Page 1

1/5 Scale Almost-Ready-To-Fly RC Jet

Assembly and operations manual

Spesifications

Type : T.A.V.S ARF PRO

Scale : 1/5th

Length : 90.2”: (2230mm)

Span : 91”: (2310mm)

Weight : 42—46 Lbs ( 14—21 Kg)

Engine : 32—38 Lbs (10—17 Kg) trust

Radio : 12 Channel (12—16 servo’s)

The F-86F Sabre by Skymaster

Thank you very much for purchasing our Skymaster ARF PRO F-86F . Please note that the photos in this instruction manual show certain views from the prototypes. Some modifications and upgrades might have taken place by

the release of the model. We have tried to produce a very scale replica of this classic jet. Many scales options are

available from Details 4 Scale. (see page 28) This manual describes the assembling of “ PRO” model. Sliding

canopy, speed brakes, landing gear and doors are factory installed. Before you start building and setting-up your

aircraft, please make sure you have read this instruction manual, and understood it. If you have any questions,

please don’t hesitate to contact us. Below are the contact details:

Office Taiwan:

No.9.39 Lane,Yuag-Chang 2nd Street, Ren-Wu Hsiang, Kaohsiung Hsien, 814, Taiwan, R.O.C.

TEL: +886 9 3299 7923

FAX: + 886 7373 1215

http://www.skymasterjet.com

Sales : skymaste@skymasterjet.com

Technical support : morne.m@pixie.co.za

SM © 2009

Page 2

Assembly & Operation Manual

Index:

INTRODUCTION....................................................................................................................................... 3

DISCLAIMER..............................................................................................................................................3

WARNING…...............................................................................................................................................3

ARF PAINT.................................................................................................................................................4

FINISHING YOUR WHITE VIPER ARF......................................................................................................4

HANDLING & TRANSPORTING ...............................................................................................................5

LIVE HINGE ……………………………..……….........................................................................................5

TOOL LIST................................................................................................................................................ 6

HEALTH…..................................................................................................................................................7

GENERAL ASSEMBLY TECHNIQUES..................................................................................................…7

RADIO EQUIPMENT & ACCESSORIES…………….................................................................................8

KIT CONTENTS…….……………...............................................................................................................9

OPTIONAL PARTS………………..……………….....................................................................................10

CONTROL LINKAGES ............................................................................................................................12

WINGS......................................................................................................................................................12

STABILIZERS...........................................................................................................................................15

FIN & RUDDER....................................................................................................................................... 17

FUSELAGE.............................................................................................................................................. 18

TAILPIPE………………………………………………………………………………………………………….19

FUEL CELLS…………………………………………………………………………………………………...…19

FUEL DIAGRAM………………………….………………………………………………………………………20

AIR SYSTEM .......................................................................................................................................... 21

AIR DIAGRAM......................................................................................................................................... 22

TURBINE INSTALLATION……………………………………………………………………………………....23

COCKPIT & CANOPY…......................................................................................................................... 24

EQUIPMENT INSTALLATION INTO THE SABRE ARF…………............................................................25

BEFORE YOU FLY.................................................................................................................................. 26

OPTIONAL SCALE PARTS……………………………………………………………………………………...28

P-2

Page 3

Assembly & Operation Manual

INTRODUCTION

Thank you for purchasing Skymaster arf pro Sabre! We have put a lot of effort and time into this model.

We at Skymaster strive to be a market leader in the ARF— jet market. We were the first company to

produce ARF—jets in the world and we would like to continue being amongst the best. Although we

have made every effort that this model was fit for shipping, we would like you to inspect the contends

and call your nearest dealer immediately if any defects or missing parts are spotted! This manual will

allow you to duplicate the factory prototypes.

LIABILITY

You have acquired a kit, which can be assembled into a fully working R/C model when fitted out with

suitable accessories, as described in the instruction manual with the kit. However, as manufacturers, we

at Skymaster are not in a position to influence the way you build and operate your model, and we have

no control over the methods you use to install, operate and maintain the radio control system components. For this reason we are obliged to deny all liability for loss, damage or costs which are incurred

due to the incompetent or incorrect application and operation of our products, or which are connected

with such operation in any way. Unless otherwise prescribed by binding law, the obligation of the Skymaster company to pay compensation is excluded, regardless of the legal argument employed. This applies to personal injury, death, damage to buildings, loss of turnover and business, interruption of business or other direct and indirect consequent damages. In all circumstances our total liability is limited to

the amount which you actually paid for this model.

BY OPERATING THIS MODEL YOU ASSUME FULL RESPONSIBILITY FOR YOUR ACTIONS.

It is important to understand that Skymaster, is unable to monitor whether you follow the instructions

contained in this instruction manual regarding the construction, operation and maintenance of the aircraft, nor whether you install and use the radio control system correctly. For this reason we at Skymaster

are unable to guarantee, or provide, a contractual agreement with any individual or company that the

model you have made will function correctly and safely. You, as operator of the model, must rely upon

your own expertise and judgment in acquiring and operating this model.

WARNING

This ‘jet’ aircraft is a high-end product and can create an enormous risk for both pilot and spectators, if

not handled with care, and used according to the instructions. Make sure that you operate your Viper

according to the AMA rules, or those laws and regulations governing model flying in the country of use.

The engine, landing gear, servos, linkages and control surfaces have to be attached properly. Please

use only the recommended servos and accessories. Make sure that the ‘Centre of Gravity’ is located in

the recommended place. Use the nose heavy end of the CG range for your first flights. A tail heavy

plane can be an enormous danger for you and all spectators. Fix any weights, and heavy items like batteries, very securely into the plane. Make sure that the plane is secured properly when you start the engine. Have a helper hold your plane from the nose before you start the engine. Make sure that all spectators are far behind, or far in front, of the aircraft when running up the engine. Make sure that you

range check your R/C system thoroughly before the 1st flight. It is absolutely necessary to range check

your complete R/C installation first WITHOUT the engine running. Leave the transmitter antenna retracted, and check the distance you can walk before ‘fail-safe’ occurs. Then start the engine, run at about

half throttle and repeat this range check. Make sure that there is no range reduction before ‘fail-safe’

occurs. If the range with engine running is less then with the engine off, please DON’T FLY at that time.

Make sure that your wing spar tube is not damaged. Check that the anti-rotation dowels for the wings

are not loose. Check that the wing, stab, fin and nose retaining bolts are tight. Please don’t ignore our

warnings, or those provided by other manufacturers. They refer to things and processes which, if ignored, could result in permanent damage or fatal injury. Secure the plane before starting engine.

P-3

Page 4

Assembly & Operation Manual

ARF Paint

The color finish on your Skymaster Sabre arf pro model was applied out of the mould.

We have used only the highest standard automotive paints to finish your model.

Should you damage the finish, Skymaster stock the color paint and hardener required

for the repair. A good automotive spray painter should also be able to mix and supply

the correct samples for repair.

If you have no experience in the use of these paints, it will be best to seek assistance.

Do not leave your model unprotected in the sun! always cover your model or park it in

the shade. Extreme temperatures will damage the paint!

Finishing Your All White SABRE ARF PRO

It is always best to fully assemble the model before painting. By doing so no damage

or glue prints will ruin the paint.

The all white model will have some release agent on the surfaces.

Use #1000 wet and dry paper to sand the entire model. Mould lines can be sanded

and filled using normal automotive fillers.

Please be extra careful when sanding near the hinge line! The hinges can easily be

damaged. When masking and painting please make sure the control surfaces are not

bend past 90—180 degrees extensively. This will cause the hinges to crack and may

cause flutter.

The rudder and clear canopy are not installed. It is best to install these components

after painting was done.

P-4

Page 5

Assembly & Operation Manual

HANDLING & TRANSPORTING

Composite models are very light but strong. These characteristics do have a down side! It is

brittle.

Take care when handling your model. DO NOT ATTEMPT TO PICK UP AN FULLY FUELLED

MODEL BY THE LEADING EDGE BY YOURSELF! The leading edges will crack and delaminate. Full size jets have specially marked access points for the hooks of cranes!

Inspect your model before and after a rough landing. Make sure all parts are safe and sound.

Inspect model before and after transport. A sudden stop can easily cause an unnoticed dent!

The wings and tails are very flight worthy structures. They are light and extremely strong , however, they will dent if mishandled. Always support these structures on clean soft foam rubber.

LIVE HINGE

Skymaster utilize this system of hinging control surfaces because it is a very strong

hinge system and is accomplished at the factory.

Occasionally, because of climatic changes, the bottom surfaces may “catch” or interfere with control travel surface actuation. Should this happen, use a fine abrasive strip

to further bevel the L.E. of the control surface.

CAUTIONS: Do not apply any primer or paint to the underside of the main surface trailing edge.

Prior to each flight, check that the ailerons and elevators actuate properly, up and

down.

Inspect the live hinges on a regular basis. If some cracks occur please repair asap with

special hinge tape available from Skymaster or its dealers.

P-5

Page 6

Tools and Adhesives

Assembly & Operation Manual

Tools etc:

This is a fairly quick and easy plane to build, for a jet model, not requiring difficult techniques or special equipment, but even the building of Skymaster aircraft requires some suitable tools! You will probably have all these

tools in your workshop anyway, but if not, they are available in all good hobby shops, or hardware stores like

"Home Depot" or similar.

1. Sharp knife (X-Acto or similar)

2. Allen key set (metric) 2.5mm, 3mm & 5mm

3. Sharp scissors, curved type for canopy

4. Pliers (various types)

5. Wrenches (metric)

6. Slotted and Phillips screwdrivers (various sizes)

7. Drills of various sizes

8. Battery drill and Dremel tool (or similar) with cutting discs, sanding tools and mills

9. Sandpaper (various grits), and/or Permagrit sanding tools (high quality - recommended)

10. Carpet, bubble wrap or soft cloth to cover your work bench (most important !)

11. Car wax polish (clear)

12. Paper masking tape

13. Denaturised alcohol, Acetone, or similar (for cleaning joints before gluing)

Adhesives:

Not all types of glues are suited to working with composite parts.

Here is a selection of what we normally use, and what we can truly

recommend. Please don’t use inferior quality glues - you will end up

with an inferior quality plane, that is not so strong or safe. Jet models

require good gluing techniques, due to the higher flying speeds, and

hence higher loads on many of the joints. We highly recommend that

you use a slow cured epoxy for gluing highly stressed joints, like the

hinges and control horns, into position and the most commonly used is

‘Aeropoxy’ (Bob Violett Models, USA). The self-mixing nozzles make

it easy to apply exactly the required amount, in exactly the right place, and

it will not run or flow onto places where you don’t want it! It takes about 1

- 2 hours to start to harden so it also gives plenty of time for accurate assembly. Finally it gives a superb bond on all fibreglass and wood surfaces. Of course there are many similar glues

available, and you can use you favorite type.

1. CA glue ‘Thin’ and ‘Thick’ types. We recommend ZAP, as this is a very high quality.

2. ZAP-O or Plasti-ZAP, odourless (for gluing the clear canopy)

3. 30 minute epoxy (stressed joints must be glued with 30 min and NOT 5 min epoxy).

4. Aeropoxy/Loctite Hysol 3462 or equivalent (optional, but highly recommended)

5. Epoxy laminating resin (12 - 24 hr cure) with hardener.

6. Milled glass fibre, for adding to slow epoxy for stronger joints.

7. Micro-balloons, for adding to epoxy for lightweight filling.

8. Thread-locking compound (Loctite, or equivalent)

At Skymaster we try our best to offer you a high quality kit,

with outstanding value-for money, and as complete as possible.

However, if you feel that some additional or different hardware

should be included, please feel free to let us know.

P-6

Page 7

Assembly & Operation Manual

HEALTH

Use a mask (available at auto paint stores) to protect from inhaling the glass or carbon

fiber dust. Use this mask whenever you are sanding or cutting fiberglass or

carbon fiber materials. Use a charcoal filter paint mask (available at auto paint supply

stores) when spraying any primer or paint. Spray out of doors or in a properly vented

spray booth. Use safety glasses any time rotary tools, such as Dremel cut-off disc or

Perma-Grit cutters, are being used.

GENERAL ASSEMBLY TECHNIQUES

We recommend to wax the model before assembling. This will help protect the finish

from an epoxy finger print. Wax will not help for CA glues!

Extra glue, extra paint, extra resin will add up to a heavy model. Plan before you glue!

The glass cloth side of parts to glue, should be sanded with #80 grit paper for best

glue adhesion.

Support the fuselage on foam pads.

Skymaster makes every attempt to insure that the parts fit. However, due to manufacturing tolerances, some parts may fit a little tight. Always trial fit parts and adjust if

needed.

Only use high quality adhesives such as the ZAP products from Pacer Technology.

For extremely high stress areas we recommend “Aeropoxy.” It is the strongest and

best gripping adhesive we have found.

If fuel or grease are on the surface, first clean with acetone or thinners.

Clean off all excess glue—excess glue is excess weight.

Always check the outside skin of the model to look for any glue residue and remove it

with Acetone before it cures. “Aeropoxy” is tough to remove once it has thoroughly

cured.

P-7

Page 8

Assembly & Operation Manual

Radio equipment

Failure to use the recommended servos, output arms, extensions, and hardware may result in a loss of control!

Throughout this manual we make use of various types of servos and radio equipment! We have used JR equipment

during the installation process. If you make use of

another manufacturer, please use equipment with similar specifications!

The Viper will require extension leads! Please use high quality extension leads. Make use of ceramic non ferrite

cores if leads exceeds 1 meter.

The trend nowadays is to use dual battery management systems and dual RX equipment. With the introduction of

2.4 Ghz even quad RX systems are considered as normal for a jet model.

Always center and install the correct output arms while on the bench, once the servo is in the aircraft access to the

servo arm screw is sometimes limited. The JR Matchbox makes this task very easy without using the complete

radio system on the work bench.

Do not save any money when buying radio equipment. The price of servo’s are far from the price of replacing the

entire model.

REMEMBER: The best equipment is only as good as the weakest link. Ask yourself if this servo or link or

lead etc is worthy of my trust to protect my very large investment...

Accessories

The full size F86 gear main gear doors are always closed. Accept when retracting. A special air or electronic sequencer is needed for this option.

1. 2 DS8511 servo’s for the elevator.

2. 1 DS8511 for rudder.

3. 2 DS8511 servo’s for ailerons

4. 2 DS8511 servo’s for flaps

5. 1 JR8511 steering servo.

6. 4 DS8401 servo’s for slats

7. 3 Standard JR577servos for Landing Gear, Door and Wheel Brake valves or check next line.

8. 1 Airpower EV5U valve + 1 x EV2U valve for landing gear + doors + brakes

9. 1 EV2U valve for speed brake

10. 1 EV2U valve for sliding canopy

11. 2 JR Matchbox for slats and flaps or Powerbox Royal with build in matchbox function.

12. Pneumatic support set for landing gear (air tubing, valves, Tee’s, fill valves, air tanks etc.)

13. Turbine motor, with thrust range between 16kg and 18kg, with ECU, fuel pump, battery and

solenoid valves, mounting strap etc. One of the common choices is the JetCat P160sx.

15. Fuel tubing, Hopper tank (or BVM UAT), festo fittings, fuel filters, fuel tube clamps etc.

16. Cable ties in various lengths. Cable management parts, Aluminum tape, safety clips etc.

Did you understand everything in this manual completely?

Then, and only then, let’s start assembling your F-86.

If not, please read it again before you start the assembly.

P-8

Page 9

Kit Contents

Assembly & Operation Manual

F86L ARF PRO Contents:

1. Right wing including L/G + Doors installed. Include flap + aileron + slat (F86L01)

2. Left wing including L/G + Doors installed. Include flap + aileron + slat (F86L02)

3. Canopy frame including sliding mechanism and cylinder (F86L03)

4. Fuselage front including nose gear + door installed. Including 3 door cylinders installed (F86L04)

5. Fuselage rear including speed brakes installed. Including 2 speedbrake cylinders (F86L05)

6. Fin + Rudder (F86L06)

7. Right stab incl elevator (F86L07)

8. Left stab incl elevator (F86L08)

9. Clear canopy glass (only on white model) (F86L09)

10. Carbon main spar (F86L11)

11. Inlet ducting (F86L10)

P-9

Page 10

OPTIONAL PARTS

Photo 1

3 x Air Tanks

1 x Retract Valve

2 x Filler & 2 x Pressure Gauges

1 x Electronic Brake Valve

5 x Air Tubing, 10 x Quick Disconnect

Assembly & Operation Manual

Sabre drop tanks.

Sabre pylons.

Fuel Tank (3) 5.4L

Photo 2

Pushrod Set

Photo 3

Photo 4

Airpower Oponal 5 in 1 Electronic

Valve & Sequencer

Control Brake, Gear and Doors

Photo 5

Stainless Steel Tail

Pipe

Cockpit

Photo 6

Photo 7

P-10

Page 11

Assembly & Operation Manual

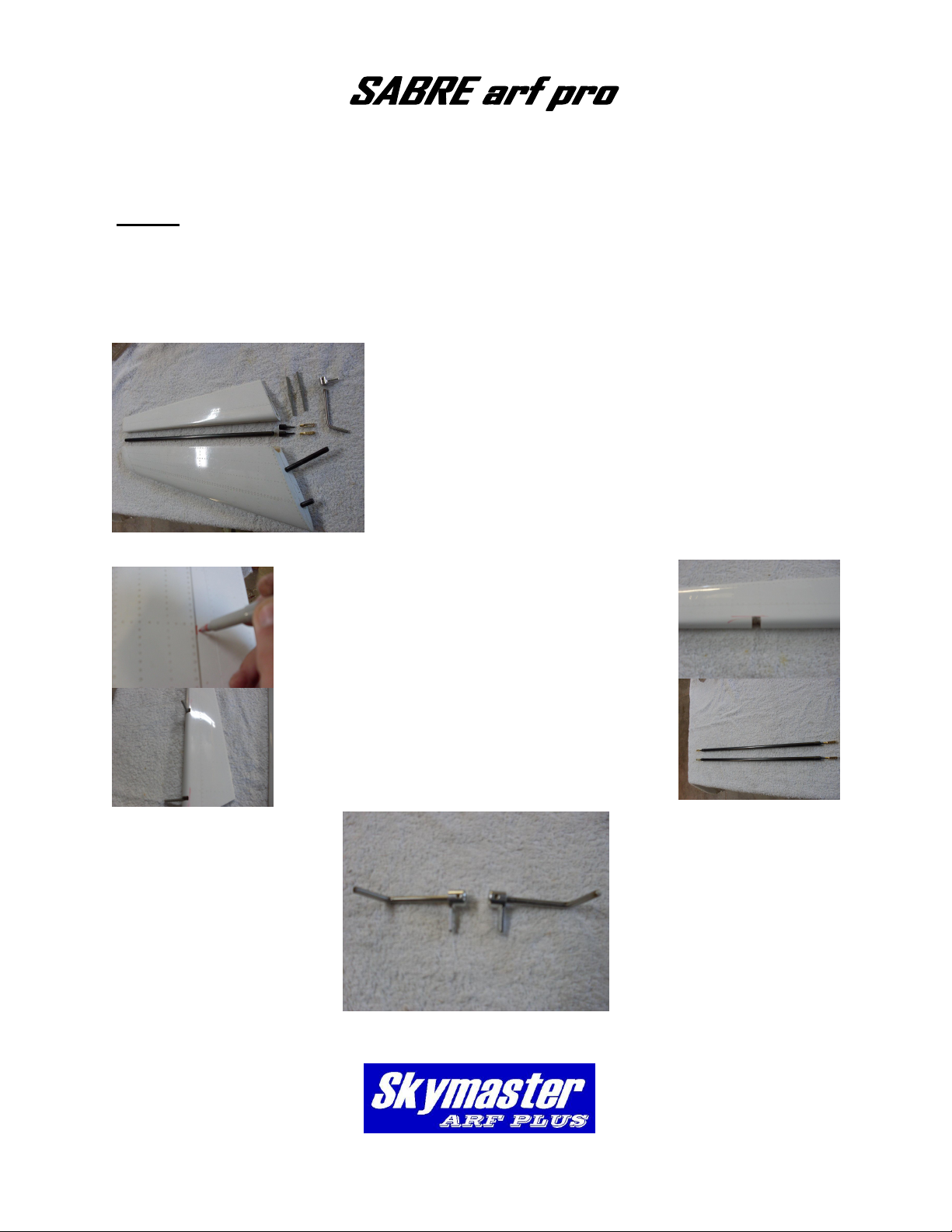

Photo 8

Bolts & Accessory pack

Belcrank wire

Servo mounng hardware

Photo 9

Belcranks (3)

Photo 10

Photo 11

Pin Hinges

Photo 12

Tygon Tubing

Tank Hardware

Photo 13

Photo 14

P-11

Page 12

Assembly & Operation Manual

CONTROL LINKAGES

Photo 15

WINGS

NOTE: Make sure to have some sort of protective

foam on the work bench. This will protect the paint

surface from unwanted dents. Assemble both

wings simultaneously. Mark √ each step.

Flaps : 80mm (2)

Aileron : 75mm (2)

Slats : 75mm (4)

Elevator : 500mm (2)

Rudder : 230mm

Steering: 50mm

Check operation of Landing gear and doors.

Remove factory self tapping screws and replace with high quality screws.

Inspect landing gear blocks. Make sure all

parts are glued.

plywood. Use dremel to clean out some glue

and ply to make sure servos will fit well.

Photo 17

Photo 16

Fit quick disconnects to air line.

Tighten brake drum.

Check the operation of brake

Remove flaps and slats from wing panel.

Remove and mark servo covers and inspect

P-12

Page 13

Assembly & Operation Manual

Fit 2 L-shape servo brackets to 2 x JR DS8511

(flap + aileron) and 2 x JR DS8401 (slats) servos.

All servos must be mounted with horns facing

down. For the flaps and slats the horn must be

closest to control surface and furthest away for

aileron.

Photo 18

Secure servo horns and centre servo’s with TX.

Secure 4 x extension wires. Use safety clips on joint.

Secure servo’s to wing. Use 4 servo screws.

Draw a line perpendicu-

lar to hinge line.

Photo 19

Mark off area for slat pushrod as indicted in photo 20.

Use file or dremel to open up hole. Repeat for other

slat servo.

Mark locaon of horns on slats.

Photo 20

Use Dremel to cut slot for control horns.

Use 30 minute epoxy to glue control horns

Aer epoxy cured, insert pushrods and secure safety

clips.

Check operaon of slats.

Secure servo covers with

x 1mm set screws.

Photo 22

P-13

4

Photo 21

Page 14

Assembly & Operation Manual

Draw line perpendicular across flap hinge line.

Cut hole in trailing edge of wing for flap pushrod.

Trial fit flap and mark locaon of horn on flap. (make

sure horn clear wing when flap in “up” posion.

Remove flap and cut slot for horn. Glue horn with 30

minutes epoxy.

Photo 23

Refit flap and cut slot for pushrod into flap leading

edge. Check operaon of flap for full movement without binding.

When happy glue flap hinges with 30 minute epoxy.

Tape flap in “up” posion while glue cure.

Take care not to get

any glue between wing and

flap. Wipe off all access glue.

Photo 24

Draw line perpendicular across aileron hinge line.

Mark locaon for pushrod and horn.

Carefully bend aileron open.

Photo 25

Cut

Cut hole for aileron pushrod.

Glue aileron horn in posion.

Insert pushrod and insert safety clips.

Check that aileron operate freely.

Secure servo covers for flaps and ailerons.

Repeat for other wing.

Cut round hole in root just to the back of main

spar. This hole for servo wires and air pipe.

Trial fit wings to fuselage and mark locaon of hole for servo wires.

Cut hole in fuselage.

slot for aileron horn.

P-14

Photo 26

Page 15

Assembly & Operation Manual

STABILIZERS

NOTE: Make sure to have some sort of protective foam on the work bench. This will

protect the paint surface from unwanted dents. Assemble both stabilizers simultaneously. All linkages are hidden. If you have a transport problem it maybe necessary to

remove stabilizers for transportation. If not then simply glue stabilizers to fuselage.

Mark √ each step.

Photo 27

Locate all parts for this section

Fit elevator to stabilizer and mark hinge line.

Cut slot in elevator for pin hinges. (Hinges pivot point

inside elevator)

Glue 3 pin hinges and secure to stabilizer. Take car

not to get glue on hinge point.

Locate 2 carbon tubes of equal length.

Make up pushrod of equal length.

Insert wire belcrank into belcrank pipes.

Mark location of belcrank in wire.

Photo 28

Photo 30

Remove and cut 3 flat slots into wire. (Note–

Belcrank must be fitted as close to side of fuselage. The wire must not be able to move sideways.

Secure belcrank to wire by means of 3 cap

crews. Use loctide.

Photo 32

P-15

Photo 29

Photo 31

Page 16

Assembly & Operation Manual

STABILIZERS

Feed pushrods through formers and secure to belcranks. Use safety clips.

Fit L-brackets to 2 x DS8511 servos.

Secure servos back to back on servo mount.

Secure pushrods to servos.

Photo 33

Check operation of elevator servos.

Make sure no slop in system.

Fit stabilizers to fuselage. The wire belcrank

must fit in slot to side of elevator. Check for

no slop. Check movement of elevators.

Photo 34

If you want to

removable, you will need to drill 2mm holes in

brass tubing holding carbon spar. Fit 2mm bolt

Photo 35

ble then simply glue stabilizer to fuselage and glue the wire belcrank to elevator.

NOTE : If you glue stabilizers it will not be possible to make fin removable. Fin will also

be glued to fuselage.

to hold stabilizer in position.

If you do not want to make stabilizer remova-

make stabilizer

P-16

Page 17

Assembly & Operation Manual

FIN & RUDDER

NOTE: Make sure to have some sort of protective

foam on the work bench. This will protect the paint

surface from unwanted dents. Mark √ each step.

Locate all parts needed

for this section.

Make up rudder push-

rod.

Photo 36 Photo 37

Fit wire belcrank in position. Fit belcrank over

wire and mark location of set srews.

Cut flat sections into wire and secure belcrank to wire with

loctide.

Fit servo to servo plate.

Feed pushrod through formers and secure pushrod to ser-

vo horn and belcrank. Use safety clips.

Photo 38

Make sure servo

horn and belcrank

form 90 degree angle.

Mark location of

pin hinges and cut

slots for hinges.

Note—the pivot point

is inside rudder leading edge.

Photo 39

and rudder.

Trial fit fin and rudder. If happy fin to fuselage.

NOTE: If fin is removable secure fin with cap screws located on 2 clamps.

Glue hinges to fin

P-17

Photo 40

Page 18

Assembly & Operation Manual

FUSELAGE

Make sure you have a good stand for fuselage. You will need to assemble the rest of the Sabre on this stand.

Locate the 4 x M5 bolts and washers for fuselage.

Align fuselage and secure with 4 bolts. Check fit

all around seem for sound joined.

Route 3 servo wires and 2 air lines neatly along

inner skin of rear fuselage.

Install servo male and female plugs for 3 servo wires.

Install 2 x quick disconnects for air line.

Photo 41

For transport the rear section is removable by

unscrewing and unplugging connections.

Turn fuselage upside down

Remove nose door bracket around oleo.

Remove the nose retract unit.

Install JR DS8511 steering

servo. Bolt with 4 x M3 bolts and lock nuts.

Centre servo and install pushrod.

Refit nose retract unit with good screws.

Refit nose door bracket around oleo.

Retract unit and check operation of unit. Close the

Photo 43

door and check clearance all around wheel.

Photo 42

P-18

Page 19

Assembly & Operation Manual

TAIL PIPE

Dril holes in mounting lugs of tail pipe.

Make 90 degree bend in each mounting lug.

Slide tail pipe through nose into position. Note: The

rear of pipe must just exit the rear former by 10mm.

Mark location of screws on turbine rail.

Dril pilot holes for self tap screws.

Secure pipe in position and glue end of pipe with

silicon glue to former.

Photo 44

Glue bellmouth with silicon glue.

FUEL CELLS

NOTE: Later versions of F86 have different tank configuraons.

This due to fact that all fuel before CG.

Rinse 3 fuel tanks and check for leaks.

Make up 3 fuel line fittings. Make sure clunk moves

freely and reaches all corners of inside of tank.

Fit to tanks. Mark pipes for “inlet” and “outlet”.

Rough the outside of tanks. Use silicon glue and glue 3

tanks in position.

Install turbine mount.

Plumb tanks using diagram

on next page.

Fill tanks and check for leaks.

Photo 45

Photo 46

Photo 47

Photo 48

Drain tanks with fuel pump and check no air bubbles

in system until last drop is drained. A good plumbing

will secure good turbine operation.

P-19

Page 20

Assembly & Operation Manual

FUEL CELL DIAGRAM

Photo 49

P-20

Page 21

Assembly & Operation Manual

AIR SYSTEM

Electronic. For mechanical you will need 4 x 2 way and 1 x 1way valve with 5

servos and sequencer. For electronic you will need 1 x EV5U and 2 x EV2U.

There are 2 options available for the air system: Mechanical or

Glue the air tanks with silicon glue in the front nose

section. I have installed the 1 large tanks for

operation of gears and doors.

Fit the 2 filler valves and 2 pressure gauges

onto accessory tray. Screw to wood and glue to

side of fuselage.

Photo 50

Photo 51

Photo 52

Plumb the landing gear, door and brake system

by using color air tubing. T all same color

tubing together until a single pipe emerge.

Fit electronic EV5U valve in front main tanks.

Route all 5 pipes to EV5U.

Plumb speed brake and canopy.

Secure 2 x 2way electronic valves adjacent to

EV5U. This will be for speed brake and canopy.

The air system will consist of :

Air up, Air down retracts (2)

Air up, Air down doors (2)

Air out brakes (1)

Air up, Air down speed brake (2)

Air up, Air down canopy (2)

Air in (2) Total of 11 pipes

Air leaks can damage your model! Please do a thorough check for air leaks. Make

sure the system can hold pressure for at least an hour in the up and down position.

Do not rush this installation.

P-21

Page 22

Assembly & Operation Manual

For scale functions such as speed brake and sliding canopy you will require additional 2 way electronic valves. The main doors in the fuselage will stay close before

and after retraction. This can easily be programmed with EV5U.

Photo 53 2 way

AIR DIAGRAM

Photo 54 Diagram for retracts

P-22

Page 23

Assembly & Operation Manual

Photo 55

Install fuel pump close to UAT. We recommend to make use of a mechanical shut off

valve as well.

TURBINE INSTALLATION

Please follow the instructions supplied

with your turbine.

Secure turbine to turbine rail via hatch

at bottom of fuselage. Leave gap of

25mm between NGV and tailpipe.

Run all turbine wires and power cables

on opposite side of servo wires.

Always secure all wires in harness. I

would suggest you install a FOD. This

will save you money in the long run.

Secure all Festo pipes with cable ties. Make

sure fuel filter and gas canister are mounted

vertical.

Install NiCad or Li Po battery in nose. I al-

ways put a fuse holder inline with power cable.

Photo 56 Photo 57

Trial fit inlet. When happy glue with silicon. NOTE: Make inlet removable for easy

maintenance.

P-23

Page 24

Assembly & Operation Manual

COCKPIT AND CANOPY (aer painng)

Check free operation of sliding canopy.

Plumb air line and fit 2 x quick

disconnects.

Fit rear cockpit to sliding floor.

Photo 58

Photo 60

Trace the shape of rear canopy and cut

to fit. Glue with canopy glue.

Trace front canopy and cut to fit. Glue

with canopy glue. Check operation of

sliding canopy.

Cut rear cockpit frame to clear cockpit

tub ( photo 61)

Cut front canopy frame to clear cockpit

tub (photo 62)

Photo 59

Photo 61

Photo 62

Slide cockpit in place. It sits on inlet duct.

Fit canopy. Check free sliding of frame.

Photo 64

Photo 63

P-24

Page 25

Assembly & Operation Manual

EQUIPMENT INSTALLATION INTO SABRE

Equipment installation is a personal venture. There is one golden rule: Do it as neat

and logical as possible! This will make faultfinding and service of components easier. The Sabre basically consist of 6 circuits!

1. Servo wires

2. Power cables

3. Data cables

4. Pneumatic pipes

5. Fuel pipes

6. RX cable / Satellite Receivers

Please try and separate these circuits as far as possible. It is advisable not to run RX

cables near any kind of electrical fields. Make all switches and filler valves and charging sockets easy accessible

The Sabre will come out tail heavy if you do not plan installation. It is very important

to install all equipment as far forward as possible.

I have installed 2 x RX + 2 X ECU batteries around inlet ring (photo 65). This is

weight of 1.2 kg together.

I have installed a UAT next to the nose gear retract. This will always be full of fuel

and will help with the final adjustment of CG.

Please wire the accessory tray outside aircraft. It is designed to slide and lock in

position. (note—tidy up wires unlike me :-))

.

Photo 65 Photo 66

P-25

Page 26

Assembly & Operation Manual

BEFORE YOU FLY

It is assumed that the builder of this kit has acquired the basic skills and knowledge

necessary to make a safe and functional radio control installation into a model.

Therefore, these notes are intended only to assist that experience.

When inserting the main spar into wing, make sure it only enters the amount required.

If you can slide complete main spar into 1 half of wing, it means the stopper were removed. Please measure correct distance for main spar and secure spar so that it does

not slide more to one side than other. It must be symmetrical to both sides.

Travel adjust measured at root. Use Expo to suite your style.

1. Elevator 25mm 2. Rudder 25mm

3. Aileron 20mm 4. Flaps take off 35mm

5. Flaps landing 65mm 6. Slats 30mm

NOTE : Make sure flaps travel same. Flaps should be deployed in landing circuit only

below 90mph. On prototype flaps and slats were mixed together. If you require separate operation a separate switch will be needed.

CG 390mm –410mm from leading edge at root. Empty tanks, UAT full

and wheels down. The CG can be changed to best fit your flying

style. A forward position is safe and nose heavy configuration. .

WARNING: Do not move CG back unless you are experience

and have some feel of model before!

Weight Dry weight will be between 40 and 45 lbs depending equipment.

PSI 80—100 psi for pneumatic system

Power Make use of battery management system. Double up on batteries

and make sure all wired can carry current needed to operate.

TX RX Do a complete range check before flight. Do this with turbine

running. Follow manufacturers instructions.

Speed Set the maximum speed to 180mph! The prototype were tested

with Jetcat P-160 turbines. More powerful turbines require extra

care and extra reinforcing.

Timer A timer can safe your model. Get into the habit of programming

the timer.

P-26

Page 27

Assembly & Operation Manual

Take-Off

Do some taxi tests before your flight! Make sure you are familiar with all settings and

make sure the model track straight on the ground without rudder input.

Choose a fine day for the maiden flight. Do not force a maiden flight!

Murphy will visit you!

Select take off flap or flight mode 1 and open throttle. Gently pull back on stick 50m

down the runway. Raise the flaps and gear at safe altitude and let the model sit on

rails.

Slow Flight

Most of the first flight should be utilized to get familiar with the slow speed flight characteristics. Select the flaps to the takeoff position; there should be no pitch change. Extend the gear and select full landing flaps; adjust the power to maintain level flight and

a speed of about 80—90mph.

Climb to a safe altitude and slow the model to the edge of a stall to know where that

edge is.

Landing

Fly a complete circuit before landing. Approach from the downwind side and lower the

LG. Fly a complete circuit getting use to the power required. On the next circuit lower

the flaps. If you have a headwind be very careful not to get below the power curve on

the downwind side. Do not use speed brakes for landing on maiden. When you are

happy and more experienced the speedbrakes will slow model down faster.

Align the model and use throttle to control the descent! The elevators will stay very active even at low speed. Flare the model just before touch down. Let the model roll out

and apply brakes.

Taxi back and do necessary adjustments to customize Sabre for your need!

We at Skymaster wish you many happy flights with your Sabre! Add some more scale

options like drop tanks etc. Before and after landing slide open canopy for extre realism. Add landing lights and machine guns and your Sabre will be just like real thing.

Anton Lin and Skymaster Team!

P-27

Page 28

Assembly & Operation Manual

OPTIONAL SCALE PARTS

The following items are available from Details4Scale. Please contact them on their

online web store: www.details4scale.com

Gun bay.

Photo 67

Photo 69

Photo 68

Photo 70

Speed brake tub

Wing tip antenna

Fuel dump post

Scale light system

Retractable landing light

Bombs and missile rack

P-28

Loading...

Loading...