Page 1

INSTALLATION INSTRUCTIONS

INSTALLATION INSTRUCTIONS

CARE AND USE MANUAL FOR:

NOTICE D’UTILISATION ET D’ENTRETIEN POUR:

WALL RANGE HOODS

HOTTES MURALES

Models covered by this instructions:

Notice d’instruction pour les modèles:

SU107

*** BEFORE INSTALLATION ***

ENSURE THERE IS NO VISIBLE OR HIDDEN DAMAGE SUSTAINED DURING SHIPPING

*** AVANT L’INSTALLATION ***

S’ASSURER QUE LES PRODUITS N’ONT SUBI AUCUN DOMMAGE PENDANT LE TRANSPORT

*** SHIPPING DAMAGE ***

MUST BE REPORTED WITHIN 5 DAYS OF RECEIPT

*** DOMMAGES DE TRANSPORT ***

DOIVENT ÊTRE NOTIFIÉS DANS LES 5 JOURS SUIVANT LA RÉCEPTION

Page 2

WARNING

Thank you for purchasing a Sirius Range Hood.

Please read all the instructions in this manual before

installing the appliance.

Save these instructions for future reference.

Only use this appliance as an exhaust ventilation system for the removal of cooking vapors. DO NOT use to expel ammable substances or any other materials

or vapors.

The installation procedures in this manual are intended for qualied installers, service technicians or persons with similar qualied background.

DO NOT attempt to install this appliance yourself.

Ensure that electrical power is turned off at source before commencing installation.

All electrical wiring must be properly installed, insulated and grounded and conform

to all applicable codes and standards.

Make sure all existing duct work is clean of grease build up, or duct work should be

replaced, if necessary, to avoid the possibility of a grease re. Check all joints on

ductwork to ensure proper connection and all joints should be properly taped. Be

careful when cutting through ceilings or walls not to damage any hidden pipes or

electrical wiring. Ensure your kitchen has sufcient air return vents to replace the

exhausted air.

Fan ducts should always be vented to the outside of your home and never into

spaces within walls, ceilings, lofts or attics. Only use rigid, smooth steel for ducting.

The exhaust point of the blower requires a 6” round or 8” connection.

2

Page 3

TABLE OF CONTENTS

BEFORE YOU BEGIN 4

DUCTING

External venting Requirements 4

ELECTRICAL

Electrical Supply 5

INSTALLATION

Positioning the Range Hood 6

Marking the Fixing Holes for the Range Hood 6

Fixing the Main Support Bracket 6

Hanging the Range Hood 7

Connecting Electricity and Ducting 7

Connecting Chimneys 9

Re-Circulating Requirements 9

OPERATING PROCEDURES

General Advice 10

Functions 10

MAINTENANCE

Cleaning the Filter 11

Cleaning the Hood 11

Substitution of the LED bar 11

WARRANTY SERVICE 12

3

Page 4

BEFORE YOU BEGIN

The manufacturer declines all responsibility

in the event of failure to observe the instructions given here for installation, maintenance and suitable operation of the product. The

manufacturer further declines all responsibility for injury due to negligence and the warranty of the unit automatically expires due

to improper maintenance and/or installation.

DUCTING

(Not applicable if the range hood is used in

re-circulating mode).

WARNING: Do not vent this appliance into

any other ductwork, spaces between walls,

ceilings, attics, garages or any other conned space.

External Venting Requirements.

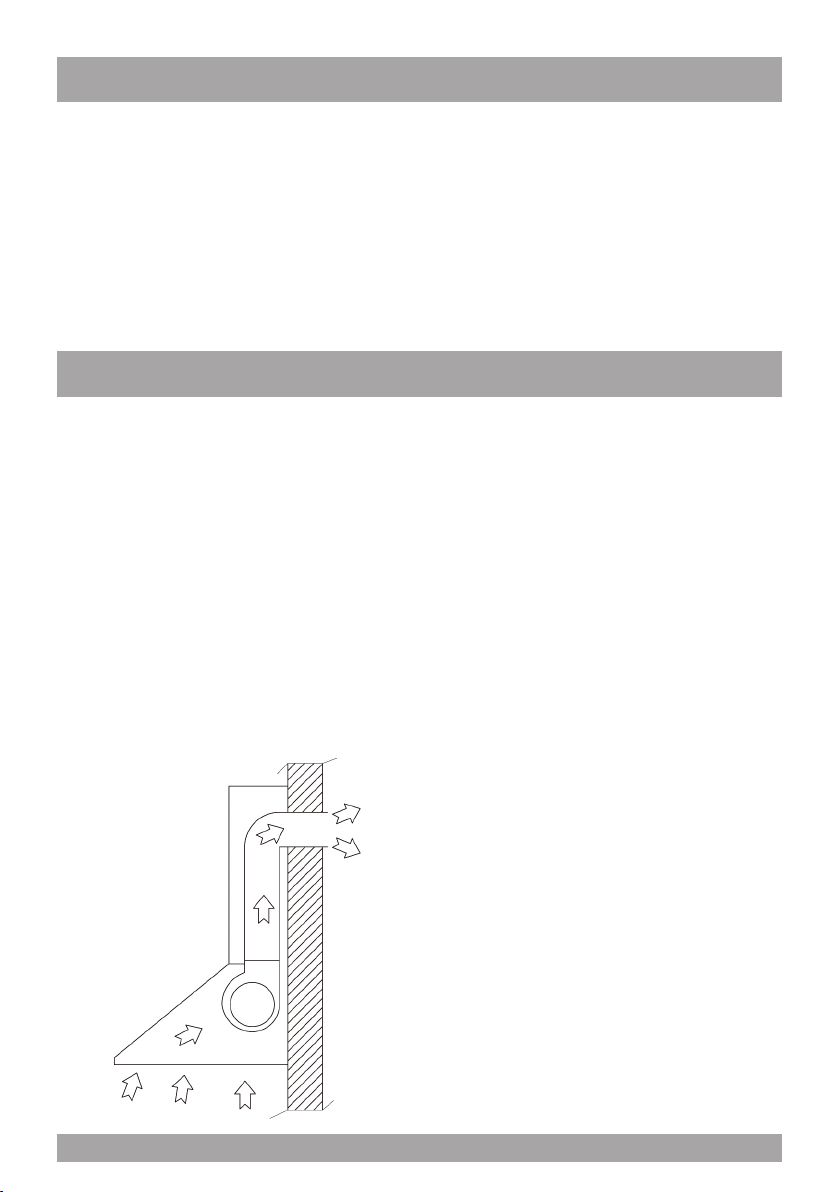

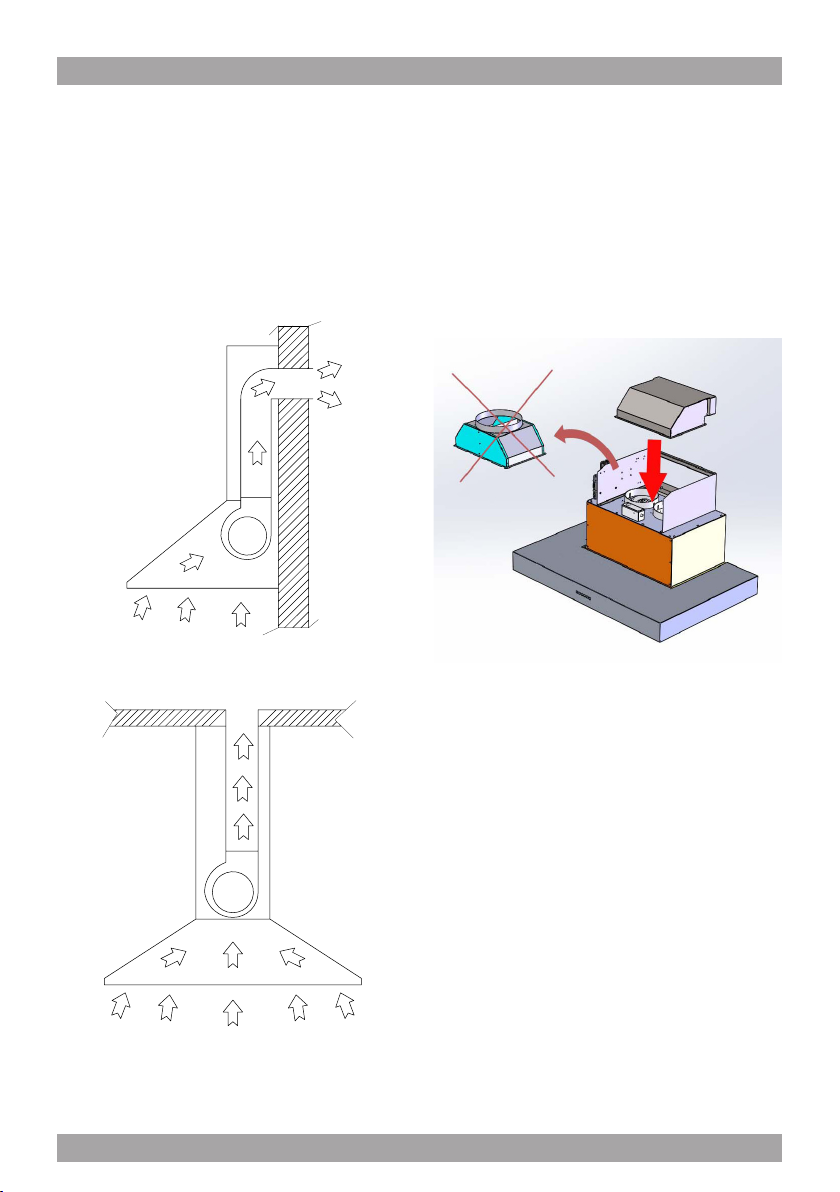

When planning new ductwork, always look

for the most direct route to the outside. Venting can be done through the roof or directly

through the back outside wall. (See Figure

1). Recommanded 18” from the top of the

hood to the rst elbow.

BEFORE YOU BEGIN: It is advisable to

test run the range hood before installation.

BEFORE STARTING – please read this

entire document and ensure you are fully

conversant with the require-ments and limitations. These units weigh approximately

125lbs and therefore require a minimum of

two people to install.

Only use rigid type metal ducting (plastic

ducting is generally not permit-ted by code).

Flexible ducting could restrict airow by up

to 50%. Always fasten connections with sheet metal screws and tape all joints with certied Silver Tape or Duct Tape.

Do not use screws to fasten ductwork to

the hood, only use tape as the screws will

stop the dampers from opening and your

hood will not work. This hood requires 8’’ for

the models with 2 motors. You can increase

the duct size of the duct run but never decrease it.

Use the shortest and most direct route possible. Always, wherever reduce the number

of transitions and turns with as few sharp

angles as possible.

g. 1

4

Two staggered 45 degree angles are better

than one 90 degree. Make these turns as far

away from the motor exhaust as possible,

with as much space between each bend as

possible.

Page 5

* Gas range or gas cook top recommanded

8”.

The ducting connection to the hood must

be in line with the central vertical axis of the

range hood 1” away from the back wall on

which the hood is to be mounted. The 1” is

important to enable the ceiling bracket (as

shown in Figure 2) to pass behind the ductwork servicing the range hood.

g. 2

ELECTRICAL

Range hoods may interrupt the proper ow of

combustion gases from replaces, gas furnaces and gas water heaters.

To minimize the risk of drawing these lethal

gases back into the home, please follow the

heating equipment manufacturers safety

standards and guidelines carefully.

Refer to NFPA and ASHRAE for additional

information.

WARNING: All electrical work must be

performed by a qualied electrician.

Please ensure that the appropriate electrical

codes or prevailing local building codes and

ordinances are adhered to.

Ensure that the electricity supply is disconnected at source. Do not use an extension

cord or adapter plug with this appliance.

This appliance must be grounded. Connect

to a properly grounded branch circuit, protected by a 15 amp circuit breaker.

Electrical Supply.

This range hood requires a 120V, 60Hz supply and draws a maximum of 3 amps. The

electrical supply to the range hood should be

at least 17” from the underside of the installed range hood.

For a typical installation, where the underside of the range hood will be 30” above the

counter top and the counter top is 36” above

the oor level, the electrical supply should be

76” above oor level and no further than 3” to

the right (as you face the wall) of the central

axis of the range hood.

5

Page 6

INSTALLATION

Positioning the Range Hood.

Determine the center point of the range hood.

This is generally the center of the range. Make

a mark on the wall a minimum of 25” above

the top of an electric range. If the range is gas,

the ideal minimum should be 30”.Using a spirit

level, draw a perfectly vertical line, starting at

the center mark, right up to the ceiling or the

highest point to where the hood will extend.

This is the central axis for the range hood.

Draw a horizontal line fractionally above where the bottom of the range hood will be positioned. This is the underside of the range hood.

Marking the Fixing Holes for the Range

Hood.

Find the marking template provided called

the “Assembly Scheme”. Place the template

against the wall. Align the horizontal line on

the wall with the horizontal line on the template (indicated by two heavy arrows). Now

align the vertical line on the wall with the

“Central Axis” line on the template.

Using a sharp object, mark the wall through

the template at the center point of the three

holes. Lower down on the template, you will

see three sets of two holes. Only two of these

holes refer to your model. Check which model you have and, using a sharp object, mark

the two correct holes. These holes are used

to anchor the range hood horizontally from inside the hood once it has been hung from the

main bracket. Remove the template.

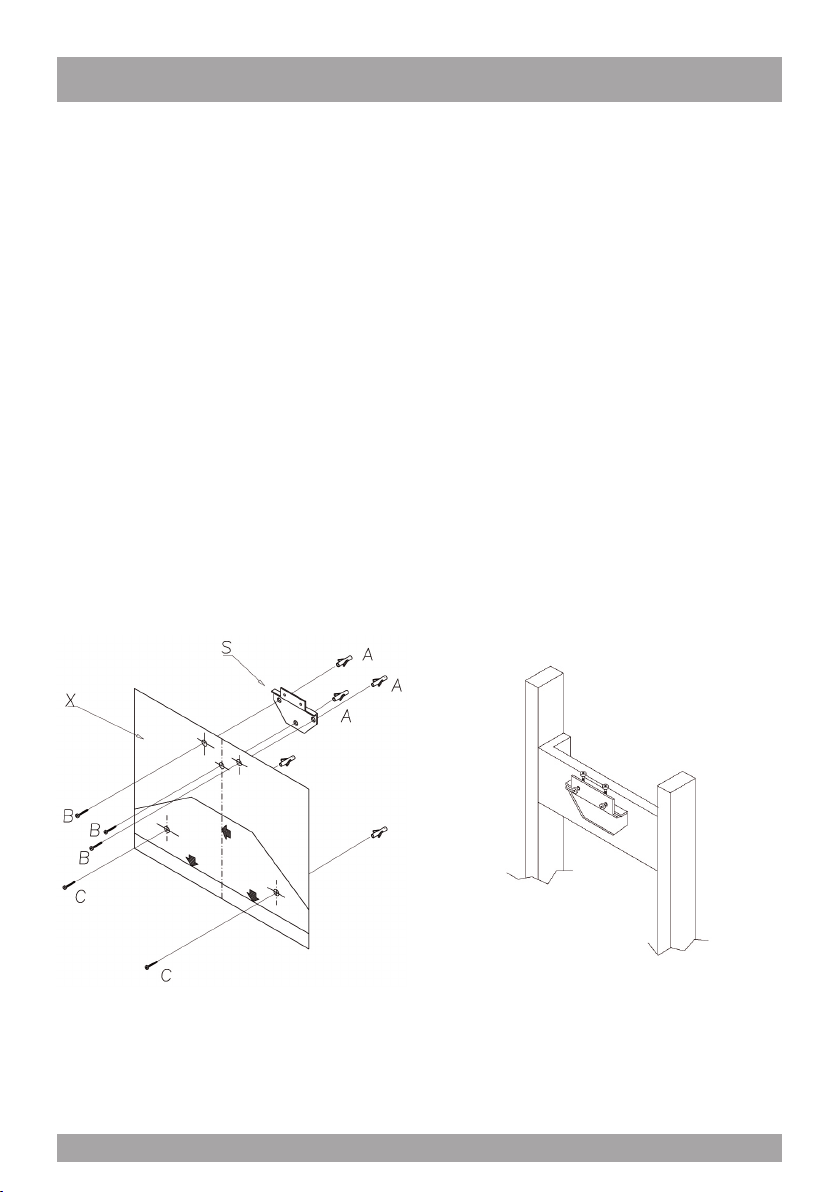

Fixing the Main Support Bracket

(CAUTION: Do not drill through any utilities inside the wall).

If the range hood will be xed to drywall we

strongly recommend that you discard the wall

plugs and screws supplied. These anchors are

only suitable for brick/masonry applications. We

suggest the use of a more appropriate anchor

system specically designed for drywall applications. Wherever possible, it is advisable to place

blocking between the studs, behind the drywall,

to attach the support bracket to, (refer to Figure 4).

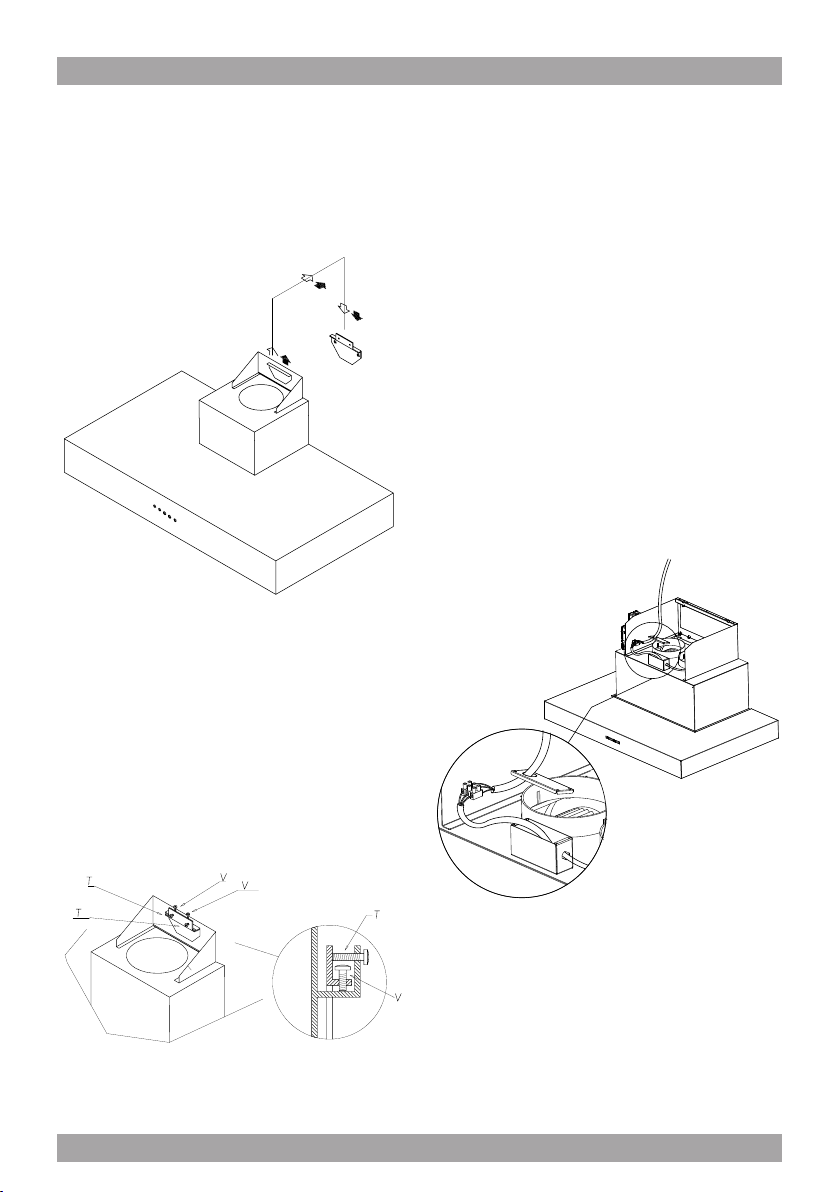

g. 3

Gently tape the template to the wall making

sure it has no creases or folds (use a tape

that will not damage the wall nish). There

are three hole positions shown for the wall

bracket.

6

g. 4

Drill the appropriate size holes at the marks

made earlier and x the Support Bracket (“S”)

securely to the wall. Ensure that any wall anchors have been tted into the lower two holes, as the range hood will cover these holes

once hung on the Support Bracket (“S”).

Page 7

Hanging the Range Hood.

Prepare the range hood for installation.

Remove all lters to ensure they do not get

damaged during the installation process.

Hang the range hood on the bracket “S” (refer to Figure 6).

g. 6

The bracket xed onto the back of the range

hood will drop into the channel on the top

of bracket “S” on the wall. Ensure the hood

is securely engaged into the support brackt

the range hood must clip in behind the extended lip on the Support Bracket (“S”).

These screws are also used to make minor

adjustments to the levelling of the range

hood. Ensure the hood is level. Locate the

two holes “C” inside the housing of the range hood and secure the range hood to the

wall once the range hood is perfectly level

and vertical. (refer to Figure 3).

Connecting Electricity and Ducting.

Please refer to the Electrical Supply section

on page 5 for the required location of the

electrical supply.

CAUTION: Make sure the power is turned

off at source. Make electrical connections

(refer to Figure 8).

Ensure that the plastic aps at the exhaust

outlet for the fan move freely and have not

become jammed or stuck.

“Lock” the range hood onto the “S” bracket

using the four machine screws supplied (refer to Figure 7).

g. 7

g. 8

7

Page 8

Connect the appropriate length of ducting to

the fan exhaust point and join up with the

ducting to the exte-rior.

Do not x the ducting to the range hood

exhaust outlet with screws-use duct

tape. Use duct tape on all joints.

Figure 9 shows venting directly through the

wall. Venting up and through the ceiling to

the exte-rior is also possible racommended

to have 18” from the top of the hood to the

rst elbow.

g. 9

The air outlet of the product is oriented upwards: in the case that one prefers the air

outlet towards the rear side of the appliance,

it is only necessary to replace the air release

piece with the other one supplied with the

appliance.

g. 10

8

Page 9

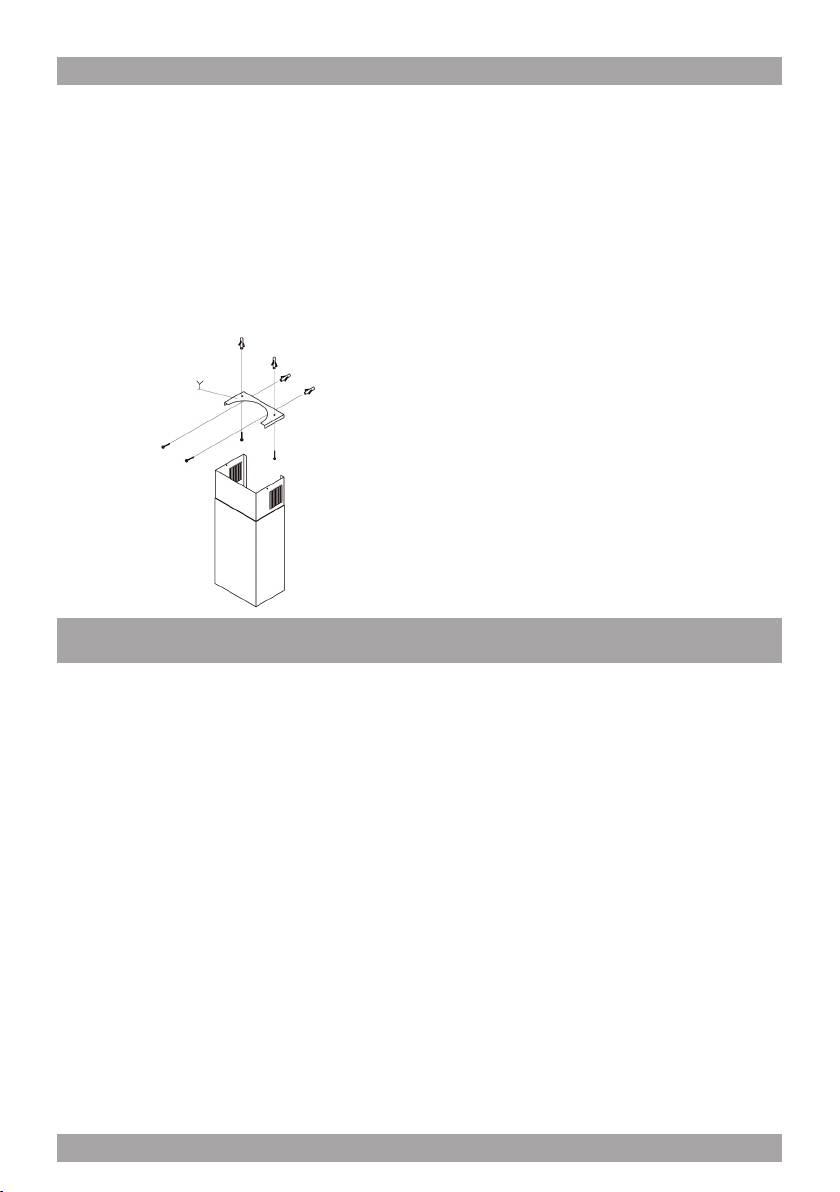

Connecting Chimneys

Remove the protective covering from the

decorative chimney and carefully slide the

sections together. Do not remove the tape

strips from inside the chimney as this protects the telescoping chimney-piece from

scratching. Holding the two chimney sections together carefully position them over

the ductwork and wiring. Position the upper

chimney so that it can be xed via the holes

on the side of the ‘Y” bracket on the ceiling

(refer to Figure 11).

The carbon lter (supplied separately) that

absorbs odors is installed behind the aluminium grease lter (refer to Fig 14).

g. 12

g. 11

Re-Circulating Requirements.

If the unit is to be used in the re-circulating

mode, t the carbon lter after the installation is complete t the deector with the

screws supplied to the upper telescope

chimney. There are holes in the back upper

edge of the decorative chimney for this purpose. A short length of ducting is connected

between the exhaust outlet on the fan and

the deector to direct the air back into the

kitchen through the vents at the top of the

upper decorative chimney.

g. 13

g. 14

9

Page 10

OPERATING PROCEDURES

Read all the instructions before operating

the appliance. Save these instructions for

future reference.

General Advice.

Ensure that the grease lters are in place.

Without these components, operating blowers could catch on to hair, ngers and loose clothing. Keep fan, lters and surfaces

clean of grease and fat. Always turn hood

fan ON when cooking. NEVER leave cooking unattended.

NEVER dispose cigarette ashes, ignitable

substances or any foreign objects into blowers.

Cooking that generates ame is not recommended as this hood is equipped with a

thermal overload that will shut down the motor if it senses excessive heat. When frying,

oil in the pan can easily overheat and ignite. Heat oil slowly in an appropriately sized

pot (covering the entire burner) to reduce

the risk of boiling over and burning.

In the event of a range top grease re, observe the following:

Switch OFF the range hood. Turn off the

cook top then smother ames with a close

tting lid, cookie sheet or other metal tray. If

the ames do not go out immediately.

FUNCTION

“Manual touch buttons Fig.15”.

A: Light ON/OFF button

B: Blower Speed 1 (low) or OFF

C: Blower Speed 2 (medium)

D: Blower Speed 3 (high)

E: Blower Speed 4 (intensive)

F: 10 Minute Timer

g. 15

The products are endowed with an electronic

device which allows the automatic switching

off after 4 hours working from the last operation.

SU Models only: Filter requires washing indicator After 30 hours of use, all the buttons

will light up to remind you that the grease lter should be cleaned. Follow the instructions

for cleaning lters in this booklet. Once the

grease lters have been cleaned and replaced, reset by pressing the timer button (F).

EVACUATE AND CALL THE FIRE DEPARTMENT.

Never pick up a aming pan – you may be

burned. DO NOT USE WATER including

wet dishcloths or towels, as a violent steam

explosion may occur.

10

Do not rely solely on this indicator - generally,

the grease lter should be washed on a regular basis to avoid grease lter res.

The blower should be turned on for approximately 5 minutes before cooking in order

to establish air currents upward through the

hood.

Use the low speeds for normal use and the

higher speeds for strong odors and fumes.

Page 11

MAINTENANCE

The range hood should provide many years of trouble free use provided it is properly

maintained. Be sure the lights are cool before

cleaning the hood - they are halogen and become extremely hot.

Cleaning the Filter.

The aluminium mesh lters should be washed by hand or in the dishwasher as required. Damaged and worn lters must be replaced immediately. (Do not operate blower

when lters have been removed). Allow lters

to dry before replacing them, otherwise water

will be drawn into the blower.

If a carbon lter has been tted, this must be

replaced every 6 months as a minimum, depending on usage and type of cooking that is

performed.

It is suggested that a spare set of carbon lters is kept on hand. These can be ordered

from the supplier of your range hood.

Cleaning the Hood

The outside and interior of your hood should

be wiped regularly with a clean, damp cloth

and mild household dish detergent or degreaser.

Do not use abrasive cleaning agents as these will destroy the brushed nish.

Substitution of the LED bar:

Using an appropriate tool, remove the LED

bar from its seat (refer to Fig. 21), disconnect

it electronically using the appropriate connector then substitute it with a LED bar with

same characteristics.

g. 21

Use a good quality non-abrasive foaming

type stainless steel cleaner for exterior surfaces.

Follow the manufacturers directions. Generally the foam is sprayed onto a clean dry

cloth and then applied to the stainless steel.

Allow the foam to react on the surface for a

few minutes and then wipe with a clean dry

cloth.

On the surfaces that are exposed directly to

heat from the cook-top, it is advisable to clean these regularly to avoid the deposits from

becoming baked on.

11

Page 12

YOU MUST REGISTER THE PURCHASE OF YOUR PRODUCT ON LINE AT HYPERLINK

“http://www.siriuscappe.com/canada/warranty.htm” TO CONVALIDATE YOUR WARRANTY.

YOU CAN FIND THE DATA OF YOUR HOODS ON A LABEL INSIDE THE HOOD. JUST REMOVE

THE GREASE FILTER TO READ IT.

To qualify for warranty service, you must notify Sirius After sale service at the email address

stated below or call toll free in Canada 1-800-463-2566 and provide the model number, description of the fault or defect and original date of purchase. Sirius reserves the right to request proof of original purchase. Sirius will at its sole option and discretion replace products

that arrive damaged through shipping, provided shipping damage is reported as stated above

within 5 business days of receipt of the shipped product or products.

ONE YEAR PARTS & SERVICE REPAIR WARRANTY:

During the rst year from date of original purchase, Sirius will, at its option, repair or replace, without

charge, any product or part which is found to be defective under normal use and service.

WHO IS COVERED:

Sirius Range Hoods warrants to the original consumer purchaser of its products that such products will

be free from defects in materials and workmanship for a period of one year from the original date of purchase. There are no other warranties, express or implied, including, but not limited to, implied warranties

of merchantability or tness for a particular purpose or application.

WHAT IS NOT COVERED:

This warranty does not extend to lters, lamps, batteries, ducts and ductwork components. This warranty does not cover normal maintenance and service or products or parts which have been subject to

misuse, negligence, accident, improper maintenance or repair, faulty installation or installation contrary

to recommended installation instructions. The warranty on glass screens is limited to manufacturing

defects only and expressly excludes cracks and breakages as a result of faulty installation.

WARRANTY SERVICE

Labor and

associated costs associated directly with removal and re-installation are expressly excluded.

The duration of any implied warranty is limited to the one year period as specied for the express warranty. Some states and provinces do not allow limitation on how long an implied warranty lasts, so the

above limitation may not apply to you.

For any service request please contact:

Sirius after sale service

Telephone (toll free):1-800-463-2566.

Sirius S.P.A.

Zona industriale Berbentina 6/A

60041 SASSOFERRATO (AN)

ITALY

Register Online! www.siriuscappe.com/canada/warranty.htm

Page 13

INSTRUCTIONS IMPORTANTES

POUR LA SÉCURITÉ

Merci d’avoir choisi une Hotte de Cuisine Sirius.

Veuillez lire attentivement toutes les instructions avant

l’installation et l’utilisation de l’appareil.

Conservez ces instructions an de pouvoir les consulter

au besoin.

Cet appareil est destiné à la ventilation générale seulement. NE L’UTILISEZ PAS

pour évacuer des vapeurs ou des substances dangereuses ou explosives.

Conez l’installation et les réparations uniquement à un professionnel, conformément aux normes de sécurité en vigueur.

N’ESSAYEZ PAS d’installer cet appareil par vous-même.

Avant l’installation veillez que l’appareil soit hors tension.

Tout le câblage électrique doit être correctement installé, isolé de mise à la terre

conformément aux codes et aux normes applicables.

Assurez-vous que les conduits d’évacuation sont propres et libres d’accumulation

de graisses ou remplacez les conduits pour éviter de provoquer un incendie.

Vériez que tous les joints du conduit sont bien xés et scellés. Faites attention

lors des travaux de maçonnerie de ne pas endommager des tuyaux ou câbles

électriques. Assurez-vous que votre cuisine est équipée de bouches de ventilation

qui évacuent l’air vicié.

Le conduit de ventilation doit toujours terminer à l’extérieur et jamais dans des

espaces clos, plafonds ou greniers. Pour le conduit utilisez seulement des éléments rigides en acier lisse. La sortie de la soufante nécessite d’un conduit rond

de 6”. Ou Huit pouces (ou 8’’).

13

Page 14

TABLE DES MATIÈRES

AVANT DE COMMENCER 15

CONDUIT

Version évacuation extérieure 15

ÉLECTRICITÉ

Alimentation Électrique 16

INSTALLATION

Positionnement de la Hotte 17

Perçage du Mur pour le Positionnement de la Hotte 17

Fixation Étrier de Support Principal 17

Accrochage de la Hotte 18

Branchement Électrique et Conduit 18

Raccordement de la Cheminée 20

Mode Recyclage 20

OPERATING PROCEDURES

Recommandations Générales 21

Fonctions 21

ENTRETIEN

Nettoyage des Filtres 22

Nettoyage de la Hotte 22

Replacement de la barre LED 22

SERVICE DE GARANTIE 24

14

Page 15

AVANT DE COMMENCER

Le fabricant décline toute responsabilité

en cas de dommages causés par un non

respect des instructions d’installation, d’utilisation et d’entretien contenues dans cette

notice. Le fabricant décline toute responsabilité causée par négligence et la garantie

cesse automatiquement en cas de mauvais

entretien et/ou installation du produit.

CONDUIT

(Ne s’applique pas si la hotte est en mode

Recyclage).

REMARQUE : Ne branchez jamais ce produit à un autre conduit d’évacuation, des

espaces entre deux murs, plafonds, greniers, garages ou espaces clos.

Version évacuation extérieure.

Lors du montage du conduit d’évacuation,

cherchez la voie la plus directe vers l’extérieur. Le conduit peut évacuer l’air par le

toit ou directement par le mur extérieur. (Voir

Fig. 1). Il est recommandé une distance de

18 pouces, à partir du sommet de la hotte

jusqu’au premier coude.

AVANT DE COMMENCER : On conseille

de vérier le fonctionnement de la hotte

avant son installation.

AVANT DE COMMENCER - Lisez attentivement cette notice an d’avoir les connaissances requises pour utiliser ce produit.

Ce produit pèse env. 125lbs et nécessite

donc un minimum de deux personnes pour

son installation.

Utilisez seulement des tuyaux rigides en

métal (les tuyaux en plastiques sont interdits

par le code).

Les conduits exibles limitent le ux d’air du

50%. Fixez toujours les raccords avec des

vis en tôle et isolez tous les joints avec du

ruban adhésif métallique (ou pour conduit).

N’utilisez pas des vis pour xer le conduit à la hotte; utilisez uniquement du ruban

adhésif, du moment que les vis peuvent empêcher l’ouverture des clapets anti retour et

en ce cas la hotte ne fonctionnera pas.

Cette hotte nécessite d’un conduit d’évacuation de 8’’ pour les modèles avec 2 moteurs. Il est possible d’utiliser un conduit

plus grand, mais pas un plus petit.

g. 1

Optez pour la voie la plus courte et la plus

directe. Evitez, si possible, le nombre des

raccords et des coudes.

Il est préférable d’utiliser deux coudes de

45° plutôt qu’un coude de 90°. Positionnez

les coudes loin de l’échappement du moteur

et évitez de les positionner trop prêt les uns

des autres.

15

Page 16

* Gaz fourneau ou gaz cuisinière recommandé: 8 pouces.

Le raccordement du conduit à la hotte doit

être en ligne avec l’axe centrale verticale de

la hotte de 1” et loin du mur postérieur sur

lequel la hotte sera positionnée. La mesure

1” est importante pour permettre au support

de plafond (voir Fig. 2) de passer derrière le

conduit de la hotte.

g. 2

ÉLECTRICITÉ

Les hottes peuvent empêcher la bonne évacuation des fumées des cheminées, des

fours et des chauffe-bains à gaz.

An de minimiser le risque que ces gaz mortels peuvent retourner dans la maison, observez les normes de sécurité et les directives

en vigueur.

Consultez les normes NFPA et ASHRAE

pour plus d’informations.

ATTENTION : Tous les travaux électriques doivent être effectués par un électricien qualié.

An d’assurer la qualité des travaux de construction et d’électricité observez les normes en vigueur.

Assurez-vous que l’alimentation électrique

est coupée. Evitez d’utiliser une rallonge ou

un adaptateur pendant cette opération.

Cet appareil doit être mis à la terre et le circuit doit être protégé par un disjoncteur de

15 amp.

16

Alimentation Électrique.

Cet appareil nécessite 120V/60Hz, une alimentation de 3amp. L’alimentation électrique

se doit trouver au moins à 17” du dessous de

la hotte installée.

Pour une installation type, où la distance entre la partie inférieure de la hotte et la surface

de la table de travail est de 30” et la distance

entre la table de travail et le sol de 36”, l’alimentation électrique se doit trouvée à 76” du

sol et pas plus de 3” à droite (en regardant le

mur) par rapport à l’axe centrale de la hotte.

Page 17

INSTALLATION

Positionnement de la Hotte.

Déterminez le centre de la hotte. Marquez

d’une croix sur le mur la hauteur de 25” si

votre table de cuisson est électrique et une

hauteur minimale de 30” si votre table de

cuisson est à gaz. En utilisant un niveau à

bulle tracez une ligne parfaitement verticale,

à partir du centre vers le plafond ou vers le

point le plus élevé où positionner votre hotte. C’est l’axe central de la hotte. Tracez une

ligne horizontale où le bas de la hotte sera

positionné. Il s’agit de la partie inférieure de

la hotte.

Perçage du Mur pour le Positionnement

de la Hotte:

Prenez le gabarit de perçage fourni, appelé

« Schéma de Montage ». Placez le gabarit

contre le mur. Alignez la ligne horizontale du

mur avec la ligne horizontale du gabarit (indiquée par les deux èches). Maintenant alignez la ligne verticale du mur avec la ligne

de l’ « axe central » du gabarit.

Utilisez un outil pointu, marquez le mur par le

gabarit au point milieu des trois trous. Au bas

du gabarit, il y a trois séries de deux trous. Seulement deux de ces trous se réfèrent à votre

modèle. Vériez quel modèle vous avez et, toujours en utilisant un outil pointu, marquez les

deux trous justes. Ces trous servent pour l’ancrage de la hotte horizontalement par l’intérieur

de la hotte, une fois quelle a été positionnée sur

le support principal. Retiré le gabarit.

Fixation Étrier de Support Principal

(ATTENTION de ne pas endommager les

conduites).

Si vous xez la hotte sur du plaque de plâtre,

on vous conseille vivement d’enlever/éliminer

les chevilles et les vis fournies. Ces ancrages

ne conviennent que pour une utilisation avec briques/maçonnerie. On vous conseille d’utiliser un

système d’ancrage plus adapté et spéciquement conçu pour la plaque de plâtre. Autant que

possible, il est préférable d’utiliser des blocages

entre les poutres, derrière la plaque de plâtre,

pour y xer l’étrier de support (voir Fig. 4).

g. 3

Appliquez doucement le gabarit sur le mur

en vous assurant qu’il est lisse et sans plis

(utilisez un ruban adhésif qui n’endommage

pas la nition du mur). Il y a trois positions de

perçage pour le support mural.

g. 4

Percez le mur aux endroits précédemment

marqués et xez bien l’étrier au mur. Assurezvous que les chevilles ont été insérées dans les

deux trous inférieurs, ainsi la hotte les couvrira

une fois qu’elle est positionnée sur l’étrier (“S”).

17

Page 18

Accrochage de la Hotte.

Préparez la hotte pour son accrochage. Enlevez les ltres pour ne pas les endommager pendant l’installation. Accrochez la hotte

sur l’étrier de support “S” (voir Fig. 6).

g. 6

L’étrier xé à la partie postérieure de la

hotte se glisse dans la rainure de la partie

supérieure de l’étrier de support “S” du mur.

Assurez-vous que la hotte est correctement

insérée dans l’étrier de support - la hotte

doit s’accrocher derrière le bord étendu de

l’Étrier de Support (“S”).

Ces vis sont également utilisées pour apporter des modications mineures au nivellement de la hotte. Assurez-vous que la

hotte est à niveau. Localisez les deux trous

pour vis “C” à l’intérieure de la hotte et xezla au mur en vous assurant qu’elle est parfaitement à niveau (voir Fig. 3).

Branchement Électrique et Conduit.

Faites référence au paragraphe Alimentation Électrique à la page 5 pour l’endroit où

effectuer le branchement.

ATTENTION : Assurez-vous que l’alimentation est coupée. Effectuez le raccordement

électrique (voir Fig. 8).

Veillez à ce que les volets en plastiques de

la sortie des fumées se bougent librement et

qu’ils ne sont pas bloqués ou coincés.

Fixez la hotte à l’étrier “S” avec les 4 vis à

métaux fournies (voir Fig. 7).

g. 7

18

g. 8

Page 19

Raccordez le conduit de longueur appropriée à la sortie d’air du ventilateur et puis

au conduit qui porte à l’extérieur.

La gure 9 montre l’évacuation à travers le

mur. Une évacuation par le plafond est également possible. Il est recommandé une distance de 18 pouces, à partir du sommet de

la hotte jusqu’au premier coude.

g. 9

Ne xez jamais le conduit à la sortie

d’évacuation de la hotte avec des vis utilisez uniquement du ruban adhésif.

Utilisez uniquement du ruban adhésif pour

tous les joints.

La sortie de l’air du produit est dirigée vers

l’haut: dans le cas où on préfère une sortie

vers la partie postérieure de la hotte, il faut

seulement remplacer le raccord par l’autre,

fourni dans l’équipement.

g. 10

19

Page 20

Raccordement de la Cheminée.

Enlevez la protection de la cheminée décorative et faites glisser soigneusement les sections ensemble. N’enlevez pas les bandes

adhésives à l’intérieur de la cheminée car

ils protègent le télescope contre les rayures.

Tenez les deux sections de la cheminée et

positionnez-les sur le conduit et le câblage.

Positionnez la cheminée supérieure de façon

qu’elle puisse être xée par les trous pour vis

du support “Y” au plafond (voir Fig. 11).

g. 11

Le ltre à charbon (fourni séparément) qui

absorbe les odeurs, se trouve derrière le

ltre à graisse en aluminium (voir Fig. 14).

g. 12

Mode Recyclage.

Si vous utilisez l’appareil en mode recyclage, insérez les ltres à charbon une fois l’installation complétée (voir Fig. 12).

Fixez le déecteur (voir Fig. 13) avec les

vis à la partie supérieure du télescope de la

cheminée. A ce propos, il y à des trous pour

vis sur l’arrière de la cheminée décorative.

Un conduit court se trouve entre la sortie

d’évacuation et le déecteur pour diriger l’air

dans la cuisine à travers des orices d’air

qui se trouvent sur la partie supérieure de la

cheminée décorative.

20

g. 13

g. 14

Page 21

OPERATING PROCEDURES

Lisez attentivement toutes les instructions

avant cette opération. Conservez ces instructions an de pouvoir les consulter au besoin.

Recommandations Générales.

Assurez-vous que les ltres sont en place.

Sans ces ltres, l’appareil peut aspirer vos

cheveux, doigts ou vêtements.

Maintenez propre de graisse le ventilateur,

les ltres et les surfaces. Mettez TOUJOURS en marche la hotte pendant la cuisson. Ne laissez JAMAIS des aliments cuire

sans surveillance.

Ne jetez JAMAIS les cendres de cigarettes,

des substances inammables ou autres

objets étrangers dans le ventilateur.

Evitez une cuisson qui peut générer des

ammes, car la hotte est équipée d’un

détecteur thermique qui arrête le moteur à

une chaleur excessive.

Lorsque vous faites des fritures, l’huile

dans la poêle peut facilement se surchauffer et s’enammer. Faites chauffer l’huile

lentement dans une casserole de taille appropriée (couvrant entièrement le brûleur)

réduisant ainsi le risque de la faire déborder

et s’enammer.

Dans le cas où l’huile s’enamme, observez

ce qui suit:

Eteignez la hotte. Eteignez la table de cuisson et étouffez les ammes avec un couvercle hermétique, une tôle à biscuits ou autre

plateau métallique. Si les ammes ne s’éteignent pas immédiatement.

SORTEZ ET APPELEZ LES POMPIERS.

Ne ramassez jamais une casserole enammée – vous pouvez vous brûler. N’UTILISEZ

JAMAIS DE L’EAU, y compris des serviettes

ou lavettes mouillées, car une explosion

peut se produire.

FONCTIONS

“Touches Sensitives Fig.15”.

A: Touche lumière ON/OFF

B: Vitesse ventilateur 1 (réduite) ou OFF

C: Vitesse ventilateur 2 (moyenne)

D: Vitesse ventilateur 3 (élevée)

E: Vitesse ventilateur 4 (intensive)

F: Minuterie 10 min

g. 15

Les produits sont doté d’un appareil électronique, qui permet l’éteindre automatique depuis 4 heures d’activité de la dernière opération.

Seulement pour modèle SU: Après 30 heures de fonctionnement de la hotte, tous les

voyants clignotent pour vous rappeler que les

ltres à graisse doivent être nettoyés. Suivez

les indications pour le nettoyage dans cette

notice. Une fois nettoyés et remplacés les ltres, réinitialisez en appuyant sur la touche

Timer (F).

Ne comptez pas uniquement sur cet indicateur. Généralement, les ltres à graisse doivent être nettoyés régulièrement, an d’éviter

toute incendie de graisse.

Allumez la hotte env. 5 minutes avant la cuisson, an d’établir des courants d’air vers le

haut et à travers la hotte. Utilisez les vitesses

basses pour une utilisation normale et les vitesses élevées pour les odeurs fortes et les

fumées.

21

Page 22

ENTRETIEN

Un entretien soigné garantit un bon fonctionnement et un bon rendement dans le temps.

Assurez-vous que les ampoules sont froides

avant de nettoyez la hotte - les ampoules halogènes deviennent très chaudes.

Nettoyage des Filtres.

Lavez les ltres à maille en aluminium à la

main ou au lave-vaisselle. Remplacez immédiatement les ltres usagés ou endommagés. N’utilisez jamais la hotte sans ses

ltres. Avant de replacer les ltres, assurezvous qu’ils sont bien secs pour ne pas endommager le ventilateur.

Remplacez le ltre au moins tous les 6 mois,

selon le type et la fréquence des cuissons.

Nous vous suggérons de garder des ltres

de recharge. Vous pouvez les commandés

auprès le fournisseur de votre hotte.

Nettoyage de la Hotte.

Nettoyez l’intérieur et l’extérieure de la hotte

avec un chiffon propre et du détergent doux.

Utilisez un détergent non abrasif sous forme

de mousse pour les parties en acier.

Lisez les instructions du fabricant.

Replacement de la barre LED :

En utilisant un outil approprié, enlever la barre LED de son siège (faites référence à la

Fig. 21), déconnecter – la électroniquement

en utilisant le connecteur approprié et puis la

replacé avec une barre LED avec les mêmes

caractéristiques.

g. 21

Généralement on conseille de vaporiser le

détergent sur un chiffon propre et de le passer sur les parties en acier inoxydable.

Laissez agir le produit sur la surface pendant

quelques minutes, puis nettoyer avec un chiffon.

Sur les surfaces qui sont exposées directement à la chaleur, on conseille de les nettoyer régulièrement pour éviter des taches

indélébiles.

N’utilisez jamais un produit abrasif qui peut

rayer et endommager l’acier.

22

Page 23

23

Page 24

IL EST NÉCESSAIRE D’ENREGISTRER EN LIGNE L’ACHAT DE VOTRE PRODUIT AU SITE HYPERLINK

http://www. siriuscappe. com/canada/warranty.htm POUR VALIDER LA GARANTIE.

VOUS TROUVEZ LES DONNÉES DE VOTRE HOTTE SUR L’ÉTIQUETTE À L’INTÉRIEUR DE LA

HOTTE. POUR LA LIRE, RETIREZ SIMPLEMENT LE FILTRE A GRAISSE.

Pour bénécier du service de garantie, informez le Service Après Vente Sirius à l’adresse e-

SERVICE DE GARANTIE

mail ci-dessous ou appelez le numéro gratuit CANADA 1-800-463-2566 et fournissez le code

du produit, la description du vice ou du défaut et la date d’achat du produit. Sirius se réserve

le droit de demander une preuve d’achat. Sirius, à sa propre discrétion, remplacera les produits endommagés pendant le transport, à condition que le dommage dû au transport est

signalé comme susmentionné, c’est-à-dire DANS LES 5 JOURS DE TRAVAIL APRÈS RÉCEPTION du produit ou des produits expédiés.

GARANTIE D’UN AN POUR LE SERVICE DE RÉPARATION:

Pendant la première année dès la date d’achat de votre produit, Sirius, à sa discrétion, réparera ou

remplacera gratuitement tout produit ou pièce qui s’avère défectueux dans des conditions normales

d’utilisation et d’entretient.

QUI EST COUVERT PAR LA GARANTIE:

Sirius Range Hoods garantit à l’acheteur original que tous ses produits commerciaux sont libres de tout

défaut de matériel et de fabrication, pour la durée d’un an à partir de la date d’achat. Il n’existe aucune

autre garantie, expresse ou tacite, y compris mais sans s’y limiter, aucune garantie de qualité commerciale ou d’adaptation à une utilisation particulière.

QU’EST-CE QUI N’EST PAS COUVERT PAR LA GARANTIE:

Cette garantie ne couvre pas les ltres, lampes, batteries, tuyaux et composants du conduit. Cette

garantie ne couvre pas l’entretien normal et le service après-vente technique standard, produits ou

pièces endommagées résultant d’une mauvaise utilisation, acte de négligence, ac- cident, entretien ou

réparation impropre, installation erronée ou installation contraire aux in- structions d’installation recommandées. La garantie sur les pièces/écrans en verre est limitée uniquement aux vices de fabrication et

exclut expressément toute rayure ou rupture résultant d’une mauvaise utilisation. Les frais de la maind’oeuvre et ceux qui sont directement associés au démontage et au remontage sont expressément

exclus.

La durée de toute garantie implicite est limitée à un an, ainsi que spécié par la garantie explicite.

Certains états et certaines provinces ne permettent pas de limitations quant à la durée d’une garantie

implicite, par conséquent les limitations ci-dessus peuvent ne pas s’appliquer à vous.

Pour toutes informations merci de contacter :

Sirius service après-vente

Téléphone (gratuit) 1-800-463-2566.

Sirius S.P.A.

Zona industriale Berbentina 6/A

60041 SASSOFERRATO (AN)

ITALY

Register Online! www.siriuscappe.com/canada/warranty.htm

90001070021 - GM 07/17

Loading...

Loading...