Page 1

SP-110C Autopilot

USER MANUAL

IMPORTANT: PLEASE RETAIN ON BOARD

Page 2

(This page intentionally left blank)

Page 3

Contents

Warning! 2

SP-110C Autopilot System 3

Initial Operational Settings (SP-110C) –

Without Rudder Feedback 17

Turn Ratio 18

Initial Operational Settings (SP-110CR) –

With Rudder Feedback 9

Compass Alignment 10

Rudder End Limits – Automatic Set Up

(Rudder Feedback Required) 11

Rudder End Limits – Manual Set Up

Main Screen Explained 22

Manual Steer Mode 22

Auto Steer Mode 23

GPS Steer Mode 24

Error Messages 25

(Rudder Feedback Required) 12

Rudder Ratio (Proportional Gain) 13

Rudder Sensitivity (Rudder Tolerance) 13

Error Gain (Integral Control Gain) 13

Rate of Change

(Derivative Gain Multiplier) 14

Rate of Turn (Max Turn Angle) 14

Dead Band 15

BOD Correction (GPS Mode) 15

Reverse Delay 15

Advanced Option s

(Recommended for Installers Only) 25

Steering Menu 26

Coms Menu 27

Elecom Menu (Compass Calibration) 27

GPS Menu (NMEA Corrections) 29

Factory Default 29

About 30

Setting up Your GPS Unit 30

Minimum Speed 16

Backlight Bright 16

Wind Mode

SP-110C Alarms 31

Definition of Terms 31

(Requires MWV NMEA Data Input) 16

Testing Procedure 32

Trouble Shooting 33

Declaration of Conformity 34

Warranty 35

Additional Information 35

Block Diagram of Full System

3

Pulse Size

18

Installation of System Components

3

Rate Tolerance

19

Display Unit

4

Period

19

Compass

5

Rate of Turn (Max Rudder Angle)

19

Rudder Feedback Unit

6

Dead Band

19

Rudder Feedback / GPS Wiring Diagrams

8

BOD Correction (GPS Mode)

20

GPS Wiring Connections

8

Reverse Delay

20

Hydraulic Reversing Motor Connection

9

Minimum Speed (Requires GPS SOG)

21

Mechanical Reversing Motor Connection

9

Backlight Bright

21

Solenoid Connection

9

Wind Mode

(Requires MWV NMEA Data Input) 21

Page 4

Warning!

• THE AUTOPILOT IS A

NAVIGATIONAL AID; AN

ADEQUATE WATCH MUST BE

MAINTAINED AT ALL TIMES

WHEN AUTOPILOT IS IN USE.

• THE AUTOPILOT MUST BE

PLACED IN MANUAL MODE

WHEN THE VESSEL IS

STATIONARY AS THE SYSTEM

WILL CONTINUE TO DRIVE THE

RUDDER TO THE END OF ITS

TRAVEL AND DAMAGE TO THE

SYSTEM MAY RESULT.

• IT IS STRONGLY

RECOMMENDED THAT THE

AUTOPILOT NOT BE USED

WHILE NAVIGATING IN

RESTRICTED WATERWAYS

AS WATER CURRENTS,

WIND CHANGES OR RADIO

TRANSMITTER INTERFERENCE

CAN ENDANGER YOUR OWN OR

OTHER VESSELS.

• IF A GPS IS CONNECTED TO

THE SYSTEM, THE AUTO MODE

WILL NOT ENGAGE BELOW A

SPEED OF ONE KNOT AND WILL

DISENGAGE FROM AUTO WHEN

THE VESSEL SLOWS TO ONE

KNOT.

2 of 35

SI-TEX SP-110C

Page 5

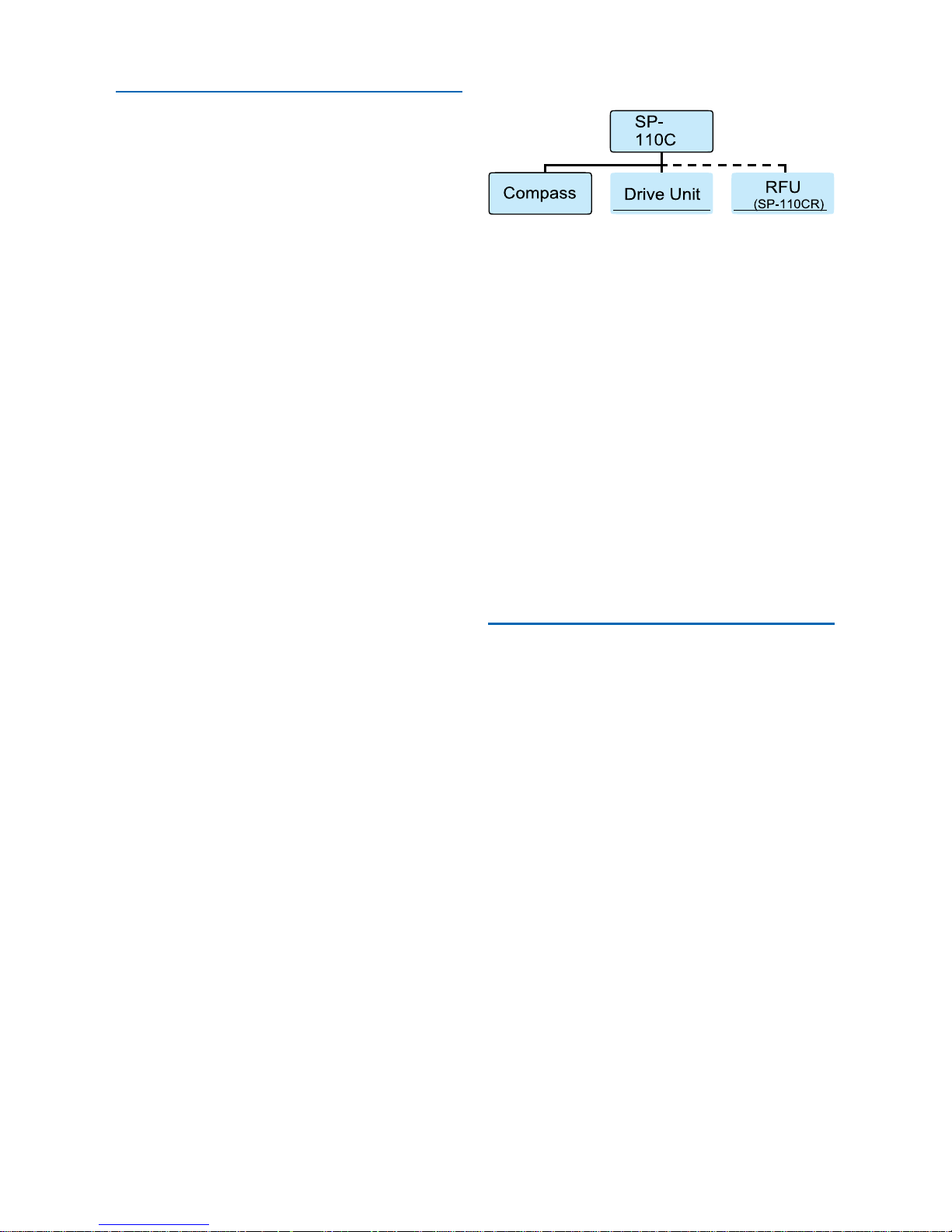

SP-110C Autopilot

System

The SP-110C Autopilot control

system comprises the following units:

• SP-110C display and control head.

• SI-TEX E-compass

• Rudder Feedback Unit

(SP-110CR only).

In addition the SP-110C has to be

connected to a drive unit which

controls the rudder actuator system

in order to complete the full autopilot

system. The actuator system

provides the physical movement to

the rudder responding to the direction

of control signals provided by the SP110C. A rudder actuator system

comprises one of the following:

• Hydraulic system with helm pump

and ram

• Mechanical steering system

The autopilot should be connected

to a:

• Reversing motor / pump set

connected into the existing

hydraulic steering system; or

• Continuously running Hydraulic

Pump with solenoid control.

• Reversing mechanical drive unit

connected to the existing steering

mechanism

Block Diagram of full system

*Dashed line (RFU) only for

applicable for SP-110CR.

The SP-110C display provides full

control of the autopilot system and

indicates different modes for heading,

course to steer and rudder angle.

The system requires a supply voltage

of 12-24 Volts DC (Up to 29V During

Charging)

Installation of System

Components

Ensure you have all the components

of the autopilot.

Tools required:

• Screwdrivers – flat blade and

Phillips head

• Side cutting pliers

• Wire strippers

• Spanners (various) or

adjustable spanner

• 70mm hole saw

• Power drill + assortment of drill bits

• Multi meter (DVM)

• Ancillaries such as tape,

connecting block, screws, cable

ties, etc.

SI-TEX SP-110C 3 of 35

Page 6

Access for wiring must be provided.

Cables have to be run to the power

switchboard, display, compass,

rudder feedback (if fitted) and

drive unit.

All wiring should be kept as far as

possible from radio aerials and aerial

cables to prevent interference to

the radio and to prevent transmitted

signals from the radio influencing

the SP-110C.

The compass must be mounted a

minimum distance of 1 metre from

any boat compass, radios, speakers

or other products with magnetic

properties to avoid interference. The

SP-110C must have a direct

connection to power supply via a 15

amp circuit breaker or a 15 amp

fused circuit and an isolating switch.

Display Unit

Position:

The SP-110C Head unit should be

mounted in a position accessible to

the steering position and protected

from direct rain or salt water.

• Select a dry position

• For in dash mounting cut a 70mm

(2.5”) hole (an optional mounting

bracket is available and may be

used for display mounting – see

your supplier)

• Drill mounting screw holes

• Mount the display using screws

supplied (304 SS – 6G)

• Fit dome plugs to cover screws

• Ensure motor (yellow) and clutch

(green) wires are not exposed

before connecting power to the

SP-110C

• Connect red wire to + 12 volts DC

(Positive)

• Connect black wire to - 12 volts DC

(Negative)

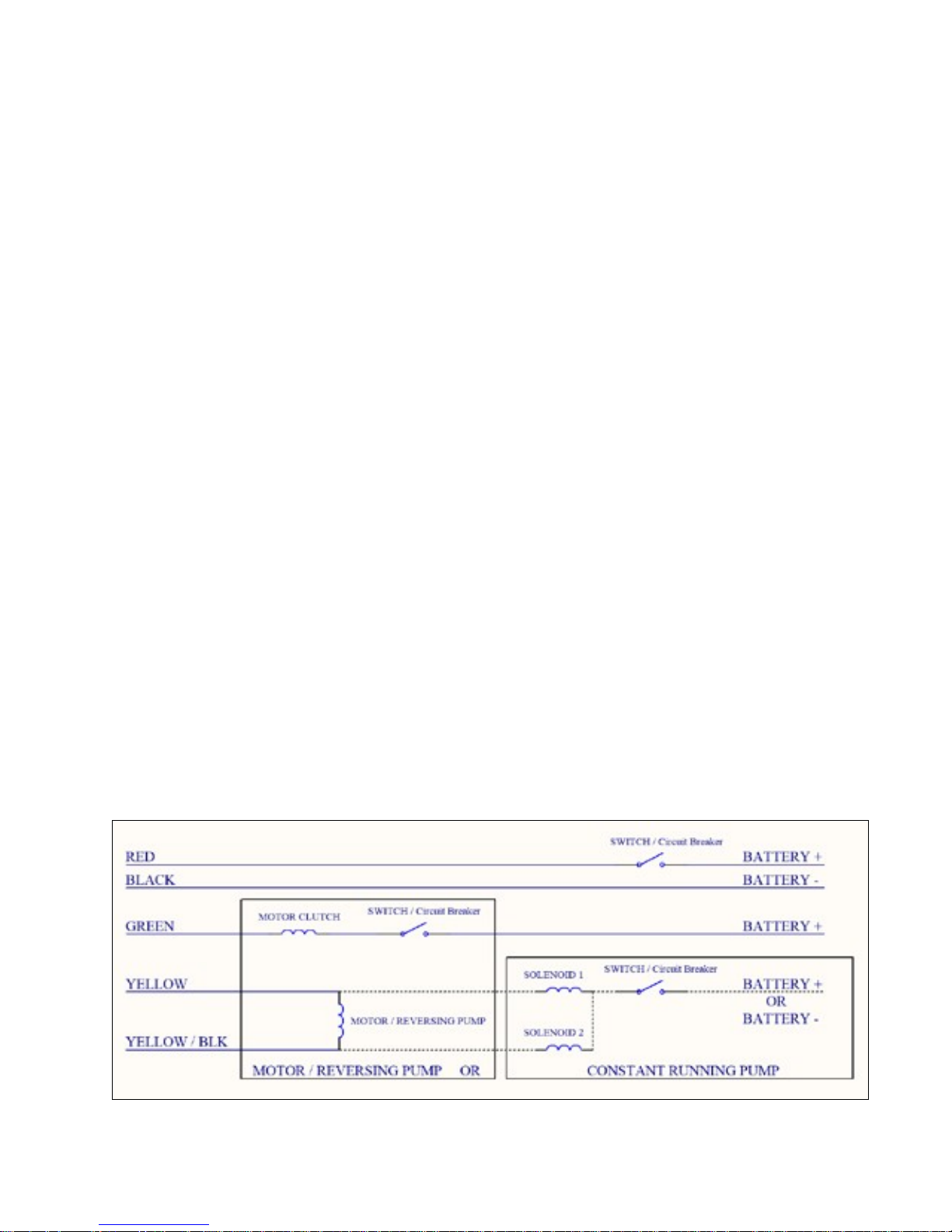

Figure 1: (below) Wiring Diagram

4 of 35

SI-TEX SP-110C

Page 7

Compass

Take care when handling the

compass as it is a sensitive piece of

equipment. The compass position

is the most important item in the

installation of the autopilot. Good

course holding is dependent on the

compass being free from magnetic

interference and exces s ive r olling

or pitching.

Position:

• Select a dry position free from

magnetic interference. (Note other

side of bulkheads and deck heads

for magnetic type objects)

• Avoid positions near radios,

speakers, aerial cables or any other

current carrying cable.

• Mount the compass horizontally

with the arrow (bow) pointing in the

same direction as the boat’s bow.

Use non-magnetic screws (316

grade stainless steel)

• Run cable to SP-110C display

position (keep away from other

cables)

• Connect compass cable to

SP-110C compass socket

Compass Mounting:

Vessel Bow

Figure 2: E-Compass V3

Figure 3: E-Compass V4

SI-TEX SP-110C 5 of 35

Page 8

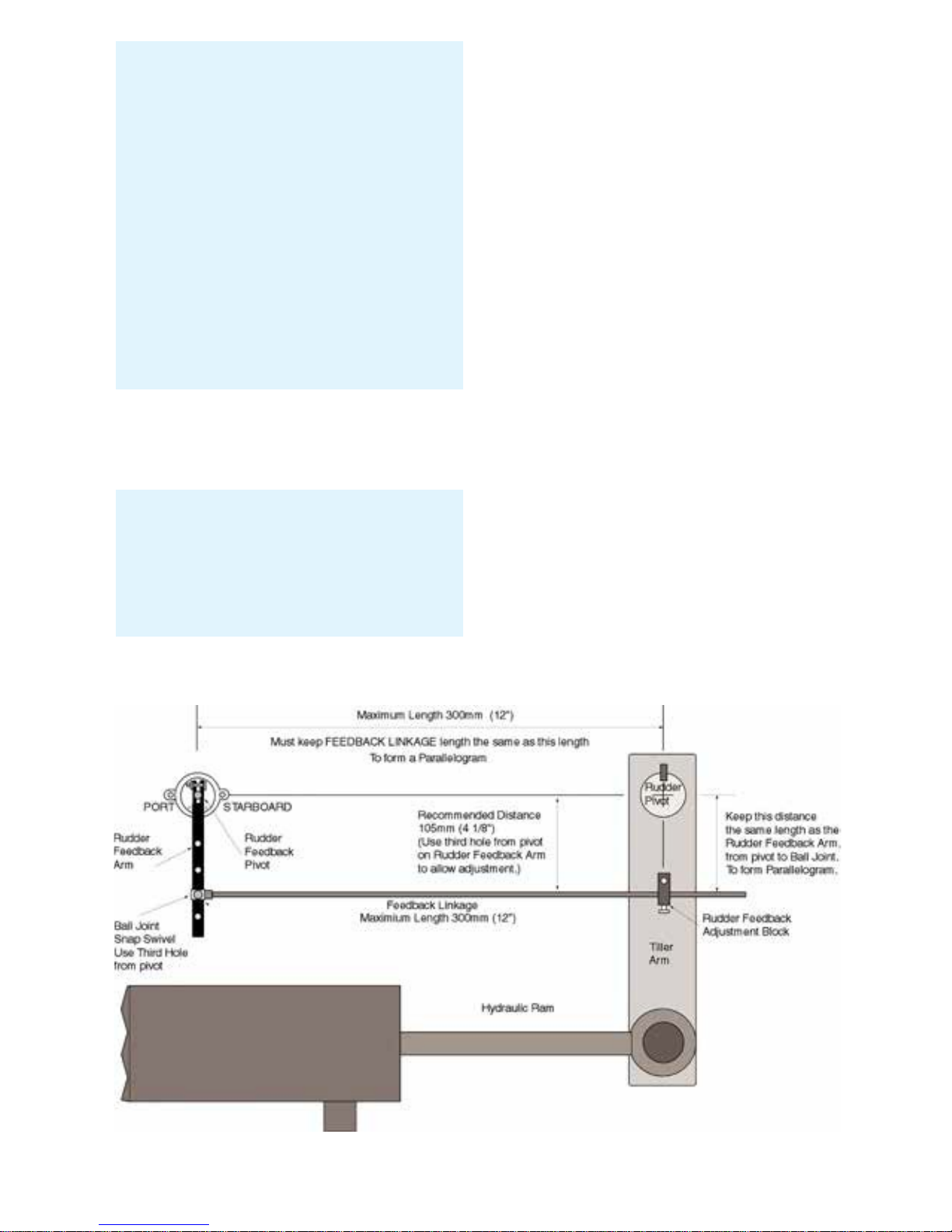

Rudder Feedback Unit

*Only for SP-110CR version.

The SP-110CR Autopilot is

supplied with an RFU (rudder

feedback unit), which provides to

the pilot a precise position of the

boat rudder.

Position:

• Refer to diagram on page 7

• Mount rudder feedback adjacent to

the tiller (rudder feedback movement

must copy the angular movement

of the tiller). Use mounting bracket

if required

• Note markings on the rudder

feedback unit. P & S indicate the

required movement of the tiller

for course correction (Port and

Starboard).

• Rudder feedback is mounted

with shaft uppermost

• Fit snap lock swivel joint to rudder

feedback arm

• Fit link block to tiller arm

• Fit link arm from rudder feedback

to tiller – adjust for correct angle

• Route cable to SP-110CR

display position

• Connect rudder feedback cable

to SP-110CR rudder socket

• When installation is complete,

slowly move the steering by hand

to ensure:

a)

The direction indicated on the

top of the RFU is correct

b)

No undue mechanical strain

is placed on the feedback or

linkage

Figure 4: Rudder feedback unit.

Page 9

6 of 35

SI-TEX SP-110C

Page 10

Rudder Feedback Installation

Diagram

Figure 5:

SI-TEX SP-110C 7 of 35

Note: The rudder feedback unit is

water resistant. However, if it is to

be mounted in a wet position, some

protection should be provided to

ensure the unit does not become

excessively expose d or submersed

in water.

The rudder feedback unit may be

mounted upside down, in which

case the blue and red wires in the

cable must be reversed (yellow

wire in cable is not used in the

feedback).

Note: The rudder feedback is

factory aligned. The arm should

not be removed or loosened on the

shaft as this will affect the “O” ring

seal.

Page 11

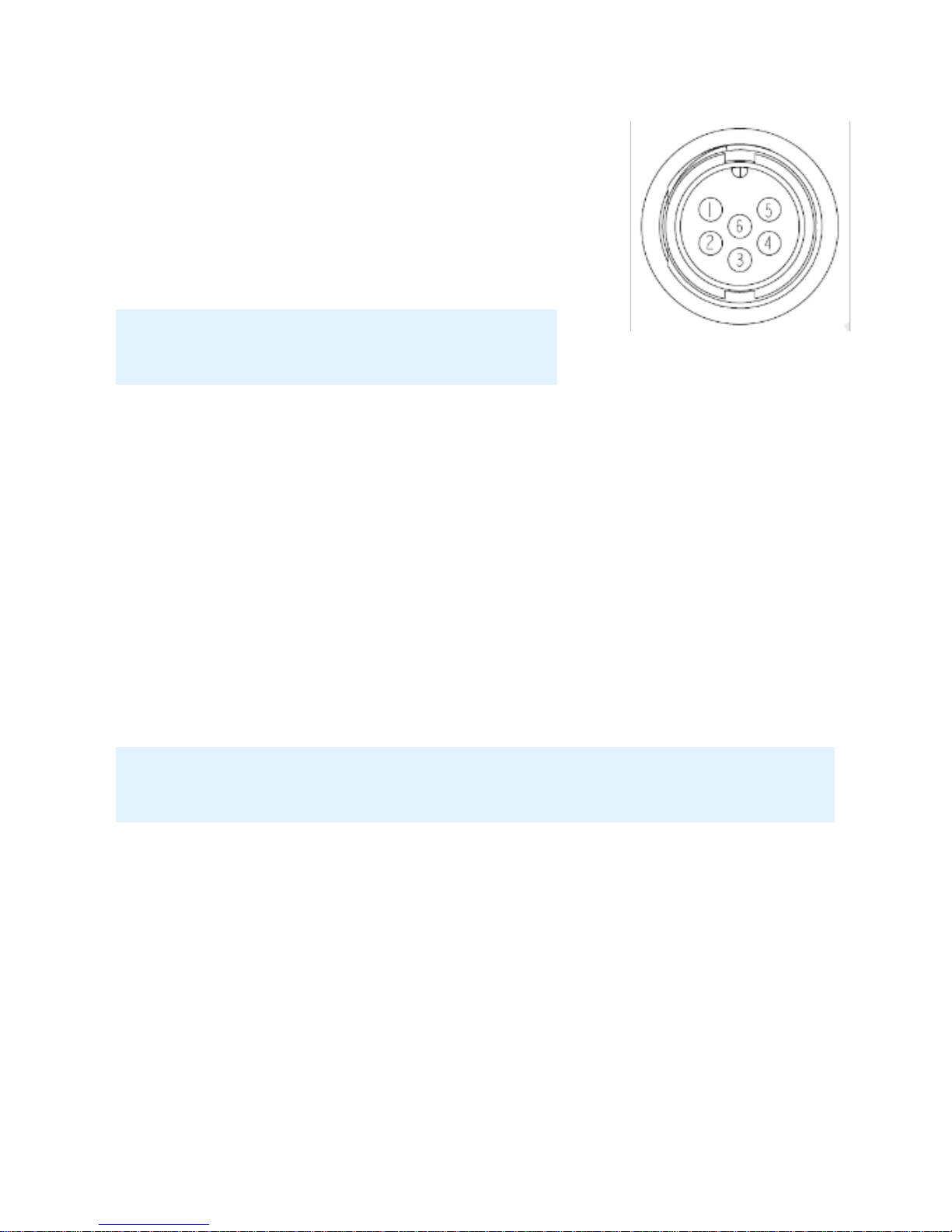

Rudder Feedback / GPS Wiring Diagrams

Pin connections from rear of plug, solder connection side.

Pin 1 has adjacent dot. See Figure 6.

Pin 1 5V Rudder Feedback Supply

Pin 2 Rudder Feedback Wiper Return

Pin 3 0V Rudder Feedback Supply

Pin 4 TX Data (heading information)

Pin 5 + GPS Input (Positive)

Pin 6 - GPS Input (Negative)

Figure 6: Pin Assignments

SP-110C View

GPS Wiring Connections

Pin connections from rear of plug, solder connection side.

Pin 5 + GPS Input (Positive) - white wir e

Pin 6 - GPS Input (Return) - green wir e

For GPS navigation, connect the GPS unit via the two wires coming from

the back of the rudder feedback plug on the SP-110C displ a y unit.

Heading Data out is also available

Pin 4 + Heading Data Out (Positive) - red wire

Pin 3 - Heading Data Out (Negative) - blue wire (0 volt line)

8 of 35

SI-TEX SP-110C

Note: For information on connecting different

brands of GPS units, refer to the relevant GPS manual

Note: Pin locations are relative to pin 1 which

always has a dot adjacent.

Page 12

Hydraulic Reversing Motor

Connection

• Route suitable two core cable

(10 amp min) from motor to

SP-110C display

• Connect motor cable to the yellow

and yellow/black motor wires at

SP-110C

Mechanical Reversing Motor

Connection

• Route suitable four core cable

(10 amp min) from motor to

SP-110C display

• Connect motor wires to the yellow

and yellow/black motor wires at

SP-110C

• Connect one clutch wire to green

wire at SP-110C

• Connect second clutch wire to

+ 12 VDC voltage supply

• Go to into Settings Page 2, and

choose solenoid negative for

common negative or solenoid

positive for common positive

Initial Operational

Settings (SP-110CR) –

With Rudder Feedback

The initial set up of the SP-110C

is done onc e the system

installation is complete and

power has been connected to

the SP-110C display control. The

set up can be done automatically

or manually Automatic installation

set up

determines the output polarity for motor

direction and rudder limit setting.

The installation procedure is

designed to work on a rudder speed

of approx. 8 to 20 seconds hard over

to hard over. The process may fail

with faster or slower rudder

movement in which case the manual

set up should be used.

The maximum r udder trave l wil l be

set to approx. 33º e ach sid e in the

automatic set up.

Solenoid Connection

• Route suitable two core cable (5

Amp min.) from solenoids to SP110C

• Connect solenoid connection to

either positive or negative supply.

• Fit diodes (eg 1N4007) to

solenoids. Ensure the line on the

diode is on the positive terminal on

solenoid.

SI-TEX SP-110C 9 of 35

Note: If a linear hydraulic drive

is used, the connections are for

mechanical drive.

Note: If the manual set procedure

is used, motor direction and both

rudder end limits must be set.

Notes:

Motor direction can be checked

with SP-110C in MANU AL by

pressing ◄ or ► once power has

been connected to the SP-110C

Page 13

Compass Alignment

Your electronic com pas s may not be

aligned correctly due to mounting etc.

SP-110C can adjust the heading

reading from the compass to account

for alignment error.

You will require an alternative

heading reference to set the

adjustment (eg. Magnetic compass /

GPS plotter etc)

To commence:

• Switch power on to SP-110C

• Wait until Main Screen is displayed

(Figure 8)

• Hold MODE button, Settings Page

1 will appear (Figure 9)

• Press MODE and AUTO buttons at

the same time. Install Options 1 will

appear (Figure 10)

• Scroll down to COMPASS

ALIGNMENT using the ► Button

• Press AUTO button to edit

• The large Orange number is the

raw heading reading from the

electronic compass

• The large Green number is the

Corrected Compass (Aligned)

heading.

• Press ◄ or ► to change the

Corrected Compass heading so it

matches your alternative reference

(Figure 7)

• Press MODE to exit back to

Settings Page 1

• Press MODE to exit back to Main

Screen

• The live compass reading on the

main screen will be the Corrected

Compass heading.

• All steering will use the Corrected

Compass heading.

Figure 7: Press ◄ or ► to

change the Corrected Compass

heading so it matches your

alternative reference

10 of 35

SI-TEX SP-110C

Page 14

Rudder End Limits –

Automatic Set up

(Rudder Feedback required)

To commence:

• Switch power on to SP-110C

• Wait until Main Screen is displayed

(Figure 8)

• Hold MODE button, Settings Page

1 will appear (Figure 9)

• Press MODE and AUT O buttons at

the same time. Install Options 1 will

appear (Figure 10)

• Press AUTO button to enter

Steering Menu (Settings Page 2)

Figure 11.

• Ensure USE RFU is set to YES

• Scroll down to END LIMIT AUTO

using the ► Button

• Press AUTO button to start set up

(Figure 12)

• Process will take between 20 and

60 seconds to complete depending

on the speed of the motor

• If process is successful display will

show CAL OK SAVING….

• Press either MODE to cancel the

installation process, display will

show ABORT CALIBRATION

• If CAL ERROR is displayed an

error has occurred

• Check the drive output is

connected and rudder feedback

is moving

• Check rudder feedback installation

• To Exit menu, press MODE button

Figure 8: Example Main Screen

(Manual Steer Mode)

Figure 9: Example Settings Page 1

Figure 10: Example Install Opt ions 1

SI-TEX SP-110C 11 of 35

Page 15

Figure 11: Example Settings Page 2

Rudder End Limits –

Manual Set up

(Rudder Feedback required)

• Switch power on to SP-110C

• Wait until Main Screen is displayed

(Figure 8)

• Hold MODE button, Settings Page

1 will appear (Figure 9)

• Press MODE and AUT O buttons at

the same time. Install Options 1 will

appear (Figure 10)

• Press AUTO button to enter

Steering Menu (Settings Page 2)

Figure 11.

• Ensure USE RFU is set to YES

• Scroll down to END LIMIT PORT

using the ► Button

• Press AUTO button to enter Port

Adjustment (Figure 12)

• Press ◄ to move rudder to Port

• Press ► to move rudder to

starboard

• If direction is incorrect, reverse

the yellow wires, or change SWAP

OUTPUT in previous menu.

• Move to Port Limit, press AUTO

button (Figure 13)

• Press AUTO again to save, or

MODE to abort.

• Scroll down to END LIMIT STBD

using the ► Button

• Press AUTO button to enter

Starboard Adjustment

• Move to Starboard Limit, press

AUTO button

• Press AUTO again to save, or

MODE to abort.

• To Exit menu, press MODE button

Figure 12: Port Limit Adjustment

Figure 13: Save Limits Confirmation

Screen

12 of 35

SI-TEX SP-110C

Page 16

Rudder Ratio

(Proportional Gain)

Factory default setting is 3 and

should only be altered during

sea trials

• With Main Screen displayed

(Figure 8)

• Hold MODE button, Settings

Page 1 will appear (Figure 9)

• Press AUTO to edit RUDDER

RATIO

• Press ► to increase setting

(larger rudder ratio)

• Press ◄ to decrease setting

(smaller rudder ratio)

• Press MODE to return to

Settings Page 1

• Press MODE to return to

Main Screen

Rudder Sensitivity

(Rudder Tolerance)

Factory default setting is 4 and

should only be altered during

sea trials

• With Main Screen displayed

(Figure 8)

• Hold MODE button, Settings

Page 1 will appear (Figure 9)

• Press ► to scroll down to

RUDDER SENSE

• Press AUTO to edit

RUDDER SENSE

• Press ► to increase setting

(more tolerance to the rudder

position error)

• Press ◄ to decrease setting

(less tolerance to the r udder

position error)

• Press MODE to return to

Settings Page 1

• Press MODE to return to

Main Screen

Error Gain

(Integral Control Gain)

Factory default setting is 5 and

should only be altered during

sea trials

• With Main Screen displayed

(Figure 8)

• Hold MODE button, Settings

Page 1 will appear (Figure 9)

• Press ► to scroll down to

ERROR GAIN

• Press AUTO to edit ERROR GAIN

SI-TEX SP-110C 13 of 35

Note: Increasing the Rudder

Sensitivity too high can cause

vessel wandering

Note: A value of 1 signifies the

minimum amount of applied rudder.

When the rudder setting is too

low, vessel track will be slow i.e.:

understeer due to too little rudder

applied. A value of 20 signifies

the maximum amount of applied

rudder. When the rudder setting is

too high, vessel track will be rapid

i.e.: oversteer due to too much

rudder applied.

Page 17

• Press ► to increase setting

(more turn to target heading)

• Press ◄ to decrease setting

(less turn to target heading)

• Press MODE to return to

Settings Page 1

• Press MODE to return to

Main Screen

Rate of Change

(Derivative Gain Multiplier)

Factory default setting is 3 and

should only be altered during

sea trials

• With Main Screen displayed

(Figure 8)

• Hold MODE button, Settings

Page 1 will appear (Figure 9)

• Press ► to scroll down to RATE

OF CHANGE

• Press AUTO to edit RATE

OF CHANGE

• Press ► to increase setting (more

dampening of error)

• Press ◄ to decrease setting (less

dampening of error)

• Press MODE to return to Settings

Page 1

• Press MODE to return to Main

Screen

Rate of Turn

(Max Turn Angle)

Factory default setting is 500°M

and should only be altered during

sea trials

• With Main Screen displayed

(Figure 8)

• Hold MODE button, Settings Page 1

will appear (Figure 9)

• Press ► to scroll down to RATE

OF TURN

• Press AUTO to edit RATE OF TURN

• Press ► to increase setting (more

attack angle)

• Press ◄ to decrease setting (less

attack angle)

• Press MODE to return to Settings

Page 1

• Press MODE to return to Main

Screen

14 of 35

SI-TEX SP-110C

Note: This limits the max turn

speed of the vessel. Reduce this

to reduce the angle of attack for

getting to target heading.

Note: Increasing Rate of Change

can help dampen Error Gain. If set

too high, vessel may never make it

to target heading.

Note: Increase Error Gain to get

on track faster. If set too high, the

vessel will overshoot the ta rget

heading.

Page 18

Dead Band

Factory default setting is 1.0° and

should only be altered during

sea trials

• With Main Screen displayed

(Figure 8)

• Hold MODE button, Settings

Page 1 will appear (Figure 9)

• Press ► to scroll down to DEAD

BAND

• Press AUTO to edit DEAD BAND

• Press ► to increase setting

(more allowance for error)

• Press ◄ to decrease setting

(less allowance for error)

• Press MODE to return to

Settings Page 1

• Press MODE to return to

Main Screen

BOD Correction

(Applies to GPS Mode only)

Factory default setting is 15 and

should only be altered during

sea trials

• With Main Screen displayed

(Figure 8)

• Hold MODE button, Settings

Page 1 will appear (Figure 9)

• Press ► to scroll down to BOD

CORRECTION

• Press AUTO to edit BOD

CORRECTION

• Press ► to increase setting

(more correction)

• Press ◄ to decrease setting

(less correction)

• Press MODE to return to Settings

Page 1

• Press MODE to return to Main

Screen

Reverse Delay

Factory default setting is 15 and

should only be altered during

sea trials

• With Main Screen displayed

(Figure 8)

• Hold MODE button, Settings

Page 1 will appear (Figure 8)

• Press ► to scroll down to

REVERSE DEL A Y

• Press AUTO to edit REVERSE

DELAY

• Press ► to increase setting

(more delay)

• Press ◄ to decrease setting

(less delay)

• Press MODE to return to

Settings Page 1

• Press MODE to return to

Main Screen

SI-TEX SP-110C 15 of 35

Note: This number increases or

decreases the angle of attack from

a GPS / PC supplied BOD (Bearing

Origin to Destination) when in GPS

mode.

Note: This delay helps reduce

shock load on the rudder drive

train, as it controls the time

between direction chang es ( eg.

Port to Starboard or Starboard to

Port changes)

Note: Increase this to reduce

rudder hunting.

Page 19

Minimum Speed

(Requires GPS)

Only used when no rudder

feedback SOG installed

Factory default setting is 1.0km

and should only be altered during

sea trials

• With Main Screen displayed

(Figure 8)

• Hold MODE button, Settings

Page 1 will appear (Figure 9)

• Press ► to scroll down to

MINIMUM SPEE D

• Press AUTO to edit MINIMUM

SPEED

• Press ► to increase setting (higher

minimum speed)

• Press ◄ to decrease setting (lower

minimum speed)

• Press MODE to return to Settings

Page 1

• Press MODE to return to Main

Screen

Backlight Bright

Factory default setting is 15

(Maximum Brightness)

• With Main Screen displayed

(Figure 8)

• Hold MODE button, Settings

Page 1 will appear (Figure 9)

• Press ► to scroll down to

BACKLIGHT BRIGHT

• Press AUTO to edit BACKLIGHT

BRIGHT

• Press ► to increase setting

(Brighter screen)

• Press ◄ to decrease setting

(Darker screen)

• Press MODE to return to

Settings Page 1

• Press MODE to return to Main

Screen

Wind Mode

(Requires MWV NMEA

data input)

Factory default setting is OFF

• With Main Screen displayed

(Figure 8)

• Hold MODE button, Settings

Page 1 will appear (Figure 9)

• Press ► to scroll down to

WIND MODE

• Press AUTO to edit WIND MODE

• Press ► to enable Wind Mode

• Press ◄ to disable Wind Mode

• Press MODE to return to Settings

Page 1

• Press MODE to return to Main

Screen

16 of 35

SI-TEX SP-110C

Note: This setting is useful for

adjusting screen brightness for day

/ night or low lit areas.

Note: When Wind Mode is ON, the

SP-110C will attempt to correct for

wind effects on vessel steering.

Note: When the vessel is below

this set speed and in Auto or GPS

mode, the SP-110C will revert

back to Manual mode.

Page 20

Initial Operational

Settings (SP110C)

– Without Rudder

Feedback

The initial set up of the SP-110C

is done once the system

installation is complete and

power has been connected to the

SP-110C display control.

Figure 14: Example Main Sc reen

(Manual Steer Mode)

Figure 15: Example Settings Page 1

Figure 16: Example Install Opt ions 1

Figure 17: Example Settings Page 2

Page 21

SI-TEX SP-110C 17 of 35

Page 22

Turn Ratio

Factory default setting is 3 and

should only be altered during

sea trials

• With Main Screen displayed

(Figure 14)

• Hold MODE button, Settings Page

1 will appear (Figure 15)

• Press AUTO to edit TURN RATIO

• Press ► to increase setting (larger

turn ratio)

• Press ◄ to decrease setting

(smaller turn ratio)

• Press MODE to return to Settings

Page 1

• Press MODE to return to Main

Screen

Pulse Size

Factory default setting is 3 and

should only be altered during

sea trials

• With Main Screen displayed

(Figure 14)

• Hold MODE button, Settings

Page 1 will appear (Figure 15)

• Press ► to scroll down to

PULSE SIZE

• Press AUTO to edit PULSE SIZE

• Press ► to increase setting

(longer pulses)

• Press ◄ to decrease setting

(shorter pulses)

• Press MODE to return to Settings

Page 1

• Press MODE to return to Main

Screen

18 of 35

SI-TEX SP-110C

Note: This sets the minimum

solenoid / motor pulse length when

hunting for the heading track.

Note: A value of 1 signifies the

minimum amount of applie d rudder.

When the rudder setting is too

low, vessel track will be slow i.e.:

understeer due to too little rudder

applied.

Page 23

Rate Tolerance

Factory default setting is 15 and

should only be altered during

sea trials

• With Main Screen displayed

(Figure 14)

• Hold MODE button, Settings Page

1 will appear (Figure 15)

• Press ► to scroll down to RATE

TOLERANCE

• Press AUTO to edit RATE

TOLERANCE

• Press ► to increase setting (more

tolerance to the rate of turn error)

• Press ◄ to decrease setting (less

tolerance to the rate of turn error)

• Press MODE to return to Settings

Page 1

• Press MODE to return to Main

Screen

Rate of Turn

(Max Rudder Angle)

Factory default setting is 500°M and

should only be altered during

sea trials

• With Main Screen displayed

(Figure 14)

• Hold MODE button, Settings Page 1

will appear (Figure 15)

• Press ► to scroll down to RATE

OF TURN

• Press AUTO to edit RATE OF

TURN

• Press ► to increase setting

(more attack angle)

• Press ◄ to decrease setting

(less attack angle)

• Press MODE to return to Settings

Page 1

• Press MODE to return to Main

Screen

Period

Factory default setting is 4 and should

only be altered during sea trials

• With Main Screen displayed

(Figure 14)

• Hold MODE button, Settings Page

1 will appear (Figure 15)

• Press ► to scroll down to PERIOD

• Press AUTO to edit PERIOD

• Press ► to increase setting (longer

delay between rudder pulses)

• Press ◄ to decrease setting

(shorter delay between rudder

pulses)

• Press MODE to return to Settings

Page 1

• Press MODE to return to Main

Screen

Dead Band

Factory default setting is 1.0°

and should only be altered during

sea trials

• With Main Screen displayed

(Figure 14)

• Hold MODE button, Settings Page

1 will appear (Figure 15)

• Press ► to scroll down to DEAD

BAND

• Press AUTO to edit DEAD BAND

• Press ► to increase setting

(more allowance for error)

• Press ◄ to decrease setting

(less allowance for error)

SI-TEX SP-110C 19 of 35

Note: This limits the max turn

speed of the vessel. Reduce this

to reduce the angle of attack for

getting to target heading.

Note: Increasing the Rate

Tolerance too high can cause

vessel wandering

Page 24

• Press MODE to return to

Settings Page 1

• Press MODE to return to Main

Screen

BOD Correction

(Applies to GPS Mode only)

Factory default setting is 15 and

should only be altered during

sea trials

• With Main Screen displayed

(Figure 14)

• Hold MODE button, Settings

Page 1 will appear (Figure 15)

• Press ► to scroll down to BOD

CORRECTION

• Press AUTO to edit BOD

CORRECTION

• Press ► to increase setting

(more correction)

• Press ◄ to decrease setting

(less correction)

• Press MODE to return to Settings

Page 1

• Press MODE to return to Main

Screen

Reverse Delay

Factory default setting is 15 and

should only be altered during

sea trials

• With Main Screen displayed

(Figure 14)

• Hold MODE button, Settings Page

1 will appear (Figure 15)

• Press ► to scroll down to

REVERSE DEL A Y

• Press AUTO to edit REVERSE

DELAY

• Press ► to increase setting

(more delay)

• Press ◄ to decrease setting

(less delay)

• Press MODE to return to

Settings Page 1

• Press MODE to return to

Main Screen

20 of 35

SI-TEX SP-110C

Note: This number increases or

decreases the angle of attack from

a GPS / PC supplied BOD (Bearing

Origin to Destination) when in GPS

mode.

Note: This delay helps reduce

shock load on the rudder drive

train, as it controls the time

between direction chang es ( eg.

Port to Starboard or Starboard to

Port changes)

Note: Increase this to reduce

rudder hunting.

Page 25

Minimum Speed

(Requires GPS SOG)

Only used when no rudder

feedback installed

Factory default setting is 1.0kn

and should only be altered during

sea trials

• With Main Screen displayed

(Figure 14)

• Hold MODE button, Settings

Page 1 will appear (Figure 15)

• Press ► to scroll down to

MINIMUM SPEE D

• Press AUTO to edit MINIMUM

SPEED

• Press ► to increase setting

(higher minimum speed)

• Press ◄ to decrease setting

(lower minimum speed)

• Press MODE to return to

Settings Page 1

• Press MODE to return to Main

Screen

Backlight Bright

Factory default setting is 15

(Maximum Brightness)

• With Main Screen displayed

(Figure 14)

• Hold MODE button, Settings

Page 1 will appear (Figure 15)

• Press ► to scroll down to

BACKLIGHT BRIGHT

• Press AUTO to edit BACKLIGHT

BRIGHT

• Press ► to increase setting

(Brighter screen)

• Press ◄ to decrease setting

(Darker screen)

• Press MODE to return to Settings

Page 1

• Press MODE to return to Main

Screen

Wind Mode

(Requires MWV NMEA

data input)

Factory default setting is OFF

• With Main Screen displayed

(Figure 14)

• Hold MODE button, Settings

Page 1 will appear (Figure 15)

• Press ► to scroll down to

WIND MODE

• Press AUTO to edit WIND MODE

• Press ► to enable Wind Mode

• Press ◄ to disable Wind Mode

• Press MODE to return to Settings

Page 1

• Press MODE to return to Main

Screen

SI-TEX SP-110C 21 of 35

Note: This setting is useful for

adjusting screen brightness for day

/ night or low lit areas.

Note: When Wind Mode is ON, the

SP-110C will attempt to correct for

wind effects on vessel steering.

Note: When the vessel is below

this set speed and in Auto or GPS

mode, the SP-110C will revert

back to Manual mode.

Page 26

Main Screen Explaine d

Manual Steer Mode

The live compass heading is

displayed in the top center, as a

bar-graph below it, and in large

green numbers near the middle

of the screen.

Below the large numbers is the

current steering mode (MANUAL

STEER), or an error in red.

The live supply voltage is displayed

top right side.

If Latitude is received via NMEA

input, it will be displayed top left

If Longitude is received via NMEA

input, it will be displayed top right

If vessel speed is received via NMEA

(SOG), it will be displayed top left.

Rudder Angle is indicated by a bar

and number. The number and bar will

be red when Port side, Green when

Starboard side, and yello w when in

center at 0°

Figure 18: Example Manual Steer

Mode Main Screen. Live Compass

heading is 185°, Rudder is at center.

Press ◄ or ► buttons to move

the rudder.

Hold MODE to enter Settings

Page 1

Press AUTO to enter Auto Steer

Mode

Hold MODE and press AUTO to enter

GPS steer mode.

22 of 35

SI-TEX SP-110C

Page 27

Auto Steer Mode

The current target heading is in large

yellow numbers near the middle of

the screen.

If a yellow bar appears within the

compass bar, it indic ates current

deviation from target heading.

Target Heading is 315°, Deviation

is shown as a yellow bar within the

compass bar.

Press ◄ or ► buttons to change the

target heading.

Hold MODE to enter Settings Page 1.

Press AUTO to enter manual steer

mode.

Briefly press MODE to toggle target

heading step size between 1° and

10° (indicated in yellow brackets).

Figure 19: Example Auto Steer Mode

Main Screen. Live Compass heading

is 314°, Target Heading is 314°

Deviation is shown as a yellow bar

within the compass bar.

SI-TEX SP-110C 23 of 35

Page 28

GPS Steer Mode

The live compass heading is

displayed in the top center, as a

bar-graph below it.

If a yellow bar appears with in the

compass bar, it ind icates current

deviation from target heading.

The current target heading received

via NMEA is in large blue numbers

near the middle of the screen. If no

NMEA heading is received, it will

display the current compass heading.

Below the large numbers is the

current steering mode (GPS

HEADING), or an error in red.

The live supply voltage is displayed

top right side.

If Latitude is received via NMEA

input, it will be displayed top left

If Longitude is received via NMEA

input, it will be displayed top right

If vessel speed is received via NMEA

(SOG), it will be displayed top left.

Rudder Angle is indicated by a bar

and number. The number and bar will

be red when Port side, Green when

Starboard side, and yello w when in

center at 0°.

Hold MODE to enter Settings Page 1.

Press AUTO to enter Manual Steer

Mode.

Press ◄ or ► to adjust BOD

correction.

Figure 20: Example GPS Steer Mode

Main Screen. Live Compass heading

is 314°, Target Heading is 313°,

Deviation is shown as a yellow bar

within the compass bar.

24 of 35

SI-TEX SP-110C

Page 29

Error Messages

There are a number of possible error messages that can be displayed on

screen, in place of the current Steer Mode text.

Examples are:

MOTOR SHORT - Over current detected on motor wires

CLUTCH SHORT - Over current detected on clutch wire

ANGLE OFF COURSE - Vessel is more then 45° from Target Heading.

RUDDER AT LIMIT - Rudder has reached the set end stop

RFU DISCONNECTED - Cannot detect the rudder feedback unit

GPS – NO GPS DATA - No NMEA XTE and no BOD received

GPS – NO GPS XTE - No NMEA XTE or APB XTE or RMB XTE received

GPS – NO GPS BOD - No NMEA BOD or APB BOD received

NO XTE – SET DEST - User needs to set a destination waypoint in GPS / PC

VESSEL TOO SLOW - Vessel is too slow to maintain steering without

rudder feedback.

If the Compass is disconnected or faulty, NO COM PASS wi ll be displ a yed in

place of the compass heading, and the compass bar will disappear.

Advanced Options

(Recommended for

installers only)

There are a number of Advanced

Options, recommended for

installers only.

• With Main Screen displayed

(Figure 14)

• Hold MODE button, Settings Page

1 will appear (Figure 15)

• Press MODE and AU TO buttons at

the same time, INSTALL OPTIONS

1 should appear (see Figure 21).

• Press ► to scroll down to desired

menu, press AUTO to enter the

menu

Figure 21: Advanced Sett in gs

(Install Options 1)

SI-TEX SP-110C 25 of 35

Page 30

Steering Menu

(Recommended for

installers only)

For setup of Rudder output and

Rudder end limits (Figure 22 and

figure 23)

• USE RFU – Choose to use Rudder

Feedback or not.

• SWAP OUTPUT – Choose to

reverse the rudder output

• SOLENOID – Choose common

connection polarity when used with

solenoids.

• END LIMIT PORT – Manually set

the Port rudder limit

• END LIMIT STBD – Manually set

the Starboard rudder limit

• END LIMIT AUTO – Automatically

set rudder lim its and rudd er output

direction

Figure 22: Advanced Steer i ng Menu

(Settings Page 2), with USE RFU

enabled

Figure 23: Advanced Steer i ng Menu

(Settings Page 2), with USE RFU

disabled

Coms Menu

(Recommended for

installers only)

This menu is used to monitor live

incoming NMEA data.

• A list of NMEA data headers is

displayed. Headers in White are

being received (Figure 24).

• Press ► to scroll down to desired

header, press AUTO to view

the data.

• Press MODE to return to list

screen.

• Press MODE again to return to

Install Options 1 menu.

• Press MODE to return to Main

Screen

(See images next page)

26 of 35

SI-TEX SP-110C

Note: The set Port and Starboard

rudder limits, and live rudder

position is displayed at the bottom

of the screen (When USE RFU set

to YES)

Page 31

Figure 24: Example Coms Menu

(COMS DIAGNOSTICS)

Figure 25: Example live HDT

(Heading True) compass data

Elecom Menu

(Compass Calibration)

To carry out this procedure the boat

must be in open waters and be able

to safely turn clockwise through 360º.

The purpose of this is to compensate

for local magnetic influences of the

vessel.

• From the Install Options 1 menu,

use ► to scroll down to ELECOM

MENU and press AUTO button.

Press ► to confirm or MODE to

exit (Figure 26)

• When the screen prompts to TURN

THE BOAT, Start turning the boat

clockwise at low speed, hold the

turn constant.

• When calibration is complete, the

screen returns to Install Options

1 menu.

Figure 26: Confirmatio n scr een

SI-TEX SP-110C 27 of 35

Page 32

Figure 27: SP-110C sending

calibration command to Elecom, and

waiting for a response

Figure 28: Start turning the boat

clockwise at low speed, hold the turn.

Figure 29: Elecom calibrat i on

successful

Figure 30: Elecom not commun ic ati ng,

or does not support Calibration mode.

Figure 31: Calibration failed, vessel

Figure 32: Calibration failed, vessel

turning too slow turning too fast.

28 of 35

SI-TEX SP-110C

Page 33

GPS Menu

(NMEA corrections)

These adjustments can be used to

improve tracking when in GPS mode.

• From the Install Options 1 menu,

use ► to scroll down to GPS

MENU and press AUTO button to

enter (Figure 33)

• Scroll to desired setting using ◄

or ►, and press AUTO to modify

setting

• Modify setting using ◄ or ►, and

press MODE to return to list of

settings.

Figure 33: Example GPS Menu

(Track Settings)

Factory Default

This will reset all settings to default

values,

• From the Install Options 1 menu,

use ► to scroll down to FACTORY

DEFAULT, press AUTO button to

enter (Figure 34)

• Follow on-screen instructions

Figure 34: Factory Default (Factory

Reset) warning screen

Figure 35: Factory Default complete.

SI-TEX SP-110C 29 of 35

Page 34

About

This displays information about the

build of the SP-110C,

• From the Install Options 1 menu,

use ► to scroll down to ABOUT,

press AUTO button to enter

(Figure 36)

• Press any button to exit back to

Install Options 1 menu.

Figure 36: About screen example.

Setting up your GPS Uni t

Because there are a great variet y

of GPS units that will work with this

autopilot, the followin g is a guide only.

For more information, consult your

GPS manual.

The GPS unit must be set up to

output “NMEA 0183” data at 4800

baud on a pair of wires, which are

connected to the SP-110C unit via

the rudder feedback connector. The

data generated must include at least

one of the following:

• The APA sentence.

• The APB sentence.

• The BOD and XTE sentences.

• If only the XTE data sentence is

available, the pilot can steer in a

restricted manner only. (See later in

this section.**)

The GPS unit must be programmed

and activated to navigate to a

waypoint, or to follow a line joining

two or more waypoints (called a

route). This unit should then send

information to the autopilot from

which can be calculated the courseto-steer.

Under the following conditions:

• Several waypoints are linked

together into a single route,

• The GPS unit is set and capable of

“auto-sequence” between them,

• An “arrival zone” of more than

0.05 NM (Nautical Miles) is set so

that the GPS can detect when the

vessel has reached a waypoint ;

then the SP-110C will be able to

steer from each waypoint to the

next without intervention.

30 of 35

SI-TEX SP-110C

Page 35

** If only the XTE information is

available from your GPS unit then

your vessel must be on track, and

heading in the correct direction,

before engaging the GPS unit.

The “auto sequence” feature is not

available in this instance.

SP-110C Alarms

A number of conditions will cause

alarms to sound and an alarm

message to flash on the display

Off Course Alarm

In AUTO mode an audible alarm of 3

“beeps” per second will sound when

boat heading is greater than 45º from

the desired course. A red message

will also be displayed on the screen

GPS Alarm

In GPS steering mode an audible

alarm of 1 “beep” per second will

sound when no GPS data is received

by the SP-110C. A red message will

also be displayed on the screen.

Compass Alarm

If there is no reading from a compass,

or no HDM / HDT data incoming, an

audible alarm of 1 “beep” per halfsecond will sound. A red message will

also be displayed on the screen.

Low Speed Alarm

When used without a rudder

feedback (RFU), if the vessel speed

goes below the low speed threshold

set in the settings, an audible alarm

of 1 “beep” per second will sound.

A red message will also be displayed

on the screen.

Definition of Terms

SP-110C Display: The

operational control unit with colour

display and push buttons.

Heading: This is the magnetic

direction of the vessel at the

current time.

Course-to-steer: The dir ection

(heading) which t he auto pil ot is

attempting to maintain.

SI-TEX SP-110C 31 of 35

Note: Prior to engaging GPS

mode, a route or destination must

be programmed and selected in

the GPS for the Autopilot to follow.

Page 36

Testing Proce dure

Initial Inspection and Testing

1. Confirm power to be connected is the required DC voltage.

2. Power Supply 12V-24V DC is available.

3. Ensure polarity of the voltage supply is correct.

4. All electrical connections are correct.

5. Loose cables are clipped or tied up.

Dockside Tests

1. Turn steering wheel fully clockwise and visually check that

moving (mechanical) parts do not foul;

2. Repeat step 1 for anti-clockwise.

3. Return Steering to centre.

4. Switch on SP-110C Autopilot system.

5. Press arrow button to operate steering in that direction.

6. Check that rudder moves in correct direction.

7. Check Rudder direction follows change request.

8. Check Course change provides sufficient Rudder movement.

9. Check compass heading display on SP-110C.

10. Return steering to centre.

32 of 35

SI-TEX SP-110C

Page 37

Trouble Shooting

SP-110C Display is completely

black

• Check power is available:

12V-24VDC

• Check boat master switch for

autopilot

• Check circuit breaker (if applicable)

• Check in-line fuse of SP-

110C red wire

• Check all wiring connections

SP-110C Does not move

rudder when AUTO is

selected

• Confirm SP-110C display is

showing

compass heading information.

• Check voltage is present at the

SP-110C motor connections

(Yellow and yellow with black

stripe) when AUTO is selected

and a course change applied.

• Confirm that the supply voltage is

12V-24VDC (Red and Black).

• Check all motor and clutch wiring

• Check motor brushes

• Check the hydraulic system:

1. Ensure there is sufficient

hydraulic fluid.

2. Purge the system of possible air

locks / contamination.

3. Ensure that any flow restricting

valves are not completely closed.

4. Check all connections for leaks.

SP-110C Display will not

change from MANUAL STEER

mode.

• Vessel speed may be below the set

threshold, and USE RFU set to NO.

• Check speed setting in settings

page 1 is greater than one

• Vessel must be moving forward at

or higher then that set speed.

SP-110C Does not

follow waypoint route

• Check GPS plotter waypoint setting

• Check GPS HEADING mode

selected on SP-110C

• Check alarm status of SP-110C

• Ensure that the GPS unit has the

correct magnetic correction factor.

• Check SP-110C compass

alignment and possible magnetic

interference

No GPS Data Alarm

• Check wiring of the GPS to the

SP-110C unit.

• Check sentence in GPS unit for

correct data output (APA/APB/BOD

& XTE)

• Check route is set up or selected in

the GPS unit

• Check location fix at the GPS unit.

Page 38

SI-TEX SP-110C 33 of 35

Customer Service

If you encounter problems during the installation or operation of this

product, or cannot find the information you need, please contact Sitex

Customer Service.

The contact numbers and e-mail address for Sitex Customer Service are:

Sitex Main Office…….………..+1-631-996-2690

Sitex Fax..………………….…..+1-631-996-2693

Sitex Customer Support E-mail address: customerservice@si-tex.com

Sitex Main Office Address:

25 Enterprise Zone Drive, Ste 2

Riverhead, NY 11901

Technical Support is available from 9:00 AM to 5:00 PM Eastern

Standard Time, Monday through Friday.

Page 39

Declaration of

Conformity

(MANUFACTURERS

DECLARATION)

Manufacturer:

SI-TEX

Electronics

Declares under our sole responsibility

that the products:

SP-110C Display, Rudder Feedback

Unit, Compass, all units

interconnected with nec es sary cables

and external connections as a system

to which this declaration relates, is in

conformity with Standard(s):

EN60945/1997

CEI IEC945/1996

For SI-TEX Marine Electronics

12

th

October 2017

Allen Schneider

34 of 35

SI-TEX SP-110C

Page 40

CERTIFICATE OF LIMITED WARRANTY

Providing you present valid proof of purchase, SI-TEX Marine Electronics warrants all parts of

each

new product against defects in material and workmanship under normal use and will repair or

exchange

any parts proven to be defective at no charge for a period of two years from the original date of

purchase, except as provided below under Limited Warranty Exceptions.

Defects will be corrected dur ing nor mal wor k ing ho urs by an authorize d SI -TEX Marine

Electronics

dealer, service center , or at the SI-TEX offic e in River he ad, NY. There will be no charge for

repair labor

for a period of one year from the date of purchase, except as provided below under Limited

Warranty

Exceptions. This Warra nty and Pro of of Purcha s e must be made available to the authorized SITEX

Marine Electronics serv ice location or dealer at the time of service.

LIMITED WARRANTY EXCE PTI ONS

SI-TEX Marine Electronics will not be respo ns ib le for equip ment w hic h has been s ubje c ted to

water

or lightning damage, acc ident, abuse, or misuse, nor any equipment on which the serial number

has been

removed, altered, or mutilated . SI-TEX Marine Electronics assumes no respons ib i lity fo r damage

incurred during installa tio n. This Limited Warranty is effective only wi th res pec t to the or iginal

purchaser. Any cost associa ted w ith trans d uc er replac e m e nt, other than the cost of the

transducer itself ,

is specifically exclud e d from the Limite d Warranty.

Travel cost incurred will no t be accep ted by SI-TEX Marine Electronics

THERE ARE NO WARRANTIES WHICH EXTEND BEYOND THE DESCRIPTION ON THE FACE

HEREOF.

SPECIFIC EXCLUSIONS

Charges for overtime, stand-by, holiday, and per diem are specifically exclud ed fro m the Limited

Warranty. fuses are consum able ite m s and are not cover e d by this Limite d Warr a nty .

Installation workmans hip or materials, except as provided directly by SI-TEX Mar ine Electr o nics

are not covered by this Limited Warranty .

SI-TEX Marine Electronics equipme nt, or par ts ther eo f which have been repaired or altered

except by

an authorized SI-TEX Marine Electr o nic s d e aler or servic e center are not warra nte d in any

respect.

Transducers, software updates, batteries, magnetrons and microwav e compo ne nts , are items

excluded from the two-year warranty and are covered by warranty for a period of one year for

both parts and labor.

SI-TEX Marine Electronics will not, at any time as s ume any costs or labo r c harg es for check o ut

or

external line fuse replac ement or pro b le ms not found to be at fault in the equipm e nt its e lf.

Page 41

THERE ARE NO WARRANTIES OR GUARANTEES EXPRESSED OR IMPLIED WHICH EXTEND

BEYOND THE DESCRIPTION OF THE FACE HEREOF, INCLUDING WARRANTIES OF FITNESS FOR

A PARTICULAR PURPOSE AND MERCHANTABILITY. SI-TEX MARINE ELECTRONICS HAS

NO OTHER LIABILITY TO PURCHASE FOR DIRECT OR CONSEQUENTIAL DAMAGE OR ANY

THEORY INCLUDING ABSOLUTE LIABILITY, TORT, OR CONTRACT. THIS LIMITED WARRANTY

CANNOT BE ALTERED OR MODIFIED IN ANY WAY AND SHALL BE INTERPRETED IN

ACCORDANCE

WITH THE LAWS OF THE STATE OF NEW YORK. THIS WARRANTY IS LIMITED TO THE

CONTINENTAL U.S.A., ALASKA, HAWAII, AND CANADA.

MAILING & SHIPP ING ADDRESS:

SI-TEX Marine Electronics

25 Enterprise Zone Drive, suite #2

Riverhead, NY 11901

(631) 996-2690

HOW TO OBTAIN SERVICE UNDER THIS WARRANTY

To provide greater flexibility, SI-TEX Marine Electronics gives you the option

to obtain service under the warr anty by either:

(a) Contacting an authorize d SI-TEX Mari ne Ele c tro nic s servic e statio n

(The closest service station may be found by contacting your dealer of purchase)

OR

(b) Shipping your equipment pr epaid via UPS, FED-EX or truck with insurance prepaid to SI-TEX

Marine

Electronics. at the addres s prov ided be low . SI-TEX Marine Electronics will whenever

possible, make all repairs covered by Limited Warranty within two weeks of receiving the

equipment

in New York and return the same to you, freight prep a id.

Please do not use the Mail Service due to delays in tracing lost packages.

(c) You must present a copy of your Purchase Sales Slip at the time you reque s t warr anty

service.

A product repair case can be started from the support section of our website at www.si-

tex.com

SI-TEX SP-110C 35 of 35

Page 42

Loading...

Loading...