Page 1

INSTRUCTION MANUAL

MODEL 511-F SEWING MACHINE

Page 2

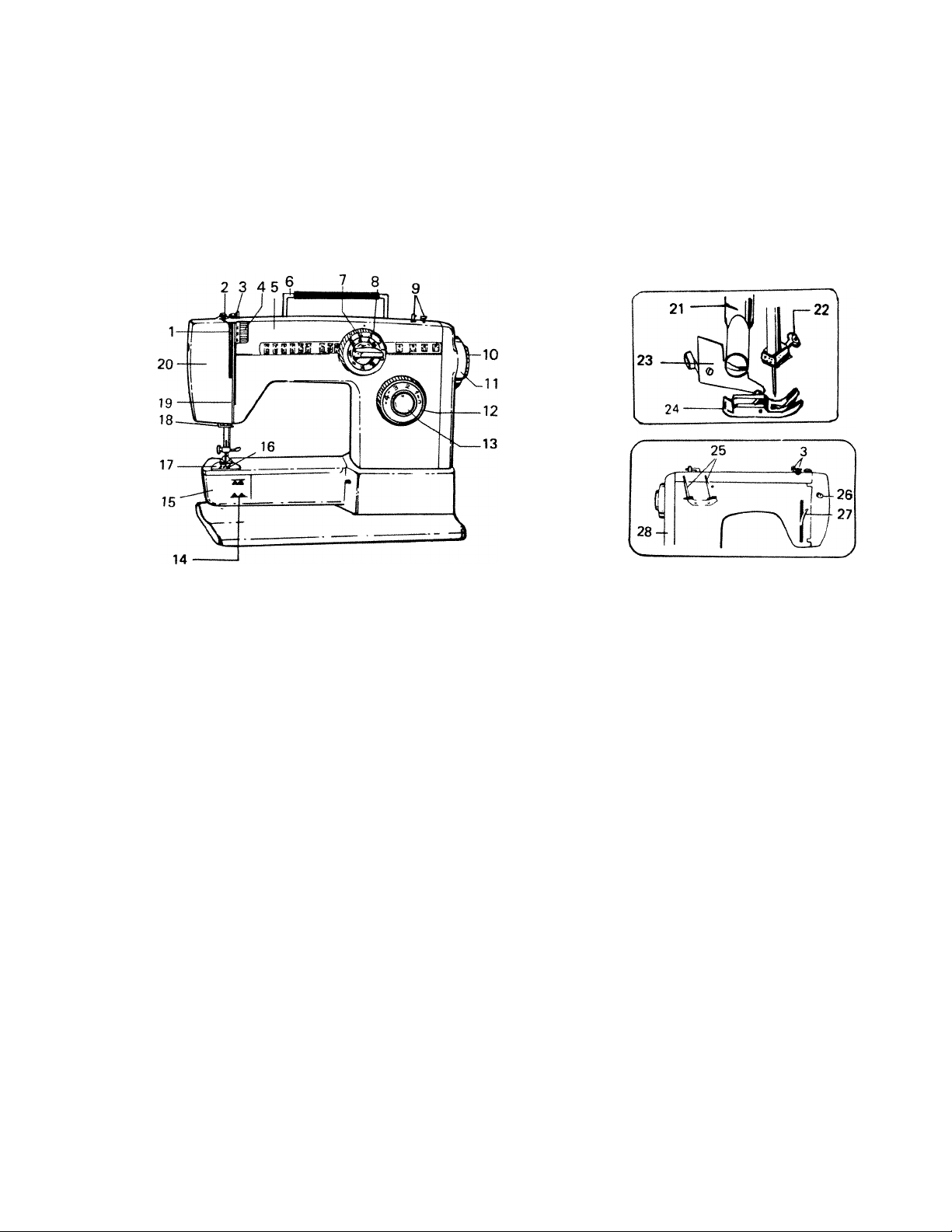

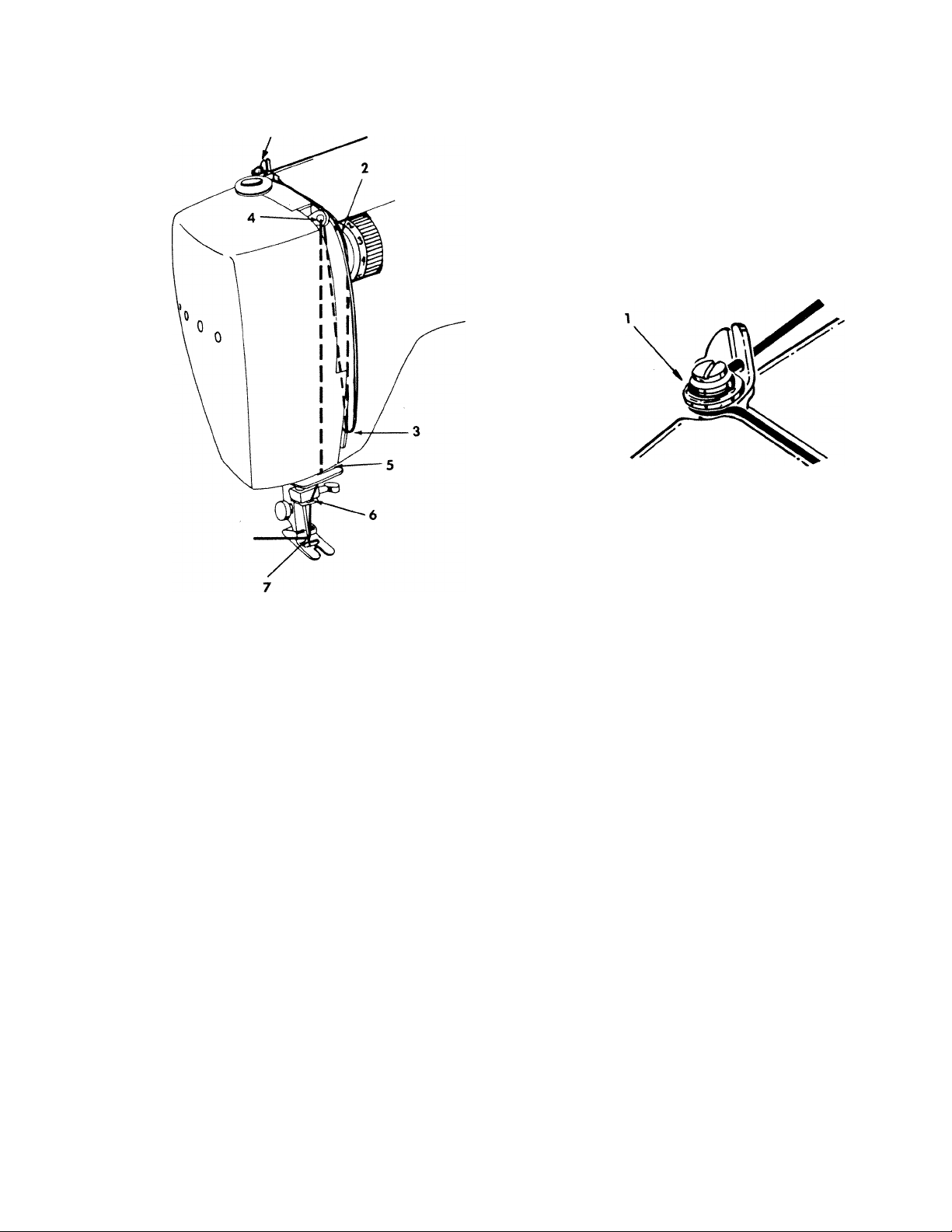

FEATURES AND PARTS

1. Thread Take-up Lever

2. Pressure Release (Darning)

3. Top Plate Thread Guide

4. Tension Regulator

5. Top Plate

6. Handle

7. Needle Position and

Pattern Selector Dial

8. Zigzag Width Control Dial

9. Bobbin Winder

10. Fly Wheel Clutch

11. Flywheel

12. Stitch Length Control Dial

13. Reverse Button

14. Drop Feed (under Shuttle Cover)

15. Shuttle Race Cover

16. Feed Dog

17. Needle Plate

18. Thread Guide

19. Thread Guide

20. Face Plate

21. Thread Cutter

22. Needle Clamp

23. Presser Foot Thumb Screw

24. Presser Foot

25. Spool Pins

26. Light Switch

27. Presser Bar Lifter

28. Motor and Belt Cover

Page 3

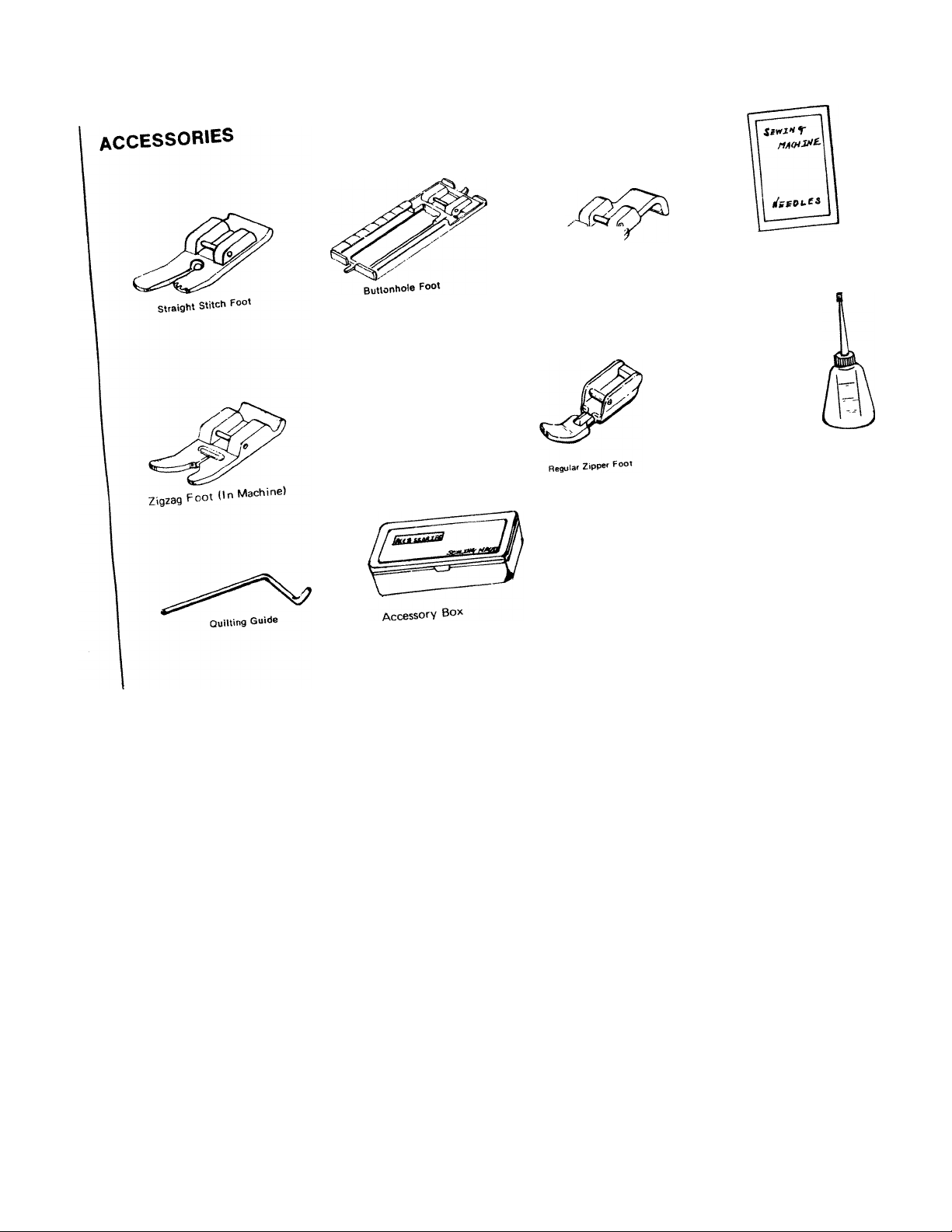

Button

Foot

Needles

Fetts

Bobbins

Seam Rippßt

screw Drivers

Oiler

Page 4

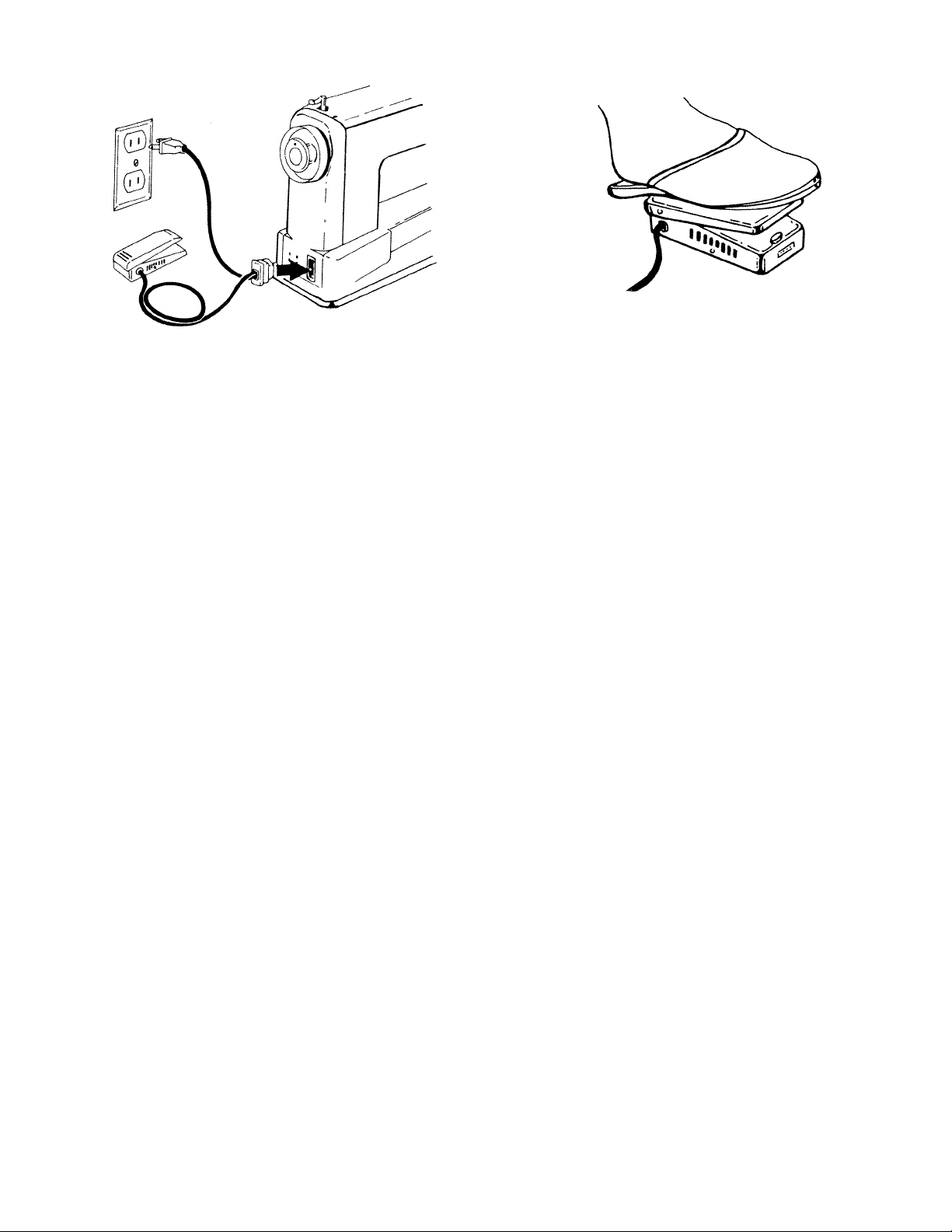

USING THE FOOT CONTROL

TO CONNECT THE FOOT CONTROL WIRES:

• Connect special plug to block on machine as

shown in diagram above.

• Connect outlet plug to electrical outlet.

• When sewing, keep children’s hands away from

foot control.and wiring.

• After sewing, disconnect plug from electrical

outlet.

TO USE THE FOOT PEDAL:

• Begin sewing by turning the hand wheel toward

you and apply gradually increasing pressure to

foot pedal.

• Sewing at a constant speed will give best results.

Page 5

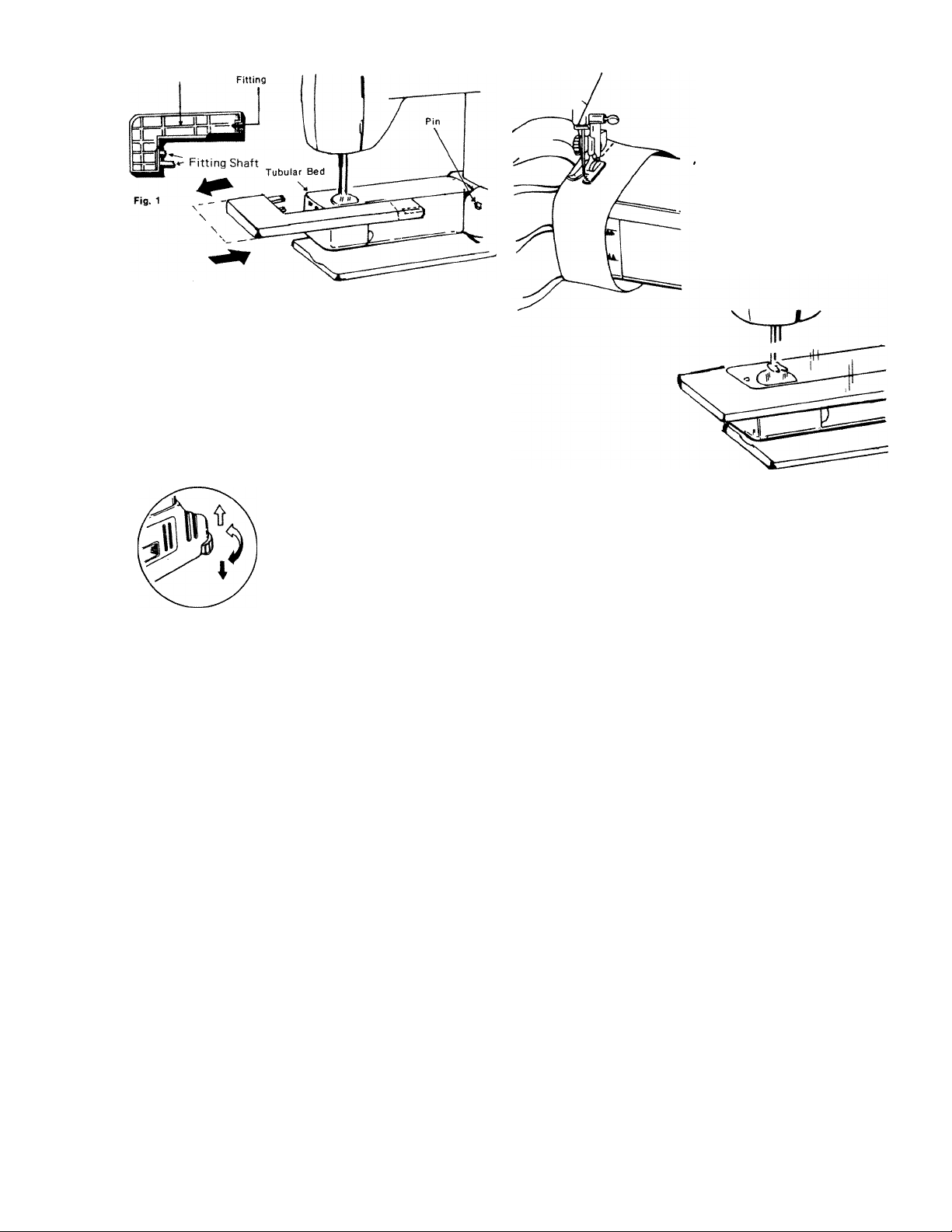

USING THE EXTENSION PLATE

Extension Plate

Fig. 2

TO ATTACH AND REMOVE THE EXTENSION PLATE:

• By sliding extension plate on tubular bed, as

shown in Fig. 2, engage fittings on plate with pin

on tubular bed, and pull to the left to remove the

extension plate.

LEVELING THE MACHINE

Level your sewing machine

when you use it on the table or

install it into the cabinet.

UP: Counter-Clockwise

DOWN: Clockwise

FREE ARM FEATURES

TUBULAR SEWING

• The free arm design

simplifies the sewing of

tubular items such as

pant cuffs, shirt and

blouse cuffs and socks.

Simply position these items

over the tubular bed of

the machine and sew.

FLAT BED SEWING

• When the extension plate is attached, you have

all the advantages of a flat bed machine for

sewing flat items, and for sewing large tubular

items such as flared pant legs.

Page 6

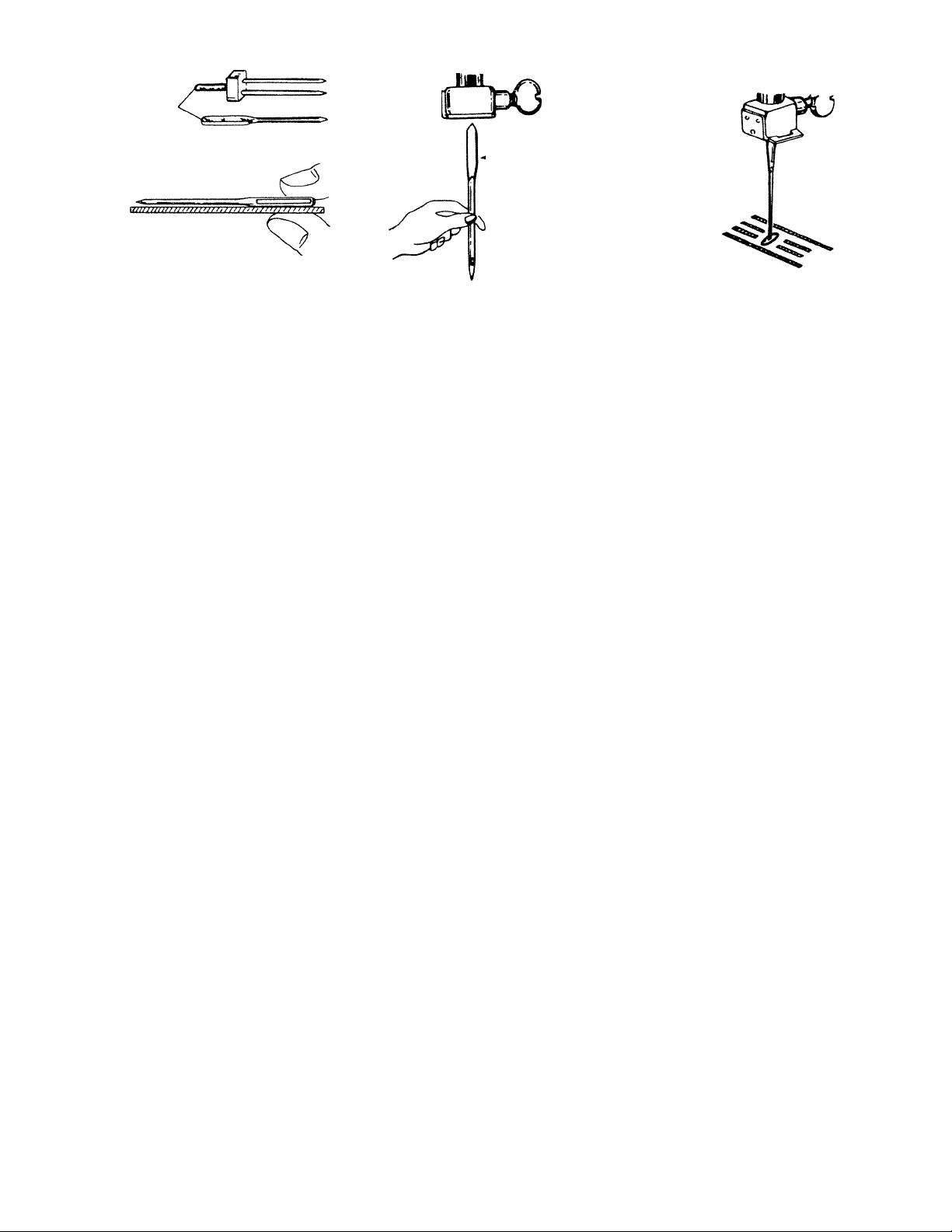

CHANGING THE NEEDLE

Flat side

Always make sure needle is

straight.

To check straightness of

needle, lay needle on a flat

surface and see that needle is

straight and parallel as shown

in above diagram.

• Needle

Clamp Screw

Flat side towards

back of machine

• Turn hand wheel toward you to

raise needle bar to its highest

position.

• Loosen needle clamp screw

and insert needle upward as

far as it will go, making sure

flat side of needle is towards

back of machine as shown

in the above diagram.

• Tighten needle clamp screw

with screwdriver.

• Follow the same procedure for

insertion of twin needle.

To make sure that needle has

been inserted correctly, turn

hand wheel toward you and

see that needle comes down

through the center of the

needle hole in the needle plate

as shown in the above diagram.

Stitch selector dial must be set

in straight stitch needle posi

tion when checking needle

alignment.

If skipped stitches occur, needle

may be incorrectly inserted.

Page 7

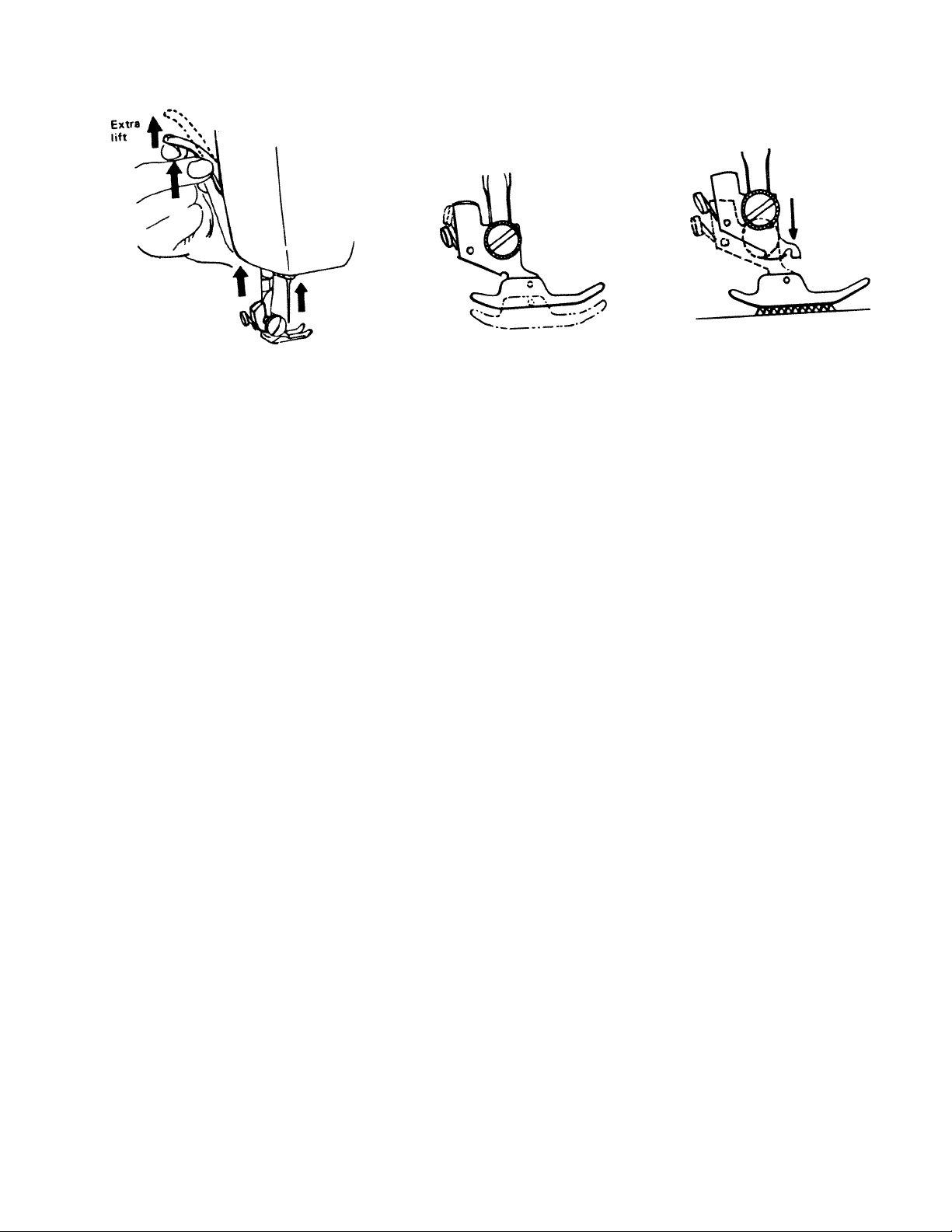

CHANGING THE PRESSER FOOT

Raise needle lis'

position and raise presser tooi

as shown. .

The extra lift for heavy fabric

makes it easier to place fabric

under the presser foot.

TO REMOVE THE PRESSER FOOT.

. Press button '

foot shank and foot wiH drop

from shank as shown above.

I It is not necessary to loosen

the thumb screw to change

presser foot.

TO ATTACH

THE PRESSER FOOT.

• Align desired presser foot to

shank as shown above.

• Lower presser p

shank will automatically attacn

to foot as shown above.

Page 8

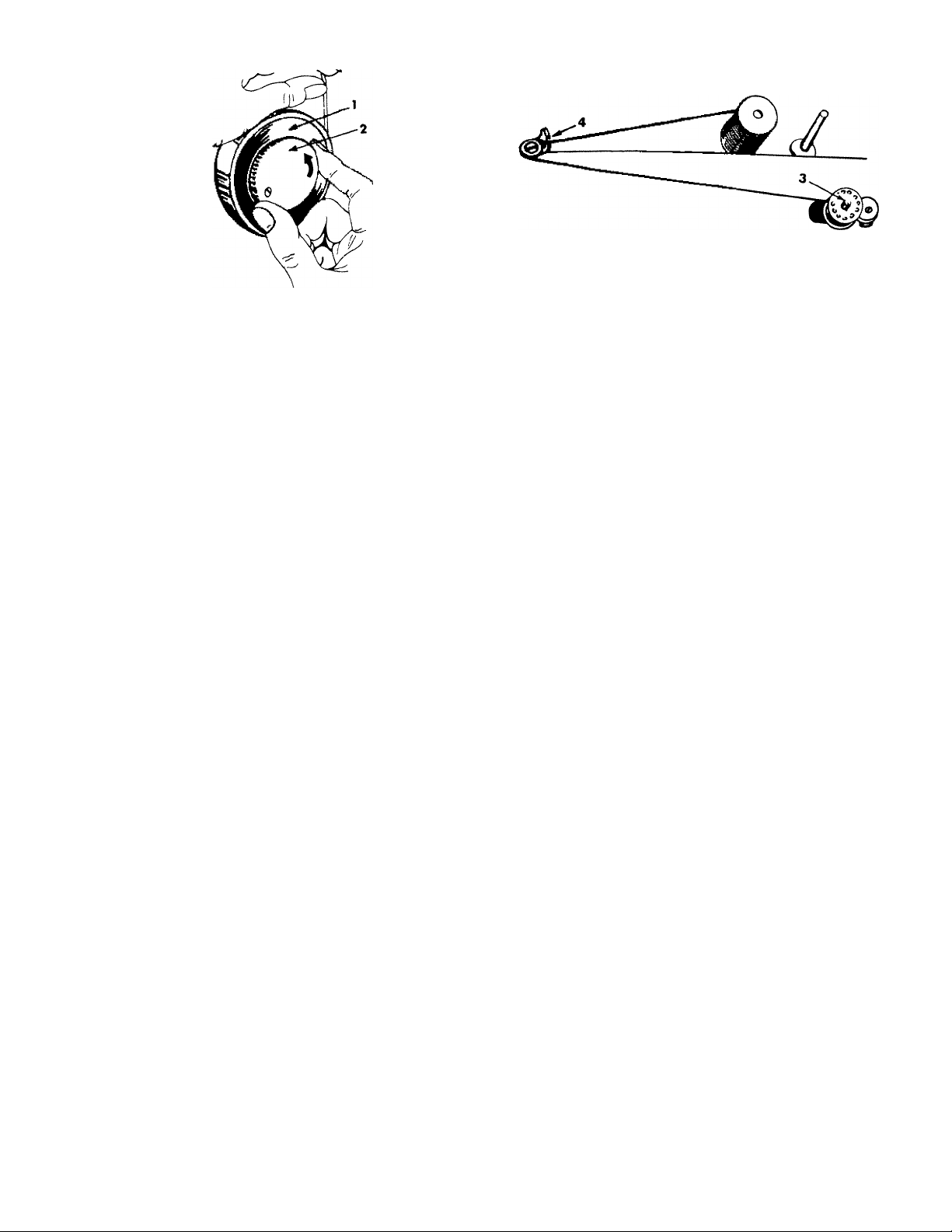

WINDING THE BOBBIN

TO DISENGAGE THE HAND WHEEL:

• Hold the hand wheel (1) with left hand, turn

clutch (2) counterclockwise with right hand to

disengage as shown.

TO WIND THREAD ONTO BOBBIN:

• Lead thread through spring thread guide (4) and

through the hole in your bobbin from the inside

out.

• Place the bobbin onto the bobbin winder shaft

(3).

• Push the bobbin winder to the right.

• Hold loose end of thread firmly and turn hand

wheel to make thread tight. Apply gradual

pressure on foot pedal until automatic shut off

disengages bobbin winder.

• Cut off loose end of thread.

Page 9

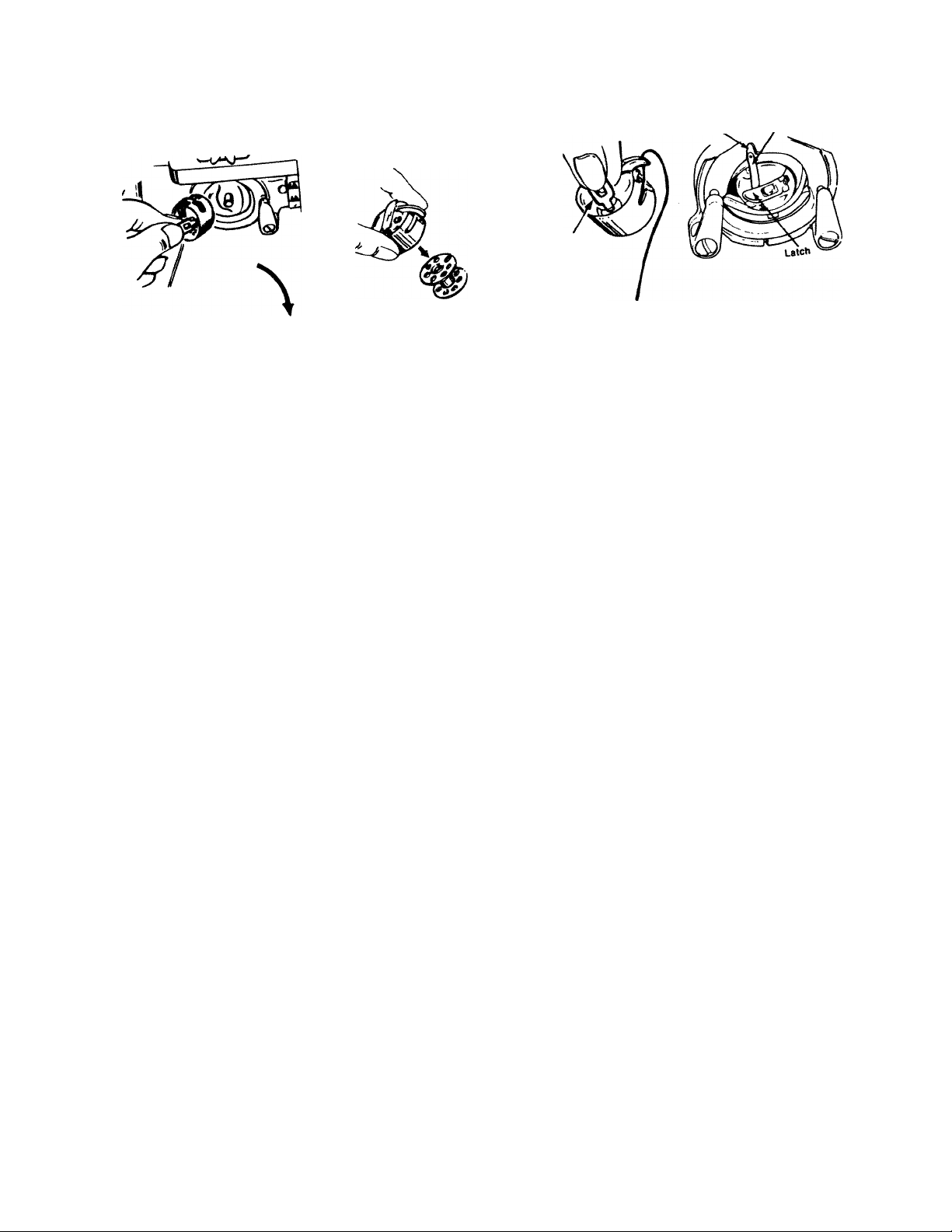

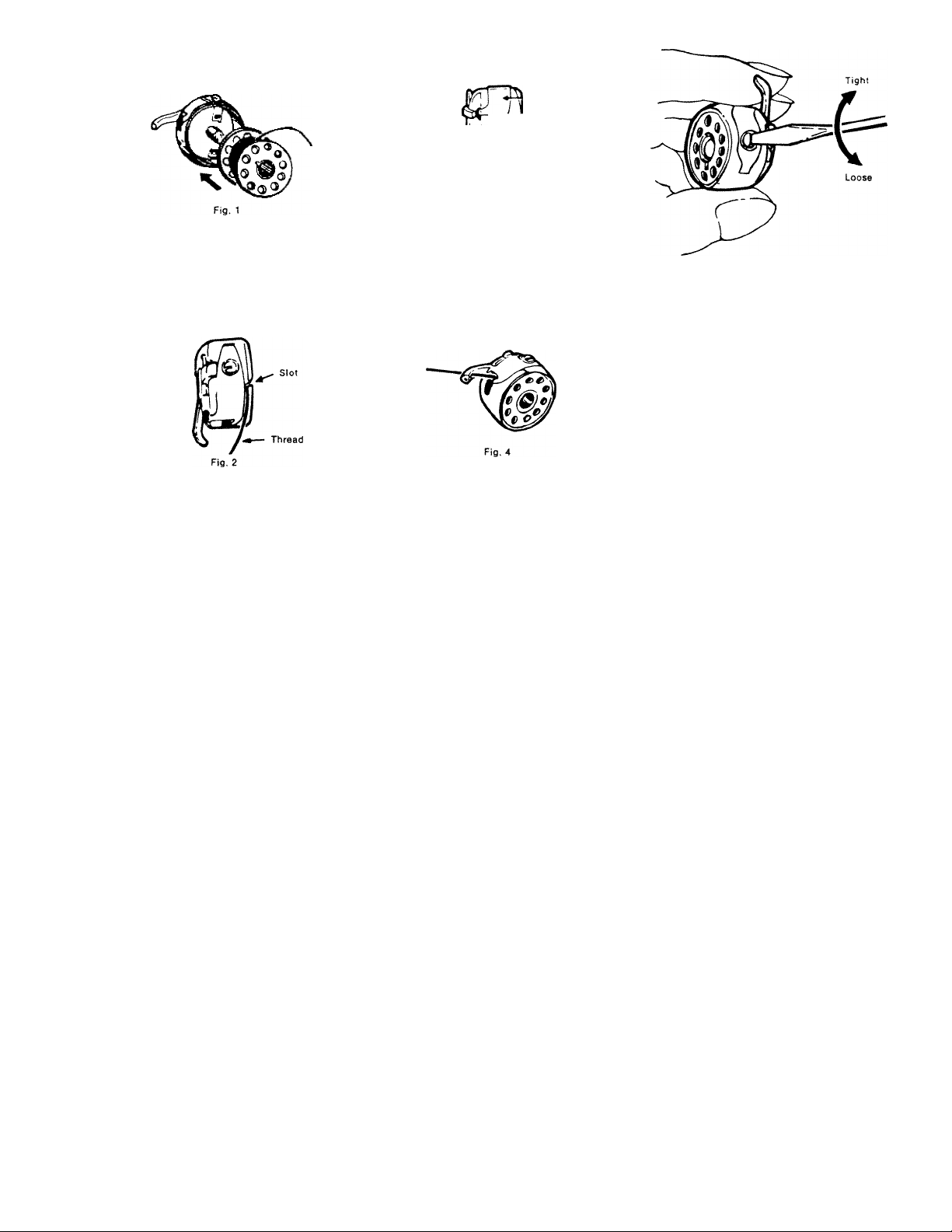

CHANGING BOBBINS

TO REMOVE THE ”e°rpoStoii, Bobbin

With two fingers ana I

. ieCvfbobbln 1,0. bobbin case by releasing

Satch.

Notch

Latch

»f-TArM THE BOBBIN CASE:

TO ATTACH THt . from bobbin.

Finget

. Pull thread at least 3 inches i

, Thread bobbin as highest

. Making sure into shuttle race by

nn«;ition insert boDui Make sure bobbin

ac <;hOWn on p3Q®

KoSng bobbin case p„ss bobbin

case trngons insirla shojue^^^.^ ,,,

cScheion P°tt b' «’b

Page 10

THREADING THE BOBBIN CASE

Pull thread at least 3 inches from

bobbin. Insert bobbin in bobbin

case so that thread will unravel

clockwise.

■ Tension Spring

Fig. 3

Draw thread under the tension

spring and into the fork-shaped

opening of the spring as shown

in Fig. 3.

Fig. 5

TO ADJUST BOBBIN TENSION:

• Turn screw on side of bobbin

case clockwise to increase

tension.

• Turn screw on side of bobbin

case counterclockwise to

decrease tension.

Pull thread into slot of bobbin

case as shown in Fig. 2.

Pull thread through hole in

bobbin case finger as shown in

Fig. 4. (Recommended for

zigzag sewing only)

Page 11

UPPER THREADING

Raise needle batto its highest position.

Ltdre"gh top p,a.e.htead guide ,1,

rti,ra“Srat"ounda;.threadguide(3,

Mt hooking thread into guide.

’ ^¿trou1htredleS'irrrn1;o^^^^

,,„avs use

bottom as different sizes or xypc

r“" T'°PoC«“'ead on the bobbin and

L“Z,bread on top will result in poor tension

quality.

10

Page 12

(TWIN NEEDLE UPPER THREADING)

• Follow threading instruction for single needle with

these exceptions.

• Place thread, matching or contrasting in color, on

both spool pins.

• Draw threads through thread guides as normal, but

separate the threads at the tension.

• Pass thread through the left disc and one thread

through the right disc.

• Now treat both threads as one until you reach the

needle eyes.

ZIGZAG DIAL: Set at desired width between "0" and

"3", if you set dial higher than 3, the needle will hit the

needle plate and break.

STITCH LENGTH: Set at desired stitch length.

ADJUSTING FEED DOG HEIGHT

M

Upper position of feed dog is used for normal sewing.

To raise feed dog.

Press drop feed button "-Allocated under shuttle cover,

to upper position.

Lower position is used for Embroidering, Mending or

Sewing on Button. Press drop feed button to

lower position.

11

Page 13

PICKING-UP LOWER BOBBIN THREAD REGULATING PRESSURE

Holding upper thread, turn hand wheel toward

you one rotation. When take-up lever is at its

highest position, pull thread to pick up loop of

lower bobbin thread.

Pull both upper and lower

thread "to the left of"

presser foot approximately

6 inches.

This will prevent jamming.

' The amount of pressure that is applied to the

fabric by the presser foot is adjusted by the

pressure cap (1). The upper position gives the

least amount of pressure while the lowest position

gives maximum pressure.

To increase the pressure, push down on the

pressure cap to obtain the desired setting. To

decrease the pressure, press down on the snap

lock ring (2) to allow the pressure cap to return

to its maximum height. Then reset to the proper

pressure.

Normally the pressure cap will be in the lowest

position. If the top layer of fabric tends to push

out further than the bottom layer of fabric,

Pressure should be decreased. This often happens

on bulky fabrics, such as wools, and on knits.

12

Page 14

ADJUSTING UPPER TENSION

Fig. t

Proper Tension

Fig. 2

Upper Thread Tension Too Loose

Fig. 3

Upper Thread Tension Too Tight

To increase upper tension, turn upper tension

regulator to higher number.

To decrease upper tension, turn upper tension

regulator to lower number.

Turning tension regulator from "0” to “9” will

increase tension. Normal sewing is performed

between “4” and “5”.

Note; Normal stitches will be performed on the red

zone at 4, 5 and 6 for regular cotton threads.

A perfect straight stitch will be formed with both

threads interlocking in fabric as shown in Fig. 1.

When using the zig zag stitch for embroidery

(satin stitching), decrease upper tension so that

top surface will look smooth at the expense of the

bottom surface.

13

Page 15

STITCHJ^NGTH^^

fabric

________________

~~~~ Z ~ u Z \ace, organdy,

------taf_feta_

_ : ,;rsev. double knit power n^ ^ ^

suits __ __ _ — — —

MED!U|«i^ings^ w^^^^ ^ -

I denim, ^ ^ —

■""^-7akefurs^vel^rs^swe^«^__ _ ^ '

— — ”” ”” ,ar rtfit

needle (Long Scarf) 1 tHBEAD

130/705H

HA X 1 European

Fine

65/9 '

light ball point.

~T^ I

light ball point

Wedge point

90/14 I ^

light or medium

ball point

Wedge point

Toofii"~|

Wedge point

heavy ball point

Wedge point

I ■•A" Silk

point

European 50

Fine Synthetics

Finemercedzed60

European 50 'u

I Fine Synthetics

I •■A" Silk

1

Mercerized M

1 European JU

» "A‘* Silk

i Synthetic

liS'Cr

I European 30

"A" Silk

1 Synthetic

, Heavy Duty Mercerized I

European 30

I Synthetic

STITCH LENGTH

1-1/4 - 1-3/^

1-3/4-2

2-1/2 -3

2-1/2 -4

vinyls, plastics

14

Page 16

FUNCTIONS OF CONTROLS

NEEDLE POSITION AND

PATTERN SELECTOR DIAL

• Raise needle bar to highest

position by turning hand wheel

toward you.

• Select desired pattern and

needle position.

• Selector dial can be turned

either clockwise or counter

clockwise.

ZIGZAG WIDTH CONTROL DIAL

• For wider zigzag stitch,

select a higher number.

• When twin needle is used,

zigzag must be limited between

positions “0” and "3” on the

dial (use of twin needle in

position higher than “3” will

result in needle striking

needle plate).

STITCH LENGTH CONTROL DIAL

• Numbers on dial denote

length of stitches.

• To increase length of stitch,

turn dial to higher number.

STITCH LENGTH GUIDE

Numbers

on dial

Stitches

per inch

0 1 2 3

No

24

Feed

12 8

4

6

REVERSE STITCH BUTTON;

• Use for reverse stitching or

tacking.

• Keeping button pressed in will

allow you to sew reverse stitch

at same length as forward

stitch.

15

Page 17

SELECTING NEEDLE POSITION

Right

• Three different needle positions, " 1 " left,'' 2 " middle

and 3 right can be selected. Also, those intermediate

positions between left and middle and right can be

selected with the dial at the middle between '' 1 2 ",

and "2 3" as shown Above.

1 - - - indicates the left hand needle position

2 - - - indicates the m i ddle needle position

3 indicates the right hand needle position

Middle

Left

STRAIGHT STITCHING

Stitch Length

Control Dial

Set the stitch length control dial to the desired

stitch length (0—4).

Set the zigzag width control knob to "O"

position.

Set the needle position dial to "2 " position.

Straight Stitch

Presser Foot

16

Page 18

CHANGING

DIRECTION OF SEWING:

REMOVING

THE MATERIAL:

CROSSING

HEAVY SEAMS:

• Before changing direction,

stop the machine at the desired

point making sure that the

needle is down through the

fabric.

• Raise the presser foot, turn

the fabric to the desired posi

tion, lower the presser foot

and continue sewing.

Note: When sewing with a twin

needle, it is necessary to raise

the needles above the fabric

before turning. Be cautious to

realign the fabric to the position

where the last stitch ends.

• After stopping the machine,

turn the hand wheel toward you

until the take up lever is at its

highest position.

• Raise the presser foot, then

draw the fabric gently to the

left rear of the machine, making

sure that the threads are under

the foot. This avoids bending

the needle.

• With two hands, lift the two

threads up and into the thread

cutter on the presser bar and

pull down firmly to cut the

threads.

17

When crowing heavy seams,

angle the fabric down into the

foot so that the foot can draw

the heavy area into the feeding

mechanism and pass over the

bulk easily.

Page 19

ZIGZAG STITCHING

Zigzag Foot

(single needle sewing)

• Set the needle position dial in the free position.

• Set the zigzag width control knob from 1 to 5.

• Set the stitch length control dial from 1 to 4.

• Now you can start sewing as you wish.

SINGLE NEEDLE ZIGZAG STITCH PATTERNS

Patterns

WVWvW

mmmmm

wmA/mv

I

Needle Position

Left, Middle

or Right

Left, Middle

or Right

Left, Middle

or Right

Left 1

Middle 2

Right 3

Left 1

Middle 2

Right 3

Stitch Length

Long

Short

Long and Short

(Repeat)

Long

Short

Single Needle Sewing

Zigzag Width Control Dial

Zigzag Width

Any point from 1 to 5

Set the indicators of

zigzag width restricting

knob 0 and 5. Gradually

move from 0 to 5 and

return to 0. (Repeat)

Zigzag width can be

regulated by zigzag

width control. Turn

quickly the control

alternately.

18

(twin needle sewing)

ZIGZAG DIAL:

Set at desired width between 0 and 3.

If you use beyond 3, needle hits the

needle plate and breaks.

STITCH LENGTH:

Set at desired stitch length.

Note: Upper threading for twin needle is

followed same way as single needle

Needle Position: Set at " 1 "

left hand needle position.

Page 20

THREE STEP ZIGZAG STITCHING

Pattern Selector and

Zigzag Width Control Dial

Stitch Length

Control Dial

VARIOUS USES:

• Stitch length should depend on the type of fabric being used.

Short stitch length for flat or woven fabrics and longer for dense

fabrics and knits.

• Mending a tear - guide the tear along the center of the pressure

foot so that stitches catch evenly on both sides. A reinforcing

fabric (interfacing) may be used underneath if desired.

• Use the same technique to make a butted seam for interfacing

such as in the inside of a collar.

• Three step zigzag for overcasting provides a smoother edge than

the regular zigzag. Length-1 Width 1-1/2.

• Understitching facings with the three step zigzag provides less bulk

and facings lie flat on the inside of garments.

• Patches are applied more permenantly with the three step zigzag.

Make patches round where possible or overlap corner stitching to

reinforce corners.

19

Page 21

BLIND STITCHING

Zigzag Foot

Blind Hem

Pattern Selector and

Zigzag Width Control Dial

Stitch Length

Control Dial

rs°e?fhe“conirols as shown on the diagram above, and attach the

. S me'’Sdo a'slown and insert into the gaide on the

. Chargee, manoaiiv anti, ne^ie is

St^sf: .a'bric .o,d a,ong the goide of

foot.

• For knits eliminate the first 1 /4 inch fold.

• The blind hem stitch provides a durable hem hmsh

that is almost invisible on garments,drapes.and curtains.

tt done easily with straight or slightly curved herns^^^

With a little practice it will be a very quick and ea y

application and the hem will never need repairing.

20

Page 22

ELASTIC BLIND STITCHING

Zigzag Foot

E lastic Blind Hem

Pattern Selector and

Zigzag Width Control Dial

Stitch Length

Control Dial

PROCEDURE:

• Set the controls as shown on the diagram above, and attach the

proper presser foot.

• Fold the fabric as shown and insert into the guide on the

presser foot.

• Turn hand wheel manually until needle is in the farthest position

to the left and make sure that needle just catches the edge of the

fold. Sew at slower speed, keeping fabric fold along the guide of

foot.

• For knits use the elastic blind hem and eliminate the first

% inch fold.

• The elastic blind hem stitch gives a stretch, durable hem finish

to knit fabrics. The two tiny zigzag stitches enable the hem

to stretch with the fabric.

It may also prevent woven fabrics from raveling.

21

Page 23

ELASTIC TRIPLE STITCHING (STRAIGHT)

I

ill

I

I

Elastic Tripie Straight Stitch

t]

Regular Straight Stitch \

Guide your fabric from the

front. Do not pull or push as

it will cause poor stitching.

Pattern Selector and

Zipzag Width Control Dial

PROCEDURE:

• The elastic triple straight stitch is used when a straight line

of stitching is desired so that seams may be pressed open

(slacks for example).

• This stitch is especialy useful where the tiny zigzag seam

will not hold its shape and the straight stitch will break.

• Apply this stitch to areas of stress on both wovens and knits (crotch

seam and under arm for example).

• Use this stitch for tightly fitted garments that need a lot of stretch,

such as ski pants, girdles and bathing suits.

• If puckering becomes a problem, use the straight stitch foot.

Note: Always fit your garment before seaming with this stitch as this stitch will bury itself

in the fabric and be difficult to remove.

Stitch Length

Control Dial

22

Page 24

ELASTIC TRIPLE STITCHING (ZIGZAG)

Elastic Triple Zigzag Stitch

Guide your fabric from the front.

Do not pull or push as it will cause

poor stitching.

Pattern Selector and

Zigzag Width Control Dial

PROCEDURE:

• A decorative topstitch can be produced with the rick-rack stitch.

Stitch around the structural lines of the garment for a special effect.

• Apply this stitch to areas of stress on both wovens and knits.

• Use narrow width of zigzag as a heavy duty triple stitch for

seams.

• Use medium and wide widths of zigzag for overcasting edges

of seams, facings and hems of heavier weight fabrics such as

terrycloth, and for attaching elastic. Use also for decorative

stitching.

23

Page 25

IKICUI STITCHING

Paper

Pattern Selector and

Zigzag Width Control Dial

Stitch Length

Control Dial

PROCEDURE:

• The tricot stitch is a very useful special ultra-stretch stitch

called smocking.

• Lingerie or tricot seams should only be about 1/8 inch finished

width.

• Fagoting can be achieved by joining the folded edge of two pieces

of fabric together with a gap between them. Use a sheer ftesh

colored piece of fabric underneath to make the fagoting much

stronger and prettier.

• Do the fapting with a piece of paper underneath and remcwe the

paper by hand washing.

24

Page 26

OVERLOOK STITCHING (OVERCASTING)

PROCEDURE:

• Overlook stitching is used for seaming and finishing the cut edge of

knit fabrics, all in one operation.

• This overlook stitch is especially good for stretch fabrics such as

Overcasting

double knit and jersey and will give a firm, neat edge finish.

• For a finished 1/4" seam, guide your fabric at the right hand

edge of the needle hole as shown.

• When your pattern calls for a 5/8" seam allowance, guide your

fabric along the 1/2" guide line on the needle plate and sew your

seam. Then trim off the excess fabric close to the stitching. On

some fabrics this method is preferable.

Note: The three step zigzag stitch can also be used for overcasting.

Pattern Selector and

Zigzag Width Control Dial

Three Step Zigzag Overcasting

25

Page 27

BUTTONHOLE PREPARATION

puH Buttonhole Foot

Seam Ripper

Pattern Selector and

Zigzag Width Control Dial

Stitch Length

Control Dial

PROCEDURE:

• Attach buttonhole foot to machine with red markings to the left.

• Always make a sample buttonhole on the same fabric us^ to make

your garment. Use a double layer of fabric with interfacing

between.

• Mark the starting and ending position of your buttonholes with

tape and use chalk to mark the cutting line.

• Pull buttonhole box forward until it is fully extended and position

over tape as shown above.

• Proceed as on page 27 "Sewing Buttonholes".

• If buttonhole appears uneven, turn stitch length dial until the left

side looks like the right side. The reverse stitching is pre-set.

• INVISIBLE BUTTON HOLE may be made by using matching

thread so that the button hole blends with the fabric.

• EXAGGERATED BUTTONHOLE may be made by running through

the buttonhole cycle a second time to make a very dense buttonhole.

To add an extra beauty to buttonholes, use a constrasting thread

color.

Example: Red buttonholes on white fabric.

• If buttonholes appear too dense for knit fabrics, release the presaire

cap half way.

26

Invisible

Exaggerated

Page 28

BUTTONHOLES ON LIGHTWEIGHT OR KNIT FABRICS

Cord String

: r-..

Place cord strung over tab on presserfoot as shown.

After finishing the buttonhole, remove the foot from

the fabric, draw the loop of the cord string up to the

bar tack, tie the loose ends and trim the balance.

Position fabric in sewing area and attach button

hole foot to the machine. Sew the buttonhole so

that stitching covers cord string.

27

Page 29

Button Foot

Other Applications

Needle Position Selector and

Zigzag Width Control Dial

PROCEDURE:

• Set drop feed button "Si" position with the needle position selector

" 1" position.

• Place button under button foot such that the needle is aligned

directly with the left hole in your button. Check alignment by

turning hand wheel and watching needle.

• Bring the needle slightly above the button and turn stitch width

knob until needle aligns with the right hole in the button.

• Run machine slowly and make 7-8 stitches.

• With needle in left hole return zigzag width knob to the "0"

position and make 3—4 stitches to tie off your button.

• Apply the above method to sewing on buttons with four holes, hooKs,

snaps, etc.

28

Page 30

Needle Position Selector and

Zigzag Width Control Dial

PROCEDURE:

• For free-nnotion sewing, press drop feed button,

and press down on outer ring of the pressure regulator

to release pressure completely.

• Place under needle of fabric into an embroidery, a

darning and a monogramming hoop.

• With the width at "O" make 5 or 6 stitches to

reinforce the starting point

• At the desired zigzag width stitch to outline the

design by moving the fabric and hoop in a side

motion. To fill the design, move the fabric and

hoop from side to side in a rhythmic motion.

• To return feed to normal, press drop feed

button, and push down on the pressure cap to

obtain the desired setting.

29

MONOGRAMM ING

Page 31

SEWING ON ZIPPERS

Regular Zipper Foot

Needle Position Selector arKi

Zigzag Width Cor^trol Dial

PROCEDURE:

• Set the needle position at " 1 " or " 3 " as needed

to sew the right side or the left side of zipper

respectively, so that the foot sews very close to

the zipper teeth. (Fig. 1)

• Set the needle position at " 3 " and make the

welting by sandwiching the cord into a bias

strip of fabric. Stitch close to cord. (Fig. 2)

• Set the needle position at " 1". Sandwich the

welting between two layers of fabric with right

sides together. Stitch a second time. The needle

stitches close to the cord through all thicknesses

(Fig. 3)

Stitch Length

Control Dial

• Attach zipper foot and adjust position depending on which side

of zipper foot you wish to use.

• Open the zipper and place it face down on the back side of the

fabric with the zipper teeth along the fabric edge.

30

Page 32

QUILTING

Needle Position Selector and

Zigzag Width Control Dial

PROCEDURE:

• Insert the quitter guide bar into the notch under the spring on the

shank and adjust the position according to the desired distance

between quilting slams.

• Stitches are easily aligned by guiding the quilter guide along the

previous seam line.

31

Page 33

CARE AND MAINTENANCE

A majority of service calls can be avoided by proper care of your machine. This involves three important

steps.

1. Cleaning - Give your machine a light cleaning after each garment is completed. For light cleaning —

brush lint from feed dogs, needle bar and hook, and oil hook. A more extensive cleaning and oiling

can be done every two months.

2. Oiling - Use sewing machine oil only. Do not use any other household oils, as they will eventually

cause problems with the machine. Oil every two months, or more often if machine is in constant use.

3. Proper Use of Needles — Always use the proper needle for your fabric and thread.

Change needles often, as they dull quickly especially on synthetic fabrics.

If you are having a problem, before calling the service man:

1. Check to see that the machine is threaded properly.

2. Replace the needle and make sure it is attached correctly.

3. Be sure that the bobbin is wound evenly.

32

Page 34

CLEANING THE MACHINE

Caution: Before cleaning the machine, be sure to disconnect

the power cord from the wall outlet.

CLEANING AND OILING THE HOOK ASSEMBLY

• Raise the needle bar to the highest position.

• Open the hinged shuttle cover and remove the

bobbin case with bobbin.

• Remove lint or dust with a soft cloth or lint brush.

• Use only the oil in the accessory box.

• Replace bobbin case (See page 8 for

instructions).

CLEANING FEED DOGS

• Lint or dust accumulated between the needle

plate and the feed dogs must be removed to

maintain good operation of the machine.

• Raise the needle bar to the highest position and

remove the needle and presser foot.

• Loosen screw on the bed cover plate and remove

the plate.

• Clean lint and dust from the bottom of the needle

plate and the feed dogs with a lint brush.

• Turn the hand wheel slowly and be sure to clean

all areas.

• Replace the removed plate.

33

Page 35

OILING

OIL

OIL

OIL

OIL

Swing open hinged face plate. Apply one drop of

oil at all points indicated by arrows.

remove the two screws on the top plate and Remove

in the accessory box

OIL

Remove screw on the bed cover plate and apolv

oil while turning the hand wheel. ^ ^

34

Loading...

Loading...