Page 1

SIRIUS Through Roof EasyKITs – “EASYROOF150T/M” and

“EASYROOF200T/M”

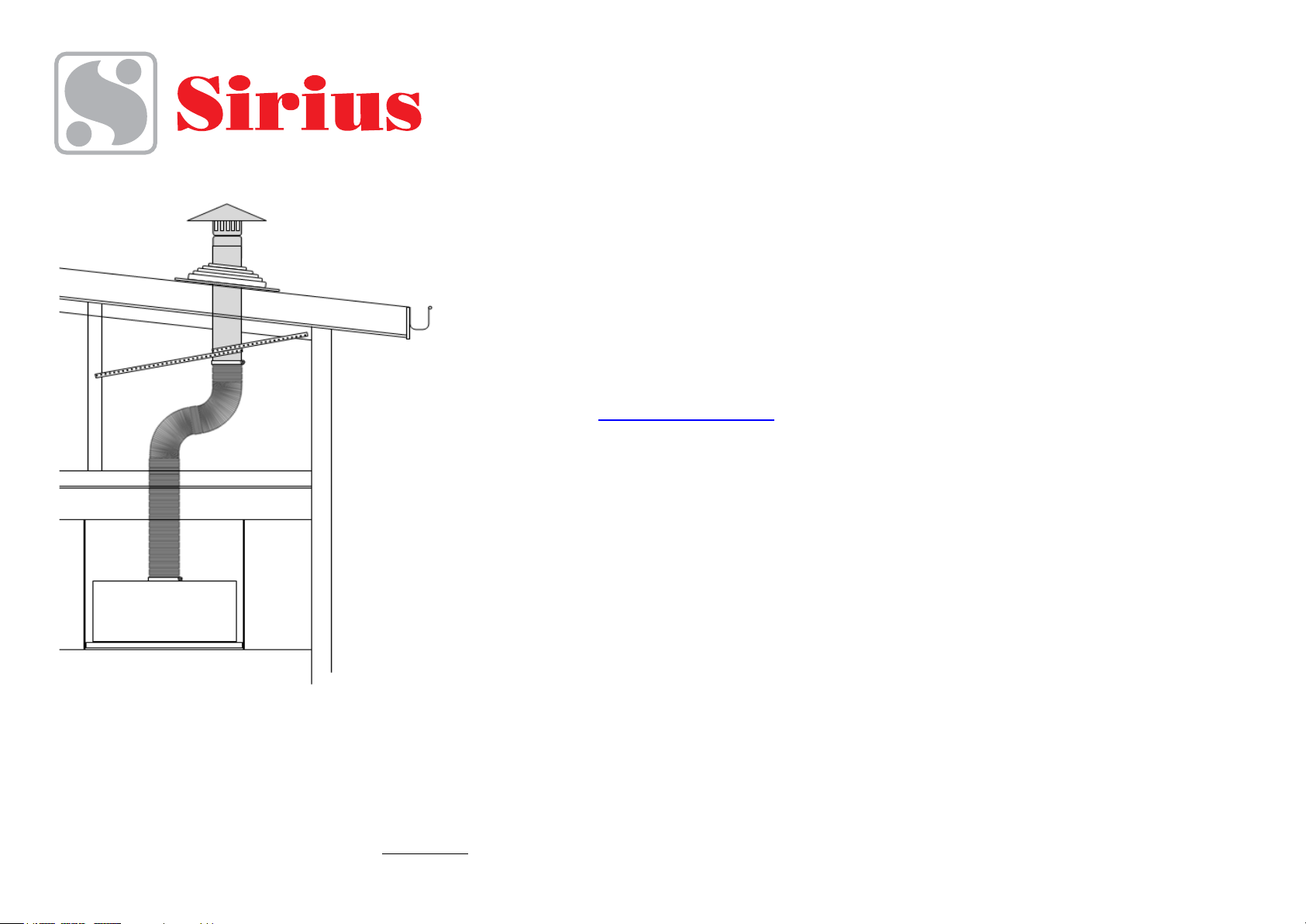

Sirius ducting kits are a high quality and simple, complete solution in a box. They provide an

ideal ventilation path to efficiently exhaust your kitchen fumes, steam, heat and odours –

filtered through your rangehood to the outside atmosphere.

Professional Ducting Range

There are 2 ducting sizes available – 150mm and 200mm. Please choose the correct size for

your rangehood and also that you specify for either a tiled or metal roof.

Please check that there is a clear

path for your ducting to run prior to installation, making sure

to look out for TV, computer, telephone and electrical cables, water and gas pipes, insulation

materials and air conditioning pipes and duct, before cutting holes.

For new homes, ideally fit the basic ducting (pipe) components at the frame up stage.

Additional lengths of ducting, joins, galvanised steel angled elbows and all other ducting

access

ories are available

from your local retailer, or Sirius online where you purchased your

SIRIUS EasyKIT.

For further advice please call our ducting consultation service on Ph: 1300 762 219 (Australia

only) or visit www.siriusbrand.com

and fill in the fields and one of our trained consultants will

assist you in the best manner possible.

Each EasyKIT comes complete with the following components, ready to be installed by a

suitably qualified and licensed tradesperson.

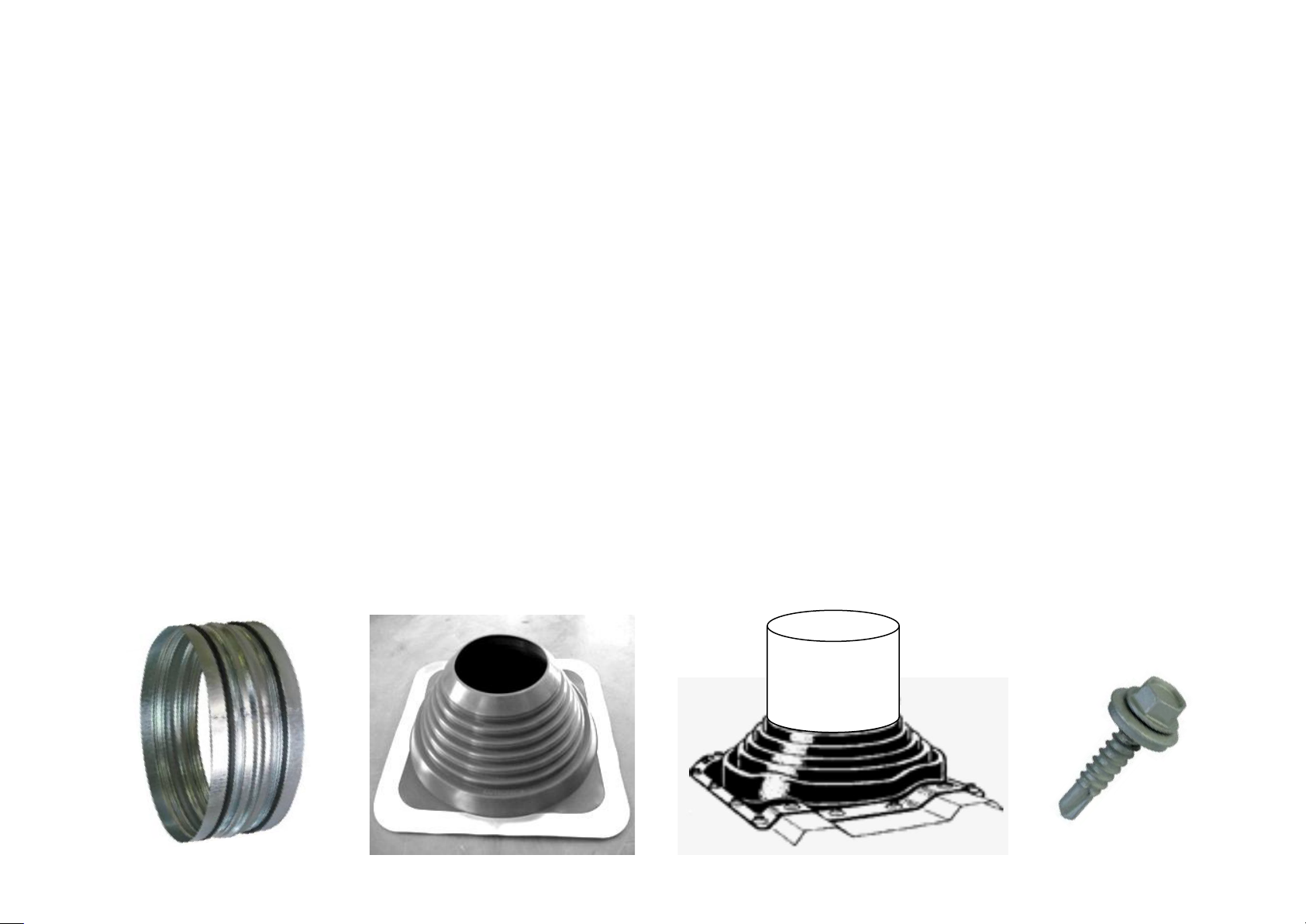

• 1 x 3m of Semi-Rigid PLUS aluminium ducting (SRPRO30/150 or SRPRO30/200)

• 1 x 1m of solid galvanised steel pipe (GP12-150 or GP12-200).

• 1 x *Silicone and soft form Aluminium roof flashing for either a tiled or metal roof.

Tiled roof (TRFG075), Metal roof (MRF-G102)

• 1 x galvanised steel roof cowl (GRC-150 or GRC-200)

• 1.5m galvanised steel, perforated bracing strap (GBS-200).

• 2 x galvanised steel duct connectors with double EPDM gasket seals (GDC150-GDC200).

• 2 x stainless steel ring clamps.

:

Installation Guide

(Disclaimer) The following instructions are provided as a guide only and in no way constitute or replace your local council requirements or Australian and New Zealand Standards and Building Codes.

1. Remove the required roofing tiles or cut the appropriate sized hole through the metal roof, being careful to watch out for insulation, cables, etc. (as above)

2. Using sharp tin snips, carefully trim the silicone cone to the correct pipe diameter. Wet the pipe with a water sp

top and slide halfway down the pipe.

the silicone cone, use an additional (3

Please note: if done correctly this will provide a very efficient seal to repel moisture. Should you accidentally over cut

rd

) ring clamp to draw in the silicone cone around the pipe.

# Please note: We don’t supply silastic sealants, self-sealing fasteners (roofing screws), nails or wood screws for the bracing

strap… as most qualified trades people have these on board and will use whatever is appropriate for your buildings materials.

ray as a lubricant and carefully fit over the

Page 2

3. Fit the 2 gasketed duct connectors into each end of the galvanised pipe (1 top & 1 bottom). Ensure that the connectors are pushed firmly into the pipe, up

to the centre rib of the connector.

4. The roof cowl can also be fitted at this stage, sliding the neck of the cowl over the duct connector fitted in the top end of the pipe. Again ensuring that it is

pushed firmly on over the gaskets and down to the centre rib.

5. Lower the bottom en

d of the pipe through the roof line and then using the bracing strap, anchor off the pipe to the roof/house frame using appropriate

fasteners as required.

6. With your hands circled around the semi-rigid ducting pipe, start from the centre of the pipe gently stretching and pulling it out to the ends… carefully form

it into the shape and length required to go from the lower end of the galvanised pipe down to the connection on top of y

a bends as possible.

(If stretched out straight the duct will cover 3 metres. Each bend will reduce the length and a sharp 90⁰ bend could reduce the overall length by as much as 0.5m)

our rangehood. Do this with as few

7. Fit the top end of the semi-rigid ducting over the gasketed connector on the lower end of the galvanised pipe and secure with 1 of the stainless steel ring

clamps, ensuring not to over tighten the screw and tear through

the aluminium. Hand tightening with a screw driver is ideal, or use a slow speed with a

cordless screwdriver or drill with a driver bit.

8. Carefully feeding/pulling through the ceiling, bring the lower end of the semi-rigid duct down to the connecting spigot on the top of the rangehood. Fit the

duct over the spigot and using the other stainless steel ring clamp, secure the duct to it. Again ensuring not to over tighten as above.

9.

After checking that the bracing strap is secure and that the galvanised pipe is in a vertical position (use a spirit level to check on at least 2 sides)… then

Metal Roof: carefully pull the silicone cone into position and form up the bonded aluminium edge as appropriate over the metal roof profile (either squared

off with the roof line or in a diamond shape). Gently lift up the edges and apply a silastic sealant around the roof under th e

edges of the flashing. Firmly

press the bonded aluminium edge of the base of the silicone cone over the roof profile again, smoothing it out as neatly as possible. Fasten down using

(self tapping) self sealing roofing screws.

Page 3

Tiled Roof: carefully place the top edge of the soft form aluminium base under the upper row of tiles…

making sure to form up an anti-capillary fold.

Then form up the left and right hand edges of the base, down neatly over the high edge

of the profile of the side tiles.

Neatly cut corner tabs and turn them under the tiles at the bottom edge of the base.

To finish… trim the base to fit or as required to help fit neatly in

result for providing a waterproof membrane over your roof.

with the size and profile of the tiles. Make sure you don’t over-cut the base and reduce the best

*Sirius roof flashings are made from a high grade, temperature stable Silicone (-50⁰C to +250⁰C) making it ideal for hot pipe installation. It is also Ozone and UV resistant making it

perfect for Australian and New Zealand weather conditions. Combined with soft form A

environmentally sensitive option to lead flashing. Especially with rainwater run-off into domestic water tanks. Sirius roof flashings also won’t react with galvanised steel and are

compatible with most painted & zincalume style roof coatings.

Professional Ducting Range

Arisit Australia Pty. Ltd. 40-44 Mark Anthony Drive, Dandenong South, VIC 3175.

luminium for easy moulding and installation to most roof profiles, and providing a more

For further advice please call our ducting consultation service on

Ph: 1300 762 219 (Australia only) or visit www.siriusbrand.com

and fill in the fields and one of our trained consultants will only

be too happy to help and assist you in the best manner possible.

Loading...

Loading...