SkyTrak 6036 Service Manual

Service Manual

Model

6036

S/N 9B0500 thru 14833

8990163

Revised February 11, 2005

Effectivity Page

August, 1997 - 001 - Original Issue

February 11, 2005 - B - Replaced all branding with JLG.

Model 6036 S/N 9B0500 thru 14833

A

Effectivity Page

B

Model 6036 S/N 9B0500 thru 14833

SECTION CONTENTS

Section Subject Page

Section 1 Safety Practices ................................................................................ 1-1

Section 2 General Instructions .......................................................................... 2-1

Section 3 Boom ................................................................................................. 3-1

Section 4 Operator's Cab .................................................................................. 4-1

Section 5 Wheel Assembly, Tires, and Axle ...................................................... 5-1

Section 6 Drive Shafts and Drop Box ................................................................ 6-1

Section 7 Transmission, Clark Series 18000..................................................... 7-1

Section 8A Engine, Perkins Series 4.236 and T4.236 ...................................... 8A-1

Section 8B Engine, Cummins Series 4B3.9 and 4BT3.9 .................................. 8B-1

Section 9 Hydraulic System .............................................................................. 9-1

Section 10 Electrical System ............................................................................. 10-1

Model 6036/6036T S/N 9B0500

thru 14833

This Page Left Blank Intentionally

SECTION 1

SAFETY PRACTICES

Section 1 Safety Practices

CONTENTS

Par Title Page

1.1 INTRODUCTION .................................1-1

1.2 SIGNAL WORDS ................................1-1

1.3 PERSONAL CONSIDERATIONS ........ 1-2

1.4 EQUIPMENT CONSIDERATIONS ...... 1-2

1.5 GENERAL CONSIDERATIONS ..........1-3

1.6 OPERATIONAL

CONSIDERATIONS ............................1-3

1.7 FINAL WORD ...................................... 1-4

1.1 INTRODUCTION

Practically all SERVICE work involves the need to

drive the forklift. The Operator’s Manual, supplied

with each forklift, contains detailed safety practices

relating to driving and operating. These practices

apply to the service technician and should be

read, understood, and practiced.

Signal Word:

Is a distinctive word on safety decals and throughout this manual that alerts the viewer to the

existence and relative degree of the hazard.

Danger

The signal word "Danger" means an extremely

hazardous situation exists on or near the machine

which would result in high probability of death or

serious injury if proper precautions are not taken.

Warning

The signal word “Warning” means a hazard exists

on or near the machine which can result in seriuos

injury or death if the proper precautions are not

taken.

Prior to performing any service on the forklift,

consideration should be given to factors that may

have an effect upon safety; not only on the mechanic, but also the bystanders.

1.2 SIGNAL WORDS

This symbol means “Attention! Become Alert!

Your Safety is Involved !” The symbol is used

with the following signal words to attract your

attention to safety messages found on safety

decals and throughout this manual. The message

that follows the symbol contains important information about Safety. To avoid injury and possible

death, carefully read the message! Be sure to

fully understand the causes of possible injury or

death.

Caution

The signal word “Caution” is a reminder of safety

practices or directs attention to unsafe practices

on or near the machine which could result in

personal injury if the proper precautions are not

taken.

IMPORTANT: The information in this manual

does not replace any safety rules used in your

area. Before operating this forklift, learn the rules

and laws for your area. Make sure the machine

has the correct equipment according to these rules

and laws.

Your safety and the safety of others in the

work area depend on your knowledge of

correct operating procedures for the machine.

6036/6036T S/N 9B0500 thru 14833

1-1

Section 1 Safety Practices

1.3 PERSONAL CONSIDERATIONS

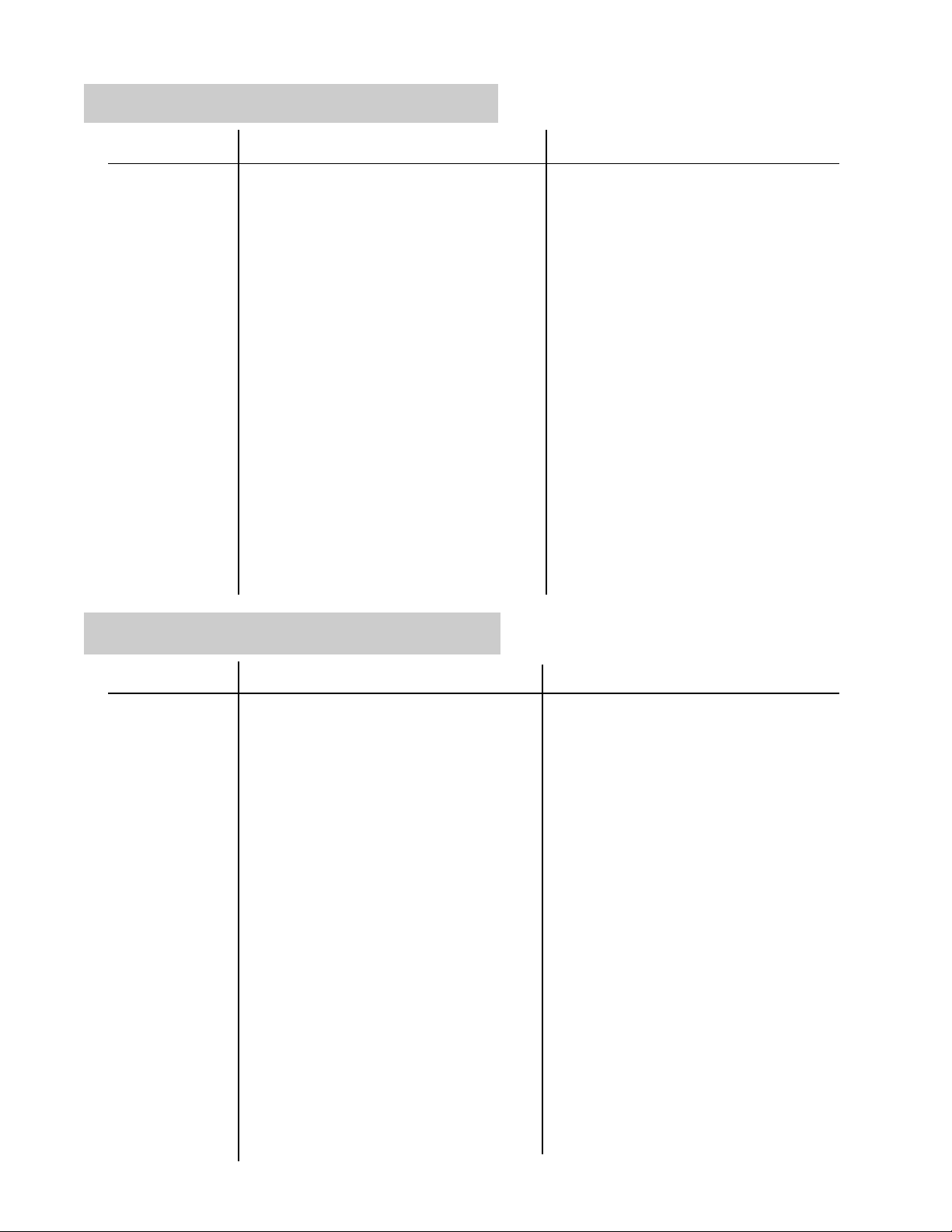

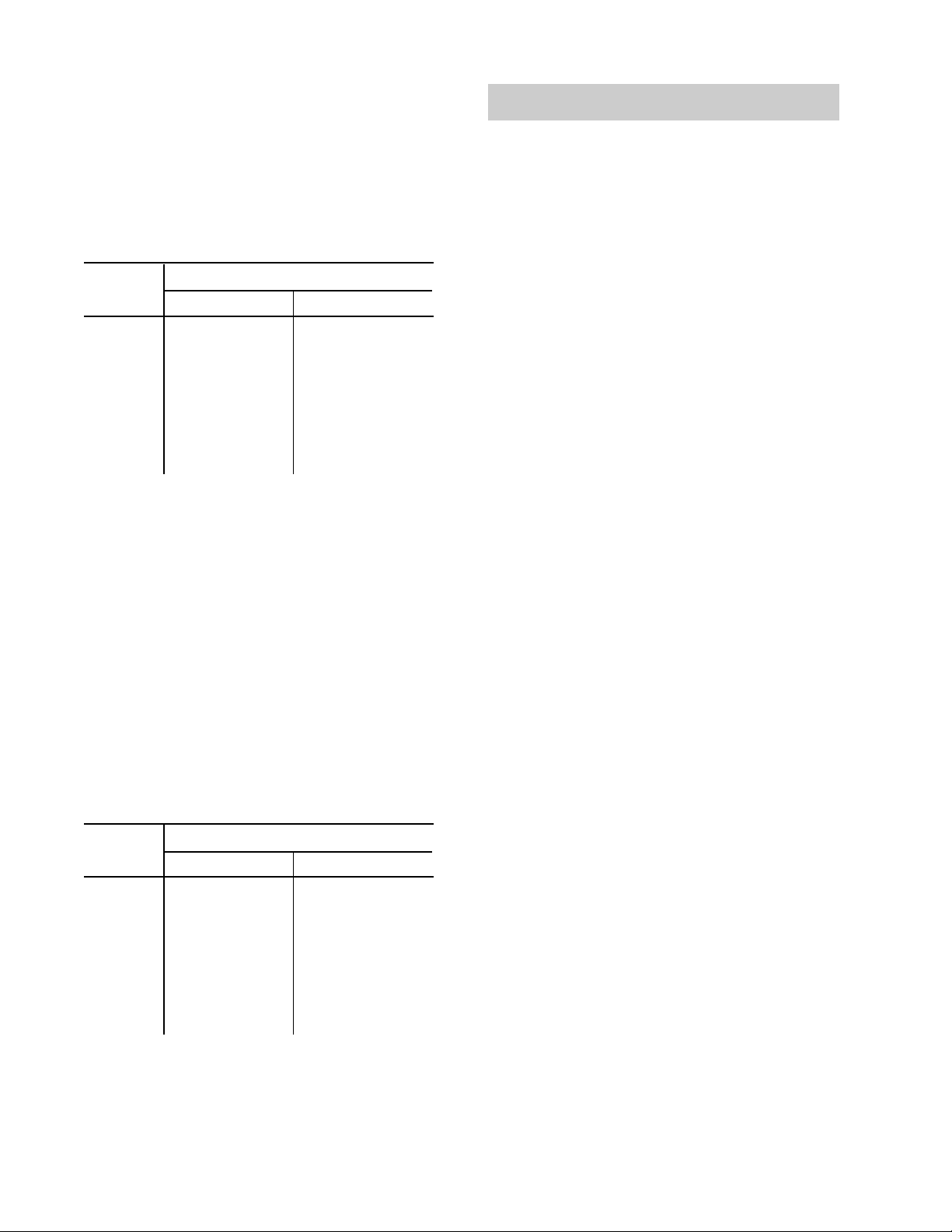

Item What to do Why

Clothing Do not wear loose clothing or jewelry. Improper clothing can catch on controls

or moving parts and cause accidents

and/or injury.

Eye Protection Always wear appropriate eye protection Permanent eye damage can be caused

when chiseling, grinding, discing, weld- if foreign matter enters the eye.

ing, painting, when repairing hydraulic

systems, or checking, testing or

charging the battery.

Breathing Wear respiratory protection if grinding or Fumes, dust and paint spray are harmful

Protection painting. when inhaled.

Hearing Always wear ear protection if noise is Continuous loud noise can damage

Protection excessive. your hearing.

Foot Wear protective footwear with reinforced To protect feet from falling objects and

Protection toe caps and oil-resistant soles. to prevent slipping.

Lifting Make sure you are capable of lifting an To avoid injury through incorrect hand-

object. Get help or use a sling on large ling of heavy components.

components.

1.4 EQUIPMENT CONSIDERATIONS

Item What to do Why

Operator’s Before using the forklift, be sure the The cab protects the operator from

Cab operator’s cab and rear window are possible serious injury or death.

secure and serviceable.

Lifting Check all lifting equipment (chains, To prevent serious injury or death due

Equipment brackets, hooks, etc.), before use. Be to falling objects.

sure equipment is the proper capacity.

Never stand under a suspended load To prevent serious injury or death.

or raised implement.

Do not work on equipment which is To prevent serious injury or death.

supported only by a hoist or jacks.

Always support equipment with blocks

or approved stands

Compressed Always use a general purpose nozzle To prevent serious injury to operator

Air to blow dust, filings, dirt, etc., from work and/or co-workers.

area. Always wear eye protection when

using compressed air to clean a work

area.

Look around before using an air hose. To prevent injury to other personnel

in the work area.

1-2

6036/6036T S/N 9B0500 thru 14833

Section 1 Safety Practices

1.4 EQUIPMENT CONSIDERATIONS (CONT.)

Item What to do Why

Hand Tools Always use the proper tool for the job. Many cuts, abrasions, and/or injuries

are caused by defective or improper

tools.

Always keep tools clean and in good Well maintained tools work better and

working order. may prevent injury.

Always use the Special Service Tools These tools will reduce the work,

recommended. labor and costs.

1.5 GENERAL CONSIDERATIONS

Item What to do Why

Solvents Use only approved cleaning fluids and Certain types of fluid cause damage

solvents that are known to be safe. to components and may cause skin

irritation.

Housekeeping Clean and remove all hazards from the To prevent accidents and injuries.

area.

First Aid Do not overlook any cut, abrasion, or What appears at first to be trivial, could

burn. Have it cleaned and dressed become painful and injurious.

properly.

Make sure you know the location Quick application of first aid procedures.

of the First Aid Box.

Cleanliness Plug all hose ends and connections To prevent dirt and foreign material from

when removing components. Clean entering the system. Dirt and abrasive

exterior of all parts before repairing. dust can reduce the efficiency and

A high pressure or steam cleaner is working life of a component and lead to

recommended. Always wear eye costly replacement. Permanent eye

protection when steam cleaning. damage can be caused if foreign matter

enters the eye.

1.6 OPERATIONAL CONSIDERATIONS

Item What to do Why

Engine Stop the engine if at all possible before To prevent serious injury and/or death.

performing any service.

Dangerous Place a warning sign on forklifts that are To prevent serious injury and/or death.

Start dangerous to start. Disconnect battery

leads if leaving the unit unattended.

6036/6036T S/N 9B0500 thru 14833

1-3

Section 1 Safety Practices

1.6 OPERATIONAL CONSIDERATIONS (cont.)

Item What to do Why

Ventilation Avoid prolonged running of the engine Exhaust fumes are highly toxic and

in a closed area with inadequate can kill.

ventilation.

Radiator Cap Always turn the radiator cap slowly to Escaping coolant can burn you ser-

the first stop to relieve pressure. iously.

Soft Ground Never work on a forklift on soft ground. To prevent serious injury and/or death.

Check for additional ballast. Seek

assistance and install suitable supports

if necessary.

Supports and Make sure safe and stable supports or To prevent serious injury and/or death.

Straps straps are installed beneath or around

a component or structural member that

may fall before commencing work.

Oil Pressure Before loosening hoses or tubes, turn A pressure explosion will cause ser-

off the engine and operate the controls ious injury.

several times to relieve pressure.

Pressure Make sure all test equipment is in good To prevent damage to the system or

Testing condition. the equipment, and to eliminate the

possibility of personal injury.

Use only gauges specified.

Comply with test procedure specified.

Leaving Lower carriage to the ground. To prevent accidental injury.

Forklift

Parking Do not park or attempt to service forklift To prevent serious injury and/or death.

on an incline. If unavoidable, block all

wheels.

Wheels and Keep tires inflated to correct pressure. To prevent dangerous travel and load

Tires handling.

Do not over-inflate tires. Over-inflation can cause tires to burst

and result in personal injury.

1.7 FINAL WORD

1-4

The safety precautions and practices in this manual

are extremely important. Not following them can

cause personal injury or death. Read this section

carefully and be sure you understand all the precautions and practices noted before attempting to

service the forklift. It is not possible to anticipate

every possible circumstance that can involve a

potential hazard.

6036/6036T S/N 9B0500 thru 14833

SECTION 2

GENERAL INSTRUCTIONS

TABLE OF CONTENTS

Section 2 General Instructions

Par. Title Page

2.1 INTRODUCTION ................................. 2-2

2.2 CLEANING .......................................... 2-2

2.3 REPLACEMENT ................................. 2-2

2.4 HOSES AND TUBES .......................... 2-2

2.4.1 Inspection .................................................... 2-2

2.4.2 Installation ................................................... 2-2

2.5 BEARINGS .......................................... 2-3

2.5.1 Removal ...................................................... 2-3

2.5.2 Cleaning ...................................................... 2-3

2.5.3 Installation ................................................... 2-3

2.6 PRESSURE TESTING

AND ADJUSTMENT ............................ 2-3

2.7 TORQUES ........................................... 2-3

2.7.1 Fasteners..................................................... 2-3

2.7.2 Bolts and Nuts ............................................. 2-3

2.7.3 Flared Fittings (37°, steel) ........................... 2-3

2.7.4 Straight Thread O-ring Fitting

(non-adjustable) ................................... 2-4

2.7.5 Straight Thread O-ring Fitting

(adjustable) ........................................... 2-4

2.8 PAINTING ........................................... 2-4

2.8.1 Orange Paint ............................................... 2-4

2.8.2 Black Paint................................................... 2-4

2.8.3 White Paint .................................................. 2-4

Par. Title Page

2.9 AFTER SERVICE

STARTUP AND CHECKS ................... 2-5

2.9.1 Starting After Servicing ................................ 2-5

2.9.2 After Electronic Component

Servicing ............................................... 2-5

2.9.3 After Hydraulic Component

Servicing ............................................... 2-5

2.9.4 After Brake System Servicing ...................... 2-5

2.9.5 After Fuel System Servicing ........................ 2-5

2.9.6 After Replacing Transmission...................... 2-5

2.9.7 After Tire Servicing ...................................... 2-5

2.9.8 After Engine Servicing ................................. 2-5

2.9.9 After Boom Servicing ................................... 2-5

2.9.10 After Axle Servicing ..................................... 2-6

2.10 FLUID LEVELS AND

LUBRICATION ..................................... 2-6

2.10.1 Wheel Ends & Oil Recommendations ......... 2-6

2.10.2 Hydraulic Reservoir ..................................... 2-7

2.10.3 Engine Oil .................................................... 2-7

2.10.4 Cooling System ........................................... 2-7

2.10.5 Splines ......................................................... 2-7

2.10.6 Drop Box ...................................................... 2-7

2.10.7 Grease Fittings ............................................ 2-7

6036/6036T S/N 9B0500 thru 14833

2-1

Section 2 General Instructions

2.1 INTRODUCTION

Appropriate service methods and proper repair

procedures are essential for safe, reliable operation of the forklift and safety of the individual doing

the work. This maintenance manual provides

general directions for accomplishing service and

repair work with tested, effective techniques.

Following them will assure reliability.

There are many variations in procedures, techniques, tools, and parts for servicing vehicles, as

well as work skills. This manual cannot possibly

anticipate all such variations and provide advice or

cautions for each one. Accordingly, anyone who

intends to depart from the instructions in this

manual must first consider personal safety and

then vehicle integrity.

2.2 CLEANING

Clean the exterior of all parts before repairing. Dirt

and abrasive dust reduce the efficient working life

of the part and lead to costly replacement.

Use cleaning fluids and solvents which are suitable for cleaning parts and do not risk the safety of

the user. Certain types of fluids damage rubber

parts and/or cause skin irritation.

The following precautions must be observed to

insure hydraulic cleanliness:

2.3 REPLACEMENT

Replace O-rings, seals, and gaskets whenever

they are disturbed. Never mix new and old seals

or O-rings regardless of condition. Always lubricate new seals and O-rings with hydraulic oil

before installation.

When replacing parts, use the correct tool.

2.4 HOSES AND TUBES

2.4.1 Inspection

1. If the hose end fittings are damaged, always

replace hoses and tubes. Damaged, dented,

crushed, or leaking hose fittings restrict oil flow

and the operation of the parts being served.

Fittings showing signs of movement from their

original position have failed and must be

replaced.

2. Be sure hoses are in good condition. If in

doubt, replace them.

3. Replace hoses if the following occur:

• chafed outer cover

• concealed corrosion of wire reinforcement.

• ballooning (replace immediately!)

• kinked, crushed, stretched, or deformed.

2.4.2 Installation

1. Flush hose and tube assemblies with a solvent

compatible with hose assemblies. Blow out

excess solvent with shop air.

2. Cap hydraulic fittings and protect threads until

installation.

3. Cap hoses and tube assemblies until installation.

4. Flush hydraulic reservoir, fuel tank, and gear

housing with a suitable solvent to remove

paint, metal chips, welding shot, etc.

5. Protect system components from airborne

contaminants. Plug all cylinder, valve, reservoir, tank, and pump openings until installation.

6. Use clean, filtered oil when filling the system.

7. System cleanliness level must be a minimum

ISO code 18/15 particle ratio count.

1. When installing a new hose, loosely connect

each end and make sure the hose takes up

the designed position before tightening the

connection. Clamps should be tightened

sufficiently to hold the hose without crushing

and to prevent chafing.

2. If a hose is replaced on a moving part, be sure

it does not foul by moving the part through its

complete range of travel.

3. Be sure any hose which has been installed is

not kinked or twisted.

4. Free moving, unsupported hoses must never

touch each other or related work surfaces.

This causes chafing reducing hose life.

2-2

6036/6036T S/N 9B0500 thru 14833

2.5 BEARINGS

2.5.1 Removal

1. Bearings should never be removed unless

absolutely necessary. Always use the

recommended puller to reduce the risk of

bearing or related component damage.

2. When bearings or bushings are removed,

check that the bearing is free from discoloration, nicks, scuffing, and signs of

overheating. If in doubt, replace the bearing

or bushing.

2.5.2 Cleaning

Bearings acceptable for service should be cleaned

in a suitable solvent and immersed in clean

lubricating oil until needed.

2.5.3 Installation

1. Be sure bearings are installed with care during

servicing, maintenance and repair.

2. Install bearings in either of the following two

ways:

• press fit on rotating parts such as shafts and

gears, and

• push fit into static locations such as

reduction gear housings.

3. When possible, always install the bearing into

the rotating part first.

Section 2 General Instructions

the oil temperature. The oil temperature can be

checked by placing a hand against the side or the

bottom of the reservoir. If the tank is too hot for

you to keep your hand against the reservoir, the oil

temperature is acceptable.

2.7 TORQUES

2.7.1 Fasteners

All fasteners are plated and equal to SAE grade 5

(PC8.8) unless otherwise specified.

2.7.2 Bolts and Nuts

Unless otherwise specified the following grade 5

(PC8.8) torque values (±10%) apply:

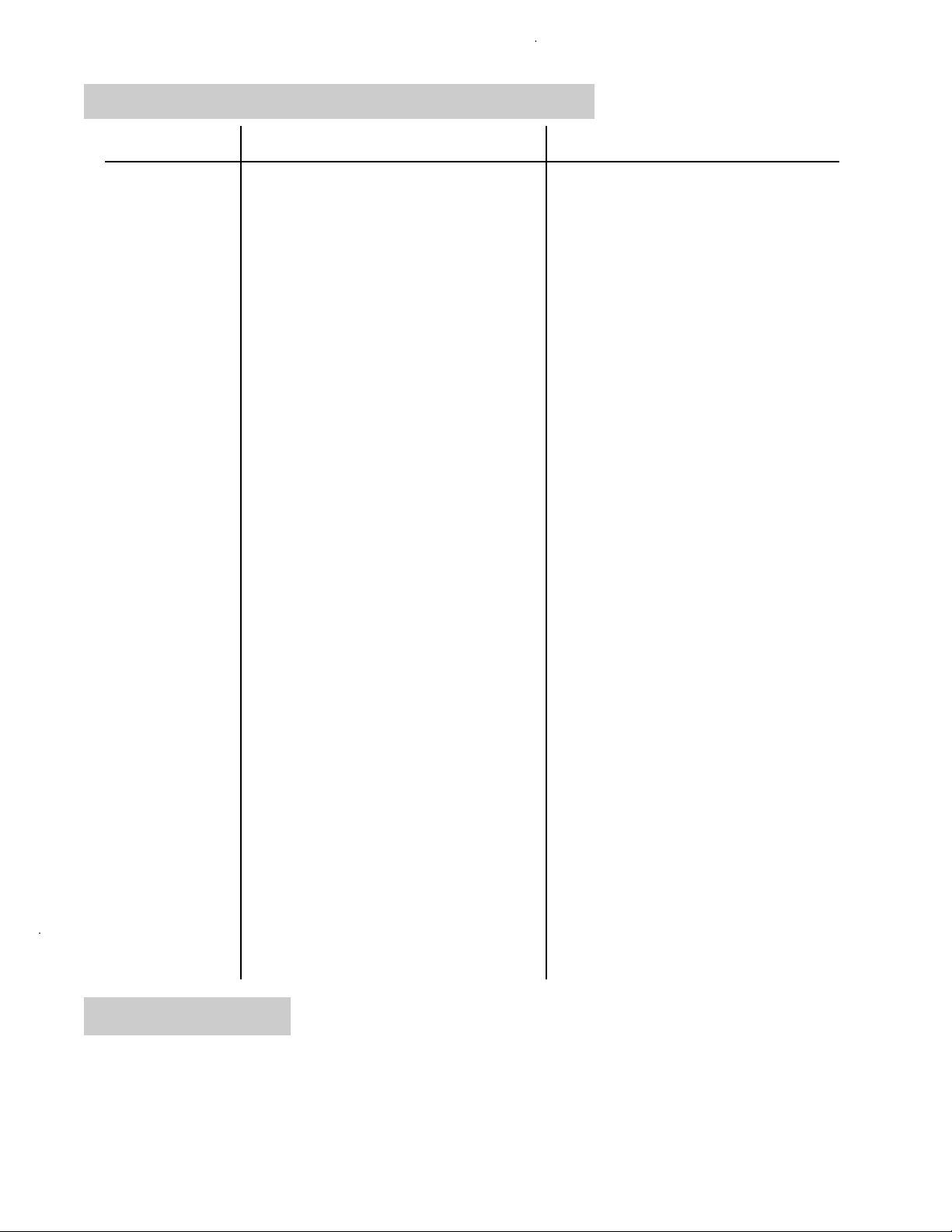

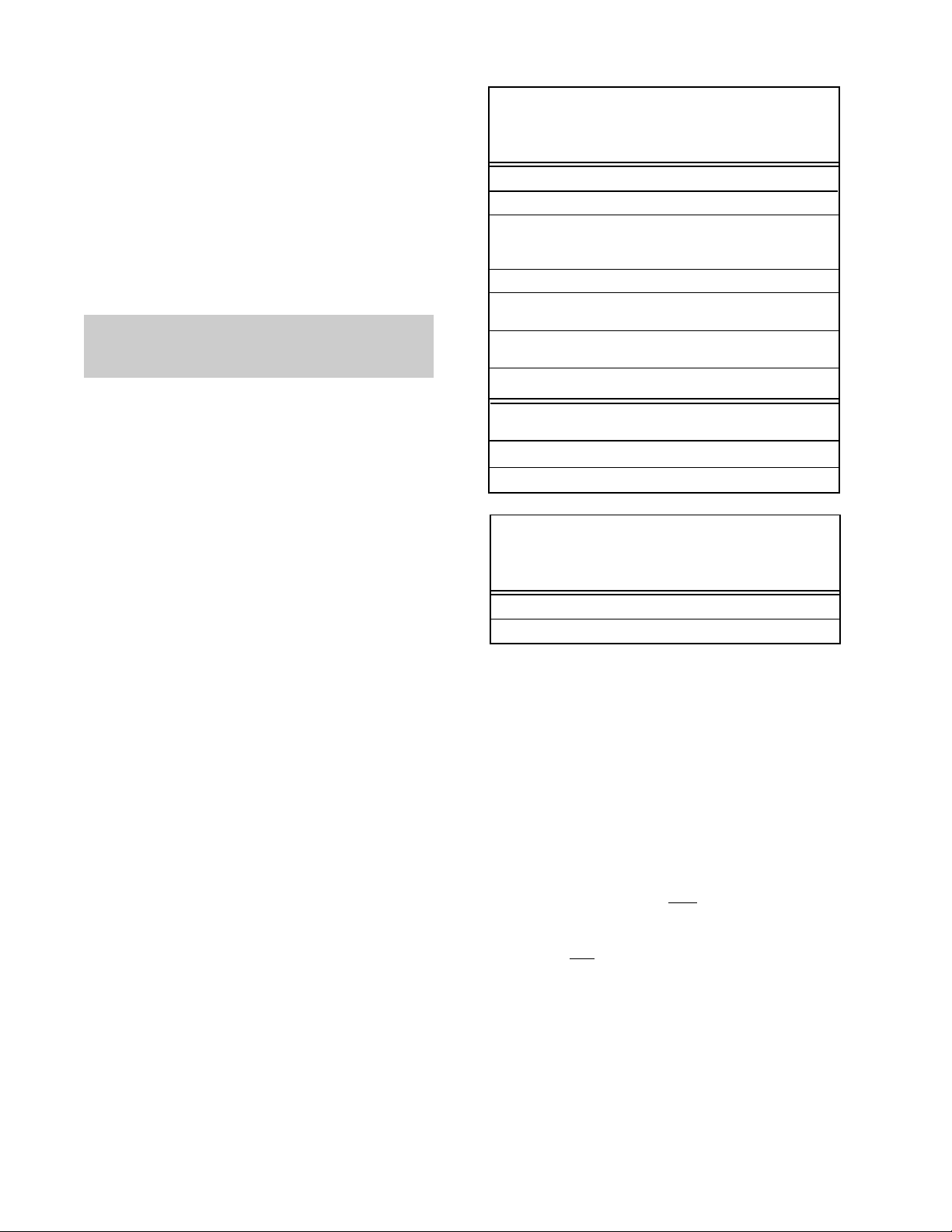

Size Torque Size Torque

Inch lb-ft Nm mm Nm lb-ft

1/4 9 12 6.0 10 7

5/16 18 24 8.0 25 18

3/8 31 42 10.0 50 37

7/16 50 68 --- --- ---

1/2 75 102 12.0 80 59

9/16 110 150 14.0 130 95

5/8 150 203 16.0 200 146

3/4 250 340 20.0 360 263

7/8 380 515 22.0 510 372

1.0 585 793 24.0 650 475

4. Use the proper tools or a press when installing

a bearing or bushing.

5. In the absence of the proper tools or press,

heat the bearings and/or casing in hot oil to

assist in the installation.

2.6 PRESSURE TESTING

AND ADJUSTMENT

Prior to pressure testing or adjustment, be sure all

hoses are in good condition and all fittings tight.

Use a pressure gauge with a range that is large

enough to measure the specified pressure.

Comply with the correct procedure to prevent

damage to the system or the equipment and to

eliminate the possibility of injury.

Be sure that hydraulic oil is at operating temperature, 80 to 120° F (27 to 49° C), before adjusting

relief valves, pressure reducing valve or sequence

valve. If necessary, operate the machine to raise

2.7.3 Flared Fittings (37o, steel)

1. Align tube and fitting

2. Tighten nut to the following torque:

SAE

Size lb-ft Nm

4 8-12 11-16

6 19-23 26-31

8 38-46 52-62

10 50-58 68-79

12 84-92 114-125

14 100-108 136-146

16 117-129 159-175

20 176-200 239-271

24 251-283 340-384

Torque

6036/6036T S/N 9B0500 thru 14833

2-3

Section 2 General Instructions

2.7.4 Straight Thread O-ring Fitting

(non-adjustable)

1. Make sure both threads and sealing surfaces

are free of burrs, nicks, scratches, or any

foreign material.

2. Lubricate O-ring with light coating of oil.

3. Torque as follows:

SAE Torque

Size lb-ft Nm

4 22-26 30-35

6 46-54 62-73

8 95-105 129-142

10 125-135 170-183

12 165-175 224-237

16 245-255 332-346

20 270-290 366-393

24 365-385 495-522

2.7.5 Straight Thread O-ring Fitting

(adjustable)

1. Inspect and correct both mating parts for

burrs, nicks, scratches, or any foreign particles.

2. Lubricate O-ring with light coat of oil.

3. Back off locknut as far as possible.

4. Screw fitting into the port by hand until the

backup washer contacts the face of the port

and is pushed all the way towards the locknut.

5. To position the fitting, unscrew by the required

amount, but not more than one full turn.

6. Hold the fitting in the desired position and

torque the locknut as follows:

SAE Torque

Size lb-ft Nm

4 14.5-17.5 20-24

6 37-43 50-58

8 75-85 102-115

10 115-125 156-170

12 155-165 210-224

16 225-235 305-319

20 260-280 353-380

24 340-360 461-488

2.8 PAINTING

Unless otherwise specified, paint all components

as follows:

2.8.1 Orange Paint

Use orange paint on all components except as

specified in paragraphs 2.8.2 and 2.8.3.

P/N 8528074 ...................... 1 gallon service paint

P/N 8528071 ...................... 16 oz Spray can

2.8.2 Black Paint

Use P/N 8528036 ............... 16 oz spray can

Boom Angle Indicator Pointer

Wheels (Early Models)

Brake Pedal

Radiator

Seat Adaptor Plate

Radiator Shroud

Transmission Oil Cooler

Axles

Drive Shafts

Drop Box

Forks

Mirrors and their Brackets

Dash Panels

Instrument Mounting Plate

Air Cleaner

Steering Column

Joystick Panel

Cab Door Handle

2.8.3 White Paint

Use P/N 8528040 ............... 16 oz spray can

Boom Extend Cylinder

Wheels (Later Models)

2-4

6036/6036T S/N 9B0500 thru 14833

Section 2 General Instructions

2.9 AFTER SERVICE

STARTUP AND CHECKS

2.9.1 Starting After Servicing

NOTE: Refer to Owners/Operators Manual for

engine cold start procedure.

1. Check fluid levels.

2. Connect negative cable to batteries if it had

been disconnected before equipment was

serviced.

3. Start engine at idle. Check for leaks from

hydraulic components, engine, axles, transmission, brakes and reservoirs.

4. Purge systems of air by operating functions.

5. Check for proper operation.

6. Retract all cylinders. Shut down and check

reservoir levels. Recheck levels when oil is

cold.

3. If a hydraulic component failed and contaminated the system, flush the system, clean the

reservoir and replace the filter.

4. Following normal hydraulic component servicing, check hydraulic fluid level and replenish

as required.

5. Start forklift and bleed systems of air.

6. Recalibrate sensors; refer to the Owners/

Operators Manual for the Total Load Control

System.

7. Check operation.

2.9.4 After Brake System Servicing

1. Check level of TRAK wet disc brake oil in

wheel ends and replenish as required.

2. Bleed brakes.

3. Check wheel end brake pressure.

4. Check operation.

2.9.5 After Fuel System Servicing

1. Drain fuel tank if it was contaminated.

7. Replace hydraulic filter if required.

2.9.2 After Electrical/Electronic

Component Servicing

1. Check torque on fastening hardware of

components being replaced.

2. Check wiring connections to components.

3. Be sure wiring connections are dry and free of

moisture.

4. Check for broken or loose wires at connector.

5. Check for brittle and frayed wire shielding.

6. Connect negative (–) cable to the batteries.

7. Start forklift and bleed hydraulic system of air.

8. Recalibrate sensors; refer to the Owners/

Operators Manual for the Total Load Control

System.

9. Check operation.

2.9.3 After Hydraulic Component

Servicing

1. Check torque on fastening hardware of

components being replaced.

2. Check that hoses are in place and tightly

connected.

2. Bleed fuel system.

3. Fill tank with clean fuel as required.

2.9.6 After Replacing Transmission

1. Check transmission fluid level and replenish

as required.

2. Replace transmission filter.

3. Check torque on drive shaft yoke hardware.

4. Refer to the Clark Maintenance Manual for

“Servicing Machine After Transmission

Overhaul”.

2.9.7 After Tire Servicing

1. Check hydrofill mixture, air pressure and

weight of tire (empty and full).

2. Check wheel nut torque.

2.9.8 After Engine Servicing

Consult the qualified service agent for proper

procedure before startup.

2.9.9 After Boom Servicing

1. Check wear pads.

2. Check chain tension adjustment.

3. Lubricate all grease points.

6036/6036T S/N 9B0500 thru 14833

2-5

Section 2 General Instructions

2.9.10 After Axle Servicing

1. Check fluid levels.

2. Check torque of drive shaft yoke hardware.

3. Check wheel nut torque.

4. Check toe-in if required.

5. Lubricate all grease points.

6. Refer to Dana Service Manual for “SECTION

1 - General Information”.

2.10 FLUID LEVELS

AND LUBRICATION

2.10.1 Wheel Ends

Use the following procedure to check fluid level on

the wheel ends:

1. Be sure that arrow on the wheel end housing

is pointing down. Level the vehicle, ground

the carriage, place the travel select lever in (N)

Neutral, engage the emergency brake switch

and shut off engine.

2. Clean the area around the magnetic drain plug

and remove the plug and check fluid level.

Add oil (refer to “IMPORTANT” statement and

tables on this page) as required to bring level

up even with the plug hole (for temperatures

below -15° F (-26° C) 75W gear oil can be

used).

3. Clean and install drain plug.

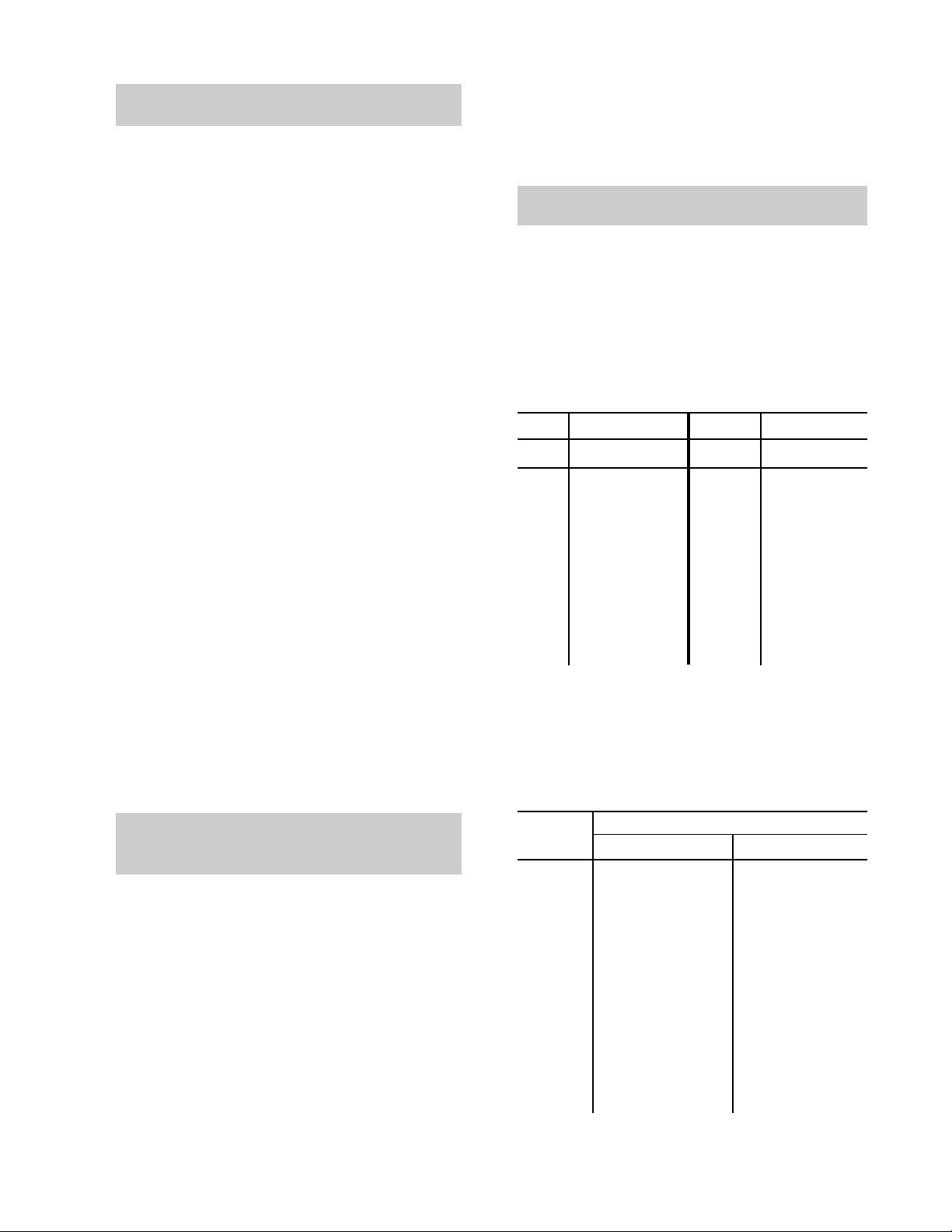

TABLE 1

Recommended oils for DANA SPICER® axles

P/N 070BP126-13 (front axle) and

070BP139-2 (rear axle) w/graphite based friction discs.

BRAND DESCRIPTION

Amoco Amoco 1000

Case IH MS-1207 (Hy-Tran® Plus)

(J.I. Case & International MS-1210/JIC145 (TCH Fluid)

Harvester)

John Deere JDM J20C (Hy-Gard®)

Ford-New Holland ESN-M2C134-D

(Hydraulic Oil 134)

Massey-Ferguson M-1141 (Permatran®III)

M-1135 Massey-Ferguson

Mobil 424

FRICTION MODIFIER PART NUMBER

BRAND

TRAK 8522043 (32 oz)

Ford C8AZ19B546A (4 oz)

TABLE 2

Recommended oil for DANA SPICER® axles

P/N 070BP126-2 (front axle) and

070BP139-1 (rear axle) with paper based friction discs.

OIL BRAND PART NUMBER

TRAK Wet Disc Brake Oil 8522042

IMPORTANT: All wheel ends are factory filled

with oil that contains friction modifier. DO NOT

add additional friction modifier to factory filled

wheel ends. The addition of friction modifier to a

factory fill will dilute the properties of the oil and

can reduce braking ability.

2-6

To assure a quiet brake condition when servicing

wheel end oil, use only recommended oils as

defined in Table 1 or Table 2 above.

If a noisy brake condition exists after a fresh fill

from oils listed in Table 1 only, add 6 ozs.

(0,18 ltr) of friction modifier per wheel end.

NEVER add more than 6 ozs. (0,18 ltr) of friction

modifier to any wheel end as too much modifier

can reduce braking ability.

NEVER add friction modifier to the recommended

oil listed in Table 2. This oil already contains

friction modifier and additional friction modifier

can reduce braking ability.

6036/6036T S/N 9B0500 thru 14833

2.10.2 Hydraulic Reservoir

With the oil cold and the forklift on a level surface

and all hydraulic cylinders retracted, check the

sight gauge on the right side of the main frame.

The oil level should be visible in the gauge window. If it is not, open the locked hydraulic fill

access door. Remove the fill cap and add

MIL-L-2104C Oil as required to bring the oil level

up to the minimum oil level line on the adjacent

decal.

2.10.3 Engine Oil

Oil level should be between the full and add mark

on the dipstick. Refer to Sections 8 and 8A for the

type of oil to add.

2.10.4 Cooling System

Check level of coolant in overflow bottle. When

coolant is hot, bottle should be 3/4 full to full.

When coolant is cool, bottle should be 1/4 to 1/2

full. Add coolant as required through the overflow

bottle (50/50 mixture of ethylene glycol and water).

Section 2 General Instructions

2.10.5 Splines

Transmission input shaft splines must be coated

with a molybdenum disulfide or Molykote compound.

2.10.6 Drop Box

Remove level plug in drop box and check level of

oil. Add fluid as required through the level plug

hole with a squeeze bottle. Bring the oil level up

even with the level plug hole and install the level

plug. Refer to Section 6 for the type of fluid to

add.

2.10.7 Grease Fittings

1. Lubricate the following grease fittings with a

multi–purpose lithium–based grease:

• Hydraulic cylinder pins ................... 10 points

• Drive shaft slip joints ........................ 3 points

• Boom chain sheaves ................ 1 or 2 points

• Boom pivot pins ............................... 2 points

• Carriage pivot pin............................. 2 points

• Axle pivot pins ................................. 4 points

• Boom Attachments ........................ All points

• Axle steer knuckles .......................... 8 points

• Axle tie rod ball joints ....................... 4 points

• Axle steer cylinder ball joints ........... 8 points

2. Wipe off excess grease.

6036/6036T S/N 9B0500 thru 14833

2-7

Section 2 General Instructions

Notes

2-8

6036/6036T S/N 9B0500 thru 14833

SECTION 3

CONTENTS

Par. Title Page

3.1 BOOM ASSEMBLY .............................. 3-1

3.1.1 Inner Boom Replacement ........................... 3-1

3.1.2 Intermediate Boom Replacement ............... 3-3

3.1.3 Outer Boom Replacement .......................... 3-5

3.1.4 Chain Replacement .................................... 3-9

3.1.5 Chain Lubrication ...................................... 3-10

3.1.6 Chain Tension Check ...............................3-10

3.1.7 Chain Tension Adjustment ....................... 3-11

3.1.8 Wear Pad Replacement ............................ 3-11

3.1.9 Hose Tensioning .......................................3-12

3.1.10 Long Term Storage Preparation ............... 3-13

3.1.11 Boom Lubrication Points ........................... 3-13

3.2 EMERGENCY

BOOM LOWERING ............................. 3-14

3.2.1 Loss of Engine Power

or Hydraulic Pump Failure ........................ 3-14

3.2.2 Hydraulic Line Failure ............................... 3-15

3.3 QUICK ATTACH ASSEMBLY ............. 3-16

3.4 TROUBLESHOOTING ........................ 3-17

3.5 SPECIFICATIONS .............................. 3-18

Section 3 Boom

BOOM

3.1 BOOM ASSEMBLY

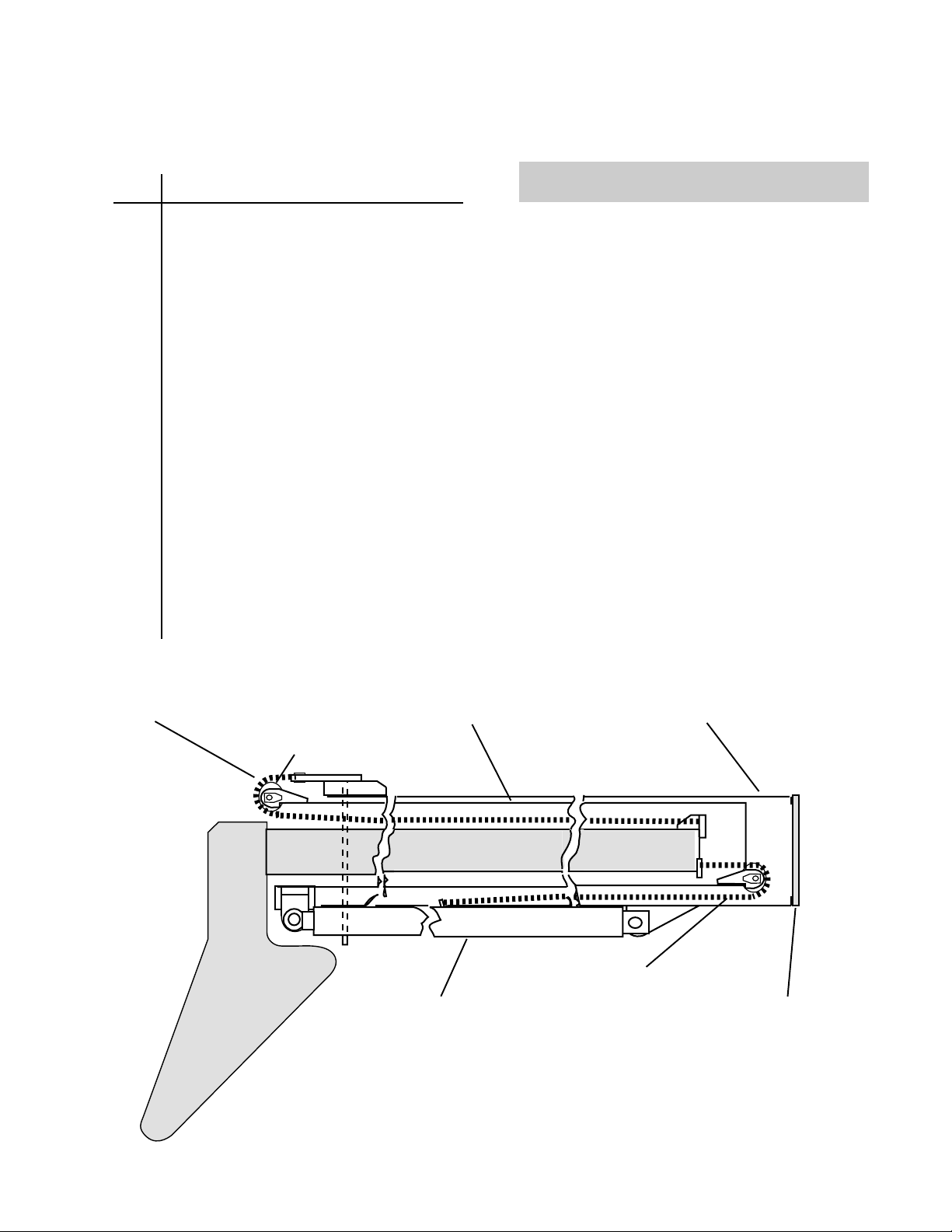

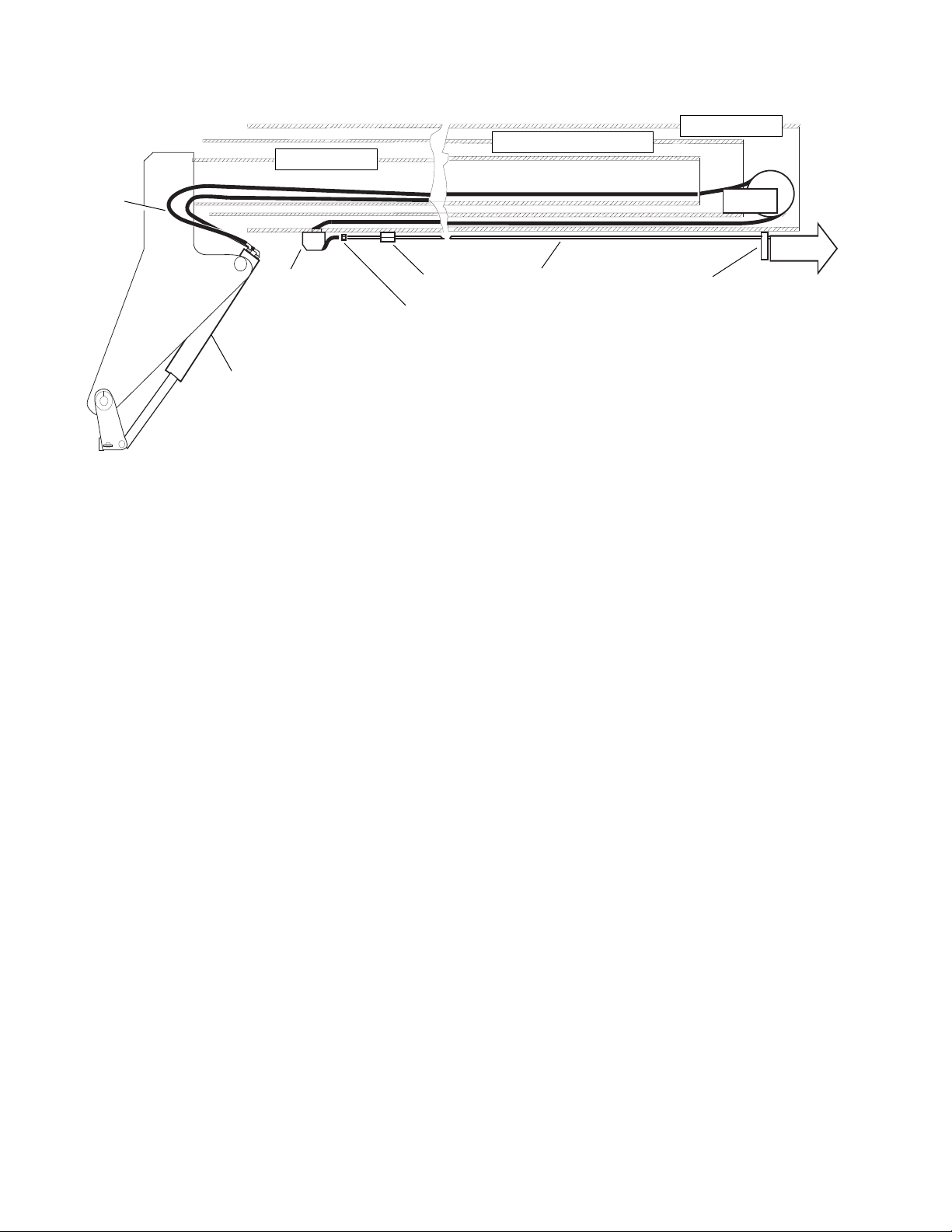

The boom assembly, Fig. 3.1, consists of inner,

intermediate, and outer booms. The intermediate

boom slides in the outer boom and the inner boom

slides in the intermediate boom. As the boom

extend/retract cylinder extends or retracts the

intermediate boom, a pair of extend chains and one

retract chain moves the inner boom in the same

direction.

IMPORTANT: The inner, intermediate and outer

boom replacement instructions in paragraphs 3.1.1

through 3.1.3 must be completed in sequence.

Replacement of two or more booms as a unit

requires special considerations that are not covered

in these instructions.

3.1.1 Inner Boom Replacement

a. Removal

1. Park forklift on level surface, engage park lock

and retract boom.

EXTEND CHAIN

EXTEND CHAIN SHEAVE

GOOSENECK

INTERMEDIATE BOOM

INNER BOOM

BOOM EXTEND/RETRACT CYLINDER

Fig. 3.1 Boom Assembly

OUTER BOOM

RETRACT CHAIN

REAR BOOM COVER

MA0011

6036/6036T S/N 9B0500 thru 14833

3-1

Section 3 Boom

INNER

BOOM

BASE END

PIN

QUICK ATTACH

PIVOT PIN

WITH GREASE

FITTING

LOCK

PIN

GOOSENECK

GRILLE TILT

CYLINDER

QUICK ATTACH

ASSEMBLY

ROD END PIN

MA0021

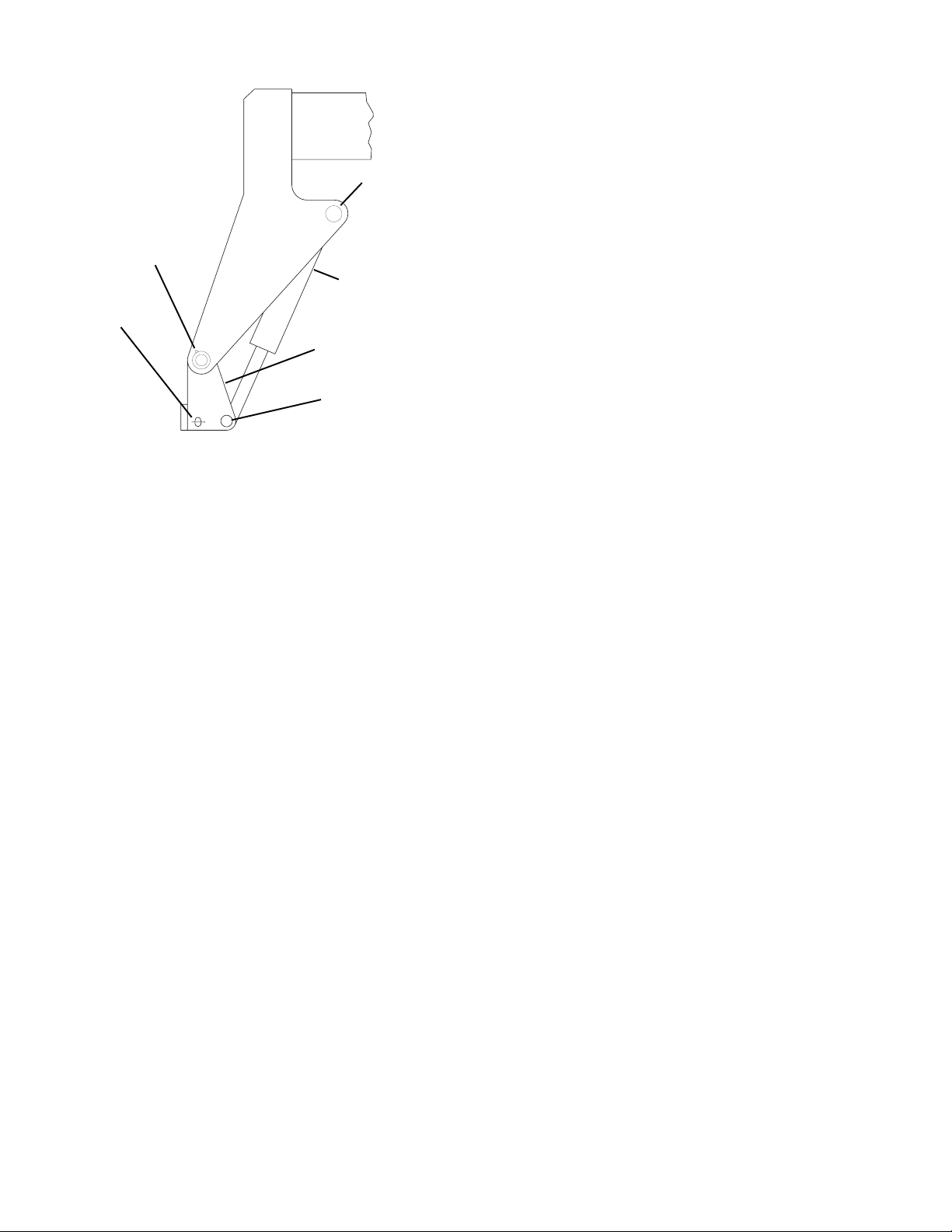

Fig. 3.2 Gooseneck

2. Prepare to replace the inner boom, Fig. 3.2, by

removing the grille tilt cylinder as described in

paragraph 9.5.8.a.

3. Remove the quick attach pivot pin, Fig. 3.2,

and quick attach assembly from the gooseneck.

4. Remove the rear boom cover, Fig. 3.1.

5. Pull the grille tilt cylinder hoses and auxiliary

hyraulics (if so equipped) out the rear boom

cover opening.

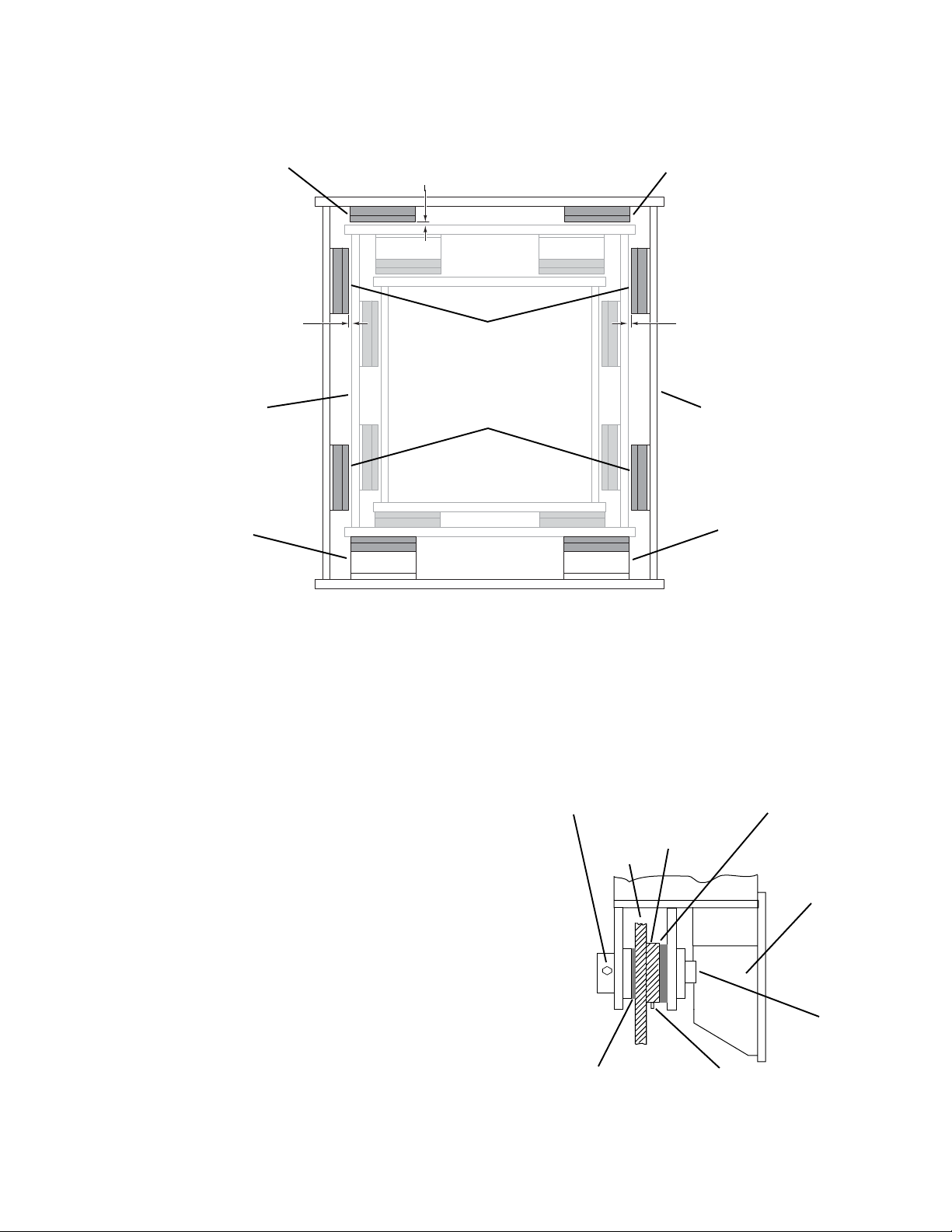

6. Working from the rear boom cover opening,

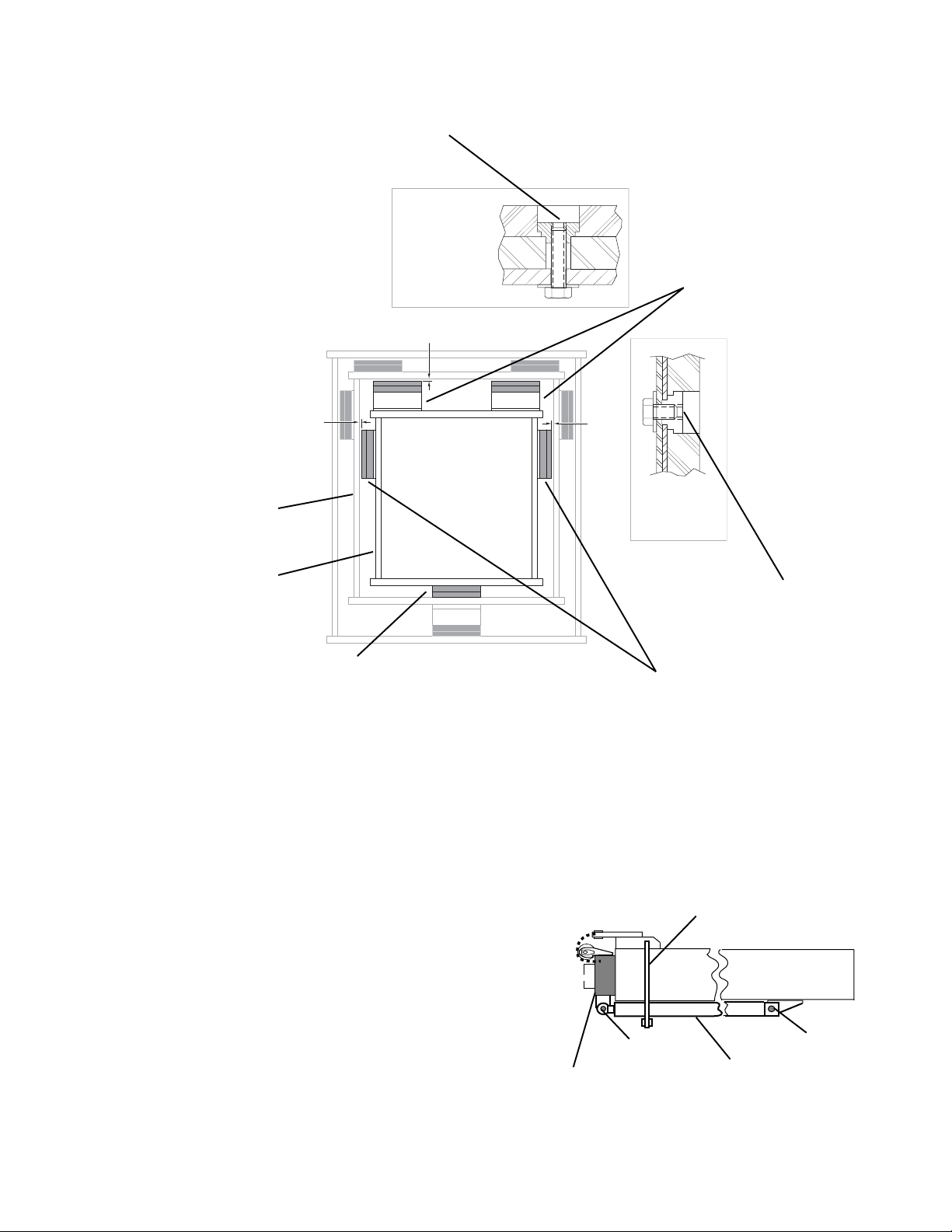

record the number of shims beneath each wear

pad as you remove the side and top wear pads

from the inner boom, Fig. 3.3.

7. Refer to Fig. 3.1 and remove the locknut and

washer or shoulder screw and locknut that

attaches the retract chain to the inner boom.

Disconnect the extend chains from the outer

boom section. Remove the chain sheave from

the front of the intermediate boom.

8. Use a sling and a suitable hoist to slide the

inner boom out the front of the intermediate

boom.

9. Refer to Fig. 3.3 and remove bottom wear pad

from the rear of the inner boom.

b. Inspection and Replacement

1. Inspect the boom and welds and contact JLG if

structural damage is detected.

2. Inspect hoses and replace if damaged.

3. Inspect and replace wear pads as described in

paragraph 3.1.8.

c. Installation

1. Refer to Fig. 3.3 and install the bottom wear

pad on the inner boom. Install a new pad if it

is excessively worn (refer to paragraph 3.1.8).

®

Apply Loctite

Removable Threadlocker 242 to

the capscrews and torque them to 31 lb-ft

(42 Nm).

2. Connect the extend chains at the top rear of

the inner boom; temporarily secure the other

end of the chains to the top front of the inner

boom.

3. Use slings and a suitable hoist to slide the

repaired or new inner boom and extend chains

into the intermediate boom.

4. Working through the rear cover opening,

temporarily install the top and side inner boom

wear pads on the inner boom, Fig. 3.3.

Replace pads that are excessively worn. Use

the same amount of shimming as used when

the pads were removed.

IMPORTANT: The ends of wear pad attaching

capscrews must not protrude beyond the wear pad

insert; the ends must range from flush to 0.19"

(5 mm) recessed in the wear pad insert (refer to

Fig. 3.3).

5. Check the wear pad gap between the inner

boom side and top wear pads and the intermediate boom. The gap should be 0.07 to

0.13" (1,8 to 3,3 mm) and equal for all top and

side wear pads. Install or remove shims as

required.

6. Install the wear pads by applying Loctite 242

to the capscrews and torquing them to 31 lb-ft

(42 Nm).

7. Secure the retract chain to the inner boom

with washers and locknuts (S/N 2515 &

Before) or shoulder screw and locknut

(S/N 2516 & After). Make sure the chain is not

twisted. Be sure the extend chains are inplace

under the chain sheave at the front of the

intermediate boom and then reassemble the

chain sheave to the mounts. Reconnect the

extend chains to the outer boom, Fig. 3.1.

8. Tie the grille tilt cylinder hoses together and

push them through the inner boom to the

opening at the inner boom gooseneck.

9. Refer to Fig. 3.2 and install the quick attach

assembly on the gooseneck with the quick

attach pivot pin. Position pin with grease

holes facing UP.

10. Using grease fittings at the ends of the pin,

lubricate the quick attach pivot pin.

11. Install the grille tilt cylinder as described in

paragraph 9.5.8.f.

3-2

6036/6036T S/N 9B0500 thru 14833

GAP MUST BE 0.07 TO

0.13" (1,8 TO 3,3 mm)

CAPSCREW ENDS TO BE FLUSH

TO 0.19" (5 mm) RECESSED IN

WEAR PAD INSERT

GAP MUST BE 0.07 TO

0.13" (1,8 TO 3,3 mm)

Section 3 Boom

PAD, SPACER, INSERT (2),

LOCK WASHER (6),

FLAT WASHER (6),

3/8-16 X 1-3/4"

CAPSCREW (6),

14 GA SHIM

INTERMEDIATE

BOOM

INNER BOOM

PAD, INSERT (1),

LOCK WASHER (2),

FLAT WASHER (2),

3/8-16 X 7/8"

CAPSCREW (2)

Fig. 3.3 Rear Wear Pads Attached to Inner Boom

12. Adjust hose tension as described in paragraphs 3.1.9.

13. Check and adjust chain tension as described

in paragraphs 3.1.6 and 3.1.7.

14. Refer to Fig. 3.1 and install the rear boom

cover.

3.1.2 Intermediate Boom Replacement

a Removal

CAPSCREW ENDS TO BE FLUSH

TO 0.19" (5 mm) RECESSED IN

WEAR PAD INSERT

PAD, #14 GA SHIM, INSERT (2),

LOCK WASHER (4),

FLAT WASHER (4),

3/8-16 X 3/4"

CAPSCREW (4)

MA0031

3. Working from the rear boom cover opening,

record the number of shims beneath each wear

pad as you remove the side and top wear pads

from intermediate boom, Fig. 3.6.

ANTI-BUCKLE BAR

OUTER BOOM

1. Refer to paragraph 3.1.1.a and remove the

inner boom.

2. Remove the rod end pin, Fig. 3.4, and retaining rings that attach the rod end of the

boom extend/retract cylinder to the intermediate boom. Lower the rod end to the antibuckle bar.

6036/6036T S/N 9B0500 thru 14833

ROD END PIN

INTERMEDIATE

BOOM

Fig. 3.4 Extend/Retract Cylinder

BASE END PIN

EXTEND/RETRACT

CYLINDER

MA0041

3-3

Section 3 Boom

4. Use a sling and a suitable hoist to slide the

intermediate boom out the front of the outer

boom.

5. Record the number of shims beneath each

wear pad as you remove the rear bottom,

Fig. 3.6, and all front wear pads, Fig. 3.5, from

the intermediate boom.

6. Examine the chain sheaves for wear and

replace if necessary.

b. Inspection and Replacement

1. Inspect the boom and welds and contact JLG if

structural damage is detected.

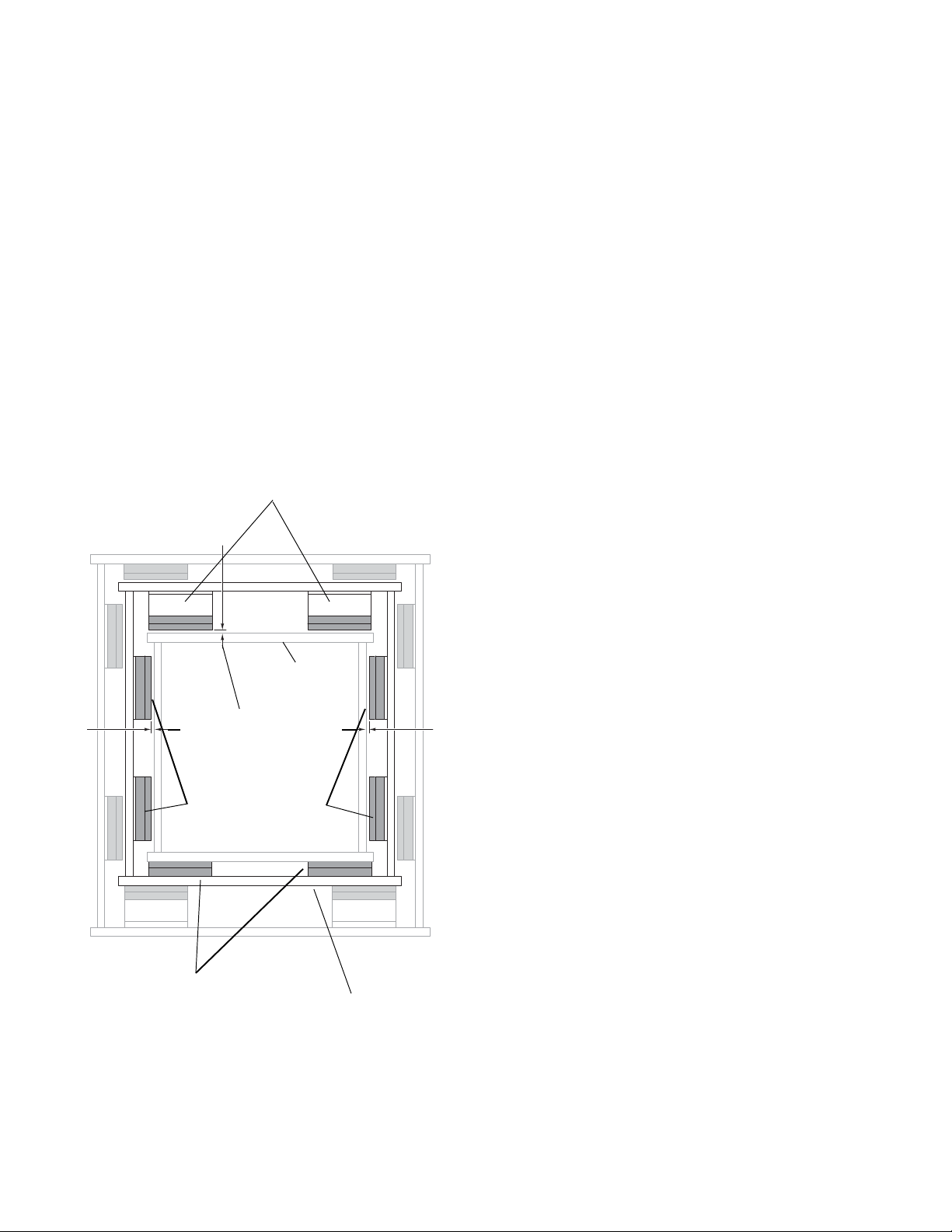

Fig. 3.5 Front Wear Pads Attached to Intermediate

PAD, INSERT (2),

SPACER, #10 GA SHIM,

FLAT WASHER (4),

LOCK WASHER (4),

3/8-16 X 1-3/4"

CAPSCREW (4)

2. Inspect hoses and replace if damaged.

3. Inspect and replace wear pads as described in

paragraph 3.1.8.

c. Installation

1. Refer to Fig. 3.6 and install the rear bottom

wear pad, Fig. 3.6, on the intermediate boom.

Install a new pad if it is excessively worn (refer

to paragraph 3.1.8). Apply Loctite® Removable

Threadlocker 242 to the capscrews and torque

them to 31 lb-ft (42 Nm).

2. Using a sling and a suitable hoist, slide the

repaired or new intermediate boom into the

outer boom.

3. Working through the rear boom cover opening,

refer to Fig. 3.6 and temporarily install the rear

top and side wear pads on the intermediate

boom. Replace pads that are excessively

worn. Use the same amount of shimming as

used when the pads were removed.

IMPORTANT: The ends of wear pad attaching

capscrews must not protrude beyond the wear pad

insert; the ends must range from flush to 0.19"

(5 mm) recessed in the wear pad insert (refer to

Fig. 3.3).

GAP MUST BE 0.07 TO

0.13" (1,8 TO 3,3 mm)

PAD, #10 GA SHIM,

INSERT (4),

LOCK WASHER (8),

FLAT WASHER (8),

3/8-16 X 3/4"

CAPSCREW (8)

PAD, INSERT (2),

LOCK WASHER (6),

FLAT WASHER (6),

3/8-16 X 7/8"

CAPSCREW (2),

3/8-16 X 1-3/4"

CAPSCREW (4)

INNER BOOM

INTERMEDIATE

BOOM

MA0051

4. Refer to paragraph 3.1.1.c and install the inner

boom.

5. Connect the extend chains at the front of the

outer boom.

6. On the front of the intermediate boom, check

the gap between the intermediate boom side

and top wear pads and the inner boom,

Fig. 3.5. The gap should be 0.07 to 0.13

inches (1,8 to 3,3 mm) and equal on all sides.

Remove or install shims as required.

7. Working through the rear boom cover opening,

refer to Fig. 3.6 and check the gap between the

intermediate boom side and top wear pads and

the outer boom. The gap should be 0.07 to

0.13 inches (1,8 to 3,3 mm) and equal on all

sides. Remove or install shims as required.

8. Install the wear pads by applying Loctite 242 to

the capscrews and torquing them to 31 lb-ft (42

Nm).

9. Refer to Fig. 3.4 and apply anti-seize compound to the rod end pin. Secure the rod end

of the boom extend/retract cylinder to the

intermediate boom with the rod end pin,

Fig. 3.4 and retaining rings.

3-4

Boom

6036/6036T S/N 9B0500 thru 14833

Section 3 Boom

PAD, INSERT (1),

LOCK WASHER (3),

FLAT WASHER (3),

3/8-16 X 7/8"

CAPSCREW (3)

GAP MUST BE 0.07 TO

0.13" (1,8 TO 3,3 mm)

GAP MUST BE 0.07 TO

0.13" (1,8 TO 3,3 mm)

PAD, #10 GA SHIM,

INSERT (2),

LOCK WASHER (4),

FLAT WASHER (4),

3/8-16 X 3/4"

CAPSCREW (4)

PAD, INSERT (1),

LOCK WASHER (3),

FLAT WASHER (3),

3/8-16 X 7/8"

CAPSCREW (3)

GAP MUST BE 0.07 TO

0.13" (1,8 TO 3,3 mm)

PAD, SPACER, #10 GA

SHIM, INSERT (1),

LOCK WASHER (2),

FLAT WASHER (2),

3/8-16 X 2"

CAPSCREW (2)

Fig. 3.6 Rear Wear Pads Attached to Intermediate Boom

3.1.3 Outer Boom Replacement

a. Removal

1. Refer to paragraphs 3.1.1.a and 3.1.2.a and

remove the inner and intermediate booms.

2. Disconnect and remove the retract chain from

the outer boom. Check the condition of the

chain and replace if worn or damaged.

3 Refer to paragraph 9.5.4.a and remove the

boom extend/retract cylinder.

4. Refer to Fig. 3.7 and remove the locknut and

capscrew that secures the slave cylinder rod

end pin. Remove the pin. Check the condition

of the bearing in the cylinder rod end; replace

bearing if worn or damaged.

5. Refer to Fig. 3.8 and disconnect the grille tilt

cylinder hoses from the tubing at the hose

guides and remove the hoses from the boom.

INTERMEDIATE

BOOM

OUTER BOOM

HOIST CYLINDER

OUTER BOOM

EXTEND/RETRACT

CYLINDER BASE

END PIN

Fig. 3.7 Outer Boom Pivot Pins

ROD END PIN

MA0061

BOOM PIVOT

PIN

FRAME

SLAVE CYLINDER

ROD END PIN

MA0071

6036/6036T S/N 9B0500 thru 14833

3-5

Section 3 Boom

HOSES

OUTER BOOM

INTERMEDIATE BOOM

INNER BOOM

HOSE GUIDE

CONNECTION

GRILLE TILT

CYLINDER

Fig. 3.8 Grille Tilt Cylinder Hoses

6. Disconnect and cap or plug the grille tilt

cylinder tubing, extend cylinder tubes and

bulkhead fittings in support plate, Fig. 3.8,

below the rear opening of the boom.

7. Loosen clamps that hold the tubing to the

bottom of the outer boom and remove the

tubing from the outer boom.

8. Attach slings and a suitable hoist to the

approximate center of gravity of the outer boom

and remove all slack from hoist cable.

NOTE: The approximate center of gravity of the

outer boom will be closer to the rear of the outer

boom.

9. Refer to Fig. 3.7 and remove the locknuts and

capscrews that secures the hoist cylinder rod

end pins. Remove the pins. Check the

condition of the bearings in the cylinder rod

ends; replace bearings if worn or damaged.

10. Refer to Fig. 3.7 and remove the capscrews

and lock washers securing boom pivot pins to

the outer boom.

11. Remove both boom pivot pins and washer

spacers from the outer boom and main frame.

12. Using the hoist, remove the outer boom from

the main frame of the forklift.

13. Check the condition of both boom pivot main

frame bearings; replace if worn or damaged.

CLAMP

TUBING

SUPPORT PLATE

TO MAIN

CONTROL

VALVE

MA0081

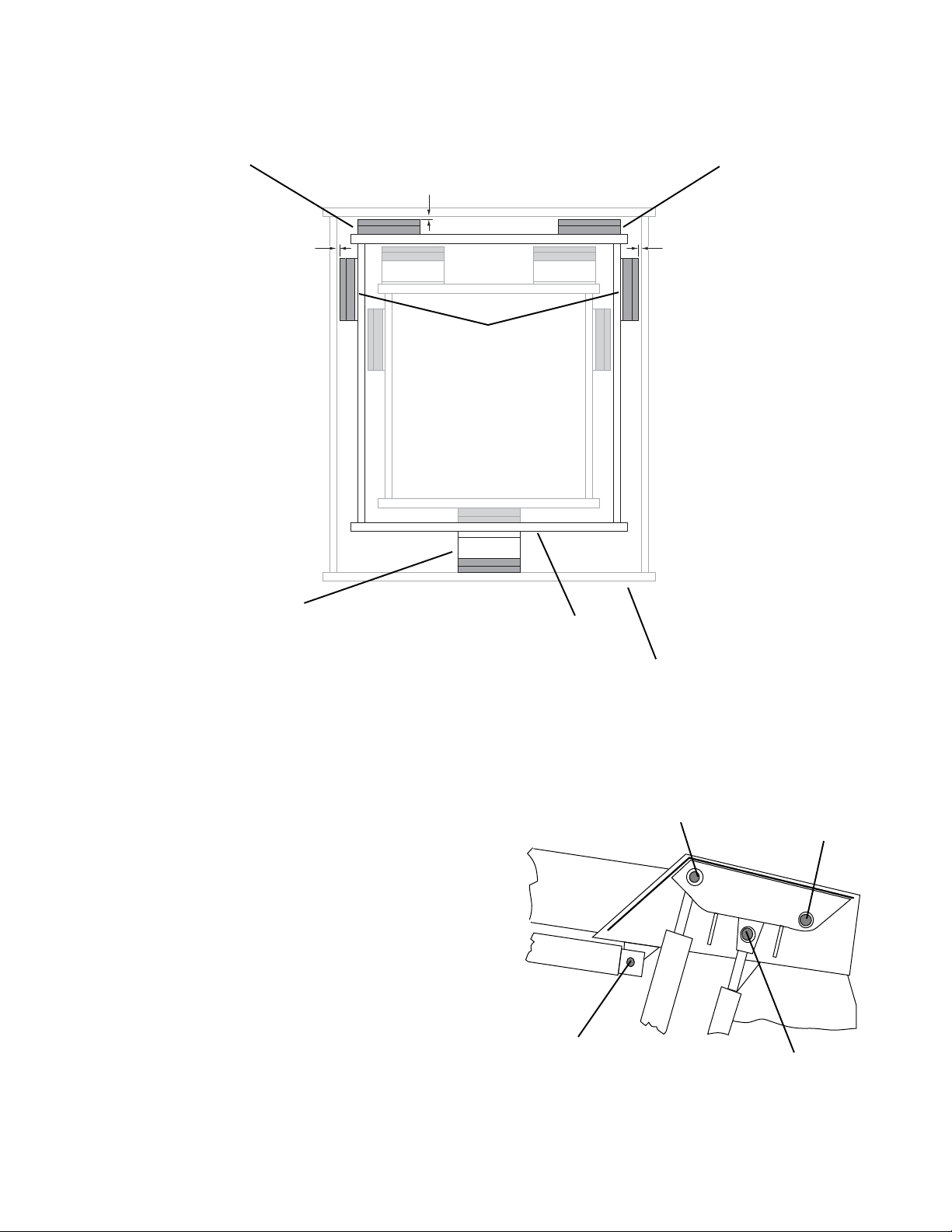

14. If the front outer boom wear pads, Fig. 3.9, are

excessively worn, temporarily replace them

with new pads. Use the same amount of

shimming as used when the pads were removed.

IMPORTANT: The ends of wear pad attaching

capscrews must not protrude beyond the wear pad

insert; the ends must range from flush to 0.19"

(5 mm) recessed in the wear pad insert (refer to

Fig. 3.3).

b. Inspection and Replacement

1. Inspect the boom and welds and contact JLG if

structural damage is detected.

2. Inspect hoses and replace if damaged.

3. Inspect and replace wear pads as described in

paragraph 3.1.8.

c. Installation

1. Using slings and a suitable hoist, align the

outer boom pivot collars with the main frame

bearings.

2. Install the boom pivot pins and washer spacers, placing the spacers on the inside of the

frame bearing, Fig. 3.10. Using No. 10 and/or

14 gauge shims, shim to maintain a gap

between the frame bearing and outer boom of

0.07 to 0.13" (1,8 to 3,3 mm).

Fig. 3.9 Front Wear Pads Attached to Outer Boom

3-6

6036/6036T S/N 9B0500 thru 14833

Section 3 Boom

PAD, INSERT (1),

LOCK WASHER (2),

FLAT WASHER (2),

3/8-16 X 7/8"

CAPSCREW (2)

GAP MUST BE 0.07 TO

0.13" (1,8 TO 3,3 mm)

INTERMEDIATE

BOOM

PAD, SPACER, #10 GA

SHIM, INSERT (1),

LOCK WASHER (3),

FLAT WASHER (3),

3/8-16 X 1-3/4"

CAPSCREW (3)

GAP MUST BE 0.07 TO

0.13" (1,8 TO 3,3 mm)

PAD, #10 GA SHIM,

INSERT (4),

LOCK WASHER (8),

FLAT WASHER (8),

3/8-16 X 3/4"

CAPSCREW (8)

PAD, INSERT (1),

LOCK WASHER (2),

FLAT WASHER (2),

3/8-16 X 7/8"

CAPSCREW (2)

GAP MUST BE 0.07 TO

0.13" (1,8 TO 3,3 mm)

OUTER BOOM

PAD, SPACER, #10 GA

SHIM, INSERT (1),

LOCK WASHER (3),

FLAT WASHER (3),

3/8-16 X 1-3/4"

CAPSCREW (3)

MA0091

(Rear Wear Pads are Attached to Intermediate Boom)

3. Install the capscrews and lock washers locking

the boom pivot pins to the outer boom.

4. Rest the front of the boom on cribbing so it is

not solely supported by the hoist.

5. Install the grille tilt cylinder tubing in clamps on

the bottom of the outer boom, (Fig. 3.8), and

connect each tube, extend tubes and bulkhead

fittings to fittings at the support plate. Connect

main valve hoses. Tighten the tube clamps.

6. Refer to Fig. 3.8 and connect the grille tilt

cylinder hoses to the tubing. Route the hoses

around hose guide bracket and into the outer

boom. Continue pushing the hoses until they

come out the rear boom cover opening.

7. Install the base end of the boom extend/retract

cylinder on the outer boom with a pivot pin, Fig.

3.7, and retaining rings. Coat the pin with

antiseize compound.

8. Reattach tubes to extend cylinder ports.

9. Attach the rod end of the slave cylinder to the

outer boom with a pivot pin and lock the pin in

place with a capscrew and locknut.

10. Attach the rod end of each hoist cylinder to the

outer boom with a pivot pin and lock the pin in

place with a capscrew and locknut.

SHIM HERE TO MAINTAIN 0.07

TO 0.13" (1,8 TO 3,3 mm) GAP

CAPSCREW AND

LOCK NUT

FRAME

DO NOT

SHIM HERE

Fig. 3.10 Boom Pivot Pin Shimming

USING #10 AND/OR 14 GA

WASHER SPACERS

FRAME

BEARING

OUTER

BOOM

BOOM PIVOT

PIN

GREASE FITTING

MA0101

6036/6036T S/N 9B0500 thru 14833

3-7

Section 3 Boom

INNER

BOOM

1-1/2"

TO

2-1/2"

(38 mm

TO

63 mm)

INTERMEDIATE

BOOM

EXTEND CHAIN

CLEVIS

CHAIN LINK

PIN AND

RETAINING

RING

OUTER BOOM

SHOULDER

SCREW AND

LOCKNUT

SHOULDER

SCREW AND

LOCKNUT

BLOCK

YOKE

EXTEND CHAIN,

LOCKNUT AND

FLAT WASHER

INNER BOOM

INTERMEDIATE BOOM

OUTER BOOM

RETRACT CHAIN

LOCKNUT AND

FLAT WASHER

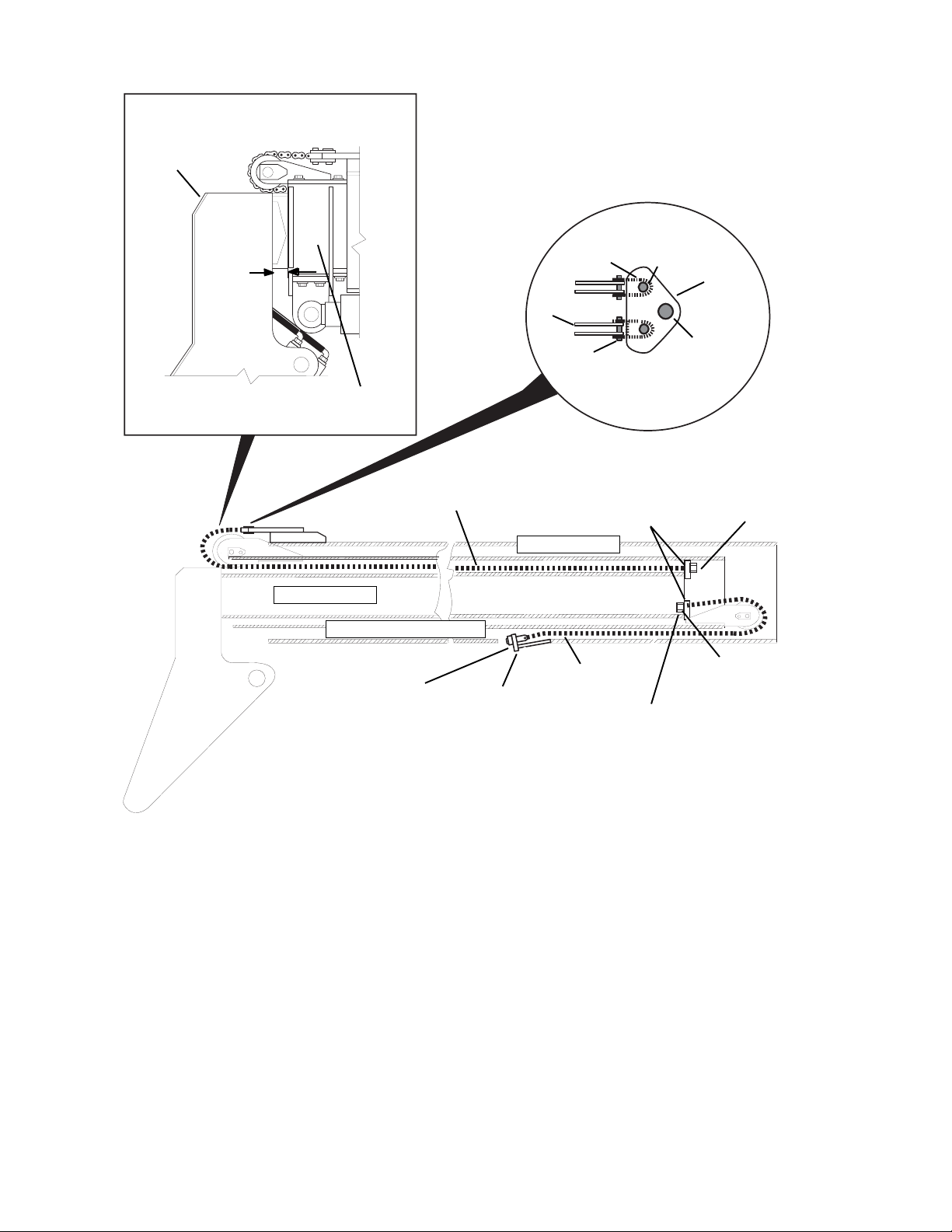

Fig. 3.11 Chain Replacement

11. Attach the two extend chains at the chain yoke,

Fig. 3.11, on top of the boom. Allow the

remaining ends of the chains to hang free until

the intermediate boom has been installed.

12. Attach the retract chain at the chain support

plate, Fig. 3.11, and route it along the bottom of

the outer boom to the rear boom cover opening.

13. Remove hoist and sling from outer boom.

14. Remove cribbing from front of boom.

15. Refer to paragraphs 3.1.2.b and 3.1.1.b and

install the intermediate and inner booms.

INNER BOOM

RETRACT CHAIN

LOCKNUT AND

FLAT WASHER

(S/N 2515 & BEFORE)

CHAIN

SUPPORT

PLATE

RETRACT

CHAIN

RETRACT CHAIN

SHOULDER SCREW

AND LOCKNUT

(S/N 2516 & AFTER)

16. Refer to Fig. 3.9 and check the wear pad gap

between the front outer boom side and top wear

pads and the intermediate boom. The gap

should be 0.07 to 0.13" (1,8 to 3,3 mm) and

equal on all sides. Remove or install shims as

required.

IMPORTANT: The ends of wear pad attaching

capscrews must not protrude beyond the wear pad

insert; the ends must range from flush to 0.19"

(5 mm) recessed in the wear pad insert (refer to

Fig. 3.3).

17. Install the wear pads by applying Loctite 242 to

the capscrews and torquing them to 31 lb-ft (42

Nm).

MA0111

3-8

18. Lubricate the outer boom pivot pins, Fig. 3.7,

with multi-purpose lithium based grease.

6036/6036T S/N 9B0500 thru 14833

Section 3 Boom

3.1.4 Chain Replacement

Two chains extend the inner boom and one chain

retracts it.

Extend Chains

IMPORTANT: Replace extend chains in pairs or

sets ONLY.

a. Removal

1. Fully retract the boom.

2. Remove the rear boom cover.

3. Refer to Fig. 3.11 and remove the extend chain

locknut and flat washer securing each chain

clevis to a block at the upper rear of the inner

boom.

4. Remove the locknut and shoulder screw that

attaches each extend chain to the yoke at the

front of the boom.

5. Pull the chains out the front of the boom.

6. Remove a chain clevis at both ends of each

chain.

b. Installation

1. Be sure the boom is fully retracted.

2. Install a chain clevis on both ends of each

chain.

3. Working from the rear boom cover opening,

remove both top intermediate boom wear pads

to gain access to rear boom chain connection.

4. Using a long rod or other suitable tool, route the

chains between the upper plates of the inner

and intermediate booms to the front boom

opening. Make sure chains are not twisted.

5. Route the chains over the chain sheave and

attach the chains to the front yoke with a

shoulder screw and locknut. Tighten the

locknut completely, then back off 1/4 turn.

6. Secure the rear of the chain to a block at the

upper rear of the inner boom with a flat washer

and locknut. The elastic collar on the locknut

must engage the chain clevis by at least one

full thread. Be sure locknuts are tightened

equally.

7. Check the position of the chain yoke at the

front of the outer boom. The front of the yoke

must be parallel to the front face of the outer

boom. If not, adjust the locknuts accordingly.

8. Refer to paragraph 3.1.5 and lubricate the

chain.

9. Refer to paragraphs 3.1.6 and 3.1.7 and check

and adjust the chains.

Retract Chain

a. Removal

1. Fully retract the boom.

2. Remove the rear boom cover.

3. On the underside of the outer boom, remove

the outer boom retract chain locknut and flat

washer, Fig. 3.11, securing the retract chain to

a chain support plate at the underside of the

outer boom.

4. Remove the inner boom retract chain locknut

and flat washer (S/N 2515 & Before) attaching

the retract chain clevis to a block at the lower

rear of the inner boom. For S/N 2516 & After

remove the shoulder screw and locknut from

the mount plates.

5. From the rear outer boom cover opening, pull

the retract chain from the space between the

outer and intermediate booms.

6. Remove a chain clevis from each end of the

chain.

b. Installation

1. Be sure the boom is fully retracted.

2. Install a chain clevis on each end of the chain.

3. Refer to paragraph 3.1.5 and lubricate the

chain.

4. Secure the rear of the chain to a block at the

lower rear of the inner boom with a flat washer

and locknut (S/N 2515 & Before). Route the

chain around the chain sheave. The elastic

collar on the locknut must engage the chain

clevis by at least one full thread. For S/N 2516

& After secure the chain clevis to the mount

plates with a shoulder screw and a locknut.

5. Using a long rod or other suitable tool, route the

chain between the lower plates of the outer and

intermediate booms to the chain support plate

opening, Fig. 3.11, on the bottom of the outer

boom.

6. Secure chain clevis to the chain support plate

using a flat washer and locknut. Torque the

locknut to 35 to 40 lb-ft (47,5 to 54,2 Nm).

7. Refer to paragraphs 3.1.6 and 3.1.7 and check

and adjust the chain.

6036/6036T S/N 9B0500 thru 14833

3-9

Section 3 Boom

3.1.5 Chain Lubrication

250 Hour Intervals

1. Remove the rear boom cover from the outer

boom.

2. Extend and retract the boom several times

applying Aerosol .0002 Waxy Film Rust

Inhibitor, TRAK part number 8526405.

3. With the boom fully extended, apply multipurpose lithium based grease to the extend

chain using a brush or grease gun.

4. Install the rear boom cover on the outer boom.

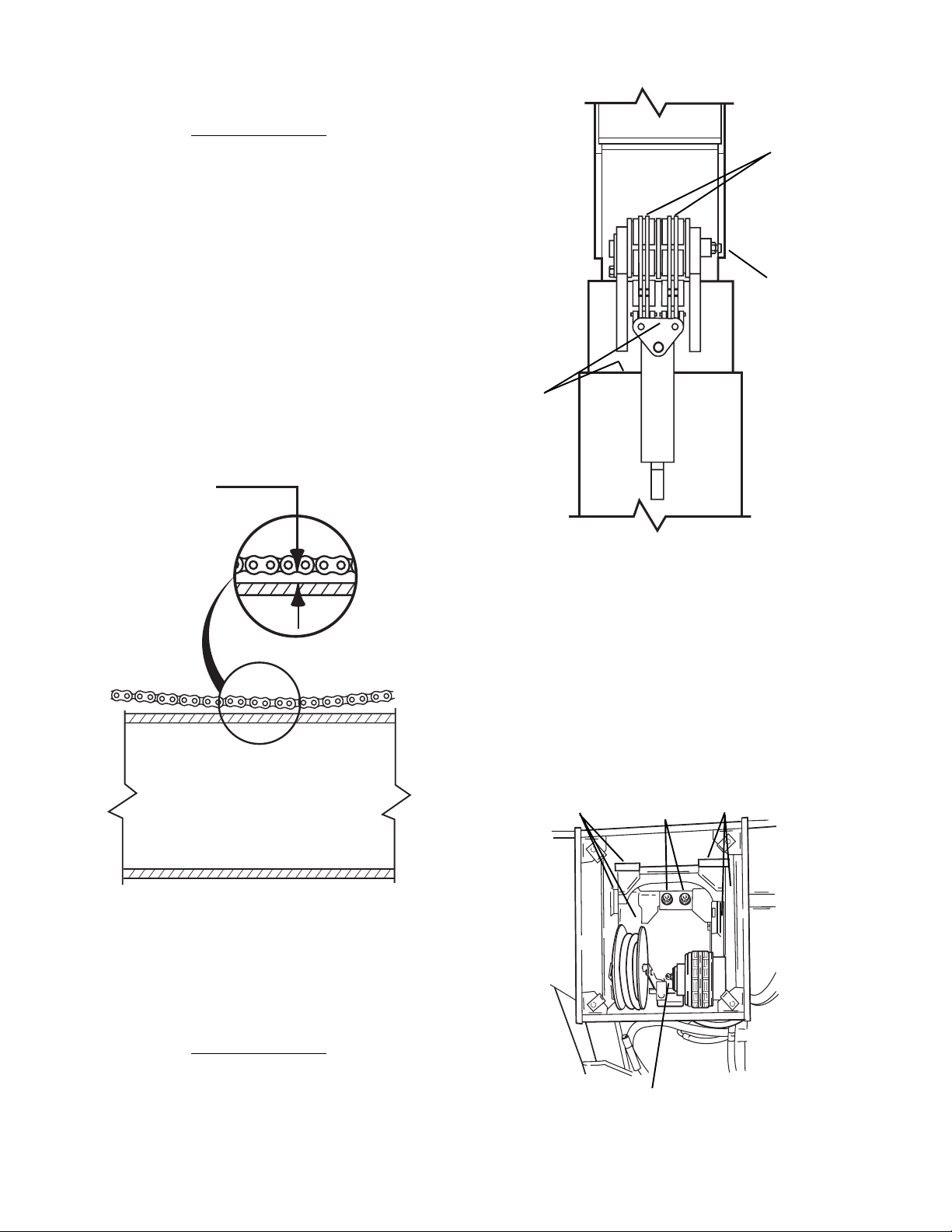

MAXIMUM CHAIN

SAG WITH BOOM

EXTENDED

IS 1-1/2" (38 mm)

FRONT FACE

OF YOKE

MUST BE

PARALLEL

TO FRONT

FACE OF

OUTER

BOOM

BOOM

EXTEND

CHAINS

EXTEND

CHAIN

SHEAVE

LUBE

FITTING

OA0531

CENTER SECTION

OF INTERMEDIATE

BOOM

Fig. 3.12 Maximum Extend Chain Sag

OA0491

Fig. 3.13 Yoke and Extend Chains

Adjust the chains so that:

• the inner boom extends 1-1/2 to 2-1/2"

(38 to 64 mm) from the front of the

intermediate boom when the boom is

retracted, Fig. 3.11, and

• the extend chains are no closer to the

intermediate boom than 1-1/2" (38 mm)

when the boom is extended, Fig. 3.12, and

• the front face of the yoke, Fig. 3.13, is

parallel to the front face of the outer boom.

WEAR

PADS

EXTEND CHAIN

LOCKNUTS

WEAR

PADS

3.1.6 Chain Tension Check

250 Hour Intervals

Check tension of boom extend chains after the

first 50 hours of operation and at 250 hour intervals thereafter.

3-10

RETRACT CHAIN SHEAVE

LUBE FITTING

Fig. 3.14 Rear Boom Cover Opening

Model 6036/6036T S/N 9B0500 thru 14833

OA0521

Section 3 Boom

Adjustment is accomplished using extend chain

adjustment locknuts, Fig. 3.14.

a. Chain Locknut Functions

Loosen extend chain locknuts to extend the inner

boom and increase extend chain sag.

Tighten outer boom retract chain locknut to retract

the inner boom and decrease extend chain sag.

b. Adjusting Procedure

1. Raise the boom to a horizontal (level) position.

Fully extend the boom, then retract it 2", which

is 1" per section (51 mm which is 25,5 mm per

section).

2. Measure sag in the extend boom chains

between the bottom of the chains and the top

of the intermediate boom at their closest point,

Fig. 3.12. Acceptable boom extend chain sag

is between 1-1/2 & 2-1/2" (38 & 64 mm). If the

measurement is less than 1-1/2" (38 mm),

adjust the boom chains as described in the

following steps.

RETRACT CHAIN

LOCKNUT

(c) Measure the chain sag, Fig. 3.12. Accept-

able boom extend chain sag is between

1-1/2 & 2-1/2" (38 & 64 mm). If the chain

sag is less than 1-1/2" (38 mm) repeat

steps (a) through (c).

3. If the distance measured in Step 1 is less than

2" but greater than 1-1/2" (less than 51 mm

but greater than 38 mm):

(a) Remove the rear cover from the outer

boom and adjust the top extend boom

chains.

(b) Tighten the locknuts, Fig. 3.14, for each

chain. Be sure each locknut is tightened

equally so that chain maintains the same

tension. Equal chain tension can be

checked by observing the position of the

yoke on the outer boom, Fig. 3.13. The

front of the yoke should be parallel with

the front edge of the boom.

(c) Cycle the boom in and out; then, with the

boom horizontal (level), fully extend the

boom and retract it 2" which is 1" per

section (51 mm which is 25,5 mm per

section).

EXTEND CYLINDER

OA0511

Fig. 3.15 Retract Chain Adjustment Locknut

3.1.7 Chain Tension Adjustment

1. Retract the boom completely to check the

position of the inner boom, Fig. 3.11. If the

distance between the front edges of the

intermediate and inner booms is between

1-1/2 & 2-1/2" (38 & 64 mm) and the extend

chain is no closer than 1-1/2" (38 mm) from

the intermediate boom, proceed no further, the

boom chains are adjusted correctly.

2. If the distance between the front edges of the

intermediate and inner booms is 2" or more

but less than 2-1/2" (51 mm or more but less

than 64 mm):

(a) Tighten the locknut, Fig. 3.15, on the

bottom of the outer boom. This retracts

the inner boom and takes up the sag in

the extend chains.

(d) Measure the chain sag. Acceptable boom

chain sag is between 1-1/2 and 2-1/2" (38

and 64 mm). If chain sag is less than 1-1/

2" (38 mm), repeat steps (a) through (d).

(e) Replace the rear cover of the outer boom.

3.1.8 Wear Pad Replacement

After the first 50 hours of operation or when

severe wear is suspected

There are 26 wear pads (Fig's 3.3, 3.5, 3.6 and

3.8) between the outer, intermediate, and inner

booms. Five are attached to the inner boom,

thirteen to the intermediate boom, and eight to the

outer. Four additional wear pads may be used in

severe twist applications.

The wear pads and wear pads with spacers are

shimmed to maintain a gap between the wear

pads and the booms of 0.07 to 0.13" (1,8 to 3,3

mm).

ANGLED

CUT

ANGLED

CUT

(b) Cycle the boom in and out; then, with the

boom horizontal (level), fully extend the

boom and retract it 2" which is 1" per

section (51 mm which is 25,5 mm per

section).

Model 6036/6036T S/N 9B0500 thru 14833

MA2070

Fig. 3.16 Boom Wear Pads

3-11

Section 3 Boom

IMPORTANT: Inspect the pads as follows:

• Replace wear pads that are less than 0.375"

(9,5 mm) thick.

• Each boom wear pad is manufactured with a

convenient wear pad indicator. This is the

angled cut at each end of all wear pads,

Fig. 3.16. The total thickness of a new wear

pad is .625" (15,9 mm), the angled cut will

provide a total wear thickness of .25"

(6,4 mm). This will leave approximately

.375" (9,5 mm) of total unused material. The

wear pads must never be worn past the

angled cut indicator because the metal pad

insert that holds the pads in place will begin

to wear into the boom pad sliding surfaces.

If pads are worn past this point it will cause

gouging on boom plate surfaces which will

result in premature wear of any new wear

pads installed if the surfaces are not ground

smooth again.

• When you install a wear pad on one side

(including top or bottom) of boom, replace

the corresponding wear pad on the other

side of the boom. Usually shimming will

remain the same when installing new wear

pads on corresponding sides of the boom.

• Apply Loctite

®

242 to all wear pad screws

and torque them to 31 lb-ft (42 Nm).

a. Inner Boom Wear Pads (Fig. 3.3)

1. All inner boom wear pads can be removed by

working through the rear boom cover opening.

2. The bottom pad may be removed by first

removing the top pads. Use a wooden wedge

between the inner and intermediate boom to

provide clearance for removing the bottom

pad.

3. Inspect the wear pads removed as described

in the preceding

b. Intermediate Boom Wear Pads

(Fig. 3.5 and 3.6)

1. The rear wear pads can be removed by

working through the rear boom cover opening.

2. The rear bottom pad may be removed by first

removing the top pads, by using a wooden

wedge between the inner and intermediate

boom, thereby providing clearance for removing the bottom pad.

3. Front pads can be removed at the front of the

boom.

IMPORTANT

notice.

4. The front bottom pad may be removed by first

removing the top pads. Lower the gooseneck

end of the inner boom to the ground until the

intermediate boom raises up to provide

clearance for removing the bottom pad.

5. Inspect the wear pads removed as described

in the preceding

c. Outer Boom Wear Pads (Fig. 3.9)

1. All outer wear pads can be removed working

at the front of the boom.

2. The front bottom pad may be removed by first

removing the top pads. Lower the gooseneck

end of the inner boom to the ground until the

intermediate boom raises up, thereby providing clearance for removing the bottom pad.

3. Inspect the wear pads removed as described

in the preceding

IMPORTANT

IMPORTANT

notice.

notice.

3.1.9 Hose Tensioning

100 Hour Intervals

Adjust grille tilt cylinder hose or auxiliary hydraulic

hose tension whenever the boom is disassembled, a hose is changed, or whenever proper hose

adjustment is in question. Check hose tension as

part of general maintenance every 100 hours.

IMPORTANT: Before you begin tensioning the

hoses make sure that the hoses are not twisted

within the boom. Keep the hose manufacturers

marking in line as a guide.

1. Park forklift on level surface, engage park lock

and fully retract and level the boom.

2. Remove the rear boom cover, Fig. 3.1.

3. If the vehicle has auxilliary hydraulics there

will be four hoses in hose clamps, Fig. 3.17b,

with the auxilliary hose clamps stacked on top

of the grille tilt cylinder hose clamps,

Fig. 3.17a. Remove the capscrews and hose

clamps, holding upper hoses in place,

Fig. 3.17b, and move aside to gain access to

the lower capscrews and hose clamps.

4. Loosen capscrews securing the hose clamps

to the inner boom, Fig. 3.17a or Fig. 3.17b.

5. Manually remove all hose slack between the

pulley and the inner boom hose clamps and

the pulley and the outer boom tubes. Pull the

hoses through the hose clamps, towards the

front of the boom, until there is 180° of hose in

contact with the pulley.

3-12

Model 6036/6036T S/N 9B0500 thru 14833

Loading...

Loading...