SINGER W612 User Manual

MOOiL 612

You are now the owner or a new ^ ^

of its kind you can possess. «titching overcasting and creative embroidery

Buttonholes, monogrammmg, stretch stitcm g

are done with ease and speed. WHITE this book

3ld you . care.uU, as a

LrlugrundTrstanLg of you, machino »ill rewa.d you vdth many hours of trouble

"^Tlr^'etllngirtachments such as rufflers, binders,

others to complement the accessories furnished with your WHITE are available fro

the store where you purchased your machine.

nf a new zigzag sewing machine .the most versatile type

WHITE SEWING MACHINE COMPANY

Cleveland, Ohio 441 I I

WHITE CONSOLIDATED INDUSTRIES, LTD.

Toronto, Ontario, Canada

Pages

Accessories-

How to Use

Hemmers

...............................

............................

...........................

Seam Gauge or Cbth Guide

Quilting Guide

Attachments

Adiustable Cord and Zipper Foot 40

' -jjt

Attachment Foot.........................

Binder

............

Edgestitcher

......................

..........................................

....................................

...................

.........................

........

Hemmers.......................................

.

.............................

Blind Stitching

.............................................

Bobbin ^

Pbcing in Shuttle ................................... '

Threading.............................................. ^

Winding...............................................

Buttonholes..................................

Buttons Sew-On

Charts . . I ■ A

N eed le-T h read-Fab ric-S t itc h ing •• •

................................

INDEX

23

25

26

.

18

Pages

Stitch Length

Trouble

Darning and Mending

Elastic or Multiple Zigzag

........................................

......................................30-31-32

.................................

Stitches

...........

Embroidery

Creative

Hoop

Features and Parts (Front View)

..................................................

..............

^

~ ~ (Back View)

...........

............

Instalbtion-Head in Cabinet....................50

Head in Portable Case

..........

Maintenance and Care.................................27

Cleaning and Oiling the Shuttle •••28

Needle Setting ................................ ^

Pressure and Feeding of Fabric 11

Thin and Light weight Fabrics

Reverse Sewing

Sewing Preparation

_ . ,»•••••••••••••

Sewing Tips

Straight Stitching-

.

.......................

.....................................

.........

..................

........

............

.................

•••••••••

^3

Tension Adjustment-.................................... °

Thread ing-Upper-

.....................

®

^

H

19

..

2

3

48

11

9

^

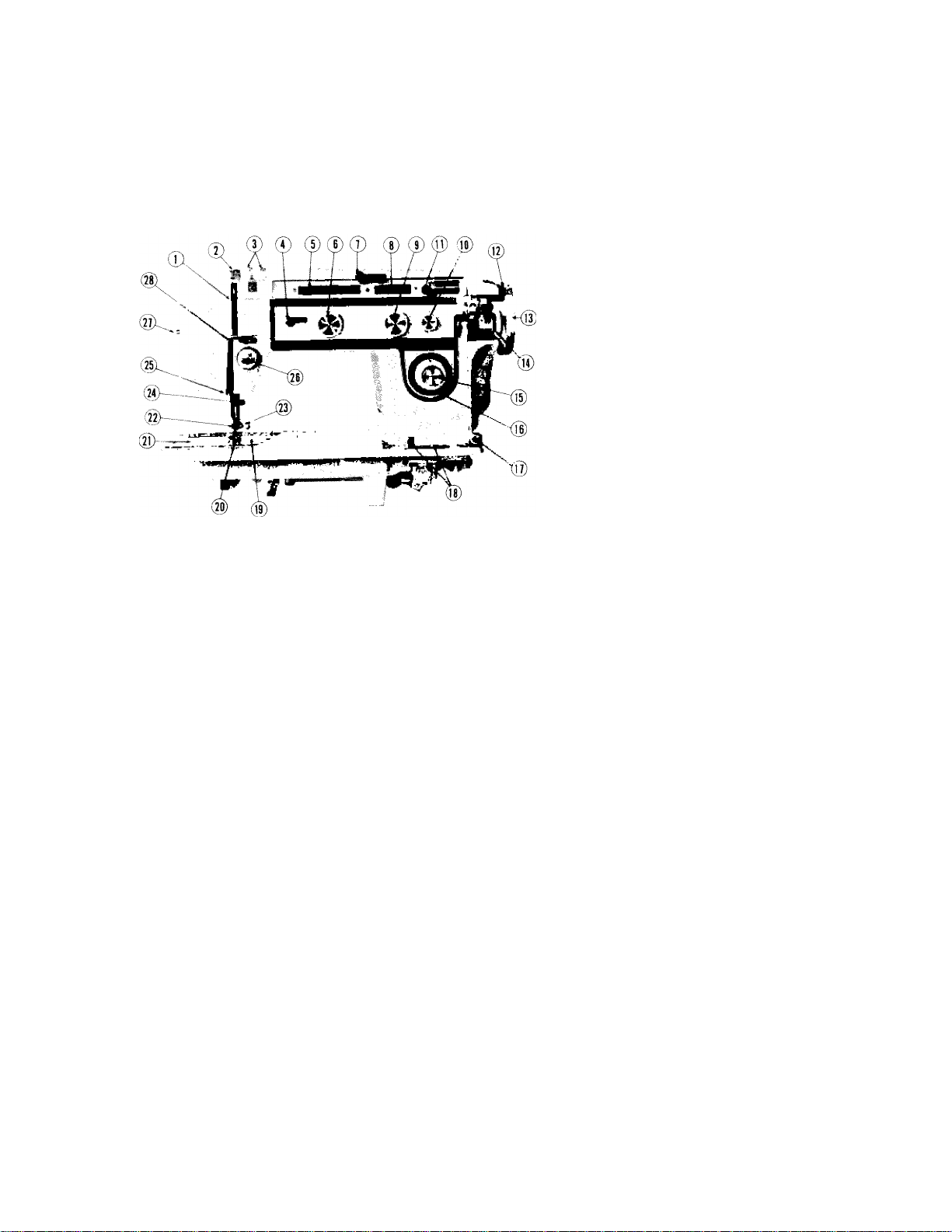

FEATURES AND PARTS

(Front View)

Fig. 1

1. Take up

2. Pressure release (darning)

3. Arm thread guides

4. Release for changing decorative

stitch designs

5. Decorative stitch dial -

6. Decorative stitch selector contro

7. Needle position lever

8. Zigzag width dial

9. Zigzag width control

10. Zigzag stitch width lock

11. Buttonhole control

12. Hand wheel

13. Clutch nut

14. Bobbin winder

15. Reverse button

16. Stitch length control

17. Bobbin winder tension

18. Drop feed buttons

19. Needle plate

20. Presser foot

21. Cover plate

22. Presser foot cbmp screw

23. Needle clamp screw

24. Needle clamp thread guide

25. Thread guide

26. Tension

27. Light switch

28. Thread bar and face latch

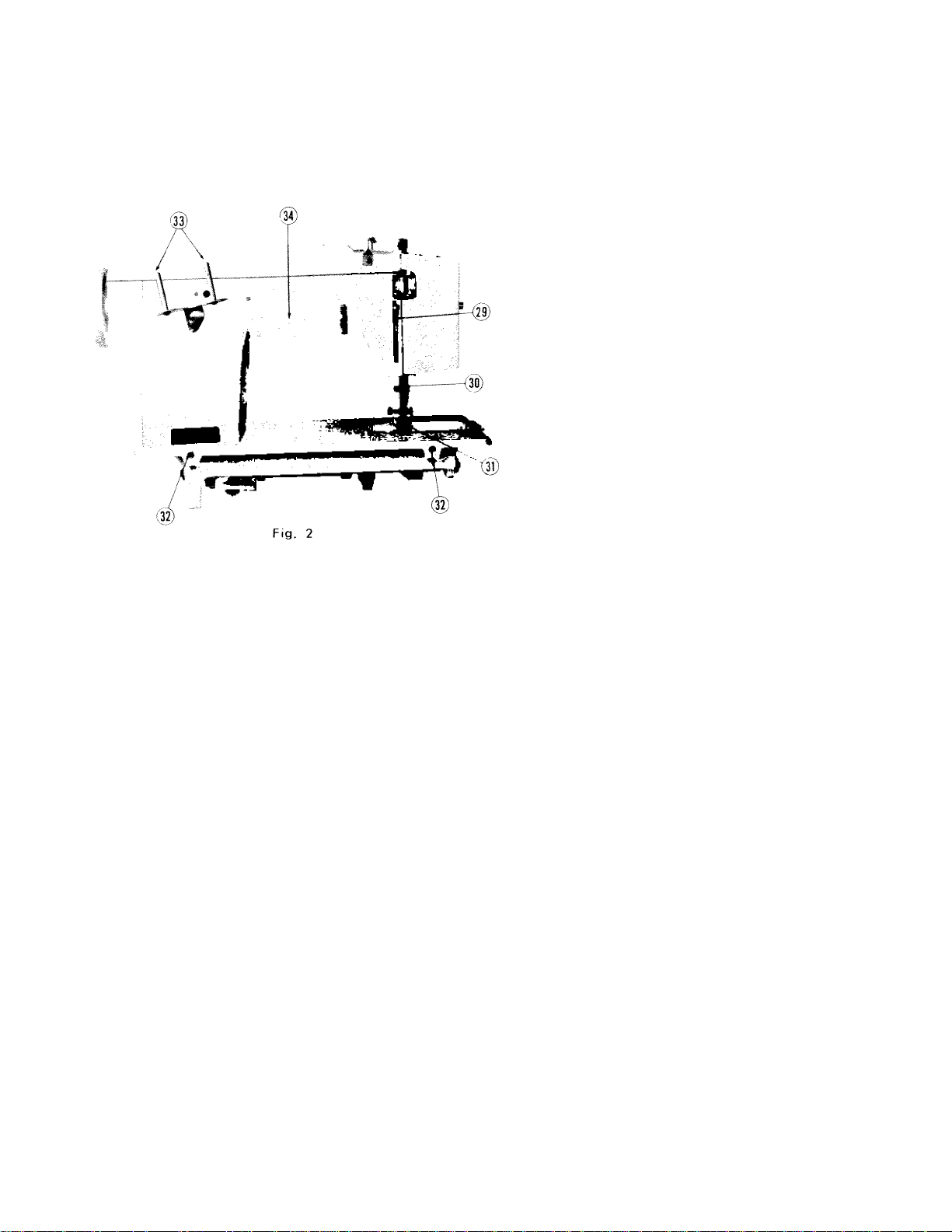

FEATURES AND PARTS

(Back View)

29. Presser Bar Lifter

30. Thread Cutter

31. Feed

32. Head Hinge Mounting Holes

33. Spool Pins

34. Handle

needle-thread-fabric-stitching guide

Extremely heavy

tarpaulin, sacking,

canvas, duck, etc.

Heavy upholstery

fabric, ticking,

denim, leatherette

Medium heavy drapery

fabric, velveteen,

suiting, felt, terry, etc.

Medium broadcbth,

percale, gingham, linen,

chintz, taffeta, sheer

wool, shantung,

sheer voile, lawn,

dimity, crepe,

handkerchief linen,

plastic film, etc.

Very sheer chiffon,

batiste, bee, organdy, 00

ninon, net, mgrquisett, etc.

Needle

No.

3 (18)

2 (16)

1 (14)

0 (11)

Machine

Stitches

Per Inch

6

to

8

8

to

10

10

to

12

12

to

14

14

to

16

(Pbstic film)

8 to 10

16

to

20

Cotton

Thread

10

to

30

30

to

40

40

to

60

60

to

80

80

to

100

100

to

150

Silk

Mercerized or

Thread Nylon

Heavy Duty

Heavy Duty

Heavy Duty

50

50

50

Fig. 3

Di>.ng=,s t,ond whe.l (5, F«. 3), fro^ -h. -.i.ching n^.chonl.g. by H,.n,n, clg,ch (6, Fs.3)

,gy,„^ yog or coontT olockw..». gppor ,h,.od

Place a spool of thread on one of the P' . . machine. Run end of thread

guide on arm and down through tension disc (9, F«. 5,)^^ ^ edge (left fbnge

Fig. 5 clutch away from you until sewing

WINDING THE BOBBIN

and from inside out) and pbce bobbin B-on

spindle of bobbin winder (7 Fig. 4.) fiHi^

the notch bobbin over small pm on spindle.

Push bobbin winder against hand wheel.

Hob thread end bosely and start machine

Bobbin will stop winding when it is filled.

mechanism is again engaged so that needle

moves when you turn the hand wheel.

Break off loose thread end used to start

the winding and thread bobbin as stated on

Page 6.

Fig. ^

SETTING THE NEEDLE

See Fig. 6. Raise the needle bar A to its highest

point, turning wheel toward you by hand.

Then loosen the needle clamp screw B and the

needle can be inserted into clamp C. Pbce needle

(flat side to right) in the needle cbmp

upward as for as it will go into the needle clomp

hole, tightening the needle clamp screw securely w.th

a screw driver.

After changing the needle make one com^

píete revolution of the balance wheel by hand

to be sure the needle is m the corree

position.

Fig. 6

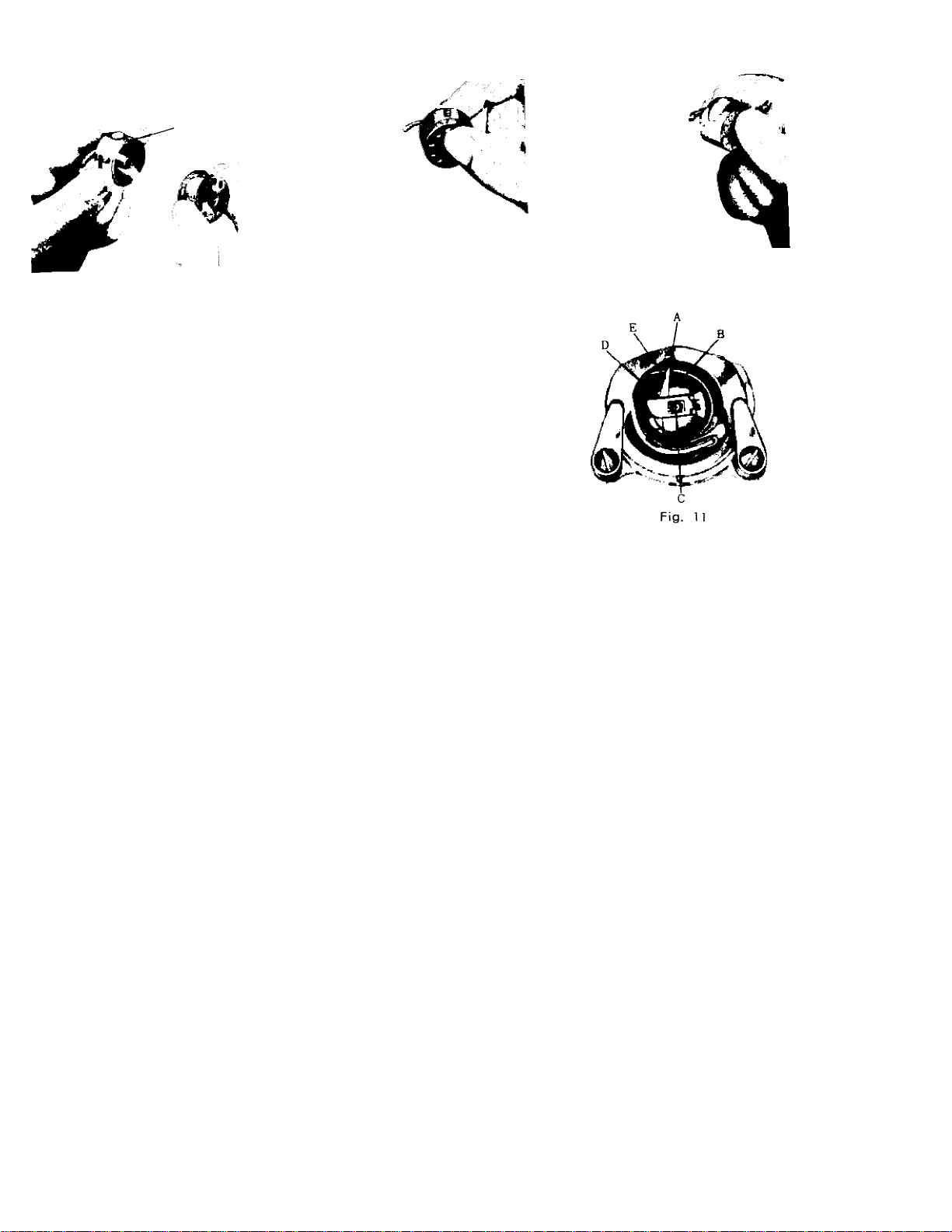

THREADING THE BOBBIN CASE

. C- Hob bobbin case between thumb and forefinger of left he

S,.p ' J bobbin 00» is on ,op. Tok. ih. bobbin between thomb ,

LX:-;':;: "Г,:: ::Г .. ьоьь. оо.

Flat sur

of needl

shank

/

Fig.

as shown in Fig. Ю-

Se"r,ensTon "spring end into the fork-.hoped opening of the spi

SLOT

Fig. 8

Fig. 9

PLACING BOBBIN CASE IN SHUTTLE

Raise needle bar to h'^hest position and slide

L 1 f. 19 Fia. 1) Hold the bobbin cose latch, (D,

F°g '»'botieen the themb aed forefinger of the '

LTth o legs, three inehe. of thread rennlng f^m .he top <^f

the bobbin cor. to the r«ht. ,nse. ond center he obbn

c„„ on the stud of the shuttle Wy K>-

bobbin cos. finger. (E). is opposite the shuttle toce "°tob A)^

Press the bobbin cos. (B) into the shuttle os tor os poss,

e l 1 rntches on the center post of the shuttle. THEN

until latch ca i . l Press bobbin case again

release the bobbin case btch, (D). Press bobbin y

nfter latch hos been rel.osed to ntok, sure the bobb.n cose

is locked securely in pk.ce. Close the cover plate.

Fig. TO

UPPER THREADING

, T^rn .he hand wheel .owand you la rois. .he

’ . Uo ,in lever to its highesf position,

fake-up lever to

2. place a spool of upper arm thread

3. Lead the thread through the upper

u yt throuah the thread guide bar to

t" tt^ion^'c: the^n around and between them

from right to left. , ^^eck spring

= ■ “TwllT o :S. .U, 10.0 .he hook, (see In.er.,

the eye P through the face

rbltS’estTthei through the needle bar

S. Thtd redt%|t RIGHT, drawing^

it through about ^ j turn the hand

of the upper thread l^sely an

v.heel towanl you until the needle^g

way down and comes uoper thread which

then can be pu , oresser foot

thread ends ? ® ¿^k of the machine, leav-

and d-- toward the bock of t ^^^

ing both threads three or rour

t‘°oLu:d ::rvXhT Piece bo.h

nm \

lUlllS

Fig. 12

Fig. 14

Fig. 13

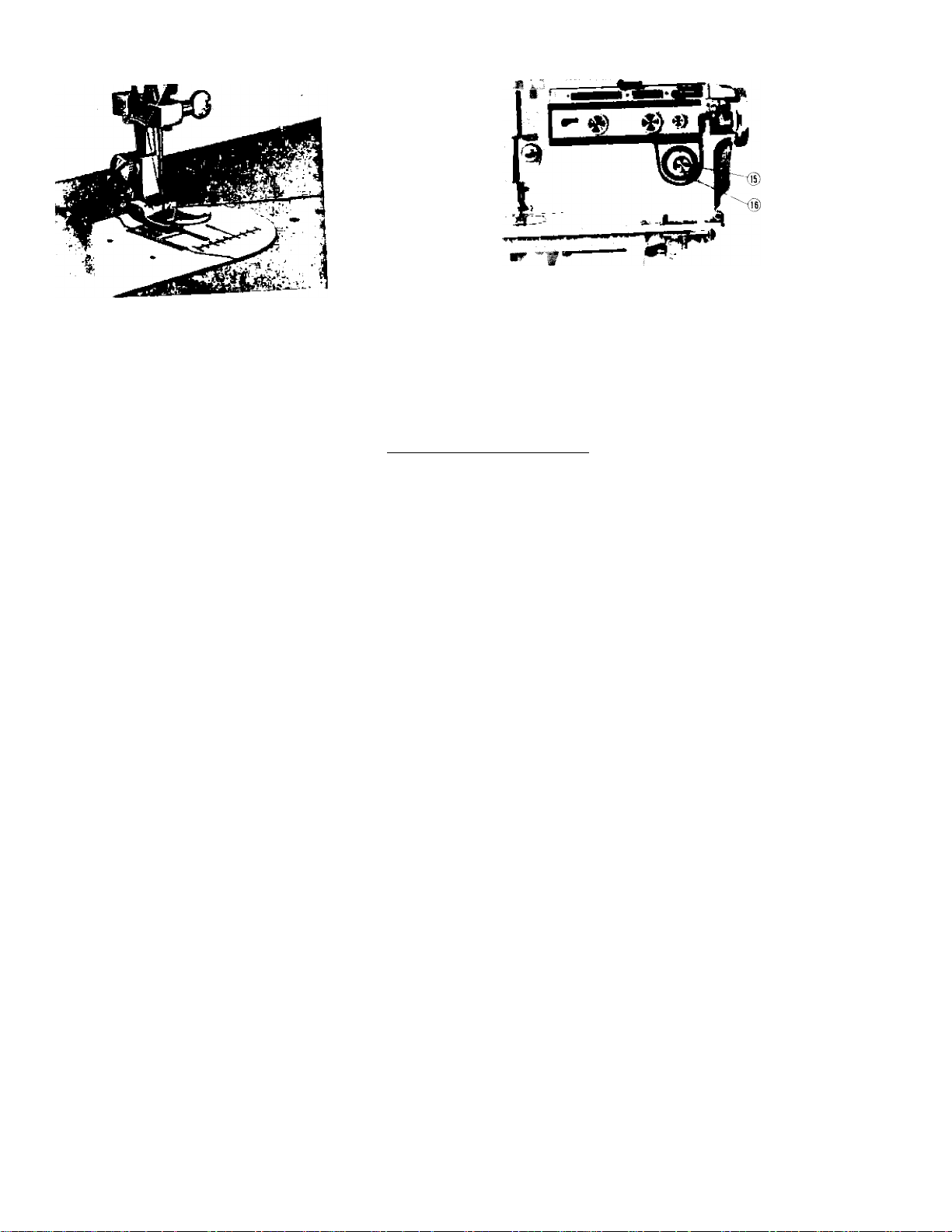

SETTING THE STITCH LENGTH

.

...................

— ■ . , , c r, ^ A Near 0 is the shortest

..:s: o'u-i r - ---- - •

le choc, is ty '>>= P-"«''

length you cnoose ...

---------------

-

Figures on indicator

Kl.^mber of stitches pej_i^

button is held in.

STITCH LENGTH CHART (APPROXIMATE

__________—-------------------------

.................

.........

1 ~2 ‘

No Feeding

1

30

SEWING IN REVERSE

25

2

3

15

4

8

5

6

10

adjusting the tensions

Always adiust the upper increase the

as the tension is release w the right, or

tension on the upper thread u number

^'°^t^’7^*;i";htrr\rte:s,on. Before adiust,ng lower tens,on

Te ‘su^e That the J tens,on, turn the

3.r::re: 'V,r^7rr si of the bobb,n case cloc.w,se tot,ghten.

counterclockwise to loosen.

pig. 16 B

Fig, 16-A

,s, ^pp-, '"To"

balanced, a perfect st,tcn w,

threads interlocking ,n a r,c 9 lower

thread forms loops over the

on the fabric (Fig. 16-C).

Fig. 16-C

Fig. 17

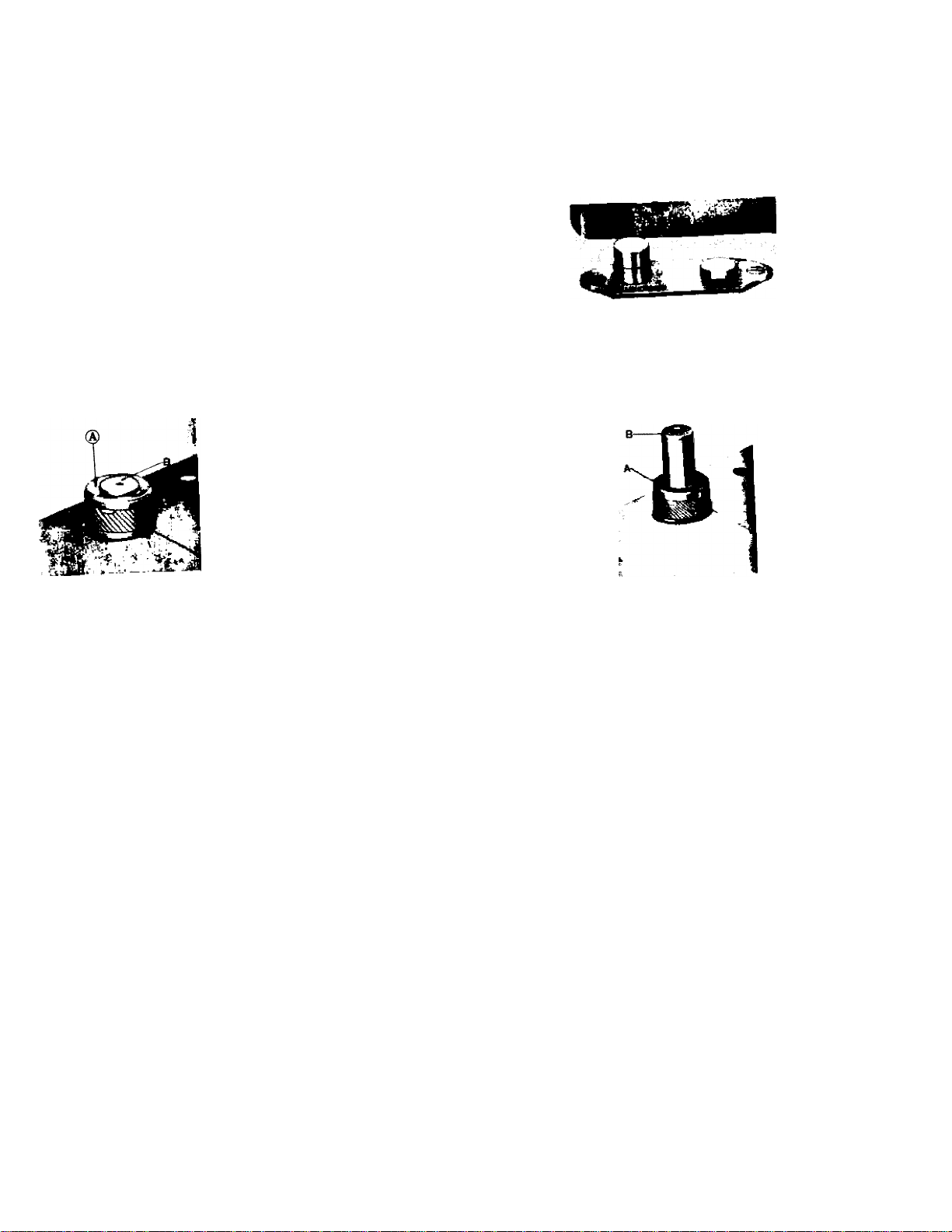

adjusting pressure and feeding of fabric

general sewing. Usually I'''''-'“'"'

-aV.:edT:,o;t::Ju":„d »i,»»y da.„. <e,,. ..

SEWING THIN OR LIGHT WEIGHT FABRICS

When lighter pressure ,s reputred ,= “'■“'“Xtr hritlTy

S,lk or flimsy matenol, the pressure cap should be about y

in Release all the way by pressing the snap lock (A^Fig.

20) and then press cap B down ogam to half-way sp L

le feed slightly by pressing the DOWN button (F,g. 18) to the

red line.

darning and mending

In order to move the fabric freely in any

direction for darning and mending, release

the pressure cap B completely by pressing

down on the snap lock (A, Fig. 20). Press

down button (Fig. 18) all the way down,

which drops the feed well below the needle

Fig. 19

plate. To return feed to normal, press the

UP button all the way down.

Fig. 18

Fig. 20

11

12

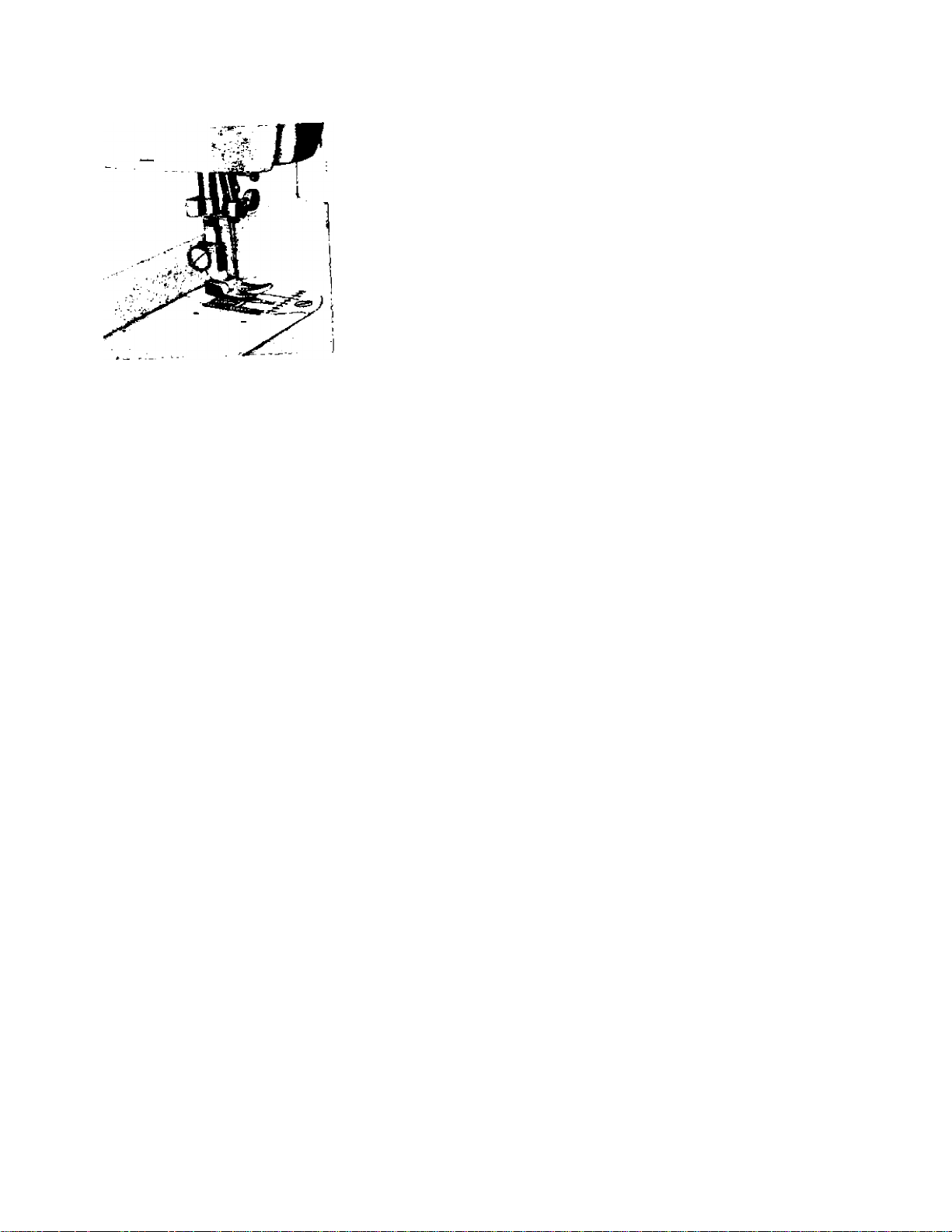

prepabing to sew

r „ to sew. Do not try to help the fee

Have take-up lever at « needle and cau

by pulling the mater.a o under presser foot. ioo».

1 1 f>r at highest point before ¡t to break.

r- 5,EH-

machine is regulated by mcr

Fio- 21-

removing the work

Re sure to stop i ,

r when the thread take-uP ever and

^ needle bar are at the h.ghest po

' '"now raise the presser foot and

the fabric back ond to the

left (Fig. Gutter

,he threads over the thread cutter^

Pull down slightly, hoUmg thread

in both hands, so as not to bend

Uate'^'le ends of thread under

the presser foot.

c*nn the machine

13

STRAIGHT STITCHING

, ,Haight sewing on fine fabric or very soft material,

„«y wont to use the straight stitch presser foot and

i.aight stitch needle plate which are included in your

.tory box. ■ Both have narrow needle slots.

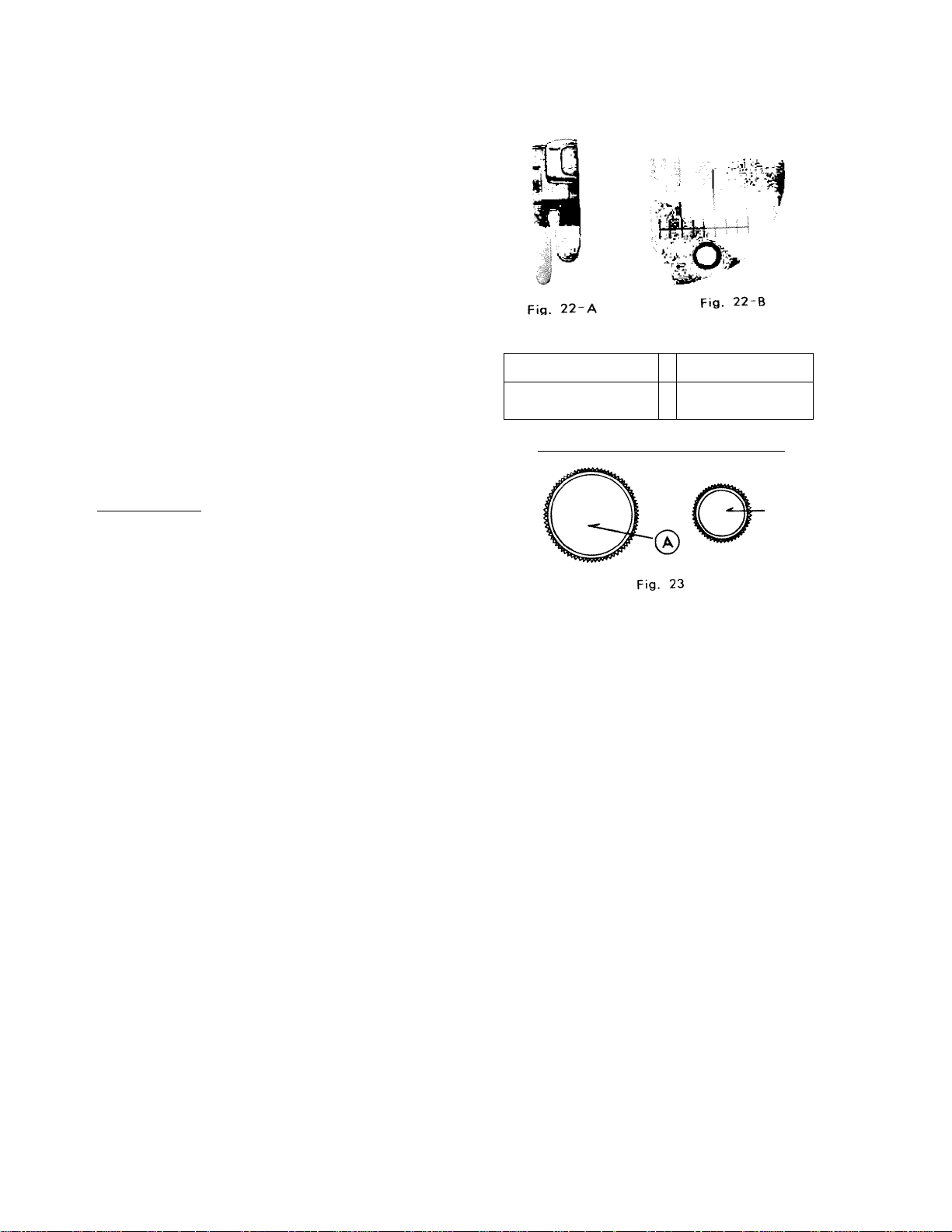

„nging the Presser Foot and Needle Plate:

) Presser Foot

(A) Loosen thumb screw (22. Fig. D and remove

ZiQZQCI pr©SS©r foot.

(B) Rephce with straight stitch presser foot (Fig.

22-A)

5 Needle Plate l i r* fnr

(A) Slide cover plate (21. Fig. D to the left as far,^

as possible.

(B) Remove screws holding needle plate (19. Fig. )

to bed plate.

(C) Remove zigzag needle plate.

(D) Replace with straight stitch needle plate (Fig.

22 “B)

. .ure to ..t the stitch width_and_butio^^

.1,

o

mzRj

^•1 *2*3*4‘5

^ZIGZ^NDICATOR BUTTONHOLE

~o—i 3 T~T

1 rsB Ei

knob “B” (F.g. 23) to .b= ¡eft a, for os .. will go

, ..il se, zigzag wrilb control "a' o. 0 posil.on.

14

CREATIVE EMBROIDERY

The satin stitch (Fig. 24) which is

short iigzag stitch and the basis (or mos embroid.ry,

sRorT ziy^uy efitfh lenath control (see page 9)

i'“™r^^Vsr::^,r:i.h::r'stopp,ng th« F=ed,„g a=,io„

(;rh®ca;tl!;oo::iy ot‘one ^w1d,h of zigzag s,,tchi„g set Fig. 24

vltU ctrsnfR Fia 23) to chosen stitch width number.

"‘"whh'h. ntac'hin. S?,' for o short stitch '•"9-';^^ ‘“f';-;;',

designs con be erode by torning ¿‘'»^zigzog^ wdth conj^rol

knob bock the stop (B, Fig. 23)

combination or wiains. i r

ZZ: tryZtra^J then proceed. After

„ Shile you will become quite skillful, varying your design,

by thf speed of the machine, stitch length, and monipulotian

of the zigzag control knob.

SAMPLES OF CREATIVE EMBROIDERY

Fig. 25

A Sew a few stitches at 5 width, then allow knob

toipnng back to 0 for a short period. Count, if necessary.

to establish a rhythm. eUwlv back and forth between numbers 2 and 5

B. Set stop at 2 then move knob 5_ ¡t to snap back quickly.

C. Set stop at 1. Gradually move ^ 1^. Do a few zigzag stitches, drop

D. Set zigzag stitch wdth stop a , operating the feed knob rhythmically it is not

feed for 3 or 4 stitches, then raiser it again. By operating

necessary to count stitches.

Fig. 25

Loading...

Loading...