Page 1

Operating Instructions

Tel: 724-941-9701 Fax: 724-941-1369 e-mail: skctech@skcinc.com

863 Valley View Road, Eighty Four, PA 15330 USA

Button Aerosol Sampler

Catalog No. 225-360

The patented* SKC Button Aerosol Sampler is a

reusable fi lter sampler with a porous curved-surface

sampling inlet designed to improve the collection

characteristics of inhalable dust (< 100 μm aerodynamic

diameter

viable analysis.

While closely following the ACGIH/ISO sampling

criteria for inhalable particulate mass at 4 L/min, the

Bu on Sampler's design also minimizes wind sensitivity, provides equal distribution

of particle loading and low intersample variation, and can be used in any orientation.

Sample analysis for inhalable dust is performed gravimetrically using NIOSH

Method 0500. Metals can be analyzed using direct-reading techniques (e.g.,

NIOSH Method 7702). Fungal spore analysis includes microscopy, immunoassay,

or polymerase chain reaction (PCR).

† Very large particles (> 100 μm) are thought to be less inhalable, but may enter the inlets of

†

) including bioaerosols for viable or non-

SKC Button Aerosol

some samplers by projection or sedimentation. The Bu on Aerosol Sampler design minimizes

collection of these particles.

Sampler

Performance Profi le

Flow Rate: 4 L/min

The Bu on Sampler closely follows the ACGIH/ISO inhalability

Construction: Sampling inlet: conductive stainless steel

Body: aluminum

Support screen: stainless steel

Clip: stainless steel and nylon

O-rings: PTFE (inlet) and BUNA-N (body)

Filters: 25 mm select as specifi ed by the method

Analysis: Inhalable dust: Gravimetric (GR)

Fungal spores: Epifl uorescence microscopy, immunoassay, or

Metals: X-ray Fluorescence (XRF)

Autoclavable: Up to approximately 273.2 F (134 C)

Tubing: 1/4-inch ID

* U.S. Patent Nos. 5,954,845 and 5,958,111

curve at 4 L/min. This provides optimum sampling. Sampling

effi ciency is maintained within ± 30% at fl ows ranging from

2 to 5 L/min.

polymerase chain reaction (PCR)

Page 2

Operation

Wear gloves and use forceps when handling fi lters.

1. For gravimetric sampling, condition and weigh a 25-mm fi lter according to

method used.

2. Unscrew the inlet of the sampler counterclockwise until it comes off and

remove the PTFE O-ring.

3. Place the 25-mm fi lter on top of the support screen inside the sampler.

Note: Representative fi lters used for calibration do not require conditioning and

weighing.

4. Place the PTFE O-ring on top of the fi lter.

5. Replace the inlet and very gently turn clockwise until moderately tight.

Caution: Excessive tightening of the inlet section can twist and tear the fi lter.

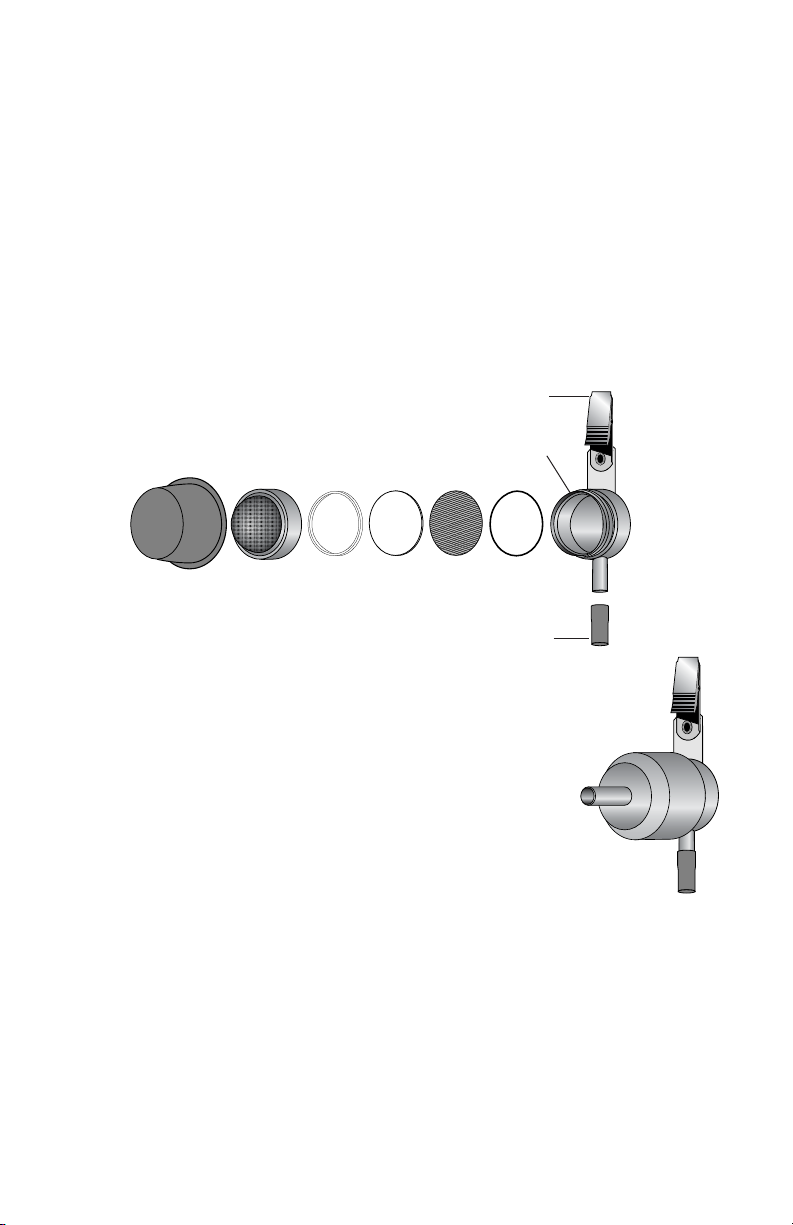

Collar Clip

Body

Cap

Inlet

Section

PTFE

O-ring

Filter

Support

Screen

BUNA-N

O-ring

Outlet Plug

Calibration

1. Ensure pump had run for 5 minutes before calibrating.

2. Using fl exible tubing, connect the outlet of the

Bu on Sampler to the inlet of a sampling pump.

3. Place the calibration adapter outlet onto the Bu on

Sampler inlet, and connect the calibration adapter

inlet to a primary standard calibrator.

4. Calibrate to 4 L/min following the instructions in the

pump and calibrator operating instructions.

5. Disconnect the calibrator and calibration adapter.

Replace the fi lter used to set the fl ow with a fresh

Button Sampler

with Calibration

Adapter

conditioned and weighed fi lter for sample collection.

Note: If using the Bu on Sampler with protective shield for abrasive blasting

sampling, calibrate the Bu on Sampler without shield using the Calibration

Adapter. Following calibration, push shield onto sampler inlet and sample.

Sampling

1. Ensure the fl ow rate has been calibrated (see Calibration).

2. Using fl exible tubing, connect the outlet of the Bu on Sampler to the inlet of

a sampling pump such as an AirChek

3. For personal sampling, clip the Bu on Sampler onto a worker’s collar or

pocket near the breathing zone. Clip the pump onto the worker’s belt or

place it in a protective pouch. Start the pump and record the start time,

worker location, and fl ow rate.

®

XR5000 Sampler.

Page 3

4. For area sampling, position the Bu on Sampler to avoid cross-dra s and

direct projection of the particles into the inlet.

5. At the end of the sampling period, stop the pump and record the stop time.

Sample Shipment

1. When sampling is complete, very gently unscrew the sampler inlet and use

forceps to remove the PTFE O-ring.

2. Using forceps, carefully remove the fi lter from the sampler.

3. Package for shipment as directed by the method or laboratory.

4. Ship samples with pertinent sampling information to an accredited laboratory

for analysis.

Analysis

Dependent upon the hazard of interest, samples taken with the Bu on Sampler

can be analyzed using gravimetric analysis, analytical techniques such as x-ray

fl uorescence, atomic absorption (AA), or inductively coupled plasma (ICP).

Growth culture, microscopy, and other assays may be used for the determination

of fungal spores, endotoxin, and bacteria.

If gravimetric analysis is used, weigh the fi lter and subtract the preweight from the

postweight. The net weight will be the dust collected.

Using the Button Sampler as an Abrasive Blasting

Sampler for Heavy Metals

SKC has designed a protective shield for the Bu on Sampler for use when sampling

in abrasive blasting environments. The shield protects the fi lter from shredding

or being overloaded by large particles thrust onto the sampler during

blasting. Tested by the U.S. Military during recent abrasive blasting operations, the

Bu on Sampler with protective shield (Abrasive Blasting Sampler for Heavy

Metals) withstood very high particle concentrations and provided recoverable

samples and meaningful exposure information. The shield is very easy to use,

simply push it onto the sampler inlet and sample (see Sampling).

‡ The Bu on Sampler with shield is not suitable for sampling silica. While silica is commonly found in

abrasive blasting environments, sampling for silica using OSHA Method ID 142 requires a cyclone.

‡

Using the Button Sampler to collect Inhalable

Bioaerosols

The patented SKC Bu on Aerosol Sampler provides superior collection of

inhalable particles including bacteria and fungal spores. Use the Bu on Sampler

with a 25-mm membrane fi lter such as MCE or PVC to collect bioaerosols for

viable or non-viable analysis. Using SKC gelatin fi lters with the Bu on Sampler

increases the survival of stress-sensitive microorganisms during sampling. The

Bu on Sampler is used with a sample pump capable of 4 L/min for personal

inhalable particulate sampling following the ACGIH/ISO criteria.

Note: Gelatin fi lters dissolve when placed on agar.

Page 4

Cleaning

Using mild soapy water, clean all parts of the Bu on Sampler before further sam-

pling. The Bu on Sampler can be brushed and/or wiped with a clean dust-free

tissue, air dried, blown dry, or wiped with isopropyl alcohol. Take particular care

in cleaning the PTFE O-ring.

The Bu on Sampler may also be autoclaved up to approximately 273.2 F (134 C).

Prepare the Bu on Sampler before autoclaving by removing the collar clip from

the sampler using a Phillips head screwdriver. Also remove the BUNA-N O-ring

from the sampler body (see page 2 for exploded view of sampler).

References

Kalatoor, S., Grinshpun, S., Willeke, K., “New Aerosol Sampler with Low Wind Sensitivity and Good Filter

Collection Uniformity,” Atmospheric Environment, Vol. 29, No. 10 (1995), pp. 1105-1112

Hauck, B., Grinshpun, S., Reponen, A., Reponen, T., Willeke, K., Bornschein, R., “Field Testing of New

Aerosol Sampling Method With a Porous Curved Surface as Inlet,” American Industrial Hygiene Association

Journal, Vol. 58, No. 10 (1997), pp. 713-719

Aizenberg, V., England, A., Grinshpun, S., Willeke, K., Carlton, G., “Metal Exposures Among Abrasive

Blasting Workers at Four U.S. Air Force Facilities,” Applied Occupational and Environmental Hygiene,

Vol. 15, No. 10 (2000), pp. 766-772

Aizenberg, V., Grinshpun, S., Willeke, K., Smith, J., Baron, P.A., “Performance Characteristics of the Bu on

Personal Inhalable Aerosol Sampler,” AIHA Journal, Vol. 61, May/June 2000, pp. 398-404

Optional Accessories

Description Cat. No.

Button Sampler, requires a 25-mm fi lter 225-360

Button Sampler Pump Kit includes Button Sampler, standard

XR5000 Sample Pump, single charger with cable, 3 feet of

Tygon tubing, and calibration adapter, requires a 25-mm fi lter 100-240 V

Abrasive Blasting Kit includes Button Sampler and protective

shield, requires a 25-mm fi lter 225-367

Button Sampler Calibration Adapter 225-361

Protective Shield, for abrasive blasting environments 225-366

Filter Transport Case, for 25-mm fi lters, conductive plastic 225-67

Replacement O-ring, PTFE P32265

210-4121

Filters (25 mm)

Glass fi ber, 1.0 μm, pk/500 225-702

PTFE with PMP support (Tefl o

Polyvinyl chloride (PVC), 5.0 μm, pk/100 225-8-04

Mixed cellulose ester (MCE), 1.2 μm, pk/100 225-1912

Gelatin,

∆ A pore size of 1.0 μm or larger is recommended for use with the Bu on Sampler due to back pressure

limitations of personal samplers.

∞

Back pressure on PTFE fi lters can vary within the same lot.

# Gelatin fi lters dissolve when placed on agar.

** Maximum operating temperature for the Cat. No. 225-1711 PTFE fi lter with PMP support is

464 F (240 C) based on the PMP support ring.

∆

®

∞**

),

3.0 μm, pk/50 225-1711

#

sterilized, pk/50 225-9551

Cat. No.

SKC Limited Warranty and Return Policy

SKC products are subject to the SKC Limited Warranty and Return Policy, which

provides SKC’s sole liability and the buyer’s exclusive remedy. To view the complete SKC Limited Warranty and Return Policy, go to h p://www.skcinc.com/

warranty.asp.

Form 3780 Rev 1303

Loading...

Loading...