Page 1

Instructions for

the use, care, and

maintenance of your

With Create-A-Stitch

MODEL NO. 6105

JCPenney

Page 2

I’AK I I VOIIR MACIIINI

Know the Paris

I ronl View .................................

H.K k View

Accessories

Iiislalliri); Maeliirie

Needles and riireail

Needle, llireatl, I airric ( hart

Changing Neetlle

(hanging I’resser I oot

Ill reading Machine

Winding (iohhiri ................................

Ihreading llp|)er Ihread

Removing Hohhin ('ase

Inserting Hohliin Case

( onIrols

Stilt h Pattern

Create-a Stitch

Stitch Width ..............................

Stitch i.engih .............................

Reverse Stitch ..........................

lension ol Upper Ihread

lension ol l.ower Ihread

(hecking I ensions

Pressure ....................................

haliric l eed

Sewing I.ight

PART II SI ARTSi:WIN(i

Keeping Stitching Straight ........................................................... 22

Pin Hasting ................................................................................ 22

Straiglil Stitching

Straight Stitch .............................................................................. 23

'Putning a Corner

Reinl'otcing Ends of Seam ....................................................... 23

Basting .................................................................................." 24

Staystitching ................................................................................ 24

Zig-Zag Stitching

Zig-Zag Stitch .............................................................................. 25

Seam I’inishing ............................................................................ 25

Edge Pinisliing ............................................................................. 26

Interlacing Darts .......................................................................... 26

Hatlacks

Shell Stitch I dging

Satin Stitch .................................................................................. 26

Stretch Stitching

Stretch Straight Stitch

Stretch Zig-Zag Stitch .................................................................. 28

Stretch Blindstitch ........................................................................ 28

TABLE OF CONTENTS

......

......................................

....................................

..................................

...............................

............................

.....................

....................

...................

...........................

.........................

....................

...............................

.............................

.......................................................................

......................................................................................

......................................................................

................................................................

1

2

Ì

4

5

6

6

7

8

9

9 licn illl ci 1 ( Hll

10

10

11

12

13

14 1 e a 1 s

14

I 5

16

16

17

17

I 8

20

21

; Bi llio ns

...............................................................................

' Zip p ers ........................................................................ .......................................................................

llec or ali vc Sl iic liin g

l‘ip Sli ic liin g

Sire lc li Z ig -Z ,i2 S tit ch

Sire lc li H li nd slii cl i

( ica le -a -S iiic Ii ............

M< >n og r;i! iis

1 m hio id er y ................

1 m is ile s

Hem s

Hui loi ilio le s

(ord ed S c.i m

'h iid iii g an d Da rn in g

Me nd ing

Palc li es

Dar ni ng

III < A RI N( , l O K Y( )U R m, u ,|,n |,

Cle an in g .......................

Oilin g

.....................

Ail) us lin g H e ll

Mo de l N um b er

lioh len is an d Pr ob ab le C au se s

(»u ara iit ee

23

26

26

27

................................

...................

.............

Hlin ds liic li

Sire lc li H li nd slit ch

..................

................................................................

.....................

...........

..............................................................

..............

..................

.............................................................

.................................................................

........................

........................................................

..................................................

................................. 29

...............................

............................

.............................. 33

.............................

..............................

.

............

.....................

...................

31

33 . 3 5

3() . 3 7

39

■■■ ■ ^0

41

43

40

42

Hack Í over

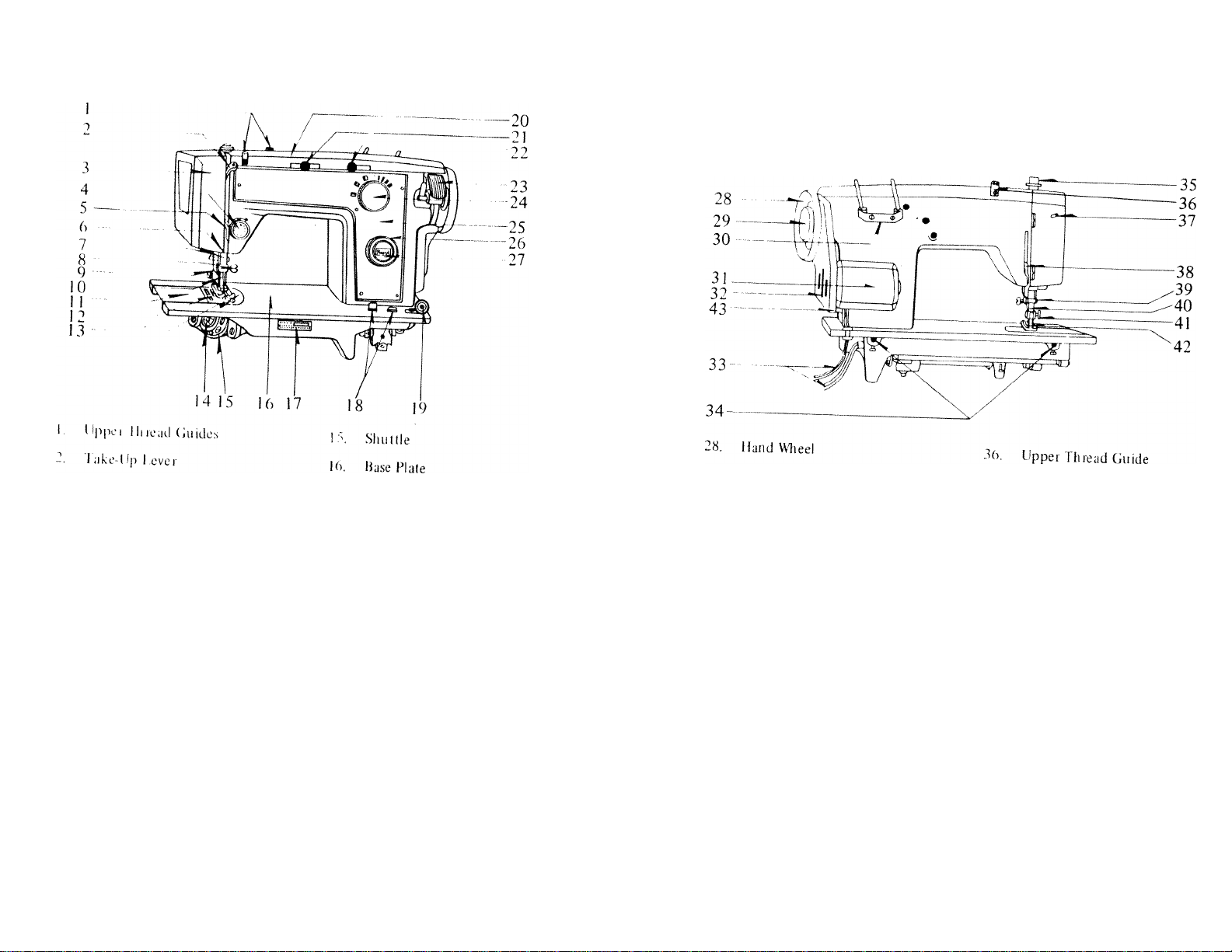

Page 3

I lUUn IVIACHIIMt

KNOW THE PARTS

FflONT VIEW

BACK VIEW

I ;ice I’lale

“t. reiision Knol)

I elision Thread Guide

lliread (iuide

Needle liar

Needle ('lamp Screw

’*■ linead (iiiide

10. Needle

11. Slide Plate

12. Fabric i-eed

13. Needle Plate

14. Bobbin ('ase

17. Model Number Plate

IH. Push Buttons Drop Feed

10. Bobbin Winder Thiead Guide

20. l op Plate

Stitch Pattern Lever

( reate-u-Stitch Lever

Bohliin Winder

24

Still h Width and Butlonhule Knob

2.S

Front Plate

26

Stitch Ungth Knob

27

Reverse Button

29. Stop Motion Knob

30. I'll read Spool Pins

31. Motor

32. Adjustable Moioi Bracket

33. Motor and Light Cords

34. Hinge Mounting Holes

35. Pressure Regulator

37, Light Switch

3S. Presser Foot Lever

3’L Thread ('lltier

40, Presser Bar

4L Presser Fool Hiniiib Screw

42, Piessei F'oot

43, Pulley Belt Cover

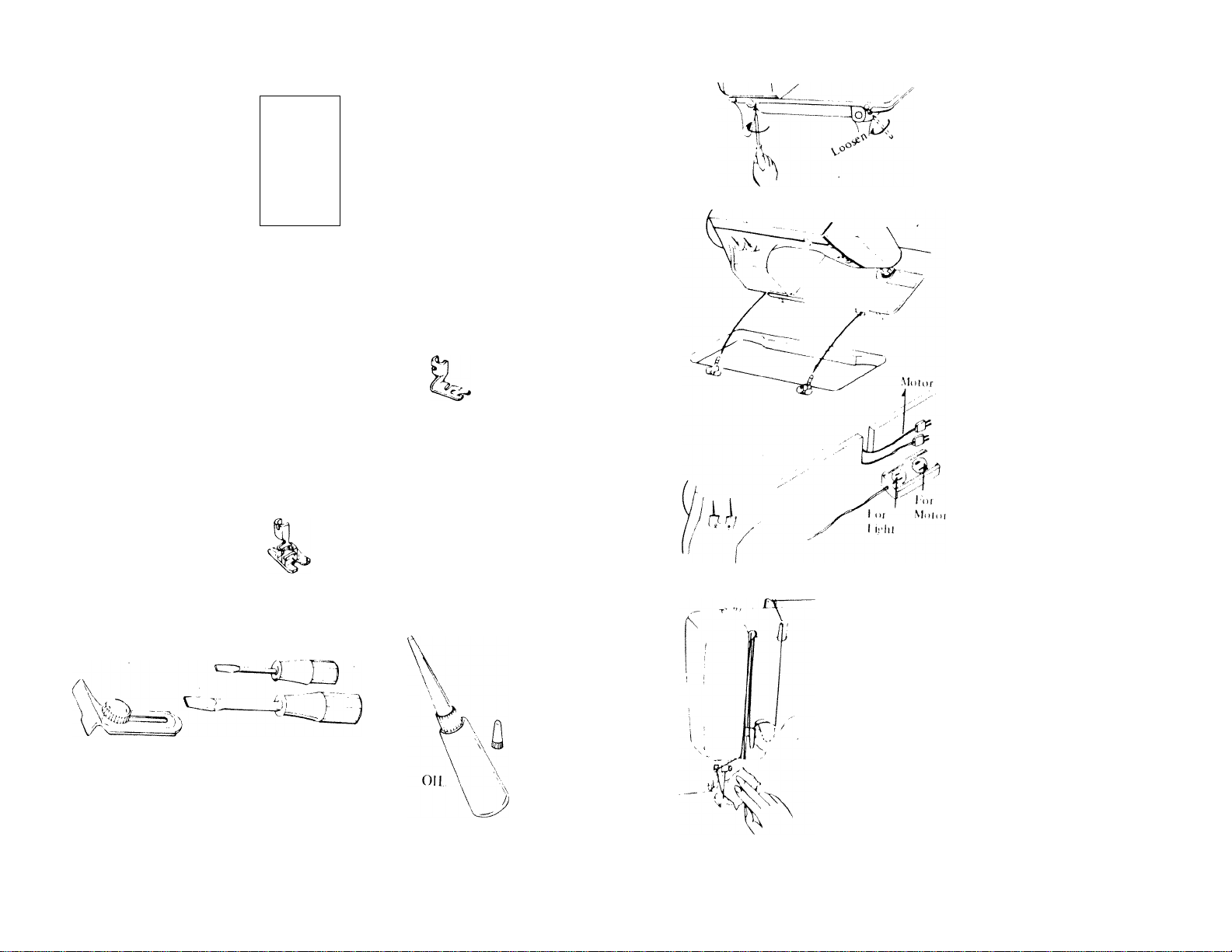

Page 4

ACCESSORIES

SEWING

MACHINE

/eedleT

If 1

„T )

4 HOBHINS

(i in muchiiie)

SrRAK.in snrni

I'OOT

Zin'I KI ooi BlilTONhoUiFOOT lUITTON SI «IN,;

non I CIUDH

(HM]' [4 ]

4 NhHDUfS

Si/e 14

zk;-zag ['Oot

‘SCRFWDRIVFKS

c

/

V-,, , .4

4 f 'HLT l>AI)S (or '111 read Spool Pins

IIEMMHR foot

r-OO]-

J

INSTALLING MACHINE

^4hu new machine can be installed i,

a cabinet or portable case.

I » place in cabinet or case;

• I oosen two set screws on back ot

machine bed until lu.les are clear.

I 'll lip hinge pins located at back

'X cabinet or ba,se o| puriatile case,

• ilnld machine in a tilled back poI'Kion and carelull> lower it down

h'l'li binge pins are inserted

into the lioles.

Iigliten both set screws secmcly

wnii screw driver.

Lor portable case, insert motor and

'iglit cords through slot in partition

ol case.

• nit machine forward until it rests

tiimly in cabinet or case.

Hug electrical cords into sockets lo

cated inside cabinet or case. Cord

H entitled witli “motor” tag must be

P ugged into socket marked “motor”

11 lagged cord goes into “light” .socket,

'■'•ice foot control on (loor or pull

4>'vcn knee lever in cabinet. Place fell

P‘1 :> ocated m'' accessory bo.x over

III lead spool pins.

L'lig cord into any 110-120 volt

electric socket.

Your machine has been oiled during

manutacturing and testing Before

sewing wipe off any .surplus oil which

'»‘IV soil remain on machine, especially

‘"‘"'»‘I needle and fabric feed Sew

'’‘ivL and lorth .several times on a scrap

'‘ilHic betöre you begin sewing a

garment, ^

Page 5

NtEDLES AND THREADS

Hie needle and thread you choose depends unon thf fahri^

cl'liuirmw'ert'abiL'' "ndT’'"‘ oflig}rt'wei"ht

orsnn rLr ’ ^“‘chtng heavy

Needle

size

9

tine

light

14

medium

16

heavy

polyester

cotton covered polyester

fine mercerized cotton (70-100)

silk A

polyester

cotton covered polyester

' mercerized cotton (50-60)

silk A

• polyester

• cotton covered polyester

mercerized cotton (50)

silk A

polyester

cotton covered polyester

mercerized cotton (40-50)

heavy duty mercerized (40)

silk D (buttonhole twist for

I h read

topstitching)

Fabric

chiffon, fine sUk, tricot, lingerie

fabrics, sheer lace, net, voile,

organdy

light weight knits and jersey, silk,

batiste, taffeta, satin, lace,

crepe

double knits, linen, poplin, gingham

pique, seersucker, velveteen, light

weight wools, fine corduroy

heavy wools, corduroy, felt,

terrycloth, canvas, tapestry,

decorative fabrics

L». only No, IS X I (7051 „ecdlex in chix .„achine^

• Always osa saioc ,y,,e and so.e of ,I,read i„ bod, „aedl. and bobbn,

■ rs-di“

• Never use a bent needle.

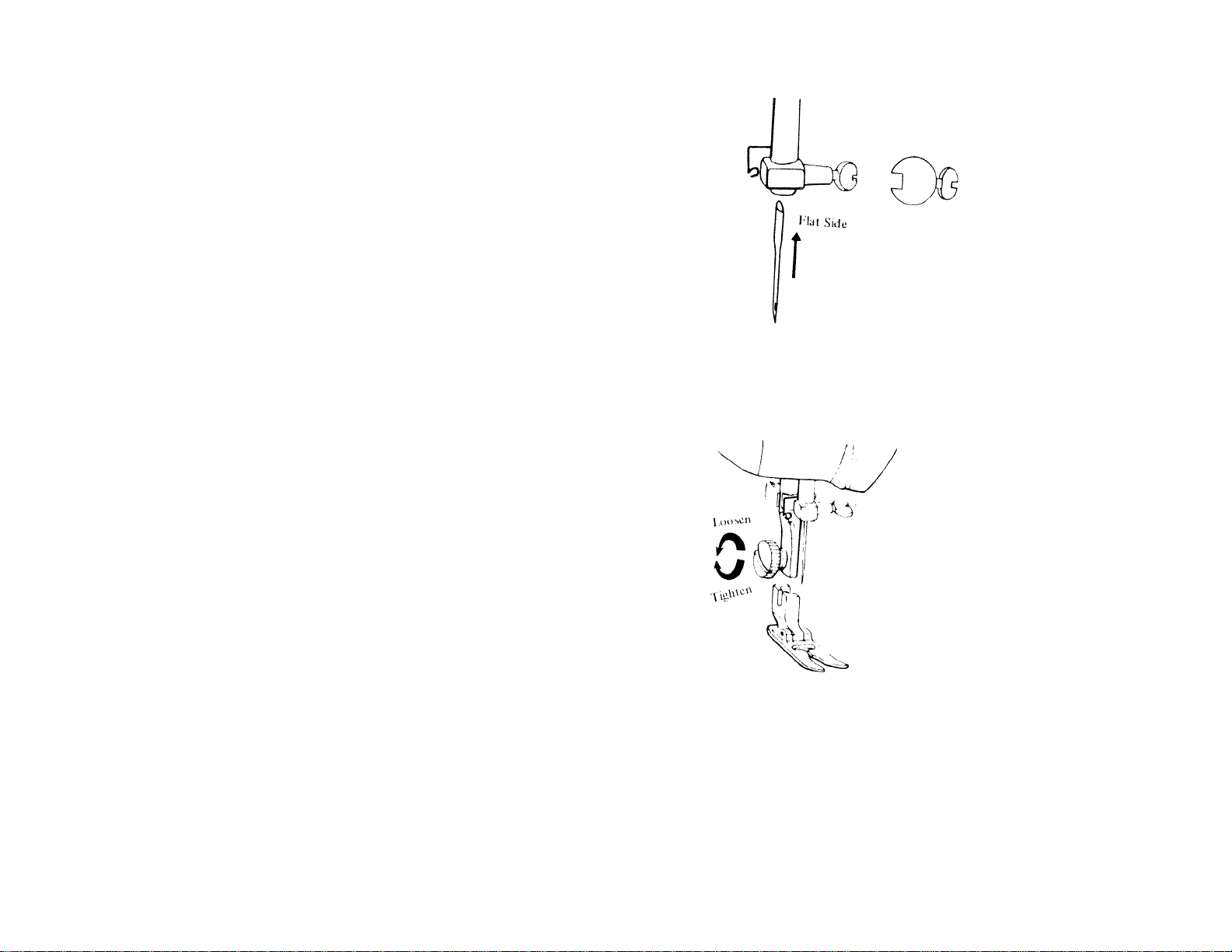

CHANGING NEEDLE

Raise needle to its higliest position

urning hand wheel toward vi

-«osen needle clamp screw and

move needle.

Insert new needle with its flji si

'‘•^■"tg right. Push up into needle'clai

far as possible. Tighten screw wi

a screwdriver.

rum hand wheel to ware you one cot

píete rotation to be sure needle

correctly positioned.

CHANGING PRESSER FOOT

Rai.se needle to its highest position In

lurning hand wheel toward you Raise

presser loot by |„„,,g p^esser too,

r loealed on back of machine

» ««.sen thumlvcrew and remove foot

I’lace grooved side o,^ selected presser

'‘’»1 apiinst presser bar. Tighten screw

seciiieiy wfiii screw-driver.

!_)« not operate machine with presser

loot lowered unless fabric is belween

presser loot and fabric feed

■ I™;,:;::,............................

...... mr

iji .„a „„

n.y danaaia iba i;!'";;;,':;:.

........

......

Page 6

I tintMUIIMU IVIACHlIMb

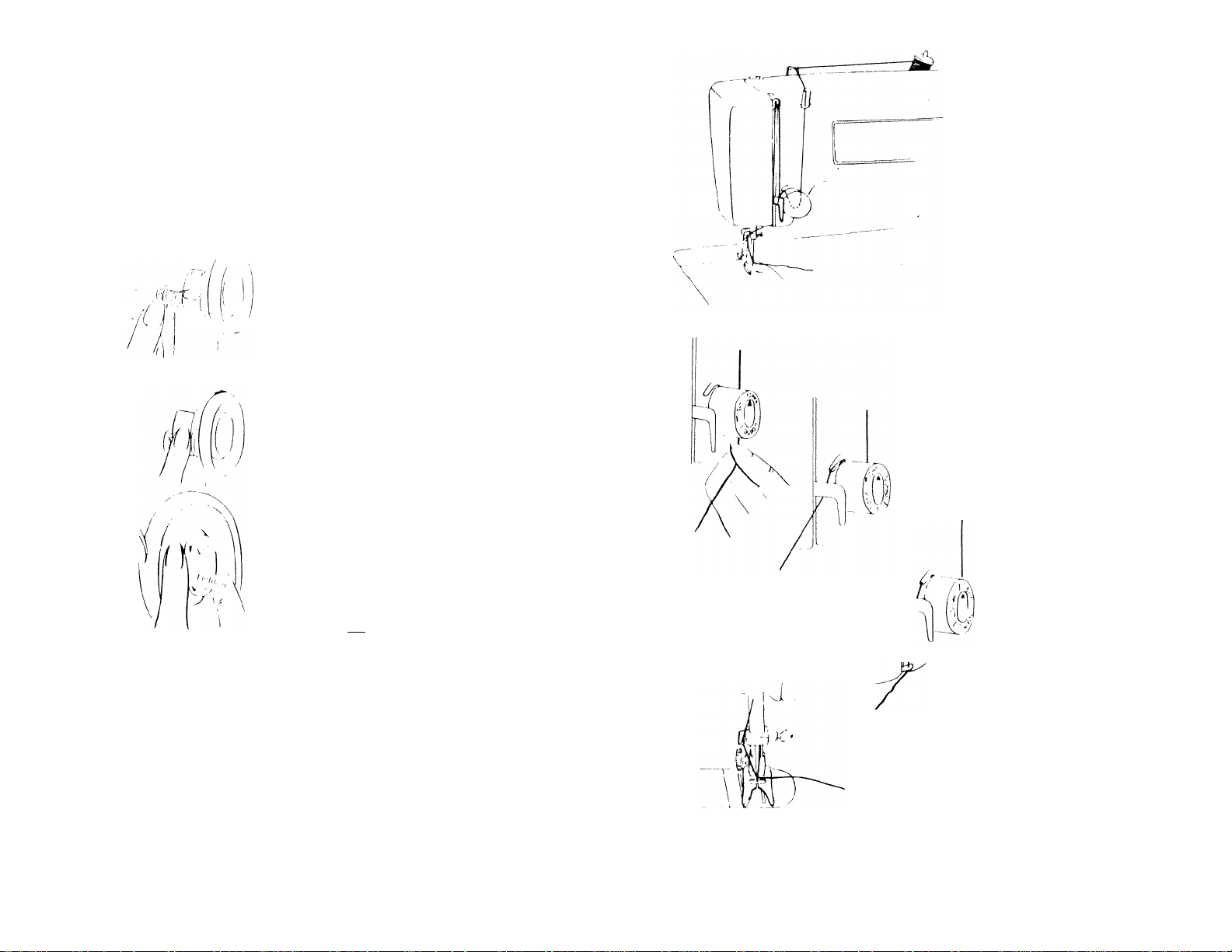

WINDING BOBBIN

I’lace spool ol thread on sp(K)l pin and

pass thread thiougli slots of both top

thread guides.

Bring tliiead down across machine and

under tension discs on Inrbbin winder

thread guide located on corner of

machine base.

Put thread through one of the holes in

empty bobbin from inside to outside.

I’lace bobbin on spindle of bobbin

winder, being sure notch in bobbin fils

over small pin on bobbin spindle.

Push cover of bobbin winder down

until rubber wheel touches hand wheel.

Release sewing mechanism by holding

hand wheel and turning slop motion

knob toward you. Hold end of thread

and press down on foot control as

when sewing. Release end of thread as

soon as winding starts. Run machine

slowly to wind bobbin evenly.

Bobbin winder will stop itself when

bobbin is trill. Do not wind so full that

thread extends beyond bobbin. Break

oil thread and remove bobbin from

spindle.

Tighten slop motion knob.

THREADING UPPER THREAD

Raise the needle to its higlrest po

tioii by turning hand wheel toward ;

Till pressei foot.

PI.ice thread on spool pin at back

m.ichine. Pass thread through slots

iwo lop thread guides, then down

illu'ad tension knob.

Place thread around bottom of line

tension knob, being sure it slides f

tween tension discs. Hold thre:

sialionary with right hand and pi

ihiead up with left hand until it sli

around w ire spring and into loop.

I owe I pressei fool.

PI.ice ihiead imder arm of tensii

ihieatl guide, and up through hole

l.ike-up level llnearliiig from riglil

Id I

( Ol u\ I

' —'

Winding Bobbin Evenly

It bobbin winds unevenly, adjust

bobbin winder thread guide by loosem

ly screw at base ofguide:

• it more (bread winds on right side

of bobbin move thread guide

slightly to the left.

• il more thread winds on left side

of bobbin iiKwe thread guide

sligliily to the light.

Bung thread down and place bell in

aim of linead guide located at holloi

ol opening 111 face plate. Draw tinca

down Ihmiigh small thread guide a

ladled to needle hai,

lineari needle from left to right.

Page 7

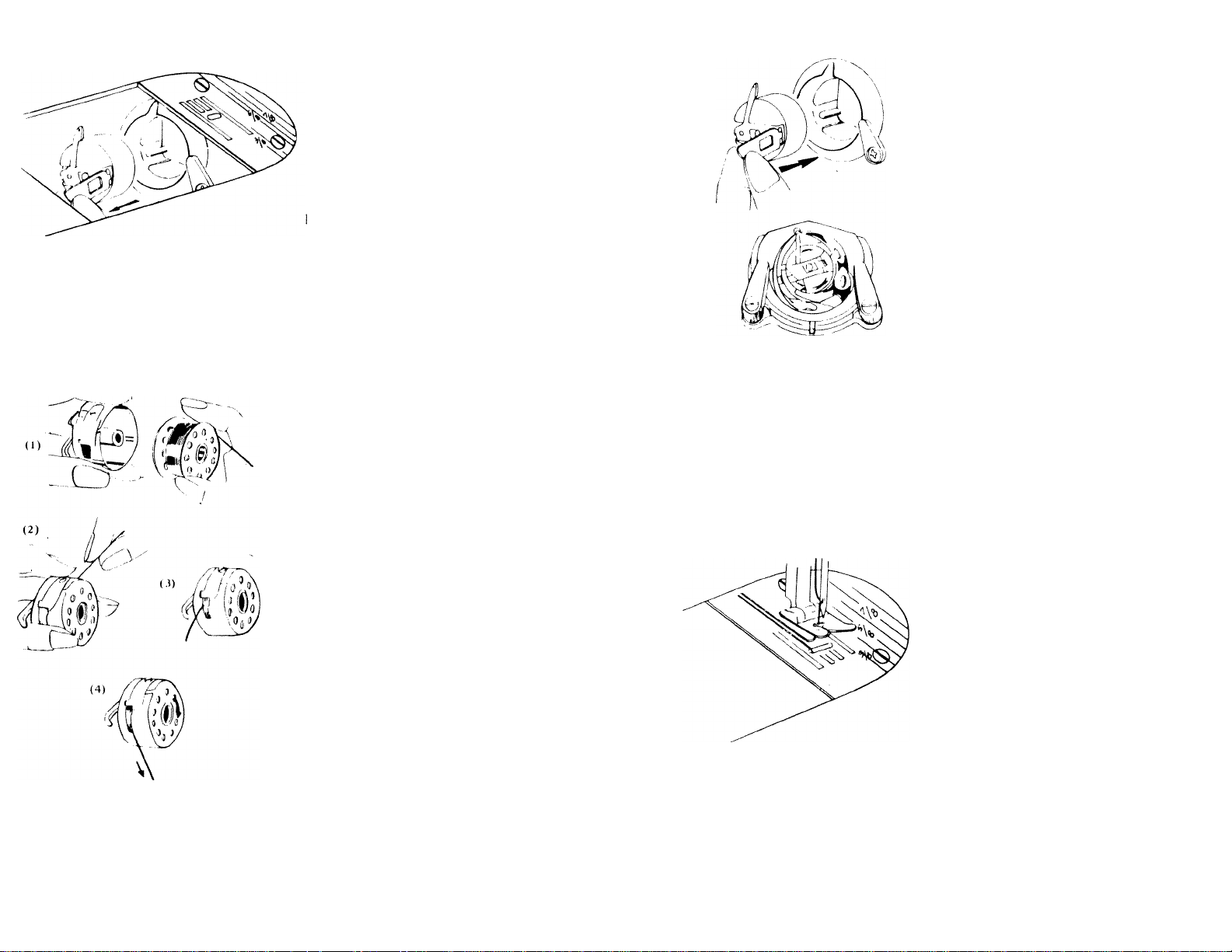

REMOVING BOBBIN CASE

K;iise needle to its highest position by

lurning hand wheel toward you. Pull

slide plate out to the left.

I,ill open hinged latch ol bobbin case

and pull case toward the left and out

of machine.

Bobbin will remain in case as long as

atch is open. 1 o remove bobbin, hold

bobbin case down, close latch and

bobbin will fall out.

THREADING BOBBIN CASE

Hold bobbin us shown in illustration

so that thread goes over top of bobbin

and away from you.

Пасе bobbin in case withoul turning

it around.

Slide tliread into slot in edge of case

and draw thread under tension spring.

Pull out thread to check that bobbin

turns clockwise.

INSERTING BOBBIN CASE

Be sure that 5 to 6 inches of thread

extends out of bobbin.

Hold bobbin case so long finger on

case points up. Open out latch.

Slip case over holder post in shuttle

and press in place until finger enters

notch. Release latch.

Close slide plate.

BRINGING UP LOWER THREAD

Raise presser foot. Hold needle thread

'1

loosely with your left hand. Turn hand

wheel toward you until needle moves

down and then up again to its higliest

irosition, catching bobbin thread and

bringing it up through hole in needle

|)late. ^

Id prevent thread from slipping out

of needle when you begin sewing, pull

both thread out about 6” and place

under presser foot toward rear of

machine.

Page 8

CONTROLS

CREATE-A-STITCH LEVER

.

..............

lilind Ivqmliir Slrelcli

■Si il til Siili h .Sllltli

STITCH PATTERN

11,0 ,ype «r,sliich.

"> чиее posaions

г

Wimi Regu'lar Si rei cl,

SliUh Slilch Stitch

Bhml Regular Streich

Silici, Siiteli Siiteli

Blirnl Regular Sire'ich

Slilch Stilch Stitch

;; he sure needle

I’leakiiig ihe needle. ^ P"-'ven| iea,,„g ||,e fabric

Creale I .

a Silici,

Si il ch Will I h

ICul lonhülc

ihsed r„r ,„,,si

-- siraiglii slilcliiiig,

■'ll'' lung, tiiicl lor making lulli(in|io|es.

' ""'""lg is loi binici stuelli,lg.

soiling is |„, ,,g,|„„g

■SIIdies - bull, ,,,eicl, sliaigbi .slilcli

mid siielcli zig-zag siiteli.

('reale-a-Si Hell

□ cz

~^:ékjìÈkJiÈ'uèk\^Ìk

é'ù'A.

«éliti,,

-MÜM-JiM АТОМШ ^

iiW-lk

Èà)^

< ic‘.iie-a-Siiieli lever moves llie neodb

Is'tt lu I,gill to,- speeial dosig,

''iiieliin».

Ills' love, IS .spiing loaded so miles

you hold ihe lever, ii will always rovci

'o llie siaiiiiig posiiioii ai iIr

Z/Vww

ic'll (siraiglil slileli).

< leme-a-.Siiteh lever enables you

oblam a zig-zag sliieh of any widil,

^"|j""> .sbieh w,ci,i,

’mid loi|uiekly reiurn loslraiglii

siik inig by simply releasing ,he love,

I’m lacking and rein forco

( leaie-a-SiiicIi lever enables you n,

meaio luimerous decorative paitoriis

"’Psnicliing. („„„mug. nioiio-

yniining, appliciuing and emhioiderim.

(See pages .U)-.12).

O'l'meni paiierns aie obiained by

"mying ihe s-jreod will, wliicli yon

inovo ilio lever and lolease ii. and by

^mynig Hie smell longll, and numbei

oi sliiclies,

l-oi III,,SI deooraiive designs, siiidi

’""ll 1 knob should be SOI fo, siraiglil

" "oiling, and smell lengib knob sol

II loi dose saiiii slilcli.

I OI besi results wlioi, making designs

iiiodeiale laie ol speed.

Wlien niadime is „01 sewing, do 1,01

'"oo-' ( leale-a-.Sliieli lever unless i|,e

noodle Is laised „m „i ,1,^ fai-,,,,..

"l'”"lil he sewing al a

Page 9

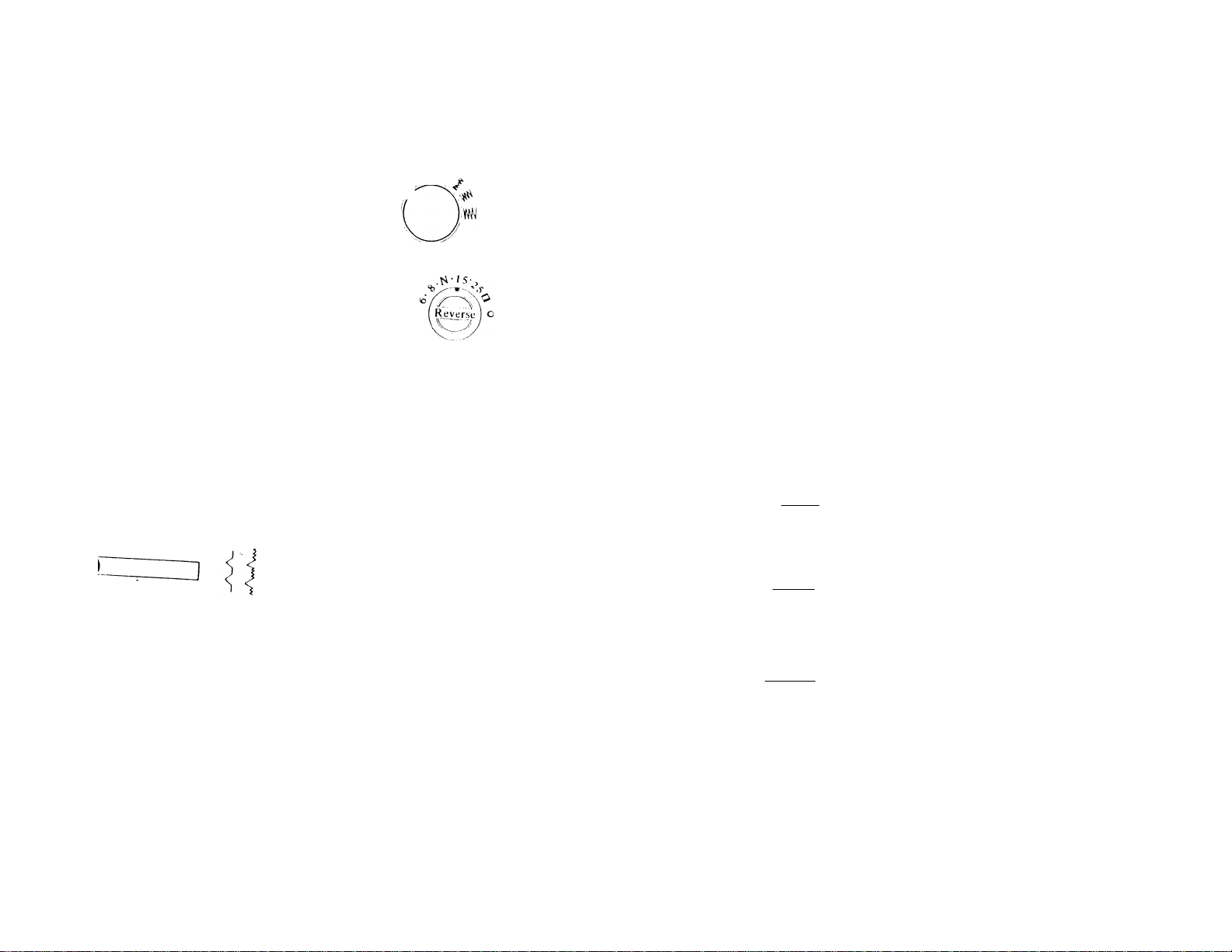

STITCH WIDTH

Stitch width knob adjusts the width

of the stitch for straight and zig-zag

'stitching, and moves the needle po

sition lor making buttonholes.

Knob niiist be set in the center for

straight stitching ( ; ). Machine has a

left position^ needle - when set for

straight stitcliing, the needle is on the

felt side of the needle plate opening.

By lurning knob to the right, you can

widen the stitch from straight to maxi

mum zig-zag width.

rhe buttonhole settings on the left

side of the knob are for dialing the

4 steps of stitching a buttonhole.

STITCH LENGTH

Stitch length knob regulates the length

of stitch - from 6 to more than ,K)

stitches per inch.

Hie numbers around the knob are the

stitch length guide. The higher the

number, the shorter the stitch. In

general, short stitches are best for

ightweight fabrics, longer ones fr)i

iieavy fabrics.

Most normal sewing is done with stitch

ength set at N - which is about 12

stitches per inch. Basting stitch is

made by using the longest possible

Stitch ** 6 stitches per inch.

A special setting is marked for button

holes. This area is used for adjust

ment of satin stitching. 0 setting is

used for embroidering and darning.

butch length can be adjusted while the

machine is running.

llie width of the stitch can be ad

justed while machine is running. If

machine is not running, raise needle

to its highest position before turning

knob.

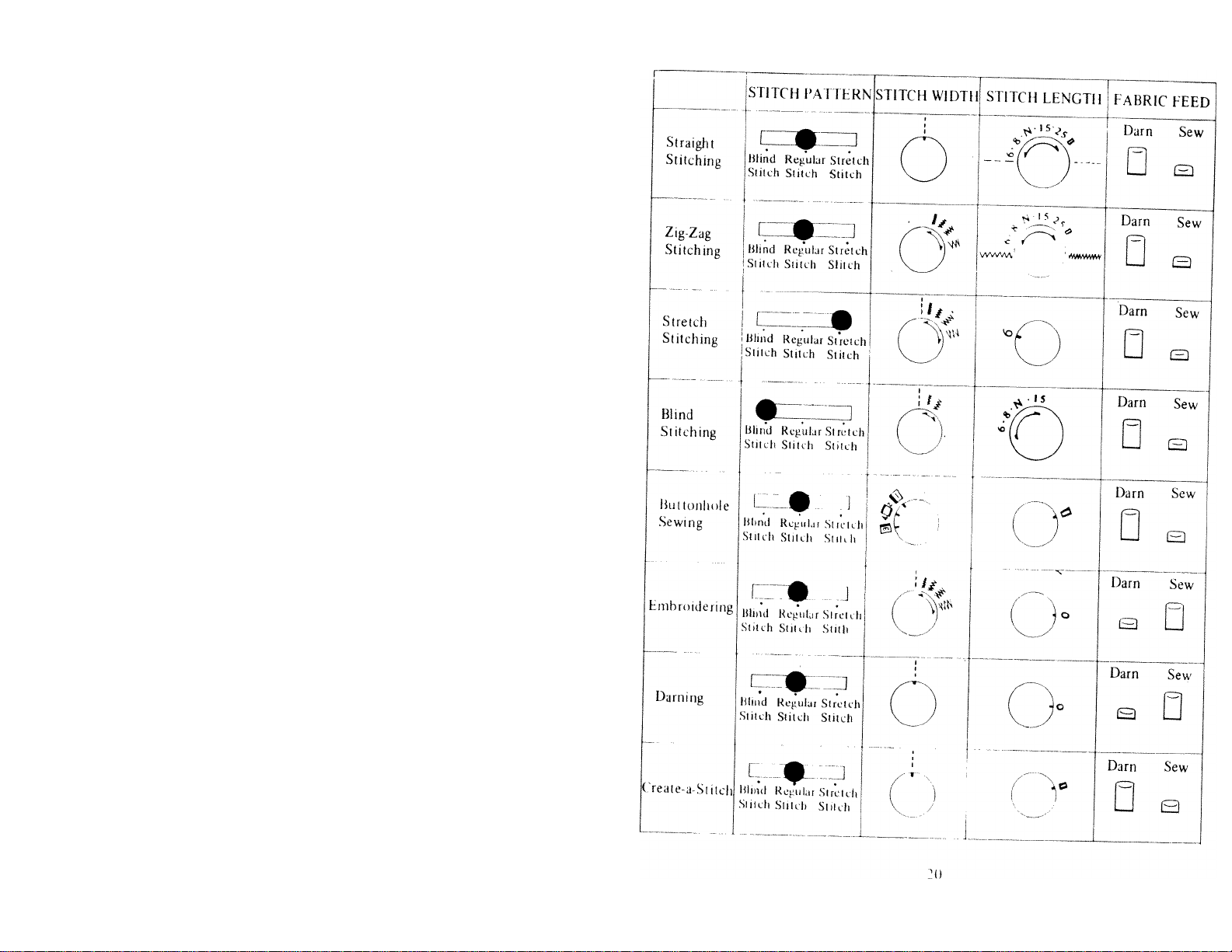

-Set com,4,1s for a specili. siilch in the following order:

1. Stitch Pattern

2. Stitch Width

Stitch Length

1.^

reverse stitch

I’ress in center button of stitch length

knob and hold for reverse stitching

Fabrtc will immediately start feeding

backwards. Release button and

machine will resume normal forward

siilchittg.

Very useful for fastening ends of seams

and darls without having to tie threads.

I I

Page 10

TENSION OF UPPER I HREAD

TENSION OF LOWER THREAD

lensioii ()| ihe uppei iIucìrI can he

easily adiUMcd by luming dial on

lioiit ()| die leiislon discs.

It you are unable to balance the siilcli

hy adjusting lension on the upper

tbiead, you may have to make a slight

Yoiii inacliiiie has been sei al the

laciiiiv I,II even iliiead leiision al

/r-

Nunn.il selling. Ilovvevci, you may

have 1(1 adpisi die leiision when using

dittereni lliieads or sewing on labiics

ol difi'eieni iliicknesses.

adjustment in Ihe bobbin lension.

lake out bobbin case, remove brrhbin

and dean ooi any dust or lint which

iias collected around Ihe ca.se.

I urn screw on bobbin case slightly in

either direction using Ihe small screw-

Pies.sei tool should he tlowm while

J liver:

adjustmeni is being made.

To increase tension turn screw

I.oosen tension somewhai w'hen zig

zag stilching. Ihe wider Ihe zig-zag,

Ihe less lension needed. Use “Loose”

selling when sewing huitonholes,

monograming and embroidering.

slightly to the right.

lo decrease tension turn screw

slightly to the left

It stitch i.s satisfactory but the seam is

puckered, it may be necessary to

lest lension before you .scw' by stilch

ing on a scrap of the same fabric and

loosen lension on both lop and bottom

threads.

ihrough the same amouni of layers.

,os>

■'“«1 >

^lytny

i oireci lension: needle and bobbin

line ad s are locked

in cenlei of seam

*ppei ih read loo loose i increase

tension by lurning

dial loward “'fighl’

Upper thread loo liglii : icdin c

lension by luiniiig

dial lovvani “I oose’

IS

CHECKING TENSIONS

An easy test lor checking lension

balance:

bold fabric on the bias and stitch

(id siiiches/inch) U" in from fold.

Grasp stilching and pull with a snap

to make threads break.

• il both til reads break (even

though not at the same place) tensions are balanced:

• if upper thread breaks - loosen

lop tension,

• it lower thread breaks - tighten

top lension.

16

Page 11

PRESSURE

D.mi Sew

[-d

or Stitching Ordinary

Fabrics

Darn .Sew

For stitching light

weight fabrics

Darn Sew

i3 I

______

r darning embroidering

sewing on bullous

Fabric I'eed up

l-'abric teed half

way down

I'ahric Iced down

I ressuie on the presser toot must be

regulated lor different types of fabrics.

Proper pressure allows fabric to feed

smoothly and evenly with no skipped

stitches.

lo adjust pressure, push down outer

ring of pressure regulator until center

button springs up. Oien push center

button down until the suitable amount

ot pressure is obtained.

As a lule, icduce prcssuie vvlien sewing

heavy lahiic or inulli|>k' layers. Iii-

cieuse piesMire when sewing lighter

weiglii labiics. Release piessuie conn

pleiely loi embroidering, and darning,

so labile can be moved in any direc

tion by hand.

FABRIC FEED

Fabric teed or teed dog moves fabric

loiwaitl Ol backward uiidei (lie presser

tool. Ii can be raised.or lowered by

pushing (he SFW-DARN bulions h>

caied on die machine base plate.

For ordinary slraiglil or /ig-zag stiidiing press SFW Inition all (he way

down. I Ills raises tabiic feed lo ils

liighesi position. For liglitweight

tabiics, press SF.W billion down only

half way (line marked on button) to

prevent teed liom marking labric.

Foi daiiiiiig, eiribroidei ing and sewing

on billions, press DARN biiUon all die’

way down lo lower die leed. Flus

allowíj labile (o be moveil freely by

hand.

The sewing light is located directly

over the needle so as to better illumi

nate the stitching area. Turn the light

on and off by pushing the switch

located on the back ol the machine.

To replace bulb, turn light off and

open lace plate. Unscrew bulb as you

do a conventional light blub. Place

new bulb in socket and screw in place.

17

lb

Page 12

PART II START SEWING

N■11%' you should be taiiiiliar wiiJi the different

pails ()| youi niadiine and how to thread it.

Hie lollowing pages explain the various stitches

>om machine can niake. along with special

sewing techniques.

Ifse the chan on the opposite page as a handy

iclerence gimle fm making any type of stitch.

•So now you le leady to sew

..............

CHART FOR MAKING DIFFERENT TYPES OF STITCHES

19

Page 13

blHLHING UPS

Wlienever you start to sew - -

• Check tliat levers and dials are set

correctly tor the stitch you want stitch pattern, width, and length.

• Use proper needle and thread for

your fabric. Needle sliould be

straighi, sharp, and inseried pro

perly. Change your needle frequeni-

ly-

• Test machine stitch on double

thickness ot a scrap of the fabric

you plan io use. Adjust machine for

length of stitch, tension and

pressure if necessary.

• Place fabric under presser foot with

bulk of material to the left of

needle. Full thread ends behind

presser foot.

• To prevent liglitweiglit fabrics from

being drawn into needle hole when

you begin stitching, start about 'A''

from edge of fabric.

• To reinforce ends of seams, begin

and end by backstitching about '/2"

from edge of fabric.

• Regulate speed of machine by in

creasing or decreasing pressure on

loot control. Run machine at a

slow even speed.

• Allow tahiic to teed lorward with

the movement of the fabric feed.

Don’t pull 4)r hold labric back as

needle may bend or break. Instead,

guide fabric gently with your liand

in front of presser foot.

• Wlien finished stitching, turn hand

wheel toward you to raise needle to

its highest position betöre removing

labric from under pressci foot, l>u||

threads over thread culler located

at back of presser bar, and press

threads down to cut.

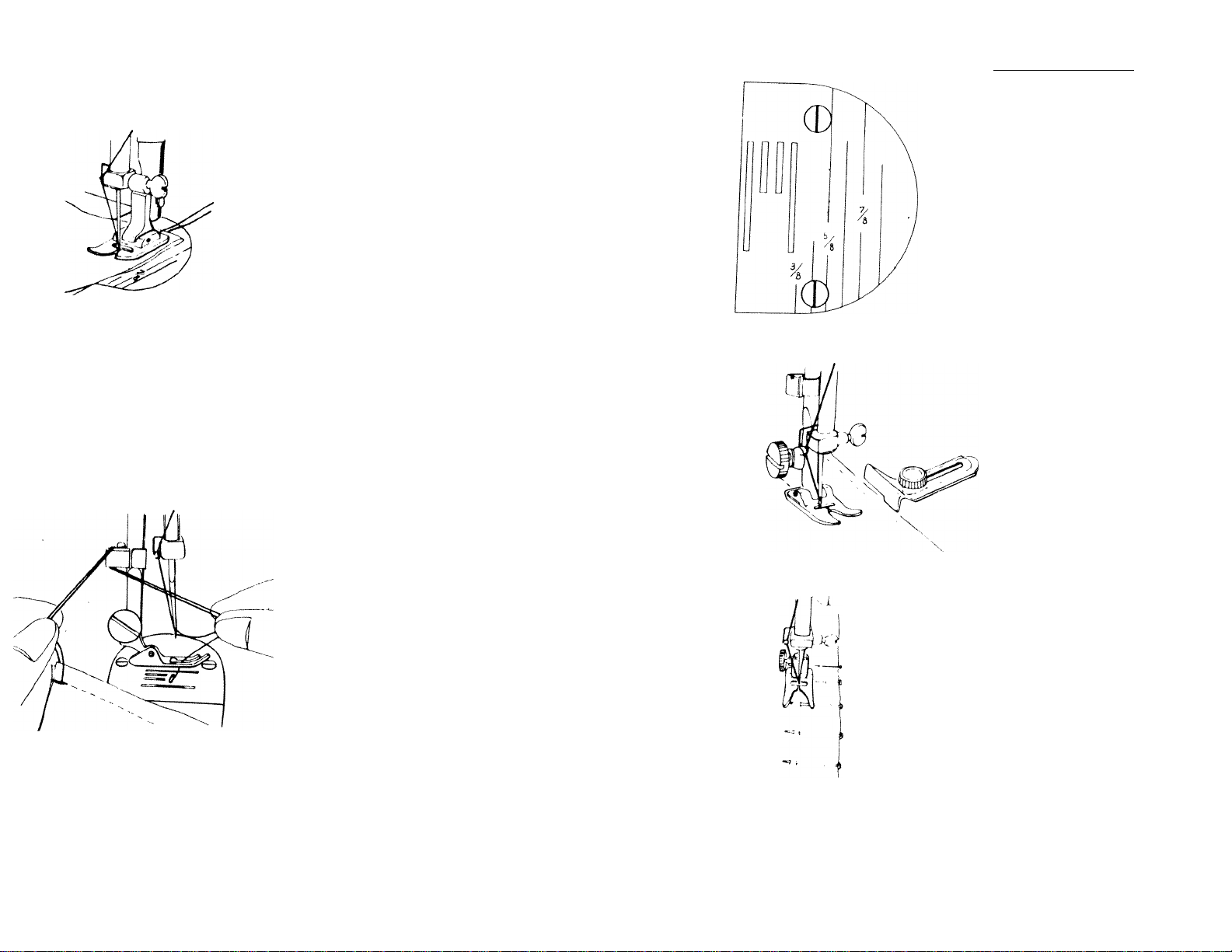

Keep Stitching Straight

Ir> help keep your stitching straight

whether stitching seams or doing dec-

rat ive stitching:

Needle Plate Use markings on needle plate as a

guide tor stitching.

Most common measurement is 5/8”

wliicti is used lor stitching seams.

Simply line edge of fabric up wiili

markings on plaie to keep stitching

straight and seam width even.

• Cloth Guide Attachment - Use as a guide for stitching seams

hlindstitching, and topstitching

Can be adjusted up to 1-5/8” fron

needle.

hasten cloth guide to machine b>

inserting ihmub screw into one ol

the two threaded holes in bed ol

machine. Adjust cloth guide to

dcMirnl distance from needle and

iigliieii ihiuiih screw.

Pin Basting

I’lace pins at right angles to pres,sei

loot with pin just nipping into fabric

at stitching line. Never place pins on

underside of fabric in contact with

labric teed or so presser foot rides ovei

head of pin.

Page 14

STRAIGHT STITCHING

dchine Setting ■

I’rcsscr

loot

Str:ii(:lit Stitch

loot or

Zig /ag loot

Hliiul HcfUilar Sluicli

Stitch Stitcli Slilch

Hits IS the most usual type of stitching. Use either the straight stitch toot for

greater control or the zig-zag foot. When using the straight stitch foot,

^e sure stitch witjth knob is set for straight stitching to prevent needle'

trom hitting presser foot. F‘<=vem neeaie

Adjust stitch length according to your fabric. 12 stitches per inch (N) is used

tor most fabrics. lengthen stitch for heavier fabrics, multiple layers, and

thicker seams.

1/ 0

Stitch

I’atteni

□

Stitch

Width

\ j

Stitch

Length

Fabric

teed

Diini Sew

Rl

U Q

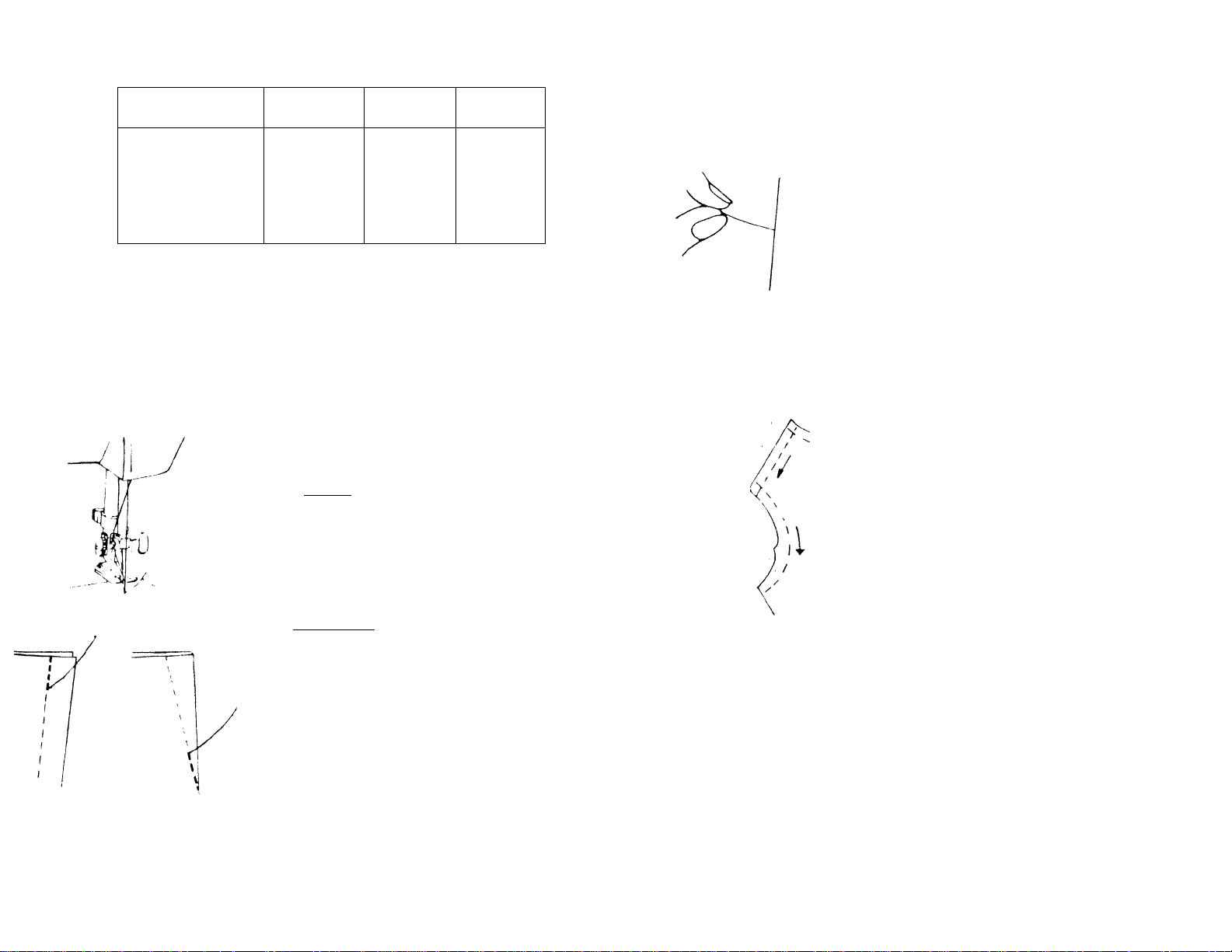

Turning a Comer

Slop stitching with needle down in

labric. Raise presser fooi and turn

tabric using needle as a pivot. Lower

presser loot and continue stitching in

new direction.

Reinforcing Ends of Seam

Reinlorce the beginning and end of

seams by backstitching to secure the

threads. Begin

‘A"

from fabric edge

and stitch in reverse to edge, then sew

forward to end of seam, then back

stitch again about

Yi".

Reinforce point

ot dart in same manner.

Basting

Machine basting is very useful for join

ing seams tor trial fittings, marking

consiruction guide lines, and basting

pleats and hems.

l*se longest stitch possible, setting

stitch length at 6. Loosen tension on

upper thread. Choose thread color to

contrast with your fabric so it can be

easily seen.

Basting stitches cati be removed easily

by clipping upper thread, then pulling

out lower thread.

Staystitching prevents stretching and

acts as a guideline for clipping and

joining curved edges. Staystitch any

edge that might stretch during handling

before the final stitching.

Staystitch on a single layer of fabric,

always stitchitig in the direction of the

gtain. i^lace slifches 1/8'* away from

scamline in the seam allowance. Use

12 stitches per inch (N) for most

fabrics.

Page 15

Machine Setti

''WvWwWv/^/iV^^WWWWAV.

AAWaVVVWVVX

'*'^AAAWv^MM/WAW^VVVVV

ili l iU t i i/ ii , nu m u , n u iu t ui M

■ ' V\\\\v .1

ng

zig-zag stitching

ever It machine is not running, raise

needle to its highest position before

adjusting stitch width knob.

Tension on upper thread usually needs

to he loosened. The wider the zig-zag,

the looser the tension. Stitches should

l‘e liai against the fabric without

causing any puckering.

■ Zig-zag stitching has many uses:

Seam Finishing

Use to “overcast” seam edges in fabrics

lhal tray to prevent raveling during

wear and washing. Press seam open

and siiicli each side separately.

Adjust stitch width and length to suit

fabric, (’lu)ose setting that will give (he

most open stitch and still secure (he

tabric edges. Avoid hansh, over-stitched

edges which become shff and shra

ndge on right side of fabric.

Use one of (wo methods:

• frim .seam edge evenly and place

• TIace stitching near edge of seam

25

You can make any mimhei of combi

nations by adjusting stitch width and

stitch length. Both knobs can be

turned while machine is running. How

stitching over raw edge of fabric best for firmly woven fabrics.

allowance and trim away excess

labric after stitching - best tor

labrics which fray easily, ligln-

weiglii fabrics, and knits which roll.

’ li

oir

S'

.......

«T

Wge Finishing

Use to finish hem edges and facing

edges to prevent raveling and to elimi

nate bulk ot turned-in edges. For firm

tabrics. stitch along edge of hem or

lacing. For loosely woven or soft

fihiics, stitch about

itien tn. fabric close to stitching.

Vz"

from edge

Interfacii^ Darts

Use to reduce-bulk when stitching a

dart in interfacing fabrics. Cut down

center ol dart to point; overlap cut

edges matching dart lines. Zig-zag

along dart line from wide end of dart

Ihrougli point. Trim both raw edges

close to stitching.

B^tacks

Use to reinforce points of strain such

as coiners of pockets, bell loops,

zipper openings, and lingerie straps.

Sot stitch width knob at medium zig

zag or wider and stitch length at FINE.

Shell Stitch Edging

Use lor a decorative edge treatment

lor lingerie and soft fabrics. Fold

undei edge of''fabric, lighten upper

thread tension so stitches will pull in

tabric, forming a scalloped edge, and

sew along folded edge.

Satin Stitch

Closely spaced zig-zag stitches which

form a smooth, satin-like surface are

called satin stitches. Use for mono

grams, appliques and embroidery. (See

pages .3 i-.?2).

Move stitch length knob to Q (||

loo close to 0, machine will not teed

hilt will continue sewing in one spot.)

I oosen tension of upper thread. The

widen the stitch, the looser the tension.

Page 16

i.1 Ht I CH i>l I ICHING

Wieii .sewing knitted or stretch fabrics, use a stretch stitch which allows the

seam to stretch along with he fabric, without breaking the thread. Select

polyester or cotton covered polyester thread which has an extra amount of

give and is designed for knits and stretch fabrics. Use a ball point needle,

especially on lightweight knits,.

STRETCH STRAIGHT STITCH

Machine Setting -

strength.

Use for stitching regular seams in knits

and stretch fabrics.

in woven fabrics, use for stitching

seams that receive a lot of strain when

worn such as side seams, crotch seams,

and armholes in sportswear and in

children’s clothes.

Also use for topstitching when you

want a heavier row of stitching with

out using buttonhole twisi thread.

Guide fabric gently, allow'ing machine

to make the back-and-forth stitches

that give stretch to the seam.

27

Stretch blindstitch has small zig-za

stitches between the larger zig-zag o

blind stitch. Use for hemming knii

and stretdi fabrics. (See page 34.)

Use for decorative stitching.

Page 17

SJ i i i Uf t liNÍU

A great variety ol decoralrve stitching can be created by using one or more

rows of a stitch pattern or by combining difïerent stitches - lop stitching,

decorative borders and trims, monograms, appliques and embroidery.

TOP Sin CUING

You can accent lines of a garment with

one or more rows of topslitching along

collars, lapels, yokes, lacing edges,

pockets, cuffs, seams and hems.

• Use straight stitch tor a more

tailored look, sewing with button

hole twist for added emphasis.

• Use stretch straiglit stitch for a

heavier row of stitching, even with

regular thread.

• Use satin stitch for wider row of

stitching, especially for borders.

Or use one of the following stitches,

varying the width for special effects.

STRETCH ZIG-ZAG STITCll

Stretch zig-zag stitch resembles rickrack trim. It is reversible, looking the

same on both the right and wrong

sides. (See page 28).

STRETCH BIJNDSTITCH

' I

" .Î

Stretch blindstitch is a very decorative

asymmetrical design, which can be va

ried by moving the stitch width knob.

(See page 28).

29

CREATE-A-STITCH

Machine Setting

Below ate jirst a lew ot the many patterns you can make with the Create-A-Stitch k

hot best results, sew at moderate rate of speed. Vary patterns by varying speed will

which you move lever, or by varying number of stitches made.

At even speed, move lever from left to right.

Tlien allow lever to slide back slowly while

holding it.

Move lever quickly to halfway point then more

slowly to extreme rigiri, 'flier, allow lever to

slide back slowly to halfway point, then more

quickly to extreme left.

Make patterns as above, then stitch 3 or 4

straight stitches before repeating design.

Use directions given for first design, but move

ever more slowly.

Alternate directions lor first and second designs.

Slide lever to extreme right before starting.

Hold urrtrl pattern is desired length, then quick

ly release lever and stitch 3 or 4 straiglit stitches

before repeating design.

At even speed, move lever slowly from left to

jéÊ .ji/É jjM

right, 'llien release lever quickly, allowing it to

spring back.

Slide lever to extreme right before starting, then

allow lever to slide back slowly whOe holding it.

nien immediately slide to extreme right again.

Move lever to extreme right and hold for several

slilches, then allow lever to slide back to left.

Move lever slowly from left to right. ITien re

lease lever so it III w spniig back only half way ;

hoki lor several stitches, then allow to spring

hack complete.

Page 18

MONOGRAMS

Many decorative stitches can be used

to add a personal loud: Iry inonograming a diess or blouse, v/riliiig a name

I »

i 1

'

_

I

on children’s clothes, or initialing

household Iinens.

Very simple straight-line monograms

can be made with the stretch straight

stitch. Use (’reate-u-Stitch lever for

more decorative touches at the ends

of each letter.

Use the satin stitch for script or block

letters, either alone or in combination

with other decorative stitches made

with the Creale-a-Stitch lever.

It stitching on very soft fabric, use a

backing of tissuepaper or interfacing

to eliminate puckering and to prevent

bobbin thread tVom showing on right

side ot tabric. Trim away excess after

stitching.

APPLIQUES

Appiic|ues aie cut-out designs ot one

fabric stitched to another.

Use a close zig-zag stitch or line satin

stitch. Or tiy varying the stitch with

the Creale-a-Stitch lever. However,

don t allow stitch to be too wide.

Stitch a sample first to decide which

method is best for your fabric:

• Baste applique design to fabric.

Stitch around entire edge of design,

llien trim away any excess fabric

around outer edge with embroidery

scissors,

• Baste applique design to tabric.

Stitch around entire design with

straight stitching; trim edges close

to stitching. Then overstitch edge

31

ot design with applique stitch.

EMBROIDERY

the needle in order to create your de

sign. Use either a straight stitch or a

zig-zag stitch.

Trace design on right side of fabric,

for best results, place tabric in an

embroidery hoop.

Remove all pressure from fabric:

• press DARN button all the way

down to lower tabric feed

• piess down on outer ring of pressure

icgulalor to relea.se pressure com

pletely ^

Place hoop under needle. Run machine

at medium speed, guiding hoop care-

tully so needle moves along pattern

lines.

Use straight stitch for outlining, and

zig-zag stitch for tilling in design.

Vaiy length of stitch simply by moving

hoop faster or slower under needle.

Place stitches close together tor a

smooth, satiny surface. Overlap

stitches for an irregular surface.

Page 19

i I I y iOl I L.O

Many of the finishing touches in a garment can be done by your machine hemming, making buttonholes, sewing on buttons, and inserting zippers.

HEMS

I wo type.sor hems can be made quickly and easily with no hand sewing by using

one of the blindstitches or the hemmer foot.

<! BLINDSTITCH

Machine Setting

Presser

I'OOt

Stitch

Pattern

Stitch

Width

Stitch

Length

Fabric

Feed

STRETCH BLINDSTITCH

Zig Zag foot

•

himt!

Shi. Ii

Kfpubr .Slri'llll

Sllltll SlMlll

o

Blindstitch consists of four straight stitches and one

zig-zag oi blind stitch. It provides a durable hem that

is almost invisible when using thread the same color

as the fabric. Only the blind stitches will show on

right side of garment. Best suited for straight orsliglitly

curved hems.

Turn up hem the desired width and press. Turn edge

in W\ press or baste in place.

Fold hem back against right side of garment with

top edge of hem extending about

ment fold.

Place garment under presser foot so that straight

stitches will fall on hem edge and zig-zag stitch just

catches on thread of folded edge. Guide fabric

evenly while stitching or use cloth guide as an aid.

Stitch slowly for better control.

Press hem.

For a less bulky hem in heavy fabrics, finish raw edge

with tape or lace to eliminate turning in raw edge.

Fold fabric so straight stitches will fall on lace or tape.

»4 ■ is

Darn Sew

'A"

to right of gar

Stretch blindstitch has small zig-zag

stitches between the larger zig-zag

Q

stitch. Use for hemming knits and

stretch fabrics.

Fold fabric and stitch same as for

blindstitch. However on knits, elimi

nate turning in raw edge to prevent

ridge from showing on right side ol

knit.

,^3

Page 20

Presser Fool

Hemmer Fool

Stitch Pattern

himtl Kc^uLir SiiL'iih

Snuli Snidi Shirli

O

Stitch Width

Stitch Length

l-abric Feed

Darn Sew

Narrow hems on mediiiin and ligliD

weigiii lahrics can be turned and

stilciied in a single operalion witliout

pinning or basting by using iliehemrner

foot. 'Hie loot forms a hem about 1/8"

wide. Use tor shi i and blouse hems,

curtains,rulfleedges, and lingerie.

Attach hemrner foot. Trim and

straigiiten fabric edge. For easy in

sertion of fabric in heiTimer foot, first

cut off corner of fabric. Then fold

edge of fabric over about 1/8", then

fold it over again for a length of 2".

Insert fabric fold into spiral opening of

foot. Move fabric back and forth until

die fold forms a scrolled shape. Draw

(abric toward you until beginning of

hem is underiieath needle. Lower foot.

Stitch slowly as you guide fabric into

henimer foot. Do not pusii or pull

(abric. (f edge of material lends to

slide oui of hemrner, guide it to the

right. It loo much malerial enleis

hemrner. draw fabric to llie left.

Mat Felled Seam

Use henimer foot lor making flat felled

seams on shirts and sportswear. Iliis

type of seam is strong and durable,

and provides a linished appearance on

both llie riglit and wrong sides.

Place fabric light sitles logeiher with

edge of boiiom piece exieiiding about

1/8" beyond edge of lop piece. Stiicli

fabric logeiher using henimer foot like

a regular presser fool. Ibc right edge

of foot as a guide for boliom fabtit,

and leli edge of long loe of fool as

guide for top fabric.

Open out fabric and place right sides

down, 1-old seam allow'anccs over lo

the left and insert in henimer fool

scroll. Sew' as you wouki for ordinary

heniniing. As a guide, run first row of

slitclies along left edge of long toe of

fool.

Machine Setting

H.ll I.K ks

I Hullun

I Opumi)^ ÿ

I

Hullnnhulc Bulhinhulu

Markings Sltic luiij,:

— BjîI.U Rn

BUTTONHOLES

Your iiiudime has a built-in buiton-

boler - jusi dial the slilch width knob

for the tour steps in stitching a liiitton-

liole.

• Mark position and length of button

hole on fabric. Length of the hole is

deierrnined by the width plus ihickne.ss of the button. Ihe finished

Iniilonhole should be 1/8" longer

than this measurement to allow loi

bar lacks at each end.

• Allach buttonhole fool which

allows you to see your markings

and smelling through the clear

plastic loot.

• loosen upper tension.

• When sewing biillonholes on knits

oi loosely Woven lahiic, use a piece

of interlacing between lahiic anil

lacing so hullonhole will retain its

shape.

• Guide fabric carefully so lines of

stitching will be straight and close

logeiher. but not touching.

• Always make a sample bullorihole

using the same lahiic before si itch

ing on your garnienl. Try slipping

the bution you will use ihrough the

hullonhole lo check the correct

leiigili ol (he hole.

Page 21

Slilcti

Widlh

Stitching Buttonhole

STlil’1 - Turn stitch width knob to »1 to

stitch left side of buttonhole. Place

fabric under buttonh(jle foot so needle

enters fabric on mark at end farthest

from you.

Stitch left side of buttonhole the

desired length. Raise needle to its hig

best position.

STIiP 2 - Turn stitch width knob to #2 for first

bartack. Make 5 or 7 stitches. Raise

needle to its highest position.

S'fliPi - Turn stitch width knob to to stitch

right side of buttonhole. Machine will

stitch in reverse. Stitch right side the

same length as left side. Rai.se needle to

its higlrest position.

STPP4

r

Siiteli

l.cigUli

Turn stitch width knob back to #4

for second bartack. Make 5 or 6

stitches’ to complete buttonhole.

furn stitch width knob to straighi

stitch symbol, and turn stitch length

knob to 0 so machine does not feed.

Make 2 or stitches to securely fasten

stitches. Draw upper thread through

to under side.

Machine Setting

Presser

[’’oot

Button Sewing

Foot

Stitch

Pattern

#

Blind Kcpolur Slreich

Sitivii Smth SiUch

0

BUTTONS

Stitch

Width

,4u

{ W

You can sew both two and four hole

buttons with your machine.

Change presser foot to the button

sewing foot and be sure to lower fabric

feed by pressing down DARN button.

Place button under button sewing

foot. Turn stitch width knob until zig

zag stitch is same widtli as the holes in

the button. Turn hand wheel toward

you and test carefully that the needle

goes through the center of first one

hole and then the other.

Hold both threads behind presser foot

and sew 5 to 6 stitches.

Turn stitch width knob to straight

stitching aiul take about 3 stitches to

lock the thread.

hor a four hole button, lift presser

foot slightly ami move fabric to permit

stitching the remaining two holes.

Hooks and snaps can also be sewn

following the same prcxiedure.

Stitch

Length

/ \

Fabric

Feed

Darn

Q

Sew

_

Cut buttiinhole open using embroidery

scissors or seam ripper, being careful

not to cut stitching on either side.

Place a pin acorss each end of button

hole to protect end stitching.

31

Thread Shank

Sew-through buttons on coats and

jackets should have a thread shank to

make them stand away from the fabiic.

Place a straight pin or sewing machine

needle on top of button between the

holes, and sew over the pin or needle.

Pull thread to back of button and

wind aiound stitches to form a firm

shank, lie thread ends securely.

38

Page 22

ZIPPERS

MENDING

Machine Setting

Presser

I’OOl

Zipper l'Oüt

1 t:flside ol needle

Stitch

Pattern

hluid RfguLit Sitckli

StUth Sutch Siitth

o

Stitch

Width

Stitch

Length

Darn Sew

Zipper fool allows you to stitch right

next to a raised area such as a zipper

or cording. The foot is adjustable so it

can be moved to the left or right side

of the needle without having to turn

the fabric.

Raise needle to its highest position,

attach zipper fool, and set controls for

straight stitching.

To adjust foot for left side of needle:

loosen screw at back of foot and slide

foot to the left so that needle passes

tlirougli notch on right side of fool.

Lower needle slowly to be sure it will

not hit zipper fool, and tigliten thumb

screw.

For right side of needle, slide foot to

tlie riglil.

Zipper package will contain easy to

follow instructions for stitching.

Fabric

Feed

Machine Setting

Presser

Foot

11

Zig-zag l oot

Stitch

Pattern

HliiiJ 'Kc^'ulaf Slrclth

Siiitli Siiit-h Siiich

0

Stitch

Width

//

lW

Stitch

Length

s.

W

Darn Sew

mi

dears and patclies can be stitched

easily and quickly with zig-zag stitch.

Tears

Trim ragged edges. Position tear under

needle and stitcli along tear catching

both sides of material.

Witen mending a three-cornered tear,

stitch from each end to center. For

large tears, place piece of fabric under

I car for reinforcement.

Patchy

Stitch patch into place around edge

of liole 01 worn area. Trim raw edges

close to stitcltiiig.

I'abric

Feed

Corded Seam

Cording gives a professional finish to

slipcovers, pillows, cliildren’s clothes

and lingerie.

First, make welting by covering cord

ing with bias fabric and stitcliing close

to the cord with zipper fool.

'Ilien stitch welting into seam using

zipper foot.

y)

40

Page 23

UAKIMINÜ

PAH I 111 CAHIIMG FOR YOUR MACHINE

Machine Setting

Fresser

I'oot

None

Stitch

Pattern Width Length Feed

#

llJuiil Rc^’Uiar .Sliftili

Slit.It Slilch Shkii

Stitch Stifeh Fabric

1

-

/ \

( J

( /

0

Worn spots on clothing and household

linens can be darned easily with your

machine.

Completely release pressure on fabric

by pushing down DARN button and

by pressing down on outer ring of

pressure regulator until center button

pops up.

For greater control, especially when

darning larger areas, place fabric in

embroidery hoop. For large holes,

baste a piece of mending material

underneath hole to use as a base for

stitching.

Place fabric under needle. Move fabric

back and forth with an even motion to

cover darning area with closely spaced

rows of stitching. Then turn fabric and

sew a second layer of stitching across

first layer of stitching.

Darn

O ■

Sew

__

CLEANING

Your machine will always work well

you take a few moments to keep

clean. If lint and bits of thread a«

cumulate under needle plate, aroun

fabric feed and in the shuttle, this wi

interfere with the operation of yoi

machine. Check occasionally and clea

whenever necessary.

• Before cleaning, disconnect cor

from outlet.

• Remove needle, presser foot, needl

plate and slide plate.

• To remove shuttle: raise needle be

to its highest position and remov

bobbin case. Turn levers away frot

shuttle and lift our retaining tin

and shuttle, by grasping center pin.

• Thoroughly clean under fabric feet

with a small brush. Remove lint am

thread from all parts of shuttle ani

wipe with a lightly oiled cloth.

• To reassemble: hold shuttle b;

center pin, and fit carefully bac

into shuttle race, forming perfec

circle with driver. Replace retainin

ring, polished side out, making sur

the bottom pin fits into notcl

Lock retaining ring by tumin

levers back into position until the

snap over the two small post;

Replace bobbin and case.

41

Page 24

UILINU

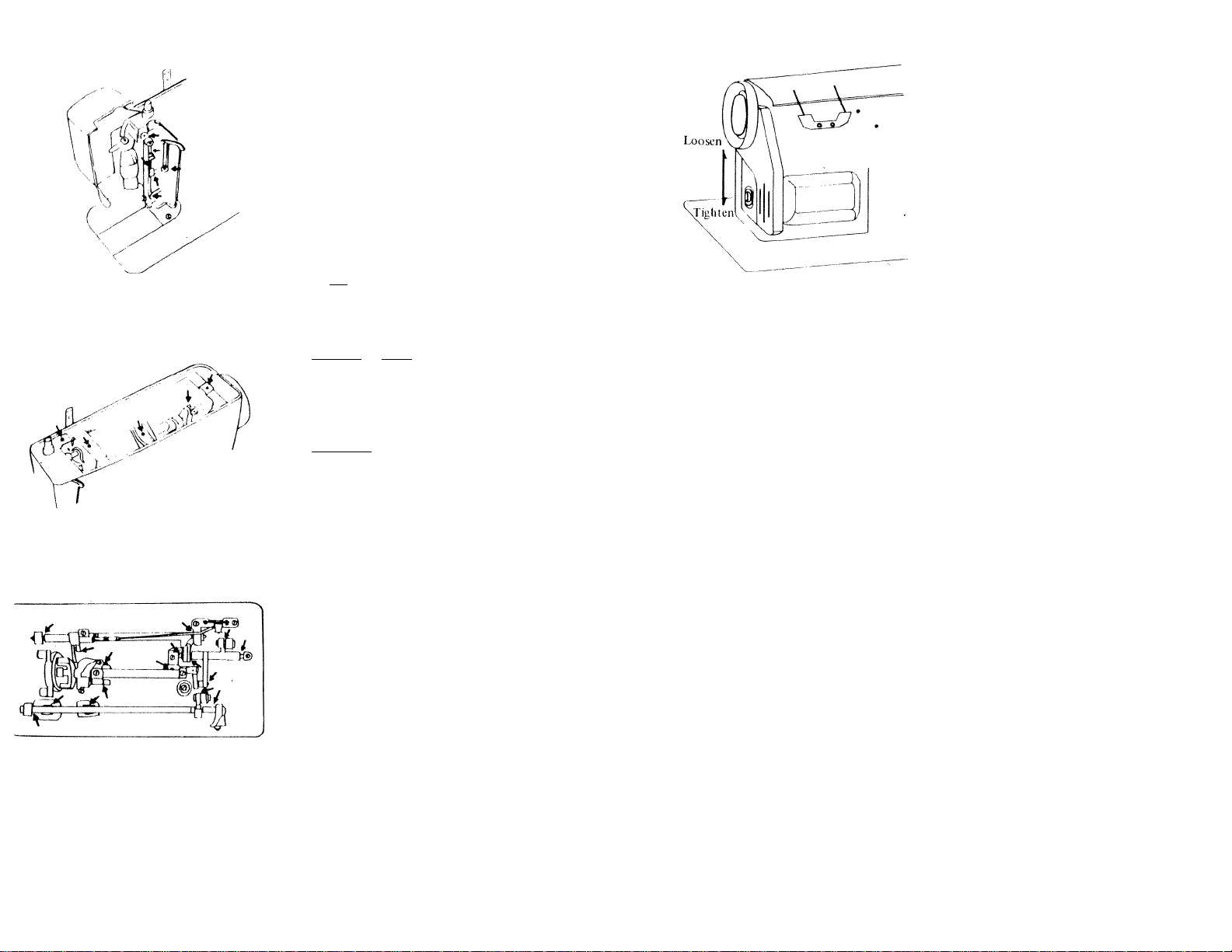

ADJUSTING BELT

Your machine needs lu be oiled once

every week if used rie(|uentJy and

every day if machine is in continual

use. If machine has not been used for

a period ol lime ihe oil will have dried^

so be sure lo oil belore you start

sewing.

Place a drop of best quality sewing

machine oil at each of the points

shown in the pictures:

Inside Face Plaje ^ swing face plate

open and oil all moving parts at

friction points.

Under Top Plate ^ remove lop plate by

unscrewing two screws located at each

end of the top plate and oil points

on top of machine head.

Underside - tilt machine head back

and oil points on underside.

It is important that you do not give

the machine too much oil which will

only run out and spot your tabric.

JC Penney Model 6105

Serial No.

When ordering replacement parts

give model no and serial no.

The tension of the motor belt can I

adjusted by moving the motor brack

located on the right side of tl

machine.

Use a screwdriver to siighily loosr

the screw securing the molor biacki

Slide bracket down to iighleii icnsh

but be careful not to tighten hr

too tiglitly. Slide bracket up toloosi

tension.

When proper adjustment is attaine

tigliten screw securely.

CATALOG NUMBER-868-2445

MODEL NUMBER 6105

When you need sereice or replacemei

parts, please be sure to give the mod

and serial numbers. They are show

on the model number plate mountc

on the front side of the machine base

After oiling machine, run Ihe iiiailmie

at high speed so that oil will peiieii.iuall moving parts. 'ITien sew a lew low's

of stitches on a scrap rrf material lo

be sure that machine sews cleanly.

Also wipe off any excess oil from lop

of niadiine.

Do not oil the motor as it has been

permanently lubricated at Ihe factory.

4.3

44

Page 25

PROBLEMS ^ AND PROBABLE CAUSES

In must cases, poor sewing results are due to a damaged needle. Always examine

needle f irst tielore checking other items.

1, SKIPPING STITCHES

l)cnl or blunt needle

wiong size needle

needle inserted incorrectly

needle threaded incorrectly

upper thread tension loo tight

pressure on presser toot too light

2. UNEVEN STITCHES

bent 01 blunt needle

wrong size needle

incorrect threading

pulling fabric while sewing

upper thread tension loo loose

|)iessurc on pressei foot tooliglit

loose presser fool

fabric feed too low

bobbin would unevenly

bobbin inserted incorrectly in case

NEEDLE BREAKS

bent needle touches needle plate or presser foot

needle inserted incorrectly

pulling fabric while sewing

loose presser fool touches needle

needle loo tine lor fabric

moving stitch ptiltern lever or stitch width

dial with needle in labric

lower THREAD breaks

• bobbin case threaded incorrectly

• bobbin case inserted incorrectly in machine

• bobbin wound unevenly

• bobbin wound too full

• bobbin tension too tiglit

• rougli edge in hole of needle plate

• bent bobbin

• poor quality thread

FABRIC PUCKERS

• bent or blunt needle

• upper thread tension too tiglrt

• botJi upper and lower tensions too tight

• using two diflerent kinds ot sizes ot thread

• fabric too sheer or soft (use tissue paper underlay)

MACHINE DOES NOT FEED FABRIC

7.

• stitch length knob set at 0

• fabric feed on DARN

• presser foot not down completely

• thread knotted under fabric

BUNCHING OF THREAD UNDER FABRIC

• upper and lower threads not drawn back under presser foot

• fabric teed on DARN

BOBBIN DOES NOT WIND PROPERLY

• incorrect threading

• bobbin winder thread guide not positioned correctly

• bobbin not positioned correctly on spindle

• bobbin winder not engaged with hand wheel

4. UPPER THREAD BREAKS

bent or blunt needle

incorrect threading

upper tension ioo tight

needle inserted incorieclly

needle touches presser foot

needle eye has sharp edges

poor quality threail

knots in thread

starling to stitch loo fast

thread jammed in shuttle

45

MACHINE RUNS SLUGGISHLY

10.

• dirt or lint between teeth of fabric feed

• dirt 01 lint in shuttle

• machine needs oiling

11. MACHINE WILL NOT SEW

• cord iu)i plugged into outlet

• cord not plugged into "Motor’’ socket in Cabinet or case

• stop motion knob not tightened

• motor licit too loose rrr broken

46

Page 26

Âccessories/Accesorios especiales

и

411 85 00-45. Presser foot for attaching

braiding, v.'hich is inserted through a guide

end Gftcched with a straight stitch in the

miedie of the oraiding,

411 as 00-45. Prensateias pera sobrecos

er cinre aecorativa. A través de ia guía, se

inrroducs ia cinta у se sobrecose ia misma

cor ei centre mediante un pespunte recto,

411 85 01—45. Tepe guide, faciütates guid

ing таре, cord етс, ¡пто braiding foot.

411 85 01—45. Guíe de cinta, fcciiitcndo ic

conducción de la cinta.

411 85 30—45. Presser foot H. The same as

presser foot A but the underside is coated

with teflon for sewing leather or plastic. 4

411 85 30—45. Ei prénsatelas H es iguai ai

prensoTelas A, pero con ia parte inferior de

teflon para coser en cuero y material sintét-

412 34 73-45. Presser foot for gathering.

The fabric is gathered as it is sewn - longer

stitch wiii produce fuller gathering. The gath

ered fabric can be sewn simultaneously tc

another ungethered fabric.

412 34 73-45. Prensateias fruncidor. Se

pone ia teia por debajo del prénsateles y

cuanto más larga sea la longitud de punta

da, mayor fruncido se obtiene.

We reserve the right to change the ma

chine equipment and the assortment of

accessories without prior notice, or make

modifications to the performance or de

sign.

Such modifications however will always

be to the benefit of the user and the prod

uct.

Nos reservamos el derecho a modificar

la máquina, el equipo ó ios accesorios

extras sin previo aviso. Tales modifica

ciones serán siempre para beneficio del

consumidor y del producto.

39

Loading...

Loading...