Skil PL201201 Owner's Manual

Owner’s Manual

Guide d’utilisation

Manual del propietario

Model/ Modelo/ Modèle: PL201201

6.5A Planer

Dégauchisseuse de 6,5 A

Cepilladora de 6,5 A

WARNING: To reduce the risk of injury, the user must read and understand the

Owner’s Manual before using this product. Save these instructions for future reference.

AVERTISSEMENT : Afin de réduire les risques de blessure, l’utilisateur doit lire et

comprendre le guide d’utilisation avant d’utiliser cet article. Conservez le présent guide

afin de pouvoir le consulter ultérieurement.

ADVERTENCIA : Para reducir el riesgo de lesiones, el usuario debe leer y comprender

el Manual del operador antes de utilizar este producto. Guarde estas instrucciones para

consultarlas en caso sea necesario.

For Customer Service

Pour le service à la clientèle

Servicio al cliente

1-877-SKIL-999 OR www.skil.com

TABLE OF CONTENTS

General Power Tool Safety Warnings .............................3-4

Safety Warnings for Planer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Symbols .....................................................5-7

Get to Know Your Planer .........................................8

Specications ..................................................8

Operating Instructions ........................................9-14

Maintenance ................................................15-17

Troubleshooting ...............................................17

Limited Warranty of Skil Consumer Portable,

Benchtop and Hd and Shd Heavy Duty Power Tools ..................18

WARNING

•

Some dust created by power sanding, sawing, grinding, drilling and other construction

activities contains chemicals known to the State of California to cause cancer, birth defects

or other reproductive harm. Some examples of these chemicals are:

–

Lead from lead-based paints.

–

Crystalline silica from bricks, cement, and other masonry products.

–

Arsenic and chromium from chemically-treated lumber.

•

Your risk from these exposures varies, depending upon how often you do this type of work.

To reduce your exposure to these chemicals:

–

Work in a well-ventilated area.

–

Work with approved safety equipment, such as dust masks that are specially designed to

lter out microscopic particles.

–

Avoid prolonged contact with dust from power sanding, sawing, grinding, drilling, and

other construction activities. Wear protective clothing and wash exposed areas with soap

and water. Allowing dust to get into your mouth or eyes or to lie on the skin may promote

absorption of harmful chemicals.

2

GENERAL POWER TOOL SAFETY WARNINGS

WARNING

below may result in electric shock, re and/or serious injury.

Read all safety warnings, instructions, illustrations and specications

provided with this power tool. Failure to follow all instructions listed

SAVE ALL WARNINGS AND INSTRUCTIONS FOR FUTURE

REFERENCE.

The term “power tool” in the warnings refers to your mains-operated (corded) power tool or

battery-operated (cordless) power tool.

Work area safety

Keep work area clean and well lit. Cluttered or dark areas invite accidents.

Do not operate power tools in explosive atmospheres, such as in the presence of

ammable liquids, gases or dust. Power tools create sparks which may ignite the dust or

fumes.

Keep children and bystanders away while operating a power tool. Distractions can cause

you to lose control.

Electrical safety

Power tool plugs must match the outlet. Never modify the plug in any way. Do not use

any adapter plugs with earthed (grounded) power tools. Unmodied plugs and matching

outlets will reduce risk of electric shock.

Avoid body contact with earthed or grounded surfaces, such as pipes, radiators,

ranges and refrigerators. There is an increased risk of electric shock if your body is earthed

or grounded.

Do not expose power tools to rain or wet conditions. Water entering a power tool will

increase the risk of electric shock.

Do not abuse the cord. Never use the cord for carrying, pulling or unplugging the power

tool. Keep cord away from heat, oil, sharp edges or moving parts. Damaged or entangled

cords increase the risk of electric shock.

When operating a power tool outdoors, use an extension cord suitable for outdoor use.

Use of a cord suitable for outdoor use reduces the risk of electric shock.

If operating a power tool in a damp location is unavoidable, use a ground fault circuit

interrupter (GFCI) protected supply. Use of a GFCI reduces the risk of electric shock.

Personal safety

Stay alert, watch what you are doing and use common sense when operating a power

tool. Do not use a power tool while you are tired or under the inuence of drugs,

alcohol or medication. A moment of inattention while operating power tools may result in

serious personal injury.

Use personal protective equipment. Always wear eye protection. Protective equipment

such as a dust mask, non-skid safety shoes, hard hat or hearing protection used for

appropriate conditions will reduce personal injuries.

Prevent unintentional starting. Ensure the switch is in the off-position before

connecting to power source and/or battery pack, picking up or carrying the tool.

Carrying power tools with your nger on the switch or energising power tools that have the

switch on invites accidents.

Remove any adjusting key or wrench before turning the power tool on. A wrench or a

key left attached to a rotating part of the power tool may result in personal injury.

Do not overreach. Keep proper footing and balance at all times. This enables better

3

control of the power tool in unexpected situations.

Dress properly. Do not wear loose clothing or jewellery. Keep your hair and clothing

away from moving parts. Loose clothes, jewellery or long hair can be caught in moving

parts.

If devices are provided for the connection of dust extraction and collection facilities,

ensure these are connected and properly used. Use of dust collection can reduce dust-

related hazards.

Do not let familiarity gained from frequent use of tools allow you to become complacent

and ignore tool safety principles. A careless action can cause severe injury within a fraction

of a second.

Power tool use and care

Do not force the power tool. Use the correct power tool for your application. The correct

power tool will do the job better and safer at the rate for which it was designed.

Do not use the power tool if the switch does not turn it on and off. Any power tool that

cannot be controlled with the switch is dangerous and must be repaired.

Disconnect the plug from the power source and/or remove the battery pack, if

detachable, from the power tool before making any adjustments, changing accessories,

or storing power tools. Such preventive safety measures reduce the risk of starting the

power tool accidentally.

Store idle power tools out of the reach of children and do not allow persons unfamiliar

with the power tool or these instructions to operate the power tool. Power tools are

dangerous in the hands of untrained users.

Maintain power tools and accessories. Check for misalignment or binding of moving

parts, breakage of parts and any other condition that may affect the power tool’s

operation. If damaged, have the power tool repaired before use. Many accidents are

caused by poorly maintained power tools.

Keep cutting tools sharp and clean. Properly maintained cutting tools with sharp cutting

edges are less likely to bind and are easier to control.

Use the power tool, accessories and tool bits etc. in accordance with these instructions,

taking into account the working conditions and the work to be performed. Use of the

power tool for operations different from those intended could result in a hazardous situation.

Keep handles and grasping surfaces dry, clean and free from oil and grease. Slippery

handles and grasping surfaces do not allow for safe handling and control of the tool in

unexpected situations.

Service

Have your power tool serviced by a qualied repair person using only identical

replacement parts. This will ensure that the safety of the power tool is maintained.

SAFETY WARNINGS FOR PLANER

Wait for the cutter to stop before setting the tool down. An exposed rotating cutter may

engage the surface leading to possible loss of control and serious injury.

Hold the power tool by insulated gripping surfaces, because the cutter may contact its

own cord. Cutting a “live” wire may make exposed metal parts of the power tool “live” and

could give the operator an electric shock.

Use clamps or another practical way to secure and support the workpiece to a stable

platform. Holding the workpiece by your hand or against the body leaves it unstable and may

lead to loss of control.

4

SYMBOLS

Safety Symbols

The purpose of safety symbols is to attract your attention to possible dangers. The safety

symbols and the explanations with them deserve your careful attention and understanding.

The symbol warnings do not, by themselves, eliminate any danger. The instructions and

warnings they give are no substitutes for proper accident prevention measures.

WARNING

“WARNING,” and “CAUTION” before using this tool. Failure to following all instructions listed

below may result in electric shock, re, and/or serious personal injury.

Be sure to read and understand all safety instructions in this Owner’s

Manual, including all safety alert symbols such as “DANGER,”

The denitions below describe the level of severity for each signal word. Please read the manual

DANGER

WARNING

CAUTION

and pay attention to these symbols.

This is the safety alert symbol. It is used to alert you to potential

personal injury hazards. Obey all safety messages that follow this

symbol to avoid possible injury or death.

DANGER indicates a hazardous situation which, if not avoided, will

result in death or serious injury.

WARNING indicates a hazardous situation which, if not avoided, could

result in death or serious injury.

CAUTION, used with the safety alert symbol, indicates a hazardous

situation which, if not avoided, will result in minor or moderate injury.

Damage Prevention and Information Messages

These inform the user of important information and/or instructions that could lead to equipment

or other property damage if they are not followed. Each message is preceded by the word

“NOTICE”, as in the example below:

NOTICE: Equipment and/or property damage may result if these instructions are not followed.

WARNING

in severe eye damage. Before beginning power tool operation, always

wear safety goggles or safety glasses with side shields and a full face

shield when needed. We recommend a Wide Vision Safety Mask for use

over eyeglasses or standard safety glasses with side shields. Always use

eye protection which is marked to comply with ANSI Z87.1.

The operation of any power tools can result in

objects being thrown into your eyes, which can result

foreign

5

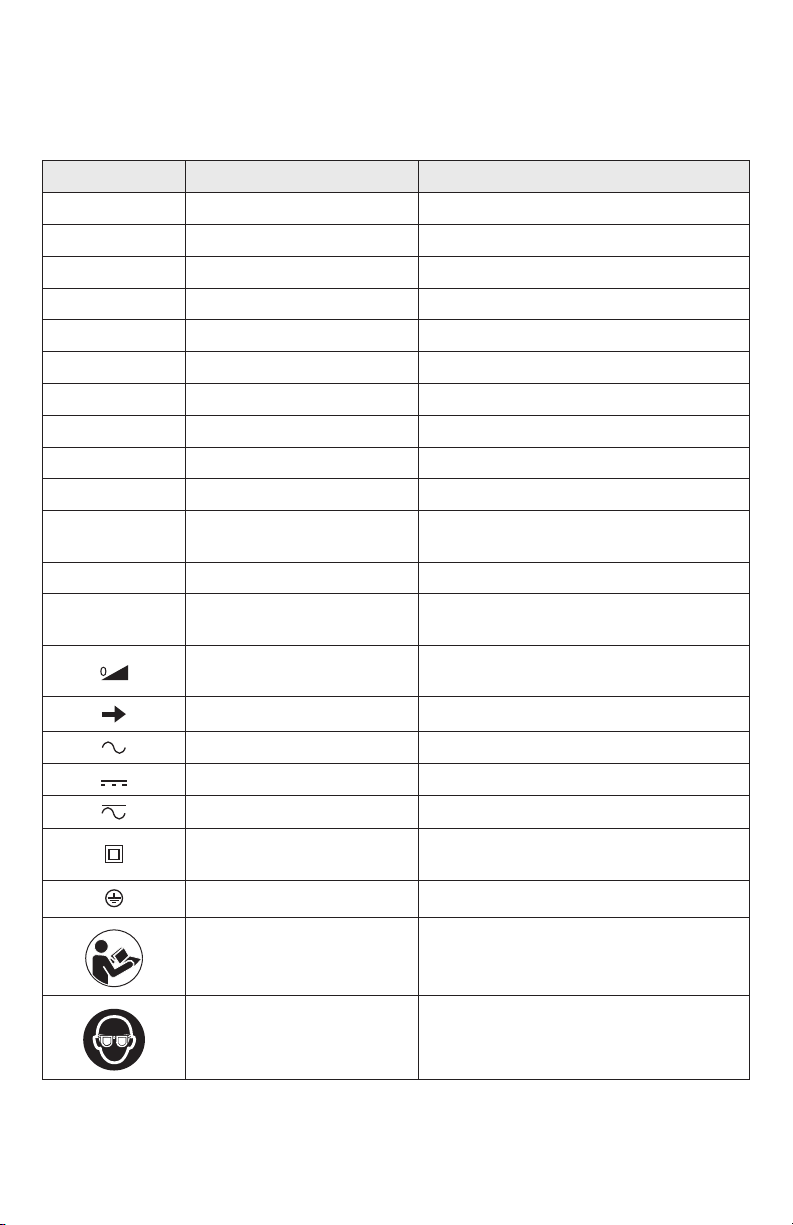

SYMBOLS (CONTINUED)

IMPORTANT: Some of the following symbols may be used on your tool. Please study them

and learn their meaning. Proper interpretation of these symbols will allow you to operate the

tool better and more safely.

Symbol Name Designation/Explanation

V Volts Voltage (potential)

A Amperes Current

Hz Hertz Frequency (cycles per second)

W Watt Power

kg Kilograms Weight

min Minutes Time

s Seconds Time

Ø Diameter Size of drill bits, grinding wheels, etc.

n

0

n Rated speed Maximum attainable speed

…/min

0 Off position Zero speed, zero torque...

1,2,3,…

I,II,III,

No load speed Rotational speed, at no load

Revolutions or reciprocation

per minute

Selector settings

Innitely variable selector

with off

Arrow Action in the direction of arrow

Alternating current Type or a characteristic of current

Direct current Type or a characteristic of current

Alternating or direct current Type or a characteristic of current

Class II tool

Revolutions, strokes, surface speed,

orbits, etc. per minute

Speed, torque or position settings. Higher

number means greater speed

Speed is increasing from 0 setting

Designates Double Insulated Construction

tools.

Earthing terminal Grounding terminal

Read manual symbol Alerts user to read manual

Wear eye protection symbol Alerts user to wear eye protection

6

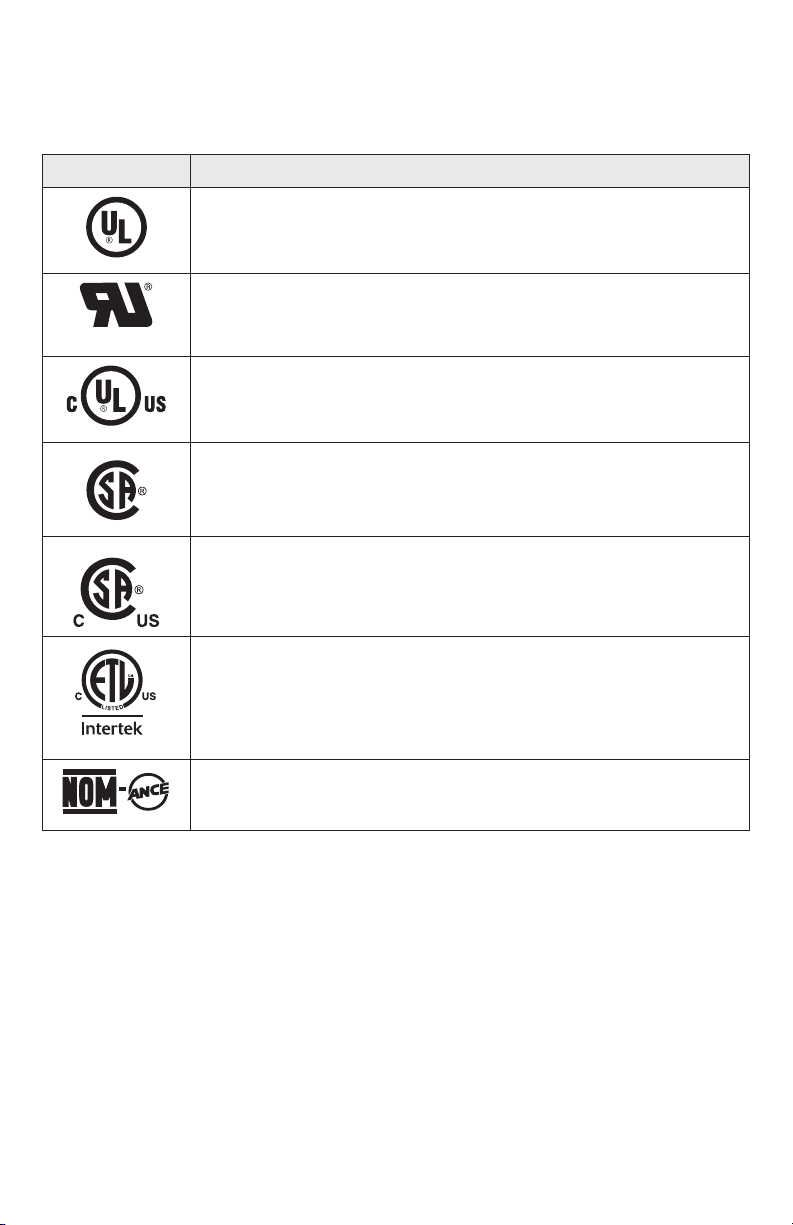

SYMBOLS (CERTIFICATION INFORMATION)

IMPORTANT: Some of the following symbols for certication information may be used on your

tool. Please study them and learn their meaning. Proper interpretation of these symbols will

allow you to operate the tool better and more safely.

Symbol Designation/Explanation

This symbol designates that this tool is listed by Underwriters Laboratories.

This symbol designates that this tool is recognized by Underwriters

Laboratories.

This symbol designates that this tool is listed by Underwriters

Laboratories, to United States and Canadian Standards.

This symbol designates that this tool is listed by the Canadian

Standards Association.

This symbol designates that this tool is listed by the Canadian

Standards Association, to United States and Canadian Standards.

This symbol designates that this tool is listed by the Intertek Testing

Services, to United States and Canadian Standards.

This symbol designates that this tool complies to NOM Mexican

Standards.

7

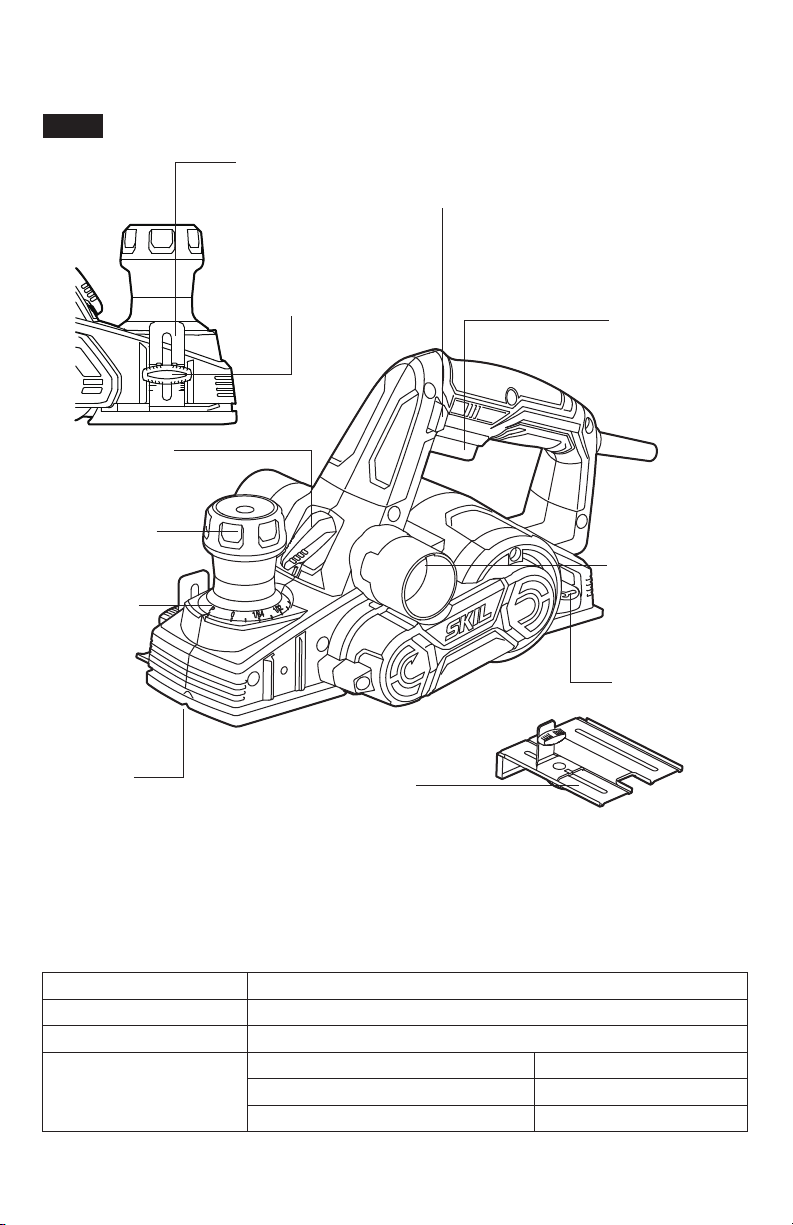

GET TO KNOW YOUR PLANER

AC Planer

Fig. 1

Rabbeting-depth

stop

Lock-off Button

Dust/ChipExtraction Guide

Switch

Cutting-DepthAdjustment

Knob

Cutting-Depth

Scale

V-groove

Locking Knob (x2)

ON/OFF Switch

Dust/ChipExtraction Ports

(x2)

Blade-change

Wrench

Edge Guide

SPECIFICATIONS

Rating 120V a.c. 60Hz

Input 6.5A

No-load speed 16000 /min

Planing width 3-1/4’’ (82mm)

Planing capacity

8

Planing depth 5/64’’ (2mm)

Rabbeting depth 5/16’’ (8mm)

OPERATING INSTRUCTIONS

WARNING

safety measures reduce the risk of starting the tool accidentally.

WARNING

result in serious personal injury.

WARNING

is misuse and could result in a hazardous condition leading to possible serious injury.

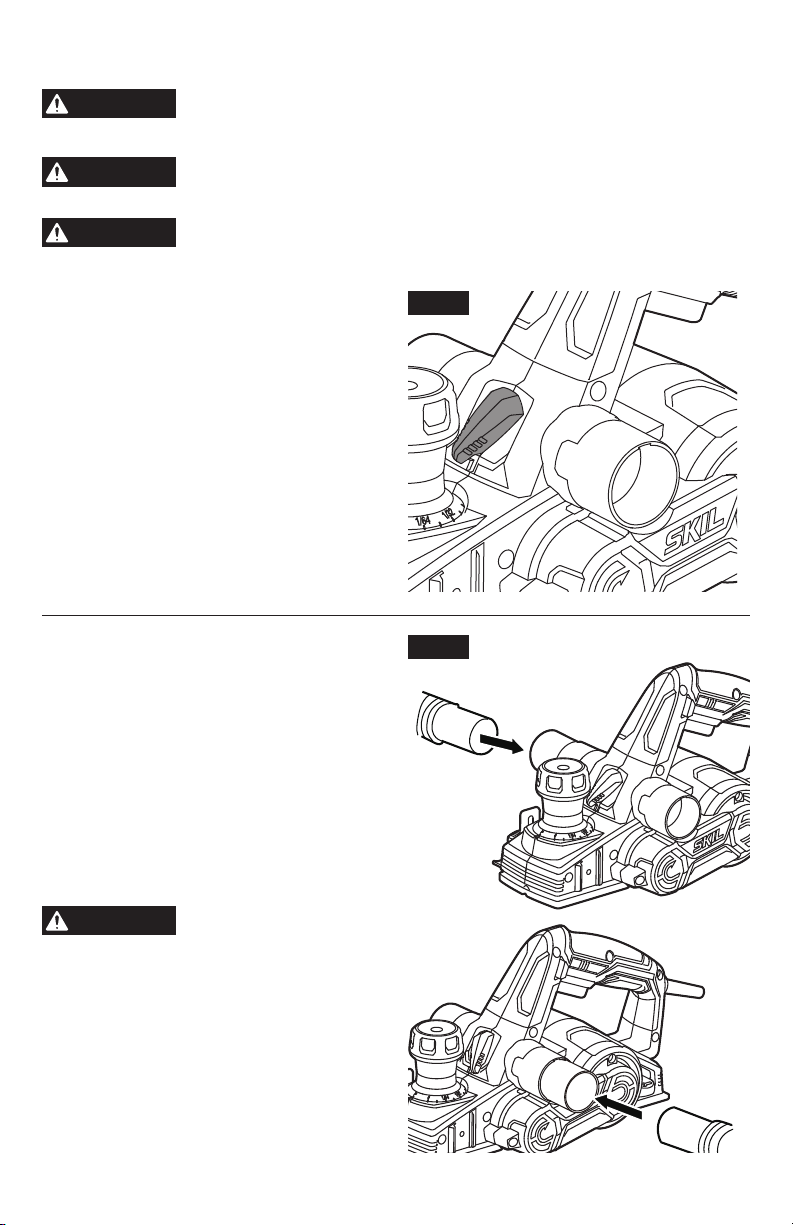

Dust/Chip Extraction Guide

Disconnect the plug from the power source before performing any

assembly, adjustments or changing accessories. Such preventive

If any parts are damaged or missing, do not operate this tool until the

parts are replaced. Use of this tool with damaged or missing parts could

Do not attempt to modify this tool or create accessories not

recommended for use with this tool. Any such alteration or modication

Fig. 2

Switch (Fig. 2)

Move the switch to the left to cause chips to be

discharged to the left;

Move the switch to the right to cause chips to

be discharged to the right.

Move the switch as your need.

Dust/Chip Extraction (Fig.3)

Your tool is equipped with two dust/chipextraction ports, which may be used with a

vacuum adapter or a dust bag to keep your

work environment cleaner.

Firmly attach the vacuum adapter or dust

bag to the extraction port. A workshop dustextraction system or a household vacuum

cleaner can be connected to the vacuum

adapter for the efficient removal of dust and

shavings.

The vacuum adapter will t 1-1/4” hoses.

WARNING

dust/chip extraction ports while knives are

rotating.

Do not attempt to remove

any obstructions from the

Fig. 3

9

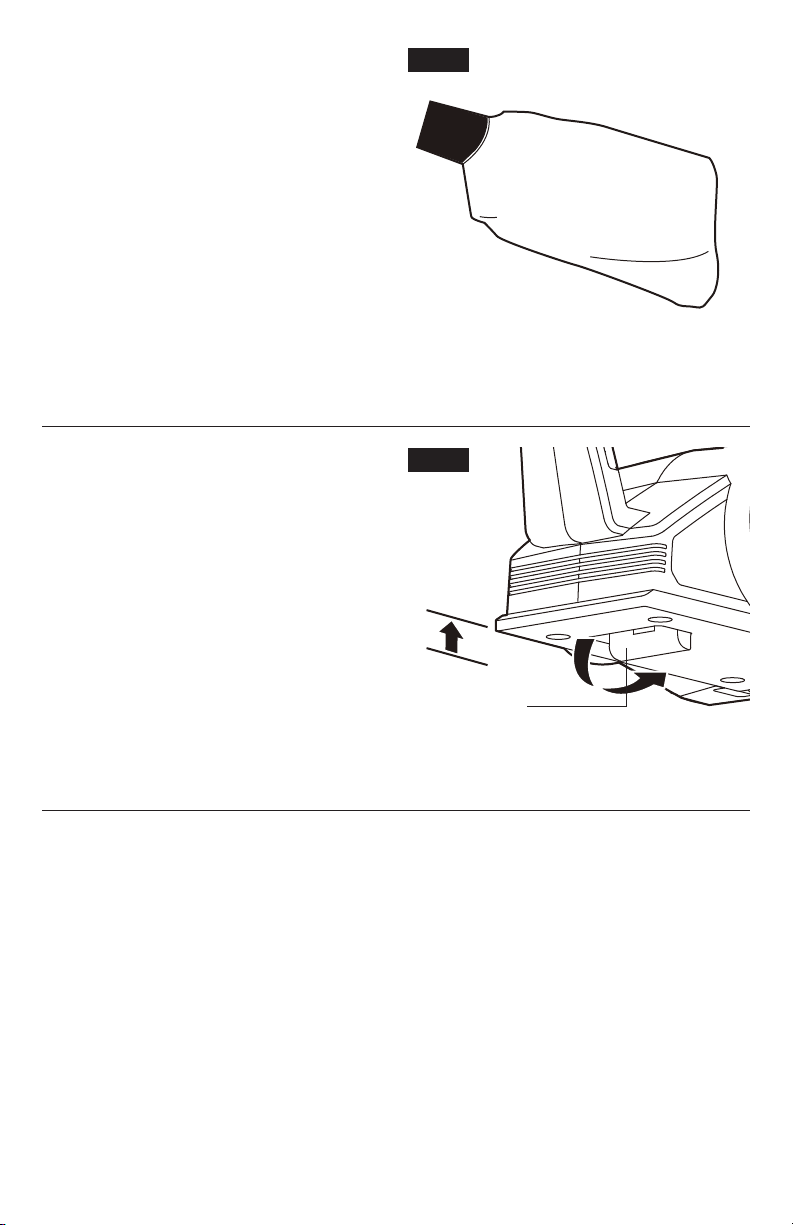

Dust Bag (Fig.4)

Attach the dust bag to the dust/chip-extraction

port for smaller jobs.

Also wear a suitable dust mask, as there may

be some residual airborne dust particles in the

area.

To attach the dust bag: Align the raised

emboss on the dust bag with the groove in the

extraction port and slide the dust bag into the

port. Then rotate the dust bag towards the front

of tool to lock it in place.

Empty the dust bag: Empty the dust bag by

unzipping the bag and then gently tapping the

bag to remove the dust. For a more thorough

cleaning of the dust bag, slip the bag off of the frame and turn bag inside out. Use a soft brush

to brush the dust off of the lining.

Fig. 4

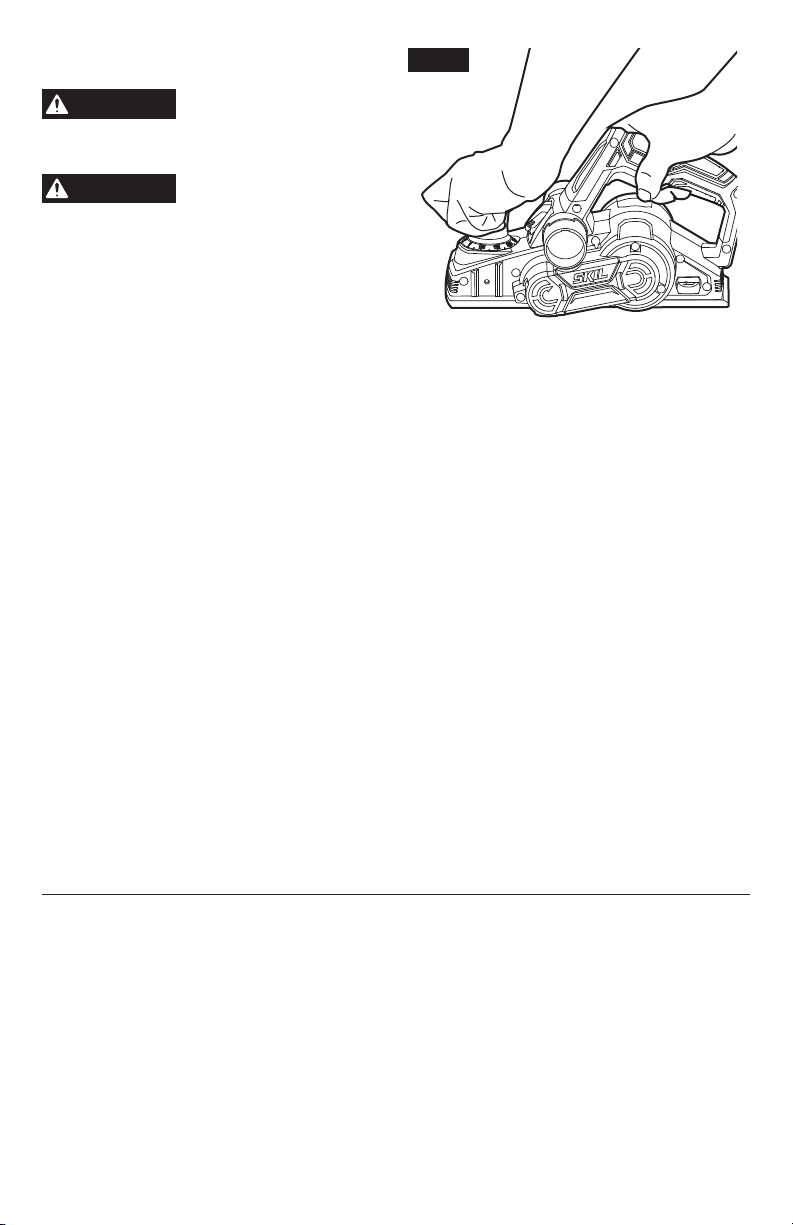

Park Rest (Fig.5)

The park rest swings down to help keep the

blade from coming into contact with the work

surface when the planer is not in use.

The tool park rest was designed to

automatically swing up and out of the way

when the back of the planer crosses the

leading edge of the workpiece.

Fig. 5

Park Rest

10

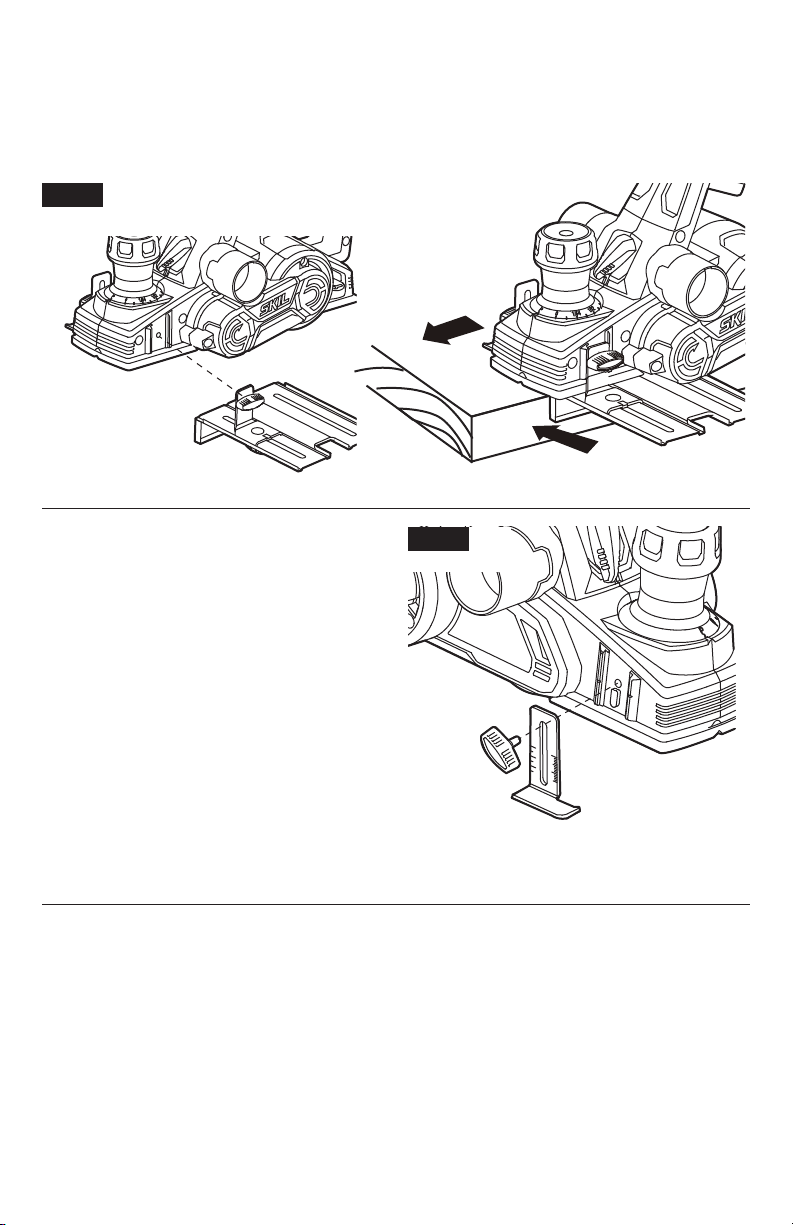

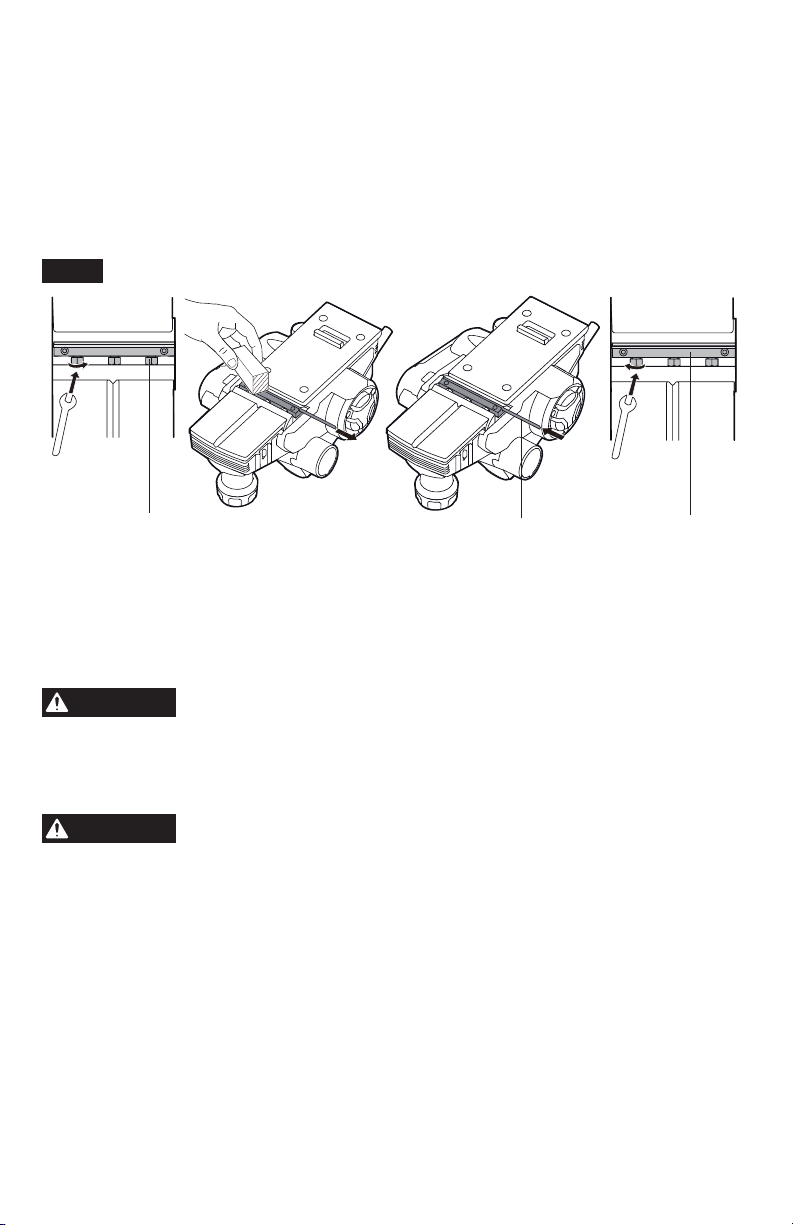

Edge Guide (Fig.6)

a. Remove the locking knob and slide the edge guide into the planer.

b. Replace the locking knob and rmly tighten it.

c. Loosen the locking nut and slide the edge guide to the desired position. Securely tighten the

locking nut.

Fig. 6

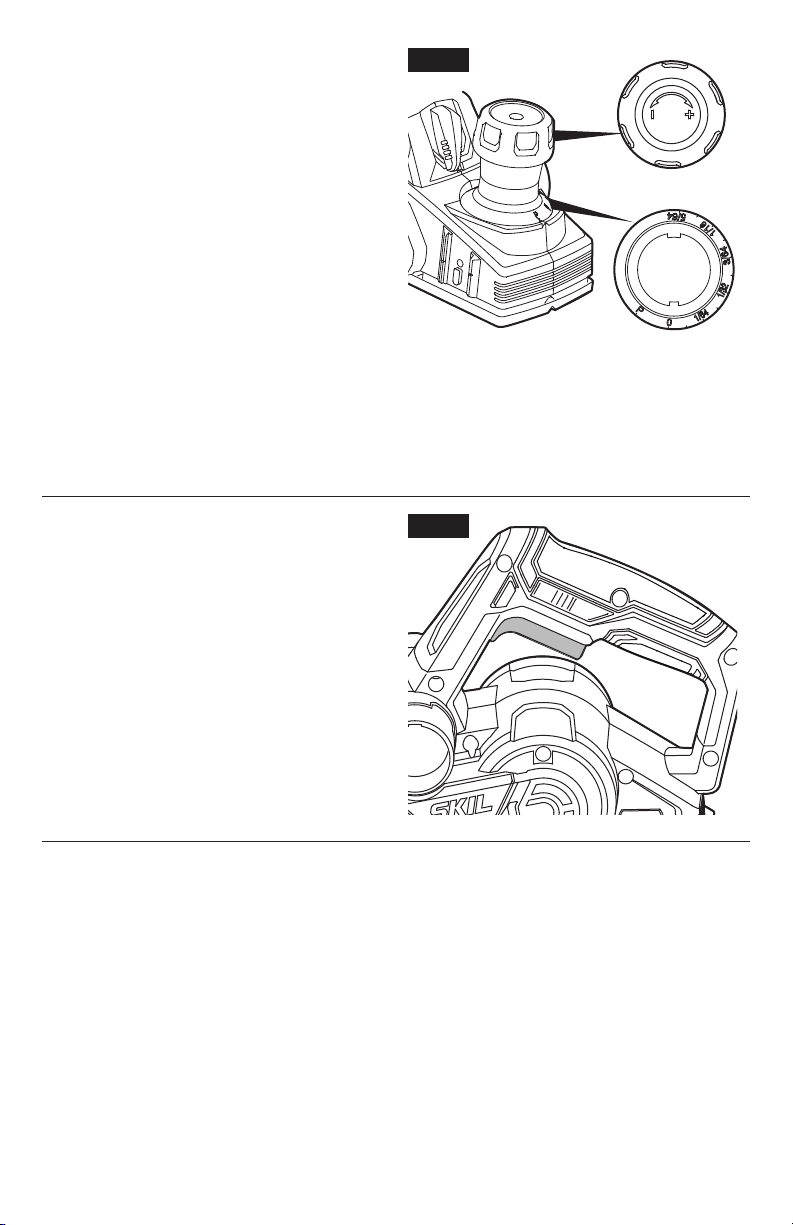

Rabbeting-Depth Stop (Fig.7)

The rabbeting-depth stop allows the user to

set any rabbeting depth from 0 to 5/16 inch (8

mm).

For best results, it is important that the blade

be properly aligned with the front base of the

tool. The width of the rabbet is controlled by

the edge guide. The final depth is achieved

by repeating the planning procedure until the

rabbeting-depth stop contacts the workpiece.

To setting the rabbeting depth:

a. Loosen the locking knob and set the desired

rabbet depth by aligning the depth scale on

the rabbeting-depth stop with the indicator

line.

b. Securely tighten locking nut.

Fig. 7

11

Adjusting the Depth of Cut (Fig.8)

The proper cutting depth should be determined

according to the hardness, gumminess or

moisture content of the material being cut, as

well as the feed rate, and is largely a matter of

experience.

Rotate the depth adjustment knob clockwise

for a deeper cut and counterclockwise for a

shallower cut.

The numbers on the cutting depth scale

indicate the depth of cut, e.g., when 1/64’’ is

next to the pointer on the front of the planer,

the depth of cut is approximately 1/64’’.

If it is necessary to more accurately determine

the depth of cut, plane a scrap piece of wood, measure the difference in thickness and adjust

the setting.

NOTICE: Always set the depth adjustment knob at the “P” position when the tool is not in use.

This retracts the planer blade, allowing the power tool to be placed down without the danger of

causing damage to the workpiece or the planer blade.

Fig. 8

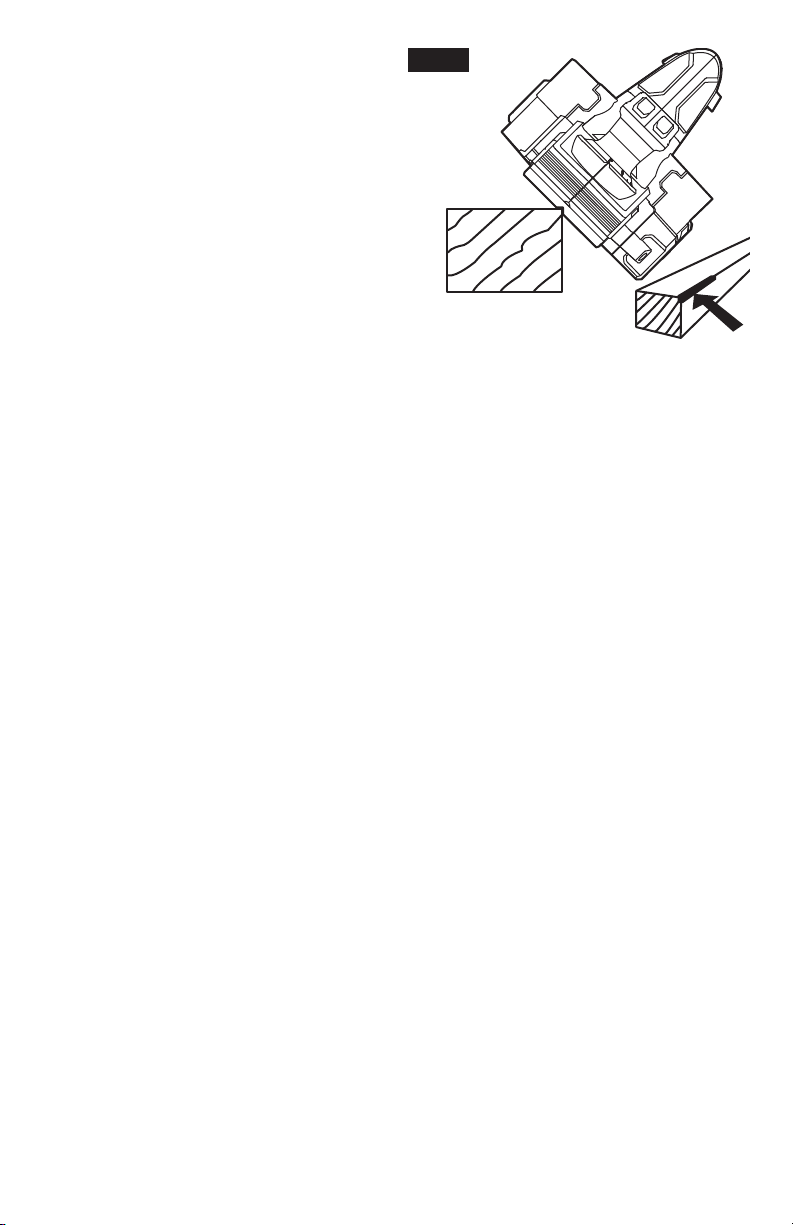

Turning ON and OFF (Fig.9)

a. Connect the power cord of your planer to a

standard household power outlet.

b. To turn the planer ON, hold the tool with both

hands, push in the lock-off button rst, and

then press the on/off trigger switch.

c. To turn the planer OFF, release the trigger

switch.

Fig. 9

12

Planing

Fig. 10

WARNING

Hold the tool with both

hands while starting the

tool, since torque from the motor can cause

the tool to twist.

WARNING

Wherever possible, clamp

the workpiece to a

workbench or clamping table.

a. Unplug the planer and adjust the edge guide

and the cutting depth as appropriate.

b. Clamp the workpiece securely on a

workbench.

c. Connect the power cord of your planer to a

standard household power outlet.

d. While standing comfortably, hold the planer rmly with both hands (Fig.10).

e. Place the front base of the planer against the workpiece surface without the blade making

any contact with the workpiece.

f. Turn on the tool, allow it to reach full speed, and guide the tool with even feed over the

surface to be planed.

g. Move the tool gently forward, applying pressure on the front of the tool at the beginning of

the planing pass and pressure at the rear of the tool at the end of the planing pass.

h. Push the planer beyond the edge of the workpiece without tilting it downwards.

NOTICE:

•

The rate of planing and the depth of cut determine the quality of the cut. For rough cutting,

you can increase the depth of cut. To achieve a smooth cut, you will need to reduce the

depth of cut and advance the planer slowly across the workpiece and make successive,

shallow cuts, as needed.

•

The proper feed rate will depend on the type of material being cut and the depth of the cut.

When planing hard materials (e.g., hardwood), as well as when utilizing the maximum planer

width, set only low planing depths and reduce the planer feed as required.

•

Practice first on a scrap piece of material to gauge the correct feed rate and the cutting

depths.

•

Planing is easier if you slightly incline the workpiece so that you plane “downhill”.

•

Moving the planer too quickly may cause a poor quality of cut and can damage the blades or

the motor. Moving the planer too slowly may burn or mar the workpiece.

•

Before turning off the tool, lift it from the workpiece.

13

Chamfering (Fig.11)

The “V” groove in the front base of the tool

allows quick and easy chamfering of workpiece

edges.

a. Place the “V” groove over the edge to be

chamfered. Be sure the blades are not

touching the workpiece.

b. Position the “V” groove absolutely at on the

edge to be beveled.

c. Grasp the tool rmly with both hands, turn

the tool on and push the planer forward with

steady pressure on the front base of the tool.

Fig. 11

14

MAINTENANCE

WARNING

To avoid accidents always disconnect the tool from the power supply

before cleaning or performing any maintenance.

Planer Blades

The planer blades have two cutting edges and may be reversed. When both cutting edges are

dull, the planer blade must be replaced.

The planer blades may not be re-sharpened. Do not attempt to sharpen or use re-sharpened

blades of any kind.

Use only blades designated for use with this model, because other blades will cause vibration,

decrease performance and may not clamp securely in the blade holder.

Replacing the Planer Blades (Fig.12)

WARNING

•

When installing blades, rst disconnect the tool from the power supply, then clean out

all chips and/or foreign matter adhering to the blade holder and the clamping element.

Use blades of the same dimensions and weight, or else the holder will oscillate and

vibrate, causing poor planing action and tool breakdown.

•

Tighten the clamping screws carefully when attaching the blades to the planer. A

loose clamping screw could be extremely dangerous. Regularly check and ensure

that the clamping screws are securely tightened.

•

Be cautious when replacing the planer blades. Do not grasp the planer blades by the

cutting edges. Injury may result due to the sharp cutting edges of the planer blades.

To remove the old planer blades:

a. Disconnect the plug from the power source.

b. Place the planer upside down on a at surface.

c. Loosen the three clamping screws with the wrench that is provided.

d. Push the blade sideways out of the blade holder. A piece of wood may be used for this

purpose.

15

To install planer blades:

a. Disconnect the plug from power source.

b. Place the planer upside down on a at surface.

c. Clean all surfaces before installing the new blade or reversing the old blade, as this will

ensure an accurate blade setting and proper tool performance.

d. Slide the blade into the blade holder of the clamping element. The blade groove must

engage with the blade holder.

e. Tighten the three clamping screws again with the wrench (provided).

Fig. 12

Clamping Screws (x3) Blade Blade Holder

NOTICE: Your planing surface will end up rough and uneven unless the blades are set

properly and securely. The blades must be mounted so that the cutting edge is absolutely

level relative to the surface of the front and rear base.

Service

CAUTION

cause serious hazard. We recommend that all tool service be performed by a SKIL Factory

Service Center or Authorized SKIL Service Station.

Preventive maintenance performed by unauthorized personnel may

result in misplacing of internal wires and components which could

General Maintenance

CAUTION

Periodically inspect the entire product for damaged, missing, or loose parts such as screws,

nuts, bolts, caps, etc. Tighten securely all fasteners and caps and do not operate this product

until all missing or damaged parts are replaced. Please contact customer service or an

authorized service center for assistance.

When servicing, use only identical replacement parts. Use of any

other parts could create a hazard or cause product damage.

Carbon Brushes

The brushes and commutator in your tool have been engineered for many hours of

dependable service. To maintain peak efciency of the motor, we recommend that the brushes

be examined every two to six months. Only genuine SKIL replacement brushes specially

designed for your tool should be used.

16

Cleaning

WARNING

Ventilation openings and switch levers must be kept clean and free of foreign matter. Do not

attempt to clean by inserting pointed objects through openings.

WARNING

ammonia and house hold detergents that contain ammonia.

The tool may be cleaned most effectively with compressed dry air. Always

wear safety goggles when cleaning tools with compressed air.

Certain cleaning agents and solvents damage plastic parts. Some of

these are: gasoline, carbon tetrachloride, chlorinated cleaning solvents,

Storage

Store the tool indoors in a place that is inaccessible to children. Keep away from corrosive

agents.

Extension Cords

WARNING

tool must be used. This will prevent excessive voltage drop, loss of power or

overheating. Grounded tools must use 3-wire extension cords that have 3-prong plugs

and receptacles.

NOTICE: The smaller the gauge number, the heavier the cord.

If an extension cord is necessary, a cord with adequate size

conductors that is capable of carrying the current necessary for your

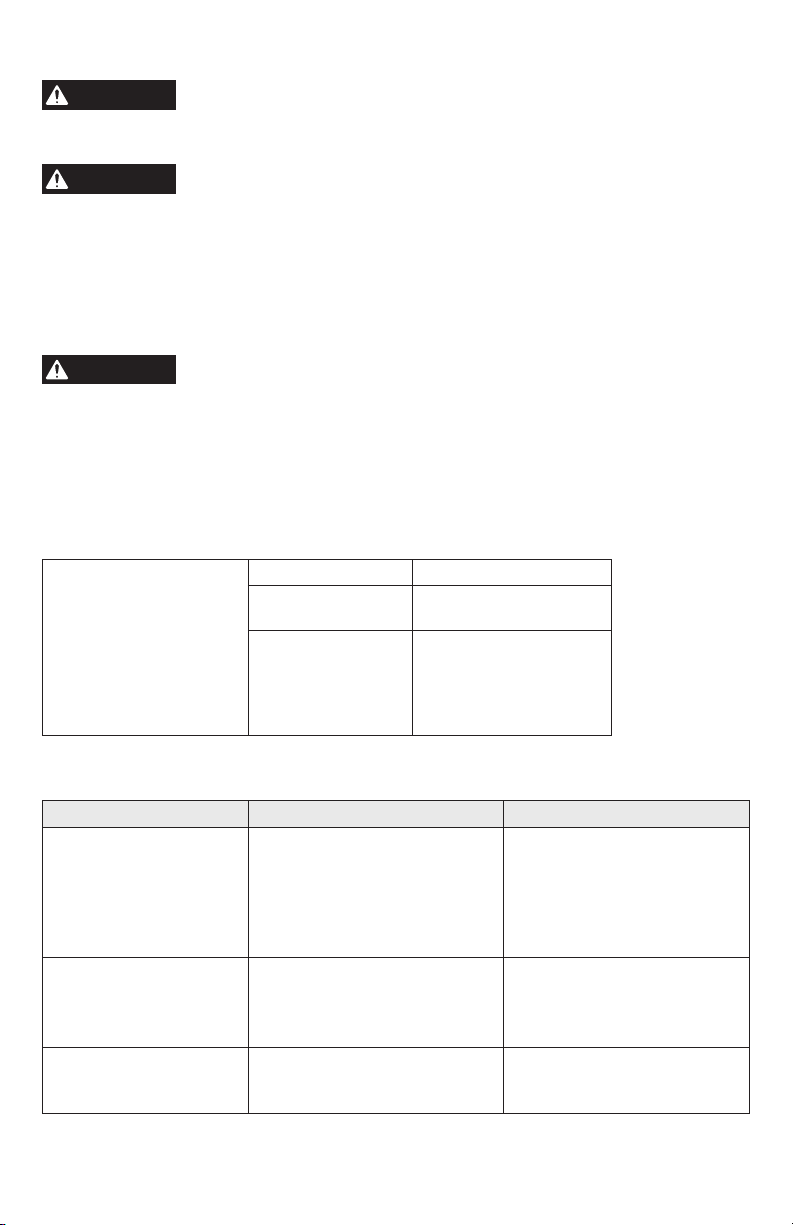

RECOMMENDED SIZES OF EXTENSION CORDS 120 VOLT

ALTERNATING CURRENT TOOLS

Tool’s Ampere Rating Cord Size in A.W.G Wire sizes in mm

3-6

6-8

8-10

10-12

12-16

Cord length in feet

25 50 100 150

18 16 16 14

18 16 14 12

18 16 14 12

16 16 14 12

14 12 - -

Cord length in meters

15 30 60 120

0.75 0.75 1.5 2.5

0.75 1.0 2.5 4.0

0.75 1.0 2.5 4.0

1.0 2.5 4.0 -

- - - -

2

TROUBLESHOOTING

Problem Cause Remedy

The motor does not start. 1. The tool is not connected to a

Planer does not plane

properly.

The motor is overheating. Cooling vents may be obstructed

power source.

2. The lock-off button is not

depressed before squeezing

the on/off switch.

1. The blade is dull.

2. Blades are not installed

correctly.

by dust or other obstacles

1 Connect the tool to a power

source.

2. Press down the lock-off

button and hold it, then

depress the switch to turn

on the planer.

1. Replace the blade.

2. Install the blades correctly

(see Installing Planer

Blades)

Clean and clear vents. Do

not cover with hand during

operation.

17

LIMITED WARRANTY OF SKIL CONSUMER PORTABLE,

BENCHTOP AND HD AND SHD HEAVY DUTY POWER TOOLS

Chervon North America (“Seller”) warrants to the original purchaser only, that all SKIL

consumer portable, benchtop and HD and SHD Heavy Duty power tools will be free from

defects in material or workmanship for a period of one year from date of purchase. SKIL

Benchtop and consumer portable power tool models will be free from defects in material or

workmanship for a period of ninety days if the tool is used for professional use.

SELLER’S SOLE OBLIGATION AND YOUR EXCLUSIVE REMEDY under this Limited

Warranty and, to the extent permitted by law, any warranty or condition implied by law,

shall be the repair or replacement of parts, without charge, which are defective in material

or workmanship and which have not been misused, carelessly handled, or misrepaired by

persons other than Seller or Authorized Service Station. To make a claim under this Limited

Warranty, you must return the complete product, transportation prepaid, to any SKIL Factory

Service Center or Authorized Service Station. For Authorized SKIL Power Tool Service

Stations, please visit www.Registermyskil.com or call 1-877-SKIL-999 (1-877-754-5999).

THIS LIMITED WARRANTY DOES NOT APPLY TO ACCESSORY ITEMS SUCH AS

CIRCULAR SAW BLADES, DRILL BITS, ROUTER BITS, JIGSAW BLADES, SANDING

BELTS, GRINDING WHEELS AND OTHER RELATED ITEMS.

ANY IMPLIED WARRANTIES SHALL BE LIMITED IN DURATION TO ONE YEAR FROM

DATE OF PURCHASE. SOME STATES IN THE U.S., SOME CANADIAN PRO V I NCES DO

NOT ALLOW LIMITATIONS ON HOW LONG AN IMPLIED WARRANTY LASTS, SO THE

ABOVE LIMITATION MAY NOT APPLY TO YOU.

IN NO EVENT SHALL SELLER BE LIABLE FOR ANY INCIDENTAL OR CONSEQUENTIAL

DAMAGES (INCLUDING BUT NOT LIMITED TO LIABILITY FOR LOSS OF PROFITS)

ARISING FROM THE SALE OR USE OF THIS PRODUCT. SOME STATES IN THE U.S.

AND SOME CANADIAN PROVINCES DO NOT ALLOW THE EXCLUSION OR LIMITATION

OF INCIDENTAL OR CONSEQUENTIAL DAMAGES, SO THE ABOVE LIMITATION OR

EXCLUSION MAY NOT APPLY TO YOU.

THIS LIMITED WARRANTY GIVES YOU SPECIFIC LEGAL RIGHTS, AND YOU MAY ALSO

HAVE OTHER RIGHTS WHICH VARY FROM STATE TO STATE IN THE U.S., PROVINCE

TO PROVINCE IN CANADA AND FROM COUNTRY TO COUNTRY.

THIS LIMITED WARRANTY APPLIES ONLY TO PRODUCTS SOLD WITHIN THE UNITED

STATES OF AMERICA, CANADA AND THE COMMONWEALTH OF PUERTO RICO. FOR

WARRANTY COVERAGE WITHIN OTHER COUNTRIES, CONTACT YOUR LOCAL SKIL

DEALER OR IMPORTER.

© Chervon North America, 1203 E. Warrenville Rd, Naperville, IL 60563.

04/19

18

Loading...

Loading...