Page 1

Operating/Safety Instructions

Consignes de fonctionnement/sécurité

Instrucciones de funcionamiento

y seguridad

IMPORTANT: IMPORTANT : IMPORTANTE:

Read Before Using Lire avant usage Leer antes de usar

Consumer Information

Renseignement des consommateurs

Información para el consumidor

Toll Free Number: Appel gratuit : Número de teléfono gratuito:

1-877-SKIL999 (1-877-754-5999) http://www.skil.com

For English Parlez-vous français? ¿Habla español?

See page 2 Voir page 12 Ver página 22

1823

SM 2610995785 3/03 3/3/03 3:28 PM Page 1

Page 2

Work Area

Keep your work area clean and well lit.

Cluttered benches and dark areas invite

accidents.

Do not operate power tools in explosive

atmospheres, such as in the presence of

flammable liquids, gases, or dust. Power

tools create sparks which may ignite the dust

or fumes.

Keep by-standers, children, and visitors

away while operating a power tool.

Distractions can cause you to lose control.

Electrical Safety

Double Insulated tools are equipped with a

polarized plug (one blade is wider than the

other.) This plug will fit in a polarized outlet

only one way. If the plug does not fit fully in

the outlet, reverse the plug. If it still does

not fit, contact a qualified electrician to

install a polarized outlet. Do not change the

plug in any way. Double Insulation

eliminates the need for the three wire grounded

power cord and grounded power supply

system. Before plugging in the tool, be certain

the outlet voltage supplied is within the voltage

marked on the nameplate. Do not use “AC

only” rated tools with a DC power supply.

Avoid body contact with grounded surfaces

such as pipes, radiators, ranges and

refrigerators. There is an increased risk of

electric shock if your body is grounded. If

operating the power tool in damp locations is

unavoidable, a Ground Fault Circuit Interrupter

must be used to supply the power to your

tool. Electrician’s rubber gloves and footwear

will further enhance your personal safety.

Don't expose power tools to rain or wet

conditions. Water entering a power tool will

increase the risk of electric shock.

Do not abuse the cord. Never use the cord

to carry the tools or pull the plug from an

outlet. Keep cord away from heat, oil, sharp

edges or moving parts. Replace damaged

cords immediately. Damaged cords increase

the risk of electric shock.

When operating a power tool outside, use

an outdoor extension cord marked "W-A"

or "W." These cords are rated for outdoor use

and reduce the risk of electric shock. Refer to

“Recommended sizes of Extension Cords” in

the Accessory section of this manual.

Personal Safety

Stay alert, watch what you are doing and

use common sense when operating a

power tool. Do not use tool while tired or

under the influence of drugs, alcohol, or

medication. A moment of inattention while

operating power tools may result in serious

personal injury.

Dress properly. Do not wear loose clothing

or jewelry. Contain long hair. Keep your

hair, clothing, and gloves away from

moving parts. Loose clothes, jewelry, or long

hair can be caught in moving parts. Keep

handles dry, clean and free from oil and

grease.

Avoid accidental starting. Be sure switch is

“OFF” before plugging in. Carrying tools with

your finger on the switch or plugging in tools

that have the switch “ON” invites accidents.

Remove adjusting keys or wrenches before

turning the tool “ON”. A wrench or a key that

is left attached to a rotating part of the tool

may result in personal injury.

Do not overreach. Keep proper footing and

balance at all times. Proper footing and

balance enables better control of the tool in

unexpected situations.

Use safety equipment. Always wear eye

protection. Dust mask, non-skid safety

shoes, hard hat, or hearing protection must be

used for appropriate conditions.

Tool Use and Care

Use clamps or other practical way to

secure and support the workpiece to a

stable platform. Holding the work by hand or

against your body is unstable and may lead to

loss of control.

Read and understand all instructions. Failure to follow all instructions

listed below, may result in electric shock, fire and/or serious personal injury.

SAVE THESE INSTRUCTIONS

-2-

!

WARNING

Power Tool Safety Rules

SM 2610995785 3/03 3/3/03 3:28 PM Page 2

Page 3

-3-

Safety Rules for Routers

Do not force tool. Use the correct tool for

your application. The correct tool will do the

job better and safer at the rate for which it is

designed.

Do not use tool if switch does not turn it

“ON” or “OFF”. Any tool that cannot be

controlled with the switch is dangerous and

must be repaired.

Disconnect the plug from the power source

before making any adjustments, changing

accessories, or storing the tool. Such

preventive safety measures reduce the risk of

starting the tool accidentally.

Store idle tools out of reach of children and

other untrained persons. Tools are

dangerous in the hands of untrained users.

Maintain tools with care. Keep cutting tools

sharp and clean. Properly maintained tools,

with sharp cutting edges are less likely to bind

and are easier to control. Any alteration or

modification is a misuse and may result in a

dangerous condition.

Check for misalignment or binding of

moving parts, breakage of parts, and any

other condition that may affect the tools

operation. If damaged, have the tool

serviced before using. Many accidents are

caused by poorly maintained tools. Develop a

periodic maintenance schedule for your tool.

Use only accessories that are

recommended by the manufacturer for

your model. Accessories that may be suitable

for one tool, may become hazardous when

used on another tool.

Service

Tool service must be performed only by

qualified repair personnel. Service or

maintenance performed by unqualified

personnel could result in a risk of injury. For

example: internal wires may be misplaced or

pinched, safety guard return springs may be

improperly mounted.

When servicing a tool, use only identical

replacement parts. Follow instructions in

the Maintenance section of this manual.

Use of unauthorized parts or failure to follow

Maintenance Instructions may create a risk of

electric shock or injury. Certain cleaning

agents such as gasoline, carbon tetrachloride,

ammonia, etc. may damage plastic parts.

Hold tool by insulated gripping surfaces

when performing an operation where the

cutting tool may contact hidden wiring or

its own cord. Contact with a "live" wire will

make exposed metal parts of the tool "live"

and shock the operator. If cutting into

existing walls or other blind areas where

electrical wiring may exist is unavoidable,

disconnect all fuses or circuit breakers

feeding this worksite.

Always make sure the work surface is

free from nails and other foreign objects.

Cutting into a nail can cause the bit and the

tool to jump and damage the bit.

Never hold the workpiece in one hand

and the tool in the other hand when in

use. Never place hands near or below

cutting surface. Clamping the material and

guiding the tool with both hands is safer.

Never lay workpiece on top of hard

surfaces, like concrete, stone, etc...

Protruding cutting bit may cause tool to

jump.

Always wear safety goggles and dust

mask. Use only in well ventilated area.

Using personal safety devices and working

in safe environment reduces risk of injury.

After changing the bits or making any

adjustments, make sure the collet nut and

any other adjustment devices are

securely tightened. Loose adjustment

device can unexpectedly shift, causing loss

of control, loose rotating components will be

violently thrown.

Never start the tool when the bit is

engaged in the material. The bit cutting

edge may grab the material causing loss of

control of the cutter.

Always hold the tool with two hands

during start-up. The reaction torque of the

motor can cause the tool to twist.

When routing or cutting, the direction of

feed with the bit’s cutting edge into the

material is very important. Always feed

the bit into the material in the same

SM 2610995785 3/03 3/3/03 3:28 PM Page 3

Page 4

direction as the cutting edge is exiting

from the material (which is the same

direction as the chips are thrown). NOTE:

inside and outside cuts will

require different

feed direction, refer to section on feeding the

router. Feeding the tool in the wrong direction,

causes the cutting edge of the bit to climb out

of the work and pull the tool in the direction of

this feed.

Never use dull or damaged bits. Sharp

bits must be handled with care. Damaged

bits can snap during use. Dull bits require

more force to push the tool, possibly

causing the bit to break.

Never touch the bit during or immediately

after the use. After use the bit is too hot to

be touched by bare hands.

Never lay the tool down until the motor

has come to a complete standstill. The

spinning bit can grab the surface and pull

the tool out of your control.

Never use bits that have a cutting

diameter greater than the opening in the

base.

Some dust created by

power sanding, sawing,

grinding, drilling, and other construction

activities contains chemicals known to

cause cancer, birth defects or other

reproductive harm. Some examples of

these chemicals are:

• Lead from lead-based paints,

• Crystalline silica from bricks and cement

and other masonry products, and

• Arsenic and chromium from chemically-

treated lumber.

Your risk from these exposures varies,

depending on how often you do this type of

work. To reduce your exposure to these

chemicals: work in a well ventilated area,

and work with approved safety equipment,

such as those dust masks that are specially

designed to filter out microscopic particles.

-4-

!

WARNING

SM 2610995785 3/03 3/3/03 3:28 PM Page 4

Page 5

-5-

IMPORTANT: Some of the following symbols may be used on your tool. Please study them

and learn their meaning. Proper interpretation of these symbols will allow you to operate the

tool better and safer.

Symbol Name Designation/Explanation

V Volts Voltage (potential)

A Amperes Current

Hz Hertz Frequency (cycles per second)

W Watt Power

kg Kilograms Weight

min Minutes Time

s Seconds Time

Diameter Size of drill bits, grinding wheels, etc.

n

0

No load speed Rotational speed, at no load

.../min Revolutions or reciprocation per minute Revolutions, strokes, surface speed,

orbits etc. per minute

0 Off position Zero speed, zero torque...

1, 2, 3, ... Selector settings Speed, torque or position settings.

I, II, III, Higher number means greater speed

Infinitely variable selector with off Speed is increasing from 0 setting

Arrow Action in the direction of arrow

Alternating current Type or a characteristic of current

Direct current Type or a characteristic of current

Alternating or direct current Type or a characteristic of current

Class II construction Designates Double Insulated

Construction tools.

Earthing terminal Grounding terminal

Warning symbol Alerts user to warning messages

Ni-Cad RBRC seal Designates Ni-Cad battery recycling

program

Symbols

0

This symbol designates

that this tool is listed by

Underwriters Laboratories.

This symbol designates

that this tool is listed by

the Canadian Standards

Association.

This symbol designates

that this tool is listed to

Canadian Standards by

Underwriters Laboratories.

This symbol

designates

that

this tool

complies

to NOM

Mexican

Standards.

This symbol designates

that this tool is listed by

Underwriters Laboratories,

and listed to Canadian

Standards by Underwriters

Laboratories.

SM 2610995785 3/03 3/3/03 3:28 PM Page 5

Page 6

-6-

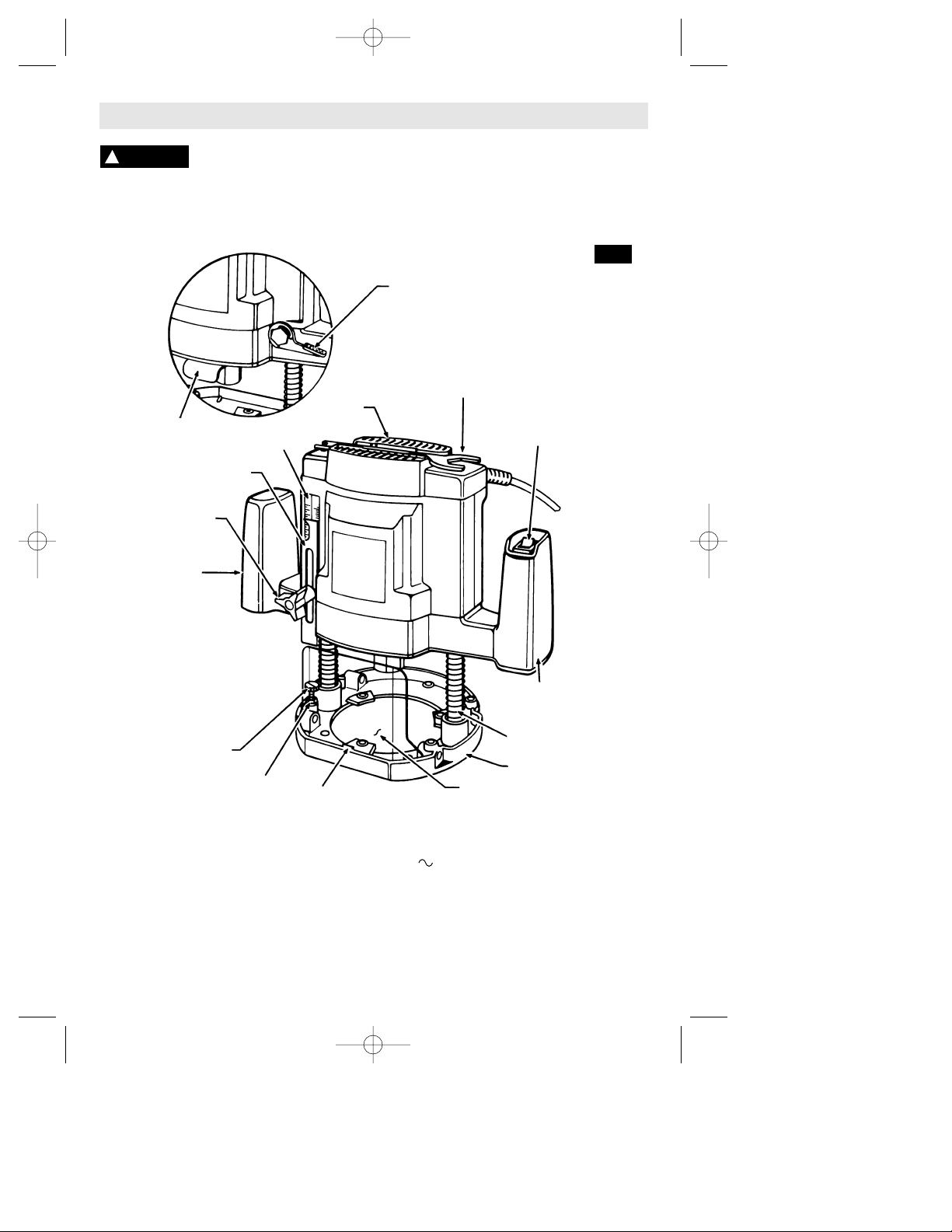

Functional Description and Specifications

Disconnect the plug from the power source before making any

assembly, adjustments or changing accessories. Such preventive safety

measures reduce the risk of starting the tool accidentally.

!

WARNING

Routers

LOCK

LEVER

COLLET LOCK

WRENCH & STORAGE AREA

ON/OFF

SWITCH

BASE

CHIP DEFLECTOR

TAB

NUT

PLUNGER SPRINGS

FINE DEPTH

ADJUSTMENT

LEFT

HANDLE

RIGHT

HANDLE

KNOB

DEPTH

GAUGE

DEPTH

SCALE

FIG. 1

VENTS

Model number 1823

Voltage rating 120 V 50 - 60Hz

Amperage rating 8.5 A

No load speed n

0

25,000/min

Collet capacities 1/4"

VIEW OF OPPOSITE SIDE OF ROUTER

SM 2610995785 3/03 3/3/03 3:28 PM Page 6

Page 7

Operating Instructions

-7-

Assembly

SELECTING BITS

A wide assortment of router bits with different

profiles are available as accessories.

To prevent personal injury.

Always remove the plug from

power source before removing or installing

bits or accessories.

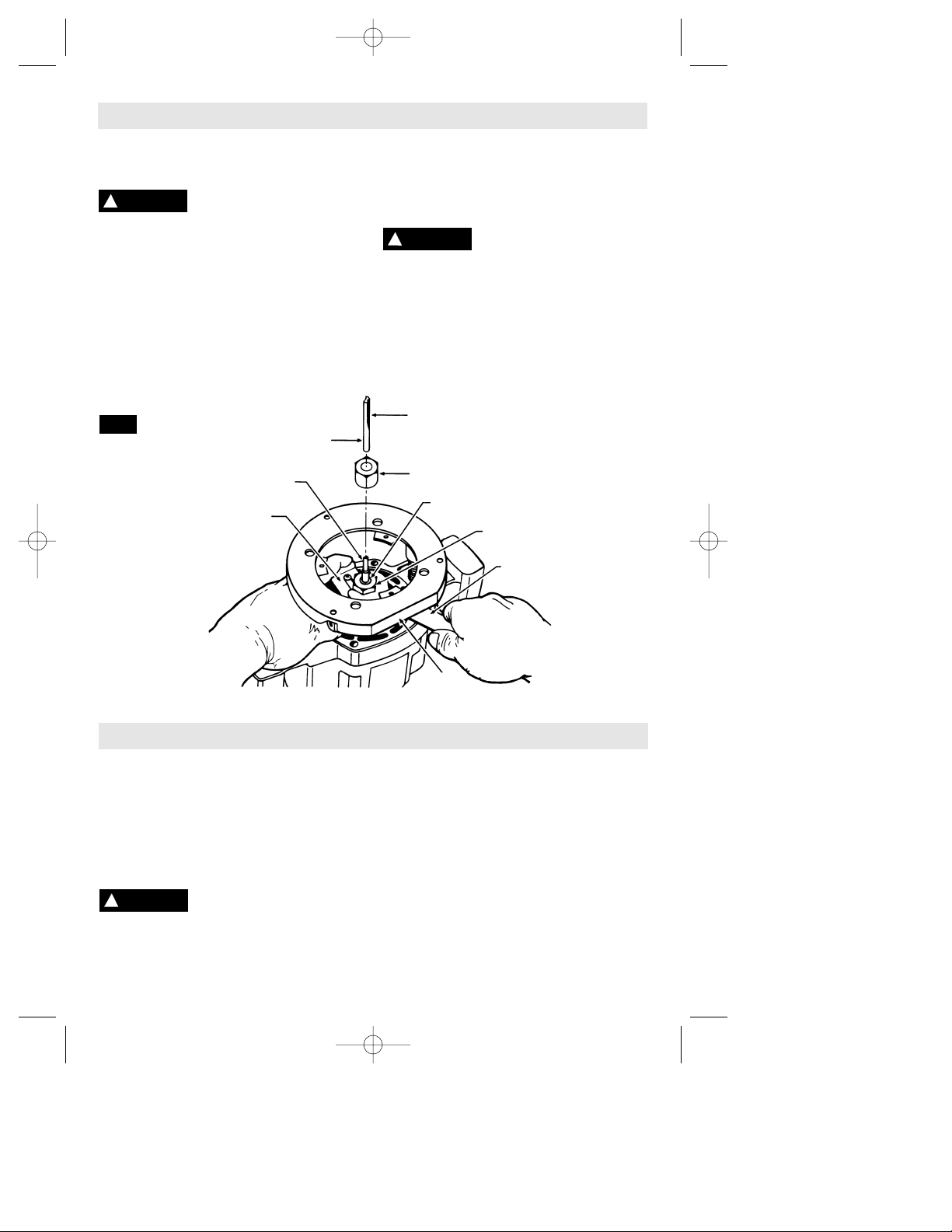

INSTALLING AND REMOVING BITS

1. Place router upside down as shown in (Fig.

2), or lay router on its side with the flat side of

base resting on the bench.

2. Press collet lock to stop rotation of collet

nut. NOTE: it may be necessary to rotate

collet nut to engage collet lock.

3. With the wrench provided, turn collet nut

counterclockwise to loosen.

4. Insert bit three fourths into the collet, and

securely tighten collet nut clockwise with the

wrench provided.

To prevent damage to tool,

do not tighten collet nut

without a bit.

REMOVING BITS

Repeat steps 1, 2 and 3 of above and remove

bit.

ATTENTION: Be sure that the diameter of the

bit shank is the same size as the inside

diameter of the collet — your router is

equipped with a 1/4" collet.

!

WARNING

CHIP DEFLECTOR

The chip deflector helps keep dust and chips

out of your face. To remove, press inward on

center of deflector until it releases from tab in

base and lift out. To attach, place deflector

into position as shown in (Fig. 1). Then flex

sides of deflector while pushing down until

tab on base snaps into slot on deflector.

Safety glasses must always

be worn.

Skil plunge routers are designed for speed,

accuracy and convenience in performing

cabinet work, routing, fluting, beading, covecutting, dove tails, etc. It will enable you to

accomplish inlay work, decorative edges and

many types of special carving.

PLUNGING ACTION

The plunge feature simplifies depth

adjustments and will allow the cutting bit to

easily and accurately enter the workpiece. To

lower, loosen lock lever (Fig. 1), and apply

downward pressure until depth gauge makes

contact with the fine depth adjustment screw,

and tighten lock lever. Loosen lever and

WRENCH

COLLET

COLLET NUT

BIT

SHANK

BIT

COLLET

LOCK

BASE

FIG. 2

!

CAUTION

!

WARNING

COLLET NUT

SM 2610995785 3/03 3/3/03 3:28 PM Page 7

Page 8

release pressure and the router will

automatically retract the bit from the

workpiece. It is advisable to retract the bit

whenever it is not engaged in workpiece.

WRENCH AND STORAGE AREA

Your router is equipped with a double-ended

wrench. The large end is for removing or

installing bits. The small end is for securing

the nut on the fine depth adjustment screw.

Your router also has a convenient storage

area located on top of your tool where your

wrench may be stored by simply sliding it into

place as shown in (Fig. 1).

DEPTH GAUGE

Your router is equipped with a depth gauge

and a depth scale calibrated in inches and

millimeters. It also features a fine depth

adjustment screw that allows the depth

gauge to stop the router at desired depths of

cut.

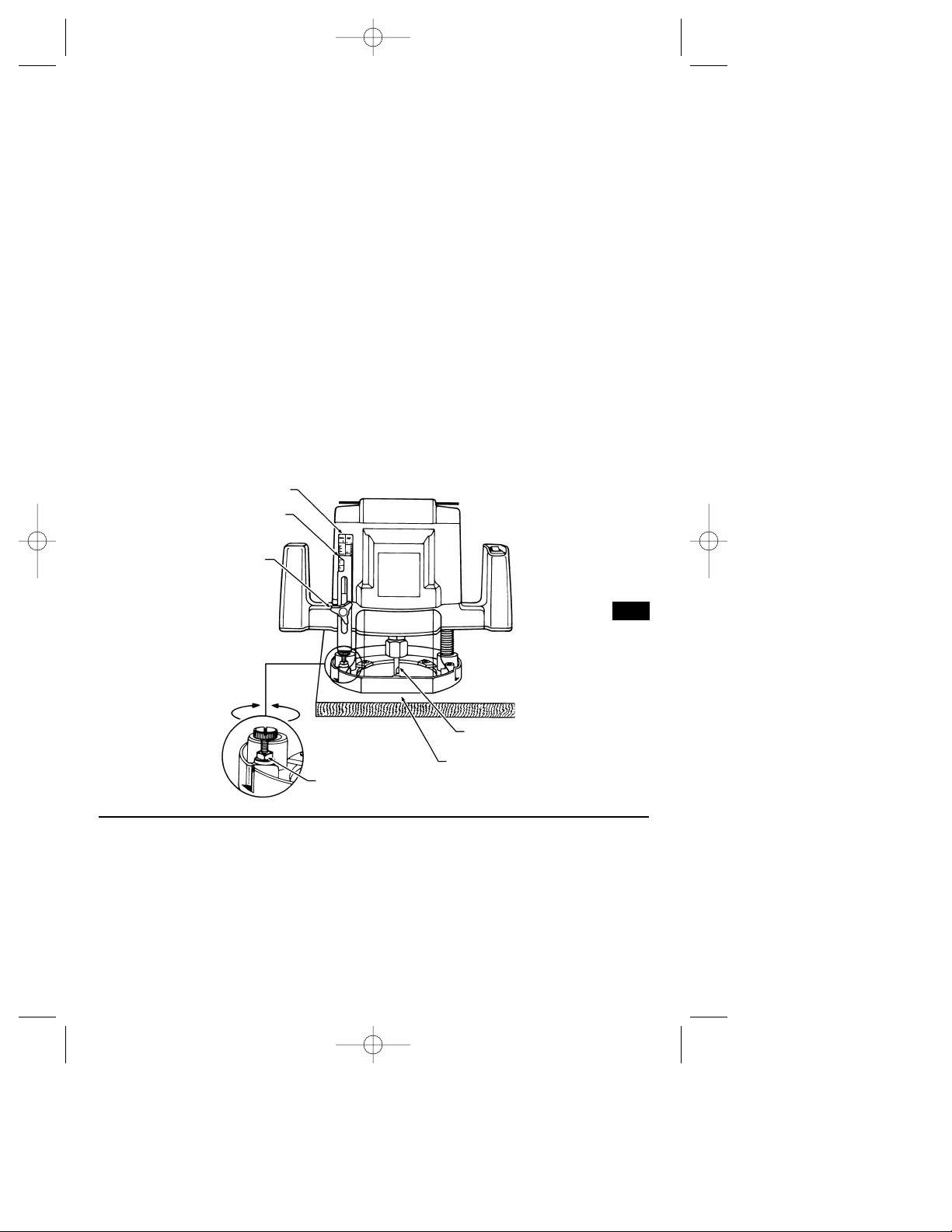

TO ADJUST DEPTH

1. Loosen knob so that the depth gauge

moves freely.

2. Loosen lock lever and push down on router

until the bit touches the work surface and the

depth gauge is resting on top of the fine

depth adjustment screw as shown in (Fig. 3),

and tighten lock lever.

3. Raise depth gauge desired amount on

scale and tighten knob. For example, if you

raise the depth gauge up 1/8" on scale you

will get a 1/8" depth of cut.

4. Loosen lock lever and lower router until

depth gauge stops on top of the fine depth

adjustment screw. Make a few practice cuts

on a piece of scrap wood to check if depth of

cut is correct. If depth of cut needs to be

changed slightly, loosen nut on fine depth

adjustment screw with the wrench provided

and rotate screw until you reach desired

depth. Half turn of the fine depth adjustment

screw equals 1/64 of an inch. Full turn equals

1/32".

5. After depth of cut is obtained securely

tighten nut on fine depth adjustment screw

with the wrench provided to maintain adjustment.

-8-

WORK SURFACE

BIT

FINE DEPTH

ADJUSTMENT HALF

TURN = 1/64"

NUT

Clockwise

To Lower

Counter-

clockwise

To Raise

SCALE

KNOB

DEPTH GAUGE

FIG. 3

ON/OFF SWITCH

Your router is equipped with an ON/OFF

switch located in the right handle. The switch

also has a red “ON” indicator that alerts user

that the router is on before plugging in tool.

To turn router on, press switch to ON. To turn

router off, press switch to OFF.

Always hold the router off the work when

turning the switch on or off. Contact the work

with the router after the router has reached full

speed, and remove it from the work before

turning the switch off. Operating in this manner

will prolong switch and motor life and will

greatly increase the quality of your work

(Fig. 1).

SM 2610995785 3/03 3/3/03 3:28 PM Page 8

Page 9

-9-

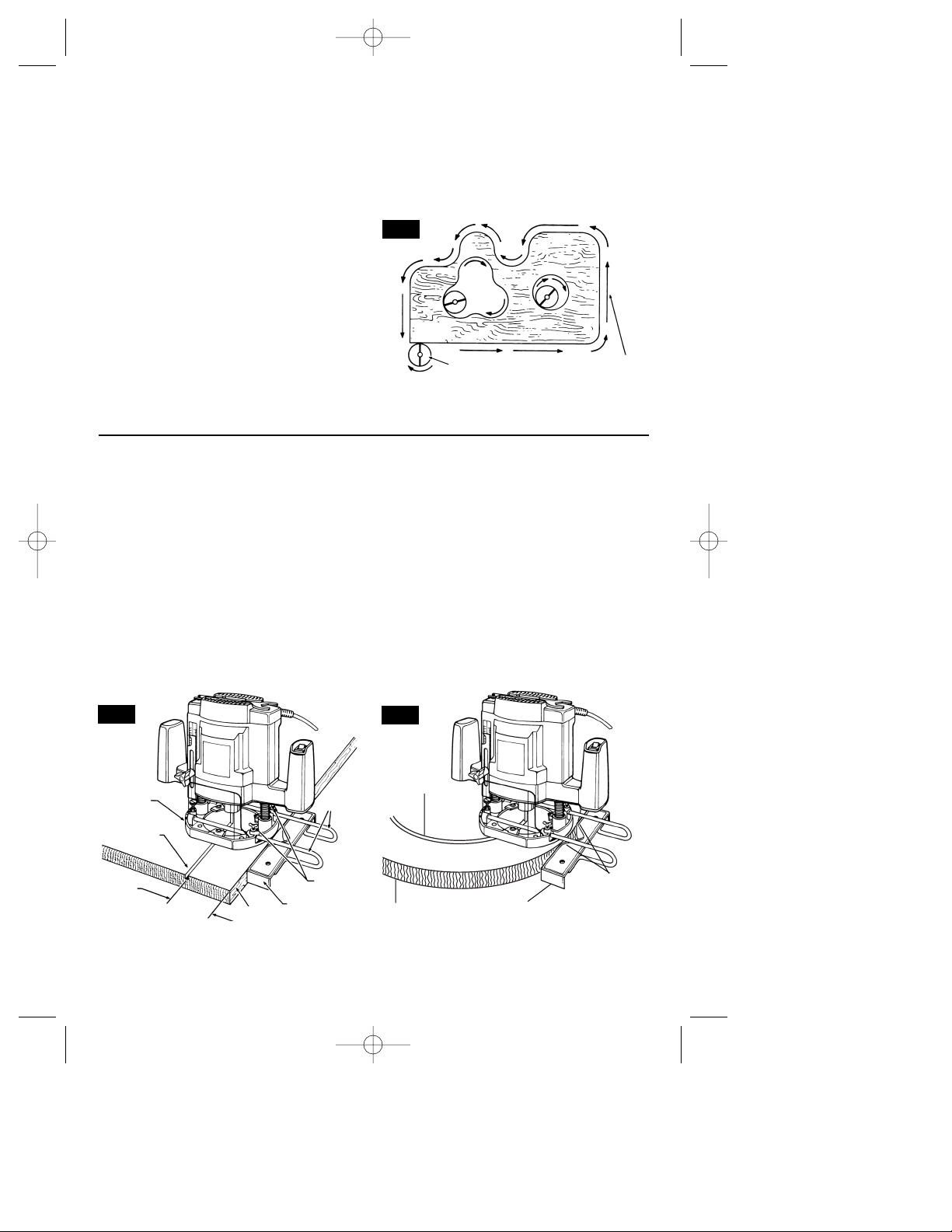

FEEDING THE ROUTER

As seen from the top of the router, the bit

turns clockwise and the cutting edges face

accordingly. Therefore, the most efficient cut

is made by feeding the router so that the bit

turns into the work, not away. Figure 4 shows

proper feed for various cuts. How fast you

feed depends on the hardness of the wood

and the size of the cut. For some materials,

several cuts of increasing depth are required.

As a general rule, it is best to pull the router

— not push. You get greater visibility, cleaner

cut, more control and less flying sawdust.

If the router is hard to control, heats up, runs

very slowly or leaves an imperfect cut,

consider these causes:

1. Wrong direction of feed — hard to control.

2. Feeding too fast — overloads motor.

3. Dull bit -— overloads motor.

4. Cut is too large for one pass — overloads

motor.

5. Feeding too slow — leaves friction burns

on work.

Feed smoothly and steadily (do not force).

You will soon learn how the router sounds

and feels when it is working best.

FIG. 4

CUTTER

WORK

DIRECTION

OF ROUTER

FEED

GUIDING ROUTER

The router can be guided through the work in

any of several ways. The method you use

depends, of course, on the demands of the

particular job and on convenience.

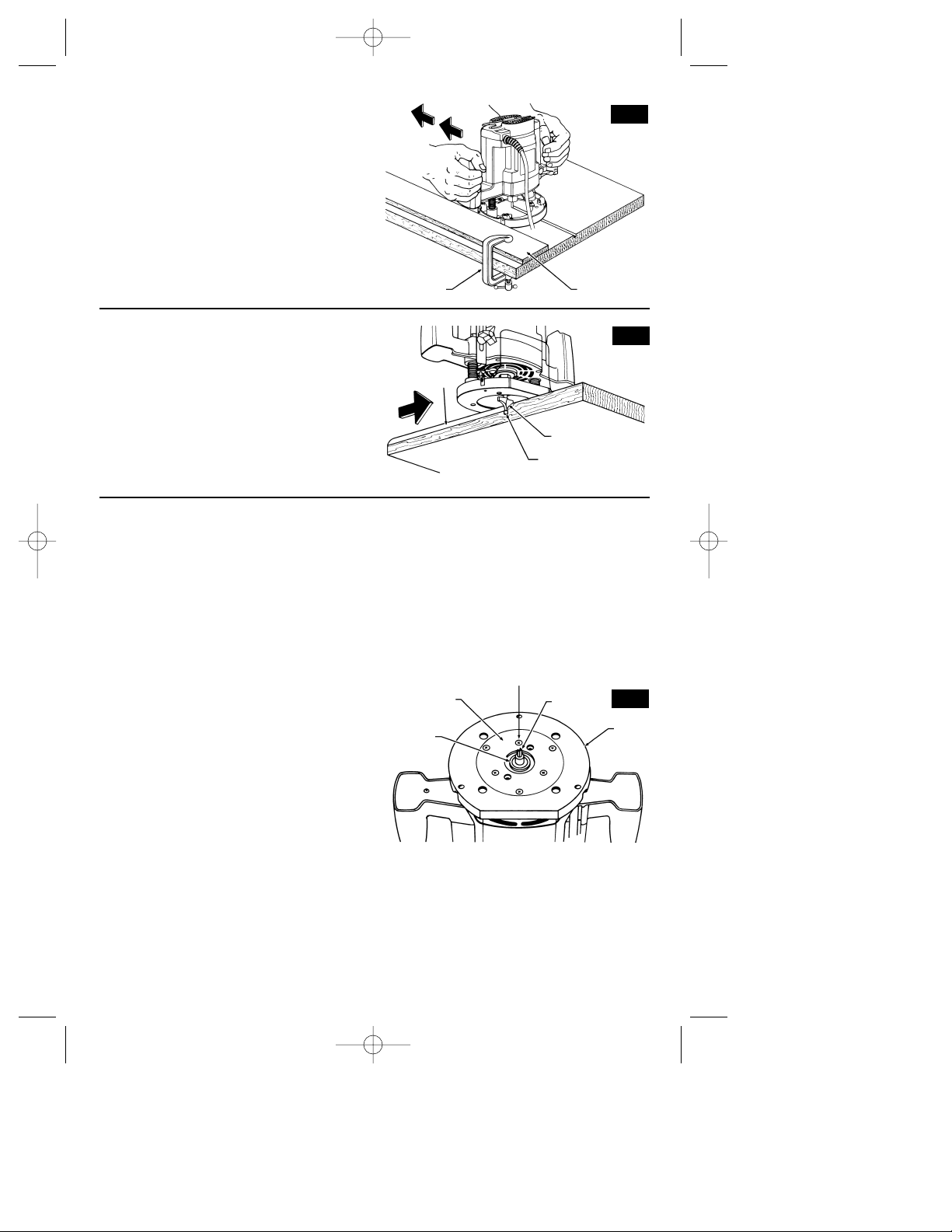

STRAIGHT AND CIRCULAR EDGE GUIDE

(Not included, available as accessory)

Use this handy accessory for ease and

accuracy in making curved and straight cuts.

ATTACHING GUIDE

Insert edge guide rods through holes in base,

slide edge guide to desired width as shown in

(Fig. 5), and secure in place with the two wing

screws provided.

One method of locating the guide is to mark

the center of groove to be cut, set the router

flat on the work with the bit just touching and

aligned over the center of groove. Bring the

guide to the edge of the work, and securely

tighten screws. Whenever in doubt about

dimensions, make a trial cut on scrap

material. For guiding along a circular edge,

the notch in the center of the edge guide will

contact the material at the two points shown

(Fig. 6).

FIG. 5

FIG. 6

DESIRED

WIDTH

CUT

BASE

EDGE GUIDE

WORK

WING

SCREWS

EDGE

GUIDE

RODS

CUT

WORK

EDGE GUIDE

POINTS OF

CONTACT

SM 2610995785 3/03 3/3/03 3:28 PM Page 9

Page 10

-10-

TEMPLATES

Using a template lets you duplicate designs or

letters uniformly time after time. This technique

requires the use of an accessory adapter plate

and a guide bushing.

ADAPTER PLATE

(Not included, available as accessory)

Attach the accessory adapter guide to the

router base with the three screws provided as

shown in (Fig. 9), and you can use a variety of

Skil guide bushings available. The accessory

adapter plate also has auxiliary holes which will

allow you to attach other guide bushings made

by Craftsman, Milwaukee, Porter Cable,

Rockwell and Black & Decker.

GUIDE BUSHINGS

(Not included, available as accessory)

The guide bushing shown in (Fig. 9), is

essentially a plate with a collar which is

inserted through the hole in accessory adapter

plate from below and fastened with screws

from above. The guide rides along the edge of

the template while the router bit, protruding

below, cuts into the work.

Be sure the thickness of the template is the

same or larger than the guide surface of the

collar.

Do not use a bit that may touch the inside of

the collar. Select a bit that is about 1/16" less

in diameter.

After attaching any guide bushing, always turn

the router upside down and lower base to

check if the bit is protruding through the center

of the collar. If adjustment is necessary loosen

the three screws that secure the adapter plate

to the base and move adapter plate until bit is

in the center of collar (Fig. 9).

FREEHAND ROUTING

Many effects are gained by using the router

freehand with a small diameter bit. Usually the

craftsman pencils the outline or script he

desires onto the work and uses the pencil line

as a guide.

BOARD GUIDES

Clamp a straight or curved board onto the

work to form a guide as shown in (Fig. 7). This

is particularly handy for panels or any large

surface area.

FIG. 7

SECURELY CLAMP

BOARD GUIDE

BOARD

GUIDE

PILOT TIPPED AND BEARING GUIDE BITS

The lower portion of a pilot tipped bit, as

shown in (Fig. 8), is a shaft with no cutting

edges. Bearing guide bits have a ball bearing

to pilot the bit.

This pilot slides along the edge of the work as

the rotating blades make the cut, forming

molding or decorative edges. The edge on

which the pilot slides should be perfectly

smooth since any irregularities are transferred

to the shaped surface.

PILOT SLIDES ALONG

EDGE OF WORK

CUTTER PART OF

PILOT TIPPED BIT

CUT

FIG. 8

BASE

BIT

ADAPTER PLATEALIGNMENT SCREWS

ADAPTER

PLATE

GUIDE

BUSHING

FIG. 9

SM 2610995785 3/03 3/3/03 3:28 PM Page 10

Page 11

-11-

Accessories

Service

Preventive maintenance

performed by unauthorized

personnel may result in misplacing of

internal wires and components which

could cause serious hazard. We

recommend that all tool service be performed

by a Skil Factory Service Center or Authorized Skil Service Station.

TOOL LUBRICATION

Your Skil tool has been properly lubricated

and is ready to use. It is recommended that

tools with gears be regreased with a special

gear lubricant at every brush change.

CARBON BRUSHES

The brushes and commutator in your tool

have been engineered for many hours of

dependable service. To maintain peak

efficiency of the motor, we recommend every

two to six months the brushes be examined.

Only genuine Skil replacement brushes

specially designed for your tool should be

used.

BEARINGS

After about 300-400 hours of operation, or at

every second brush change, the bearings

should be replaced at Skil Factory Service

Center or Authorized Skil Service Station.

Bearings which become noisy (due to heavy

load or very abrasive material cutting) should

be replaced at once to avoid overheating or

motor failure.

Cleaning

To avoid accidents always

disconnect the tool from

the power supply before cleaning or

performing any maintenance. The tool may

be cleaned most effectively with compressed

dry air. Always wear safety goggles when

cleaning tools with compressed air.

Ventilation openings and switch levers must

be kept clean and free of foreign matter. Do

not attempt to clean by inserting pointed

objects through openings.

Certain cleaning agents

and solvents damage

plastic parts. Some of these are: gasoline,

carbon tetrachloride, chlorinated cleaning

solvents, ammonia and household detergents

that contain ammonia.

!

WARNING

!

WARNING

Maintenance

!

CAUTION

If an extension cord is

necessary, a cord with

adequate size conductors that is capable

of carrying the current necessary for your

tool must be used. This will prevent

excessive voltage drop, loss of power or

overheating. Grounded tools must use 3wire extension cords that have 3-prong

plugs and receptacles.

NOTE: The smaller the gauge number, the

heavier the cord.

RECOMMENDED SIZES OF EXTENSION CORDS

120 VOLT ALTERNATING CURRENT TOOLS

!

WARNING

Tool’s

Ampere

Rating

Cord Size in A.W.G.

Wire Sizes in mm

2

3-6

6-8

8-10

10-12

12-16

18 16 16 14 .75 .75 1.5 2.5

18 16 14 12 .75 1.0 2.5 4.0

18 16 14 12 .75 1.0 2.5 4.0

16 16 14 12 1.0 2.5 4.0 —

14 12 — — — — — —

25 50 100 150 15 30 60 120

Cord Length in Feet Cord Length in Meters

(*= standard equipment)

(**= optional accessories)

BITS

For fast smooth cutting, keep bits sharp. A dull

bit slows cutting speed, makes rougher cuts,

discolors or burns the work through excessive

heat and overloads the motor.

ROUTER DUST COLLECTION

(Not included, available as accessory)

If you have a shop vacuum system you may

want to purchase the Skil 91812 Dust

Collection Hood for improved accuracy and

utility, particularly in freehand routing.

SM 2610995785 3/03 3/3/03 3:28 PM Page 11

Page 12

-12-

Vous devez lire et comprendre toutes les instructions. Le non-respect, même partiel,

des instructions ci-après entraîne un risque de choc életrique, d'incendie et/ou de

blessures graves.

CONSERVEZ CES INSTRUCTIONS

AVERTISSEMENT

!

Aire de travail

Veillez à ce que l'aire de travail soit propre et bien

éclairée. Le désordre et le manque de lumière favorisent

les accidents.

N'utilisez pas d'outils électriques dans une

atmosphère explosive, par exemple enprésence de

liquides, de gaz ou de poussières inflammables. Les

outils électriques créent des étincelles qui pourraient

enflammer les poussières ou les vapeurs.

Tenez à distance les curieux, les enfants et les

visiteurs pendant que vous travaillezavec un outil

électrique. Ils pourraient vous distraire et vous faire

faire une fausse manoeuvre.

Sécurité électrique

Les outils à double isolation sont équipés d'une fiche

polarisée (une des lames est pluslarge que l'autre),

qui ne peut se brancher que d'une seule façon dans

une prise polarisée. Si la fiche n'entre pas

parfaitement dans la prise, inversez sa position ; si

elle n'entre toujours pasbien, demandez à un

électricien qualifié d'installer une prise de courant

polarisée. Ne modifiez pas la fiche de l'outil. La

double isolation élimine le besoin d'un cordon

d'alimentationà trois fils avec mise à la terre ainsi que

d'une prise de courant mise à la terre. Avant de brancher

l'outil, assurez-vous que la tension de la prise

correspond, à celle indiquée sur la plaque signalétique.

N'utilisez pas d'outils prévus pour courant alternatif

seulement avec une source de courant continu.

Évitez tout contact corporel avec des surfaces mises à

la terre (tuyauterie, radiateurs, cuisinières,

réfrigérateurs, etc.). Le risque de choc électrique est

plus grand si votre corps est encontact avec la terre.Si

l'utilisation de l'outil électrique dans un endroit humide

est inévitable, un disjoncteur de fuite à la terre doit être

utilisé pour alimenter votre outil. Des chaussures et des

gants en caoutchouc d'électricien contribueront à

accroître davantage votre sécurité personnelle.

N'exposez pas les outils électriques à la pluie ou à

l'eau. La présence d'eau dans un outil électrique

augmente le risque de choc électrique.

Ne maltraitez pas le cordon. Ne transportez pas l'outil

par son cordon et ne débranchez pas la fiche en tirant

sur le cordon. N'exposez pas le cordon à la chaleur, à

des huiles, à des arêtes vives ou à des pièces en

mouvement. Remplacez immédiatement un cordon

endommagé. Un cordon endommagé augmente le

risque de choc électrique.

Lorsque vous utilisez un outil électrique à l'extérieur,

employez un prolongateur pour l'extérieur marqué «

W-A » ou « W ». Ces cordons sont faits pour être utilisés

à l'extérieur et réduisent le risque de choc électrique.

Reportez-vous aux « Dimensions recommandées des

cordons de rallonge » dans la section Accessoires de ce

manuel.

Sécurité des personnes

Restez alerte, concentrez-vous sur votre travail et

faites preuve de jugement. N'utilisez pas un outil

électrique si vous êtes fatigué ou sous l'influence de

drogues, d'alcool ou de médicaments. Un instant

d'inattention suffit pour entraîner des blessures graves.

Habillez-vous convenablement. Ne portez ni

vêtements flottants ni bijoux. Confinez les cheveux

longs. N'approchez jamais les cheveux, les vêtements

ou les gants des pièces en mouvement. Des vêtements

flottants, des bijoux ou des cheveux longs risquent

d'être happés par des pièces en mouvement. Gardez les

poignées sèches, propres et exemptes d'huile et de

graisse.

Méfiez-vous d'un démarrage accidentel. Avant de

brancher l'outil, assurez-vous que son interrupteur est

sur ARRÈT. Le fait de transporter un outil avec le doigt

sur la détente ou de brancher un outil dont l'interrupteur

est en position MARCHE peut mener tout droit à un

accident.

Enlevez les clés de réglage ou de serrage avant de

démarrer l'outil. Une clé laissée dans une pièce

tournante de l'outil peut provoquer des blessures.

Ne vous penchez pas trop en avant. Maintenez un bon

appui et restez en équilibre entout temps. Un bonne

stabilité vous permet de mieux réagir à une situation

inattendue.

Utilisez des accessoires de sécurité. Portez toujours

des lunettes ou une visière. Selon les conditions, portez

aussi un masque antipoussière, des bottes de sécurité

antidérapantes, un casque protecteur et/ou un appareil

antibruit.

Utilisation et entretien des outils

Immobilisez le matériau sur une surface stable au

moyen de brides ou de toute autre façon adéquate. Le

fait de tenir la pièce avec la main ou contre votre corps

Règles de Sécurité Générales

SM 2610995785 3/03 3/3/03 3:28 PM Page 12

Page 13

-13-

offre une stabilité insuffisante et peut amener un

dérapage de l'outil.

Ne forcez pas l'outil. Utilisez l'outil approprié à la

tâche. L'outil correct fonctionne mieux et de façon plus

sécuritaire. Respectez aussi la vitesse de travail qui lui

est propre.

N'utilisez pas un outil si son interrupteur est bloqué.

Un outil que vous ne pouvez pas commander par son

interrupteur est dangereux et doit être réparé.

Débranchez la fiche de l'outil avant d'effectuer un

réglage, de changer d'accessoire oude ranger l'outil.

De telles mesures préventives de sécurité réduisent le

risque de démarrage accidentel de l'outil.

Rangez les outils hors de la portée des enfants et

d'autres personnes inexpérimentées. Les outils sont

dangereux dans les mains d'utilisateurs novices.

Prenez soin de bien entretenir les outils. Les outils de

coupe doivent être toujours bien affûtés et propres.

Des outils bien entretenus, dont les arêtes sont bien

tranchantes, sont moins susceptibles de coincer et plus

faciles à diriger.Toute altération ou modification

constitue un usage erroné et peut causer un danger.

Soyez attentif à tout désalignement ou coincement des

pièces en mouvement, à tout bris ou à toute autre

condition préjudiciable au bon fonctionnement de

l'outil. Si vous constatez qu'un outil est endommagé,

faites-le réparer avant de vous en servir. De nombreux

accidents sont causés par des outils en mauvais état.

Élaborez un calendrier d'entretien périodique de votre

outil.

N'utilisez que des accessoires que le fabricant

recommande pour votre modèle d'outil. Certains

accessoires peuvent convenir à un outil, mais être

dangereux avec un autre.

Réparation

La réparation des outils électriques doit être confiée à

un réparateur qualifié. L'entretien ou la réparation d'un

outil électrique par un amateur peut avoir des

conséquences graves. Ainsi, des fils internes peuvent

être mal placés ou pincés, des ressorts de rappel de

protecteur peuvent être montés erronément.

Pour la réparation d'un outil, n'employez que des

pièces de rechange d'origine. Suivez les directives

données à la section « Réparation » de ce manuel.

L'emploi de pièces non autorisées ou le non-respect des

instructions d'entretien peut créer un risque de choc

électrique ou de blessures. Certains agents nettoyants

tels qu'essence, tétrachlorure de carbone, ammoniac,

etc., peuvent abîmer les pièces en plastique.

Tenez l'outil par les surfaces isolées de prise en

exécutant une opération lorsque l'outil de coupe peut

venir en contact avec des fils cachés ou son propre

cordon. Le contact avec un fil sous tension rendra les

parties métalliques exposées de l'outil sous tension et

causera des secousses électriques à l'opérateur. Pour

couper dans des murs existants ou autres endroits

aveugles pouvant dissimuler des fils électriques,

débranchez tous les fusibles ou les disjoncteurs

alimentant ce lieu de travail.

Assurez-vous toujours que la surface de travail est

exempte de clous et autres objets étrangers. La coupe

dans un clou peut faire sauter la lame et l'outil, et ainsi

abîmer la lame.

Ne tenez jamais le matériau d'une main et l'outil de

l'autre lorsque vous en faites usage. Ne placez jamais

les mains sous la surface de coupe ou à proximité de

celle-ci. Il est plus sûr de cramponner le matériau et de

guider l'outil des deux mains.

Ne posez jamais le matériau sur des surfaces dures

telles que le béton, la pierre, etc. ... La lame de coupe

en saillie peut faire sauter l'outil.

Portez toujours des lunettes de sécurité et un masque

anti-poussières. N'utilisez l'outil qu'à un endroit bien

aéré. L'utilisation de dispositifs de sécurité personnelle

et le travail dans un environnement sûr réduisent les

risques de blessures.

Après avoir changé les lames ou effectué quelque

réglage que ce soit, assurez-vous que l'écrou de la

douille et tout autre dispositif de réglage sont bien

serrés. Un dispositif de réglage lâche peut bouger

soudainement et causer ainsi une perte de contrôle avec

projection violente des composants en rotation.

Ne mettez jamais l'outil en marche alors que la lame

est enfoncée dans le matériau. Le tranchant de la lame

peut se coincer dans le matériau et vous faire perdre le

contrôle du couteau. Tenez toujours le couteau des

deux mains durant la mise en marche. Le couple de

réaction du moteur peut faire tordre l'outil.

Quand on toupille ou on coupe, le sens de l’avance

par rapport au mouvement du tranchant de l’outil

dans le matériau est très important. Toujours

travailler en opposition, c’est à dire faire avancer

l’outil dans le matériau dans la direction du bord

Règles de sécurité concernant les toupies

SM 2610995785 3/03 3/3/03 3:28 PM Page 13

Page 14

tranchant lorsque celui-ci quitte le matériau (ce qui

est aussi le sens d’évacuation des copeaux).

REMARQUE : Les coupes intérieures et extérieures

nécessiteront des sens de déplacement différents référez-vous à la section consacrée au sens de

déplacement de la toupie. Si l'outil est introduit dans le

mauvais sens, le tranchant de la lame peut sortir du

matériau et tirer l'outil dans le sens de cette

introduction.

N'utilisez jamais de lames émoussées ou abîmées.

Les lames affilées doivent être maniées soigneusement.

Les mèches abîmées peuvent se rompre brusquement

durant l'usage. Les lames émoussées nécessitent plus

de force pour pousser l'outil, causant éventuellement un

bris de la lame.

Ne touchez jamais la lame durant ou immédiatement

après l'usage. Après usage, la lame est trop chaude

pour être touchée à main nue.

Ne posez jamais l'outil avant que le moteur ne se soit

arrêté complètement. La lame en rotation peut saisir la

surface et vous faire perdre le contrôle de l'outil.

N’utilisez jamais des fers dont le diamètre de coupe est

supérieur à celui de l’ouverture pratiquée dans la base.

Les travaux à la machine

tel que ponçage, sciage,

meulage, perçage et autres travaux du bâtiment

peuvent créer des poussières contenant des produits

chimiques qui sont des causes reconnues de cancer,

de malformation congénitale ou d’autres problèmes

reproductifs. Ces produits chimiques sont, par

exemple :

• Le plomb provenant des peintures à base de plomb,

• Les cristaux de silices provenant des briques et du

ciment et d’autres produits de maçonnerie, et

• L’arsenic et le chrome provenant des bois traités

chimiquement.

Le niveau de risque dû à cette exposition varie avec la

fréquence de ces types de travaux. Pour réduire

l’exposition à ces produits chimiques, il faut travailler

dans un lieu bien ventilé et porter un équipement de

sécurité approprié tel que certains masques à poussière

conçus spécialement pour filtrer les particules

microscopiques.

-14-

AVERTISSEMENT

!

SM 2610995785 3/03 3/3/03 3:28 PM Page 14

Page 15

-15-

Symboles

Important : Certains des symboles suivants peuvent être utilisés sur votre outil. Veuillez les étudier et apprendre

leur signification. Une interprétation appropriée de ces symboles vous permettra d'utiliser l'outil de façon plus

efficace et plus sûre.

Symbole Nom Désignation/Explication

V Volts Tension (potentielle)

A Ampères Courant

Hz Hertz Fréquence (cycles par seconde)

W Watt Puissance

kg Kilogrammes Poids

min Minutes Temps

s Secondes Temps

Diamètre Taille des mèches de perceuse, meules,

etc.

n

0

Vitesse à vide Vitesse de rotation, à vide

.../min Tours ou mouvement alternatif par Tours, coups, vitesse en surface, orbites,

minute etc., par minute,

0 Position d'arrêt Vitesse zéro, couple zéro ...

1, 2, 3, ... Réglages du sélecteur Réglages de vitesse, de couple ou de

l, ll, lll, ... position. Un nombre plus élevé signifie

une vitesse plus grande.

Sélecteur variable à l'infini avec arrêt La vitesse augmente depuis le réglage 0

Flèche Action dans la direction de la flèche

Courant alternatif Type ou caractéristique du courant

Courant continu Type ou caractéristique du courant

Courant alternatif Type ou caractéristique du courant

ou continu

Construction classe II Désigne des outils construits avec double

isolation

Borne de terre borne de mise à la terre

Symbole d'avertissement Alerte l'utilisateur aux messages

d'avertissement.

Sceau Ni-Cad RBRCmc Désigne le programme de recyclage des piles

Ni-Cad.

0

Ce symbole signifie que cet

outil est approuvé par

Underwriters Laboratories.

Ce symbole signifie que cet

outil est approuvé par

l'Association canadienne de

normalisation.

Ce symbole signifie que

cet outil est approuvé

conformément aux normes

canadiennes par Underwriters

Laboratories.

Ce symbole

signifie que

cet outil se

conforme aux

normes

mexicaines

NOM.

Ce symbole signifie que cet outil

est approuvé par Underwriters

Laboratories et qu’il a été

homologué selon les normes

canadiennes par Underwriters

Laboratories.

SM 2610995785 3/03 3/3/03 3:28 PM Page 15

Page 16

-16-

Description fonctionnelle et spécifications

Débranchez la fiche de la prise de courant avant d'effectuer quelque assemblage

ou réglage que ce soit ou de changer les accessoires. Ces mesures de sécurité

préventive réduisent le risque d'une mise en marche accidentelle de l'outil.

AVERTISSEMENT

!

Toupies

LEVIER DE VERROUILLAGE

VERROUILLAGE DE DOUILLE

CLÉ ET LOGEMENT

INTERRUPTEUR

MARCHE/ARRÊT

BASE

DÉFLECTEUR DE

COPEAUX

LANGUETTE

ÉCROU

RESSORTS DE PLONGEUR

RÉGLAGE PRÉCIS

DE PROFONDEUR

POIGNÉE

GAUCHE

POIGNÉE

DROITE

BOUTON

GUIDE DE

PROFONDEUR

ÉCHELLE

GRADUÉE

FIG. 1

PRISES

D’AIR

Numéro de modèle 1823

Tension nominale 120 V 50 à 60Hz

Intensité nominale 8,5 A

Vitesse à vide n0 25 000/min

Capacités de la douille 6 mm

SM 2610995785 3/03 3/3/03 3:28 PM Page 16

Page 17

-17-

Assemblage

CHOIX DE FERS

Un vaste assortiment de fers pour toutes sortes de profils

sont disponibles à titre d’accessoires.

Pour éviter le risque de

blessure, débranche toujours

le cordon de la source d’alimentation avant de substituer

les fers ou autres accessoires.

INSTALLATION ET RETRAIT DES FERS

1. Placez la toupie à l’envers comme illustré à la fig. 2, ou

placez la toupie sur son côté, le côté plat de la base

reposant sur l’établi. Le côté plat de la base peut

également être utilisé comme guide de bord ou pour la

coupe de près.

2. Appuyez sur le verrouillage de la douille pour faire

cesser la rotation de l’écrou de douille. REMARQUE : il

peut être nécessaire de tourner l’écrou de douille pour

verrouiller la douille.

3. À l’aide de la clé fournie, tournez l’écrou de douille en

sens inverse des aiguilles d’une montre pour desserrer.

4. Insérez le fer jusqu’aux trois quarts dans la douille et

serrez solidement l’écrou de douille dans le sens des

aiguilles d’une montre avec la clé fournie.

Pour éviter d’endommager

l’outil, ne serrez pas l’écrou

de douille en l’absence du fer.

RETRAIT DES FERS

Répétez les étapes 1, 2 et 3 ci-dessus et retirez le fer.

ATTENTION : Assurez-vous que le diamètre de la queue

du fer est le même que celui de l’intérieur de la douille.

Votre toupie est équipée d’une douille de 6mm.

AVERTISSEMENT

!

MISE EN GARDE

!

Consignes de fonctionnement

DÉFLECTEUR DE COPEAUX

Le déflecteur de copeaux permet d’éliminer la poussière

et les copeaux de la zone de travail. Pour le déposer,

appuyez au centre du déflecteur jusqu’à ce qu’il se

détache de la languette de retenue à la base de la toupie

et que vous puissiez l’enlever. Pour le reposer, placez le

déflecteur dans la position indiquée à la fig. 1. Comprimez

les côtés flexibles du déflecteur et enfoncez-le en place

jusqu’à ce que la languette de la base s’engage dans la

fente du déflecteur.

Portez toujours des lunettes

de sécurité.

Les toupies pour la coupe en plongée Skil ont été

conçues pour assurer vitesse et précision et faciliter les

travaux de menuiserie, de rainurage et de profilage, et

l’exécution de cannelures, baguettes, gorges, queues

d’arronde, etc. Elles permettent d’effectuer des travaux

d’assemblage, des moulures décoratives et toutes sortes

de découpes spéciales.

COUPE EN PLONGÉE

La fonction plongée simplifie les réglages en profondeur

et permet au fer de pénétrer facilement et avec précision

dans la pièce à tailler. Pour abaisser le fer, desserrez le

levier de verrouillage (fig. 1) et pesez jusqu’à ce que la

jauge de profondeur vienne en contact avec une des vis de

réglage de précision, puis resserrez le levier de

verrouillage. Desserrez le levier, relâchez la pression et la

toupie rétracte automatiquement le fer de la pièce. Il est

recommandé de rétracter le fer quand il ne sert pas.

FER

ÉCROU DE

DOUILLE

ÉCROU DE DOUILLE

DOUILLE

BASE

VERROUILLAGE

DE DOUILLE

QUEUE

FER

AVERTISSEMENT

!

CLÉ

FIG. 2

SM 2610995785 3/03 3/3/03 3:28 PM Page 17

Page 18

-18-

CLÉ ET RANGEMENT

La toupie est équipée d’une clé plate double. L’extrémité

la plus grande sert à monter et démonter les fers ; la plus

petite à serrer les écrous des vis de réglage de précision

en profondeur. Un logement aménagé à la partie

supérieure permet de ranger la clé en la glissant en place,

tel qu’il est indiqué à la fig. 1.

GUIDE DE PROFONDEUR

Votre toupie est équipée d’un guide de profondeur et

d’une échelle de profondeur graduée en pouces et en

millimètres. Elle est également dotée d’une vis de réglage

précis de la profondeur qui permet au guide d’arrêter la

toupie à plusieurs profondeurs de coupe désirées.

POUR RÉGLER LA PROFONDEUR

1. Desserrez le bouton de sorte que le guide de

profondeur se déplace librement.

2. Desserrez le levier de verrouillage et appuyez sur la

toupie jusqu’à ce que le fer touche à la surface du

matériau et que le guide de profondeur repose sur le

dessus de la vis de réglage précis de profondeur comme

illustré à la fig. 3, puis serrez le levier de verrouillage.

3. Remontez le guide de profondeur de la valeur désirée

sur l’échelle graduée et serrez le bouton. Par exemple, si

vous remontez le guide de 3 mm sur l’échelle, vous

obtiendrez une profondeur de coupe de 3 mm.

4. Desserrez le levier de verrouillage et abaissez la toupie

jusqu’à ce que le guide de profondeur s’arrête sur le

dessus de la vis de réglage précis de profondeur.

Effectuez quelques coupes d’essai dans une retaille pour

vous assurer que la profondeur est exacte. S’il y a lieu de

modifier légèrement la profondeur, desserrez l’écrou sur

la vis de réglage précis de profondeur à l’aide de la clé

fournie et tournez la vis jusqu’à ce que vous atteigniez la

profondeur désirée. Un demi-tour de la vis de réglage

précis de profondeur équivaut à 0,39 mm de pouce. Un

tour complet équivaut à 0,79".

5. Après avoir obtenu le réglage désiré, serrez

fermement l’écrou de la vis de réglage précis de

profondeur à l’aide de la clé fournie pour maintenir le

réglage.

SURFACE DE TRAVAIL

FER

RÉGLAGE PRÉCIS DE

PROFONDEUR UN

DEMI-TOUR = 0,39 mm

ÉCROU

sens des

aiguilles d’une

montre pour

baisser

sens contraire

aux aiguilles

d’une montre

pour releve

ÉCHELLE GRADUÉE

BOUTON

GUIDE DE PROFONDEUR

FIG. 3

INTERRUPTEUR MARCHE/ARRÊT

Votre toupie est équipée d’un interrupteur

MARCHE/ARRET situé dans la poignée droite.

L’interrupteur possède également un témoin de

MARCHE rouge qui avise l’utilisateur que la toupie est en

marche avant de brancher l’outil.

Pour mettre la toupie en marche, appuyez sur

l’interrupteur à la position de MARCHE. Pour arrêter la

toupie, appuyez sur l’interrupteur à la position d’ARRET.

Éloignez toujours la toupie du matériau avant de la

mettre en MARCHE ou de l’arrêter. Ne la posez sur le

matériau qu’après qu’elle a atteint sa vitesse maximale ;

de même, soulevez-la avant de relâcher la gâchette pour

l’arrêter. De cette façon vous prolongerez la durée de

l’interrupteur et du moteur et vous améliorerez

énormément les résultats (fig. 1).

SM 2610995785 3/03 3/3/03 3:28 PM Page 18

Page 19

-19-

DÉPLACEMENT DE LA TOUPIE

Regardant du dessus de la toupie, le fer tourne dans le

sens des aiguilles d’une montre et les tranchants sont

orientés en conséquence. En effet, pour effectuer une

coupe efficace, il faut déplacer la toupie de sorte que les

tranchants mordent dans la pièce en s’en approchant et

non pas dans le sens opposé. La figure 4 indique

différentes façons de procéder pour diverses

configurations de coupe. La vitesse de déplacement

dépend de la dureté du bois et de la dimension de la

coupe. Pour certains matériaux, il faut procéder en

plusieurs étapes progressives. D’une façon générale, il

est préférable de tirer la toupie et non de la pousser. Vous

bénéficierez ainsi d’une meilleure visibilité, d’une coupe

plus nette, d’une plus grande maîtrise et réduirez les

projections de copeaux.

Si la toupie est difficile à manœuvrer, surchauffe, tourne

très lentement ou produit une coupe imparfaite, vérifiez

les causes suivantes :

1. Déplacement dans le mauvais sens : manœuvre

difficile.

2. Déplacement trop rapide : surcharge du moteur.

3. Fer émoussé : surcharge du moteur.

4. Coupe exagérée pour une passe : surcharge du

moteur.

5. Déplacement trop lent : traces de brûlures sur la pièce.

Déplacez la toupie lentement et uniformément sans la

forcer. Vous réussirez rapidement à interpréter les sons

qu’émet la toupie et saurez juger quand elle fonctionne à

son régime normal.

FIG. 4

SENS DE

DÉPLACEMENT

DE LA TOUPIE

COUTEAU

PIÈCE

GUIDAGE DE LA TOUPIE

Il y a plusieurs manières de guider la toupie. La méthode

utilisée dépend des exigences pratiques de la pièce à

réaliser bien entendu.

GUIDE DE COUPE RECTILIGNE ET CIRCULAIRE

(Non fourni, disponible à titre d’accessoire)

Utilisez cet accessoire pratique pour faciliter l’exécution

de coupes courbées et rectilignes précises.

POSE DU GUIDE

Introduisez les tiges du guide dans la base, faites glisser

le guide à la largeur désirée (voir fig. 5) et immobilisez-le

en place avec les deux vis à oreilles fournies.

Un moyen de régler le guide est de faire une marque au

centre de la rainure à découper, puis de poser la toupie à

plat sur la pièce, le fer touchant à peine la surface et

s’alignant avec la marque au centre de la rainure. Glissez

le guide jusqu’au bord de la pièce et serrez fermement les

vis. En cas de doute sur les dimensions, effectuez une

coupe d’essai dans une retaille. Pour guidage le long

d'un bord circulaire, l'encoche au centre du guide de

bords viendra en contact avec le matériau aux deux

points indiqués (voir fig. 6).

FIG. 5

LARGEUR

DÉSIRÉE

COUPE

BASE

GUIDE DE

COUPE

PIÈCE

VIS À

OREILLES

TIGES

DU GUIDE

DE COUPE

FIG. 6

COUPE

PIÈCE

GUIDE DE

COUPE

POINTS DE

CONTACT

SM 2610995785 3/03 3/3/03 3:28 PM Page 19

Page 20

FERS À GUIDE ET À ROULEMENT

La partie inférieure d’un fer à guide (voir fig. 8) est

simplement un prolongement de la tige sans les

tranchants. Les fers avec guide à roulement sont pourvus

d’un roulement à billes.

Le guide se déplace le long du bord de la pièce pendant

que les tranchants effectuent la coupe pour former une

moulure ou une bordure décorative. La surface du bord

sur lequel glisse le guide se déplace doit alors être

parfaitement lisse, sinon les irrégularités se transmettent

automatiquement au profil de la coupe.

-20-

PLANCHES GUIDES

À l’aide de serres, fixez une planche rectiligne ou

curviligne à la pièce pour former un guide (voir fig. 7).

Cette méthode est surtout pratique pour les panneaux ou

pièces de grande dimension.

FIG. 7

PLANCHE GUIDE FERMEMENT ASSUJETTIE

PLANCHE

GUIDE

LE GUIDE SE DÉPLACE LE

LONG DU BORD DE LA PIÈCE

TRANCHANTS DU

FER À GUIDE

COUPE

FIG. 8

GABARITS

L’usage d’un gabarit vous permet de reproduire des

motifs ou lettres de façon uniforme aussi souvent que

vous le désirez. Cette technique nécessite l’utilisation

d’une plaque adaptatrice pour accessoires et d’une

plaquette-guide.

PLAQUE ADAPTATRICE POUR ACCESSOIRES

(Non fournies, disponibles à titre d’accessoires)

Fixez le guide adaptateur pour accessoires à la base de la

toupie à l’aide des trois vis fournies comme illustré à la

fig. 9. Cet adaptateur vous permettra d’utiliser

l’assortiment de plaquettes-guides de marque Skil

disponibles. L’adaptateur possède également des trous

auxiliaires qui vous permettront de fixer d’autres

plaquettes-guides de marques Craftsman, Milwaukee,

Porter Cable, Rockwell et Black & Decker.

PLAQUETTES-GUIDES

(Non fournies, disponibles à titre d’accessoires)

La plaquette-guide illustrée à la fig. 9 se compose

essentiellement d’une plaquette munie d’un collet à

introduire par dessous dans l’ouverture de la plaque

adaptatrice et à fixer avec des vis depuis le dessus. Le

guide se déplace le long du bord du gabarit alors que le

fer, qui dépasse au dessous, découpe la pièce.

Assurez-vous que l’épaisseur du gabarit est égale ou

supérieure à celle de la surface guide du collet.

N’utilisez pas de fers qui pourraient venir en contact avec

la paroi intérieure du collet. Choisissez un fer de

diamètre environ 1,6 mm plus petit.

Après le montage d’une plaquette-guide, tournez

toujours la toupie à l’envers et abaissez-en la base pour

vérifier si le fer est bien centré dans le collet. Sinon,

desserrez les trois vis de fixation de l’adaptateur pour

pouvoir le déplacer et centrer le fer dans le collet (fig. 9).

TOUPILLAGE À MAIN LEVÉE

On peut produire de nombreux effets spéciaux en

utilisant la toupie à main levée avec un fer de petit

diamètre. En général, l’artisan reproduit sur la pièce,

avec un crayon, le motif ou les lettres qu’il souhaite

découper, après quoi il suit le tracé ainsi préparé.

BASE

FER

VIS D’ALIGNEMENT DE PLAQUE ADAPTATRICE

ADAPTATEUR

PLAQUETTE

-GUIDE

FIG. 9

SM 2610995785 3/03 3/3/03 3:28 PM Page 20

Page 21

-21-

Accessoires

Entretien

L’entretien préventif

effectué par des employés

non autorisés peut entraîner un positionnement

erroné des composants et des fils internes, et ainsi

causer des dangers sévères. Il est recommandé que

l’entretien et la réparation de nos outils soient confiés

à un centre de service-usine Skil ou à un centre de

service après-vente Skil agréé.

GRAISSAGE DE L’OUTIL

Votre outil Skil a été convenablement graissé et est

prêt à utiliser. Il est recommandé que les outils à

engrenages soient regraissés avec une graisse

spéciale à l’occasion de tout remplacement de balais.

BALAIS DE CHARBON

Les balais et le collecteur de votre outil ont été conçus

pour donner plusieurs heures de fonctionnement sans

aléas. Pour maintenir le moteur en forme, nous

recommandons d’examiner les balais tous les deux à

six mois. Vous ne devriez utiliser que les balais de

rechange d’origine Skil qui conviennent spécialement

à votre outil.

ROULEMENTS

Après environ 300 à 400 heures d’utilisation, ou à tous

les deux remplacements des balais, il faudrait confier

le remplacement des roulements à un centre de

service-usine Skil ou à un centre de service aprèsvente Skil agréé. Les roulements qui sont devenus

bruyants (à cause de sciage de matériaux très abrasifs

ou de durs efforts) devraient être remplacés à l’instant

pour éviter la surchauffe et la défaillance du moteur.

Nettoyage

Pour éviter le risque

d’accidents, débranchez

toujours l’outil de la prise de courant avant de

procéder au nettoyage ou à l’entretien. Vous pouvez

très bien le nettoyer à l’air comprimé. Dans ce cas,

portez toujours des lunettes de sécurité.

Gardez les prises d’air et les interrupteurs propres et

libres de débris. N’essayez pas de les nettoyer en

introduisant des objets pointus dans leurs ouvertures.

Certains produits de

nettoyage et dissolvants

dont la gazoline, le tétrachlorure de carbone, les

nettoyeurs chlorés, l’ammoniaque et les détergents

ménagers contenant de l’ammoniaque peuvent

abîmer les pièces en plastique.

Maintenance

MISE EN GARDE

!

AVERTISSEMENT

!

AVERTISSEMENT

!

Si un cordon de rallonge

s'avère nécessaire, vous

devez utiliser un cordon avec conducteurs de

dimension adéquate pouvant porter le courant

nécessaire à votre outil. Ceci préviendra une chute

excessive de tension, une perte de courant ou une

surchauffe. Les outils mis à la terre doivent utiliser des

cordons de rallonge trifilaires pourvus de fiches à trois

broches ainsi que des prises à trois broches.

REMARQUE : Plus le calibre est petit, plus le fil est gros.

DIMENSIONS DE RALLONGES RECOMMANDÉES

OUTILS 120 VOLTS COURANT ALTERNATIF

AVERTISSEMENT

!

Intensité

nominale

de l’outil

Longueur en pieds

Longueur en mètres

3-6

6-8

8-10

10-12

12-16

18 16 16 14 .75 .75 1.5 2.5

18 16 14 12 .75 1.0 2.5 4.0

18 16 14 12 .75 1.0 2.5 4.0

16 16 14 12 1.0 2.5 4.0 —

14 12 — — — — — —

25 50 100 150 15 30 60 120

Calibre A.W.G.

Calibre en mm

2

(* = équipement standard)

(** = accessoire en option)

FERS

Pour la coupe en rapidité et en douceur, utilisez des fers

bien affûtés. Un fer émoussé ralentit la vitesse de coupe,

rend la coupe irrégulière, décolore ou brûle la pièce par

frottement excessif et surcharge le moteur.

RAMASSE-POUSSIÉRE POUR TOUPIE

(Non fournies, disponibles à titre d’accessoires)

Si votre atelier est équipé d’un système d’aspiration de la

poussière, vous auriez peut-être intérêt à vous procurer

la hotte aspirante Skil 91812, particulièrement pour le

toupillage à main levée.

SM 2610995785 3/03 3/3/03 3:28 PM Page 21

Page 22

-22-

Lea y entienda todas las instrucciones. El incumplimiento de todas las instrucciones

indicadas a continuación puede dar lugar a sacudidas eléctricas, incendios y/o lesiones

personales graves.

CONSERVE ESTAS INSTRUCCIONES

Area de trabajo

Mantenga el área de trabajo limpia y bien iluminada.

Las mesas desordenadas y las áreas oscuras invitan a

que se produzcan accidentes.

No utilice herramientas mecánicas en atmósferas

explosivas, tales como las existentes en presencia de

líquidos, gases o polvos inflamables. Las

herramientas mecánicas generan chispas y éstas

pueden dar lugar a la ignición del polvo o los vapores.

Mantenga a las personas que se encuentren

presentes, a los niños y a los visitantes alejados al

utilizar una herramienta mecánica. Las distracciones

pueden hacer que usted pierda el control.

Seguridad eléctrica

Las herramientas con aislamiento doble están

equipadas con un enchufe polarizado (un terminal es

más ancho que el otro). Este enchufe entrará en un

tomacorriente polarizado solamente de una manera.

Si el enchufe no entra por completo en el

tomacorriente, déle la vuelta. Si sigue sin entrar,

póngase en contacto con un electricista competente

para instalar un tomacorriente polarizado. No haga

ningún tipo de cambio en el enchufe. El aislamiento

doble elimina la necesidad del sistema de cordón de

energía de tres hilos conectado a tierra y la fuente de

energía conectada a tierra. Antes de enchufar la

herramienta, asegúrese de que la tensión del

tomacorriente suministrada se encuentre dentro del

margen de la tensión especificada en la placa del

fabricante. No utilice herramientas con capacidad

nominal "AC solamente" ("AC only") con una fuente de

energía DC.

Evite el contacto del cuerpo con las superficies

conectadas a tierra tales como tuberías, radiadores,

estufas de cocina y refrigeradores. Hay mayor riesgo

de que se produzcan sacudidas eléctricas si su cuerpo

está conectado a tierra. Si la utilización de la herramienta

mecánica en lugares húmedos es inevitable, se debe

usar un interruptor de circuito para fallos a tierra para

suministrar la energía a la herramienta. Los guantes de

goma para electricista y el calzado antideslizante

aumentarán más la seguridad personal.

No exponga las herramientas mecánicas a la lluvia ni

a situaciones húmedas. La entrada de agua en una

herramienta mecánica aumentará el riesgo de que se

produzcan sacudidas eléctricas.

No abuse del cordón. Nunca use el cordón para llevar las

herramientas ni para sacar el enchufe de un

tomacorriente. Mantenga el cordón alejado del calor, el

aceite, los bordes afilados o las piezas móviles. Cambie

los cordones dañados inmediatamente. Los cordones

dañados aumentan el riesgo de que se produzcan

sacudidas eléctricas.

Al utilizar una herramienta mecánica a la intemperie,

utilice un cordón de extensión para intemperie

marcado "W-A" o "W". Estos cordones tienen capacidad

nominal para uso a la intemperie y reducen el riesgo de

que se produzcan sacudidas eléctricas. Consulte

"Tamaños recomendados de los cordones de extensión"

en la sección Accesorios de este manual.

Seguridad personal

Manténgase alerta, fíjese en lo que está haciendo y

use el sentido común cuando utilice una herramienta

mecánica. No use la herramienta cuando esté

cansado o se encuentre bajo la influencia de drogas,

alcohol o medicamentos. Un momento de distracción

al utilizar herramientas mecánicas puede dar lugar a

lesiones personales graves.

Vístase adecuadamente. No se ponga ropa holgada ni

joyas. Sujétese el pelo. Mantenga el pelo, la ropa y

los guantes alejados de las piezas móviles. La ropa

holgada, las joyas o el pelo largo pueden quedar

atrapados en las piezas móviles. Mantenga los mangos

secos, limpios y libres de aceite y grasa.

Evite el arranque accidental. Asegúrese de que el

interruptor esté en la posición "OFF" (apagado) antes

de enchufar la herramienta. El llevar las herramientas

con el dedo en el interruptor o el enchufar herramientas

que tengan el interruptor en la posición "ON" (encendido)

invita a que se produzcan accidentes.

Quite las llaves de ajuste o de tuerca antes de

encender la herramienta. Una llave de ajuste o de

tuerca que se deje puesta en una pieza giratoria de la

herramienta puede ocasionar lesiones personales.

No intente alcanzar demasiado lejos. Mantenga un

apoyo de los pies y un equilibrio adecuados en todo

momento. El apoyo de los pies y el equilibrio adecuados

permiten un mejor control de la herramienta en

situaciones inesperadas.

Utilice equipo de seguridad. Use siempre protección

de los ojos. Se debe utilizar una máscara antipolvo,

zapatos de seguridad antideslizantes, casco o protección

de los oídos según lo requieran las condiciones.

Utilización y cuidado de las herramientas

Utilice abrazaderas u otro modo práctico de fijar y

soportar la pieza de trabajo a una plataforma estable.

ADVERTENCIA

!

Normas de seguridad para herramientas mecánicas

SM 2610995785 3/03 3/3/03 3:28 PM Page 22

Page 23

-23-

La sujeción de la pieza de trabajo con la mano o contra

el cuerpo resulta inestable y puede ocasionar pérdida de

control.

No fuerce la herramienta. Use la herramienta correcta

para la aplicación que desea. La herramienta correcta

hará el trabajo mejor y con más seguridad a la capacidad

nominal para la que está diseñada.

No utilice la herramienta si el interruptor no la

enciende o apaga. Toda herramienta que no se pueda

controlar con el interruptor es peligrosa y debe ser

reparada.

Desconecte el enchufe de la fuente de energía antes

de hacer cualquier ajuste, cambiar accesorios o

guardar la herramienta. Estas medidas de seguridad

preventivas reducen el riesgo de arrancar la herramienta

accidentalmente.

Guarde las herramientas que no esté usando fuera del

alcance de los niños y otras personas no capacitadas.

Las herramientas son peligrosas en las manos de los

usuarios no capacitados.

Mantenga las herramientas con cuidado. Conserve las

herramientas de corte afiladas y limpias. Las

herramientas mantenidas adecuadamente, con bordes

de corte afilados, tienen menos probabilidades de

atascarse y son más fáciles de controlar. Toda alteración

o modificación constituye un uso incorrecto y puede

tener como resultado una situación peligrosa.

Compruebe la desalineación o el atasco de las piezas

móviles, la ruptura de piezas y cualquier otra

situación que pueda afectar el funcionamiento de las

herramientas. Si la herramienta está dañada, haga

que realicen un servicio de ajustes y reparaciones a la

herramienta antes de usarla. Muchos accidentes son

causados por herramientas mantenidas

deficientemente. Establezca un programa de

mantenimiento periódico para la herramienta.

Utilice únicamente accesorios que estén

recomendados por el fabricante de su modelo. Los

accesorios que pueden ser adecuados para una

herramienta pueden volverse peligrosos cuando se

utilizan en otra herramienta.

Servicio

El servicio de ajustes y reparaciones de una

herramienta debe ser realizado únicamente por

personal de reparaciones competente. El servicio o

mantenimiento realizado por personal no competente

podría ocasionar un peligro de que se produzcan

lesiones. Por ejemplo: Los cables internos pueden

colocarse mal o pellizcarse, los resortes de retorno de

los protectores de seguridad pueden montarse

inadecuadamente.

Al realizar servicio de ajustes y reparaciones de una

herramienta, utilice únicamente piezas de repuesto

idénticas. Siga las instrucciones que aparecen en la

sección Mantenimiento de este manual. El uso de

piezas no autorizadas o el incumplimiento de las

instrucciones de Mantenimiento puede ocasionar un

peligro de que se produzcan sacudidas eléctricas o

lesiones. Ciertos agentes de limpieza, tales como

gasolina, tetracloruro de carbono, amoníaco, etc.,

pueden dañar las piezas de plástico.

Sujete siempre la herramienta por las superficies de

agarre aisladas al realizar una operación en la que la

herramienta de corte pueda entrar en contacto con

cables ocultos o con su propio cordón. El contacto con

un cable con corriente transmitirá corriente a las piezas

metálicas al descubierto y hará que el operador reciba

sacudidas eléctricas. Si el corte en paredes existentes u

otras áreas ciegas donde puedan existir cables

eléctricos es inevitable, desconecte todos los fusibles o

cortacircuitos que alimentan el lugar de trabajo.

Asegúrese siempre de que la superficie de trabajo no

tenga clavos ni otros objetos extraños. El corte de un

clavo puede hacer que la broca y la herramienta salten y

que la broca se dañe.

Nunca tenga la pieza de trabajo en una mano y la

herramienta en la otra al utilizarla. Nunca ponga las

manos cerca o debajo de la superficie de corte. Es

más seguro fijar con abrazaderas el material y guiar la

herramienta con ambas manos.

Nunca ponga la pieza de trabajo sobre superficies

duras, tales como hormigón, piedra, etc... la broca de

corte que sobresale podrá hacer que la herramienta

salte.

Use siempre gafas de seguridad y máscara antipolvo.

Use la herramienta únicamente en un área bien

ventilada. La utilización de dispositivos de seguridad

personal y el trabajar en un entorno seguro reducen el

riesgo de que se produzcan lesiones.

Después de cambiar las brocas o de hacer ajustes,

asegúrese de que la tuerca del portaherramienta y

otros dispositivos de ajuste estén apretados

firmemente. Un dispositivo de ajuste flojo puede

desplazarse inesperadamente, causando pérdida de

control, y los componentes giratorios flojos saldrán

despedidos violentamente.

Nunca arranque la herramienta cuando la broca esté

acoplada en el material. El borde de corte de la broca

puede engancharse en el material, causando pérdida de

Normas de seguridad para fresadoras

SM 2610995785 3/03 3/3/03 3:28 PM Page 23

Page 24

control de la cortadora. Sujete siempre la herramienta

con las dos manos durante el arranque. El par de

reacción del motor puede hacer que la herramienta se

tuerza.

Al fresar o cortar, el sentido de avance con el borde

de corte de la broca hacia el interior del material es

muy importante. Haga avanzar siempre la broca

hacia el interior del material en el mismo sentido en

que el borde de corte esté saliendo del material (que

es el mismo sentido en que se lanzan las virutas).

NOTA: Los cortes interiores y exteriores requerirán un

sentido de avance distinto; consulte la sección sobre

avance de la fresadora. El hacer avanzar la herramienta

en sentido incorrecto hace que el borde de corte de la

broca se salga de la pieza de trabajo y tire de la

herramienta en el sentido de este avance.

Nunca use brocas desafiladas o dañadas. Las brocas

afiladas se deben manejar con cuidado. Las brocas

dañadas pueden romperse bruscamente durante el uso.

Las brocas desafiladas requieren más fuerza para

empujar la herramienta, con lo que es posible que la

broca se rompa.

Nunca toque la broca durante ni inmediatamente

después de la utilización. Después del uso, la broca

está demasiado caliente como para tocarla con las

manos desnudas.

Nunca deje la herramienta hasta que el motor se haya

detenido por completo. La broca que gira puede

engancharse en la superficie y tirar de la herramienta

haciendo que usted pierda el control.

Nunca utilice brocas que tengan un diámetro de corte

mayor que la abertura de la base.

Cierto polvo generado por el

lijado, aserrado, amolado y

taladrado mecánicos, y por otras actividades de

construcción, contiene agentes químicos que se sabe

que causan cáncer, defectos de nacimiento u otros

daños sobre la reproducción. Algunos ejemplos de

estos agentes químicos son:

• Plomo de pinturas a base de plomo,

• Sílice cristalina de ladrillos y cemento y otros

productos de mampostería, y

• Arsénico y cromo de madera tratada químicamente.

Su riesgo por causa de estas exposiciones varía,

dependiendo de con cuánta frecuencia realice este tipo

de trabajo. Para reducir su exposición a estos agentes

químicos: trabaje en un área bien ventilada y trabaje con

equipo de seguridad aprobado, como por ejemplo

máscaras antipolvo que estén diseñadas especialmente

para impedir mediante filtración el paso de partículas

microscópicas.

-24-

ADVERTENCIA

!

SM 2610995785 3/03 3/3/03 3:28 PM Page 24

Page 25

-25-

Símbolos

Importante: Es posible que algunos de los símbolos siguientes se usen en su herramienta. Por favor,

estúdielos y aprenda su significado. La interpretación adecuada de estos símbolos le permitirá utilizar la

herramienta mejor y con más seguridad.

Símbolo Nombre Designación/explicación

V Volt Tensión (potencial)

A Ampere Corriente

Hz Hertz Frecuencia (ciclos por segundo)

W Watt Potencia

kg Kilogramo Peso

min Minuto Tiempo

s Segundo Tiempo

Diámetro Tamaño de las brocas taladradoras,

muelas, etc.,

n

0

Velocidad sin carga Velocidad rotacional sin carga

.../min Revoluciones o alternación por minuto Revoluciones, golpes, velocidad de

superficie, órbitas, etc., por minuto

0 Posición "off" (apagado) Velocidad cero, par motor cero...

1, 2, 3, ... Graduaciones del selector Graduaciones de velocidad, par motor o

I, II, III, posición. Un número más alto significa

mayor velocidadselector settings

Selector infinitamente variable con La velocidad aumenta desde la

apagado graduación de 0

Flecha Acción en la dirección de la flecha

Corriente alterna Tipo o una característica de corriente

Corriente continua Tipo o una característica de corriente

Corriente alterna o continua Tipo o una característica de corriente

Construcción de clase II Designa las herramientas de construcción

con aislamiento doble.

Terminal de toma de tierra Terminal de conexión a tierra

Símbolo de advertencia Alerta al usuario sobre mensajes de

advertencia

Sello RBRCTM de Ni-Cd Designa el programa de reciclaje de baterías

de Ni-Cd

0

Este símbolo indica que esta

herramienta está catalogada

por Underwriters

Laboratories.

Este símbolo indica que esta

herramienta está catalogada

por la Canadian Standards

Association.

Este símbolo indica que

Underwriters Laboratories ha

catalogado esta herramienta

indicando que cumple las

normas canadienses.

Este símbolo

indica que esta

herramienta

cumple con la

norma mexicana

oficial (NOM).

Este símbolo indica que esta

herramienta está catalogada por

Underwriters Laboratories y que

Underwriters Laboratories la ha