Page 1

®

SM 1619X05087 12-09:SM 1619X05087 12-09 1/4/10 9:18 AM Page 1

IMPORTANT: Read Before Using

Operating/Safety

Instructions

2354

Call Toll Free for Consumer

Information & Service Locations

1-877-SKIL999 (1-877-754-5999)

www.skil.com

1619X05087 12/09

Page 2

SM 1619X05087 12-09:SM 1619X05087 12-09 1/4/10 9:18 AM Page 2

General Power Tool Safety

Warnings

WARNING

!

follow the warnings and instructions may result

in electric shock, fire and/or serious injury.

Read all safety warnings

and instructions. Failure to

SAVE ALL WARNINGS AND

INSTRUCTIONS FOR FUTURE

REFERENCE

The term “power tool” in all of the warnings

refers to your mains-operated (corded) power

tool or battery-operated (cordless) power tool.

Work area safety

Keep work area clean and well lit. Cluttered

or dark areas invite accidents.

Do not operate power tools in explosive

atmospheres, such as in the presence of

flammable liquids, gases or dust. Power

tools create sparks which may ignite the dust

or fumes.

Keep children and bystanders away while

operating a power tool. Distractions can cause

you to lose control.

Electrical safety

Power tool plugs must match the outlet.

Never modify the plug in any way. Do not use

2

any adapter plugs with earthed (grounded)

power tools. Unmodified plugs and matching

outlets will reduce risk of electric shock.

Avoid body contact with earthed or grounded

surfaces such as pipes, radiators, ranges and

refrigerators. There is an increased risk of

electric shock if your body is earthed or

grounded.

Do not expose power tools to rain or wet

conditions. Water entering a power tool will

increase the risk of electric shock.

Do not abuse the cord. Never use the cord for

carrying, pulling or unplugging the power tool.

Keep cord away from heat, oil, sharp edges or

moving parts. Damaged or entangled cords

increase the risk of electric shock.

When operating a power tool outdoors, use

an extension cord suitable for outdoor use.

Use of a cord suitable for outdoor use reduces

the risk of electric shock.

If operating the power tool in damp locations is

unavoidable, use a Ground Fault Circuit

Interrupter (GFCI) protected supply. Use of an

GFCI reduce the risk of electric shock.

Personal safety

Stay alert, watch what you are doing and use

common sense when operating a power tool.

Do not use a power tool while you are tired or

3

Page 3

SM 1619X05087 12-09:SM 1619X05087 12-09 1/4/10 9:18 AM Page 4

under the influence of drugs, alcohol or

medication. A moment of inattention while

operating power tools may result in serious

personal injury.

Use personal protective equipment. Always

wear eye protection. Protective equipment

such as dust mask, non-skid safety shoes, hard

hat, or hearing protection used for appropriate

conditions will reduce personal injuries.

Prevent unintentional starting. Ensure the

switch is in the off-position before connecting

to power source and / or battery pack, picking

up or carrying the tool. Carrying power tools

with your finger on the switch or energizing

power tools that have the switch on invites

accidents.

Remove any adjusting key or wrench before

turning the power tool on. A wrench or a key

left attached to a rotating part of the power tool

may result in personal injury.

Do not overreach. Keep proper footing and

balance at all times. This enables better

control of the power tool in unexpected

situations.

Dress properly. Do not wear loose clothing or

jewelry. Keep your hair, clothing and gloves

away from moving parts. Loose clothes,

jewelry or long hair can be caught in moving

parts.

4

If devices are provided for the connection of

dust extraction and collection facilities,

ensure these are connected and properly

used. Use of dust collection can reduce dust-

related hazards.

Power tool use and care

Do not force the power tool. Use the correct

power tool for your application. The correct

power tool will do the job better and safer at the

rate for which it was designed.

Do not use the power tool if the switch does

not turn it on and off. Any power tool that

cannot be controlled with the switch is

dangerous and must be repaired.

Disconnect the plug from the power source

and/or the battery pack from the power tool

before making any adjustments, changing

accessories, or storing power tools. Such

preventive safety measures reduce the risk of

starting the power tool accidentally.

Store idle power tools out of the reach of

children and do not allow persons unfamiliar

with the power tool or these instructions to

operate the power tool. Power tools are

dangerous in the hands of untrained users.

Maintain power tools. Check for misalignment or

binding of moving parts, breakage of parts

and any other condition that may affect the

5

Page 4

SM 1619X05087 12-09:SM 1619X05087 12-09 1/4/10 9:18 AM Page 6

power tool’s operation. If damaged, have the

power tool repaired before use. Many

accidents are caused by poorly maintained

power tools.

Keep cutting tools sharp and clean. Properly

maintained cutting tools with sharp cutting

edges are less likely to bind and are easier to

control.

Use the power tool, accessories and tool bits

etc. in accordance with these instructions,taking

into account the working conditions and the

work to be performed. Use of the power tool

for operations different from those intended

could result in a hazardous situation.

Battery tool use and care

Recharge only with the charger specified by

the manufacturer. A charger that is suitable

for one type of battery pack may create a risk

of fire when used with another battery pack.

Use power tools only with specifically

designated battery packs. Use of any other

battery packs may create a risk of injury and

fire.

When battery pack is not in use, keep it

away from other metal objects like paper

clips, coins, keys, nails, screws, or other

small metal objects that can make a

connection from one terminal to another.

Shorting the battery terminals together may

cause burns or a fire.

Under abusive conditions, liquid may be

ejected from the battery, avoid contact. If

contact accidentally occurs, flush with

water. If liquid contacts eyes, additionally

seek medical help. Liquid ejected from the

battery may cause irritation or burns.

Service

Have your power tool serviced by a qualified

repair person using only identical

replacement parts. This will ensure that the

safety of the power tool is maintained.

6

7

Page 5

SM 1619X05087 12-09:SM 1619X05087 12-09 1/4/10 9:18 AM Page 8

SAFETY RULES FOR CORDLESS

SCREWDRIVERS

Hold power tools by insulated gripping surfaces

when performing an operation where the

cutting tools may contact hidden wiring.

Contact with a “live” wire will make exposed metal

parts of the tool “live” and shock the operator.

Use clamps or other practical way to secure

and support the workpiece to a stable

platform. Holding the work by hand or

against your body leaves it unstable and may

lead to loss of control.

Do not drill, fasten or break into existing

walls or other blind areas where electrical

wiring may exist. If this situation is

unavoidable, disconnect all fuses or circuit

breakers feeding this worksite.

Battery tools are always in an operative

condition. Be aware of the possible hazards.

Always wear safety goggles or eye

protection when using this tool.

Secure the workpiece, never hold it in your

hand or across legs. The drilling action may

cause you to lose control of the

workpiece and injury may occur.

When installing a bit, insert the shank of the bit

well within the collet. If the bit is not inserted

deep enough, the grip of the collet over the bit is

reduced and the loss of control is increased.

8

Do not run the tool while carrying it at your

side. A spinning bit could become entangled

with clothing and injury may result.

Do not use dull or damaged bits and

accessories. Dull or damaged bits have a

greater tendency to bind in the workpiece.

WARNING

!

Some dust created by

power sanding, sawing,

grinding, drilling, and other construction

activities contains chemicals known to

cause cancer, birth defects or other

reproductive harm. Some examples of

these chemicals are:

• Lead from lead-based paints,

• Crystalline silica from bricks and cement

and other masonry products, and

• Arsenic and chromium from chemically-

treated lumber.

Your risk from these exposures varies,

depending on how often you do this type of

work. To reduce your exposure to these

chemicals: work in a well ventilated area, and

work with approved safety equipment, such

as those dust masks that are specially

designed to filter out microscopic particles.

Battery/Charger

Before using battery charger, read all

instructions and cautionary markings on (1)

battery charger, (2) battery pack, and (3)

product using battery.

9

Page 6

SM 1619X05087 12-09:SM 1619X05087 12-09 1/4/10 9:18 AM Page 10

Do not disassemble charger or operate the

charger if it has received a sharp blow, been

dropped or otherwise damaged in any way.

Replace damaged cord or plugs

immediately. Incorrect reassembly or

damage may result in electric shock or fire.

Do not recharge battery in damp or wet

environment. Do not expose charger to rain

or snow. If battery case is cracked or

otherwise damaged, do not insert into

charger. Battery short or fire may result.

Charge battery pack in temperatures above

+32 degrees F (0 degrees C) and below +113

degrees F (45 degrees C). Store tool and

battery pack in locations where

temperatures will not exceed 120 degrees F

(49 degrees C). This is important to

prevent serious damage to the battery cells.

Place charger on flat non-flammable

surfaces and away from flammable

materials when re-charging battery pack.

The charger and battery pack heat during

charging. Carpeting and other heat insulating

surfaces block proper air circulation which

may cause overheating of the charger and

battery pack. If smoke or melting of the case

are observed unplug the charger immediately

and do not use the battery pack or charger.

Use of an attachment not recommended or

sold by Skil may result in a risk of fire,

electric shock or injury to persons.

10

Battery Care

WARNING

!

away from metal objects. For example, to

protect terminals from shorting DO NOT place

batteries in a tool box or pocket with nails,

screws, keys, etc. Fire or injury may result.

DO NOT PUT BATTERIES INTO FIRE OR

EXPOSE TO HIGH HEAT. They may explode.

When batteries are not in

tool or charger, keep them

Battery Disposal

WARNING

!

remove any com ponent projecting from the

battery terminals. Fire or injury may result.

Prior to disposal, protect exposed terminals

with heavy insulating tape to prevent shorting.

If equipped with a lithium-ion battery, the battery

must be collected, recycled or disposed of in an

environ mentally sound manner.

participating in an industry program to collect

and recycle these batteries at the end of their

useful life, when taken out of service in the

United States or Canada. The RBRC program

Do not attempt to

disassemble the battery or

Lithium-ion Batteries

“The EPA certified RBRC

Battery Recycling Seal on the

lithium-ion (Li-ion) battery

indicates Robert Bosch Tool

Corporation is voluntarily

11

Page 7

0

SM 1619X05087 12-09:SM 1619X05087 12-09 1/4/10 9:18 AM Page 12

provides a convenient alterative to

placing used Li-ion batteries into the trash or

the munici pal waste stream, which may be

illegal in your area.

Please call 1-800-8-BATTERY for information

on Li-ion battery recycling and disposal

bans/restrictions in your area, or return your

batteries to a Skil/Bosch/Dremel Service Center

for recycling. Robert Bosch Tool Corporation’s

involvement in this program is part of our

commitment to preserving our environment

and conserving our natural resources.”

Battery Removal Instructions

Run motor until battery is completely

discharged before attempting to remove

battery from your tool.

1. Remove the four (4) housing screws with a

flat blade screwdriver.

2. Remove housing cover by lifting upward

from front end of tool.

3. Disconnect lead wires from switch.

4. Wrap heavy insulating tape around battery

terminals or enclose in a sealable plastic bag

to prevent possible shorting.

5. Dispose of battery through your local waste

removal authority or a Skil Service Center.

12

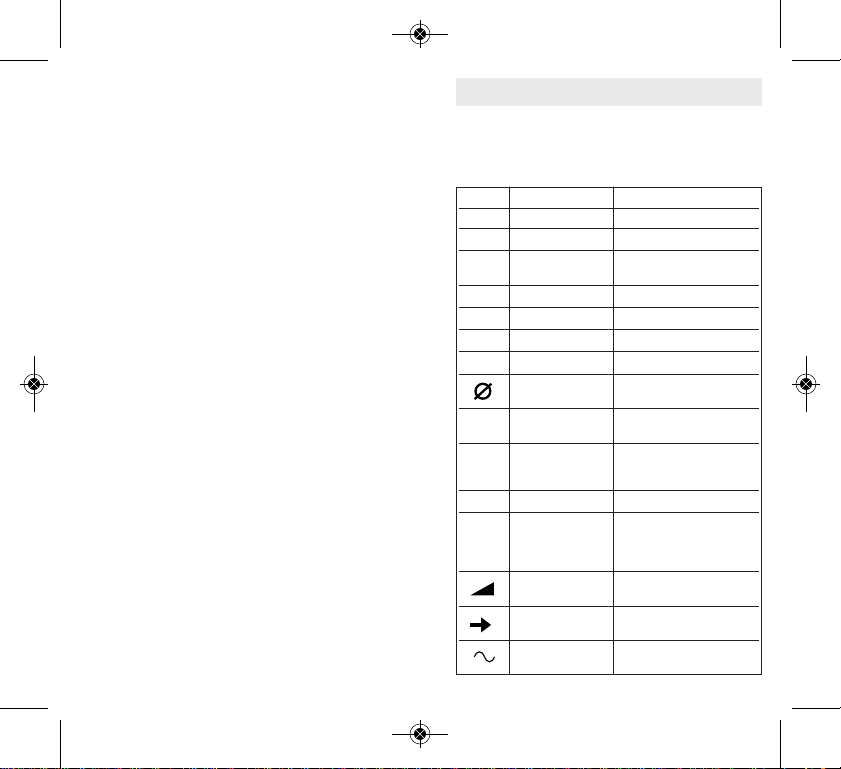

SYMBOLS

IMPORTANT:Some of the following symbols may be

used on your tool. Please study them and learn their

meaning. Proper interpretation of these symbols will

allow you to operate the tool better and safer.

Symbol Name Designation/Explanation

V Volts Voltage (potential)

A Amperes Current

Hz Hertz Frequency

(cycles per second)

W Watt Power

kg Kilograms Weight

min Minutes Time

s Seconds Time

Diameter Size of drill bits,

grinding wheels, etc.

n0 No load speed Rotational speed,

at no load

.../min Revolutions or Revolutions, strokes,

reciprocation per surface speed, orbits etc.

minute per minute

0 Off position Zero speed, zero torque...

1, 2, 3, ... Selector settings Speed, torque or

I, II, III, position settings.

Higher number means

greater speed

Infinitely variable Speed is increasing

selector with off from 0 setting

Arrow Action in the

direction of arrow

Alternating current Type or a characteristic

of current

13

Page 8

®

SM 1619X05087 12-09:SM 1619X05087 12-09 1/4/10 9:18 AM Page 14

Symbol Name Designation/Explanation

Direct current Type or a characteristic

of current

Alternating or Type or a characteristic

direct current of current

Class II construction Designates Double

Insulated Construction tools.

Earthing terminal Grounding terminal

Warning symbol Alerts user to

warning messages

Li-ion RBRC seal Designates Li-ion

program battery recycling

This symbol designates

that this tool is listed by

Underwriters Laboratories.

This symbol designates

that this tool is listed

by the Canadian

Standards Association.

This symbol designates that this

tool is listed to Canadian Standards

by Underwriters Laboratories.

This symbol designates that

this tool is listed by Underwriters

Laboratories, and listed to

Canadian Standards by

Underwriters Laboratories.

This symbol designates that

this tool complies to NOM

Mexican Standards.

14

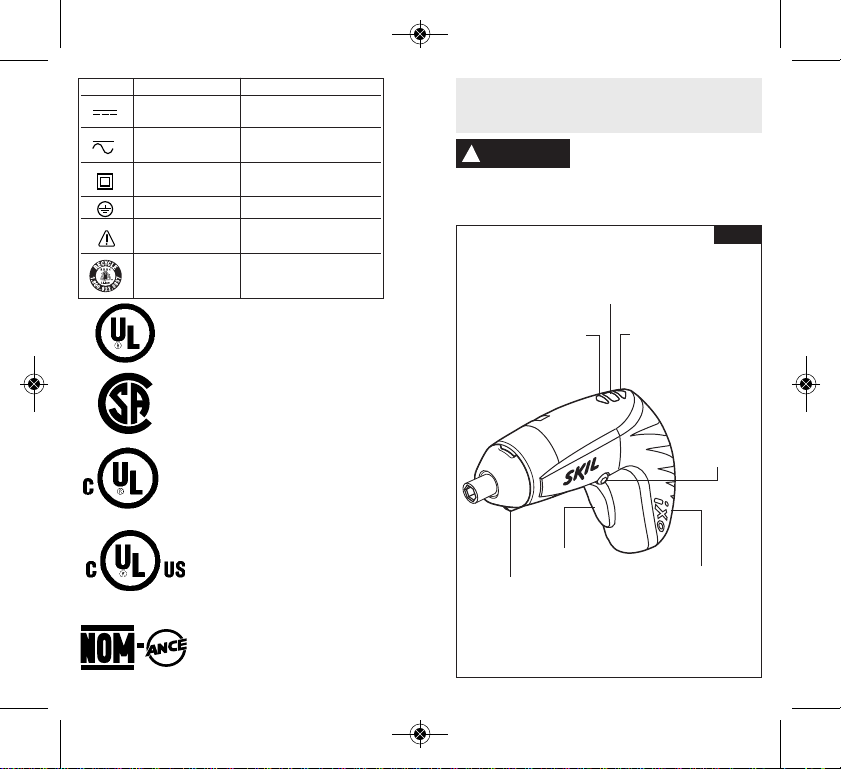

FUNCTIONAL DESCRIPTION

AND SPECIFICATIONS

WARNING

!

Be aware of the possible hazards.

Battery tools are always in

an operative condition.

Palm Size Cordless Screwdriver

CHARGING

INDICATOR LIGHT

FORWARD/REVERSE

INDICATOR LIGHTS

TRIGGER

SITE-LIGHT™

FORWARD/REVERSE

INDICATOR LIGHTS

FORWARD/

REVERSING

RUBBERIZED

15

FIG. 1

LEVER &

TRIGGER

LOCK

GRIP

Page 9

SM 1619X05087 12-09:SM 1619X05087 12-09 1/4/10 9:18 AM Page 16

Model number 2354

Voltage rating 4 V MAX

No load speed n0 200/min

Charger 2607225503

Charge time 3-5 hr

Collet capacity 1/4"

Drilling Wood 3/32" (2 mm)

Screw Sizes 3/16" (5 mm)

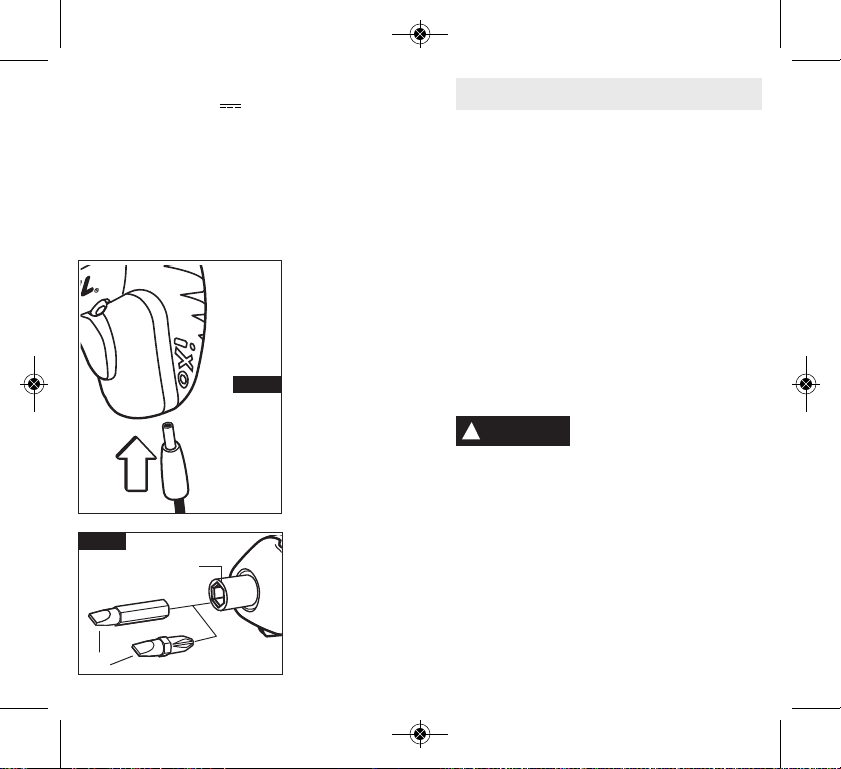

FIG. 2

FIG. 3

MAGNETIC BIT

HOLDER

BIT

16

OPERATING INSTRUCTIONS

The Skil model 2354 Cordless Screwdriver has a

magnetic bit holder that accepts any 1/4" hex bit.

The low RPM capability of this model is not a

deficiency. On the contrary, low speed means

high torque and high torque is a definite plus for

efficient driving. The low speed also provides

more control to prevent stripout of the screw and

damage to the work surface.

TRIGGER "ON-OFF" SWITCH

TO TURN THE TOOL "ON" squeeze the trigger

switch. TO TURN THE TOOL "OFF", release the

trigger switch, which is spring loaded and will

return to the "OFF" position automatically (Fig.1).

FORWARD/REVERSING LEVER &

TRIGGER LOCK

WARNING

!

prevent accidental starts and accidental discharge.

Your tool is equipped with a forward/

reversing lever and trigger lock located above

the trigger (Fig. 1). This lever was designed for

changing rotation of the bit, and for locking the

trigger in an “OFF” position.

FORWARD/REVERSE INDICATOR LIGHTS

Your tool is equipped with lights which

indicate the rotation of the bit.

For forward rotation, (with bit pointed away

from you) move the lever to the far left and a

After tool use, lock trigger in

“OFF” position to help

17

Page 10

SM 1619X05087 12-09:SM 1619X05087 12-09 1/4/10 9:18 AM Page 18

green indicator light depicting a forward arrow

will light up.

For reverse rotation move the lever to the far

right and the green indicator light depicting a

reverse arrow will light up.

To stop in either direction just release the

trigger. To activate trigger lock move lever to

the center off position (Fig. 1).

AUTOLOCK™

Your tool is equipped with an automatic locking

system. This feature will lock the bit holder in

one position when the trigger switch is

released. This will allow you to tighten or loosen

a nut or screw by rotating the tool by hand with

the switch off. This is convenient when higher

turning torque is needed.

SITE-LIGHT™

Your tool is also equipped with a light that turns

on automatically when the switch is

activated for better visibility during operation

(Fig. 1). The Site-Light™ is maintenance free

and was designed to last the life of your tool.

CHARGING THE TOOL

For Model # F012235400: Plug charger into

your standard power outlet, then insert charger

plug into tool (Fig. 2).

The green charging indicator light on the tool

will turn “ON”. This indicates that the battery is

receiving a fast charge. Fast-charging will

automatically stop when the battery is fully

charged.

When the indicator light turns “OFF” fast

charging is complete.

If the green charging indicator light turns red

during use, this indicates the battery needs to

be charged.

After normal usage, the battery requires

approximately 3 to 5 hours charging time to

reach full capacity. The tool may be used even

though the light may still be on. The light may

require more than 3 hours to turn off depending

on temperature.

The purpose of the light is to indicate that the

battery is fast-charging. It does not indicate the

exact point of full charge. The light will turn off

in less than 3 hours if the battery was not

completely discharged.

When the battery is fully charged, unplug the

charger (unless you're charging another tool).

INSERTING BITS

Your tool is equipped with an magnetic bit

holder. Simply push the bit into the bit holder as

far as it will go (Fig. 3).

FASTENING WITH SCREWS

The procedure shown in figure. 4 will enable

you to fasten materials together with your

Cordless Screwdriver without stripping,

splitting, or separating the material.

First, clamp the pieces together and drill the first

hole 2/3 the diameter of the screw. If the

18

19

Page 11

SM 1619X05087 12-09:SM 1619X05087 12-09 1/4/10 9:18 AM Page 20

material is soft, drill only 2/3 the proper length.

If it is hard, drill the entire length.

Second, unclamp the pieces and drill the

second hole the same diameter as the screw

shank in the first or top piece of wood.

Third, if a flat head screw is used, countersink

the hole to make the screw flush with the

surface. Then, simply apply even pressure when

driving the screw. The screw shank clearance

hole in the first piece allows the screw head to

pull the pieces tightly together.

FASTENING WITH

SCREWS

1. Drill 2/3 diameter and

2/3 of screw length for

soft materials, full

length for hard

materials.

Apply a slight

even pressure

when driving

screws.

FIG. 4

2. Drill same

diameter as

screw shank.

3. Countersink

same

diameter

as screw

head.

Screw

MAINTENANCE

Service

WARNING

!

maintenance performed by un au thorized

personnel may result in misplacing of

internal wires and components which could

cause serious hazard.

Your Skil tool has been properly lubricated

and is ready for use.

The motor in your tool has been engineered for many

hours of dependable service. To maintain peak

efficiency of the motor, we recommend it be examined

every six months. Only a genuine Skil replacement

motor specially designed for your tool should be used.

WARNING

!

charger from the power supply before

cleaning. The tool may be cleaned most

effectively with com pressed dry air. Always

wear safety goggles when cleaning tools with

compressed air.

NO USER SERVICE ABLE

PARTS INSIDE. Preventive

TOOL LUBRICATION

D.C. MOTORS

Cleaning

To avoid accidents, always

disconnect the tool and/or

20

21

Page 12

®

SM 1619X05087 12-09:SM 1619X05087 12-09 1/4/10 9:18 AM Page 22

Ventilation openings and switch levers must be

kept clean and free of foreign matter. Do not

attempt to clean by inserting pointed objects

through opening.

CAUTION

!

Certain cleaning agents

and solvents damage

plastic parts. Some of these are: gasoline, car -

bon tetrachloride, chlorinated cleaning

solvents, ammonia and household detergents

that contain ammonia.

IXO ATTACHMENTS

(AVAILABLE SEPARATELY)

The new SKIL model 2354 Cordless

Screwdriver is compatible with Skil’s innovative

iXO attachment system. These attachments

are available separately, and may not be

included with all iXO models. For details on

available attachments, please check the Skil

website: www.Skiltools.com

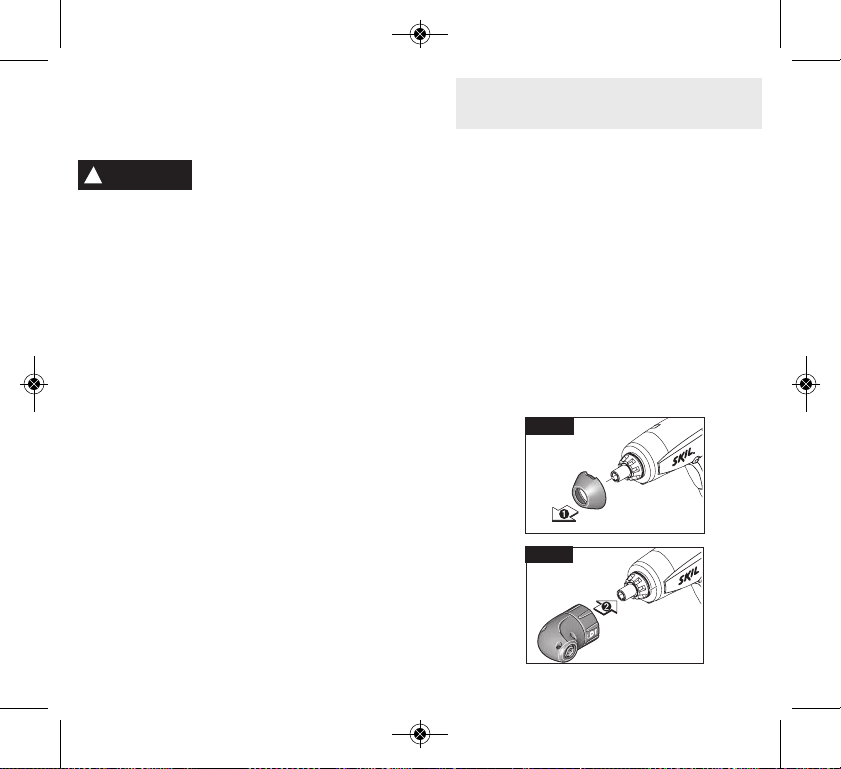

ASSEMBLY (see Figures 6-7)

For assembly of the attachments, pull the

rubber cap off the tool. Align the attachment

with the end of the tool. Firmly push the

attachment onto the tool until it is securely

fastened. The attachments can be mounted in

varying positions offset by 45˚.

FIG. 6

FIG. 7

22

23

Page 13

SM 1619X05087 12-09:SM 1619X05087 12-09 1/4/10 9:18 AM Page 24

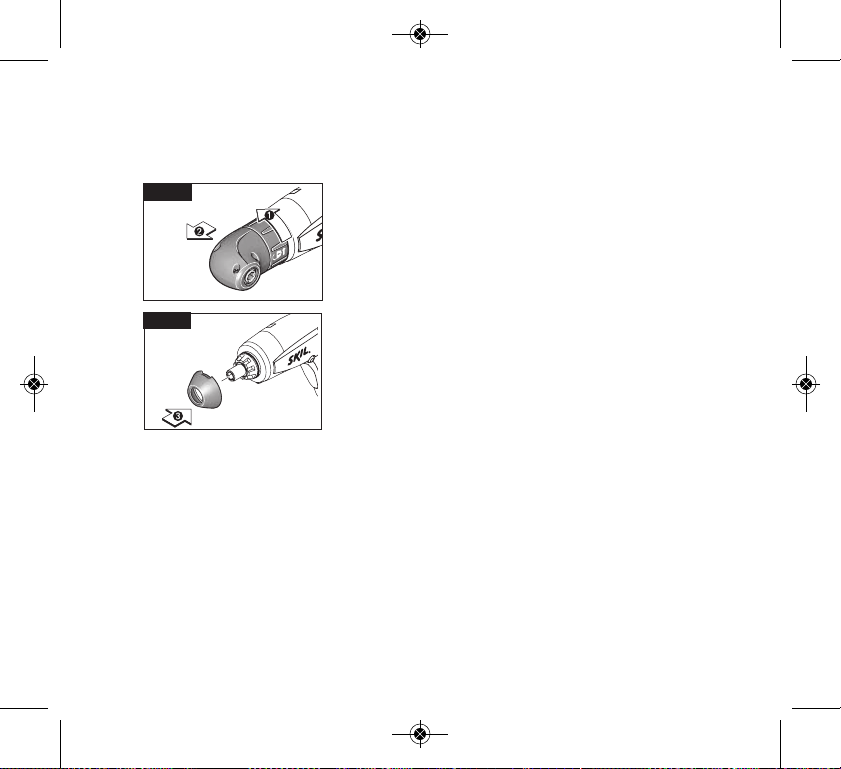

REMOVING (see Figures 8-9)

To remove the attachments, turn the release

ring in the direction of release arrow and pull

the attachment off the end of the tool. Gently,

push the rubber cap on to the end of the tool.

FIG. 8

FIG. 9

Images of right angle attachment used

for informational purposes only

LIMITED WARRANTY OF SKIL CONSUMER PORTABLE,

BENCHTOP AND HD AND SHD HEAVY DUTY

Robert Bosch Tool Corporation ("Seller") warrants to the original

purchaser only, that all SKIL consumer portable, benchtop and HD and

SHD Heavy Duty power tools will be free from defects in material or

workmanship for a period of one year from date of purchase. SKIL

Benchtop and consumer portable power tool models will be free from

defects in material or workmanship for a period of ninety days if the tool

is used for professional use.

POWER TOOLS

SELLER’S SOLE OBLIGATION AND YOUR EXCLUSIVE REMEDY under

this Limited Warranty and, to the extent permitted by law, any warranty

or condition implied by law, shall be the repair or replacement of parts,

without charge, which are defective in material or workmanship and

which have not been misused, carelessly handled, or misrepaired by

persons other than Seller or Authorized Service Station. To make a claim

under this Limited Warranty, you must return the complete product,

transportation prepaid, to any SKIL Factory Service Center or Authorized

Service Station. For Authorized SKIL Power Tool Service Stations,

please visit www.skil.com or call 1-877-SKIL-999 (1-877-754-5999).

THIS LIMITED WARRANTY DOES NOT APPLY TO ACCESSORY ITEMS

SUCH AS CIRCULAR SAW BLADES, DRILL BITS, ROUTER BITS,

JIGSAW BLADES, SANDING BELTS, GRINDING WHEELS AND OTHER

RELATED ITEMS.

ANY IMPLIED WARRANTIES SHALL BE LIMITED IN DURATION TO ONE

YEAR FROM DATE OF PURCHASE. SOME STATES IN THE U.S., SOME

CANADIAN PRO V INCES DO NOT ALLOW LIMITATIONS ON HOW LONG

AN IMPLIED WARRANTY LASTS, SO THE ABOVE LIMITATION MAY

NOT APPLY TO YOU.

IN NO EVENT SHALL SELLER BE LIABLE FOR ANY INCIDENTAL OR

CONSEQUENTIAL DAMAGES (INCLUDING BUT NOT LIMITED TO

LIABILITY FOR LOSS OF PROFITS) ARISING FROM THE SALE OR USE

OF THISPRODUCT. SOME STATES IN THE U.S. AND SOME CANADIAN

PROVINCES DO NOT ALLOW THE EXCLUSION OR LIMITATION OF

INCIDENTAL OR CONSEQUENTIAL DAMAGES, SO THE ABOVE

LIMITATION OR EXCLUSION MAY NOT APPLY TO YOU.

THIS LIMITED WARRANTY GIVES YOU SPECIFIC LEGAL RIGHTS,

AND YOU MAY ALSO HAVE OTHER RIGHTS WHICH VARY FROM

STATE TO STATE IN THE U.S., PROVINCE TO PROVINCE IN CANADA

AND FROM COUNTRY TO COUNTRY.

THIS LIMITED WARRANTY APPLIES ONLY TO PRODUCTS SOLD

WITHIN THE UNITED STATES OF AMERICA, CANADA AND THE

COMMONWEALTH OF PUERTO RICO. FOR WARRANTY COVERAGE

WITHIN OTHER COUNTRIES, CONTACT YOUR LOCAL SKIL DEALER

OR IMPORTER.

© Robert Bosch Tool Corporation 1800 W. Central

Road Mt. Prospect, IL 60056-2230

24

25

Page 14

®

SM 1619X05087 12-09:SM 1619X05087 12-09 1/4/10 9:18 AM Page 26

IMPORTANT : Lire avant usage

Consignes de

fonctionnement/

sécurité

2354

Pour obtenir des informations et

les adresses de nos centres

de service après-vente,

appelez ce numéro gratuit

1-877-SKIL999 (1-877-754-5999)

www.skil.com

26

1619X05087 12/09

Avertissements généraux concernant

la sécurité des outils électroportatifs

AVERTISSEMENT

!

toutes les consignes de sécurité. Si l'on n'observe

pas ces avertissements et ces consignes de

sécurité, il existe un risque de choc électrique,

d'incendie et/ou de blessures corporelles graves.

Veuillez lire tous les

avertissements et

CONSERVEZ TOUS LES

AVERTISSEMENTS ET TOUTES LES

CONSIGNES DE SÉCURITÉ POUR

RÉFÉRENCE FUTURE.

Dans tous les avertissements, le terme « outil

électroportatif » se rapporte à des outils branchés

sur le secteur (avec fil) ou à des outils alimentés

par piles (sans fil).

Sécurité du lieu de travail

Maintenez le lieu de travail propre et bien

éclairé. Les risques d’accident sont plus élevés

quand on travaille dans un endroit encombré ou

sombre.

N’utilisez pas d’outils électroportatifs dans des

atmosphères explosives, comme par exemple

en présence de gaz, de poussières ou de

liquides inflammables. Les outils électroportatifs

produisent des étincelles qui risquent d’enflammer

les poussières ou les vapeurs.

27

Page 15

SM 1619X05087 12-09:SM 1619X05087 12-09 1/4/10 9:18 AM Page 28

Éloignez les enfants et les visiteurs quand vous

vous servez d’un outil électroportatif. Vous

risquez une perte de contrôle si on vous distrait.

Sécurité électrique

Les fiches des outils électroportatifs doivent

correspondre à la prise. Il ne faut absolument

jamais modifier la fiche. N’utilisez pas

d’adaptateur de prise avec des outils

électroportatifs munis d’une fiche de terre. Le

risque de choc électrique est moindre si on utilise

une fiche non modifiée sur une prise qui lui

correspond.

Évitez tout contact du corps avec des surfaces

reliées à la terre tels que tuyaux, radiateurs,

gazinières ou réfrigérateurs. Le risque de choc

électrique augmente si votre corps est relié à la

terre.

N’exposez pas les outils électroportatifs à la

pluie ou à l’humidité. Si de l’eau pénètre dans un

outil électroportatif, le risque de choc électrique

augmente.

Ne maltraitez pas le cordon. Ne vous en servez

jamais pour transporter l’outil électroportatif,

pour le tirer ou pour le débrancher. Éloignez le

cordon de la chaleur, des huiles, des arêtes

coupantes ou des pièces mobiles. Les cordons

abîmés ou emmêlés augmentent les risques de

choc électrique.

Si vous utilisez un outil électroportatif à

l’extérieur, employez une rallonge conçue pour

28

l’extérieur. Ces rallonges sont faites pour

l’extérieur et réduisent le risque de choc électrique.

S'il est absolument nécessaire d'utiliser l'outil

électroportatif dans un endroit humide, utilisez

une alimentation protégée par un disjoncteur de

fuite de terre (GFCI).L'utilisation d'un disjoncteur

GFCI réduit les risques de choc électrique.

Sécurité personnelle

Restez concentré, faites attention à ce que vous

faites, et servez-vous de votre bon sens lorsque

vous utilisez un outil électroportatif. N'employez

pas d’outils électroportatifs quand vous êtes

fatigué ou sous l’emprise de drogues, d’alcool

ou de médicaments. Quand on utilise des outils

électroportatifs, il suffit d’un moment d’inattention

pour causer des blessures corporelles graves.

Utilisez des équipements de sécurité

personnelle. Portez toujours une protection

oculaire. Le port d'équipements de sécurité tels

que des masques antipoussières, des chaussures

de sécurité antidérapantes, des casques de

chantier et des protecteurs d'oreilles dans des

conditions appropriées réduira le risque de

blessure corporelle.

Évitez les démarrages intempestifs. Assurezvous que l'interrupteur est dans la position arrêt

(Off) avant de brancher l'outil dans une prise de

courant et/ou un bloc-piles, de le ramasser ou de

le transporter. Le transport d'un outil

électroportatif avec le doigt sur la gâchette ou le

29

Page 16

SM 1619X05087 12-09:SM 1619X05087 12-09 1/4/10 9:18 AM Page 30

branchement de cet outil quand l'interrupteur est

en position de marche (ON) est une invite aux

accidents.

Enlevez toutes les clés de réglage avant de

mettre l’outil électroportatif en marche. Si on

laisse une clé sur une pièce tournante de l’outil

électroportatif, il y a risque de blessure corporelle.

Ne vous penchez pas. Conservez toujours une

bonne assise et un bon équilibre. Ceci vous

permettra de mieux maîtriser l’outil électroportatif

dans des situations inattendues.

Habillez-vous de manière appropriée. Ne portez

pas de vêtements amples ou de bijoux. Attachez

les cheveux longs. N’approchez pas les

cheveux, les vêtements ou les gants des pièces

en mouvement. Les vêtements amples, les bijoux

ou les cheveux longs risquent d’être happés par les

pièces en mouvement.

Si l’outil est muni de dispositifs permettant le

raccordement d’un système d’aspiration et de

collecte des poussières, assurez-vous que ces

dispositifs sont raccordés et utilisés

correctement. L'utilisation d'un dépoussiéreur

peut réduire les dangers associés à l'accumulation

de poussière.

Utilisation et entretien des outils

électroportatifs

Ne forcez pas sur l’outil électroportatif. Utilisez

l’outil électroportatif qui convient à la tâche à

effectuer. L’outil qui convient à la tâche fait un

meilleur travail et est plus sûr à la vitesse pour

lequel il a été conçu.

Ne vous servez pas de l’outil électroportatif si

son interrupteur ne parvient pas à le mettre en

marche ou à l’arrêter. Tout outil électroportatif

qui ne peut pas être commandé par son

interrupteur est dangereux et doit être réparé.

Débranchez la fiche de la prise ou enlevez le

bloc-pile de l’outil électroportatif avant tout

réglage, changement d’accessoires ou avant de

ranger l’outil électroportatif. De telles mesures

de sécurité préventive réduisent le risque de

démarrage intempestif de l’outil électroportatif.

Rangez les outils électroportatifs dont vous ne

vous servez pas hors de portée des enfants et ne

permettez pas à des personnes qui ne

connaissent pas l’outil électroportatif ou qui

ignorent ces consignes de s’en servir. Les outils

électroportatifs sont dangereux dans les mains

d’utilisateurs inexpérimentés.

Entretenez les outils électroportatifs. Vérifiez

que les pièces mobiles sont alignées

correctement et ne coincent pas. Vérifiez qu’il

n’y a pas de pièces cassées ou d’autre

circonstance qui risquent d’affecter le

fonctionnement de l’outil électroportatif. Si

l’outil est abîmé, faites-le réparer avant de

l’utiliser. De nombreux accidents sont causés par

des outils électroportatifs mal entretenus.

30

31

Page 17

SM 1619X05087 12-09:SM 1619X05087 12-09 1/4/10 9:18 AM Page 32

Maintenez les outils coupants affûtés et propres.

Les outils coupants entretenus correctement et

dotés de bords tranchants affûtés sont moins

susceptibles de coincer et sont plus faciles à

maîtriser.

Utilisez l'outil électroportatif, les accessoires et

les embouts d'outil, etc. conformément à ces

instructions, en tenant compte des conditions de

travail et des travaux à réaliser. L'emploi

d’outils électroportatifs pour des tâches différentes

de celles pour lesquelles ils ont été prévus peut

résulter en une situation dangereuse.

Utilisation et entretien des outils à piles

Rechargez les piles uniquement avec le

chargeur spécifié par le fabriquant. Un chargeur

qui convient à un type de bloc-piles peut entraîner

un risque d’incendie quand il est utilisé avec un

autre bloc-piles.

Utilisez des outils électroportatifs uniquement

avec les bloc-piles spécifiquement désignés

pour eux. L’utilisation de tout autre bloc-piles peut

créer un risque de blessures et d’incendie.

Lorsque le bloc-piles n’est pas utilisé, gardez-le

à distances d’autres objets métalliques tels que

des trombones, des pièces de monnaie, des

clés, des clous, des vis ou de tout autre objet

métallique pouvant faire une connexion entre

une borne et une autre. Court-circuiter les bornes

des piles peut causer des brûlures ou un incendie.

32

Dans des conditions abusives, du liquide peut

être éjecté de la pile ; dans un tel cas, évitez tout

contact avec ce liquide. Si un contact se produit

accidentellement, rincez avec de l’eau. Si le

liquide entre en contact avec les yeux, consultez

un médecin. Du liquide éjecté de la pile peut

causer des irritations ou des brûlures.

Entretien

Faites réparer votre outil électroportatif par un

agent de service qualifié n’utilisant que des

pièces de rechange identiques. Ceci assure que

la sécurité de l’outil électroportatif est préservée.

CONSIGNES DE SÉCURITÉ POUR

TOURNEVIS SANS FIL

Tenez les outils électroportatifs par les surfaces

isolées de préhension en exécutant une

opération au cours de laquelle les outils de

coupe peuvent venir en contact avec les fils

cachés. Le contact avec un fil sous tension rendra

les pièces métalliques exposées de l'outil sous

tension et causera des chocs à l'opérateur.

Utilisez des brides ou d’autres moyens pratiques de

brider ou de supporter la pièce sur une

plate-forme stable. Tenir la pièce à la main ou

contre le corps est instable et risque de résulter en une

perte de contrôle.

Ne percez, fixez et ne rentrez pas dans des murs

existants ou autres endroits aveugles pouvant

abriter des fils électriques. Si cette situation est

33

Page 18

SM 1619X05087 12-09:SM 1619X05087 12-09 1/4/10 9:18 AM Page 34

inévitable, débranchez tous les fusibles ou les

disjoncteurs alimentant ce site.

Les outils à piles sont toujours en état de marche.

Soyez conscient des dangers éventuels.

Portez toujours des lunettes à coques latérales ou

des lunettes de protection en utilisant cet outil.

Fixez l'ouvrage, ne le tenez jamais dans votre

main ou sur vos jambes. Le per çage peut vous faire

perdre le contrôle de l'ouvrage et vous blesser.

En posant un foret, insérez la tige du foret bien à

l'intérieur de la douille. Si le foret n'est pas inséré

assez profondément, la prise de la douille sur le foret

est réduite et la perte de contrôle est accrue.

Ne faites pas fonctionner la outil en la

transportant à vos côtés. Le foret en rotation peut

s'emmêler à vos vêtements et vous blesser.

N'utilisez pas de forets et d'accessoires émoussés

ou endommagés. Les forets ou accessoires

émoussés peuvent gripper fréquemment dans

l'ouvrage, causant ainsi une réaction de couple.

AVERTISSEMENT

!

Les travaux à la

machine tel que

ponçage, sciage, meulage, perçage et autres

travaux du bâtiment peuvent créer des poussières

contenant des produits chimiques qui sont des

causes reconnues de cancer, de malformation

congénitale ou d’autres problèmes reproductifs.

Ces produits chimiques sont, par exemple :

• Le plomb provenant des peintures à base de plomb,

• Les cristaux de silices provenant des briques et du

ciment et d’autres produits de maçonnerie, et

• L’arsenic et le chrome provenant des bois

traités chimiquement.

Le niveau de risque dû à cette exposition varie avec la

fréquence de ces types de travaux. Pour réduire

l’exposition à ces produits chimiques, il faut

travailler dans un lieu bien ventilé et porter un

équipement de sécurité approprié tel que certains

masques à poussière conçus spécialement pour

filtrer les particules microscopiques.

Chargeur de pile

Avant d'utiliser le chargeur de pile, lisez toutes

les consignes et tous les marquages

d'avertissement sur (1) le chargeur de pile, (2)

le bloc-pile et (3) le produit utilisant la pile.

Ne désassemblez pas le chargeur et ne

l'utilisez pas s'il a reçu un choc violent, s'il est

tombé ou s'il a été endommagé par ailleurs.

Remplacez immédiatement les cordons ou les

fiches abîmés. Un remontage incorrect ou des

dommages peuvent provoquer un incendie ou des

secousses électriques.

Ne rechargez pas la pile dans un environnement

mouillé ou humide. N'exposez pas le chargeur à

la pluie ou la neige. Si le boîtier de la pile est

fissuré ou endommagé par ailleurs, ne l'insérez

pas dans le chargeur. Il pourrait y avoir un

incendie ou un court-circuit de pile.

Chargez le bloc-piles à des températures de

plus de 0 degrés C (+32°F) et de moins de 45

degrés C (+113°F). Rangez l'outil et le bloc-

34

35

Page 19

SM 1619X05087 12-09:SM 1619X05087 12-09 1/4/10 9:18 AM Page 36

piles à des endroits dont la température ne

dépasse pas 49 degrés C (+120°F). Ceci est

important pour prévenir des dommages

considérables aux éléments des piles.

Posez le chargeur sur une surface plate

ininflammable et à distance de matériaux

inflammables lorsqu’on recharge un bloc-piles.

Le chargeur et le bloc-piles s’échauffent pendant

la charge. Le coussinet de mousse souple et

autres surfaces isolantes empêchent la

circulation normale de l’air, ce qui peut provoquer

une surchauffe du chargeur et du bloc-piles. S’il y

a dégagement de fumée ou si le boîtier fond,

débranchez le chargeur immédiatement et

n’utilisez ni le chargeur, ni le bloc-piles.

L'utilisation d'un accessoire non recommandé

ni vendu par Skil peut causer des risques

d'incendie, de chocs électriques ou de

lésions corporelles.

Entretien des piles

AVERTISSEMENT

!

le chargeur, gardez-les à l’écart d’objets

métalliques. Ainsi, pour éviter un court-circuitage

des bornes, NE PLACEZ PAS les piles dans la boîte à

outils ou dans la poche avec des clous, des vis, des

clés, etc. Ceci peut provoquer un incendie ou des

blessures.

NE METTEZ PAS LES PILES AU FEU ET NE LES

EXPOSEZ PAS À UNE CHALEUR ÉLEVÉE. Elles

peuvent exploser.

Lorsque les piles ne

sont pas dans l’outil ou

Mise au rebut des piles

AVERTISSEMENT

!

piles ou d’enlever tout composant faisant saillie

des bornes de piles, ce qui peut provoquer un

incendie ou des blessures. Avant la mise au rebut,

protégez les bornes exposées à l’aide d’un ruban

isolant épais pour prévenir le court-circuitage.

Ne tentez pas de

désassembler le bloc-

Piles lithium-ion

Si le produit est équipé d'une pile lithium-ion, la pile

doit être ramassée, recyclée ou mise au rebut d'une

manière qui ne soit pas nocive pour l'environnement.

“Le sceau RBRC de recyclage des

piles, homologué par l’EPA

(Agence pour la protection de

l’environnement des États-Unis),

lithium-ion (Li-ion) indique que Robert Bosch Tool

Corporation participe volontairement à un

programme industriel de ramassage et de recyclage

de ces piles au terme de leur vie utile, pourvu qu’elles

soient mises hors service aux États-Unis ou au

Canada. Le

programme du RBRC offre une alternative pratique à

la mise des piles au Li-ion usées au rebut ou au

ramassage d’ordures municipal, ce qui pourrait être

interdit dans votre région.

Veuillez appeler le 1-800-8-BATTERY pour obtenir de

plus amples renseignements sur le recyclage des

piles au Li-ion et sur les restrictions ou interdictions

de mise au rebut qui s’appliquent à votre région ou

qui se trouve sur les piles au

36

37

Page 20

0

SM 1619X05087 12-09:SM 1619X05087 12-09 1/4/10 9:18 AM Page 38

renvoyez vos piles à un Centre de Service

Skil/Bosch/Dremel pour recyclage. La participation de

Robert Bosch Tool Corporation à ce programme

s'insère dans le contexte de notre engagement à

préserver notre environnement et à conserver nos

ressources naturelles.”

Instructions de retrait de pile

Faire fonctionner le mo teur jusqu'à ce que la pile

soit entièrement déchargée avant de tenter de

retirer la pile de l'outil.

1. Retirer les quatre (4) vis du boîtier à l'aide

d'un tournevis à lame plate.

2. Retirer le couvercle du boîtier en soulevant vers

le haut depuis l'extrémité avant de l'outil.

3. Débrancher les fils conducteurs de la interrupteur.

4. Enrouler un ruban isolant épais autour des

bornes de la pile ou enfermer dans un sac en plastique

scellable pour prévenir d'éventuels courts-circuits.

5. Mettre la pile au rebut en ayant re cours aux

autorités locales de ramassage des déchets ou un

centre de service Skil.

38

SYMBOLES

IMPORTANT : Certains des symboles suivants peuvent

être utilisés sur votre outil. Veuillez les étudier et

apprendre leur signification. Une interprétation

appropriée de ces symboles vous permettra d'utiliser

l'outil de façon plus efficace et plus sûre.

Symbole Nom Désignation/Explication

V Volts Tension (potentielle)

A Ampères Courant

Hz Hertz Fréquence

(cycles par seconde)

W Watt Puissance

kg Kilogrammes Poids

min Minutes Temps

s Secondes Temps

Diamètre Taille des mèches de

perceuse, meules, etc.

n0 Vitesse à vide Vitesse de rotation,

à vide

.../min Tours ou Tours, coups, vitesse en

mouvement alternatif surface, orbites, etc.,

par minute par minute

0 Position d'arrêt Vitesse zéro, couple zéro ...

1, 2, 3, ... Réglages du Réglages de vitesse, de

I, II, III, sélecteur couple ou de position. Un

nombre plus élevé signifie

une vitesse plus grande.

Sélecteur variable à La vitesse augmente

l'infini avec arrêt depuis le réglage 0

Flèche Action dans la direction

de la flèche

Courant alternatif Type ou caractéristique

du courant

39

Page 21

®

SM 1619X05087 12-09:SM 1619X05087 12-09 1/4/10 9:18 AM Page 40

Symbole Nom Désignation/Explication

Courant continu Type ou caractéristique

du courant

Courant alternatif Type ou caractéristique

ou continu du courant

Construction classe II Désigne des outils construits

avec double isolation

Borne de terre Borne de mise à la terre

Symbole Alerte l'utilisateur aux

d'avertissement messages d'avertissement.

Sceau Li-ion RBRC Désigne le programme de

recyclage des piles Li-ion.

Ce symbole signifie que

cet outil est approuvé par

Underwriters Laboratories.

Ce symbole signifie que

cet outil est approuvé par

l'Association canadienne

de normalisation.

Ce symbole signifie que cet outil

est approuvé conformment aux

normescanadiennes par

Underwriters Laboratories.

Ce symbole signifie que cet

outil est approuvé par

Underwriters Laboratories et

qu’il a été homologué selon

les normes canadiennes par

Underwriters Laboratories.

Ce symbole signifie que

cet outil se conforme aux

normes mexicaines NOM.

40

DESCRIPTION FONCTIONNELLE

ET SPÉCIFICATIONS

AVERTISSEMENT

!

marche. Soyez conscient des dangers éventuels.

Tournevis de poche sans fil

TÉMOIN LUMINEUX

TÉMOINS DU SENS

DE ROTATION

GÂCHETTE

ÉCLAIRAGE

D’APPOINT

SITE-LIGHT™

Les outils à piles sont

toujours en état de

DE CHARGE

41

FIG. 1

TÉMOINS DU SENS

DE ROTATION

LEVIER DE

MARCHE AVANT/

ARRIÈRE ET

VERROUILLAGE

DE GÂCHETTE

POIGNÉE

CAOUTCHOUTÉE

Page 22

SM 1619X05087 12-09:SM 1619X05087 12-09 1/4/10 9:18 AM Page 42

Numéro de modèle 2354

Tension nominale 4 V MAX

Régime à vide n0 200/min

Chargeur 2607225503

Temps de Charge 3-5 hr

Capacité de la douille 6 mm

Perçage du bois (2 mm) 3/32 po

Tailles de vis (5 mm) 3/16 po

FIG. 2

FIG. 3

PORTE-EMBOUT

MAGNÉTIQUE

EMBOUT

42

CONSIGNES DE FONCTIONNEMENT

Le tournevis sans fil Skil modèle 2354 possède un

porte-embout magnétique pouvant recevoir tout

embout hexagonal de 1/4 po. La capacité bas

régime de ce modèle ne constitue pas une lacune.

Au contraire, le bas régime signifie un couple élevé

et le couple élevé est un avantage très net pour

enfoncer efficacement une vis. Le bas régime

permet également un plus grand contrôle pour

empê cher que la vis ne foire et que la surface de

travail soit abîmée.

GÂCHETTE DE COMMANDE MARCHE/ARRÊT

Pour mettre l’outil en marche, appuyez sur la

gâchette. Pour mettre l’outil à l’arrêt, relâchez la

gâchette qui est à ressort et reviendra

automatiquement à la position d’arrêt (Fig. 1).

LEVIER DE MARCHE AVANT/ARRIÈRE

ET VERROUILLAGE DE GÂCHETTE

AVERTISSEMENT

!

en position d'arrêt pour éviter les risques de

démarrage accidentel et de décharge accidentelle.

Votre outil est équipé d’un levier de marche

avant/arrière et d’un verrouillage de gâchette se

trouvant au-dessus de la gâchette (Fig. 1). Ce levier

a été conçu de manière à changer la rotation de

l'embout et verrouiller la gâchette en position d'arrêt.

TÉMOINS DU SENS DE ROTATION

Votre outil est muni de témoins qui indiquent le

sens de rotation de l'embout.

Après avoir utilisé l'outil,

verrouillez la gâchette

43

Page 23

SM 1619X05087 12-09:SM 1619X05087 12-09 1/4/10 9:18 AM Page 44

Pour la marche avant (avec l'embout dirigé dans le

sens opposé à soi), poussez le levier à fond à

gauche, et un témoin vert montrant une flèche

orientée vers l'avant s'allumera.

Pour la marche arrière, poussez le levier à fond à

droite, et le témoin vert montrant une flèche

orientée vers l'arrière s'allumera.

Pour arrêter dans un sens ou dans l'autre, il vous

suffit de relâcher la gâchette. Pour bloquer la

gâchette, mettez le levier au centre (Fig. 1).

AUTOLOCK™

Votre outil est muni d'un système de blocage

automatique. Ce système verrouille le porteembout dans une position lorsque la gâchette est

relâchée. Ceci vous permet de serrer ou de

desserrer un écrou ou une vis en faisant tourner

l'outil à la main quand l'outil est dans la position «

OFF » (Arrêt). Ceci est très pratique quand vous

avez besoin d'un couple de serrage élevé.

ÉCLAIRAGE D’APPOINT SITE-LIGHT™

Votre outil est également doté d’une lampe qui

s’allume automatiquement quand on appuie sur la

gâchette pour améliorer la visibilité pendant

l’utilisation (Fig. 1). L’éclairage d’appoint SiteLight™ ne nécessite aucun entretien, il a été conçu

pour durer aussi longtemps que votre outil.

CHARGE DE L'OUTIL

Pour le modèle N° F012235400 : branchez le

chargeur dans votre prise de courant standard, puis

insérez la fiche du chargeur dans l'outil. (Fig. 2)

Le témoin vert de charge sur l'outil s'allumera.

Ceci indique que la pile reçoit une charge rapide. La

charge rapide s'arrêtera automatiquement lorsque

la pile est à pleine charge.

Le témoin S'ÉTEINT au terme de la charge rapide.

Si le témoin de charge vert devient rouge pendant

l'utilisation, cela signifie que la pile doit être rechargée.

Après une utilisation normale, la pile nécessite une

charge d'environ 3-5 heures pour atteindre sa pleine

capacité. On peut utiliser l'outil même si le témoin est

encore allumé. Il peut falloir plus de 3 heures pour

que le témoin s'éteigne, suivant la température.

Le témoin a pour but d'indiquer que la pile est

en charge rapide. Il n'indique pas le point exact de

pleine charge. Le témoin s'éteindra en moins de 3

heures si la pile n'était pas entièrement déchargée.

Lorsque la pile est entièrement chargée,

débranchez le chargeur (à moins que vous ne

chargiez un autre outil).

INSERTION DES EMBOUTS

Votre outil est muni d'un porte-embout magnétique.

Enfoncez simplement l'embout au maximum dans

le porte-embout (Fig. 3).

FIXATION À L'AIDE DE VIS

La procédure illustrée à la Fig. 4 vous permettra de fixer

des matériaux ensemble à l'aide de votre tournevis

sans fil sans dévêtir, fendre ou séparer le matériau.

Fixez d’abord les pièces ensemble à l’aide d’une

bride, et percez le premier trou aux 2/3 du diamètre

44

45

Page 24

SM 1619X05087 12-09:SM 1619X05087 12-09 1/4/10 9:18 AM Page 46

de la vis. Si le matériau est tendre, percez

uniquement les 2/3 de la lon gueur voulue. Si le

matériau est dur, percez toute la longueur.

Détachez ensuite les pièces et percez le

deuxième trou du même diamètre que la tige de la vis

dans la première pièce ou la pièce supérieure de bois.

En troisième lieu, si une vis à tête plate est

employée, fraisez le trou pour mettre la vis de niveau

avec la surface. Puis exercez tout simplement une

pression uniforme en enfon çant la vis. Le trou de

dégagement de la tige de la vis dans la pre mière

pièce permet à la tête de la vis de tirer les pièces

fermement ensemble.

FIXATION

À L’AIDE DE VIS

1. Percez les 2/3 du diamètre

et les 2/3 de la longueur de

la vis pour les matériaux

tendres, la longueur complète

pour les matériaux durs.

Exercez une légère

pression uniforme

en enfonçant les

vis.

FIG. 4

2. Percez le

même

diamètre que

la tige de la

vis.

3. Fraisez le

même

diamètre

que la

tête de la

vis.

Vis

ENTRETIEN

Service

AVERTISSEMENT

!

PIÈCE SUSCEPTIBLE D’ÊTRE ENTRE TENUE PAR

L’UTILISATEUR. L’entretien préventif exécuté par

des personnes non autorisés peut entraîner un

positionnement erroné des composants et des fils

internes, ce qui peut présenter de graves dangers.

GRAISSAGE DE L’OUTIL

Votre outil Skil a été graissé de manière

appropriée et il est prêt à l’usage.

MOTEURS C.C.

Le moteur de votre outil a été conçu pour de

nombreuses heures d’utilisation fiable. Pour

maintenir l’efficacité maximale du moteur, nous

recommandons de l’examiner tous les six mois.

Seul un moteur de remplacement Skil authentique,

conçu spécialement pour votre outil, doit être utilisé.

AVERTISSEMENT

!

toujours l’outil et/ou le chargeur de la source de

courant avant de nettoyer. La façon la plus efficace

de nettoyer l’outil est à l’aide d’air sec comprimé.

Portez toujours des lunettes de sécurité en nettoyant

les outils à l’air comprimé.

Les prises d’air et les leviers de commutation

doivent être gardés propres et exempts de corps

IL N’EXISTE À

L’INTÉRIEUR AUCUNE

Nettoyage

Pour éviter les

accidents, débranchez

46

47

Page 25

®

SM 1619X05087 12-09:SM 1619X05087 12-09 1/4/10 9:18 AM Page 48

étrangers. Ne tentez pas de nettoyer en insérant

des objets pointus à travers l’ouverture.

MISE EN GARDE

!

dissolvants abîment les pièces en plastique.

Parmi ceux-ci se trouvent: l’essence, le

tétrachlorure de carbone, les dissolvants de

nettoyage chlorés, l’ammoniaque ainsi que les

détergents domestiques qui en contiennent.

Certains agents de

nettoyages et certains

INSTRUCTIONS D'UTILISATION

COMPLÉMENTS IXO

(VENDUS SÉPARÉMENT)

Le nouveau tournevis sans fil Skil modèle 2354

est compatible avec le système de fixation

innovateur iXO de Skil. Ces compléments sont

vendus séparément, et ils ne peuvent pas être

inclus avec tous les modèles iXO. Pour tous

détails sur les compléments disponibles,

veuillez consulter le site web de Skil :

www.Skiltools.com

ASSEMBLAGE (VOIR FIGURES 6-7)

Pour assembler les compléments, tirez sur le

capuchon en caoutchouc afin de le détacher

de l'outil. Alignez le complément avec le bout

de l'outil. Poussez fermement le complément

sur l'outil jusqu'à

ce qu'il soit

solidement en

place. Les

c om p lé m e n ts

peuvent être

montés dans

d i f f é r e n t e s

positions avec

inclinaison de 45

degrés.

FIG. 6

FIG. 7

48

49

Page 26

SM 1619X05087 12-09:SM 1619X05087 12-09 1/4/10 9:18 AM Page 50

RETRAIT (VOIR FIGURES 8-9)

Pour retirer les compléments, faites tourner la

bague de dégagement dans le sens de la flèche

et tirez sur le complément pour le faire sortir du

bout de l'outil. Poussez doucement sur le

capuchon en caoutchouc pour le remettre en

place sur le bout de l'outil.

FIG. 8

FIG. 9

Les images montrant la fixation à angle droit

ne sont fournies qu'à titre informatif.

GARANTIE LIMITÉE DES OUTILS ÉLECTRIQUES GRAND

PUBLIC SKIL PORTATIFS, DE TABLE ET POUR USAGE

Robert Bosch Tool Corporation (le « Vendeur ») garantit à l'acheteur

initial seulement que tous les outils électriques grand public SKIL

portatifs, de table et pour usage industriel HD et SHD seront exempts de

vices de matériau ou de façon pendant une période d'un an depuis la

date d'achat. Les modèles d'outils électriques grand public SKIL

portatifs et de table seront exempts de vices de matériau ou de façon

pendant une période de quatre-vingt-dix jours si l'outil est utilisé

professionnellement.

INDUSTRIEL HD ET SHD

50

LA SEULE OBLIGATION DU VENDEUR ET LE SEUL RECOURS DE

L’ACHETEUR sous la présente garantie limitée, et dans la mesure où la

loi le permet sous toute garantie ou condition implicite qui en

découlerait, sera l’obligation de remplacer ou réparer gratuitement les

pièces défectueuses en termes de matériau ou de façon, pourvu que

lesdites défectuosités ne soient pas attribuables à un usage abusif ou à

quelque réparation ou altération bricolée par quelqu’un d’autre que le

Vendeur ou le personnel d’une station-service agréée. En cas de

réclamation sous la présente garantie limitée, l’acheteur est tenu de

renvoyer l’outil complet en port payé à un centre de service-usine SKIL

ou une station-service agréée. Pour trouver les coordonnées de la

station-service agréée SKIL la plus proche, veuillez visiter www.skil.com

ou téléphoner au 1-877-SKIL-999 (1-877-754-5999).

LA PRÉSENTE GARANTIE NE S’APPLIQUE PAS AUX ACCESSOIRES

TELS QUE LAMES DE SCIE CIRCULAIRE, MÈCHES DE PERCEUSES,

FERS DE TOUPIES, LAMES DE SCIES SAUTEUSES, COURROIES DE

PONÇAGE, MEULES ET AUTRES ARTICLES DU GENRE.

TOUTE GARANTIE IMPLICITE SERA LIMITÉE À UNE DURÉE À UN AN À

COMPTER DE LA DATE D’ACHAT. COMME CERTAINS ÉTATS

AMÉRICAINS ET CERTAINES PROVINCES CANADIENNES

N’ADMETTENT PAS LE PRINCIPE DE LA LIMITATION DE LA DURÉE

DES GARANTIES IMPLICITES, IL EST POSSIBLE QUE LES

LIMITATIONS CI-DESSUS NE S’APPLIQUENT PAS À VOTRE CAS.

EN AUCUN CAS LE VENDEUR NE SAURAIT ÊTRE TENU POUR

RESPONSABLE DES INCIDENTS OU DOMMAGES INDIRECTS

(INCLUANT, MAIS NE SE LIMITANT PAS AUX PERTES DE PROFITS)

CONSÉCUTIFS À LA VENTE OU À L’USAGE DE CE PRODUIT. COMME

CERTAINS ÉTATS AMÉRICAINS ET CERTAINES PROVINCES

CANADIENNES N’ADMETTENT PAS LE PRINCIPE DE LA LIMITATION

OU DE L’EXCLUSION DES DOMMAGES INDIRECTS ET SECONDAIRES,

IL EST POSSIBLE QUE LES LIMITATIONS OU EXCLUSIONS CI-DESSUS

NE S’APPLIQUENT PAS À VOTRE CAS.

CETTE GARANTIE LIMITÉE VOUS DONNE DES DROITS PRÉCIS, ET

VOUS POUVEZ ÉGALEMENT AVOIR D'AUTRES DROITS QUI VARIENT

D'UN ÉTAT À L'AUTRE AUX ÉTATS-UNIS, D'UNE PROVINCE À L'AUTRE

AU CANADA, ET D'UN PAYS À L'AUTRE.

CETTE GARANTIE LIMITÉE S'APPLIQUE UNIQUEMENT AUX OUTILS

VENDUS AUX ÉTATS-UNIS D'AMÉRIQUE, AU CANADA ET DANS LE

COMMONWEALTH DE PORTO RICO. POUR CONNAÎTRE LA

COUVERTURE DE GARANTIE DANS LES AUTRES PAYS, CONTACTEZ

VOTRE IMPORTATEUR OU REVENDEUR SKIL LOCAL.

Exportado por: Robert Bosch Tool Corporation Mt.

Prospect, IL 60056 -2230, E.U.A.

51

Page 27

®

SM 1619X05087 12-09:SM 1619X05087 12-09 1/4/10 9:18 AM Page 52

IMPORTANTE: Leer antes de usar

Instrucciones de

funcionamiento

y seguridad

2354

Llame gratis para obtener

información para el consumidor y

ubicaciones de servicio

1-877-SKIL999 (1-877-754-5999)

www.skil.com

52

1619X05087 12/09

Advertencias generales de seguridad

para herramientas mecánicas

ADVERTENCIA

!

instrucciones. Si no se siguen las advertencias e

instrucciones, el resultado podría ser sacudidas

eléctricas, incendio y/o lesiones graves.

Lea todas las advertencias

de seguridad e

GUARDE TODAS LAS ADVERTENCIAS E

INSTRUCCIONES

PARA REFERENCIA FUTURA

La expresión “herramienta mecánica” en todas las

advertencias se refiere a su herramienta mecánica

alimentada por la red eléctrica (herramienta

alámbrica) o su herramienta mecánica alimentada

por baterías (herramienta inalámbrica).

Seguridad del área de trabajo

Mantenga el área de trabajo limpia y bien

iluminada. Las áreas desordenadas u oscuras

invitan a que se produzcan accidentes.

No utilice herramientas mecánicas en

atmósferas explosivas, como por ejemplo en

presencia de líquidos, gases o polvos

inflamables. Las herramientas mecánicas

generan chispas que pueden incendiar el polvo o

los vapores.

Mantenga alejados a los niños y a las personas

que estén presentes mientras esté utilizando una

herramienta mecánica. Las distracciones pueden

hacerle perder el control de la herramienta.

53

Page 28

SM 1619X05087 12-09:SM 1619X05087 12-09 1/4/10 9:18 AM Page 54

Seguridad eléctrica

Los enchufes de las herramientas mecánicas

deben coincidir con el tomacorriente. No

modifique nunca el enchufe de ningún modo. No

use enchufes adaptadores con herramientas

mecánicas conectadas a tierra (puestas a

tierra). Los enchufes no modificados y los

tomacorrientes coincidentes reducirán el riesgo de

sacudidas eléctricas.

Evite el contacto del cuerpo con las superficies

conectadas o puestas a tierra, tales como

tuberías, radiadores, estufas y refrigeradores.

Hay un aumento del riesgo de sacudidas eléctricas

si el cuerpo del operador se conecta o pone a tierra.

No exponga las herramientas mecánicas a la

lluvia o a condiciones mojadas. La entrada de

agua en una herramienta mecánica aumentará el

riesgo de que se produzcan sacudidas eléctricas.

No maltrate el cordón de energía. No use nunca

el cordón para transportar la herramienta

mecánica, tirar de ella o desenchufarla.

Mantenga el cordón alejado del calor, el aceite,

los bordes afilados o las piezas móviles. Los

cordones dañados o enganchados aumentan el

riesgo de que se produzcan sacudidas eléctricas.

Cuando utilice una herramienta mecánica en el

exterior, use un cordón de extensión adecuado

para uso a la intemperie. La utilización de un

cordón adecuado para uso a la intemperie reduce

el riesgo de que se produzcan sacudidas

eléctricas.

54

Si es inevitable utilizar una herramienta

mecánica en un lugar húmedo, utilice una fuente

de energía protegida por un interruptor de

circuito accionado por corriente de pérdida a

tierra (GFCI). El uso de un GFCI reduce el riesgo

de sacudidas eléctricas.

Seguridad personal

Manténgase alerta, fíjese en lo que está

haciendo y use el sentido común cuando esté

utilizando una herramienta mecánica. No use

una herramienta mecánica cuando esté cansado

o bajo la influencia de drogas, alcohol o

medicamentos. Un momento de distracción

mientras esté utilizando herramientas mecánicas

podría causar lesiones corporales graves.

Use equipo de protección personal. Use siempre

protección de los ojos. El equipo de protección,

como por ejemplo una máscara antipolvo, calzado

de seguridad antideslizante, casco o protección de

oídos, utilizado para las condiciones apropiadas,

reducirá las lesiones corporales.

Evite el arranque accidental. Asegúrese de que

el interruptor esté en la posición de apagado

antes de conectar la herramienta a la fuente de

energía y / o al paquete de batería, levantar la

herramienta o transportarla. Transportar

herramientas mecánicas con un dedo en el

interruptor o encender herramientas mecánicas

que tengan el interruptor en la posición de

encendido invita a que se produzcan accidentes.

55

Page 29

SM 1619X05087 12-09:SM 1619X05087 12-09 1/4/10 9:18 AM Page 56

Quite todas las llaves de ajuste o de tuerca antes

de encender la herramienta mecánica. Una llave

de tuerca o de ajuste que se deje colocada en una

pieza giratoria de la herramienta mecánica podría

causar lesiones corporales.

No intente alcanzar demasiado lejos. Mantenga

un apoyo de los pies y un equilibrio apropiados

en todo momento. Esto permite controlar mejor la

herramienta mecánica en situaciones inesperadas.

Vístase adecuadamente. No use ropa holgada ni

alhajas holgadas. Mantenga el pelo, la ropa y

los guantes alejados de las piezas móviles. La

ropa holgada, las alhajas holgadas o el pelo largo

pueden quedar atrapados en las piezas móviles.

Si se proporcionan dispositivos para la conexión

de instalaciones de extracción y recolección de

polvo, asegúrese de que dichas instalaciones

estén conectadas y se usen correctamente. El

uso de dispositivos de recolección de polvo puede

reducir los peligros relacionados con el polvo.

Uso y cuidado de las herramientas

mecánicas

No fuerce la herramienta mecánica. Use la

herramienta mecánica correcta para la

aplicación que desee realizar. La herramienta

mecánica correcta hará el trabajo mejor y con más

seguridad a la capacidad nominal para la que fue

diseñada.

No use la herramienta mecánica si el interruptor

no la enciende y apaga. Toda herramienta

56

mecánica que no se pueda controlar con el

interruptor es peligrosa y debe ser reparada.

Desconecte el enchufe de la fuente de energía

y/o el paquete de batería de la herramienta

mecánica antes de hacer cualquier ajuste,

cambiar accesorios o almacenar herramientas

mecánicas. Dichas medidas preventivas de

seguridad reducen el riesgo de arrancar

accidentalmente la herramienta mecánica.

Guarde las herramientas que no esté usando

fuera del alcance de los niños y no deje que

personas que no estén familiarizadas con la

herramienta mecánica o con estas instrucciones

utilicen la herramienta. Las herramientas

mecánicas son peligrosas en manos de usuarios

que no hayan recibido capacitación.

Mantenga las herramientas mecánicas.

Compruebe si hay piezas móviles desalineadas

o que se atoran, si hay piezas rotas y si existe

cualquier otra situación que podría afectar el

funcionamiento de la herramienta mecánica. Si

la herramienta mecánica está dañada, haga que

la reparen antes de usarla. Muchos accidentes

son causados por herramientas mecánicas

mantenidas deficientemente.

Mantenga las herramientas de corte afiladas y

limpias. Es menos probable que las herramientas

de corte mantenidas apropiadamente, con bordes

de corte afilados, se atoren, y dichas herramientas

son más fáciles de controlar.

57

Page 30

SM 1619X05087 12-09:SM 1619X05087 12-09 1/4/10 9:18 AM Page 58

Utilice la herramienta mecánica, los accesorios,

las brocas de la herramienta, etc., de acuerdo

con estas instrucciones, teniendo en cuenta las

condiciones de trabajo y el trabajo que se vaya a

realizar. El uso de la herramienta mecánica para

operaciones distintas a aquéllas para las que fue

diseñada podría causar una situación peligrosa.

Uso y cuidado de las herramientas

alimentadas por baterías

Recargue las baterías solamente con el

cargador especificado por el fabricante. Un

cargador que es adecuado para un tipo de paquete

de batería puede crear un riesgo de incendio

cuando se utiliza con otro paquete de batería.

Utilice las herramientas mecánicas solamente

con paquetes de batería designados

específicamente.El uso de cualquier otro paquete

de batería puede crear un riesgo de lesiones e

incendio.

Cuando el paquete de batería no se esté usando,

manténgalo alejado de otros objetos metálicos,

tales como sujetapapeles, monedas, llaves,

clavos, tornillos u otros objetos metálicos

pequeños que pueden hacer una conexión de un

terminal a otro. Si se cortocircuitan los terminales

de la batería uno con otro, se pueden causar

quemaduras o un incendio.

En condiciones abusivas, es posible que se

eyecte líquido de la batería. Evite el contacto. Si

se produce un contacto accidental, enjuáguese

58

con agua. Si el líquido entra en contacto con los

ojos, obtenga además ayuda médica. El líquido

que salga eyectado de la batería puede causar

irritación o quemaduras.

Servicio de ajustes y reparaciones

Haga que su herramienta mecánica reciba

servicio de un técnico de reparaciones

calificado, utilizando únicamente piezas de

repuesto idénticas. Esto asegurará que se

mantenga la seguridad de la herramienta

mecánica.

NORMAS DE SEGURIDAD PARA

ATORNILLADORES INALÁMBRICOS

Sujete las herramientas mecánicas por las

superficies de agarre aisladas cuando realice

una operación en la que las herramientas de

corte puedan entrar en contacto con cables

ocultos. El contacto con un cable que tenga

corriente hará que ésta pase a las partes metálicas

descubiertas de la herramienta y que el operador

reciba sacudidas eléctricas.

Use abrazaderas u otro modo práctico de sujetar y

soportar la pieza de trabajo en una plataforma

estable. Si se sujeta la pieza de trabajo con la mano o

contra el cuerpo, se crea una situación inestable que

podría causar pérdida de control.

No tala dre, sujete, ni rompa en paredes existentes u

otras áreas ciegas donde puedan haber conexiones

eléctricas. Si esta situación es inevitable, desconecte

59

Page 31

SM 1619X05087 12-09:SM 1619X05087 12-09 1/4/10 9:18 AM Page 60

todos los fusibles o interruptores de circuito que

suministran energía a este lugar de trabajo.

Las herramientas accionadas por baterías se

encuentran siempre en condiciones de funcionamiento.

Conozca los posibles peligros.

Use siempre gafas de seguridad o protección de los

ojos cuando utilice esta herra mienta.

Fije la pieza de trabajo; no la tenga nunca en la mano

ni sobre las piernas. La acción de taladrado puede

hacer que pierda el control de la pieza de

trabajo y se podrán producir lesiones.

Al instalar una broca, introduzca el cuerpo de la broca

bien a fondo en el portaherramienta. Si la broca no se

introduce hasta una profundidad suficiente, se reduce el

agarre del portaherramienta sobre la broca y se aumenta

la pérdida de control.

No tenga en marcha la herramienta mientras la lleva a

su lado. La broca tala dradora que gira puede

charse en la ropa y se pueden producir lesiones.

engan

No utilice brocas ni accesorios desafilados o dañados.

Las brocas o accesorios desafilados o dañados pueden

atascarse frecuentemente en la pieza de trabajo.

ADVERTENCIA

!

Cierto polvo generado por el

lijado, aserrado, amolado y

taladrado mecánicos, y por otras actividades de

construcción, contiene agentes químicos que se sabe

que causan cáncer, defectos de nacimiento u otros

daños sobre la reproducción. Algunos ejemplos de

estos agentes químicos son:

• Plomo de pinturas a base de plomo,

• Sílice cristalina de ladrillos y cemento y otros

productos de mampostería, y

• Arsénico y cromo de madera tratada químicamente.

Su riesgo por causa de estas exposiciones varía,

dependiendo de con cuánta frecuencia realice este tipo

de trabajo. Para reducir su exposición a estos agentes

químicos: trabaje en un área bien ventilada y trabaje

con equipo de seguridad aprobado, como por ejemplo

máscaras antipolvo que estén diseñadas

especialmente para impedir mediante filtración el paso

de partículas microscópicas.

Batería/cargador

Antes de utilizar el cargador de baterías, lea

todas las instrucciones e indicaciones de

precaución que se encuentran en (1) el

cargador de baterías, (2) el paquete de baterías

y (3) el producto que utiliza baterías.

No desarme el cargador ni lo haga funcionar si

ha recibido un golpe brusco, se ha caído o se

ha dañado de cualquier modo. Cambie el

cordón o los enchufes dañados inmediatamente.

El reensamblaje incorrecto o los daños pueden

ocasionar sacudidas eléctricas o incendio.

No recargue la batería en un entorno húmedo o

mojado. No exponga el cargador a lluvia ni

nieve. Si la caja de baterías está agrietada o

dañada de algún otro modo, no la introduzca en

el cargador. Se puede producir un cortocircuito

de las baterías o un incendio.

Cargue el paquete de baterías a temperaturas

superiores a +32 grados F (0 grados C) e

inferiores a +113 grados F (45 grados C). Guarde

60

61

Page 32

SM 1619X05087 12-09:SM 1619X05087 12-09 1/4/10 9:18 AM Page 62

la herramienta y el paquete de baterías en

lugares donde las temperaturas no superen 120

grados F (49 grados C). Esto es importante para

evitar daños graves a los elementos de la batería.

Ponga el cargador sobre superficies planas

ininflamables y alejado de materiales

inflamables cuando recargue el paquete de

baterías. El cargador y el paquete de baterías se

calientan durante el proceso de carga. Las

alfombras y otras superficies termoaislantes

bloquean la circulación adecuada de aire, lo cual

puede causar sobrecalentamiento del cargador y

del paquete de baterías. Si observa humo o que

la carcasa se está derritiendo, desenchufe

inmediatamente el cargador y no utilice el

paquete de baterías ni el cargador.

El uso de un accesorio no recomendado ni

vendido por Skil puede constituir un peligro

de incendio, sacudidas eléctricas o lesiones a

las personas.

Cuidado de las baterías

ADVERTENCIA

!

cargador, manténgalas alejadas de objetos

metálicos. Por ejemplo, para evitar que los terminales

hagan corto circuito, NO ponga las baterías en una caja

de herramientas o en un bolsillo con clavos, tornillos,

llaves, etc. Se puede producir un incendio o lesiones.

NO ARROJE LAS BATERIAS AL FUEGO NI LAS EXPONGA

AL CALOR INTENSO. Pueden explotar.

Cuando las baterías no están

en la herra mienta o en el

Eliminación de las baterías

ADVERTENCIA

!

los com ponentes que sobresalen de las terminales de

la batería. Se pueden producir lesiones o un incendio.

Antes de tirarla, proteja las terminales que están al

descubierto con cinta adhesiva aislante gruesa para

prevenir cortocircuitos.

No intente desarmar la

batería ni quitar ninguno de

Baterías de iones de litio

Si este producto está equipado con una batería de iones de

litio, dicha batería debe recogerse, reciclarse o eliminarse

de manera segura para el medio ambiente.

“El sello de reciclaje de baterías RBRC

certificado por la EPA que se encuentra en

la batería de iones de litio (Li-ion) indica

que Robert Bosch Tool Corporation está

programa de la industria para recoger y reciclar estas

baterías al final de su vida útil, cuando se retiran de servicio

en los Estados Unidos y Canadá. El programa RBRC

proporciona una alternativa conveniente a tirar las baterías

de Li-ion usadas a la basura o a la corriente municipal de

aguas residuales, lo cual quizás sea ilegal en su área.