Page 1

Congratulations on your purchase!

Thank you for choosing a Sirius product.

S-DDH1.1 INDUCTION DOWNDRAFT

INSTALLATION AND OPERATION MANUAL

1

1

Page 2

DEAR CUSTOMER

The built-in induction cooktop is intended for household use only. Materials used for packaging are nature

friendly and may be recycled, deposited or destroyed without any threat to the environment.

In order to recognize these features, all packing materials are marked with relevant symbols.

When you plan to replace your rangehood, deposit your old appliance with the authorized depot dealing with

used household appliances.

INSTALLATION

Instructions for use have been prepared for the user, and describe the particulars and handling of the

appliance. These instructions apply to different models from the same family of appliances, therefore you may

find information and descriptions that may not apply to your particular appliance.

INSTALLATION INSTRUCTIONS

He appliance should be connected to the power supply in accordance with the instructions from the chapter

“Electrical connections” and in line with the standing regulations and standards. The connections should be

carried out by a qualified personnel only.

FIRE HAZARD PROTECTION

Appliances are allowed to be mounted on one side next to a high kitchen cabinet, the height of which may

exceed that of the appliance. On the opposite side however, only a kitchen cabinet of equal height as the

appliance is allowed.

The symbol on the product or on its packaging indicates that this product

may not be treated as household waste. Instead it shall be handed

over to the applicable collection point for the recycling of electrical and

electronic equipment. By ensuring this product is disposed of correctly,

you will help prevent potential negative consequences for the environment

and human health, which could otherwise be caused by inappropriate

waste handling of this product. For more detailed information about

recycling of this product, please contact your local city office, your

household waste disposal service or the shop where you purchased the

product. This appliance is marked according to the European directive

2002/96/EC on waste electrical and electronic equipment (WEEE).

2

Page 3

IMPORTANT WARNINGS ABOUT THE COOKING HOB

4

IMPORTANT WARNINGS ABOUT THE DOWNDRAFT

TECHNICAL DRAWING

INSTALLATION SEQUENCE

INSTALLING THE INDUCTION DOWNDRAFT

DUCTING TO SEM 7 / SEM 8 MOTOR

(SIDE OR BOTTOM VENTING

DUCTING TO SEM 7 / SEM 8 MOTOR

(FRONT OR REAR VENTING

DUCTING FROM MOTOR TO WALL VENT

ELECTRICAL CONNECTION

CONNECTION TO THE POWER SUPPLY

TECHNICAL INFORMATION

5

6

7

8

11

12

14

14

16

17

INDUCTION COOKTOP FUNCTIONS

SAFETY FUNCTION AND ERROR SIGNALS

CLEANING AND MAINTENANCE

USING THE DOWNDRAFT

ELECTRICAL CONNECTION OF THE DOWNDRAFT

FUNCTIONS OF THE DOWNDRAFT

CLEANING AND MAINTENANCE OF THE DOWNDRAFT

TROUBLESHOOTING

AFTER SALES SERVICE

INSTALLATION GUIDE

20

30

31

32

33

35

36

36

37

38

3

Page 4

IMPORTANT WARNINGS

ABOUT THE INDUCTION COOKTOP

• The appliance may be installed and connected to

the power supply only by a qualified technician.

• Particular areas of the cooktop surface (adjacent

to the induction zones) are hot during operation.

• Hot oil ignites, so be sure to prepare food (such

as fries) under constant supervision.

• Induction zones may not be left in operation

empty, without any cookware on top.

• Never use the induction cooktop as a working

surface. Sharp objects may damage the cooktop.

• Never place any metal objects upon the induction

hotplate, such as knives, forks, spoons, pot lids

etc., as they may get very hot.

• Preparation of food in aluminium or plastic

cookware is not allowed. Never place any plastic

objects or aluminium foil upon the cooktop

surface.

• In case any other appliances are plugged in the

electric mains close to the cooktop, prevent the

plug cable from connecting with the cooking

zones.

• Never store any flammable objects or chemicals,

like cleaning agents, sprays, detergents, etc.,

below the appliance.

• Never use cracked or broken ceramic glass

cooktop. In case you notice any visible cracks on

the surface, cut the power supply immediately.

• In case of any malfunctions, disconnect the

appliance from the power supply and call service

department.

• Do not use high-pressure steam cleaner or hot

steam to clean the appliance.

• The appliance is manufactured in compliance

with the relevant effective safety standards.

• The appliance is not intended for use by children

• The hob can not be activated by external timers

or remote controls systems.

• Be careful not to drop objects or crockery on the

induction surface. Even light objects (e.g. a salt

shaker) can crack or damage the cooktop.

• If the appliance is built in over an oven with a

pyrolytic system, it should not be operated while

the pyrolytic process is in progress because it

can trigger the overheating protection of the

cooktop.

• Don’t connect the hob to the power supply

with an extension cable or multiple sockets,

because they don’t assure a sufficient safety (e.g.

overheating risk of multiple sockets).

• After using the cooktop, remove all cookware

from the cooking surface. Do not rely on the pot

detector.

• Connect the power cable to a permanent

connection.

• Stationary appliances not fitted with means for

disconnection from the supply mains having a

contact separation in all poles that provide full

disconnection under overvoltage category III, the

instructions state that means for disconnection

must be incorporated in the fixed wiring in

accordance with the wiring rules.

• If the glass is broken, please disconnect not only

the supply chain of the cooking appliance but

that of the downdraft also.

WARNING

Unattended cooking on a hob with fat or oil can

be dangerous and may result in fire.

• NEVER try to extinguish a fire with water, but

switch off the appliance and then cover flame e.g.

with a lid or a fire blanket.

WARNING

Fire danger: Do not store items on the cooking

surfaces.

• If the supply cord is damaged, it must be

replaced by the manufacturer, its service agent

or similarly qualified persons in order to avoid any

kind of hazard.

• You may also find these instructional materials on

the website of the manufacturer.

4

Page 5

IMPORTANT WARNINGS

ABOUT THE DOWNDRAFT

• It is designed to work in both ducted mode with

outside evacuation, and recirculating mode.

• These hoods have been designed for personal

use in the home. The appliance must be used

by adults. Make sure that the appliance is out of

reach of children. Make sure that children do not

operate the controls.

• When the appliance is delivered, check the overall

appearance of the packaging.

Any remarks should be written on the delivery

coupon, of which you keep a copy.

Your appliance is designed for normal domestic

use. It is not designed for commercial or industrial

use, or for purposes other than those for which it

was designed.

• Any consequences of or damage from incorrect

installation or incorrect use of the appliance will

not be covered by the manufacturer’s guarantee.

• Do not ever change or try to change the

characteristics of this appliance. This would be

a danger. Repairs must be performed only by an

authorised technician.

Always disconnect the hood before carrying out

cleaning or maintenance operations.

• Adequately ventilate the room when a cooker

hood and other appliances, powered by energy

other than electricity, are used simultaneously,

so that the hood does not suck any combustion

fumes.

• It is not allowed to cook food over open flames

(flambé) or operate gas hobs without pots

or pans on them under the hood itself (the

flames sucked into the hood might damage the

appliance).

• Frying with oil must be done under constant

supervision as hot oils and fats may ignite

• Respect the guidelines for cleaning and

replacement of grease filters. Accumulated

deposits of grease are a fire hazard.

• Never use steam or high-pressure devices

for cleaning your hood (regulations regarding

electrical safety).

• Never use the rangehood without the grease

filters.

• The minimum distance between the downdraft

(closed) and the surface above it must be at least

800mm.

• When handling the downdraft, never put your

hands in the field of action of the extractable unit.

• This appliance can be used by children aged

from 8 years old. Children shall not play with this

appliance. Cleaning and user maintenance shall

not be made by children without supervision

• NEVER try to extinguish a fire with water, but

switch off the appliance and then cover the flame

e.g. with a lid or a fire blanket.

• If the supply cord is damaged, it must be

replaced by the manufacturer, its service agent

or similarly qualified persons in order to avoid a

hazard.

• If the supply cord of the appliance is provided

with a hob, this must be easily accessible.

• You may also find these instructional materials on

our website: www.siriusbrand.com.

In the case of the version with external motor, for

normal downdraft operation, it is necessary to

use an external motor made by Sirius.

• Keep these instructions for use with the

appliance.

• If the appliance should be sold or passed on

to others, make sure that the instructions are

passed on with it.

• We thank you for taking note of these

suggestions before installing and using the

appliance.

• They have been written for your personal safety

and the safety of others.

5

Page 6

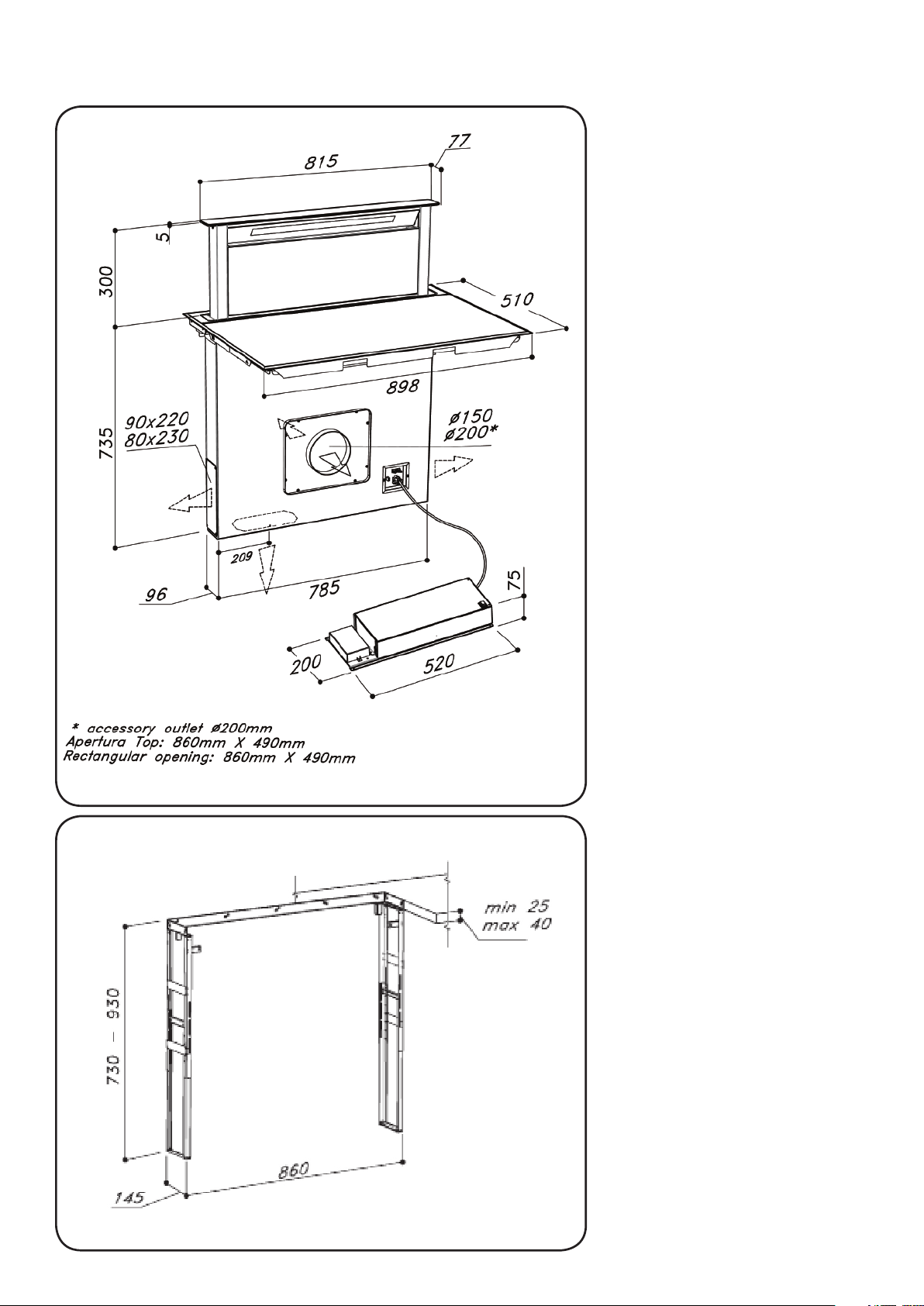

TECHNICAL DRAWING

6

Page 7

INSTALLATION SEQUENCE

HOLE CUT FOR INSTALLING THE HOB

Step 1

DOWNDRAFT INSTALLATION COOKING HOB INSTALLATION

INSERTION OF THE METAL INSTALLATION

STRUCTURE

Step 2

Step 3

Step 4

7

Page 8

INSTALLATION OF INTEGRATED

INDUCTION DOWNDRAFT

CAUTION

• The installation and the connection of the product

to the mains electricity must only be carried out

by qualified personnel.

• The kitchen unit into which the product is to be

installed must be realised in materials (including

adhesives and finishes) that are resistant to a

temperature of 100°C.

• After the installation, the product must be

accessible for any servicing requirements.

• Overhead cabinets must be a minimum of

800mm for installaton or removal of downdraft

section.

• The cornice of the worktop can have a thickness

greater than the worktop because an opening is

maintained in the front part of the kitchen unit of

at least 5mm (refer to design below) to ensure an

adequate passage of air to avoid overheating the

product.

• Before cutting the hole, check inside the kitchen

unit where the product will be housed to ensure

that there are no obstructions such as parts of

the unit’s structure or anything else that could

cause problems for a correct installation. Check

that the overall dimensions of the downdraft and

the cooking hob are compatible with the kitchen

cabinets so that the installation is feasible.

• Induction hob may be built into the 25 to 40

mm thick worktops.

BUILT-IN INDUCTION HOB

OPENING DIMENSIONS

S-DDH1.1

A 898mm

B 510mm

C 860mm

D 490mm

E 45

F 5

G 50

8

Page 9

• A horizontal and vertical space of at least 20mm

from the lower surface of the cooking hob and at

least 20mm from the downdraft must be foreseen

so as to create a passage for the air necessary to

cool the product (refer to the above illustration).

• There must be an opening of at least 50mm the

whole width of the kitchen unit in the lower and

rear part of the furniture to allow for the passage

of air to avoid the product overheating.

• Ensure that the passage of air in the lower part of

the kitchen unit permits a constant flow of air to

cool the product, i.e., a vent in kicker.

• Fitting the oven underneath the cooking hob is

possible with fan-cooled ovens. Before installing

the oven, remove the rear wall of the kitchen

unit where the oven will be fitted into the kitchen

furniture.

There must also be a minimum aperture of 5mm

in the front part and above all in the lower part

of the kitchen furniture to ensure an adequate

passage of air necessary to cool the product.

PRE-INSTALLATION CHECKS

Connect all of the electrical components to the unit

and motor to make sure both the unit and the motor

are functioning properly.

(NOTE: The motor plug is fitted with a dummy

plug - with the exception of SEM1 motor - to

protect the connection from dust. Ensure the

red dummy plug is removed and replaced

with the two pin motor plug from the power

transformer box. Failure to do so will result in

only two speeds operating).

Before installing the product, check that all

components are not damaged. If any components

are damaged, contact the retailer and do not go

ahead with the installation.

Before installing the downdraft, remove the safety

spacer highlighted in the photograph

(Fig. 1, Page 38).

Furthermore, carefully read all the instructions as

follows:

• Utilise an air extraction duct that has a maximum

length of not more than 7 metres.

• Limit the number of curves in the duct because

each curve reduces the efficiency of the

extraction equal to 1 linear metre (E.g., if two 90°

curves are utilised, the length of the duct must

not exceed 5 metres in length).

• Avoid drastic changes of direction.

• Utilise a duct with a 200mm diameter along its

whole length.

• Utilise a duct that is manufactured from material

approved to the norm. The supplying company

will not respond to problems of flow capacity or

noise if there is a lack of respect of the previously

mentioned instructions and the guarantee will be

annulled.

1. Position the support bracket of the downdraft in

the rear part of the realised aperture (refer to Fig.

2).

2. The bracket must be positioned approximately

two/three millimetres from the upper surface of

the worktop, as shown in Fig.3.

3. Fix the support bracket of the downdraft to the

worktop by utilising the screws supplied in the

case of wood worktops. For worktops realised in

materials different to wood, utilise the appropriate

screws.

4. Utilise the upper and lower holes positioned in the

support bracket of the downdraft in accordance

with the thickness of the worktop into which the

product is installed.

5. Fix the two worktop reinforcement telescopic

structures to the lower sides of the support

bracket of the downdraft, as shown in Fig. 4.

6. After fixing the reinforcement structures, adjust

their telescopic travel so as to reach the base

underneath (Fig. 5). Fix the structure to the base

underneath utilising the screws supplied.

7. Check that the worktop is perfectly level then

block the travel of the structures utilising the four

self-threading screws, positioned as in Fig. 6.

8. Insert the downdraft into the installed support

bracket (refer to Fig. 7). The fixtures positioned

on the downdraft must coincide perfectly with the

support bracket installed in the kitchen unit (refer

to Fig. 8).

9. Install the cooking hob ensuring that the opening

at the rear of the product coincides perfectly with

the downdraft (refer to Fig. 9).

9

Page 10

INSTALLING THE FOAM GASKET

Before installing the cooking hob in its appropriate

position in the worktop, apply the adhesive gasket in

expanded polyurethane supplied with the product to

the lower part of the cooking hob.

WARNING

Unattended cooking on a hob with fat or oil can

be dangerous and may result in fire.

The gasket should be attached to the appliance in

the following way:

• Remove the protective film from the gasket.

• Then, attach the gasket to the lower side of

the glass, approximately 2-3 millimetres from

the edge.

• The gasket must be attached along the entire

length of the glass edge and should not overlap at the corners.

• When installing the gasket, make sure that

the glass does not come into contact with

any sharp objects.

INSTALLATION PROCEDURE

• The worktop must be perfectly level.

• Place the cooking hob into the previously real

ised opening in the worktop.

• Press the induction hob down forcefully onto

the worktop, in correspondence to the edges

of the cooking hob.

• If the downdraft is not perfectly aligned with

the induction hob, adjust the alignment

screws (Fig. 10A) on the right and left of

the product. Screw in the screws to lift

the downdraft and unscrew to lower the

downdraft.

• Before the installation, the screws indicated

in Fig. 10B must be unscrewed as much as

possible so as to keep the downdraft near to

the rear part of the kitchen cabinetry.

• If the downdraft is not centred correctly with

the cooking hob after the installtion has been

carried out, utilise the adjustment screws Fig.

10B to shift is forwards by screwing in the

screws on both the right and left side of the

product.

1. Check that the downdraft inside the kitch unit

is perfectly vertical. FIx it utilising the brackets

supplied (Fig.11)

2. Permanently fix the downdraft utilising the

two screws indicated in Fig. 12

3. Connect the electrical cables of the

downdraft as shown in Fig. 13 and then carry

out the connection to the mains electricity in

accordance with the information reported on

the relative technical date plate.

Position the metal box containg the electronic

components in an easily accessible position

in the case of any servicing requirements.

10

Page 11

Ducting to SEM 7 motor (200mm ducting)

For SEM 8 motor with SDD2 L EMTC 880/1180 - 200mm option only.

1B: Connect a duct expander (Part ‘H’) to rectangular to round adapter (Part ‘A’), then connect

length of ducting (Part ‘K.2’) to the 200mm outlet.

2B: Secure to the motor with a universal ring clamp (Part ‘G’).

• See page 12 for ducting to vent (N/A for SEM 7 motor)

PART ‘B’

PART ‘A’

PART ‘H’

Ducting to SEM 8 motor (200mm ducting)

BOTTOM VENT

OPTION

WALL

SIDE VENT

OPTION

OUTSIDEINSIDE

MIN HEIGHT FROM GROUND

500mm - 2mtrs

PART ‘B’

PART ‘A’

PART ‘H’

PART ‘K.2’

PART ‘K.2’

PART ‘G ’

11

Page 12

INSTALLATION INSTRUCTIONS

FOR SEM 7, SEM 8

FRONT OR REAR VENTING

(For side or bottom venting instructions, see pages 7 - 9)

STEP 2:

If venting from front, check to see if front adaptor

plate (Part ‘D’) is attached.

• If venting from the rear, remove 200mm adaptor

plate (Part ‘D’) and replace with front cover plate

(Part ‘E’).

Remove & replace with

cover plate (Part ‘C’)

STEP 3:

• Carefully lower downdraft into cutout cabinetry.

• Fix the downdraft inside the cabinet, using the

special fixing brackets (Part ‘F’) supplied with the

product.

• Insert the brackets in the lower side of the

downdraft in such a way that there is a 2 mm

distance between the lower side of bracket and

the bottom of the cabinet.

• This distance will allow the traction to be

positioned downwards of the product, at the

moment of fixing, in order to have the stainless steel trim perfectly adhering with the work

surface.

• Before inserting the screws, please make sure

that the appliance is perfectly perpendicular with

the work surface, ensuring unit is square and

levelled with spirit level before turning on. (Fig. 5)

Remove & replace with

cover plate (Part ‘C’)

(Fig. 7)

Part ‘F’

2mm

Remove & replace with

cover plate (Part ‘C’)

NB: If the unit is not levelled, the downdraft will

shudder when rising. This could cause damage

to your unit, which is not covered by warranty.

This is installation damage.

12

(Fig. 5)

Page 13

STEP 4:

1. Use 200mm ducting (Part ‘K.2’).

2. The ducting fits directly onto the collar on the front adaptor plate (Part ‘D’).

3. Fix in place using a universal ring clamp (Part ‘G’).

Ducting to SEM 8 motor (internal motor)

PART ‘K.1’ / ‘K.2’

Ducting to SEM 7 motor (external motor)

PART ‘K.1’ / ‘K.2’

PART ‘G’

OUTSIDEINSIDE

WALL

PART ‘K.2’

PART ‘G’

URC-25/325

SEM 7

MIN HEIGHT FROM GROUND

500mm - 2mtrs

13

Page 14

DUCTING FROM MOTOR TO WALL VENT: (SEM 8)

1. Run the length of ducting to the motor. (Additional lengths of ducting can be attached using an

additional internal connector pieces.)

NOTE: No connector required as it connects directly to the collar of the motor.

2. Secure with another universal ring clamp (Part ‘G’).

NOTE: The location of the motor is to be no less than 2 metres away from the downdraft. Failure to

do so may result in additional noise level of the downdraft. Maximum distance is 7 metres, however

3 - 5 metres is optimum to minimise noise and maximise performance.

3. Using another length of semi-rigid duct run from the exit collar on the SEM 8 to a predetermined exit point

and connect to weatherproof vent with a clamp.

See www.siriusbrand.com for multiple vent options or see our nearest retail partner.

ELECTRICAL CONNECTION

Power transformer can be located anywhere beneath

the bench. It must be accessible for servicing.

NOTE

We recommend installing the power transformer

at least 10 cm above floor level and at a suitable

distance from all heat sources (e.g. oven sides or

cook top).

WARNING

Place the power transformer at a distance of no

less than 65 cm from gas cooktops.

14

7 METRE POWER CORD

POWER TRANSFORMER

Page 15

ELECTRICAL CONNECTION

NOTE

This appliance complies with the European

Directives 2006/95/EC (Low Voltage

Directive) and 2004/108/EC (Electromagnetic

Compatibility).

While installing the appliance and carrying

maintenance operation, make sure it is disconnected

from the electrical network or the fuses are cut out or

removed.

Check that:

• Power is connected.

• Feeder lines (mains) are in good conditions.

• The cables diameter complies with installation

regulations.

WARNING

The downdraft connection to the electrical

network must be carried out only by

professional and qualified technicians.

The downdraft must be connected to a properly

installed and suitable electrical network.

The electrical system must comply with VDE0100

standard.

DANGER

If the rangehood presents any anomaly,

disconnect the appliance or remove the

fuse corresponding to the appliance

power disconnecting line.

If the appliance has no plug or if the plug is not

easily accessible, then a device needs to be fitted to

disconnect off from the electric network; this device

must have an opening distance between contacts on

all poles of at least 3 mm.

CAUTION

This appliance is fitted with an H05 VVF 3 conductor,

0.75 mm2 (neutral, phase, and ground) power cord.

This can be connected up to a 220 - 240 V

monophase electrical network through a CEI 60083

approved power socket (10AMP power socket),

which must remain accessible after installation, in

compliance with installation regulations. We decline

any responsibility in case of accidents caused by

a lack of ground connection or incorrect ground

connection. The appliance must be fed through a

differential protection device (RCD), with a nominal

residual current not exceeding 30mA. If the power

cord is damaged, call the after-sales service to avoid

any risk.

WARNING

After having replaced the filters, reinstall

the front stainless steel panel, otherwise

the Downdraft is not enabled to function.

NOTE

Water splashing against the enclosure from any

direction shall have no harmful effect, utilizing either:

a) an oscillating fixture, or b) A spray nozzle with no

shield.

Test a) is conducted for 10 minutes. Test b) is

conducted (without shield) for 5 minutes minimum.

Oscillating tube: Test duration: 10 minutes, or spray

nozzle (same as IPX3 spray nozzle with shield

removed).

(Fig. 8)

15

Page 16

CONNECTION TO THE POWER SUPPLY

• Connections may be carried out by a

qualified technician only. The earthing

protection must comply with the standing

regulations.

• Connection terminals are revealed when the

connection box cover is removed.

• Prior any attempted connection check that

the voltage indicated on the rating plate is in

line with your home power supply.

• The rating plate is located underneath the

appliance.

• The cooking hob operates at 220V-240V~.

In order to make a fixed connection to

the mains, insert an all-pole circuit breaker

between the appliance and the mains. This

device shall have a contact separation in

all poles, providing full disconnection under

over-voltage category III conditions.

• Such appliances are allowed to be mounted

on one side next to a high kitchen cabinet,

the height of which may exceed that of the

appliance. On the opposite side however,

only a kitchen cabinet of equal height as the

appliance is allowed.

• Upon the completion of installation, live wires

and isolated cables must be adequately

protected against accidental touching.

WARNING

Before attempting any repairs on the appliance,

disconnect the power supply. In accordance

with the mains voltage the appliance should be

connected in line with the attached diagram.

The earthing wire (PE) must be connected to the

terminal marked with the earthing symbol.

The connection cable must lead through the

relief safety device, protecting it from accidental

pulling out.

INSTALLATION DIAGRAM

• Cooktops models SDDH1.1 are equipped

with power cables.

• The connection needs to be made on the

terminals of the power cable directly during

the connection with the electrical net as you

can find both in the rating plate and in the

electrical scheme here below.

BASIC ADJUSTMENT OF SENSOR TO THE

AMBIENCE

Upon each connection to the power supply

the sensors of the appliance are automatically

adjusted to the environment to ensure their

proper function. All displays turn on and are fully

illuminated for a few seconds.

During the adjustment procedure the sensors

must be free of any objects, otherwise the

adjustment procedure will be interrupted until

such objects are removed from the sensor

surface. During this period the regulation of the

cooktop is impossible.

16

Page 17

TECHNICAL INFORMATION

SDDH1.1

Width

Rated Voltage

Type of Switch

220-240V ~ o 380-415V

Electronic Sensors

Cooking zones (Ø,mm/kWx)

Forward left

184 x 220, 2,1 (P=3,7)

898 x 630

2N~50/60 Hz

NOTE

In case sugar or other heavily sweetened

substance is spilled on the hotplate, wipe is

immediately and remove the sugar residues

with a plstic scraper although the cooking

zone is still hot, otherwise the hotplate may be

dameged. Avoid cleaning the cookplate while

the cooking zones are still hot, as you may

damage the hob.

Middle left

Middle

Middle right

Forward right

Total power (W)

184 x 220, 2,1 (P=3,7)

-

184 x 220, 2,1 (P=3,7)

184 x 220, 2,1 (P=3,7)

7400

P=Extra powerful setting

HOTPLATE FUNCTION PRINCIPAL

• Induction hob is fitted with four cooking

zones.

• Hob surface is completely flat and

smooth,without edges to accumulate dirt.

• The cooking hob is equipped with a highly

functional induction cooking zone. The

heat is formed directly in the bottom of the

cooking plate. This way, the required extent

of energy is considerably smaller compared

to traditional heaters, which operate on

radiation principals.

• Glass ceramic hotplate is not heated directly,

but only by return heat transmitted by the

dish. This heat figures as “remaining heat”

after the hotplate is turned off. The induction

hotplate generates heat from the induction

coil, installed underneath the ceramic glass

surface. The coil stabilises the magnetic field.

APPROPRIATE COOKWARE FOR INDUCTION

HOTPLATES

• Induction hotplate will function perfectly only

if appropriate cookware is used.

• Cookware should be in the middle of the

hotplate during cooking.

• The appropriate cookware is the one which

enables induction, for example steel, enamel

or steel alloy cookware. Pots made from steel

alloy with copper or aluminium bottom, or

glass pots are inappropriate.

• When buying cookware, check if it bears

the label “allows induction”.

17

Page 18

Hotplate may be damaged if:

• It is turned on and left empty, or an empty

dish is placed on it;

• You use clay dishes which leave scratches

on the ceramic glass surface;

• You fail to wipe the dish bottom dry prior

placing it on the induction cooktop; heat

induction is obstructed and the hotplate

may be damaged;

• You fail to use the appropriate dishes that

can be magnetized: steel dishes, enamel

or steel alloy dishes; induction hotplate will

Cooking zones

184x220mm

(SINGLE)

184x220mm

(SINGLE) IN

BRIDGED MODE

184x220mm

(DOUBLE) IN

BRIDGED MODE

Min. pan bottom Ø

min.

Ø 115mm Ø 180mm

Ø

135mm

2 ZONES -

4 ZONES Ø 330mm Ø 400mm

Max. pan

bottom

Ø

Ø 180mm

380x220

mm

not function otherwise.

MAGNET TEST POWER REGULATION

Hotplate may be damaged if:

• Heating power of the hotplates may be set

at nine different levels.

The following chart indicates illustrative use

of each power setting.

Use small magnet to test if the dish bottom is

magnetic. Only dishes where magnet sticks to

the bottom are suitable for induction cooking.

Dish recognition

One of great advantages of the induction

hotplate is pot recognition. Even if there are no

dishes upon the hotplate, or the dish diameter

is smaller than the diameter of the relevant

hotplate, there are no thermal energy losses.

When the hotplate is on, the power indicator

displays letter “U”. If you place the dish over

that hotplate within the following 10 minutes,

the hotplate recognizes the dish and turns on

to the preset power value.

At the moment you remove the dish from

the hotplate, power is suspended. If you

place smaller dish upon the hotplate and it

is recognized, the hotplate will only use the

amount of energy required to heat the dish

according to its size.

Power

setting

0

1-2

3

4-5

6

7-8

9

A

P

Purpose

Off, using remaining heat

Maintaining warm food, slow

simmer of smaller quantities

Slow simmer (continuation of

cooking after a powerful start-up)

Slow cooking (continuation) of

larger quantities, roasting larger

chunks

Roasting, browning

Roasting

Start of cooking, roasting

Automatic initial setting

Especially powerful setting for

extremely large quantities of food

18

Page 19

ENERGY SAVING TIPS

• When buying cookware be careful in

selecting size: pot diameter usually refers

to the top edge of the dish, which is often

larger than the dish bottom.

Steam-pressure pots (economic pots),

which use pressure in tightly sealed interior,

are especially economic, and save both

time and energy. Shorter cooking time

leaves more vitamins in food.

• Always leave enough water in steampressure pots, otherwise it may result in

overheating which may damage both the

pot and the hotplate.

• Always cover the cookware with lids of

appropriate size.

• Use such dish size to accommodate the

quantity of food to be prepared. If you use

excessively large pot for small amount of

food, you will consume considerably more

energy.

19

Page 20

INDUCTION COOKTOP FUNCTIONS

HOB CONTROL ELEMENTS

1. Induction hotplate front left

2. Induction hotplate middle left

3. Induction hotplate middle right

4. Induction hotplate middle

5. Induction hotplate front right

6. Hob control panel

7. Downdraft control unit

A. ON/OFF sensor of cooktop

B. Power level indicator

C. Pause and recall function sensor

D. Sensor (-) of timer

E. Sensor (+) of timer

SLIDE CONTROL POWER

F. Slide control

G. Warming function sensor

H. Booster

20

Page 21

HOB CONTROL

• After turning the ceramic glass hob on all displays come on for a moment. The hob is ready

for op-eration.

• The hob is fitted with electronic sensors which are switched on if you touch the relevant circle

for at least one second.

• Each sensor activation is followed by a sound signal.

• Avoid placing any objects on sensor surface (possible error signalization).

• Always keep the sensor surface clean.

ACTIVATING THE HOB

• Touch the (A) sensor for at least one second.

• The hob is activated and above the A button a LED turns on. (S-H1)

NOTE

You need to select the next setting within 10 seconds, otherwise the hob switches

off again.

ACTIVATING THE HOB

• If you have switched on the cooking hob by utilising the sensor (A), the required cooking zone

can be chosen within the next 10 seconds.

• Set the power level 1-9 by touching the slider (F).

• At the first touch, the level is set according to the part of the slider that you touch. Upon the

slider, the control LEDs light up, according to the level set. By sliding along the slider, the

power level setting is changed. By sliding to the right, the level increasing, while sliding to the

left decreases the level. When you move your finger away from the slider, the cooking field

starts to operate at the level set.

• If a specific point of slide control is pressed for at least 3 seconds, the automatic cooking is

activated (see Automatic fast heating).

Changing hotplate power settings

• By touching or sliding along the slide sensor (F) you change power setting.

• When you remove the finger from the slide sensor, the hotplate starts to operate at selected

power.

21

Page 22

SWITCHING HOTPLATES OFF

• Selected hotplate must be activated.

• By touching the slide sensor (F) at the start, bring he power setting to “0”. Short beep

confirms the OFF position.

SWITCHING THE HOB OFF

• The hob is switched off by pressing the main (A) sensor.

• The sound signal beeps and all indicators go off, except for those hotplates which are still hot

and display the warning “H” sign as an indication of the remaining heat.

• If you switch the hob off prior end of cooking session, use the remaining heat and save

electric energy.

LOCKING THE CONTROL UNIT

• By activating the key lock protection you can stop the operation of the appliance and the use

of hotplates.

Activating the control unit lock

• The cooktop must be turned on.

Model SDDH1.1

• Simultaneously press “C” and “I” and immediately after again the button “C”. All displays

show the letter “L”. The block is active.

• The safety lock secures all sensors operated by mistake, except the sensor “A”.

• If the hob is turning off when the lcok function is activated, this function will remain in memory

until the hob is switched off again.

Unlock the control:

• The hob must be switched on.

• Temporary Unlock: Simultaneously press “C and I”. Now you can use the controls. When

switched on, the hob will be locked again.

• Permanent Unlock: Simultaneously press “C and I” and immediately after the button (I) again.

When switched on again, the block is off.

Deactivating the control unit lock

• The cooktop must be turned on.

• Press the sensor (C) for 1 second; after that, the unlocking is confirmed by a beep.

22

Page 23

PAUSE FUNCTION

NOTE

The execution of the function is only possible if at least one zone is on.

The pause condition may also be activated with cooking zone specific errors, here,

the error display is hidden. Also residual heat indication, special messages such as

A, P or no pan are hidden; the pause display has priority. If there is a general error

during the pause, the control switches off and terminates the mode.

Activating the Pause function

• Press the sensor (C) for at least 1 second, the corresponding LED turns on above the key and

all displays show the symbol “II”.

While the Pause function is active:

• Any Timer (also Egg-timer) set before the pause will be stopped during the pause and

continue when pause mode is disactivated.

• A selected booster or heat up time automatic function is terminated.

• Residual heat calculation and maximum operation time limitations will not be interrupted and

keep on working in the background.

• Functional LED’s such as Timer, multi-zone, keep on glowing according to their status.

NOTE

The pause mode can only be active for maximum 10 min. If the pause mode is not

deactivated within 10min the control switches off automatically.

Throughout the pause time the (A) button can be used to switch the control off. In

this case the pause mode is also deactivated.

Deactivating the pause mode:

• Press the (C) followed, the LEDs light up above the cursor of one of cooking zones.

• Within 10 seconds press and scroll from the left to the right on the cursor of the illuminated

area. The LED above the pause key turns off and the condition before the pause mode is

restored.

RECALL FUNCTION

If the control was accidentally switched off through the main switch (A) all settings can be

restored us-ing the recall function. After switching the control off from the main switch the user

has 6s to switch the control on again and then he has another 6s to press the pause button (C) in

order to recall the settings. The recall function can only be used if at least one cooking zone was

active (cooking level >0) independent from key lock.

23

Page 24

REMAINING HEAT INDICATOR

Glass ceramic hob also features remaining heat indicator “H”. Hotplates are not heated directly, but

through return heat radiating from the dish.

As long as the symbol “H” is on after the hotplate was switched off, the remaining heat may be used for

warming up food or for melting.

Even when the symbol “H” disappears, the hotplate may still be hot.

DANGER

Be careful of burns!

EXTRA POWERFUL SETTING

(HOTPLATES MARKED “P”

Extra powerful setting may be additionally switched on for fast cooking on indicated hotplates. This extra

hotplate power is used for heating large quantities of food.

After switching on, the extra power is activated for 10 minutes then automatically switches back on to the

maximum normal level 9.

During the time extra power is activated, the power of other hotplates is limited. This is indicated on the

power display by intermittently flashing the selected cooking level and limited power for a few seconds.

Activated extra powerful setting

• Press the (H) sensor of the required cooking zone, the extra cooking is active. The display shows “P”

Premature turning extra powerful setting off

• Press and scroll on the cursor of the wanted zone, unit you get the “0” if you want to turn off the zone

of until the wanted cooking level.

HEAT UP TIME AUTOMATIC

When automatic cooking mode is activated the hotplate will operate at maximum power for a limited

period of time and then automatically switch to the reduced power level to resume cooking. It may be

switched on in any of the hotplates for all power settings except for setting “9” where power is set at

maximum all the time.

Automatic cooking mode is activated on any idle hotplate.

• Choose the required continuous cooking level and hold it for 3 seconds.

• The activated heat up time automatic will be displayed through alternating between “A” and the

selected continuous cooking level on the display.

24

Page 25

As soon as the parboiling time is over, the preselected continuous cooking level is valid again.

Once the time from the chart below expires, the function is switched off and “A” disappears. You can also

switch the automatic cooking mode off anytime by bringingpower setting to “0”.

Power setting 1 2 3 4 5 6 7 8

Max. power cooking time 48” 1’44” 2’28” 3’12” 4’08” 1’20” 1’68” 2’16”

BRIDGE FUNCTION

With the bridge function two separate cooking elements/inductors with the same diameter and equal

power can be turned on at the same time and controlled with only one operation.

Activating Bridge Function

Whether the two zones are working at a different level, whether they are at level “0”:

• Simultaneously press anywhere on the slider (F) of the zones:

1 e 2, 3 e 5

• Now the two areas work together, the LEDs to the right of the corresponding displays turn on. The

level is shown on the display of the control zone, in the meanwhile the controlled zone’s displays turns

off.

• When thisfunction is active, you can set a timer, the LED lights on near both displays of the zones,

moreover it’s not possible setting a particularly powerful cooking function.

• If in 10 uninterrupted minutes no cookware is detected on one of the two elements, the bridge function

is automatically deactivated, the uncovered cooking element is switched off and the covered cooking

element remains as the single cooking element switched on with the set cooking level.

Deactivating Bridge Function

• The end of the Bridge Function can be done by repeating the simultaneous selection of both cooking

elements (the same as activation).

If the bridge function is deactivated while in operation, than both cooking elements go to level “0” and can

be set again.

25

Page 26

WARMING FUNCTION

The warming function is used to keep cooked food warm.

Hence this function can also be used as melting or simmer function.

Activating heating function:

• Pressing the special function key (G) of a cooking zone activates the “melting” function. The first LED

is activated.

• If the special function key is pressed a second time, “warming” level two is activated. The second LED

is activated.

• If the special function key is pressed a third time, “simmering” level three is activated. The third LED is

activated.

• If the special function key is pressed a fourth time the warming function ends.

SAFETY SWITCH OFF

Maximum continuous operation of a particular hotplate is limited, and the duration is displayed in the

above chart. When the hotplate is switched off by the safety mechanism, the indicator displays symbols

“0”, or “H” in case there is any remaining heat left.

In such cases switch the hotplate off by touching the slide sensor (F) at the start, bring the power set-ting

to “0”.

Power setting 1 2 3 4 5 6 7 8

Hours lapse prior

safety switch off

6 6 5 5 4 1’5 1’5 1’5 91,5

Example: Set the hotplate to power level 5 and leave it operate for some time. If you do not change the

above setting, the safety mechanism will switch the hotplate off after 4 hour.

PROTECTION FROM OVERHEATING

Induction hotplate is also fitted with safety device against overheating which protects electronic parts from

damages. This device operates on several levels. When temperature of the hotplate excessively rises,

it switches on two-stage fan. If this is not enough, extra powerful heating is deactivated, and finally the

safety device either reduces the heating power of certain hotplates or turns them off completely. When the

hotplate cools off, the full power of hotplate is again available.

26

Page 27

TIMER

Use of timer facilitates cooking by setting the time of hotplate operation.

Turning timer on

• The cooktop must be turned on and the zone where you want to set the timer must be working.

• Simultaneously press sensor (D) and (E), the timer’s display shows “0.00”, and the LED to the right of

the display, of the first active cooking zone from the left, lights on.

• Simultaneously press (D + E) as many times as necessary, to select the zone where you want to set

the timer. The LED lights on only for the active cooking zones.

• Within 10 seconds since pressing the (D + E) set the timer value by pressing the sensors (D) or (E).

• The value of the timer can be displayed:

- in minutes and seconds up to 9min 59sec;

- in hours and minutes up to 9h 59min, in this case the word “min” is shown under the timer’s display.

NOTE

Operation time can be set for each hotplate separately.

27

Page 28

Changing present cooking time

• Cooking time can be changed anytime during the operation.

• Simultaneously press sensor (E) and (D).

• Simultaneously press (D + E) as many times as necessary, to select the zone of which you want to

adjust the timer. The zone is identified by the lighting on of the LED to the right of the display.

• Press the sensors (D) or (E).

• If time is not modified in 10 seconds since pressing the sensor (D+E), the timer is keeping the countdown before the adjusting operation.

Checking remaining cooking time

• Last set timer is always displayed, (the LED to the right of the display of the cooking zone in question

has a lighting stronger than the others).

• Simultaneously press sensor (E) and (D).

• Simultaneously press (D + E) as many times as necessary, to select the zone of which you want to see

the remaining time. The zone is identified by the lighting on of of the LED to the right of the display.

• The timer’s display will display the remaining time of the selected cooking zone.

Turning timer off

When preset time elapses, a beep signals the end, and the hotplate is switched off.

Switch off the alarm by pressing the sensor (D) or (E) or it switches off automatically after two minutes.

If you want to switch off the timer prior to the end of the preset time:

• Simultaneously press sensor (E) and (D).

• Simultaneously press (D + E) as many times as necessary, to select the zone of which you want to

disable the timer. The zone is identified by the lighting on of the LED to the right of the display.

• Press (D) to the value “0”.

• The illuminated point to the left part of the display is turned off and the timer is deactivated.

ALARM TIMER FUNCTION

Timer can be used as alarm if it is already employed in timer control of one of the hotplates.

Time setting

• Touch the sensor (A) to activate the cooking hob.

• Simultaneously press sensor (E) and (D) to activate the alarm.

The timer’s display shows “0.00” and:

- If some cooking zone is active: the LED to the right of the display, of the first active cooking zone

from the left, lights on.

Simultaneously press (D + E) as many times as necessary to select alarm. The respective LED is located

between the keys (E) and (D).

28

Page 29

- if no cooking zone is active: the alerter’s LED lights on.

• The timer value is set by pressing sensors (D) or (E).

It’s possible setting time is seconds and minutes also for the alerter:

or in hours and minutes.

Switching the alarm off

When the preset time expires a beep is heard which you can either turn off by touching the (D) or (E)

sensors, or leave it to turn off automatically after 2 minutes.

If you want to switch the timer off prior expiry of preset time:

• Simultaneously press sensor (E) and (D).

• Simultaneously press (D + E) as many times as necessary to select the alerter, the respective LED

lights on.

• Press (D) until the value »0«. The alerter is deactivated.

29

Page 30

SAFETY FUNCTIONS AND ERROR SIGNALS

ERROR CODE ERROR DESCRIPTION INSTRUCTION MANUAL

E03 + continuous

tone, or XXX

E21

E22 or Er22

E20 or Er20

E36 or Er36

E31 or Er31

Permanent use of keys; Control unit

cuts off after 10 sec. Water or cooking

utensils on the glass above the control

unit.

Control unit cuts off after controlling

due to overheating to avoid damage to

electronics.

Defective Key evaluation. Control unit

cuts. Short-circuit or discontinuation in

the range of the key evaluation.

Flash-failure faulty. Microcontroller

faulty.

Control unit cuts off. Short-circuit Contact authorized center for

Configuration data incorrect.

Configuration of induction necessary.

Cleaning of the operational surface.

If the problem persists, Contact

authorized center for technical

assistance - specifying the error code.

Contact authorized center for

technical assistance - specifying the

error code.

Contact authorized center for

technical assistance - specifying the

error code.

Contact authorized center for

technical assistance - specifying the

error code.

technical assistance - specifying the

error code.

Contact authorized center for

technical assistance - specifying the

error code.

E47 or Er47

E2

EA

U400

E5

E6

Communication error between TC and

induction.

Overheating of the induction coils. Contact authorized center for

Error on the power board. Component

failure.

Secondary voltage of the power unit

to high (primary > 300V). Control

unit cuts off after 1 sec releasing

a permanent tone. Control unit is

wrongly connected.

Error on filter board. Contact authorized center for

Error on power unit. Contact authorized center for

Contact authorized center for

technical assistance - specifying the

error code.

technical assistance - specifying the

error code.

Contact authorized center for

technical assistance - specifying the

error code.

1) Contact authorized center for

technical assistance - specifying the

error code.

2) Contact an electrician check your

home network.

technical assistance - specifying the

error code.

technical assistance - specifying the

error code.

30

E8

E9

Incorrect fan speed; error on fan left or

right.

Coil temperature sensor defective. Contact authorized center for

Air exhaust blocked, for example by

paper.

Contact authorized center for

technical assistance - specifying the

error code.

technical assistance - specifying the

error code.

Page 31

CLEANING AND MAINTENANCE OF

INDUCTION HOB

Ceramic glass hob should be cleaned only when completely cooled

down, preferably after each use, otherwise even the slightest stains

remaining after cooking may burn into the hob surface with each

following use.

For regular maintenance of ceramic-glass hob use special cleansing

agents, produced in such way to create protective film upon the

surface.

Fig. A

Before each use, wipe the dust and other particles from the hob, they

may scratch the surface (Fig. A).

Caution: use of steel wool, abrasive cleaning sponges, and abrasive

detergents can scratch the surface of the hob. The surface may also

be damaged by the use of aggressive sprays and inappropriate liquid

chemicals (Fig. A and B).

Pattern marks can be erased by the use of aggressive cleansing

agents or rough and damaged cookware bottoms (Fig. B).

Minor stains are removed with moist soft cloth; after that the surface

Fig. B

should be wiped dry (Fig. C).

Water stains are removed with gentle vinegar solution, but you must

not wipe the frame with it (certain models only), since it may lose its

glow. Never use any aggressive sprays or limestone removers (Fig. C).

Fig. C

Fig. D

Major stains are removed with special ceramic-glass cleansers. Follow

strictly the manufacturer’s instructions.

Be careful to remove any remains of cleansing agent from the hob

surface, otherwise they will be heated during the next use and can

damage the hob (Fig. C).

Stubborn and burnt stains are removed with special ceramic-glass

scraper. Be careful, however, not to touch the hotplate surface with the

scraper handle (Fig. D).

Handle the scraper with utmost care to avoid injuries!

Sugar and sugar containing food may permanently damage the

ceramic-glass hob surface (Fig. E), so the remains of sugar and sugar

containing food must be scraped off from the hob surface immediately,

when the hotplates are still hot (Fig. D).

Discoloring of ceramic-glass hob has no effect whatsoever on its

operation and stability. In most cases, it appears as the consequence

of burnt in food remains, or as a result of dragging pots and pans

(especially aluminium or copper bottom cookware) across the surface,

and such discoloring is rather hard to remove.

Note: All described faults are mostly esthetical and do not affect

directly the operation of the appliance. Remedy of such faults is not

covered by warranty.

Fig. E

31

Page 32

USE

The product has been designed to extract fumes,

grease and cooking steam. It has been designed

to work in both suctioning mode, with external

venting evacuation, and re-circulating mode.

External venting

The product can be installed with an external

discharge outlet. In this case, install the extraction

ducting to the outside of the building (extraction

ducting not supplied).

Recirculating with SEM10

In case fumes and vapour cannot be evacuated

outside, the appliance can be used in the

recirculating mode. (Part No. ‘FLANGE’).

CAUTION

Installation must comply with the regulations

in force regarding the ventilation of enclosed

environments. In particular, discharged air must

not be conveyed into a duct used for fumes

discharge or discharge from appliances using

gas or other combustible materials. The use of

discontinued ducts is not allowed without the

approval of a qualified technician.

GREASE FILTER REMOVALMOUNTING THE

ACTIVATED CHARCOAL FILTER (SEM 10 ONLY)

The removal and fitting of the grease and carbon

filters need to be carried out with the downdraft

in the open position. To do this, select; then

remove the front panel by simultaneously pulling on

both sides of the upper part. The panel will rotate

forwards to make it possible to access the grease

filters (Fig. 15). Remove the grease filters to access

the carbon filters (Fig. 16). The replacement of the

charcoal filters has to be carried out accordingly to

the effective use of the Downdraft, and in any case

at least once every 6 months.

Fig. 15

Fig. 16

32

WARNING

After having replaced the filters, reinstall

the front stainless steel panel, otherwise the

Downdraft will not function.

Page 33

ELECTRICAL CONNECTION OF THE

DOWNDRAFT

CAUTION

This appliance is fitted with an H05 VVF 3

conductor, 0.75 mm2 (neutral, phase, and

ground) power cord.

This can be connected up to a 220 - 240 V

mono-phase electrical network through a

CEI 60083 approved power socket, which

must remain accessible after installation, in

compliance with installation regulations.

We decline any responsibility in case of

accidents caused by a lack of ground

connection or incorrect ground connection.

The appliance must be fed through a differential

protection device (RCD), with a nominal residual

current not exceeding 30mA.

If the power cord is damaged, call the aftersales

service to avoid any risk.

Once the installation is completed it is necessary

to give electricity supply to the Downdraft pressing

the red button placed above the metallic box with

the wiring boards inside.

33

Page 34

ELECTRICAL CONNECTION FUNCTIONS OF THE DOWNDRAFT

A. Light ON/OFF key

WARNING

Connecting the product to the mains electricity

must be carried out by technically qualified and

specialised personnel.

The product must be connected to an electrical

system correctly designed and in-stalled.

The electrical system must comply with

VDE0100 standard.

The light switches on and off only when the

carriage is fully OPEN.

Pressing this button with the carriage closed will

cause the carriage to open and then the light will

switch on.

The button also serves to switch off the light if it

is on.

B. ON/OFF key

CAUTION

If the product shows signs of a fault, disconnect

the appliance or remove the fuse corresponding

to the disconnection line of the appliance.

• If the product is not provided with a plug or

if the plug is not easily accessible, it will be

necessary to install a thermomagnetic circuit

breaker switch on the electricity line between

the product and the electrical system to which

it is connected to that has a contact aperture of

the poles of at least 3mm.

NOTE

This appliance complies with the European

Directives 2006/95/EC (Low Voltage Directive)

and 2004/108/EC

(Electromagnetic Compatibility).

While installing the appliance and carrying

maintenance operation, make sure it is

disconnected from the electrical network or the

fuses are cut out or removed.

Check that:

• Power is connected.

• Feeder lines (mains) are in good condition.

• The cable diameter complies with installation

regulations.

This raises the extraction carriage upward

movement and when it is fully open, it sets the

second extraction speed.

With the carriage open: it switches off the motor

and if on, the light; then it retracts the extraction

carriage.

C. (-) Key

This reduces the speed of the extractor motor

from the 4th speed until the motor switches

off, without closing the pull-out carriage.

D. Indicators

This signals the speed setting, by only the

relevant LED switching on.

E. (+) Key

This increases the speed of the extractor

motor, from 1st to 4th speed, without moving

the extractor panel.

F. Timer

10 min after setting, it serves to stop the

extractor motor, close the carriage and switch

the lights off, if they are on.

The set function is signalled by the flashing

LEDs “D” for the set speed.

The timer can be cancelled by pressing the

key again.

34

Page 35

TIMER

OTHER FUNCTIONS

As a result of the new EU65 “Energy label” and

EU66 “Ecodesign” regulations issued by the

European Commission, which came into force as

from January 1st, 2015, our products have been

adapter to comply with these new requirements.

All of the models complying with the energy label

requirements, are equipped with new electronics

including a timer device for suction speeds control,

when the air capacity exceeds 650m3/h. Internal

motor models, with maximum air capacity higher

thank 650m3/h, are equipped with a timer device

that automatically switched the suction speed

from 4th to 3rd speed, after 6 minutes operation.

External motor models are equipped with remote

motos that, as for internal motor versions, include a

timer device that switches down the suction speed

when it exceeds 650m3/h. (See External Motors

intructions). Remote motors, whose air capacity

exceeds 650m3/h at both the 4th and 3rd speeds,

will have the following by default timer control

functions: The suction speed, after 6 minutes

of operation. If the appliance is working at 3rd

speed, it is automatically switched to 2nd speed,

after 7 minutes operation. Operation speeds can

also be changed during operation. The energy

consumption of the appliance in standby mode is

lower than 0.5W.

Automatic turn off:

After 4 hours of continuous working from the

last setup, the appliance turns off and closes

austomatically.

Grease filters saturation:

After 30 hours of working, the speed indicators “D”

will all flash simultaneously signalling the grease

filters saturation.

To reset this alarm, hold down the “TIMER” button

for at least 3 seconds, while the carriage is open.

Calibration:

The rangehood carries out its self calibration every

3 complete cycles of its extractable unit.

By pushing the “TIMER” key 6 times consecutively

(MAX break between one push and the other is 3

seconds) all the LEDs will flash and tge calibration

will be reset.

After the next 3 cycles the downdraft the will carry

out its self-calibration.

Stand-by:

When the extractable unit is closed and the light

is switched off, the control panel, after 6 seconds,

activates the Stand-by function, reducing the

brightness of the LEDs. This function can be

stopped by pressing ON/OFF or LIGHT key.

Security system:

If there is an obstacle while the extractable unit is

closing, the Downdraft stops closing and and rises

again thanks to a security system.

WARNING

This operation has to be carried out

by a specialized technician.

35

Page 36

CLEANING AND MAINTENANCE OF THE

DOWNDRAFT

Careful maintenance ensures proper operation and

good performances over time.

CAUTION

The hood must be disconnected from the electrical network, both by unplugging

the appliance from the socket and activating the magnetic circuit breaker (safety

cut-out), before removing the metal grease filters. After cleaning operations,

replace the metal grease filters as outlined in the installation instructions.

MAINTENANCE HOW TO PROCEED? ACCESSORY PRODUCTS TO USE

External

surfaces and

accessories

Filter cleaning

NB: Filters should be replaced approximately every 6 months, depending on style and frequency of

cooking. For high fat cooking it is recommended the clean the filters every 2 weeks.

Do not use metallic

scrubbers, abrasive products,

or hard brushes.

After 30 hours of operation,

the downdraft will signal the

grease filter saturation.

The saturation is signaled by

the blinking of the 4 central

leds. To reset, hold down the

timer button for at least

3 seconds, while the carriage

is open.

To clean the external surfaces of the rangehood

and the light housing screen use only commercially

available household detergents diluted in water. Then

rinse with clean water and dry with a soft cloth.

The grease filters can be washed by hand or in the

dishwasher. These filters need to be cleaned on a

regular basis, otherwise they may represent a fire

risk. If frying or cooking with oil, the filers need to be

cleaned more regularly.

Refit the grease filters and front panel, making sure

that the panel is properly fitted at the sides so that it it

does not cause the downdraft to stop operating.

TROUBLESHOOTING

PROBLEM SOLUTION

The rangehood

does not work.

The rangehood

has low

performance.

The rangehood

stops in the

middle of

operation.

36

Check that:

• There is not a power outage.

• A specific speed has actually been selected.

• The 6 pin connection is inserted properly.

• The red reset key, found over the electrical system box, is pushed.

• Make sure that the wires of the 9 pole connection are inserted properly in the

connector itself (during the connection phase, an excessive pressure could bend the

contacts).

Check that:

• The motor speed selected is sufficient for the quantity of fumes and vapors present

in the room.

• The kitchen is ventilated well enough to allow air for intake.

• The non-return valves of the suctioning unit are free to rotate.

• The ducting is clear and not obstructed.

• Unit is only working on 2 speeds - refer to page 5.

• The correct minimum diameter ducting has been used

Check that:

• There is not a power outage.

• The safety switch has not tripped (RCD or safety switch).

Page 37

AFTER SALES SERVICE

Any maintenance operation on your appliance should

be carried out by:

• Either Arisit Pty Ltd;

• Or a qualified professional technician, authorized

for that brand if out of warranty.

Contact www.siriusbrand.com

1300 762 219

NOTE

When calling, please mention the appliance

details: Production date, (Fig. 9A), Type (Fig. 9B)

and equipment (Fig. 9C).

This information is mentioned on the rating

label and the production date one placed on the

lower side of the downdraft.

(Fig. 9A)

(Fig. 9B)

(Fig. 9)

(Fig. 9C)

37

Page 38

INSTALLATION GUIDE

FIG. 1

FIG. 3

FIG. 2

FIG. 4

38

FIG. 5

FIG. 6

Page 39

FIG. 7

FIG. 8

FIG. 9

FIG. 11

FIG. 10

FIG. 12

39

Page 40

FIG. 13

FIG. 14

FIG. 15

FIG. 16

40

Page 41

PARTS LIST

A

B

C

D

E

G

H

K

RECTANGULAR TO ROUND DUCTING ADAPTOR SPS-81020

BOTTOM/SIDE COVER COLLAR SPS-51070102735

BOTTOM/SIDE EXIT PLATE SPS-20059000094

FRONT/REAR VENT ADAPTOR SPS-20059120071

FRONT/REAR VENT COVER PLATE SPS-75059000082

F

J

L

UPRIGHT FIXING BRACKETS SPS-77002002999

UNIVERSAL RING CLAMP URC25-215

150MM TO 200MM DUCT EXPANDER GDR 150/200

200MM DIAMETER CONNECTOR PIECE GDC-200

K.2 - DUCTING 200MM SRPRO 30/200

DUCTING CONNECTOR FOR SEM 10 INSTALLATIONS ONLY Part no. ‘FLANGE’

41

Page 42

PARTS LIST - INCLUDED PIECES

PART A

Rectangular to round ducting adaptor

SPS-81020

PART C

Bottom/side exit connector

SPS-20059000094

PART B

Bottom/side cover collar

SPS-51070102735

PART D

Front/rear vent adaptor

SPS-20059120071

Front/rear vent cover plate

SPS-75059000082

42

PART FPART E

Upright fixing brackets

SPS-77002002999

Page 43

PARTS LIST - OPTIONAL PIECES

To be purchased separately

PART G

Universal ring clamp

URC25-215/325

PART J

200mm diameter connector piece

GDC-200

PART H

150mm to 200mm Duct expander

GDR 150/200

Part K.2

Semi rigid aluminium ducting 200mm

SRPRO 30/200

PART L

Ducting connector for SEM 10 installations only

Part no. ‘FLANGE’

43

Page 44

44

Loading...

Loading...