Skype EP9N User Manual

OWNERS MANUAL

MODEL EP-9N

R134a AC SERVICE CENTER

RECOVERY

RECYCLING

VACUUM

RECHARGING

WARNING - DO NOT MIX REFRIGERANTS (R134a) ONLY

July 11, 2000

2

SKYE International Holdings, Inc., 7441 Tower Street, Fort Worth TX. 76118

FOR TECHNICAL SUPPORT AND CUSTOMER

SERVICE PLEASE CALL

1-800 722 SKYE (7593)

RECORD YOUR EQUIPMENT DETAILS BELOW:

MODEL NO. |

............................................ |

SERIAL NO. |

............................................ |

DATE PURCHASED. |

............................................ |

PURCHASED FROM. |

............................................ |

Thank you for choosing SKYE. With proper set up and maintenance your equipment will provide years of trouble free service. To activate your warranty, fill out and mail in the enclosed card and the EPA certification form today.

Thanks Again.

WARNING: KNOW WHICH REFRIGERANT YOU ARE RECOVERING. RISK OF EXPLOSION - NEVER RECOVER ANY REFRIGERANT CONTAINING MORE THAN 3% HYDROCARBONS (Propane, Butane, etc.).

2

3

TABLE OF CONTENTS

Ownership Information |

2 |

Important Information, Warnings & Cautions |

4 |

Illustrations |

5 |

Machine Set Up |

6 |

Recovery Procedure - Vapor |

7 |

Evacuation |

8 |

Charging |

8, 9 |

Auxiliary Recycling |

10 |

Non Condensable Gas (NCG) Venting |

10 |

Temperature/Pressure Chart |

11 |

Equipment Service & Maintenance |

12 |

Purge Procedure |

12 |

Filter Change Procedure |

12 |

Compressor Oil Drain & Refill Procedure13 |

|

Vacuum Pump Service Procedure |

13 |

Compressor Oil Level Check |

14 |

Trouble Shooting Chart |

15 |

Replacement Parts List |

16-17 |

Warranty |

18 |

Electrical Schematic |

19 |

Flow Diagram |

20 |

Operating Flow Chart |

21 |

3

4

WARNING:

1.This equipment operates at high pressures and at high voltages and if improperly used may cause personal injury.

2.Must be operated by qualified and certified personnel.

3.Read instructions carefully before operating or servicing.

4.To prevent personal injury from refrigerants operators must wear safety glasses, gloves and protective clothing.

5.Do not operate equipment if damaged.

6.Safety devices require the use of authorized refillable tanks.

7.Do not use this equipment in the vicinity of spilled or open containers of gasoline.

8.Use this equipment in locations with mechanical ventilation that provides at least four air changes per hour or locate the equipment at least 18 inches above the floor.

9.Service hoses must have shut off devices within 12 inches (30 cm) of the connection point to the system being serviced to prevent the loss of refrigerant.

IMPORTANT:

•Change filter (FA1) and compressor oil (S131-EST) every 30 hours.

•Check the compressor oil every 10 hours.

•Compressor must not be operated unless it contains the specified 8 oz. (flat side compressors) or 12 oz. (round side compressors) of oil.

•Your compressor is filled initially at factory.

•Change the vacuum pump oil (SA132) monthly or every 30 hours. Fill to top of fill line.

•Close the tank valves after each machine use.

•Always replace caps on inlet and outlet ports.

•Routinely check your fittings for leaks.

CAUTION:

It is important not to allow liquid to settle at any time in the suction side when the compressor is not running as this may enter the compressor and cause damage next time the unit is turned on. TO PREVENT THIS, DO NOT PRESS THE OFF BUTTON WHEN THE COMPRESSOR IS RUNNING; allow it to evacuate the system completely and shut off automatically. Then press the OFF button.

WARNING: Improper operation will void your warranty.

To reduce the risk of fire, avoid the use of an extension cord because the extension cord may overheat. However, if you must use an extension cord, the cord shall be AWG 14 minimum.

Avoid breathing AC refrigerant and lubricant vapor or mist. Exposure may irritate eyes, nose and throat. To remove HFC 134a from the AC system, use service equipment certified to meet the requirements of SAE J2210 (HFC 134a recycling equipment). Additional health and safety information may be obtained from refrigerant and lubricant manufacturers.

NEW STORAGE TANKS MUST BE EVACUATED before use to remove any air and moisture.

REFRIGERANTS

The SKYE EP9N AC Service Center must be used with R134a only.

IMPORTANT: PREVENT ACCIDENTAL REFRIGERANT LOSS

REFRIGERATION LOSSES MOSTLY OCCUR THROUGH LOOSE CONNECTIONS AND SCHRADER VALVES. CHECK YOUR FITTINGS AND VALVES.

ALWAYS CHECK THAT THE O-RINGS IN THE VALVE CAPS ARE IN GOOD CONDITION AND ENSURE CAPS ARE TIGHT.

LEAK TEST FITTINGS & HOSE CONNECTIONS PERIODICALLY USING AN ELECTRONIC LEAK DETECTOR OR SOAPY WATER.

CLOSE TANK VALVES WHEN NOT IN USE.

WARNING: ELECTRICAL FAULTS MUST BE REPAIRED BY A QUALIFIED ELECTRICIAN.

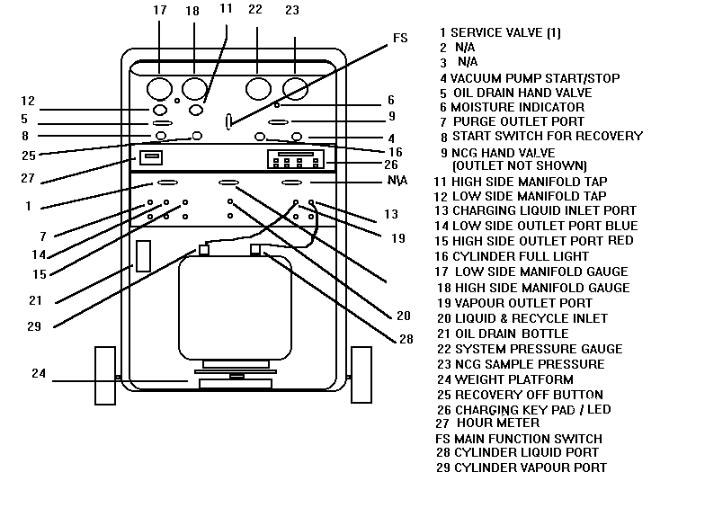

KNOW YOUR UNIT

4

5

Your SKYE EP9N is designed for vapor and liquid Refrigerant RECOVERY, RECYCLING, VACUUM and RECHARGE of systems containing R134a ONLY.

The ventilation fans run when the unit is connected to power.

DO NOT LAY THE UNIT DOWN - THIS MAY CAUSE LIQUID REFRIGERANT TO SETTLE IN THE COMPRESSOR.

The EP9N unit comes complete with.

1 x 96" Red service hose with R134a HIGH SIDE service adapter.

1 x 96" Blue service hose with R134a LOW SIDE service adapter. 1 x Dual valve storage tank with float.

1 x Oil measuring bottle for recovered oil drain.

1 x Vapor outlet to storage tank hose with ABB one end.

1 x Liquid charging/utility hose with ABB and one quick connect fitting.

EP9N MACHINE CONTROL LAYOUT

ESSENTIAL PRE-OPERATING PROCEDURES

5

6

BEFORE OPERATING YOUR SKYE MACHINE FOR THE FIRST TIME, THE FOLLOWING

PROCEDURES MUST BE CARRIED OUT.

Your new unit and the storage tank must be evacuated (vacuumed) prior to use.

Set Up Procedure: (REFER TO THE ILLUSTRATED LAYOUT ON PAGE 5.)

1.Open both the tank valves to vent the factory nitrogen charge (if any).

2.Disconnect the hose from the LOW SIDE SERVICE HOSE PORT, feed the power cord and each service hose through the hole in the side panel then connect the RED service hose to the HIGH SIDE SERVICE HOSE PORT.

3.Confirm the SERVICE VALVE is in the ON (Horizontal) position, place the storage tank on the scale platform, connect the vapor out hose to the storage tank vapor port and connect the float lead to the tank. Remove the quick connect fitting from the liquid charging/utility hose, connect one end to the

storage tank liquid port and the other end to the LOW SIDE SERVICE HOSE PORT. Connect the machine to power. (Check tank valve handles for proper port identification - DO NOT GO BY

COLOR.)

4. Turn the FUNCTION SELECTOR clockwise to the VACUUM position, open the BLUE MANIFOLD VALVE and turn the VACUUM PUMP SWITCH on. Operate the vacuum pump tank for a minimum of 20 minutes. While vacuuming, remove the 2 fan shroud screws nearest the side panel with the hose hole and install the HOSE HANGER using the same screws.

5.When the vacuum is complete, CLOSE the BLUE MANIFOLD VALVE, turn the FUNCTION SELECTOR clockwise to the CLOSED position, close the TANK LIQUID VALVE then turn the VACUUM PUMP OFF. Remove the hose from the storage tank liquid port.

6.Connect the hose to an R134a bottle containing at least 10 lbs, open the valve on the bottle then turn it upside down for liquid. Press the scale keypad ON button, allow warm-up, then press the ZERO button for 2 seconds. Turn the FUNCTION SELECTOR clockwise to the RECOVER position, press the RECOVER ON button and slowly open the BLUE MANIFOLD VALVE. The machine will start recovering and the scale LCD will start counting up as refrigerant flows into the storage tank.

7.When 10 to 12 lbs. of refrigerant is in the storage tank, close the valve on the R134a bottle and allow the machine to stop automatically (the BLUE gauge will indicate 10” to 15” vacuum). Close the BLUE MANIFOLD VALVE, turn the FUNCTION SELECTOR clockwise to the CLOSED position and press the RECOVER OFF button. Disconnect power.

9.Remove the hose from the R134a bottle and machine then replace the quick connect fitting. Connect the BLUE service hose to the LOW SIDE SERVICE HOSE PORT. Connect the hose with the quick connect to the storage tank liquid port and to the LIQUID CHARGING PORT.

YOUR MACHINE IS NOW READY FOR USE

TO RECOVER VAPOR Or LIQUID REFRIGERANT

6

7

IMPORTANT: Before recovering refrigerant with your SKYE machine, the vehicle AC system must be off.

OPERATING INSTRUCTIONS:

1.Close the high side and low side manifold valves and connect the (RED) high side and

(BLUE) low side service hoses to the AC system.

2.Open the storage tank VAPOR port and connect the machine to power.

3.Turn the FUNCTION SELECTOR to RECOVER and press the RECOVER ON button.

NOTE: If you want to measure to amount of refrigerant being recovered, press the scale keypad ON button, wait for warm-up to complete then press and hold the zero button for 2 seconds. When the LCD reads 0 lbs. 00 oz. proceed to next step.

4.Open the manifold valves slowly. The unit will operate automatically and recover and recycle all the refrigerant in the AC system.

5.When the pressure in the AC system drops to approximately 10" VACUUM, the compressor will stop. This does not mean that all the refrigerant has been recovered as there may be refrigerant trapped in the oil or in an accumulator which will slowly evaporate. The compressor will restart automatically and recover this refrigerant. When the gauges remain at 0 PSI or below for at least 2 minutes recovery is complete. Close the low side and the high side manifold valves. If the system pressure rises during this time allow the machine to continue the recovery process.

6.Turn the FUNCTION SELECTOR to the CLOSED position and press the RECOVER OFF button.

7.Close the storage tank VAPOR port.

8.Drain the RECOVERED OIL into the measuring bottle by opening the RECOVERED OIL DRAIN VALVE. You may replace this amount of new oil back into the AC system.

NOTE: If the unit stops during recovery and when you press the RECOVER ON button the CYLINDER FULL light glows, your tank is full and must be replaced. All new tanks must be evacuated before use.

EVACUATION (VACUUM) PROCEDURE

7

Loading...

Loading...