Page 1

Congratulations on your purchase!

Thank you for choosing a Sirius product.

S-DD2-L FLUSH TOP

DOWNDRAFT INSTALLATION INSTRUCTIONS FOR

SEM 1, SEM 2, SEM 7, & SEM 8 motors

SDD2 L EMTC 580 EAN #9351116001063

SDD2 L EMTC 880 EAN #9351116001094

SDD2 L EMTC 1180 EAN #9351116001193

SDD2 L EMTC 580 WH EAN #9351116001070

SDD2 L EMTC 880 WH EAN #9351116001278

SDD2 L EMTC 1180 WH EAN #9351116001285

1

Page 2

S-DD2-L FLUSH TOP

INSTALLATION GUIDE

TO THE ATTENTION OF THE USER

INSTALLATION GUIDELINES

APPLIANCE DIAGRAMS

PRE-INSTALLATION CHECKS

INSTALLING THE RANGEHOOD

INSTALLATION INSTRUCTIONS

FOR SEM 1 AND SEM 2

150MM SIDE OR BOTTOM VENTING

FOR SEM 7 AND SEM 8

200MM SIDE OR BOTTOM VENTING

FOR SEM 1, SEM 2, SEM 7, AND SEM 8

150MM / 200MM FRONT OR REAR VENTING

DUCTING FROM MOTOR TO VENT (SEM 1 & 8 ONLY)

3

3

4

5

6

8

9

10

12

ELECTRICAL CONNECTION

HOW THE RANGEHOOD WORKS

CLEANING THE RANGEHOOD

TROUBLESHOOTING

REPLACING THE LIGHT

PARTS LIST

WIRING DIAGRAM

The symbol on the product or on its packaging indicates that this product

may not be treated as house-hold waste. Instead it shall be handed

over to the applicable collection point for the recycling of electrical and

electronic equipment. By ensuring this product is disposed of correctly,

you will help prevent potential negative consequences for the environment

and human health, which could otherwise be caused by inappropriate

waste handling of this product. For more detailed information about

recycling of this product, please contact your local city office, your

household waste disposal service or the shop where you purchased the

product. This appliance is marked according to the European directive

2002/96/EC on waste electrical and electronic equipment (WEEE).

12

14

15

15

16

17

20

2

Page 3

S-DD2-L FLUSH TOP

INSTALLATION GUIDE

TO THE ATTENTION OF THE USER

This rangehood is designed to work with ducted

outside evacuation.

WARNING

Keep these instructions for use with the appliance. If

the appliance should be sold or passed on to others,

make sure that the instructions are passed on with

it. We thank you for taking note of these suggestions

before installing and using the appliance. They have

been written for your personal safety and the safety

of others.

SAFETY INSTRUCTIONS

These hoods have been designed for personal

use in the home. The appliance must be used by

adults. Make sure that the appliance is out of reach

of children and that they do not use it to play with.

Make sure that children do not operate the controls.

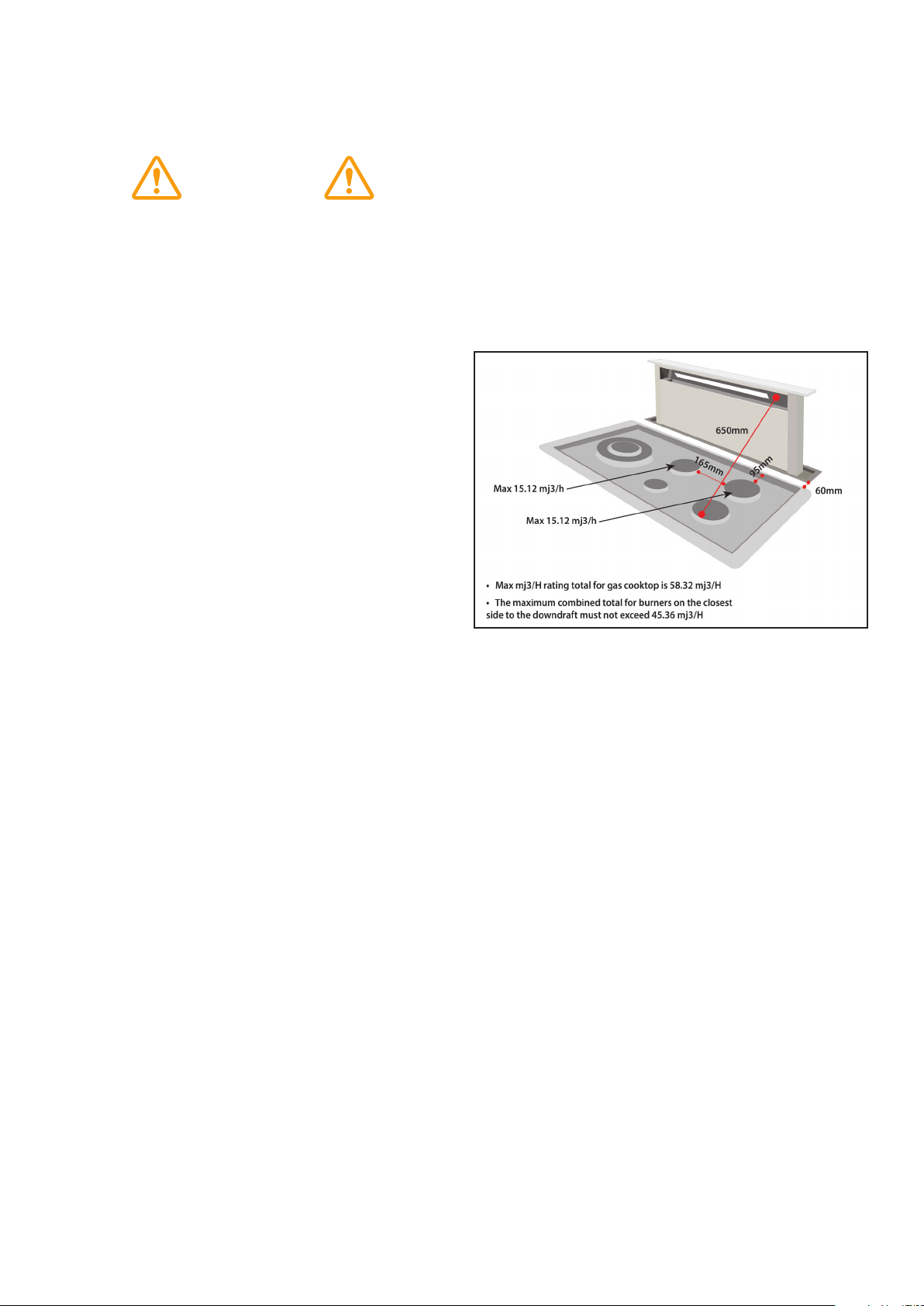

INSTALLATION GUIDELINES FOR

GAS COOKTOP APPLICATIONS

• A minimum 60mm gap must be left between the

stainless steel frame and the nearest edge of the

cooktop.

• The minimum distance between the border of the

gas cooktop and the nearest burner must not be

less than 95mm

• For the downdraft to operate at a premium, the

distance between the downdraft opening and the

furthest burner shall not exceed 650mm.

• Distance between the burners on the side closest

to the downdraft shall not be closer than 165mm.

• When the appliance is delivered, check the overall

appearance of the packaging. Check PARTS

LIST on page 17 for all included parts prior

to discarding packaging.

Any remarks should be written on the delivery

coupon, of which you keep a copy.

Your appliance is designed for normal domestic

use. It is not designed for commercial or industrial

use, or for purposes other than those for which it

was designed.

• Any consequences of or damage from incorrect

installation or incorrect use of the appliance will

not be covered by the manufacturer’s guarantee.

• Do not ever change or try to change the

characteristics of this appliance. This would be

a danger. Repairs must be performed only by an

authorised technician.

• Always disconnect the hood before carrying out

cleaning or maintenance operations.

• Adequately ventilate the room when a rangehood

and other appliances, powered by energy other

than electricity, are used simultaneously, so that

the hood does not suck any combustion fumes.

• It is not allowed to cook food over open flames

(flambé) or operate gas hobs without pots

or pans on them under the hood itself (the

flames sucked into the hood might damage the

appliance).

• Frying under the appliance must be done under

constant supervision as hot oils and fats may

ignite.

• Respect the guidelines for cleaning and

replacement of grease filters. Accumulated

deposits of grease are a fire hazard.

• This appliance must not be used over cook tops

powered by wood or coal or in any case, over

cook tops with power levels that could damage

the appliance.

• Never use steam or high-pressure devices

for cleaning your hood (regulations regarding

electrical safety).

• Never use the rangehood without the grease

filters.

• The minimum distance between the Downdraft

(closed) and the surface above it must be at least

800 mm.

• When handling the downdraft, never put your

hands in the field of action of the extractable unit.

At Sirius, we are constantly seeking to improve

our products. We reserve the right to modify their

technical, functional, or aesthetic characteristics

deriving from their upgrading.

Motors manufactured and approved by Sirius only

are to be used at all times. Failure to comply with this

will result in the forfeit of the manufacturer warranty.

The air collected must not be conveyed into a flue

used for smoke or fumes from appliances powered

by anything other than electricity (central heating

systems, bathroom and toilet exhausts, etc.). As

far as discharging exhaust air is concerned, please

follow the guidelines given by competent authorities.

3

Page 4

S-DD2-L FLUSH TOP

INSTALLATION GUIDE

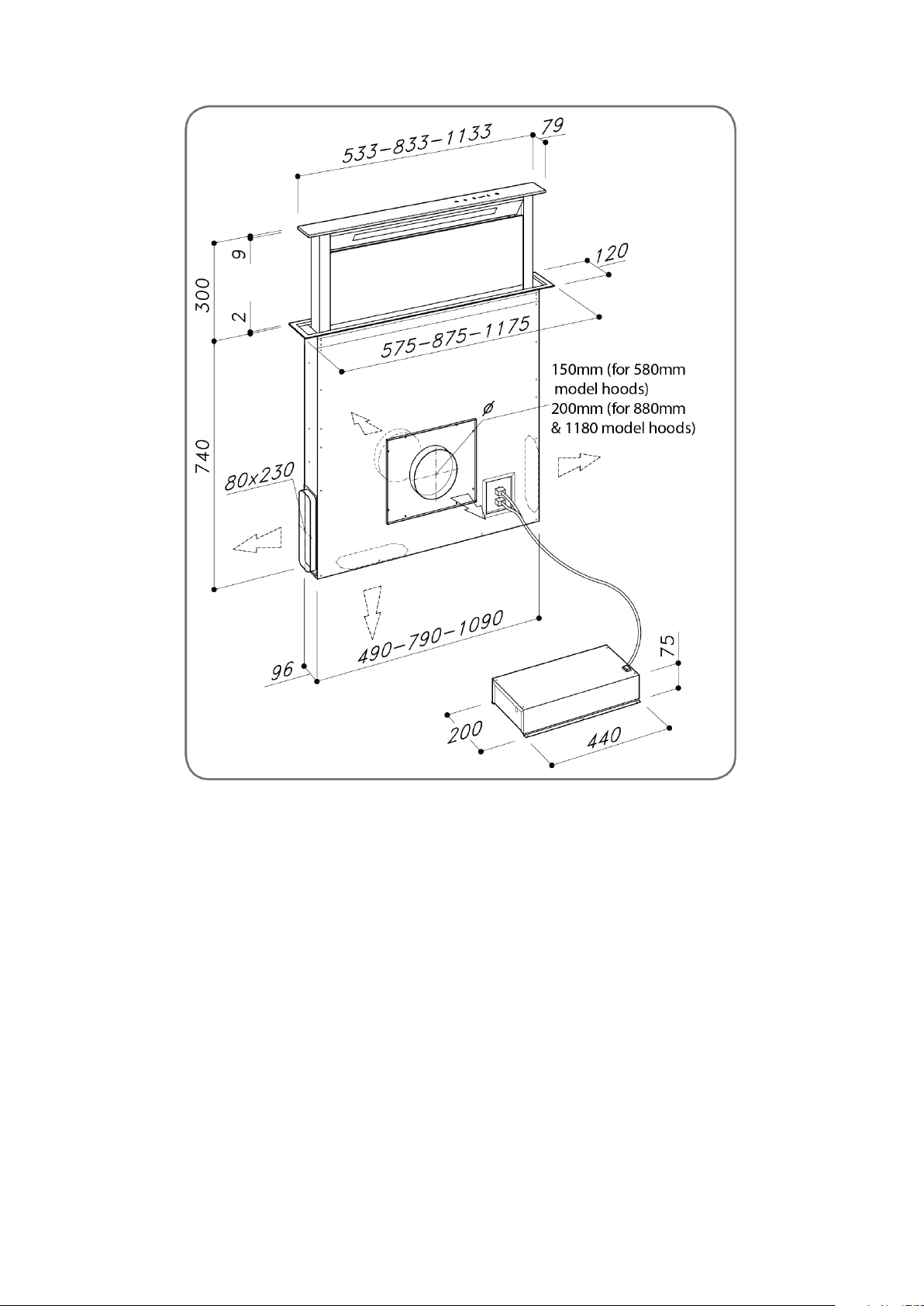

APPLIANCE DIAGRAMS

DUCTING TYPES

• Side / bottom venting - SEM 1, SEM 2 motor

• Side / bottom venting - SEM 7, SEM 8 motor

• Front / rear venting - SEM 1, SEM 2, SEM 7, SEM 8 motor

• Side / bottom venting - SEM 10 motor

4

pg.7

pg.8

pg.10

see separate

installation

guide

Page 5

S-DD2-L FLUSH TOP

INSTALLATION GUIDE

NOTE

Check PARTS LIST on page 17 for all included

parts prior to discarding packaging.

PRE-INSTALLATION CHECKS

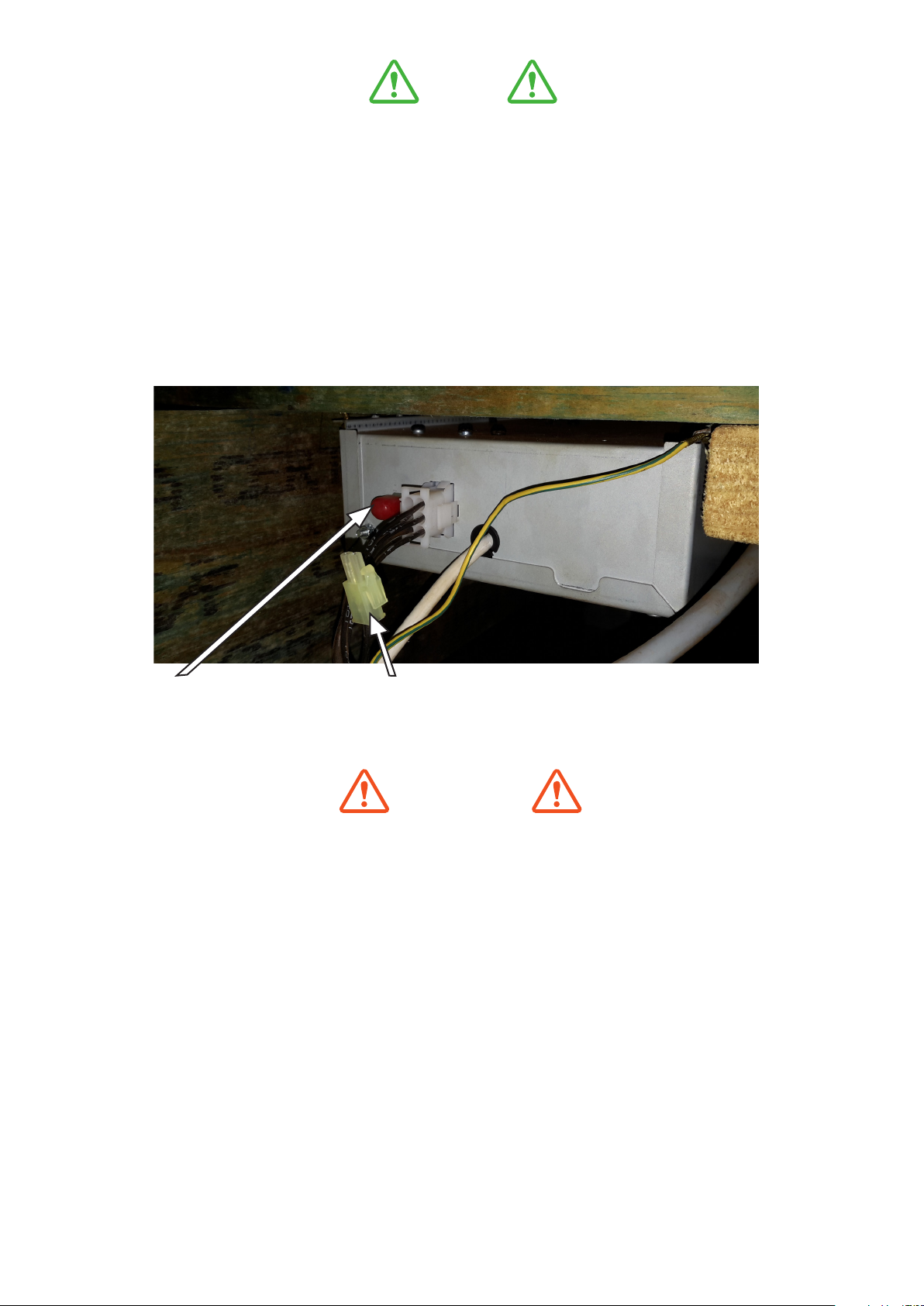

Connect all of the electrical components to the unit and motor to make sure both the unit and the motor are

functioning properly.

(NOTE: The motor plug is fitted with a dummy plug - with the exception of SEM1 motor - to protect

the connection from dust. Ensure the red dummy plug is removed and replaced with the two

pin motor plug from the power transformer box. Failure to do so will result in only two speeds

operating).

Red dummy plug Two pin motor plug

Remove all plugs and proceed with installation if both unit and motor are fully operational.

CAUTION

Installation must comply with the regulations in force regarding the ventilation of enclosed environments.

In particular, discharged air must not be conveyed into a duct used for fumes discharge or discharge from

appliances using gas or other combustible materials. Air cannot be ducted into roof space.

The use of discontinued ducts is not allowed without the approval of a qualified technician.

BEFORE YOU INSTALL

Sirius warranty covers only Sirius product. If you choose to install a non-Sirius branded accessory such as

flexible ducting, Sirius will only warrant the hood and motor. If installation is found to be the cause of failure or

issue then charges will apply for service and parts.

Flexible ducting is not permitted under any circumstances. Flexible ducting has been found to increase noise

levels, increase vibration and reduce airflow. Sirius Semi-rigid or solid ducting can be used in lieu. There is a

range available to suit any application.

Available at www.siriusbrand.com

A reduction in the duct diameter from stated ducting size will void warranty.

If you are in doubt about the ducting, please contact Sirius on 1300 762 219 prior to

installation.

5

Page 6

S-DD2-L FLUSH TOP

INSTALLATION GUIDE

INSTALLING THE RANGEHOOD

• Before carrying out the appliance installation,

please check that all components are not

damaged, in such a case contact your retailer

and do not carry out any installation operation.

Before the installation of the downdraft, please

remove the safety piece you can see in the

picture (Fig. 1). Leave all other protective tape

in place at this point. Furthermore, please

read carefully all of the following installation

instructions.

• Use Sirius ducting with a maximum length of 7

metres to the motor.

• Limit the number of elbows in the ducting, since

each elbow reduces the air capacity of 1 linear

meter. (Ex: if you use no. 2 x 90° elbows, the

length of piping should not exceed 5 meters).

• Avoid abrupt direction changes. (Optimum angle

45° when required)

• Use a 150 mm for 580mm models, - 200mm

ducting for larger models - constant diameter

pipe for the whole length.

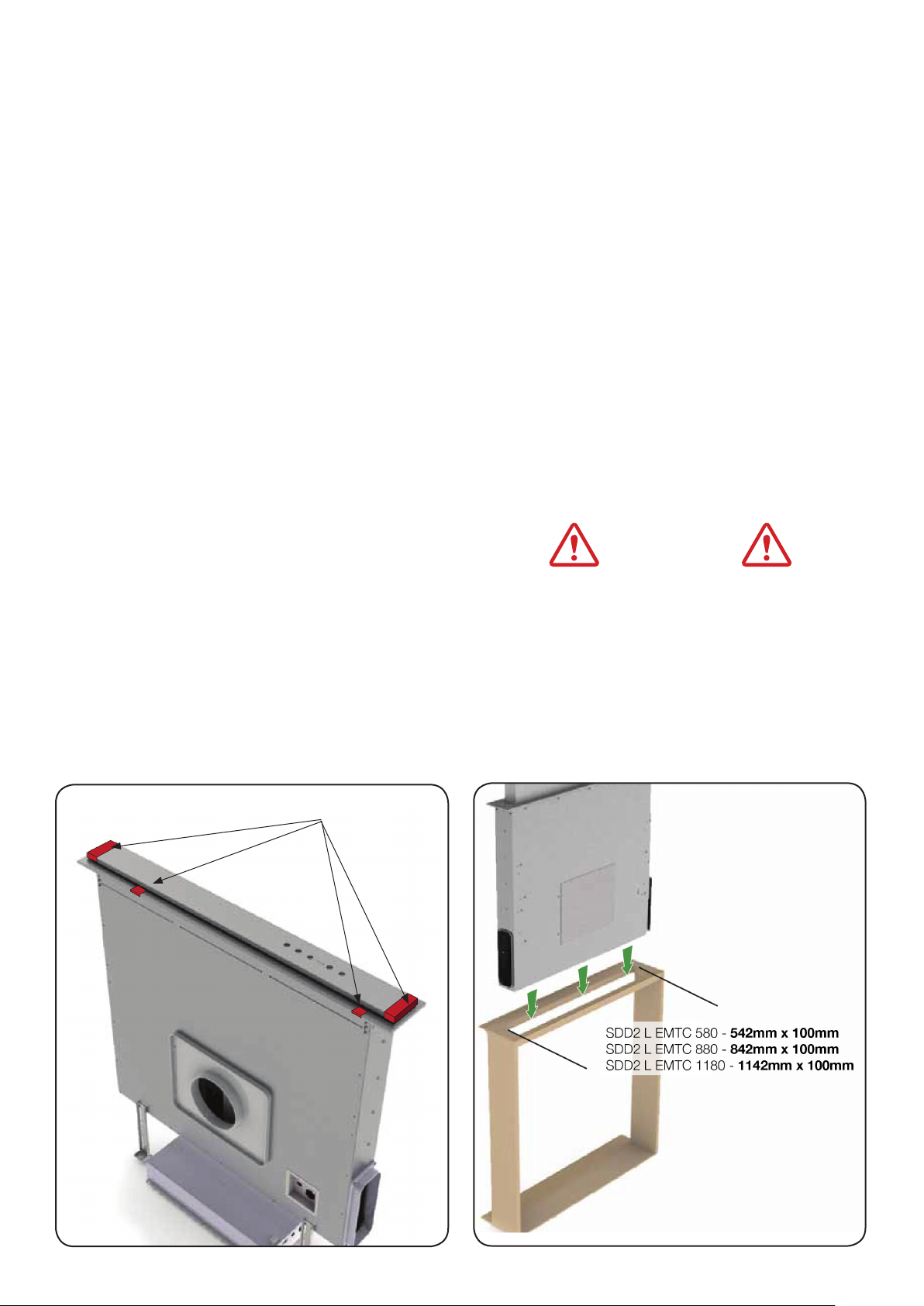

STEP 1:

Refer to cutout dimensions required per unit as they

vary for each unit.

1. Before making the cutout, check that there are no

structural or other parts inside the cabinet where

the appliance is to be placed which could hinder

a proper installation. Check that the dimensions

of the downdraft and the cooktop are compatible

with the cabinet so that the installation can be

carried out properly.

2. Make a rectangular cutout in the back of the

cooktop:

• 542mm x 100mm for the 580mm model

• 842mm x 100mm for the 880mm model

• 1142mm x 100mm for the 1180mm model.

3. Put the downdraft in the opening, inserting it from

above as shown in (Fig. 2)

Use ducting approved by standards enforced - see

www.siriusbrand.com.au for approved ducting

The manufacturer shall not be deemed responsible

for air capacity or noise problems caused by failure to

comply with the above instructions and no warranty

on the product shall be provided.

(Fig. 1) (Fig. 2)

NB: Remove only red parts

Technical specifications and product sizes

can be varied by the manufacturer without

notice. Cut out dimensions are indicitive only

and physical measurement should be taken as

a precautionary measure to ensure no issues

arise with fitment.

WARNING

6

Page 7

INSTALLATION INSTRUCTIONS

SIDE OR BOTTOM VENTING

(For front or rear venting instructions, see pages 10-12)

S-DD2-L FLUSH TOP

INSTALLATION GUIDE

STEP 2:

1. Remove front 150mm or 200mm adaptor plate

(Part ‘D’) (Fig. 3)

2. Replace Part ‘D’ with front cover plate (Part ‘E’)

Remove & replace

with Part ‘E’

STEP 3:

1. Remove side or bottom cover plate (Part C).

(Fig. 4)

2. Connect air outlet collar (Part ‘B’) to the same

fixing points as removed from side or bottom

cover plate (Part ‘C’) and tighten.

(Fig. 3) (Fig. 4)

STEP 4:

• Carefully lower downdraft into cutout cabinetry.

• Fix the downdraft inside the cabinet, using the

special fixing brackets (Part ‘ F’) supplied with the

product.

• Insert the brackets in the lower side of the

downdraft in such a way that there is a 2 mm

distance between the lower side of bracket and

the bottom of the cabinet.

• This distance will allow the traction to be

positioned downwards of the product, at the

moment of fixing, in order to have the stainless steel trim perfectly adhering with the work

surface.

• Before inserting the screws, please make sure

that the appliance is perfectly perpendicular with

the work surface, ensuring unit is square and

levelled with spirit level before turning on. (Fig. 5)

2mm

Remove & replace

with Part ‘B’

Part ‘F’

Remove & replace

with Part ‘B’

NB: If the unit is not levelled, the downdraft will

shudder when rising. This could cause damage

to your unit, which is not covered by warranty.

This is installation damage.

(Fig. 5)

7

Page 8

S-DD2-L FLUSH TOP

INSTALLATION GUIDE

STEP 5:

• Connect rectangular to round adaptor (Part ‘A’) to

air outlet (Part ‘B’), (Fig. 6).

• Secure both ends with duct tape

(Fig. 6)

STEP 6A: Ducting to SEM 1 motor (150mm ducting)

This step covers ducting for SDD2 L EMTC 580 models only. For 880mm & 1180mm models, see Step 6B.

1A: Connect the top of the 150mm connector piece (Part ‘I’) to the round outlet on adaptor (Part ‘A’), then

connect length of 150mm ducting (Part ‘K.1’) to the bottom of the 150mm connector piece (Part ‘I’).

2A. Secure to the motor with a universal ring clamp (Part ‘G’).

• See page 12 for ducting from motor to vent (N/A for SEM 2 motors)

BOTTOM VENT

OPTION

SIDE VENT

OPTION

PART ‘B’

PART ‘A’

PART ‘I’

PART ‘K.1’

PART ‘G’

STEP 6A: Ducting to SEM 2 motor (150mm ducting)

PART ‘K.1’

PART ‘B’

PART ‘A’

PART ‘I’

PART ‘K.1’

8

PART ‘G’

OUTSIDEINSIDE

WALL

SEM 2 MOTORS

MIN HEIGHT FROM GROUND

500mm - 2mtrs

Page 9

S-DD2-L FLUSH TOP

INSTALLATION GUIDE

STEP 6B: Ducting to SEM 7 motor (200mm ducting)

This step covers ducting for SDD2 L EMTC 880 and 1180mm models. For the 580mm model, see Step 6A.

For SEM 8 motor with SDD2 L EMTC 880/1180 - 200mm option only.

1B: Connect a duct expander (Part ‘H’) to rectangular to round adapter (Part ‘A’), then connect

length of ducting (Part ‘K.2’) to the 200mm outlet.

2B: Secure to the motor with a universal ring clamp (Part ‘G’).

• See page 12 for ducting to vent (N/A for SEM 7 motor)

PART ‘B’

PART ‘A’

PART ‘H’

STEP 6B: Ducting to SEM 8 motor (200mm ducting)

BOTTOM VENT

OPTION

SIDE VENT

OPTION

OUTSIDEINSIDE

WALL

MIN HEIGHT FROM GROUND

500mm - 2mtrs

PART ‘B’

PART ‘A’

PART ‘H’

PART ‘K.2’

PART ‘K.2’

PART ‘G ’

9

Page 10

S-DD2-L FLUSH TOP

INSTALLATION GUIDE

INSTALLATION INSTRUCTIONS

FOR SEM 1, SEM 2, SEM 7, SEM 8

FRONT OR REAR VENTING

(For side or bottom venting instructions, see pages 7 - 9)

STEP 2:

If venting from front, check to see if front adaptor

plate (Part ‘D’) is attached.

• If venting from the rear, remove 150mm or

200mm adaptor plate (Part ‘D’) and replace with

front cover plate (Part ‘E’).

Remove & replace with

cover plate (Part ‘C’)

STEP 3:

• Carefully lower downdraft into cutout cabinetry.

• Fix the downdraft inside the cabinet, using the

special fixing brackets (Part ‘F’) supplied with the

product.

• Insert the brackets in the lower side of the

downdraft in such a way that there is a 2 mm

distance between the lower side of bracket and

the bottom of the cabinet.

• This distance will allow the traction to be

positioned downwards of the product, at the

moment of fixing, in order to have the stainless steel trim perfectly adhering with the work

surface.

• Before inserting the screws, please make sure

that the appliance is perfectly perpendicular with

the work surface, ensuring unit is square and

levelled with spirit level before turning on. (Fig. 5)

Remove & replace with

cover plate (Part ‘C’)

(Fig. 7)

Part ‘F’

2mm

Remove & replace with

cover plate (Part ‘C’)

NB: If the unit is not levelled, the downdraft will

shudder when rising. This could cause damage

to your unit, which is not covered by warranty.

This is installation damage.

(Fig. 5)

10

Page 11

S-DD2-L FLUSH TOP

INSTALLATION GUIDE

STEP 4:

1. Use 150mm ducting (Part ‘K.1’) for S-DD2-L-EMTC 580 versions or 200mm ducting (Part ‘K.2’) for

S-DD2-L-EMTC 880 and 1180 versions.

2. The ducting fits directly onto the collar on the front adaptor plate (Part ‘D’).

3. Fix in place using a universal ring clamp (Part ‘G’).

Ducting to SEM 1 / SEM 8 motor (internal motor)

PART ‘K.1’ / ‘K.2’

Ducting to SEM 2 / SEM 7 motor (external motor)

PART ‘K.1’ / ‘K.2’

PART ‘G’

OUTSIDEINSIDE

WALL

PART ‘K.1’ / ‘K.2’

11

PART ‘G’

URC-25/325

SEM 2 / SEM 7

MIN HEIGHT FROM GROUND

500mm - 2mtrs

Page 12

S-DD2-L FLUSH TOP

INSTALLATION GUIDE

DUCTING FROM MOTOR TO WALL VENT: (SEM 1 and SEM 8)

1. Run the length of ducting to the motor. (Additional lengths of ducting can be attached using an

additional internal connector pieces.)

NOTE: No connector required as it connects directly to the collar of the motor.

2. Secure with another universal ring clamp (Part ‘G’).

NOTE: The location of the motor is to be no less than 2 metres away from the downdraft. Failure to

do so may result in additional noise level of the downdraft. Maximum distance is 7 metres, however

3 - 5 metres is optimum to minimise noise and maximise performance.

3. Using another length of semi-rigid duct run from the exit collar on the SEM 1 / SEM 8 to a predetermined

exit point and connect to weatherproof vent with a clamp.

See www.siriusbrand.com for multiple vent options or see our nearest retail partner.

ELECTRICAL CONNECTION

Power transformer can be located anywhere beneath

the bench. It must be accessible for servicing.

NOTE

We recommend installing the power transformer

at least 10 cm above floor level and at a suitable

distance from all heat sources (e.g. oven sides or

cook top).

WARNING

Place the power transformer at a distance of no

less than 65 cm from gas cooktops.

7 METRE POWER CORD

POWER TRANSFORMER

12

Page 13

ELECTRICAL CONNECTION

S-DD2-L FLUSH TOP

INSTALLATION GUIDE

NOTE

This appliance complies with the European

Directives 2006/95/EC (Low Voltage

Directive) and 2004/108/EC (Electromagnetic

Compatibility).

While installing the appliance and carrying

maintenance operation, make sure it is disconnected

from the electrical network or the fuses are cut out or

removed.

Check that:

• Power is connected.

• Feeder lines (mains) are in good conditions.

• The cables diameter complies with installation

regulations.

WARNING

The downdraft connection to the electrical

network must be carried out only by

professional and qualified technicians.

The downdraft must be connected to a properly

installed and suitable electrical network.

The electrical system must comply with VDE0100

standard.

DANGER

If the rangehood presents any anomaly,

disconnect the appliance or remove the

fuse corresponding to the appliance

power disconnecting line.

If the appliance has no plug or if the plug is not

easily accessible, then a device needs to be fitted to

disconnect off from the electric network; this device

must have an opening distance between contacts on

all poles of at least 3 mm.

CAUTION

This appliance is fitted with an H05 VVF 3 conductor,

0.75 mm2 (neutral, phase, and ground) power cord.

This can be connected up to a 220 - 240 V

monophase electrical network through a CEI 60083

approved power socket (10AMP power socket),

which must remain accessible after installation, in

compliance with installation regulations. We decline

any responsibility in case of accidents caused by

a lack of ground connection or incorrect ground

connection. The appliance must be fed through a

differential protection device (RCD), with a nominal

residual current not exceeding 30mA. If the power

cord is damaged, call the after-sales service to avoid

any risk.

WARNING

After having replaced the filters, reinstall

the front stainless steel panel, otherwise

the Downdraft is not enabled to function.

NOTE

Water splashing against the enclosure from any

direction shall have no harmful effect, utilizing either:

a) an oscillating fixture, or b) A spray nozzle with no

shield.

Test a) is conducted for 10 minutes. Test b) is

conducted (without shield) for 5 minutes minimum.

Oscillating tube: Test duration: 10 minutes, or spray

nozzle (same as IPX3 spray nozzle with shield

removed).

(Fig. 8)

13

Page 14

S-DD2-L FLUSH TOP

INSTALLATION GUIDE

HOW THE RANGEHOOD WORKS

Light On/Off Decrease fan

speed

A: Light ON/OFF key

The light switches on and off only when the carriage

is fully OPEN.

Pressing this button with the carriage closed will

cause the carriage to open and then the light will

switch on .

The button also serves to switch off the light if it is on.

B: ON/OFF key

This starts the extraction carriage upward movement

and when it is fully open, it sets the second extraction

speed.

With the carriage open: it switches off the motor and

if on, the light; then it retracts the extraction carriage.

C: Decrease fan speed key

This reduces the speed of the extractor motor from

the 4th speed until the motor switches off, without

closing the pullout carriage.

D: Fan speed Indicators

• This signals the speed setting, by only the

relevant LED switching on.

• Lights flashing signals reminder to wash mesh

grease filters. (see grease filter saturation)

E: Increase fan speed key

Fan speed

indicators

Automatic turn off:

After 4 hours of continuous working from the

last setup, the appliance turns off and closes

automatically. This ensures the unit cannot

accidentally be left running whilst away.

Grease filters saturation:

After 30 hours of working, the speed indicators “D”

will all flash simultaneously, signaling the grease filters

saturation.

To reset this alarm, hold down the “TIMER” button

for at least 3 seconds, while the carriage is open.

Calibration:

The rangehood carries out its self-calibration every 3

complete cycles of its extractable unit.

By pushing the “TIMER” key 6 times consecutively

(MAX break between one push and the other is 3

sec.) all the LEDs will flash and the calibration will be

reset.

After the next 3 cycles the downdraft will carry out its

self-calibration.

Stand-by:

When the extractable unit is closed and the light

is switched off, the control panel, after 6 seconds,

activates the Stand-by function, reducing the

brightness of the leds.

This function can be stopped by pressing ON/OFF

or LIGHT key.

Increase fan

speed

10 min shut-off

timer

This increases the speed of the extractor motor, from

1st to 4th speed, without moving the extractor panel.

F: 10 Minute shut-off timer

10 min after setting, it serves to stop the extractor

motor, close the carriage and switch the lights off,

if they are on. The set function is signalled by the

flashing LEDs “D” for the set speed. The timer can

be cancelled by pressing the key again.

Safety close function:

If an obstacle is preventing the downdraft from

lowering completely, the downdraft will automatically

raise to prevent damage to the unit.

WARNING

This operation has to be carried out by a

specialised technician.

14

Page 15

INSTALLATION GUIDE

CLEANING THE RANGEHOOD

Careful maintenance ensures proper operation and

good performances over time.

CAUTION

The hood must be disconnected from the electrical network, both by unplugging

the appliance from the socket and activating the magnetic circuit breaker (safety

cut-out), before removing the metal grease filters. After cleaning operations,

replace the metal grease filters as outlined in the installation instructions.

MAINTENANCE HOW TO PROCEED? ACCESSORY PRODUCTS TO USE

S-DD2-L FLUSH TOP

External

surfaces and

accessories

Filter cleaning

NB: Filters should be replaced approximately every 6 months, depending on style and frequency of

cooking. For high fat cooking it is recommended the clean the filters every 2 weeks.

Do not use metallic

scrubbers, abrasive products,

or hard brushes.

After 30 hours of operation,

the downdraft will signal the

grease filter saturation.

The saturation is signaled by

the blinking of the 4 central

leds. To reset, hold down the

timer button for at least

3 seconds, while the carriage

is open.

To clean the external surfaces of the rangehood

and the light housing screen use only commercially

available household detergents diluted in water. Then

rinse with clean water and dry with a soft cloth.

The grease filters can be washed by hand or in the

dishwasher. These filters need to be cleaned on a

regular basis, otherwise they may represent a fire

risk. If frying or cooking with oil, the filers need to be

cleaned more regularly.

Refit the grease filters and front panel, making sure

that the panel is properly fitted at the sides so that it it

does not cause the downdraft to stop operating.

TROUBLESHOOTING

PROBLEM SOLUTION

The rangehood

does not work.

The rangehood

has low

performance.

The rangehood

stops in the

middle of

operation.

Check that:

• There is not a power outage.

• A specific speed has actually been selected.

• The 6 pin connection is inserted properly.

• The red reset key, found over the electrical system box, is pushed.

• Make sure that the wires of the 9 pole connection are inserted properly in the

connector itself (during the connection phase, an excessive pressure could bend the

contacts).

Check that:

• The motor speed selected is sufficient for the quantity of fumes and vapors present

in the room.

• The kitchen is ventilated well enough to allow air for intake.

• The non-return valves of the suctioning unit are free to rotate.

• The ducting is clear and not obstructed.

• Unit is only working on 2 speeds - refer to page 5.

• The correct minimum diameter ducting has been used

Check that:

• There is not a power outage.

• The safety switch has not tripped (RCD or safety switch).

15

Page 16

S-DD2-L FLUSH TOP

INSTALLATION GUIDE

REPLACING THE LIGHT

1. Lift the unit, then press the red button on the

power transformer - cutting power to the unit.

3. Disconnect the flat cable and remove the top

panel.

2. Remove the two screw under the top panel, and

the three on the back (five screws in total).

4. Remove the screws holding the panel wth the light

globe.

5. Pull the panel out of the rangehood. Disconnect

the cable. Twist the light globe, and pull to remove.

6. Insert new light globe and twist into place.

Reconnect cable, panel and screws. When all parts

are in place, push red button on transformer box to

restart rangehood.

16

Page 17

AFTER SALES SERVICE

Any maintenance operation on your appliance should

be carried out by:

• Either Arisit Pty Ltd;

• Or a qualified professional technician, authorized

for that brand if out of warranty.

Contact www.siriusbrand.com

1300 762 219

S-DD2-L FLUSH TOP

INSTALLATION GUIDE

NOTE

When calling, please mention the appliance

details: Production date, (Fig. 9A), Type (Fig. 9B)

and equipment (Fig. 9C).

This information is mentioned on the rating

label and the production date one placed on the

lower side of the downdraft.

(Fig. 9A)

PARTS LIST

A

B

C

D

E

F

G

RECTANGULAR TO ROUND DUCTING ADAPTOR SPS-81020

BOTTOM/SIDE COVER COLLAR SPS-51070102735

BOTTOM/SIDE EXIT PLATE SPS-20059000094

FRONT/REAR VENT ADAPTOR SPS-20059120071

FRONT/REAR VENT COVER PLATE SPS-75059000082

UPRIGHT FIXING BRACKETS SPS-77002002999

UNIVERSAL RING CLAMP URC25-215

(Fig. 9B)

(Fig. 9)

(Fig. 9C)

H

J

K

L

150MM TO 200MM DUCT EXPANDER GDR 150/200

I

150MM DIAMETER CONNECTOR PIECE GDC-150

200MM DIAMETER CONNECTOR PIECE GDC-200

K.1 - DUCTING 150MM

K.2 - DUCTING 200MM

DUCTING CONNECTOR FOR SEM 10 INSTALLATIONS ONLY Part no. ‘FLANGE’

17

SRPRO 30/150

SRPRO 30/200

Page 18

S-DD2-L FLUSH TOP

INSTALLATION GUIDE

PARTS LIST - INCLUDED PIECES

PART A

Rectangular to round ducting adaptor

SPS-81020

PART C

Bottom/side exit connector

SPS-20059000094

PART B

Bottom/side cover collar

SPS-51070102735

PART D

Front/rear vent adaptor

SPS-20059120071

Front/rear vent cover plate

SPS-75059000082

PART FPART E

Upright fixing brackets

SPS-77002002999

18

Page 19

PARTS LIST - OPTIONAL PIECES

To be purchased separately

S-DD2-L FLUSH TOP

INSTALLATION GUIDE

PART G

Universal ring clamp

URC25-215/325

PART I

150mm diameter connector piece

GDC-150

PART H

150mm to 200mm Duct expander

GDR 150/200

PART J

200mm diameter connector piece

GDC-200

Part K.1 / K.2

Semi rigid aluminium ducting 150mm / 200mm

SRPRO 30/150 or SRPRO 30/200

PART L

Ducting connector for SEM 10 installations only

Part no. ‘FLANGE’

19

Page 20

WIRING DIAGRAMS

YEAR WARRANTY

WHEN SIRIUS DUCTING IS USED

S-DD2-L FLUSH TOP

INSTALLATION GUIDE

ARISIT PTY LIMITED (Australia)

ABN 23 091 515 294

40-44 Mark Anthony Drive

Dandenong South VIC 3175

P: Sales & Service: 1300 762 219

F: Sales & Service: (03) 9768 0838

E: arisit@arisit.com

ARISIT PTY LIMITED (New Zealand)

1A Howe Street Newton, Auckland 1145

PO Box 68-140 Newton, Auckland 1145

P: (09) 306 1020 - Fax: (09) 302 0077

E: sales2@aristonappliances.co.nz

www.arisit.com

www.arisitwarranties.com.au

www.siriusbrand.com

20

Sirius Hoods and ducting products are only available

from our select group of Sirius Professional Stockists

nationwide. For the latest list of Sirius Stockists

near you, please refer to www.siriusbrand.com

All efforts have been made to ensure that the

information provided in this brochure is correct at

the time of printing. Due to continuous product

improvement and ongoing development, Sirius

reserves the right to make changes to the

products and technical data without prior notice.

Some products appearing in this brochure may

be for illustrative purposes only. Diagrams are

indicative measures only. Prior to commencing

cabinetry cutouts the operating/installation

instructions accompanying the product must

be referred to at www.siriusbrand.com

Loading...

Loading...