SINGER W4910 User Manual

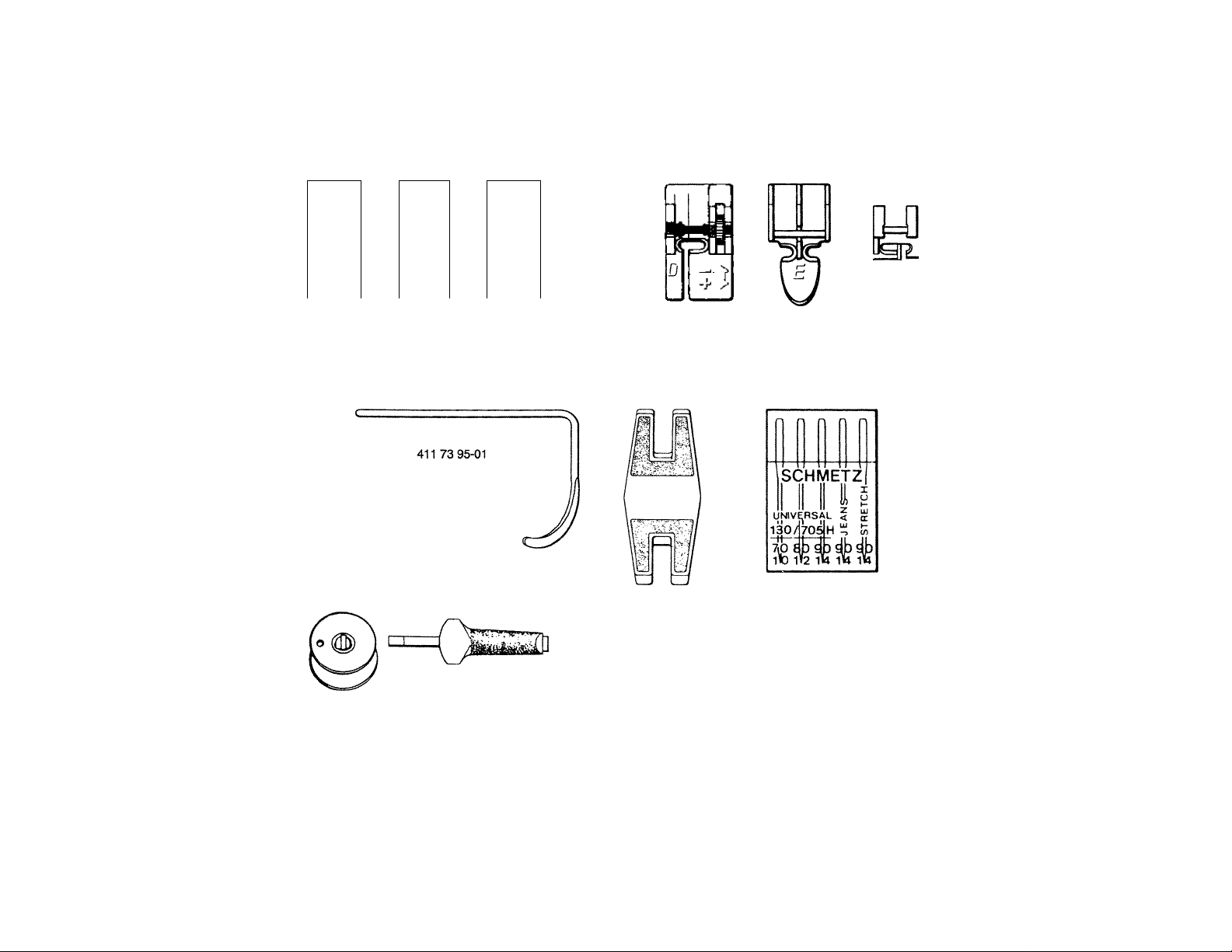

Standard accessories delivered with the machine

mg

'sx L-

f

---------

f -S

i

^q

QJ

(t

---r

h

412 03 73-01 411 77 91 -01 412 03 74-01 411 73 89-01 411 53 31 -02 411 73 93-01 411 85 27-01

411 1732-01

411 78 90-01

J

«-'V ■■'•J

;

412 0612-01

411 78 83-01

m.

401 55 55-01

401 53 99-01

Fli:-

For you and your new sewing machine

This booklet has been prepared to let you know how to

operate this sewing machine and how to make use of all

its sewing possibihties.

You will, for sure, get many pleasant hours with your

new sewing machine and be successful in obtaining many

fine results.

k

We reserve the right to change the machine equipment

and the assortment of extra accessories without prior

notice, or make modifications in the design or appearan

ce of the machine, which do not negatively affect the

function.

m m m m m

Table of contents

Instructions

Machine parts

Front and rear of the machine, names of parts

Unpacking and putting away the machine

Connecting the machine........................................................ 7

Free arm, extension table

Function switches................................................................ 8-9

Thread guide for bobbin winding main switch,

reverse feed, limiting the speed, needle stop

position

Function.................................................................................. 10

Presser bar lever, presser foot pressure

Lowering the feed dog, bobbin winding

Threading, thread tension.............................................. 12-14

Changing the needle and presser foot

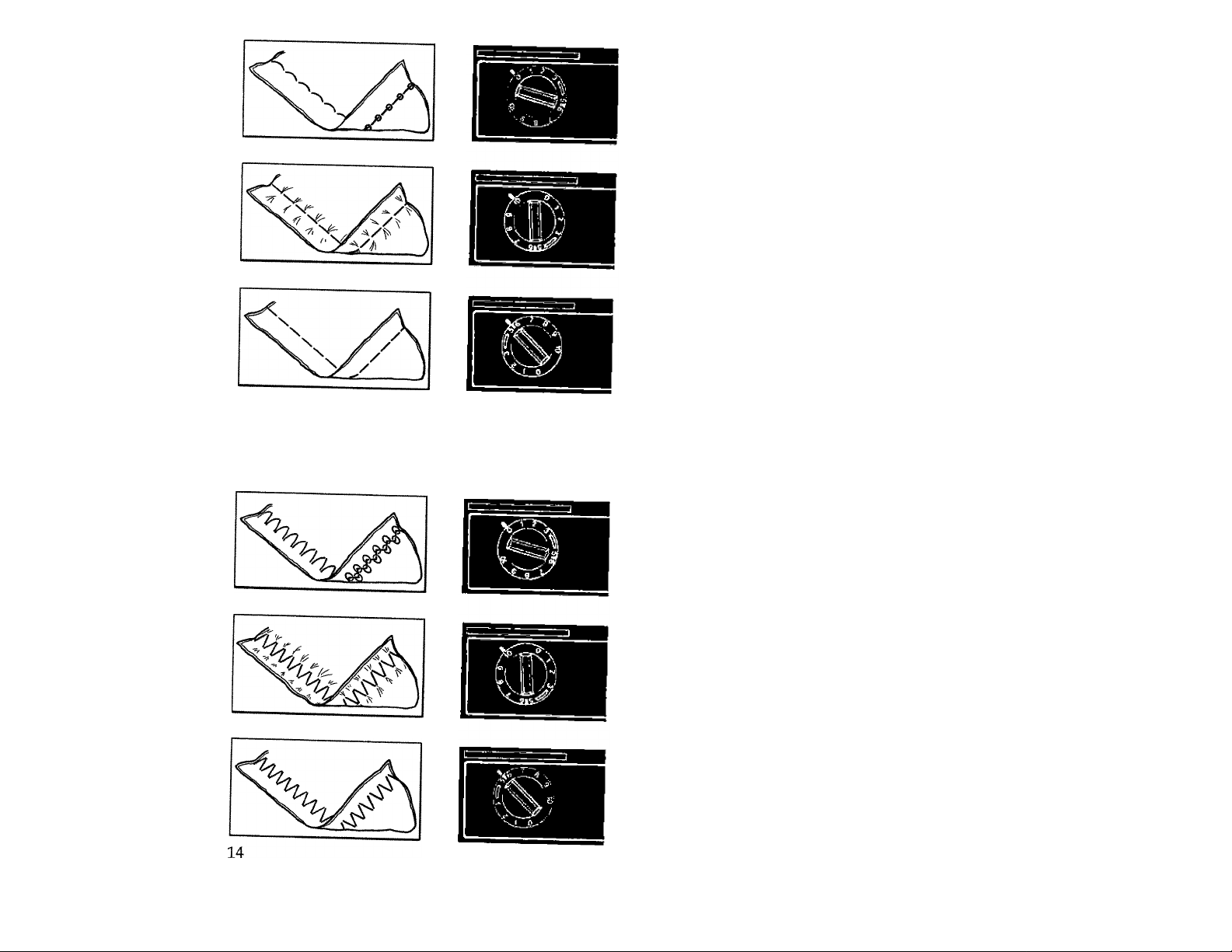

Stitch settings and sewing................................................. 16

General hints......................................................................... 17

Stitches.............................................................................. 18-38

Maintenance..................................................................... 39-40

Care of the machine

Changing the light bulb

Fault-finding

Accessory box.................................................................. 43-44

Presser feet, needle and thread, etc.

Needle assortment

Extra accessories.............................................................. 46-48

Index................................................................................ 49

.....................................................................

..............

..........................

..............................

....................................................................

...............................................................

4_5

6

11

15

41-42

45

Sewing

Straight stitching............................................................... ig

Top stitching

Basting, gathering....................................................... 19

Sewing in zippers

Zig-zag stitching

Sewing on lace

Gathering, bound edges

Appliqués

Three-step zig-zag............................................................ 24

Overcasting, terry cloth............................................. 24

Mending

Overcast stitch.................................................................. 26

Blindstitching

Double-action stitch

Bridging stitch.................................................................. 30

Reinforced straight stitch

Overlock............................................................................ 32

Flatlock............................................................................. 33

Reinforced zig-zag (Ric-Rac)

Decorative stitches

Buttonholes..................................................................... 35

Ordinary buttonholes

Reinforced buttonholes

Corded buttonholes

Cutting the buttonhole

Sewing on buttons............................................................ 33

Precision setting for buttonholing

...............................................................

.................................................

...............................................................

.....................................................

.............................................

....................................................................

.....................................................................

..........................................................

........................................................

.................................................

...........................................

...........................................................

.................................................

...............................................

.....................................................

...............................................

20-21

22

27—28

18

22

23

23

25

29

31

34

34

35

36

37

37

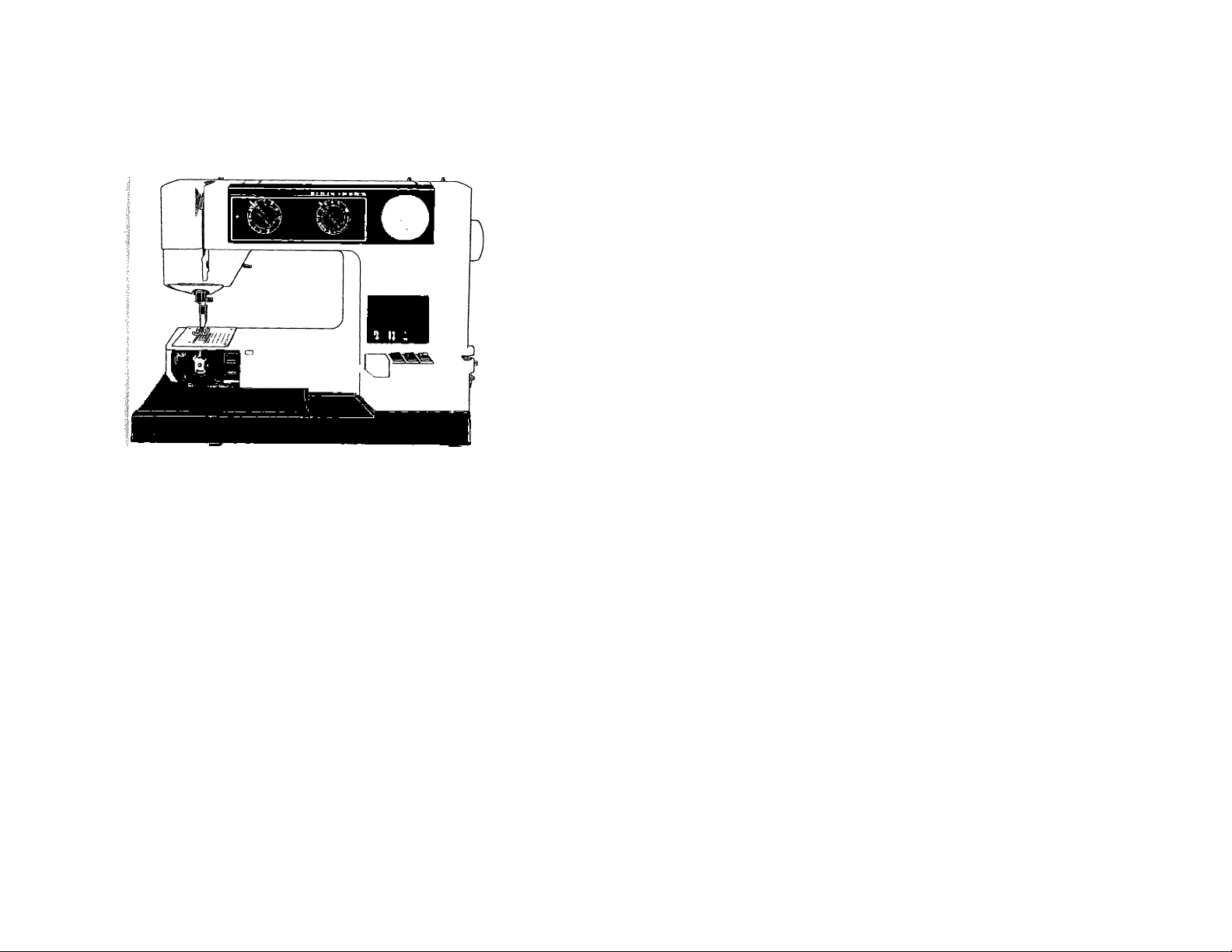

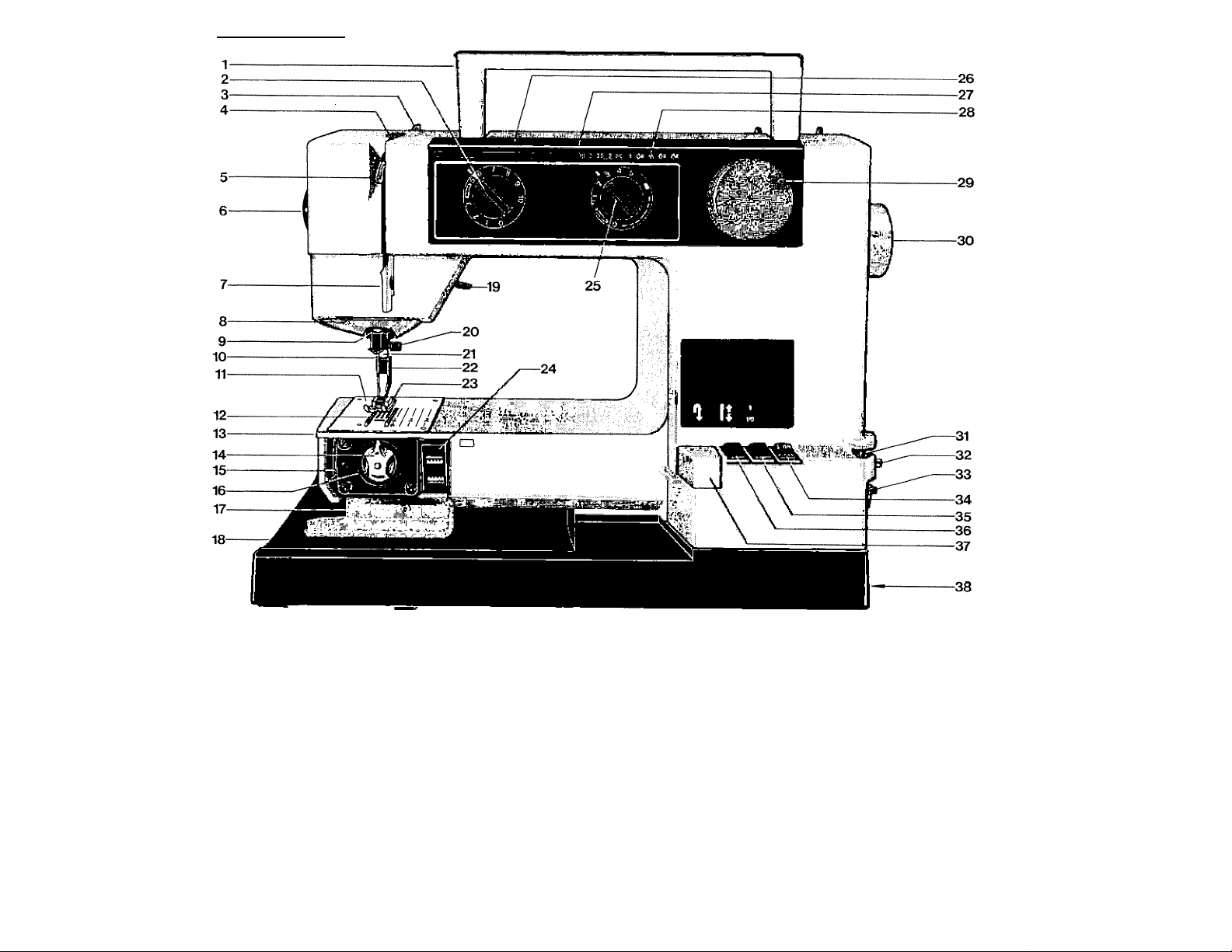

Machine parts

1. Handle

2. Thread tension dial

3. Thread guide

4. Thread tension discs

5. Thread take-up lever

6. Presser foot pressure dial

7. Front thread guide with thread

take-up spring

8. Sewing light

9. Needle bar

10. Needle

11. Needle plate (stitch plate)

12. Feed dog

13. Free arm

14. Bobbin case

15. Thread cutter

16. Shuttle (hook)

17. Door for shuttle (hook)

18. Baseplate

19. Presser bar lever

20. Needle clamp screw

21. Presser bar 35.

22. Presser foot ankle 36.

23. Presser foot

24. Drop feed button

25. Stitch length dial

26. Stitch symbols

27. Recommended presser foot

28. Recommended stitch length

29.

30. Handwheel

31.

32.

33.

34.

37.

38.

Stitch selector

Thread guide for bobbin winding

Bobbin winding spindle

Automatic bobbin winding stop

Main switch

Speed control switch

Needle position switch

Reverse feed button

Socket for foot control

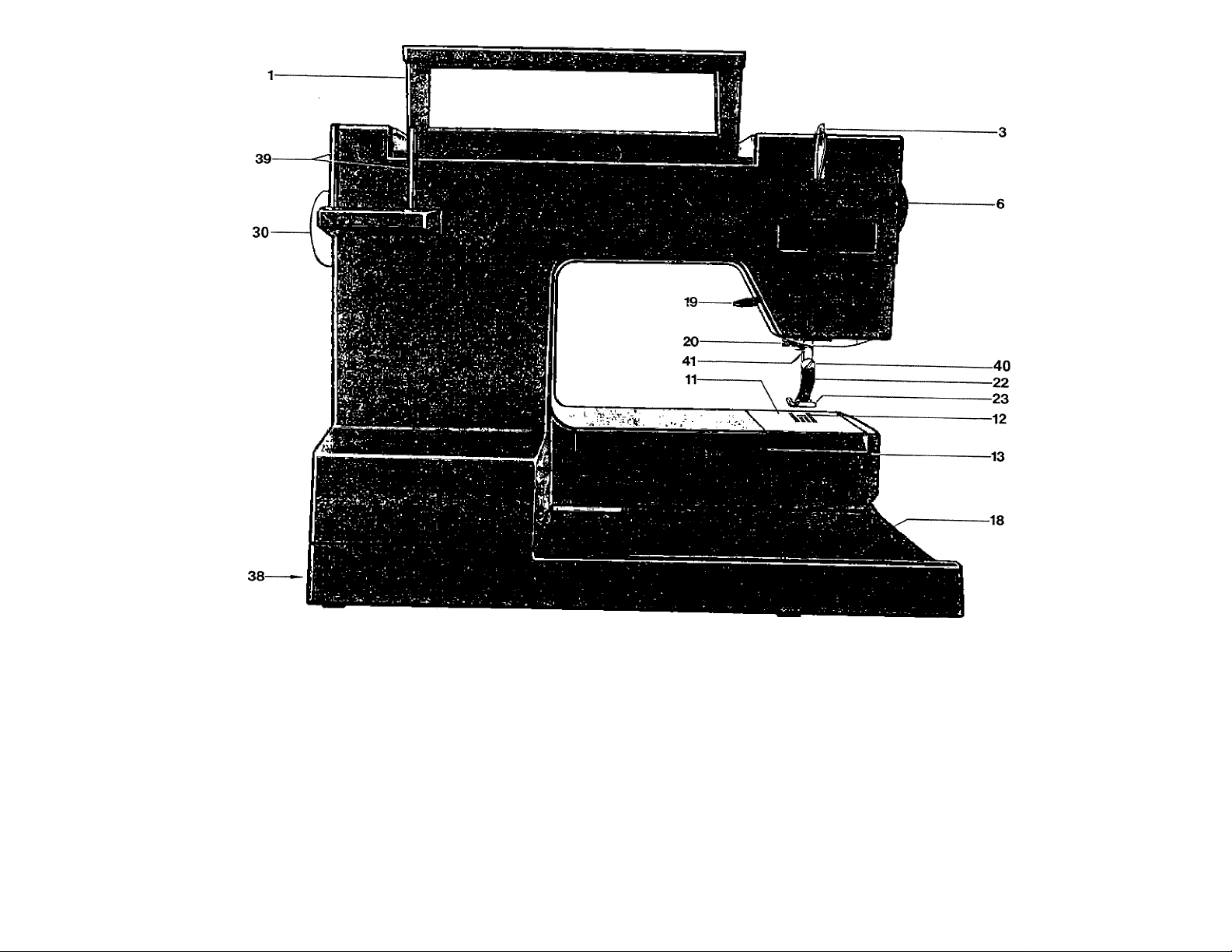

Macnme parts

1. Handle

3. Thread guide

6. Presser foot pressure dial

11. Needle plate

12. Feed dog

13. Free arm

18. Baseplate

19. Presser bar lever

20. Needle clamp screw

22. Presser foot ankle

23. Presser foot

30. Handwheel

38. Socket for foot control

39. Spool pins

40. Screw for edge guide

41. Thread cutter

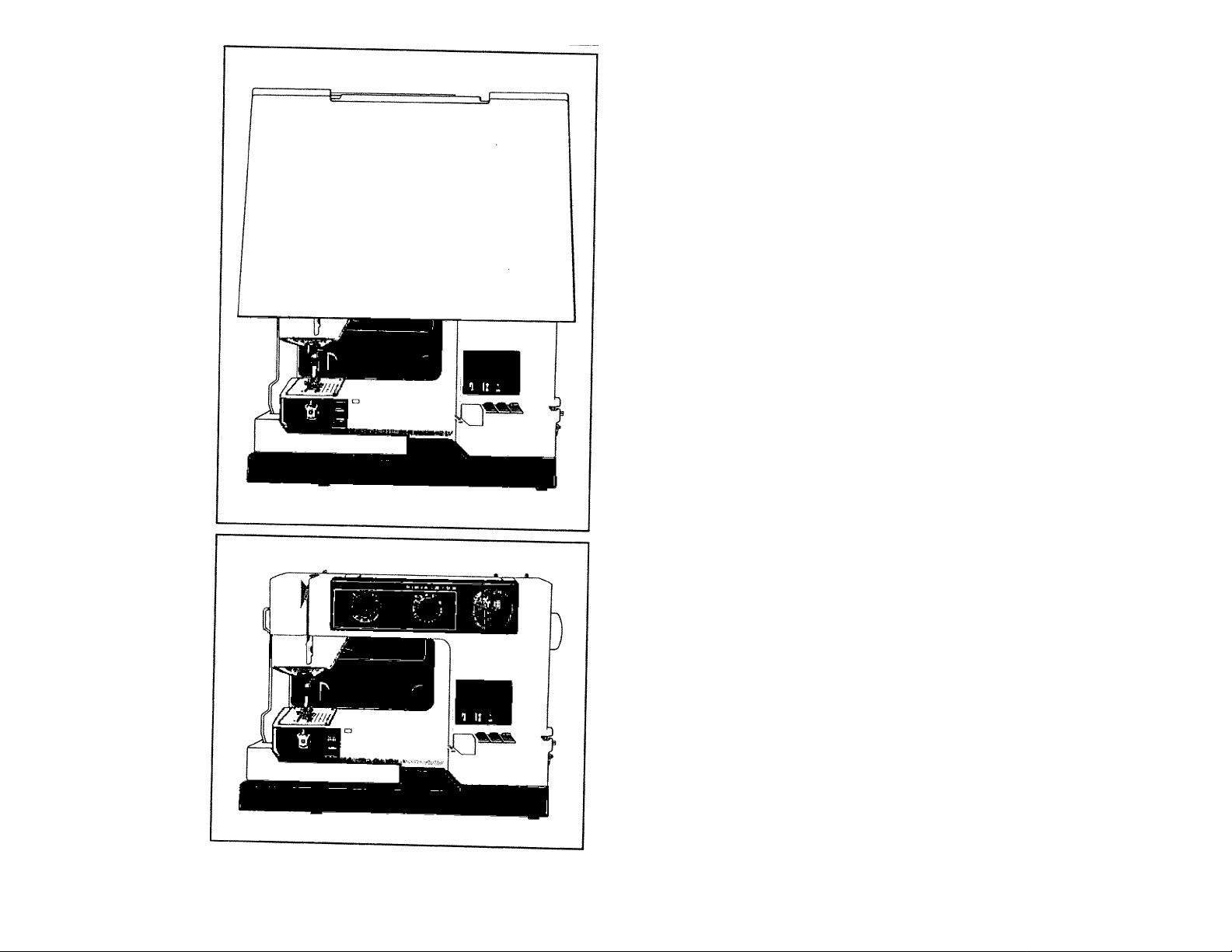

Unpacking and putting away the machine

Unpacking

Place the machine on the table, with the recess for the

handle furthest away from you, and fold down the

handle. Lift off the cover and put it aside. Remove the

extension table and the foot control and slide the acces

sory box to the left from the machine.

Wipe the machine clean before you start sewing, and

be especially careful with the stitch plate and the space

around the needle. The machine is equipped with a

number of presser feet and these are packed in two

plastic bags. Regarding the placing of the accessories,

please refer to page 43 under “Accessory box”.

Putting the machine away

Pull the plugs out of the wall outlet and the socket of

the machine. Wind the cords around your hand, starting

at the foot control and push them into the control com

partment. Place the control in the rear compartment of

the accessory box, with the wider end downward. The

bottom of the foot control should be turned toward the

machine.

Lower the presser foot. Make sure that aU accessories

are correctly placed in the box. Slide the accessory box

into place and put the extension table into the box.

Fold down, the handle and put on the cover.

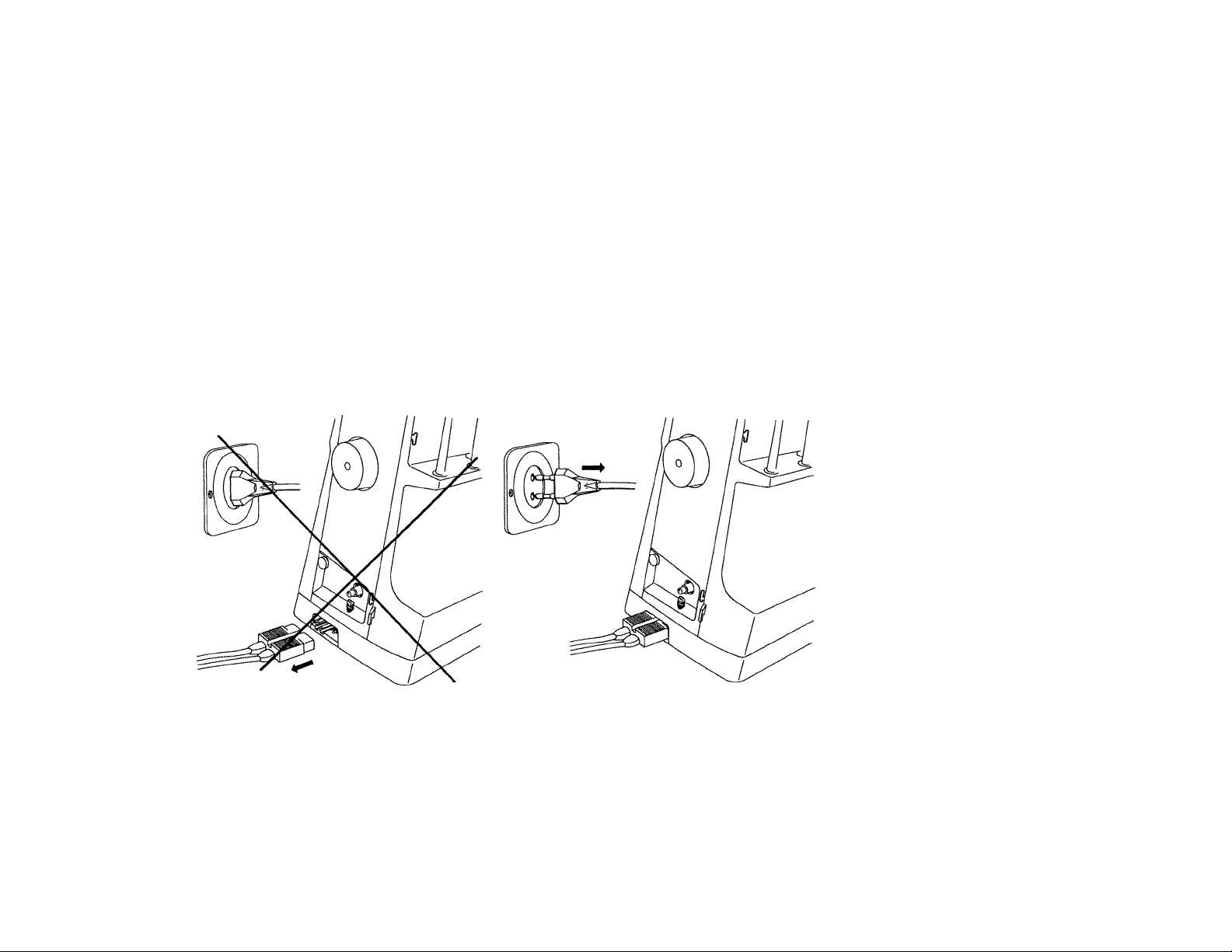

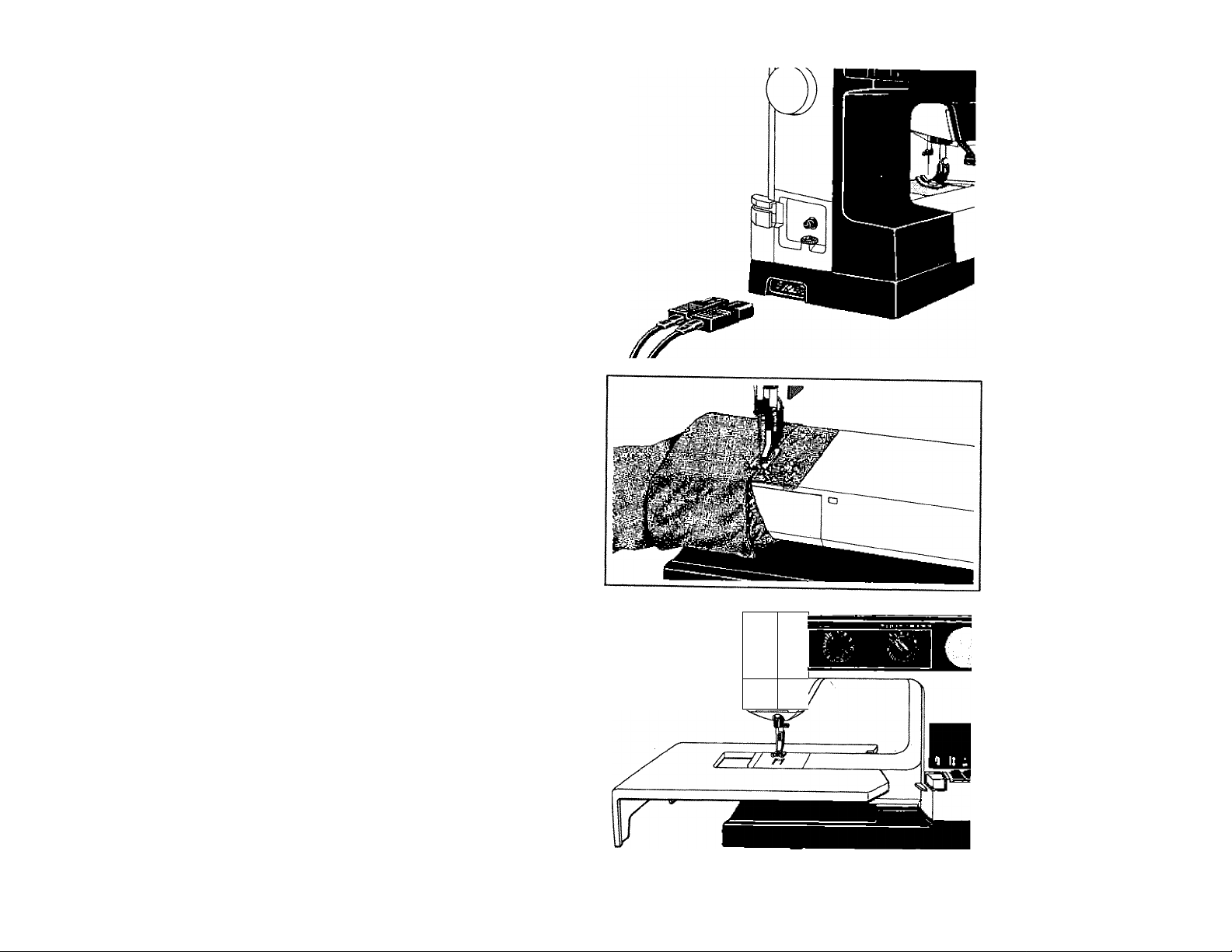

Connecting the foot control

Remove the cord from the foot control and place the

control under the table. Insert the foot control plug into

the socket on the right-hand side of the machine.

Connecting to the wall outlet

The voltage (V) and frequency (Hz) are indicated

under the base of the machine. Check that these values

correspond to those of the electricity source before

connecting the machine.

Free arm

Trouser legs and sleeves can be drawn onto the free

arm, making it easy to sew, mend or patch these parts.

The free arm also makes it much easier to attach collars

and cuffs as well as sew small children’s clothes, or dam

socks and stockings on the machine.

Connecting the machine

Extension table

When you need a larger working surface, attach the

extension table.

When positioning the extension table over the free

arm, fit the two studs into the holes at the rear of the free

ami. Pull out the catch under the front of the table and fit

it into the hole for this purpose on the free arm.

When removing the table, pull out the catch and lift

the table away.

"

L

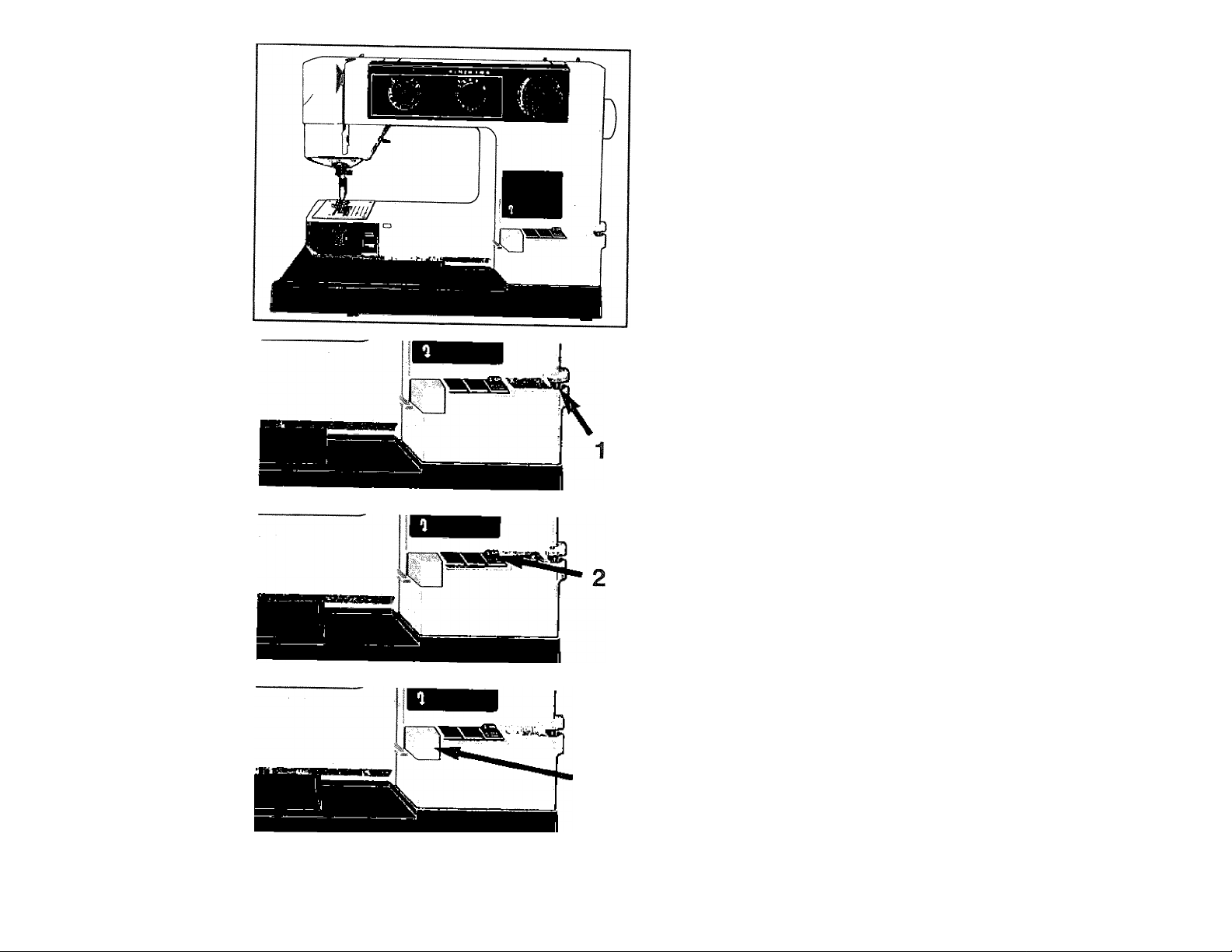

Function switches

Function switches

The thread guide for bobbin winding is located on the

front of the machine to the far right. The main switch is

located to the left of the thread guide.

The reverse feed button is located closest to the free

arm.

Thread guide for bobbin winding (1)

The thread gmde for bobbin winding is for use when

bobbin winding. Read more about bobbin winding on

page 11.

Main switch (2)

The light and the machine are turned on by pressing

the inner part of the main switch. This makes it easy to

see that the machine is ready for sewing.

Reverse feed button (3)

As long as you keep the reverse feed button depressed

the machine will sew in reverse but will revert to ordina

ry sewing as soon as you release it. Excellent for fasten

ing off.

The longest stitch length when reverse feeding is

3 mm.

K'-'

V

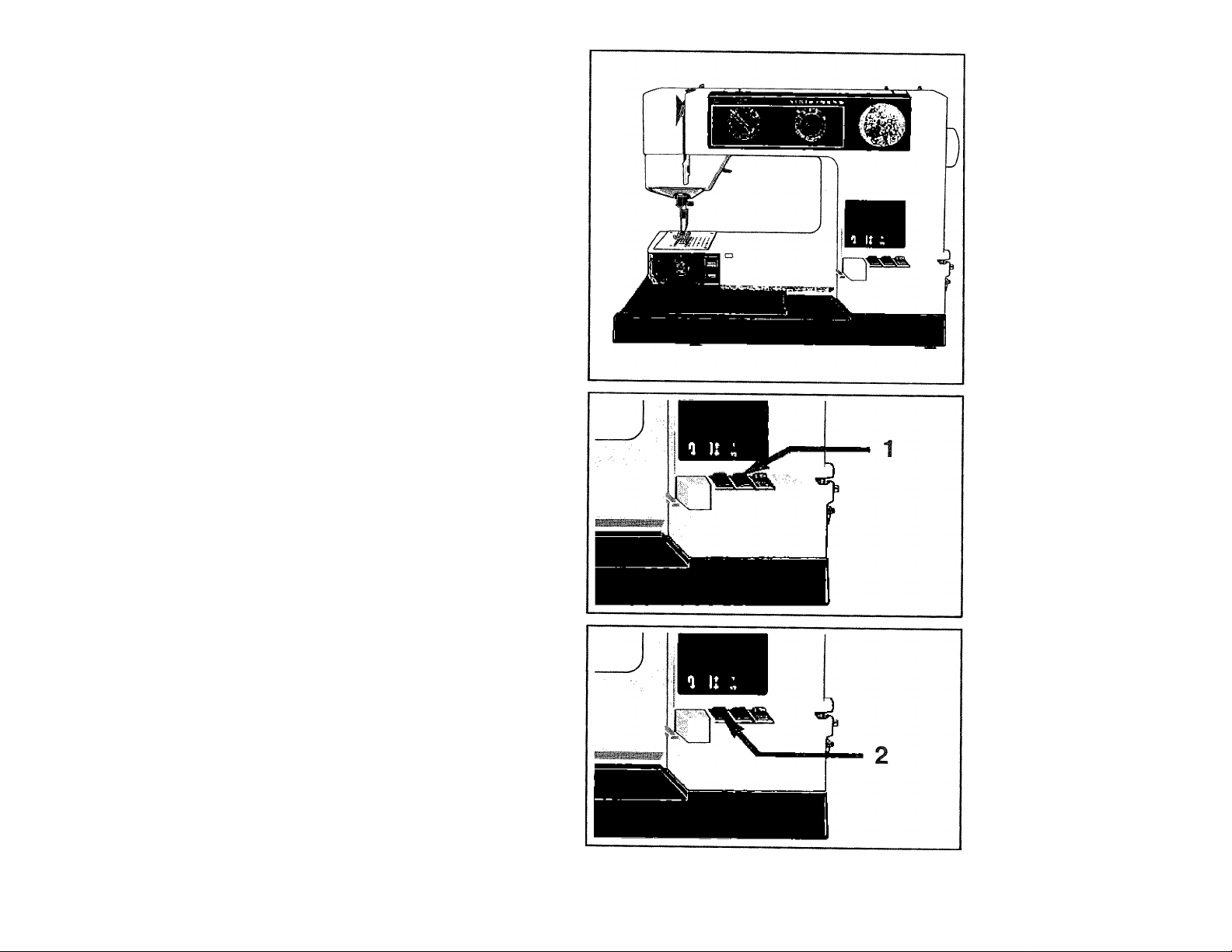

Function switches

In addition to the setting possibilities described earlier

the machine also has a switch for reducing the speed and

one for setting the needle stop-right position.

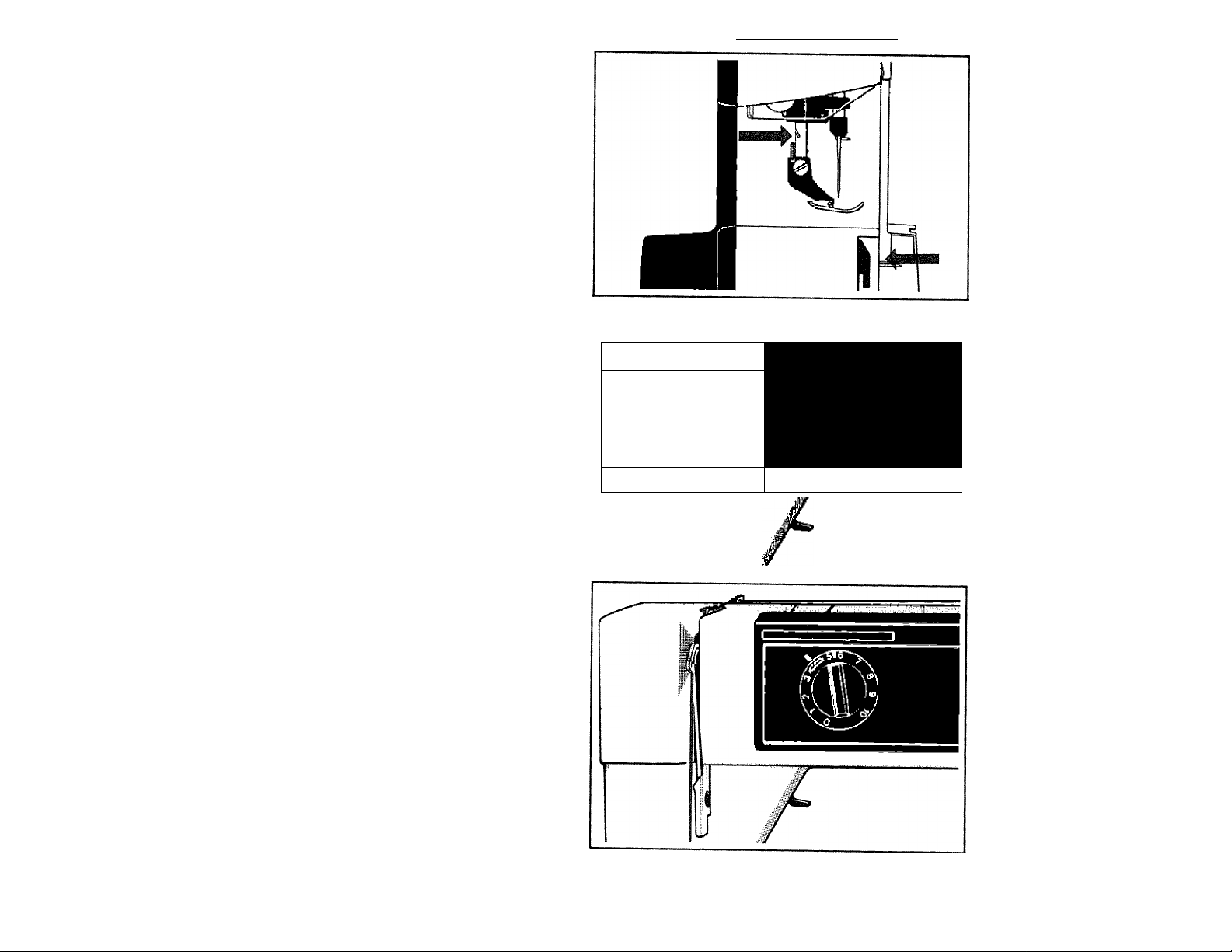

Limiting the speed (1)

When sewing with the inner part of the switch de

pressed you can regulate the speed of the machine up to

the highest speed. If you push the outer part of the switch

down and carefully press the foot control, the machine

will initially make a short pause between each stitch.

This will give you time to check that you are sewing

exactly where you want to. This is a great help for

precision sewing and when you wish to move the fabric

by hand, e.g. when basting. Remember to lower the feed

dog when basting. When you press the foot control

again, the machine will sew at an even and slow speed.

You have full needle power the whole time. With the

foot control completely depressed, the speed will be

approximately half of the maximum speed.

Function switches

Needle position switch (2)

With this switch you can choose the position at which

the needle should stop. When the iimer part of the switch

is depressed, the needle will stop at its upper position for

use when removing the fabric at the end of a seam. When

the outer part of the switch is depressed, the needle will

stop in the fabric, and hold it securely for pivoting (lifting

the presser foot and turning the fabric to sew aroimd a

corner).

When the switch is in the intermediate position the

needle will stop at any position. You can then turn the

handwheel until the needle is in the position you require.

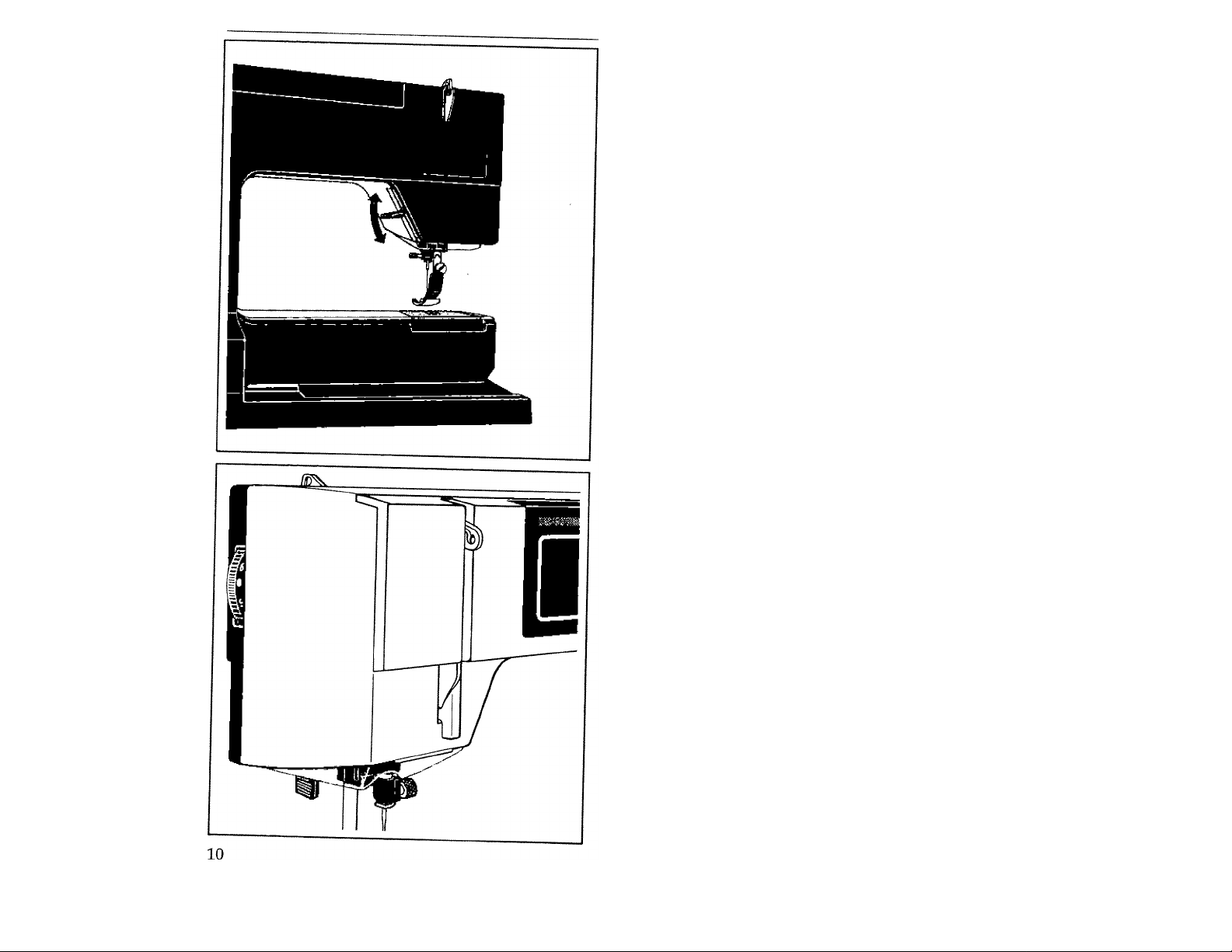

Function

Presser bar lever

By means of the presser bar lever at the rear of the

machine, the presser foot can be raised and lowered.

When raising, the presser foot will remain in the raised

position, but the height can be increased by 1.5 mm by

pushing the presser bar lever upward and holding it in

this position. This is useful when you want to put gar

ments with thick seams under the presser foot.

The presser foot should be lowered while sewing.

f

'îc

Presser foot pressure

The presser foot pressure can be adjusted with the aid

of a marked dial on the left side of the machine. Normal

pressure is obtained by setting the dial at the white dot

but for some fabrics it may be better to reduce or in

crease the pressure. The higher the number, the greater

the pressure.

By setting the dial at the symbol ^ the presser foot

pressure is completely released. This setting should be

^ed when free-hand sewing with the darning foot, i.e.

darning, monogramming, machine embroidery and quilt

ing.

If you turn the graded dial for the pressure foot pres

sure to the lowest number, it is possible to dam with

presser foot A.

Lower the feed dog and move the fabric forward,

backward and sideways by hand.

Lowering the feed dog

You lower the feed dog by pushing in the upper part of

the push-button. In order to raise the feed dog again push

in the lower part.

The feed dog should be lowered for a certain type of

darning and when sewing on buttons. It is also easier to

get thick garments under the presser foot if the teeth of

the feed dog are not above the level of the stitch plate.

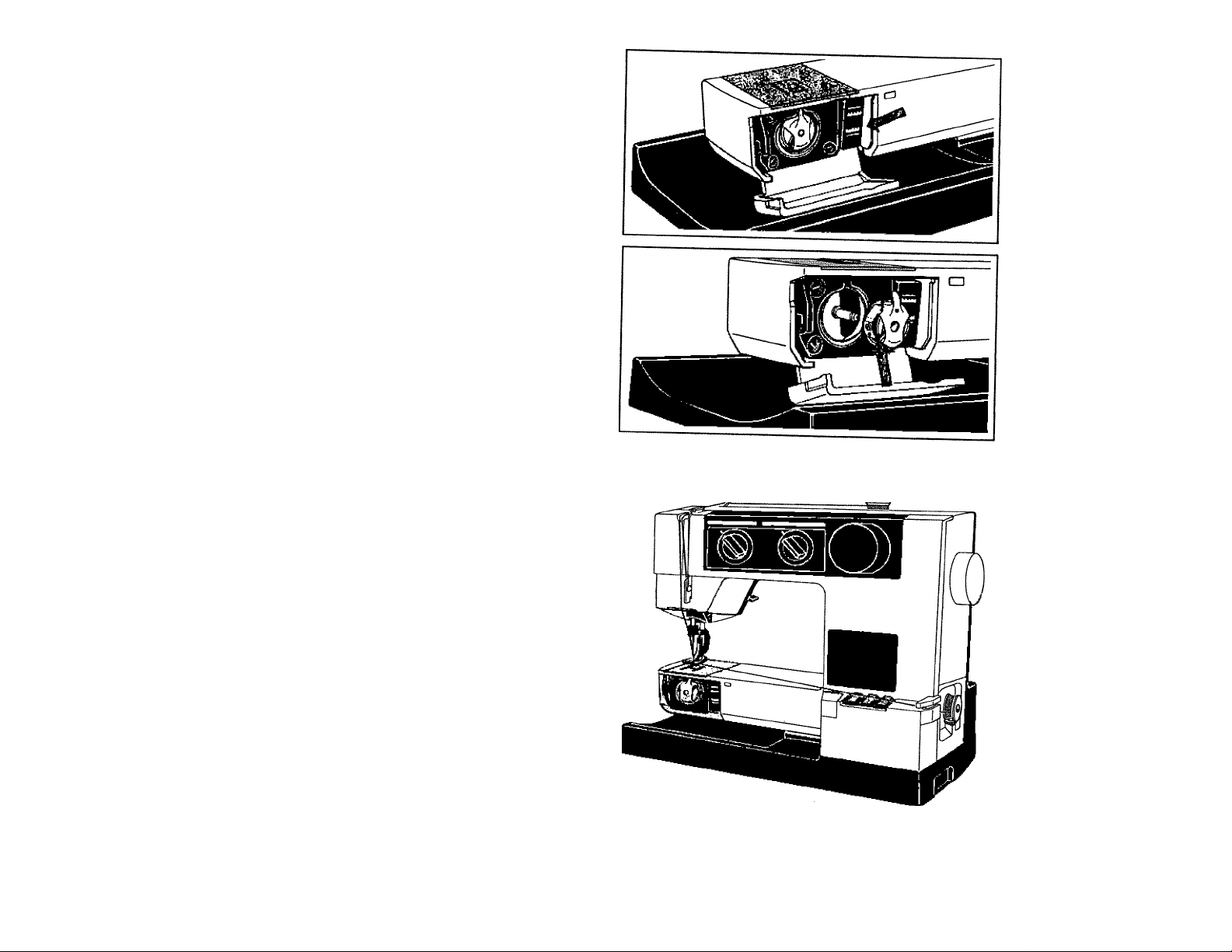

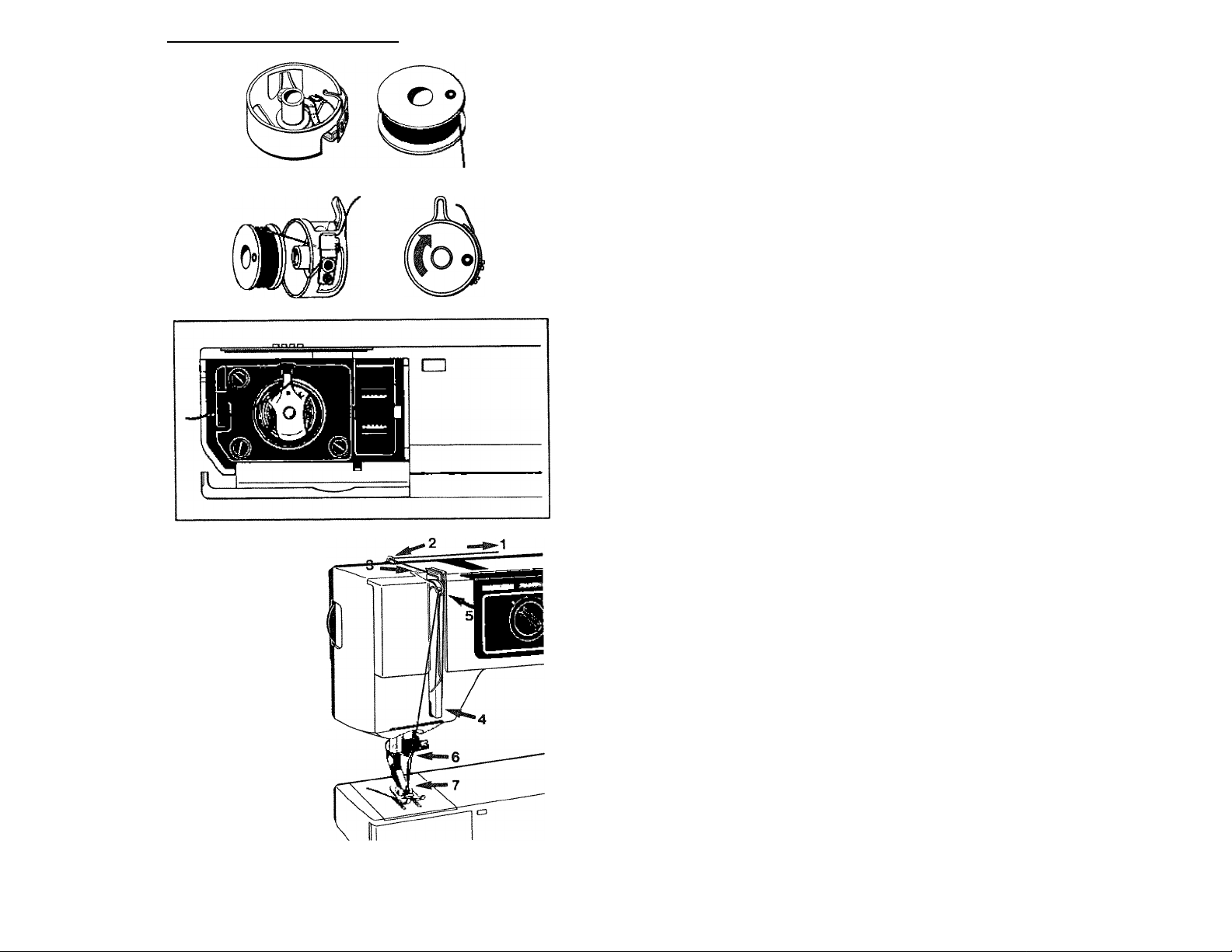

Removing the bobbin case

Open the door in front of the shuttle by means of the

small recess on the left side.

Grip the bobbin case with the thumb and index finger

so that the latch is depressed and pull the bobbin case

out. The bobbin will remain in the case as long as the

latch IS depressed. When you release the latch, the bobbin will be released.

Bobbin winding

Turn the empty bobbin until the small round mark on

one side is outward.

Slide the bobbin onto the bobbin winding spindle

located on the right side of the machine.

Raise the presser foot and pull the thread from the

thread guide by the needle clamp through the groove on

the thread guide at the right of the machine. Wind the

thread around the bobbin a couple of times, beginning

from underneath. If you are using a metal presser foot,

allow the thread to go through the eye of the needle and

under the presser foot. Never run the thread direct from

the eye of the needle to the bobbin because you will run

the risk of bending the needle. Hold the thread end and

lightly depress the foot control. As soon as winding starts

you can release the thread end.

The machine will automatically stop when the bobbin

is full. Remove the bobbin.

_LQ^^ring the feed dog, bobbin winding

11

Threading, thread tension

Threading the lower thread

When the bobbin winding is finished, place the bobbin

beside its case with the marking upward. The thread

should run as shown in the figure. Place the bobbin in its

case without turning it around.

Slide the thread into the slot on the edge of the bobbin

case. Pull the thread in under the tension spring. Check

that the bobbin rotates in the direction of the arrow

(clockwise) when the thread is pulled.

The thread must be pulled in the direction of the

spring, otherwise the spring will be overloaded.

Insertion of the bobbin case

Slide the thread behind the projection of the bobbin

case and to the right. Put the bobbin case into place.

Press the bobbin case until it clicks to ensure that it fits

properly.

The thread cutter is located to the left of the bobbin

case. Hold the thread end and draw the thread from

underneath and up toward the thread cutter. By doing so

the thread will be cut off and kept in place.

Shut the door.

r:

f

S(:

12

Threading the upper thread

Raise the presser foot. Check that the needle is at its

highest position. Place the spool of thread on the left

spool pin 1 and thread the machine for sewing.

Slide the thread into thread guide 2 on the upper arm

and draw it upward. Then draw the thread to the front

between the tension discs 3 and down around thread

guide 4. Continue threading by drawing the thread from

the right into the slot on thread take-up lever 5 and draw

it down to the needle, ensuring that it goes through

thread guide 6.

Thread the needle from the front. Due to the white

color of the presser foot ankle the needle-eye is clearly

seen and the threading of the needle, 7, is easier. Pull the

thread under the presser foot about 15 cm (6") toward

the rear.

Thread cutters

On the back of the presser bar you will find a notch,

the thread cutter, by means of which you can easily cut

off the threads when you have finished sewing. There is a

special thread cutter for the bobbin thread. See page 12

“Insertion of the bobbin case”.

Tension of the upper thread

The dial which regulates the tension of the upper

thread is graduated from 0-10. The higher the number,

the tighter the tension. Normal thread tension is ob

tained by setting the dial at the white index. Your ma

chine has been tested using the thread which accompa

nies it and with the thread tension dial at the white

index.

If using a coarser thread, it may be necessary to alter

the thread tension slightly. Also the type of fabric may

require that the tension be adjusted.

ti

------------------

y

* 1,—

Threading, thread tension

1

There is also a mark on the thread tension dial for the

tension that is suitable for making buttonholes. This set

ting is also suitable for satin stitching, decorative stitch

ing, topstitching, embroidering, etc.

13

Ihread tension

Correct and incorrect thread tension

In order to easily understand the importance of correct

thread tension, you can try different thread tensions by

sewing on a scrap of fabric. Begin by using an excessively

loose tension, i.e. set the tension dial near “0”. Look at

the fabric and you will find that the lower thread lies

straight and the upper thread is drawn underneath the

fabric. If, however, you set the dial at the highest num

ber, the opposite will occur, or the seam may pucker.

The thread tension is correct when the threads inter

lock in the middle of both layers of fabric.

Please note that even the best quality thread may vary

m thickness. When sewing in fine fabrics, the knot may

sometimes be visible.

Always check that the thread tension is correct by first

sewing on a scrap of the same fabric, folded double, that

you intend to work with.

Loading...

Loading...