Page 1

GENERAL

-J02028 REV. 2010-09-07

REMOTE CONTROL GARAGE DOOR OPENER KITS

Kit Numbers

91558-01A (Transmitter/Receiver Kit), 91561-01 (Transmitter

Kit), 91562-01 (Receiver Kit)

Models

For model fitment information, see the P&A retail catalog or

the Parts and Accessories section of www.harley-davidson.com

(English only).

Additional Parts Required

2011 and later Softail models will require separate purchase

of an Electrical Connection Harness (Part No. 72673-11).

Tools and Supplies Required

Electrical Contact Lube (Part No. 99861-02) or equivalent is

required after battery cable disconnection.This item is available

from a Harley-Davidson dealer.

The rider's safety depends upon the correct installation

of this kit. Use the appropriate service manual pr ocedures.

If the procedure is not within your capabilities or you do

not have the correct tools, have a Harle y-Da vidson dealer

perform the installation. Improper installation of this kit

could result in death or serious injury. (00333a)

NOTE

This instruction sheet refers to service manual information. A

service manual for this year/model motorcycle is required for

this installation and is available from a Harley-Da vidson dealer .

Electrical Overload

It is possible to overload your vehicle's charging system

by adding too many electrical accessories. If the combined

electrical accessories operating at any one time consume

more electrical current than the vehicle's charging system

can produce, the electrical consumption can discharge

the battery and cause damage to the vehicle's electrical

system. See an authorized Harley-Davidson dealer for

advice about the amount of current consumed by additional electrical accessories or for necessary wiring

changes. (00211c)

When installing any electrical accessory, be certain not

to exceed the maximum amperage rating of the fuse or

circuit breaker protecting the affected circuit being modified. Exceeding the maximum amperage can lead to electrical failures, which could result in death or serious injury .

(00310a)

The Remote Control Transmitter in kits 91558-01A and 9156101 requires up to 0.5 Amps additional current from the electrical

system.

Kit Contents

See Figure 27, Table 1, Table 2 and Table 3.

FCC NOTICES

NOTE

Changes or modifications to this unit not expressly approved

by the manufacturer could void the user's authority to operate

the equipment.

This equipment has been tested and found to comply with the

limits for Class B digital devices pursuant to Par t 15, Subpart

B of the FCC Rules. These limits are designed to provide

reasonable protection against harmful interference in a residential environment.This equipment generates, uses, and can

radiate radio-frequency energy, and if not installed and used

in accordance with the instruction manual, may cause harmful

interference to radio communications. However, there is no

guarantee that interference will not occur in a particular

installation.

If this equipment does cause harmful interference to radio or

television reception, which can be determined by turning the

equipment off and on, the user is encouraged to try to correct

the interference by one or more of the following measures:

• Re-orient or relocate the receiving antenna.

• Increase the distance between the equipment and the

receiver.

• Connect the equipment to an outlet on a circuit different

from that to which the receiver is connected.

• Consult the dealer or an experienced radio/TV technician

for help.

-J02028 1 of 16

Page 2

RECEIVER INSTALLATION

is06654

Kits 91558-01A and 91562-01 only

1. Unplug the power cord from the garage door drive unit to

prevent door activation during installation.

2. Select an unswitched 110V power outlet in the garage

located either highest in the garage, closest to the front

of the garage, or both. Plug the Harley-Davidson remote

control garage door opener receiver (14) into this outlet.

NOTE

For some brands of garage door opener systems, it may

be necessary to plug in the Harley-Davidson receiver at a

location some distance from the door opener. With those

systems, if the Harley-Davidson receiver is plug ged in too

close to the original opener receiver, the effective transmission range may be significantly reduced on both systems.

3. Find the two garage door activation switch ter minals at

one of the following locations:

• The existing wall-mounted, hard-wired garage door opener

button.

• The garage door drive unit to which the garage door

opener button is connected.

4. See Figure 27. Fasten the stripped end of the HarleyDavidson garage door opener receiver cable assembly

(15) to the door opener terminals that activate the door

opener drive unit. Ref er to the door opener manuf acturer's

documentation for terminal locations and connections.

NOTE

Do not remove the wires originally connected to the door

opener button or drive unit terminals.

5. Assemble and install the garage door opener button or

door opener drive unit in the original location.

6. Route the Harley-Davidson garage door opener receiver

cable assembly connected in Step 4 to the power outlet

selected in Step 2.

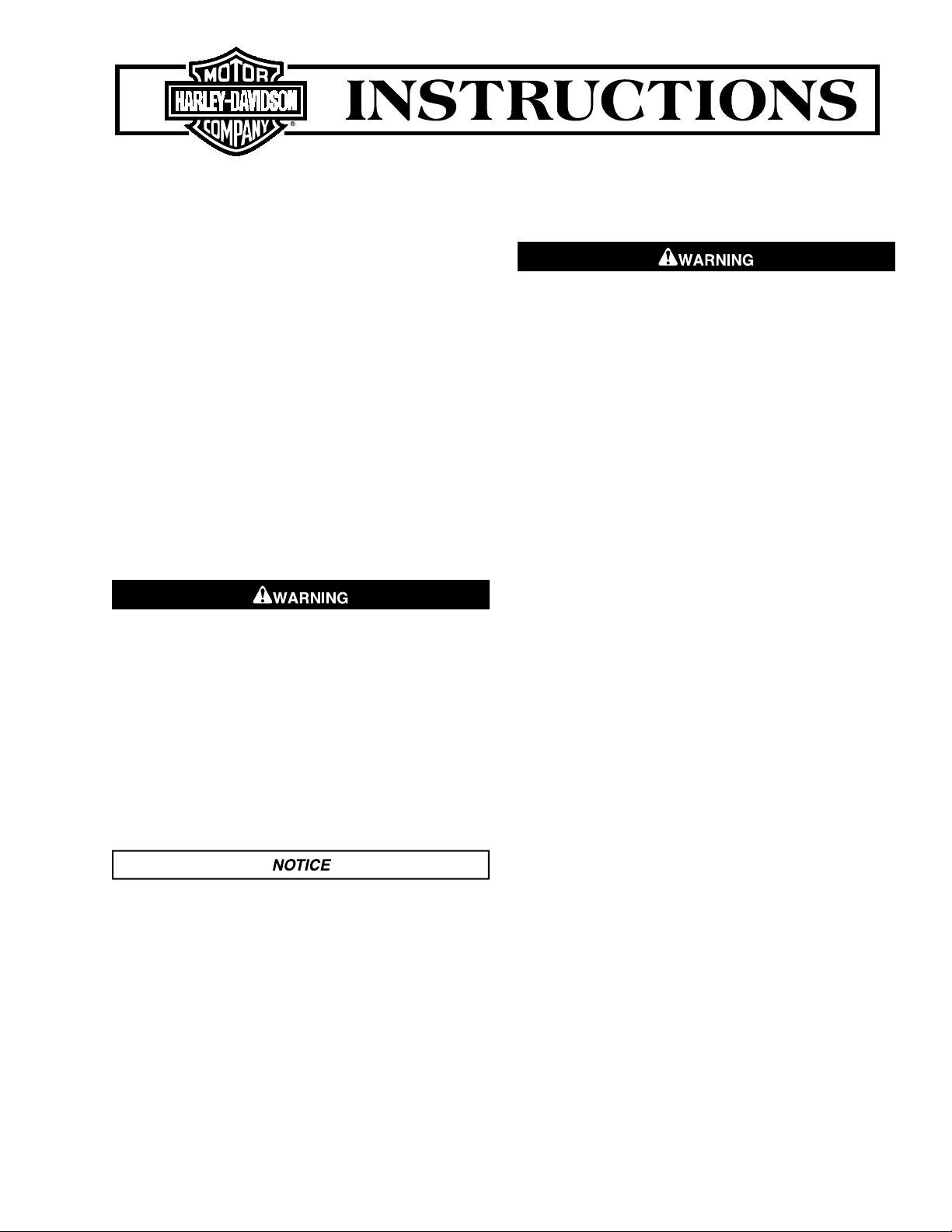

7. See Figure 1. Plug the connector on the Harley-Da vidson

garage door opener receiver cable assemb ly into the back

of the Harley-Davidson garage door opener receiver in

the location shown.

8. Plug the garage door opener receiver into the selected

power outlet. Plug the power cord from the garage door

drive unit into the power outlet.

9. Press the wall-mounted garage door opener button to test

the button operation.

VEHICLE PREPARATION

NOTE

For vehicles equipped with security siren:

• Verify that the Hands-Free Fob is present.

• Turn the ignition key switch to IGNITION.

For V-Rod models only:

Remove the air box aluminum cover per service manual

instructions.

For EFI models EXCEPT V-Rod:

To prevent spray of fuel, purge system of high-pressure

fuel before supply line is disconnected. Gasoline is

extremely flammable and highly explosive, which could

result in death or serious injury. (00275a)

Follow service manual instructions to purge the fuel supply of

high pressure gasoline and remove the fuel supply line.

For ALL vehicles with main fuse:

T o prevent accidental vehic le start-up, whic h could cause

death or serious injury, remove main fuse before proceeding. (00251b)

1. Refer to the service manual and follow the instructions to

remove the main fuse.

All models except V-Rod: Remove and retain the seat

and all mounting hardware.

For vehicles with main circuit breaker:

T o prevent accidental vehic le start-up, whic h could cause

death or serious injury, disconnect negative (-) battery

cable before proceeding. (00048a)

1. Refer to the service manual and follow the instructions to

remove the seat and disconnect the negative (black) battery cable from the negative (-) battery terminal. Retain all

seat mounting hardware.

For Carbureted Models:

Gasoline can drain from the carburetor fuel line when

disconnected from fuel valve fitting. Gasoline is extremely

Figure 1. Garage Door Opener Receiver, Back View

-J02028 2 of 16

flammable and highly explosive, which could result in

death or serious injury.Wipe up spilled fuel immediately

and dispose of rags in a suitable manner. (00256a)

2. Turn the fuel supply valve to OFF. Remove the fuel line

from the valve.

Page 3

For Dyna, Softail and Sportster models:

1

3

2

is06667

3

1

2

is06668

When servicing the fuel system, do not smoke or allow

open flame or sparks in the vicinity . Gasoline is extremely

flammable and highly explosive, which could result in

death or serious injury. (00330a)

3. The fuel tank must be removed or slightly raised to access

wiring underneath. See the correct section (Carbureted

or EFI Engine) of the service manual for fuel tank bolt

removal instructions.

If the fuel tank must be removed, follo w the instructions

in the service manual to remove the instrument console

(if equipped) from the fuel tank before removing the tank.

TRANSMITTER INSTALLATION

Kits 91558-01A and 91561-01 only

NOTE

Transmitter effective range may vary between motorcycle

models. For best garage door opener range, position the

transmitter on the motorcycle as far as possible from large

metal surfaces.

For best garage door opener performance, keep the transmitter and wires as far from vehicle heat sources as possible

Do not cover the view of the circuitry on the transmitter when

fastening the foam tape retainer pad to the transmitter or

mounting the transmitter to the vehicle. A red LED on the circuitry side must remain visible for programming the receivertransmitter. For best adhesion, use isopropyl alcohol to clean

the surfaces to which the tape pad will mount.

1. See Figure 27. Remove the liner from the adhesive

backing on one side of the tape pad (3). Carefully position

the pad to the plastic casing of the transmitter (1), and

press firmly into place.

2. Find specific model instructions in the sections that follow .

Dyna Models

1. Remove the fuel tank mounting bolts. See the correct

section (Carbureted or EFI Engine) of the service manual.

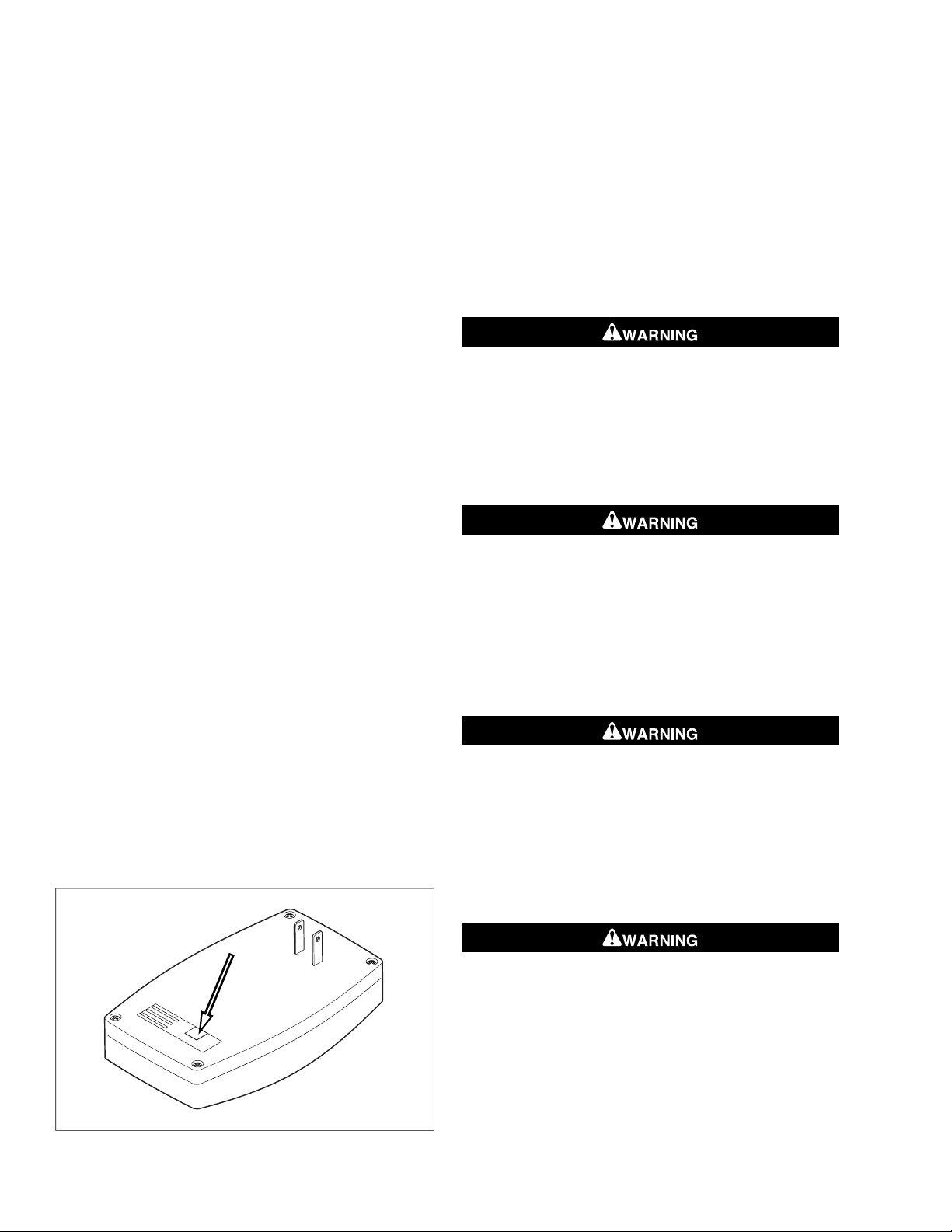

2. See Figure 2. Use cable straps to fasten the transmitter

to the Dyna wire harness (3), located under the seat and

near the battery compartment. Route the transmitter wires

forward along the right side of the frame.

Proceed to the Harness Connection section.

1. Orange/white wire

2. Ground connection

3. Strap transmitter to wire harness

Figure 2.Transmitter Mounting (Dyna)

1999 and Earlier Softails

1. Remove the fuel tank mounting bolts. See the correct

section (Carbureted or EFI Engine) of the service manual.

2. See Figure 3. Remove the ground screw (1), located on

the top of the frame, under the seat near the fuel tank.

3. See Figure 27. Use cable straps (8) from the kit to fasten

only the transmitter case and the short section of

conduit to the motorcycle wires leading forward toward

the headlamp.

Proceed to the Harness Connection section.

-J02028 3 of 16

1. Ground connection

2. Garage opener transmitter

3. Orange/white wire

Figure 3.Transmitter Mounting (1999 and Earlier Softails)

Page 4

2000 and Later Softails, Except Deuce (FXSTD)

2

3

1

is06711

4

3

2

1

is06712

3

1

2

4

is06713

1. Remove the fuel tank mounting bolts. See the correct

section (Carbureted or EFI Engine) of the service manual.

2. Remove the rear splash guard (inner fender) per service

manual instructions.

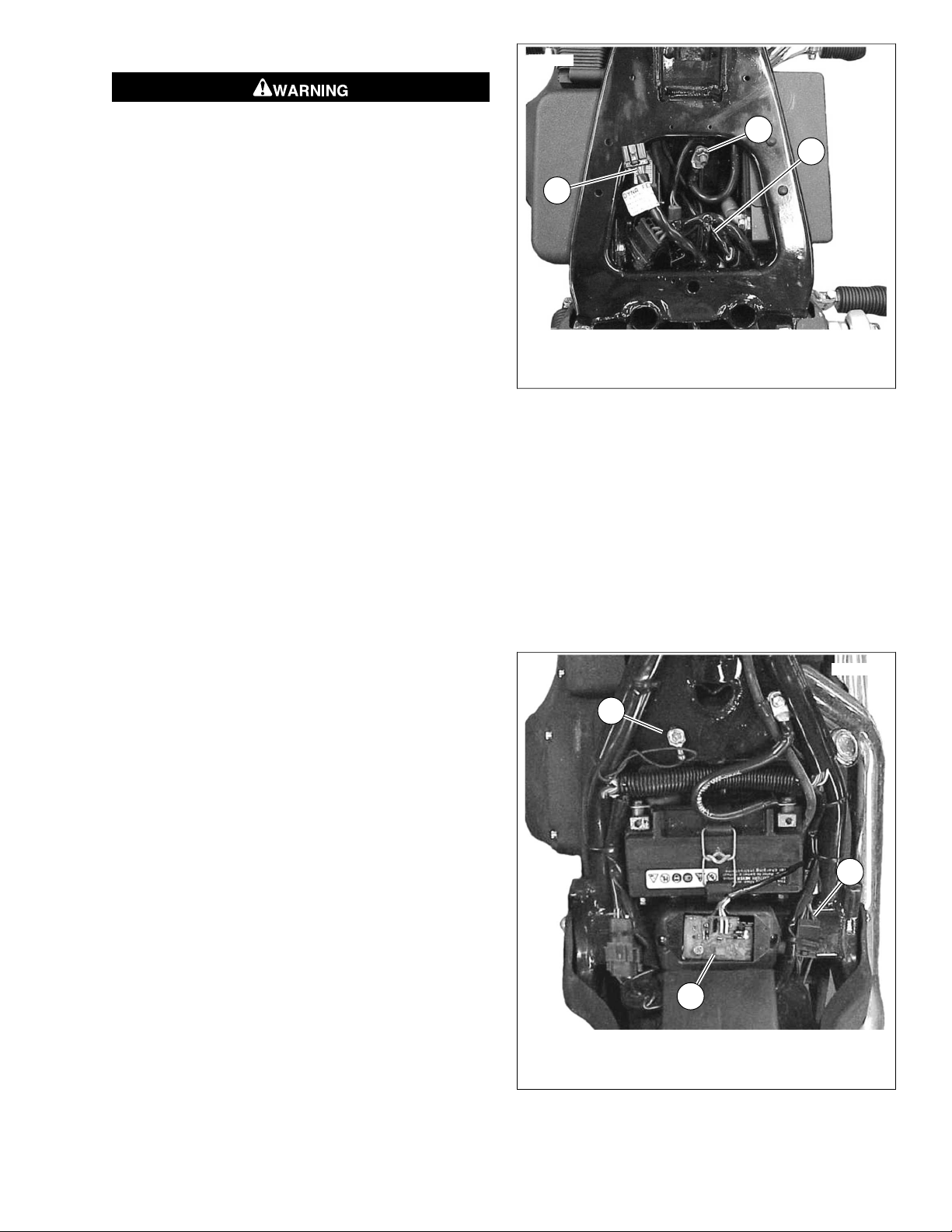

3. See Figure 4. Use cable straps from the kit to fasten the

transmitter (3) to the wire harness located between the

frame, rear fork (2), and rear tire (1).

4. See Figure 5. Route the transmitter wires (2) up to the

battery compartment (4) and along the r ight side of the

frame.

Proceed to the Harness Connection section.

2000 and Later Softail Deuce (FXSTD)

1. Remove the fuel tank mounting bolts. See the correct

section (Carbureted or EFI Engine) of the service manual.

2. Remove the liner from the adhesive backing of the tape

pad on the transmitter.

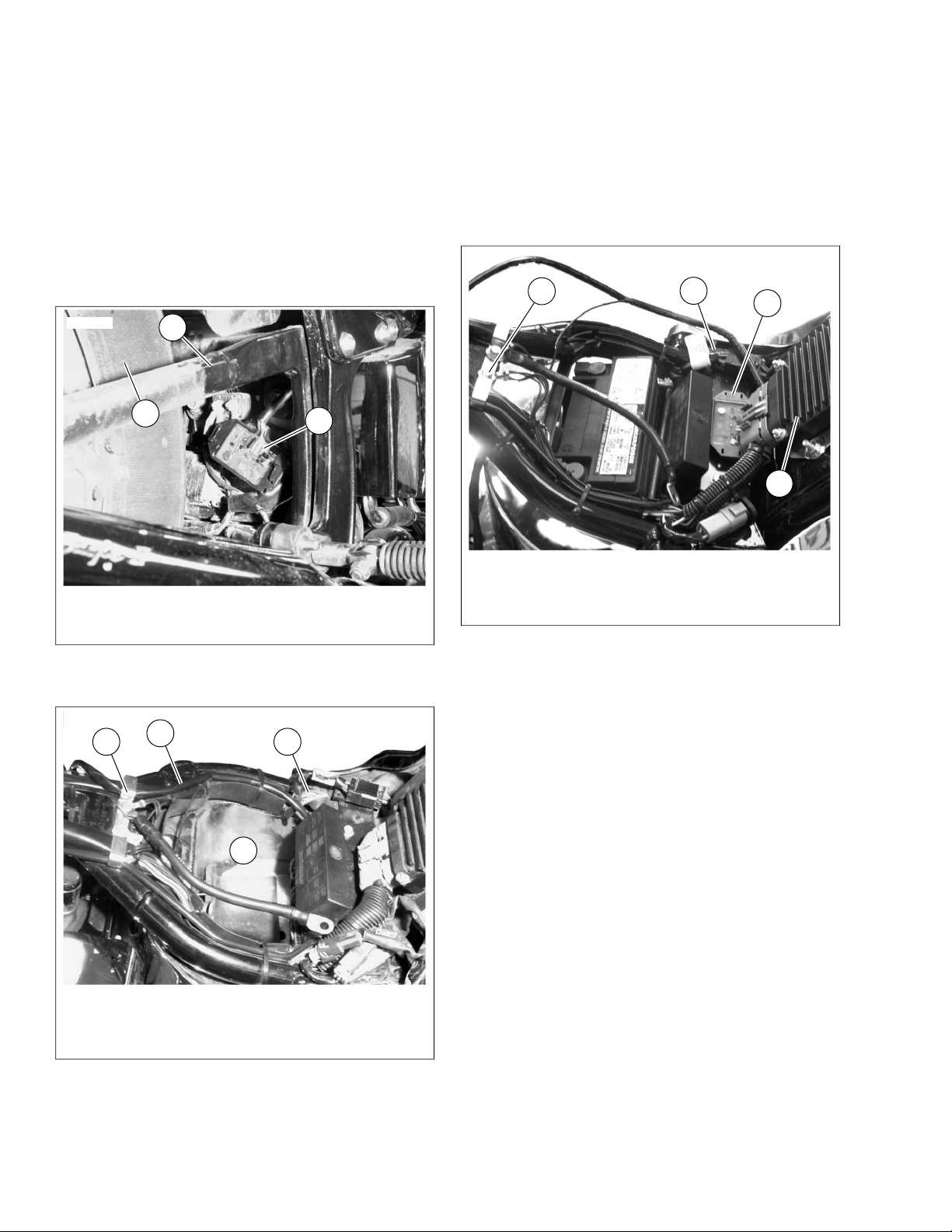

3. See Figure 6. Mount the transmitter to the surface below

the ECM/ignition module. Route the tr ansmitter wires forward along the right side of the frame.

Proceed to the Harness Connection section.

1. Rear wheel and tire

2. Rear fork

3. Transmitter

Figure 4.Transmitter Mounting, 2000 and Later Softails,

Except Deuce (FLSTC Shown)

1. Ground connection

2. Transmitter wires to headlamp

3. Orange/white wire

4. Battery compartment (reference)

Figure 5. P o wer and Gr ound Connections, 2000 and Later

Softails (FLSTC Shown)

1. Ground connection

2. Orange/white wire

3. Transmitter

4. ECM/ignition module

Figure 6.Transmitter Mounting, 2000 and Later Deuce

1994-2003 Sportster Models

1. Remove the fuel tank. See the correct section (Carbureted

or EFI Engine) of the service manual.

2. See Figure 7. Position the transmitter (1) to the main wire

harness in the area under the seat, as far as possible from

the oil tank, and fasten the transmitter to the harness using

cable straps from the kit.

Proceed to the Harness Connection section.

-J02028 4 of 16

Page 5

3

1

2

is06715

1. Transmitter mounting location

is06716

4

6

5

3

2

1

is06717

2. Wires to headlamp

3. Ignition module

Figure 7.Transmitter Mounting and Wire Routing, (2003

or Earlier Sportster Models)

2004 and Later Sportster Models

1. Remove the fuel tank. See the correct section (Carbureted

or EFI Engine) of the service manual.

2. Remove the electrical side cover, located on the left side

of the motorcycle near the battery.

3. See Figure 27. Position the transmitter (1) behind the

electrical side cover. Orient the transmitter so the printed

circuit side faces away from the battery, and fasten the

transmitter to the wire harness next to the main fuse holder

using cable straps (8) from the kit.

Proceed to the Harness Connection section.

FLHR Touring Models

1. Remove the headlamp from the nacelle per the instructions

in the service manual.

2. Remove the liner from the adhesive backing of the tape

pad on the transmitter.

3. See Figure 8. Mount the transmitter to the right side of the

frame near the fork tube.

Proceed to the Harness Connection section.

Figure 8.Transmitter Mounting Near Fork Tube (FLHR)

FLHT , FLHX and FLTR Touring Models;Trike Models

1. Remove the outer fairing per the instructions in the service

manual.

2. Remove the liner from the adhesive backing of the tape

pad on the transmitter.

3. See Figure 9 (FLHT, FLHX models) or Figure 10 (FLTR

models). Mount the transmitter to the upper inside of the

fairing.

Proceed to the Harness Connection section.

1. Mount transmitter to fairing

2. Headlamp connector

3. Orange/white wire

4. Black wire

5. White wire

6. Yellow wire

Figure 9.Wires for Transmitter Connections (FLHT/X)

-J02028 5 of 16

Page 6

1

5

6

2

3

4

is06718

1. Mount transmitter to fairing

1

3

2

is06720

1

3

2

is06721

1

2

is06722

2. Headlamp connector

3. Orange/white wire

4. Black wire

5. White wire

6. Yellow wire

Figure 10.Wires for Transmitter Connections (FLTR)

2002-2003 V-Rod Models

1. See Figure 11. Remove the screw (3) fastening the front

left louvered cover (1) to the motorcycle. Lift the louvered

cover off the tabs (2) to remove the cover.

2. See Figure 12. Use cab le ties to f asten the transmitter (1)

to the motorcycle wire casing (2) as shown.

Proceed to the Harness Connection section.

1. Transmitter

2. Tie transmitter cable to wire casing

3. Connector with black (ground) and orange wires

Figure 12.Transmitter Mounting (2002-2003 V-Rod Only)

2007 and Later V-Rod Models

1. See Figure 11. Remove the screw (3) fastening the front

left louvered cover (1) to the motorcycle. Lift the louvered

cover off the tabs (2) to remove the cover.

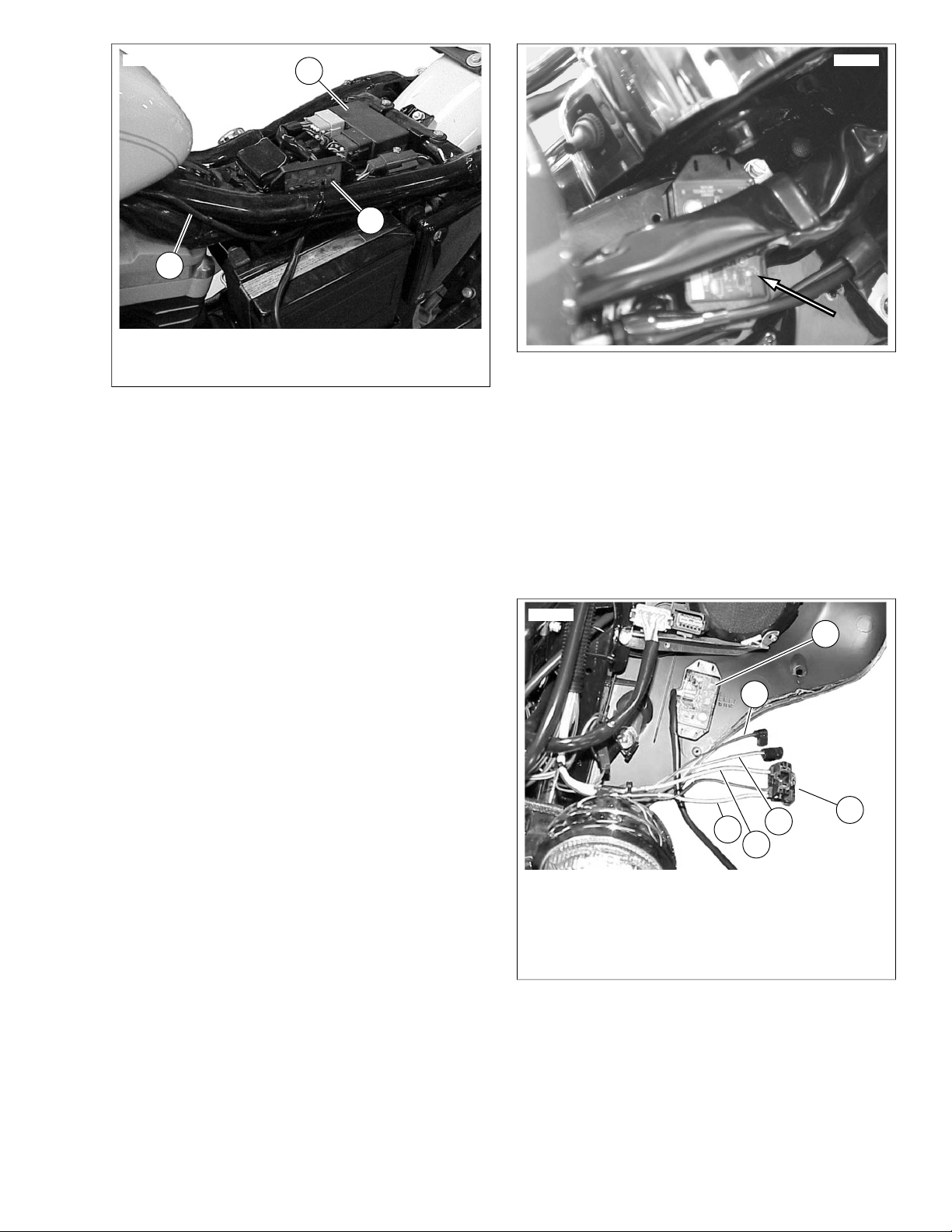

2. See Figure 13. Remove the air box cover. Rotate the

transmitter (1) so the exposed circuit side faces up. Tuck

the transmitter under the fuse block wire harnesses. Use

two cable straps from the kit through the flanges of the

transmitter to secure the transmitter to the fuse block

harnesses.

Proceed to the Harness Connection section.

1. Transmitter

2. Fuse block wire harness (2)

Figure 13.Transmitter Mounting (2004 and Later V-Rod)

1. Louvered cover

2. Tab (2)

3. Screw

Figure 11. Left-Side Louvered Cover (2002-2003 V-Rod

Shown)

-J02028 6 of 16

Page 7

HARNESS CONNECTION

1

3

2

4

is06725

General

Splicing of wire leads is necessary in the installation of the

garage door opener to the vehicle. Find the instructions for a

specific model in the sections that follow, and refer to the service manual appendix for proper wire splicing procedures.

9. Insert the rubber boot into the open pin connector of the

Electrical Connection Harness.

10. Loosen or remove the four scre ws holding the ECM to the

mounting bracket. Route the Electrical Connection Harness

under the ECM connector. Tighten the four screws to

45-55 in-lbs (5.1-6.2 Nm).

11. Proceed to the Yellow and White Lead Connections

section for the specific model.

Be sure to follow manufacturer's instructions when using

the UltraT orch UT-100 or any other radiant heating de vice.

Failure to follow manufacturer's instructions can cause a

fire, which could result in death or serious injury . (00335a)

• Avoid directing heat toward any fuel system component.

Extreme heat can cause fuel ignition/explosion resulting

in death or serious injury.

• Avoid directing heat toward any electrical system component other than the connectors on which heat shrink

work is being performed.

• Always keep hands a way from tool tip area and heat shrink

attachment.

For 2011 and later Softail models: Proceed to the following

section.

For Touring and Trike models: Proceed to that section.

For ALL OTHER models: Proceed to Black Lead Connection

for the specific model.

2011 and Later Softail Models

NOTES

Requires separate purchase of Electrical Connection Harness

(H-D Part No. 72673-11).

Electrical connectors are identified in the service manual by

the number and letter shown here within brackets.

1. Locate the Digital Technician connector [91A] (a gra y sixway Deutsch pin connector with a rubber boot) under the

seat. Place the Electrical Connection Harness at connector

[91A], but DO NOT connect at this time.

2. Route the garage door opener wires over to the Electrical

Connection Harness. Remov e the orange/white wire from

the conduit. Cut the orange/white and black wires to a

suitable length to easily reach the sealed splice connectors

on the Electrical Connection Harness. DO NOT cut the

yellow or white wires.

3. Splice the black garage door opener wire to the black

wires in the Electrical Connection Harness.

4. Splice the orange/white garage door opener wire to the

red/yellow wires in the Electrical Connection Harness.

5. Use a heat gun or suitable radiant-heating device to shrink

the connector to the wires.

6. Use the heat gun or heating device to seal the open end

of the sealed splice connector on the red/blue wires in

the Electrical Connection Harness.

7. Pull the rubber boot out from the gray Digital Technician

pin connector [91A]. Cut the boot off of the wires.

8. Connect the socket housing of the Electrical Connection

Harness to connector [91A].

Touring and Trike Models

1. Cut the yellow, white and orange/white transmitter wires

to about the same length as the transmitter black ground

wire. Cut to allow enough wire to easily strip and splice

the wires.

1. Black (ground) wire

2. Yellow wire

3. White wire

4. Orange/white wire

Figure 14.Wires for Transmitter Connections (FLHR)

2. FLHR Touring Models: See Figure 14. Cut the yellow

(2), black (1) and white (3) headlamp wires inside the

nacelle, staggering the lengths a bit to avoid all three

splices being together.

FLHT and FLHX Touring and T rike Models: See Figure

9. Cut the yellow (6), black (4) and white (5) headlamp

wires inside the fairing, staggering the lengths a bit to

avoid all three splices being together.

FLTR Touring Models: See Figure 10. Cut the yellow

(6), black (4) and white (5) headlamp wires inside the

fairing, staggering the lengths a bit to avoid all three

splices being together.

ALL Touring/T rike Models: Slide the wov en wire conduit

from the kit (see Figure 27, Item 9) over all three headlamp

wires.

3. See Figure 15, the 2 into 1 splice configuration. Use a red

sealed splice connector (Figure 27, Item 4) from the kit to

splice the black garage door opener transmitter wire to

the black wires from the headlamp.Trim back the transmitter wire harness casing as needed to assist splicing.

-J02028 7 of 16

Page 8

1

2

3

is02055a

1. 1 into 1 splice

2. 2 into 1 splice

3. 3 into 1 splice

Figure 15. Splice Configurations

NOTE

Electrical connectors are identified in the service manual by

the number and letter shown here within brackets.

4. Use the remaining red sealed splice connector to splice

the orange/white transmitter wire to the orange/white wire

on the unused position lamp connector [29B]:

• For FLHR Touring Models, tied to the main harness

inside the nacelle.

• For ALL OTHER Touring/Trike Models, tied to the

interconnect harness near the headlamp.

5. See Figure 27. Use a blue sealed splice connector (5)

from the kit to splice the white transmitter wire to the white

headlamp wires. Use the remaining blue sealed splice

connector to splice the yellow transmitter wire to the yello w

headlamp wires.

6. Slide the wire conduit over the splice area of the three

headlamp wires.

7. Proceed to the Receiver and T ransmitter Pr ogramming

section to program the garage door opener controls.

BLACK LEAD CONNECTION TO GROUND

2. See Figure 27. Select the correct ring terminal (6 or 7)

from the kit to fit the ground screw.

3. Cut the black wire on the garage door opener wire harness

to easily reach the ground location, and crimp the ring

terminal to the end of the wire per the Packard crimping

tool instructions in the service manual appendix.

4. See Figure 5. Install the ring terminal onto the ground

screw threads. Fasten the ground screw to the frame and

secure per the torque specification in the service manual.

5. Proceed to the Orange/White Lead Connection section

for the specific model.

Sportster Models

1. Remove the electrical side cover, located on the left side

of the motorcycle near the battery.

2. Route the garage door opener wire harness through the

top of the frame under the seat to the circuit breaker located on the inside of the electrical side cover.

3. See Figure 16. Remove the ground screw (1), located:

• Under the seat on some 1996-2003 models, or

• Near the swingarm on 1995 or earlier models, and 1996-

2003 models without a screw under the seat.

• On the engine near the starter on 2004 and later models.

4. See Figure 27. Select the correct ring terminal (6 or 7)

from the kit to fit the ground screw.

5. Cut the black wire on the garage door opener wire harness

to easily reach the ground location, and crimp the ring

terminal to the end of the wire per the Packard crimping

tool instructions in the service manual appendix.

6. Install the ring terminal onto the ground screw threads.

Fasten the ground screw at the original location, and

secure per the torque specification in the service manual.

7. Proceed to the Orange/White Lead Connection section

for the specific model.

Dyna Models

1. Remove the nut from the ground stud, located on the top

of the frame, under the seat near the fuel tank.

2. See Figure 27. Select the correct ring terminal (6 or 7)

from the kit to fit the ground stud.

3. See Figure 2. Cut the b lack ground wire (2) on the gar age

door opener wire harness to easily reach the ground location, and crimp the ring terminal to the end of the wire per

the Packard crimping tool instructions in the service

manual appendix.

4. Install the ring terminal to the ground connection, and

secure per the torque specification in the service manual.

5. Proceed to the Orange/White Lead Connection section

for the specific model.

2010 and Earlier Softail Models

1. Remove the ground screw , located on the top of the fr ame,

under the seat near the fuel tank.

-J02028 8 of 16

Page 9

1

1

is01103

1. Ground screws (black wire)

Figure 16. Ground Connections (Sportster Models)

2002-2003 V-Rod Models

1. Cut the black transmitter ground wire to within easy reach

of one of the ground screws located on the engine cam

covers. Remove the ground screw.

2. See Figure 27. Select the 1/4 in. (6.4 mm) ring terminal

(7) from the kit. Crimp the ring terminal onto the black

transmitter wire per the Packard crimping tool instructions

in the service manual appendix.

3. Fasten the ring terminal to the engine with the ground

screw, and secure per the torque specification in the service manual.

4. Proceed to the Orange/White Lead Connection section

for the specific model.

2004 and Later V-Rod Models

1. See Figure 15, the 2 into 1 splice configuration. Use a red

sealed splice connector (Figure 27, Item 4) from the kit to

splice the black wire (13) from the kit to the black transmitter ground wire according to the instructions in the

service manual appendix.

Slip the conduit (10) from the kit over the spliced ground

wire.

2. Route the ground wire and conduit along the motorcycle

frame to the left of the air box, next to the main harness

to a location under the left-side louvered cover.

3. Cut the black transmitter ground wire and conduit to within

easy reach of one of the ground studs located on each

end of the battery ground cable.

4. Select the 1/4 in. (6.4 mm) ring terminal (7) from the kit.

Crimp the ring terminal onto the black transmitter wire per

the Packard crimping tool instructions in the service

manual appendix.

5. Fasten the blac k wire ring terminal to the negative terminal

mounting post on the battery.Tighten the terminal fastener

to 60-96 in-lbs (7-10 Nm).

6. Proceed to the Orange/White Lead Connection section

for the specific model.

ORANGE/WHITE LEAD CONNECTION TO SWITCHED POWER SOURCE

Use the service manual wiring diagrams for a specific model

and year vehicle to locate a power source that is fed through

the ignition switch.

2003 and Earlier Dyna Models

The garage door opener switched power source is an

orange/white (O/W) main harness power lead under the seat

or inside the side cover.

1. Remove the electrical side cover, located on the left side

of the motorcycle near the battery.

2. See Figure 2. Carefully slice open an area of the main

harness wrap under the seat or inside the side cover at

an accessible point, and cut an orange/white main harness

power lead.

3. Pull only the orange/white wire out of the longer piece of

conduit on the garage door opener wire harness. Cut the

excess length from the orange/white wire to within easy

reach of the cut orange/white wires on the main vehicle

harness.

4. See Figure 15, the 2 into 1 splice configuration. Use a red

sealed splice connector (Figure 27, Item 4) from the kit to

splice the garage door opener wire harness power lead

to the main harness orange/white wires per the instructions

in the service manual appendix.

5. Proceed to the Yellow and White Lead Connections

section for the specific model.

2004 and Later Dyna Models

The garage door opener switched power source is an open

fuse position on the fuse panel. See the FUSES section of the

service manual and the correct wiring diagram in the service

manual appendix.

1. Remove the electrical side cover, located on the left side

of the motorcycle near the battery, b y firmly grasping both

sides and pulling outward.

2. Remove the electrical panel from the vehicle per service

manual instructions.

3. See Figure 27. Get the orange/white fuse block adapter

wire (12) from the kit. Note the terminal on each end (see

Figure 17). Only the terminal with the spring tabs will fit

into this fuse block. Carefully cut the unused terminal from

the wire and discard it.

4. See Figure 18. Locate the fuse cavity (1) indicated as

"OPEN" on the fuse block cover in the right fuse block.

Insert the terminal on the orange/white adapter wire until

it stops. Refer to a nearby factory installed terminal for

comparison to verify proper orientation and depth.

-J02028 9 of 16

Page 10

5. Pull only the orange/white wire out of the longer piece of

2

3

1

is02589

is06515

is06516

conduit on the garage door opener wire harness. Cut the

excess length from the orange/white wire to within easy

reach of the adapter wire.

6. See Figure 15, the 1 into 1 splice configuration. Use a

blue sealed splice connector (Figure 27, Item 5) from the

kit to splice the garage door opener wire harness power

lead to the adapter wire per the instructions in the service

manual appendix.

7. See Figure 27. Install the 2A fuse (11) from the kit into the

"OPEN" fuse cavity to complete the circuit.

8. Install the electrical panel per the instructions in the service

manual. Install the electrical panel cover by aligning the

pins with the rubber bushings in the electrical panel and

pushing firmly into place.

9. Proceed to the Yellow and White Lead Connections

section for the specific model.

1. CUT this terminal from wire

2. LEAVE this terminal on wire

3. Spring tabs (2)

Figure 17. Fuse Block Adapter Wire (Dyna and Softail)

Figure 18. "OPEN" Fuse Block Ca vity (2004 and Later Dyna)

2003 and Earlier Softail Models

The garage door opener switched power source is the

orange/white (O/W) wire in the tail lamp harness under the

seat.

1. See Figure 2. Carefully slice open an area of the tail lamp

harness (1) wrap at an accessible point under the seat,

and cut the orange/white wire.

2. Pull only the orange/white wire out of the longer piece of

conduit on the garage door opener wire harness. Cut the

excess length from the orange/white wire to within easy

reach of the cut orange/white wires under the seat.

3. See Figure 15, the 2 into 1 splice configuration. Use a red

sealed splice connector (Figure 27, Item 4) from the kit to

splice the garage door opener wire harness power lead

to the cut orange/white wires per the instructions in the

service manual appendix.

4. Proceed to the Yellow and White Lead Connections

section for the specific model.

2004-2010 Softail Models

The garage door opener switched power source is an open

fuse position on the fuse panel. See the FUSES section of the

service manual and the correct wiring diagram in the service

manual appendix.

1. Remove the fuse block cover. Remove the two hex head

screws fastening the fuse block bracket, and pull the

bracket and fuse block assembly away from the vehicle

frame.

2. Press the tab retaining the left fuse block, and slide the

block out of the mounting slots.

3. See Figure 27. Get the orange/white fuse block adapter

wire (12) from the kit. Note the terminal on each end (see

Figure 17). Only the terminal with the spring tabs will fit

into this fuse block. Carefully cut the unused terminal from

the wire and discard.

4. See Figure 19. Locate the fuse cavity (1) indicated as

"P&A IGN" on the fuse block cov er in the right fuse bloc k.

Insert the terminal on the orange/white adapter wire until

it stops. Refer to a nearby factory installed terminal for

comparison to verify proper orientation and depth.

5. Pull only the orange/white wire out of the longer piece of

conduit on the garage door opener wire harness. Cut the

excess length from the orange/white wire to within easy

reach of the adapter wire.

6. See Figure 15, the 1 into 1 splice configuration. Use a

blue sealed splice connector (Figure 27, Item 5) from the

kit to splice the garage door opener wire harness power

lead to the adapter wire per the instructions in the service

manual appendix.

7. See Figure 27. Install the 2A fuse (11) from the kit into the

"P&A IGN" fuse cavity to complete the circuit.

8. Slide the fuse block into the mounting slots in the fuse

block bracket until it clicks firmly into place. Install the

bracket and fuse block assembly into position and fasten

with the two hex head screws removed earlier. Tighten

securely.

9. Proceed to the Yellow and White Lead Connections

section for the specific model.

Figure 19. "P&A IGN" Fuse Block Ca vity (2004-2010 Softail)

Sportster Models

The garage door opener switched power source is an

orange/white (O/W) main harness power lead inside the electrical side cover or under the seat.

-J02028 10 of 16

Page 11

NOTE

1

2

is01106

2

3

1

is06729

2

1

is06730

On some Sportster models the ignition module must be

removed to access the orange/white wire in the main harness.

1. See Figure 20. Carefully slice open an area of the main

harness wrap inside the electrical side cover or under the

seat at an accessible point, and cut an orange/white main

harness power lead.

1. Left side cover containing circuit breaker silver

terminal (red wire)

2. Stock wire harness (orange/white wire)

Figure 20. Power Connections (Sportster Models)

1. Connector [29A] with orange/white wire

2. White headlamp wire

3. Yellow headlamp wire

Figure 21.Wire Splice Locations (2002-2003 V-Rod)

2. Pull only the orange/white wire out of the longer piece of

conduit on the garage door opener wire harness. Cut the

excess length from the orange/white wire to within easy

reach of the cut orange/white wires inside the side cover

or under the seat.

3. See Figure 15, the 2 into 1 splice configuration. Use a red

sealed splice connector (Figure 27, Item 4) from the kit to

splice the garage door opener wire harness power lead

to the main harness orange/white wires per the instructions

in the service manual appendix.

4. Proceed to the Yellow and White Lead Connections

section for the specific model.

2002-2004 V-Rod Models

NOTE

Electrical connectors are identified in the service manual by

the number and letter shown here within brackets.

1. See Figure 21 or Figure 22. Cut the orange/white main

vehicle harness wire near the unused position lamp connector [29A] (1).

2. Pull only the orange/white wire out of the longer piece of

conduit on the garage door opener wire harness. Cut the

excess length from the orange/white wire to within easy

reach of the cut orange/white wires at connector [29A].

3. See Figure 15, the 2 into 1 splice configuration. Use a red

sealed splice connector (Figure 27, Item 4) from the kit to

splice the garage door opener wire harness power lead

to the main harness orange/white wires per the instructions

in the service manual appendix.

4. Proceed to the Yellow and White Lead Connections

section for the specific model.

1. Connector [29A] with orange/white wire

2. Headlamp harness

Figure 22.Wire Splice Locations (2004 V-Rod)

2005 and Later V-Rod Models

NOTE

Electrical connectors are identified in the service manual by

the number and letter shown here within brackets.

1. See Figure 23. Cut the orange/white main vehicle harness wire near the headlamp pin connector [38A] (1).

2. Pull only the orange/white wire out of the longer piece of

conduit on the garage door opener wire harness. Cut the

excess length from the orange/white wire to within easy

reach of the cut orange/white wires at connector [38A].

3. See Figure 15, the 2 into 1 splice configuration. Use a red

sealed splice connector (Figure 27, Item 4) from the kit to

splice the garage door opener wire harness power lead

to the main harness orange/white wires per the instructions

in the service manual appendix.

4. Proceed to the Yellow and White Lead Connections

section for the specific model.

-J02028 11 of 16

Page 12

1

is06731

1. Headlamp connector [38]

is06726

Figure 23.Wire Splice Locations (2005 and Later V-Rod)

YELLOW AND WHITE LEAD CONNECTIONS TO HEADLAMP

Dyna Models

1. See Figure 24. Use cab le str aps from the kit to fasten the

remaining transmitter wires (yellow and white) and conduit

to the motorcycle wires leading to the headlamp. Lift the

fuel tank as needed to feed the wires under the tank and

toward the headlamp.

kit to splice the white transmitter wire to the white headlamp wires. Use the remaining blue sealed splice connector to splice the yellow transmitter wire to the yellow

headlamp wires.

5. Proceed to the Receiver and T ransmitter Pr ogramming

section to program the garage door opener controls.

Softail Models

1. Use cable straps from the kit to fasten the remaining

transmitter wires (yellow and white) and conduit to the

motorcycle wires leading to the headlamp. Lift the fuel

tank as needed to feed the wires under the tank and

toward the headlamp.

NOTE

For 2011 and later Softail models, the headlamp circuit wires

in the vehicle harness are blue with a white or yellow tracer,

rather than solid white and solid yellow as described in the

following steps.

2. Cut the yellow and white wires in the main vehicle harness

headlamp circuit at an accessible point. Cut excess length

from the yellow and white transmitter wires if necessary.

Trim back the transmitter wire harness casing as needed

to assist splicing. Cut to allow enough wire to easily str ip

and splice the wires.

3. Slide the woven wire conduit (9) from the kit over the

yellow and white transmitter wires.

4. See Figure 15, the 1 into 1 splice configuration. Use a

blue sealed splice connector (Figure 27, Item 5) from the

kit to splice the white transmitter wire to the white headlamp wires. Use the remaining blue sealed splice connector to splice the yellow transmitter wire to the yellow

headlamp wires.

5. Slide the woven wire conduit over the yellow and white

wire connections after splicing.

6. Proceed to the Receiver and T ransmitter Pr ogramming

section to program the garage door opener controls.

Figure 24.Transmitter Wire Routing to Headlamp (Dyna)

2. Route the wires into the headlamp housing through the

grommet on the lower rear of the housing.

NOTE

To route the transmitter wires through the grommet, push a

hooked piece of wire through the grommet from the inside of

the headlamp housing.

A light coat of liquid soap, window cleaner or all-purpose lubricant may be needed to pull the wires back through the

grommet with the hooked wire.

In some applications the transmitter wires may not fit through

the headlight housing grommet. In that case, the wires must

be spliced outside the headlamp housing.

3. Cut the yellow and white wires in the headlamp housing

several inches from the headlamp connector. Cut excess

length from the yellow and white transmitter wires if

necessary. Cut to allow enough wire to easily strip and

splice the wires.

4. See Figure 15, the 1 into 1 splice configuration. Use a

blue sealed splice connector (Figure 27, Item 5) from the

Sportster Models

1. Route the remaining transmitter wires (yellow and white)

and conduit through the top of the frame under the fuel

tank and up to the headlamp. Use cable straps from the

kit to fasten the wires to the harness.

2. Route the wires into the headlamp housing through the

grommet on the lower rear of the housing.

NOTE

To route the transmitter wires through the grommet, push a

hooked piece of wire through the grommet from the inside of

the headlamp housing.

A light coat of liquid soap, window cleaner or all-purpose lubricant may be needed to pull the wires back through the

grommet with the hooked wire.

In some applications the transmitter wires may not fit through

the headlight housing grommet. In that case, the wires must

be spliced outside the headlamp housing. See Figure 25.

-J02028 12 of 16

Page 13

2

1

is06727

1. White and yellow headlamp wires

2. Cut headlamp wire casing to access wires

Figure 25.White and Yellow Wire Optional External Splice

Location (Sportster Models)

3. Cut the yellow and white wires in the headlamp housing

several inches from the headlamp connector. Cut excess

length from the yellow and white transmitter wires if

necessary. Cut to allow enough wire to easily strip and

splice the wires.

4. See Figure 15, the 1 into 1 splice configuration. Use a

blue sealed splice connector (Figure 27, Item 5) from the

kit to splice the white transmitter wire to the white head-

lamp wires. Use the remaining blue sealed splice connector to splice the yellow transmitter wire to the yellow

headlamp wires.

5. Proceed to the Receiver and T ransmitter Pr ogramming

section to program the garage door opener controls.

V-Rod Models

1. Cut the yellow and white wires in the main vehicle harness

headlamp circuit at an accessible point several inches

from the headlamp connector. Cut e xcess length from the

yellow and white transmitter wires if necessary.Trim back

the transmitter wire harness casing as needed to assist

splicing. Cut to allo w enough wire to easily strip and splice

the wires.

2. See Figure 27. Slide the woven wire conduit (9) from the

kit over the yellow and white transmitter wires.

3. See Figure 15, the 1 into 1 splice configuration. Use a

blue sealed splice connector (Figure 27, Item 5) from the

kit to splice the white transmitter wire to the white headlamp wires. Use the remaining blue sealed splice connector to splice the yellow transmitter wire to the yellow

headlamp wires.

4. Slide the woven wire conduit over the yellow and white

wire connections after splicing.

5. Install the front left louvered cover onto the motorcycle.

6. Proceed to the Receiver and T ransmitter Pr ogramming

section to program the garage door opener controls.

-J02028 13 of 16

Page 14

RECEIVER AND TRANSMITTER

1

2

is06733

PROGRAMMING

After the receiver and transmitter are installed, the receiver

must be programmed to receive the transmitter frequency.This

process may require two people, depending upon how f ar apart

the receiver and transmitter are during the programming process.

NOTE

V erify that the ignition key s witch is in the OFF position bef ore

installing the main fuse or attaching the negative battery cable.

1. Models with main fuse: Refer to the service manual and

follow the instructions to install the main fuse.

Models with main circuit breaker: Refer to the service

manual and follow the instructions to attach the negative

battery cable.

Apply a light coat of Harley-Davidson electrical contact

lubricant (Part No. 99861-02), petroleum jelly or corrosion

retardant material to the negative battery terminal.

2. Check that a red LED is illuminated on the front of the

Harley-Davidson garage door opener receiver (in the

garage), indicating power to the receiver.

3. See Figure 26. Press and hold the SET button on the

Harley-Davidson garage door opener receiver.The LED

on the transmitter (on the vehicle) blinks continuously

while the SET button is pressed.

1. SET button

2. LED

Figure 26. Garage Door Opener Receiver, Front View

4. Turn the ignition key switch to IGNITION, but do not start

the vehicle. Operate the headlamp beam switch using one

of these sequences:

• With the headlamp on LO beam, switch to HI, then LO.

• With the headlamp on HI beam, switch to LO, then HI.

When the receiver acquires a signal from the transmitter, the

LED on the transmitter turns off.

5. Release the SET button on the receiver.

Be sure that all lights and switches operate properly bef ore

operating motorcycle. Low visibility of rider can result in

death or serious injury. (00316a)

NOTE

Clear all obstructions away from between the transmitter and

receiver before testing the operation of the gar age door opener.

6. Test the garage door opener, and headlamp high beam

and low beam operation.

NOTE

When the transmitter is activated by toggling the headlamp

switch, the red LED on the transmitter illuminates for one

second to indicate that the transmitter is functioning correctly.

After installing seat, pull upward on seat to be sure it is

locked in position. While riding, a loose seat can shift

causing loss of control, which could result in death or

serious injury. (00070b)

7. Refer to the service manual, and follow instructions to

install or close the seat.

8. Turn the ignition key switch to OFF.

9. Install any parts that were removed for transmitter install-

ation.

TROUBLESHOOTING

Headlamp Switch Tog gled, but Garage Door Opener Does Not Function.

With the ignition key switch turned to IGNITION:

1. Does the LED on the vehicle transmitter flash when the

headlamp switch is toggled?

• YES. Proceed to Step 2.

• NO. Proceed to Step 3.

2. Does the LED on the garage-mounted receiver flash once

when the signal is transmitted from the vehicle?

• YES. Proceed to Step 4.

• NO. Proceed to Reset the Receiver.

3. Verify proper connections to the vehicle power wires,

headlamp wires and ground.

4. See Receiver Installation near the front of these

instructions.

a. Verify that the receiver is properly wired to the

existing garage door opener unit.

b. Verify that the receiver is spaced a sufficient dis-

tance from the existing garage door opener receiver.

Reset the Receiver

1. Unplug the receiver from the 110 Volt power outlet.

2. Wait ten seconds.

3. Press and hold the program button on the receiver , While

holding the button down, plug the receiver into the po wer

outlet.The red LED will flash rapidly.

4. Release the program button. The receiver is now reset,

and all memory is erased.

5. Program the receiver again. See the Receiver and

Transmitter Programming section earlier in these

instructions.

-J02028 14 of 16

Page 15

SERVICE PARTS

2b 2a

3

8

6

4

1

7

5

14

10

11

15

13

12

9

is06735

Figure 27. Service Parts, Remote Control Garage Door Opener Kits

Table 1. Service Parts, Garage Door Opener Kit 91558-01A

3

• Foam tape, double-sided, 1.0 inch (25.4 mm) x 1.5 inch (38.1 mm)

4

• Sealed splice connector, #18-20 AWG (red) (2)

5

• Sealed splice connector, #14-16 AWG (blue) (2)

6

• Ring Terminal, #18-22 AWG, for 5/16 inch (7.9 mm) stud

7

• Ring Terminal, #18-22 AWG, for 1/4 inch (6.4 mm) stud

8

• Cable strap, black, 7.75 inch (20 cm) long (8)

9

• Wire conduit, woven polyester, 3.0 inch (76 mm) long

10

• Wire conduit, #8 x 2.75 ft. (0.84 M) long (for 2004 and later V-Rod models)

11

• Fuse, blade type, 2 Amp

12

• Fuse block adapter wire, orange/white

13

• Wire, insulated, black, #20 AWG, 34 inch (0.86 M) long

Part NumberDescription (Quantity)Item

Not sold separatelyTransmitter assembly1

91650-01AHardware kit (includes items 3 through 13)2a

Not sold separately

70585-93

70586-93

9859

9858

10006

70599-02

Not sold separately

54305-98

70329-04

Not sold separately

91560-01Receiver assembly14

Not sold separatelyReceiver cable assembly15

-J02028 15 of 16

Page 16

SERVICE PARTS

Table 2. Service Parts,Transmitter Kit 91561-01

3

• Foam tape, double-sided, 1.0 inch (25.4 mm) x 1.5 inch (38.1 mm)

4

• Sealed splice connector, #18-20 AWG (red) (2)

5

• Sealed splice connector, #14-16 AWG (blue) (2)

6

• Ring Terminal, #18-22 AWG, for 5/16 inch (7.9 mm) stud

7

• Ring Terminal, #18-22 AWG, for 1/4 inch (6.4 mm) stud

8

• Cable strap, black, 7.75 inch (20 cm) long (8)

9

• Wire conduit, woven polyester, 3.0 inch (76 mm) long

Table 3. Service Parts, Receiver Kit 91562-01

Part NumberDescription (Quantity)Item

Not sold separatelyTransmitter assembly1

91650-01Hardware kit (includes items 3 through 9)2b

Not sold separately

70585-93

70586-93

9859

9858

10006

70599-02

Part NumberDescription (Quantity)Item

91560-01Receiver assembly14

Not sold separatelyReceiver cable assembly15

-J02028 16 of 16

Loading...

Loading...