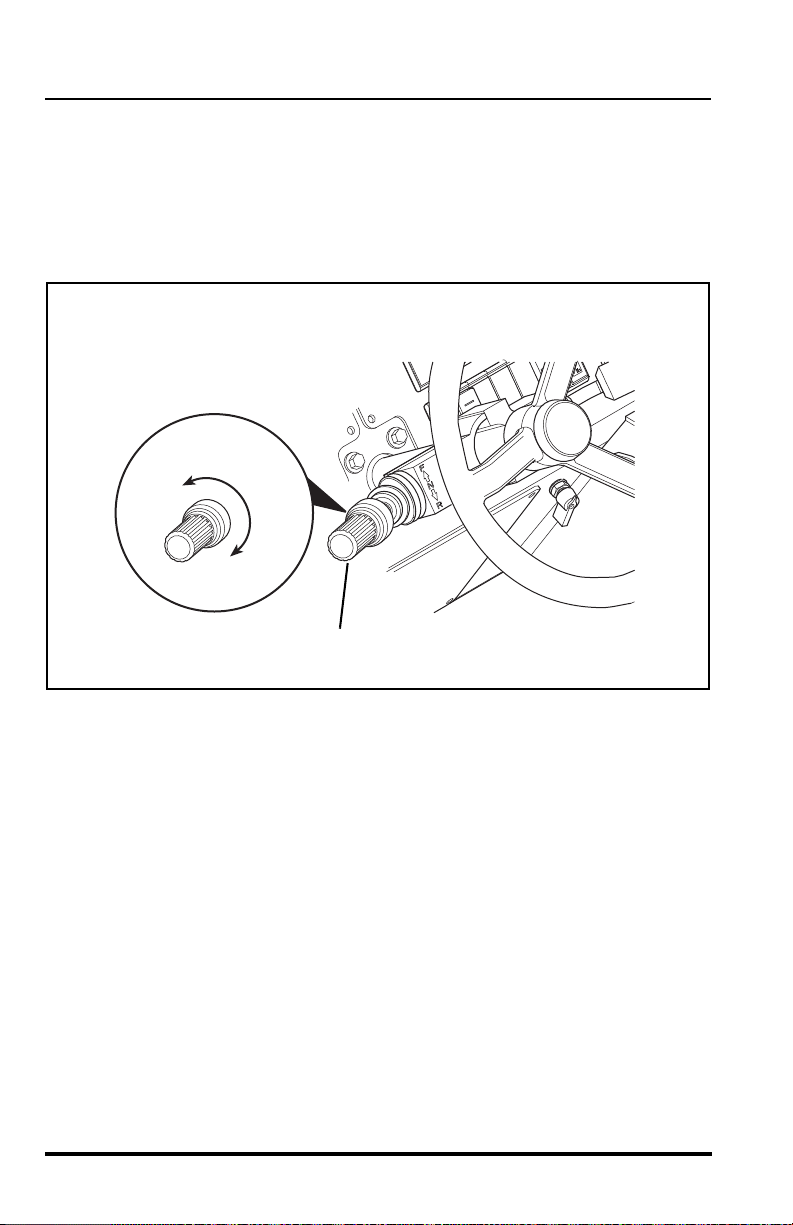

Gear Select Lever

The Gear Select Lever (1) has a twist grip handle with four positions.

Vehicles have four forward gears and three reverse gears.

NOTE: When traveling up a slope, shift to a lower gear as appropriate to

avoid “lugging” the engine.

Use first gear for highest torque and pulling power. Use higher gears for

higher ground speed. The recommendations listed in the “Load Capacity

To Travel Speed Tables” begining on page 94 a re guidelines only. Always

use good judgement when traveling with a load.

30

Model MMV Rev. 10/11

Operation

OS2120

2

OM1830

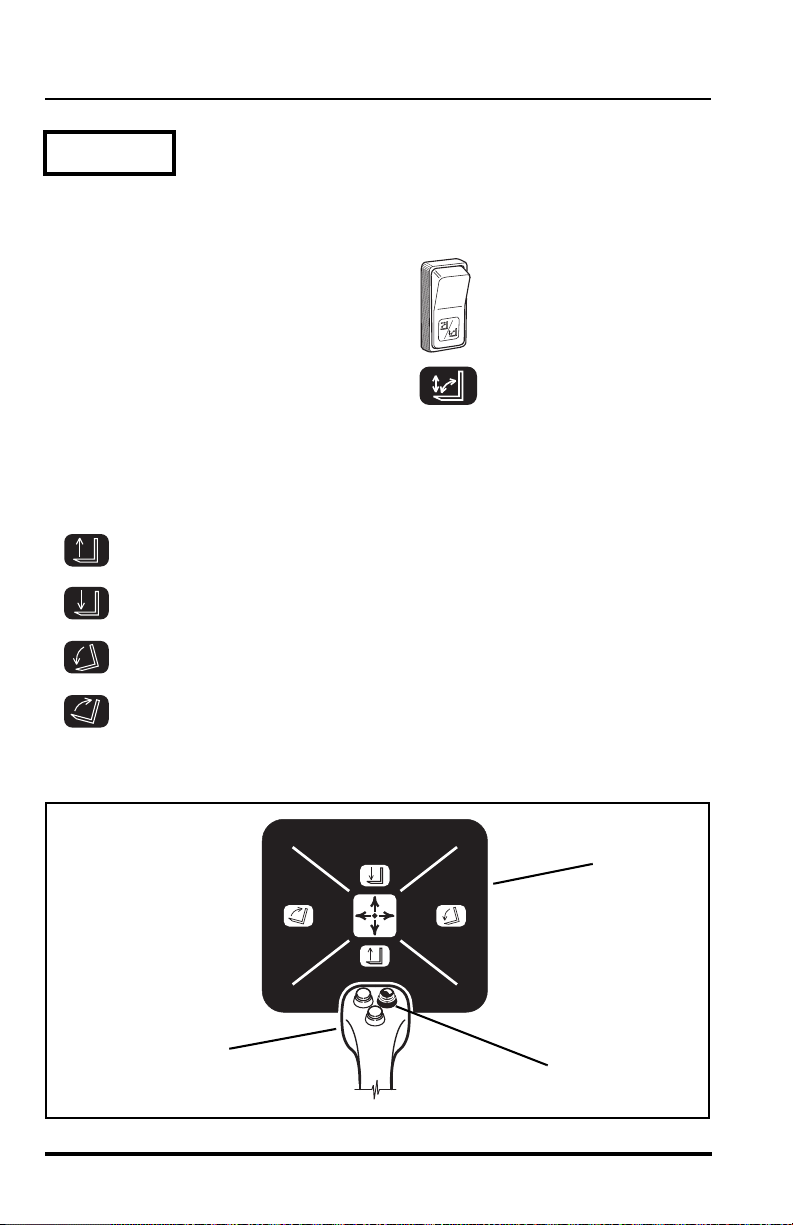

Attachment Tilt Mode Switch

The Attachment Tilt Mode Switch (2) ha s

two positions which allow the operator t o

chose between the Lift/Lower function

and the Extend/Retract function

accompanying the Attachment Tilt capability. For detailed information, see

“Multi-Function Joystick Operation” starting on page 32.

Model MMV Rev. 10/11

31

Operation

OM1880

2

1

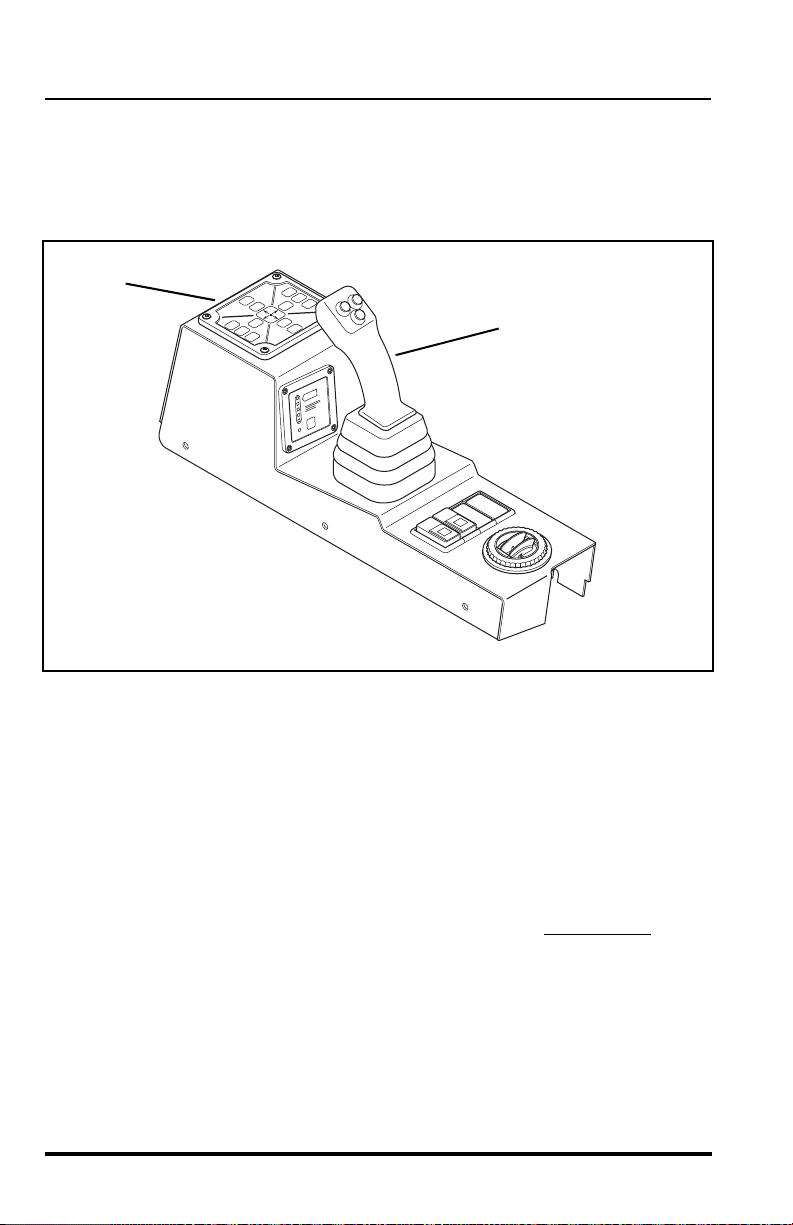

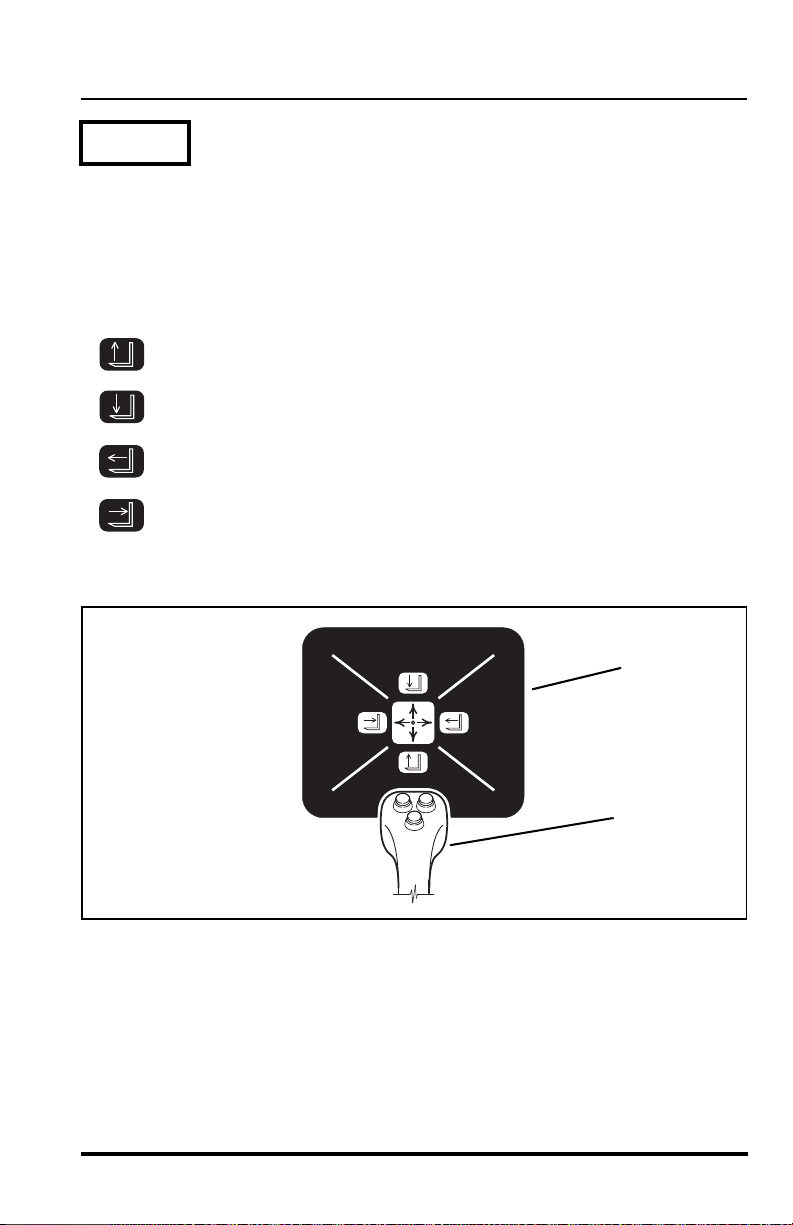

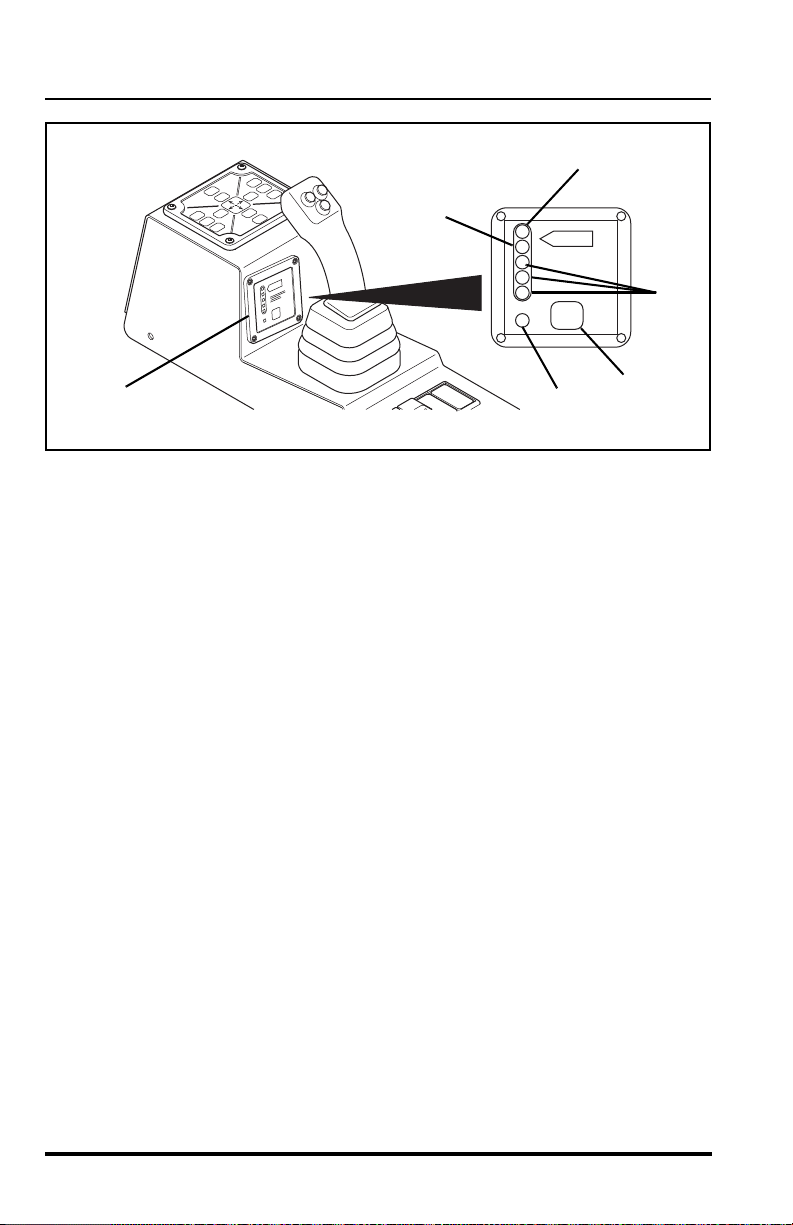

Multi-Function Joystick Operation

The joystick (1) is equipped with four buttons that enable the joysti ck to

operate in three specific modes. The joystick controls boom movement,

attachment tilt and frame sway control.

The logic panel (2) (located in front of the joystick) will illuminate the specific

mode that corresponds with the movement of the joystick (1) and the

selected buttons.

Two functio ns can be accomplished at the same time by mo ving the joystick

in between quadrants. For example; in Mode 1, moving th e joyst ick forward

and to the left will lower and retract the boom simultaneously.

The speed of the function depends directly upon the amount of joystick

travel in the corresponding direction. Increasing the engine speed will also

increase the function speed.

IMPORTANT! Be aware that joystick modes will change immediately

upon

depressing or releasing of any button when the joystick is in an off-center

position.

32

Model MMV Rev. 10/11

Operation

OS0600

3

OM0660

4

Mode 1

Boom Control (Default)

(No buttons depressed)

This mode is accomplished by using the multi-function joystick (3) without

depressing any of the buttons. All four function lights will illuminate on the

logic panel (4).

Boom Lift............................... move handle backward

Boom Lower.......................... move handle forward

Boom Extend .........................move handle to the right

Boom Retract.........................move handle to the left

Model MMV Rev. 10/11

33

Operation

1

OM1830

For the attachment tilt mode covered in Mode 2A and 2B on the following

pages, use the attachment tilt mode switch (1) locate d in the upper bank of

switches to the right of the steering wheel.

34

Model MMV Rev. 10/11

Operation

OM0670

OS0671

2

OM0680

4

3

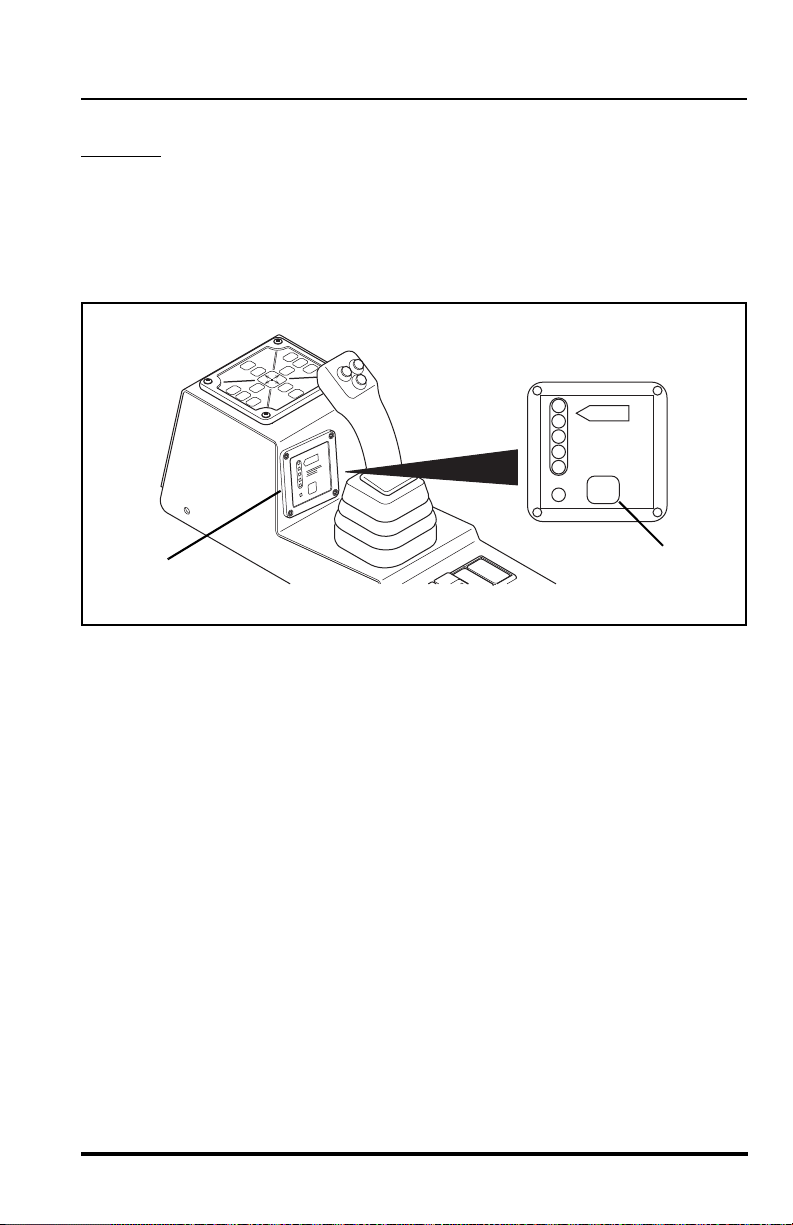

Mode 2A

Attachment Tilt Up/Down & Boom Extend/Retract

(Right button depressed)

Press the top of the attachment tilt mode

switch in.

Press and hold the right button (2) on the top side of the muti-function

joystick (3). As the mode is activated the corresponding lights will illuminate

on the logic panel (4).

Attachment Tilt Up................. move handle backward

Attachment Tilt Down............ move handle forward

Boom Extend .........................move handle to the right

Model MMV Rev. 10/11

Boom Retract.........................move handle to the left

35

Operation

OM0690

OS0610

1

OM0700

3

2

Mode 2B

Boom Lift/Lower & Attachment Tilt Up/Down

(Right button depressed)

Press the bottom of the attachment tilt

mode switch in.

Press and hold the right button (1) on the top side of the muti-function

joystick (2). As the mode is activated the corresponding lights will illuminate

on the logic panel (3).

Boom Lift ...............................move handle backward

Boom Lower ..........................move handle forward

36

Attachment Tilt Down ............move handle to the right

Attachment Tilt Up.................move handle to the left

Model MMV Rev. 10/11

Operation

OS0611

4

OM0710

7

5

6

4

6

Mode 3

Boom Lift/Lower & Frame Sway Right/Left

(Depress left & front buttons simultaneously, then hold eith er button)

This mode is accomplished by using the multi-function joystick (4) and

depressing the front (5) and left (6) buttons simultaneously, then while

holding either button, move the joystick to the required function. As the

mode is activated the corresponding lights will illuminate on the logic panel

(7).

Boom Lift............................... move handle backward

Boom Lower.......................... move handle forward

Frame Sway Right .................move handle to the right

Frame Sway Left....................move handle to the left

Model MMV Rev. 10/11

37

Operation

OM0880

2

OM1880

1

Fork Shift Control Switches

The left (1) and right (2) fork shift switches shift the individual forks on the

carriage to the left or right. The rocker switches are spring loaded to return

to the center (stop) position when released.

Left Fork, Shift to the Left ..............press top of left switch

Left Fork, Shift to the Right............press bottom of left switch

Right Fork, Shift to the Left............press top of right switch

Right Fork, Shift to the Right..........press bottom of right switch

Seat Belt

Always wear the seat belt when operating the vehicle. The seat belt has

one retractable strap (3) for easy installation and removal. Insert the seat

belt tang into the receptacle (4) to fasten. Press the center red button ( 5) to

unfasten the seat belt.

38

Model MMV Rev. 10/11

Operation

OM1840

3

4

5

WARNING: Serious bodily injury or death may result

from failure to wear the seat belt installed on this vehicle. The seat

belt is a critical component of the Operator’s Protective Structure,

and is provided for the operators protection in case of vehicle

upset. The seat belt MUST be worn whenever this vehicle is operated.

IMPORTANT! Inspect the seat belt every time it is used, looking for cut or

worn webbing, or any defect in the latch assembly. If any wear or damage is

noted, DO NOT operate the vehicle until the seat belt is replaced.

Before the engine is started, adjust the seat as required for position and

comfort. Then adjust the seat belt as follows:

1. Grasp both free ends of the belt and make certain that the belt webbing is not twisted or entangled in any portion of the seat assembly.

2. With your back straight in the seat, couple the retractable end of the

belt into the receptacle end of the belt.

3. With the belt as low on your body as possible, pull the retractable

end of the belt to away from the receptacle end of the belt until it is

tight across the lap.

4. To release the belt latch, depress the red button (5) an d pull the

free end (3) from the buckle (4).

Model MMV Rev. 10/11

39

Operation

OM1840

1

2

3

Operators Seat Adjustments

The operator’s seat can be adjusted three ways:

Fore and Aft Adjustment

Pull the handle (1) outward to adjust the seat forwar d an d

backward. Release the handle to lock the seat in the desired

position.

Suspension Adjustment

Turn the knob (2) on the front of the seat to adjust the suspension to

correspond with the operator’s weight. Turn clockwise to increase

stiffness. Turn counter-clockwise to reduce the stiffness.

Backrest Angle Adjustment

The angle of the seat backrest can be adjusted t o suit th e ope rator.

Move the lever (3) located on the left side the seat backrest to

adjust the angle.

40

Model MMV Rev. 10/11

Operation

OM1550

OH2570

OM1830

4

Interior Cab Light

The interior cab light is

located on the top of the

cab just behind the operators head. The interior cab light will operate with

the ignition switch in the OFF or RUN positions.

The interior cab light is operated with a slide type switch located on the light

assembly. To turn the interior light ON, push the switch on the light to the

rear ON position. Return the switch to the center OFF position to turn the

interior light OFF.

When the blackout light system is activated the interior cab light will not

operate.

Worklights

The worklights are

activated with a rocker

switch (4) located in the

upper bank of switches on the right side of the fr ont dash. There are three

positions - OFF, Boom Worklight and Boom & Rear Worklights. The lights

only work when the ignition switch is in the RUN position and the blackout

light system switch is in the OFF position. When the blackout light syste m is

activated these lights will not operate.

Model MMV Rev. 10/11

41

Operation

OS1900

OM1850

1

2

3

4

5

Parking Lights, Headlights & High/Low

Beam Switch

With the ignition switch ON use the turn signal

switch (1) to control the high/low beam headlights,

turn ON the parking lights and the headlights. Turn the twist grip end (2) of

the turn signal switch counter-clockwise to the first position (3) to turn the

parking lights ON. Turn the twist grip to the second position (4) to turn the

headlights and parking lights ON. Turn the twist grip clockwise to the OFF

position (5) to turn all the lights OFF. Pull the turn signal switch toward you

to switch from low beam to high beam. When the hig h bea m is ON the high

beam indicator light on the front dash panel will illuminate. When the

blackout light system is activated these lights will not operate.

42

Model MMV Rev. 10/11

Operation

OM0840

OM0850

OM1830

6

7

Blackout Light System Activation Switch

The blackout light system activation switch (6) is a

rocker switch, located in the upper bank of switches on

the right side of the front dash. This switch has two

positions system ON and system OFF. This switch

must be in the ON position and the ignition switch in the RUN position

before the blackout driving lights or marker lights can become functional.

Blackout Drive/Marker Lights

This switch (7) is located in the upper bank of switches on the right side of

the front dash. The blackout light system activation switch must be in the

ON position. The blackout drive/marker switch has two positions:

Drive/Marker Lights ON ..................Press bottom of switch

Marker Lights Only ON ...................Press top of switch

Model MMV Rev. 10/11

43

Operation

OS1910

OS1920

OM1860

2

4

3

1

Directional Signals

The directional signals

are activated from the

lever (1) on the right side of the steering wheel. To activate the left turn

signal (2); raise the lever. To activate the right turn signal (3); lower the

lever. To dea ctivate either directional signal, the lever must be manually

returned to the center position. The lever will not cancel automatically after

a turn. When the blackout light system is activated the directional signals

will not operate.

Emergency Flashers

To activate the emergency

flashers; push the emergency

flashers switch (4) located on the front dash to the right of the steering

wheel. When the blackout light system is activated the emergency flashers

will not operate.

44

Model MMV Rev. 10/11

Operation

OU1190

7

5

6

8

9

Door Latches

There are two door latches. The outside latch (5) is a pull-to-relea se type.

The inside latch (6) is also a pull-to-release latch.

Door Window Latch

The door window (7) can be swung open by releasing the window from

inside the cab. Release the window from the door with the window latch

handle (8). Pivot the handle out of the way and swing the window open.

Swing the window all the way open and lock in place on the outside of the

cab. The window can be released from inside the cab using the window

release located on the inside of the cab or from the outside, using the

outside release (9) located on the cab door window. The inside and outside

latches are both turn to release locks.

CAUTION: DO NOT operate the vehicle with the door

window swinging free. Damage to the door window could result if

door window is not secured in the OPEN or CLOSED position.

The door window must be latched in the OPEN or the CLOSED position

during operation of the vehicle.

Model MMV Rev. 10/11

45

Operation

2.

3.

1.

OU09201

3

1

2

5

OM2090

4

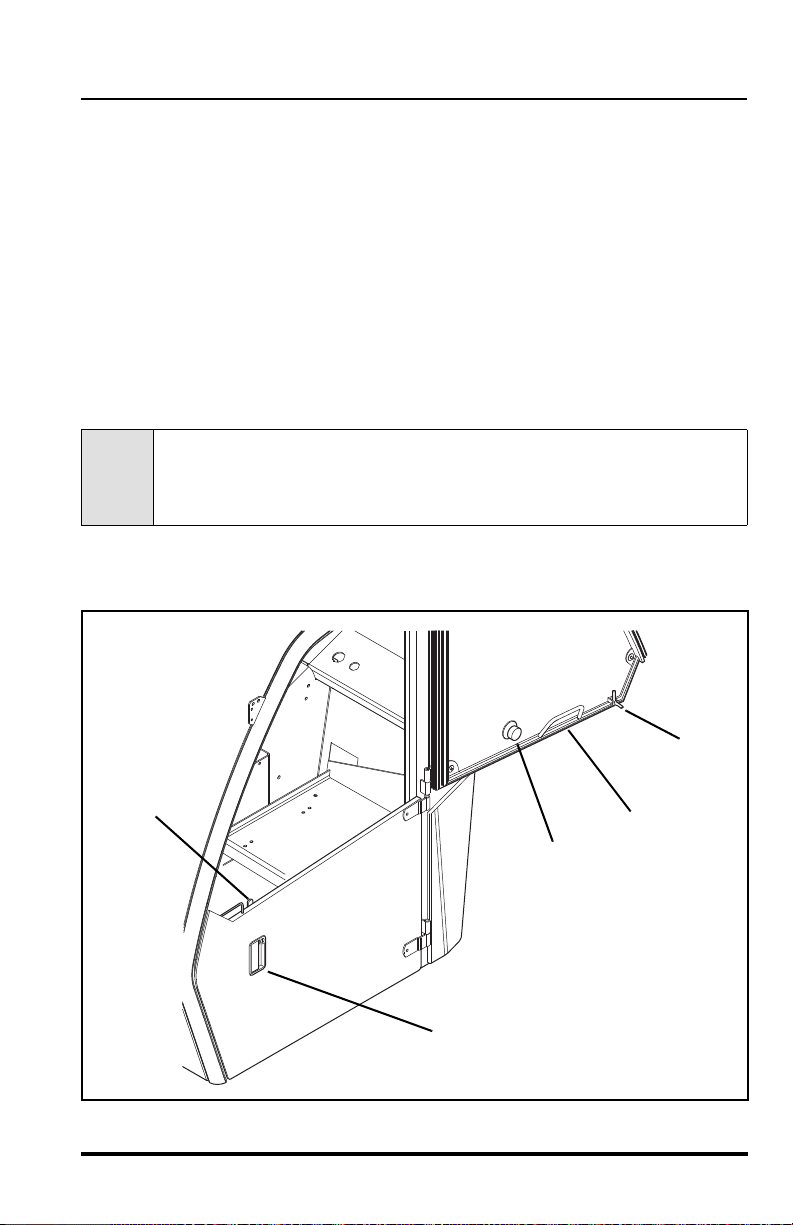

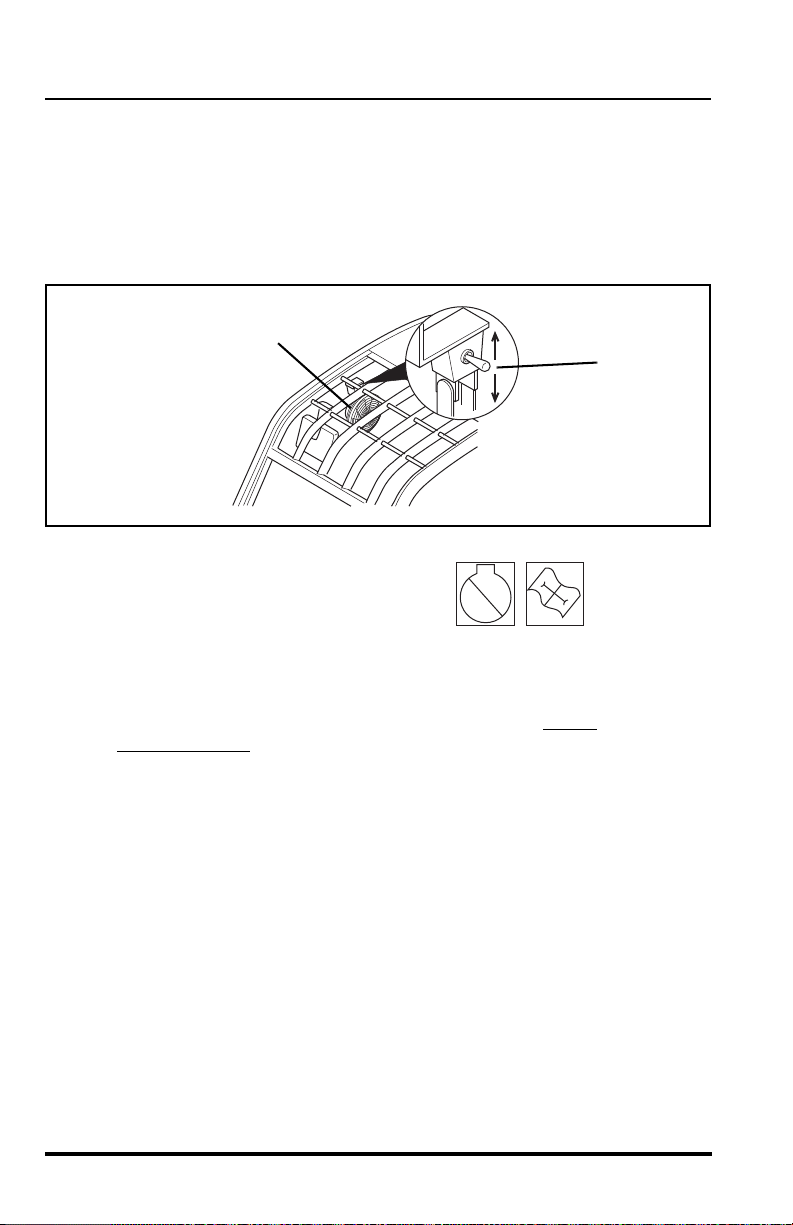

Rear Window Latch

The rear window (1) can be partially opened and secured in place with the

rear window latch. To open the window , grab the latch ha ndle (2) and pull up

and then push the window outward. To close and secure the window, pull

the latch handle up and then inward.

NOTE: In an emergency situation, the operator can exit through the rear

window opening by removing the latch pin (3) on the window la tch. The window is then free to swing open.

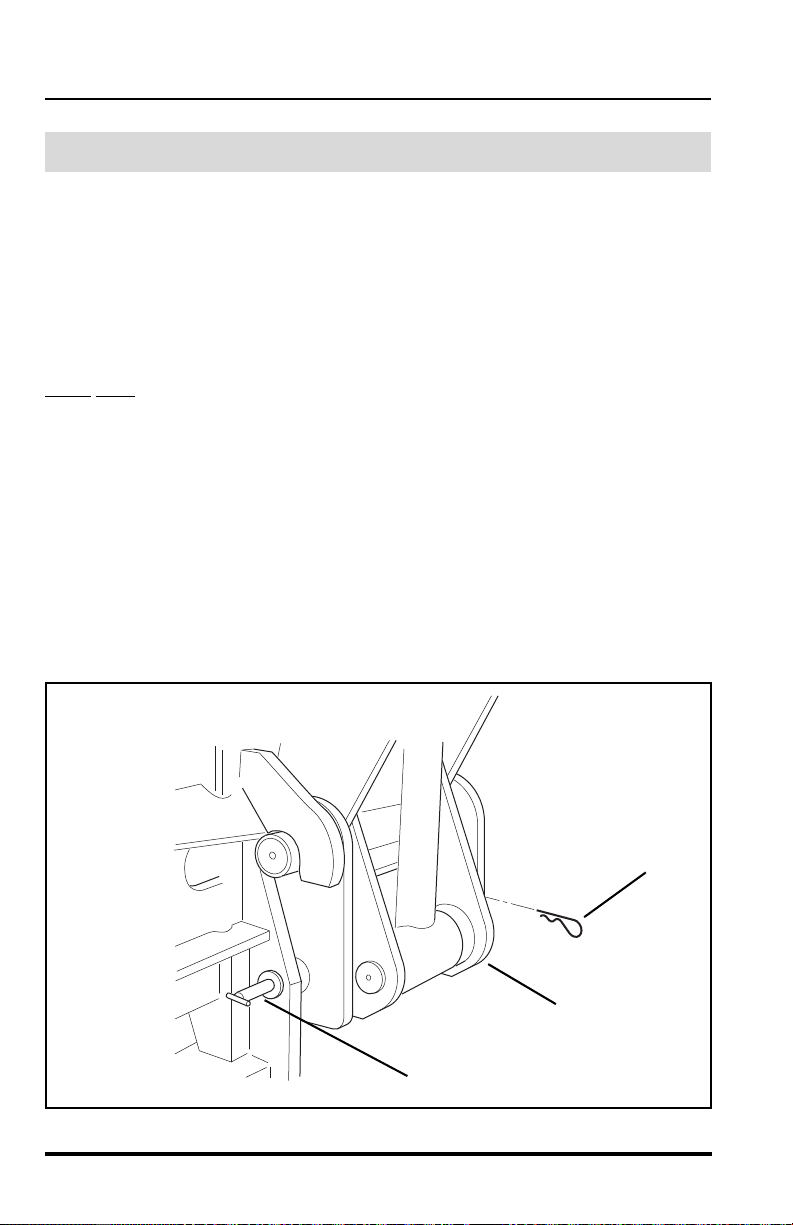

Rifle Mount

Stow rifle in stowage mount as follows:

• Position butt of M-16 rifle in the lower

mount (4) with trigger guard forward.

• Position barrel of M-16 rifle in upper

mount (5).

• Check that M-16 rifle is held tightly.

Remove rifle from stowage mount as follows:

• Pull the handle of the upper mount (5)

to the side.

• Remove the barrel of M-16 rifle from

the upper mount.

• Remove the butt of M-16 rifle from the

lower mount (4).

46

Model MMV Rev. 10/11

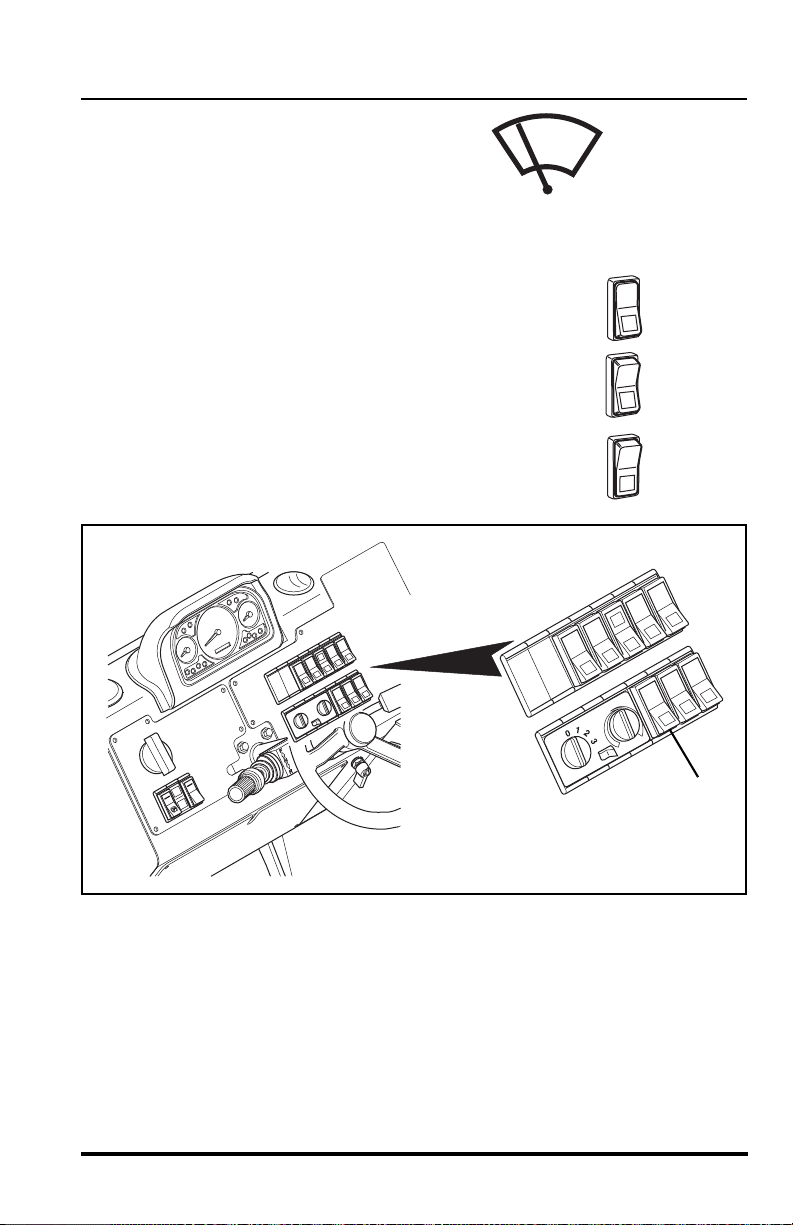

Front Windshield Wiper

OS19301

OH2591

OH2601

OH2611

OM1830

6

The three position front wiper switch (6) is

located in the lower bank of switches to the

right of the steering wheel. this single rocker

switch controls the speed of the front

windshield wiper.

• Push the TOP of the rocker switch in to turn the

front wiper OFF.

• Place the rocker switch in the MIDDLE position to

operate the wiper at LOW speed.

• Push the BOTTOM of the rocker switch in to

operate the wiper at HIGH speed.

Operation

Model MMV Rev. 10/11

47

Operation

OS19401

OH2591

OH2611

OM1830

1

2

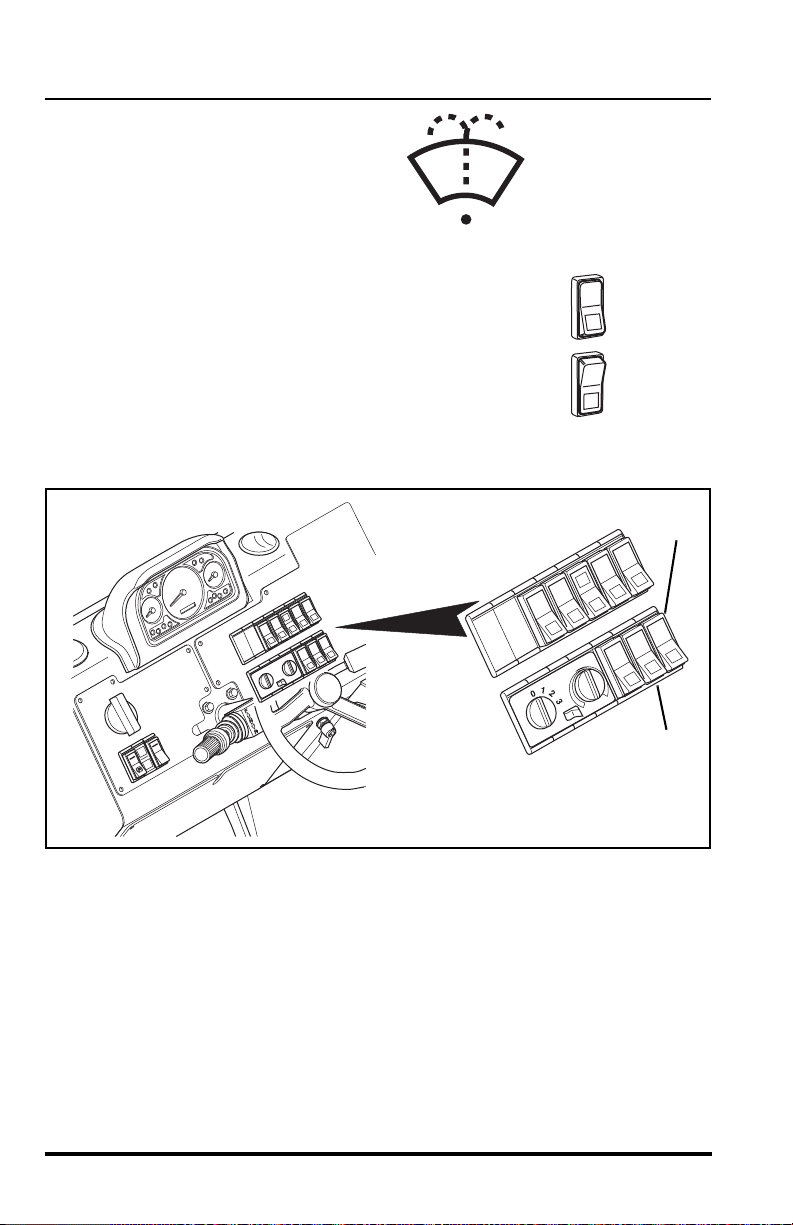

Windshield Washer Control

This rocker switch (1) is spring loaded

to return to the OFF position when

released. This switch is located in the

lower bank of switches to the right side

of the steering wheel.

• Release the switch to deactivate the washer

control.

• Press and hold the BOTTOM of the r ocker switch

in to activate the windshield washer. The rocker

switch is spring loaded and will return to the OFF

position when released.

48

Model MMV Rev. 10/11

Operation

OS2100

OM1520

OH2591

OH2601

OH2611

OM1530

OU0170

3

4

5

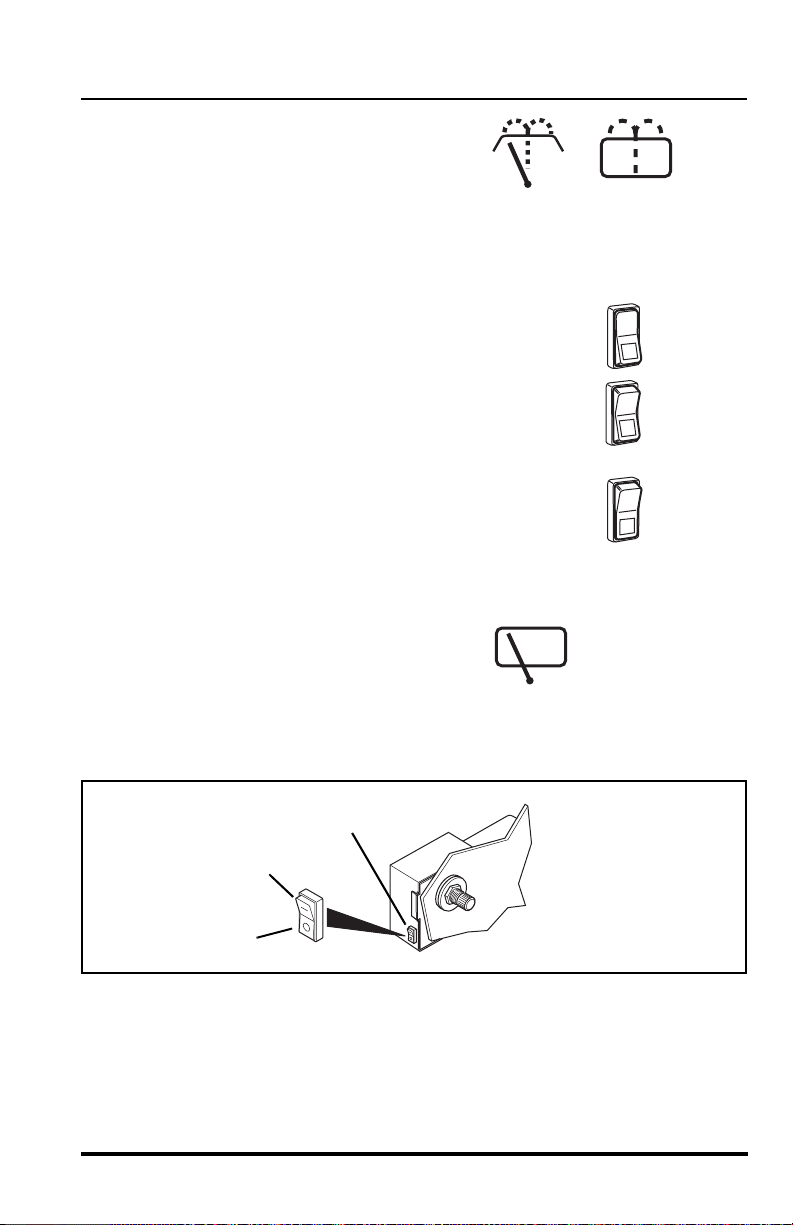

Skylight Wiper/Washer & Rear

Window Washer

The skylight (roof) wiper/washer switch and

rear window washer (2) is located in the

lower bank of switches to the right of the steering wheel. It controls the

skylight wiper, skylight washer along with the rear window washer. When

the skylight washer is activated, the rear window washer is also activated.

• Push the TOP of the rocker switch in to turn the

skylight (roof) wiper OFF.

• Place the rocker switch in the MIDDLE position to

turn the skylight (roof) wiper ON. This wiper is a

single speed wiper.

• Push and hold the BOTTOM of the rocker switch

to activate the skylight (roof) and rear window

washers. The rocker switch is spring loaded and

will return to the skylight (roof) wiper, ON position,

when the washer position is released.

Rear Window Wiper

The rear window wiper rocker switch (3) is

located on the motor housing of the rear

wiper.

The switch has two positions; wiper ON (4) and wiper OFF (5).

Model MMV Rev. 10/11

49

Operation

OS1950

OS1960

OM1830

4

1

2

3

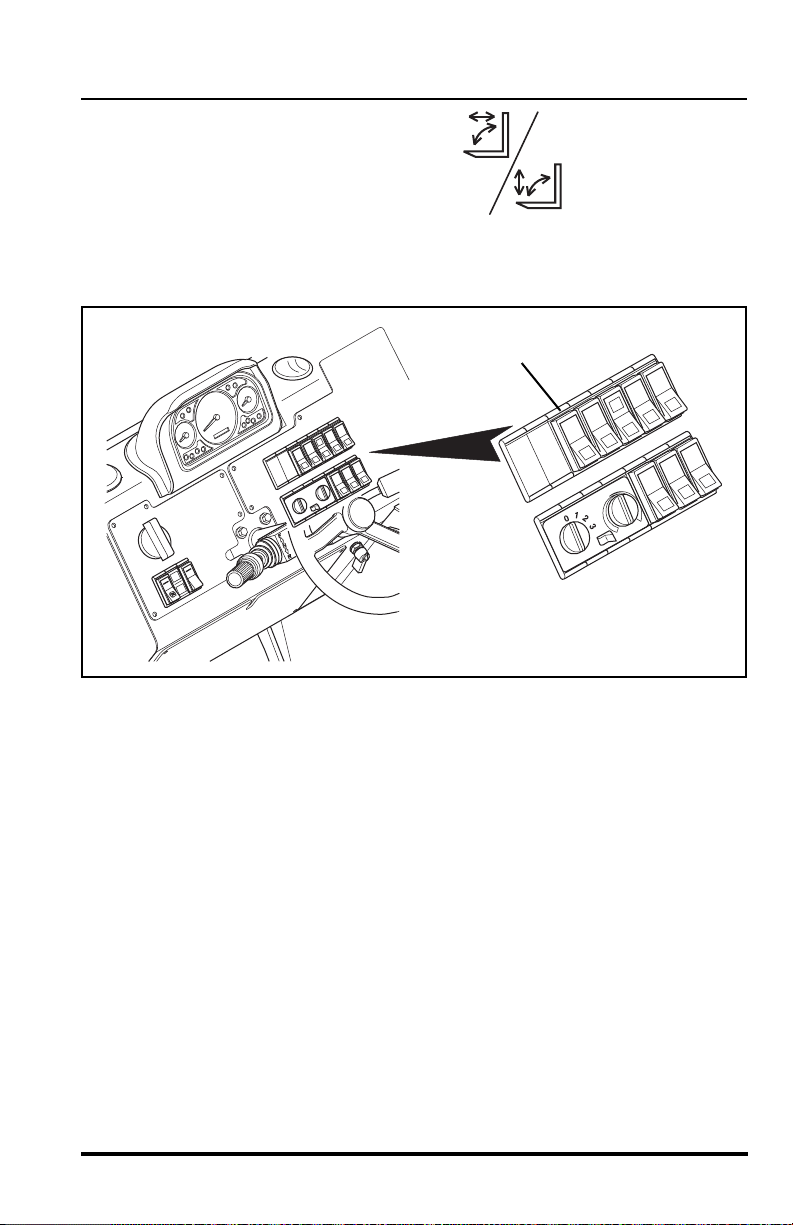

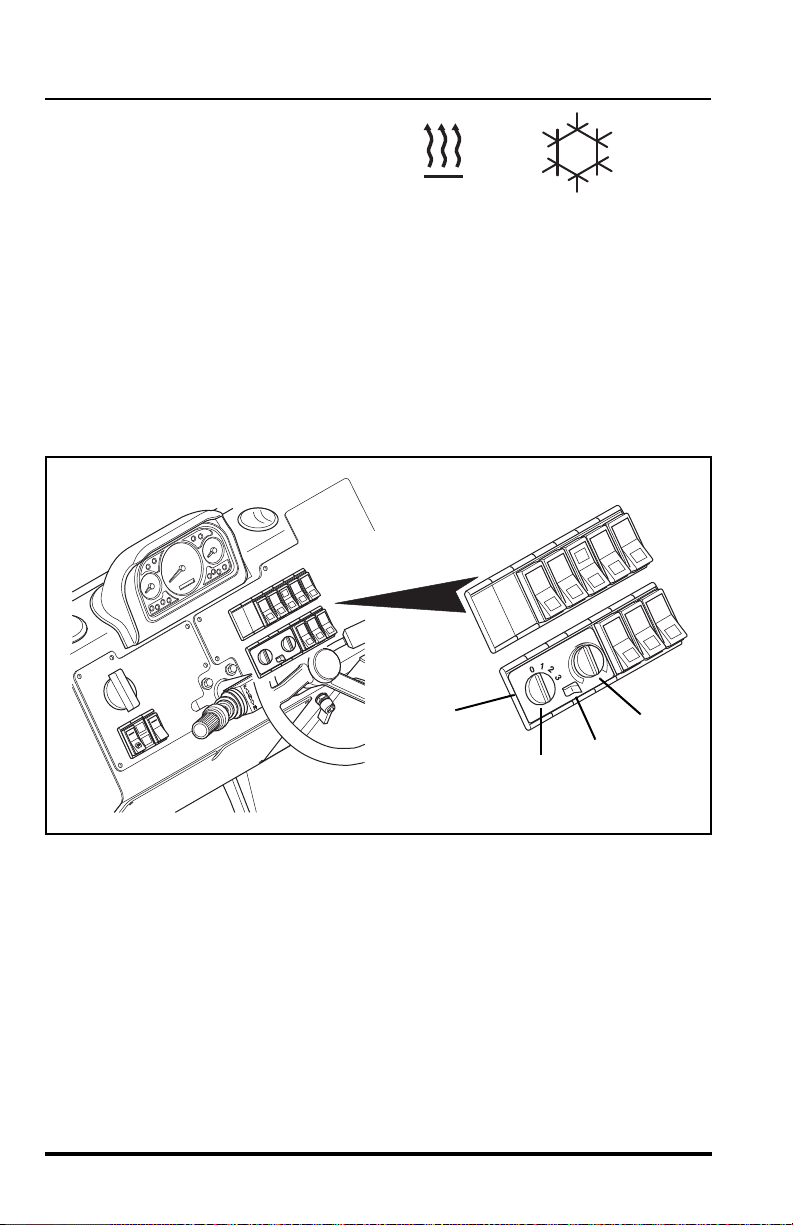

Cab Heater/Air Conditioning

Controls

The cab heater and air conditioning

controls (1) are located next to the

lower bank of switches on the right side of the front dash. From left to right

the control panel consists of: a variable speed fan con tr ol kn ob (2), an A/C

on-off rocker switch (3) and a temperature control knob (4).

Control of air flow is made by opening, closing or redirecting the air vent

louvers in four seperate locations inside the cab. For instance, if the front

glass needs rapid defrosting, red irect the air flow at the front two vents

(directing the vent louvers toward the glass) and close the remaining two

vents. This will increase the volume of air flow to the front glass and speed

defrosting.

50

Model MMV Rev. 10/11

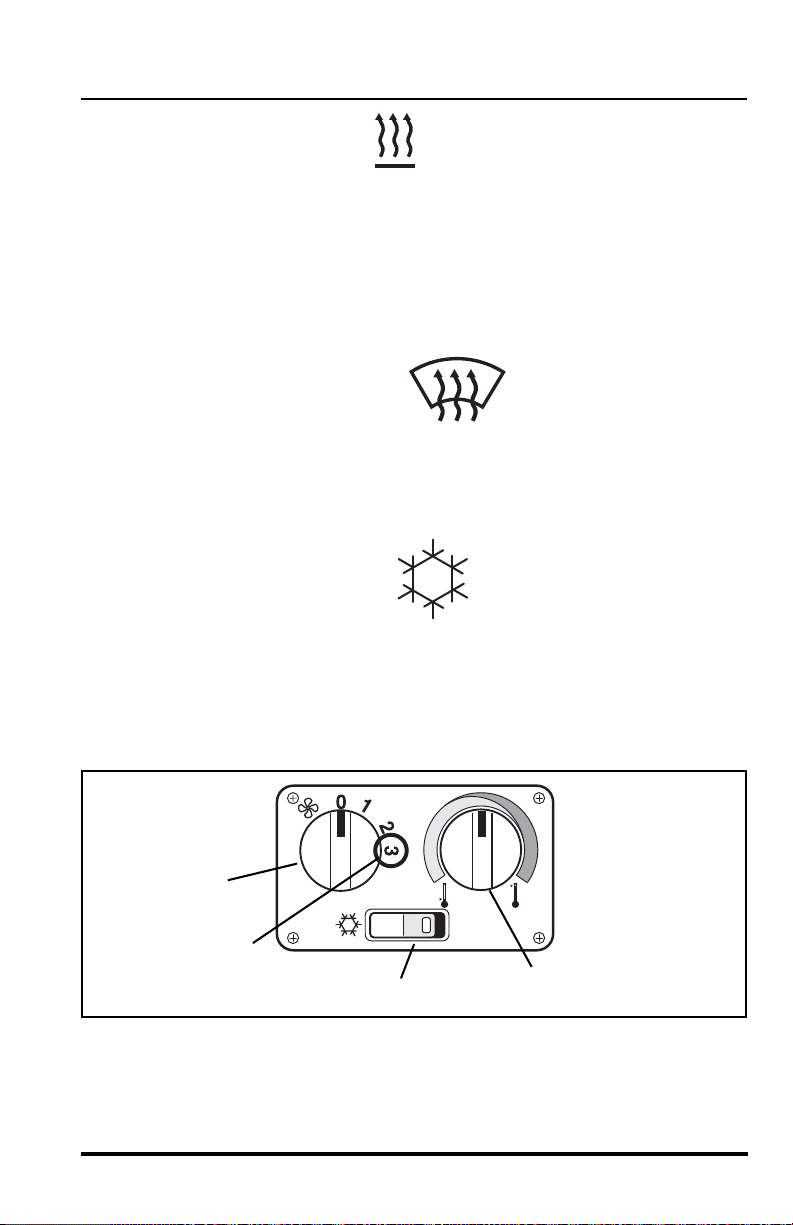

To heat the cab:

OS1950

OA1390

OS1960

OU0930

4

5

2

3

• turn A/C rocker

switch (3) to the

OFF position,

• turn temperature control knob (4) to far right position

(RED = HOT),

• direct desired air flow by adjusting vent louvers,

• turn fan control (2) to “3” (5) to assure rapid warm-up.

To defrost the cab:

• turn temperature control

knob (4) to the far right

position (RED = HOT),

• direct desired air flow by adjusting vent louvers,

• turn fan control (2) to “3” (5) to assure rapid defrost.

To cool the cab:

• turn A/C rocker switch

(3) to the ON position,

• turn temperature

control knob (4) to the far left position (BLUE = COOL),

• direct desired air flow by adjusting vent louvers,

Operation

• turn fan control (2) to “3” (5) to assure rap id cool-down.

Model MMV Rev. 10/11

51

Operation

OM2100

1

2

OH3290

Cab Circulation Fan

The cab circulation fan (1) is located at the top right side of the cab just

above the operators seat. The fan has a three position toggle switch (2)

located on the fan mount. The fan can be operated at HIGH speed (switch

down) or LOW speed (switch up). The fan can be swive led to direct the flow

in the desired direction.

Engine Function Indicator Lights

The engine function indicator lights

(3) are located in the switch bank on

the left side of the front dash. The

light indicates any faults that arise in the engine during operatio n.

The light contains a RED light (4) and a AMBER light (5).

If the RED light (4) comes ON during operation, STOP

IMMEDIATELY

and diagnose the fault by activating the ECM

diagnostic system. Activate the system with the accelerator pedal.

the engine

52

Activate the system and read the code as indicated by the RED

light (4). Contact your local Cummins dealer for an explanation of

these codes or refer to the Cummins Engine Owners Manual or call

the Cummins Customer Assistance Center at 1-800-34 3-7357.

If the AMBER light (5) comes ON during operation, the engine

diagnostic system has detected a fault within the engine. Stop the

engine and diagnose the fault by activating the ECM diagnostic

system.

Model MMV Rev. 10/11

Activate the system and read the code as indicated by the light.

OM1870

3

4

5

Contact your local Cummins dealer for an explanation of these

codes or refer to the Cummins Engine Owners Manual or call the

Cummins Customer Assistance Center at 1-800-343-7357.

Cummins ECM Diagnostic System Activation

With the engine OFF, turn the ignition switch to the RUN position.

DO NOT start the engine.

Completely depress and release the accelerator pedal three times.

This will activate the system, both the AMBER light and RED light

will come ON momentarily and then both will begin to flash the

code. If the system has been activated with the accelerator pedal

and no faults are present, both the AMBER light and the RED light

will come ON and stay ON.

Operation

ECM Light Code Identification

The AMBER light will flash one time to identify the start of the code

followed by a one or two second pause. Then the RED light will

flash the code sequence, pausing for one or two seconds between

numbers. The AMBER light will flash once after the RED light has

flashed the code to signify the end of that fault code.

Model MMV Rev. 10/11

53

Operation

0000000

RPM X 100

5

10

15

30

20

25

F

1/2

E

104

176

80

248

120

°C

°F

D

r/min

OU0010

1

2

3

4

5

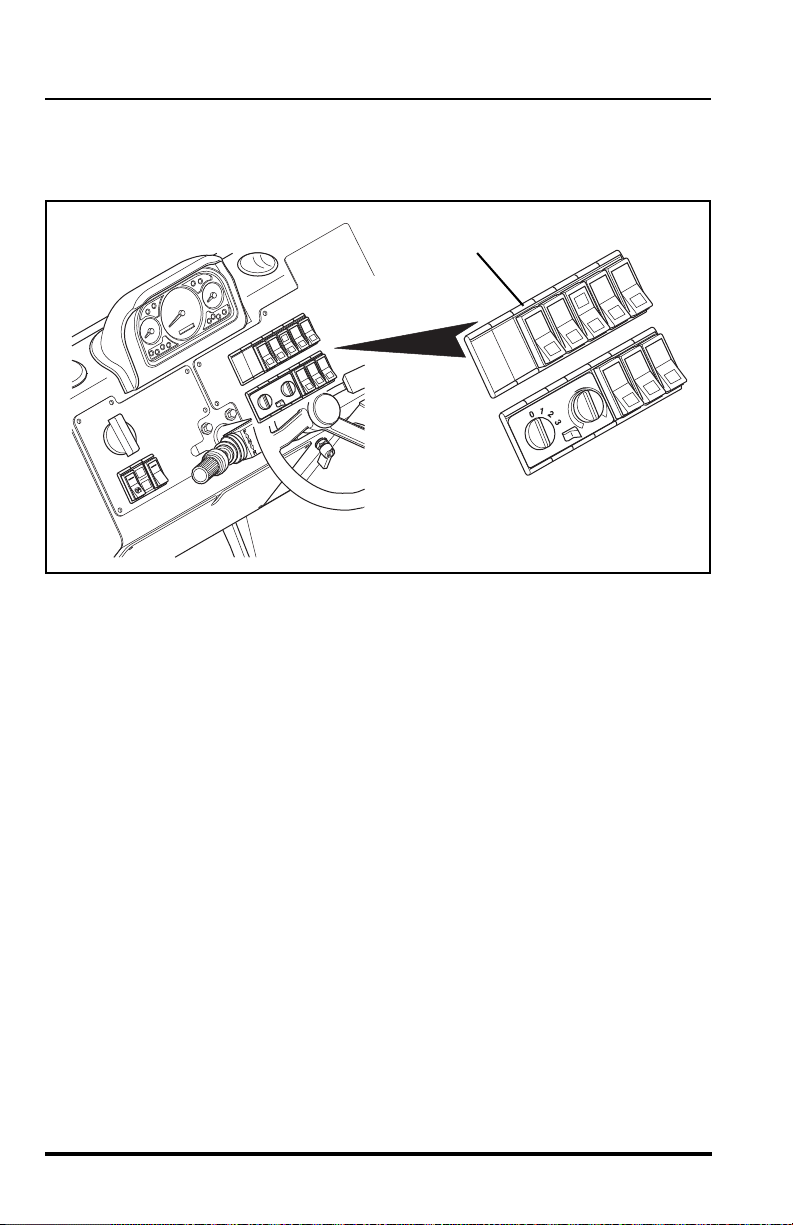

Front Dash Panel

The front dash panel (1) provides the operator wit h important information. It

is “user friendly” and only provides the oper ator with the inf ormation needed

at any given time.

Front Dash Panel Light Test

To test the front dash panel lights; turn the ignition switch to the RUN

position, ALL the lights (13 total) will come ON for three seconds as a test

function. During this time an audible alarm will sound. Replace any bulbs

that DO NOT come ON during this test.

Do not forget to refasten your seat belt before operation. Always wear the

seat belt when operating the vehicle.

54

Model MMV Rev. 10/11

Operation

OH2260

OS1970

OU0050

OU0040

Function Indicator Lights

There are four “hidden” function indicator lights in the front dash panel that

illuminate only when a specific function has been activated. They are:

Parking Brake Indicator (2)

This light illuminates any

time the parking brake is

applied and the ignition

switch is in the RUN

position.

Stabil-TRAK Mode Indicator

Lights (3 & 4)

One of these lights will illuminate

when the Stabil-TRAK system

has been ACTIVATED in the

“Locked” Mode (3) or the “Slow Pivot” Mode (4). Refer to

“Understanding the Stabil-TRAK™ System” on page 73 for a

detailed explanation.

Engine Air-Intake Heater Indicator (5)

This light illuminates, with the

ignition switch in the RUN position,

any time the ambient temperature

drops below 40° F (4° C). The engine grid heater then becomes

active and the engine should not be cranked until the light goes

OFF. Once the light goes OFF it indicates that the grid heater is at

the proper temperature and the eng ine is read y to star t.

NOTE: This indicator light may come ON when the engine is running to indicate that the post heat function is active. This is a normal condition when

ambient temperatures are below 40° F (4° C).

Model MMV Rev. 10/11

55

Operation

OT0990

OT1000

OT1010

Warning Indicator Lights

There are seven additional “hidden” indicator lights in the front dash panel

that will illuminate during critical circumstances. all seven warning indicator

lights demand immediate attention and vehicle servicing. In many cases,

the vehicle should be shut down AS SOON AS PRACTICAL

serious mechanical failure.

The warning indicator lights are:

Transmission Temperature Warning

Indicator (1)

This light illuminates when the

transmission oil temperature is too

high; above 250° F (121° C). An audible alarm will also sound. Stop

and idle the vehicle with the transmission in (N) Neutral, allowing

time for cooling. If the light does not go out after two minutes, shut

the vehicle down.

Hydraulic Oil Temperature Warning

Indicator (2)

This light illuminates when the

hydraulic oil temperature is too high;

above 195° F (91° C). Stop and idle the

engine, allow time for cooling. If the light does not go out after five

minutes, shut the vehicle down.

Engine Oil Pressure W arning Indicator (3)

to prevent

56

This indicator light will come ON if the

engine is not started. This is normal. If

the light comes ON while the engine is

running, this indicates that the engine oil pressure is t oo lo w. When

the engine is running an audible alarm will also sound when the low

oil pressure light is ON.

SHUT THE VEHICLE DOWN AS SOON AS PRACTICAL.

Model MMV Rev. 10/11

Alternator Charging Warning Indicator (4)

OH2560

OT1020

OT1030

0000000

RPM X 100

5

10

15

30

20

25

F

1/2

E

104

176

80

248

120

°C

°F

D

r/min

OU0010

1

2

3

4

6

5

This light illuminates to indicate a weak or

improperly working charging system or the

batteries are dead. Service the engine

alternator or batteries.

Engine Air Filter Restriction Warning

Indicator (5)

This light illuminates when a restricted

engine air filter is detected. If the light is ON,

service the air filter(s).

Hydraulic Oil Filter Restriction

Warning Indicator (6)

This light illuminates when a restricted

hydraulic oil filter is detected. If the light is

ON, service the hydraulic oil filter.

Operation

Model MMV Rev. 10/11

57

Operation

OM1600

0000000

RPM X 100

5

10

15

30

20

25

F

1/2

E

104

176

80

248

120

°C

°F

D

r/min

OU0010

1

2

3

4

5

Low Brake Pressure Warning Indicator (1)

This light is located on the lower right

side of the front dash panel.

The light will come ON and the buzzer

sounds when service brake hydraulic system pressure drops below

the safe operating level. Under normal conditions, the light and

buzzer will go out quickly after engine start. If the light or buzzer

does not go out or comes ON during vehicle operation, shut off

engine immediately, investigate, and repair before operating. DO

NOT operate vehicle when low brake pressure light or buzzer is on.

WARNING: Operating the vehicle with the service

brake system malfunctioning will cause reduced braking ability or

no braking ability when the service brake pedal is depressed.

Death or serious personal injury could result from the inability to

stop or slow the vehicle.

If the low brake pressure light or buzzer remains ON, place the

travel select lever in (N) NEUTRAL, place the neutral lock lever in

the (N) NEUTRAL LOCK position, engage the parking brake switch

and turn the engine OFF.

Have the service brake system serviced before using the vehicle

again. Contact your local JLG Authorized Service Center (ASC)

immediately to repair the system.

Model MMV Rev. 10/11

58

Gauges and Indicators

OH24701

r/min

OU0020

OU0030

OT0980

Fuel Level Gauge (2)

Make sure the vehicle is level to

ensure an accurate fuel level

reading. The fuel gauge located

on the left side of the front dash panel, indicates the amount of fuel

in the fuel tank. Refuel before the fuel gauge reaches the “E” to

prevent running out of fuel. Capacit y o f th e fu el tan k is 50 . 2 gallo ns

(190 liters) total capacity with a usable capacity of 45 gallons

(171 liters). If the engine ever runs out of fuel, the fuel system will

need to be bled. Refer to “Bleeding Fuel System” page 160.

Engine Tachometer (3)

The tachometer is the gauge in

the center of the front dash panel

and indicates speed of the

engine in revolutions per minute

(rpm).

Hourmeter (4)

The hourmeter records engine

operating hours and has a total

readout of 99,999.99 hours. It is

located on the front dash panel in the lower portion of the

tachometer.

Operation

Engine Coolant Temperature

Gauge (5)

The engine coolant temperature

gauge is located on the right side

of the front dash panel. Glance at

the gauge on a regular basis during operation. The gauge monit ors

the temperature at which the engine is operating. If the gaug e goes

over 210° F (99° C) the engine coolant is too hot. Idle the en gine for

1 minute prior to shutting the vehicle down. If the radiator is boiling

over, SHUT THE VEHICLE DOWN AS SOON AS PRACTICAL.

Model MMV Rev. 10/11

59

Operation

OS1900

OH2510

0000000

RPM X 100

5

10

15

30

20

25

F

1/2

E

104

176

80

248

120

°C

°F

D

r/min

OU0010

1

2

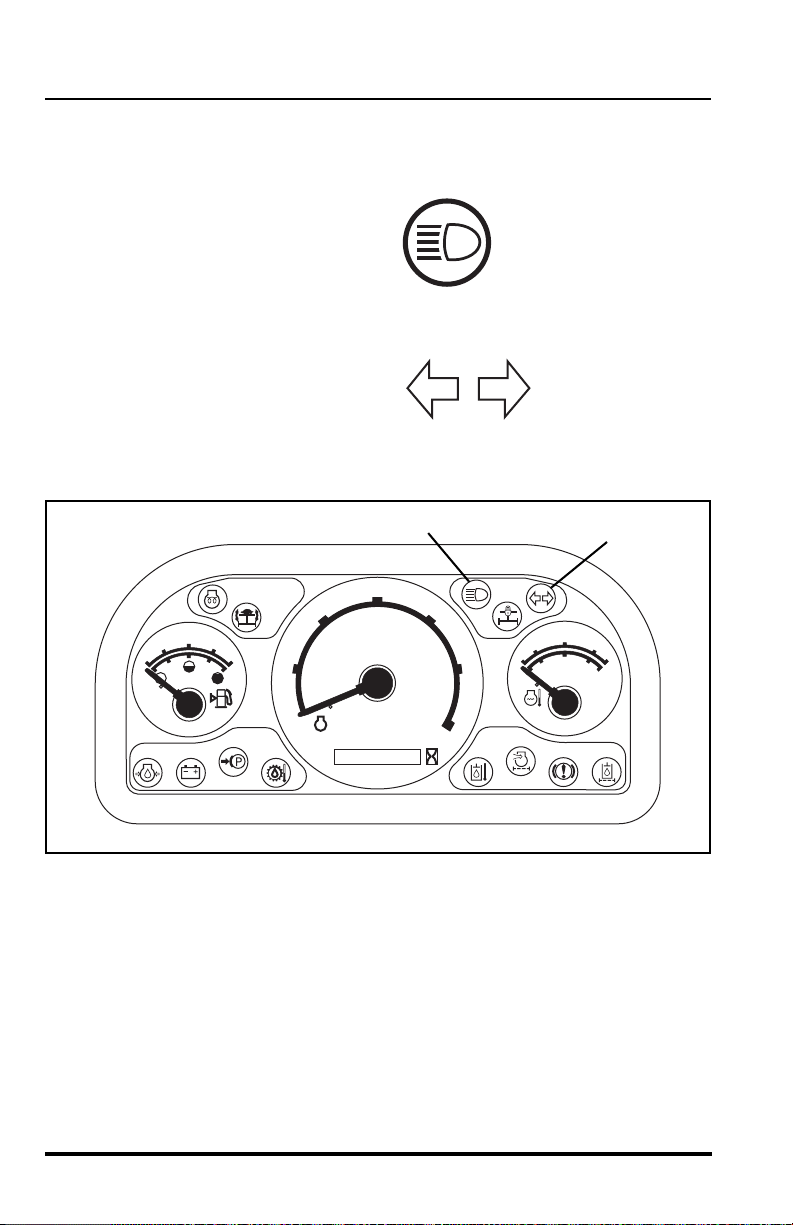

Additional Indicator Lights

There are two additional “hidden” indicato r lights in the front dash panel that

will illuminate only when the road lights are activated.

High Beam Indicator (1)

Whenever the headlights are

on “high” beam this light will

illuminate and remain ON until

the headlights are switched to

“low” beam.

Turn Signal Indicator (2)

The turn signal indicator light

will illuminate and flash when

the turn signals are activated

in either direction or when the hazard lights have been activated.

60

Model MMV Rev. 10/11

Operation

OS0232

3

OM0961

4

5

6

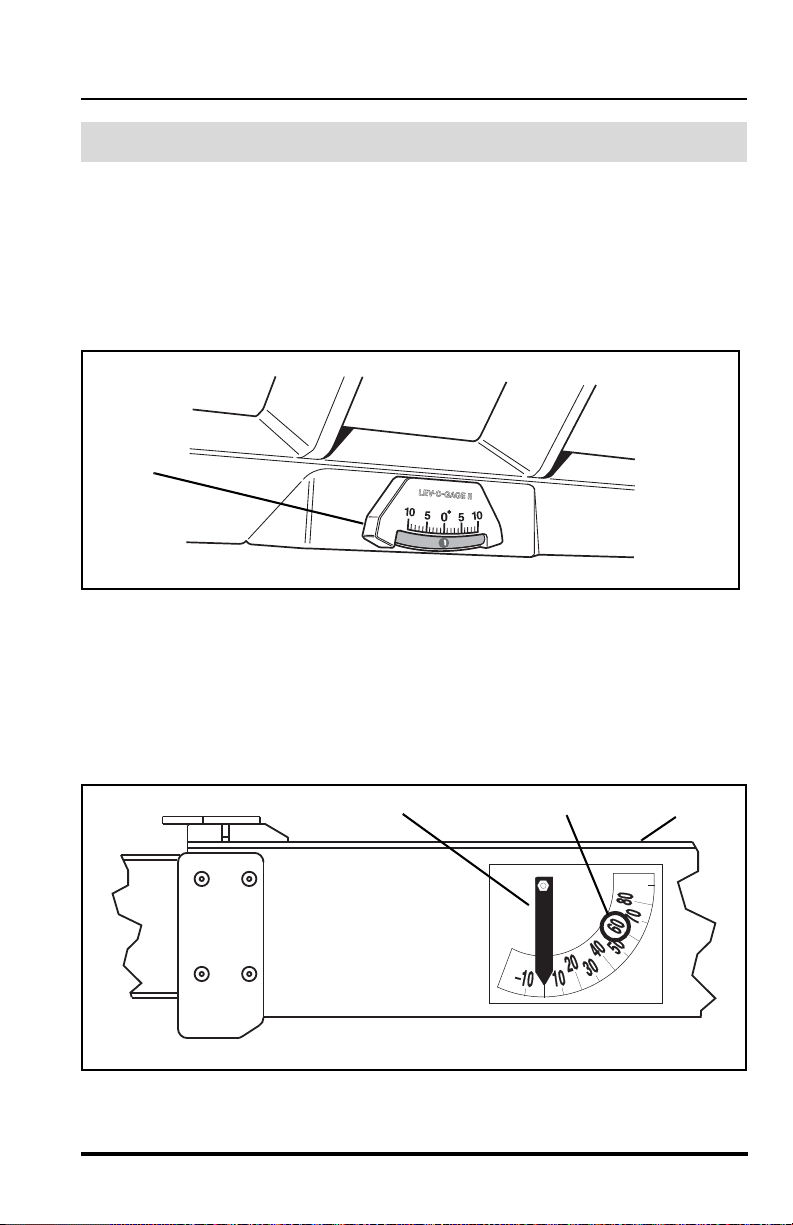

Instruments and Indicators

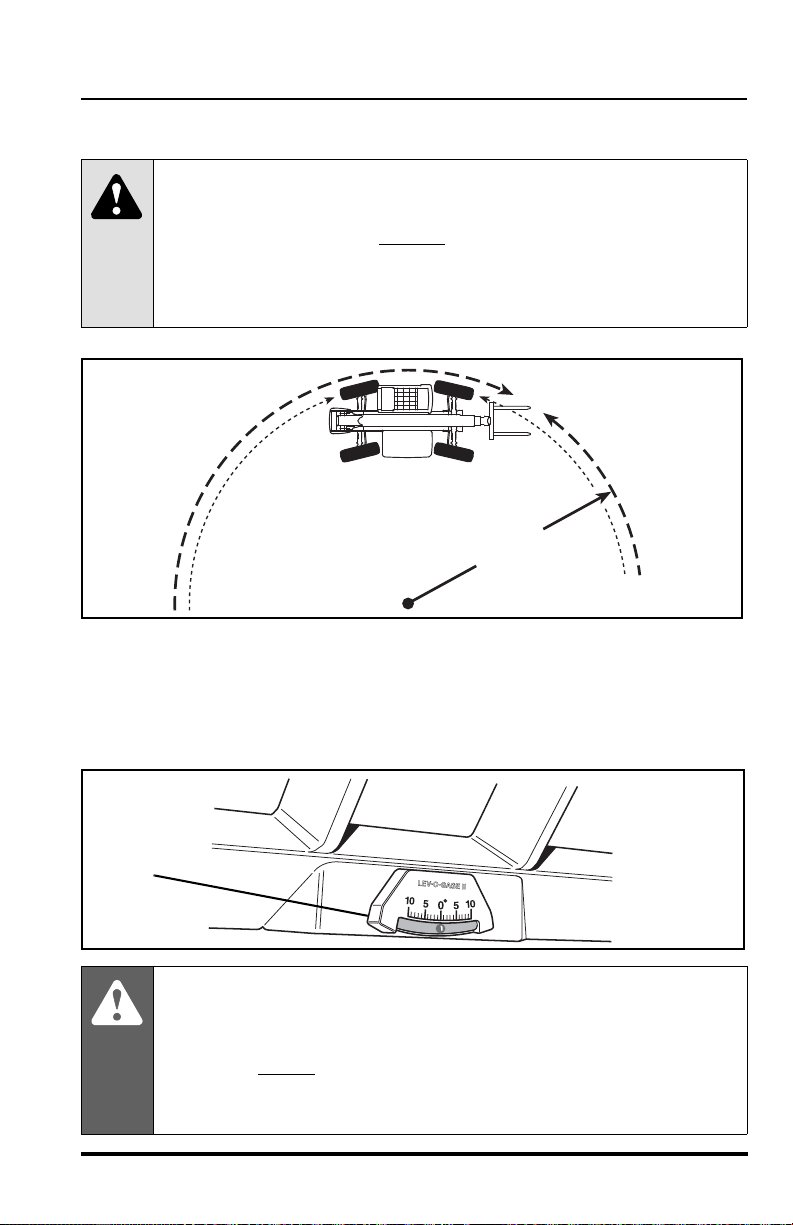

Frame Level Indicator

The frame level indicator (3) is mounted on the top inside of the cab. It is a

bubble type indicator which allows the operator to tell if the vehicle has

been positioned in a level condition. Always frame sway the vehicle either

right or left until the indicator reads zero degrees (0°). If zero cannot be

achieved, then reposition the vehicle until it is level before placing the load.

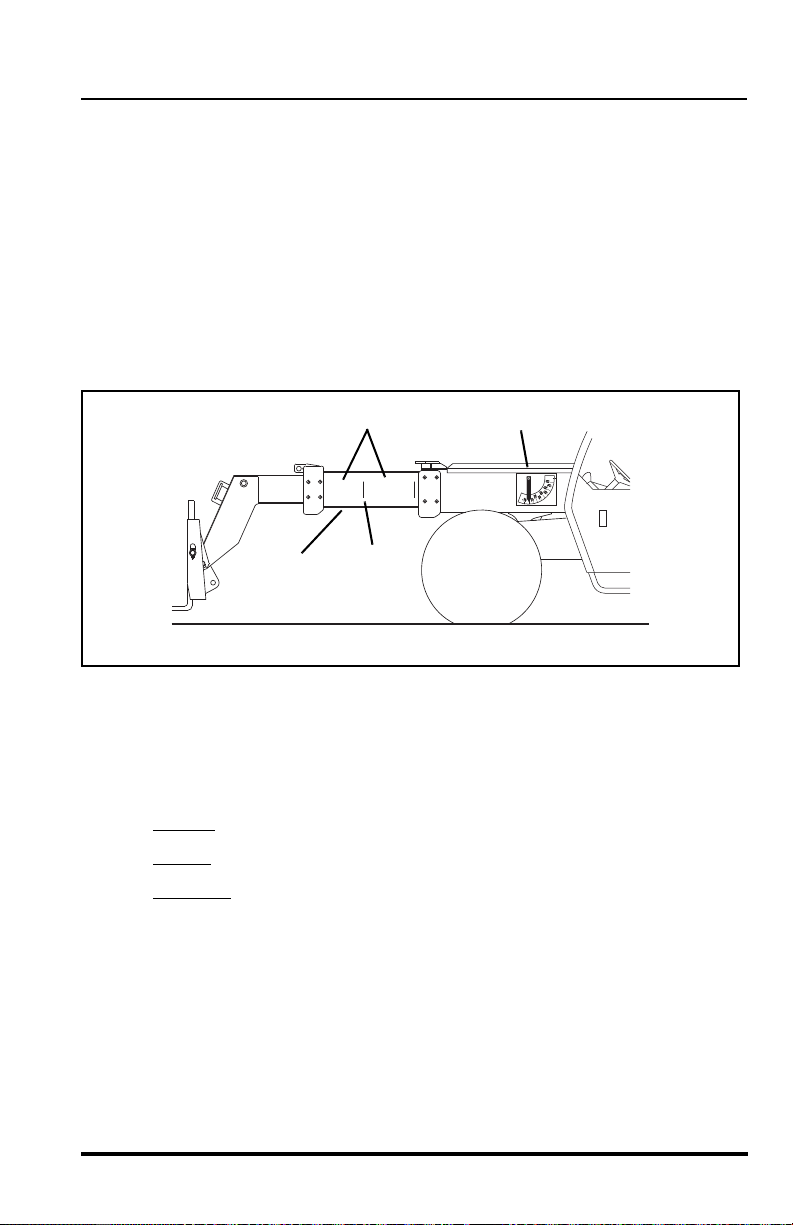

Boom Angle Indicator

The boom angle indicator is a plumb arrow (4) with angular graduations (5)

from -10° to + 80°. It is located on the left side of the boom (6) and is visible

from the operators position. Use this indicator to dete rmin e the b oom ang le

when reading the capacity chart (see “Using the Capacity Chart” on

page 92).

Model MMV Rev. 10/11

61

Operation

OS1470

2

1

OM1670

3

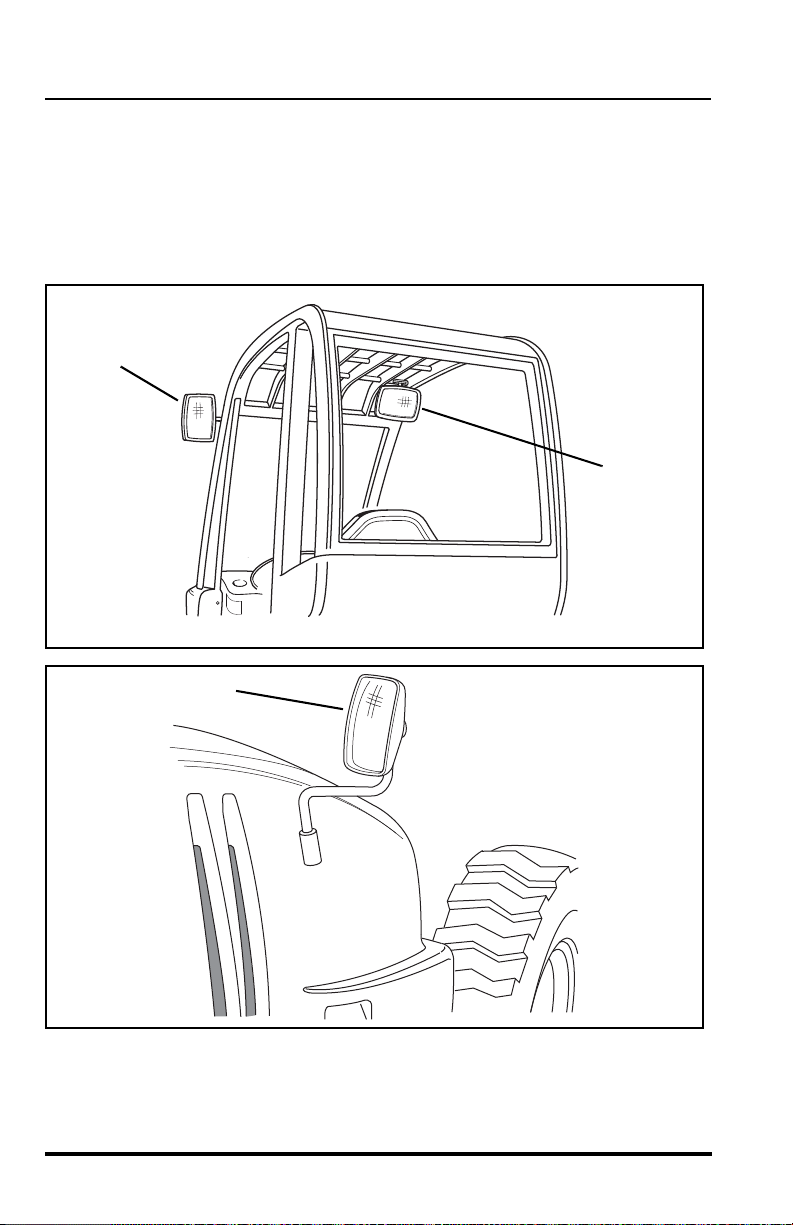

Rear View Mirrors

Three rear view mirrors are provided to aid the operator’s rear visibility. The

mirrors are adjustable and need to be adjusted to obtain the best rear view

possible for the operator. There is one mirror (1) on the left front side of the

cab and a second mirror (2) inside the cab in the upper right front corner.

The third mirror (3) is located on the side of the engine ho od.

62

Model MMV Rev. 10/11

Operation

Load Moment Indicator

WARNING: The Load Moment Indicator (L M I) system

is not intended to be an absolute

charts. DO NOT exceed rated capacities! Any attempt to lift or

carry loads in excess of those shown on the capacity chart may

cause vehicle tipover, loss of load or structural damage which

could result in death or serious personal injury.

The load moment indicator is a feature which continually monitors the load

on the rear axle as loads are being lifted and extended. The system alerts

the operator when the ground pressur e on the rea r of the ve hic l e ha s

decreased to a point that the rear of the vehicle could raise up off the

ground. This system indicates the level of forward stability and not

necessarily of sideways stability. The display panel (4) is mounted in front of

the joystick on the right side console.

1. The display has a green power light (5) next to the te st button (6) to

inform the operator that the system is active. This light will come

ON when the ignition is turned to the RUN position.

2. The display has a series of three green lights (7), one amber light

(8), one red light (9) and an audib l e a lar m tha t inf orms t he op er ator

of each operating load range.

3. As the load is extended and reaches 100% of the vehicles capacity,

the three green lights will be lit and the amber light will flash.

replacement for the capacity

4. As the load goes over 100% of the vehicles capacity the red light

will come ON and an audible alarm will sound, alerting the operator

that the load should be retracted.

Model MMV Rev. 10/11

63

Operation

100%

TEST

OM1890

4

6

5

7

8

9

64

Model MMV Rev. 10/11

Operation

100%

TEST

OM1890

2

1

Load Moment Indicator System Test

ALWAYS

Changing Display Settings

The display has muting and dimming settings which allow the operator to

set the level of brightness and the sound level of the alarm. There are four

possible combinations.

To change the settings, PRESS and HOLD the test button (1) continuously

while the display sequences through each combination. Release the test

button when the preferred combination occurs. The combinations are:

test the LMI system before starting to work with a load.

1. Turn the ignition to the RUN position.

2. Momentarily press the test button (1) on the load moment indicator

display (2). ALL the lights should flash ON and the audible alarm

will sound. This will tell you that the display is functioning properly.

• Full Brightness with Full Volume

• Full Brightness with Muted Volume

• Dim Brightness with Full Volume

• Dim Brightness with Muted Volume

Model MMV Rev. 10/11

65

Operation

Pre-Operation Inspection

1. Check safety belt for damage. Check for frayed or cut seat belt

webbing, damaged buckles or loose mounting brackets. Make any

necessary repairs before operating the vehicle.

2. Check all four tires and rims for damage. Check for proper tire pressure, add air if required. Observe the condition of each tire looking

specifically for punctures, cracks, cuts, gouges, bulges or any ot her

damage. Check the condition of each rim for bent flanges or any

other damage. Make any necessary repairs before operating the

vehicle.

3. Check and add engine oil if required. This procedure is explained in

greater detail on page 152.

4. Check and add transmission oil if required. This procedure is

explained in greater detail on page 169.

5. Check the cooling system overflow bottle for coolant. Add coolant if

required. This procedure is explained in greater d etail on page 148.

Remove any debris blocking the radiator cooling fins.

6. Check the hydraulic oil level sight glass and add hydraulic oil if

required. This procedure is explained in greater detail on page 164.