Page 1

Owner’s Manual

Guide d’utilisation

Manual del propietario

Model/ Modelo/ Modèle: RT1322-00

14 Amp Plunge and Fixed Base Router

Toupie à base xe et en plongée de 14 A

Rebajadora de 14 amperios con base ja y base de

penetración

WARNING: To reduce the risk of injury, the user must read and understand the

Owner’s Manual before using this product. Save these instructions for future reference.

AVERTISSEMENT : Afin de réduire les risques de blessure, l’utilisateur doit lire et

comprendre le guide d’utilisation avant d’utiliser cet article. Conservez le présent guide

afin de pouvoir le consulter ultérieurement.

ADVERTENCIA : Para reducir el riesgo de lesiones, el usuario debe leer y comprender

el Manual del operador antes de utilizar este producto. Guarde estas instrucciones para

consultarlas en caso sea necesario.

For Customer Service

Pour le service à la clientèle

Servicio al cliente

1-877-SKIL-999 OR www.skil.com

Page 2

TABLE OF CONTENTS

General Power Tool Safety Warnings .............................3-4

Safety Warnings for Router .....................................5-6

Symbols .....................................................7-9

Get to Know Your Router ..................................... 10-11

Specications .................................................11

Operating Instructions .......................................12-30

Maintenance ................................................31-32

Extension Cords ...............................................32

Troubleshooting ...............................................32

Limited Warranty of SKIL Consumer Tools ..........................33

WARNING

•

Some dust created by power sanding, sawing, grinding, drilling and other construction

activities contains chemicals known to the State of California to cause cancer, birth defects

or other reproductive harm. Some examples of these chemicals are:

–

Lead from lead-based paints.

–

Crystalline silica from bricks, cement, and other masonry products.

–

Arsenic and chromium from chemically-treated lumber.

•

Your risk from these exposures varies, depending upon how often you do this type of work.

To reduce your exposure to these chemicals:

–

Work in a well-ventilated area.

–

Work with approved safety equipment, such as dust masks that are specially designed to

lter out microscopic particles.

–

Avoid prolonged contact with dust from power sanding, sawing, grinding, drilling, and

other construction activities. Wear protective clothing and wash exposed areas with soap

and water. Allowing dust to get into your mouth or eyes or to lie on the skin may promote

absorption of harmful chemicals.

2

Page 3

GENERAL POWER TOOL SAFETY WARNINGS

WARNING

below may result in electric shock, re and/or serious injury.

Read all safety warnings, instructions, illustrations and specications

provided with this power tool.

Failure to follow all instructions listed

SAVE ALL WARNINGS AND INSTRUCTIONS FOR FUTURE

REFERENCE.

The term “power tool” in the warnings refers to your mains-operated (corded) power tool or

battery-operated (cordless) power tool.

Work area safety

Keep work area clean and well lit

Do not operate power tools in explosive atmospheres, such as in the presence of

ammable liquids, gases or dust.

fumes.

Keep children and bystanders away while operating a power tool.

you to lose control.

. Cluttered or dark areas invite accidents.

Power tools create sparks which may ignite the dust or

Distractions can cause

Electrical safety

Power tool plugs must match the outlet. Never modify the plug in any way. Do not use

any adapter plugs with earthed (grounded) power tools.

outlets will reduce risk of electric shock.

Avoid body contact with earthed or grounded surfaces, such as pipes, radiators,

ranges and refrigerators.

or grounded.

Do not expose power tools to rain or wet conditions.

increase the risk of electric shock.

Do not abuse the cord. Never use the cord for carrying, pulling or unplugging the power

tool. Keep cord away from heat, oil, sharp edges or moving parts.

cords increase the risk of electric shock.

When operating a power tool outdoors, use an extension cord suitable for outdoor use.

Use of a cord suitable for outdoor use reduces the risk of electric shock.

If operating a power tool in a damp location is unavoidable, use a ground fault circuit

interrupter (GFCI) protected supply.

There is an increased risk of electric shock if your body is earthed

Use of a GFCI reduces the risk of electric shock.

Unmodied plugs and matching

Water entering a power tool will

Damaged or entangled

Personal safety

Stay alert, watch what you are doing and use common sense when operating a power

tool. Do not use a power tool while you are tired or under the inuence of drugs,

alcohol or medication.

serious personal injury.

Use personal protective equipment. Always wear eye protection.

such as a dust mask, non-skid safety shoes, hard hat or hearing protection used for

appropriate conditions will reduce personal injuries.

Prevent unintentional starting. Ensure the switch is in the off-position before

connecting to power source and/or battery pack, picking up or carrying the tool.

Carrying power tools with your nger on the switch or energising power tools that have the

switch on invites accidents.

Remove any adjusting key or wrench before turning the power tool on.

key left attached to a rotating part of the power tool may result in personal injury.

Do not overreach. Keep proper footing and balance at all times.

control of the power tool in unexpected situations.

A moment of inattention while operating power tools may result in

Protective equipment

A wrench or a

This enables better

3

Page 4

Dress properly. Do not wear loose clothing or jewellery. Keep your hair and clothing

away from moving parts.

parts.

If devices are provided for the connection of dust extraction and collection facilities,

ensure these are connected and properly used.

related hazards.

Do not let familiarity gained from frequent use of tools allow you to become complacent

and ignore tool safety principles

of a second.

Loose clothes, jewellery or long hair can be caught in moving

Use of dust collection can reduce dust-

. A careless action can cause severe injury within a fraction

Power tool use and care

Do not force the power tool. Use the correct power tool for your application.

power tool will do the job better and safer at the rate for which it was designed.

Do not use the power tool if the switch does not turn it on and off.

cannot be controlled with the switch is dangerous and must be repaired.

Disconnect the plug from the power source and/or remove the battery pack, if

detachable, from the power tool before making any adjustments, changing accessories,

or storing power tools.

power tool accidentally.

Store idle power tools out of the reach of children and do not allow persons unfamiliar

with the power tool or these instructions to operate the power tool.

dangerous in the hands of untrained users.

Maintain power tools and accessories. Check for misalignment or binding of moving

parts, breakage of parts and any other condition that may affect the power tool’s

operation. If damaged, have the power tool repaired before use.

caused by poorly maintained power tools.

Keep cutting tools sharp and clean.

edges are less likely to bind and are easier to control.

Use the power tool, accessories and tool bits etc. in accordance with these instructions,

taking into account the working conditions and the work to be performed.

power tool for operations different from those intended could result in a hazardous situation.

Keep handles and grasping surfaces dry, clean and free from oil and grease.

handles and grasping surfaces do not allow for safe handling and control of the tool in

unexpected situations.

WARNING

WARNING

always wear safety goggles or safety glasses with side shields and a full face shield when

needed.

WARNING

Such preventive safety measures reduce the risk of starting the

Properly maintained cutting tools with sharp cutting

When using power tools, basic safety precautions should always be

followed to reduce the risk of re, electric shock, and personal injury.

The operation of any tool can result in foreign objects being propelled into

your eyes, resulting in severe eye damage. When operating power tool,

If any parts are missing, do not operate the tool until the missing parts

have been replaced. Doing so could result in serious personal injury.

Any power tool that

Power tools are

Many accidents are

The correct

Use of the

Slippery

Service

Have your power tool serviced by a qualied repair person using only identical

replacement parts.

If any part of this router is missing or should break, bend,

any electrical component fail to perform properly: shut off the power switch and remove the

plug from the power source and have the missing, damaged, or failed parts replaced before

resuming operation.

4

This will ensure that the safety of the power tool is maintained.

or fail in any way; or should

Page 5

SAFETY WARNINGS FOR ROUTER

Hold the power tool by insulated gripping surfaces only, because the cutter may

contact its own cord.

“live” and could give the operator an electric shock.

Use clamps or another practical way to secure and support the workpiece to a stable

platform.

to loss of control.

Maintain a rm grip

Never attempt to use the router motor without rst installing it in an approved xed

base.

Make sure that the motor housing does not move up or down when clamped in the

xed base. If the motor is not securely clamped into the base, injury could result and

adjustments will not be accurate.

Do not hand-hold the router in an upside down or horizontal position.

separate from the base if not properly attached according to the instructions.

Tighten the collet/nut securely to prevent the cutter bit from slipping.

not securely tightened, the cutter bit may detach during use, causing serious personal injury.

Never tighten the collet/nut without a cutter bit installed in the collet/nut.

Never hold the piece being cut in your hands or across your legs.

support and clamp the workpiece properly in order to minimize body exposure, bit binding, or

loss of control.

Always keep the chip shield clean and in place.

Stay alert and clear the router cutter bit path of any obstructions before starting the

motor.

Inspect and remove all nails from lumber before routing.

Check to see that the cord will not “hang up” during routing operation.

Make sure that the cutter bit is not in contact with the workpiece before the switch

is turned on. The bit must always be running at full speed before contacting the

workpiece.

Keep hands clear

Provide clearance under the workpiece

Keep cutting pressure constant.

Use only sharp cutter bits

and burn the workpiece.

Never use this router motor with a cutter bit larger than 3-1/2 inches in diameter.

Always use cutter bits that are designed for this router. Never use cutter bits which

are larger in diameter than the opening in the router sub-base.

cutter diameters larger than the opening could cause possible loss of control or create other

hazardous condition that could cause serious personal injury.

The sub-base on this router has an opening of 1-1/4 inches.

larger diameter, install and use a sub-base with a larger diameter opening.

Do not use large router cutter bits for freehand routing.

freehand routing could cause loss of control or create hazardous conditions that could result in

serious personal injury. If using a router table, large bits should be used for edging only.

Be sure that the cutter bit is centered in a template guide

template guide applications to avoid personal injury or damage to nished work.

Do not remove more than 1/8 inch in a single pass.

loss of control that could result in personal injury.

Holding the work by your hand or against the body leaves it unstable and may lead

Failure to heed this warning could result in personal injury and damage to the motor.

Keep cutting area clear of all foreign objects while the motor is running.

Cutting a “live” wire may make exposed metal parts of the power tool

on the router with both hands to resist starting torque.

The motor can

If the collet/nut is

It is important to

of the cutter bit when the motor is running to prevent personal injury.

for the router cutter bit when through-cutting.

Do not overload the motor.

that are not chipped or cracked. Blunt cutter bits will cause stalling

Cutter bits that have

To use cutter bits with a

Use of large cutter bits when

(sold separately) prior to

Excessive depth of cut can result in

5

Page 6

After completing a cut, turn the motor OFF and let it come to complete stop before

removing router from workpiece. Let the motor come to a complete stop before putting

the router down.

Only use router tables with on-board switch-controlled receptacles.

tables with all the appropriate safety features could result in serious personal injury.

Disconnect the tool from the power source

cutter bits.

If you are changing a bit immediately after use, be careful not to touch the collet/nut

or cutter bit with your hands or ngers.

burns. Always use the wrench provided.

Avoid “climb cutting;” see “Feeding the Router” section in this manual.

increases the chance for loss of control resulting in possible serious injury.

Only use router bits suitable for the no-load speed of the tool.

Never use router bits with a diameter exceeding the maximum diameter specied in the

technical data section.

WARNING

WARNING

WARNING

could shock the operator and cause serious injury. Make sure that hidden electrical wiring,

water pipes, or other hazards are not in the cutting path.

Cutter bits coast after the power is turned off.

Failure to use router

before making any adjustments or changing

The heat buildup from cutting could cause severe

“Climb cutting”

Bits, sockets, and tools get hot during operation. Wear gloves when

touching them.

Wear ear protection. Exposure to noise can cause hearing loss.

To avoid injury, hold the tool by the insulated gripping surfaces only. If the

tool contacts hidden wiring or its own cord, exposed metal parts of the tool

6

Page 7

SYMBOLS

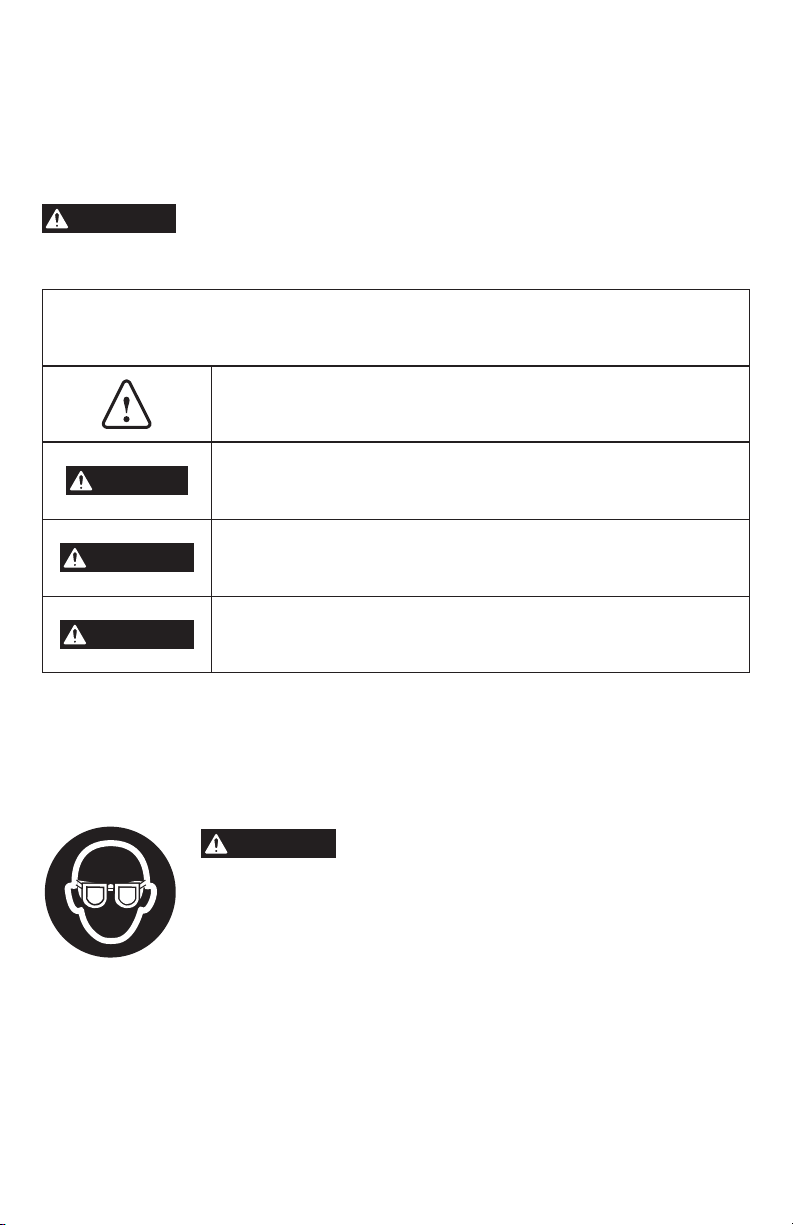

Safety Symbols

The purpose of safety symbols is to attract your attention to possible dangers. The safety

symbols and the explanations with them deserve your careful attention and understanding.

The symbol warnings do not, by themselves, eliminate any danger. The instructions and

warnings they give are no substitutes for proper accident prevention measures.

WARNING

“

WARNING

below may result in electric shock, re, and/or serious personal injury.

Be sure to read and understand all safety instructions in this

Manual, including all safety alert symbols such as “

,” and “

CAUTION

” before using this tool. Failure to following all instructions listed

DANGER

Operator’s

,”

The denitions below describe the level of severity for each signal word. Please read the manual

DANGER

WARNING

CAUTION

and pay attention to these symbols.

This is the safety alert symbol. It is used to alert you to potential

personal injury hazards. Obey all safety messages that follow this

symbol to avoid possible injury or death.

DANGER indicates a hazardous situation which, if not avoided, will

result in death or serious injury.

WARNING indicates a hazardous situation which, if not avoided, could

result in death or serious injury.

CAUTION, used with the safety alert symbol, indicates a hazardous

situation which, if not avoided, will result in minor or moderate injury.

Damage Prevention and Information Messages

These inform the user of important information and/or instructions that could lead to equipment

or other property damage if they are not followed. Each message is preceded by the word

“NOTICE”, as in the example below:

NOTICE:

Equipment and/or property damage may result if these instructions are not followed.

WARNING

in severe eye damage. Before beginning power tool operation, always

wear safety goggles or safety glasses with side shields and a full face

shield when needed. We recommend a Wide Vision Safety Mask for use

over eyeglasses or standard safety glasses with side shields. Always use

eye protection which is marked to comply with ANSI Z87.1.

The operation of any power tools can result in

objects being thrown into your eyes, which can result

foreign

7

Page 8

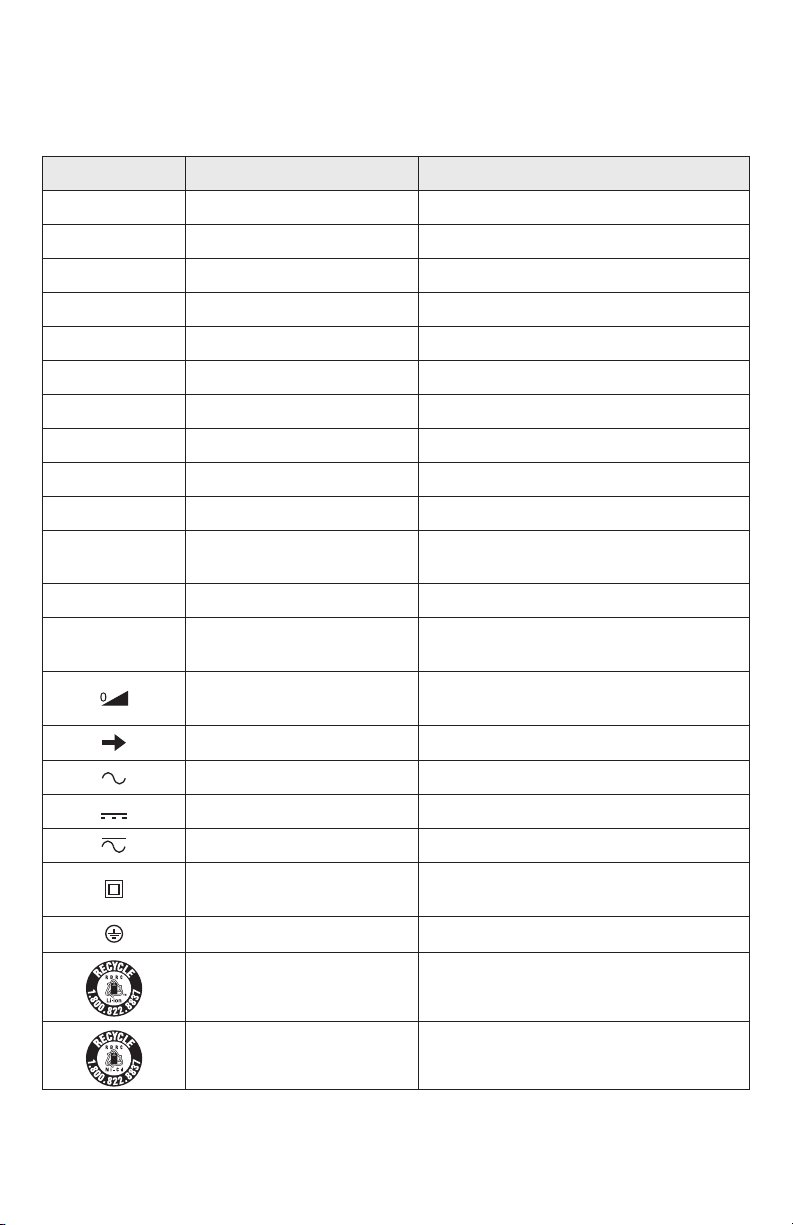

SYMBOLS (CONTINUED)

IMPORTANT:

and learn their meaning. Proper interpretation of these symbols will allow you to operate the

tool better and safer.

Symbol Name Designation/Explanation

…/min

1,2,3,…

Some of the following symbols may be used on your tool. Please study them

V Volts Voltage (potential)

A Amperes Current

Hz Hertz Frequency (cycles per second)

W Watt Power

kg Kilograms Weight

min Minutes Time

s Seconds Time

Ø Diameter Size of drill bits, grinding wheels, etc.

n

0

n Rated speed Maximum attainable speed

0 Off position Zero speed, zero torque...

I,II,III,

No load speed Rotational speed, at no load

Revolutions or reciprocation

per minute

Selector settings

Revolutions, strokes, surface speed,

orbits, etc. per minute

Speed, torque or position settings. Higher

number means greater speed

Innitely variable selector

with off

Arrow Action in the direction of arrow

Alternating current Type or a characteristic of current

Direct current Type or a characteristic of current

Alternating or direct current Type or a characteristic of current

Class II tool

Earthing terminal Grounding terminal

Li-ion RBRC seal

Ni-Cad RBRC seal

Speed is increasing from 0 setting

Designates Double Insulated Construction

tools.

Designates Li-ion battery recycling

program

Designates Ni-Cad battery recycling

program

8

Page 9

Symbol Name Designation/Explanation

Read manual symbol Alerts user to read manual

Wear eye protection symbol Alerts user to wear eye protection

SYMBOLS (CERTIFICATION INFORMATION)

IMPORTANT:

tool. Please study them and learn their meaning. Proper interpretation of these symbols will

allow you to operate the tool better and safer.

Symbol Designation/Explanation

Some of the following symbols for certication information may be used on your

This symbol designates that this tool is listed by Underwriters Laboratories.

This symbol designates that this tool is recognized by Underwriters

Laboratories.

This symbol designates that this tool is listed by Underwriters

Laboratories, to United States and Canadian Standards.

This symbol designates that this tool is listed by the Canadian

Standards Association.

This symbol designates that this tool is listed by the Canadian

Standards Association, to United States and Canadian Standards.

This symbol designates that this tool is listed by the Intertek Testing

Services, to United States and Canadian Standards.

This symbol designates that this tool complies to NOM Mexican

Standards.

9

Page 10

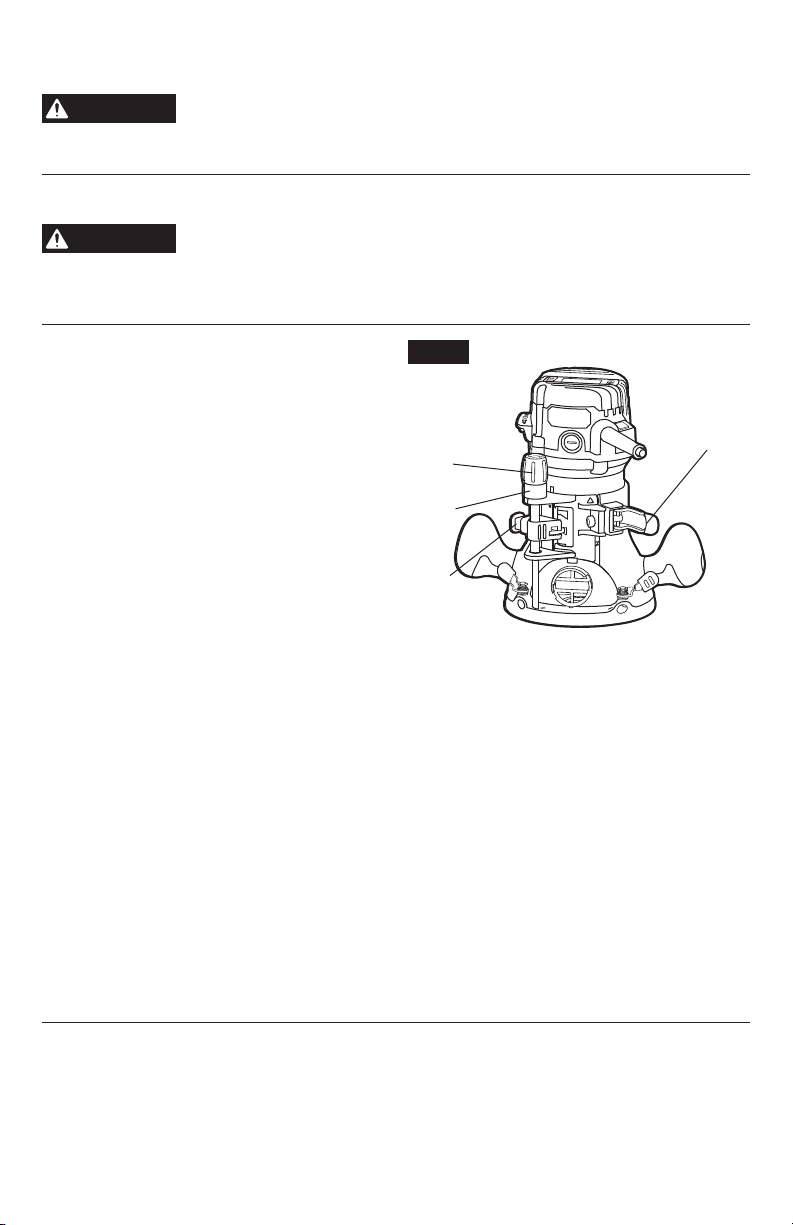

GET TO KNOW YOUR ROUTER

Fig. 1

“Live Tool Indicator”

Light

Spindle-lock

Button

Motor-housing Top Cap

Variable-Speed

Selection Chart

Motor Housing

Fixed Base

Handle

Chip Shield

Non-Marring Sub-Base

Self-Releasing Collets/Nuts System

Digital Display

ON/Off Toggle

Switch

Fine-Adjustment

Dial

Coarse-Adjustment

Knob

Edge-Guide

Lever

Edge Guide

Mounting Slot

10

Replaceable

Carbon

Brushes

Motor Clamp

Edge-Guide

Mounting

Slot

Vacuum port

Page 11

Fine-Adjustment Dial

Depth Scale

Plunge-Depth

Locking Lever

Depth-Rod

Locking Knob

Depth Rod

Depth-Stop

Turret

Pin

Plunge Base

Clear Plastic

Chip Shield

Quick-release

Lever

Edge-Guide

Mounting Slot

Quick-release

Lever

Vacuum Port

SPECIFICATIONS

Power Input 120V~,60Hz,14A

No-Load Speed 10,000-25,000 RPM

Collet Capacities 1/4 in. and 1/2 in.

Sub-Base Opening (Diameter for

cutter bit use)

1-1/4 inches (for both bases)

Non-Marring

Sub-Base

11

Page 12

OPERATING INSTRUCTIONS

Selecting the Cutter Bit

This router comes with a 1/2” collet and 1/4” collet sleeve that accept cutter bits with 1/2” and

1/4” shanks, respectively. The 1/2” collet is installed on the tool, and the 1/4” collet sleeve can

be installed inside the 1/2” collet.

WARNING

larger cutter bit will not t through the sub-base opening, will cause damage to the sub-base

and the motor, and could cause serious personal injury to the operator.

WARNING

result in accidental starting, which can cause serious personal injury.

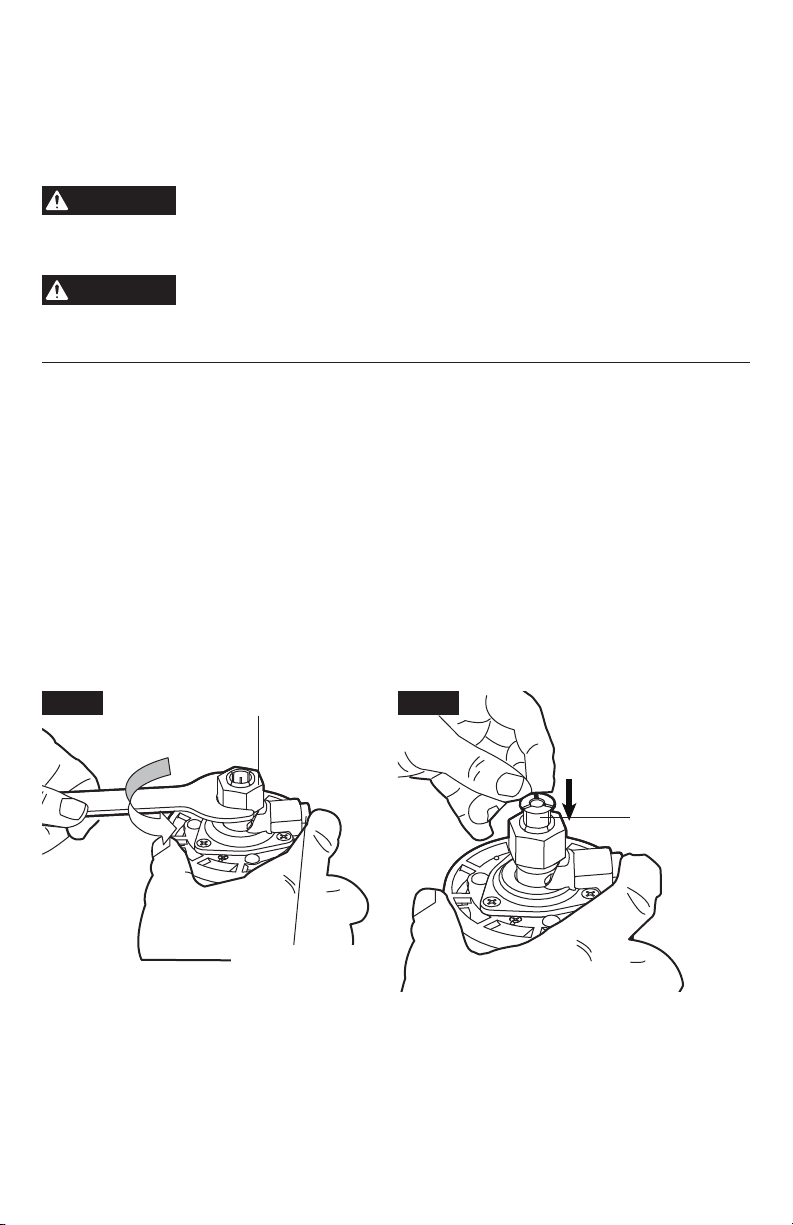

Install the 1/4” Collet Sleeve (gs 2a and 2b)

1. Disconnect the plug from the power supply.

2. Remove the router motor housing from the xed base or the plunge base.

NOTICE:

base or plunge base in this manual.

3. Set the router motor upside down on the motor-housing top cap with the collet pointing up.

4. Press the spindle-lock button to engage and lock the spindle shaft and the 1/2” collet. Place

5. Insert the 1/4” collet sleeve into the 1/2” collet assembly as far as it will go (g 2b).

6. With the 1/4” collet sleeve inserted and the spindle-lock button pressed in to engage the

Fig. 2a

See the instructions for installing and removing the motor housing from the xed

the wrench (included) on the 1/2” collet and turn it counterclockwise to loosen the collet

slightly to accept the 1/4” collet sleeve (g 2a).

shaft, place the wrench on the 1/2” collet and turn it clockwise until the 1/4” collet sleeve is

tightened in it.

Do not use a router cutter bit that has a cutter bit diameter larger

than 1-1/4 inches with the sub-bases that are supplied with this router. A

Always turn the motor off and unplug the router before making any

adjustments or installing accessories. Failure to unplug the router could

1/2” Collet

Fig. 2b

1/4” Collet

Sleeve

Spindle-lock

Button

Remove the 1/4” Collet Sleeve

1. Disconnect the plug from the power supply.

2. With the spindle-lock button pressed in to engage the shaft, place the wrench on the 1/2”

collet and turn it counter-clockwise to loosen the collet slightly to remove the 1/4” collet

sleeve.

12

Page 13

Installing and Removing the Cutter Bit

Installing the Cutter Bit

1. Turn the motor off and unplug the router from

the power source.

2. Remove the motor housing from the xed or

plunge base.

NOTICE:

removing the motor housing from the xed or

plunge base in this manual.

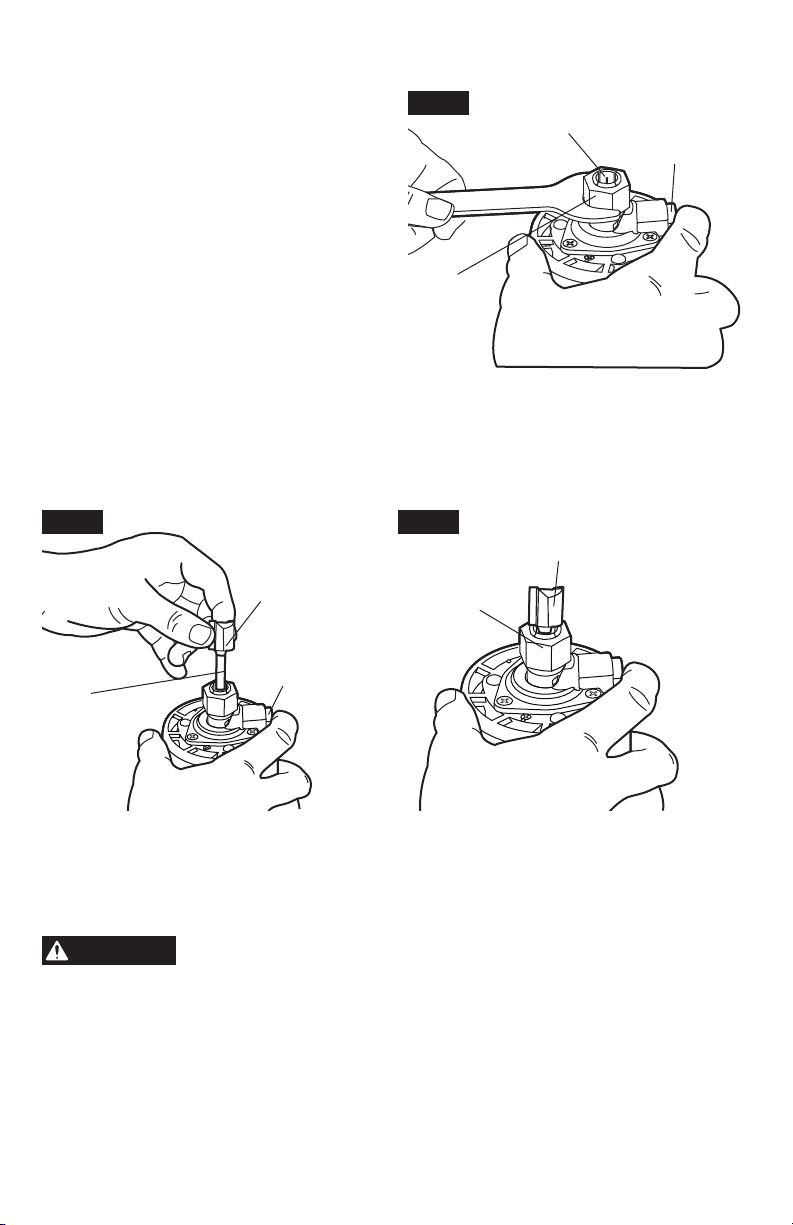

3. Set the motor upside down on the motor-

4. Press the spindle-lock button to engage and

5. Place the wrench on the collet/nut and turn

6. Insert the cutter bit shank into the collet/nut assembly as far as it will go, then back the

Fig. 3a

See the instructions for installing and

housing top cap, with the collet/nut pointing

up.

lock the spindle shaft and collet/nut (Fig. 3).

it counterclockwise to loosen the collet/nut

slightly so that it can accept the cutter bit shank.

shank out until the cutters are approximately 1/8 to 1/4 inch away from the face of the collet/

nut (Fig. 3a, 3b).

Cutters

Spindle-lock

Button

Fig. 3

Fig. 3b

Collet/Nut

Nut

Collet

Cutters

Spindle-lock

Button

Bit Shank

NOTICE:

the cutter bit must be inserted into the collet/nut at least 5/8 inch.

7. With the cutter bit inserted and the spindle-lock button pressed in to engage the shaft, place

causing serious personal injury.

NOTICE:

installed.

Removing the Cutter Bit

1. Turn the motor off and unplug the router from the power source.

2. Remove the motor housing from the xed or plunge base.

To ensure proper gripping of the cutter-bit shank and minimize run-out, the shank of

the wrench on collet/nut and turn it clockwise until the collet/nut is rmly tightened on the

cutter-bit shank.

WARNING

To prevent damage to the tool, do not tighten the collet/nut without a cutter bit

Tighten the collet/nut securely to prevent the cutter bit from slipping. If the

collet/nut is not securely tightened, the cutter bit may detach during use,

13

Page 14

NOTICE:

3. Set the motor housing upside down on the motor-housing top cap, with the collet/nut

4. Press the spindle-lock button to engage and lock the spindle shaft and the collet/nut (Fig. 3).

5. Place the wrench on the collet/nut and turn it counterclockwise to loosen the collet/nut

See the instructions for installing and removing the motor housing from the xed or

plunge base in this manual.

pointing up.

slightly; remove the cutter bit shank.

Collet/Nut Care

Before each use, inspect the collet/nut to make sure that it is clean and that it is gripping the

cutter bit properly.

With the router cutter bit removed, press the spindle-lock button and turn the collet/nut

counterclockwise until it is free from the motor spindle shaft. Blow the collet with compressed

air, and clean the tapered inside of the collet/nut with a tissue or a ne brush.

Always make sure that the cutter-bit shank, collet/nut, and motor spindle are clean and free of

woodchips, dust, residue, grease, and rust before installing a cutter bit or collet/nut.

Apply a slight amount of machine oil to the spindle shaft if it looks dry.

Replace a worn or damaged collet/nut immediately.

NOTICE:

router cutter bit. If the cutter bit seems to be stuck after use, loosen collet/nut a little more until

it releases.

The collet/nut is self-releasing; it is not necessary to strike the collet/nut to free the

Cutter Bits

For faster, more accurate cutting results, keep cutter bits clean and sharp. Remove all

accumulated pitch and gum from cutter bits after each use.

When sharpening cutter bits, sharpen only the inside of the cutting edge. Never grind the

outside diameter. Be sure, when sharpening the end of a cutter bit, to grind so that the

clearance angle is the same as was originally ground.

Installing and Removing the Router Motor Housing

WARNING

and damage to the motor.

NOTICE:

and router cutter bit you are going to use already installed in motor housing. See “Installing

and Removing the Cutter Bit”.

Before installing the motor housing in the xed or plunge base, have the collet/nut

WARNING

the motor off and unplug the router could result in accidental starting, which can cause serious

personal injury.

14

Never use the router motor without installing it into either an approved

xed or plunge base. Failure to do so could result in serious personal injury

Always turn the motor off and unplug the router from the power source

before making any adjustments or installing accessories. Failure to turn

Page 15

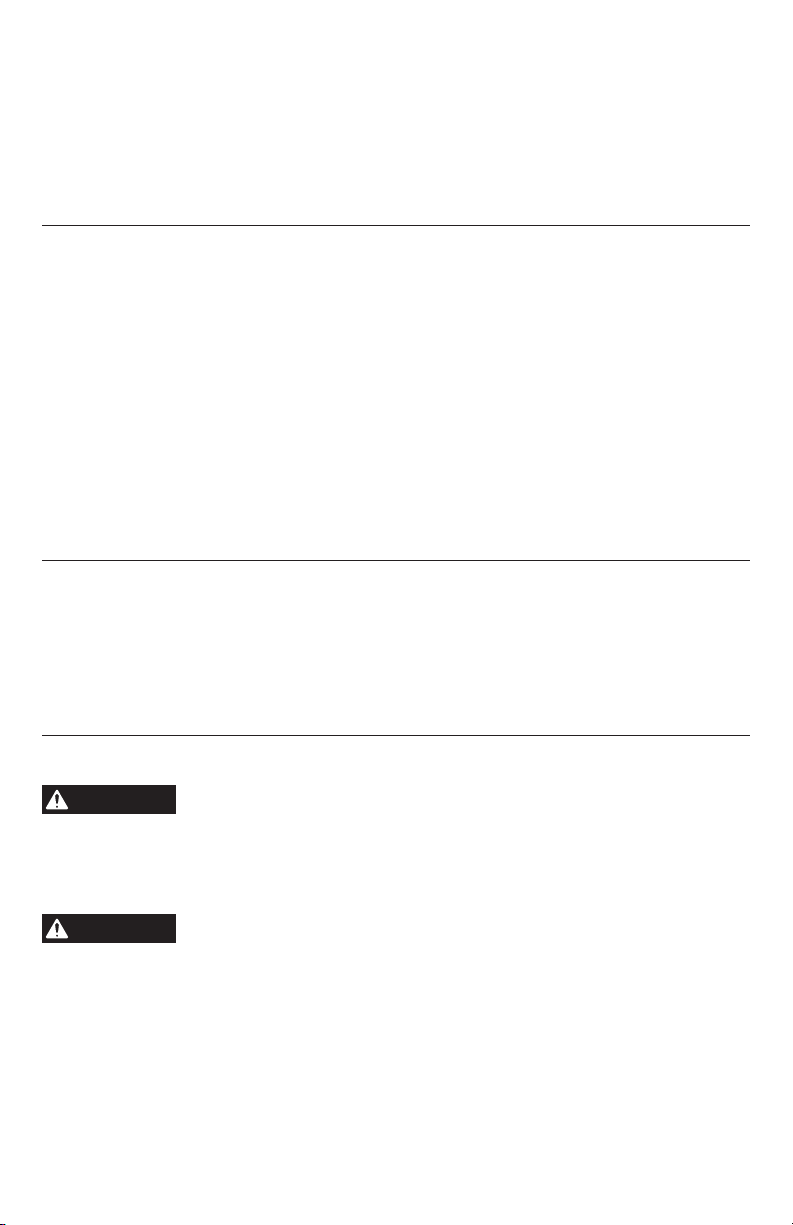

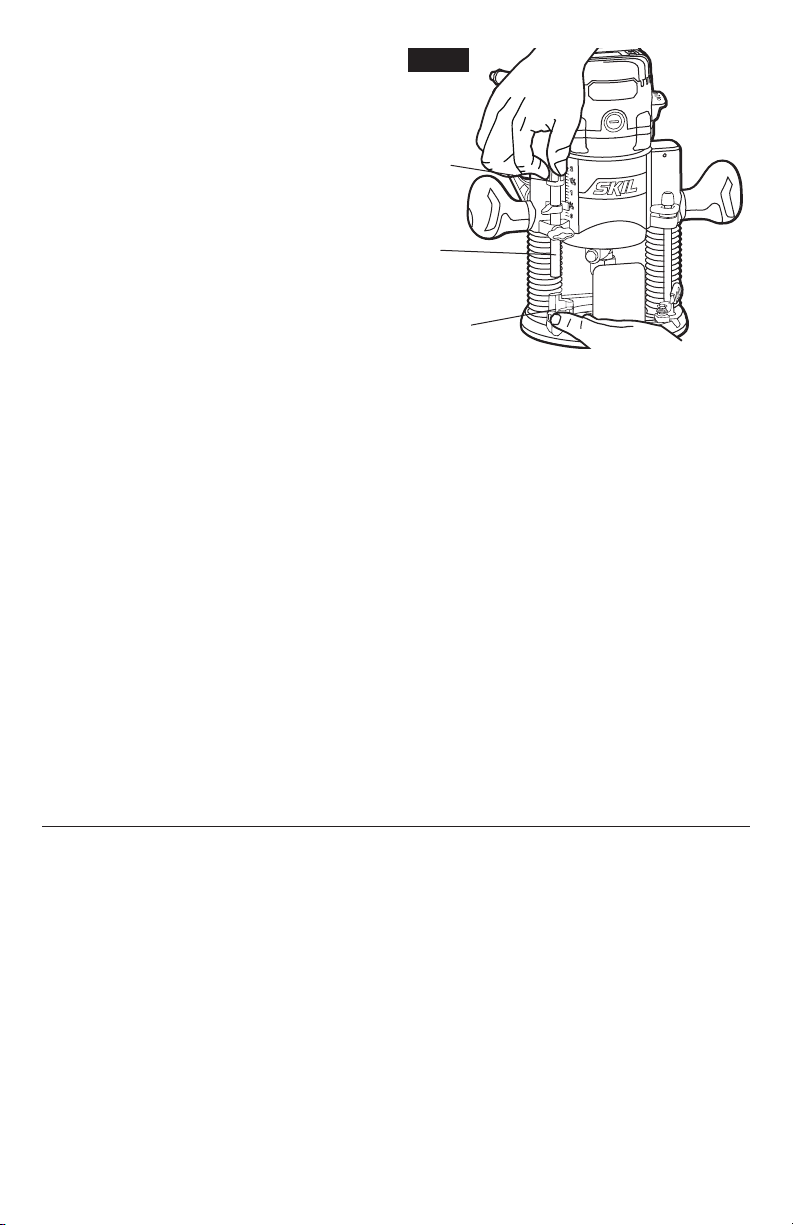

To Install Motor Housing in Fixed Base

(Fig. 4)

1. Turn the router motor off and unplug the

router from the power source.

2. Place the xed base on a at surface.

3. With the back of the xed base facing you,

open the motor clamp (A).

4. Press in the coarse-adjustment knob (B)

while you align the motor slot (C) with the pin

(D) in the xed base.

5. When the motor’s slot is aligned and

engaged into the base’s pin, slide the motor

down into the xed base.

6. The router motor will now slide up or down

to set coarse adjustments when the coarseadjustment knob is pressed in.

7. After all adjustments are made, close the motor clamp securely.

To Install Motor Housing in Plunge Base

(Fig. 5)

1. Turn the motor off and unplug the router from

the power source.

2. Place the plunge base on a at surface.

3. With the back of the plunge base facing you,

open the motor clamp (A) and make sure

that the plunge action is in the “UP” position

and the plunge depth locking lever (B) is

locked.

4. With the motor housing slot (C) aligned with

the plunge base pin (D), lower the motor

housing into the plunge base, engaging the

pin into the slot.

5. Slide the motor into the base as far as it will

go.

6. Close the motor clamp securely.

To Remove the Motor Housing from the Fixed Base (Fig. 4)

1. Turn the motor off and unplug the router from the power source.

2. Place the router (xed base and motor housing) on a at surface.

3. With the back of the router facing you, open the motor clamp (A).

4. Push in the coarse-adjustment knob (B) to release the motor slot (C) from the pin (D) in the

xed base, while you lift the router motor free of the xed base.

5. Set the motor housing upside down on the motor-housing top cap with the collet pointing up

and remove the cutter bit.

To Remove the Motor Housing from the Plunge Base (Fig. 5)

1. Turn the motor off and unplug the router from the power source.

2. Place the router (plunge base and motor housing) on a at surface.

3. With the back of the plunge base facing you, open the motor clamp (A) and make sure that

the plunge action is in the “UP” position with the plunge depth locking lever (B) locked.

4. Lift the motor straight up out of the base, sliding the motor housing “slot” (C) free from the

pin in the plunge base.

Fig. 4

B

Fig. 5

D

D

C

A

CA

B

15

Page 16

5. Set the motor housing upside down on the motor-housing top cap with the collet pointing up

and remove the bit.

WARNING

personal injury.

Always remove the cutter bit from collet/nut when the router is not being

used. Leaving bits installed could result in accidents causing serious

Adjusting the Depth of Cut

WARNING

removing collets/nuts, cutter bits, cleaning the product, or when it is not in use. Disconnecting

the router will prevent accidental starting, which could cause serious personal injury.

Your router should never be turned on or be connected to the power

source when you are assembling parts, making adjustments, installing or

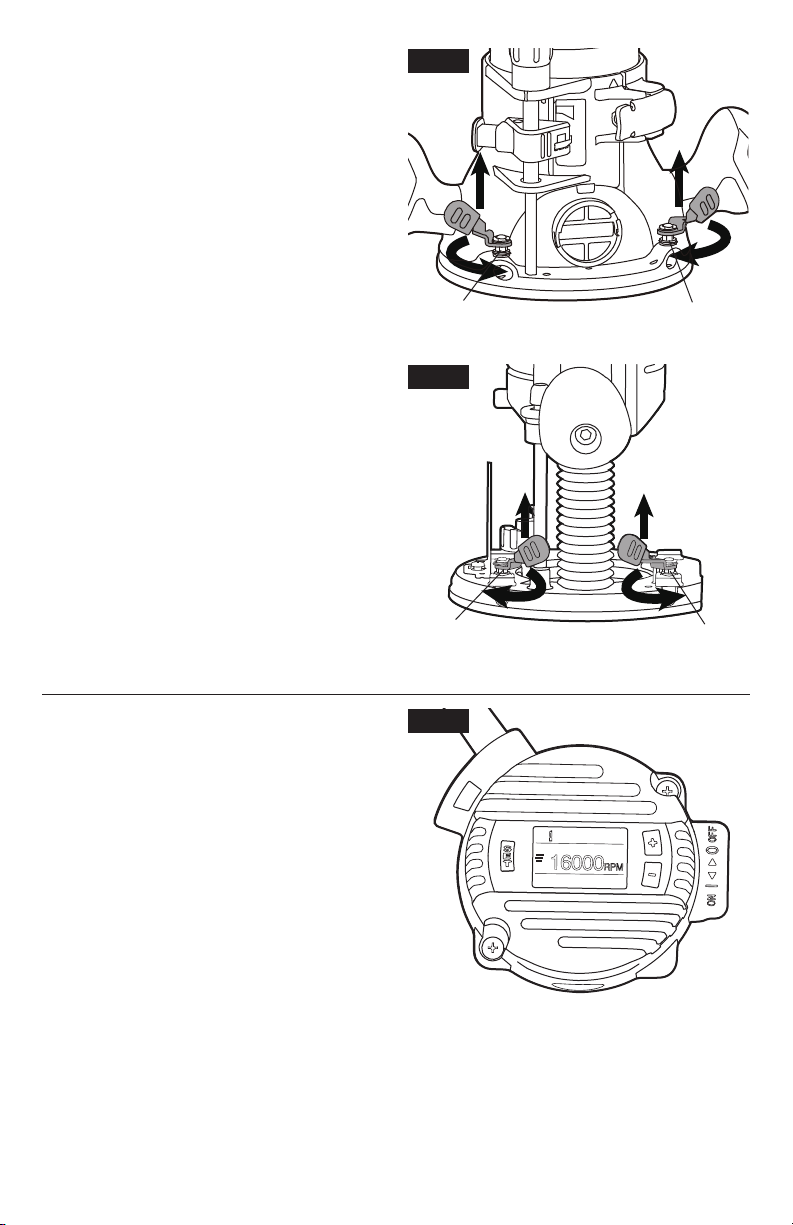

Depth Adjustment With Fixed

Fig. 6

Base (FIG. 6)

All depth adjustments on the xed

Notice:

base must be made with the motor clamp

open.

For all xed base routers, the cutter bit

Notice:

depth equals the amount of the cutter that is

exposed below the surface of the sub-base.

The xed base is designed with a micrometerne adjustment system. When the bit is

lowered to the approximate position desired

(coarse setting), the system then can be microadjusted to the precise depth required.

Coarse Adjustment

Depressing the coarse-adjustment knob (B) allows you to quickly lower or raise the cutter bit

to an approximate depth setting.

Fine Adjustments

NOTICE:

adjustments. Test it by turning the ne-adjustment dial (C) clockwise and counter-clockwise to

see if the bit lowers and raises.

The depth-indicator ring (D) located on the ne-adjustment dial is marked in 1/256- inch

increments. Turning the ne-adjustment dial counterclockwise 180° (1/2 turn), lowers the

cutter bit 1/32 inch. One full turn counterclockwise 360° (zero “0” to zero “0”) lowers the bit

1/16 inch.

NOTICE:

adjustment dial. This allows the user to begin adjustments from any reference point desired.

NOTICE:

broken by too much side thrust and torque. Larger cutter bits will cause a rough cut and be

difcult to guide and control. For these reasons, do not exceed 1/8-in. depth of cut in a single

pass.

Be sure that the micrometer-ne adjustment system is engaged before making ne

The depth-indictor ring (D) may be reset to zero “0” without moving the ne-

Making a single, deep cut is never advisable. Smaller diameter cutter bits are easily

C

D

B

A

16

Page 17

Depth Adjustment With The Plunge Base

Plunging Action

The plunge base feature simplies the depth

adjustments and allows the cutter bit to be

accurately lowered down into the workpiece for

more precise set-ups.

To lower the cutter bit, release the plungedepth locking lever by moving it “Up” to the

unlocked position. Apply an even, downward

pressure on the plunge action until the cutter

bit reaches the desired depth, then move

the plunge-depth locking lever “Down” to the

locked position. (Fig. 7)

To raise the bit and the plunge action, unlock

the plunge-depth locking lever and the plunge

action will automatically retract from the

workpiece and return to the raised position.

NOTICE:

cutting in the workpiece.

Plunge Action with Depth Rod and

Depth-Stop Turret (Fig. 8)

The depth rod and the depth-stop turret are

used to control the plunge action cutting depth

as follows:

1. Turn the motor off and unplug the router from

2. Place the router on a at, level surface.

3. With the cutting bit already installed, lower

4. To set a desired depth-of-cut, rotate the depth-stop turret until either appropriate selected

5. Slide the clear plastic depth indicator (D) until the red line on the indicator is lined up with

6. To set a desired cutting depth, slide the depth rod up until the red line on the clear plastic

7. Unlock the plunge-depth locking lever (F) to allow the bit to automatically retract to the up

8. The desired depth-of-cut may now be achieved by plunging the router down until the depth

NOTICE:

always be closed securely.

Always have the plunge action in the raised position and locked when the bit is not

the power source.

the plunge action until the cutter bit makes

contact with the at, level surface on which

the router is sitting. Lock the plunge-depth

locking lever (F). This position is zero “0”: the

point from which further depth adjustments

can be made.

step of the turret (A) is aligned directly under the depth rod (B). Loosen the depth-rod

locking knob (C) and lower the depth rod until it contacts the selected step on the turret.

ZERO - “0” marked on the bottom of the depth scale. (This is now indicating point at which

the bit makes contact with the workpiece).

depth indicator points to your desired cutting depth on the depth scale (E). Secure the depth

rod at this position by tightening the depth-rod locking knob (C).

position.

rod contacts the selected step on the depth-stop turret.

When making depth adjustments on the plunge base, the motor clamp should

Fig. 7

Fig. 8

E

C

B

F

D

A

17

Page 18

Using the Depth-Stop Turret to Set Up Deep

Fig. 9

Cuts (Fig. 9)

NOTICE:

Making a single, deep cut is never

advisable. Smaller diameter cutter bits are

easily broken by too much side thrust and

torque. Larger cutter bits will cause a rough cut

and be difcult to guide and control. For these

A

reasons, do not exceed 1/8-in. depth of cut in a

single pass.

To produce deep cuts, always make several

progressively deeper cuts by starting with the

B

highest step on the depth-stop turret, and, after

each cut, rotate the turret to the next lower step

until the lowest step is reached.

C

Each of the steps progresses by 1/4 inch

increments. The 4 steps represent a total of “0”

inch to 3/4-inch with a full 360º rotation of the turret. Repeat this process if necessary.

Micro-adjustments with the Depth Rod and Depth-Stop Turret (Fig. 9)

The depth rod has a ne-adjustment knob (A) that turns a screw (B) (inside the rod) either

clockwise or counterclockwise to lower or raise the depth rod on the turret (C) for micro-ne

adjustments of the plunge depth.

Each complete revolution of the ne adjustment knob adjusts the plunging depth by

approximately 1/32 inch.

A reference indicator line is embossed into the depth rod under the ne-adjustment knob to

set a reference point of “0”.

When micro-adjusting the plunge depth, always make sure that the ne-adjustment knob has

been turned down (clockwise) several revolutions from the top before setting the depth rod

and depth-stop turret.

Always set your micro-adjustments with the plunge action locked in the raised, (or up) position.

To use the ne-adjustment knob after the depth rod and turret have been set, check the nal

depth setting and micro-adjust as follows:

•

To micro-increase the plunge depth, raise the fine-adjustment knob by turning the knob

counterclockwise the desired amount.

•

To micro-reduce the plunge depth, lower the fine-adjustment knob by turning the knob

clockwise the desired amount.

18

Page 19

Toggle “On/Off” Switch

Use the toggle switch located on the top cap of

the motor housing to turn the router “ON” and

“OFF”.

The left side of the toggle switch hood (as you

face it) is marked “I” for “On” and the right side

(as you face it) is marked “O” for “Off”.

To turn the motor “ON”, push the toggle switch

to the left side marked “I”, or “On”. To turn the

motor “OFF” push the toggle switch to the right

side marked “O”, or “Off”.

Contact the workpiece with the router and

cutter bit only after the router has reached full

speed. Turn the router motor “OFF” and allow

the cutter bit to come to a complete stop before

removing the router and cutter bit from the workpiece.

Fig. 10

Soft-Start Feature

The soft-start feature minimizes torque twist, customary in larger router motors, by limiting the

speed at which the motor starts. This increases the motor’s life.

Electronic Feedback Control

The electronic feedback control maintains a constant speed under load to provide a smooth

nish.

LED Worklights (Fig. 11)

Your router motor has 3 built-in worklights,

located around the collet/nut, to provide high

visibility of workpiece when cutting. These

lights are always “On” when the toggle switch

is in the “On” position.

Fig. 11

19

Page 20

“Live Tool Indicator” Light

(Fig. 12)

Your router also has a “Live Tool Indicator”

green light, located on the motor housing top

cap where the power cord enters the motor

housing. This green light is always on when

router motor is plugged into power source.

Fig. 12

"Live Tool

Indicator" Light

Edge Guide

The router kit includes an edge guide. This edge guide can be used as an aid in routing

applications such as decorative edging, straight-edge planing and trimming, grooving,

dadoing, and slotting.

To assemble the edge guide, insert two edge-guide rods into the holes on the edge guide, and

then use two screws (included) to lock the edge-guide rods in place.

To attach the edge guide to the xed or plunge base, simply insert the edge-guide rods into

the edge-guide mounting slots either from the left or the right. Adjust the edge guide to the

desired position.

For xed base, secure the edge guide by turning the edge-guide levers toward two handles

(Fig.13a); for plunge base, secure the edge guide by turning two edge-guide levers toward the

right hand (Fig.13b).

Fig. 13a

Edge Guide

Lever

Edge Guide

Rods

Fig. 13b

20

LOCK

Edge Guide

Screws

LOCK

LOCK

Edge Guide Levers

Page 21

NOTICE:

a. If the inner screws on the xed base wear

down or become loose, tighten the inner

screws:

•

Pull the edge-guide lever up to strip from the

hex nut of the inner screw, turn the edgeguide lever clockwise (for the right edge

guide lever) or counterclockwise (for the left

edge guide lever) then push the edge-guide

lever down (Fig.14).

•

Turn the lever counterclockwise (for the right

edge-guide lever) or clockwise (for the left

edge-guide lever) to secure the edge-guide rod.

b. If the inner screws on the plunge base wear

down or loosen, to tighten the inner screws:

•

Pull the edge-guide lever up to strip from the

hex nut of the inner screw, turn the edgeguide lever clockwise (for the left edge guide

lever) or counterclockwise (for the right edge

guide lever) then push the edge-guide lever

down (Fig.15).

•

Turn the edge-guide lever counterclockwise

(for the left edge guide lever) or clockwise

(for the right edge guide lever) to secure the

edge-guide rod.

Fig. 14

Hex Nut of

Inner Screw

Fig. 15

Hex Nut of

Inner Screw

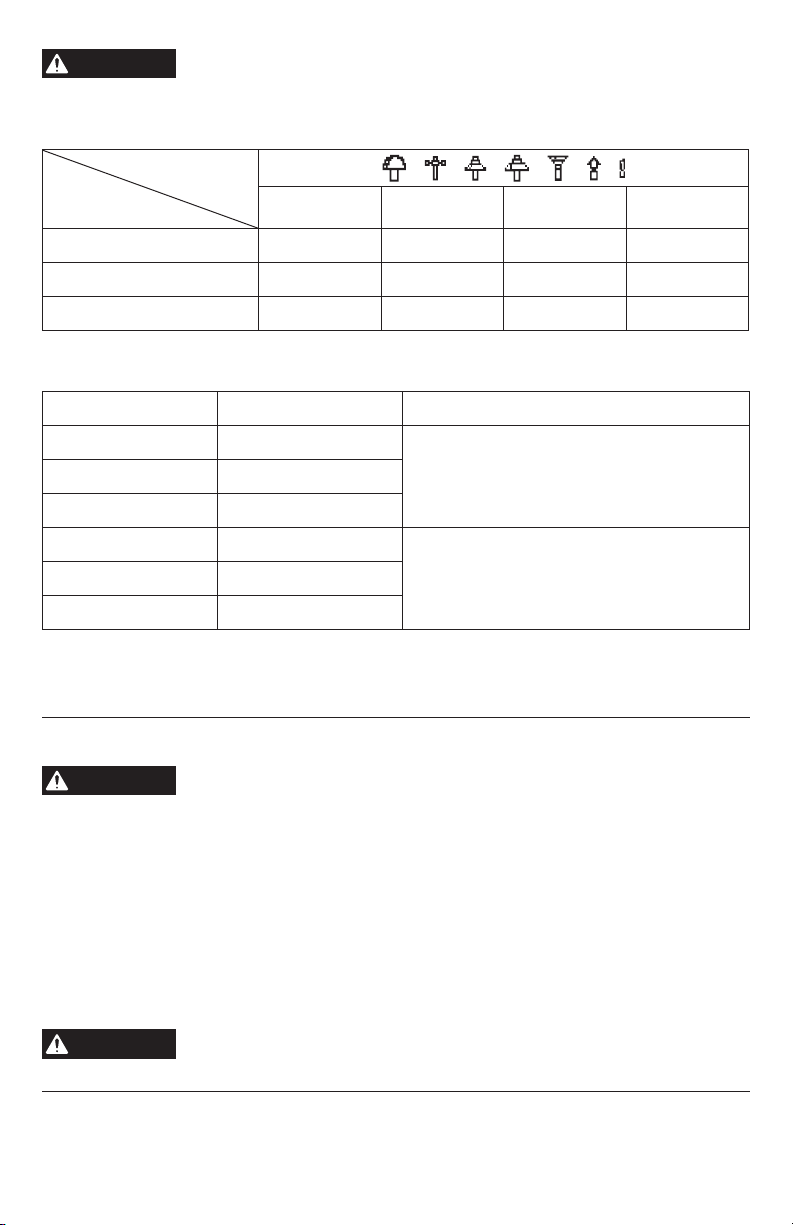

Electronic Variable-Speed Control

NOTICE:

The chart below and all the

Hex Nut of

Inner Screw

Fig. 16

Hex Nut of

Inner Screw

specications appear on the display of the

router are only for reference for your operation.

The electronic speed control feature allows the

motor speed to be matched to the cutter size

and material hardness for an improved nish

and extended bit life.

1/4

2

3

16000

PLASTICS

1/2

2

RPM

Your motor-housing top cap has a “VariableSpeed Selection Chart” located above the “ON/

OFF” toggle switch, to help you determine the

correct speed for the cutter bit being used.

Press “SET” to scroll through the settings of

the cutter type, cutter size, and the cutting

material.

Press “+” or “-” directly to choose the cutting speed according various materials of workpieces

after making above settings.

21

Page 22

WARNING

NOTICE:

being cut.

Reduce the speed when using extra-large bits (cutting diameter of 1 inch or greater), or heavy

cutting bits. Changing the rate of feed can also improve the quality of the cut.

The speed charts above indicate the relationship between speed settings and the cutting

application. Exact settings are determined by operator experience and preference, and also

by recommendations made by manufacturers of cutter bits.

Choose the applicable cutting speed according the bit diameter and the material

Bit

Size

Materials Hardness

Plastic 6 4 3 2

Softwood 6 4 2 1

Hardwood 5 3 2 1

DIAL SETTING RPM APPLICATION

1 10,000

2 11500/13,000

3 14500/16,000

4 17500/19,000

5 20500/22,000

6 23500/25,000

Before operating your router follow all safety instructions in this manual.

Failure to do so could result in serious personal injury.

0-1” 1.25-2” 2.25-2.5” 3-3.5”

Non-ferrous metal, hardwoods, larger

diameter cutter bits

Softwoods, plastics, countertops, smaller

diameter cutter bits

Placing the Router onto the Workpiece and Starting the Cut

WARNING

NOTICE:

feel for the set-up, the router’s speed, the depth of cut, and how the cutter bit reacts to the

workpiece.

Much of routing is a trial-and-error process of making various adjustments, followed by test

cuts. To avoid ruining good material, make your test cuts on scrap materials.

How you place your router onto a workpiece (starting the cut) with a xed base depends on

the type of routing you are going to produce: edge routing or internal routing, as discussed on

the following pages.

For ease of operation and to maintain proper control, your router has two handles: one on

each side of the router base. When operating the router, always hold it rmly with both hands.

Making test cuts is essential with most routing applications. A test cut will give a

WARNING

22

Before operating the router follow all safety instructions in this manual.

Failure to do so could result in serious personal injury.

Always be alert and watch what you are doing. Never operate the router

when you are fatigued.

Page 23

Deep Cuts

The proper cutting depth for each pass is always determined by the material, the cutter-bit

size and type, and power of the motor.

Always make several progressively deeper cuts: start at one depth and then make several

passes, each time increasing the cutting depth, until your desired depth is reached.

Making a cut that is too deep will stress the router motor and the cutter bit, and it may burn the

workpiece and dull the cutter bit. It could also “grab” too much of the workpiece and cause you

to lose of control of the router, causing a serious accident.

To be certain that your depth settings are correct, always make test cuts in scrap material

similar to your workpiece before beginning the nal cutting operation.

Remember, knowing the right depth for each cut comes with routing experience.

Edge Routing or Internal Routing

For ease of operation and to maintain proper control, your router has two handles, one on

each side of the router base. When operating the router, always hold it rmly with both hands

(Fig. 16 and 16a).

Edge Routing (Figs. 16a and 16b)

1. With the depth-of-cut set, place the router on the edge of workpiece, making sure that the

cutter does not contact the workpiece. With the plunge base, lock the plunge action in the

DOWN position, ready to cut.

2. Clamp an edge guide (board or metal straightedge) in place to help guide the router base.

3. Turn the router “On”, and allow the motor to reach the selected speed.

4. To begin your cut, gradually feed the cutter bit into the edge of the workpiece.

5. When the cut is complete, turn motor “Off” and allow cutter bit come to a complete stop

before removing it from the workpiece.

6. Unplug the router from the power source, and inspect the nished cut in the workpiece.

Fig. 16a

Fig. 16b

WARNING

control, causing possibly serious personal injury.

WARNING

personal injury.

Always securely clamp your workpiece and keep a rm grip on the router

base with both hands at all times. Failure to do so could result in loss of

Removing the cutter bit from the workpiece while it is still rotating could

damage the workpiece and result in loss of control, causing serious

Edge Guide

23

Page 24

Internal Routing with Fixed Base

Fig. 17

(Figs. 17, 17a, 17b and 18)

1. With the depth-of-cut set, tilt the router

and place it on the workpiece with only the

leading edge of the sub-base contacting the

workpiece (Fig. 17).

2. Turn the motor “On” and allow motor build up

to its full speed, being careful not to let the

cutter bit contact workpiece.

3. To begin your cut, gradually lower the cutter

bit into the workpiece until the sub-base is

ush with the workpiece (see Fig. 17a, 17b).

4. When the cut is completed, turn the motor

“Off” and allow the cutter bit come to a

complete stop before removing it from the

workpiece.

5. Unplug the router from the power source,

place the router upside down on the

worktable, and inspect the nished cut in the

workpiece.

WARNING

grip on the router base with both hands at all

times. Failure to do so could result in loss of

control, causing possible serious personal

injury. If using a router table, large cutter bits

should be used for edging only.

WARNING

is still rotating could damage the workpiece

and result in loss of control, causing serious personal injury.

Always securely clamp your

workpiece and keep a rm

Removing the cutter bit

from the workpiece while it

Fig. 17a

Fig. 17b

Fig. 18

Routing

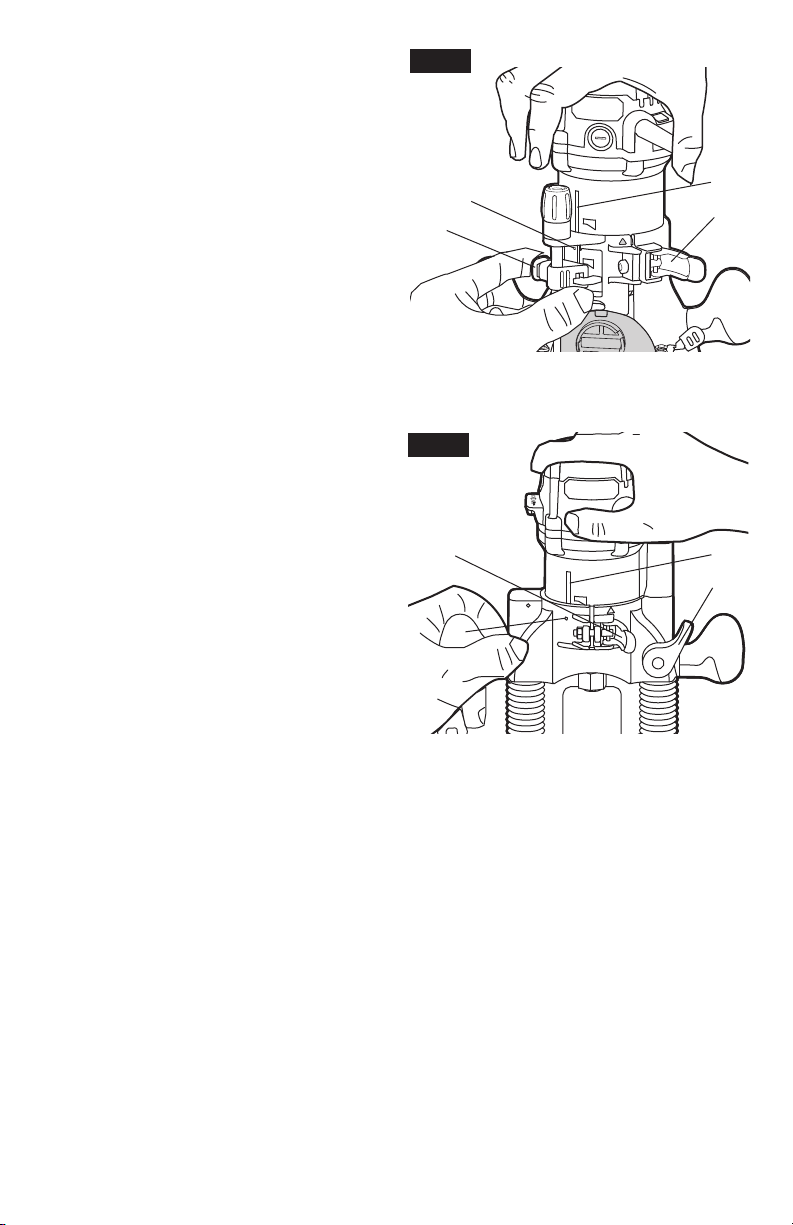

Internal Routing with Plunge Base

1. With the depth-of-cut set, and the plunge

action locked in the raised (Up) position, turn

the motor “ON” and let the motor build up to

its full selected speed (Fig. 19).

2. To begin your cut, unlock the plunge-depth

locking lever and gently lower the plunge

action evenly into the workpiece.

3. When the desired depth-of-cut is achieved,

lock the plunge-depth locking lever (Down)

and proceed to make your cut.

4. When the cut is completed, turn the motor

“OFF” and allow the cutter bit to come to a

complete stop.

5. When the cutter bit comes to a complete

stop, unlock the plunge-depth locking lever (Up) and the plunge action will automatically

retract the cutter bit from workpiece.

Fig. 19

Edge

Guide

Plunge Up

Feed Direction

24

Page 25

WARNING

personal injury.

6. Unplug the router from the power source, place the router on worktable, and inspect the

nished cut in the workpiece.

WARNING

loss of control, causing serious personal injury.

Removing the cutter bit from the workpiece while it is still rotating could

damage the workpiece and result in loss of control, causing serious

Always securely clamp the workpiece in place, and keep a rm grip on the

router base with both hands at all times. Failure to do so could result in

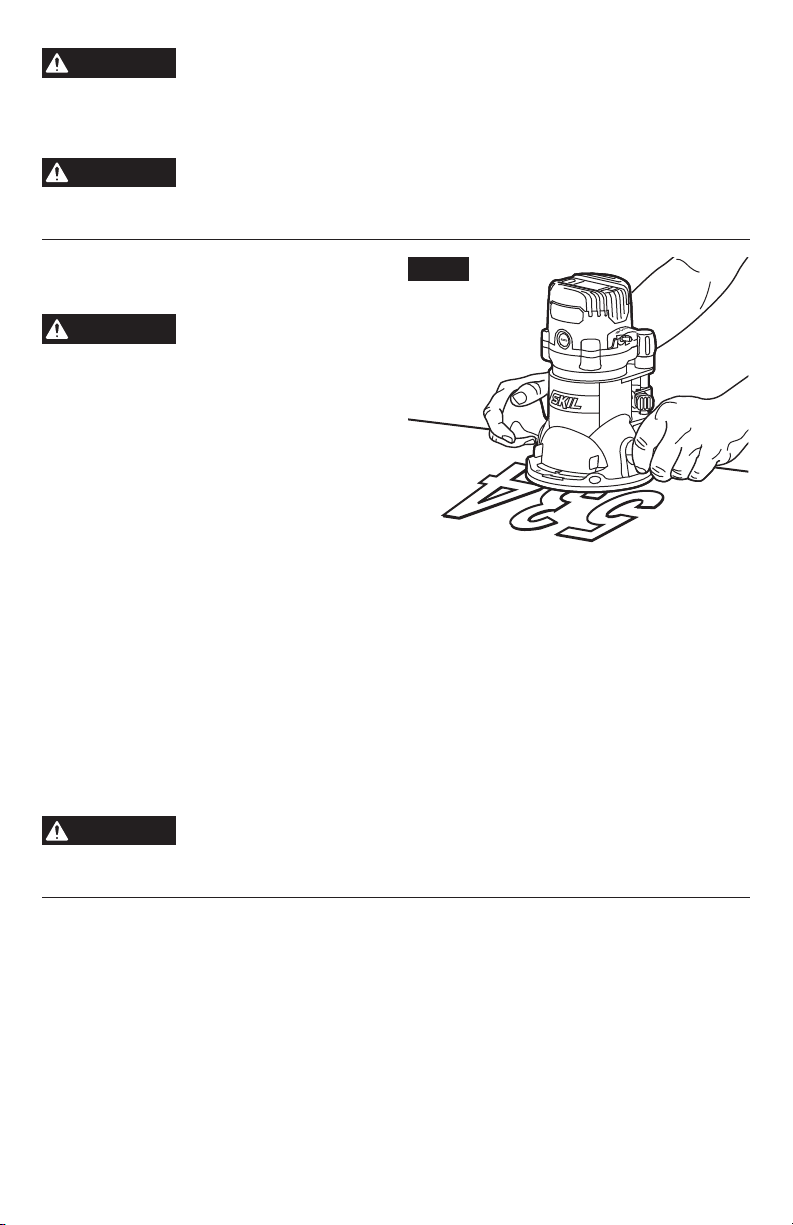

Freehand Routing with the Fixed

Fig. 20

Base (Fig. 20)

WARNING

Use of large cutter bits when freehand routing

could cause loss of control or create other

hazardous conditions that could result in

personal injury. If using a router table, large

bits should be used for edging only.

When used freehand, the router becomes a

exible and versatile tool. This exibility makes

it possible to easily rout signs, relief sculptures,

etc.

When freehand routing:

1. Draw or lay out the pattern on the workpiece.

2. Choose the appropriate bit.

3. Follow the instructions for INTERNAL ROUTING, and route the pattern in two or more

passes. Do not exceed 1/8-in. depth of cut in a single pass. This will help provide better

control, as well as serve as a guide on the next passes.

NOTICE:

Straight bits and ball mills are often used to make relief carvings. Veining bits are used to

carve small, intricate details.

NOTICE:

by too much side thrust and torque. Larger bits will cause a rough cut and be difcult to guide

and control. For these reasons, do not exceed 1/8- in. depth of cut in a single pass.

A core-box bit or V-groove bit is often used for routing letters and engraving objects.

Making a single deep cut is never advisable. Smaller-diameter bits are easily broken

WARNING

loss of control causing possible serious personal injury.

Do not use large cutter bits

for freehand routing.

Always securely clamp your workpiece in place, and keep a rm grip on

the router base with both hands at all times. Failure to do so could result in

25

Page 26

Edging with a Pilot Bit (Figs. 21a and 21b)

The arbor-type bits with pilots are excellent for edge shaping any workpiece edge that is

straight, or is curved at a curvature equal to or greater than the radius of the bit to be used.

The pilot prevents the bit from making an excessively deep cut, and holding the pilot rmly in

contact with the workpiece edge throughout prevents the cut from becoming too shallow.

Top-Edge Shaping

Whenever the workpiece thickness, together with the desired depth of cut (as adjusted by

router depth setting) are such that only the top part of the edge is to be shaped (leaving at

least a 1/16 in. thick uncut portion at the bottom), the pilot can ride against the uncut portion,

which serves to guide it (Fig. 21a).

Whole-Edge Shaping

If the workpiece is too thin or the bit is set so low that there will be no uncut edge against

which to ride the pilot, an extra board must be placed under the workpiece to act as a guide

(Fig. 21b). This “guide” board must have exactly the same contour, “straight or curved”, as the

workpiece edge. If it is positioned so that its edge is ush with the workpiece edge, the bit will

make a full cut (in as far as the bit radius). On the other hand, if the guide is positioned (out

from the workpiece edge), the bit will make less than a full cut, which will alter the shape of the

nished edge.

Fig. 21a

Spindle Lock

Motor Housing

Fig. 21b

Spindle

Collet/Nut

Cutter-bit

Pilot

TOP EDGE SHAPING

NOTICE:

can be made with the pilot against the workpiece edge (a small pilot exposes all of the bit; a

large pilot reduces this amount by 1/16 in.).

Any of the piloted cutter bits can be used without a pilot for edge shaping with guides.

The size (diameter) of the pilot that is used determines the maximum cut width that

WARNING

control causing possible serious personal injury.

Fixed Base

Sub-base

Always securely clamp your workpiece and keep a rm grip on the router

base with both hands at all times. Failure to do so could result in loss of

Work-piece

Whole Edge of Workpiece

WHOLE EDGE SHAPING

Workpiece

Guide Board

26

Page 27

Feeding the Router (Fig. 22)

Fig. 22

External Cuts

The secrets to professional routing are a

careful set-up for the cut, selecting the proper

depth of cut, knowing how the cutter bit reacts

in your workpiece, and the rate and direction of

feed of the router.

The cutter bit rotates clockwise.

NOTICE:

When installed in a router table, the

-

BIT RO TATION

Internal

cuts

ROUTER FEED

DIRECTION

direction of rotation will be counterclockwise

and other planning is required.

Direction of Feed-External Cuts

Feeding the bit from left to right will cause the

ROUTE END GRAINS FIRST

ROUTER FEED DIRECTION

bit to pull the router towards the workpiece

(Fig. 22).

If the router is fed in the opposite direction (right to left), the rotating force of the cutter bit will

tend to throw the bit away from the workpiece. This is called “Climb-Cutting.” “Climb-Cutting”

may cause loss of control, possibly resulting in personal injury. When “Climb-Cutting” is

required (e.g., backing around a corner), exercise extreme caution to maintain control of the

router.

The high speed of the cutter bit during a proper feeding operation (left to right), results in very

little kickback under normal conditions. However, if the cutter bit strikes a knot, an area of hard

grain, or a foreign object, “Kickback” may result. Kickback may damage your workpiece and

could cause you to lose control of the router, possibly causing personal injury. Kickback is

always in the opposite direction of the clockwise cutter bit rotation, or counterclockwise.

To guard against and help prevent Kickback, plan your set-up and direction of feed so that

you’re always keeping the sharp edges of the cutter bit biting straight into uncut wood. Always

inspect your workpiece for knots, hard grain, and foreign objects.

WARNING

Kickback causes the power tool to jerk back toward the user, causing

possible loss of control and serious injury. Always take precautions against

kickback as described in the operator’s manual.

27

Page 28

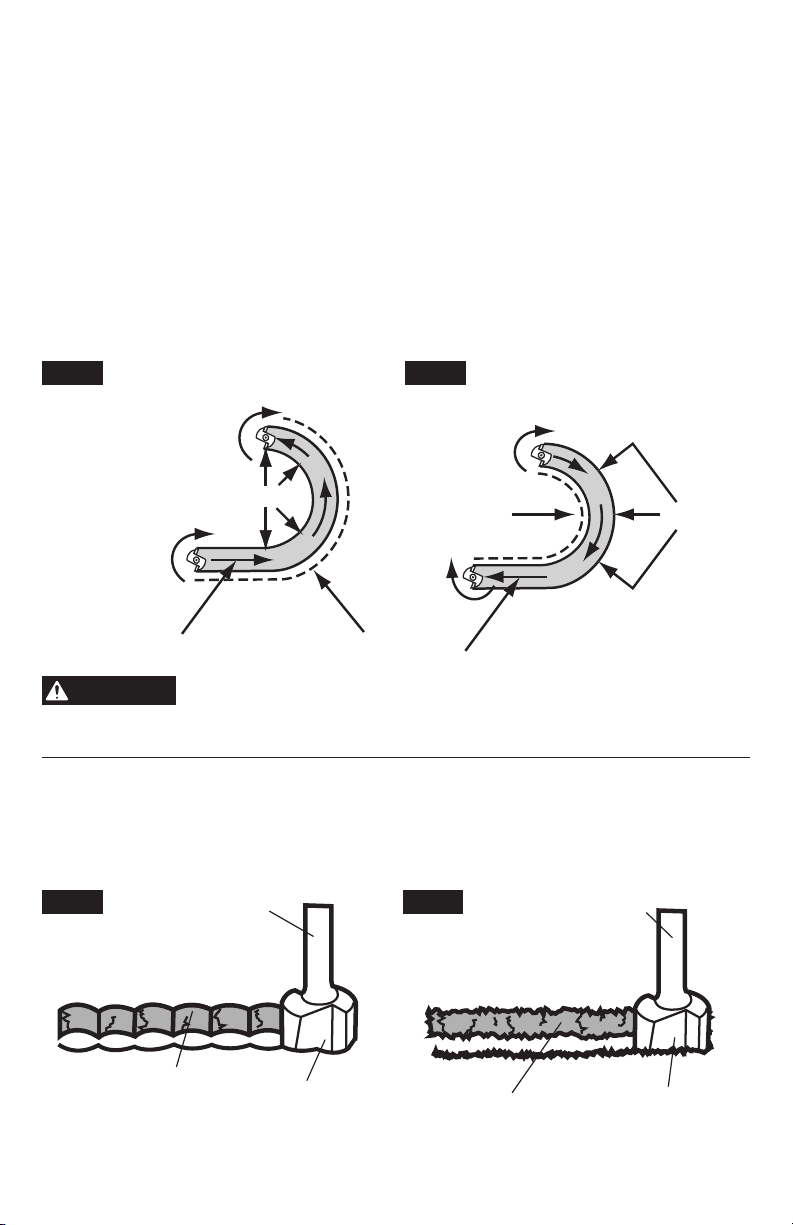

Direction of Feed- Internal Cuts (Figs. 23a and 23b)

When making an internal cut, such as a groove, dado, or slot, always have the guide you are

using with the router (edge guide, straight edge, or board guide) on the right-hand side of the

router as you make the cut (Fig.23a).

When the guide is positioned on the right hand side of the router, the router travel should be

from left to right and “counterclockwise” around curves (see Fig. 23a).

This counterclockwise action around the curve could cause “Climb cutting”. Always be alert

and exercise extreme caution to maintain control of the router when making this type of cut

around curves.

When the guide is positioned as shown in Fig. 23b, the router travel should be from left to right

and clockwise around curves.

If there is a choice, the set-up in Fig. 23a is easier to use, but there is the possibility of “Climb

Cutting” around curves. In either case, Fig. 23a or Fig. 23b, the sideways thrust of the router

cutting is always against the guide, as is proper.

Fig. 23a

GUIDE OUTSIDE

Bit Rotation

Fig. 23b

GUIDE INSIDE

Thrust

Bit Rotation

Router Feed

Direction

WARNING

loss of control causing possible serious personal injury.

Always securely clamp the workpiece in place, and keep a rm grip on the

router base with both hands at all times. Failure to do so could result in

Guide

Bit Rotation

Guide

Bit Rotation

Router Feed Direction

Thrust

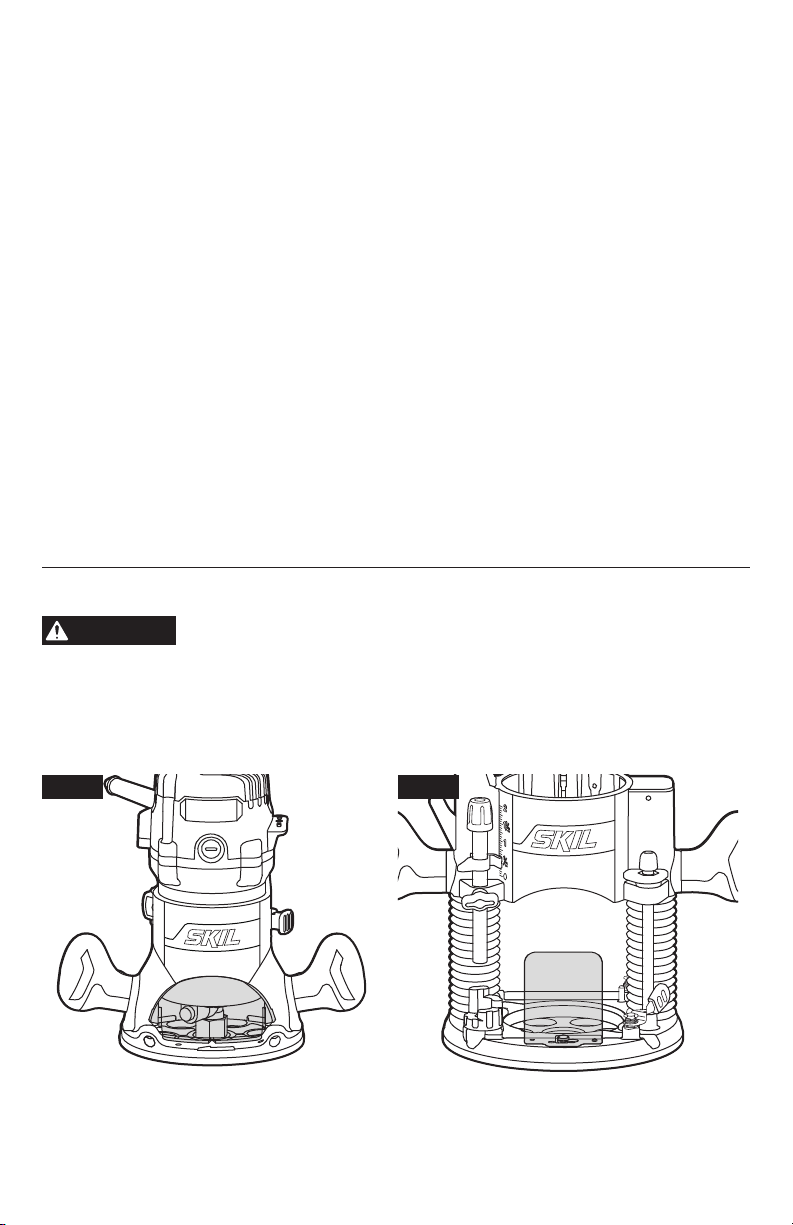

Rate of Feed (Figs. 24a and 24b)

The proper rate of feed depends on several factors: the hardness and moisture content of the

workpiece, the depth of cut, and the cutting diameter of the bit. When cutting shallow grooves

in soft woods such as pine, you may use a faster rate of feed. When making deep cuts in

hardwoods such as oak, you should use a slower rate of feed.

Fig. 24a

Bit Shank

Fig. 24b

Bit Shank

28

Cut

TOO FAST

Cutter

Cut

Cutter

TOO SLOW

Page 29

Feeding Too Fast (Fig. 24a)

Clean and smooth cuts can only be achieved when the cutter bit is rotating at a relatively high

speed, taking very small bites and producing tiny, clean cut chips.

Forcing the feed of the cutter bit forward too rapidly slows the rotation speed of the cutter bit,

and the bit takes larger bites as it rotates. Bigger bites mean bigger chips and a rough nish.

This forcing action can also cause the router motor to overheat.

Under extreme force-feeding conditions, the rotations can become so slow and the bites

become so large that chips become partially cut off, causing splintering and gouging of the

workpiece.

The router will make clean, smooth cuts if it is allowed to run freely without the overload

of forced feeding. You can detect forced feeding by the sound of the motor. Its usual highpitched whine will sound lower and stronger as it loses speed. Holding the router against the

workpiece will also come more difcult.

Feeding Too Slowly (Fig. 24b)

When you feed the cutter bit too slowly, the rotating cutter bit does not cut into new wood

rapidly enough to take a bite. Instead, it scrapes away sawdust-like particles. This scraping

produces heat, which can glaze, burn, and mar the cut in the workpiece and, in extreme

cases, overheat the cutter bit.

When the cutter bit is scraping instead of cutting, the router is more difcult to control as you

feed it.

With the reduced load on the motor caused by the slow feed, the cutter bit has a tendency to

bounce off the sides of the cut in the workpiece, producing a cut with a rippled nish instead of

clean straight sides.

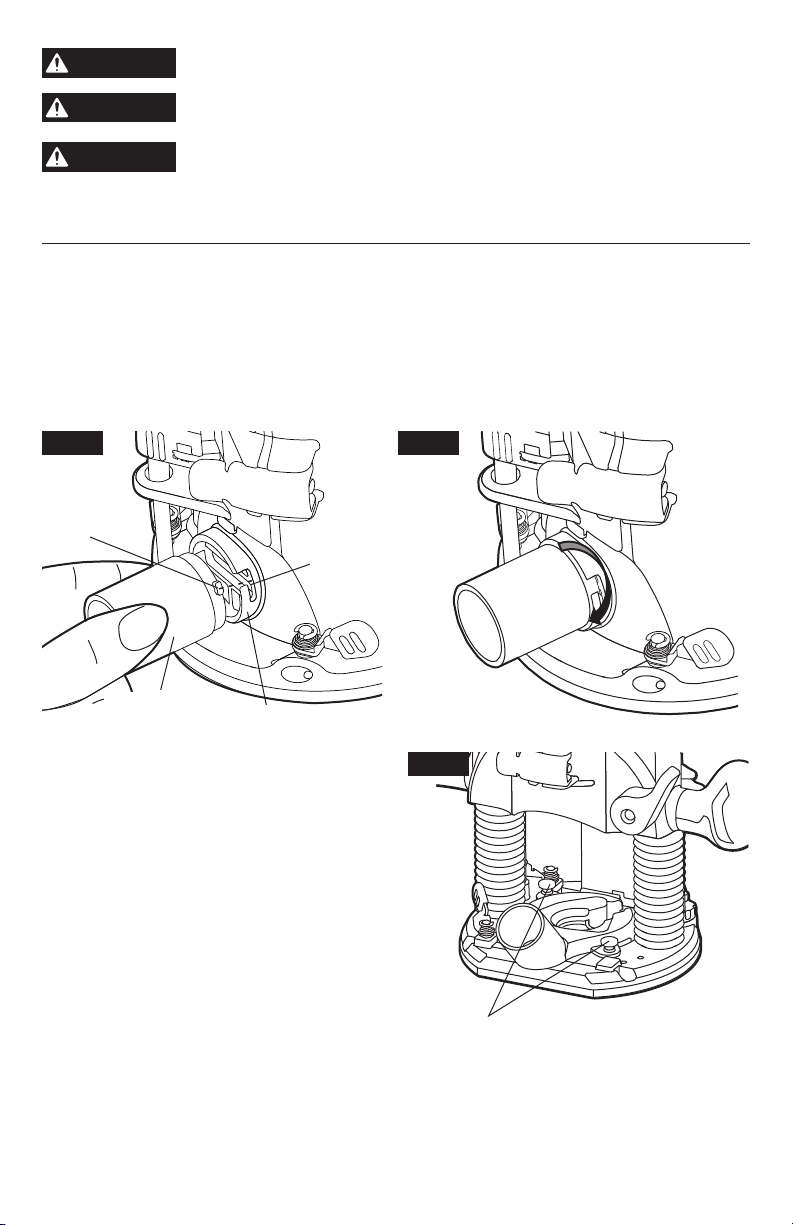

Chip Shield (Figs. 25a and 25b)

WARNING

To remove the chip shield from the xed base, press inward on the tabs until the chip shield

releases from base and then remove the chip shield. To attach, place the chip shield back in

position and ex the sides while pushing in the shield until it snaps back into place (Fig. 25a).

The chip shield on the plunge base is held in position with a screw. To remove the chip shield

from the plunge base, simply loosen the screw and take the chip shield off the base (Fig. 25b).

Fig. 25a

Always wear eye protection. The chip shields are not intended as safety

guards.

Fig. 25b

29

Page 30

WARNING

CAUTION

WARNING

the motor off and unplug router could result in accidental starting, which can cause serious

personal injury.

The chip shield helps to keep dust and chips away from the operator; it will

not stop objects larger than woodchips thrown from the bit.

Always have the appropriate chip shield in place on the base when

operating the router.

Always turn the motor off and unplug the router from the power source

before making any adjustments or installing accessories. Failure to turn

Dust Collection with Vacuum Adapter

Two vacuum adapters are included with the router bases. Each adapter is sized to accept a

1-1/4-in. vac hose adapter.

Attach the vacuum adapter onto the xed base (Figs. 26a and 26b)

To attach the vacuum onto the vacuum port at back of the xed base, rst install the included

vacuum adapter onto the vacuum port. Align the two tabs on the adapter with the two slots on

the vacuum port, and secure it by turning it clockwise (Figs. 26a and 26b).

Fig. 26a

Tab

Slot

Fig. 26b

Vacuum

Adapter

Attach the vacuum adapter onto the plunge

base (Fig.27)

To attach the vacuum adapter onto the plunge

base, position and secure it to the back of the

base with the two thumb screws (included), as

shown in Fig. 27.

Vacuum Port

30

Fig. 27

Two Thumb Screws Included

Page 31

MAINTENANCE

Service

WARNING

cause serious hazard.

Service Center or Authorized Skil Service Station.

Tool Lubrication

Your SKIL tool has been properly lubricated and is ready to use. It is recommended that tools

with gears be re-greased with a special gear lubricant at every brush change.

Carbon Brushes

The brushes and commutator in your tool have been engineered for many hours of

dependable service. To maintain peak efciency of the motor, we recommend that the brushes

be examined every two to six months. Only genuine SKIL replacement brushes specially

designed for your tool should be used.

Replacement of Carbon Brushes

(Fig. 28)

1. Unplug the router motor before inspecting or

replacing brushes.

2. Replace both carbon brushes when either

has less than 1/4-in. length of carbon

remaining, or if the spring or wire is damaged

or burned.

3. Using a slotted screwdriver, remove the

black plastic cap on each side of the router

motor (Fig. 28) and carefully withdraw the

spring-loaded brush assemblies. Keep

brushes clean and sliding freely in their

guide channels.

NOTICE:

sure that the brushes go back in the same way they came out. This will avoid the need for a

break-in period.

4. Insert new brush assemblies into the guide channels with the carbon part going in rst,

5. Remember to replace both end caps after inspecting or servicing brushes. Tighten the caps

To reinstall the same brushes, make

being certain to t the two metal “ears” into their slots in the channel (Fig. 28).

snugly, but do not over-tighten. The router should be allowed to “run in” (run at no load

without a cutter bit) for 5 minutes before use, to seat the new brushes properly.

WARNING

Cleaning

WARNING

most effectively with compressed dry air. Always wear safety goggles when cleaning tools with

compressed air.

Ventilation openings and switch levers must be kept clean and free of foreign matter. Do not

attempt to clean by inserting pointed objects through openings.

Preventive maintenance performed by unauthorized personnel may

result in misplacing of internal wires and components which could

We recommend that all tool service be performed by a Skil Factory

Fig. 28

Cap

Ears Brushes

For your safety, always turn off the switch and unplug the router motor

from the power source before performing any maintenance or cleaning.

To avoid accidents always disconnect the tool from the power supply

before cleaning or performing any maintenance. The tool may be cleaned

31

Page 32

CAUTION

ammonia and house hold detergents that contain ammonia.

Certain cleaning agents and solvents damage plastic parts.

these are: gasoline, carbon tetrachloride, chlorinated cleaning solvents,

Some of

Storage

Store the tool indoors in a place that is inaccessible to children. Keep away from corrosive

agents.

EXTENSION CORDS

WARNING

used. This will prevent excessive voltage drop, loss of power or overheating. Grounded tools

must use 3-wire extension cords that have 3-prong plugs and receptacles.

The smaller the gauge number, the heavier the cord.

NOTE:

If an extension cord is necessary, a cord with adequate size conductors

that is capable of carrying the current necessary for your tool must be

RECOMMENDED SIZES OF EXTENSION CORDS 120 VOLT

ALTERNATING CURRENT TOOLS

Tool's

Ampere

Rating

3-6 18 16 16 14 0.75 .075 1.5 2.5

6-8 18 16 14 12 0.75 1.0 2.5 4.0

8-10 18 16 14 12 0.75 1.0 2.5 4.0

10-12 16 16 14 12 1.0 2.5 4.0 —

12-16 14 12 — — — — — —

Cord Size in A.W.G. Wire Sizes in mm

Cord Length in Feet Cord Length in Meters

25 50 100 150 15 30 60 120

2

TROUBLESHOOTING

Problem Cause Remedy

The router does not

work

The surface of the

workpiece is not smooth

after cutting

Bit cannot be installed 1. Bit size is inappropriate for

1. Plug is not plugged into the

power source

2. Switch is in “OFF” position. 2. Put the switch to “ON”

3. The carbon brushes have

worn out completely.

1. The bit is dull. 1. Change to a sharp bit.

2. Routing at an inappropriate

bit speed

the collet/nut.

1. Plug the cord into the power

source.

position.

3. Remove the brush caps, and

replace the old brushes with

new ones.

2. Select an appropriate bit

speed.

1. Use 1/4-in shaft bits with

the 1/4-inch collet; use 1/2in shaft bits with the 1/2-inch

collet.

32

Page 33

LIMITED WARRANTY OF SKIL CONSUMER PORTABLE, HD,

SHD AND MAG HEAVY DUTY POWER TOOLS

Chervon North America (“Seller”) warrants to the original purchaser only, that all SKIL

consumer portable, HD, SHD and MAG Heavy Duty power tools will be free from defects

in material or workmanship for a period of one year from date of purchase. SKIL consumer

portable power tool models will be free from defects in material or workmanship for a period of

ninety days if the tool is used for professional use.

SELLER’S SOLE OBLIGATION AND YOUR EXCLUSIVE REMEDY under this Limited

Warranty and, to the extent permitted by law, any warranty or condition implied by law,

shall be the repair or replacement of parts, without charge, which are defective in material

or workmanship and which have not been misused, carelessly handled, or misrepaired by

persons other than Seller or Authorized Service Station. To make a claim under this Limited

Warranty, you must return the complete product, transportation prepaid, to any SKIL Factory

Service Center or Authorized Service Station. For Authorized SKIL Power Tool Service

Stations, please visit www.Registermyskil.com or call 1-877-SKIL-999 (1-877-754-5999).

THIS LIMITED WARRANTY DOES NOT APPLY TO ACCESSORY ITEMS SUCH AS

CIRCULAR SAW BLADES, DRILL BITS, ROUTER BITS, JIGSAW BLADES, SANDING

BELTS, GRINDING WHEELS AND OTHER RELATED ITEMS.

ANY IMPLIED WARRANTIES SHALL BE LIMITED IN DURATION TO ONE YEAR FROM

DATE OF PURCHASE. SOME STATES IN THE U.S., SOME CANADIAN PRO V INCES DO

NOT ALLOW LIMITATIONS ON HOW LONG AN IMPLIED WARRANTY LASTS, SO THE

ABOVE LIMITATION MAY NOT APPLY TO YOU.

IN NO EVENT SHALL SELLER BE LIABLE FOR ANY INCIDENTAL OR CONSEQUENTIAL

DAMAGES (INCLUDING BUT NOT LIMITED TO LIABILITY FOR LOSS OF PROFITS)

ARISING FROM THE SALE OR USE OF THIS PRODUCT. SOME STATES IN THE U.S.

AND SOME CANADIAN PROVINCES DO NOT ALLOW THE EXCLUSION OR LIMITATION

OF INCIDENTAL OR CONSEQUENTIAL DAMAGES, SO THE ABOVE LIMITATION OR

EXCLUSION MAY NOT APPLY TO YOU.

THIS LIMITED WARRANTY GIVES YOU SPECIFIC LEGAL RIGHTS, AND YOU MAY ALSO

HAVE OTHER RIGHTS WHICH VARY FROM STATE TO STATE IN THE U.S., PROVINCE

TO PROVINCE IN CANADA AND FROM COUNTRY TO COUNTRY

THIS LIMITED WARRANTY APPLIES ONLY TO PRODUCTS SOLD WITHIN THE UNITED

STATES OF AMERICA, CANADA AND THE COMMONWEALTH OF PUERTO RICO. FOR

WARRANTY COVERAGE WITHIN OTHER COUNTRIES, CONTACT YOUR LOCAL SKIL

DEALER OR IMPORTER.

© Chervon North America, 1203 E. Warrenville Rd, Naperville, IL 60563.

10/19

33

Page 34

TABLE DES MATIÈRES

Avertissements de sécurité généraux

relatifs aux outils électriques ..................................35-37

Consignes de sécurité pour la toupie ...........................37-39

Symboles ..................................................40-42

Familiarisez-vous avec votre toupie ............................43-44

Caractéristiques techniques .....................................44

Mode d’emploi ..............................................45-65

Entretien ...................................................66-67

Rallonges .....................................................67

Dépannage ....................................................68

Garantie limitée de l’outil sans l SKIL .............................69

AVERTISSEMENT

•

La poussière créée pendant le ponçage, le sciage, le polissage, le perçage et d’autres

activités liées à la construction peut contenir des produits chimiques reconnus par l’État

de la Californie comme étant la cause de cancers, d’anomalies congénitales et d’autres

problèmes liés aux fonctions reproductrices. Voici des exemples de ces produits chimiques :

–

Plomb provenant de peintures à base de plomb.

–

Silice cristallisée contenue dans les briques, le ciment et d’autres produits de maçonnerie.

–

Arsenic et chrome contenus dans le bois d’œuvre traité avec des produits chimiques.

•

Les risques liés à l’exposition à ces produits varient selon le nombre de fois où vous

pratiquez ces activités. Pour réduire votre exposition à ces produits chimiques :

–

travaillez dans un endroit bien ventilé;

–

munissez-vous de l’équipement de sécurité approuvé tel que des masques antipoussières

conçus spécialement pour ltrer les particules microscopiques;

–

évitez l’exposition prolongée à la poussière causée par le ponçage mécanique, le sciage, le

polissage, le perçage et d’autres activités liées à la construction. Portez un équipement de

protection et lavez à l’eau et au savon toutes les parties exposées. Les poussières pénétrant

dans votre bouche ou dans vos yeux et les poussières se déposant sur votre peau peuvent

causer l’absorption de produits chimiques dangereux.

34

Page 35

AVERTISSEMENTS DE SÉCURITÉ GÉNÉRAUX RELATIFS AUX

OUTILS ÉLECTRIQUES

AVERTISSEMENT

électrique.

électrique, un incendie ou des blessures graves.

Le non-respect des consignes de sécurité ci-dessous peut occasionner un choc

Lisez tous les avertissements et toutes les instructions,

illustrations et spécications fournis avec cet outil

CONSERVEZ TOUS LES AVERTISSEMENTS ET TOUTES

LES INSTRUCTIONS AFIN DE POUVOIR LES CONSULTER

ULTÉRIEUREMENT.

L’expression « outil électrique » utilisée dans les avertissements correspond aux outils

électriques alimentés sur secteur (à l) ou alimentés par piles (sans l).

Mesures de sécurité dans l’aire de travail

Maintenez l’aire de travail propre et bien éclairée.

encombrées sont propices aux accidents.

N’utilisez pas d’outils électriques dans un endroit présentant un risque d’explosion, par

exemple en présence de liquides, de gaz ou de poussières inammables.

produisent des étincelles pouvant causer un incendie en raison de la poussière et des fumées.

Gardez les enfants et les autres personnes à l’écart lorsque vous utilisez un outil

électrique.

Une distraction peut vous faire perdre la maîtrise de l’outil.

Les aires de travail sombres et

Les outils électriques

Consignes de sécurité relatives à l’électricité

Les ches des outils électriques doivent correspondre à la prise. Ne modiez jamais

la che de quelque façon que ce soit. N’utilisez pas d’adaptateur avec les outils

électriques mis à la terre.

réduit les risques de choc électrique.

Évitez de toucher à des surfaces mises à la terre, par exemple, un tuyau, un radiateur,

une cuisinière ou un réfrigérateur.

augmente les risques de choc électrique.

N’exposez pas les outils électriques à la pluie ni à tout environnement humide.

L’inltration d’eau dans un outil électrique augmente les risques de choc électrique.

N’utilisez pas le cordon d’alimentation de façon à l’endommager. Ne transportez jamais

un outil électrique en le tenant par son cordon, et ne tirez jamais sur le cordon pour le

débrancher. Tenez le cordon d’alimentation éloigné des sources de chaleur, de l’huile,

des objets coupants et des pièces mobiles.

élevés si le cordon d’alimentation est endommagé ou emmêlé.

Lorsque vous utilisez un outil électrique à l’extérieur, utilisez une rallonge conçue pour

être utilisée à l’extérieur.

Si vous n’avez d’autre choix que d’utiliser un outil électrique dans un endroit humide,

utilisez une alimentation protégée par un disjoncteur différentiel.

disjoncteur différentiel réduit les risques de choc électrique.

L’utilisation de ches non modiées dans les prises compatibles

Le contact du corps avec une surface mise à la terre

Les risques de choc électrique sont plus

Ce type de rallonge réduit les risques de choc électrique.

L’utilisation d’un

Sécurité personnelle

Soyez vigilant, prêtez attention à ce que vous faites et usez de votre jugement lorsque

vous utilisez un outil électrique. N’utilisez pas un outil électrique lorsque vous êtes

fatigué ou sous l’effet de drogues, d’alcool ou de médicaments

lorsque vous utilisez des outils électriques peut occasionner des blessures graves.

. Un moment d’inattention

35

Page 36

Utilisez un équipement individuel de protection. Portez toujours des lunettes de sécu-

. Le port d’équipement de protection, comme un masque antipoussières, des chaussures

rité

de sécurité antidérapantes, un casque de protection et des protecteurs auditifs, lorsque les

conditions l’exigent, réduit les risques de blessures.

Prenez des mesures an d’éviter que l’outil se mette en marche accidentellement.

Assurez-vous que l’interrupteur est à la position d’arrêt avant de brancher l’outil sur

une source d’alimentation ou un bloc-piles, de ramasser l’outil ou de le transporter.