Page 1

- 1 -

SVS-560CF

OPERATIONS MANUAL

Page 2

- 2 -

This manual uses the following symbols for easy understanding safety instructions. Always

follow these instructions carefully.

WARNING

Always follow this safety instruction to prevent death or

injury.

CAUTION

Follow this safety instruction to avoid possible injury or

damage to your property.

Symbol “△” is a CAUTION or WARNING label indicating the

safety instruction.

WARNING

This symbol is an Electrical Shock WARNING label.

Symbol is an instruction that you must not violate.

(This symbol instructs NOT to disassemble the system

components)

Symbol is an operation instruction that you must follow.

(This symbol shows the main power OFF instruction.)

Page 3

- 3 -

WARNING <For System Operators>

Always follow this instruction to prevent death or personal injury.

Turn power

off

During

abnormality.

If smoke or a small of burning occurs, a fire or an electrical

short circuit may result. Turn the power switch OFF and

shut down the power supply immediately. Never try to

repair the system yourself. Call for service.

Do not open

Cabinet.

High voltage exists in the instrument. Contact with voltage

may cause possible injury or death.

Do not touch

back

side of the

equipment.

Harmful line voltage is present on back side of the

equipment. Never try to touch back side while power is

turned on.

Avoid

excessive

shock

to display

unit.

The LCD display module contains a liquid. Do not apply

any mechanical shock to the display. If the display broken,

liquid may leak and injure your skin and eyes.

Do not use

with poor

ventilation.

If you cover this unit or use in an enclosed place, it may

malfunction or become damaged as a result of overheating.

Use only where there is sufficient ventilation.

Page 4

- 4 -

Installation Cautions <For service Personnel>

Follow installation instructions to avoid personal injury and system malfunction.

Installation in

rigid location.

Mount your SVS-560/460 on a rigid frame or base to prevent your unit

from working loose.

Use correct

Installation

materials.

Use the installation materials provided in the standard accessory pack

only. If you use hardware of insufficient strength, your system may

loosen causing damaged.

Keep away from

direct sunlight.

Keep your system out of direct sunlight as it may become damaged by

overheating.

Keep away from

water.

Take care not to get water on or in your unit as it may be damaged

and/or cause an electrical shock.

Keep away from

heat source.

Keep your system away from other heat source as it may malfunction,

be damaged, or burn.

Use correct

power source.

Operate your system within the specified power voltage. An incorrect

power supply may cause

Page 5

- 5 -

Maintenance Cautions<For Maintenance Personnel>

Use the following safety precaution internal inspection.

Discharge

capacitors.

High voltage may be retained in the capacitors if the high-tension

circuit several minutes after you have turned the power switch off.

Check that

power is OFF

To prevent an electrical injury due to erroneous power switching, make

sure that the main power supply and the system power switch are both

in the off position. Additionally, attach a safety label showing that

service is in progress.

Avoid EMI.

Take care not to damage the ESDs (Electrostatic Sensitive Devices)

by static electricity from carpet and cloths.

Avoid dust.

Wear a safety mask so as not to breath in dust during inspection or

cleaning inside your system instruments.

Page 6

- 6 -

Operation Notes <For operators>

Observe the following operation notes, otherwise the system failure or deterioration can result. And

periodical inspection and maintenance are required for keeping the system in an optimum condition.

Backup important

data.

The waypoint and other registered data may become

unreadable by unexpected failure. We recommend recording

this data separately.

Use correct

transducer only.

If you use incorrect transducer, the transmitter circuit may be

damaged due to a matching error. Consult is for system

information.

Check transducer

Connection before

power on

Do not turn the power switch ON if the transducer is

disconnected or if it is not inserted into the water. If done,

the transducer or transmitter circuit may be damaged.

Always clean the

transducer

Since transducer performance can drop due to accumulated

bottom growth, keep the transducer clean. Never paint

transducer surface.

Transducer must

be installed by

authorized

personnel.

Consult us for transducer installation by authorized

personnel.

WARNING

This product is designed to assist a navigation.

When you are sailing, use the certified chart from the

Government or IMO.

Page 7

- 7 -

SVS-560/460 Series

CAUTION

The SVS-560/460 Series Color LCD Chartplotter & Fishfider Systems employs the latest in proven

technology to provide accurate fish & bottom information. The Plotter functions of SVS-560/460 series

are totally dependent upon the capability of the navigation source to provide accurate position

information. This device is only an aid to navigation. It should be used in conjunction with all other

navigation accuracy. For safety, always resolve any uncertainty before continuing navigation.

There is no direct relationship between the color of water areas and their depth. The navigator shall

always query the area for depth information and use the official paper chart.

CAUTION

The performance of LCD displays are degraded by continuous direct exposure to ultraviolet rays.

Locate your SVS-560/460 series Display away from direct sunlight. When not in use. Keep the display

covered.

DISPLAY BREAKAGE WARNING

The LCD display module contains a liquid. If the display is broken and the liquid contacts your skin,

wash it off immediately in running water for 15 minutes. If the liquid contacts your eyes, immediately

flush your eyes with running water for 15 minutes. Contact a physician if any abnormal symptom is

experienced.

INDICATION NOTICE

*: It is important or warning notice on front of article

#: It is only functions for the SVS-560CF/SVS-460CF on front of

article.

[ ]: Keyboard.

Page 8

- 8 -

SVS-560/460 series Introduction

Fix Text Below, so that Words Do Not Separated Strangely at End of each Line.

For centuries, sailors have been searching for a reliable and precise method of travelling the world’s

waterways. From celestial navigating to the modern navigation techniques as Loran, Decca navigator,

Omega or Transit Satnav, each system has had its problems with weather, range and reliability.

Without doubt, the “Global Positioning System”, or GPS for short, is the most significant advance in

navigation: it provides the navigator a position 24 hours a day, 365 days a year in any weather

condition. GPS is a satellite based navigation system which provides suitably equipped users with

accurate position, velocity and time data. Originally the GPS, developed by the U.S. Department of

Defense, was conceived for military purposes, but now it is used in a host of civilian applications.

GPS navigation uses satellite signals to determine your position in relation to a set of satellites orbiting

the earth. The GPS constellation of satellites continuously sends radio signals, containing the precise

position for each satellite back to earth. By knowing the position of 3 or 4 satellites and calculating

various time differences between transmitted signals, the GPS receiver can determine its present

position anywhere on earth, and thanks to continuous updates, calculate speed and course

information.

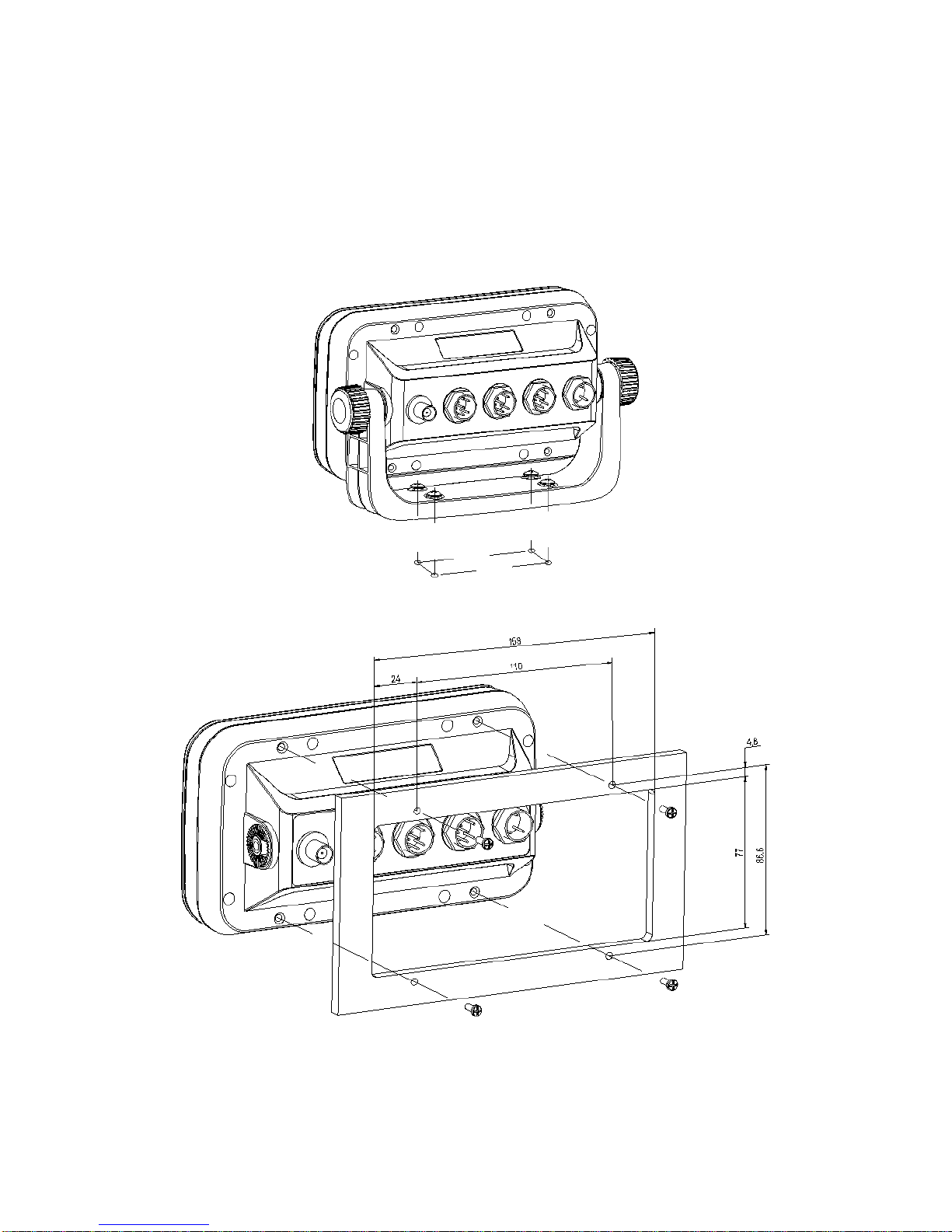

Display Unit Installation

Temporarily install the mounting bracket on the Genesis display unit and place the unit at the selected

location.

CAUTION

The Smart4/5 series display unit is unstable when the mounting bracket is not secured. Hold the unit in

place at all times.

Check the suitability of the location and make any adjustments. When all is satisfactory, use the holes

in the mounting bracket as a guide and mark the holes locations on the mounting surface.

Drill a 1/4 in. diameter hole at each marked location. Mount the Smart4/5 series display bracket using

Page 9

- 9 -

bolts through the mounting surface. Place large flat washers on the opposite side of the mounting

surface from the bracket and then install lock washers and nuts. Tighten securely.

Install the display unit into the mounting bracket. Check alignment and operation of the pivots and

security of the mounting. Make any adjustments necessary to prevent binding and assure even

meshing of the pivot locking washers. It is advised to remove the display unit and store it in a safe

place to prevent damage during the rest of the installation process.

Page 10

- 10 -

SVS-560/460 series Introduction

HOW GPS WORKS

Currently, the GPS constellation consists of 26 orbiting satellites (including 3 spares), but this number

will increase in the future.

The GPS receiver computes an accurate position by calculating the distance to the GPS satellites that

orbit the earth. Signals are required from 3 satellites for two dimensional (2D) position calculation

whilst 4 satellites are required for three dimensional (3D) position calculation.

As mentioned earlier, GPS satellites are not geostationary, but they are orbiting the earth as illustrated

on the following figure:

[The GPS constellation]

Note that position is repeatedly fixed through the following three steps while any 3 satellites are in line

of sight.

The position calculation procedure is indicated in the following three steps:

1. GPS satellites continuously transmit their own precise orbital data and the GPS receiver computes

their locations by receiving this data.

2. In this receiving process, the GPS receiver measures very accurate distances to the satellites, using

the "Spread Spectrum Modulation" method. Excellence in GPS's position-fixing accuracy is mainly due

to this technology.

3. When the satellite locations and their distances are known, the GPS receiver fixes its own position

by triangulation:

Page 11

- 11 -

SVS-560/460 series Introduction

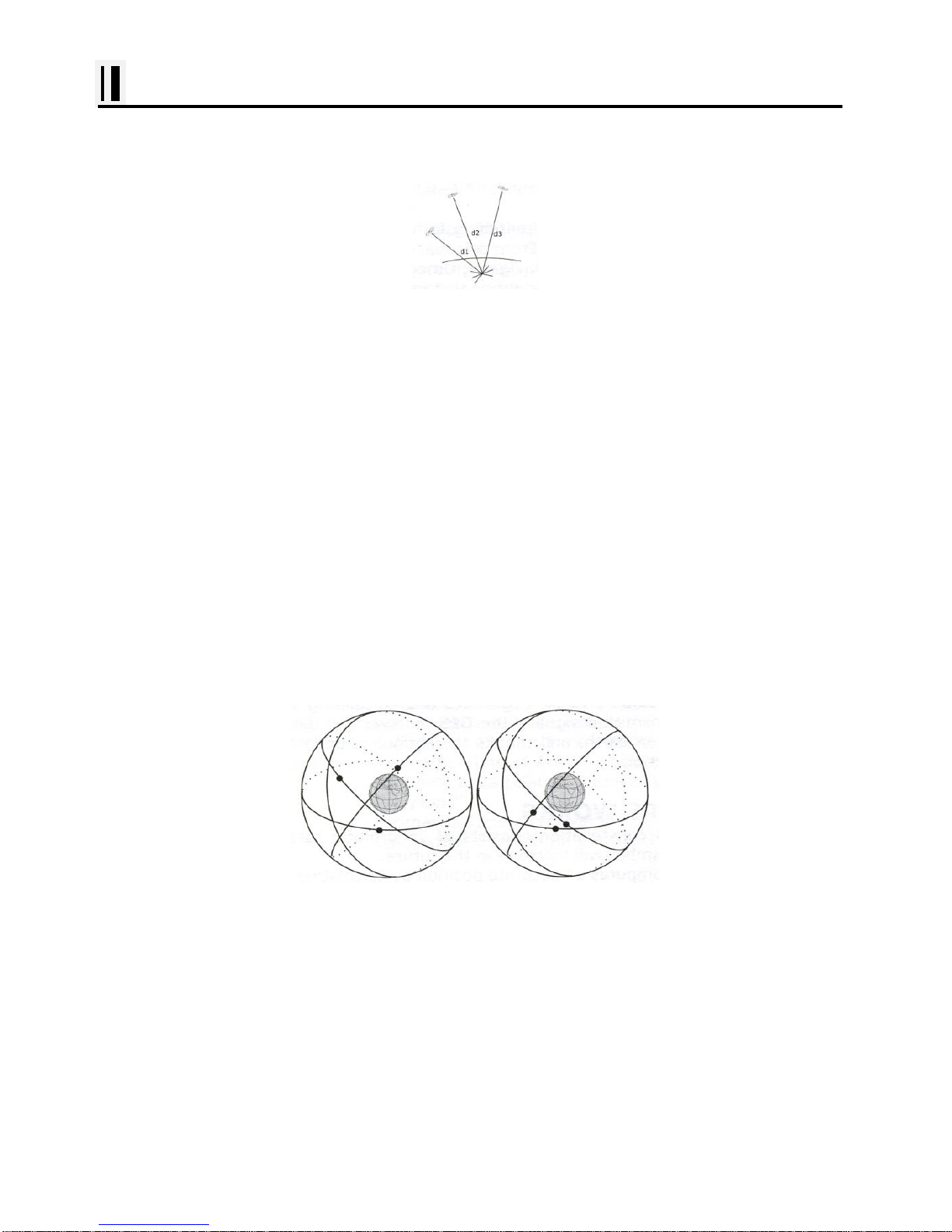

[The GPS position calculation]

As illustrated in the previous figure, the position is calculated as the meeting point of three

spheres, which are drawn around the three satellites with diameters d1, d2 and d3.

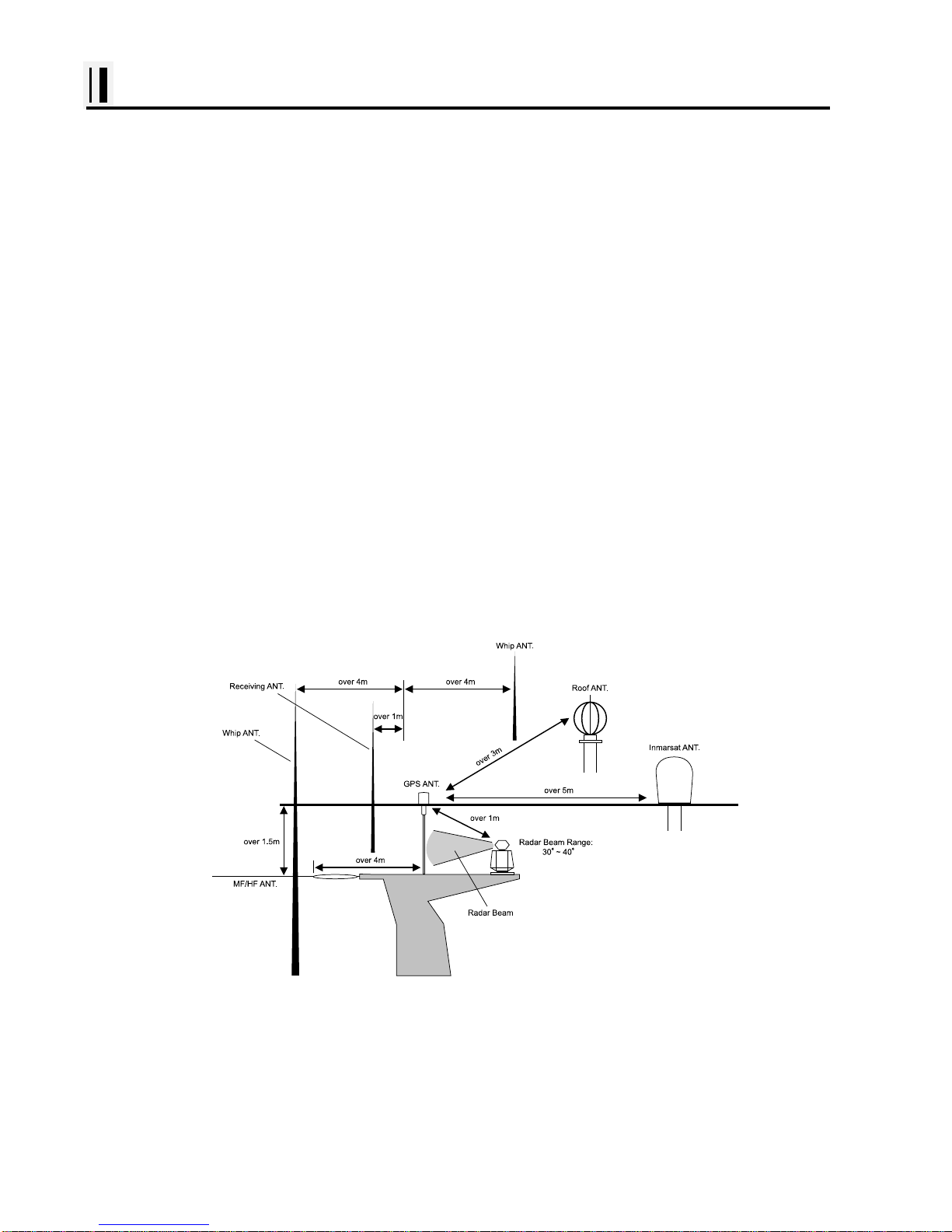

Position Fixing Accuracy: HDOP

The GPS fix accuracy is due to the locations of 3 satellites in the sky. High accuracy is obtainable

when the satellites are widely scattered in the sky; on the

contrary, accuracy is reduced when the satellites have gathered in a narrow space. In the following

figure, in both cases it is possible to obtain the GPS fix, but in the left case the accuracy will be higher

than the right:

[HDOP]

The index for position-fixing accuracy is called HDOP ("Horizontal Dilution Of Precision"). The smaller

the HDOP value, the more accurately the position can be fixed.

Page 12

- 12 -

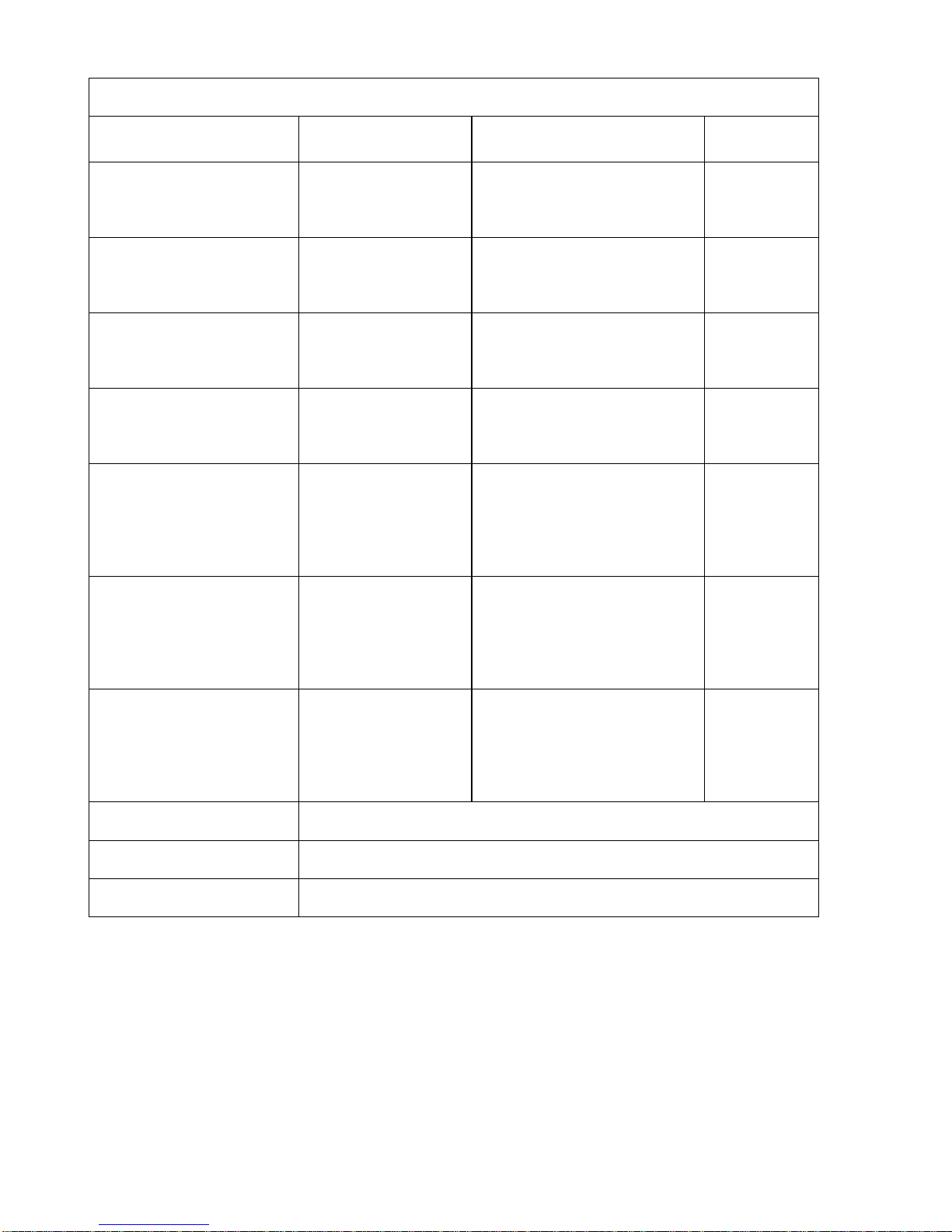

Installation of GPS ANTENA

The installation of the GPS ANTENNA.

The GPS ANT must be installed at the highest area of the boat and the easiest place to receive the

signal from the satellites. If there are obstacles around the GPS ANT, it isn't able to receive all signals.

The receiving time could be longer or the receiving power would be weaker. Please, follow the

instruction for your installation.

1. Keep from a metal.

2. Over 4m away from a MF/HF ANT, VHF or HF whip ANT.

3. Over 1.5m higher than MF/HF ANT.

4. Over 1m away from a receiving ANT.

5. Don't put the GPS ANT into the range of radar's beam. (Range: 30°~40°)

6. Over 1m away from the scanner of the radar.

7. Over 5m away from the ANT of the Inmarsat.

8. Over 3m away form the ANT of the roof.

9. Over 2m away from the engine.

10. Over 0.5m away from the metal surface.

※Warning: Not less than 0.5m away from the metal surface.

If the environment can't be satisfied from 1 to 10, have NO. 10 satisfied and consider the others.

Page 13

- 13 -

SVS-560/460 series Introduction

#Fishfinder - How it works-

The SVS-560/460CF echo sounder consists of a transceiver display unit and a dual frequency

transducer. An electronic signal pulse is generated in the transmitter section of the display unit.

When coupled to the transducer, this signal is converted into an ultrasonic signal and is transmitted

toward the bottom. The signal travels through the water until it strikes an object or the bottom. It is

reflected back , hits the transducer surface, and is reconverted into an electronic signal by the

transducer. Then it is amplified in the receiver section, processed in the main logic section, and

displayed, as an image on a LCD screen. (Picture 3)

When your boat travels from point A to point B as shown in Picture 1, the beam of the transducer

installed on your boat shown a cross-sectional view in the water.

Picture 2 indicates a cutaway view under the water when your boat moves from A to point B.

The screen shows the latest scan data at its right position. After the next

scan, the previous data is moved to the left and the latest scan data is

shown at the right position. When your boat moves from point A to point

B, the screen shows the scan data as shown in Picture 3.

Page 14

- 14 -

Installation of the Transducer

A careful installation will assure maximum performance from your new SVS-560/460

series.

Display Unit Location

Select a location for your Display unit that provides easy viewing from all likely operator’s positions.

The display unit is designed to be mounted on either a console or from an overhead surface. The

Display unit is also designed for flush mounting using six threaded holes on the rear panel. Locate the

display in an area with protection from the elements and avoid direct sunlight on the viewing window.

Also, consider access to the rear panel of the unit for connecting power and cables to the various

remote sensors. The mounting surface must be flat and solid to support the unit and prevent vibration.

There should be access to the inside of the surface to permit through bolt fastening for the mounting

bracket.

Display Unit Installation

Temporarily install the mounting bracket on the SVS-560/460 series display unit and place the unit at

the selected location.

CAUTION

The Display unit is unstable when the mounting bracket is not secured. Hold the unit in place

at all times.

Check the suitability of the location and make any adjustments. When all is satisfactory, use the holes

in the mounting bracket as a guide and mark the holes locations on the mounting surface.

Page 15

- 15 -

Installation of the Transducer

Drill a 1/4 in. diameter hole at each marked location. Mount the Display unit bracket using bolts

through the mounting surface. Place large flat washers on the opposite side of the mounting surface

from the bracket and then install lock washers and nuts. Tighten securely.

Install the display unit into the mounting bracket. Check alignment and operation of the pivots and

security of the mounting. Make any adjustments necessary to prevent binding and assure even

meshing of the pivot locking washers. It is advised to remove the display unit and store it in a safe

place to prevent damage during the rest of the installation process.

Power Connection

Power is supplied to the Unit through a connector on the rear panel of the display unit.

Route the power cable from the Unit location to the ship’s power distribution panel.

Connect the black wire to a battery negative (-) terminal of the power panel.

Connect the white wire to a fused battery positive (+) terminal of the power panel ( 12 to 24 Vdc

nominal). If a fused terminal is not available, install an in-line fuse holder.

Transducer Connection

There are many transducers available which may be used to expand the capabilities of the SVS560/460 Fishfinder Unit. Connectors for these accessories are provided on the rear panel of the

Fishfinder Unit.

See table on following page for list of optional transducers

Page 16

- 16 -

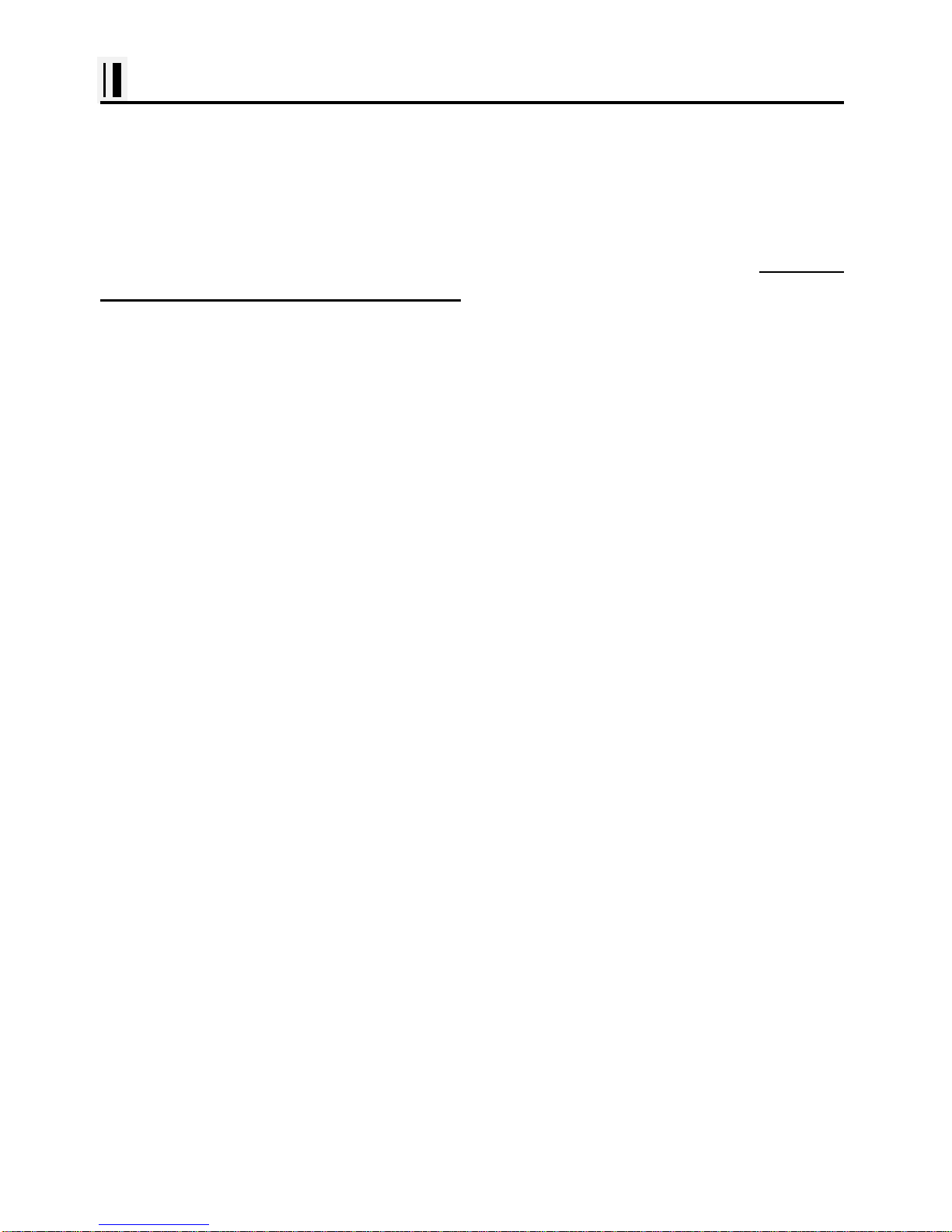

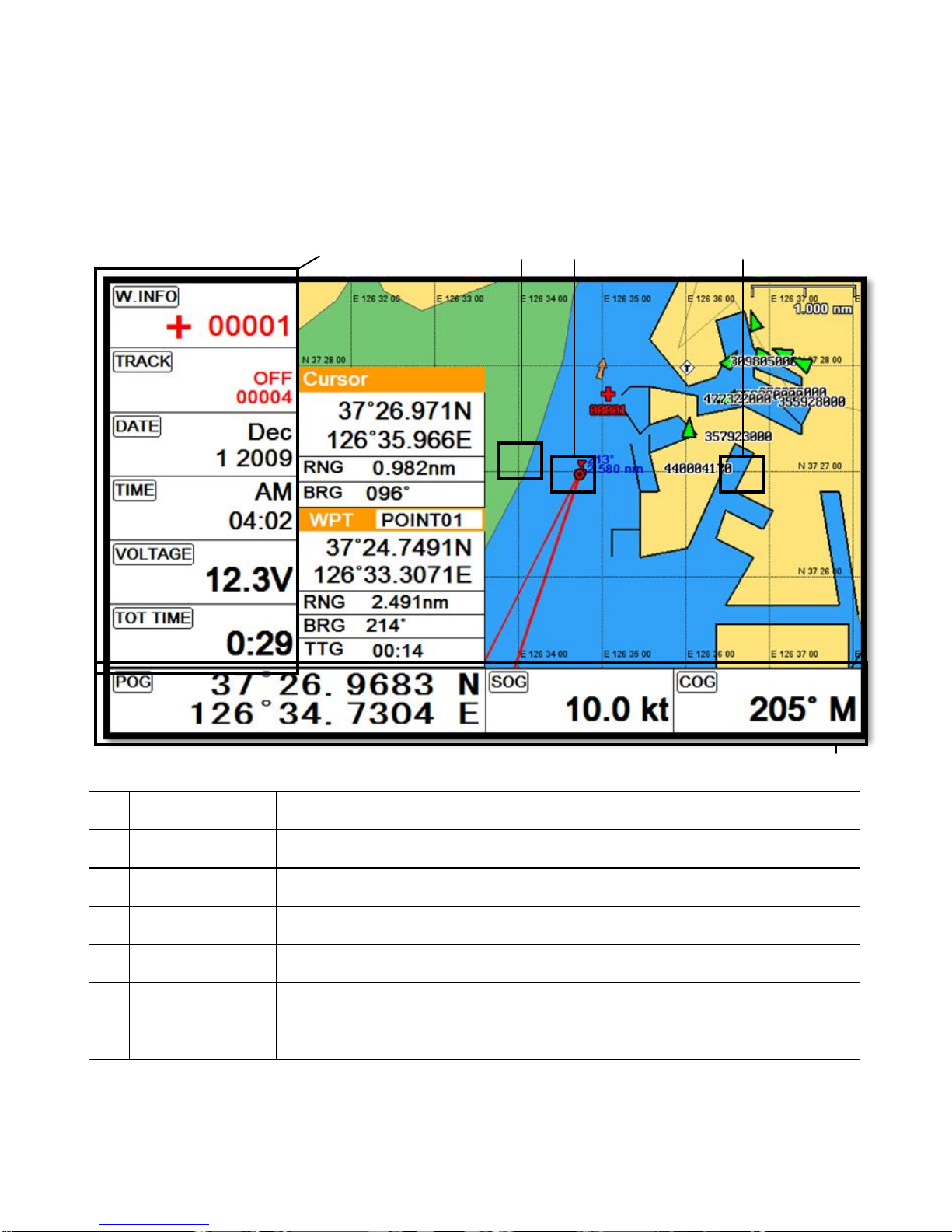

SVS-560/460 Transducer Options

Model #

Beam Angles

Type

Hole Size

250/50/200ST-CX

45º @ 50kHz

11º @ 200kHz

Plastic transom mount w/

depth, spd, temp.

N/A

1700/50/200T-CX

45º @ 50kHz

11º @ 200kHz

Bronze thru hull depth &

temp.

7/8"

500/50/200ST-CX

45º @ 50kHz

11º @ 200kHz

Bronze thru hull depth,

speed, & temperature

2"

P319/50/200T-ES

45º @ 50kHz

12º @ 200kHz

Plastic thru-hull flush mount

with temp

2"

B-60-0 - CX

(for 0º to 7º hull dead

rise)

45º @ 50kHz

12º @ 200kHz

Bronze thru Hull, Tilted

Element Flush Mount, Depth

& Temperature Only

2.375"

B-60-12 - CX

(for 8º to 15º hull dead

rise)

45º @ 50kHz

12º @ 200kHz

Bronze thru Hull, Tilted

Element Flush Mount, Depth

& Temperature Only

2.375"

B-60-20 - CX

(for 16º to 24º hull dead

rise)

45º @ 50kHz

12º @ 200kHz

Bronze thru Hull, Tilted

Element Flush Mount, Depth

& Temperature Only

2.375"

810-15

15ft Transducer Extension Cable

810-30

30ft Transducer Extension Cable

Digital A Cable

Adapter Cable for use with All Dual Freq. CVS-106 Versions

*All SVS Transducers come with a Conxall (Model #CX-128) 8 pin Conn. On the end of the

transducer cable

Page 17

- 17 -

Installation of the Transducer

Installing the Transducer Cable-

Thru-Hull and transom-Mount Installation

cable, with the connector attached, is supplied with the transducer. During the installation, do not cut

the transducer cable or remove the connector. Do not try shorten or splice the cable. The

transducer cable includes several wires, along with shielding and insulation. If the cable is cut, it

cannot be repaired. (Cutting the cable will also void the warranty.) During installation, if you need to

drill any holes for the cable, they must be large enough to accept the connector .(3/4" or 19mm)

This will allow you to complete the installation without cutting the wire.

1st) For a transom-mount installation - Route the cable up and over the top edge of transom. Secure

the cable using cable clamps. (These clamps are available from your local marine equipment supplier.)

If you do not want to expose the cable on the deck, you may drill a new hole (3/4" or 19mm) through

the transom for the cable. (Remember - this hole must be large enough to accept the cable with the

connector attached. Do not cut the cable!) To seal the opening, use a feed-thru cap where the cable

passes through the transom.

2nd) For either type of installation - Run the cable through the interior of the boat.

3rd) Be careful not to tear the cable jacket when passing it through bulkheads and other parts of

your boat. Secure the cable in place using Nylon Wire Ties. Coil the extra cable and tie it out of the

way.

4th) If transducer cable is not long enough, 15 & 30 foot extension cables are available from SI-TEX

When you attach the extension cable, be sure that the connections are tight and watertight. Use Dow

Corning DC-4 or an equivalent sealing compound to protect the connector assemblies.

Page 18

- 18 -

Installation of the Transducer

Installing the Power Cable-

1st) The 6-foot power cable supplied with the display unit should reach the source of DC power.

Connect the power leads directly to the main battery isolation switch or breaker, or route the power

leads to the DC power distribution panel. At the power source, connect the red wire to the positive

terminal (+), and the black wire to the negative terminal (-). The negative terminal may also be called

"ground" or "earth." (The display unit is internally protected if you accidentally reverse the polarity of

the power wires.)

2nd) Attach the red or positive wire to a 5 amp circuit breaker. If the unit is connected directly to the

boat's battery, include a 2amp in-line fuse. (In-line fuses are available at most marine supply stores.)

3rd) To prevent any interference or electrical noise, separate the Fishfinder power wiring as much as

possible from other devices. See the section on "EMC Installation Guidelines."

4th) If you need to extend the power wiring by more than 10 feet, use a larger wire size. This will

allow the wires to deliver the correct voltage in spite of the longer wire distance. For runs of 20 to 35

feet, use #14 AWG wire. If you need to extend the power wiring, be sure all electrical connections

are solid and durable. Insulate all connections using heat-shrink tubing or electrical tape. You may use

crimp connectors or a terminal strip, but be sure to use good-quality marine-grade parts.

5th) Plug in the power cable at the rear of the display unit.

6th) When you press the Power button, the display unit should turn on. If the unit will not turn on and

you suspect that you may have reversed the power connections, check the DC power lines all the way

back to the battery. If the polarity is not correct, reconnect the leads properly and try again.

(The display unit is internally protected if you accidentally reverse the polarity of the power wires.)

Page 19

- 19 -

Installation of the Transducer

Installing a Thru-Hull Transducer

Follow these instructions if you are installing the thru-hull transducer.

1st) Once you have decided where to install the transducer, drill the hole for the part. Begin by

drilling a small pilot hole (1/8" or 3mm) from the inside of the hull. (This small hole can be filled easily if

the mounting location is not suitable.) Before you drill the hole, be sure you will be able to reach the

large nut on the top of the transducer, once it has been mounted. Also be sure there will be enough

clearance for the cable. If there is a strake or other feature on the hull, drill from the outside of the hull

instead.

2nd) Drill a larger hole from the outside of the hull using the appropriate size hole saw or paddle bit

for the selected transducer.

3rd) Uncoil the transducer cable. Remove the large hex nut from the housing and slide it over the end

of the cable.

4th) Thread the cable through the hole to the inside of the hull. Never pull or carry the transducer in

place by pulling on the transducer cable.

5th) Apply a thin layer of sealant (1/8"" or 3mm) to the transducer between the upper flat surface of

the transducer and the faring block. Use a high quality marine sealant suitable for underwater use.

(Caution do not use 3M 5200) Also apply a thin layer up the side walls. this should cover all of the

threads where the part will touch the hull material, plus an additional 1/4""(6mm). This will seal the

threads for the large hex nut.

6th) Push the transducer housing (with the sealant applied) into the hole from the outside of the hull.

Twist the housing slightly to squeeze out any excess sealant and to get a good seal. Be sure that the

transducer is aligned so that the correct part of the unit is toward the bow of the vessel. Hold or prop

the transducer in place temporarily.

Page 20

- 20 -

Installation of the Transducer

Installing a Thru-Hull Transducer

7th) Go to the inside of the hull and slide the hex nut over the end of the cable. Fit the hex nut over

the end of the transducer and tighten it. (On a vessel with a wooden hull, do not tighten the nut

completely right away. Allow some time for the wood to swell after the vessel is put in the water. Be

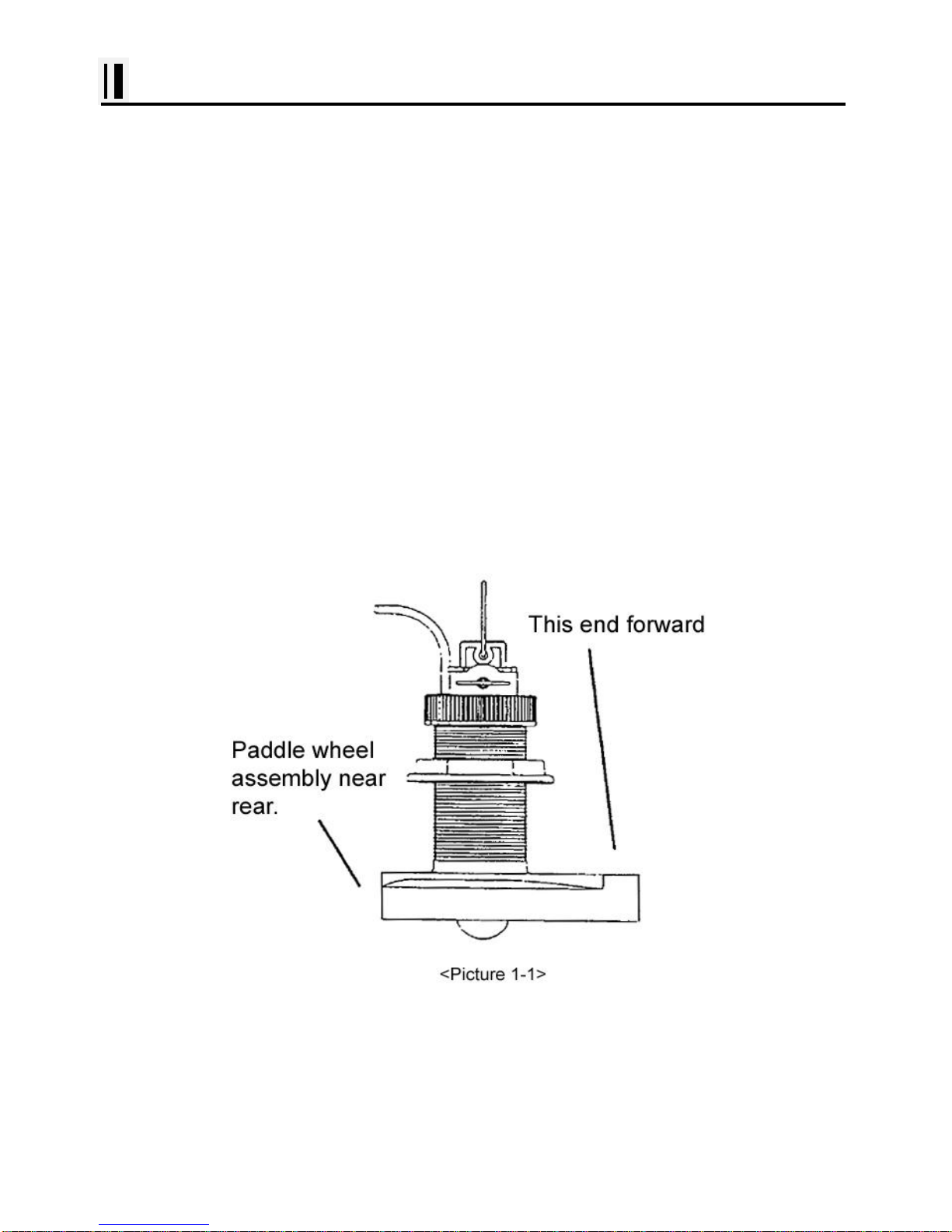

sure that the correct end of the transducer is pointing forward see Picture 1-1

8th) Remove any excess sealant from the outside of the unit to assure smooth water flow over the

face of the transducer.

9th) As soon as the boat is placed in the water, check for leaks. Check again within 3 to 5 hours.

(You may not be able to see a small leak right away.) If there are any leaks, you must repeat the

installation procedure.

Page 21

- 21 -

Installation of the Transducer

Positioning the Transom-Mount Transducer

Follow these instruction if you are installing the transom-mount transducer.

Begin by finding the best location for the mounting bracket. Here are the rules:

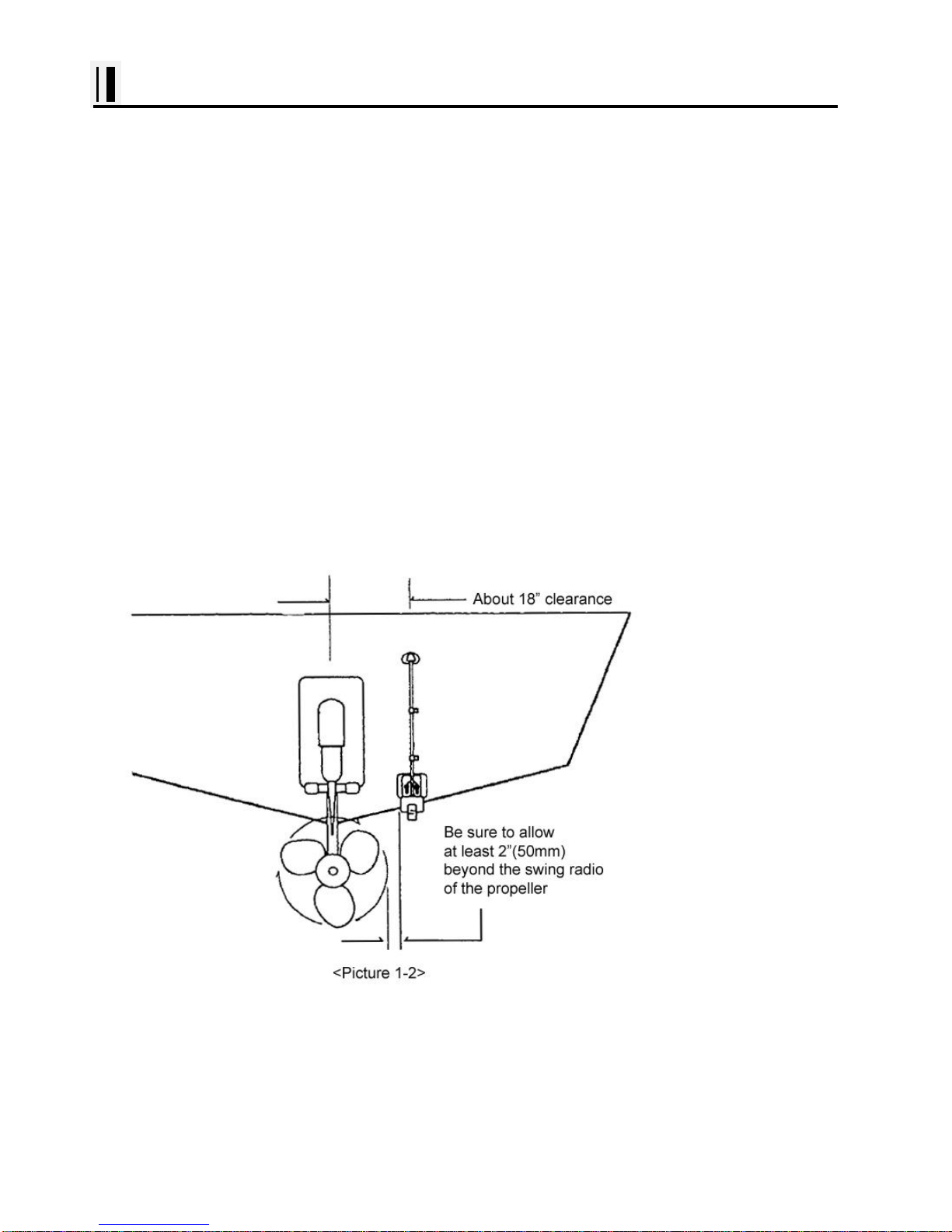

If your boat has one propeller (outboard or inboard-outboard), mount the transducer about

18"(455mm) to the side of the centerline of the boat. See Picture 1-2 Choose the side that is on the

down stroke of the propeller.(This is usually the starboard side of the boat.) This will reduce any

interference cause by air bubbles.

If your boat has twin propellers (outboard or inboard-outboard), place the transducer near the

centerline of the boat.

If the propeller can be turned to steer the boat, allow at least 2"(50mm) beyond the swing radius of the

propeller. This will prevent the propeller from damaging the transducer when it is turned.

Do not mount the transducer behind any hull fittings, intakes, or other parts which extend from the hull.

These may cause turbulence or air bubbles.

If the boat will be carried

on a trailer, be sure the

transducer will not hit any

rollers, bunks or fittings

on the trailer.

Page 22

- 22 -

Installation of the Transducer

Mounting the Transom-Mount Transducer

Follow these instructions if you are installing the transom-mount transducer.

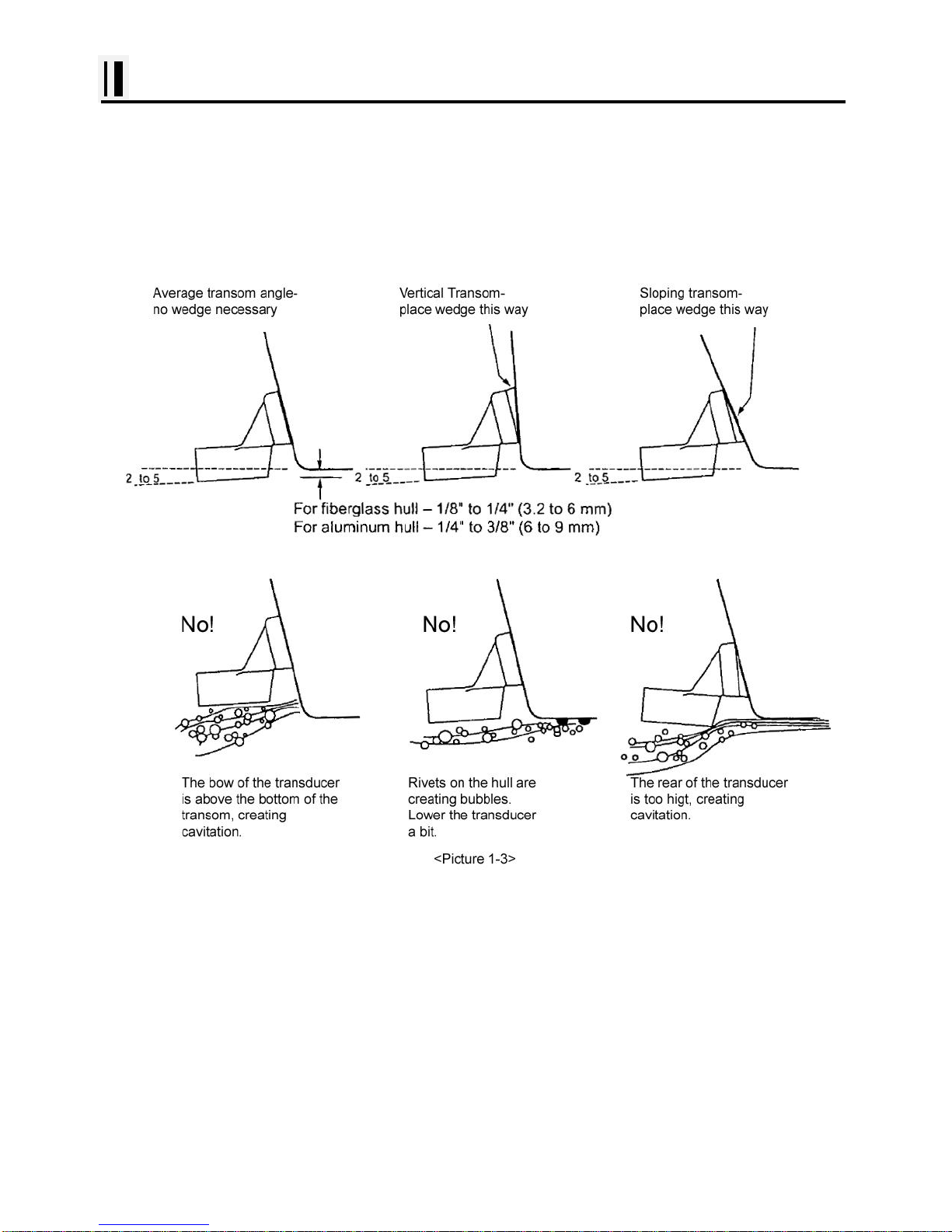

1st). On a boat with a fiberglass hull, the leading edge of the transducer should extend 1/8""(3.2mm) to

1/4""(6mm) below the bottom edge of the hull. See picture 1-3. On an aluminum hull, the transducer

should extend a bit more - 1/4"(6mm) to 3/8"(9mm). If the boat will be operated at high speeds, the

transducer may be mounted closer to the centerline of the hull.

2nd) The lower surface of the transducer should tilt down toward the rear at a slight angle(2° to 5°). The

mounting bracket includes a wedge. Depending on the angle of the transom on your boat, you may

need this wedge to get the correct angle for the bottom of the transducer.

3rd) Looking at the rear of the boat, be sure the bracket is vertical (perpendicular to the water line).

4th) Hold the bracket (and the wedge, if used) against the transom and trace the position of the screw

slots.

5th) Remove the bracket. The screws in the outer slots should be placed about 1/4"(6mm) up from

the bottom of each slot. The screw in the center slot should be placed 1/4" (6mm) down from the top.

(This will allow you to adjust the bracket up or down a bit.)

Drill pilot holes 3/4""(19mm) deep. Use a 9/64" (3.5mm) drill bit. To prevent drilling too deeply, wrap

masking tape around the drill bit about 7/8" (22mm) from the tip. Drill in only as far as the tape marker.

If you are attaching the bracket to a fiberglass hull, you can minimize any surface cracking of the gel

coat. Before drilling each pilot hole, drill a shallow hole (chamfer) at each location about 1/16" (1.5mm)

deep. Use a 1/4"(6mm) drill bit.

6th) Attach the bracket to the hull using the pinhead screw with flat washers. Before you tighten the

screws, apply a good-quality marine sealant to the pilot hole. This will protect the hull from water

penetration. Do not tighten the screws completely yet.

Page 23

- 23 -

Installation of the Transducer

7th) Tilt the transducer in the brackets until it is positioned as illustrated in Picture 1-3

8th) Once the bracket is in the correct position, you can tighten the screws.

Page 24

- 24 -

Getting Started

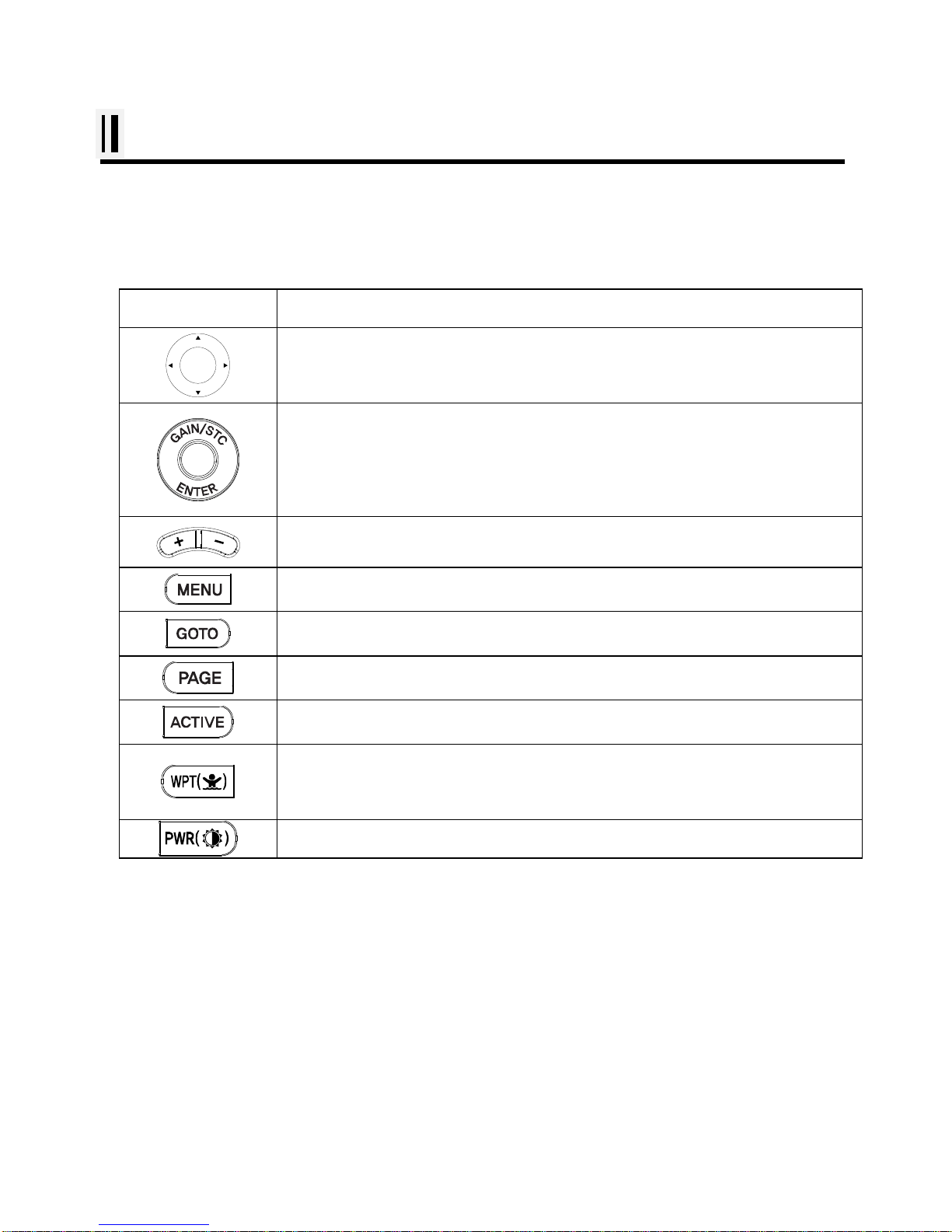

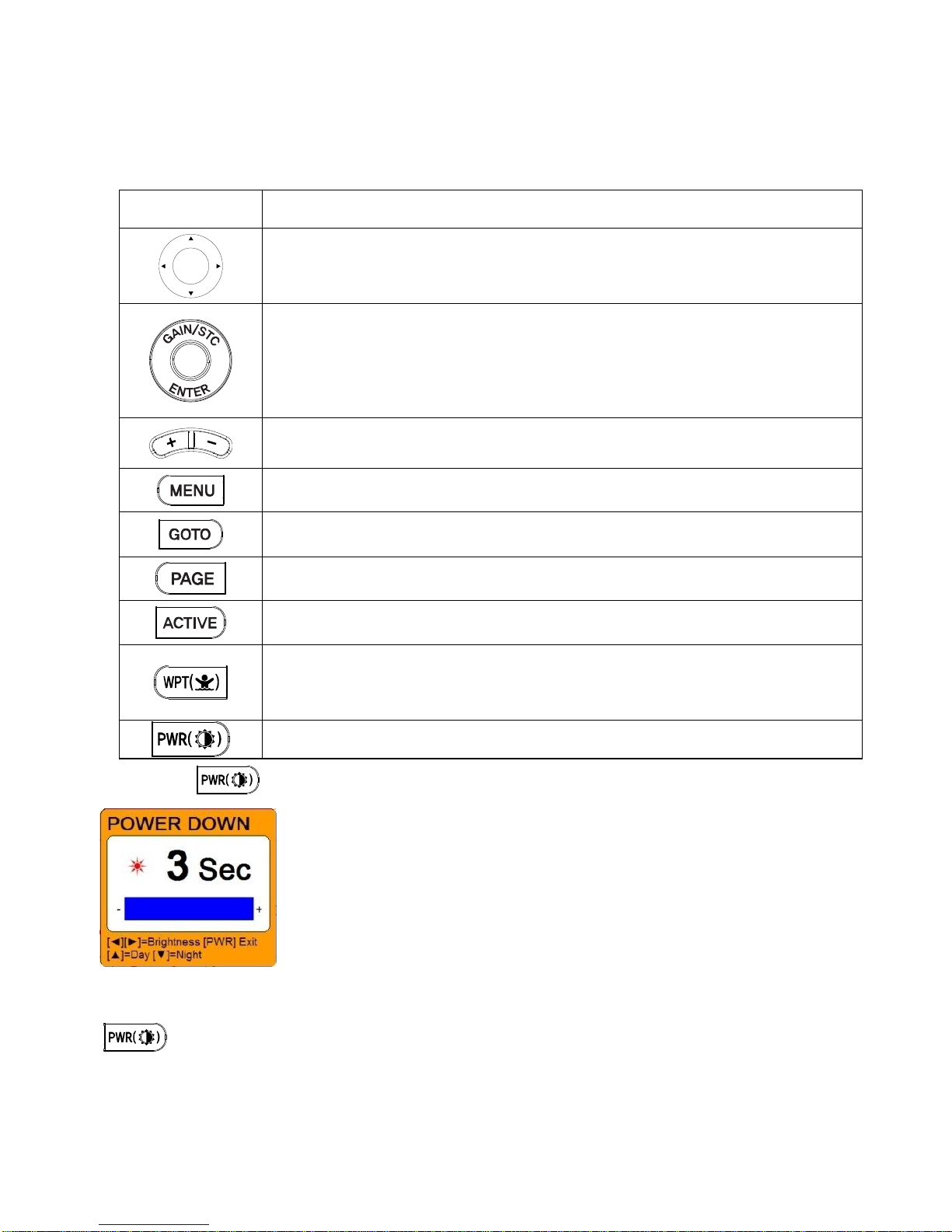

1. The Keyboard

1.1. Model:SVS-560C/SVS-460C

KEY

Description

use this to select menu items, move the on-screen cursor

Rotary: use this to select menu items

Button: push the end of the everything to confirm a selection or entry

Change the chart of scale

Open the menu

Select the Goto function

Select the configuration & modification you wish.

Select the activated section

Press to place a waypoint and access the waypoint option.

Press and hold to place a MOB marker at your current position.

Power “on/off”, brightness and day/night mode .

Page 25

- 25 -

1.2 Model: SVS-560CF/SVS-460CF

1.3. How to use

(Fig.1.1)

1.3.1. Turn on

Switch on.

1.3.2 Turn off

KEY

Description

use this to select menu items, move the on-screen cursor and Choosing the

frequency

Rotary: use this to select menu items and Adjustment of gain & STC level with

turning.

Button: push the end of the everything to confirm a selection or entry

Change the chart of scale and Setting up the depth range

Open the menu

Select the Goto function

Select the configuration & modification you wish.

Select the activated section

Press to place a waypoint and access the waypoint option.

Press and hold to place a MOB marker at your current position.

Power “on/off”, brightness and day/night mode.

Page 26

- 26 -

Keep pressing to switch off.

1.3.3. Adjust brightness

Pressing (Fig.1.1) and controlling the brightness with [◀] [▶].

1.3.4. Use day/night mode

Pressing (Fig.1.1) and changing the day and night with [▲][▼].

Page 27

- 27 -

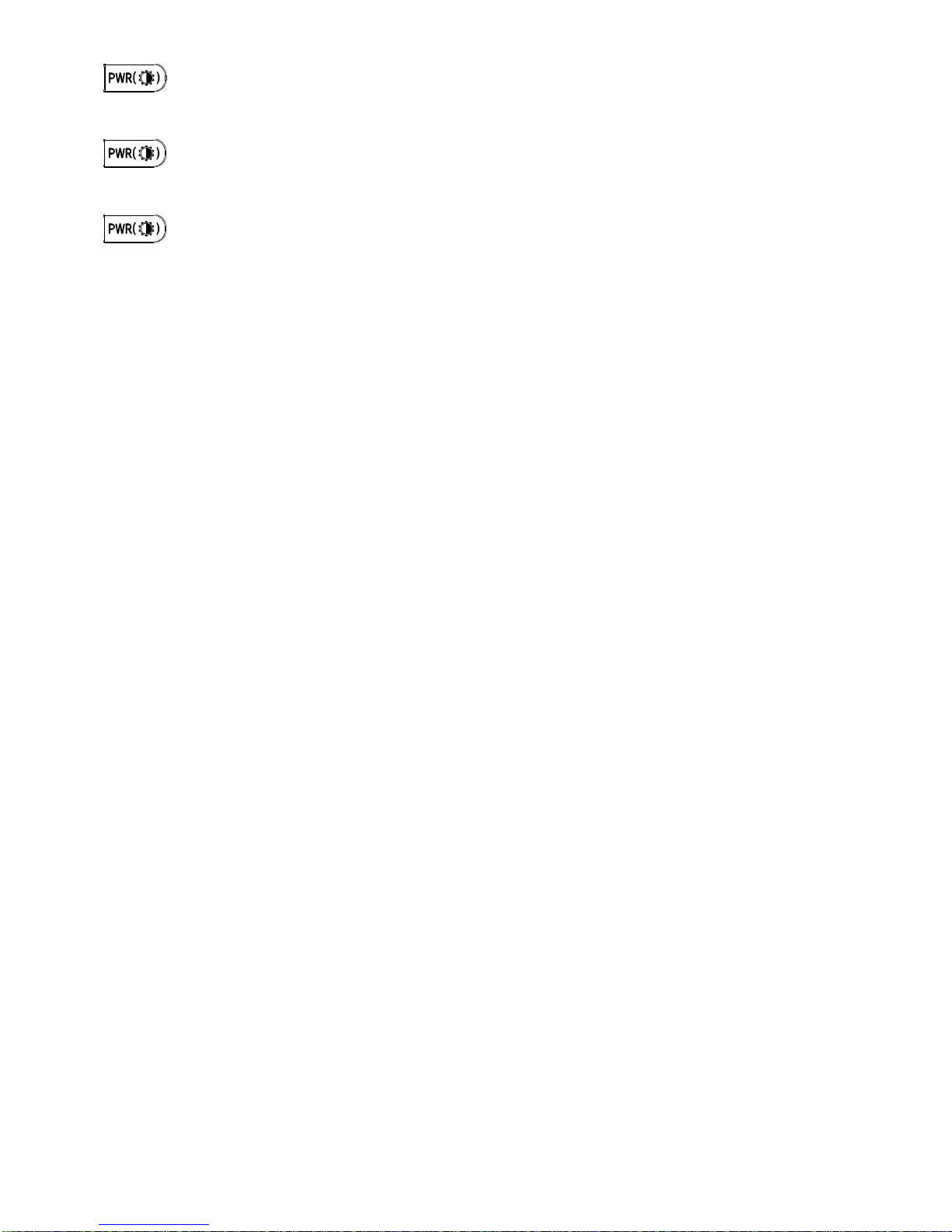

2. Specification of the connectors

Page 28

- 28 -

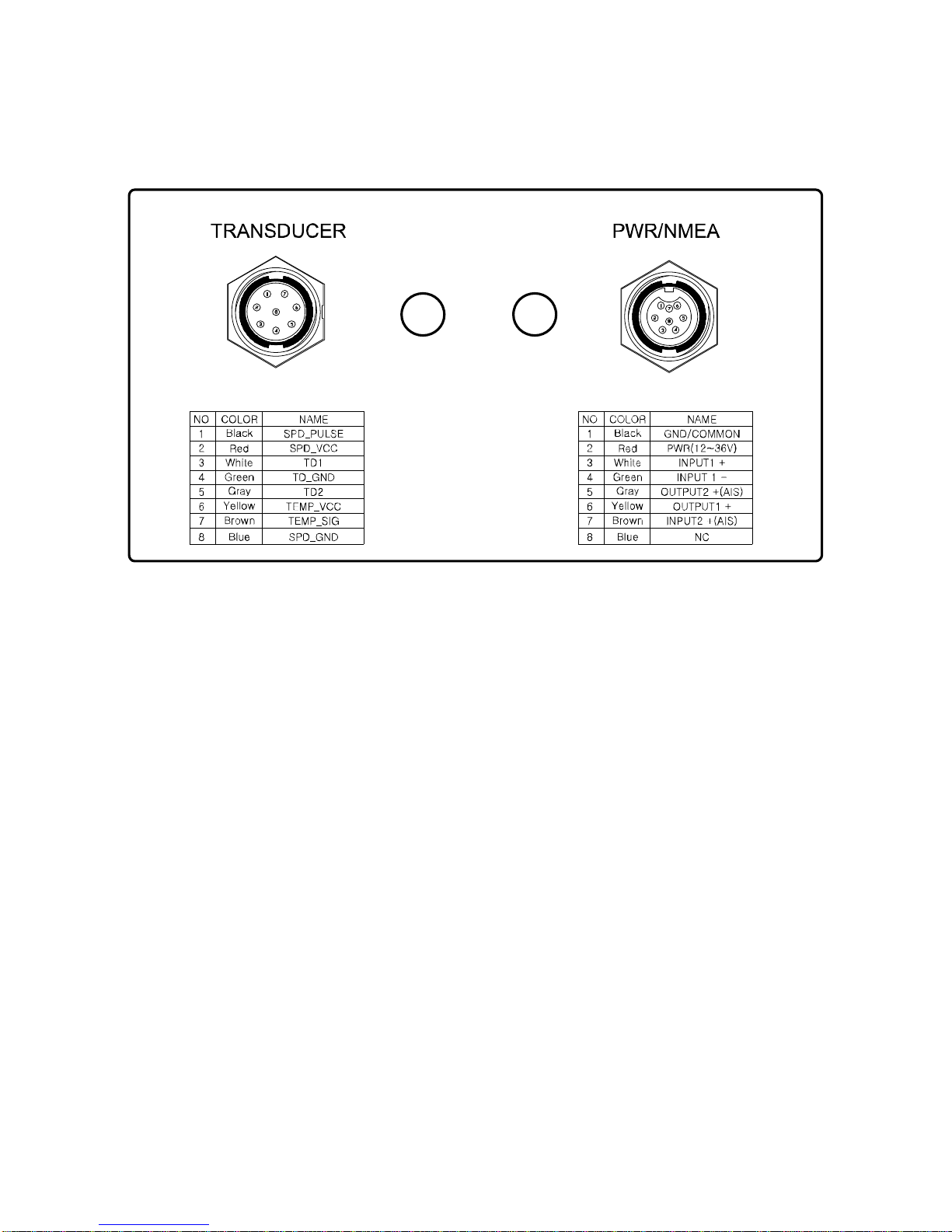

3. Screen Overview

3.1. Chartplotter page

①

Vessel icon

The present position.

②

Cursor

Showing the cursor icon.

③

AIS target

Showing the received AIS target.

④

Databar

Showing various data on the top or bottom.

⑤

Sidebar

Showing various data on the right or left.

⑥

Cursor INFO

The information of the cursor.

⑦

WPT INFO

The information of WPT such as LAT/LOT, Range, etc.

①

④

⑤

③

②

⑥

⑦

Page 29

- 29 -

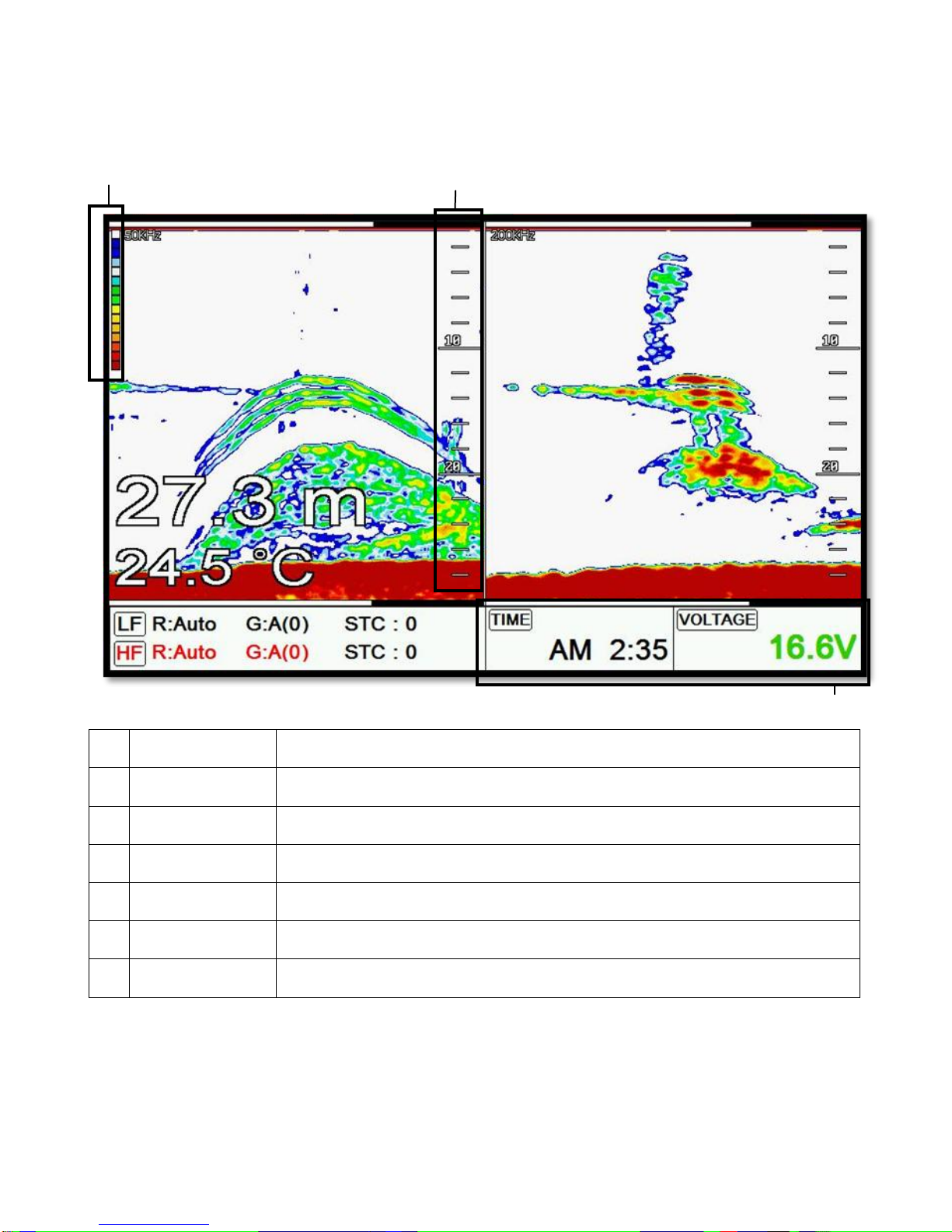

3.2. Fishfinder page

.

①

Palette

Showing the chosen colors.

②

Depth bar

The current depth.

③

Low Frequency

Showing 50KHz.

④

High Frequency

Showing 200KHz.

⑤

LF INFO

The information of Low Frequency, 50KHz.

⑥

HF INFO

The information of High Frequency, 200KHz.

⑦

Databar

Showing various data on the top or bottom

⑦ ③ ④ ⑤ ⑥ ① ②

Page 30

- 30 -

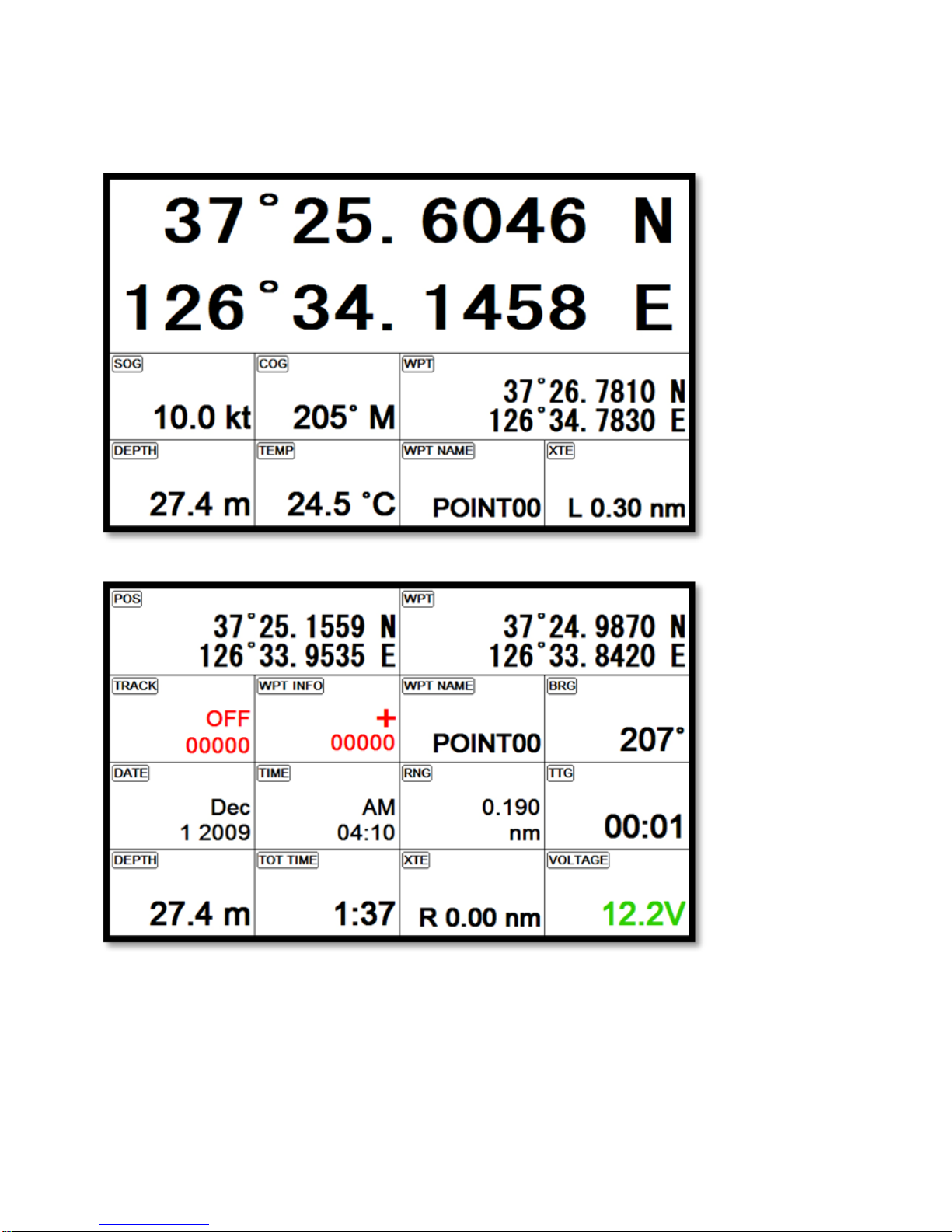

3.3. Navigation Data page

3.3.1. Navigation Data Type1

3.3.2. Navigation Data Type2

Page 31

- 31 -

3.4. Highway page

①

WPT name

The current WPT name.

②

Direction of steer

The best direction of the steering.

③

WPT icon

The remaining distance of the WPT.

④

Vessel

The out of the range from the best.

⑤

XTE Range

The range of the XTE alarm.

⑥

Navigation Data

The information of the various data.

①

②

⑥ ③ ④

⑤

Page 32

- 32 -

3.5. Steering page

①

WPT name

Name of the WPT.

②

Direction of steer

The best direction of the steering.

③

WPT icon

Showing the WPT and the bearing

④

Navigation Data

Information of the various data.

①

② ④ ③

Page 33

- 33 -

3.6. GPS Status page

①

Receiver status

The current GPS status.

②

Position of SAT.

Position of the satellites.

③

SNB Graph

Showing the WPT and the bearing.

④

Navigation Data

Information of the various data.

* Colors of the GPS status

Black:

Tracked, but no signal

Blue:

Tracked, but not used, Satellite

Green:

Used Satellite

Light Blue:

SBAS Satellite

④ ① ②

③

Page 34

- 34 -

Page 35

- 35 -

4. Databar

Showing various data on the top or bottom.

4.1. Mode

▶[MENU]->Advance->Setup->Customizing->Databar->Mode

Databar has three meanings as below.

4.1.1. Fix Mode 1

Showing the largest LAT/LOT.

4.1.2. Fix Mode 2

Showing the LAT/LOT, SOG, COG and userdata.

4.1.3. Customizing

Showing various data as what the user wants.

▶[MENU]->Advance->Setup->Customizing->Databar->Edit

(Fig.1.2.1)

The databar is coming as (Fig.1.2.1), and choose the frame with [◀][▶].

Four frames are available as (Fig 1.2.2).

Page 36

- 36 -

(Fig.1.2.2)

When choosing the frame, setting up in each box as (Fig.1.2.3).

(Fig.1.2.3)

When finishing the set up, press to exit.

(*Please, refer “Customizing” for further question.)

4.2. Display

▶[MENU]->Advance->Setup->Customizing->Databar->Display

Page 37

- 37 -

Setting the databar, “Shown/Hidden”.

4.3. Position

▶[MENU]->Advance->Setup->Customizing->Databar->Position

Setting the databar position on the top or bottom.

5. Cursor

5.1. Calling the cursor

Press [◀][▶][▼][▲] on the chart, the cursor comes out.

5.2. Moving

Press [◀][▶][▼][▲], the cursor is moving to the direction.

Press [◀][▼] together, the cursor is moving to “↙”.

Press [▶][▼] together, the cursor is moving to “↘”.

Press [◀][▲] together, the cursor is moving to “↖”.

Press [▶][▲] together, the cursor is moving to “↗”.

5.3. Removing the cursor

Press to remove the cursor.

5.4. Cursor information window

①

Latitude/Longitude

LAT/LON of the cursor.

②

Range

Distance between the cursor and the present position.

③

Bearing

Bearing from the present position to the cursor.

5.5 . Cursor information window shown/hidden

▶MENU->Advance->Setup->Customizing->INFO window->Cursor

①

②

③

Page 38

- 38 -

Cursor information window “Shown/Hidden”.

6. Page

▶ [PAGE]

Choosing the various pages that set up pages or customized.

Move the red box to choose the page.

(Fig.1.3)

6.1. Page mode

▶[MENU]->Advance->Setup->Customizing->Page mode

Two ways to choose the page.

6.1.1. Standard

With seeing the set up page, choosing the page or modifying.

6.1.2. Flip

Showing the set up pages in order.

(* In Flip mode, modifying the order is available.)

6.2. Modify

After choosing the page in (Fig1.3), keep pressing until the window comes out as

(Fig.1.3.1).

Selected (red color)

Page 39

- 39 -

(Fig.1.3.1)

Choosing the frame with [◀][▶].

Two frames as (Fig 1.3.2).

(Fig.1.3.2)

After choosing the box, choose the page as (Fig.1.3.3).

(Fig.1.3.3)

When finishing, press to exit.

Page 40

- 40 -

7. Active

▶[ACTIVE]

When pressing [ACTIVE], the red box moves to to chartplotter or fishfinder.

(*All key functions change to chartplotter or fishfinder)

Selected (red color)

Page 41

- 41 -

8.Sidebar

Databar on the right or left.

(*Sidebar is available only in the full chartplotter and the full fishfinder)

8.1. Display

▶[MENU]->Advance->Setup->Customizing->Sidebar->Display

Choosing the sidebar, “Shown/Hidden”.

8.2. Position

▶[MENU]->Advance->Setup->Customizing->Sidebar->Position

Choosing the sidebar on the right or left.

8.3. Edit

▶[MENU]->Advance->Setup->Customizing->Sidebar->Edit

After finishing all of them as (Fig.1.4), press to exit.

(*Please, refer “Customizing” for further question)

Page 42

- 42 -

(Fig.1.4)

9. Navigation Data

Navigation data is available in Navigation data page, Steering page, Highway page as (Fig.1.5).

(Fig.1.5)

9.1. Type

▶[MENU]->Advance->Setup->Customizing->Navigation data->Type

Two types of Navigation data page.

9.1.1.Type1

Large LAT/LOT as (Fig.1.6.1).

(*Editing the LAT/LOT is unavailable)

9.1.2. Type2

Various data as (Fig.1.6.2).

Page 43

- 43 -

(Fig.1.6.1) (Fig.1.6.2)

9.2. Edit

(*If there is no navigation data on the page, editing the navigation data is unavailable)

▶[MENU]->Advance->Setup->Customizing->Navigation data->Edit

After finishing as (Fig.1.6.3), press to exit.

(*Please, refer “Customizing” for further question)

(Fig.1.6.3)

Page 44

- 44 -

10.MOB

If a person or missing an object overboard and you need to get present position, use the MOB function.

10.1. Inputing

Keep pressing until the window comes out as [Fig.10.1] and then “MOB” comes out with

alarm.

10.2. Exiting the alarm

When alarming, press and you may exit the alarm.

10.3. Removing

While MOB is setting, press again and you may remove the “MOB”.

(*MOB is not stored in the flash memory)

Page 45

- 45 -

11. MircoSD

Inserting the micro SD as (Fig.1.7).

(Fig.1.7)

12. Save Userdata

▶[MENU]->Userdata->Save Userdata

Userdata is stored in the external Micro SD. So if you want to save the userdata, a micro SD must be

inserted in the slot.

(*Userdata is in “..\HY\UserData\”)

Page 46

- 46 -

12.1. WPT

WPT can be stored in a micro SD.

When storing, give it a name and you will be able to store many WPT’ in the micro SD.

12.2. Route

Route can be stored in a micro SD.

When storing, give it a name and you will be able to store many routes in the micro SD.

12.3. Track

12.3.1. Type1

Track can be stored in a micro SD.

When storing, give it a name and you will be able to store many tracks in the micro SD.

12.3.2. Type2

Track can be stored in a micro SD.

Index will be a standard in Type2. After choosing the index, stored it.

12.4. User Line

User Line can be stored in a micro SD.

When storing, give it a name and you will be able to store many user lines in the micro SD.

12.5. User Name

User Name can be stored in a micro SD.

When storing, give it a name and you will be able to store many user names in the micro SD.

Page 47

- 47 -

13. Load Userdata

▶[MENU]->Userdata->Load Userdata

Userdata loads from the stored micro SD. If you need to load the userdata, the stored micro SD must

be inserted in the slot.

(*Userdata is in “..\HY\UserData\”)

13.1. WPT

WPT loads from the stored micro SD.

All of WPT in the micro SD show on the list. Choose one of them and it will show.

There are two ways to load WPT.

First, showing the stored WPT as well as the existing on the sceen. After loading the stored, you will

see the window and press .

Second, showing only stored WPT. After loading the stored, press [ENTER].

13.2. Route

Route loads from the stored micro SD.

Page 48

- 48 -

All of route in the micro SD show on the list. Choose one of them and it will show.

13.3.Track

13.3.1. Type1

13.3.Track

13.3.1. Type1

Track loads from the stored micro SD.

All of track in the micro SD show on the list. Choose one of them and it will show.

13.3.2. Type2

Track loads from the stored micro SD.

Index will be a standard in Type2. After choosing the index, stored it.

13.4. User Line

User line loads from the stored micro SD.

All of user line in the micro SD show on the list. Choose one of them and it will show.

13.5. User Name

User name loads from the stored micro SD.

All of user name in the micro SD show on the list. Choose one of them and it will show.

Page 49

- 49 -

Chartplotter getting started

1. GOTO

1.1. Goto type1

1.1.1. Setting

▶[MENU]->Navigation->Goto type->type1

Setting GOTO with creating a route at the same time.

Move the cursor to the position where you want to go and press [ENTER].

(*While navigating, WPT can be added in the route)

1.1.1.2. Exit/Store

If you want to exit, remove the cursor and press [GOTO]. The window to store or not shows up.

Choose one of them and you will exit.

(*If you have one WPT in the route, the WPT will be stored. If you have more than two, all of WPT and

the route will be stored together)

1.2. Goto type2

1.2.1. Setting

▶[MENU]->Navigation->Goto type->type2

Direct GOTO where you want to go. Only one destination is available.

1.2.2. Exit/Store

If you want to exit, remove the cursor and press [GOTO]. The window to store or not shows up.

Choose one of them and you will exit.

1.2.3. Changing

While navigating, you can change a new destination. Move the cursor and press [GOTO] for the new

destination.

Page 50

- 50 -

2. WPT

2.1. List

▶[MENU]->Userdata->WPT->List

Editing, creating, erasing and navigating are available on the WPT list.

①

List

Showing all of the stored WPT.

②

Name

Name of the WPT.

③

Symbol

Symbol of the WPT.

④

Color

Color of the WPT.

⑤

Latitude/Longitude

LAT/LOT of the WPT.

⑥

Depth

Depth of the WPT.

⑦

Bearing

Bearing between the WPT and the present position.

⑧

Range

Distance between the WPT and the present position.

⑨

Date & Time

Date and time of the WPT when stored

2.2. Setting the WPT symbol

①

②

③ ④ ⑤ ⑥ ⑦ ⑧ ⑨

Selected(blue color)

Page 51

- 51 -

▶[MENU]->WPT Symbol

Choose the symbol and press [ENTER].

The chosen symbol will show when inputting WPT.

2.3. Setting WPT Color

▶[MENU]->WPT Color

Choose the color and press [ENTER].

The chosen color will show when inputting WPT.

2.4. Creating

2.4.1. Creating on the list

▶[MENU]->Userdata->WPT->List->[+]

Selected(red color)

Selected(red color)

Page 52

- 52 -

Adding WPT with pressing .

(*When adding, LAT/LOT show the present position and current symbol/color show for the WPT)

2.4.1. Inputting on the chart

Call the cursor and move the position where you want, and press .

(*The current symbol/color show for the WPT)

2.5. Erasing

2.5.1. Erasing on the list

▶[MENU]->Userdata->WPT->List->[-]

Choose the WPT you want to erase and press .

2.5.2. Erasing on the chart

Call the cursor and put it on the WPT, and press [ENTER].

Page 53

- 53 -

2.6 Erasing all of WPT

▶[MENU]->Userdata->WPT->List->[PAGE]

On the WPT list, press .

2.7. Moving the WPT

1. Call the cursor and move it on the WPT, and press [ENTER].

2. Choose “Move”.

3. Move the WPT to the position where you want to move, and press [ENTER].

2.8. Navigating

2.8.1. Navigating on the list

▶[MENU]->Userdata->WPT->List->[GOTO]

Choose the WPT on the list and press .

2.8.2. Navigating on the chart

Page 54

- 54 -

Call the cursor and move it on the WPT, and press [ENTER]. Choose “GOTO” to start.

Page 55

- 55 -

2.9. Sorting

▶[MENU]->Userdata->WPT->List->[MENU]

Sorting the order of WPT on the list.

Page 56

- 56 -

2.10. Editing

▶[MENU]->Userdata->WPT->List

Editing the WPT on the list.

1. Choose the WPT as the blue and press [ENTER].

2. Choose the item as the green and you may begin to edit.

3. After finishing, press to exit.

Edit Selected(green color)

WPT Selected(Blue color)

Page 57

- 57 -

3. Route

3.1. List

▶[MENU]->Userdata->Route->List

①

List

Showing the stored WPT

②

Name

Name of the route

③

Number of WPT

Number of WPT in the route

④

Total distance

Total distance of the route

⑤

Display

Shown/Hidden the route on the chart

⑥

Date & Time

Date and time of the WPT when stored

⑦

Start WPT

The beginning of the route

⑧

End WPT

The end of the route

①

②

③

④

⑤

⑥ ⑦ ⑧

Page 58

- 58 -

3.2. Route detail

▶[MENU]->Userdata->Route->List->[PAGE]

①

List

Showing the stored WPT

②

Name

Name of the WPT

③

Symbol

Symbol of the WPT

④

Color

Color of the WPT

⑤

Latitude/Longitude

LAT/LOT of the WPT

⑥

Depth

Depth of the WPT

⑦

Bearing

Bearing between the WPT and the present position

⑧

Range

Distance between the WPT and the present position

⑨

Date & Time

Date and time of the WPT when stored

①

②

③ ④ ⑤ ⑥ ⑦ ⑧ ⑨

Page 59

- 59 -

3.3. Creating

Two ways to create route

The first uses “GOTO type1” and the second is “Creating new route” on the list.

3.3.1. Using “GOTO”

Use “GOTO type1” and create a route. Press [ENTER] to start.

Press to exit and choose “Store” if needed.

3.3.2. Creating new route on the list

▶MENU->Userdata->Route->List

Press on the list to create a route.

Selected(Blue color)

Page 60

- 60 -

3.4. Edit

▶MENU->Userdata->Route->List

Choose the route on the list to edit.

3.5. Detail edit

▶[MENU]->Userdata->Route->List->[PAGE]

Choose the route on the list and press . The window of Route detail shows.

3.5.1. Adding WPT

Two ways to add WPT

3.5.1.1. Adding the stored WPT

▶[MENU]->Userdata->Route->List->[PAGE]->[MENU]

(Fig.2.1)

Page 61

- 61 -

Press on the Route detail and you may add the stored WPT as (Fig.2.1).

3.5.2.1. Adding new WPT

Press on Rout detail and you may add new WPT.

3.5.3. Erasing WPT

Choose the WPT and press .

3.6. Navigating

▶[MENU]->Userdata->Route->List->[GOTO]

Choose the route on Route list and press .

3.4. Erasing

Choose the route and press .

4. Track

The maximum point is 50,000.

Two ways to manage the track. The first is to manage the total 50,000 points by colors. The second is

to divide 50,000 points in five rooms, and you can store 10,000 points for the maximum in each room.

Tracking has two types, “by time and by distance”.

4.1. Track on/off

▶[MENU]->Track

Shown/Hidden the track.

4.2. Choosing the track

4.2.1. By time

▶[MENU]->Userdata->Track->Track Setup->Record Setup->Time

Tracking by the set time.

4.2.2. Setting the time interval

▶[MENU]->Userdata->Track->Track Setup->Time Interval

Setting the time interval.

4.2.3. By distance

▶[MENU]->Userdata->Track->Track Setup->Record Setup->Distance

Tracking by the set distance.

Page 62

- 62 -

4.2.4. Setting the distance interval

▶[MENU]->Userdata->Track->Track Setup->DIST Interval

Setting the distance interval.

4.3. Setting the thickness

▶[MENU]->Userdata->Track->Track Setup->Thickness

Setting the track thickness.

4.4. Track Color

▶[MENU]->Track Color

Choose the color and press [ENTER].

(* The number next the color shows the number point of the track color)

4.5. Track type

4.5.1. Type1

▶[MENU]->Userdata->Track->Track Setup->Type1

4.5.1.1. Erasing

▶[MENU]->Userdata->Track->Erase

Selected(red color)

Page 63

- 63 -

Choose the color and press [ENTER].

(*The number next the color shows the number point of the track color.)

4.5.1.2. Erasing all of track

▶[MENU]->Userdata->Track->Erase

Press .

4.5.2. Type2

▶[MENU]->Userdata->Track->Track Setup->Type2

4.5.2.1. Select index

▶[MENU]->Userdata->Track->Select Index

Five rooms in the index. The maximum is 10,000 points in each room.

In Type2, storing, loading and erasing are available to manage in the room.

4.5.2.2. List

Showing the information of each room.

(Fig.2.2)

①

List

Showing the track room

①

②

③ ④ ⑤ ⑥ ⑦

⑧

Page 64

- 64 -

②

Number of Point

Total track point in the track room

③

Date&Time

Date and time of the track room when stored

④

Color

Color of the track room

⑤

On/Off

Shown the track On/OFF.

⑥

Display

Show/Hidden the track room

⑦

Start Point

The beginning of the track room

⑧

End Point

The end of the track room

4.5.2.3. Erasing

Choose the track room on the list and press .

Page 65

- 65 -

5. Measuring the distance and bearing

Measuring two points, “A” and “B”.

1. Call the cursor and move it on the point, “A”.

2. Move the cursor on the point, “B”.

3. The cursor windows provides the distance and bearing between A and B.

4. Press to exit.

6. User Line

Adding lines directly on the chart.

1. Call the cursor.

2. Press [ENTER] and “User Line” shows.

3. Move the cursor to the beginning point and press [ENTER].

4. Keep moving the cursor and press [ENTER] each time.

5. Press to exit.

A point

B point

Range

Bearin

Page 66

- 66 -

7. User Name

Adding a place name directly on the chart.

1. Call the cursor and move it to the point.

2. Press [ENTER] and choose “User Name”.

4. Inputting letters with [◀][▶][▼][▲].

5. Press to exit.

8. Correction Offset

When the chart position is wrong, making it correct.

1. Call the cursor and move it to the correct position.

2. Press [ENTER] and choose “Correction Offset”.

Start point

Page 67

- 67 -

(* The maximum range of Correction Offset is 5nm.)

Page 68

- 68 -

Chartplotter operation

1. Map Orientation

▶[MENU]->Advance->Map Setup->Map Orientation

1.1. True Motion

▶[MENU]->Advance->Map Setup->Map Orientation->True motion

The True Motion is in the way the vessel position is presented. In True Motion mode, the vessel icon

moves over the map while the map remains stationary.

(* It is not available to operate on Course up and Head up.)

1.2. North Up/South Up/East Up/West Up

▶[MENU]->Advance->Map Setup->Map Orientation->Up mode

They setting the vessel present position remains fixed in the center of the Main Screen while the map

moves under it.

1.3. Course Up

▶[MENU]->Advance->Map Setup->Map Orientation->Up mode

The Course Up mode screen orientation is determined by whether or not navigation is in progress.

During navigation vessel present position is in the center of the Screen and the course line to the

destination is straight up. As your present position changes, the map moves under the stationary

vessel icon.

(*If navigation is stopped, the Main Screen appears as Head up.)

1.4. Head Up

▶[MENU]->Advance->Map Setup->Map Orientation->Up mode

For Head Up mode, vessel present position is fixed in the center of the Main Screen and vessel

heading is upward. As your present position changes, the map moves under the vessel icon.

Page 69

- 69 -

2. Map setup

▶[MENU]->Advance->Map Setup

2.1. Map orientation

2.1.1. True motion

You can select “True motion”

(☞ The default setting is OFF.)

2.1.2. Up mode

You can select “Map Orientation”

(☞ The default setting is North Up.)

2.2. UserData Display

Setting up shown/hide the user data on the display.

2.3. INFO Display

Setting up shown/hide common item between the HY-MAP and the C-MAP on the display.

2.4. Map scale

Setting up the map scale on the display.

2.5. Palette

It is possible to the palette used to enhance the visibility of the screen depending on the surround light

condition. The possible choices are listed in the table below:

2.5.1. Normal

It set the maps are displayed in ordered to use colors as similar as possible to the ones used in the

original paper charts.

2.5.2. Sunlight

It is designed to enhance the visibility of the screen when Smart4/5 seriesis exposed to the sunlight.

The maps are much brighter than in the other displays.

2.5.3. NOAA

Allows setting NOAA paper chart colors presentation.

Page 70

- 70 -

(*It is available NOAA menu on C-MAP.)

2.6. LAT. Modification

Though GPS information is accurate, there could be an error in the chart at latitude. The error can be

modified in the chart latitude modification.

2.7. LOT. Modification

Though GPS information is accurate, there could be an error in the chart at longitude. The error can

be modified in the chart longitude modification.

2.8. Chart

Select the chart among HY-MAP,C-MAP and External map.

2.9-1. HY-Map (*Only for *HY-MAP mode.)

2.9-1.1. Depth Line

Setting up 2m,5m,10m,20m,50m of the depth line on the HY-MAP.

2.9-1.2. Rock

Setting up the Rock on the HY-MAP

(☞ The default setting is shown.)

2. 9-1.3. Fishing Banks

Setting up the Fishing Banks on the HY-MAP.

(☞ The default setting is shown.)

2.9-1.4. Land Color

Select the land color as you want.

(☞ The default setting is yellow.)

2.9-1.5. Lighthouse Info

Setting up the Lighthouse on the HY-MAP.

(☞ The default setting is shown.)

2.9-1.6. EEZ

Setting up the EEZ line on the HY-MAP.

2.9-1.7. Screen Magnification

Setting up the Screen Magnification on the HY-MAP.

Page 71

- 71 -

(*MAX Magnification [ ON = 0.05nm, OFF = 0.2nm])

2.9-1.8. Zoom mode

Choosing how to zoom-in/out.

(☞ The default setting is Turbo.)

2.9-2. C-Map (*Only for *C-MAP mode.)

2. 9-2.1. SAT.Image

Setting up the overlay Satellite Image on the C-MAP.

(☞ The default setting is shown.)

2.9-2.2. Font & Symbols

On charts it is possible to set the size of all names and symbols drawn on the charts, selecting

between Normal size and Large size.

(☞ The default setting is normal.).

2.9-2.3. Mixing Level

When the map coverage at the current zoom level does not fill the entire screen, the chartplotter draws

the rest of the map expanding the cartographic information read from, at most, two zoom levels above

the current zoom level. For this reason the map is drawn three times; firstly it draws the two levels

before the current level and then the current level. The area covered by the cartographic data read

from the previous levels is identified by a dotted pattern. When the cursor is moved area not covered

by data of the currents level the chartplotter zooms out to the first level covered by cartographic data.

The default setting is ON.

(☞ The default setting is on.)

2.9-2.4. Perspective View

Chart data may be projected in perspective mode during navigation. This function allows setting the

panoramic View of the chart.

As the upper side of the map is more compressed than the lower side, a wider map area is visible. The

perspective view allows showing more chart information immediately ahead and around the cursor.

(☞ The default setting is off.)

2.9-2.5. Chart Boundaries

Page 72

- 72 -

Sets ON/OFF the displaying of the chart boundaries, which represents the boundaries of the charts

available on the chartplotter. Selecting Auto instead, if we are in background charts only the first chart

levels contained in the C-CARD are displayed, if we are in a charts level contained in the C-CARD the

next four charts level are displayed.

(☞ The default setting is auto.)

2.9-2.6. Multi Language

Select language for name of the place, lighthouse or buoy.

(☞ The default setting is English.)

2.9-2.7. QuickView

It is available to set up. Place the cursor on buoys or icons on the C-MAP, the information window is

shown up automatically.

(☞ The default setting is hidden.)

3. Vessel

3.1. Vessel Icon Size

The size of the present position is adjustable from 0 to 9. The biggest size is ‘0’.

(☞ The default setting is 9.)

3.2. Heading Line

The length of the heading line is adjustable from 50 until 300. The bigger number, the longer line. The

heading line is used in modes of the true motion and the north up.

(☞ The default setting is 270.)

3.3. Vessel style (Circle/Arrow/Vessel)

Select the vessel symbol among Circle, Arrow and vessel.

(☞ The default setting is circle.)

3.4. Orient. Resolution

Sets you preferred Rolling Road Scale.

(☞ The default setting is 0.)

4. Cursor Icon

Select the cursor icon between Cross to Arrow.

Page 73

- 73 -

(☞ The default setting is Cross.)

5. Alarm

5.1. Navigation

5.1. 1. Arrival Alarm:

When you approach into the waypoint range, it gives you a notice with alarm.

(☞ The default setting is OFF.)

5.1.2. Arrival Radius:

It is to adjust the range of arrival from your waypoint. If you have a route, it changes to the next

waypoint automatically.

(☞ The default setting is 0.05nm.)

5.1.3. XTE Alarm:

If you are out of the course, it gives you a notice with alarm.

(☞ The default setting is OFF.)

5.1.4. XTE Radius:

It is to adjust the range of the off course.

(☞ The default setting is 0.25nm.)

5.2. Anchor

5.2.1. Anchor Alarm:

It is necessary when your vessel anchors.

(☞ The default setting is OFF.)

5.2.2. Anchor Radius:

If you vessel is out of the range of the anchor, it gives you notice with alarm.

(☞ The default setting is 0.05nm.)

5.3. Interval

5.3.1. Interval Alarm:

It alarms every time you set.

(☞ The default setting is OFF.)

5.3.2. Interval Time

Page 74

- 74 -

The time is available from one minute until sixty minutes.

(☞ The default setting is 3 min.)

5.4 User Line

5.4.1. User Line Alarm

It alarms if it breaks into the setting area.

(☞ The default setting is OFF.)

5.4.2. User Line Radius

It sets the range of the course alarm.

(☞ The default setting is 0.05nm.)

Page 75

- 75 -

Page 76

- 76 -

AIS getting started

1. What is AIS?

AIS is an Automatic Identification System. It has been introduced to improve the safety of navigation

by assisting in the efficient operation of ship to ship, ship reporting and VTS applications. The system

should enable operators to obtain information from the ship automatically, requiring a minimum of

involvement of ship’s personnel, and should have a high level of availability.

Connecting to the chart plotter an AIS receiver, vessels with AIS transponder within VHF range are

displayed on screen giving he skipper or navigator a visual interpretation of the data of nearby vessels.

This improves safety, and specifically for collision avoidance reasons.

2. AIS system definitions

CPA

Closest Point of Approach is the closest distance that will be achieved between

your vessel and the tracked target, based on your vessel’s speed and direction

and the target’s speed and direction.

TCPA

Time to Closest Point of Approach is the time remaining until the CPA will occur.

Name

Name of ship, 20 characters.

MMSI

Maritime Mobile Service Identity.

MMSI number

A unique 9 digit number that is assigned to DSC radio station. It primarily registers

the boat information in the U.S. Coast Guard’s national distress database for use

in emergency situations.

Target

It is a vessel equipped with AIS. Information about the targets is being received by

AIS Receiver and displayed on the screen.

Active Target

Target located within the Activation Range. Active target is represented by oriented

triangle with COG and Heading vectors. Rate of turn may also be displayed.

Selected

Target

Target selected with cursor. Can view AIS information window.

Page 77

- 77 -

Dangerous

Target

Target detected by CPA or TCPA Alarm. Dangerous target is Active Target by

definition. For better visibility Dangerous Target symbol is charged from basic color

to red color.

Sleeping

Target

Target located outside the Activation Range. Sleeping target is represented by a

small oriented triangle.

Lost Target

When the AIS info is not received from that vessel. The presentation will be

marked X on the target.

3. AIS information window

Press [ENTER] key on Target which wants to see. It shows Information of “AIS INFO” window.

(Fig.3.1)

Page 78

- 78 -

4. Quick INFO on AIS target

Choose “AIS information window” on (Fig.3.1) and AIS data shows under the AIS target.

(*Up to four kinds of data is available to choose in Quick INFO)

Page 79

- 79 -

AIS operation

▶[MENU]->AIS

1. AIS On/Off

Turns the display of AIS targets overlay on the screen On or Off.

(☞ The default setting is On.)

2. List

2.1. List

(Fig.3.2)

①

Name

Name of the AIS target

②

MMSI

MMSI of the AIS target

③

Range

Distance between the AIS target and the present position

④

BRG

Bearing between the AIS target and the present position

①

② ③ ④

Selected(blue color)

Page 80

- 80 -

Page 81

- 81 -

2.2. Detail

Choose the AIS target and press [ENTER].

2.3. Goto

Choose the AIS target and press .

Page 82

- 82 -

Page 83

- 83 -

2.4. Sort

Press to choose how to sort on (Fig.3.2).

3. Display radius

Displays range rings centered on your current position.

(☞ The default setting is OFF.)

4. AIS target size

Choose the size of AIS tartget.

(☞ The default setting is Large.)

5. Display vessels by Color

Different types of AIS transmissions can be selected to display different colors of icons on the chart

Page 84

- 84 -

display.

6. Display vessels by Type

Different types of AIS transmissions can be selected to display different types of icons on the chart

display.

7. Filter AIS types

This function allows you to turn on or off reception from different types of AIS transmissions, for

instance if you only wanted to view Class B vessels on the chart display then select Class B On and all

the others Off.

8. Alarm

8.1. CPA Alarm

The CPA alarm is the closest approach alarm, this allows you to set a distance when the alarm will

sound if a vessel comes within that distance .

(☞ The default setting is OFF.)

8.2. CPA Range

The values allowed are from 0.1nm to 10nm.

(☞ The default setting is OFF.)

8.3. TCPA Alarm

The TCPA alarm is the time that a vessel will take to be in the same position as you currently are.

(☞ The default setting is OFF.)

8.4. TCPA Range

The values allowed are from 1 to 50 min.

(☞ The default setting is 1 min.)

8.5. Radius Alarm

When any AIS target breaks into the radius, alarming.

8.6. Radius

The values allowed are from 0.1nm to 10nm.

(☞ The default setting is OFF.)

8.7. Ignore Vessels if Speed Less

Page 85

- 85 -

If you want the alarms to ignore vessels that are travelling at less than a particular speed then switch

ON.

8.8. Speed less than

The values allowed are from 0.1kt to 9.9kt.

9. Set up AIS outs etc

9.1. Mark vessels as lost after

Setting the time of “Lost target”.

(☞ The default setting is 7min.)

9.2. Remove lost vessels after

If the updating AIS target is unavailable in the set time, erasing the AIS target on the screen..

(☞ The default setting is 10min.)

9.3. Vessel target

It is available to setup the own vessel’s AIS target display on the screen.

(☞ The default setting is On.)

10. Others

10.1. Labels on vessels

This menu controls what details are displayed alongside the vessels icons on the chart display.

10.2. Cursor Box info

When you move the cursor in chart mode over an AIS target a box appears showing details of that

vessel.

10.3. Messages List

This window displays lists of specific AIS messages, such as Safety Messages that the unit has

received. Scrolling down the list and highlighting a message allows you to see the contents by

pressing the [ENTER] key. Whilst in the main list pressing the [MENU] key when a message is

highlighted will erase that message, pressing the [►] [◄] keys will allow you to view any other pages

of messages.

★ AIS SART Messages

If an AIS SART message is received it will immediately be displayed on whatever screen you are

Page 86

- 86 -

viewing. If the “Status” shows “Test” then no further action is required as it is just a test transmission. If

the “ Status” shows “Active” it will also show the MMSI, Name and position, the SART icon should now

be displayed on your chart screen at that location. Monitor your VHF radio on Channel 16 and

establish whether any other station has received this SART message, if not take the appropriate action.

10.4. Test View

Showing the text massage of SART Message.

(☞ The default setting is Off.)

10.5. Fishing net

10.5.1. Fishing net

Display the programmed Fishing net AIS target.

(☞ The default setting is Off.)

10.5.2. Select name

Program the name of Fishing Net

10.5.3. Alarm

The alarm goes off when no Fishing net AIS target is in setting range.

(☞ The default setting is Off.)

10.5.4. Alarm Radius

Setup the Fishing net alarm range.

(☞ The default setting is 0.05nm.)

Page 87

- 87 -

Page 88

- 88 -

#Fishfinder getting started

1. Choosing the frequency

In dual frequency mode, choosing the frequency with [▲][▼].

(*The chosen frequency shows in red)

2. Auto/Manual Gain

Press [ENTER] to choose” AUTO/Manual” of Gain.

3. Gain/STC

Choose “Gain” and “STC” with [◀][▶].

4. Controlling Gain

1. Choose the frequency.

2. Choose the gain.

Selected

Page 89

- 89 -

3. Twisting the rotary key to control the gain.

5. Controlling STC

1. Choose the frequency.

2. Choose the STC.

3. Twisting the rotary key to control the STC.

6. Mode

▶[MENU]->Mode

Three kinds in Fishfinder.

6.1. Normal

Normal mode (with Auto Range active) displays the sounder image with the surface at the top of the

screen and the sea bottom in the lower part of the screen. The depth scale indicates the depth range

appearing in the display. Bottom contours and fish echoes are displayed at the depths where they are

detected. If the depth Range is set manually to a value less than actual water depth, sea bottom

echoes are not displayed, but all other echoes within the Range setting are displayed.

6.2. Bottom Zoom

Page 90

- 90 -

Bottom Zoom magnifies the sounder display from the sea bottom toward the surface for a short

distance. The sea bottom contour is displayed and additional contour lines are added at intervals

above the sea bottom to aid in determining distances of echoes near the bottom. Use the Sounder

Menu to set the magnified Bottom Range from 2.5 to 20m (10 to 60ft.). Default setting is 10m (40ft.). If

the depth Range is set manually, the setting must place the sea bottom echo in the lower portion of the

screen for Bottom Zoom to be effective.

6.3. Bottom Lock

Bottom Lock divides the Fishfinder main screen image for the selected Fishfinder into two sections.

The left hand section displays a Normal Mode image. The right hand section of the screen displays the

Fishfinder image relative to the sea bottom. The sea bottom appears as a straight line with the

Fishfinder image magnified for a short distance toward the surface. A scale

appears on the right for estimating distances of echoes near the bottom. Use the Fishfinder Manu to

set the magnified Bottom range from 2.5 to 20m (10 to 60ft.). Default setting is 10m (40ft.). If the depth

Range is set manually, the setting must place the sea bottom echo in the

lower portion of the screen for Bottom Lock to be effective.

Page 91

- 91 -

Fishfinder modes are selectable for single frequency or dual and some functions, for example bottom

zoom or lock.

7. VRM

▶ [WPT]

The VRM (movable marker) shown by the green line can be moved up and down.

It is convenient to measure the depth by aligning with the target such as school of fish.

Page 92

- 92 -

[Fig.2.1]

#Fishfinder operation

1.Menu

▶ [MENU]

1.1. Userdata

It is same as Chartplotter. PLS refer the Chartplotter operation manual.

1.2. Deep Depth Range

Smart4/5 selects the best condition for measuring the depth automatically in the environment of the

sea.

(☞ The default setting is Auto.)

1.3. Shift

A user selects this function to see more detailed bottom of the sea. When you turn up the shift, the

range of Fish finder shall go up from the shift range. For example, if you raise 5m of shift at 20m range,

the surface shall start 5m and the bottom range shall be 25m.

(☞ The default setting is 0m.)

1.4. Mode

Page 93

- 93 -

Fish finder modes are selectable for single frequency or dual and some functions.

1.5. Bottom Zoom Range

Select the range of the bottom zoom or lock. It is necessary to modify the bottom.

(☞ The default setting is 10m.)

1.6. Fish symbol

Fish symbol with sizes and levels show for targets.

(*Fish symbol is only for reference. This could be different from the real.)

1.7. Fish size

Setup to display of the size of fish.

(☞ The default setting is Off.)

1.8. Interference Rejection

When there are another boats around you on sailing, your Fish finder could be disturbed to work. The

step of the function is from off to level 2. The bigger number, the more rejection.

(☞ The default setting is OFF.)

1.9. Noise Rejection

Your Fish finder could be disturbed by the engine noise. This function can reject the noise from the

engine or other machinery instruments.

(☞ The default setting is OFF.)

2. Advanced Menu

▶ [MENU] -> Advance

2.1. Display

2.1.1. A-scope

A-scope shows the research under the water by a scope to see the environment under the water.

(☞ The default setting is OFF.)

2.1.2. Image Speed:

Select the speed of Fish finder image from 4X until 1/32X.

(☞ The default setting is 1X.)

2.1.3. White Line

Page 94

- 94 -

It is necessary to research a detailed fish on the bottom or a seaweed under the sea. The color of the

bottom changes into white or black to see the bottom easier than red.

(☞ The default setting is OFF.)

2.1.4.Depth

Shown/Hidden the depth range on the screen.

(☞ The default setting is shown.)

2.1.5.Depth Font

Select the depth range font size on the screen.

(☞ The default setting is Large.)

2.1.6.TEMP

Shown/Hidden the temperature on the screen.

(☞ The default setting is Hidden.)

2.1.7.TEMP Font

Select the temperature font size on the screen.

(☞ The default setting is Large.)

2.1.8. Image Filtering

This function is reduction of the noise.

(☞ The default setting is On.)

2.2. Color

2.2.1. Color Level

This function adjusts the colors. Make it upper level, the color becomes darker.

(☞ The default setting is OFF.)

2.2.2. Color Rejection

There are 16 color levels for Fish finder. The color bar is on the left of the Fish finder. If the level is

higher, the color of the bar is deleted one by one.

2.2.3. Screen Color

Select he back ground color of the Fish finder for your convenience.

2.3. Pulse

Page 95

- 95 -

Select the pulse of the output from the transducer. Levels are among Low, Medium and High, which

depends upon the depth. Low is proper to research precise a fish school but it is not suitable to

measure a deep depth. High is opposite from Low.

(☞ The default setting is Medium.)

2.4. Output Power

Select the output from the installed transducer. Levels are from off to 3. It should be careful about the

depth. If you set high level in a sallow depth, the Fish finder screen turns to red. You see nothing

expect red on the screen.

(☞ The default setting is 3.)

2.5. Alarm

2.5.1. Depth

2.5.1.1. Deep Depth Alarm

It alarms when the set deep depth is out of the range.

(☞ The default setting is OFF.)

2.5.1.2. Deep Depth Range

Setup the range of deep depth alarm

(☞ The default setting is 0M.)

2.5.1.3. Shallow alarm

It alarms when the set shallow depth is out of the range.

(☞ The default setting is OFF.)

2.5.1.4. Shallow range

Setup the range of shallow depth alarm

(☞ The default setting is 0M.)

2.5.2. TEMP(Temperature)

2.5.2.1. High alarm

It alarms when the set high temperature is out of the range.

(☞ The default setting is OFF.)

2.5.2.2. High Range

It alarms when the set high temperature is out of the range.

(☞ The default setting is 0.)

2.5.2.3. Low alarm

It alarms when the set low temperature is out of the range.

Page 96

- 96 -

(☞ The default setting is OFF.)

2.5.2.4. Low range

It alarms when the set low temperature is out of the range.

(☞ The default setting is 0.)

2.5.3. Fish-School

2.5.3.1. Alarm

It alrams when it detects school of fish.

It will detect school of fish depend on set depth, range and level of the fishfinder.

(☞ The default setting is OFF.)

2.5.3.2. Fish-school Depth

If the alram is on, It is available to setup the depth of the Fish-school

(☞ The default setting is 10m.)

2.5.3.3.Alarm range

If the the alram is on, It is available to setup the Range(hight) of the Fish-school.(The bar, next of

display is shown)

(☞ The default setting is 50m.)

2.5.3.4. Alarm Interval

If the the alram is on, It is available to setup the alarm interval.

(☞ The default setting is middle)

2.5.3.5. Color Level

If the the alram is on, It is available to setup the color level.

It is available to setup the color level

2.6. Water Temp

The error of water temp value can be corrected.

(setting:-10.0~10.0℃,-10~10°F)

(☞The default setting is 0.)

2.7. TD Setup

Choosing the frequency of the TD.

2.8. Speed Source

Switch the Sensor/NMEA.

- InsideSensor: Use the built-in speed meter for sensor.

- NMEA: Use the external input value for NMEA.

(☞The default setting is NEMA.)

Page 97

- 97 -

.

Page 98

- 98 -

.

Page 99

- 99 -

General operation

1.GPS

It is available to control and confirm information in GPS receiver.

1.1. Coordinate System

It sets coordinate system of GPS or Loran.