Skil PWRCORE 12 OS592701 Owner's Manual

WARNING: To reduce the risk of injury, the user must read and understand the

Owner’s Manual before using this product. Save these instructions for future reference.

AVERTISSEMENT : Afin de réduire les risques de blessure, l’utilisateur doit lire et

comprendre le guide d’utilisation avant d’utiliser cet article. Conservez le présent guide

afin de pouvoir le consulter ultérieurement.

ADVERTENCIA : Para reducir el riesgo de lesiones, el usuario debe leer y comprender

el Manual del operador antes de utilizar este producto. Guarde estas instrucciones para

consultarlas en caso sea necesario.

Owner’s Manual

Guide d’utilisation

Manual del propietario

For Customer Service

Pour le service à la clientèle

Servicio al cliente

Brushless Multi-Tool

Outil multifonction sans balai

Herramienta multiuso sin escobillas

Model/ Modelo/ Modèle: OS592701

TM

1-877-SKIL-999 OR www.skil.com

2

TABLE OF CONTENTS

General Power Tool Safety Warnings .............................3-5

Safety Warnings for Multi-Tool ....................................5

Symbols .....................................................6-9

Get to Know Your Multi-Tool .....................................10

Specications ..............................................10-11

Operating Instructions .......................................12-21

Maintenance ...................................................22

Troubleshooting ...............................................22

Limited Warranty of SKIL Cordless Tool ............................23

WARNING

•

Some dust created by power sanding, sawing, grinding, drilling and other construction

activities contains chemicals known to the State of California to cause cancer, birth defects

or other reproductive harm. Some examples of these chemicals are:

–

Lead from lead-based paints.

–

Crystalline silica from bricks, cement, and other masonry products.

–

Arsenic and chromium from chemically-treated lumber.

•

Your risk from these exposures varies, depending upon how often you do this type of work.

To reduce your exposure to these chemicals:

–

Work in a well-ventilated area.

–

Work with approved safety equipment, such as dust masks that are specially designed to

lter out microscopic particles.

–

Avoid prolonged contact with dust from power sanding, sawing, grinding, drilling, and

other construction activities. Wear protective clothing and wash exposed areas with soap

and water. Allowing dust to get into your mouth or eyes or to lie on the skin may promote

absorption of harmful chemicals.

3

GENERAL POWER TOOL SAFETY WARNINGS

WARNING

Read all safety warnings, instructions, illustrations and specications

provided with this power tool. Failure to follow all instructions listed

below may result in electric shock, re and/or serious injury.

SAVE ALL WARNINGS AND INSTRUCTIONS FOR FUTURE

REFERENCE.

The term “power tool” in the warnings refers to your mains-operated (corded) power tool or

battery-operated (cordless) power tool.

Work area safety

Keep work area clean and well lit. Cluttered or dark areas invite accidents.

Do not operate power tools in explosive atmospheres, such as in the presence of

ammable liquids, gases or dust. Power tools create sparks which may ignite the dust or

fumes.

Keep children and bystanders away while operating a power tool. Distractions can cause

you to lose control.

Electrical safety

Power tool plugs must match the outlet. Never modify the plug in any way. Do not use

any adapter plugs with earthed (grounded) power tools. Unmodied plugs and matching

outlets will reduce risk of electric shock.

Avoid body contact with earthed or grounded surfaces, such as pipes, radiators,

ranges and refrigerators. There is an increased risk of electric shock if your body is earthed

or grounded.

Do not expose power tools to rain or wet conditions. Water entering a power tool will

increase the risk of electric shock.

Do not abuse the cord. Never use the cord for carrying, pulling or unplugging the power

tool. Keep cord away from heat, oil, sharp edges or moving parts. Damaged or entangled

cords increase the risk of electric shock.

When operating a power tool outdoors, use an extension cord suitable for outdoor use.

Use of a cord suitable for outdoor use reduces the risk of electric shock.

If operating a power tool in a damp location is unavoidable, use a ground fault circuit

interrupter (GFCI) protected supply. Use of a GFCI reduces the risk of electric shock.

Personal safety

Stay alert, watch what you are doing and use common sense when operating a power

tool. Do not use a power tool while you are tired or under the inuence of drugs,

alcohol or medication. A moment of inattention while operating power tools may result in

serious personal injury.

Use personal protective equipment. Always wear eye protection. Protective equipment

such as a dust mask, non-skid safety shoes, hard hat or hearing protection used for

appropriate conditions will reduce personal injuries.

Prevent unintentional starting. Ensure the switch is in the off-position before

connecting to power source and/or battery pack, picking up or carrying the tool.

Carrying power tools with your nger on the switch or energising power tools that have the

switch on invites accidents.

Remove any adjusting key or wrench before turning the power tool on. A wrench or a

key left attached to a rotating part of the power tool may result in personal injury.

4

Do not overreach. Keep proper footing and balance at all times. This enables better

control of the power tool in unexpected situations.

Dress properly. Do not wear loose clothing or jewellery. Keep your hair, clothing and

gloves away from moving parts. Loose clothes, jewellery or long hair can be caught in

moving parts.

If devices are provided for the connection of dust extraction and collection facilities,

ensure these are connected and properly used. Use of dust collection can reduce dust-

related hazards.

Do not let familiarity gained from frequent use of tools allow you to become complacent

and ignore tool safety principles. A careless action can cause severe injury within a fraction

of a second.

Power tool use and care

Do not force the power tool. Use the correct power tool for your application. The correct

power tool will do the job better and safer at the rate for which it was designed.

Do not use the power tool if the switch does not turn it on and off. Any power tool that

cannot be controlled with the switch is dangerous and must be repaired.

Disconnect the plug from the power source and/or remove the battery pack, if

detachable, from the power tool before making any adjustments, changing accessories,

or storing power tools. Such preventive safety measures reduce the risk of starting the

power tool accidentally.

Store idle power tools out of the reach of children and do not allow persons unfamiliar

with the power tool or these instructions to operate the power tool. Power tools are

dangerous in the hands of untrained users.

Maintain power tools and accessories. Check for misalignment or binding of moving

parts, breakage of parts and any other condition that may affect the power tool’s

operation. If damaged, have the power tool repaired before use. Many accidents are

caused by poorly maintained power tools.

Keep cutting tools sharp and clean. Properly maintained cutting tools with sharp cutting

edges are less likely to bind and are easier to control.

Use the power tool, accessories and tool bits etc. in accordance with these instructions,

taking into account the working conditions and the work to be performed. Use of the

power tool for operations different from those intended could result in a hazardous situation.

Keep handles and grasping surfaces dry, clean and free from oil and grease.

Slippery handles and grasping surfaces do not allow for safe handling and control of the tool

in unexpected situations.

Battery tool use and care

Recharge only with the charger specied by the manufacturer. A charger that is suitable

for one type of battery pack may create a risk of re when used with another battery pack.

Use power tools only with specically designated battery packs. Use of any other battery

packs may create a risk of injury and re.

When battery pack is not in use, keep it away from other metal objects, like paper clips,

coins, keys, nails, screws or other small metal objects, that can make a connection

from one terminal to another. Shorting the battery terminals together may cause burns or a

re.

Under abusive conditions, liquid may be ejected from the battery; avoid contact. If

contact accidentally occurs, ush with water. If liquid contacts eyes, additionally seek

medical help. Liquid ejected from the battery may cause irritation or burns.

Do not use a battery pack or tool that is damaged or modied. Damaged or modied

batteries may exhibit unpredictable behaviour resulting in re, explosion or risk of injury.

5

Do not expose a battery pack or tool to re or excessive temperature. Exposure to re or

temperature above 265 °F may cause explosion.

Follow all charging instructions and do not charge the battery pack or tool outside the

temperature range specied in the instructions. Charging improperly or at temperatures

outside the specied range may damage the battery and increase the risk of re.

Service

Have your power tool serviced by a qualied repair person using only identical

replacement parts. This will ensure that the safety of the power tool is maintained.

Never service damaged battery packs. Service of battery packs should only be performed

by the manufacturer or authorized service providers.

SAFETY WARNINGS FOR MULTI-TOOL

Hold the power tool by insulated gripping surfaces, when performing an operation

where the cutting tool may contact hidden wiring. Cutting tool contacting a “live” wire may

make exposed metal parts of the tool “live” and could give the operator an electric shock.

A suitable breathing respirator must be worn while sanding lead paint, some woods

and metal to avoid breathing the harmful/toxic dust or air.

Always wear safety goggles and a dust mask when sanding, especially when sanding

over-head.

The machine is not suitable for wet sanding.

Do not use sanding paper larger than needed. Extra paper extending beyond the sanding

pad can cause serious lacerations.

Secure the workpiece. A workpiece clamped with clamping devices or in a vice is held more

securely than by hand.

Keep hands away from the cutting range. Do not reach under the workpiece. Contact with

the blade can lead to injuries.

Keep your hands away from the motor-housing vents. Hot air comes from the vents during

operation.

6

SYMBOLS

Safety Symbols

The purpose of safety symbols is to attract your attention to possible dangers. The safety

symbols and the explanations with them deserve your careful attention and understanding.

The symbol warnings do not, by themselves, eliminate any danger. The instructions and

warnings they give are no substitutes for proper accident prevention measures.

WARNING

Be sure to read and understand all safety instructions in this Owner's

Manual, including all safety alert symbols such as “DANGER,”

“WARNING,” and “CAUTION” before using this tool. Failure to following all instructions listed

below may result in electric shock, re, and/or serious personal injury.

The denitions below describe the level of severity for each signal word. Please read the manual

and pay attention to these symbols.

This is the safety alert symbol. It is used to alert you to potential

personal injury hazards. Obey all safety messages that follow this

symbol to avoid possible injury or death.

DANGER

DANGER indicates a hazardous situation which, if not avoided, will

result in death or serious injury.

WARNING

WARNING indicates a hazardous situation which, if not avoided, could

result in death or serious injury.

CAUTION

CAUTION, used with the safety alert symbol, indicates a hazardous

situation which, if not avoided, will result in minor or moderate injury.

Damage Prevention and Information Messages

These inform the user of important information and/or instructions that could lead to equipment

or other property damage if they are not followed. Each message is preceded by the word

“NOTICE”, as in the example below:

NOTICE: Equipment and/or property damage may result if these instructions are not followed.

WARNING

The operation of any power tools can result in

foreign

objects being thrown into your eyes, which can result

in severe eye damage. Before beginning power tool operation, always

wear safety goggles or safety glasses with side shields and a full face

shield when needed. We recommend a Wide Vision Safety Mask for use

over eyeglasses or standard safety glasses with side shields. Always use

eye protection which is marked to comply with ANSI Z87.1.

7

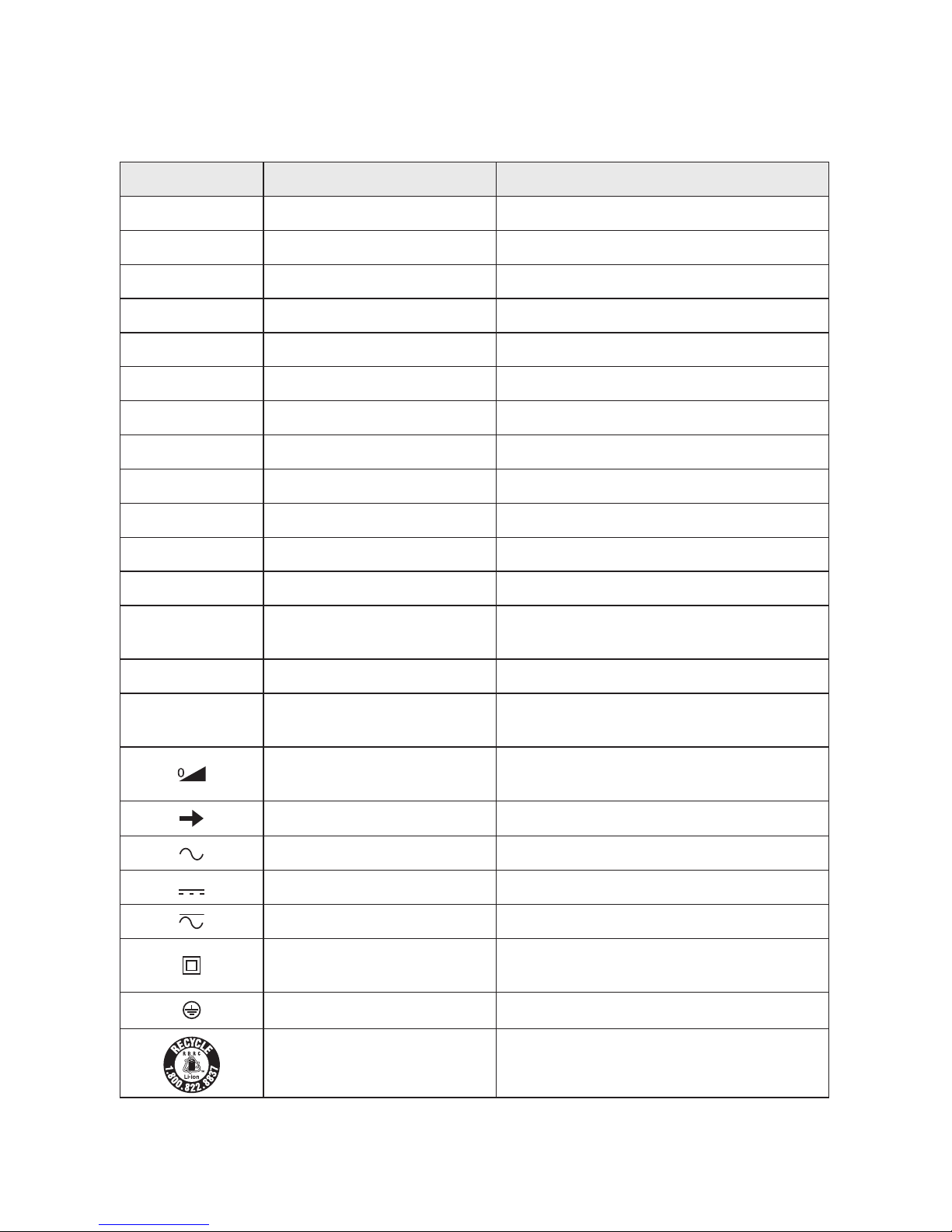

SYMBOLS (CONTINUED)

IMPORTANT: Some of the following symbols may be used on your tool. Please study them

and learn their meaning. Proper interpretation of these symbols will allow you to operate the

tool better and more safely.

Symbol Name Designation/Explanation

V Volts Voltage (potential)

A Amperes Current

Hz Hertz Frequency (cycles per second)

W Watt Power

kg Kilograms Weight

min Minutes Time

s Seconds Time

Wh Watt-hours Battery capacity

Ah Ampere-Hours Battery capacity

Ø Diameter Size of drill bits, grinding wheels, etc.

n

0

No load speed Rotational speed, at no load

n Rated speed Maximum attainable speed

…/min

Revolutions or reciprocation

per minute

Revolutions, strokes, surface speed,

orbits, etc. per minute

0 Off position Zero speed, zero torque...

1,2,3,…

I,II,III,

Selector settings

Speed, torque or position settings. Higher

number means greater speed

Innitely variable selector

with off

Speed is increasing from 0 setting

Arrow Action in the direction of arrow

Alternating current Type or a characteristic of current

Direct current Type or a characteristic of current

Alternating or direct current Type or a characteristic of current

Class II construction

Designates Double Insulated Construction

tools.

Earthing terminal Grounding terminal

Li-ion RBRC seal

Designates Li-ion battery recycling

program

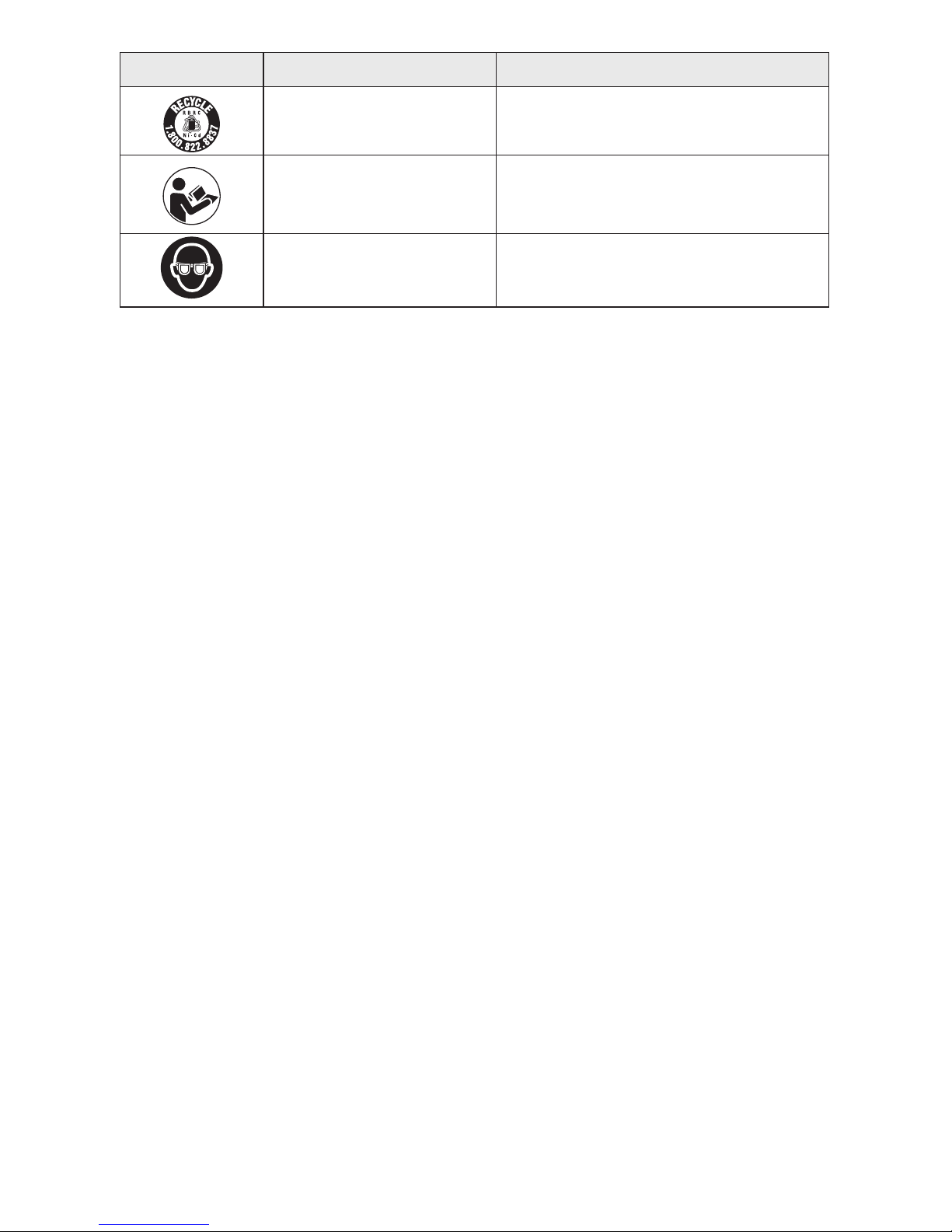

8

Symbol Name Designation/Explanation

Ni-Cad RBRC seal

Designates Ni-Cad battery recycling

program

Read manual symbol Alerts user to read manual

Wear eye protection symbol

Always wear safety goggles or safety

glasses with side shields and a full face

shield when operating this product.

9

SYMBOLS (CERTIFICATION INFORMATION)

IMPORTANT: Some of the following symbols for certication information may be used on your

tool. Please study them and learn their meaning. Proper interpretation of these symbols will

allow you to operate the tool better and more safely.

Symbol Designation/Explanation

This symbol designates that this tool is listed by Underwriters Laboratories.

This symbol designates that this tool is recognized by Underwriters

Laboratories.

This symbol designates that this tool is listed by Underwriters

Laboratories, to United States and Canadian Standards.

This symbol designates that this tool is listed by the Canadian

Standards Association.

This symbol designates that this tool is listed by the Canadian

Standards Association, to United States and Canadian Standards.

This symbol designates that this tool is listed by the Intertek Testing

Services, to United States and Canadian Standards.

This symbol designates that this tool complies to NOM Mexican

Standards.

10

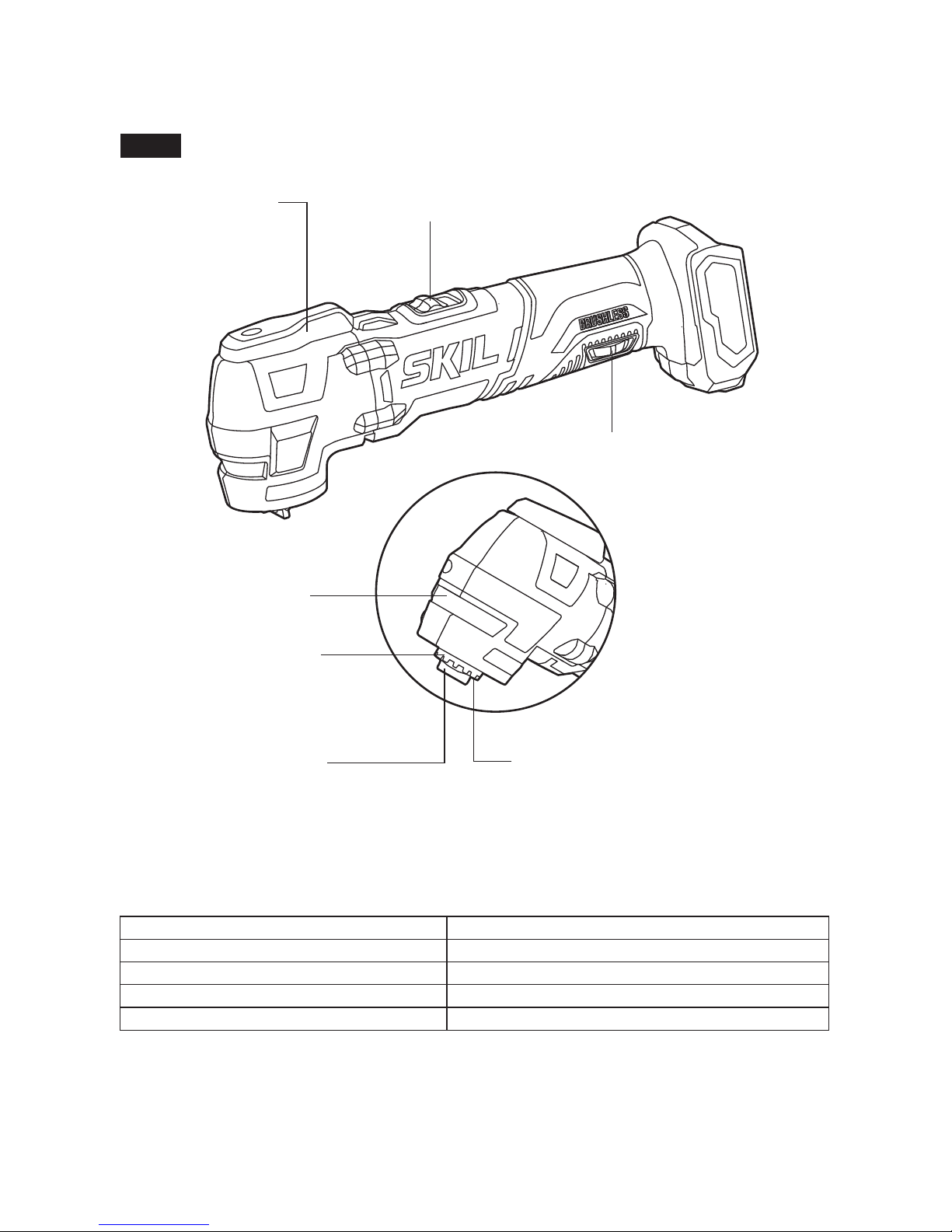

GET TO KNOW YOUR MULTI-TOOL

PWRCORE 12 Brushless Multi-Tool

Fig. 1

Clamping lever ON/OFF switch

Variable-speed dial

Halo light

Drive shaft

Locking rod Ribs

SPECIFICATIONS

Rated voltage 12V d.c.

Max oscillation rate 11000~18000 /min

Oscillation angle ±1.8°

Recommended working temperature 14~104°F (-10~40°C)

Recommended storage temperature 32~104°F (0-40°C)

11

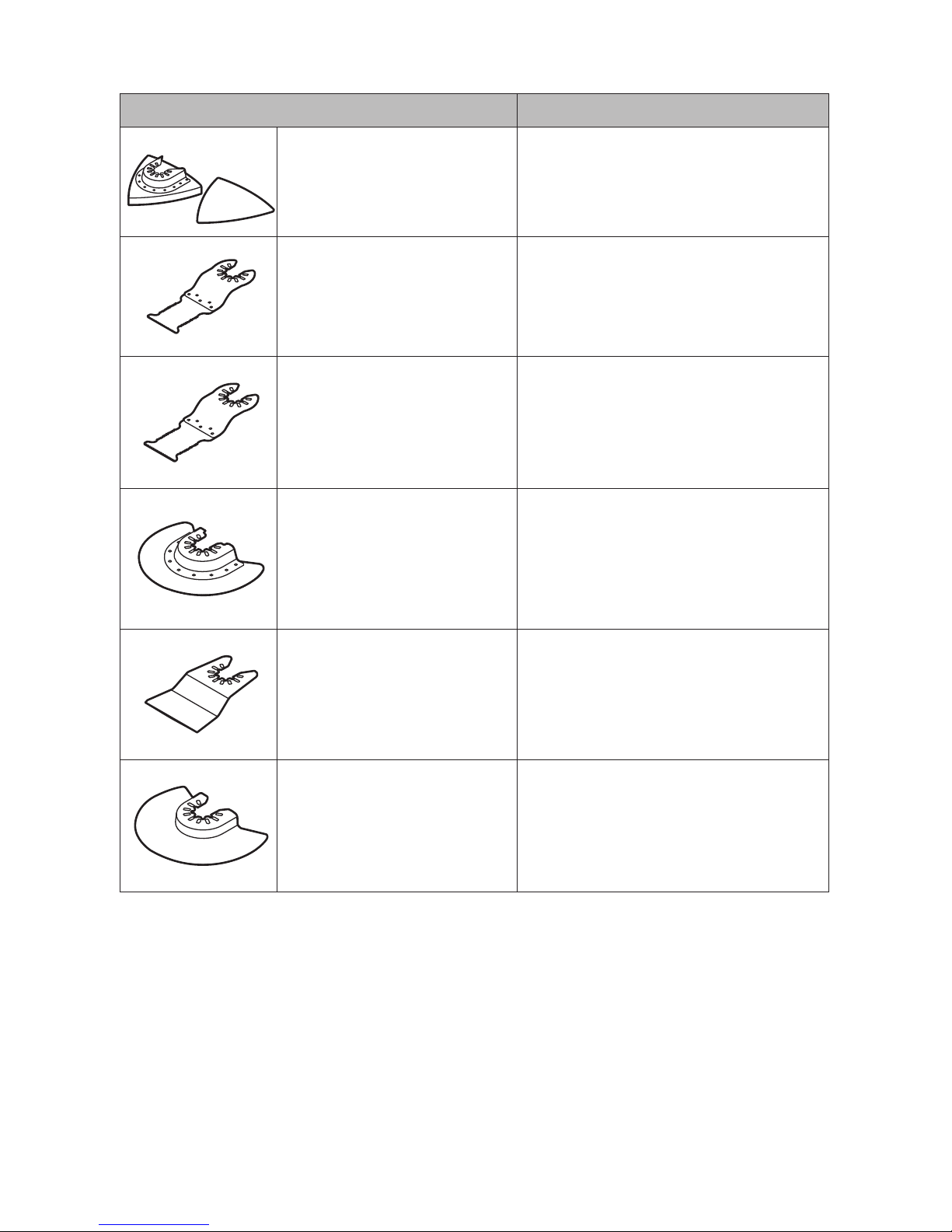

SELECTING THE ACCESSORY FOR YOUR APPLICATION

Accessory Materials

Sanding Base Plate and

Sandpaper

Bare or Painted Wood, Plaster, and

other surfaces, depending on sandpaper

grit

Bi-Metal Plunge-Cut Blade

Wood, Plastic, Drywall, Soft Metals, and

other materials

Wood Plunge-Cut Blade (HCS) Wood, Plastic, Drywall

Flush Circular Blade (HCS)

Wood, Plastic, Drywall, Non-Ferrous

Metals, Thin Sheet Metal, and other

materials

Rigid Scraper Blade

Paint & Varnish, Bonded Carpet, Soft

Adhesives, Vinyl Flooring, Wood, and

other oor coverings

Carbide Grout-Removal Blade

Tile or Tile Crevice, Grout, Plaster,

Porous Concrete, and Masonry

12

OPERATING INSTRUCTIONS

WARNING

To reduce the risk of re, personal injury, and product damage due to

a short circuit, never immerse your tool, battery pack or charger in

uid or allow a uid to ow inside them. Corrosive or conductive uids, such as seawater,

certain industrial chemicals, and bleach or bleach-containing products, etc, can cause a short

circuit.

WARNING

If any parts are damaged or missing do not operate this product until

the parts are replaced. Use of this product with damaged or missing parts

could result in serious personal injury.

WARNING

Do not attempt to modify this multi-tool or create accessories not

recommended for use with this multi-tool. Any such alteration or modi-

cation is misuse and could result in a hazardous condition leading to possible serious injury.

WARNING

To prevent accidental starting that could cause serious personal

injury, always remove the battery pack from the multi-tool when

assembling parts, making adjustments, or cleaning the tool.

This cordless multi-tool must be used only with the battery packs and charger listed

below:

Battery Pack

Charger

2Ah 4Ah

SKIL BY500101 SKIL BY519801 SKIL QC535701

NOTICE:

Please refer to the charger and battery manual for detailed operating information.

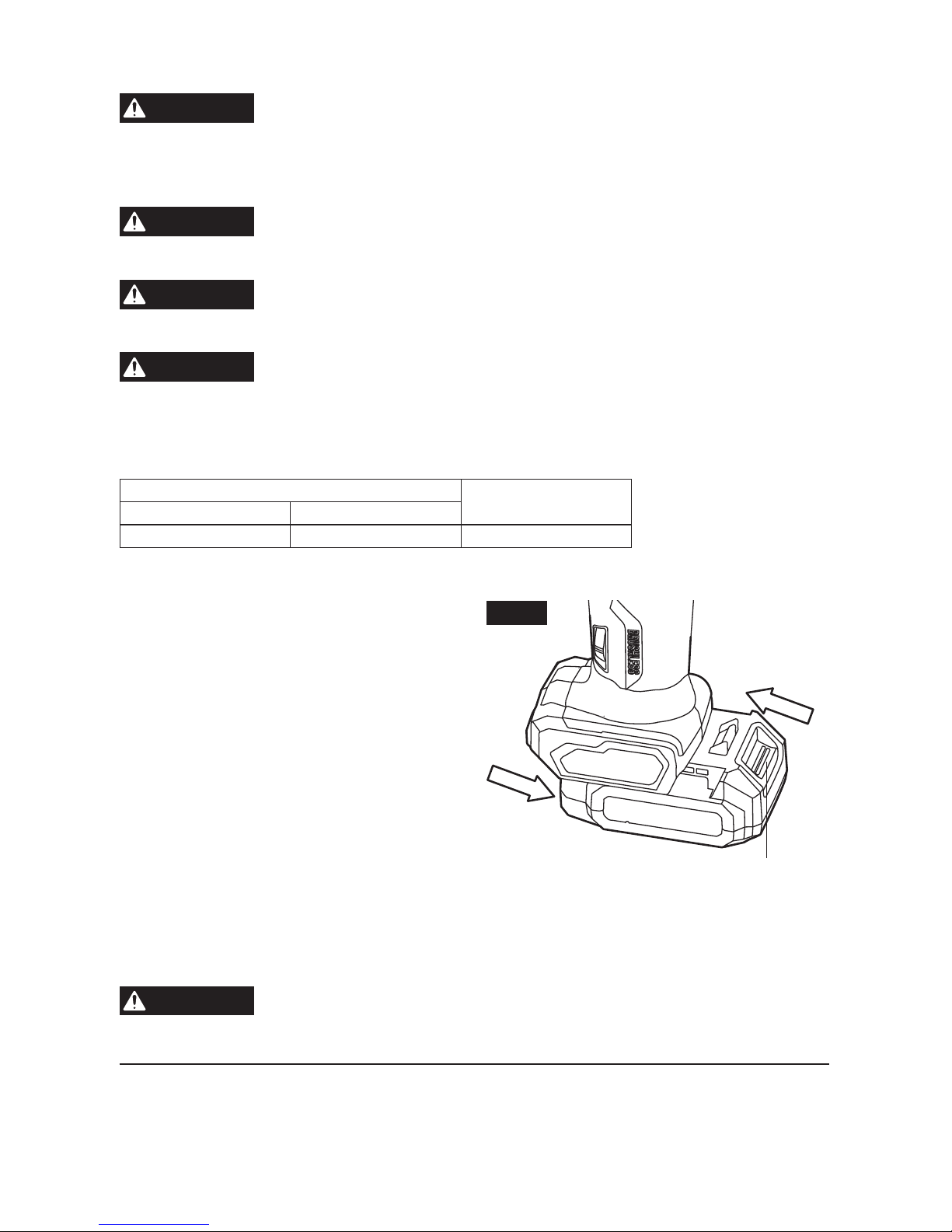

To Attach/Detach Battery Pack

(Fig.2)

Make sure that the ON/OFF switch is in the

“OFF” position when attaching or detaching the

battery pack.

To attach the battery pack:

Align the raised rib on the battery pack with the

grooves of the tool, and then slide the battery

pack onto the tool.

To detach the battery pack:

Depress the battery-release button, located

on the front of the battery pack, to release the

battery pack. Pull the battery pack out and

remove it from the tool.

NOTICE: When placing the battery pack on the tool, be sure that the raised rib on battery pack

aligns with the groove inside the tool and that the latches snap into place properly. Improper

attachment of the battery pack can cause damage to internal components.

WARNING

Battery tools are always in operating condition. Therefore, the ON/

OFF Switch should always be in OFF position when not in use or

carrying at your side.

Fig. 2

Detach

Attach

Battery-release

Button

13

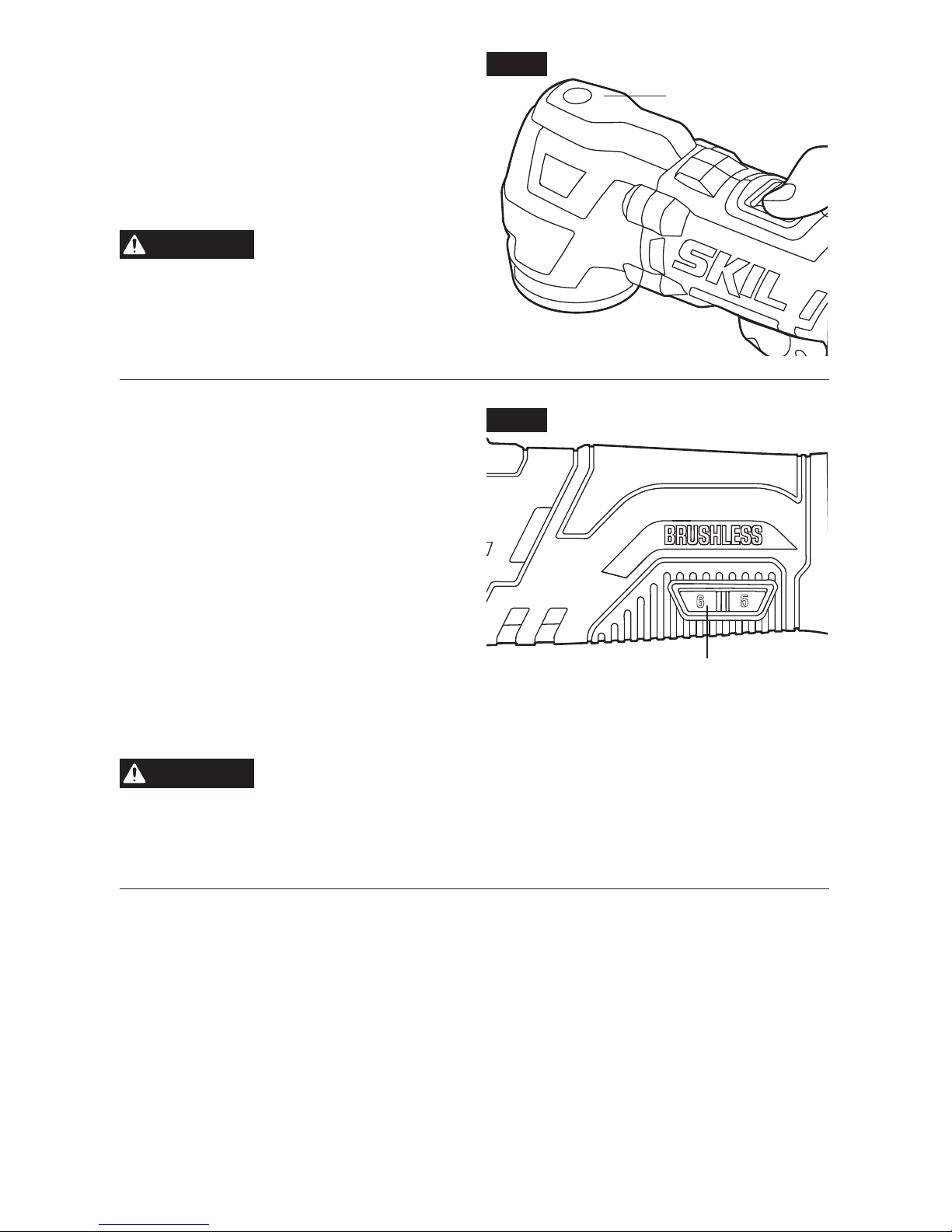

ON/OFF Switch (Fig.3)

Hold the tool rmly in the soft grip area and

keep your hands away from the blade.

To turn the tool ON, push the on/off switch

forward.

To turn the tool OFF, pull the on/off switch

backward.

WARNING

After tool use, turn the

tool off to help prevent

accidental starts and possible injury.

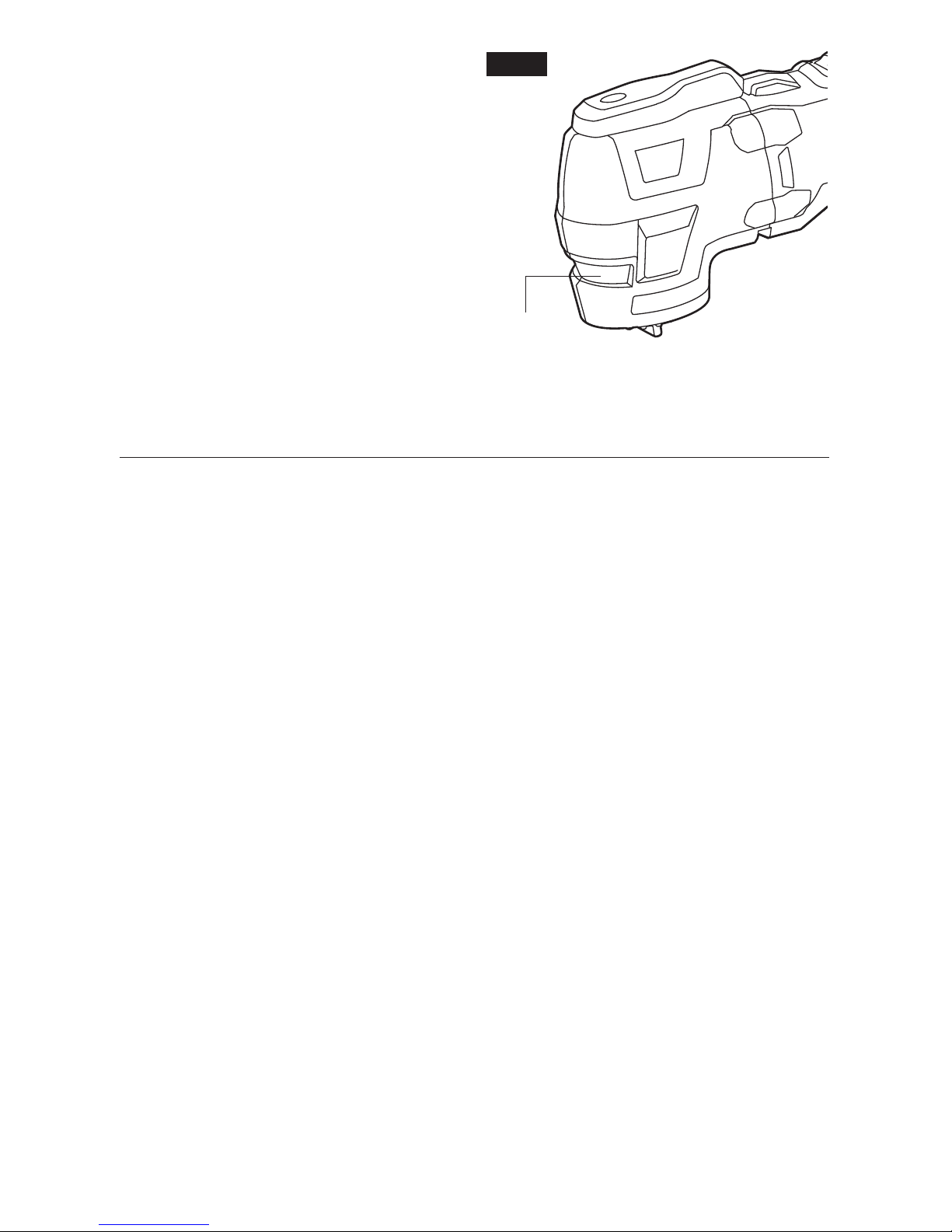

Variable-Speed Dial

Your tool is equipped with a variable-speed

dial, which allows you to match the proper speed to the material being cut, sawed,

scraped, or sanded, thereby enhancing the

overall performance of your tool and helping to

save the accessory from undue wear.

a. The variable-speed dial is used to adjust the

oscillation rate of the accessory.

b. Turn the dial to increase or decrease the

speed (Fig.4).

Position “1” selects the slowest speed.

Position “6” selects the fastest speed.

c. Adjust the accessory speed for optimum

performance.

NOTICE: Determine the optimum speed by making a trial cut in a scrap piece of material.

WARNING

Adjust the speed only when the tool is off or when the tool is running

at no-load (i.e., accessory is not in contact with any material). Make

sure to hold the tool rmly in the soft grip area with one hand, keeping the tool under

control, when adjusting the speed when running at no-load. Failure to obey this caution

could cause loss of control and result in serious personal damage.

Fig. 3

ON/OFF switch

Fig. 4

Variable-speed dial

14

Halo Light

Your tool is equipped with a Halo light, located

on the head of the tool. This provides additional light without shadows on the surface of the

work piece for operation in lower-light areas.

The Halo light will automatically turn on when

the on/off switch is in “ON” position, and off

when the on/off switch is in “OFF” position.

(Fig.5)

When the tool and/or battery pack becomes

overloaded or too hot, the internal sensors will

turn the tool off. If the tool and/or battery pack

are overloaded, the halo light will ash rapidly.

Rest the tool for a while or place the tool and

battery pack separately under air ow to cool.

The Halo light will ash more slowly to indicate that the battery is at low-battery capacity. Re-

charge the battery pack.

Fig. 5

Halo light

15

Installing and Removing

Accessories

WARNING

Always turn the tool off

and remove the battery

pack before assembling parts.

WARNING

Wear protective gloves

when changing accesso-

ries. Accessories become hot after prolonged

use, and the sharp edges of the accessories

will cause personal injury.

WARNING

Check that the accessories are correctly at-

tached.

Incorrect or insecurely attached acces-

sories can come loose during operation and

cause a hazard.

To install the accessory (Fig.6)

a. Make sure that the ON/OFF switch is in the

OFF position and remove the battery pack.

b. Turn the clamping lever counterclockwise

about 140° until an audible “click” signals

that the lever has been fully engaged to

unlock the clamp mechanism.

c. Rotate the locking rod 90° clockwise, and

then pull out the locking rod.

d. Ensure that the locking rod and the

drive shaft are clean before installing the

accessory.

e. Position the accessory on the drive shaft,

making sure that all the grooves on the

accessory align with the ribs on the drive

shaft.

f. Insert the locking rod into the drive shaft,

then press the locking rod and rotate it 90°

counterclockwise so that it is secured in the

drive shaft.

g. Turn the clamping lever clockwise. An

audible “click” will signal that the lever has

been fully engaged to lock the clamping

mechanism. After hearing the click, continue

to turn the lever until it returns to its original

position.

Fig. 6c

Fig. 6a

140

o

Fig. 6b

90

o

16

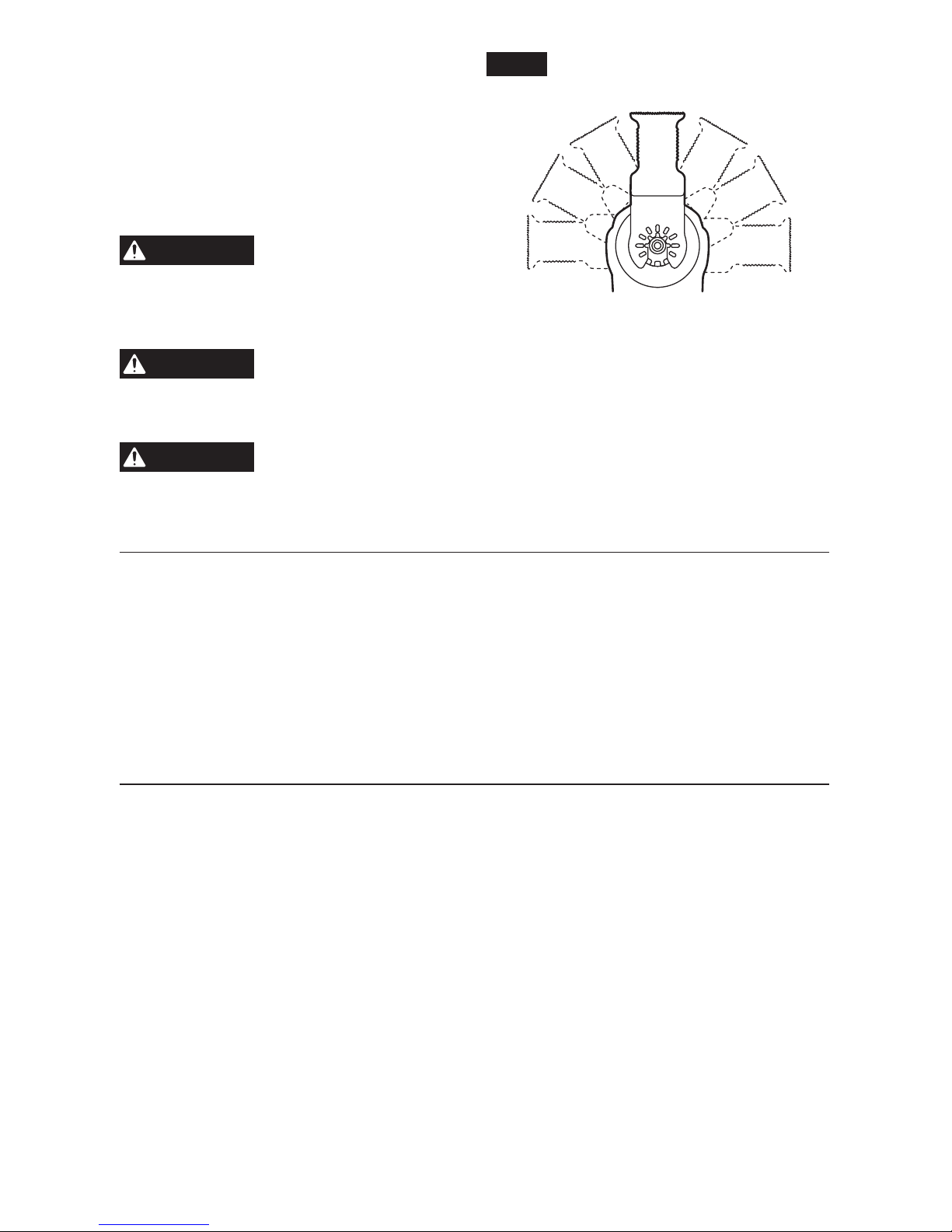

NOTICE: Attach the accessory in the desired

orientation for the task at hand. The shaft is

congured so that the application tool can be

installed around the tool in 30° increments

(Fig.7). Do not attach the plunge-cut blade,

ush circular blade, rigid scraper blade, or

carbide grout-removal blade so that they face

backwards, as attachment in this position may

cause serious injury.,

WARNING

Make sure that the ribs of

the tool drive shaft and

the lock pattern of accessories t each

other. Misalignment can lead to unstable

attachment, causing personal injury.

WARNING

Do not attach the plunge-

cut blade, ush circular blade, rigid scraper blade or carbide grout-removal blade so that they face backwards, as operation in this position may cause

serious injury.

CAUTION

To avoid pinching skin, hold the clamping lever rmly when fastening

an accessory. Do not place hands or ngers between the lever and

the tool body to guard against bruising when locking the clamping lever. Do not place

your hands or ngers between the locking rod and drive shaft.

To Remove the Accessory

a. Make sure that the ON/OFF switch is in the OFF position and remove the battery pack.

b. Turn the clamping lever counterclockwise until you hear a “click” to signal that the lever has

been fully engaged to unlock the clamp mechanism.

c. Rotate the locking rod 90° clockwise, and then pull it off.

d. Remove the accessory from the tool.

NOTICE: Do not allow the locking rod face downward when removing the accessory. It may

cause the accessory to fall off unexpectedly.

Fig. 7

-90

o

-60

o

60

o

-30

o

30

o

0

o

90

o

17

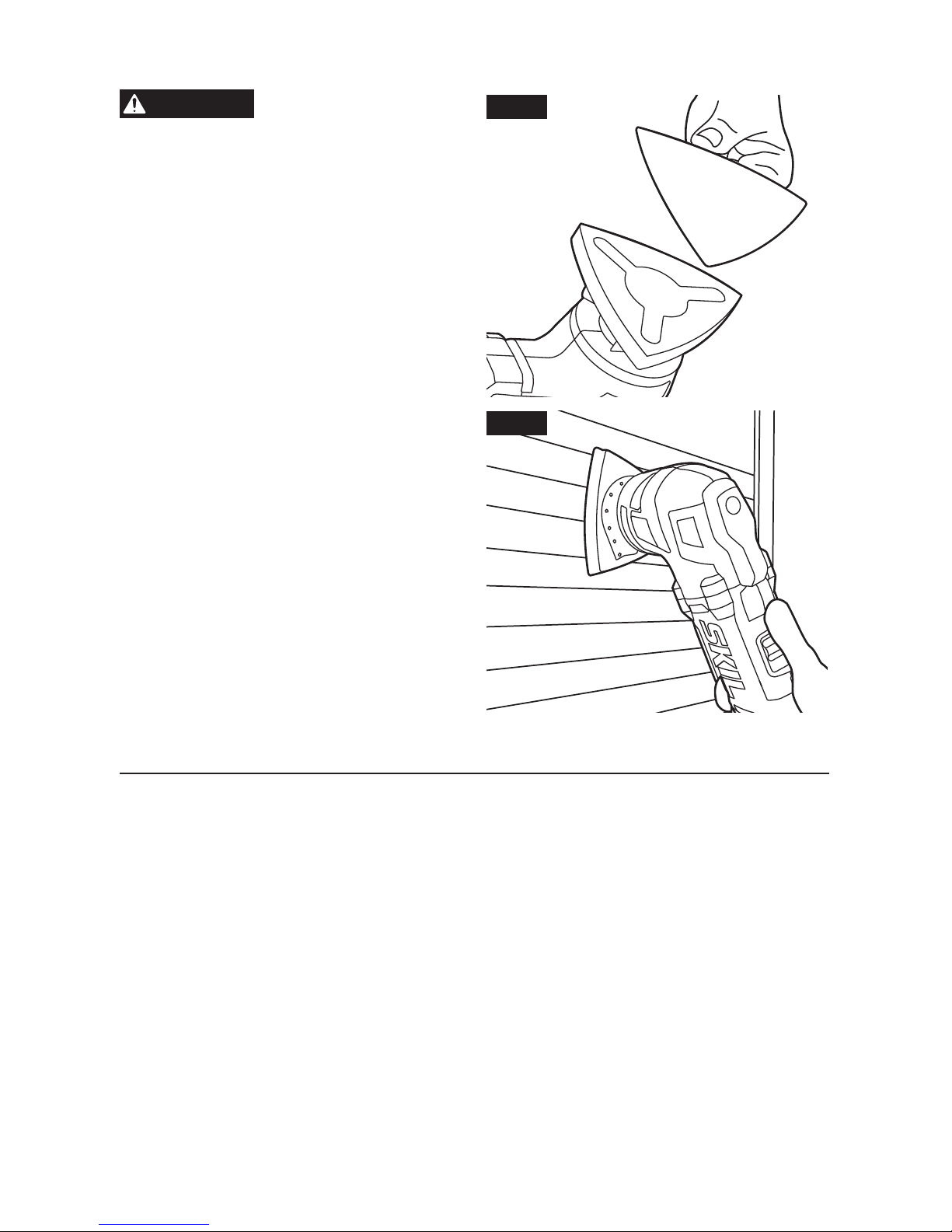

Using with Sanding Base Plate Set (Fig.8)

WARNING

- Always wear safety goggles or safety

glasses with side shields during power

tool operation. If operation is dusty, also

wear a dust mask.

- Wear protective gloves.

a. Align the sandpaper with the sanding plate

and use your hand to press it rmly onto the

sanding plate.

b. It is recommended to sand a test sample of

the workpiece rst to select the best sanding

paper.

c. Select a higher speed range when sanding

with the multi-tool.

d. Allow the tool to reach its full selected speed

before allowing it to contact the workpiece.

Press the power tool with the sanding

plate set rmly against the workpiece. This

provides for good adhesion and prevents

premature wear.

e. Work with the entire surface of the sanding

plate and sanding paper, not just the tip.

When one tip or corner of the sanding paper

is worn, the sandpaper can be removed,

turned 120°, and reattached.

f. Sand the workpiece in a continuous motion

with moderate pressure. Excessive pressure

does not increase the rate of removal. It will

result in unwanted sanding marks and cause

the sanding paper to wear more quickly. It

can also cause tool overload.

Fig. 8a

Fig. 8b

18

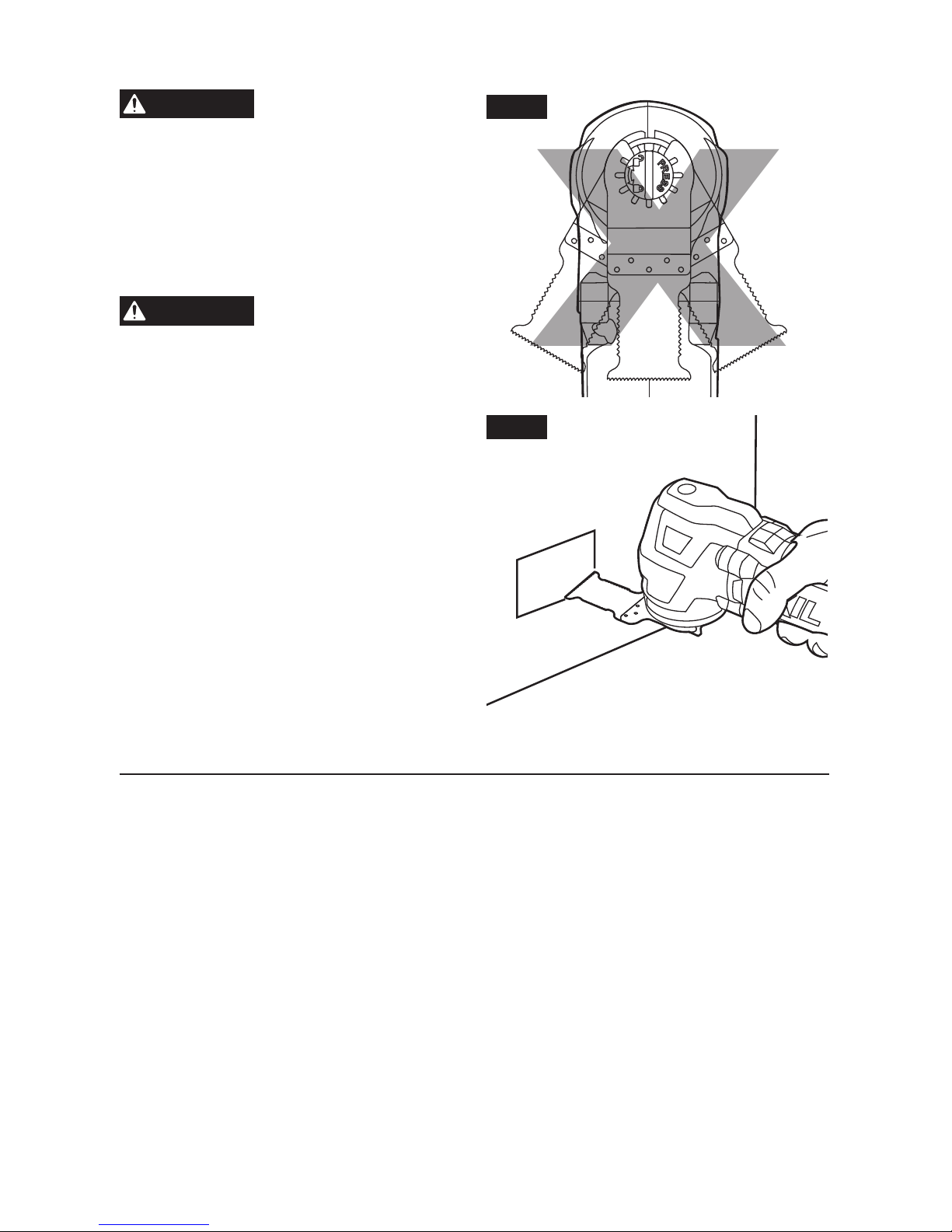

Using with Plunge-Cut Blade (Fig.9)

WARNING

- Always wear safety goggles or safety

glasses with side shields during power

tool operation. If the operation is dusty,

also wear a dust mask.

- Wear protective gloves.

- Use sharp, undamaged blades only.

Deformed or blunt blades or blades that

are otherwise damaged can break.

WARNING

Do not attach the plunge-

cut blade facing backward, as operation in this position may

cause serious injury (Fig. 9a).

The plunge-cut blade is intended to make

precise cuts to aid in the installation of ooring

or wall materials.

a. Select a medium to high speed for making

the initial plunge. You can increase speed

for faster cutting after the initial cut.

b. Allow the tool to reach its full selected speed

before allowing it to contact the workpiece.

c. Do not force the tool during the plunge cut.

Let the speed of the tool do the work.

d. While keeping the teeth of the blade in the

work surface, move the back of the tool in

a slow, sideways motion, which will help to

expedite the cut.

e. Make sure that the tool comes to a

complete stop before you remove it from the

workpiece.

X

Fig. 9a

Fig. 9b

19

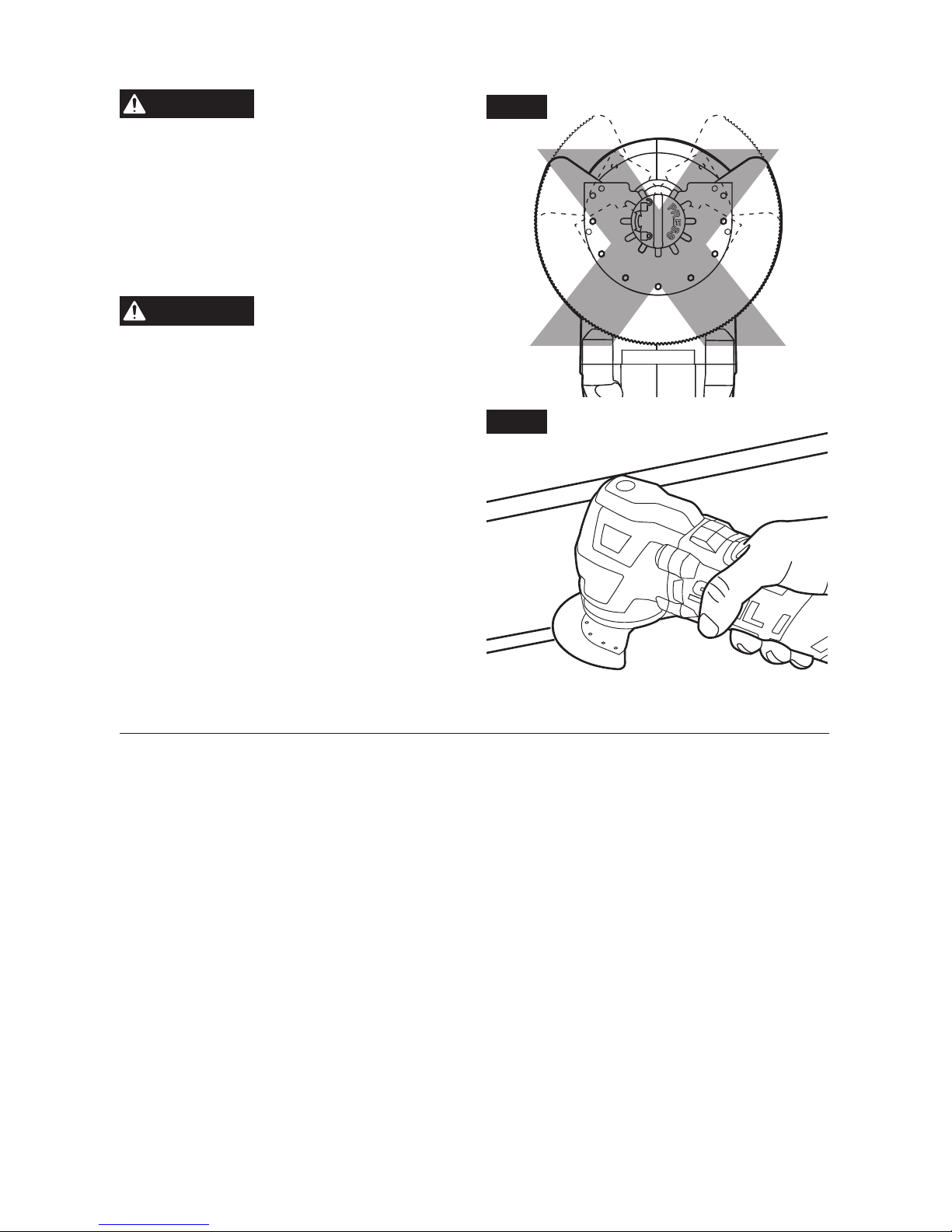

Using with Flush Circular Blade (Fig.10)

WARNING

- Always wear safety goggles or safety

glasses with side shields during power

tool operation. If the operation is dusty,

also wear a dust mask.

- Wear protective gloves.

- Use sharp, undamaged blades only.

Deformed or blunt blades or blades that

are otherwise damaged can break.

WARNING

Do not attach the ush

circular blade facing

backward, as operation in this position may

cause serious injury (Fig. 10a).

The ush circular blade is ideal for making

cuts in wood, plaster, drywall, non-ferrous

metals, thin sheet metal, and other materials.

The blade works best on softer woods, such

as pine. For harder woods, the blade life

will be limited. Allow the tool to reach its full

selected speed before allowing it to contact the

workpiece.

X

Fig. 10a

Fig. 10b

20

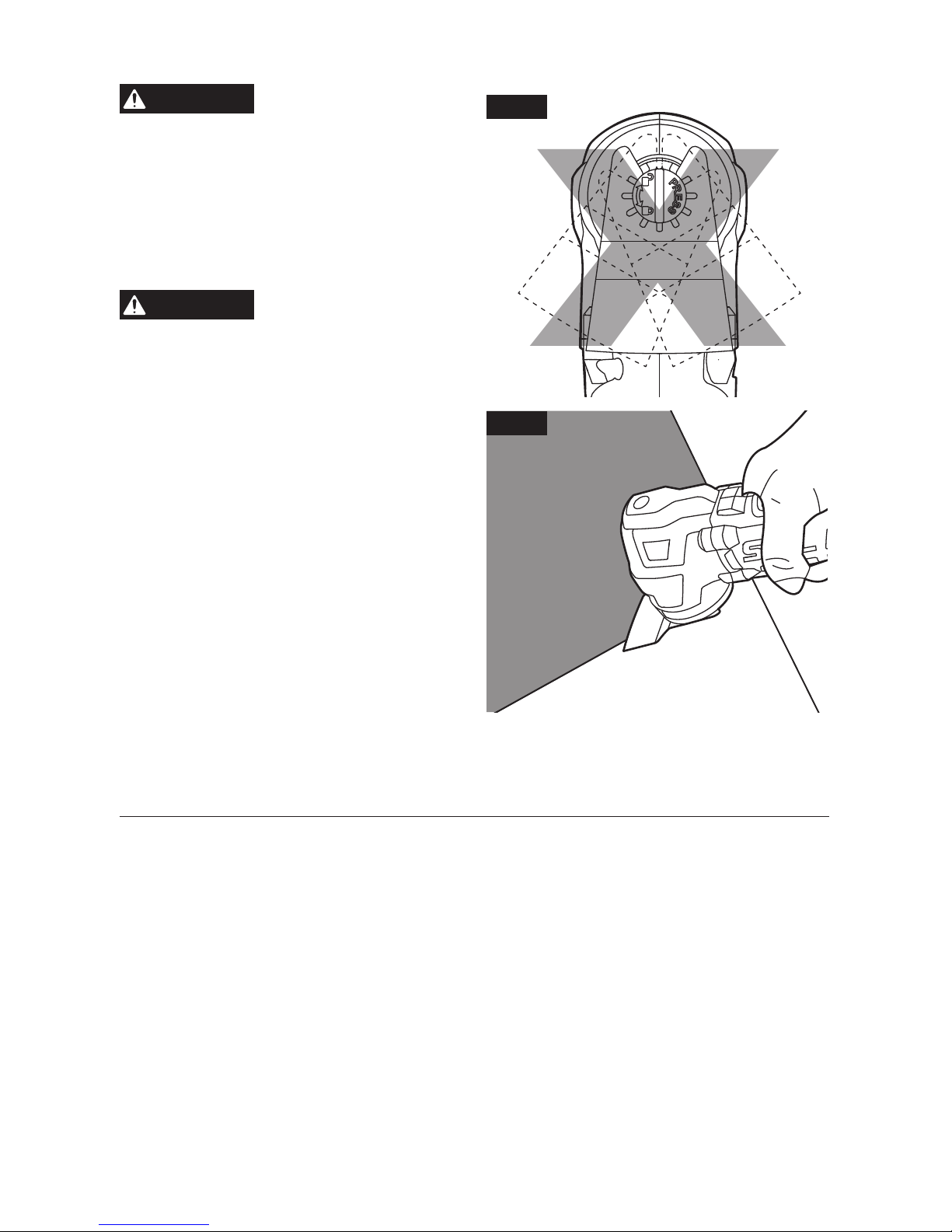

Using with Rigid Scraper Blade (Fig.11)

WARNING

- Always wear safety goggles or safety

glasses with side shields during power

tool operation. If the operation is dusty,

also wear a dust mask.

- Wear protective gloves.

- Use sharp, undamaged blades only.

Deformed or blunt blades or blades that

are otherwise damaged can break.

WARNING

Do not attach the rigid

scraper blade facing

backward, as operation in this position may

cause serious injury (Fig. 11a).

Scrapers are suitable for removing old coats

of varnish or adhesives and removing bonded

carpeting. Select low to medium speed.

Carpet/vinyl ooring is removed more easily if

it is scored prior to removal, so that the scraper

blade can move underneath the ooring

material.

a. To cut and remove carpet, rst place the

rigid scraper blade vertically on the carpet,

then turn the tool on, allow the tool to reach

its full selected speed before allowing it to

contact the workpiece, and cut through the

carpet to the oor.

b. Next, place the blade at between the carpet

and the oor to remove the adhesive and

free the carpet from the oor.

c. Put the tool on the workpiece at a at angle

(not more than 20°) and make sure that the locking rod does not make contact with surface

during the scraping process, so as to not cut into the surface.

d. Begin with light pressure. Excessive pressure can gouge or damage surfaces.

X

Fig. 11a

Fig. 11b

21

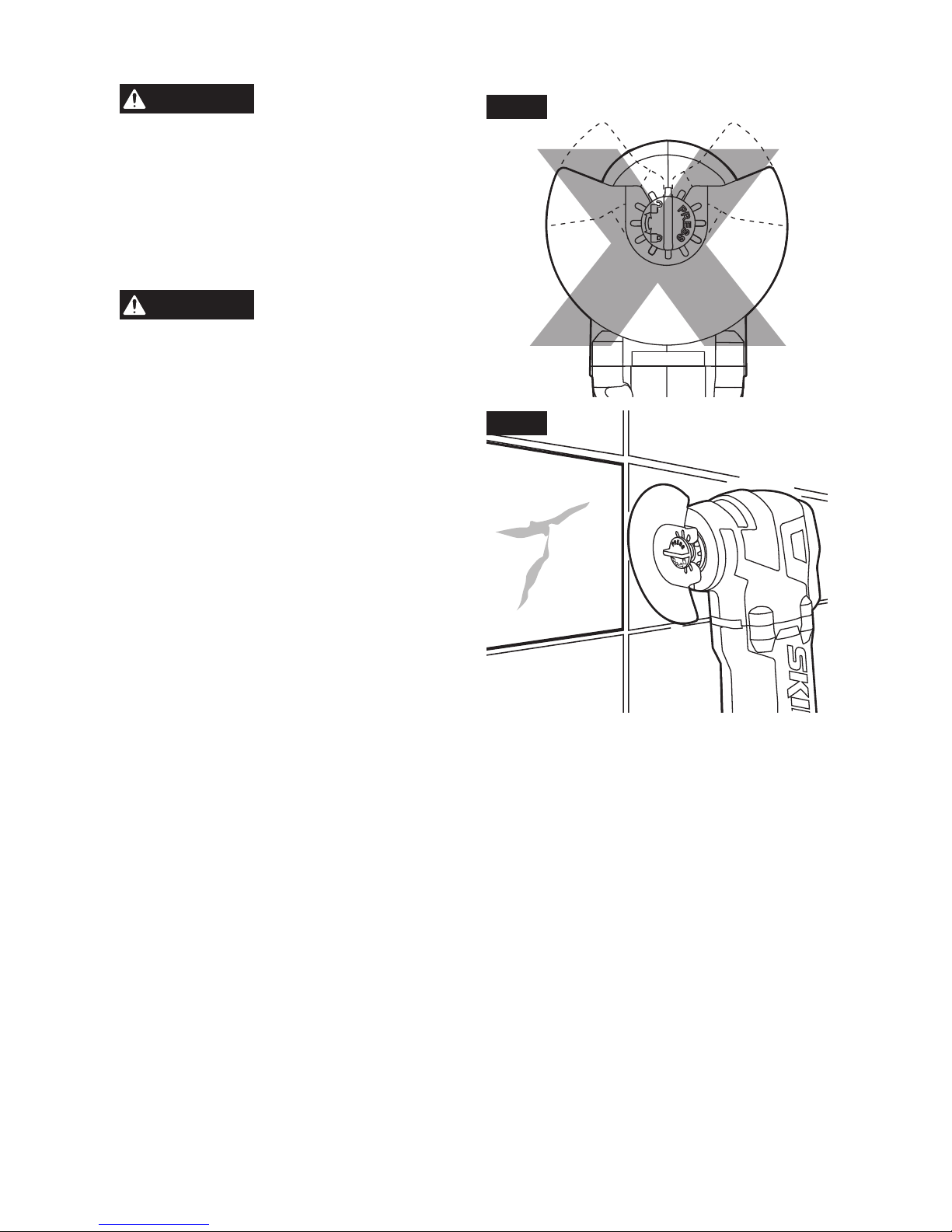

Using with Carbide Grout-Removal Blade (Fig.12)

WARNING

- Always wear safety goggles or safety

glasses with side shields during power

tool operation. If the operation is dusty,

also wear a dust mask.

- Wear protective gloves.

- Use sharp, undamaged blades only.

Deformed or blunt blades or blades that

are otherwise damaged can break.

WARNING

Do not attach the carbide

grout-removal blade

facing backward, as operation in this

position may cause serious injury (Fig.

12a).

Grout-removal blades are ideal for removing

damaged or cracked grout. They can also

be used to cut plaster, porous concrete, and

masonry. Select a medium to high speed.

a. To remove grout, place the carbide grout-

removal blade against the workpiece at a

90° angle. Allow the tool to reach its full

selected speed before allowing it to contact

the workpiece. Use a back-and-forth motion

to make several passes along the grout line.

b. Try to keep the grout-removal blade aligned

with the grout line and be careful not to apply

too much side pressure on the grout blade

during the process.

c. Cut out the grout around the tile, then use a

hand chisel to remove the tile from the wall.

If the blade jams during the grout removal process, you can use a brush to clean the grit and

resume work.

NOTICE: When cutting grout, masonry and porous cement, take into consideration that the

accessories wear heavily when used for longer periods of time.

X

Fig. 12a

Fig. 12b

22

MAINTENANCE

WARNING

To avoid serious personal injury, always remove the battery pack

from the tool when cleaning or performing any maintenance.

Service

WARNING

Preventive maintenance performed by unauthorized personnel may

result in misplacement of internal wires and components which could

cause serious hazard. We recommend that all tool service be performed by a SKIL Factory

Service Center or Authorized SKIL Service Station.

General Maintenance

WARNING

When servicing, use only identical replacement parts. Use of any

other parts could create a hazard or cause product damage.

Periodically inspect the entire product for damaged, missing, or loose parts such as screws,

nuts, bolts, caps, etc. Securely tighten all fasteners and caps and do not operate this product

until all missing or damaged parts are replaced. Please contact customer service or an

authorized service center for assistance.

Cleaning

WARNING

The tool may be cleaned most effectively with compressed dry air. Always

wear safety goggles when cleaning tools with compressed air.

Ventilation openings and switch levers must be kept clean and free of foreign matter. Do not

attempt to clean by inserting pointed objects through openings.

WARNING

Certain cleaning agents and solvents damage plastic parts. Some of

these are: gasoline, carbon tetrachloride, chlorinated cleaning solvents,

ammonia and house hold detergents that contain ammonia.

Storage

Store the tool indoors in a place that is inaccessible to children. Keep away from corrosive

agents.

TROUBLESHOOTING

Problem Cause Remedy

Tool does not work. 1. Battery pack is depleted.

2. Battery pack is not installed

properly.

3. Burned out switch.

1. Charge the battery pack.

2. Conrm that the battery pack

is locked and secured to the

tool.

3. Have the switch replaced by

an Authorized SKIL Service

Center or Service Station.

Strong vibration or loud

noise during operation.

Accessory is not installed

securely.

Reinstall the accessory

according to “Installing and

Removing Accessories”

The Halo light ashes

rapidly.

The tool has stopped working

to protect internal circuits from

overheating.

Turn the tool OFF, wait for the

tool to cool down, then start the

tool again.

The Halo light ashes

slowly.

Low battery. Charge the battery.

Loading...

Loading...