Page 1

SM 1619X04663 05-11:SM 1619X04663 05-11 5/3/11 8:14 AM Page 1

IMPORTANT: IMPORTANT : IMPORTANTE:

Read Before Using Lire avant usage Leer antes de usar

Operating/Safety Instructions

Consignes de fonctionnement/sécurité

Instrucciones de funcionamiento y seguridad

1817

1827

1830

Call Toll Free for

Consumer Information

& Service Locations

1-877-SKIL999 (1-877-754-5999) www.skil.com

For English Version Version française Versión en español

See page 2 Voir page 19 Ver la página 36

Pour obtenir des informations

et les adresses de nos centres

de service après-vente,

appelez ce numéro gratuit

Llame gratis para

obtener información

para el consumidor y

ubicaciones de servicio

Page 2

SM 1619X04663 05-11:SM 1619X04663 05-11 5/3/11 8:14 AM Page 2

General Power Tool Safety Warnings

WARNING

!

Read all safety warnings and all instru ctions. Failure to follow the

warnings and instructions may result in electric shock, fire and/or serious injury.

SAVE ALL WARNINGS AND INSTRUCTIONS FOR FUTURE REFERENCE

The term “power tool” in the warnings refers to your mains-operated (corded) power tool or

battery-operated (cordless) power tool.

Work area safety

Keep work area clean and well lit. Cluttered

or dark areas invite accidents.

Do not operate power tools in explosive

atmospheres, such as in the presence of

flammable liquids, gases or dust. Power

tools create sparks which may ignite the dust

or fumes.

Keep children and bystanders away while

operating a power tool. Distractions can

cause you to lose control.

Electrical safety

Power tool plugs must match the outlet.

Never modify the plug in any way. Do not

us e a ny adapter pl ug s with earthe d

(grounded) power tools. Unmodified plugs

and matching outlets will reduce risk of electric

shock.

Avoid body contact with earthed or grounded

surfaces such as pipes, radiators, ranges

and refrigerators. There is an increased risk

of electric shock if your body is earthed or

grounded.

Do not expose power tools to rain or wet

conditions. Water entering a power tool will

increase the risk of electric shock.

Do not abuse the cord. Never use the cord

for carrying, pulling or unplugging the power

tool. Keep cord away from heat, oil, sharp

edges or moving parts. Damaged or entangled

cords increase the risk of electric shock.

When operating a power tool outdoors,

use an extension cord suitable for outdoor

use. Use of a cord suitable for outdoor use

reduces the risk of electric shock.

If operating the power tool in damp locations

is unavoidable, use a Ground Fault Circuit

Interrupter (GFCI) protected supply. Use of

an GFCI reduces the risk of electric shock.

Personal safety

Stay alert, watch what you are doing and

us e co mmon sense w hen opera ting a

power tool. Do not use a power tool while

you are tired or under the influence of drugs,

alcohol or medication. A moment of inattention

while operating power tools may result in

serious personal injury.

Use personal protective equipment. Always

wear eye protection. Protective equipment

such as dust mask, non-skid safety shoes, hard

hat, or hearing protection used for appropriate

conditions will reduce personal injuries.

Prevent unintentional starting. Ensure the

sw itch is in th e o ff-po sitio n b efore

connecting to power source and / or battery

pa ck, picki ng up or carrying the t ool.

Carrying power tools with your finger on the

switch or energizing power tools that have the

switch on invites accidents.

Remove any adjusting key or wrench before

turning the power tool on. A wrench or a

key left attached to a rotating part of the

power tool may result in personal injury.

Do not overreach. Keep proper footing and

balance at all times. This enables better

co ntrol of the power to ol in unexpe ct ed

situations.

Dress properly. Do not wear loose clothing

or jewelry. Keep your hair, clothing and

gloves away from moving parts. Loose

clothes, jewelry or long hair can be caught in

moving parts.

If devices are provided for the connection

of dust extraction and collection facilities,

ensure these are connected and properly

used. Use of dust collection can reduce dust-

related hazards.

Power tool use and care

Do not forc e the power to ol. Use the

correct power tool for your application. The

correct power tool will do the job better and

safer at the rate for which it was designed.

Do not use the power tool if the switch does

not turn it on and off. Any power tool that

ca nn ot be co nt ro ll ed wi th th e swi tc h is

dangerous and must be repaired.

-2-

Page 3

SM 1619X04663 05-11:SM 1619X04663 05-11 5/3/11 8:14 AM Page 3

Disconnect the plug from the power source

and/or the battery pack from the power tool

before making any adjustments, changing

accessories, or storing power tools. Such

preventive safety measures reduce the risk of

starting the power tool accidentally.

Store idle power tools out of the reach of

children and do not allow persons unfamiliar

with the power tool or these instructions to

operate the power tool. Power tools are

dangerous in the hands of untrained users.

Maintain power tools. Check for misalignment

or binding of moving parts, breakage of

parts and any other condition that may

affect the power tool’s operation. If damaged,

have the power tool repaired before use.

Ma ny acci de nt s ar e ca us ed by poorly

maintained power tools.

Safety Rules for Routers

Hold power tool by insulated gripping

surfaces when performing an operation

where the cutting tool may contact hidden

wiring or its own cord. Contact with a "live"

wire will make exposed metal parts of the

tool "live" and shock the operator.

Use clamps or another practical way to

secure and support the workpiece to a

stable platform. Holding the work by hand or

against your body leaves it unstable and may

lead to loss of control.

Always make sure the work surface is

free from nails and other foreign objects.

Cutting into a nail can cause the bit and the

tool to jump and damage the bit.

Never hold the workpiece in one hand and

the tool in the other hand when in use.

Never place hands near or below cutting

surface. Clamping the material and guiding

the tool with both hands is safer.

Never lay workp ie ce on top of hard

surfaces, li ke co nc re te, stone, etc. ..

Protruding cutting bit may cause tool to jump.

Alway s wear safety goggles and dust

mask. Use only in well ventilated area.

Using personal safety devices and working in

safe environment reduces risk of injury.

Keep cutting tools sharp and clean. Properly

maintained cutting tools with sharp cutting

edges are less likely to bind and are easier to

control.

Use the power tool, accessories and tool

bits etc. in accordance with these instructions,

taking into account the working conditions

and the work to be performed. Use of the

power tool for operations different from those

intended could result in a hazardous situation.

Service

Have your power tool serviced by a qualified

re pa ir person u sing on ly identical

replacement parts. This will ensure that the

safety of the power tool is maintained.

After changing the bits or making any

adjustments, make sure the collet nut and

any ot her ad justmen t devices are

se cu re ly ti gh tened. L oo se ad ju st me nt

device can unexpectedly shift, causing loss

of control, loose rotating components will be

violently thrown.

Never start the too l wh en the bi t is

engaged in the material. The bit cutting

edge may grab the material causing loss of

control of the cutter.

Al wa ys hold the to ol with two ha nd s

during start-up. The reaction torque of the

motor can cause the tool to twist.

The direction of feeding the bit into the

material is very important and it relates to

the direction of bit rotation. When viewing

th e tool from t he to p, the bit rot at es

clockwise. Feed direction of cutting must

be counter-clockwise. NOTE: inside and

outside cu ts will req ui re differe nt feed

direction, refer to se ction on fee ding the

router. Feed in g the to ol in the wro ng

direction, causes the cutting edge of the bit

to climb out of the work and pull the tool in

the direction of this feed.

Never use dull or damaged bits. Sharp

bits must be handled with care. Damaged

-3-

Page 4

SM 1619X04663 05-11:SM 1619X04663 05-11 5/3/11 8:14 AM Page 4

bits can snap during use. Dull bits require

more force to push the tool, possibly causing

the bit to break.

Never touch the bit during or immediately

after the use. After use the bit is too hot to

be touched by bare hands.

Additional Safety Warnings

GFCI and personal protection devices like

electrician’s rubber gloves and footwear will

further enhance your personal safety.

Do not use AC only rated tools with a DC

power supply. While the tool may appear to

work, the electrical components of the AC

rated tool are likely to fail and create a hazard

to the operator.

Keep handles dry, clean and free from oil

and grease. Slippery hands cannot safely

control the power tool.

Develop a periodic maintenance schedule

for your tool. When cleaning a tool be

careful not to disassemble any portion of

th e tool sinc e interna l wires may be

misplaced or pinched or safety guard return

sp rings may be improperly moun ted.

Certain cleaning agents such as gasoline,

carbon tetrachloride, ammonia, et c. may

damage plastic parts.

Risk of injury to user. The power cord must only

be serviced by a Skil Factory Service Center or

Autho rized Skil Service Station.

Never lay the tool down until the motor

has come to a complete standstill. The

spinning bit can grab the surface and pull the

tool out of your control.

Never use bi ts t hat ha ve a cut ti ng

diameter greater than the opening in the

base.

WARNING

!

drilling, and other construction activities

contains chemicals known to cause cancer,

birth defects or other reproductive harm.

Some examples of these chemicals are:

• Lead from lead-based paints,

• Crystalline silica from bricks and cement and

other masonry products, and

• Arsenic and chromiu m from chemicallytreated lumber.

Yo ur ri sk from these expo su re s var ie s,

depending on how often you do this type of

work. To reduce your exposure to these

chemicals: work in a well ventilated area, and

work with approved safety equipment, such as

those dust masks that are specially designed

to filter out microscopic particles.

Some dust created by power

sanding, sawing, grinding,

-4-

Page 5

0

SM 1619X04663 05-11:SM 1619X04663 05-11 5/3/11 8:14 AM Page 5

Symbols

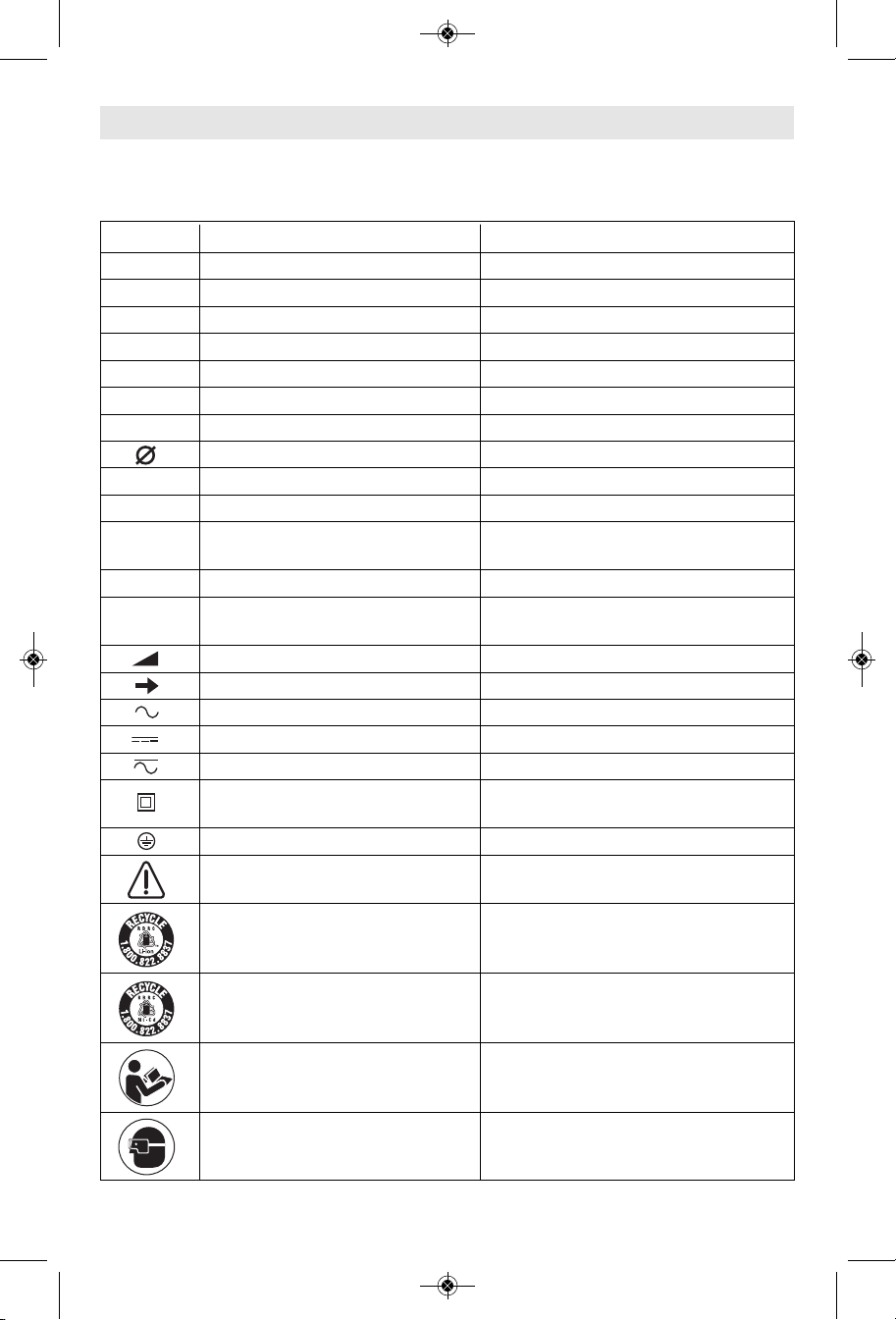

IMPORTANT: Some of the following symbols may be used on your tool. Please study them

and learn their meaning. Proper interpretation of these symbols will allow you to operate the

tool better and safer.

Symbol Name Designation/Explanation

V Volts Voltage (potential)

A Amperes Current

Hz Hertz Frequency (cycles per second)

W Watt Power

kg Kilograms Weight

min Minutes Time

s Seconds Time

Diameter Size of drill bits, grinding wheels, etc.

n

0

n Rated speed Maximum attainable speed

.../min Revolutions or reciprocation Revolutions, strokes, surface speed,

0 Off position Zero speed, zero torque...

1, 2, 3, ... Selector settings Speed, torque or position settings.

I, II, III, Higher number means greater speed

No load speed Rotational speed, at no load

per minute orbits etc. per minute

Infinitely variable selector with off Speed is increasing from 0 setting

Arrow Action in the direction of arrow

Alternating current Type or a characteristic of current

Direct current Type or a characteristic of current

Alternating or direct current Type or a characteristic of current

Class II construction Designates Double Insulated

Construction tools.

Earthing terminal Grounding terminal

Warning symbol Alerts user to warning messages

Li-ion RBRC seal Designates Li-ion battery recycling

program

Ni-Cad RBRC seal Designates Ni-Cad battery recycling

program

Read manual symbol Alerts user to read manual

Wear eye protection symbol Alerts user to wear eye protection

-5-

Page 6

SM 1619X04663 05-11:SM 1619X04663 05-11 5/3/11 8:14 AM Page 6

Symbols (continued)

IMPORTANT: Some of the following symbols may be used on your tool. Please study them

and learn their meaning. Proper interpretation of these symbols will allow you to operate the

tool better and safer.

This symbol designates that this tool is listed by Underwriters Laboratories.

This symbol designates that this tool is recognized by Underwriters Laboratories.

This symbol designates that this tool is listed by Underwriters Laboratories,

to United States and Canadian Standards.

This symbol designates that this tool is listed by the Canadian Standards

Association.

This symbol designates that this tool is listed by the Canadian Standards

Association, to United States and Canadian Standards.

This symbol designates that this tool is listed by the Intertek Testing

Services, to United States and Canadian Standards.

This symbol designates that this tool complies to NOM Mexican Standards.

Conforms to

UL Standard 60745-1

UL Standard 60745-2-17

Certified to

CAN/CSA Standard C22.2 No. 60745-1

CAN/CSA Standard C22.2 No. 60745-2-17

-6-

Page 7

SM 1619X04663 05-11:SM 1619X04663 05-11 5/3/11 8:14 AM Page 7

Functional Description and Specifications

WARNING

!

Di sc onnect t he plug fro m the pow er source bef or e making an y

assembly, adjustments or changing accessories. Such preventive safety

measures reduce the risk of starting the tool accidentally.

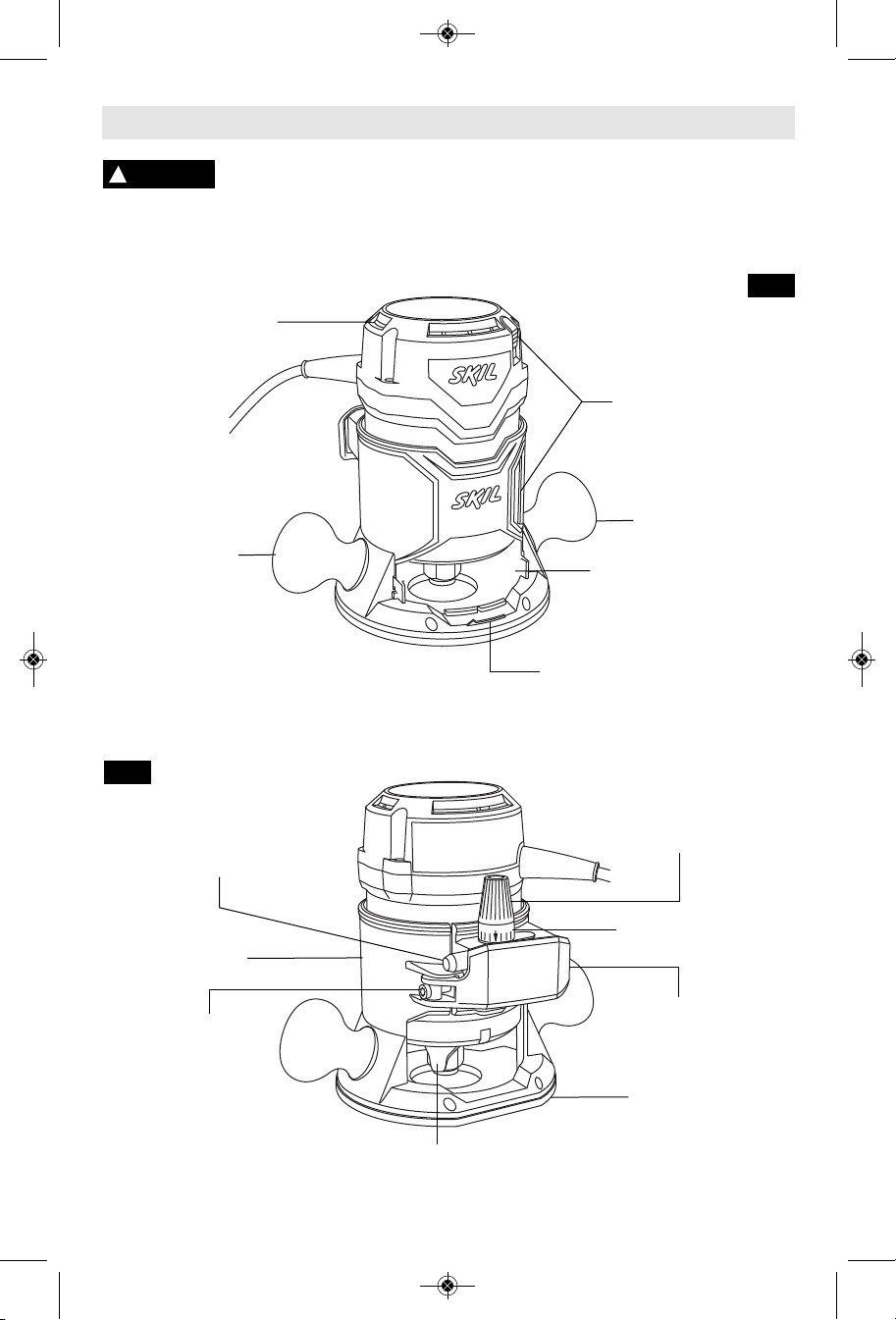

Fix Base Router

VENTILATION

OPENINGS

HANDLE

FIG. 1

2-POSITION

SLIDE "ON/OFF"

SWITCH

HANDLE

CHIP DEFLECTOR

BIT ROTATION ARROW

FIG. 2

BASE RELEASE

BUTTON

BASE (TYPE A)

BASE CLAMP

TENSION

ADJUSTMENT

SCREW

FINE

ADJUSTMENT

KNOB

INDICATOR RING

BASE CLAMP

LEVER

SUB-BASE

COLLET LOCK

-7-

Page 8

1

1

/

2

1

1

/

2

0

SM 1619X04663 05-11:SM 1619X04663 05-11 5/3/11 8:14 AM Page 8

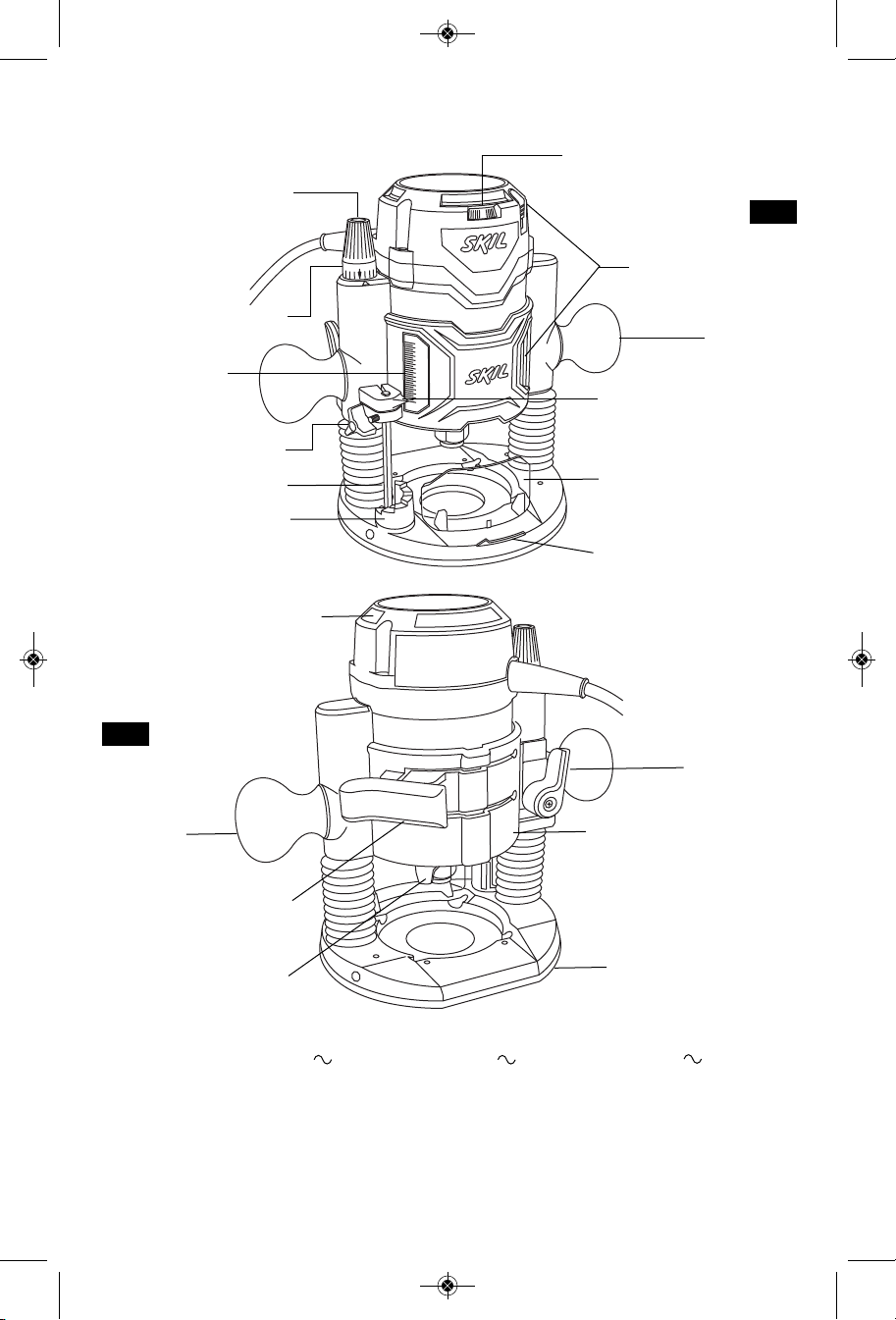

Plunge Base Router

FINE

ADJUSTMENT

KNOB

INDICATOR RING

DEPTH SCALE

DEPTH ROD KNOB

DEPTH ROD

DEPTH STOP TURRET

(Model 1827 & 1830 only)

VARIABLE SPEED DIAL

FIG. 3

2-POSITION

SLIDE "ON/OFF"

SWITCH

HANDLE

DEPTH INDICATOR

CHIP DEFLECTOR

BIT ROTATION ARROW

VENTILATION

OPENINGS

FIG. 4

PLUNGE LOCK

LEVER

HANDLE

BASE (TYPE B)

BASE CLAMP

LEVER

COLLET LOCK

SUB-BASE

Model number 1817 1827 1830

Voltage rating 120V 60Hz 120V 60Hz 120V 60Hz

Amperage rating 9.5A 10A 10A

No load speed n

Collet capacities 1/4", 1/2" 1/4", 1/2" 1/4", 1/2"

On models 1817, 1827 & 1830 router motor unit must be used with either

25,000/min n0 10,500-25,000/min n0 10,500-25,000/min

0

fixed base type A, or plunge base Type B.

-8-

Page 9

SM 1619X04663 05-11:SM 1619X04663 05-11 5/3/11 8:14 AM Page 9

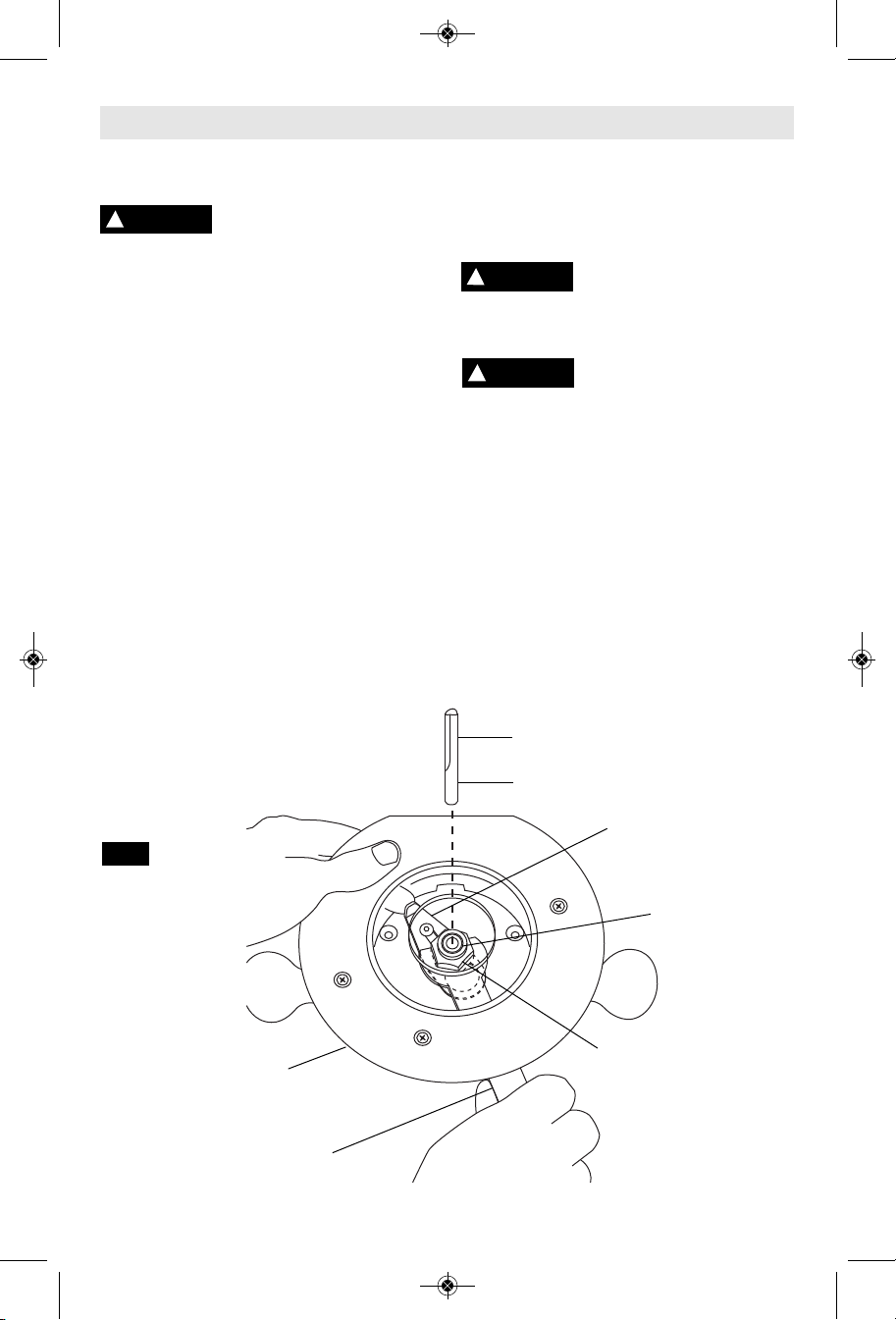

Assembly

A wide assortment of router bits with different

profiles is available separately.

WARNING

!

from power source before removing or

installing bits or accessories.

Place router upside down with the top of the

router resting on the bench. Another option is

to remove the motor from the base before

installing the bit.

1. Remove the chip shield.

2. Press collet lock to stop rotation of armature

3. Next, use the collet wrench to loosen the

4. Insert the shank of the router bit into the

5. With the router bit inserted and the collet

INSTALLING A ROUTER BIT

shaft. NOTE: it may be necessary to rotate

collet chuck assembly to engage collet lock

(Fig. 5).

collet nut in counter-clockwise direction

(viewed from under the router).

collet chuck assembly as far as it will go,

then back the shank out until the cutters are

approximately 1/8" to 1/4" away from the

collet nut face.

lock holding the armature shaft, use the

To prevent personal injury,

al ways remov e the plug

collet wrench to firmly tighten the collet nut

in a clockwise direction (viewed from under

the router). To ensure proper gripping of the

router bit, the shank of the router bit must be

inserted at least 5/8" into collet.

WARNING

!

base, do not use router bits greater than 2"

in diameter as they will not fit through the

sub-base.

CAUTION

!

without a bit.

NOTE: The router bit shank and collet chuck

should be cle an a nd free of dust , wo od,

residue and grease before assembling.

REMOVING THE ROUTER BIT

1. Press collet lock to stop rotation of armature

shaft and turn the collet chuck assembly in a

counter-clockwise direction.

2. Once the collet chuck assembly is loosened

continue to turn the collet chuck assembly

until it pulls the collet free from its taper, and

the router bit can be removed.

NOTE: The collet chuck is self-extracting; it is

NOT necessary to strike the collet chuck to

free the router bit.

Wh en the templ et guide

ha s been re mo ved from

To prevent damage to tool,

do not tighten collet nut

FIG. 5

1/4" BIT

SHANK

COLLET LOCK

COLLET

COLLET NUT

BASE

WRENCH

-9-

Page 10

SM 1619X04663 05-11:SM 1619X04663 05-11 5/3/11 8:14 AM Page 10

All router models are designed to accept 1/2"

COLLET CHUCK CARE

and 1/4" shank bits. 1/4" shank bits require a

1/4" adapt er sleeve. With the router bit

removed, continue to turn the collet nut counterclockwise until it is loose. To assure a firm grip,

occasionally blow out the collet chuck and clean

with a tissue or fine brush. The collet chuck

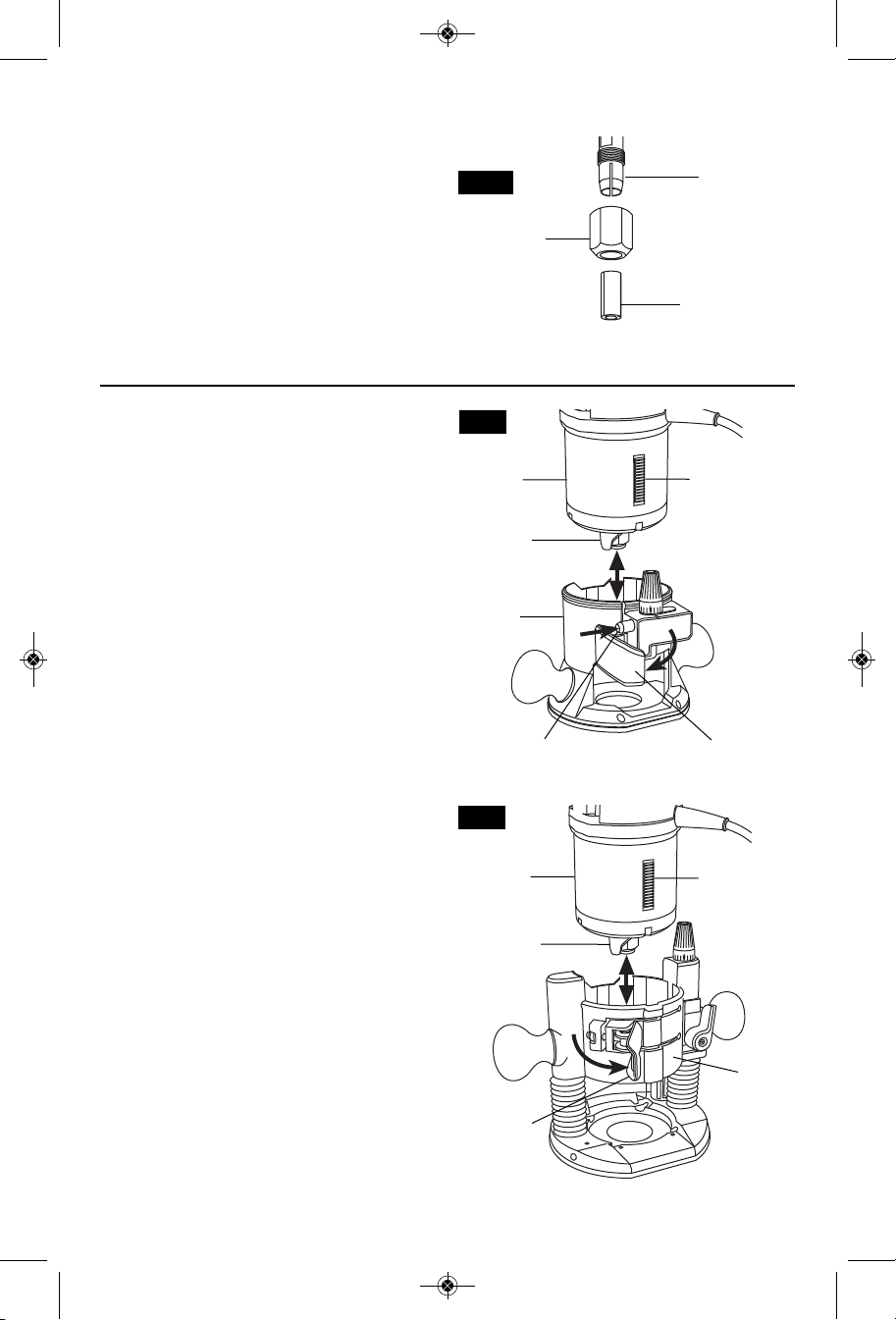

assembly is made up of two component parts

as illustrated (Fig. 6); check to see that the

adapter sleeve, if needed, is properly seated in

the collet nut and lightly thread the collet nut

back onto the 1/2" collet chuck. Replace a worn

or damaged collet chuck assembly immediately.

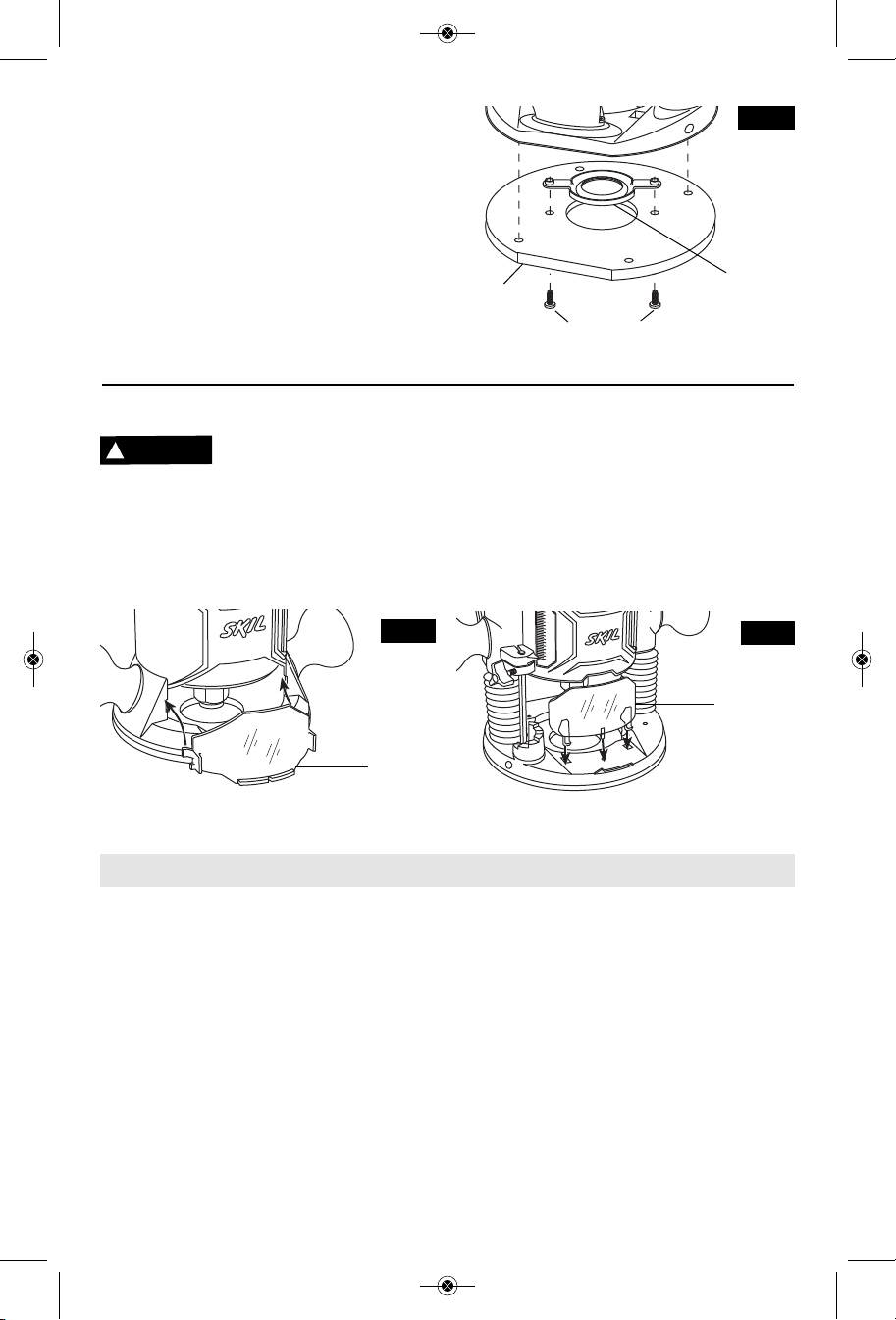

REMOVING MOTOR FROM BASE

To remove motor from fixed base:

1. Hold router in vertical position.

2. Open base clamp lever.

3. Push base release button in direction of

arrow and pull motor unit upwards from

base. Just before the motor is completely

out of the base, it will stop moving.

4. Depress the collet lock to fully disengage the

motor unit from the base (Fig. 7).

To remove motor from plunge base:

1. Hold router in vertical position.

2. Open base clamp lever, and pull motor unit

upwards from base. Just before the motor is

completely out of t he base, it will stop

moving.

3. Depress the collet lock to fully disengage the

motor unit from the base (Fig. 8).

INSTALLING MOTOR INTO BASE

To install motor into fixed base:

1. Release the base clamp lever.

2. Depress collet lock on motor unit.

3. Align the fine adjust rack with the fine adjust

knob.

4. Depress base release button and slide

motor unit until the top of fine adjust rack is

level with the top of base.

5. Lock the base clamp lever.

To install motor into plunge base:

1. Release the base clamp lever.

2. Depress collet lock on motor unit.

3. Align the fine adjust rack with the slot on the

back of the plunge base.

4. Slide motor unit into base until fully seated.

5. Lock the base clamp lever.

FIG. 6

FIG. 7

BASE RELEASE

FIG. 8

-10-

COLLET

MOTOR

UNIT

COLLET

LOCK

FIXED

BASE

BUTTON

MOTOR

UNIT

COLLET

LOCK

BASE

CLAMP

LEVER

COLLET CHUCK ASSEMBLY

1/2" COLLET

CHUCK

NUT

1/4" ADAPTER

SLEEVE

FINE ADJUST

RACK

BASE CLAMP

LEVER

FINE ADJUST

RACK

PLUNGE

BASE

Page 11

1

1

/

2

1

1

/

2

0

SM 1619X04663 05-11:SM 1619X04663 05-11 5/3/11 8:14 AM Page 11

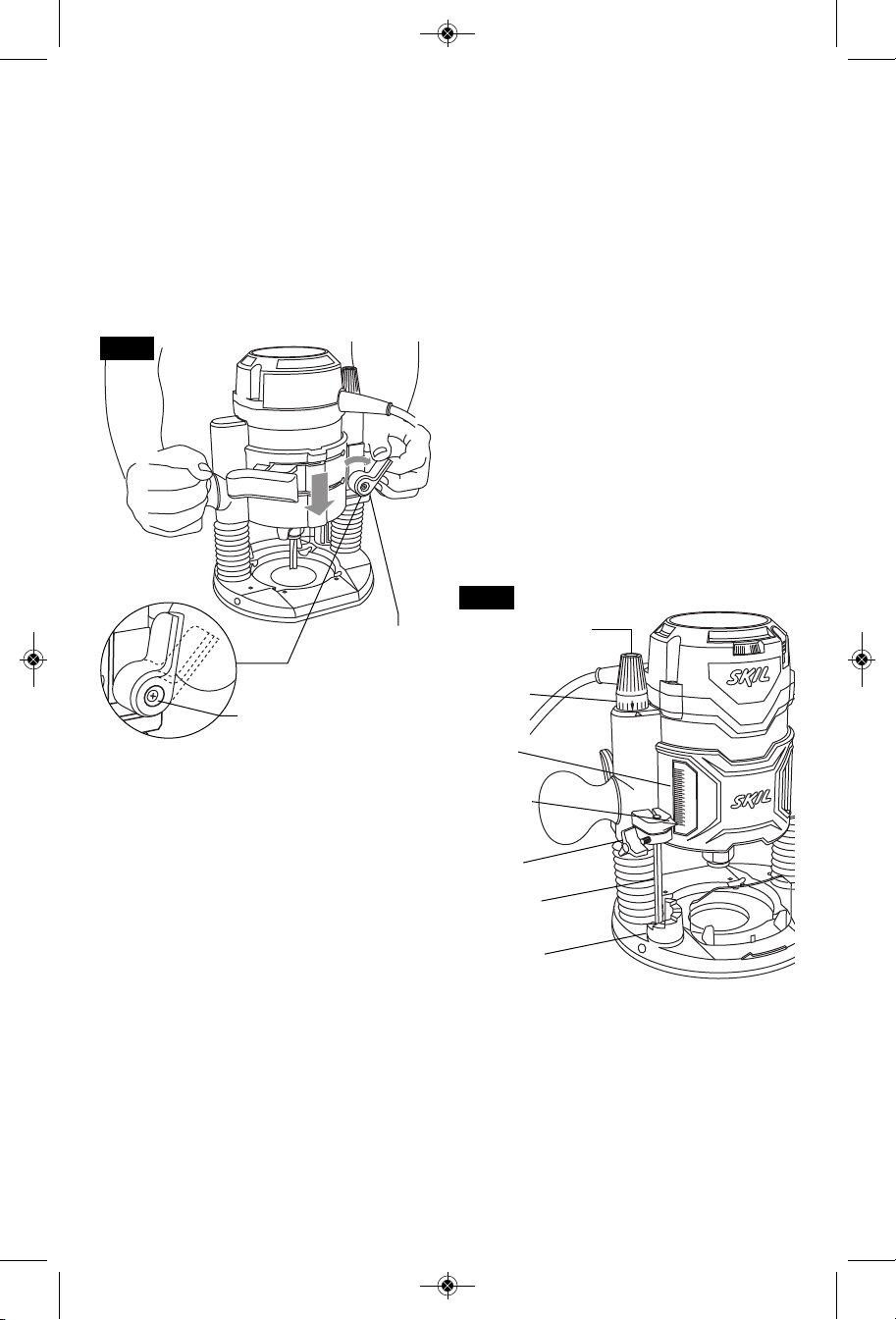

TEMPLATE GUIDE ADAPTER

INSTALLING

(Not included, available as accessory)

Place template guide adapter over the holes

in the center of the sub-base, align the two

threaded holes in the bottom of adapter with

the countersunk holes in sub-base. Fasten

adapter with the screws provided (Fig. 9).

To ensure proper alignment of the template

guide to the armature shaft, a centering cone

(optional accessory) should be used.

CHIP DEFLECTOR

WARNING

!

Always wear eye protection.

The chip deflector is n ot

intended as a safety guard.

The chip deflectors help keep dust and chips

out of your face, it will not stop objects larger

than dust thrown from the bit.

To remove chip shield from the fixed base,

press inward on deflector tabs until it releases

FIG. 10

FIG. 9

TEMPLATE

GUIDE

ROUTER

ADAPTER

SUB-BASE

MOUNTING

SCREWS

from base a nd remo ve. To attach, place

deflector into position as shown in (Fig. 10).

Then press inward of deflector tabs while

pushing until it snaps into place.

To remove chip shield from the plunge base,

press inward on either side of the deflector until

it releases from base and remove. To attach,

place d efl ect or into position as shown in

(Fig. 10a). Then press inward of deflector either

side while pushing until it snaps into place.

FIG.

CHIP

DEFLECTOR

Operating Instructions

Skil routers are designed for speed, accuracy

and con venience in performing cabinet work,

routing, fluting, beading, cove-cutting, dove

tails, etc. They will enable you to accomplish

inlay work, decorative edges and many types

of special carving.

DEPTH ADJUSTMENT WITH FIXED BASE

The fine adjustment knob allows precise bit

height adjustments on your router.

To use the fine adjustment feature, release the

base clamp lever, and turn the knob clockwise

to lower, or counterclockwise to raise the bit

(Fig. 2).

FINE ADJUSTMENT KNOB

CHIP

DEFLECTOR

(Note that one full turn of the knob will raise or

lower the bit approximately 1/16" of an inch.)

After making depth adjustments, re-clamp the

motor.

NOTE: All depth adjustments must be made

with the base clamp lever released.

DEEP CUTS

For deeper cuts, make several progressively

deeper cuts by starting at one depth and then

make several subsequent passes, increasing

the cutting depth with each pass.

To be certain that your depth settings are as

desired, you may want to make test cuts in

scrap material before beginning work.

-11-

Page 12

1

1

/

2

1

1

/

2

0

SM 1619X04663 05-11:SM 1619X04663 05-11 5/3/11 8:14 AM Page 12

DEPTH ADJUSTMENT WITH PLUNGE

BASE PLUNGING ACTION

Th e pl unge feat ur e si mplifie s de pt h

adjustments and will allow the cutting bit to

easily and accurately enter the workpiece. To

lower, loosen plunge lock lever (Fig. 11), and

apply downward pressure until you reach

desired depth, then tighten plunge lock lever.

Loosen lever and release pressure and the

router will automatically retract the bit from the

workpiece. It is advisable to retract the bit

whenever it is not engaged in work piece.

FIG. 11

PLUNGE

LOCK LEVER

RESTRAINING SCREW

ADJUSTING THE PLUNGE LOCK LEVER

You can adjust or reposition the plunge lock

lever for comfort, or to compensate for wear.

1. With the plunge lock lever in the locked

position (upright position), remove (counter

clockwise) the retaining screw located in the

middle of the lever.

2. Move lever to desired location, replace the

restraining screw and washer and tighten

(clockwise).

DEPTH ROD AND TURRET

The depth rod and depth stop turret are used

to control cutting depth as follows:

1. With the bit installed, gently lower the motor

until the tip of the router bit just contacts the

level surface the router is sitting on. This is

the “zero” position, from which further depth

adjustments can be accurately made.

2. To set a desired depth of cut, rotate the

depth stop turret until the lowest step is

aligned with the depth rod. Loosen the depth

indicator knob and lower the depth rod unit it

contacts the lowest step of the turret. Slide

the depth indicator until the line indicator

points to zero on the depth scale, indicating

the point at which the bit just contacts the

work (Fig. 12).

3. To set a desired cutting depth, slide the

depth rod up until the depth indicator point

attains the desired cutting depth, and secure

the rod in position by firmly tightening the

depth indicator knob.

4. The desir ed dep th of cut may n ow b e

achieved by plunging the router until the

depth rod contacts the selected stop on the

turret.

DEEP CUTS

For deeper cuts, make several progressively

deeper cuts by starting with the highest step on

the depth turret, and after each cut, rotate the

depth turret to progressively lower steps as

desired, until the final depth (lowest step or flat)

is reached. Steps progress by 1/8" increments.

To be certain that your depth settings are as

desired, you may want to make test cuts in

scrap material before beginning work.

FIG. 12

FINE ADJUSTMENT

KNOB

INDICATOR

RING

DEPTH

SCALE

DEPTH

INDICATOR

KNOB

DEPTH ROD

DEPTH STOP

TURRET

DEPTH ADJUSTMENT WITH PLUNGE

BASE FINE ADJUSTMENT KNOB

The fine depth adjustment knob allows precise

bit height adjustments on your router.

To use the fine adjustment feature, turn the

knob clockwise to lower, or counterclockwise

to raise the bit.

(Note that one full turn of the knob will raise or

lower the bit approximately 1/16" of an inch.)

-12-

Page 13

SM 1619X04663 05-11:SM 1619X04663 05-11 5/3/11 8:14 AM Page 13

2-POSITION SLIDE "ON/OFF" SWITCH

The tool can be switched "ON" by the 2 position slide switch located on the upper and

lower right side of the motor (Fig. 1).

TO TURN THE TOOL "ON", slide either the

upper or lower switch UP to the I position.

TO TURN THE TOOL "OFF", slide either the

upper or lower switch downward to the O

position.

Always hold the router off the work when

turning the switch on or off. Contact the work

wi th t he router only after t he r outer has

reached desired speed, and remove it from the

work before turning the switch off. Operating in

this manner will prolong switch and motor life

and will greatly increase the quality of your

work.

Always hold the tool with both hands while

starting the tool, since torque from the motor

can cause the tool to twist.

SOFT START FEATURE

Electronic feedback control minimizes torque

twist customary in larger routers by limiting the

speed at which motor starts.

The electronic speed control feature allows

motor speed to be matched to cutter size and

ma terial hardnes s fo r i mp roved finish ,

extended bit life, and higher performance.

Speed changes are achieved by rotating the

dial on or between any one of the six numbers

(Fig. 3). Speed may be changed while tool is

on. The reference numbers on the dial facilitate

re-setting control to desired speed.

The speed chart indicates the relationship

be tween setti ngs an d appl icati on, ex act

settings are determined by operator experience

and preference. The bit manufacturer may also

have a speed recommendation.

DIAL

SETTING RPM APPLICATION

(Included on all models)

ELECTRONIC VARIABLE

SPEED CONTROL

(Models 1827 & 1830 only)

1 10,500

2 13,500

3 16,500

4 20,000

5 22,500

6 25,000

}

}

Nonferrous metals,

larger diameter bits,

and cutters

Softwoods, plastics,

counter tops, smaller

diameter bits, and

cutters

Your tool is also equipped with a Site-Light™

for better visibility during operation.

When the tool is plugged in, the lights will turn

on automatically.

The Site-Light™ is maintenance free and was

designed to last the life of your tool.

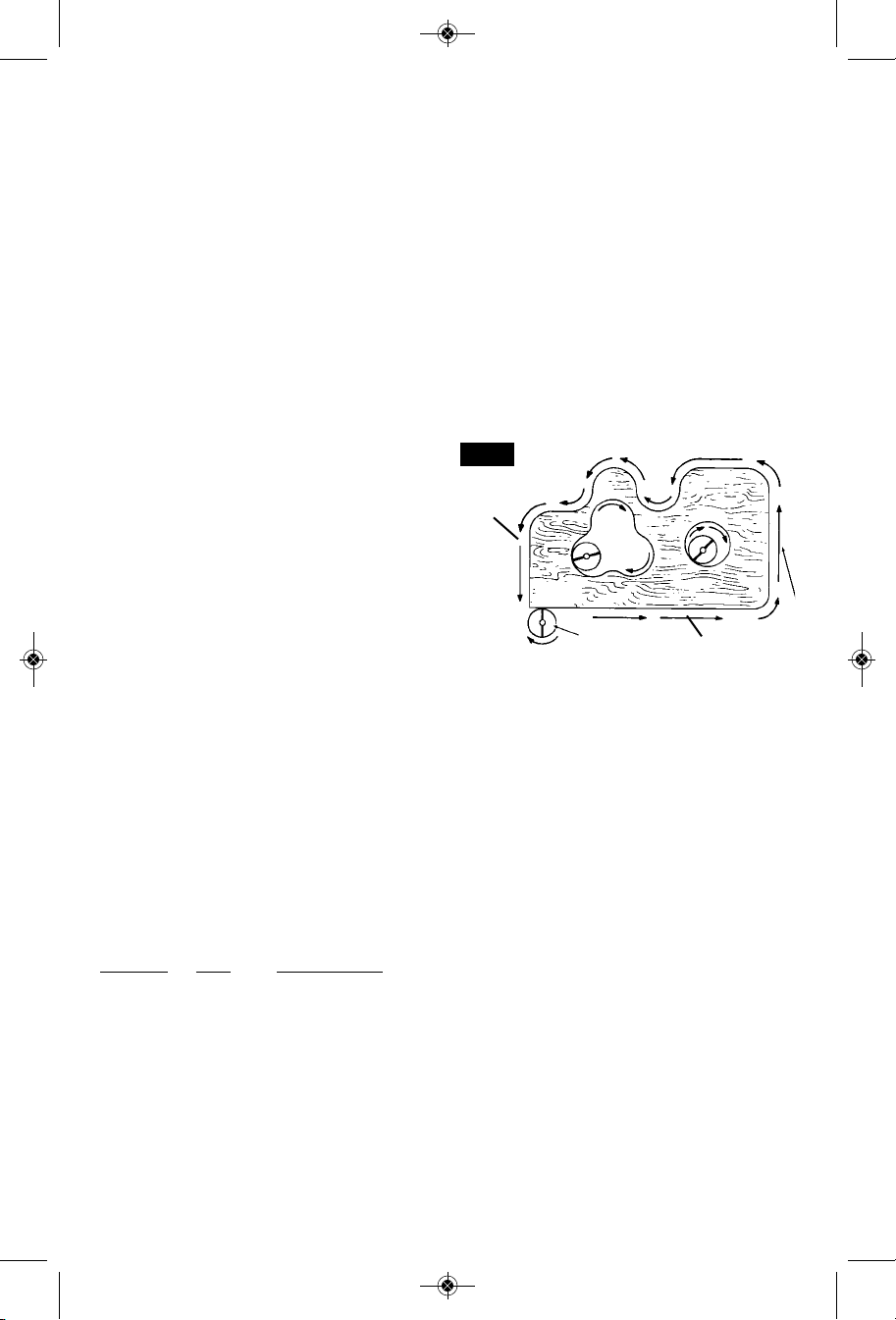

As seen from the top of the router, the bit turns

cl ockwise an d the cuttin g e dges face

accordingly. Therefore, the most efficient cut is

made by feeding the router so that the bit turns

into the work, not away. Figure 13 shows

proper feed for various cuts. How fast you feed

depends on the hardness of the material and

the size of the cut. For some materials, it is

best to make several cuts of increasing depth.

SITE-LIGHT™

FEEDING THE ROUTER

FIG. 13

START

HERE

WORK

BIT

If the router is hard to control, heats up, runs

ve ry sl owly or le aves an imperfect cu t,

consider these causes:

1. Wrong direction of feed — hard to control.

2. Feeding too fast — overloads motor.

3. Dull bit — overloads motor.

4. Cut is too large for one pass — overloads

motor.

5. Feeding too slow — leaves friction burns on

work.

Feed smoothly and steadily (do not force). You

will soon learn how the router sounds and feels

when it is working best.

RATE OF FEED

When routing or doing related work in wood

and plastics, the best finishes will result if the

depth of cut and feed rate are regulated to

keep the motor operating at high speed. Feed

the router at a moderate rate. Soft materials

require a faster feed rate than hard materials.

DIRECTION OF

ROUTER FEED

-13-

Page 14

SM 1619X04663 05-11:SM 1619X04663 05-11 5/3/11 8:14 AM Page 14

The router may stall if improperly used or

overloaded. Reduce the feed rate to prevent

possible damage to the tool.

Always be sure the collet nut is tightened

securely before use.

GUIDING THE ROUTER

The router can be guided through the work in

any of several ways. The method you use

depends, of course, on the demands of the

particular job and on convenience.

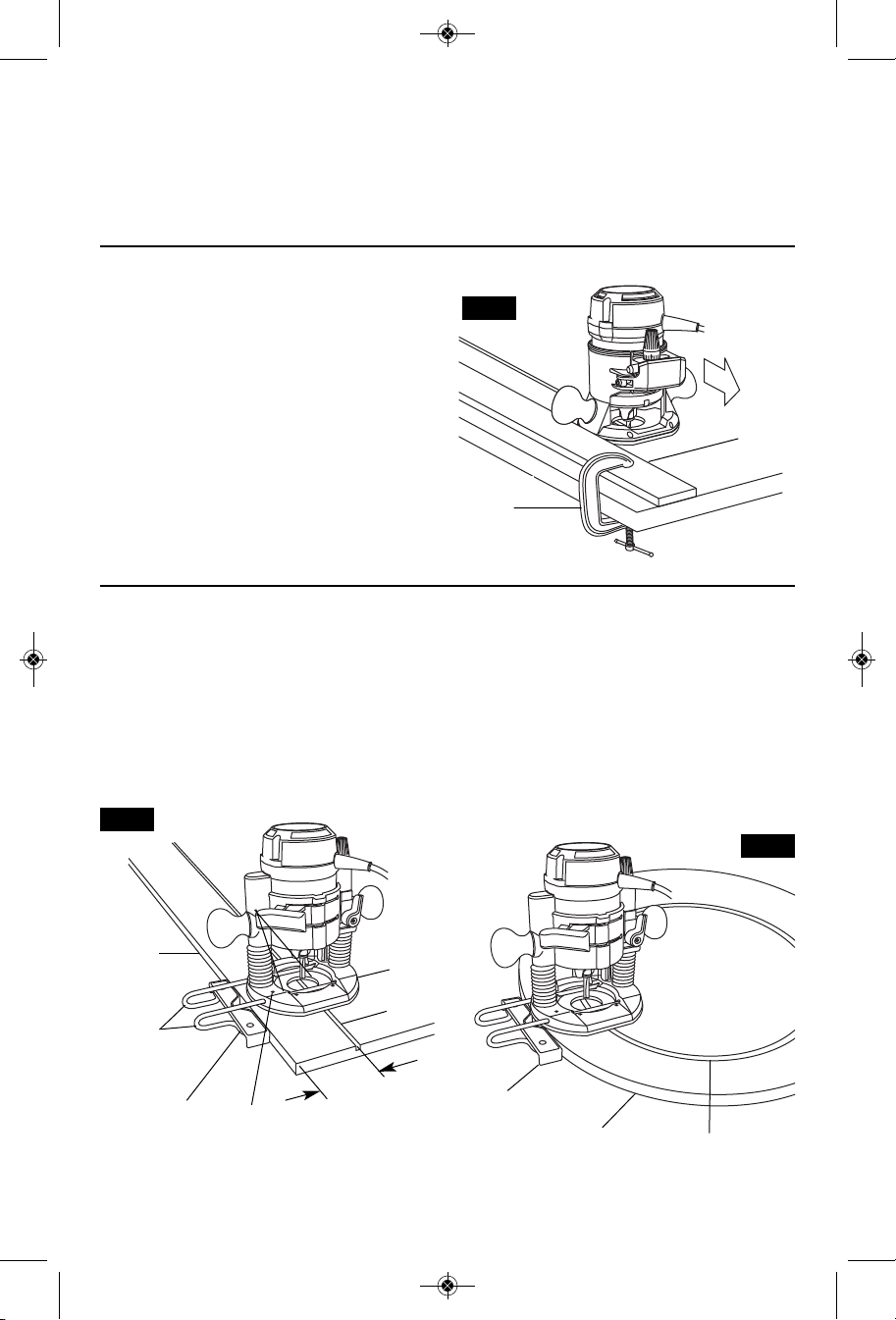

For routing operations such as grooving or

dadoing, it is often necessary to guide the

tool in a line parallel to a straight edge. One

me th od of obt ai ni ng a st ra ig ht cut is to

securely clamp a board or other straightedge

to the work surface, and guide the edge of

the router sub-base along this path (Fig. 14).

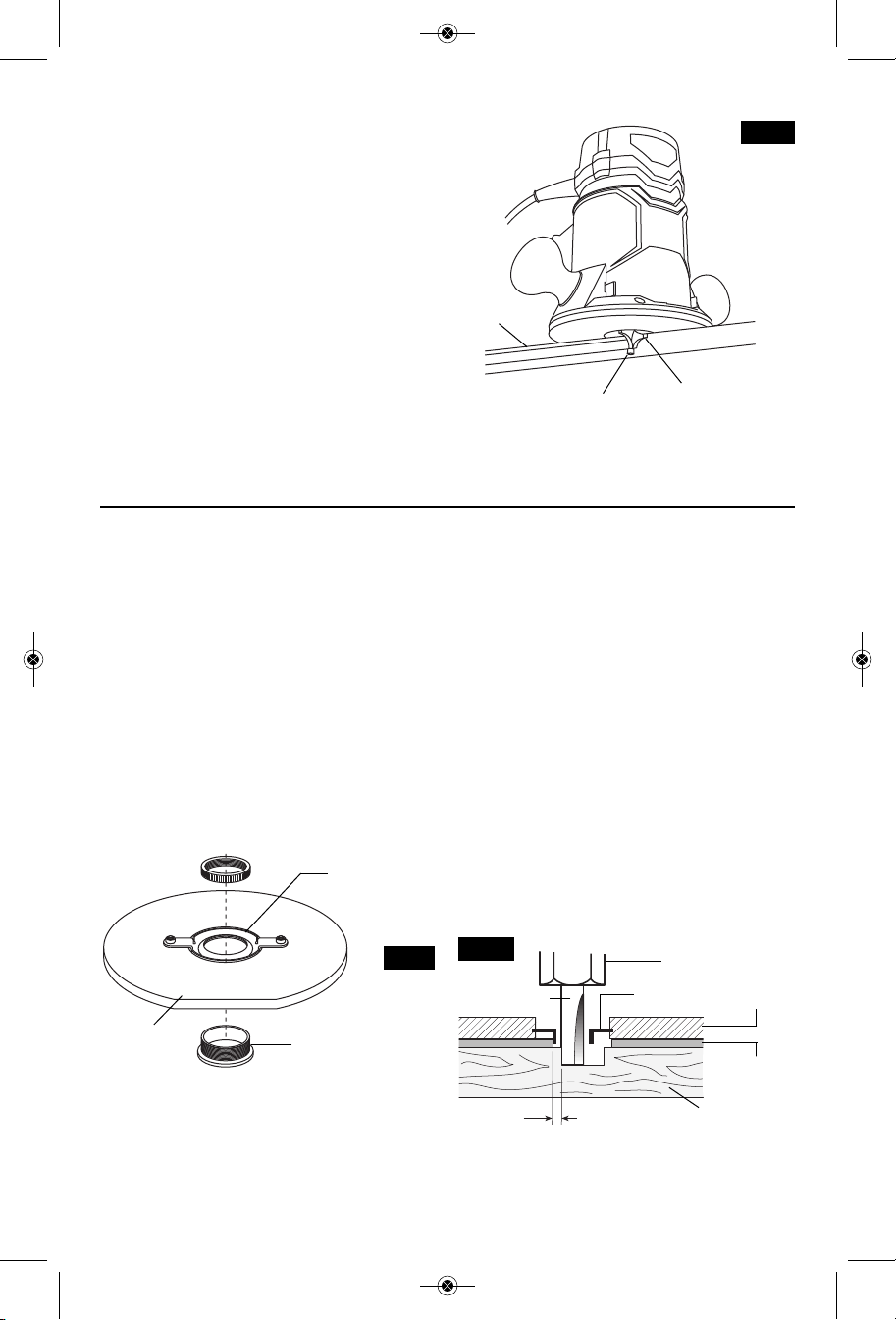

STRAIGHT AND CIRCULAR EDGE GUIDE

(Not included, available as accessory)

Us e this ha nd y accessor y for e as e and

accuracy in making curved and straight cuts.

ATTACHING GUIDE

Insert edge guide rods through holes in base,

slide edge guide to desired width as shown in

(Fig. 15), and secure in place by tightening the

screw at the bottom of the router.

FIG. 15

Always use router bits with the short est

cu tting len gth ne cessary t o prod uce the

desired cut. This will minimize router bit runout and chatter.

FIG. 14

SECURELY

CLAMP

BOARD

GUIDE

FEED DIRECTION

BOARD

GUIDE

One method of locating the guide is to mark

the center of groove to be cut, set the router

flat on the work with the bit just touching and

aligned over the center of groove. Bring the

guide to the edge of the work, and securely

tighten screws. Whenever in doubt about

dimensions, make a trial cut on scrap material.

For guiding along a circular edge, the notch

in the center of the edge guide will contact

the ma te ri al at t he two po ints s ho wn

(Fig. 16).

FIG. 16

WORK

EDGE

GUIDE

RODS

EDGE

GUIDE

WING

SCREWS

DESIRED

WIDTH

BASE

CUT

-14-

EDGE

GUIDE

WORK

CUT

Page 15

SM 1619X04663 05-11:SM 1619X04663 05-11 5/3/11 8:14 AM Page 15

PILOT TIPPED AND BEARING GUIDE BITS

The lower portion of a pilot tipped bit, as

shown in (Fig. 17), is a shaft with no cutting

edges. Bearing guide bits have a ball bearing

to pilot the bit.

This pilot slides along the edge of the work as

the rotating blades make the cut, forming

molding or decorative edges. The edge on

which the pilot slides should be perfectly

CUT

smooth since any irreg ularities are transferred

to the shaped surface.

PILOT SLIDES

ALONG EDGE

FIG. 17

CUTTER PART OF

PILOT TIPPED BIT

OF WORK

Using template patterns lets you duplicate

TEMPLATES

designs or letters uniformly time after time.

This technique requires the use of an template

guide adapter and a template guide.

TEMPLATE GUIDES

(Not included, available as accessory)

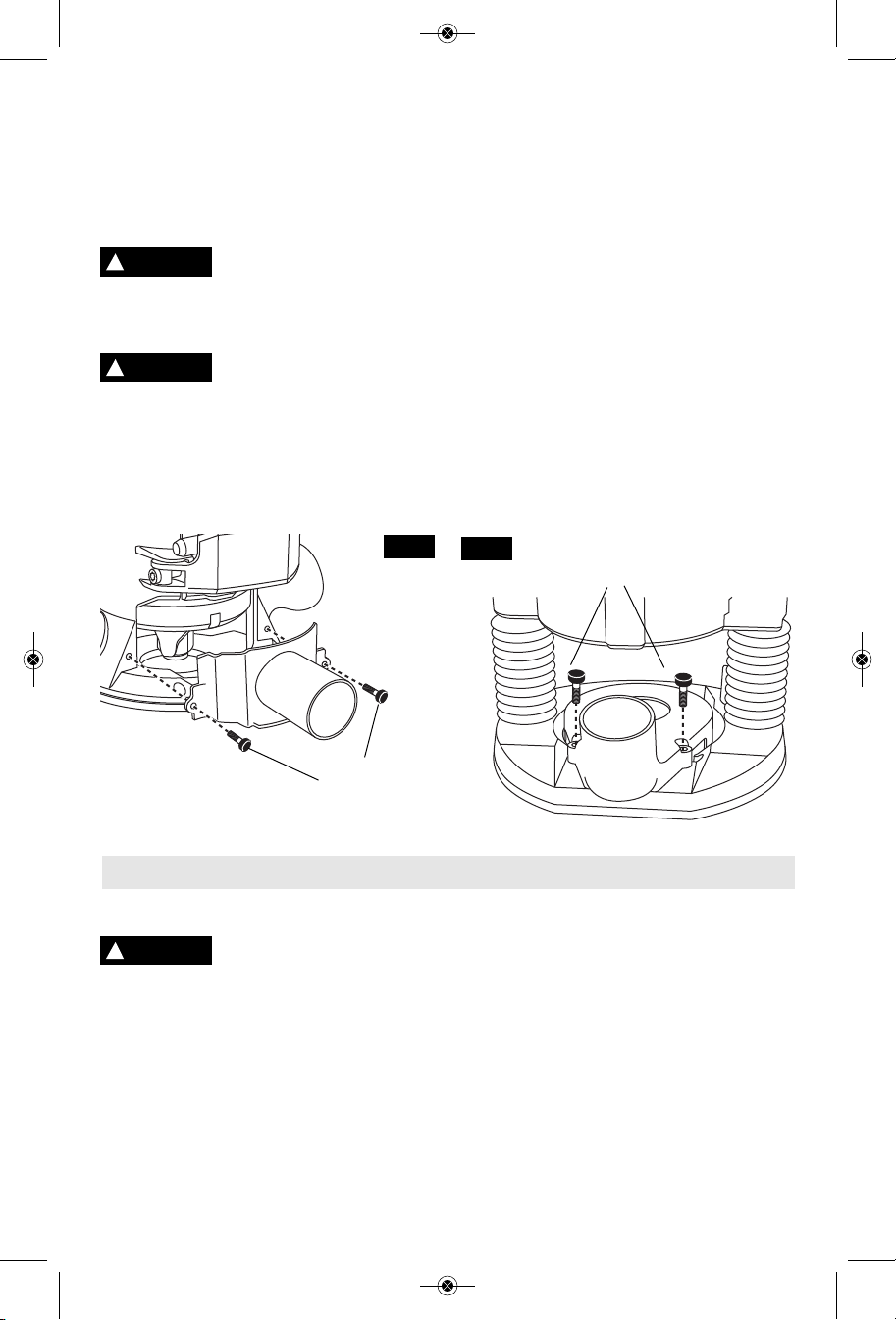

The template guide shown in (Fig. 18), is

essen tially a pl ate with a collar which is

inserted through the hole in sub-base and

te mplate g ui de ada pt er from bel ow and

fastened with a knurled retaining nut. The

template guide rides along the edge of the

templat while the router bit, protruding below,

cuts into the work.

KNURLED

NUT

TEMPLATE GUIDE

ADAPTER

(optional accessory)

FIG. 18

ROUTER

SUB-BASE

TEMPLATE GUIDE

(optional accessory)

ATTENTION: Be sure the thickness of the

templat is the same or larger than the guide

surface of the collar.

Do not use a bit that may touch the inside of

the collar. Select a bit that is about 1/16" less

in diameter than the template guide adapter

opening.

Template guides are used with a number of

special accessories, such as hinge templates.

In addition, speci al t empla tes are easily

prepared for cutting repeated patterns, special

designs, inlays, and other applications. A

template pattern may be made of plywood,

hardboard, metal or even plastic, and the

design can be cut with a router, jigsaw, or

other suitable cutting tool.

Remember that the pattern will have to be

made to compensate for the distance between

the router bit and the template guide (the

“offset”), as the final workpiece will differ in size

from the template pattern by that amount, due

to the bit position (Fig. 19).

FIG. 19

ROUTER BIT

OFFSET

COLLET NUT

TEMPLATE

GUIDE

ROUTER

SUB-BASE

TEMPLATE

PATTERN

WORKPIECE

-15-

Page 16

SM 1619X04663 05-11:SM 1619X04663 05-11 5/3/11 8:14 AM Page 16

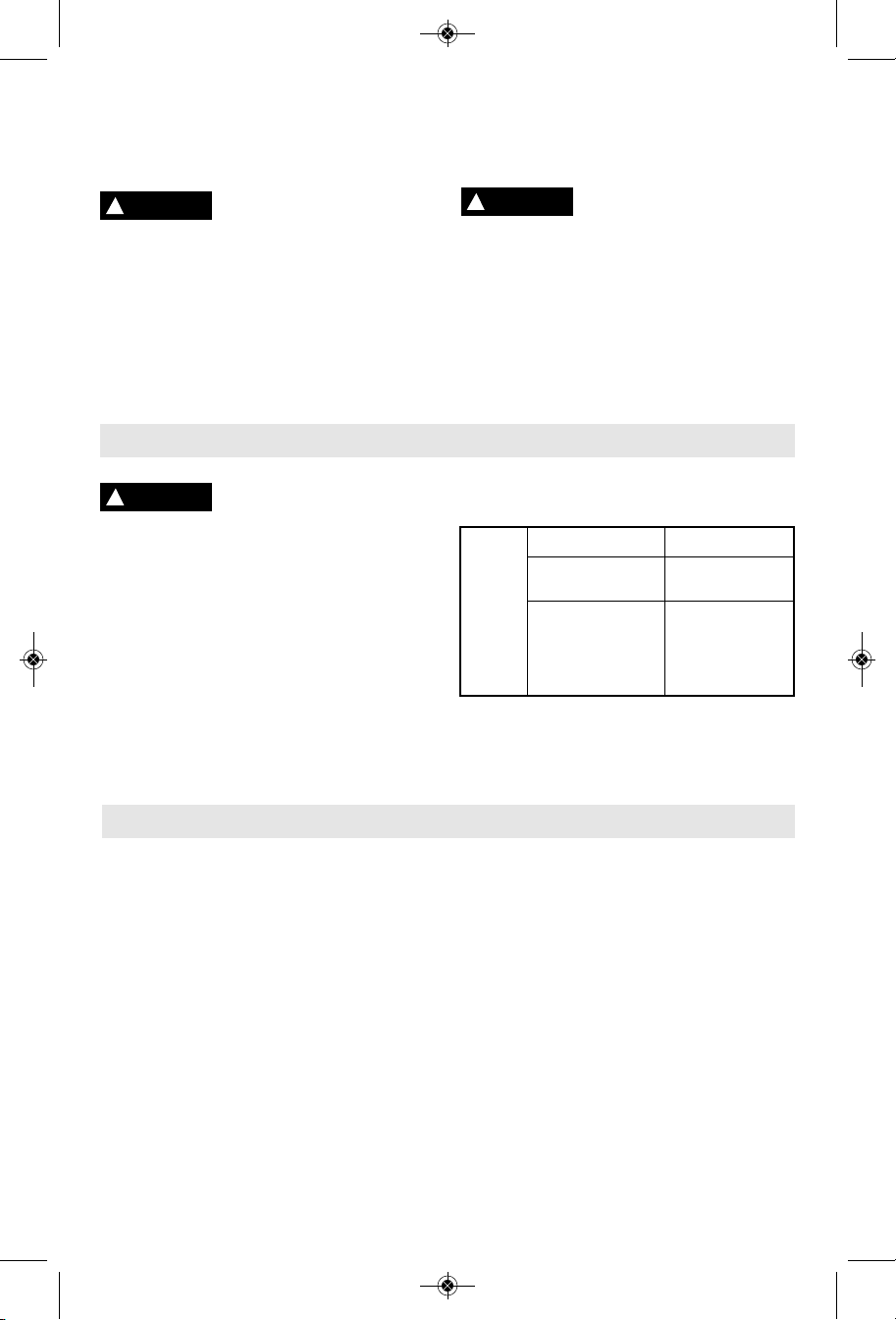

ROUTER DUST COLLECTION

There are two optional dust extraction hood

accessories. Each dust extraction hood is

sized to accept 35mm vacuum hoses. Each

accessory pack includes an adapter that will

connect the hood to 1-1/4” and 1-1/2” vacuum

hoses.

!

WARNING

manual for use of these accessories.

Do not reach in area of the bit while the

router is ON or plugged in.

CAUTION

!

extraction hood at the same time as any

other dust extraction hood.

FIXED BASE DUST EXTRACTION

(Not included, available as accessory)

This dust extraction hood is designed for use

with the fixed base when routing is done in the

mi ddle of the wo rkpiece, suc h as when

Read and understand these

in st ru ct ions an d to ol

To avoid entangling hoses,

do not u se th is dust

FIG. 20

creating slots or routing patterns for inlays. If

you have a shop vacuum system, you can

attach the dust extraction hood for improved

visibility, accuracy and utility, particularly in

freehand routing.

To attach, position as shown and secure

adapter to base with the mounting screws

provided (Fig. 20).

PLUNGE BASE DUST EXTRACTION

(Not included, available as accessory)

This dust extraction hood is designed for use in

the plunge base when routing is done in the

mi ddle of the wo rkpiece, suc h as when

creating slots or routing patterns for inlays. If

you have a shop vacuum system, you can

attach the dust extraction hood for improved

visibility, accuracy and utility, particularly in

freehand routing.

To attach, position as shown and secure

adapter to base with the mounting screws

provided (Fig. 21).

FIG. 21

MOUNTING

SCREWS

MOUNTING

SCREWS

Maintenance

Service

WARNING

!

per so n nel may resu lt in misplacing of

internal wires and components which

co ul d ca us e se ri ou s ha za rd . We

recommend that all tool service be performed

by a Skil Factory Service Center or Autho rized

Skil Service Station.

Your Skil tool has been properly lubricated

and is ready to use. It is recommended that

tools with gears be regreased with a special

gear lubricant at every brush change.

Pr ev entive mai ntenance

performed by unauthorized

TOOL LUBRICATION

The brushes and commutator in your tool have

CARBON BRUSHES

been engineered for many hours of dependable

service. To maintain peak efficiency of the

motor, we recommend every two to six months

the brush es be examined. Only genuine Skil

replace ment brushes specially designed for

your tool should be used.

BEARINGS

After about 300-400 hours of operation, or at

every second brush change, the bearings

should be replaced at Skil Factory Service

Center or Au thorized Skil Service Station.

Bearings which become noisy (due to heavy

-16-

Page 17

SM 1619X04663 05-11:SM 1619X04663 05-11 5/3/11 8:14 AM Page 17

load or very abrasive material cut ting) should

be replaced at once to avoid overheating or

motor failure.

Cleaning

WARNING

!

th e power supply before cleaning or

performing any main tenance. The tool may

be cleaned most effectively with compressed

dry air. Always wear safety gog gles when

cleaning tools with compressed air.

To avoid accidents always

dis connect the t ool from

Extension Cords

WARNING

!

adequate size conductors that is capable of

carrying the current necessary for your tool

must be used. This will prevent excessive

voltage drop, loss of power or overheating.

Grounded tools must use 3-wire extension

cords that have 3-prong plugs and receptacles.

NOTE: The smaller the gauge number, the

heav i er the cord.

If an ex tension co rd is

ne cessary, a co rd with

Ventilation openings and switch levers must

be kept clean and free of foreign matter. Do

not at tempt to clean by inserting pointed

objects through openings.

CAUTION

!

plastic parts. Some of these are:

ca rb on t et rachlo ri de , ch lo ri nated cleanin g

solvents, ammonia and house hold detergents

that contain ammonia.

RECOMMENDED SIZES OF EXTENSION CORDS

120 VOLT ALTERNATING CURRENT TOOLS

Tool’s

Ampere

Rating

3-6

6-8

8-10

10-12

12-16

Ce rtain cleanin g agen ts

an d so l vents damage

gasoline,

Cord Size in A.W.G.

Cord Length in Feet Cord Length in Meters

25 50 100 150 15 30 60 120

18 16 16 14 0.75 0.75 1.5 2.5

18 16 14 12 0.75 1.0 2.5 4.0

18 16 14 12 0.75 1.0 2.5 4.0

16 16 14 12 1.0 2.5 4.0 —

14 12 —— ————

Wire Sizes in mm

2

* 1/2" Collet Chuck

* Collet nut wrench

* 1/4" Adapter Sleeve

* Canvas Carrying Bag (models 1827

& 1830 only

** Edge Guide

Accessories

** Dust Extraction Hoods

** Template Guides

** Template Guide Adapter

(*= standard equipment)

(**= optional accessories)

-17-

Page 18

SM 1619X04663 05-11:SM 1619X04663 05-11 5/3/11 8:14 AM Page 18

Trouble Shooting

WARNING

!

PROBLEM 1. Power cord is not plugged in.

REMEDY 1. Plug tool into power source.

PROBLEM 1. Extension cord has insufficient gauge or is too long.

REMEDY 1. Replace with adequate extension cord (Page 17).

PROBLEM 1. Bit is not properly set into collet.

REMEDY 1. See “Installing a Router Bit” section of this manual (page 9).

Read instruction manual first! Remove plug from the power source before

making adjustments or assembling accessories.

TROUBLE: TOOL WILL NOT START

2. Power source fuse or circuit breaker tripped.

3. Cord damaged.

4. Burned out switch.

2. Replace fuse or reset tripped circuit breaker. (If the product repeatedly causes

the circuit or fuse to trip/blow, discontinue use immediately and have it serviced by

an Authorized Skil Service Center or Service Station.)

3. Inspect cord for damage. If damaged, have cord replaced by an Authorized Skil

Service Center or Service Station.

4. Have switch replaced by an Authorized Skil Service Center or Service Station.

TROUBLE: TOOL DOES NOT COME UP TO SPEED

2. If equipped with variable speed, tool may not set at maximum RPM.

3. Low house voltage.

2. If equipped with variable speed, check speed setting.

3. Contact your electric company.

TROUBLE: ACCESSORY BINDS, STALLS MOTOR,

OR KICKS BACK WHEN ROUTING

2. Bit is damaged or dull.

3. Cut is too aggressive for one pass.

4. Incorrect router speed for application

5. Router is being fed in the wrong direction or at an improper rate.

2. Discard and replace with new accessory.

3. Adjust bit depth to proper setting as referenced in the “Operations” section of

this manual (pages 11-12), or as recommended by accessory manufacturer.

4. See router speed chart for application recommendations (page 13)

5. See “Feeding the Router” section of this manual for feeding tips (page 13)

-18-

Page 19

SM 1619X04663 05-11:SM 1619X04663 05-11 5/3/11 8:14 AM Page 19

Avertissements généraux concernant la sécurité des outils électroportatifs

!

AVERTISSEMENT

choc électrique, d'incendie et/ou de blessures corporelles graves.

Veuillez lire tous les avertissements et toutes les consignes de sécurité. Si l'on

n'observe pas ces avertissements et ces consignes de sécurité, il existe un risque de

CONSERVEZ TOUS LES AVERTISSEMENTS ET TOUTES LES CONSIGNES

DE SÉCURITÉ POUR RÉFÉRENCE FUTURE.

Dans les avertissements, le terme « outil électroportatif » se rapporte à votre outil branché sur le secteur (avec fil) ou

à votre outil alimenté par piles (sans fil).

Sécurité du lieu de travail

Maintenez le lieu de travail propre et bien éclairé.

Les risques d’accident sont plus élevés quand on

travaille dans un endroit encombré ou sombre.

N’utilisez pas d’outils électroportatifs dans des

atmosphères explosives, comme par exemple en

présence de gaz, de poussières ou de liquides

inflammables. Les outils électroportatifs produisent

des étincelles qui risquent d’enflammer les poussières

ou les vapeurs.

Éloignez les enfants et les visiteurs quand vous vous

servez d’un outil électroportatif. Vous risquez une

perte de contrôle si on vous distrait.

Sécurité électrique

Les fiches des outils électroportatifs doivent

correspondre à la prise. Il ne faut absolument jamais

modifier la fiche. N’utilisez pas d’adaptateur de prise

avec des outils électroportatifs munis d’une fiche de

terre. Le risque de choc électrique est moindre si on

utilise une fiche non modifiée sur une prise qui lui

correspond.

Évitez tout contact du corps avec des surfaces reliées

à la terre tels que tuyaux, radiateurs, gazinières ou

réfrigérateurs. Le risque de choc électrique augmente

si votre corps est relié à la terre.

N’exposez pas les outils électroportatifs à la pluie ou

à l’humidité. Si de l’eau pénètre dans un outil

électroportatif, le risque de choc électrique augmente.

Ne maltraitez pas le cordon. Ne vous en servez

jamais pour transporter l’outil électroportatif, pour le

tirer ou pour le débrancher. Éloignez le cordon de la

chaleur, des huiles, des arêtes coupantes ou des

pièces mobiles. Les cordons abîmés ou emmêlés

augmentent les risques de choc électrique.

Si vous utilisez un outil électroportatif à l’extérieur,

employez une rallonge conçue pour l’extérieur. Ces

rallonges sont faites pour l’extérieur et réduisent le

risque de choc électrique.

S'il est absolument nécessaire d'utiliser l'outil

électroportatif dans un endroit humide, utilisez une

alimentation protégée par un disjoncteur de fuite de

terre (GFCI). L'utilisation d'un disjoncteur GFCI réduit

les risques de choc électrique.

Restez concentré, faites attention à ce que vous

faites, et servez-vous de votre bon sens lorsque vous

utilisez un outil électroportatif. N'employez pas

d’outils électroportatifs quand vous êtes fatigué ou

sous l’emprise de drogues, d’alcool ou de

médicaments. Quand on utilise des outils

électroportatifs, il suffit d’un moment d’inattention pour

causer des blessures corporelles graves.

Utilisez des équipements de sécurité personnelle.

Portez toujours une protection oculaire. Le port

d'équipements de sécurité tels que des masques

antipoussières, des chaussures de sécurité

antidérapantes, des casques de chantier et des

protecteurs d'oreilles dans des conditions appropriées

réduira le risque de blessure corporelle.

Évitez les démarrages intempestifs. Assurez-vous que

l'interrupteur est dans la position arrêt (Off) avant de

brancher l'outil dans une prise de courant et/ou un

bloc-piles, de le ramasser ou de le transporter. Le

transport d'un outil électroportatif avec le doigt sur la

gâchette ou le branchement de cet outil quand

l'interrupteur est en position de marche (ON) est une

invite aux accidents.

Enlevez toutes les clés de réglage avant de mettre

l’outil électroportatif en marche. Si on laisse une clé

sur une pièce tournante de l’outil électroportatif, il y a

risque de blessure corporelle.

Ne vous penchez pas. Conservez toujours une bonne

assise et un bon équilibre. Ceci vous permettra de

mieux maîtriser l’outil électroportatif dans des situations

inattendues.

Habillez-vous de manière appropriée. Ne portez pas

de vêtements amples ou de bijoux. Attachez les

cheveux longs. N’approchez pas les cheveux, les

vêtements ou les gants des pièces en mouvement.

Les vêtements amples, les bijoux ou les cheveux longs

risquent d’être happés par les pièces en mouvement.

Si l’outil est muni de dispositifs permettant le

raccordement d’un système d’aspiration et de

collecte des poussières, assurez-vous que ces

dispositifs sont raccordés et utilisés correctement.

L'utilisation d'un dépoussiéreur peut réduire les

dangers associés à l'accumulation de poussière.

Sécurité personnelle

-19-

Page 20

SM 1619X04663 05-11:SM 1619X04663 05-11 5/3/11 8:14 AM Page 20

Utilisation et entretien des outils

électroportatifs

Ne forcez pas sur l’outil électroportatif. Utilisez l’outil

électroportatif qui convient à la tâche à effectuer.

L’outil qui convient à la tâche fait un meilleur travail et

est plus sûr à la vitesse pour lequel il a été conçu.

Ne vous servez pas de l’outil électroportatif si son

interrupteur ne parvient pas à le mettre en marche ou

à l’arrêter. Tout outil électroportatif qui ne peut pas

être commandé par son interrupteur est dangereux et

doit être réparé.

Débranchez la fiche de la prise ou enlevez le bloc-pile

de l’outil électroportatif avant tout réglage,

changement d’accessoires ou avant de ranger l’outil

électroportatif. De telles mesures de sécurité

préventive réduisent le risque de démarrage intempestif

de l’outil électroportatif.

Rangez les outils électroportatifs dont vous ne vous

servez pas hors de portée des enfants et ne permettez

pas à des personnes qui ne connaissent pas l’outil

électroportatif ou qui ignorent ces consignes de s’en

servir. Les outils électroportatifs sont dangereux dans

les mains d’utilisateurs inexpérimentés.

Règles de sécurité concernant les toupies

Entretenez les outils électroportatifs. Vérifiez que les

pièces mobiles sont alignées correctement et ne

coincent pas. Vérifiez qu’il n’y a pas de pièces

cassées ou d’autre circonstance qui risquent

d’affecter le fonctionnement de l’outil électroportatif.

Si l’outil est abîmé, faites-le réparer avant de

l’utiliser. De nombreux accidents sont causés par des

outils électroportatifs mal entretenus.

Maintenez les outils coupants affûtés et propres. Les

outils coupants entretenus correctement et dotés de

bords tranchants affûtés sont moins susceptibles de

coincer et sont plus faciles à maîtriser.

Utilisez l'outil électroportatif, les accessoires et les

embouts d'outil, etc. conformément à ces

instructions, en tenant compte des conditions de

travail et des travaux à réaliser. L'emploi d’outils

électroportatifs pour des tâches différentes de celles

pour lesquelles ils ont été prévus peut résulter en une

situation dangereuse.

Entretien

Faites réparer votre outil électroportatif par un agent

de service qualifié n’utilisant que des pièces de

rechange identiques. Ceci assure que la sécurité de

l’outil électroportatif est préservée.

Tenez l'outil électroportatif par les surfaces isolées

de prise en exécutant une opération lorsque l'outil de

coupe peut venir en contact avec des fils cachés ou

son propre cordon. Le contact avec un fil sous tension

rendra les parties métalliques exposées de l'outil sous

tension et causera des secousses électriques à

l'opérateur.

Utilisez des brides ou d’autres moyens pratiques de

brider ou de supporter la pièce sur une plate-forme

stable. Tenir la pièce à la main ou contre le corps est

instable et risque de résulter en une perte de contrôle.

Assurez-vous toujours que la surface de travail est

exempte de clous et autres objets étrangers. La coupe

dans un clou peut faire sauter la lame et l'outil, et ainsi

abîmer la lame.

Ne tenez jamais le matériau d'une main et l'outil de

l'autre lorsque vous en faites usage. Ne placez jamais

les mains sous la surface de coupe ou à proximité de

celle-ci. Il est plus sûr de cramponner le matériau et de

guider l'outil des deux mains.

Ne posez jamais le matériau sur des surfaces dures

telles que le béton, la pierre, etc. ... La lame de coupe

en saillie peut faire sauter l'outil.

Portez toujours des lunettes de sécurité et un masque

anti-poussières. N'utilisez l'outil qu'à un endroit bien

aéré. L'utilisation de dispositifs de sécurité personnelle

et le travail dans un environnement sûr réduisent les

risques de blessures.

Après avoir changé les lames ou effectué quelque

réglage que ce soit, assurez-vous que l'écrou de la

douille et tout autre dispositif de réglage sont bien

serrés. Un dispositif de réglage lâche peut bouger

soudainement et causer ainsi une perte de contrôle avec

projection violente des composants en rotation.

Ne mettez jamais l'outil en marche alors que la lame

est enfoncée dans le matériau. Le tranchant de la lame

peut se coincer dans le matériau et vous faire perdre le

contrôle du couteau.

Tenez toujours le couteau des deux mains durant la

mise en marche. Le couple de réaction du moteur peut

faire tordre l'outil.

Le sens d'introduction de la lame dans le matériau

est très important, et il est lié au sens d'introduction

de la lame. Lorsque vous regardez l'outil depuis le

dessus, la lame tourne en sens horaire. Le sens

d'introduction du couteau doit être anti-horaire.

-20-

Page 21

SM 1619X04663 05-11:SM 1619X04663 05-11 5/3/11 8:14 AM Page 21

REMARQUE : Les coupes intérieures et extérieures

nécessiteront des sens de déplacement différents référez-vous à la section consacrée au sens de

déplacement de la toupie. Si l'outil est introduit dans le

mauvais sens, le tranchant de la lame peut sortir du

matériau et tirer l'outil dans le sens de cette

introduction.

N'utilisez jamais de lames émoussées ou abîmées.

Les lames affilées doivent être maniées

soigneusement. Les mèches abîmées peuvent se

rompre brusquement durant l'usage. Les lames

émoussées nécessitent plus de force pour pousser

Avertissements supplémentaires concernant la sécurité

L’emploi d’un GFCI et de dispositifs de protection

personnelle tels que gants et chaussures d’électricien

en caoutchouc améliorent votre sécurité personnelle.

N’utilisez pas un outil conçu uniquement pour le

C.A. sur une alimentation en C.C. Même si l’outil

semble fonctionner, les composants électriques d’un

outil prévu pour le C.A. tomberont probablement en

panne et risquent de créer un danger pour

l’utilisateur.

Maintenez les poignées sèches et exemptes d’huile

et de graisse. On ne pas maîtriser un outil

électroportatif en toute sécurité quand on a les mains

glissantes.

Créez un agenda d’entretien périodique pour votre

outil. Quand vous nettoyez un outil, faites attention

de n’en démonter aucune pièce car il est toujours

possible de mal remonter ou de pincer les fils

internes ou de remonter incorrectement les

ressorts de rappel des capots de protection.

Certains agents de nettoyage tels que l’essence, le

tétrachlorure de carbone, l’ammoniaque, etc. risquent

d’abîmer les plastiques.

Risque de blessure pour l'utilisateur. Le cordon

d'alimentation électrique ne doit être réparé que par

un Centre de service usine de Skil ou par une Station

service agréée de Skil.

l'outil, causant éventuellement un bris de la lame.

Ne touchez jamais la lame durant ou immédiatement

après l'usage. Après usage, la lame est trop chaude

pour être touchée à main nue.

Ne posez jamais l'outil avant que le moteur ne se soit

arrêté complètement. La lame en rotation peut saisir la

surface et vous faire perdre le contrôle de l'outil.

N’utilisez jamais des fers dont le diamètre de coupe est

supérieur à celui de l’ouverture pratiquée dans la base.

!

AVERTISSEMENT

meulage, perçage et autres travaux du bâtiment

peuvent créer des poussières contenant des

produits chimiques qui sont des causes reconnues

de cancer, de malformation congénitale ou

d’autres problèmes reproductifs. Ces produits

chimiques sont, par exemple :

• Le plomb provenant des peintures à base de plomb,

• Les cristaux de silices provenant des briques et du

ciment et d’autres produits de maçonnerie, et

• L’arsenic et le chrome provenant des bois traités

chimiquement.

Le niveau de risque dû à cette exposition varie avec la

fréquence de ces types de travaux. Pour réduire

l’exposition à ces produits chimiques, il faut travailler

dans un lieu bien ventilé et porter un équipement de

sécurité approprié tel que certains masques à

poussière conçus spécialement pour filtrer les

particules microscopiques.

Les travaux à la machine

tel que ponçage, sciage,

-21-

Page 22

0

SM 1619X04663 05-11:SM 1619X04663 05-11 5/3/11 8:14 AM Page 22

Symboles

IMPORTANT : Certains des symboles suivants peuvent être utilisés sur votre outil. Veuillez les étudier et apprendre

leur signification. Une interprétation appropriée de ces symboles vous permettra d'utiliser l'outil de façon plus

efficace et plus sûre.

Symbole Nom Désignation/Explication

V Volts Tension (potentielle)

A Ampères Courant

Hz Hertz Fréquence (cycles par seconde)

W Watt Puissance

kg Kilogrammes Poids

min Minutes Temps

s Secondes Temps

Diamètre Taille des mèches de perceuse, meules, etc.

n

0

n Vitesse nominale Vitesse maximum pouvant être atteinte

.../min Tours ou mouvement alternatif par Tours, coups, vitesse en surface, orbites,

0 Position d'arrêt Vitesse zéro, couple zéro ...

1, 2, 3, ... Réglages du sélecteur Réglages de vitesse, de couple ou de position. Un

l, ll, lll, ... nombre plus élevé signifie une vitesse plus grande

Vitesse à vide Vitesse de rotation, à vide

minute etc., par minute

Sélecteur variable à l'infini avec arrêt La vitesse augmente depuis le réglage 0

Flèche Action dans la direction de la flèche

Courant alternatif Type ou caractéristique du courant

Courant continu Type ou caractéristique du courant

Courant alternatif ou continu Type ou caractéristique du courant

Construction classe II Désigne des outils construits avec double

isolation

Borne de terre Borne de mise à la terre

Symbole d'avertissement Alerte l'utilisateur aux messages

d'avertissement.

Sceau Li-ion RBRC Désigne le programme de recyclage

des piles Li-ion.

Sceau Ni-Cad RBRC Désigne le programme de recyclage

des piles Ni-Cad.

Symbole de lecture du mode Alerte l’utilisateur pour lire le mode

d’emploi d’emploi

Symbole de port de lunettes Alerte l’utilisateur pour porter des lunettes

de sécurité de sécurité

-22-

Page 23

SM 1619X04663 05-11:SM 1619X04663 05-11 5/3/11 8:14 AM Page 23

Symboles (suite)

IMPORTANT : Certains des symboles suivants peuvent être utilisés sur votre outil. Veuillez les étudier et apprendre

leur signification. Une interprétation appropriée de ces symboles vous permettra d'utiliser l'outil de façon plus

efficace et plus sûre.

Ce symbole signifie que cet outil est approuvé par Underwriters Laboratories.

Ce symbole indique que cet outil est reconnu par Underwriters Laboratories.

Ce symbole signifie que cet outil est approuvé par Underwriters Laboratories selon les

normes des États-Unis et du Canada.

Ce symbole signifie que cet outil est approuvé par l'Association canadienne

de normalisation.

Ce symbole signifie que cet outil est approuvé par l'Association canadienne de normalisation

selon les normes des États-Unis et du Canada.

Ce symbole signifie que cet outil est approuvé par Intertek Testing Services selon

les normes des États-Unis et du Canada

Ce symbole signifie que cet outil se conforme aux normes mexicaines NOM.

Conforme à

Norme UL 60745-1

Norme UL 60745-2-17

Certifié conforme à

Norme CAN/CSA C22.2 N° 60745-1

Norme CAN/CSA C22.2 N° 60745-2-17

-23-

Page 24

SM 1619X04663 05-11:SM 1619X04663 05-11 5/3/11 8:14 AM Page 24

Description fonctionnelle et spécifications

!

AVERTISSEMENT

préventive réduisent le risque d'une mise en marche accidentelle de l'outil.

Débranchez la fiche de la prise de courant avant d'effectuer quelque assemblage

ou réglage que ce soit ou de changer les accessoires. Ces mesures de sécurité

Défonceuse à embase fixe

OUVERTURES DE

VENTILATION

POIGNÉE

FLÈCHE DU SENS DE

FIG. 1

INTERRUPTEUR COULISSANT

« MARCHE/ARRÊT »

À 2 POSITIONS

POIGNÉE

DÉFLECTEUR À

COPEAUX

ROTATION

FIG. 2

DÉBLOCAGE DE

EMBASE DE TYPE A

VIS DE RÉGLAGE

DE LA TENSION DU

DISPOSITIF DE

SERRAGE DE

L’EMBASE

BOUTON DE

L’EMBASE

BOUTON DE

RÉGLAGE FIN

ANNEAU INDICATEUR

LEVIER DE

SERRAGE DE

L’EMBASE

SOUS-EMBASE

BLOCAGE DE

LA DOUILLE

-24-

Page 25

1

1

/

2

1

1

/

2

0

SM 1619X04663 05-11:SM 1619X04663 05-11 5/3/11 8:14 AM Page 25

Défonceuse à embase plongeante

MOLETTE DE VARIATION DE VITESSE

(modèle 1827 et 1830 seulement)

BOUTON DE

RÉGLAGE FIN

ANNEAU INDICATEUR

ÉCHELLE DE

PROFONDEUR

BOUTON DE L’INDEX

DE PROFONDEUR

TIGE DE PROFONDEUR

TOURELLE DE BUTÉE

DE PROFONDEUR

FIG. 3

2-POSITION

SLIDE "ON/OFF"

SWITCH

POIGNÉE

INDEX DE PROFONDEUR

DÉFLECTEUR À COPEAUX

FLÈCHE DU SENS DE ROTATION

OUVERTURES DE

VENTILATION

FIG. 4

LEVIER DE

BLOCAGE DE

LA PLONGÉE

POIGNÉE

EMBASE DE TYPE B

LEVIER DE SERRAGE

DE L’EMBASE

BLOCAGE DE

SOUS-EMBASE

LA DOUILLE

Numéro de modèle 1817 1827 1830

Tension nominale 120V 60Hz 120V 60Hz 120V 60Hz

Intensité nominale 9,5A 10A 10A

Régime à vide n0 25,000/min n0 10,500-25,000/min n0 10,500-25,000/min

Capacités de la douille 1/4", 1/2" 1/4" 1/2" 1/4", 1/2"

Sur les modèles 1817, 1827& 1830, il faut utiliser l’ensemble du moteur de défonceuse soit avec l’embase fixe

de type A, soit avec l’embase plongeante de type B.

-25-

Page 26

SM 1619X04663 05-11:SM 1619X04663 05-11 5/3/11 8:14 AM Page 26

Assemblage

Il existe un grand nombre de fers de défonceuse avec

des profils variés qui sont disponibles séparément.

!

AVERTISSEMENT

toujours la prise avant de monter ou de démonter

des fers ou des accessoires.

INSTALLATION D’UN FER DE DÉFONCEUSE

Retournez la défonceuse et posez son dessus sur

l’établi. On peut également retirer le moteur de

l’embase avant d’installer le fer.

1. Enlevez le pare-copeaux.

2. Appuyez sur le blocage de la douille pour empêcher

l’arbre du rotor de tourner. REMARQUE : Il se peut

qu’il faille tourner l’ensemble de douille pour

enclencher le blocage de la douille (Fig. 5).

3. Ensuite, à l’aide de la clé à douille, desserrez l’écrou

de douille en tournant en sens anti-horaire (vu du

dessous de la défonceuse).

4. Enfoncez la queue du fer de défonceuse à fond

dans l’ensemble de douille puis ressortez-la de

manière à écarter les tranchants d’environ 1/8 à

1/4 po de la face de l’écrou de douille.

5. Une fois le fer de défonceuse enfoncé et avec le

blocage de douille maintenant l’arbre du rotor,

serrez fermement l’écrou de douille en sens horaire

(vu du dessous de la défonceuse) à l’aide de la clé

Pour éviter toute blessure

corporelle, débranchez

à douille. Pour assurer la préhension appropriée

du fer de la défonceuse, la tige du fer de la

défonceuse doit être insérée à au moins 5/8 po

dans la douille.

!

AVERTISSEMENT

n’utilisez pas de fers de défonceuse d’un diamètre

supérieur à 2 po car ils sont trop grands pour la

sous-embase.

!

MISE EN GARDE

l’écrou de douille quand celle-ci est vide.

REMARQUE : Il faut nettoyer la queue du fer de

défonceuse et la douille et en enlever la poussière, le

bois, les débris et la graisse avant le montage.

DÉMONTAGE DU FER DE DÉFONCEUSE

1. Appuyez sur le blocage de la douille pour empêcher

l’ arbre du rotor de tourn er puis desserrez

l’ensemble de douille en tournant en sens antihoraire.

2. Une fois l’ensemble de douille desserré, continuez

de tourner jusqu’à ce qu’il arrache la douille de son

cône, ce qui permet d’enlever le fer de défonceuse.

REMARQUE : La douille est à extraction automatique.

Il n’est PAS nécessaire de la frapper pour libérer le fer

de défonceuse.

FER 1/4 PO

Si le guide de gabarit a

été retiré de l’embase,

Po ur éviter d ’abîmer

l’ outil, ne serrez pas

FIG. 5

QUEUE

BLOCAGE DE

LA DOUILLE

DOUILLE

ÉCROU DE DOUILLE

EMBASE

CLÉ

-26-

Page 27

SM 1619X04663 05-11:SM 1619X04663 05-11 5/3/11 8:14 AM Page 27

ENTRETIEN DU MANDRIN-DOUILLE

Tous les modèles de défonceuses sont conçus de façon

à être compatibles avec des fers à tige de 1/2 po et de

1/4 po. Les fers à tige de 1/4 po nécessitent l’emploi

d’un manchon adaptateur de 1/4 po. Après avoir retiré

le fer de la défonceuse, continuez à faire tourner l’écrou

de la douille dans le sens contraire des aiguilles d’une

montre jusqu’à ce qu’il soit complètement desserré.

Pour assurer une prise ferme, soufflez de temps en

temps sur le mandrin-douille et nettoyez-le avec un

chiffon propre ou une brosse fine. L’ensemble de

mandrin-douille se compose de deux pièces différentes,

comme on peut le voir sur l’illustration (Fig. 6) ;

inspectez visuellement pour déterminer que le manchon

adaptateur (s’il est nécessaire) est bien à sa place dans

DÉMONTAGE DU MOTEUR D’UNE EMBASE

Pour retirer le moteur d’une embase fixe :

1. Tenez la défonceuse en position verticale.

2. Ouvrez le levier de serrage de l’embase.

3. Appuyez sur le bouton de déblocage de l’embase

dans le sens de la flèche et tirez sur l’ensemble de

moteur pour le faire sortir de l’embase. Le moteur

cessera de bouger juste avant de sortir complètement

de l’embase.

4. Appuyez sur le bouton de déblocage du mandrin

pour dégager totalement l’ensemble de moteur de

l’embase (Fig. 7).

Pour retirer le moteur d’une embase plongeante :

1. Tenez la défonceuse en position verticale.

2. Ouvrez le levier de serrage de l’embase et tirez sur

l’ensemble de moteur pour le faire sortir de la base

par le haut. Le moteur cessera de bouger juste avant

de sortir complètement de l’embase.

3. Appuyez sur le bouton de déblocage du mandrin

pour dégager totalement l’ensemble de moteur de

l’embase (Fig. 8).

INSTALLATION DU MOTEUR SUR UNE EMBASE

Pour installer le moteur sur une embase fixe :

1. Desserrez le levier de serrage de l’embase.

2. Appuyez sur le dispositif de blocage de la douille qui

se trouve sur l’ensemble de moteur.

3. Alignez la crémaillère de réglage fin avec le bouton de

réglage fin.

4. Appuyez sur le bouton de déblocage de l’embase et

faites glisser le l’ensemble de moteur jusqu’à ce que

le haut de la crémaillère de réglage fin soit au même

niveau que le sommet de l’embase.

5. Serrez le levier de serrage de l’embase.

Pour installer le moteur sur une embase plongeante :

1. Desserrez le levier de serrage de l’embase.

2. Appuyez sur le dispositif de blocage de la douille qui

se trouve sur l’ensemble de moteur.

3. Alignez la crémaillère de réglage fin avec la fente qui

se trouve à l’arrière de l’embase plongeante.

4. Faites glisser le l’ensemble de moteur dans l’embase

le mandrin-douille, et enfilez légèrement à nouveau

l’écrou de la douille dans le mandrin-douille de 1/2 po.

Remplacez immédiatement tout ensemble de mandrindouille usé ou endommagé.

ENSEMBLE DE MANDRIN-DOUILLE

FIG. 6

ÉCROU DE LA

DOUILLE

jusqu’à ce qu’il soit bien à sa place.

5. Serrez le levier de serrage de l’embase.

MANDRIN-DOUILLE

DE 1/2 PO

MANCHON

ADAPTATEUR DE 1/4 po

FIG. 7

ENSEMBLE

DU MOTEUR

BLOCAGE

DE LA

DOUILLE

EMBASE

FIXE

BOUTON DE

DÉBLOCAGE DE L’EMBASE

CRÉMAILLÈRE

DE RÉGLAGE FIN

LEVIER DE SERRAGE

DE L’EMBASE

FIG. 8

ENSEMBLE

DU MOTEUR

BLOCAGE

DE LA

DOUILLE

LEVIER DE

SERRAGE DE

L’EMBASE

CRÉMAILLÈRE

DE RÉGLAGE FIN

EMBASE

PLONGEANTE

-27-

Page 28

1

/

2

1

1

/

2

0

SM 1619X04663 05-11:SM 1619X04663 05-11 5/3/11 8:14 AM Page 28

L’ADAPTATEUR POUR GUIDE DE GABARIT

INSTALLATION DE

(non compris, disponible comme accessoire)

Placez l’adaptateur pour guide de gabarit sur les trous

situés au centre de la sous-embase, placez les deux

trous filetés situés en dessous de l’adaptateur en face

de s t rous fraisés de la sous-embase. Fixez

l’adaptateur à l’aide des vis fournies (Fig. 9).

Pour assurer l’alignement correct du guide de gabarit

avec l’arbre d’armature, veuillez utiliser un cône de

centrage (accessoire en option).

DÉFLECTEUR À COPEAUX

!

AVERTISSEMENT

Il faut toujours porter une

protection oculaire. Le

déflecteur à copeaux n’est pas prévu pour servir de

capot de sécurité.

Le déflecteur à copeaux empêche la poussière et les

copeaux de vous frapper le visage mais il n’est pas

ca pable d’arrêter des objets plus gros que la

poussière éjectée par le fer.

Pour enlever le pare-copeaux de l’embase fixe,

appuyez sur les languettes du déflecteur pour les

pousser vers l’intérieur jusqu’à ce que le pare-copeaux

FIG. 10

FIG. 9

SOUS-EMBASE

DE LA

DÉFONCEUSE

VIS DE

MONTAGE

se sépare de l’embase, puis retirez-le. Pour le fixer en

place, placez le déflecteur en position comme illustré à

la Fig. 10. Puis appuyez à nouveau sur les languettes du

déflecteur pour les pousser vers l’intérieur jusqu’à ce

que le pare-copeaux s’enclenche à sa place.

Pour retirer le pare-copeaux de l’embase plongeante,

appuyez vers l’intérieur de l’un quelconque des côtés du

déflecteur jusqu’à ce que le pare-copeaux se sépare de

l’embase, puis retirez-le. Pour le fixer en place, placez le

déflecteur en position comme illustré à la Fig. 10a. Puis

appuyez à nouveau vers l’intérieur du déflecteur d’un

côté ou de l’autre tout en poussant jusqu’à ce que le

pare-copeaux s’enclenche à sa place.

ADAPTATEUR

POUR GUIDE

DE GABARIT

FIG. 10a

DÉFLECTEUR

À COPEAUX

DÉFLECTEUR

À COPEAUX

Instructions d’utilisation

Les défonceuses Skil sont conçues pour apporter

ra pidité, préci sion et facilité lors des trava ux

d’ébénisterie, de toupillage, de la réalisation de

cannelures, de baguettes, de congés, de queues

d’aronde, etc. Elles vous permettent de faire de la

marqueterie, des chants décoratifs et de nombreux

types de découpages spéciaux.

RÉGLAGE DE LA PROFONDEUR AVEC LE BOUTON

DE RÉGLAGE FIN DE L’EMBASE FIXE

Le bouton de réglage fin permet d’effectuer un réglage

précis de la hauteur du fer sur votre défonceuse.

Pour utiliser la fonction de réglage fin, desserrez le

levier de serrage de l’embase et faites tourner le bouton

dans le sens des aiguilles d’une montre pour abaisser la

hauteur du fer ou dans le sens contraire des aiguilles

d’une montre pour élever la hauteur du fer (Fig. 2).

(Veuillez noter qu’un tour complet du bouton déplace

le fer d’environ 1/16 po). Après avoir terminé le

réglage de la profondeur, resserrez le moteur.

REMARQUE : Il faut effectuer tous les réglages de

profondeur avec le levier de serrage de l’embase

desserré.

TOUPILLAGES PROFONDS

Pour faire des toupillages profonds, faites plusieurs

toupillages de profondeurs croissantes en démarrant

à une profondeur donnée puis en faisant des passes

successives tout en augmentant la profondeur de

coupe à chaque passe.

Pour vous assurer que votre profondeur de coupe est

co rrecte, no us vous conseillons de faire des

to upillages d’essai dans une chute avant de

commencer le travail.

-28-

Page 29

1

1

/

2

1

1

/

2

0

SM 1619X04663 05-11:SM 1619X04663 05-11 5/3/11 8:14 AM Page 29

RÉGLAGE DE LA PROFONDEUR AVEC LA FONCTION

DE PLONGÉEDE L’EMBASE PLONGEANTE

La fonction de plongée simplifie les réglages de la

profondeur et permet au fer de pénétrer l’ouvrage

facilement et précisément. Pour abaisser, desserrez le

levier de verrouillage de la plongée (Fig. 11), et faites

pression vers le bas jusqu’à ce que vous ayez atteint la

profondeur désirée, puis serrez à nouveau le levier de

verrouillage de la plongée. Desserrez le levier et relâchez

la pression, et la défonceuse rétractera

automatiquement le fer pour le faire sortir de l’ouvrage.

Il est recommandé de rétracter le fer quand il n’est pas

engagé dans un ouvrage.

FIG. 11

LEVIER DE

VERROUILLAGE

DE L’ACTION DE

PLONGEE

VIS DE RETENUE

RÉGLAGE DU LEVIER DE VERROUILLAGE DE

Vous pouvez ajuster ou repositionner le levier de

verrouillage de l’action de plongée pour augmenter le

confort ou pour tenir compte de l’usure.

1. Le levier de verrouillage de l’action de plongée étant

dans la position verrouillée (position verticale), retirez

(en tournant dans le sens contraire des aiguilles

d’une montre) la vis de retenue qui est située sur la

partie médiane du levier.

2. Mettez le levier dans la position désirée, remettez la

vis de retenue et la rondelle en place, puis serrez (en

tournant dans le sens des aiguilles d’une montre).

La tige de profondeur et la tourelle de profondeur sont

utilisées pour contrôler la profondeur de coupe de la

façon suivante :

1. Avec le fer installé, abaissez doucement le moteur

jusqu’à ce que la pointe du fer de la défonceuse

effleure la surface plane sur laquelle la défonceuse

repose. Il s’agit de la position « zéro », à partir de

laquelle il est possible d’effectuer d’autres réglages de

la profondeur avec une grande précision.

2. Pour régler une profondeur de coupe désirée, faites

tourner la tourelle de butée de profondeur jusqu’à ce

que le repère le plus bas soit aligné avec la tige de

profondeur. Desserrez le bouton de repère de la

L’ACTION DE PLONGÉE

TIGE DE PROFONDEUR ET TOURELLE

DE PROFONDEUR

profondeur et abaissez la tige de profondeur jusqu’à

ce qu’elle entre en contact avec le repère le plus bas

de la tourelle. Faites glisser le repère de profondeur

jusqu’à ce que l’indicateur pointe sur le zéro sur

l’échelle de profondeur, montrant ainsi le point auquel

le fer de la défonceuse effleure l’ouvrage (Fig. 12).

3. Pour régler une profondeur de coupe désirée, faites

glisser la tige de profondeur jusqu’à ce que le repère

de profondeur ait atteint la profondeur de coupe

désirée, et assujettissez la tige en position en serrant