Page 1

CORDLESS DRILL/DRIVER

2244 (F0152244..)

ORIGINAL INSTRUCTIONS 6

GB

NOTICE ORIGINALE 9

F

ORIGINALBETRIEBSANLEITUNG 14

D

ORIGINELE GEBRUIKSAANWIJZING 18

NL

BRUKSANVISNING I ORIGINAL 23

S

ORIGINAL BRUGSANVISNING 26

DK

N

ORIGINAL BRUKSANVISNING 30

FIN

ALKUPERÄISET OHJEET 34

E

MANUAL ORIGINAL 38

P

MANUAL ORIGINAL 43

I

ISTRUZIONI ORIGINALI 47

H

EREDETI HASZNÁLATI UTASÍTÁS 51

CZ

PŮVODNÍM NÁVODEM K POUŽÍVÁNÍ 56

TR

ORİJİNAL İŞLETME TALİMATI 60

PL

INSTRUKCJA ORYGINALNA 64

RU

ПОДЛИННИК РУКОВОДСТВА

ПО ЭКСПЛУАТАЦИИ

68

www.skilmasters.com

SKIL Europe BV - Konijnenberg 60 04/09 1619X04348

4825 BD Breda - The Netherlands

ОРИГІНАЛЬНА ІНСТРУКЦІЯ

UA

З ЕКСПЛУАТАЦІЇ

GR

ΠΡΩΤΟΤΥΠΟ Ο∆ΗΓΙΩΝ ΧΡΗΣΗΣ 78

RO

INSTRUCŢIUNI DE FOLOSIRE

ORIGINALE

BG

ОРИГИНАЛНО РЪКОВОДСТВО

ЗА ЕКСПЛОАТАЦИЯ

SK

PÔVODNÝ NÁVOD NA POUŽITIE 92

HR

ORIGINALNE UPUTE ZA RAD 97

SRB

ORIGINALNO UPUTSTVO ZA RAD 100

SLO

IZVIRNA NAVODILA 104

EST

ALGUPÄRANE KASUTUSJUHEND 108

LV

ORIĢINĀLĀ LIETOŠANAS PAMĀCĪBA 112

LT

ORIGINALI INSTRUKCIJA 116

AR

FA

127

125

ME77

73

83

87

Page 2

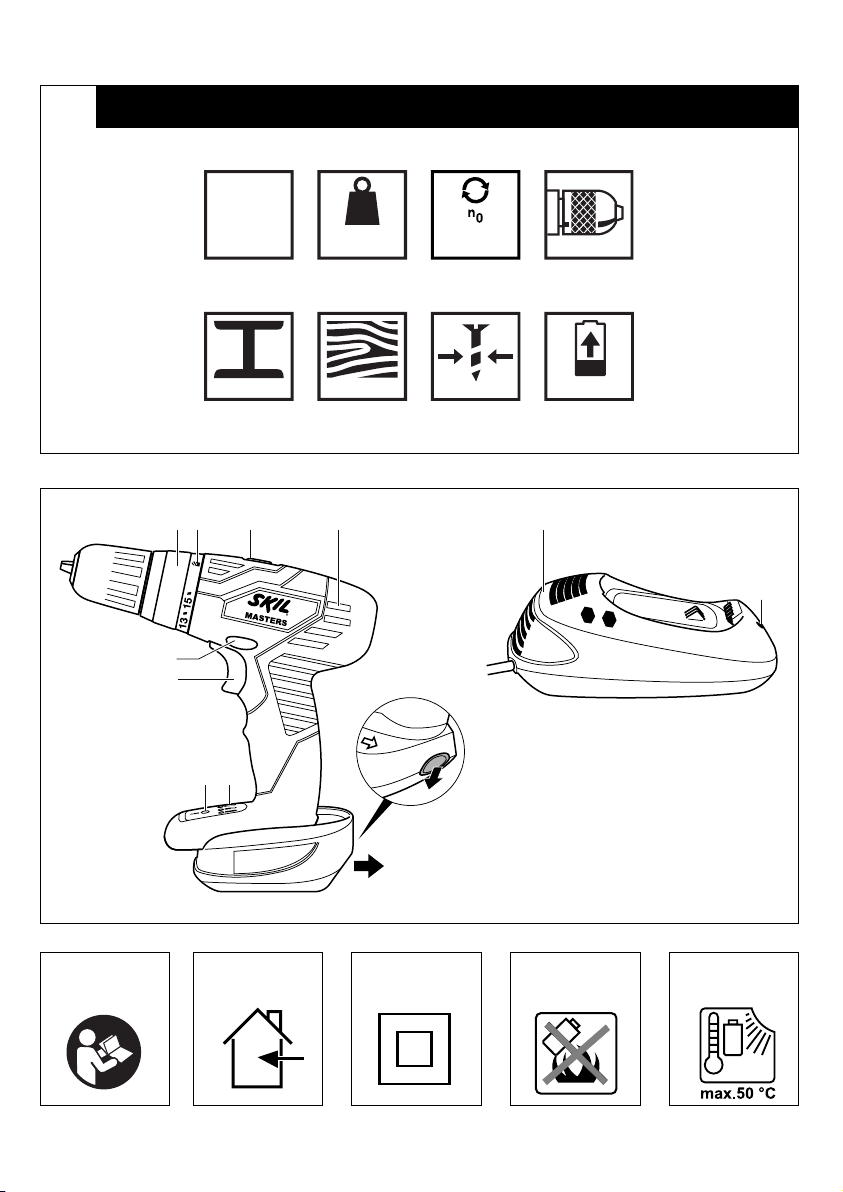

1

2244

2

14,4

Vol t

C

D

F

E

A

G

H

EPTA 01/2003

1,2 kg

30 mm10 mm

J

0-375/

1400/min

6 mm

0,8-10 mm

1 HOUR

K

B

3

4 5 6

2

7

Page 3

8

0

9

/K

3

Page 4

!

@

E

#

DC

15

1

4

Page 5

$

%

F

66%

^ &

H

G

34-66%

11-33%

11%

ACCESSORIES SKIL Nr.

14,4 V 1,3 Ah Li-ion

5

2607336262

Page 6

GB

Cordless drill/driver 2244

INTRODUCTION

• This tool is intended for drilling in wood, metal, ceramic

and plastic; tools with electronic speed control and left/

right rotation are also suitable for screwdriving and

thread cutting

• Read and save this instruction manual 3

TECHNICAL SPECIFICATIONS 1

Max. torque for hard screwdriving application according to

ISO 5393: 36 Nm

TOOL ELEMENTS 2

A Switch for on/off and speed control

B Green charging light

C Ring for torque control

D Lock-position (clutch)

E Switch for changing direction of rotation

F Gear selector

G Battery level indicator

H Spot light

J Ventilation slots

K Charger

SAFETY

GENERAL SAFETY INSTRUCTIONS

WARNING! Read all safety warnings and all

instructions. Failure to follow the warnings and

instructions may result in electric shock, fire and/or serious

injury. Save all warnings and instructions for future

reference. The term “power tool” in the warnings refers to

your mains-operated (corded) power tool or batteryoperated (cordless) power tool.

1) WORK AREA SAFETY

a) Keep work area clean and well lit.

Cluttered or dark areas invite accidents.

b) Do not operate power tools in explosive

atmospheres, such as in the presence of flammable

liquids, gases or dust. Power tools create sparks

which may ignite the dust or fumes.

c) Keep children and bystanders away while operating

a power tool. Distractions can cause you to lose

control.

2) ELECTRICAL SAFETY

a) Power tool plugs must match the outlet.

Never modify the plug in any way. Do not use any

adapter plugs with earthed (grounded) power tools.

Unmodifi ed plugs and matching outlets will reduce risk

of electric shock.

b) Avoid body contact with earthed or grounded

surfaces such as pipes, radiators, ranges and

refrigerators. There is an increased risk of electric

shock if your body is earthed or grounded.

c) Do not expose power tools to rain or wet conditions.

Water entering a power tool will increase the risk of

electric shock.

d) Do not abuse the cord. Never use the cord for

carrying, pulling or unplugging the power tool.

Keep cord away from heat, oil, sharp edges or

moving parts. Damaged or entangled cords increase

the risk of electric shock.

e) When operating a power tool outdoors,

use an extension cord suitable for outdoor use.

Use of a cord suitable for outdoor use reduces the risk

of electric shock.

f) If operating a power tool in a damp location is

unavoidable, use an earth leakage circuit breaker.

Use of an earth leakage circuit breaker reduces the risk

of electric shock.

3) PERSONAL SAFETY

a) Stay alert, watch what you are doing and use

common sense when operating a power tool.

Do not use a power tool while you are tired or

under the influence of drugs, alcohol or medication.

A moment of inattention while operating power tools

may result in serious personal injury.

b) Use personal protective equipment. Always wear

eye protection. Protective equipment such as dust

mask, non-skid safety shoes, hard hat, or hearing

protection used for appropriate conditions will reduce

personal injuries.

c) Prevent unintentional starting. Ensure the switch is

in the off-position before connecting to power

source and/or battery pack, picking up or carrying

the tool. Carrying power tools with your fi nger on the

switch or energising power tools that have the switch

on invites accidents.

d) Remove any adjusting key or wrench before turning

the power tool on. A wrench or a key left attached to a

rotating part of the power tool may result in personal

injury.

e) Do not overreach. Keep proper footing and balance

at all times. This enables better control of the power

tool in unexpected situations.

f) Dress properly. Do not wear loose clothing or

jewellery. Keep your hair, clothing and gloves away

from moving parts. Loose clothes, jewellery or long

hair can be caught in moving parts.

g) If devices are provided for the connection of dust

extraction and collection facilities, ensure these are

connected and properly used. Use of dust collection

can reduce dust-related hazards.

4) POWER TOOL USE AND CARE

a) Do not force the power tool. Use the correct power

tool for your application. The correct power tool will

do the job better and safer at the rate for which it was

designed.

b) Do not use the power tool if the switch does not turn

it on and off. Any power tool that cannot be controlled

with the switch is dangerous and must be repaired.

c) Disconnect the plug from the power source and/or

the battery pack from the power tool before making

any adjustments, changing accessories, or storing

power tools. Such preventive safety measures reduce

the risk of starting the power tool accidentally.

6

Page 7

d) Store idle power tools out of the reach of children

and do not allow persons unfamiliar with the power

tool or these instructions to operate the power tool.

Power tools are dangerous in the hands of untrained

users.

e) Maintain power tools. Check for misalignment or

binding of moving parts, breakage of parts and any

other condition that may affect the power tool’s

operation. If damaged, have the power tool repaired

before use. Many accidents are caused by poorly

maintained power tools.

f) Keep cutting tools sharp and clean.

Properly maintained cutting tools with sharp cutting

edges are less likely to bind and are easier to control.

g) Use the power tool, accessories and tool bits etc.,

in accordance with these instructions, taking into

account the working conditions and the work to be

performed. Use of the power tool for operations

different from those intended could result in a

hazardous situation.

5) BATTERY TOOL USE AND CARE

a) Recharge only with the charger specified by the

manufacturer. A charger that is suitable for one type of

battery pack may create a risk of fi re when used with

another battery pack.

b) Use power tools only with specifically designated

battery packs. Use of any other battery packs may

create a risk of injury and fi re.

c) When battery pack is not in use, keep it away from

other metal objects like paper clips, coins, keys,

nails, screws, or other small metal objects that can

make a connection from one terminal to another.

Shorting the battery terminals together may cause

burns or a fi re.

d) Under abusive conditions, liquid may be ejected

from the battery; avoid contact. If contact

accidentally occurs, flush with water. If liquid

contacts eyes, additionally seek medical help. Liquid

ejected from the battery may cause irritation or burns.

6) SERVICE

a) Have your power tool serviced by a qualified repair

person using only identical replacement parts.

This will ensure that the safety of the power tool is

maintained.

SAFETY INSTRUCTIONS FOR CORDLESS DRILL/

DRIVERS

• Avoid damage that can be caused by screws, nails and

other elements in your workpiece; remove them before

you start working

• Always check that the supply voltage is the same as the

voltage indicated on the nameplate of the charger

(chargers with a rating of 230V or 240V can also be

connected to a 220V supply)

• In case of electrical or mechanical malfunction,

immediately switch off the tool or unplug charger from

power source

• SKIL can assure fl awless functioning of the tool only

when the correct accessories are used which can be

obtained from your SKIL dealer

• Use only accessories with an allowable speed matching

at least the highest no-load speed of the tool

• The tool/charger is not intended for use by persons

(including children) with reduced physical, sensory or

mental capabilities, or lack of experience and

knowledge, unless they have been given supervision or

instruction concerning use of the tool/charger by a

person responsible for their safety

• Ensure that children do not play with the tool/charger

• Secure the workpiece (a workpiece clamped with

clamping devices or in a vice is held more securely than

by hand)

• Hold the power tool only by the insulated gripping

surfaces when performing an operation where the

accessory may contact hidden wiring or its own

power cord (contact with a “live” wire will also make

exposed metal parts of the power tool “live” and shock

the operator)

• Use suitable detectors to find hidden utility lines or

call the local utility company for assistance (contact

with electric lines can lead to fi re or electrical shock;

damaging a gas line can result in an explosion;

penetrating a water pipe will cause property damage or

an electrical shock)

• Do not work materials containing asbestos

(asbestos is considered carcinogenic)

• Dust from material such as paint containing lead, some

wood species, minerals and metal may be harmful

(contact with or inhalation of the dust may cause

allergic reactions and/or respiratory diseases to the

operator or bystanders); wear a dust mask and work

with a dust extraction device when connectable

• Certain kinds of dust are classifi ed as carcinogenic

(such as oak and beech dust) especially in conjunction

with additives for wood conditioning; wear a dust

mask and work with a dust extraction device when

connectable

• Follow the dust-related national requirements for the

materials you want to work with

• Ensure that switch E 2 is in the middle (locking)

position before making any adjustments or changing

accessories as well as when carrying or storing the tool

CHARGING/BATTERIES

• Charge battery only with the charger that is supplied

with the tool

• Do not touch the contacts in the charger

• Do not expose tool/charger/battery to rain

• Do not charge battery in damp or wet environments

• Store tool/charger/battery in locations where

temperature will not exceed 50°C or drop below 0°C

• Do not use charger when damaged; take it to one of the

offi cially registered SKIL Service Stations for a safety

check

• Do not use charger when cord or plug is damaged; cord

or plug should be replaced immediately at one of the

offi cially registered SKIL Service Stations

• Do not use battery when damaged; it should be

replaced immediately

• Do not disassemble charger or battery

• Do not attempt to recharge non-rechargeable batteries

with the charger

7

Page 8

• If you anticipate long periods of non-use for the tool, it

is best to unplug the charger from its power source

• Explanation of symbols on charger/battery

3 Read the instruction manual before use

4 Only use the charger indoors

5 Double insulation (no earth wire required)

6 Batteries may explode when disposed of in fi re,

so do not burn battery for any reason

7 Store tool/charger/battery in locations where

temperature will not exceed 50°C

8 Do not dispose of the charger together with

household waste material

9 Do not dispose of the battery together with

household waste material

WHEN CONNECTING NEW 3-PIN PLUG (U.K. ONLY):

• Do not connect the blue (= neutral) or brown (= live) wire

in the cord of the charger to the earth terminal of the

plug

• If for any reason the old plug is cut off the cord of the

charger, it must be disposed of safely and not left

unattended

USE

• Combined switch A 2 for on/off and speed control

Control the speed steplessly from zero to maximum by

putting less or more pressure on the trigger

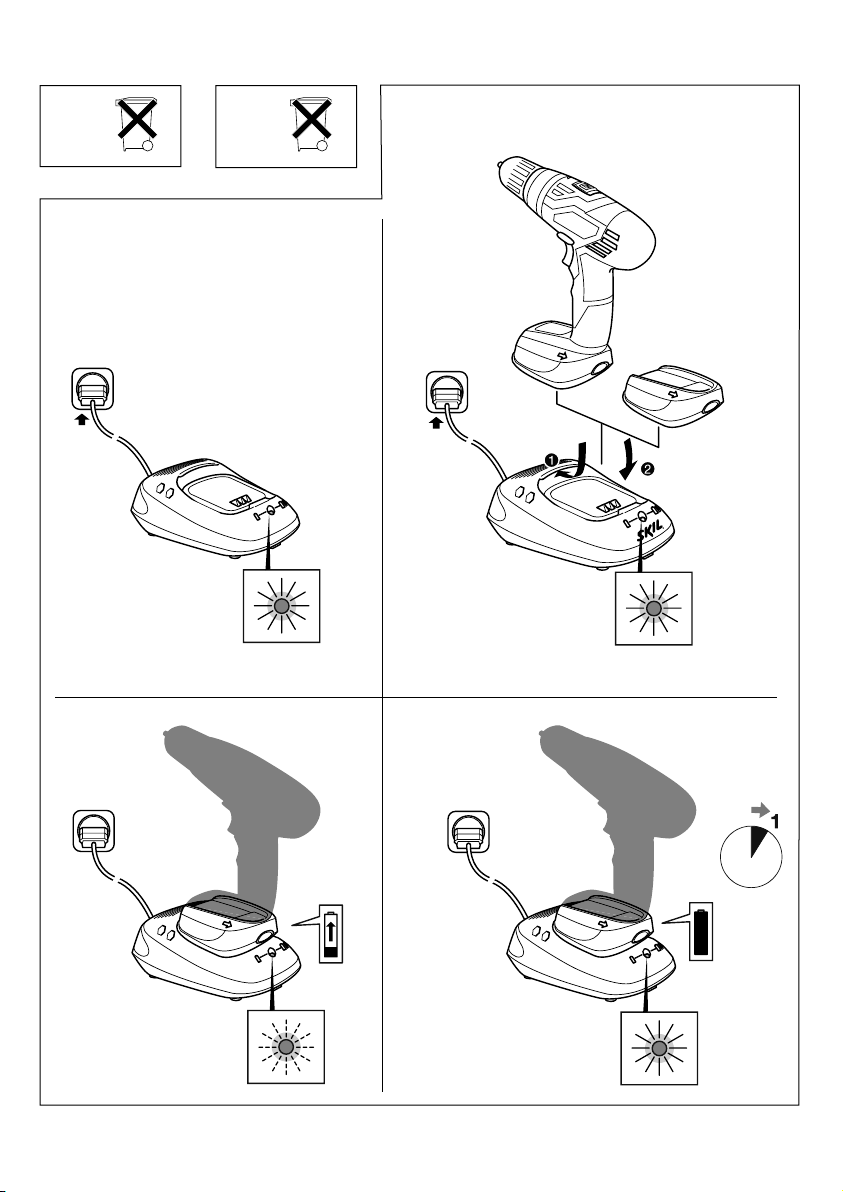

• Charging battery 0

! a lithium-ion battery that is new or has not been

used for a longer period does not develop its full

capacity until after approximately 3 charging/

discharging cycles

- connect charger to power source as illustrated

- green light B will turn on indicating that the charger is

ready for operation

- insert battery into charger as illustrated

! the battery can also remain in the tool while

charging; in that case the tool cannot be switched

on

- green light B will blink indicating that the battery is

receiving a charge

- after approximately 1 hour the battery is fully charged

and green light B stays on after blinking, at which

time the charger automatically switches to

maintenance-charging

! remove battery from charger after charging

period has ended thereby lengthening the service

life of the battery

IMPORTANT:

- if green light B does not blink after inserting a battery,

this may mean:

1) that the battery is too cold or too hot (charger only

charges batteries when its temperature is between

0°C and 45°C); the charger then automatically

switches to maintenance-charging, until a

temperature between 0°C and 45°C is reached, at

which time the charger will automatically switch to

normal charging

2) that the battery should be replaced

- the lithium-ion battery can be charged at any time

(interrupting the charging procedure does not

damage the battery)

- the lithium-ion battery does not have to be empty

before charging (no “memory-effect” as with nickelcadmium batteries)

- while charging, the charger and the battery may

become warm to touch; this is normal and does not

indicate a problem

- ensure that the outside surface of the battery is clean

and dry before inserting into charger

- do not charge at temperatures below 0°C and over

45°C; this will seriously damage the battery as well

as the charger

- do not remove battery from tool while it is running

- if you anticipate long periods of non-use for the tool,

it is best to unplug the charger from its power source

- when the lithium-ion battery is empty, the tool is

switched off automatically

- a signifi cantly reduced working period after charging

indicates that the battery is worn out and should be

replaced

• Changing direction of rotation !

- when not properly set in left/right position,

switch A 2 cannot be activated

! change direction of rotation only when tool is at a

complete standstill

• Changing drill bits @

- insert the bit as deep as possible in the chuck

- use screw bits in combination with a bitholder

! do not use bits with a damaged shank

! only use sharp bits

• Torque control (VariTorque) #

- output torque will increase as clutch ring C is rotated

from 1 to 15; position D will lock up the clutch to

permit drilling or driving heavy duty work

- when turning in a screw, fi rst try VariTorque position 1

and increase until the desired depth has been

reached

• Mechanical gear selection $

- set selector F to desired speed

! actuate the gear selector while tool is running

slowly

HIGH POWER

- high torque

- for screwdriving and drilling large diameters

- for tapping thread

HIGH SPEED

- lower torque

- for drilling small diameters

• Battery level indicator %

- shows how much energy the battery has left

- indicator G automatically lights on when activating

switch A 2

• Spot light H ^

Spot light H automatically lights on when activating

switch A 2

• Battery protection

Switches off the tool automatically when

1) the load is too high

2) the battery temperature is not within the allowable

operating temperature range of -10 to +60°C

3) the lithium-ion battery is nearly empty (to protect

against deep discharge)

8

Page 9

- in either case the 3 LED-lights of battery level

indicator G will fl ash rapidly

! do not continue to press the on/off switch after

the tool is switched off automatically; battery may

be damaged

• Automatic spindle-lock

- when switch A 2 is not pressed, the spindle is

locked

- allows you to use the tool as a screwdriver (even

when the battery is empty)

• Holding and guiding the tool &

! while working, always hold the tool at the grey-

coloured grip area(s)

- keep ventilation slots J 2 uncovered

- do not apply too much pressure on the tool; let the

tool do the work for you

APPLICATION ADVICE

• When drilling ferrous metals

- pre-drill a smaller hole, when a large hole is required

- lubricate drill bit occasionally with oil

• When turning in a screw at/near the cross cut end or an

edge of wood, pre-drill a hole in order to avoid cracking

of the wood

• For an optimal use of the tool a steady pressure on the

screw is required, especially while removing

• When screwdriving in hard wood one should pre-drill a

hole

MAINTENANCE / SERVICE

• Keep tool and charger clean

- clean charging contacts in charger with alcohol or

contact cleaner

! unplug charger from power source before

cleaning

• If the tool/charger should fail despite the care taken in

manufacturing and testing procedures, repair should be

carried out by an after-sales service centre for SKIL

power tools

- send the tool or charger undismantled together with

proof of purchase to your dealer or the nearest SKIL

service station (addresses as well as the service

diagram of the tool are listed on

www.skilmasters.com)

ENVIRONMENT

• Do not dispose of electric tools, accessories and

packaging together with household waste material

(only for EU countries)

- in observance of European Directive 2002/96/EC on

waste of electric and electronic equipment and its

implementation in accordance with national law,

electric tools that have reached the end of their life

must be collected separately and returned to an

environmentally compatible recycling facility

- symbol 8 will remind you of this when the need for

disposing occurs

• The battery must be kept separate from the natural

environment and should not be disposed of as normal

domestic waste (symbol 9 will remind you of this when

the need for disposing occurs)

! prior to disposal protect battery terminals with

heavy tape to prevent short-circuit

CE DECLARATION OF CONFORMITY

• We declare under our sole responsibility that this

product is in conformity with the following standards or

standardized documents: EN 60 335, EN 60 745,

EN 55 014, in accordance with the provisions of the

directives 2006/95/EC, 2004/108/EC, 98/37/EC (until

Dec. 28, 2009), 2006/42/EC (from Dec. 29, 2009 on)

• Technical file at: SKIL Europe BV (PT-SEU/PJE),

4825 BD Breda, NL

09 SKIL Europe BV A. v.d. Kloot

NOISE/VIBRATION

• Measured in accordance with EN 60 745 the sound

pressure level of this tool is 74 dB(A) and the sound

power level 85 dB(A) (standard deviation: 3 dB), and the

vibration ✱ (hand-arm method; uncertainty K =

1.5 m/s²)

✱ when drilling in metal <2.5 m/s²

✱ when screwdriving <2.5 m/s²

• The vibration emission level has been measured in

accordance with a standardised test given in

EN 60 745; it may be used to compare one tool with

another and as a preliminary assessment of exposure to

vibration when using the tool for the applications

mentioned

- using the tool for different applications, or with

different or poorly maintainted accessories, may

signifi cantly increase the exposure level

- the times when the tool is switched off or when it is

running but not actually doing the job, may

signifi cantly reduce the exposure level

! protect yourself against the effects of vibration by

maintaining the tool and its accessories, keeping

your hands warm, and organizing your work

patterns

F

Perceuse/visseuse sans fil 2244

INTRODUCTION

• Cet outil est conçu pour le perçage dans le bois, le

métal, la céramique et les matières plastiques; les outils

avec réglage électronique de la vitesse et rotation à

droite/à gauche sont également appropiés pour le

vissage et le fi letage

• Lisez et conservez ce manuel d’instructions 3

SPECIFICATIONS TECHNIQUES 1

Couple max. vissage dur suivant ISO 5393: 36 Nm

9

Loading...

Loading...