Page 1

OWNER'S

OPERATING

AND

MAINTENANCE

MANUAL

U/

1/

■r-»

MODEL

616

Page 2

INDEX

Pages

Accessories-..................................................23

How to Use............................................24

Hemmers

...............................................

25

Seam Gauge or Cloth Guide ...............26

Quilting Guide ......................................26

Attachments

.................................................

34

Adjustable Cord and Zipper Foot 40

Attachment Foot...................................35

Binder

..................................................

37

Edgestitcher..........................................35

Hemmers

.........................................

38-39

Rüffler....................................................42

Blind Stitching............................................... ^ g

Bobbin

Placing in Shuttle

.................................

7

Threading............................................... 6

Winding

Buttonholes

Buttons Sew-On

..................................................

...................................................

............................................

5

20

22

Charts

Needle-Thread-Fabric-Stifching

...........

4

Pages

Stitch Length

.........................................

Trouble........................................30-31-32

Darning and Mending...................................11

Elastic or Multiple Zigzag

Stitches

........

19

Embroidery

Creative

...............

-— .............................14

Hoop......................................................15

Features and Parts (Front View) .................. 2

(Back View)

Installation-Head in Cabinet

........................

.............

3

50

Head in Portable Case.............48

Maintenance and Care

..................................

27

Cleaning and Oiling the Shuttle •••28

Needle Setting •••

pressure and Feeding of Fabric

Thin and Light weight Fabrics

Reverse Sewing

Sewing Preparation

...........................................

.................

...........

................:............................

.......................................

6

11

11

1 2

Sewing Tips..............................................44-45

Straight Stitching..........................................13

Tension Adjustment

.....................................

10

Threading-Upper............................................ 8

9

9

Page 3

NEEDLE-THREAD-FABRIC-STITCHING GUIDE

Fabric

Extremely heavy

tarpaulin, sacking,

canvas, duck, etc.

Heavy upholstery

fabric, ticking,

denim, leatherette

Medium heavy drapery

fabric, velveteen,

suiting, felt, terry, etc.

Medium broadcloth,

percale, gingham, linen,

chintz, taffeta, sheer

wool, shantung, etc.

Sheer voile, lawn,

dimity, crepe,

handkerchief linen,

plastic film, etc.

Very sheer chiffon,

batiste, lace, organdy,

ninon, net, marquisett, etc.

Need le

4

3 (18)

2 (16)

1 (14)

0 (11)

00

No.

Machine

Stitches

Per Inch

6

to

8

8

to

10

10

to

12

12

to

14

14

to

16 100

(Plastic film)

8 to 10

16

to

20

Cotton

Thread

10

to

30

30

to

40

40

to

60

60

to

80

80

to

100

to

150

Mercerized

Thread

Heavy Duty

Heavy Duty

Heavy Duty

50

50

50

Silk

or

Nylon

J

Page 4

Fig. 3

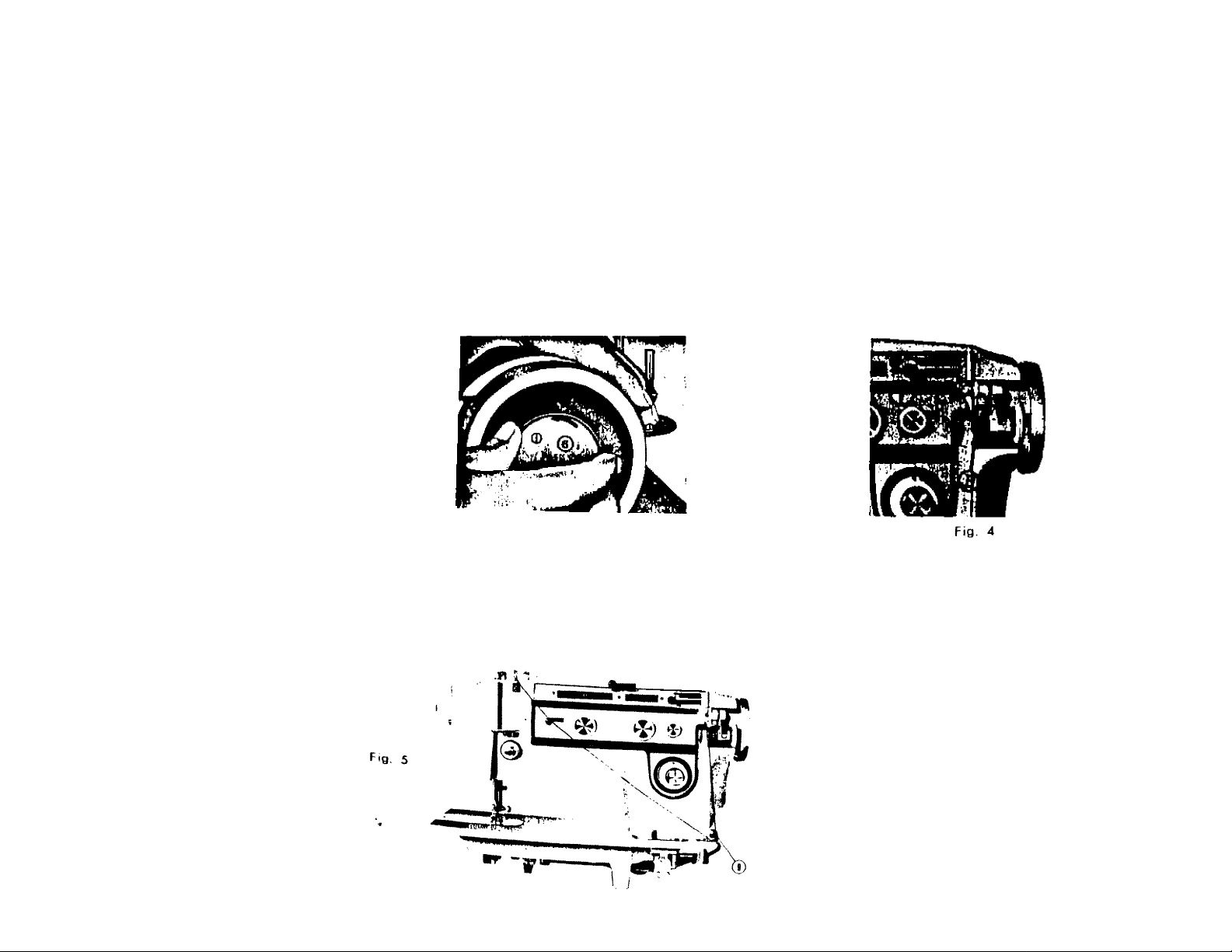

WINDING THE BOBBIN

toward ^rom ihe slifching mechanism by Kjrning clutch (6, Fig.3)

Quide on arm°' on one of the spool pins. Lead thread through the upper thread

you or counter clockwise.

an own through tension disc(9. Fig. 5,)at base of machine. Run end of thread

through a hole in bobbin edge (left fbnge

and from inside out) and place bobbin 0.on

spindle of bobbin winder (7, Fig. 4,) fitting

the notch bobbin over small pin on spindle.

Push bobbin winder against hand wheel.

Hold thread end loosely and start machine

slow ly.

Bobbin will stop winding when it is filled.

Turn clutch away from you until sewing

mechanism is again engaged so that needle

moves when you turn the hand wheel.

Break off loose thread end used to start

the winding and thread bobbin as slated on

Page 6.

Page 5

SETTING THE NEEDLE

See Fig. 6. Raise the needle bar to its highest

point, turning wheel toward you by hand.

Then loosen the needle clamp screw B and the

needle can be inserted into clamp C. Place needle

(flot side . lo right) in the needle clamp and push it

upward as far as it will go into the needle clamp

hole, tightening the needle clamp screw securely with'

a screw driver.

After changing the needle make one com

plete revolution of the balance wheel by hand pj

to be sure the needle is in the correct ^

position.

Fig. 6

Flat ^rlace

oi needle

shank

i]/

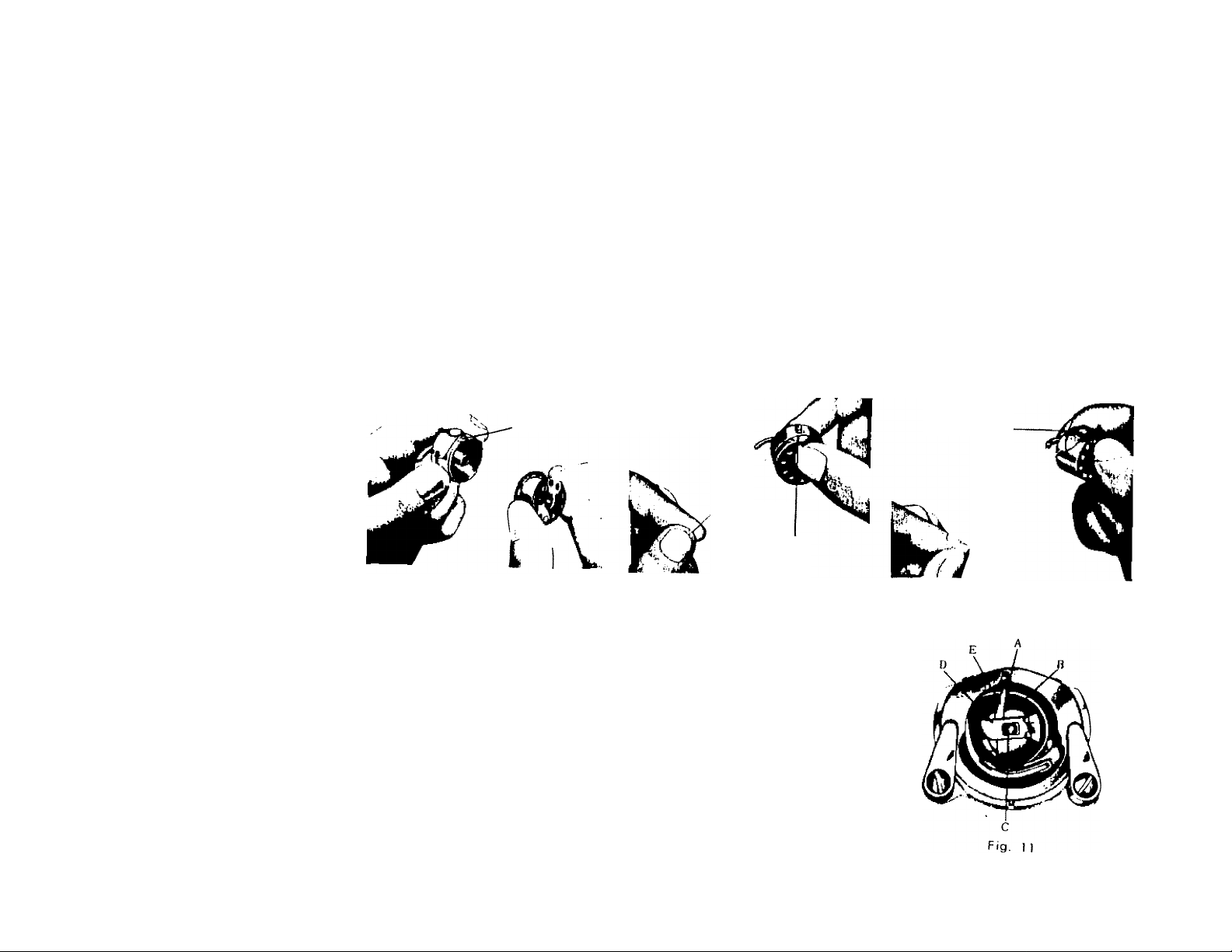

THREADING THE BOBBIN CASE

Step 1 (illustrated in Fig. 8). Hold bobbin case between thumb and forefinger of left hand

so that the slot in the edge of the bobbin case is on top. Take the bobbin between thumb and’

forefinger of right hand so that the thread on top leads from left to right.

Step 2. Insert bobbin into bobbin case, pull the thread into the slot of the bobbin case as

shown in Fig. 9. and draw it under tension spring and into the fork-shaped opening of the spring

as shown in Fig. 10.

Page 6

SLOT

TENSION SPRING

SLOT

Fig. 8

Fig. 9

placing bobbin case in shuttle

Raise needle bar to highest position, and slide cover plate

F' Hold the bobbin cose latch, (D,

•9- etween the thumb and forefinger of the left hand,

ih k •tiree inches of thread running from the top of

me bobbin case to the right. Insert and center the bobbin

a e on the stud of the shuttle body, (C). Be sure the

Pre,opposite the shuttle race notch (A).

fl

I » L °

I” Case (B) into the shuttle as far as possible

reeJ^ t THEN

after I t k i'” latch, (D). Press bobbin case again

is lo released to make sure the' bobbin case

locked securely in place. Close the cover plate.

Fig. 10

Page 7

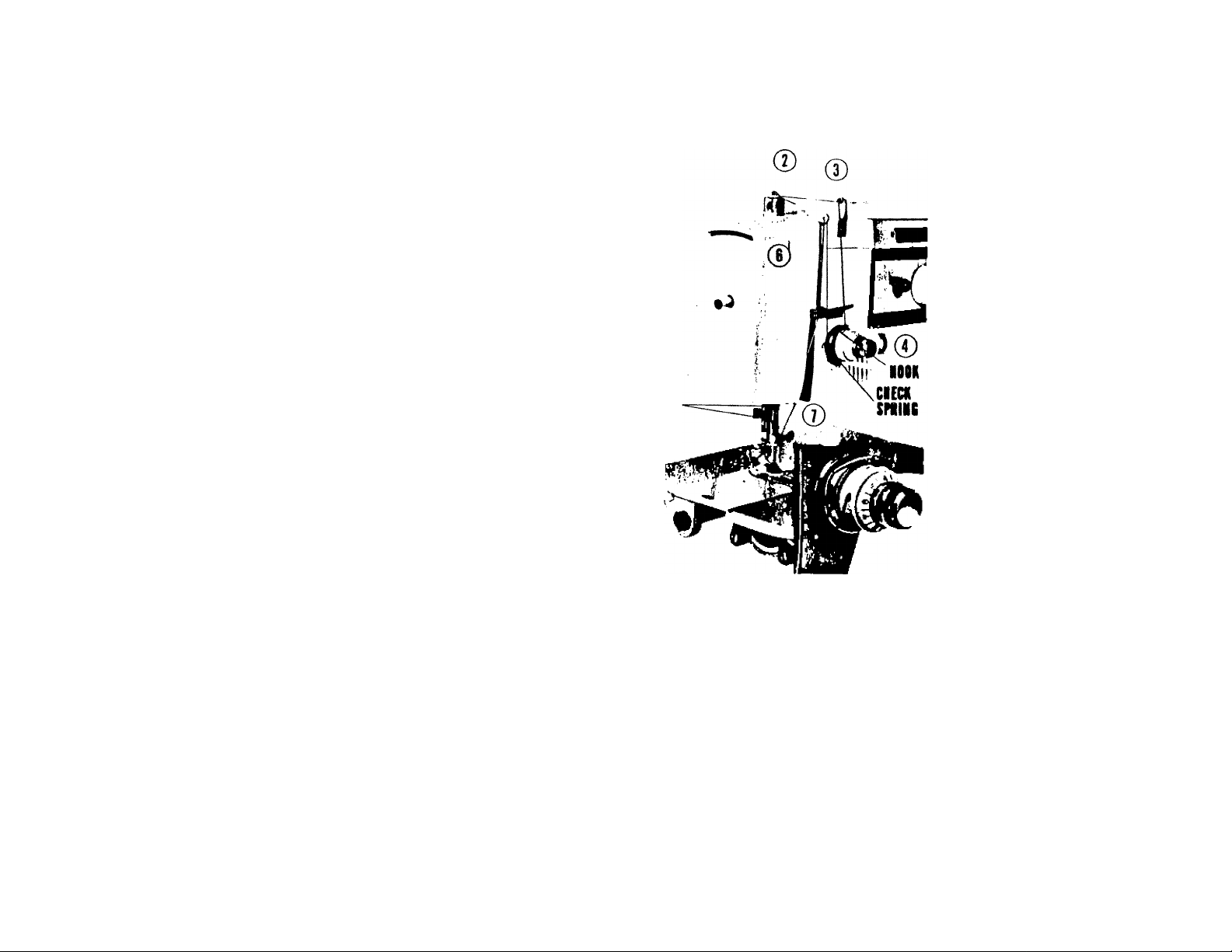

UPPER THREADING

1. Turn the hand wheel toward you to raise the

take-up lever to its highest position.

2. Place a spool of thread on the spool pin

3. lead the thread through the upper arm thread

guides.

4. Run the thread through the thread guide bar to

the tension discs, then around and between them

from right to left.

5. Draw the thread up through the check spring

and with a slight tug into the hook, (See insert

Fig. 12)

6. Pass the thread under the bar and up through

the eye of the take-up lever from right to left.

7. Lead thread down under bar, through the face

plate guides and then through the needle bar

guide from the back.

8. Thread needle FROM LEFT TO RIGHT, drawing

it through about 3 or 4 inches. Hold the end

of the upper thread loosely and turn the hand

wheel toward you until the needle goes all the

way down and comes back up. A loop (Fig

13) will be formed over the upper thread which

L " straight. Place both

thread ends under the slot of the presser foot

and draw toward the back of the machine, leav

ing both threads three or four inches long

THREAD.

lUIDES

St

Vf

Fifl. 12

ir

b

Page 8

m

i

D

IH

X

■ t

i

Fig. 13

Fig. 14

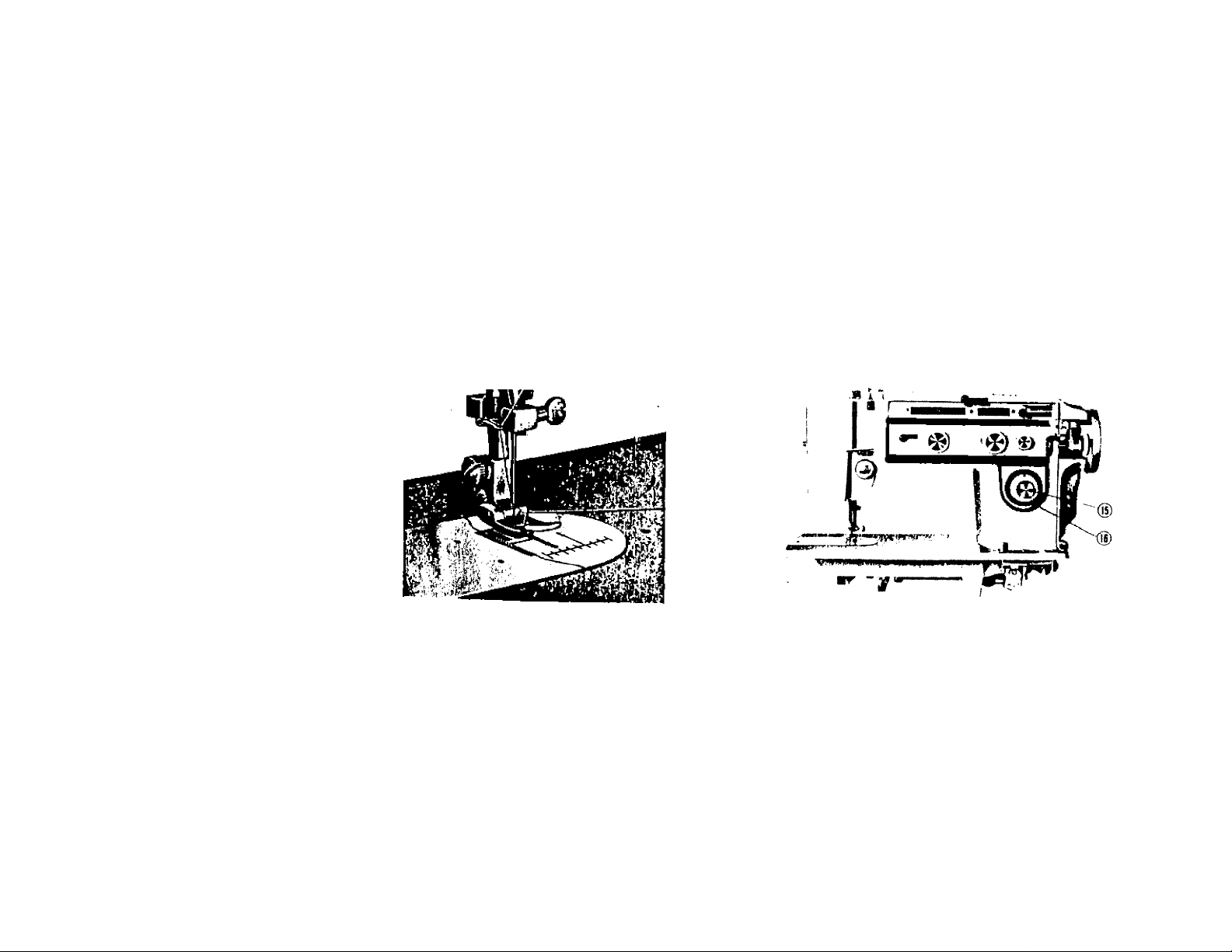

SETTING THE STITCH LENGTH

stitclT stilch is regulated by control 16 Fig. 14. Near 0 is the shortest

SIC an 5 is the longest, but the control may be set at any spot between the markings for a

vane y ot lengths. Turn the knob to the right to lengthen and to 'the left to shorten the stitch,

e number stitch length you choose is indicated by the pointer.

STITCH LENGTH CHART (APPROXIMATE)

Figures on indicator

Number of stitches per inch

0

No Feeding

30

1

25

2

. 3

15

4

8

5

6

SEWING IN REVERSE

When you wish to sew backward to lie the threads at the beginning or end of a seam, press

m e button (15 Fig. 14) as far as it will go. The machine will sew backward as long as the

button IS held in.

Page 9

10

ADJUSTING THE TENSIONS

Always adjust the upper tension with the presser foot down,

as the tension is released when it is raised. To increase the'

tension on the upper thread, turn dial (Fig. 15) to the right, or

clockwise; to decrease, turn to the left. The higher the nun^ber

on the dial the tighter the tension. Before adjusting lower tension

be sure that the machinp is threaded properly.

When it is necessary to change the bobbin tension, turn the

small screw (Fig. 17) on side of the bobbin case clockwise to tighten

counterclockwise to loosen.

Fig. 16 A

When the upper and under tensions are properly

balanced, a perfect stitch will be formed with both

threads interlocking in fabric (Fig. 16-A)

When the upper tension is too light, the lower

thread is pulled up over the upper thread which is

lying flat on the fabric (Fig. 16-B)

When the upper tension is too loose, the upper

thread forms loops over the lower thread lying flat

on the fabric (Fig. 16-C).

Fig. 16 B

G

bar

the

SI

V

silk

dov

20)

the

red

Fig. 16-C

B

Page 10

ADJUSTING PRESSURE AND FEEDING OF FABRIC

GENERAL SEWING. Usually for si raight sewing and various embroidery work, the pressure

bar cap or darning release (Fig. 19) is at its lowest position and the feed at its highest level-wilh

the drop feed button marked UP pressed all the way down. (Fig. 18)

SEWING THIN OR LIGHT WEIGHT FABRICS

when lighter pressure is required to sew satisfactorily on thin

silk or flimsy material, the pressure cap should be about halfway

down. Release all the way by pressing the snap lock (A, Fig.

20) and then press cap B down again to half-way spot. Lower

the feed slightly by pressing the DOWN button (Fig. 18) to the

red line. Fig. 18

DARNING AND MENDING

In order to move the fabric freely in any

direction for darning and mending, release

the pressure cap B completely by pressing

down on the snap lock (A, Fig. 20). Press

DOWN button (Fig. 18) all the way down,

which drops the feed well below the needle

Fig. 19

plate. To return feed to normal, press the

UP button all the way down.

rig 20

) 1

Page 11

I >

PREPARING TO SEW

Have Itike-up lever at highest point before starting to sew. Do not try to help the feeding

by pulling the material as this may deflect the needle and cause it to break.

NEVER run machine without material under presser foot.

place material and threads in position under the presser foot and lower the presser foot. You

ate now ready to begin sewing. By having the needle at its highest point, it is not necessary

to touch the hand wheel to start the machine. You merely press the control. The ispeed of the

tnachine is regulated by increasing or decreasing the amount of pressure exerted on the control.

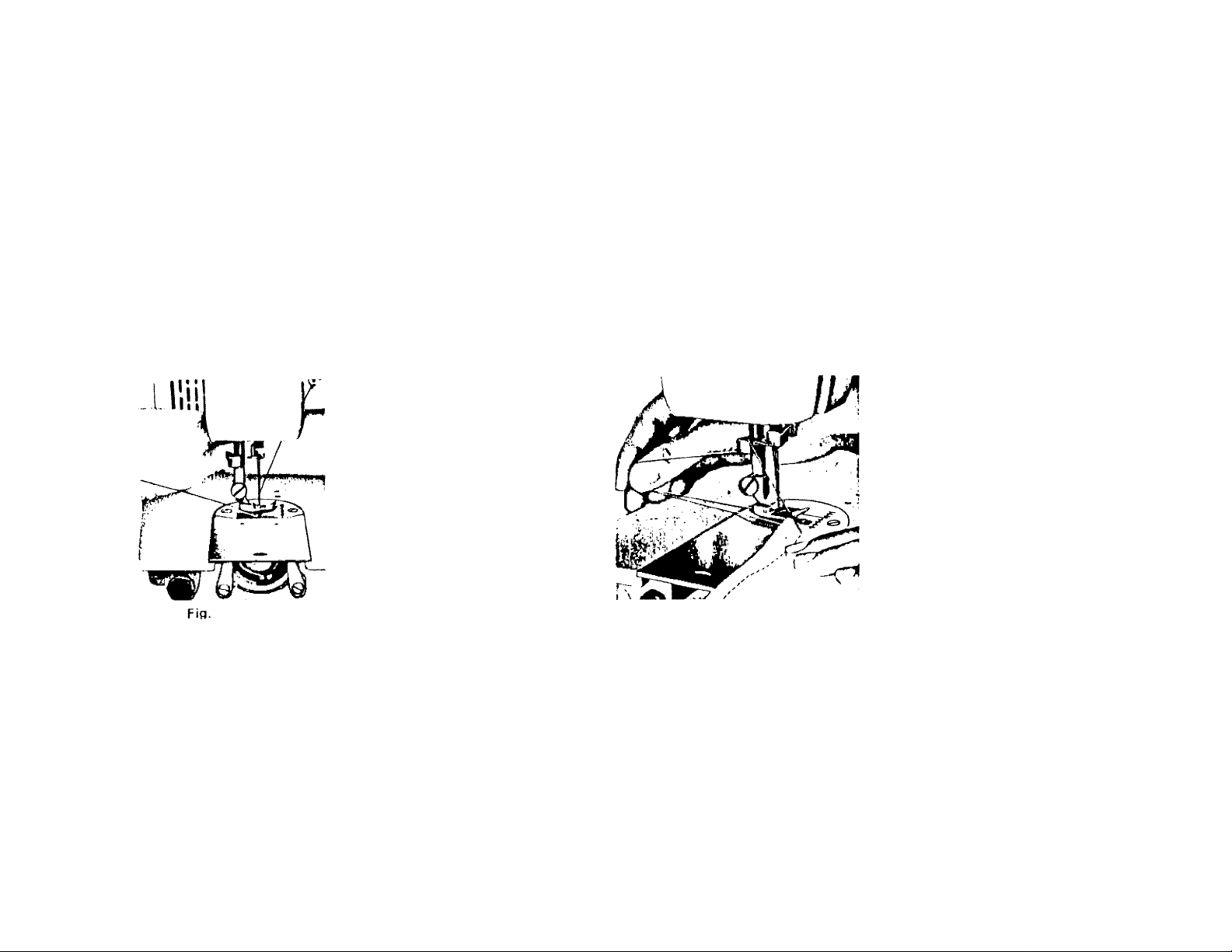

REMOVING THE WORK

Be sure to stop the machine

when the thread take-up lever and

needle bar are at the highest po

sition.

Now raise the presser foot and

draw the fabric back and to the

left (Fig. 21, B) and pass

the threads over the thread cutter.

Pull down slightly, holding thread

in both hands, so as not to bend

the needle.

Leave the ends of thread under

21-A

the presser foot.

Fig. 21-B

Page 12

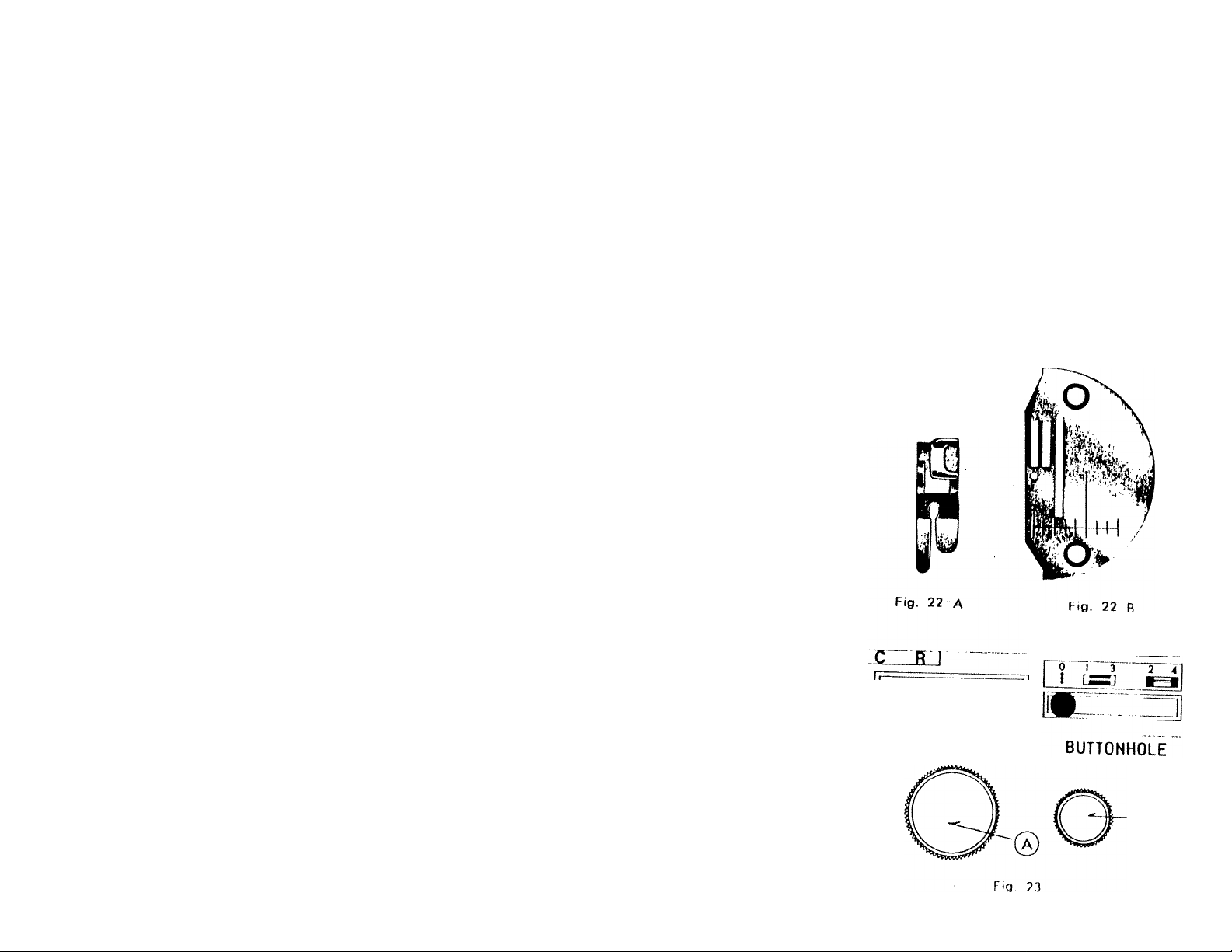

STRAIGHT STITCHING

For straight sewing on fine fabric or very soft material

'he stra,ght stitch needle plate which are included in your

accessory ox. Both have narrow needle slots.

Changing the Presser Foot and Needle Plate-

(1) Presser Foot

(A) Loosen thumb screw (22, Fig. 1) and remove

zigzag presser foot.

(B) Replace with straight stitch presser foot (Fig

22 A)

(2) Needle Plate

(A) Slide cover plate (21. Fig. 1) to the left as far

os possible.

(B) Rernove screws holding needle plate (19, Fig. 1)

io bed plate.

(C) Remove zigzag needle plate.

D) Replace with straight stitch needle plate (Fig

22 B) s a-

Re

kbuttonhole control

or I e needle will break in striking the foot or

13

[jy -2-3;4^

ZIGZAG INDICATOR

^ Turn knob "B" (F,g. 23) to the left os far as it will go

set zigzag width control "A ” at 0 position.

Page 13

M

CREATIVE EMBROIDERY

Th(

le satin stitch (Fig. 24) which is really just a very

short zigzag stitch and the basis for most embroidery, is

obtained by setting stitch length control (see page 9)

as near 0 as possible without stopping the feeding action

and zigzag width at. 5, (Fig. 23).

To stitch continuously at one width of zigzag stitching, set

zigzag width stop (B. Fig. 23) to chosen stitch width number.

With the machine set for a short stitch length, different

designs can be made by turning the zigzag width control

knob bock and forth between 0 and 5 or any other

combination of widths. Try setting the stop (B, Fig. 23)

at I and various other numbers.

Set a rhythm for yourself and then proceed. After

a while you will become quite skillful, varying your designs

by the speed of the machine, stitch length, and manipulation

of the zigzag control knob.

Be sure zigzag presser foot and zigzag needle plate are in glace

'/I

Hi lUWU wm uiM wu uiiit uut uuu uumi uiu

jiilffUntmi (mn jlmwi ßmt mill JmlLlflim.

widilillllllil til fcMMiti tl h>in

mt

Fig. ,24

SAMPLES OF CREATIVE EMBROIDERY

Fig. 25

A. Sew a few stitches at 5 width, then allow knob

to spring back to 0 for a short period. Count, if necessary,

to establish a rhythm.

B. Set stop at 2 then move knob slowly back and forth between numbers 2 and 5.

C. Set stop at 1. Gradually move knob from 1 to 5, allowing it to snap back quickly.

D. Set zigzag stitch width stop at 4, stitch length at il^. Do a few zigzag stitches, drop

feed for 3 or 4 stitches, then raiser it again. By operating the feed knob rhythmically it is not

necessary to count stitches.

Fig. 25

St

Lc

in.

tf

di

P

f<

Oi

m

h.

tf

P

ai

Page 14

E. Drop feed, set stitch width lock at 5, take 3 or 4 stitches, leave needle in fabric left of

stitches. Pivot fabric on needle to make next daisy petal. Continue until flower design is complete.

Lock threads by setting stitch width at 0 and taking 3 or 4 stitches in center of design.

EMBROIDERING WITH A HOOP

It is easy to follow a stamped design or to

work free hand when embroidering or monogram-

h'9- 26). Release the pressure from

the foot by pressing down on the snap lock ring

way.

Stretch the fabric in an embroidery hoop, and

place under the needle after removing the pressef

°°1 I stitch width at the size you prefer

is ^1 rl encounter skip stitches, the fabric is not stretched tight enough or a darning spring

i

darner. Push the drop feed button down all the

and lower the presser bar lifter. Then operate the

me at a rather high speed while moving the

the *^ne^edT^ '^'•h both hands. Work carefully and be sure to keep fingers out of the path of

IcJ

(see attachments available from your dealer illustrated in the back of this book),

darn or monogram without hoop

15

place^r*^! '^°''n or monogram without embroidery hoop, leave zigzag presser foot in

j. ^ l’ ® a pressure on presser foot, set stitch length at 0, set zigzag stitcl» width to suit,

^^eave teed in sewing position,

^ K L ornirig or monograming in this manner, the fabric must be held taut or skipped slitrfies

'"III be encountered

Page 15

DECORATIVE STITCH DESIGN PATTERNS

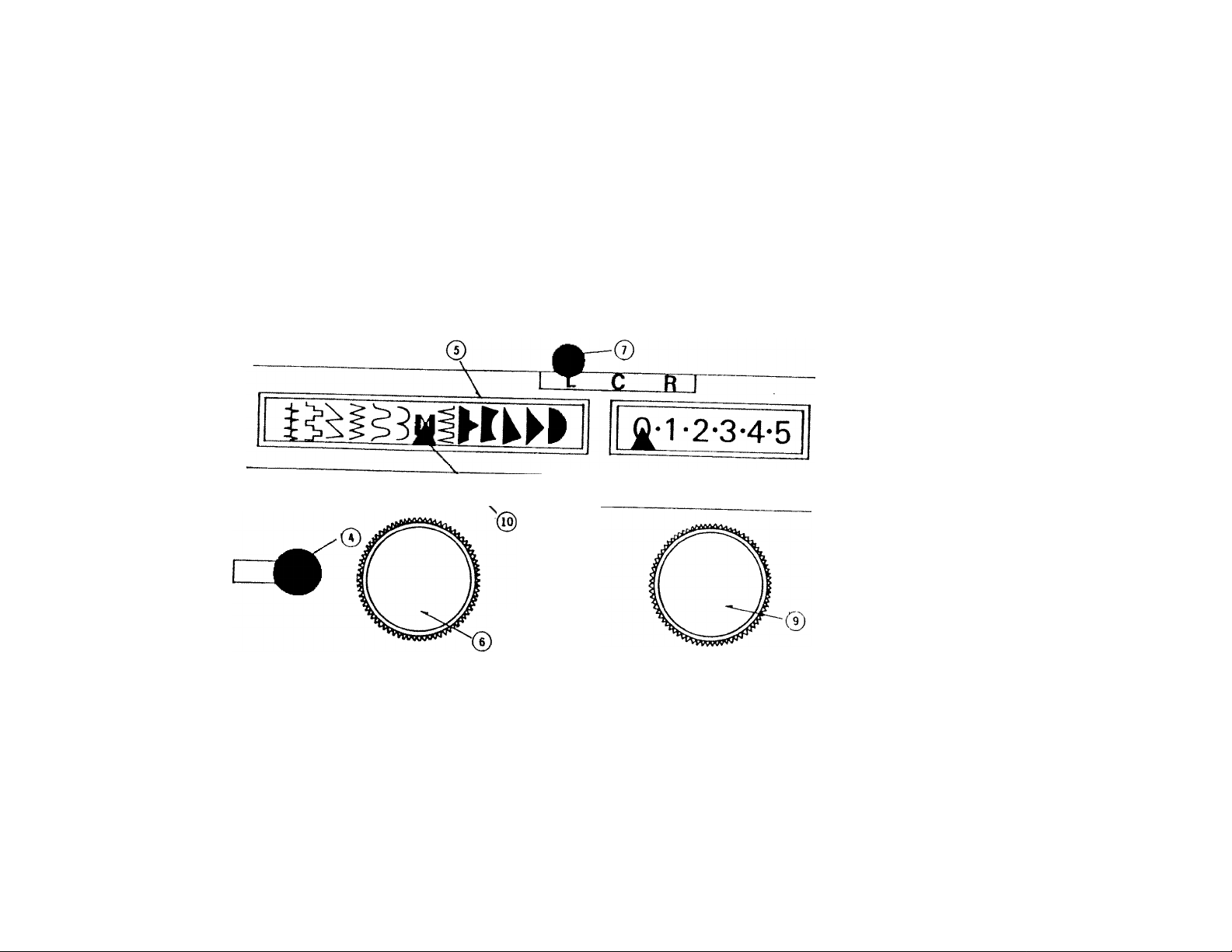

To sow the decorative design patterns illustrated on the Decorative Stitch Dial (5 Fig. 27)' set

the machine as follows;

(1) Move release lever 4 to the right and latch

(2) Select desired pattern by turning knob 6 so that indicator 10 points to pattern selected.

(3) Unlatch lever 4 and move back its left hand position

(4) Set zigzag width control 9 at 0 t

(5) Set buttonhole (ever 11 (Fig. 28) at 0

(6) Set stitch length control 16 (Fig. l) as near 0 as possible without stopping the feeding

action for best appearance.

(7) For changes in selected design move needle positioning lever 7 to its different positions

(L-C-R) ^

ELASTIC DECORATIVE STITCHES ZIGZAG INDICATOR

Fig. 27

Page 16

_ELASTIC-DECORATI\I^TITCHES ZIGZAG INDICATOR BUTTONHOlJ

elastic and multiple zigzag stitch designs

To sdeci desired design as illustrated by 5 (Fig. 28) set machine as follows:

1 Move release lever 4 to the right and latch

(3) Unlatch pattern by turning knob 6 so that indicator 10 points to pattern selected

U Unlatch lever 4 and return to its left hand position

5 t """die position lever 7 in its “L” position for best results

iet buttonhole control 1 1 at 0

17

To '"'"o ’>

control lO iFir"]'! "’"’T T'Ocog width indicator u at 2 and stitch length

as cose to 0 as possible without stopping the feeding action.

Page 17

BLIND STITCH HEM

Use sicindard zigzag foot and needle plate

(1)

Set stitch length control 16 (Fig. 1) at number 3 or 4

(2)

Set machine to sew blind hem (See page 16)

(3)

Set needle position control 7 (Fig. 27) at right hand position

(4)

Set buttonhole control 11 (Fig. 28) at 0 position

(5)

Set zigzag width control 9 (Fig. 27) at 0 position

Blind Hemming.

Blind stitch hems provide a durable hem finish that is almost

invisible and comparable to hand sewing.

Prepare the garment in the same manner as for hand hemming.

STEP

1

Step 1. If hem with folded edge is used make first fold deep.

Step. 2. Turn hem to the depth desired and baste K" from upper edge. Press in place.

Step 3. Fold hem back toward right side of garment leaving extended.

Step 4. Place garment under presser foot and sew blind hem.

STEP

2

STEP

3

STEP

4

COMPLETED

Page 18

f"'

"'i

J

'■

19

ELASTIC OR MULTIPLE ZIGZAG STITCHES

/

<

>

<

>

<

>

<

>

<

>

Fig. 30

<

>

/

Use when applying elastic waist bands

<

<

to skirts and dresses. Be sure to

>

stretch the elastic as it is applied, to

insure fullness required in the garment.

>

<

>

<

>

<

>

<

\

There are hundreds of other uses for these stitch designs which wi

apparent as you use the machine.

The multiple zigzag stitch and the serpentine stitch

are the best for sewing on stretch fabrics.

Use when replacing worn blanket bindings as

they afford both a decorative and durable

finish.

II b

e come

Page 19

20

BUTTONHOLES

To establish the correct length buttonhole required add H

inch to the Cutting space for bar tacks.

To obtain the length of the cutting space, the opening

through which the button passes is measured by adding

the width “a” and thickness “b” of the button (Fig. 32-A).

First mark the beginning and end of the buttonhole on

the fabric with a basting line or tailor’s chalk. Make one

or two buttonholes on scrap fabric (following directions

below) to be sure the machines adjustments

(1) Set zigzag stitch width control at 0.

(2) Replace presser foot with special purpose buttonhole

foot. It provides maximum visibility and allows closely

spaced stitches to feed evenly (Fig. 32).

(3) Set stitch length knob 16 (Fig. 1) as near 0 as possible

without stopping the feeding action.

(4) Set buttonhole control lever 11 (Fig. 33) at 0 and then to

the first buttonhole setting, between numbers 1 and 3.

This will set the width of the buttonhole sides.

(5) Lower needle carefully into the mark on the fabric

indicating the start of the buttonhole.

Lower presser foot and sew. full length of left hand

side of the buttonhole (Fig.32-B, Step 1).

ore

correct.

Fig 32-B

Page 20

(6) Move buttonhole control os for to the right os possible. It will then latch into

position for bar tacking. Sew four or five stitches. Step 2.

( ) Push buttonhole control down slightly and manually move to position between

Numbers I and 3, being sure it is against the Slop.

will set the machine to sew in reverse. Sew right hand side of buttonhole.

(8) Move buttonhole control as far to the right as possible, it will then latch into

position for bar lack. Sew four or five stitches. Step 4.

ul onhole control at 0 position, extreme left, and lake two or three stitches to

fasten bar lack to prevent ravelling.

(10) Cut the buttonhole opening with seam ripper, being careful not to cut the stitching.

If you plan to make buttonholes on

sheer or soft material, place tarlatan or

paper under fabric which can be lorn

away after stitching.

When making additional buttonholes,

I

i

4i|yTT0NH0LE

be sure to turn the buttonhole control

knob to 0 and back to the number I

position to pul the machine in lotwcitrl

stitching.

21

Page 21

SEWING ON BUTTONS

t>l Remove p„„er loo, „„d „p|„c. wi,h b„,lo„ ,ew,„g ,oo,

\riQ. j4)

(2) Push drop feed button “DOWN" oil the way (Fig.38)

OJ Set zigzag width control 6 (Fig. 1) at Q

¡4) Se, needle position control 7 (Fig. 1) ot L position

(s; Set machine at M position (See Page 16)

(6) Place ballon >o ihe bole on ihe lef, bond ide d direcly „„der

Ibe needle (F.g^ 35). iben gonily lower ibe prerser fool (Fig 36)

ver Ibe „gblhond bole ,n ihe buMon. Tarn bond wheel slowly

t)y nancl to o© Sure iHe needle entor« k t • i •

ir. . .. ^ neeaie enters both holes tn button without

deflecting needle, correct width if necessary

"-die goes in|^o the center of each hole, run the machine

ot medium speed making six or eight stitches, stopping with the

needle m the left hole.

(9) To lock the zigzag stitch and prevent ravelling, set the stitch

width at 0, and take a few stitches in the same hole If you

wish you may place a rounded toothpick over the button, between

the two holes, and sew button to fabric in reguhr way

Remove the toothpick and wind thread under the button, forming

a shank to fasten. ^

ApjTly the above method to sew on buttons with four holes hooks

and snaps, etc. If a four hole button is to be sewn, follow the

same procedure above for the two hole button

Now bl, pre„.r foo, digbdy and move Fabric ,o perm,, .,i,cbl„g

fR (f'9. 1) am,I needle co„,e, down'ejclly

labnc W.lh Ibe same pracedere os for sewing two bole buPlons.

Fig . 3 8

Page 22

5»

16

(i3)

23

11)

ti

0

.

,

t n

j ,3-]

> «

f'

2. Package of Needles (5)

3. Large Screw Driver

4. Small Screw Driver

5. Bobbins (3)

6. Felt Washers (2) (for spool pins)

7. Quilter Guide

8. Cloth Guide

9. Button Sewing Foot Fig. 29 '

10. Prong Type Buttonhole Foot

11. Presser Foot for Straight Sewing

12. Narrow Hemmer

13. Thumb Screw

14. Needle Plate for Straight Sewing

ACCESSORIES (Fig 39)

1. plastic Oiler (Sealed and Filled)

(graduated)

m

Fig. 39

Page 23

24

HOW TO USE ACCESSORIES

Narrow Hemmer: W,.h needle ai its highest position replace regular pres-

ser foot with narrow hemmer (Fig. 40) being sure to tighten it securely m

place. Set needle position lever at “L” position, pattern selector lever at

M position and zigzag stitch width control at 0 for straight stitched hem

or at number 3 for zigzag stitched hem. Set stitch length control to suit'

For a plain narrow hem make a inch double fold

for about two inches along edge of fabric. Hold each

end of the two inch fold, slip underneath hemmer. Bring

fold up into the scroll of hemmer. draw fabric forward to

end and fasten with point of needle. lower presser bar

lifter. Gently pull end of thread as you start stitching

(Fig. 41 for straight stitched hem and Fig. 42 for zigzag

stitched hem).

Guide material slightly to left and it will take a double

turn through scroll.

The narrow hem provides an excellent finish for edges

of ruffles or any other dainty work.

Page 24

25

LACE TRIMMED HEM

lace In ihe sloTne^ ft'^eeTle (F.'q”'«!F ‘''"'''''a. inserì

roi ‘7ictrcr„tre-

Ho^rTbf invisible stitching

laierl bo°"i„',c"'S ""i "I»' ’■iol" l»nd side of fabric

aoll o.er o„; siw”!, then^r”.- I" ■*'«

,s pressed on the wrong side. ^''»ching ,s completed the

french seam

P'^ce^of'^r^a^I'.tnf in^iVoi each other and the top

making

French

enoogh to catch Both edges^^IL^lTr^w-r^.^fieV _

1

;

Fig. 46

allowing hem to^°oil over In-

seam.

For cord nn ! f . '°P

™ with satin stitch. This can be

used for covering chairs and so

(Fig 45)

HEMMING ACROSS

A SEAM

To hem across a seam, cut

I e seam folds at an angle so

they w, I lead into the hemmer Fig 45

gradually. Press seam open 5,;,r-h .l

extreme edge to hold it together^and seam

may be necessary ,o pull the materfol °Lhd ”" 'T'

over the seam. (Fig. 46) oienoi slightly wtien he

nf tlie

".s It

nun mg

Page 25

■/'6

QUILTING GUIDE

Use this guide for making parallel rows of straight

or decorative siilchmg. Attach standard presser foot

blip U shaped holder on guide under presser fool

thumb screw from the back and tighten screw (Fig 47)

Ad|usl the curved bar for the distance desired be

tween rows of stitches and set so it presses slightly

on the fabric. By letting the guide ride on the pre

vious stitching line, successive rows will’ be at equal

distance apart. (Fig. 50).

Fig, 48

Fig. 49

SEAM GAUGE OR CLOTH GUIDE

Use the seam gauge as a guide for straight seams

and even rows of top stitching along edge of fobnc

frig. 51;

Fasten Gauge (Fig 48) with accompanying screw i

(Fig. 49) in threaded hole in bed of machine Adjust !

Fig . 5 1

to desired width. |

(Tfr-

Fig. 47

J

Fig. 50

Page 26

a

Fig. 52

CARE AND MAINTENANCE OF

YOUR MACHINE

HOW TO OIL YOUR MACHINE

Use only a good sewing machine.oil. do not use any com-

*^on household oils.

Your machine should be oiled occasionally to keep if op

erating smoothly-how often depends on the amount of sew-

'^9 you do.

Once a year oil your machine thoroughly as indicated by

'he arrows on Figs. 52, 53 and 54.

Avoid over oiling.

27

Fig. 54

Page 27

V8

CLEANING AND OILING THE SHUTTLE

(See Fig. 55 and 56)

Ihe stitch forming mechanism occasionally becomes

clogged with loose threads and lint. This will interfere with

the efficient operation of the machine. Cleaning and

removal of the lint will safeguard the performance.

To remove the shuttle assembly, proceed as follows;

1. Turn the balance wheel until the needle reaches jU

highest position. Tilt head back on its hinges.

2. Remove bobbin case.

3. Turn the two shuttle race cover clamps (B) outward

and remove the shuttle race cover (C) and the shuttle

body (D).

4. Clean the shuttle race, the shuttle, and shuttle race

cover by removing all threads, lint, etc.

When the cleaning has been completed, proceed as

follows to replace the shuttle assembly:

1. Turn the balance wheel until the needle reaches its

highest position.

2. Place shullle body, (D), in roce ogain,! shullle driver and odjusl inlo poiilion

4. Put bobbin into bobbin case.

5. Put the bobbin cose into the shuttle, fitting tongue into notch E of race cover.

position

secure ly

Page 28

ADJUSTING AND CHANGING “V” BELT

0

29

fl

-rnift

iniiii

.4

Fig. 57

Following are the instructions for adjusting and changing the "V” belt;

) Remove three screws holding rear cover (Fig. 59) and fip it out at the bottom Then

pivoting around the hand wheel away from the front of the machine.

2) To adjust V belt, loosen screws (A, Fig. 58) and move bracket B up to loosen bell and

down to tighten,

^3) To remove "V" bell:

(A) Remove lop cover,

(B) loosen screws A" (Fig. 58) and move bracket “b” to its highest position.

(C) Slip bell off motor pulley and then over hand wheel.

(D) Replace V bell by slipping it over hand wheel and then over motor pulley

(E) Adjust as noted under No. 3.

Fig. 58

Fig. 59

Page 29

Page 30

31

Trouble

Sk ipping

Stitches

Irregular

Stitches

Uneven

Stitches

Probable Cause

Bent needle

Needle placed

incorrectly in clamp

Too fine a needle

for thread being used

Upper thread tension

too loose

Improper threading

Bobbin not wound

evenly

Pulling or holding

material

Not enough tension

on upper thread

Poor quality thread

Needle too fine for

thread being used

Correction

Discard and replace.

See instruction page No. 6.

See needle and thread chart, page No. 4.

Tighten upper tension.

See threading instruction, page No. 8.

Rewind bobbin.

Avoid pulling or holding material, just guide it.

Increase tension.

Try different thread.

See needle and thread chart, page No. 4,

Page 31

T rouble

Upper Thread

Break ing

Probable Cause

Improperly threaded Refer to threading instructions, see page No 8

and re thread machine.

Correction

Material

Puckering

Too much tension

Starting with take-up

in incorrect position

Improper setting of

needle

Bent or eye of needle

too sharp

Bent or blunt needle

Tensions too fight

Dull needle

Stitch length too long

Loosen tension on upper thread by turning

t read tension knob to lower number.

Always start sewing with lake-up lever in

highest position.

Refer to needle setting instruction, see page No. 6.

Try a new needle.

Discard all blunt or bent needles and replace

with new.

See tension adjustment, page No, 10,

Change needle.

Reduce stitch length.

Page 32

Your sewing machine comes equipped with the basic set of accessories describ

ed earlier in this book.

The following pages illustrate additional time saving attachments that have

been designed specifically for your machine. They are available at modest

cost from your dealer. |f your dealer cannot supply you with these items,

ask him to order them for you by part number. Then you s»/il| be assured

of receiving the genuine part designed for best performance with your

machine.

If a sewing machine dealer is not available mail your inquiry directly to:

WHITE SEWING MACHINE COMPANY

11750 BEREA ROAD

Cleveland, Ohio 44111

In Canoda:

33

WHITE CONSOLIDATED INDUSTRIES, LTD.

1470 BIRCHMOUNT ROAD

SCARBOROUGH. ONTARIO. CANADA

Page 33

34

SOME OF THE ATTACHMENTS AVAILABLE FOR YOUR MACHINE

/L

FART it 1403

Ruffler

^ i

PART #82528

Allochment Foot

PART #76553

PART #76552

PART #4990

Darning Spring

PART #74159

Binder

PART #76551

PART tt 1873

Cording & Zipper Fool

V

part # 76554

Edgeslitcher

t:

PART # 76550

Page 34

D

tr)

Fig. 60

EDGESTITCHER

The edgeslilcher is used in making

dainty laqe insertions, edgings and

piping.

The slots in the edgestitcher serve

as guides in sewing together various

pieces of material. If you want to

sew lace, lace and embroidery, or

lace and tucked strips together, place

ihe piece of material that will be on

•op in slot 1 (Fig. 61) and the lower

fabric in slot 4. For instance, if you

ore sewing lace edging to a finished

edge of fabric, place the fabric in

slot I and the lace in slot 4 (Fig

62).

ATTACHMENTS

Be sure the needle positioning lever is in the

extreme left hand position.

ATTACHMENT FOOT

In order to attach binder, edgestitcher and the hem-

iners, it is necessary to remove the presser foot and re

place it with the attachment foot, (Fig. 60)

Mount binder, edgestitcher or hemmers by sliding

the attachment to the left as possible and tiqhteninq

the screw.

The mounting slot enables you to sew as close to

or as far away from the edge as desired. Just move

the attachment to the correct position before tightening

the mounting screw.

' ly I. ■

Fig . 6 1

I I't (" )?

35

Page 35

36

,о dre. 1=Ç= and ".cenai unde, '¿e needle^ond Ьск ^oMhe^^ed.ennch.

h aie anu uu^is v.. .■—

_______

,b. tend „Гса“;':ГьаХа“СаГ,о„-.,-сЬ^ Нан Г'ьЬ^ Тн.“!»(ГЬа’пТ and ,Ье lace ,n

L !.gld, b=,ng sere Ihe ial.nc lí',he »me manne,. g , ,,

Rick-rock can be sev/n lo the edge of ^ ^ p,p,„g ,o ,he Mi

J:J"x 1:;''Гп*оГ'’;те,^pie» lebt in do. 2 and ,Ье folded edge ol ibe p.pn.g » ,be

and"S Ь,'»^е°,о''пГап'ЬаГТо u.e .he edgeClchec. Tbe,e are

hundreds of other uses.

Fig. 64

Fig. 63

Page 36

BINDER

Ih,s attachment sending widdTs ol^comm

^'°;he°;prmo:lh'of b,!: '¡ccC. . used for unfolded bios strips

FOLDED BINDING (Fig 69)

Cut a point on folded binding, insert in appropriate

by sliding binder to right or left.

TWO-TONE BINDING (Fig. 7o)

Two bindings can be sewn on fobric «¿9« °T-

operotion When two are used, always skip

tween widths, inserting each in correct size slot.

HAND-CUT BIAS BINDING (Fig. 69)

Cut %, mch bios binding fold in hol^F for - -of e

of inches Cut binding diogonolly toward end, almost to

flld Slip foW into center of binder. Draw bock unf

cut opens and binding encircles open end o J

stitching to be sure it ts on the edge, ad,ust if necessa y.

See Figs. 67

and 68 for sug

gestions on

how to use the

binder. There

are hundreds

of other uses.

37

material in one operation,

erciolly folded bias binding.

;ut I^ÍB inch wide.

- y

Fig. 70

Fig. 68

Page 37

J8

THE SET OF HEMMERS

Before attacfiing any of the hemmers, be sure bob

bin thread is pulled up. Then, with hemmer in place,

hold top thread loosely and turn handwheel one full

turn toward you, making a loop under hemmer. Grasp

bobbin thread with both hands and slip horizontal

ly under hemmer toward back. Bobbin thread will

catch loop and carry upper thread to back of hem

mer.

Fold material to suit for two inches along edge,

hold at each end of fold. Slip fold into guide and

up over spoon (Fig. 71 ). Fold hem in material back of hemmer.

and fasten with point of needle. Pull on threads gently as you start stitchi

HEMMER SET

You can make a hem 3-4, %, or in width, depending upon which

hemmer you use. For a few of the many uses see Figs. 72, 73, 74 75 76

and 77

Fig. 71

Draw forward to end of hem

ing.

Page 38

HEMMER SET

39

Fig. 72

F icj. 74

Fig. 73

'<■

( if) 77

Page 39

40

THE ADJUSTABLE CORDING

AND ZIPPER FOOT

This attachment is used to make and

insert covered cording, and to sew in

zippers. Loosen thumb screw to slide

foot to either right or left of needle.

CORDING. Fold bias strip of fabric

over cord. Loosen thumb screw and

set foot so needle is centered in needle

hole. Machine baste cord in place

(Fig. 78 ' 80).

To sew covered cord to material, reset adjustable

foot so needle stitches closer to cord, and on edge

of base fabric.

SEWING IN ZIPPER

Fig . 8 0

Loosen thumb screw and slide foot so needle enters

center of needle hole. Guide metal of zipper along

edge of foot (Fig. 80). Stitching should be close to

zipper to allow easy opening and closing. Adjust to

sew from either right or left side, whichever is more

convenient.

Page 40

ADJUSTABLE CORDING AND ZIPPER FOOT

4)

Fig. 81

f ig fn

Page 41

A 7

RÜFFLER

It

W f

pp

' ''

4

Fig. 84 Pig

Fig. 86

The ruffler will produce yards of delicate ruffling or precision pleafina

a dress etc. ^ P'eating a skirl, adding fullness lo the bod.ce of

Page 42

RÜFFLER

43

Fig. 87

Fig. 88

Page 43

44

SEWING TIPS

When a dainty hair line finish is particularly desirable for the inside seams of sheer collars,

facings, and yokes, seam allowance that would ordinarily show through is eliminated by following

the seam outline with a narrow zigzag stitch.

Trim seam allowance close to line of stitching. Turn and press.

EVENLY SPACED BUTTONHOLES

To make a row of buttonholes evenly spaced and accurately stitched, draw the outlines for

the buttonholes on one long strip of tissue paper. Pin this pattern to position on the garment

with fabric strips under each marking. Stitch around the outlines then tear paper away

Page 44

Fig. 94

SHAPING DARTS IN INTERFACINGS

3

K

Center

Cut interfacing down center between dart lines. Over

lap cut edges, matching dart lines. Zigzag stitch along

marking line from point to wide end of dart. Trim both

45

Fig. 95

Page 45

46

OVERCASTING WORN EDGES

Ziy/ay stilch along the worn edges, catching the fabric as

the needle swings to the left, and allowing the needle to just

pass over the edge of the fabric on the right (Fig. 98)

PATCHING

Machine baste patch into

place under hole or worn area

which has been cut away.

Then zigzag stitch the patch

into place by overcasting

around edge of hole (Fig. 99).

j#..

Fig, 99

STRAIGHT OR THREE CORNERED TEAR

Fig, 98

Zigzag stitch along a straight tear catching fabric on left and

right side of tear by swing of needle. Be sure your tensions

are not too tight or puckering will be encountered.

In mending a three cornered tear, start zigzag stitch from

each end and work to center (Fig. 100).

Page 46

PLAIN BOUND BUTTONHOLE

Cut sirnigfil or bias sirips of fabric 2" wide

rmrl 1" longer ihnn the desired bullonholes.

I’lace rigfil sides logelfier over positions for

bu I lon(\ole s. Mark exact length of

tonhole in center of each strip place a pin

ifirough center of the marking. Begin to

stitch at the pin; marking an oblong box

above and below the line ’

Run a few stitches beyond starting point to

reinforce. View t.

Slasfi through the center line of the box to

within ' 1 ' of each end then diagonally into

each corner, View 2. Turn the strip through

the opening, press seoms flat across the ends

so the facing will not be visible from the right

side. Fold the strip to meet in the center of

the opening Baste the folds together across

the opening. View 3.

Turri grjfment bock at eoch end and stitch

ocross the strip, securing the triangular slashed

section to the plealorj strip and press, View 4.

Bring facing of garment to position and baste

around each buttonhole. Insert the point of a pin

through each corner and slash through the

center and into each corner pin. Turn under

the rav/ edges and slip stitch the facing to the

underside of the buttonhole. View 5. Press

the finished buttonfiole, Viev/ 6.

,i

' across

each

but

each end.

47

Page 47

4H

FOR PORTABLE INSTALLATION

Pleciso recid ihese important instructions which

were written to oid you in placing your new

sewing machine on its portable bose.

First, remove the nail which holds the foot

control msicJo the base to avoid damage in ship

ping. If a small plastic clump is fastened

to the back and not to the top of the partition

at one end of the base, remove it, too.

After unpacking the sewing machine unit,

being certain to take out the instruction book,

guarantee and accessory box, lay the unit face

down on a table. You will see two clamping

screws A entering head hinge holes B on the

underside of the back.

On the base you will find two head hinges

C which will fit into holes B. Lower the base

onto the sewing machine fitting hinges C into

holes B. Tighten screws A securely with a

screw driver.

With machine in sewing position attach plas

tic clamp D to top of partition with screw pr

ovided so that it may be turned across the bed

of the machine, to hold it down. (On some

bases the clamp may be positioned in the pro

per spot).

To make the electrical connection draw the

two wires through the slot in the partition of

the base. plug the cord labeled "Motor” into

the receptacle marked "Motor" on the block

attached to the outer section of the base. Then

insert the other cord into the "Light" receptacle.

Place the foot control on the floor, insert

plug into a wall outlet (110-115 volts) and you

are ready to sew. But first read the instruction

book to become familiar with the threading of

the machine, tension adjustments and all the

other features designed to make sewing a ple

asure.

Page 48

49

Loading...

Loading...