Skype EP6 User Manual

SKYE

________________________________________________________

AC SERVICE EQUIPMENT

________________________________________________________

OWNERS MANUAL

SuperSKYE

MODEL EP6

R12/R134a A/C SERVICE CENTER

WARNING -- DO NOT MIX REFRIGERANTS

January 1, 2001

EP6manb

SKYE International Holdings, Inc., 7441 Tower Street, Fort Worth TX. 76118

FOR TECHNICAL SUPPORT AND CUSTOMER

SERVICE PLEASE CALL

2

1-800 722 SKYE (7593)

RECORD YOUR EQUIPMENT DETAILS BELOW:

MODEL NO. ............................................

SERIAL NO. ............................................

DATE PURCHASED. ............................................

PURCHASED FROM. ............................................

Thank you for choosing SKYE. With proper set up and maintenance your

equipment will provide years of trouble free service. To activate your warranty, fill

out and mail in the enclosed card and the EPA certification form today.

Thanks Again.

TABLE OF CONTENTS

2

Ownership Information ------------------------------------- 2

Important Information, Warnings & Cautions -------- 4

Know Your Machine (Illustrations) ---------------------- 5, 6

Set Up Procedure ------------------------------------------- 7, 8

Tank Precharge / Recharge Procedure --------------- 8

Display Procedure ------------------------------------------- 9

Automatic Routine Procedure --------------------------- 10, 11

Recovery Procedure --------------------------------------- 12, 13

Vacuum Procedure (Includes Oil Charge) ----------- 13, 14

Charging Procedures -------------------------------------- 14 - 16

Non-Condensable Gas Venting ------------------------- 16, 17

Recovered Oil Drain Procedure ------------------------- 17

Change Gas (Refrigerant) Procedure ----------------- 18, 19

3

Filter Change Procedure ---------------------------------- 19, 20

Flush Procedure --------------------------------------------- 20 - 22

Help Procedure ---------------------------------------------- 22, 23

Display Mode Procedure ---------------------------------- 23, 24

Tank Size Selection Procedure ------------------------- 24

System Stats ------------------------------------------------- 24, 25

Update Procedure ------------------------------------------ 25

Additional Features ---------------------------------------- 25, 26

Equipment Service & Maintenance -------------------- 26

Troubleshooting Tips -------------------------------------- 27

Pressure Temperature Chart ---------------------------- 28

Warranty ------------------------------------------------------ 29

⌦WARNING:

3

4

1. THIS EQUIPMENT OPERATES AT HIGH PRESSURES AND AT HIGH VOLTAGES

AND IF IMPROPERLY USED MAY CAUSE PERSONAL INJURY.

2. MUST BE OPERATED BY QUALIFIED PERSONNEL.

3. READ INSTRUCTIONS CAREFULLY BEFORE OPERATING OR SERVICING.

4. TO PREVENT PERSONAL INJURY FROM REFRIGERANTS OPERATORS MUST

WEAR SAFETY GLASSES, GLOVES AND PROTECTIVE CLOTHING.

5. DO NOT OPERATE EQUIPMENT IF DAMAGED.

⌦IMPORTANT:

• Close the tank liquid valve after each charge operation.

• Change filter after every 10 hours of recovery operation. Use SKYE # 256100 only.

• Check the vacuum pump oil regularly.

• Change the vacuum pump oil monthly. Fill with 8 ounces. Use SKYE # 276030.

• Close all tank valves when the machine is not in use.

• Always replace caps on ports not in use.

• Check your fittings and hoses for leaks regularly.

• If machine does not turn on, check fuse(s). (SKYE #246435 for 120VAC or SKYE #

246445 for 240VAC)

⌦CAUTION:

∗ This machine is computer controlled. DO NOT turn power off while performing a function

unless absolutely necessary. If power is turned off, allow at least 10 seconds before

turning on again. DO NOT place magnetic tools on the control panel surfaces. This may

cause damage to the computer components and program.

WARNING: Improper operation will void your warranty.

NEW STORAGE TANKS MUST BE EVACUATED before use to remove any air and moisture.

REFRIGERANTS

The SUPERSKYE EP6 AC Service Center is designed for use with R12 and R134a.

IMPORTANT: PREVENT ACCIDENTAL REFRIGERANT LOSS

" REFRIGERATION LOSSES OCCUR THROUGH LOOSE CONNECTIONS AND

SCHRADER VALVES. CHECK YOUR FITTINGS AND VALVES.

" ALWAYS CHECK THAT THE O-RINGS IN THE VALVE CAPS ARE IN GOOD

CONDITION AND ENSURE CAPS ARE TIGHT.

" LEAK TEST FITTINGS & HOSE CONNECTIONS PERIODICALLY USING AN

ELECTRONIC LEAK DETECTOR OR SOAPY WATER.

" CLOSE STORAGE TANK VALVES WHEN YOUR MACHINE IS NOT IN USE.

" WARNING: ELECTRICAL FAULTS MUST BE REPAIRED BY A QUALIFIED

ELECTRICIAN.

KNOW YOUR UNIT

4

Your SUPERSKYE EP6 is designed for vapor and/or liquid refrigerant RECOVERY/

RECYCLING, VACUUM and RECHARGE of systems containing R12 or R134a.

DO NOT LAY THE UNIT DOWN -- THIS WILL CAUSE LOSS OF VACUUM PUMP OIL.

The EP6 unit comes with:

1 x 96" R12 Red service hose with ABB on one end.

1 x 96" R12 Blue service hose with ABB on one end.

1 x 96" R134a Red service hose with Service Adapter on one end.

1 x 96" R134a Blue service hose with Service Adapter on one end.

2 x 30 lb. (14.6 Kg) Dual valve storage tanks with floats. (1 x R12, 1 x R134a)

2 x 8 oz. (240 cc) Oil measuring bottles. (1 x oil drain, 1 x oil charge)

2 x 32" R12 tank hoses with ABB on both ends.

2 x 32" R134a tank hoses with ABB on both ends.

1 x Temperature probe with 10’ lead.

1 x Set of clutch voltage probes with 48” leads. (1 x Red, 1 x Black)

1 x 8 oz. (240 cc) Bottle of Vacuum Pump Oil.

EP6 CONTROL MENU LAYOUT

MAIN SKYE

MENU

DISPLAY

REFRIGERANT SELECTED

AUTO RECOVER VACUUM

BUTTON BAR

MENU

5

MENU 2 SKYE

CHARGE NCG

REFRIGERANT SELECTED

RECOVERED

OIL DRAIN

BUTTON BAR

CHANGE

MENU

3

MENU 3

CHANGE

FILTER

REFRIGERANT SELECTED

SKYE

SET

UP

FLUSH HELP MENU

BUTTON BAR

4

MENU 4 SKYE

REFRIGERANT SELECTED

5

6

DISPLAY

TANK

SYSTEM

BUTTON BAR

UPDATE

MAIN

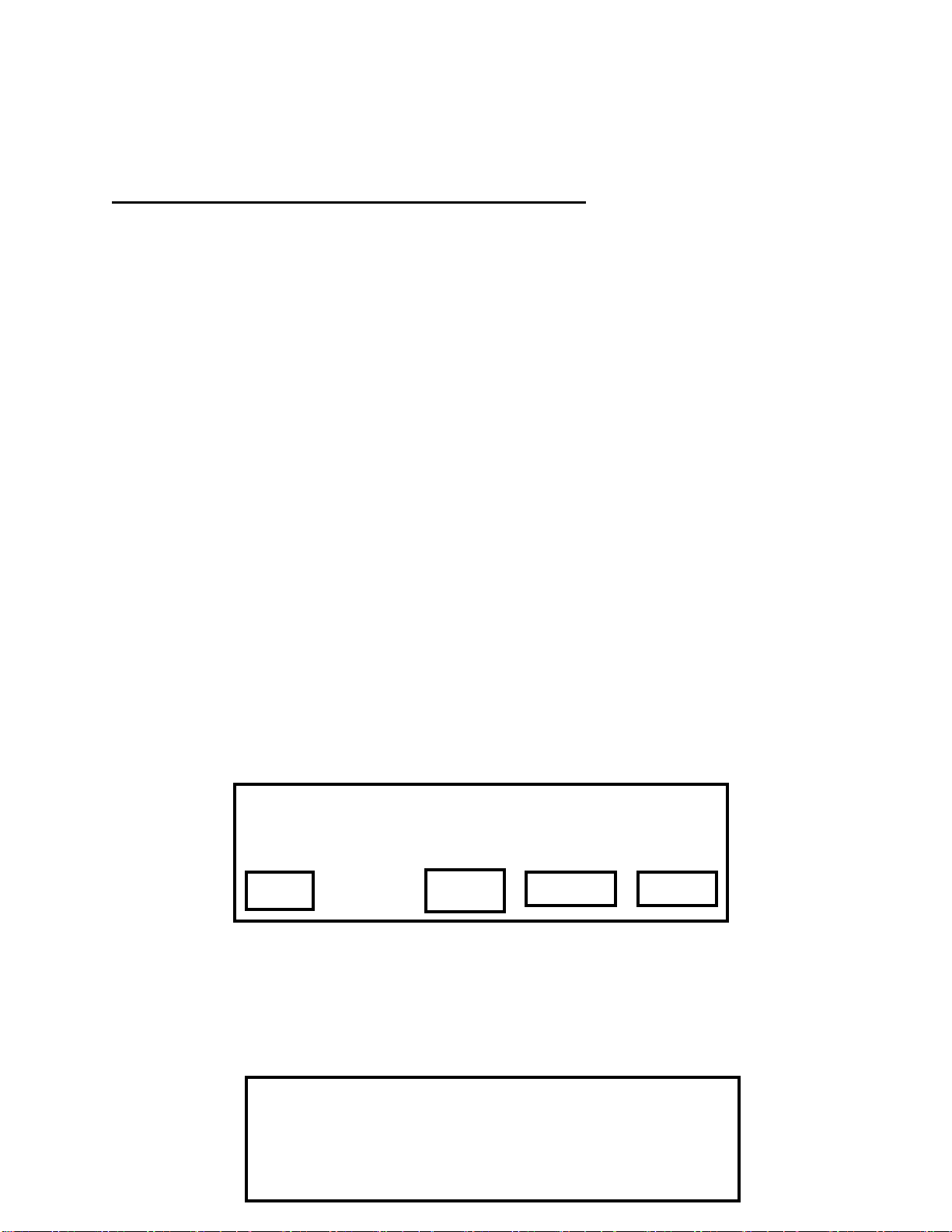

HOSE CONNECTION LAYOUT

LOW

SIDE

HIGH

SIDE

TANK

LIQUID

TANK

VAPOR

MOISTURE

INDICATOR

#

R134a

#

R134a

#

R134a

#

R134a

#

#

R12

#

R12

NOTE: PORTS MAY BE REVERSED TOP TO BOTTOM

#

R12

#

R12

WORKING DISPLAY

Tank Wgt ___ lbs _____ oz FUNCTION %

Full

______ ______ _______ ___

LO PRESS HI PRESS SYS PRESS Clutch

VDC

____

____ ____ ____ TIME

Duct Amb Sys

EXIT

Set Up Procedure

6

7

BEFORE OPERATING YOUR SUPERSKYE MACHINE FOR THE FIRST TIME READ THE

INSTRUCTION MANUAL THEN COMPLETE THE FOLLOWING PROCEDURES.

Your new EP6 must be prepared for use prior to any operation with refrigerant. Follow the

steps in the SET UP selection from MENU 3. This procedure can be used once at the time of

initial set up. It will be deactivated at completion of set up.

THE DEFAULT REFRIGERANT FOR SET UP IS R134a.

1. Fill the vacuum pump reservoir with 4 ounces of the oil provided by unscrewing the vent

cap/dipstick assembly and pouring it into the fill tube. Add an additional 4 ounces after the

motor starts in step 6 then replace the cap/dipstick assembly.

2. Determine which refrigerant you are going to use for the initial set up of the machine then

select the appropriate storage tank. Connect the appropriate short hoses to the tank and

machine (vapor to vapor/liquid to liquid), place the tank on the scale platform, open both

tank valves then connect the tank float lead.

3. Connect the machine to power and turn the master power switch ON. Select MENU 4 then

press the TANK SIZE button and select the tank size you are using (default is 30 lb.).

Return to MENU 4 and press the DISPLAY MODE button. The next screen allows you to

select your preferred weight (lbs & oz or Kg), pressure (PSI, KPa or mBAR) and

temperature (Fahrenheit or Celsius) measurements to be displayed. Press the desired

button for each option, select your desired measurement method then press the EXIT

button to return to the main option screen. Repeat as necessary to select your preferred

methods (default is lbs/oz, PSI and Fahrenheit). Once the measurement selection is

completed, press EXIT to return to the main menu. Press the MENU button to return to

MENU 3 and press the SET UP button.

a. If you are setting up for R134a, connect the tank hoses to the corresponding machine

and tank ports ( VAPOR to VAPOR/LIQUID to LIQUID ) and open both tank valves.

b. If you are setting up for R12, PRESS and HOLD the CHANGE GATE button and

move the access gate manually then connect the tank hoses to the corresponding

machine and tank ports ( VAPOR to VAPOR/LIQUID to LIQUID ) and open both tank

valves.

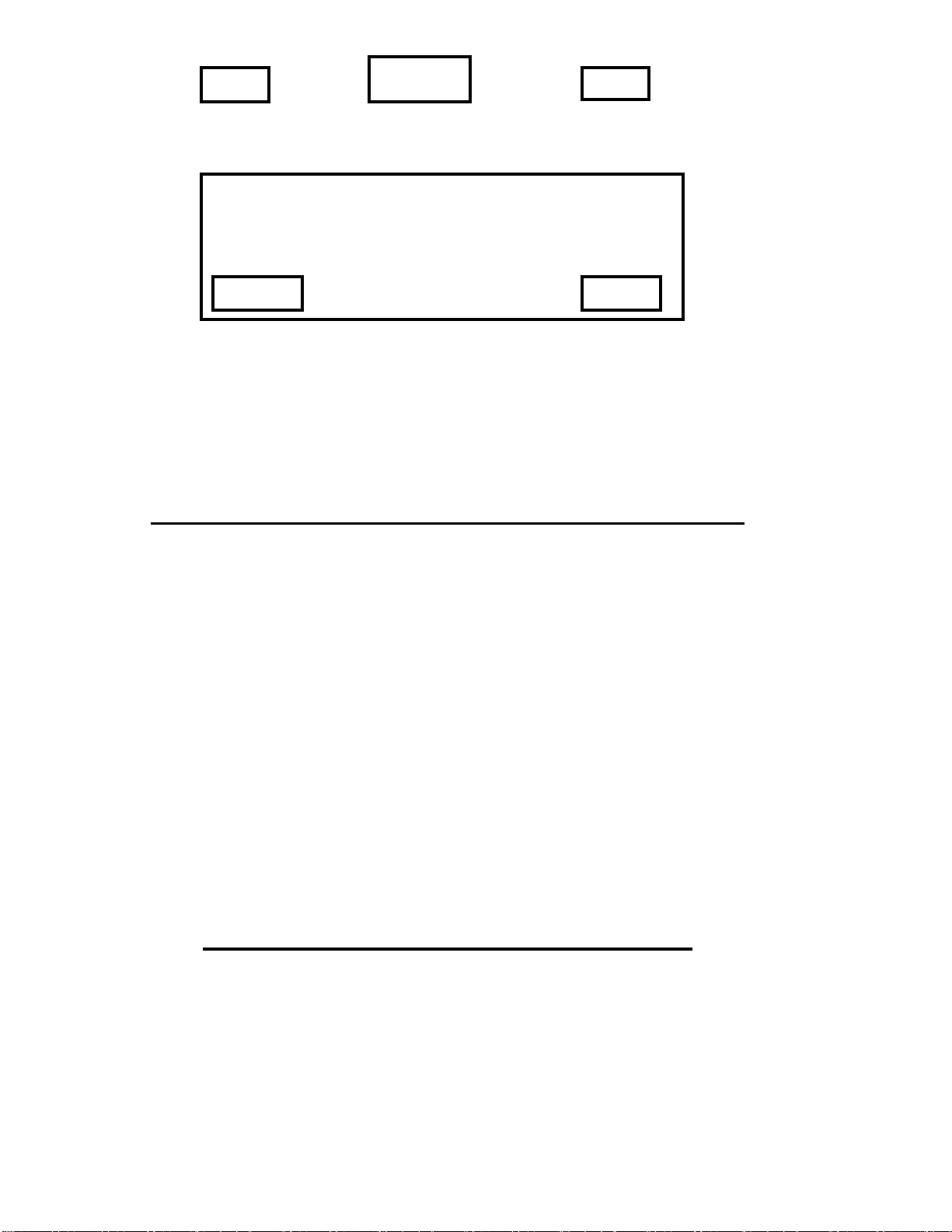

DISPLAY

MODE

DEFAULT SET UP IS R134a

PRESS AND HOLD CHANGE GATE

BUTTON TO MOVE GATE

CHANGE

GATE

CONTINUE EXIT

4. Press the CONTINUE button then press the R12 or R134a button on the following screen to

confirm the refrigerant selected. You have the option to move the gate again at this time.

CONFIRM GATE POSITION FOR

REFRIGERANT SELECTED

7

R134a

CHANGE

GATE

R12

5. When the button for the desired refrigerant is pushed, the next screen will be displayed.

CONTINUE EXIT

CONNECT TANK

OPEN TANK VALVES

REFRIGERANT ________

6. Press the CONTINUE button to initiate the automatic preparation sequence. DO NOT

interrupt this sequence. The service hoses may be connected to the machine while this

operation is in process.

7. When the set up cycle is completed, the machine will stop and display the MAIN MENU.

The set up function is now inoperative and cannot be used again. Your storage tank must

be precharged now.

8

PRECHARGE / RECHARGE STORAGE TANK

IMPORTANT: Be sure that new tanks are in a vacuum before charging.

1. To precharge / recharge the tank with R134a, close the tank liquid valve and remove the

short liquid hose from the tank and machine. Connect the R134a liquid hose to the low

side service hose port on the machine and a virgin R134a bottle, open the valve on the

virgin bottle, turn it upside down and set it in front of the machine.

To precharge / recharge the tank with R12, close the liquid valve on the storage tank and

leave the hose connected to the tank and machine. Connect the R12 low side service hose

to the virgin R12 bottle, open the valve on the virgin bottle, turn it upside down and set it in

front of the machine.

2. Press the RECOVER button and allow the machine to recover at least 7 lbs. of refrigerant

into the storage tank. When the desired amount of refrigerant is precharged, close the

valve on the virgin bottle and allow the machine to shut off automatically.

3. When done precharging / recharging with R134a, return the short liquid hose to the tank

liquid and machine liquid ports and reinstall the low side service hose.

YOUR EP6 IS NOW READY FOR USE

8

DISPLAY PROCEDURE

_

When DISPLAY is selected the screen will change to the working display. This should be the

first screen used when the machine is connected to an AC system to allow the technician to

determine the A/C system’s condition. This screen allows AC system checks and trouble

shooting with the greater ability to locate and diagnose problems than allowed by normal

gauge set methods.

TANK WEIGHT: Displays the gross weight of the tank.

FUNCTION: Displays RECOVER when recovering and VACUUM when vacuuming.

% FULL: Displays the storage tank % full based on empty weight plus refrigerant.

LO: Displays the low side pressure of the AC system.

HI: Displays the high side pressure of the AC system.

SYS: Displays the internal machine pressure.

CLUTCH: Displays the clutch voltage in DC volts.

TIME: Displays timer in timed functions

DUCT: Displays the temperature reading at the AC system duct when in use.

SYS: Displays the temperature of the refrigerant in the machine and tank.

AMB: Displays the temperature of air around the machine.

EXIT: Return to the main menu or previous screen.

Tank Wgt _____ _____ Function %

lbs oz Full

_____ _____ _____ ___

LO PRESS HI PRESS SYS PRESS Clutch

____

___ ____ _____ TIME

Duct Amb Sys

Empty tank weights: 16 lbs for 30 lb. capacity / 25 lbs for 50 lb. capacity.

Note: This reading will display weight fluctuations when the motor is

running. This will not affect the critical measurements.

VDC

EXIT

9

AUTOMATIC ROUTINE PROCEDURE

9

Loading...

Loading...