Page 1

MDS 1

Radome 0.9 Feet

MDS 8

Radome 1.5 Feet

MDS 9

Radome 1.8 Feet

MDS 10

Open 4 or 5 Feet

Copyright 2008 Seiwa - Hong Kong

All rights reserved. Printed in Italy. No part of this publication may be reproduced or distributed in any form or by any

means, or stored in a database or retrieval system, without prior written permission of the publisher.

User Manual

code: (D 050608e)

Page 2

Safety Precaution

HIGH VOLTAGE WARNING

Dangerously high voltages are present within the RADAR scanner unit. There are

no internal connections or adjustments necessary for installation. Only a qualified

radar service technician should remove the cover. Technicians must exercise extreme care when working inside the unit. Always remove power before removing

the cover. Some capacitors may take several minutes to discharge, even after

switching off the radar. Before touching the magnetron or any high voltage components, ground them with a clip lead.

MICROWAVE RADIATION HAZARD

The microwave energy radiated by a radar antenna is harmful to humans, especially to one’s eyes. Never look directly into an open waveguide or into the path of

radiation from an enclosed antenna. Radar and other radio frequency radiation

can upset cardiac pacemakers. If someone with a cardiac pacemaker suspects

abnormal operation, immediately turn off the equipment and move the person

away from the antenna. Turn off the radar whenever it is necessary to work on

the antenna unit or on other equipment in the beam of the radar.

MAGNETRON PREHEATING

When starting your RADAR for the first time or when restarting it after a two

month or longer non-operating period, preheat the magnetron at least 30 minutes in standby mode.

Please read through this manual before the first operation. If you have any questions, please contact the Company’s customer service or your local dealer.

4 User Manual

Page 3

Contents

Safety Precaution ................................................................................. 4

HIGH VOLTAGE WARNING ................................................................................. 4

MICROWAVE RADIATION HAZARD ......................................................................... 4

MAGNETRON PREHEATING ................................................................................. 4

About this User Manual ................................................................................. 7

INTRODUCTION ................................................................................. 7

CONVENTIONS USED ................................................................................. 8

HOW THIS USER MANUAL IS ORGANIZED ............................................................... 8

IF YOU NEED ASSISTANCE ................................................................................. 8

EQUIPMENT SUPPLIED ................................................................................. 8

1. Radar Installation ................................................................................. 9

2. Functions ............................................................................... 23

Optional Equipment ................................................................................. 8

1.1 INSTALLATION CONSIDERATIONS ................................................................... 9

1.2 PREPARE THE RADAR FOR INSTALLATION ........................................................ 9

1.3 INSTALLATION PROCEDURE ......................................................................... 10

1.4 ELECTRICAL AND DATA CONNECTIONS .......................................................... 10

1.5 CONNECTION PROCEDURE ........................................................................... 10

1.6 RADAR JUNCTION BOX CONNECTIONS ........................................................... 11

1.6.1 Jumper To Control Radar On/Off Operation ........................................... 13

1.6.1.1 Radar Powered On all the time ................................................ 13

1.6.1.2 Radar Powered On/Off Controlled by an External Switch ............. 13

1.6.1.3 Radar Power On/Off Controlled by the Chart Plotter Software ...... 13

1.6.2 Alternative Power Connection ............................................................. 13

1.6.2.1 Power Connections ................................................................ 13

1.7 SOFTWARE CONFIGURATION ........................................................................ 13

1.7.1 I/O Setup ............................................................................... 13

1.7.2 Warming Up ............................................................................... 14

1.7.3 Transmission On ............................................................................... 14

1.7.4 Radar calibration ............................................................................... 14

1.7.4.1 Heading Line ........................................................................ 14

1.7.4.2 Antenna Parking Position ....................................................... 14

1.7.4.3 Sector Transmission Off ......................................................... 15

1.7.4.4 Transmission Trigger Delay .................................................... 15

1.7.4.5 Automatic and Manual Tune ................................................... 18

Manual Tune ........................................................................ 19

Automatic Tune .................................................................... 20

1.7.4.6 Save Tuning to User C-CARD .................................................. 21

1.7.4.7 Load Tuning from User C-CARD ............................................... 21

2.1 BASIC ............................................................................... 23

2.1.1 Cross Cursor ............................................................................... 23

2.1.2 Chart Overlay ............................................................................... 23

2.1.3 Range ............................................................................... 24

2.1.4 Orientation ............................................................................... 24

2.1.5 Motion Mode ............................................................................... 24

2.1.6 Echo Trails Settings ........................................................................... 25

2.1.7 Target Expansion .............................................................................. 25

2.2 SENSITIVITY ............................................................................... 25

2.2.1 Interference Rejection ....................................................................... 25

2.2.2 Gain Adjustment ............................................................................... 25

2.2.3 STC (Sensitivity Time Constant) Adjustment ......................................... 25

2.2.4 FTC (Fast Time Constant) Adjustment .................................................. 26

2.2.5 MBS (Main Bang Suppression) Adjustment ............................................ 26

User Manual

5

Page 4

2.3 RADAR FEATURES ............................................................................... 26

2.3.1 Cursor Window ............................................................................... 26

2.3.2 Heading Marker ............................................................................... 26

2.3.3 Degree Scale ............................................................................... 27

2.3.4 Range Rings ............................................................................... 27

2.3.5 Compass Rose ............................................................................... 28

2.3.6 EBL & VRM ............................................................................... 28

2.3.6.1 Handling of EBL/VRM ............................................................. 29

2.3.7 Parallel Cursor ............................................................................... 29

2.3.8 Center Offset ............................................................................... 30

2.3.8.1 Handling of Center Offset ....................................................... 30

2.3.9 Status Bar ............................................................................... 30

2.4 CHART FEATURES ............................................................................... 31

2.4.1 Chart Overlay Mode ........................................................................... 31

2.4.2 Chart Synchronization ....................................................................... 31

2.4.3 Cursor Echo ............................................................................... 31

2.5 GUARD ZONES ............................................................................... 31

2.5.1 Handling of Guard Zone ..................................................................... 32

3. Radar Pages ............................................................................... 33

4. Technical Specifications ............................................................................... 37

5. Troubleshooting ............................................................................... 43

6. Frequently Asked Questions ............................................................................ 45

A. What is Radar? ............................................................................... 49

B. Installation ............................................................................... 53

Analytical Index ............................................................................... 55

2.5.2 Guard Zone Sensitivity ....................................................................... 32

3.1 PAGES SELECTION ............................................................................... 33

3.1.1 Selection by Soft Key ......................................................................... 33

3.2 STATUS BAR ............................................................................... 34

3.3 MENU HANDLING ON FULL PAGES ................................................................. 35

3.4 SELECTION OF THE "ACTIVE" VIEW IN SPLIT/COMBO PAGES ............................ 35

4.1 MDS 1 ............................................................................... 37

Antenna unit ............................................................................... 37

Dimensions and Mounting ............................................................................ 37

4.2 MDS 8 ............................................................................... 38

Antenna unit ............................................................................... 38

Dimensions and Mounting ............................................................................ 39

4.3 MDS 9 ............................................................................... 39

Antenna unit ............................................................................... 39

Dimensions and Mounting ............................................................................ 40

4.4 MDS 10 ............................................................................... 41

Antenna unit ............................................................................... 41

Dimensions and Mounting ............................................................................ 41

A.1 GENERAL ............................................................................... 49

A.1.1 Antenna ............................................................................... 49

A.1.2 Side Lobe ............................................................................... 49

A.2 CHARACTERISTICS OF RADAR WAVE ............................................................. 50

A.2.1 Targets difficult to display on screen .................................................... 50

A.2.2 Shadow zones of Radar ...................................................................... 50

A.2.3 False echoes ............................................................................... 51

A.2.3.1 Ghost echoes ....................................................................... 51

A.2.3.2 Multiple echoes ..................................................................... 51

A.2.3.3 False echoes caused by side lobe ............................................ 51

A.2.3.4 Distant False echoes caused by duct phenomenon ..................... 52

A.2.3.5 Radar interference ................................................................ 52

B.1 MORE INSTALLATION CONSIDERATIONS ........................................................ 53

B.1.1 Shifting from keel line ........................................................................ 53

B.1.2 Obtaining sufficient dip angle .............................................................. 53

B.2 INSTALLING SCANNER UNIT ......................................................................... 53

6 User Manual

Page 5

About this User Manual

INTRODUCTION

Your RADAR consists of two main components, the RADAR scanner unit and a

ColorMax Series display unit. The display unit is a user-supplied plotter capable of

running the radar operating application. The RADAR scanner unit includes the

radar antenna, transmitter, receiver and necessary electronics to deliver radar

information to the user’s plotter. The mounting hardware kit, interconnection cable

and a Radar junction box are included in the Radar scanner box.

Any menu operation and functions activation in this User Manual is related to the

following chart plotter models (see the following table). Whenever it is necessary,

a note has been inserted for those models with operational differences.

CHART PLOTTER NAME SOFTWARE SN Radar Serial Port Available from Sw

EXPLORER II Plus S5egSWctc All 2 or 3 11.00

EXPLORER II Plus S3egSWctcj All 2 or 3 11.00

EXPLORER II Plus XSegSWctcj After February 2005 2 or 3 11.00

COLOR MAX WIDE E S4egSW7wc All 2 or 3 11.00

COLOR MAX WIDE I S4igSW7wc All 2 11.00

COLOR MAX WIDE E S3egSW7wc All 2 or 3 11.00

COLOR MAX WIDE I S3igSW7wc All 2 11.00

COLOR MAX SEALINK E S4egSW8wc All 2 or 3 11.00

COLOR MAX SEALINK I S4igSW8wc All 2 11.00

COLOR MAX 11 XSegSW11c After February 2005 2 or 3 11.00

COLOR MAX 11 S3egSW11c All 2 or 3 11.00

COLOR MAX PRO S4egSW11c All 2 or 3 11.00

TRAWL PLOT 12 S5egSW12c All 2 or 3 11.00

TRAWL PLOT 12* XSegSW12c After February 2005 2 or 3 11.00

COLOR MAX 15 S5egSW15c All 2 or 3 11.00

COLOR MAX 15 S3egSW15c All 2 or 3 11.00

NOTE The serial Port 3 is usually used for the Smart GPS.

NOTE* To connect the TRAWL PLOT below s/n 4129999 (before February 2005)

please contact your local dealer (to make the hardware change necessary).

The Radar full functionality, as described in this User Manual, is obtained only

when the scanner is included in an integrated system including chart plotter,

gyrocompass and GPS antenna.

Please read carefully this User Manual to learn the operating features for your

Radar. Please refer to your chart plotter User Manual for all other operating instructions.

User Manual

7

Page 6

CONVENTIONS USED

Throughout this User Manual, the labelled keys are shown in capital letters enclosed in square brackets, for example [ENTER]; the software keys are shown in

small capital letters enclosed in square brackets, for example [EDIT].

Menu operations are in bold characters listed by keys sequence with the menu

names enclosed between inverted commas, for example [MENU] + "ALARMS"

+ [ENTER] means: press the [MENU] key, using the cursor key select the Alarms

menu and then press [ENTER].

HOW THIS USER MANUAL IS ORGANIZED

♦ CHAPTER 1: Radar Installation

Installation of the Radar and set up of the hardware configuration.

♦ CHAPTER 2: Functions

How to connect the chart plotter and the Radar; and how to operate

them.

♦♦

♦ CHAPTER 3: Radar Pages

♦♦

Description of the available Radar pages, full and split pages.

♦♦

♦ CHAPTER 4: Technical Specifications

♦♦

Technical specification and dimensions of the Radar.

♦♦

♦ CHAPTER 5: Troubleshooting

♦♦

♦♦

♦ CHAPTER 6: Frequently Asked Questions

♦♦

♦♦

♦ APPENDIX A: What is Radar?

♦♦

♦♦

♦ APPENDIX B: Installation

♦♦

The Analytical Index is at the end of this User Manual.

IF YOU NEED ASSISTANCE

If your chart plotter does not operate properly, please refer to the chart plotter

User Manual.

EQUIPMENT SUPPLIED

♦ Scanner Unit, Radar scanner with cable

♦ Fasteners, stainless steel:

♦ 1 Radar Junction Box

♦ 1 Template, for locating mounting holes

♦ 1 Switch, Rocker type, DPST

♦ 2 Fuses, 5A (spare)

Optional Equipment

♦ Magnetic Heading Sensor

♦ Extended length cables, 15 or 20 meters

8 User Manual

4 Bolts, hex metric M8 x 25U (approx. 3/8 dia. x 1 in. long)

4 Flat washer

4 Lock washer

Page 7

1. Radar Installation

This chapters illustrates the instructions on electrical connections of the Radar

and the necessary software settings to operate it.

In order for the Radar to communicate with the Chart Plotter, the software

configuration explained in the Par. 1.7 is mandatory.

1.1 INSTALLATION CONSIDERATIONS

Prior to the actual installation of the RADAR scanner unit, several factors must be

considered to ensure maximum performance. The scanner must be located so

that passengers and crew are not exposed to the direct Radar beam. The scanner

unit should be mounted on the centerline of your vessel in a location that has an

unobstructed view forward and the rest of the area around the scanner is as

unobstructed as possible. A location as high as practical to improve maximum

range is preferable, keeping in mind that minimum range objects may be overlooked if mounted too high. Place the units in before large structures and exhaust

stacks. Large structure or stacks cause blind spots. Contamination from engine

exhaust on the scanner housing reduces radar performance.

Antennas for GPS, radio communication or other equipment should not be in the

radar beam. Use non-metallic extension poles to move the active area of antennas above the radar beam.

In selecting a location, consider the suitability of the mounting surface. It must be

flat and approximately levelled with the vessel’s water line. The surface must

support the weight of the scanner and have access to the under side for installation of the four mounting bolts.

NOTE The recommended mounting surface thickness is 3/8 to 1/2 in. (9 mm to 13

mm). If the mounting surface is thin, a doubler should be added. If it is

thicker, longer bolts must be purchased. The scanner will be damaged if bolts

penetrate more than 9/16 in. (15 mm).

WARNING

Also, consider the cable route from the scanner to the operator’s location. Avoid

routing the interconnecting cable through areas of possible damage from moving

objects, machinery, and exposure to chemicals or high temperature.

1.2 PREPARE THE RADAR FOR INSTALLATION

Unpack your new RADAR and check that the contents correspond to the packing

list. Do not remove the cover from the unit. There are no connections or adjustments inside the unit that are needed for installation or operation. The cable

must remain attached. For ease of handling, coil the cable and place it on top of

the scanner. Then secure it with tape. Invert the scanner and make sure the four

mounting holes are clear to accept bolts.

Working at higher elevations may become necessary while installing the scanner

unit. Observe safety measures and take sufficient precaution to avoid personal

injury or damage to the equipment.

User Manual

9

Page 8

1.3 INSTALLATION PROCEDURE

♦ Prepare the mounting surface by making sure it is clean and flat.

NOTE It is a better to check the accuracy of the template by measuring the actual

dimension between the hole locations. The reproduction process and moisture absorption can affect accuracy.

♦ Use the template provided to mark the location of four mounting holes.

Align the template squarely with the centerline of the vessel and with

the arrow pointing forward.

♦ Drill four 3/8 in. (10 mm) diameter holes through the mounting sur-

face.

♦ Check that each bolt (with lock washer and flat washer) protrude through

the mounting surface at least 5/16 in. (8 mm) but less than 9/16 in.

(15 mm). The scanner will be damaged if bolts protrude more than 9/

16 in. (15 mm).

♦ Apply sealant around each mounting hole.

♦ Place the Radar scanner unit on the mounting surface. Orient the scan-

ner with the index mark on the housing facing forward (cable gland

facing aft).

♦ Install and tighten four M8 x 25U (M8 x 1 in.) mounting bolts.

♦ Uncoil the scanner cable.

♦ Secure the cable near the scanner to support the weight of the cable

and prevent strain on the watertight cable seal. If the cable is to pass

through tubing or a bulkhead, protect the unfinished end. Do not use

the unfinished wires or fabric braid to pull the cable. Attach a fish cord

only to the cable jacket.

♦ Route the cable to the operator’s location, securing it at appropriate

points along the way. Make a drip loop and apply sealant at the entry

point of an exterior bulkhead.

1.4 ELECTRICAL AND DATA CONNECTIONS

The cable from RADAR scanner unit provides all power, data and control connections necessary for operation. The large black and white leads are for power

connections and connect directly to a 12 to 24 VDC power buss; the five small

leads, in the fabric braid, connect to the Radar Junction Box; and the two remaining small leads connect to the On/Off control switch. The On/Off control switch

does not switch the main power leads to the scanner unit, but it does provide a

signal that controls DC power inside the scanner unit.

1.5 CONNECTION PROCEDURE

NOTE In the following procedures, small wires must be stripped and tinned, and

10 User Manual

then connected to the proper connections in the Radar Junction Box, and to

pins on the On/Off control switch. If you are uncertain of your skill in

completing these tasks, it is strongly advised to obtain the services of a

qualified technician. It is essential to the operation and reliability of your

RADAR that these procedures are accomplished properly.

♦ Arrange the free end of the scanner cable so that the unfinished leads

will reach their intended points for connections. The two large wires

must reach a power panel; the five leads in the braided fabric jacket

must reach the Radar Junction Box and the two remaining leads must

Page 9

reach the desired location for the On/Off control switch. If the leads

must go in different directions, first route the five leads in the fabric

braid to the Junction Box. Then extend the shorter leads using the

same size or larger size wire.

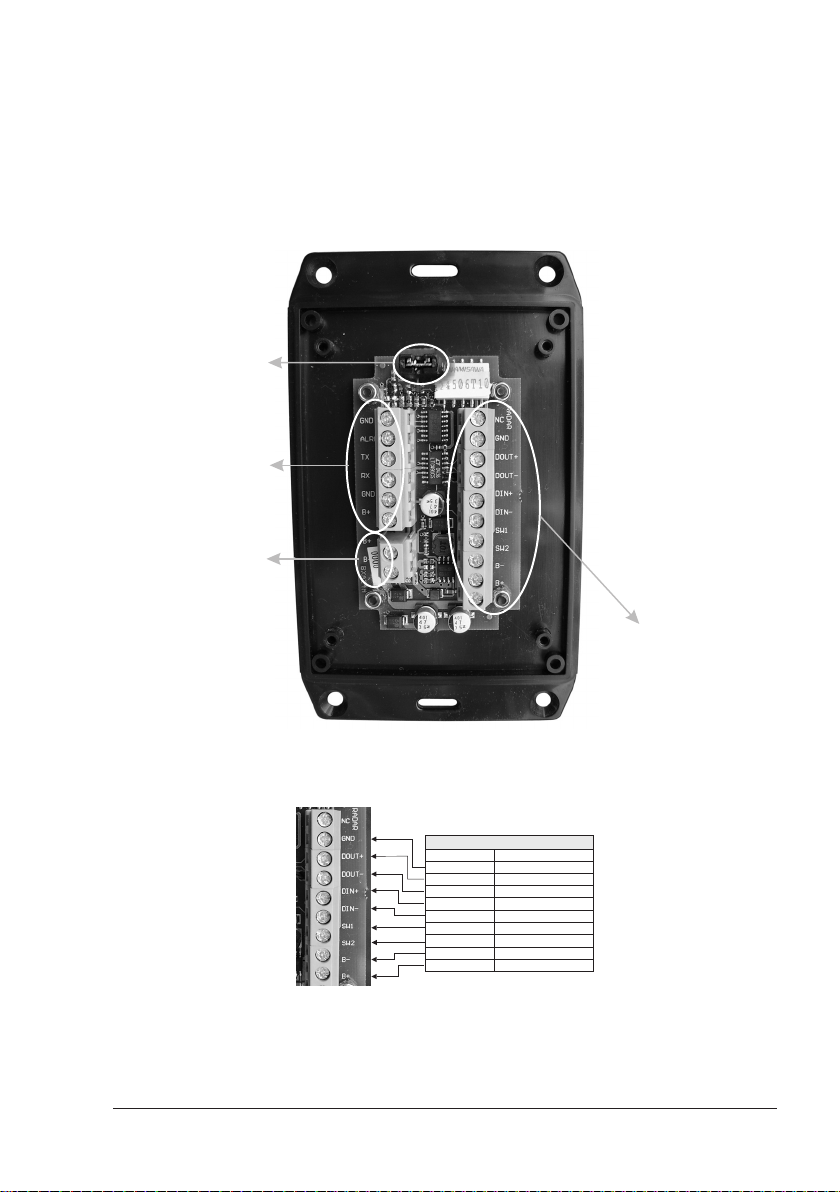

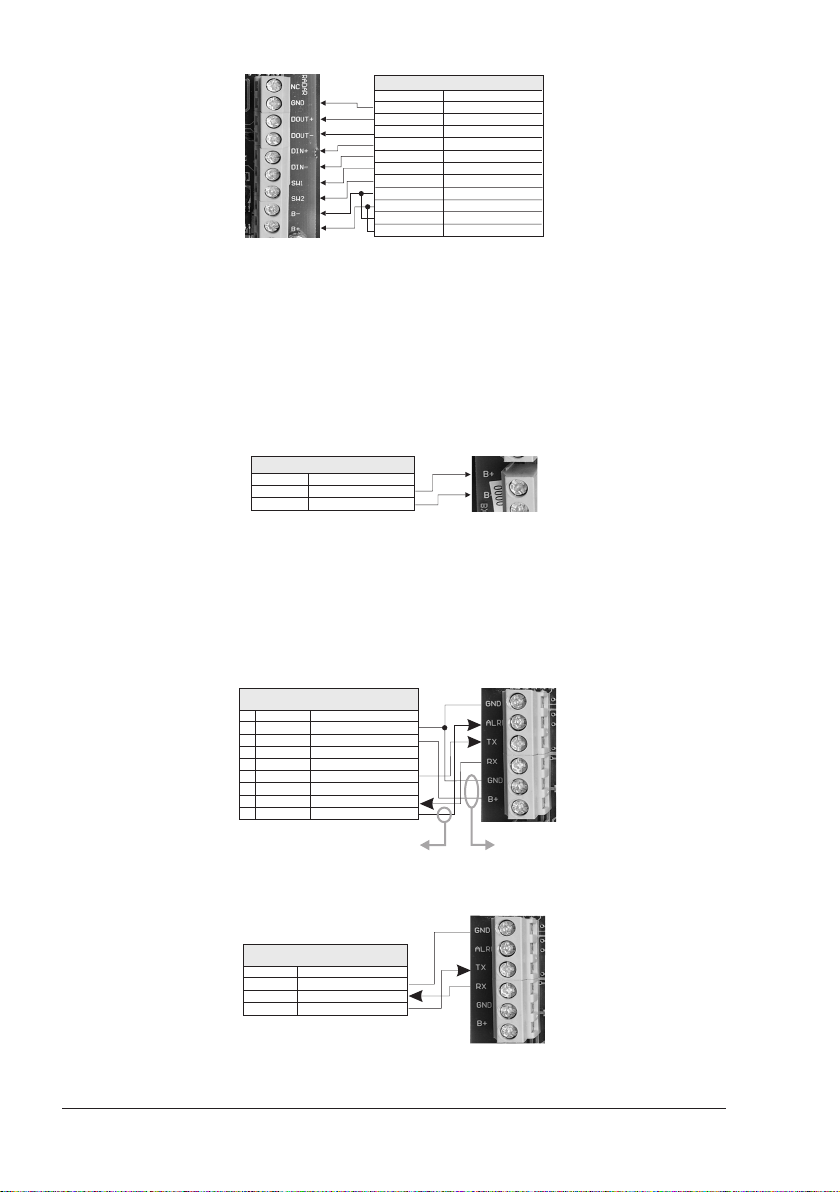

1.6 RADAR JUNCTION BOX CONNECTIONS

Referring to the diagram below, connect the color coded wires from the Radar

cable to the designated place on Terminal strip A in Radar Junction Box as follows.

MOUNTING

INSTRUCTIONS

1. Open the box unscrewing

the 4 bottom screws.

2. Connect the Radar cable

to the terminal A

JUMPER for RADAR

ON/OFF SWITCH

Terminal C

CHART PLOTTER

(see connection tables)

Terminal B

POWER SUPPLY

(see Radar specifications)

3. Connect the Power

supply to the terminal B

4. Connect the chart plotter

cable to the terminal C

5. Set up the jumper for

RADAR ON/OFF switch:

5a. Mount to permanently

power ON the Radar;

5b. Connect to a switch

to manually power

on/off the Radar.

5c. Remove to control

the power ON/OFF

via the chart plotter

with the external

alarm output signal.

Terminal A

RADAR

(see Radar cable label)

Terminal Strip A

Fig. 1.6a - Terminal Strip A Connection for MDS 1/MDS 8/MDS 9

User Manual

Fig. 1.6 - Junction Box

RADAR CABLE

WIRE COLOR FUNCTION

BLACK

ORANGE

YELLOW

BROWN

RED

GREEN

BLUE

BLACK (large wire)

WHITE (large wire)

DATAGND

DATAOUT+

DATAOUT-

DATAIN+

DATAIN-

POWER ON/OFF SWITCH 1

POWER ON/OFF SWITCH 2

RADAR SUPPLY-

RADAR SUPPLY+

11

Page 10

RADAR CABLE

WIRE COLOR FUNCTION

BLACK

ORANGE

YELLOW

BROWN

RED

GREEN

BLUE

BLACK (large wire)

WHITE (large wire)

BLUE (large wire)

RED (large wire)

DATAGND

DATAOUT+

DATAOUT-

DATAIN+

DATAIN-

POWER ON/OFF SWITCH 1

POWER ON/OFF SWITCH 2

RADAR SUPPLY-

RADAR SUPPLY+

MOTOR POWER-

MOTOR POWER+

Fig. 1.6a1 - Terminal Strip A Connection for MDS 10

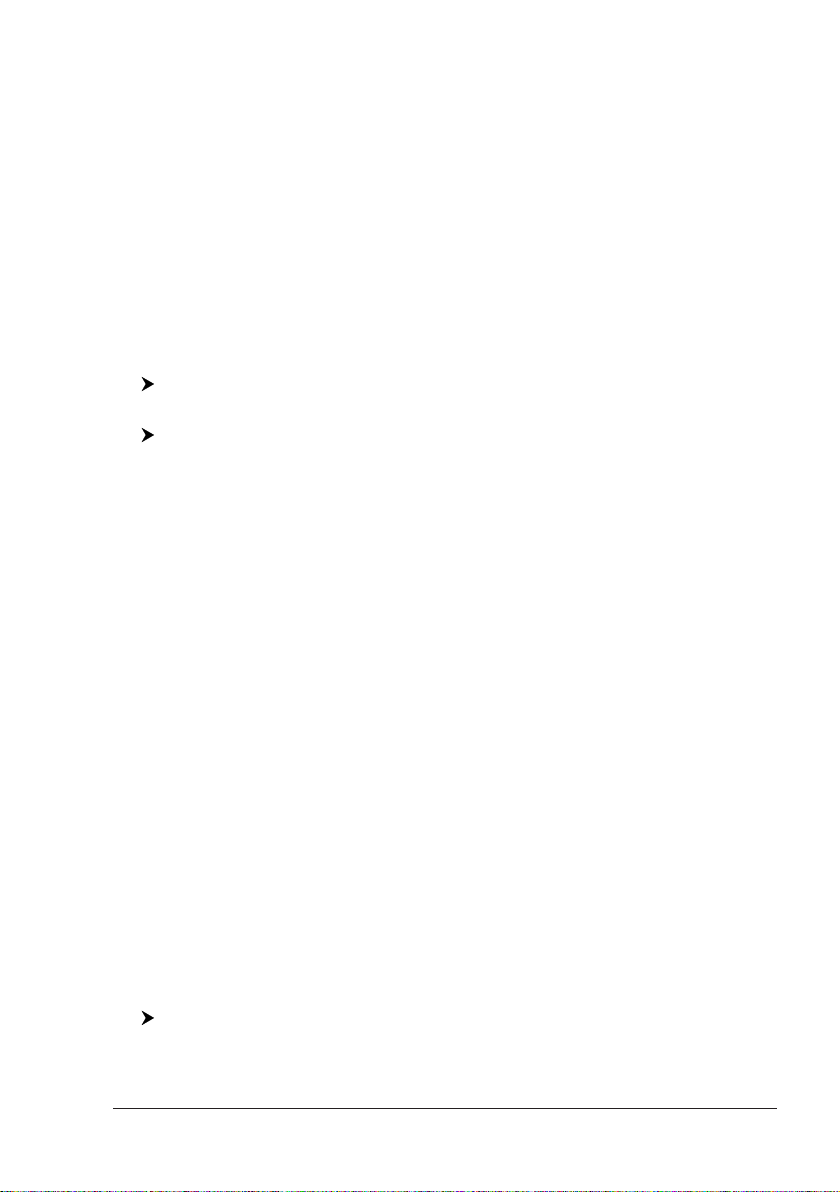

Terminal Strip B IS TO BE CONNECTED TO POWER SUPPLY (12 TO 24 VDC NOMINAL)

Do not omit the in-line fuse unless a dedicated and fused terminal is available. If

so, install a 5 Amp fuse. If you are installing a MDS 10 open scanner Radar, it is

important to also connect the Red (+) to positive power terminal, and Blue (-) to

negative power terminal, as this provides power to scanner motor.

This terminal leads the power to the Scanner unit and to the chat plotter (*).

NOTE(*)Only if the chart plotter power wires are connected to Terminal strip C, on B+

and GND terminals.

12-24V POWER SUPPLY

WIRE COLOR FUNCTION

POWER SUPPLY+

RED

POWER SUPPLY-

BLACK

Fig. 1.6b - Terminal Strip B

B+

-

B

Please make sure that the connected power supply is able to supply the

current at the voltage required by the Radar to operate.

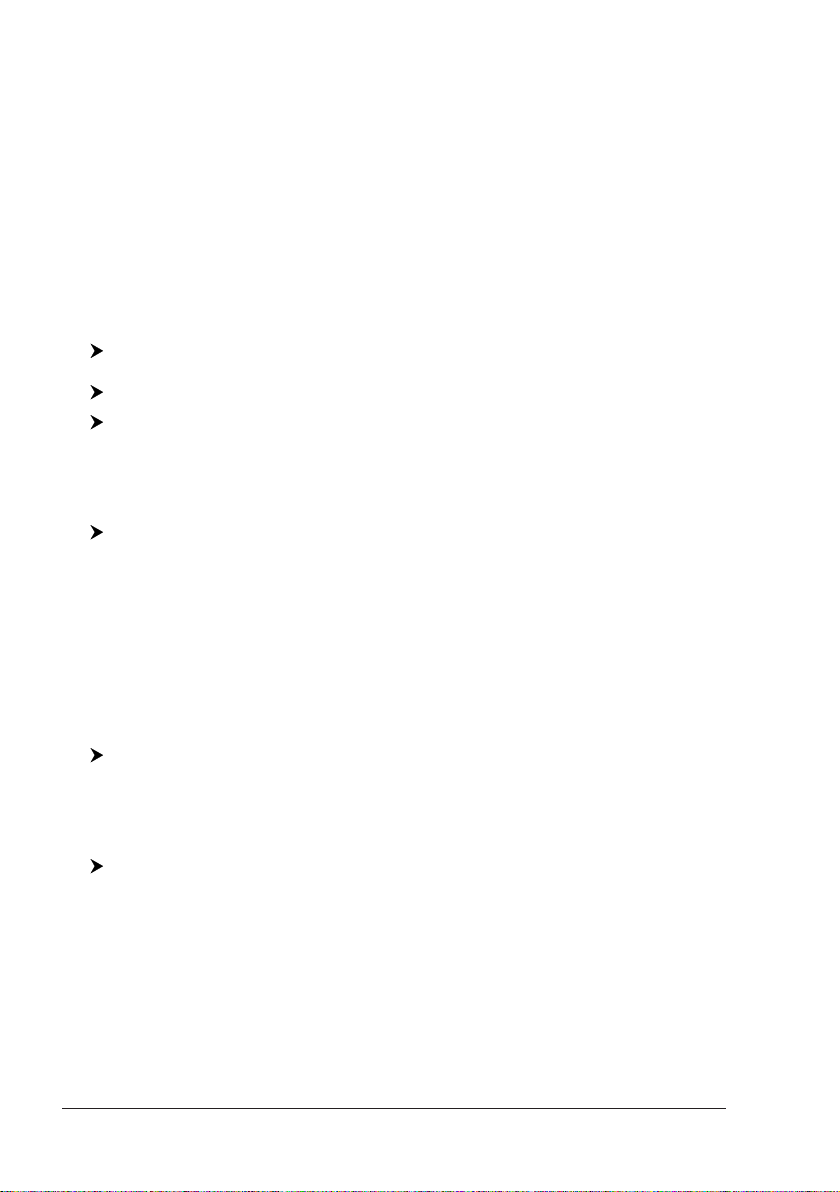

Terminal Strip C

See connection tables to determine proper way to connect the chart plotter to

Radar Junction Box.

WARNING

POWER & I/O CABLE

CONNECTION TO PORT 2

PIN WIRE COLOR FUNCTION

1

2

3

4

5

6

7

Connect to control the Radar ON/OFF via the chart plotter. Make sure that:

1) This signal is not used for any other operation (external alarm)

The jumper is removed on the junction box2)

8

BLACK

RED

WHITE

GREEN

GRAY

YELLOW

BROWN

BLUE

GND/COMMON

POWER INPUT+ (10-35 Vdc)

INPUT 1+

INPUT 1-

OUTPUT 2+

OUTPUT 1+

INPUT 2+

OUTPUT EXTERNALALARM

+

Connect to power the

chartplotter via the junction box

Fig. 1.6c - Connection to Port 2

QUICK DISCONNECT

BRACKET CABLE

WIRE COLOR FUNCTION

GND

BLACK

INPUT 2+

BROWN

OUTPUT 2+

GRAY

Fig. 1.6c1 - Connection to Port 2 for Quick Disconnect Bracket Cable

12 User Manual

Page 11

1.6.1 Jumper To Control Radar On/Off Operation

1.6.1.1 Radar Powered On all the time

Leave jumper located at top of Radar Junction Box mounted. This will keep powered On at all times.

1.6.1.2 Radar Powered On/Off Controlled by an External Switch

The two remaining small leads, the Green wire and the Blue wire, connect to the

On/Off control switch. The On/Off control switch does not switch the main power

leads to the scanner unit, but it does provide a signal that controls DC power

inside the scanner unit.

1.6.1.3 Radar Power On/Off Controlled by the Chart Plotter Software

NOT AVAILABLE FOR COLOR MAX WIDE I/E & COLOR MAX SEALINK I/E

Remove jumper. Connect the EXTERNAL ALARM signal of the chart plotter to

TERMINAL Strip C, Terminal ALR (see connection tables).

Setting up the chart plotter I/O in the following mode:

[MENU] + [MENU] + "ADVANCED" + [ENTER] + "Input/Output" + [ENTER]

+ "RADAR" + [ENTER] + "EXT. ALARM" + [ENTER]

Power the Radar On/Off directly from:

[MENU] + "POWER" + [ENTER] + "ON"/"OFF" + [ENTER]

1.6.2 Alternative Power Connection

You can feed the Power supply to the Radar directly.

1.6.2.1 Power Connections

♦ Route the large black and white wires directly to the power panel. No

switch is required.

♦ Connect the large black wire to the battery negative (—) terminal of

the power panel.

♦ Connect the large white wire (with the in-line fuse) to the battery posi-

tive (+) terminal of the power panel (12 to 24 VDC nominal). Do not

omit the in-line fuse unless a dedicated and fused terminal is available.

If so, install a 5 Amp fuse. If you are installing a MDS 10 open scanner

Radar, it is important to also connect the Red (+) to positive power

terminal, and Blue (-) to negative power terminal, as this provides

power to scanner motor.

This completes the installation of your Radar scanner unit.

Please proceed with setting up the data ports in your chart plotter, following the

instructions below.

1.7 SOFTWARE CONFIGURATION

First you have to install the Radar. Refer to the following paragraphs to configure

the chart plotter to operate with the Radar.

1.7.1 I/O Setup

Setting up the chart plotter I/O depends upon which port is used to connect the

Radar. If you use the connecting cable supplied with the Radar, the Port2 is the

default setting. In this case follow the procedure:

User Manual

[MENU] + [MENU] + "ADVANCED" + [ENTER] + "Input/Output" + [ENTER]

+ "Port 2 Input" + [ENTER] + "RADAR" + [ENTER]

13

Page 12

1.7.2 Warming Up

It has to be noted that at start-up the Radar needs a variable time from 90 to 120

seconds to heat up the magnetron (microwave emitting tube). During this time it

is not possible to turn on the transmission.

Radar pages are visible but with a small overlapping message window showing

the time remaining to Warm Up completion:

"Radar Warming Up! xx seconds remaining!"

At completion of the Warm Up sequence the following message will be displayed:

"Radar Warming Up! Warm Up Completed!"

This window shall remain open for 2 seconds, then it will close automatically.

At this point the Radar is ready for operation. Transmission is turned Off and

"STAND BY" message is displayed at the center of the Radar page.

1.7.3 Transmission On

Turn On the transmission pressing:

NOTE or following the procedure:

The Radar image is displayed on the screen.

[ENTER]

[MENU] + "TRANSMISSION" + [ENTER] + "ON" + [ENTER]

or using soft keys:

any soft key + [TX]

1.7.4 Radar calibration

At first installation it is necessary to properly calibrate the Radar:

The Radar calibration includes:

[MENU] + "TUNING" + [ENTER]

♦ Heading Line

♦ Antenna Parking Position (ONLY FOR MDS 9/MDS 10)

♦ Sector Transmission Off (ONLY FOR MDS 9/MDS 10)

♦ Transmission Trigger Delay

1.7.4.1 Heading Line

This function is used if the Radar Antenna was not installed pointing directly

parallel with the centerline of the vessel. Adjusting the heading line ensures that

targets are shown relative to your ship’s bow.

♦ select Head Up mode

[MENU] + "ORIENTATION" + [ENTER] + "HEAD UP" + [ENTER]

♦ Press [CLEAR] until the Radar page is shown.

♦ Select a target about 1- 2NM and adjust the vessels speed to accurately

head to the target (preferably on a flat calm day).

♦ If the target is not shown directly ahead on the Radar full page display,

adjust heading the line to correct the target heading:

[MENU] + "TUNING" + [ENTER] + "HEADING LINE" +

[ENTER] + Apply the Heading Correction + [ENTER]

♦ The screen updates as the heading line is adjusted. Repeat the steps until

the target is shown correctly.

1.7.4.2 Antenna Parking Position

AVAILABLE ONLY FOR MDS 9/MDS 10

When the Radar is turned Off, the antenna comes to a stop. If you want to have

the antenna to stop in a specific position, the Antenna Parking Position function

can be used to choose the desired antenna position. This function only controls

the antenna position at which the power to the motor is cut off. The distance

14 User Manual

Page 13

through which it comes to a stop from this point depends on temperature and

wind conditions. The setting of antenna does not affect the operation of the Radar

at all. To set the antenna position follow this procedure:

[MENU] + "TUNING" + [ENTER] + "ANTENNA PARKING POSITION" +

[ENTER]

Use the cursor keys to adjust the position (between 0 and 90).

The displayed number represents the change from the default setting. The final

setting that parks the antenna straight ahead will likely be a few degrees left or

right from the default setting.

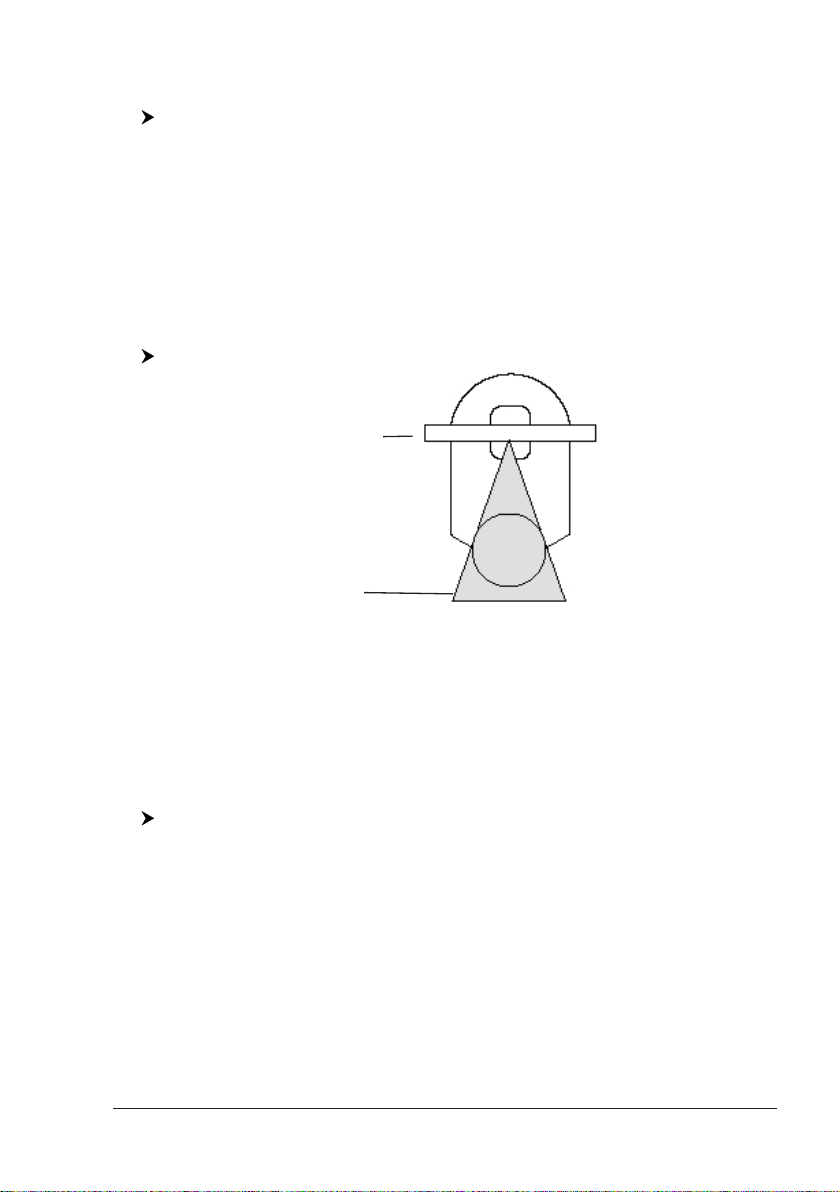

1.7.4.3 Sector Transmission Off

AVAILABLE ONLY FOR MDS 9/MDS 10

This is used to block transmission and target reflection in some special application for fixed installation like sea watching. Within this sector, targets can not be

detected.

Selecting the Sector Transmission Off from the menu:

[MENU] + "TUNING" + [ENTER] + "SELECT TRANSMISSION OFF" + [ENTER]

Radar antenna

Sector OFF

Fig. 1.7.4.3 - Sector Off

1.7.4.4 Transmission Trigger Delay

Tuning the Transmission Trigger Delay (TTD) allows making accurate distance

measurement. In practice, you need to align the start of the sweep with the

leading edge of the transmission pulse.

IMPORTANT: The unit comes with a default Tuning value already setup by the

factory but to obtain maximum precision you should finely adjust this value. Use

the following procedure.

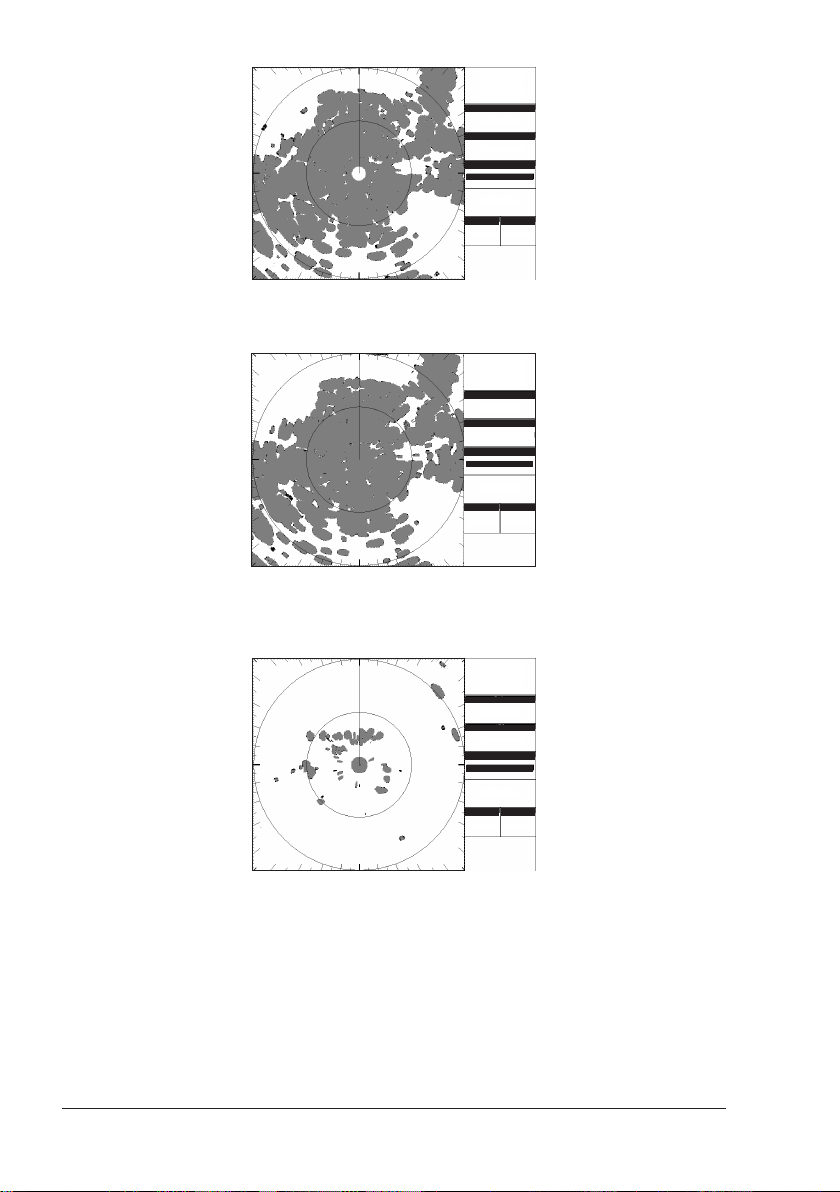

♦ Enter the Transmission Trigger Delay page.

[MENU] + "TUNING" + [ENTER] + "TRANSMISSION TRIGGER DELAY" +

[ENTER]

Since the STC is automatically turned off when entering this page, the screen

appear completely covered with clutter, this is a mandatory condition to

allow properly setting the TTD. The screen should appear as follows:

User Manual

15

Page 14

Transmission

Trigger Delay

Tuning

Gain

055

MBS

050

Trans. Trigger Delay

095

Done

Rings

RNG

1/8 Nm1/4 Nm

Fig. 1.7.4.4 - Transmission Trigger Delay tuning (I)

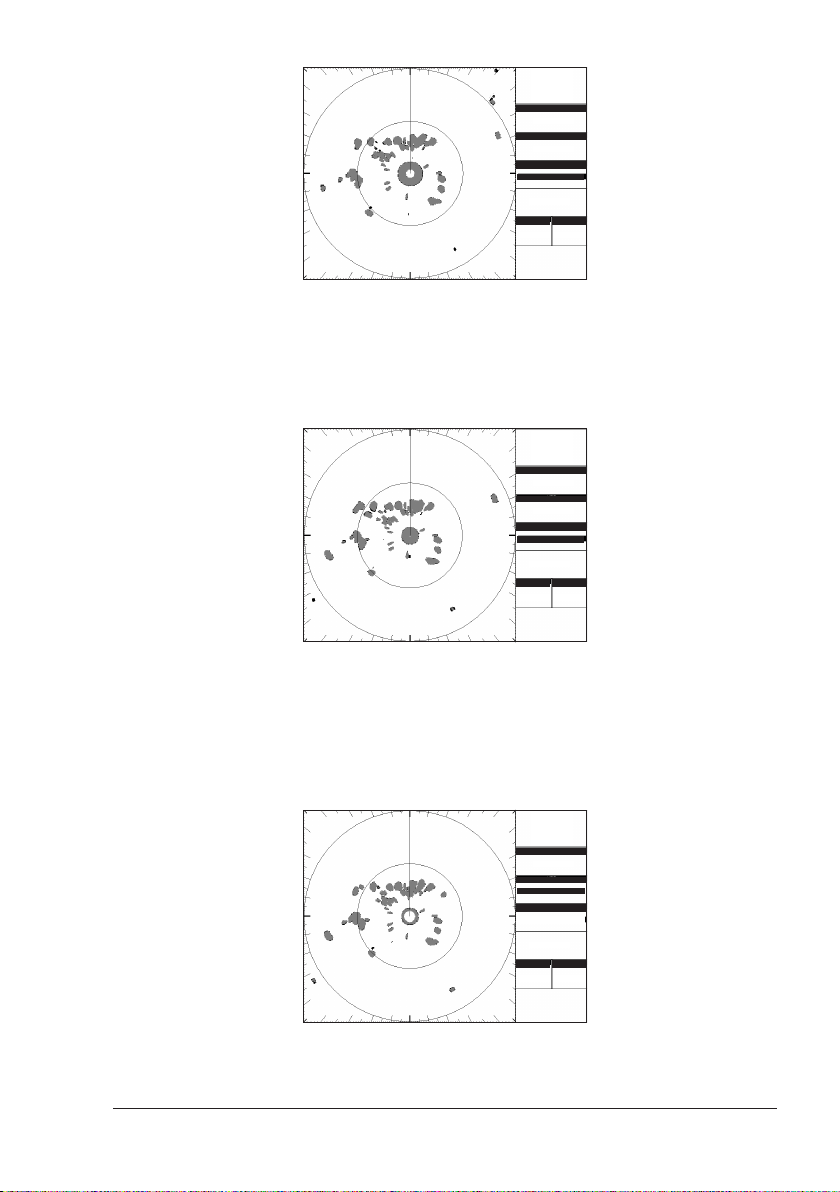

♦ Set MBS to 0. The white spot in the Radar origin will disappear.

Transmission

Trigger Delay

Tuning

Gain

055

MBS

050

Trans. Trigger Delay

095

Done

Rings

RNG

1/8 Nm1/4 Nm

Fig. 1.7.4.4a- Transmission Trigger Delay tuning (II)

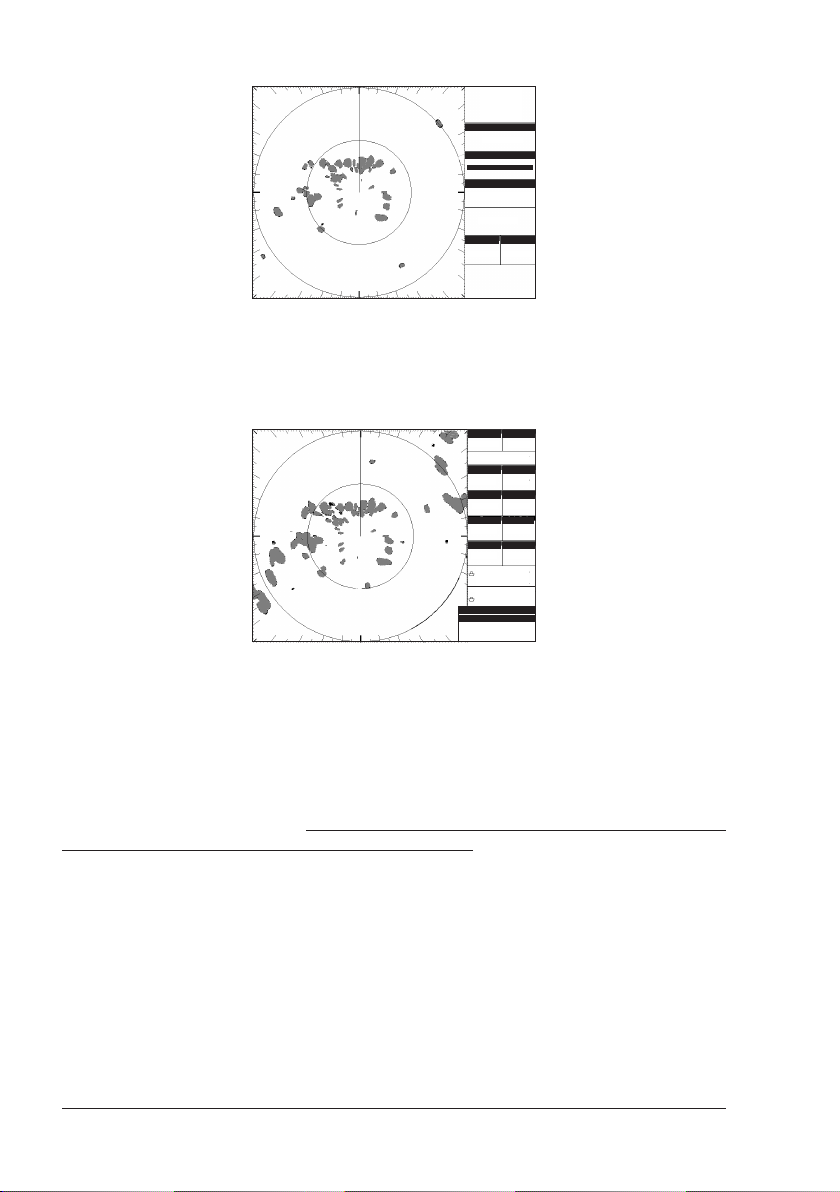

♦ Slowly decrease the GAIN value until the clutter clears out and you can

clearly distinguish a round spot in the Radar origin:

Transmission

Trigger Delay

Tuning

Gain

031

MBS

000

Trans. Trigger Delay

095

Done

Rings

RNG

1/8 Nm1/4 Nm

Fig. 1.7.4.4b - Transmission Trigger Delay tuning (III)

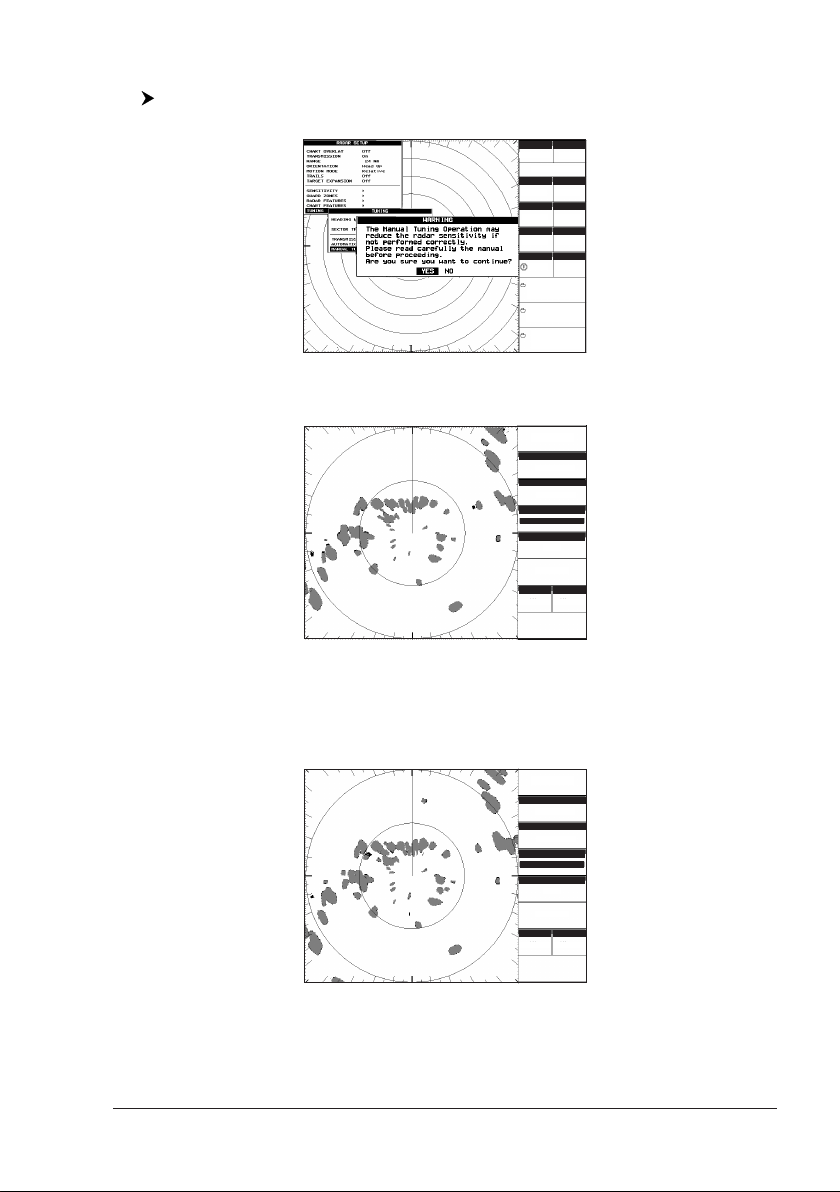

♦ If the Transmission Trigger Delay is properly tuned the spot in the Radar

origin should appear as in the picture above. In any case to be sure your

TTD is properly tuned try to decrease the Transmission Trigger Delay until a

hole start forming in the center of the round spot:

16 User Manual

Page 15

Transmission

Trigger Delay

Tuning

Gain

031

MBS

000

Trans. Trigger Delay

079

Done

Rings

RNG

1/8 Nm1/4 Nm

Fig. 1.7.4.4c - Transmission Trigger Delay tuning (IV)

♦ Now increase the TTD until the hole closes (not more than just the value to

make it close). The increase rate should be very slow: just increase by a

single step at the time and wait until you see the effect on the screen. When

the hole in the center of the spot closes you have reached the optimal TTD

setting.

Transmission

Trigger Delay

Tuning

Gain

031

MBS

000

Trans. Trigger Delay

095

Done

Rings

RNG

1/8 Nm1/4 Nm

Fig. 1.7.4.4d - Transmission Trigger Delay tuning (V)

♦ The spot in the Radar origin is the transmission pulse itself. Targets within

such range are not detectable because their echoes are completely overwritten

by the Radar still transmitting. Such spot is called Main Bang. To remove it

from the screen it is necessary to properly set the MBS (Main Bang Suppression) control. To do this, increase slowly the MBS. The spot is progressively

deleted from the inside toward the outside

Transmission

Trigger Delay

Tuning

Gain

031

MBS

039

Trans. Trigger Delay

095

Done

Rings

RNG

1/8 Nm1/4 Nm

Fig. 1.7.4.4e - Transmission Trigger Delay tuning (VI)

User Manual

17

Page 16

♦ Continue increasing the MBS until the spot completely disappear:

Transmission

Trigger Delay

Tuning

Gain

031

MBS

067

Trans. Trigger Delay

095

Done

Rings

RNG

1/8 Nm1/4 Nm

Fig. 1.7.4.4f - Transmission Trigger Delay tuning (VII)

♦ Select DONE to exit the TTD tuning menu saving your settings.

♦ The main Radar page is displayed. Please note that since initially Gain was

decreased, now it’s necessary to increase it back in order to achieve maximum sensitivity:

Rings

RNG

4Nm

1Nm

O

HDG 000 T

Heading

Motion

Relative Head Up

STC/FTC

Gain

55

59/Off

Int. Rej.

Exp

Off Of f

G.Z

Trails

Off Of f

SOG 1.0 Kts

O

COG 000 T

DST 9.468

nm

O

BRG 000 T

SENSITIVITY

GAIN

STC 059

FTC Off

INTERF.REJECTION

Fig. 1.7.4.4g - Transmission Trigger Delay tuning (VIII)

055

Off

Once the calibration has been performed, the calibration data is retained. However if a Clear RAM operation is performed it may be necessary to repeat the

calibration.

1.7.4.5 Automatic and Manual Tune

NOT NECESSARY AT FIRST INSTALLATION

The Tune control is used to tune the receiver in the Radar antenna for maximum

target returns on the display. The Radar comes from the factory already tuned so

this operation is not necessary at first installation. In general Radar Tuning may

be necessary if any component of the Radar is replaced for maintenance.

The Radar receiver can be tuned in Automatic or Manual mode. In Automatic Tune

mode, the Radar tunes itself automatically on all range scales. It is recom-

mended to execute the Tune function in Automatic mode. This generally

ensures that the Radar receiver is always tuned to receive the maximum signal.

If you choose the Manual Tune, you will need to adjust it again after 10 minutes,

after you have turned on the Radar, since the required setting will change after

the magnetron has warmed.

NOTE The Manual Tune function should be made only by professional operators.

18 User Manual

Page 17

Manual Tune

1/4 1/8

Done

Coarse Tuning

082

Manual Tuning

STC

059

128

Rings

RNG

1/8 Nm1/4 Nm

Fine Tuning

128

Gain

1/4 1/8

Done

Coarse Tuning

055

Manual Tuning

STC

059

130

Rings

RNG

1/8 Nm1/4 Nm

Fine Tuning

128

Gain

x

To execute manual tuning follow the procedure:

[MENU] + "TUNING" + [ENTER] + "MANUAL TUNE" + [ENTER]

♦ The following Warning message is displayed:

Rings

RNG

24 Nm

4Nm

O

HDG 007 T

Heading

Motion

Relative Head Up

STC/FTC

Gain

82

67/Off

Int. Rej.

Exp

Off Of f

G.Z

Trails

Off Of f

SOG 1.0 Kts

O

COG 007 T

DST 0.518

nm

O

BRG 072 T

O

43 33.715N

O

010 17.199E

Fig. 1.7.4.5 - Manual Tune Warning message

♦ Press [ENTER] to proceed, the Manual Tuning page is displayed:

Fig. 1.7.4.5a - Manual Tune page

♦ Try increasing or decreasing the Course Tuning very slowly and in small

steps from its middle value (128) until you obtain the maximum echo returns. If no land or ship targets are available, you may tune for maximum

STC.

♦ Once the Course Tuning has been set, repeat the same procedure with the

Fine Tuning:

User Manual

Fig. 1.7.4.5b - Manual Tuning procedure (I)

19

Page 18

Manual Tuning

Gain

055

STC

059

Coarse Tuning

130

Fine Tuning

131

Done

Rings

RNG

1/8 Nm1/4 Nm

x

1/4 1/8

Fig. 1.7.4.5c - Manual Tuning procedure (II)

♦ Select DONE to exit the Manual Tuning page saving your settings.

Automatic Tune

To execute automatic tuning follow the procedure:

[MENU] + "TUNING" + [ENTER] + "AUTOMATIC TUNE" + [ENTER]

♦ The following Warning message is displayed to alert the user that the Auto

Tuning procedure may require up to 10 minutes. Please note that during

Auto Tuning all the Radar functionalities are disabled.

Rings

RNG

24 Nm

4Nm

O

HDG 000 T

Heading

Motion

Relative Head Up

STC/FTC

Gain

82

67/Off

Int. Rej.

Exp

Off Of f

G.Z

Trails

Off Of f

SOG 1.0 Kts

O

COG 000 T

DST 4.385

nm

O

BRG 096 T

O

42 49.451N

O

010 14.734E

Fig. 1.7.4.5d - Automatic Tune Warning message

♦ Press [ENTER] to proceed, the Automatic Tuning starts and the following

Window is displayed on the screen:

Rings

RNG

1

6

6Nm

1Nm

O

7

HDG 007 T

Heading

Motion

Relative Head Up

Gain

STC/FTC

100

0

0/Off

100

Int. Rej.

Exp

Off Of f

G.Z

Trails

Off Of f

SOG 1.0 Kts

O

COG 000 T

DST 4.385

nm

O

BRG 096 T

O

42 49.451N

O

010 14.734E

Fig. 1.7.4.5e - Automatic Tune page

♦ When the Auto Tuning completes the Warning Message is hidden and all

Radar functionalities return to be available.

20 User Manual

Page 19

1.7.4.6 Save Tuning to User C-CARD

This is useful to avoid the user having to retune up Radar after a Clear RAM

operation or a software update. The following data will be saved:

♦ Heading Line angle

♦ Antenna Parking Position

♦ Sector Transmission Off Start Angle

♦ Sector Transmission Off End Angle

♦ Transmission Trigger Delay

♦ Course Tune

♦ Fine Tune

Insert the User C-CARD into the slot, then follow the procedure:

[MENU] + "TUNING" + [ENTER] + "SAVE TUNING TO USER C-CARD" +

[ENTER]

The file name is given automatically as TUNING1.

1.7.4.7 Load Tuning from User C-CARD

Loads the complete settings from the User C-CARD and changes the active menu

settings.

Insert the User C-CARD into the slot, then follow the procedure:

[MENU] + "TUNING" + [ENTER] + "LOAD TUNING FROM USER C-CARD" +

[ENTER]

User Manual

21

Page 20

22 User Manual

Page 21

2. Functions

2.1 BASIC

2.1.1 Cross Cursor

When on the Full Radar page or when the focus is on the Radar window, moving

the Cursor Keys will show the cursor on the screen. It is automatically hidden

when the Cursor is not used for more than 5 seconds. It can temporarily be

hidden to check for small targets under it by pressing [CLEAR].

When the Cursor Keys are moved a popup window will show the position of the

Cursor, the Distance and Bearing from the cursor to the vessels position.

It is context-sensitive. The following table reports the list of objects and the labels

that appear under the cursor:

♦ Center of Radar CTR

♦ EBL/VRM E/V

♦ Parallel Cursor ///

♦ Guard Zone GZ

♦ Ship Heading Marker HM

Cross Cursor

Fig. 2.1.1 - The Cross Cursor in the default Radar picture

2.1.2 Chart Overlay

Chart Overlay function merges Radar and chart data into a single picture by

drawing Radar targets over the cartography. When in Chart Overlay mode, the

chart inherits the Radar page setting, e.g. Orientation, True Motion mode (for

more information refer to Chapter 6, 6.16).

To enable (On) or disable (Off ) the Chart Overlay follow this procedure:

NOTE Requires a heading and a position sensor connected to the chart plotter

User Manual

AVAILABLE ONLY IN THE RADAR FULL PAGE

[MENU] + "CHART OVERLAY" + [ENTER]

through an NMEA 0183 interface. The heading sensor can be either a

gyrocompass or a fluxgate compass. The gyrocompass provides the best

performance in all conditions.

23

Page 22

Fig. 2.1.2 - Chart Overlay

2.1.3 Range

Selects the Radar range among 1/8, 1/4, 1/2, 3/4, 1, 1 + 1/2, 2, 3, 4, 6, 8, 12,

16, 24, 36 and 48 Nm (the maximum range depends on the antenna used).

To select the Radar Range value follow this procedure:

[MENU] + "RANGE" + [ENTER]

NOTE Changing scale takes about 5 seconds.

Also it is possible to select the Range in Radar page using [ZOOM IN]/[ZOOM

OUT].

2.1.4 Orientation

The Radar orientation option allows to choose the display mode, Head Up (HU),

North Up (NU) or Track Up (TU), that refers to the top of the screen as it relates

to the direction of the boat.

The Radar direction modes are described in the following table:

Head Up : The Radar picture is displayed with the vessel’s current heading upwards. As the heading

North Up : The Radar picture is stabilized and displayed with north upwards. As heading changes, the ship’s

Track Up : The Radar picture is stabilized and displayed with the currently selected Course Leg upwards. As

NOTE Head Up cannot be selected in True Motion mode.

changes the picture will rotate. It doesn’t require heading information. It is the default value.

Heading Marker moves. Requires a heading sensor connected to the chart plotter.

heading changes, the ship’s heading marker moves. If you select a new course leg, the picture

rotates to display the new course leg upwards. Requires a heading sensor connected to the chart

plotter.

To change the orientation mode follow this procedure:

[MENU] + "ORIENTATION" + [ENTER]

2.1.5 Motion Mode

Allows choosing between two different presentation of targets and ship position over the

Radar screen Relative Motion (RM) and True Motion (TM). See the following table:

True : In True Motion, fixed Radar targets maintain a constant position on the screen, while your own ship

Relative : In Relative Motion your own ship’s position remains fixed on the Radar screen and all Radar

NOTE True Motion is only available in North Up and Track Up modes (not in Head Up

mode). Also True Motion requires a heading sensor and GPS position

information.

moves across the Radar image at the appropriate speed and heading. A map-like image is thus

displayed, with all moving vessels traveling in true perspective to each other and to fixed

landmasses. As your ship’s position approaches the edge of the screen, the Radar center offset

is automatically reset to reveal the area ahead of your ship.

targets move relative to your own ship. It is the default for the Radar display.

24 User Manual

Page 23

To change the Motion mode follow this procedure:

[MENU] + "MOTION MODE" + [ENTER]

2.1.6 Echo Trails Settings

Echo Trails causes the persistence of the Radar targets on the screen for the time

specified. Selecting an appropriate trail plotting time help determining the speed

and course of a target vessel and help prevent collision with it. Selects Radar

Trails among Continuous, 15 seconds, 30 seconds, 1 Minute, 3 Minutes, 6 Minutes

(or disables - Off). To choose the Echo Trails follow this procedure:

[MENU] + "ECHO TRAILS" + [ENTER]

2.1.7 Target Expansion

Target Expansion is used to enlarge the target size without changing the range.

This function is useful to see and detect very small targets in open seas. To enable

(On) or disable (Off) the Target Expansion follow this procedure:

[MENU] + "TARGET EXPANSION" + [ENTER]

2.2 SENSITIVITY

To select the Sensitivity menu follow this procedure:

NOTE The Sensitivity menu can be also opened by pressing:

2.2.1 Interference Rejection

Reduces the interference caused by Radar signals from other Radar units. It is

possible to turn Interference Rejection to Off, Level 1 (weak), Level 2 (middle),

Level 3 (strong). The higher you set the Interference Rejection value the less

interference you will receive.

To select the Interference Rejection value follow this procedure:

[MENU] + "SENSITIVITY" + [ENTER]

[ENTER]

directly from the Radar page when the Cross Cursor is not placed over any

features.

[MENU] + "SENSITIVITY" + [ENTER] + "INTERF REJECTION" + [ENTER]

2.2.2 Gain Adjustment

Controls the Radar Gain. To see more details on the screen, increase the receiver

sensitivity by selecting a higher gain percentage. If there is too much detail or if

the screen is cluttered, lowering the sensitivity may increase the clarity of the

display.

To select the Gain value follow this procedure:

[MENU] + "SENSITIVITY" + [ENTER] + "GAIN" + [ENTER]

NOTE The Gain can be also controlled by pressing:

[GAIN]

directly from the Radar page, after pressing any soft keys.

2.2.3 STC (Sensitivity Time Constant) Adjustment

Reduces the effects of the sea clutter that can adversely affect displayed targets.

To select the STC value follow this procedure:

NOTE The STC can be also controlled by pressing:

NOTE At low scales (as 1/4 of mile) some attempts are necessary to adjust STC value.

User Manual

[MENU] + "SENSITIVITY" + [ENTER] + "STC" + [ENTER]

[STC]

directly from the Radar page, after pressing any soft keys.

25

Page 24

2.2.4 FTC (Fast Time Constant) Adjustment

Reduces the effects of rain, snow, fog and cloud that can adversely affect displayed targets.

To select the FTC value follow this procedure:

NOTE The FTC can be also controlled by pressing:

NOTE At low scales (as 1/4 of mile) some attempts are necessary to adjust FTC value.

[MENU] + "SENSITIVITY" + [ENTER] + "FTC" + [ENTER]

[FTC]

directly from the Radar page, after pressing any soft keys.

2.2.5 MBS (Main Bang Suppression) Adjustment

The MBS adjustment is fundamental for getting clear near center spot image. In

general, you must adjust MBS and STC and Gain to obtain desired Radar image.

To select the MBS value follow this procedure:

AVAILABLE ONLY FOR MDS 9/MDS 10

[MENU] + "SENSITIVITY" + [ENTER] + "MBS" + [ENTER]

2.3 RADAR FEATURES

2.3.1 Cursor Window

The content of the Cursor Window depends on cursor location.

It shows detailed information on the cursor Lat/Lon, the cursor bearing and range,

the center of the screen, EBL/VRM, Guard Zone, Heading Marker and Parallel

Cursor. It is hidden when the cursor is hidden.

To turn On or Off the Cursor Window follow this procedure:

[MENU] + "RADAR FEATURES" + [ENTER] + "CURSOR WINDOW" + [ENTER]

Cursor Window

Fig. 2.3.1- The Cursor Window

2.3.2 Heading Marker

The Heading Marker (HM) is the line from the own vessel’s position to the edge of

the picture at the vessel’s current heading with respect to the North indicated by

the compass.

26 User Manual

Page 25

Heading Marker (HM)

Fig. 2.3.2- The Heading Marker

The Heading Marker is updated each time the Radar image is updated. It can

temporarily be hidden to check for small targets under it by positioning the Cross

Cursor over it and pressing [CLEAR].

To turn On or Off the display of the Heading Marker follow this procedure:

[MENU] + "RADAR FEATURES" + [ENTER] + "HEADING MARKER" + [ENTER]

2.3.3 Degree Scale

The Degree Scale is the graduated scale located on the most external visible

range ring edge of the Radar page, with major ticks at 0, 10, 20, …, 350 degrees

and minor ticks at 5, 15, 25, …, 355 degrees.

Degree Scale

Fig. 2.3.3- The Degree Scale

To hide (Off ) or unhide (On) the display of the Degree Scale follow this procedure:

[MENU] + "RADAR FEATURES" + [ENTER] + "DEGREE SCALE" + [ENTER]

2.3.4 Range Rings

The Range Rings are concentric rings centered on the ship position, equally spaced.

User Manual

27

Page 26

Range Rings

Fig. 2.3.4- The Range Rings

They are used to give an immediate idea of the range of targets from the ship.

Their number and spacing are adjusted automatically accordingly with the Range

Scale. The indication of the Range Rings interval is indicated in the Status Bar

(see Par. 3.2.1).

To turn On or Off the display of the Range Rings follow the procedure:

[MENU] + "RADAR FEATURES" + [ENTER] + "RANGE RINGS" + [ENTER]

2.3.5 Compass Rose

The Compass Rose is an icon used to identify four main directions: North, South,

East and West. It is North oriented.

Compass Rose

Fig. 2.3.5- The Compass Rose in the default Radar picture

NOTE Requires a heading and position sensor connected to the chart plotter

To hide (Off ) or unhide (On) the display of the Compass Rose follow the procedure:

[MENU] + "RADAR FEATURES" + [ENTER] + "COMPASS ROSE" + [ENTER]

2.3.6 EBL & VRM

Electronic Bearing Lines (EBL) and Variable Range Marker (VRM) are used to

measure the range (distance) and the bearing between two points. A standard

28 User Manual

Page 27

VRM is displayed by default as a circle with its center located on your vessel’s

position, and EBL is displayed as a line from the vessel's position to the edge of

the Radar picture display.

EBL/VRM

Fig. 2.3.6 - EBL & VRM display

2.3.6.1 Handling of EBL/VRM

Positioning the Cross Cursor on the EBL/VRM activates a pop up message "E/V"

underneath the cursor. It is possible to allow to Move, Hook and Hide it.

♦ [MOVE]: Allows moving EBL/VRM from the own ship's position to any

location of the Radar page. Pressing [CONFIRM] once more confirms the

new position; pressing [CANCEL] resets the original position.

♦ [HOOK]: hooks the EBL/VRM cross point allowing changing bearing and

range using the Cursor Keys. Pressing [CONFIRM] once more confirms

the new range and bearing, pressing [CANCEL] resets the original range

and bearing values.

♦ [OFF]: disables the EBL/VRM.

Up to 2 EBL/VRM's may be placed on the Radar screen at the same time. To turn

EBL/VRM On or Off or to select 1 EBL/VRM, 2 EBL/VRM or both (1+2) EBL/VRM,

follow this procedure:

[MENU] + "RADAR FEATURES" + [ENTER] + "EBL/VRM" + [ENTER]

2.3.7 Parallel Cursor

A set of parallel lines with first line passing through the ship’s position and next

lines being placed equally spaced and extending from the ship’s position towards

one direction.

User Manual

29

Page 28

Parallel Cursor

Fig. 2.3.7 - Parallel Cursor display

The user can change the angle of the lines and the range between lines. It is used

to measure the bearing of other boats, navigate at a fixed distance from the

coast, measure the distance between two points.

The display of the Parallel Cursor can be turned On or Off following this procedure:

[MENU] + "RADAR FEATURES" + [ENTER] + "PARALLEL CURSOR" + [ENTER]

2.3.8 Center Offset

Allows to move the Radar center in any location of the screen.

2.3.8.1 Handling of Center Offset

If the Radar is in Relative Motion mode, positioning the Cross Cursor on the

center of the Radar image, allows editing the Center Offset ("CTR" message is

shown under the cursor position).

The soft keys are automatically displayed:

♦ [MOVE]: hooks the Radar image center allowing the user, using the

Cursor Keys, to move it at any location on the Radar screen. At this

point pressing [ENTER] confirms the new position of the center, pressing [CLEAR] resets the position of the Radar image at 0,0.

♦ [OFFSET]: opens an edit window where it is possible to edit the X Offset

and Y Offset position in pixel at which the center of the screen is positioned.

♦ [CTR SCRN]: resets screen offset position to 0,0.

NOTE In True Motion mode the user cannot change the screen center position.

To set the Center Offset follow this procedure:

[MENU] + "RADAR FEATURES" + [ENTER] + "CENTER OFFSET" + [ENTER]

2.3.9 Status Bar

Allows to display the Status Bar on the screen. Note that in Radar Split pages the

Status Bar is displayed always in compact mode to allow for more space for the

graphical data.

To enable (On) or disable (Off ) the Status Bar displaying follow the procedure:

30 User Manual

AVAILABLE ONLY IN THE RADAR SPLIT PAGES

[MENU] + "RADAR FEATURES" + [ENTER] + "STATUS BAR" + [ENTER]

Page 29

2.4 CHART FEATURES

2.4.1 Chart Overlay Mode

Selects which cartographic objects are to be displayed when Chart Overlay function is active in Radar Full page.

The following chart presets are available:

AVAILABLE ONLY IN THE RADAR FULL PAGE.

♦ Full: Full cartographic representation.

♦ Medium: includes “Low” settings plus Ports & Services and Auto Chart Boundaries.

♦ Low: includes also area fills, important city names, Nav-Aids & Lights and

Underwater Object icons.

♦ Minimum: only the coast lines and elevation objects, no area fill.

♦ As Cartography: inherits settings from the current cartography setting.

♦ Custom: Custom chart representation.

To select the desired Chart Overlay Mode follow this procedure:

[MENU] + "CHART FEATURES" + [ENTER] + "CHART OVERLAY MODE" +

[ENTER]

2.4.2 Chart Synchronization

When Chart Synchronization is enabled, the chart display is synchronized to the

Radar display. This function is enabled when Home mode is active (e.g. by pressing [CLEAR] from the chart screen). An alert window showing the message "Radar - Chart Synchronization mode On" is displayed.

To enable (On) or disable (Off ) the Chart Synchronization follow this procedure:

AVAILABLE ONLY IN THE RADAR CHART SPLIT PAGE

[MENU] + "CHART FEATURES" + [ENTER] + "CHART SYNCHRONIZATION" +

[ENTER]

2.4.3 Cursor Echo

This function allows to correlate targets on the Radar display with objects in the

chart.

Moving the Radar cursor on Radar display will cause moving another cursor over

the chart. The cursor over the chart shall be positioned over the same Lat/Lon of

the cursor over the Radar.

When the Cursor Echo function is enabled, the Radar cursor in the chart display is

always shown even if the cursor in the Radar display is hidden.

To enable (On) or disable (Off ) the Cursor Echo follow this procedure:

CHART FEATURES" + [ENTER] + "CART. OBJECTS DISPLAY" + [ENTER]

AVAILABLE ONLY IN THE RADAR CHART SPLIT PAGE

[MENU] + "CHART FEATURES" + [ENTER] + "CURSOR ECHO" + [ENTER]

2.5 GUARD ZONES

Your Radar allows a function to help you avoid a collision. It is possible to set an

alarm to trigger when a target is within a specified zone, the Guard Zone.

It is allowed to display up to 2 Guard Zones, Sector or Circular.

User Manual

31

Page 30

Guard Zone

Fig. 2.5 - Guard Zone display

When a Guard Zone is active, the Guard Alarm sounds when a target enters its

area.

NOTE A Guard Zone only operates when the whole zone is displayed on the screen.

In addition, a Guard Zone is inactive for 10 seconds after it is placed or resized, to avoid inappropriate alarms during positioning.

2.5.1 Handling of Guard Zone

Positioning the Cross Cursor over a Guard Zone, causes the message "GZ" to be

displayed under the cursor. It is possible to handle the Guard Zone.

♦ [HOOK]: allows changing Guard Zone range by moving up/down Cursor

Keys. Pressing [CONFIRM] to confirm, [CANCEL] otherwise.

♦ [TYPE]: allows changing Guard Zone type: press [SECTOR] to select the

Sector Guard Zone, press [CIRCULAR] to select the Circular Guard Zone.

♦ [OFF]: disables the Guard Zone.

2.5.2 Guard Zone Sensitivity

It defines a limit (selectable from 0 to 100) under which echoes activate an alarm

condition, when detected inside a Guard Zone.

Guard Zone Sensitivity default is 50.

The value 100 is the most sensitive (the system is always on, every detected echo

cause an alarm condition) and the value 000 is the least sensitive (same as switching

the alarm off).

To turn the alarm On or Off follow this procedure:

[MENU] + "GUARD ZONES" + [ENTER] + "GUARD ZONE" + [ENTER]

32 User Manual

Page 31

3. Radar Pages

This section will assist you to select the preferred Radar page.

NOTE The Radar display page is available only if the Radar is connected and powered

3.1 PAGES SELECTION

The Page Selection menu allows you to change the Radar page displayed. To

access this menu:

COLOR MAX 11/COLOR MAX PRO/COLOR MAX 15:

TRAWL PLOT 12:

The menu now shows five selections related to the Radar: Radar Full page ("RADAR"), Radar Split Chart page ("RADAR/CHART"), Radar Split Fish Finder page

("RADAR/FF"), Radar Split Highway page ("RADAR/NAV DATA"), Radar Combo

Page ("RADAR/FF/CHART/NAV DATA"). Move the cursor to select the desired

item and then press [ENTER].

On, and the Radar is in Transmit mode (see Chapter 1).

[MENU] + [MENU] + "PAGE" + [ENTER] + "RADAR" + [ENTER] + select the

desired page + [ENTER]

[DATA] + "RADAR" + [ENTER] + select the desired page + [ENTER]

[PAGE] + "RADAR" + [ENTER] + select the desired page + [ENTER]

The Radar Full page

Radar Split Chart page

Radar Split Fish Finder page

Radar Split Data page Radar Combo page

Fig. 3.1 - Available Radar pages

3.1.1 Selection by Soft Key

The default soft keys configuration can be customized. When the Radar is connected, any soft key can be assigned any of the Radar pages.

From the Chart page, pressing and holding down any of the four soft key shows a

pop-up window on the top of the soft key pressed that contains all possible data

pages assignable to the soft key pressed. Move the Cursor key up/down to place

User Manual

33

Page 32

the selector on the desired item; move the Cursor key to the right or press [ENTER]

to set the selected item; move the Cursor key to the left or press [CLEAR] to

close the pop-up window.

In the picture below, the four soft keys are customized to select four among the

five available Radar pages:

Fig. 3.1.1 - Radar page selection by Soft Key

Press [RD STD] to show the Full page, [RD+MAP] to show the Radar Split Chart

page, [RD+FF] to show the Radar Split Fish Finder page, [RD+DTA] to show the

Radar Split Data page and [COMBO 4] to show the Radar/Chart/Fish Finder/

Highway page.

3.2 STATUS BAR

You may choose to select the data displayed in the boxes in the system set up.

1

RNG (Radar Range) and Range rings interval

Current Heading

2

Motion Mode and Heading Mode indication

3

Gain and STC/FTC indication

4

Expansion and Interference Rejection

5

Guard Zone alarms and Trails

6

Ship Speed Over Ground and Course Over

7

Ground

Ship Distance and Bearing from destination

8

Ship Lat/Lon

9

Cursor Window

10

Fig.3.2 - The Default Status Bar

1

3

5

7

10

2

4

6

8

9

Note that in Radar Split pages the Status Bar displayed always in compact mode

to allow more space for the graphical data (see Par. 2.3.9):

34 User Manual

Page 33

RANGE and Range rings interval

1

Guard Zone alarms

2

Current Heading

3

Heading Mode indication

4

Motion Mode indication

5

Distance to Destination

6

Bearing to Destination

7

Ship Speed Over Ground

8

Course Over Ground

9

2

1

Fig.3.2a - The "compact" Status Bar

3

4

5

7

6

8 9

3.3 MENU HANDLING ON FULL PAGES

When in Radar Full page pressing [MENU] once opens the Radar Setup menu.

Pressing [MENU] twice opens the Main menu.

3.4 SELECTION OF THE "ACTIVE" VIEW IN SPLIT/

COMBO PAGES

Yellow frame

Fig. 3.4- Selection of active View

When in Split/Combo pages, the active view is highlighted by a focus (Yellow

frame). The keyboard commands are related to that focused view. To move the

focus press [MENU] twice.

User Manual

35

Page 34

36 User Manual

Page 35

4. Technical Specifications

This chapter provides specifications of the several types of Radar.

4.1 MDS 1

Antenna unit

♦ Power supply : 10.8 to 31.2 VDC

♦ Power consumption : 30W or less

♦ Preheat times : 90 sec

♦ Aerial : Radome 0.9 Feet

♦ Peak power output : 2kW

♦ Transmitting frequency : 9445+/-30MHz

♦ Beam width (degree) Horizontal : 7°

♦ Vertical : 25°

♦ Side Lobes Within +/-10° : <=-20dB

♦ Rotation : 30rpm

♦ Pulse Length (μsec)/PRF (Hz) S : 0.1/2200

♦ M, M1 : 0.3/1100

♦ L, M2 : 0.8/550

♦ IF center frequency : 60MHz (Linear amplifier)

♦ IF bandwidth S : 6MHz

♦ M, M1 : 6MHz

♦ L, M2 : 3MHz

♦ Noise figure : 10dB nominal

♦ Operating Temperature : -25°C ~ +55° C

♦ Operation in wind (relative) : 100 knots

♦ Water Resistance : IPX6 (IEC60529)

♦ Preheat times output (by 5 sec step) : 85 sec to 5 sec

Dimensions and Mounting

Fig. 4.1 - Radar MDS 1 (I)

User Manual

37

Page 36

Weight: 4.5 kg (10 lb) without cable

Weight: 5.5 kg (12.5 lb) 10m cable included

Fig. 4.1a - Radar MDS 1 (II)

4.2 MDS 8

Antenna unit

♦ Power supply : 10.8 to 41.6 VDC

♦ Power consumption : 30W or less

♦ Preheat times : 90 sec

♦ Aerial : Radome 1.5 Feet

♦ Peak power output : 2kW

♦ Transmitting frequency : 9445+/-30MHz

♦ Beam width (degree) Horizontal : 4.7°

♦ Vertical : 25°

♦ Side Lobes Within +/-10° : <=-20dB

♦ Rotation : 30rpm

♦ Pulse Length (μsec)/PRF (Hz) S : 0.1/2200

♦ M, M1 : 0.3/1100

♦ L, M2 : 0.8/550

♦ IF center frequency : 60MHz (Linear amplifier)

♦ IF bandwidth S : 6MHz

♦ M, M1 : 6MHz

♦ L, M2 : 3MHz

♦ Noise figure : 10dB nominal

♦ Operating Temperature : -25°C ~ +55°C

♦ Operation in wind (relative) : 100 knots

♦ Water Resistance : IPX6 (IEC60529)

♦ Preheat times output (by 5 sec step) : 85 sec to 5 sec

38 User Manual

Page 37

Dimensions and Mounting

Fig. 4.2 - Radar MDS 8 (I)

Weight: 8.1 kg (18.0 lb)

: 6.8 kg (15.0 lb) without

Weight cable

10m cable included

Fig. 4.2a - Radar MDS 8 (II)

4.3 MDS 9

Antenna unit

♦ Power supply : 10.8 to 41.6 VDC

♦ Power consumption : 45W or less

♦ Preheat times : 120 sec

♦ Aerial : Radome 1.8 Feet

♦ Peak power output : 4kW

♦ Trasmitting frequency : 9410+/-30MHz

♦ Beam width (degree) Horizontal : 4.0°

♦ Vertical : 25°

♦ Side Lobes Within +/-10° : <=-20dB

♦ Rotation : 24rpm

♦ Pulse Length (μsec)/PRF (Hz) S : 0.1/2000

♦ M, M1 : 0.25/2000

User Manual

39

Page 38

♦ L, M2 : 0.5/1000

♦ L, L1 : 1.0/500

♦ IF center frequency : 60MHz (Linear amplifier)

♦ IF bandwidth S : 6MHz

♦ M, M1 : 6MHz

♦ L, M2 : 3MHz

♦ L, L1 : 3MHz

♦ Noise figure : 6.0dB or less

♦ Operating Temperature : -25°C ~ +55°C

♦ Operation in wind (relative) : 100 knots

♦ Water Resistance : IPX6 (IEC60529)

♦ Preheat times output (by 5 sec step) : 115 sec to 5 sec

Dimensions and Mounting

Fig. 4.3 - Radar MDS 9 (I)

Weight: 9.7 kg (21.5lb) 10m cable included

Weight: 8.4 kg (19.0lb) without cable

Fig. 4.3a - Radar MDS 9 (II)

40 User Manual

Page 39

4.4 MDS 10

Antenna unit

♦ Power supply : 10.8 to 41.6 VDC

♦ Power consumption : 80W or less

♦ Preheat times : 120 sec

♦ Aerial : Open 4 or 5 Feet

♦ Peak power output : 4kW

♦ Trasmitting frequency : 9410+/-30MHz

♦ Beam width (degree) Horizontal : 2.4° or 1.7°

♦ Vertical : 25°

♦ Side Lobes Within +/-10° : <=-23dB

♦ Outside +/-10°: <=-32dB

♦ Rotation : 24rpm

♦ Pulse Length (μsec)/PRF (Hz) S : 0.06/4000

♦ M, M1 : 0.15/2000

♦ L, M2 : 0.4/1000

♦ L, L1 : 1.0/500

♦ IF center frequency : 60MHz (Linear amplifier)

♦ IF bandwidth S : 20MHz

♦ M, M1 : 20MHz

♦ L, M2 : 5MHz

♦ L, L1 : 5MHz

♦ Noise figure : 5.0dB or less

♦ Operating Temperature : -25°C ~ +55°C

♦ Operation in wind (relative) : 70 knots

♦ Water Resistance : IPX6 (IEC60529)

♦ Preheat times output (by 5 sec step) : 115 sec to 5 sec

Dimensions and Mounting

3.5 feet 1067 (47 1/4)

4.5 feet 1372 (59 1/16)

User Manual

Fig. 4.4 - Radar SWR 10 (I)

41

Page 40

Fig. 4.4a - Radar MDS 10 (II)

Weight: 21.2 Kg (47lb) 4 feet

Weight: 21.9 Kg (49lb) 5 feet

42 User Manual

Page 41

5. Troubleshooting

5.1 The Radar page is not available

This means you didn’t configure the I/O setup to connect to the Radar. Enter the

I/O Setup menu (see procedure at Par. 1.7.1) and select the Radar on the serial

port to which the Radar is connected.

5.2 The message "Please Turn On Radar" is displayed on the

Radar window

This means that even if the I/O Setup has been configured for Radar, no Radar is

being detected. This may depend on several factors:

♦ Verify that the correct serial port is set in the I/O Setup menu, eventually

try setting the Radar on another serial port.

♦ Check that the Radar is connected to the chart plotter, to the same serial

port as set in the I/O Setup menu, in case try connecting it to another

serial port.

♦ Verify that all the connections in the Junction Box are done properly.

♦ Verify using a Voltage Meter that the Radar power supply level at the Junc-

tion Box is at least 12V. The Radar is able to operate with 10V but some

volts may be dropped due to the cable length.

If everything above is correct, try shorting the green and the blue wires in cable

coming from the Radar. If the Radar still doesn’t work you need to call for assistance.

5.3 The Radar preheating countdown timer is displayed but

when the preheating terminates it restarts over and over

again

The power supply level is too low. This may be caused by battery low, cable too

long, cable section to narrow.

5.4 Too much clutter near the Radar screen center

This is a typical phenomenon with Radar. Echoes from nearby vessel may hit

other objects like other vessels or other objects randomly and reflections can be

received by Radar antenna due to very short distance between the objects. This is

normal condition in a port where nearby targets (such as sailboat masts) may

cause multiple reflections. In this case, increase the STC and decreasing the

GAIN.

5.5 During navigation in open sea the center of the screen is

covered by a large spot

It means that most probably the Transmission Trigger Delay and/or the Main Bang

Suppression need to be correctly tuned (refer to Par. 1.7.4.4).

5.6 After turning transmission On, the Radar page remains

completely black

The Gain setting could be too low or STC setting too high. The Radar is probably

not properly tuned. Execute the Automatic Tuning procedure to restore optimal

performance (refer to Par. 1.7.4.5).

User Manual

43

Page 42

5.7 The Radar sensitivity appears to be low

Radar sensitivity depends on several factors. To increase sensitivity act as follows:

♦ Execute the Automatic Tuning procedure to ensure that the Radar is per-

fectly tuned.

♦ Increase the GAIN.

♦ Reduce the STC, since the STC has the effect to reduce the echo intensity

of nearby targets.

♦ Turn Off the FTC, since it has the effect to reduce the echoes intensity of

big targets.

5.8 Radar targets are delayed with respect to the antenna

rotation

The Radar image on the GPS is updated every 2.5 seconds as information is

acquired from the antenna. This could cause a mis-match between the actual

target position and the targets shown on the screen.

5.9 Radar target appear to be pulsing

This is a rather common problem for any Radar. For long distance targets, when

the Radar pulse hits a target, the reflection strength which depends on the hit

angle. Perpendicular hits give the strongest echo. Hard objects give stronger echo

and soft objects give weaker echo.

To eliminate the pulsing effect of Radar targets the Echo Trails function may be

used (see Par. 2.1.6).

5.10 Stationary target appear to be oscillating around their

actual position

Radar targets may appear to be oscillating around their actual position due to the

movement of your vessel. In fact even a minimum oscillation of the position

where the Radar is located may cause an apparent movement of the targets

detected.

For short distance targets, surface waves lower the detectivity. The STC should be

adjusted to properly to maximize the detectivity.

44 User Manual

Page 43

6. Frequently Asked Questions

6.1 What should I do at first Radar installation?

At first installation its necessary to:

1) properly set up the Radar calibration

2) set up the I/O to detect the Radar

6.2 How can I turn Radar power On/Off

Radar power On/Off can be either directly controlled from the chart plotter (NOT

AVAILABLE FOR COLOR MAX WIDE I/E & COLOR MAX SEALINK I/E) or by an external switch

depending on how you have set up your chart plotter.

In case the power is managed by the chart plotter you can turn power On by

pressing [MENU] when in the Radar Page. Otherwise you have to turn power On

by acting on the external switch.

NOTE For a pratical matter we suggest to use Radar Powered On/Off controlled by

6.3 How should I setup the chart plotter to control the Radar

Please refer to Chapter 1 for wiring schematic.

6.4 How can I turn Radar Transmission On/Off?

Press [ENTER] in the Radar page or enter the Radar Main Menu and set Transmission On from the related menu choice. Transmission can be set in Stand-by

only from the Radar menu.

an external switch, because at a glance we can check the Radar status without

having to switch to the Radar page.

power On/Off?

6.5 What is the preheating?

Each time you power On the Radar you must allow 90 to 120 seconds (depending

on the Radar model) to warm up the Radar. Operating the Radar before this time

could cause damage to it. For this reason the chart plotter doesn't allow operating

the Radar until the preheating is complete.

6.6 Some time the preheating takes less than 90 seconds, is

this normal?

Yes it is. It means that the Radar was already powered on at the time you turned